Page 1

SERVICE MANUAL

RA SERIES INDEX DRIVES

MODELS 400RA, 401RA, 512RA & 662RA

WARNING

This is a controlled document. It is your responsibility to deliver this information to the end user of the

CAMCO/FERGUSON product. Failure to deliver this could result in your liability for injury to the user or damage

to the machine. For copies of this manual call your Customer Service Representative 800-645-5207.

The Driving Force in Automation

Page 2

TABLE OF CONTENTS

INTRODUCTION................................................................................................................................... 2

WARNINGS AND CAUTIONS............................................................................................................... 2

OIL SEAL REMOVAL............................................................................................................................2

SP ARE P AR TS KIT ............................................................................................................................... 2

DISASSEMBL Y ..................................................................................................................................... 3

REMOVAL OF BEARINGS ................................................................................................................... 4

INPUT SHAFT / CAM REMOVAL ......................................................................................................... 4

PRIOR TO REASSEMBL Y .................................................................................................................... 4

ASSEMBL Y ........................................................................................................................................... 4

ASSEMBLING INPUT SHAFT .............................................................................................................. 5

ASSEMBLY OF OUTPUT SHAFT........................................................................................................ 5

SETTING CAM...................................................................................................................................... 6

HOW TO ORDER PARTS ..................................................................................................................... 7

EXPLODED P AR TS DRAWING............................................................................................................ 8

P ARTS LIST .......................................................................................................................................... 9

Page 3

INTRODUCTION

This service manual pertains to the disassembly and assembly of CAMCO’s RA Series Index Drive MODELS

400RA, 401RA,512RA, & 662RA.

The manual is to be used in conjunction with the General Service Manual which describes the lubrication and

general maintenance of CAMCO Index Drives.

An exploded view of your specific Index Drive is included in this manual. Also included is a complete Bill of

Materials for your convenience in identifying and ordering spare or replacement parts.

Some users of Index Drives have the facilities and trained personnel to accomplish service repair. You must

determine the extent to which intricate servicing should be done in your own facility. When in doubt, CAMCO

recommends that CAMCO trained servicemen make the repairs.

WARNINGS AND CAUTIONS

Statements in this manual preceded by the words WARNING or CAUTION and printed in italics are very

important. We recommend you take special notice of these during service or repair.

WARNING

Means there is the possibility of personal injury to yourself or others.

CAUTION

Means there is the possibility of damage to the CAMCO unit.

OIL SEAL REMOVAL

The only repair possible without disassembly of the indexer is replacement of oil seals. To remove oil seals, drill

a number of holes into the case of the seal. The seal may then be removed with a pointed tool. Be sure to

remove all metallic chips created during the drilling of removal holes. A new seal may be installed as outlined in

the “Oil Seal Installation Recommendations” section of the “General Service Manual”.

SPARE PARTS KIT

CAMCO offers a Spare Parts Kit for all CAMCO index drive models CAMCO builds. These kits include oil seals,

bearings, shims and cam followers. These are components that will most likely require replacement during

repair of your index drive. CAMCO recommends a Spare Parts Kit be purchased and kept on hand prior to any

disassembly of your CAMCO drive.

A compete list of components supplied in the Spare Parts Kit can be found in the parts list located in the rear of

this manual. The asterisk behind the item number indicates those parts supplied with the Spare Parts Kit.

BEFORE STARTING

Before starting disassembly of your CAMCO unit you should read and review the following instructions. These

provide important information on parts and procedures necessary to successfully complete your repair.

Comply with all Warnings and Cautions

Read the “Trouble Shooting Guide” section of your “General Service Manual” before disassembling CAMCO

units. CAMCO recommends returning defective equipment for inspection and repair whenever possible.

CAMCO uses Loctite™ to secure all screws and setscrews, If you encounter a fastener that is difficult to

remove, apply heat to the screw and remove while still warm.

.

2

Page 4

Page 5

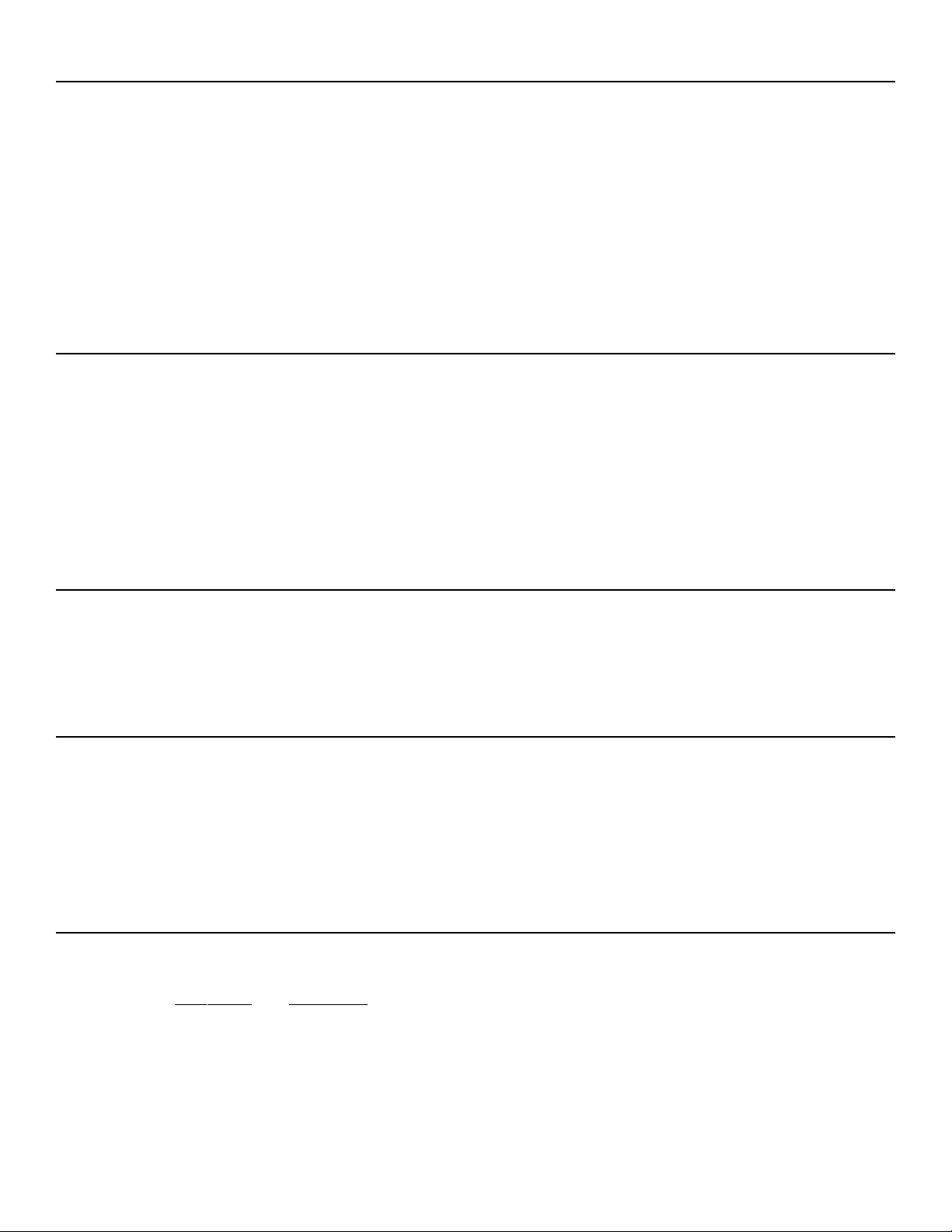

10. REMOVING SHAFT FROM OUTPUT

ASSEMBL Y.

To remove the output shaft from the cover it will

be necessary to use an arbor press and

push from the back side of the shaft using

caution not to damage the parts.

C. Tap on the end of the input shaft to drive the

opposite cartridge from the housing. Then

drive the shaft in the opposite direction for

removal of other cartridges.

NOTE: Keep shims with their respective cartridges

you will be asked to reinstall or replace with the

same shim thickness during assembly .

D. Remove the input shaft/cam assembly

through the large cartridge hole (does not

apply to 662RA see Step E).

E. The 662RA requires removal of the cam

locknuts while still in the housing and

pressing the shaft through the hole

previously occupied by the input cartridge

and removed in Step C. This will

automatically remove the bearing cone from

one end of the input shaft. The use of an

arbor press is recommended but this

procedure can be accomplished by driving

the shaft through with a soft faced hammer.

Fig. 4 Pressing out shaft.

11. REMOVAL OF BEARINGS.

A. Use a wheel puller to remove the cone

portion of bearing from the shaft.

B. Removal of the upper bearing cup from the

output cover will require light tapping on the

backside of the cup with a round aluminum

bar and a hammer working around the

perimeter as you tap to prevent binding.

Continue this procedure until the cup is free

of the cover.

C. Removal of the lower output bearing cup

from the output cover requires prying from

the backside or drilling and tapping of jack

screw holes or the use of a pulley puller.

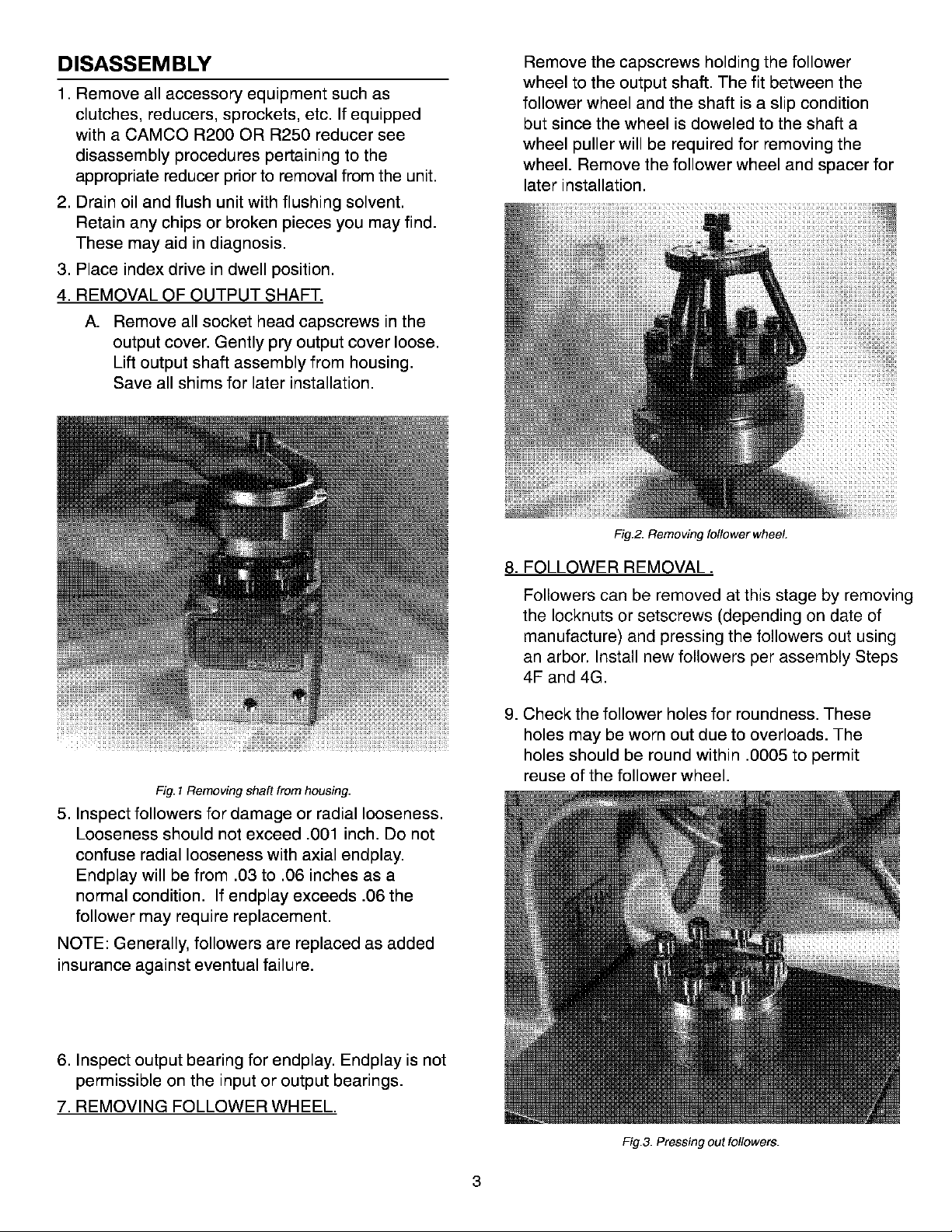

12. INPUT SHAFT REMOVAL.

NOTE: The output shaft must be removed prior to

input shaft removal

A. Rotate the input shaft and inspect all parts

for damage. Endplay in the output shaft is

not permissaable.

B. Remove all input bearing cartridge

capscrews.

Fig. 5 Removing input shaft.

F. Remove cam through the output opening.

13. REMOV AL OF CAM FROM OUTPUT SHAFT

(400RA, 401RA AND 512RA)

A. Use a wheel puller to remove the bearing

cones from the input shaft.

B. Using a spanner wrench remove the cam

locknuts.

C. Remove the spacers from the shaft.

D. Use an arbor press to remove cam from

shaft, using caution not to damage parts.

4

Page 6

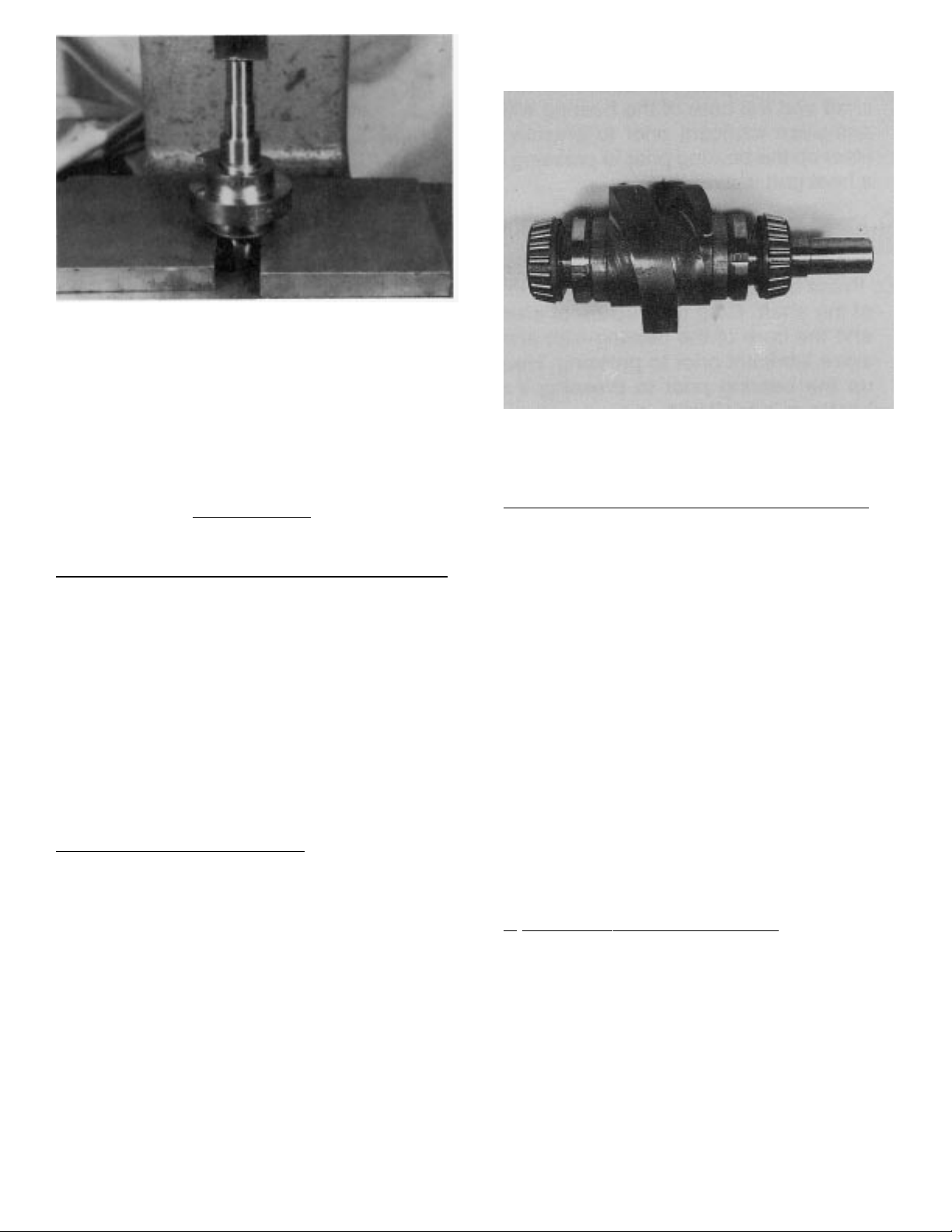

Fig. 6. Pressing out camshaft.

14. Remove the input bearing cups from the

cartridges with a pulley puller, by prying or by

drilling and tapping for jack screws.

Fig. 7. Assembled camshaft.

ASSEMBLY

PRIOR TO REASSEMBLY .

Clean and deburr all parts before reassembling.

Follow tightening torque and Loctite™

recommendations as outlined in the “General

Service Manual”.

1. Use an arbor to press the bearing cups into the

cartridges. Coat the outside of the cup and the

bore of the cartridge with an anti-seize lubricant

prior to pressing. Fill cavity of cartridge with

bearing grease recommended in the “General

Service Manual”.

2. ASSEMBLING INPUT SHAFT.

A. Use an arbor to press the cam into shaft.

Be sure key is installed into shaft first.

Apply anti-sieze lubricant to shaft and bore

prior to pressing.

B. Install spacers on both sides of the cam as

removed in disassembly Step 13C.

C. Use a spanner wrench to install the cam

locknuts. Adjust nut to center cam on shaft.

D. Use arbor to press bearing cones onto

shaft. Coat shaft and bearing bore with antisieze lubricant prior to pressing. The bore

of the bearing should be heated prior to

pressing if a heat gun is available.

3. INST ALLING INPUT SHAFT INT O HOUSING.

(On the 662RA the prior assembly steps were

done inside the housing).

A. Slip the input/cam shaft assembly through

the large cartridge opening.

B. Install the input cartridges. Be sure to install

the same exact shims or equivalent height

as was removed in disassembly Step 12C.

C. Tighten cartridge mounting screws.

D. If endplay exists remove an equal amount of

shims from each side until there is a small

amount of drag from the bearings. In rare

instances it may be necessary to remachine

the cartridges if all shims have been

removed and endplay still exists.

H. Loosen input cartridge screws and rotate

the cartridge top to the most rearward

position attainable within the slots provided

in the cartridge.

4. ASSEMBLY OF OUTPUT SHAFT.

A. Press bearing cups into cover. Coat the

outside of the cup and the bore in the cover

with an anti-sieze lubricant prior to pressing.

B. Press bearing cone on the output end of the

shaft. Coat the outside of the shaft and the

bore of the bearing with anti-sieze lubricant

prior to pressing. Heat up the bearing prior

to pressing if a heat gun is available.

5

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

PARTS LIST FOR 512RA INDEX DRIVE (STANDARD CONFIGURATION CONT.)

26 ....................................................06C01055009300 OUTPUT RISINGLE EXTENDEDR (REQUIRED ON 90 AND

........................................................ SOME 120 DEGREE MOTION UNITS)

27 ....................................................95A33001010000 SIGHT PLUG 3/8-18 N.P .T. *FS

28 ....................................................95A33004010000 GREASINGLE EXTENDED FITTING #B-1610 *FS

29 ....................................................95A26000600000 S.H.C.S. 5/16-18 X 2 *FS

30 ....................................................86D07328640021 BEARING CONE 34300 CLASS 2

31 ....................................................86D07328640022 BEARING CUP 34478 CLASS 2

32*...................................................86D07328300022 BEARING CUP 13621 CLASS 2

33*...................................................86D07328300021 BEARING CONE 13687 CLASS 2

34 ....................................................84D07329240000 OIL SINGLE EXTENDEDAL C/R 14262

35 ....................................................06B01809008700 GASKET COVER CC *FS

36 ....................................................06A02638009000 “SPACER, OUTPUT -CC”

37 ....................................................06A02663018800 “SHIM, .002 THK”

37 ....................................................06A02663028800 “SHIM, .003 THK”

38 ....................................................95A26016450000 SHCS 3/8-16 X 3/4

39 ....................................................80C64329009100 MTG PLATE AL T R225

39 ....................................................80L07456009100 “MTG PLATE, SSV-7300C REDUCER”

39 ....................................................80L07457009100 MOUNT PLATE 7300 CONE REDUCER

14

Page 16

Page 17

P ARTS LIST FOR 662RA INDEX DRIVE (STANDARD CONFIGURATION CONT .)

ITEM NO. PART NUMBER DESCRIPTION

34 ....................................................84D07329320000 OIL SINGLE EXTENDEDAL C/R 19400

35 ....................................................08C01810008700 GASKET COVER CCM *FS

36 ....................................................08B02624009000 SPACER OUTP CCM

37*...................................................08A01325018800 SHIM .002 THK

37*...................................................08A026710298800 SHIM .003 THK

37*...................................................08A01325028800 SHIM .005 THK

37*...................................................08A01325038800 SHIM .010 THK

38 ....................................................95A26016470000 SHCS 3/8-24 X 1

39 ....................................................80C01938009100 MOUNTING PLATE 7300 REDUCER

39 ....................................................80C02238009100 MOUNTING PLATE 7350 REDUCER

........................................................

*.......................................................Indicates parts supplied with Spare Parts Kit # 662RA SPK

16

Page 18

© Industrial Motion Control, LLC 2004 All rights reserved

This publication is for information purposes only and should not be considered a binding Printed in U.S.A.

description of the product except if confirmed in writing by Industrial Motion Control, LLC. SKU 0069 / Revision 3/1/04

Michigan Office

550 Forest Avenue, Unit #14

Plymouth, Ml 48170

USA

ph: 734-459-8080

fax: 734-459-8110

UK Office

432 Perth Avenue

Slough Trading Estate

Slough, Berkshire SL1 TS

United Kingdom

ph: +44 (0)1753-786-100

fax: +44 (0)1753-786-101

Belgium Office

33 Parc Industriel

B-1440 Braine-le-Château

Belgium

ph: +32 (0)2 367-1311

fax: +32 (0)2 366-1891

Industrial Motion Control, LLC 1444 S. Wolf Road, Wheeling, IL 60090 Phone: 847-459-5200 Fax: 847-459-3064

www.camcoindex.com www.ferguson-co.com

The Driving Force in Automation

Loading...

Loading...