Page 1

C-200

RBC1

RBC1----50

RBC1RBC1

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUALINSTRUCTION MANUAL

50

5050

PN 163189

REVISION B

1/2003

Page 2

Notice

Users of this equipment must comply with operating procedures and training of operation

personnel as required by the Occupational Safety and Health Act (OSHA) of 1970,

Section 6 and relevant safety standards, as well as other safety rules and regulations of

state and local governments. Refer to the relevant safety standards in OSHA and

National Fire Protection Association (NFPA), section 86 of 1990.

Caution

Setup and maintenance of the equipment should be performed by qualified personnel who

are experienced in handling all facets of this type of system. Improper setup and

operation of this equipment could cause an explosion that may result in equipment

damage, personal injury or possible death.

Dear Customer,

Thank you for choosing Despatch Industries. We appreciate

the opportunity to work with you and to meet your heat

processing needs. We believe that you have selected the

finest equipment available in the heat processing industry.

At Despatch, our service does not end after the purchase

and delivery of our equipment. For this reason we have

created the Service Products Division within Despatch. The

Service Products Division features our Response Center for

customer service. The Response Center will direct and track

your service call to ensure satisfaction.

Whenever you need service or replacement parts, contact

the Response Center at 1-800-473-7373: FAX 612-781-

5353.

Thank you for choosing Despatch.

Sincerely,

Despatch Industries

Page 3

Page 4

Page 5

PREFACE

This manual is your guide to the Despatch oven. It is organized to give you the

information you need quickly and easily.

The INTRODUCTION section provides an overview of

the Despatch oven.

The THEORY OF OPERATION section details the

function and operation of assemblies and

subassemblies on the Despatch oven.

The INSTRUCTIONS section provides directions on

unpacking, installing, operating and maintaining the

Despatch oven.

The APPENDIX section contains special instructions

on air atmosphere and nitrogen atmosphere Burn-In

ovens, a Troubleshooting Table, a list of Accessories

and a Warranty.

Refer to the manufacturer’s manual for instructions on the use of the controls.

The parts are listed in the corner of the prints, the electrical items on the electrical print

and the mechanical items on the mechanical prints.

An efficient way to learn about the oven would be to read the manual while working with

the corresponding oven control system. This will give you practical hands-on

experience with information in the manual and the oven.

Before operating the equipment, be sure you understand all of the technical information

contained in this manual. Information skipped, not understood or misunderstood could

create the possibility of operating the equipment in an unsafe manner. This can cause

damage to the oven or personnel or reduce the efficiency of the equipment.

NOTE:

Read the entire

INTRODUCTION and THEORY

OF OPERATION before

installing the oven.

WARNING:

Failure to heed warnings in this

instruction manual and on the

oven could result in personal

injury, property damage or

death.

1

Page 6

TABLE OF CONTENTS

PREFACE.......................................................................................................................1

INTRODUCTION.............................................................................................................4

Special Features..........................................................................................................4

Specifications ..............................................................................................................5

Dimensions ..............................................................................................................5

Capacities ................................................................................................................5

Temperature ............................................................................................................6

Power.......................................................................................................................7

Power Requirements............................................................................................7

THEORY OF OPERATION .............................................................................................8

Temperature Control....................................................................................................8

Power Switch...............................................................................................................9

Air Circulation ..............................................................................................................9

Chamber Design..........................................................................................................9

Airflow Switch ..............................................................................................................9

Alarm...........................................................................................................................9

Chamber Door Handle...............................................................................................10

Damper Control ......................................................................................................... 10

Determining Damper Settings................................................................................10

Full Closed Position............................................................................................10

Full Open Position.............................................................................................. 11

Minimum Opening for Dissipation of Live Load ..................................................11

Other Damper Settings.......................................................................................11

OVEN INSTRUCTIONS................................................................................................13

Unpacking and Inspection .........................................................................................13

Warning Signs Missing..............................................................................................14

Set-up........................................................................................................................15

Power Connection ..................................................................................................... 16

Operating...................................................................................................................17

Loading the Oven...................................................................................................17

Oven Temperature Limit ........................................................................................18

Product Temperature Limit.....................................................................................18

Operator Training Requirements............................................................................18

Pre-Startup Checklist.............................................................................................19

Startup ...................................................................................................................19

Maintenance..............................................................................................................21

Checklist ................................................................................................................21

Inspection and Cleaning.........................................................................................22

Vents..................................................................................................................22

Chamber.............................................................................................................22

Control Cabinet and Fan ....................................................................................22

Chamber Door Gasket........................................................................................23

Recirculation Motor.............................................................................................23

Oven Exterior......................................................................................................23

Oven Chamber Interior.......................................................................................23

Door Hinges and Latches...................................................................................23

2

Page 7

Automatic Damper..............................................................................................24

Controls and Indicators.......................................................................................24

Loose Screws, Bolts and Fasteners ...................................................................24

Lubrication..........................................................................................................24

Tests...................................................................................................................... 25

OPTIONAL ACCESSORIES .........................................................................................26

Door Switch ............................................................................................................... 26

Recorder....................................................................................................................26

Redundant High-Limit................................................................................................26

Disconnect Switch ..................................................................................................... 27

Stacking Option ......................................................................................................... 27

Replacement .............................................................................................................28

Parts.......................................................................................................................28

Nitrogen and Liquid Nitrogen.....................................................................................28

Theory of Operation...............................................................................................28

Operator Training Requirements............................................................................29

Operation...................................................................................................................29

Nitrogen Atmosphere.................................................................................................31

Purge Rate.............................................................................................................31

Maintain Rate.........................................................................................................32

Troubleshooting.........................................................................................................33

Circuit Board Check...............................................................................................35

3

Page 8

INTRODUCTION

This instruction manual covers the operation and

maintenance of the Despatch RBC1-50 Burn-In

oven.

NOTE:

Read the entire

INTRODUCTION and THEORY

OF OPERATION before

installing the oven.

Special Features

The sturdy construction and three-inch insulation top and bottom and four-inches of

insulation on the sides of the Despatch RBC1-50 Burn-In ovens contribute to excellent

temperature uniformity.

Other special features include the following:

• Unique Despatch design to combine higher fan volume of forced recirculated air

with a system of perforated stainless steel walls for the ultimate in temperature

uniformity.

• Welded double wall construction and fiberglass insulation to reduce heat loss.

Silicone rubber gaskets further minimize heat leakage.

• Rapid response heater.

• Scratch-resistant baked enamel exterior and stainless steel interior for easy

cleaning.

4

Page 9

Specifications

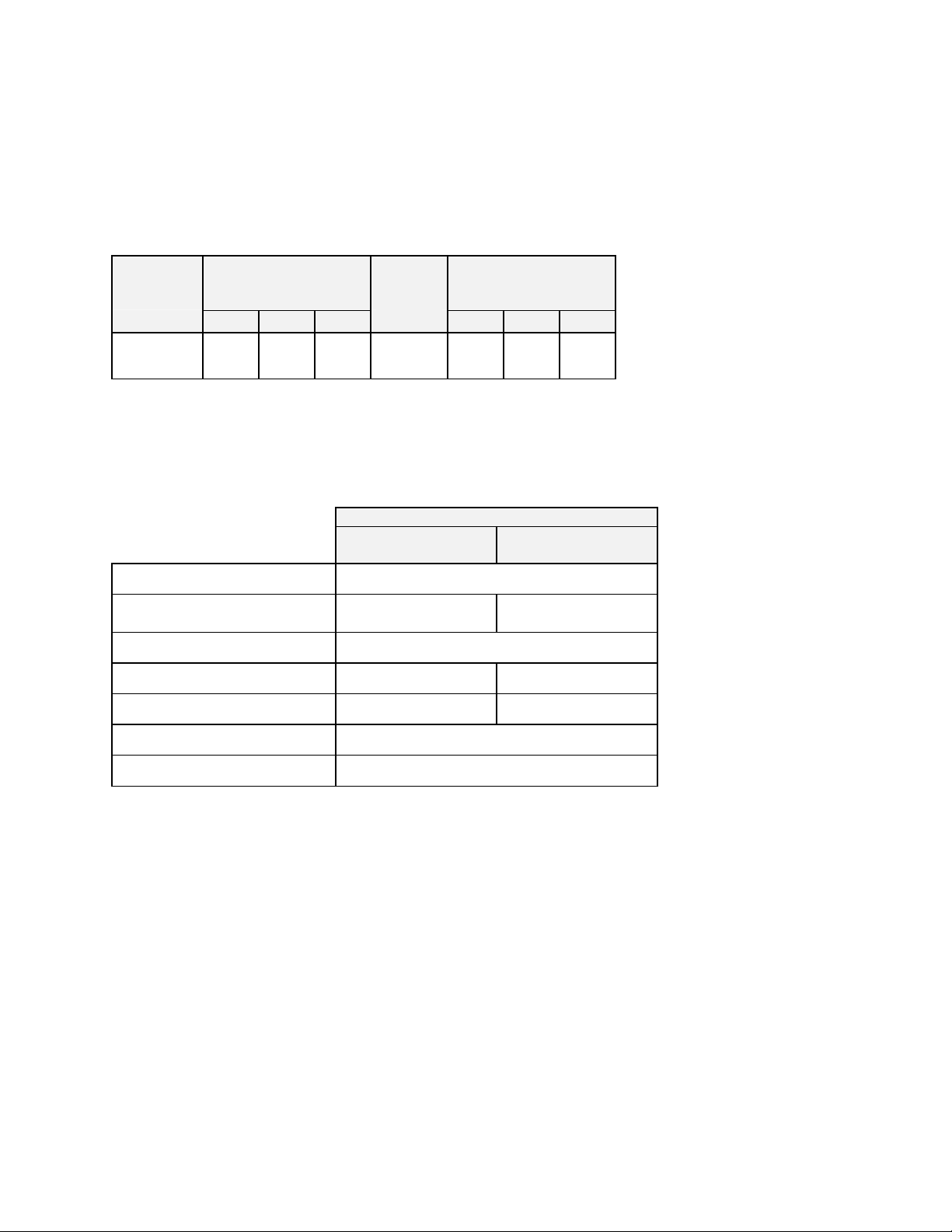

Dimensions

Model Chamber Size

in (cm)

W D H W D H

RBC1-50 18

(46)

25

(64)

(46)

Capacities

Maximum Load 150 Lbs

Fresh Air/ Exhaust Capacity at

125 °C (255 °F)

Recirculating Fan 600 CFM 1 HP

Capacity

feet3

(liters)

18

4.7

(133)

RBC1-50

Air Atmosphere

51 CFM N/A

Overall Size

in (cm)

46

(117)

36

(91)

MODEL

RBC1-50

Nitrogen Atmosphere

31.50

(80)

Fresh Air Inlet 2.5” Diameter N/A

Exhaust outlet 2.18” Diameter N/A

# of Doors 1

Approximate Weight 470 Lbs. (213 KG)

5

Page 10

Temperature

RBC1-50

Time to Temperature 25°C - 80°C

(approximate minutes with 25°C - 125°C

no live load)

25°C - 260°C

Recovery Time to 125°C with door open 1 Min.

Temperature Uniformity at

260°C*

Operating Temperature Range

(Based on 25°C ambient, and dampers fully open)

(1)

25°C - 150°C

(2)

125°C*

RBC1-50

Air Atmosphere

4

10

14

34

>1 Min. >1 Min.

<±1°C

±1°C

50° - 260°C 15° - 260°C

Nitrogen Atmosphere

4

10

14

30

<±1°C

±1°C

Control Stability

Repeatability ±0.5°C

Cooldown Time 125° - 60°C

Dissipation/Mean Temperature Rise

125°C

150°C

(1)

Time to temperature will be slightly longer for lower voltages due to heater kW derating (empty oven).

(2)

Figures are based on a nine-point survey in an empty oven. Uniformity can vary slightly depending

on unit and operating conditions.

(3)

∆

In control stability figures represent the change in ambient temperature.

(4)

Dissipation is reduced by 17% on 50-Hertz operation. Temperature gradient/mean temperature rise is

with an evenly distributed live load.

(3)

40 Min. 11 Min.

(4)

80°C

±0.5°C per 5°C ∆

800 Watts/4°C

1,300 Watts/6°C

1,400 Watts/6°C

Note: Testing performed on 240V-1PH-60HZ.

6

Page 11

Power

Line voltages may vary in some geographical locations.

If your line voltage is much lower than the oven voltage

rating, warm up time will be longer and motors may

overload or run hot. If your line voltage is higher than

nameplate rating, the motor may run hot and draw

excessive amps.

If the line voltage varies more than 10% from the oven

voltage rating, some electrical components such as

relays, temperature controls, etc. may operate

erratically.

Power Requirements

WARNING:

All grounding and safety

equipment must be in compliance

with applicable codes, ordinances

and accepted safe practices.

WARNING:

Failure to read this warning

can result in death, serious

bodily injury or property

damage. All conductors

must be copper unless the

specific terminal is marked

for use with aluminum

conductors.

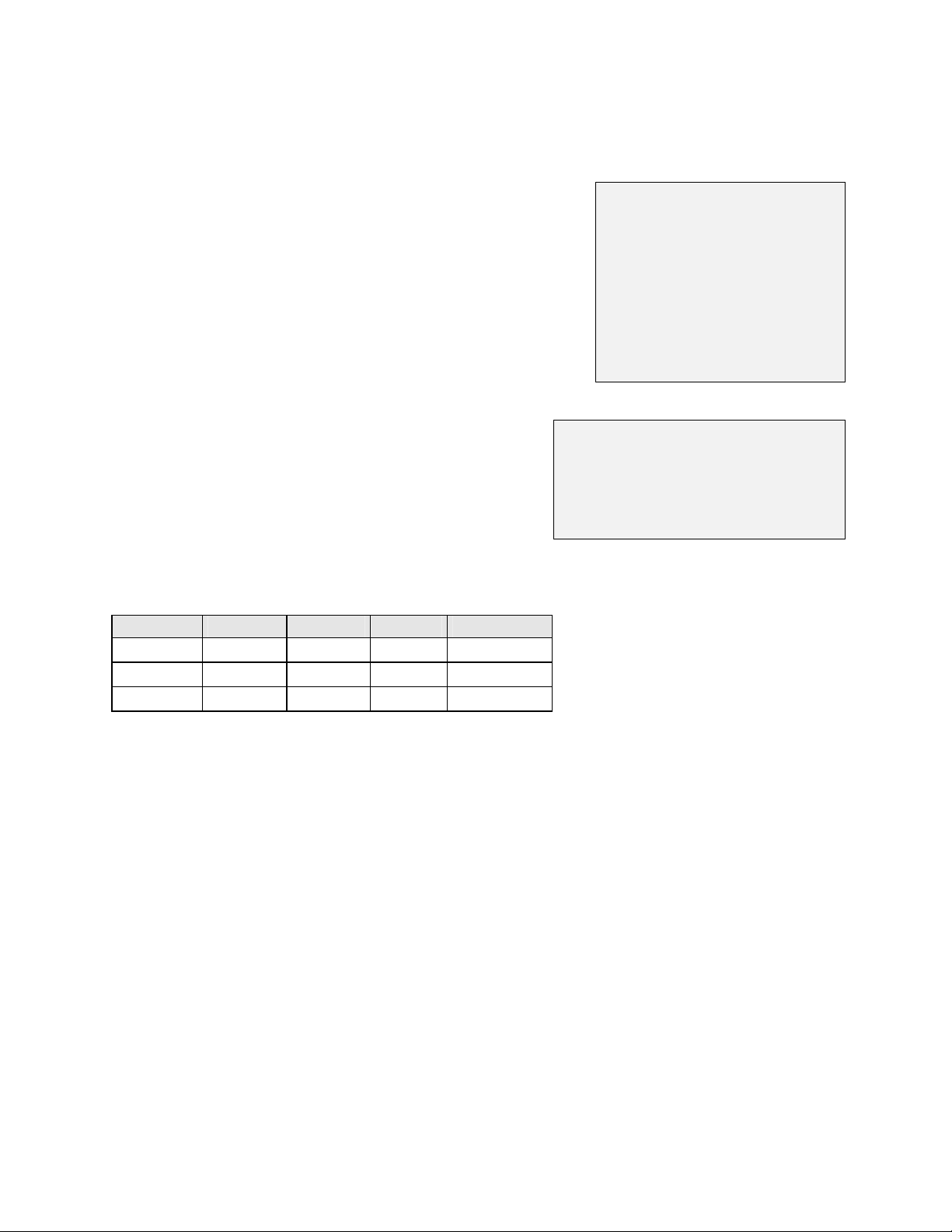

Volts Amps Hertz Phase Heater KW

208 23 60 1 3

220 24 50 1 3.4

240 24 60 1 4

7

Page 12

THEORY OF OPERATION

Despatch RBC1-50 Burn-In ovens are made for the accelerated life testing of

microcircuit electronic devices to identify early mortality. The Despatch RBC1-50 ovens

are ideally suited for:

• high-dissipation forward-bias burn-in,

• high temperature reverse-bias burn-in,

• stabilization baking of integrated circuits and other semiconductor devices.

Air atmosphere ovens recirculate air through the chamber. They can add heat and

remove dissipated heat. Air is taken from the burn-in room and circulated through the

oven. Heat is added by electric resistance elements, or removed through automatically

controlled exhaust.

Temperature Control

A modular microprocessor based digital temperature controller regulates the process.

The control utilizes a time-proportioning voltage signal to control heating, and a milliamp

signal to control cooling with minimal temperature fluctuations.

The controller temperature-sensing element, located in the air return plenum area,

senses the median air temperature of the oven. The controller automatically controls

heat dissipated by sending a signal to the automatic damper modulator. This automatic

damper controls the amount of fresh air drawn into the chamber, preventing excessive

cooling and conserving energy.

The high limit control protects the product and/or the oven from overheating. If the

product being processed has a critical high temperature limit, the high limit setpoint

should be set to a temperature somewhat below the temperature at which the product

could be damaged. If the product does not have a critical high temperature limit, the

high limit setpoint should be set 5 to 15 degrees higher than the maximum-programmed

setpoint at which the oven will operate. When the high limit trips, the alarm horn will

sound.

Please refer to the manufacturer’s manual on the control and high limit.

8

Page 13

Power Switch

The POWER switch controls power to the control circuit, chamber recirculating fan

motor relay, control cabinet fan, and any options that were included at the time of

purchase.

Air Circulation

A Despatch centrifugal fan draws air through the heater section, moves it evenly across

the chamber, past the temperature sensors and back to the heater. The fresh air is

controlled manually and a modulating damper controls the exhaust.

Chamber Design

The chamber (in which the load is processed) has air supply and exhaust ducts on

opposite sides. The ducts and perforated panels provide uniform airflow and

temperature distribution throughout the chamber.

Airflow Switch

The airflow switch senses the differential pressure between the inlet and outlet side of

the recirculating fan. If there is no air pressure, the switch disconnects power to the

heater, and the alarm horn will signal. An On/Off indicator is visible through a window

on the switch. The switch is located in the upper equipment compartment, behind the

equipment panel and next to the recirculating motor.

Alarm

When there is a high limit condition, or when there is no air pressure sensed by the

airflow switch, an alarm will sound and a red pilot light will be lit. To silence the alarm,

depress the momentary ALARM SILENCE switch. The red light will remain on until the

alarm condition is cleared.

9

Page 14

Chamber Door Handle

The door handle positively engages a cam with a catch in one-quarter turn. The

silicone rubber gasket provides a seal around the door as the handle is moved to the

latched position.

Damper Control

The oven is equipped with a manually adjustable

fresh air damper. The damper blade located on the

rear of the oven. The damper adjustment controls

the flow of fresh air into the chamber. If the damper

is in the full open position, the maximum amount of

fresh air is distributed into the chamber.

The exhaust has a modulating damper motor, which is done automatically by the

controller. No adjustments are necessary.

Determining Damper Settings

WARNING: This oven is not

designed for use with flammable

material. If your process

involves flammable material,

contact Despatch Industries.

The optimum setting for the amount of fresh air that should be distributed into the

chamber depends on several factors. These factors include ambient environment

temperature, load conditions, load distribution, heat up and cool down rates, desired

temperature uniformity and most importantly the desired operating temperature. To

consider all of these variables at any one point in time is not practical and there are

engineering tradeoffs that should be considered. Therefore guidelines should be used

to determine the fresh air damper setting.

In general, the damper should be set so that the amount of fresh air flowing into the

chamber agrees with the desired operating temperature conditions. The following

outline shows the considerations involved with various damper position settings.

Full Closed Position

When the fresh air damper is in the full closed position, the chamber will be able to

achieve the maximum attainable heat up rates for the chamber. In addition, the

chamber will use the minimum amount of power to operate at the desired temperature.

In almost all cases, the fresh air damper should be in the full closed position in order to

efficiently operate at the maximum operating temperature for the chamber.

10

Page 15

Full Open Position

When the fresh air damper is in the full open position, the chamber will operate at its

minimum operating temperature.

Friction heat from the air recirculation system builds up in the chamber. This causes

chamber temperature to rise slightly even though the heating system is not turned on.

After the recirculation motor has been on for an extended period of time, the chamber

will reach a thermal equilibrium temperature.

When the damper is not set to the full open position, the chamber has no way to readily

dissipate the heat generated by the friction. With the fresh air damper fully open, the

thermal equilibrium temperature is the minimum operating temperature of the chamber.

Minimum Opening for Dissipation of Live Load

To determine the minimum setting for the fresh air damper, only open the damper so

that the fresh air dissipates the heat from live load. To conserve energy, the cooling

output should be trying to control the setpoint temperature with minimal fluctuations.

Close the damper if the heater continues to be cycled on and off. If the cooling is full on

and the chamber temperature is over the setpoint, open the damper.

Other Damper Settings

The damper can be set to several other distinct operating positions. In most cases, the

damper setting is influenced by specific performance factors. Some of these

performance factors are uniformity; cool down rates and required dissipation.

The uniformity of the chamber is influenced by the inside chamber pressure of the

system. The pressure inside the chamber is dependant on the amount of fresh air

flowing into the chamber. When a large volume of fresh air is flowing into the chamber,

the chamber becomes slightly pressurized and the overall temperature uniformity

improves. The slightly pressurized chamber produces the effect of "pushing" the air to

the corners of the chamber. Typically the corners of the chamber will improve with

respect to temperature distribution while the core of the chamber will maintain excellent

uniformity characteristics regardless of the damper position. Therefore, the

pressurization of the chamber typically is a factor when the chamber is loaded heavily.

The best uniformity results, with respect to the product, are achieved when the chamber

is loaded uniformly.

11

Page 16

NOTE: Overpressurizing the chamber can cause hot air to blow out around the door

seal and cause the area around the door to be hot to the touch. To stop this hot air

from entering the room, close the damper slightly until the air stops blowing.

12

Page 17

OVEN INSTRUCTIONS

Failure to heed warnings in this instruction

manual and on the oven could result in death,

personal injury or property damage.

WARNING:

Do not use oven in wet, corrosive or

explosive atmospheres.

Unpacking and Inspection

Remove all packing materials and thoroughly inspect the oven for damage of any kind

that could have occurred during shipment.

• See whether the carton and plastic cover sheet inside carton are still in good

condition.

• Look at all outside surfaces and corners of the oven for scratches and dents.

• Check the oven controls and indicators for normal movement, bent shafts,

cracks, chips or missing parts such as knobs and lenses.

• Check the door and latch for smooth operation.

If there is damage that may have occurred during shipment, follow these instructions.

1. Contact the shipper immediately and file a written damage claim.

2. Contact Despatch Industries to report your findings and to order replacement

parts for those that were damaged or missing.

3. Send a copy of your filed damage claims to Despatch.

4. Next, check to make sure you have received all the required materials. Your

shipment should include:

• One (1) Despatch oven

• One (1) Instruction manual

• Any special options that were ordered at time of purchase

13

Page 18

Warning Signs Missing

If it appears that any warning, danger, caution or information label or sign has been

damaged or lost, contact Despatch Industries for replacements. Call or write:

Service Products Division

Despatch Industries

P.O. Box 1320

Minneapolis, MN 55440

Call Toll Free 800-473-7373

14

Page 19

Set-up

1. Select the location for installing your

oven.

2. Install an exhaust stack from the

exhaust discharge stack to the outside of the building, if required.

• If a round exhaust stack is used, a minimum area greater than the area of

the exhaust stack is required.

• The flashing through the roof or wall must be capable of handling an

exhaust stack temperature up to 260°C (500°F).

• All stacks must comply with state and local building codes to insure that

surrounding combustible surfaces are below 71°C (160°F).

• Design the exhaust stack to limit the amount of restrictions to insure

proper airflow. If more than two (2) elbows are used in the stack, over all

airflow will be reduced.

a. The exhaust could be vented into a burn-in room atmosphere or

other exhaust system capable of handling the total rated heat

dissipation in:

BTUH

×

b. We recommend that the ovens be vented to the outside or to an

area that could use the heat. The maximum exhaust temperature

could reach the maximum operating temperature of the oven.

3. Place oven on a bench top or directly on the floor. The oven must have a

minimum 2-inch clearance in the rear to provide proper ventilation. When placed

next to another cabinet, or next to another oven, a 3-inch clearance is required.

The doors will still open.

4. Make sure oven is level and plumb; this will assure proper heat distribution and

operation of all mechanical components.

5. The atmosphere where the oven is used should be clean, free of solvent vapors.

Good results depend on a clean workspace.

3,412 KW ×

KW

WARNING:

Do not use the oven in wet, corrosive or

explosive atmospheres.

BTUH

+

2,500

KW

HP Fan ionRecirculat

15

Page 20

Power Connection

Be sure the oven is connected to the power source

shown on the nameplate. Connect the oven directly

to your electric supply, with all grounding and safety

equipment, according to applicable codes, ordinances

and accepted safe practices.

Line voltages may vary in some geographical

locations. If your line voltage is much lower than the

oven voltage rating, the warm up time will be longer

and the motors may overload or run hot. If the line

voltage varies more than ±10% from the oven voltage

rating, the temperature control may operate

erratically.

WARNING

Failure to read this warning

can result in death, serious

bodily injury or property

damage. All conductors must

be copper unless the specific

terminal is marked for use with

aluminum conductors.

WARNING

All grounding and safety

equipment must be in

compliance with applicable

codes, ordinances and

accepted safe practices.

:

:

16

Page 21

Operating

Users and operators of this oven must comply

with operating procedures and training of

operating personnel as required by the

Occupational Safety and Health Act (OSHA)

of 1970, Section 5 and relevant safety standards, and other safety rules and regulations

of state and local governments. Refer to the relevant safety standards in OSHA and

National Fire Protection Association (NFPA), Section 86 of 1990.

Loading the Oven

Despatch Industries cannot be responsible for either the process or process

temperature used, or for the quality of the product being processed. It is the

responsibility of the purchaser and operator to see that the product undergoing

processing in a Despatch oven is adequately protected from damage.

Carefully following the instructions in this manual will help the purchaser and operator in

fulfilling that responsibility.

Distribute the workload evenly so that airflow

is not restricted. Do not overfill your oven.

The workload should not take up more than

two-thirds of the cross-sectional air-delivery

area.

WARNING

Do not use oven in wet, corrosive or

explosive atmospheres.

WARNING

Do not heat any closed containers,

flammable solvents or other flammable

material in this oven. (Examples: spray

can, sealed jar of water, alcohol,

kerosene, oil, paper, etc.)

:

:

17

Page 22

Oven Temperature Limit

Do not attempt to exceed the maximum or minimum operating temperature of this oven.

Product Temperature Limit

If the product has a critical high temperature

limit, the HIGH-LIMIT control should be used

as a process HIGH-LIMIT. When used as a

process HIGH-LIMIT, the control should be

set to a temperature somewhat below the

temperature at which the product would be

damaged. A pyrometer could be used to

determine the process HIGH-LIMIT setting. If

the destructive temperature of the product is

already known, this could be used as a point

below which the process HIGH-LIMIT could

be set.

NOTE

Despatch Industries cannot be

responsible for either the process or

process temperature used, or for the

quality of the product being

processed. It is the responsibility of

the purchaser and operator to see that

the product undergoing processing in

a Despatch Industries burn-In oven is

adequately protected from damage.

Carefully following the instructions in

this manual will assist the purchaser

and operator in fulfilling that

responsibility.

:

Operator Training Requirements

All users must be thoroughly trained under the supervision of experienced personnel.

The operator must be aware of the possible dangers of:

• Suffocation from nitrogen,

• Frostbite from nitrogen as a liquid or as a frozen gas,

• Fire.

Users must demonstrate an understanding of the equipment and its operation to assure

knowledge of and practice of safe and proper operating procedures. Users should

receive regular retraining and testing as required to maintain a high level of proficiency

and effectiveness.

Training should include the:

• function of controls and safety devices,

• handling of special atmospheres (on units with LN2 or GN2).

18

Page 23

Pre-Startup Checklist

• Know the system. Read this manual carefully. Make use of its instructions and

explanations. Safe, continuous, satisfactory, trouble-free operation depends

primarily on the degree of your understanding of the system and your willingness to

keep all parts in proper operating condition.

• Check line voltage. Voltage must correspond to nameplate requirements of motors

and controls. Refer to the section on power connections in the INTRODUCTION of

this manual.

• Fresh air and exhaust. Do not be careless about restrictions in and around the fresh

air and exhaust openings and stacks. Under no condition permit them to become so

filled with dirt that they appreciably reduce the air quantity. The proper ventilation

clearances should be fulfilled at all times. Refer to the Set-up instructions in this

manual.

Startup

For fastest oven heat-up time, close the fresh-air vent. After the desired temperature is

reached, the vent may be adjusted as needed.

1. Start Fan.

• Open oven door.

• Press Power switch to the ON

position. You will hear the

recirculating fan start.

• Shut oven door.

• Check that the control and high limit display turns on.

2. Operate the temperature control as desired. Refer to the manufacturer’s

instruction manual on the operation of the control.

3. When the oven nears temperature set on the

control, the heater will start cycling on and

off.

4. When the chamber temperature is above

setpoint on control, the cooling output of the control will start driving the damper

open, which will exhaust air from the chamber.

WARNING

Do not heat any closed containers,

flammable solvents or other flammable

material in this oven. (Examples: spray

can, sealed jar of water, alcohol,

kerosene, oil, paper, etc.)

:

WARNING

Hot surfaces may exist around

door, inside cabinet, product, and

fixtures. Handle with care.

:

19

Page 24

5. If temperature of the chamber exceeds the high-limit setting on the control, the

heater will shut down and the Alarm Horn and red pilot light will energize. The

heater will shut off. To silence the alarm:

• Depress the Alarm Silence switch, this is a momentary switch, it will return

to its normal position when released.

• The alarm horn will be silenced, but the red alarm pilot light will remain lit.

• When the overtemperature condition clears, press RESET on the control.

• The heater should be back on and the control should be functioning

correctly.

• If the high-limit trips repeatedly, verify the cause of overtemperature and

correct problem.

6. If the fan stops running during process, the Airflow switch will trip and the Alarm

Horn and pilot light will energize. The heater will shut off.

• Shut down the chamber and correct the problem.

7. Shut down chamber by lowering the

setpoint on the control, usually to ambient,

20°C (70°F).

8. Turn the power switch to OFF.

WARNING

On all manual and on all auto

processes, the fans should remain

in operation until oven temperature

is below 150°C (300°F).

:

20

Page 25

Maintenance

Do not attempt any service on this oven before

opening the main power disconnect switch.

WARNING

Disconnect the main power switch

or power cord before attempting

any repair or adjustment.

:

Checklist

• Keep equipment clean. Gradual dirt accumulation retards airflow. A dirty oven

can result in unsatisfactory operation such as unbalanced temperature in the

work chamber, reduced heating capacity, reduced production, overheated

components, etc. Keep the walls, floor and ceiling of the oven work chamber free

of dirt and dust. Floating dust or accumulated dirt may produce unsatisfactory

work results. Keep all equipment accessible. Do not permit other materials to be

stored or piled against it.

• Protect controls against excessive heat. This is particularly true of controls,

motors or other equipment containing electronic components. Temperatures

greater than 51.5°C (125°F) should be avoided.

• Establish maintenance & checkup schedules. Do this promptly and follow the

schedules faithfully. Careful operation and maintenance will be more than paid

for in continuous, safe and economical operation.

• Maintain equipment in good repair. Make repairs immediately. Delays may be

costly in added expense for labor and materials and in prolonged shut down.

• Practice safety. Make it a prime policy to know what you are doing before you do

it. Make CAUTION, PATIENCE, and GOOD JUDGMENT the safety watchwords

for the operation of your oven.

• Lubrication. Fan motor bearings are permanently lubricated. All door latches,

hinges, door operating mechanisms, bearing or wear surfaces should be

lubricated to ensure easy operation.

21

Page 26

Inspection and Cleaning

The purpose of inspection is to determine cleanliness, proper operation and condition of

the oven, including its controls indicators and moving parts.

Vents

Make sure intake and exhaust openings are clean and free of blockages. Any dirt

accumulation in the air circuit can unbalance temperatures and airflow patterns.

Chamber

Keep perforated panels and other surfaces of the chamber clean. Use a vacuum

cleaner to clean perforated panels.

Control Cabinet and Fan

Keep the control cabinet fan and the intake grill clean.

Make sure there is a 2-inch clearance behind the

oven to provide adequate ventilation.

Remove dust and cobwebs from heat sinks.

Control cabinet temperature should not exceed 52°C

(125°F).

WARNING

High voltage is present on

terminals inside control cabinet.

Turn off main power disconnect

before cleaning inside of control

cabinet. Do not use any

cleaning equipment that may

pull wires.

:

22

Page 27

Chamber Door Gasket

Check the gasket on the chamber door as follows.

1. Open the door.

2. Visually inspect the gasket-sealing surface.

3. Squeeze the gasket between your fingers to check for damage and tears.

4. Close the door on a piece of paper at many points around the gasket. The

gasket should seal tight enough to require a slight pull to remove the paper.

Recirculation Motor

Fans, motors and shaft should be clean and free of dust and oil or grease. The

recirculation motor is permanently lubricated and does not require any lubrication.

Oven Exterior

Clean oven exterior with Dupont No. 7 polish or equal, or with soap and water. Do not

clean while the oven is hot. Do not use abrasives or chemicals.

Oven Chamber Interior

Clean the oven interior with soap and water or stainless steel cleaner. Under normal

conditions, a major cleaning should be done once a year.

Door Hinges and Latches

Check operation of the chamber door to see whether it opens easily and closes

securely, without jerking or slamming.

23

Page 28

Automatic Damper

1. Put the oven in operation (without a load in the chamber) and wait until the

temperature is stabilized.

2. Set the controller to about 10°C lower.

3. While looking at the damper control motor and linkage, when the setpoint is first

turned down, the dampers should move to the wide-open position.

4. Then, as the chamber temperature drops, the dampers should start to close

when the difference between the chamber temperature and the setpoint is less

than 4°C.

5. When the chamber temperature has dropped between 1°C and 2°C above the

setpoint, the damper should be fully closed.

6. At lower chamber temperatures (compared to the setpoint), the damper remains

closed and the heater is turned on.

7. Reset the temperature controller.

Controls and Indicators

Check all controls for proper operation. Switches should move easily, indicators should

light or give a correct signal, and controls should perform intended function.

Loose Screws, Bolts and Fasteners

Check tightness of all screws, bolts and fasteners. Notice whether the oven vibrates or

makes unusual noises while starting, running or stopping. Make sure switches and

control knobs and indicators are securely fastened.

Lubrication

Fan motor bearings are permanently lubricated. All door latches, hinges, door operating

mechanisms, bearing or wear surfaces should be lubricated to ensure easy operation.

24

Page 29

Tests

Tests should be performed carefully and regularly. The safety of personnel as well as

the condition of equipment may depend upon the proper operation of any one of the

functions of the temperature control. Test the control every 40 hours. Check that the

heater LED is cycling on and off, indicating that the heater is working. Also at this time,

check the high limit function to make sure it is working properly. Refer to

manufacturer’s instruction manual on the controls, if necessary.

To test the high limit:

1. Set the HIGH LIMIT instrument to its highest temperature.

2. Set the CONTROL instrument to your normal process temperature and let

chamber stabilize at that temperature.

3. Adjust the HIGH LIMIT slowly downward toward the temperature of the oven until

the heater is shut off.

4. The HIGH LIMIT alarm indicator should flash and a high limit alarm message

should be displayed. The alarm horn should sound.

5. Verify that the heater relay has been disabled by checking that 2LED on the

control panel circuit board is not lit.

6. Return the HIGH LIMIT setpoint value to their original value.

7. Press the Reset key.

25

Page 30

OPTIONAL ACCESSORIES

This section provides operating instructions on the standard options for the RBC1-50

Burn-In oven.

Door Switch

The door switch is wired to shut off the fan and

heater. In addition, when the N2 and LN2 options are

installed the door switch will shut these down. The

door switch may be defeated manually by pulling

out the actuator.

WARNING

Disconnect the main power

switch or power cord before

attempting any repair or

adjustment.

WARNING

Do not use oven in wet, corrosive

or explosive atmospheres.

:

:

Recorder

The circular chart recorder, mounted on top of the

oven, is used to record the user’s process. This is

done by an independent thermocouple, located

next to the control thermocouple. The charts used

are 24hr/7day. This option is available in a single

pen for stand-alone units or a two pen for units

using the stacking option. See the manufacturer’s

manual on the recorder instrument attached to this manual.

WARNING

Failure to heed warnings in this

instruction manual and on the

oven could result in personal

injury, property damage or

death.

:

Redundant High-Limit

The redundant high-limit is located on the equipment panel behind the control panel

door. The temperature is sensed by an independent thermocouple, located next to the

control thermocouple. To operate the redundant high-limit, set the dial to the desired

temperature, this is usually set at a temperature just below the safe maximum

temperature of the product, but not too low to interfere with the process. If temperature

of the chamber exceeds the high-limit setting on the redundant high-limit, the heater will

shut down and the Alarm Horn and red pilot light will energize. The heater will shut off.

To silence the alarm:

• Depress the Alarm Silence switch, this is a momentary switch, it will return to

its normal position when released.

• The alarm horn will be silenced, but the red alarm pilot light will remain lit.

• When the overtemperature condition clears, press RESET on the redundant

high-limit.

26

Page 31

• The heater should be back on and the chamber should be functioning

correctly.

If the high-limit trips repeatedly, verify the cause of overtemperature and correct

problem. See the manufactures manual on the redundant high-limit instrument attached

to this manual.

Disconnect Switch

The disconnect switch is located on the upper front of the control panel, above the

controller. The OFF position is when the handle turned to the left, and ON is when it

turned to the right. To access the equipment behind the control panel, the disconnect

switch must be in the OFF position. This prevents access to the equipment panel while

power is on the oven.

Stacking Option

When ordered, this option lets the user to stack two ovens; one on top of the other using

specially designed stacking hardware. Using this option still requires that each oven

have its own power supplied to it

27

Page 32

Replacement

Parts

To order or return parts, contact the Service Products Division at Despatch. The

Service Products Division features our Response Center for customer service. When

returning parts, a Despatch representative will provide you with an MRA (Material

Return Authorization) number. The MRA number must be attached to the returned part

for identification. When you are ordering parts, be sure to give the model number, serial

number and the part number. This will expedite the process of obtaining a replacement

part.

When you have a

612-781-5353.

service

need, contact the

Response Center

WARNING

Disconnect the main power switch

or power cord before attempting

any repair or adjustment.

:

at

1-800-473-7373

: FAX

Nitrogen and Liquid Nitrogen

The standard air-atmosphere oven can be converted to a nitrogen-atmosphere with a

factory installable kit. The following are instructions on the operation of the nitrogen

(N2) and liquid nitrogen (LN2) cooling option for the RBC1-50 Burn-In oven.

Theory of Operation

The nitrogen atmosphere option uses nitrogen (N2) to displace oxygen from the

chamber, thus eliminating oxidation of components. The heat is dissipated from the

oven by liquid nitrogen (LN2). Nitrogen enters the chamber and reduces the oxygen

level to the desired level. The flowmeter keeps the desired N2 entering into the

chamber, maintaining a low concentration of oxygen while a burn-in cycle is in progress.

28

Page 33

Operator Training Requirements

Users and operators of this oven must comply

with operating procedures and training of

operating personnel as required by the

Occupational Safety and Health Act (OSHA)

of 1970, Section 5 and relevant safety

standards, and other safety rules and

regulations of state and local governments.

Refer to the relevant safety standards in

OSHA and National Fire Protection

Association (NFPA), Section 86 of 1990.

WARNING

Suffocation can occur in a nitrogen

atmosphere oven chamber if it is not

thoroughly purged with room air

before a person goes inside it.

Before entering an oven chamber,

run the oven for at least five minutes

with the nitrogen (or any other inert)

gas turned off, doors open and

recirculating fan running. Only then

should a person work inside the oven

chamber with the doors closed.

:

Operation

1. Connect the nitrogen (N2) supply line to the

inlet located in the rear of the oven.

2. Set the pressure regulator to 40PSIG.

3. Connect the liquid nitrogen (LN2) supply to the inlet located on the box in the rear

of the oven.

4. Adjust the regulator to 35PSIG max.

5. Check nitrogen plumbing for leaks, using

soapy water solution.

6. As gas nitrogen is odorless, all leaks should

be stopped to prevent the possibility of

suffocation in a small work area in which a

nitrogen leak might displace much of the oxygen in the atmosphere.

7. Start chamber, and turn the Nitrogen (N2) switch ON.

8. The pilot light on the switch indicates that the solenoid valve is open and nitrogen

(N2) is entering the chamber.

9. Adjust the flowmeter, which is located in the front control panel, and set to

desired flow rate. The flow rate should set so that it creates a slightly positive

pressure in the chamber, which counteracts leaks and keeps the oxygen content

at a safe, low level of concentration.

10. When the oven nears temperature set on the control, the heater will start cycling

on and off.

WARNING

Do not use oven in wet, corrosive

or explosive atmospheres.

CAUTION

Nitrogen & carbon dioxide

gases can cause asphyxiation if

used in confined or poorly

ventilated areas.

:

:

29

Page 34

11. When the chamber temperature is above

setpoint on control, the cooling output of

the control will start cycling the liquid

nitrogen (LN2) solenoid valve, which will

cool the chamber.

WARNING

Failure to heed this warning can

result in severe frostbite to eyes or

skin. Do not touch frosted pipes or

valves.

:

30

Page 35

Nitrogen Atmosphere

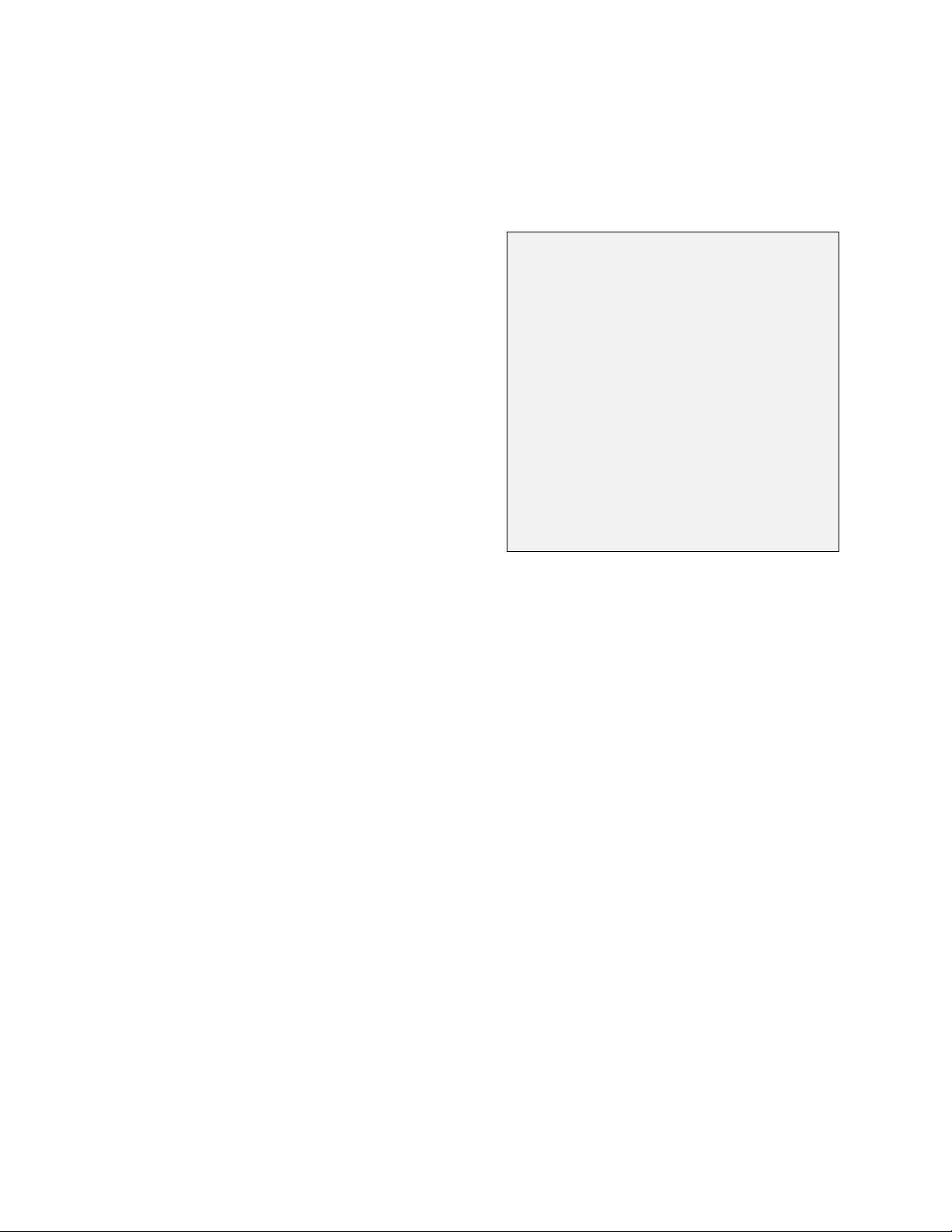

Purge Rate

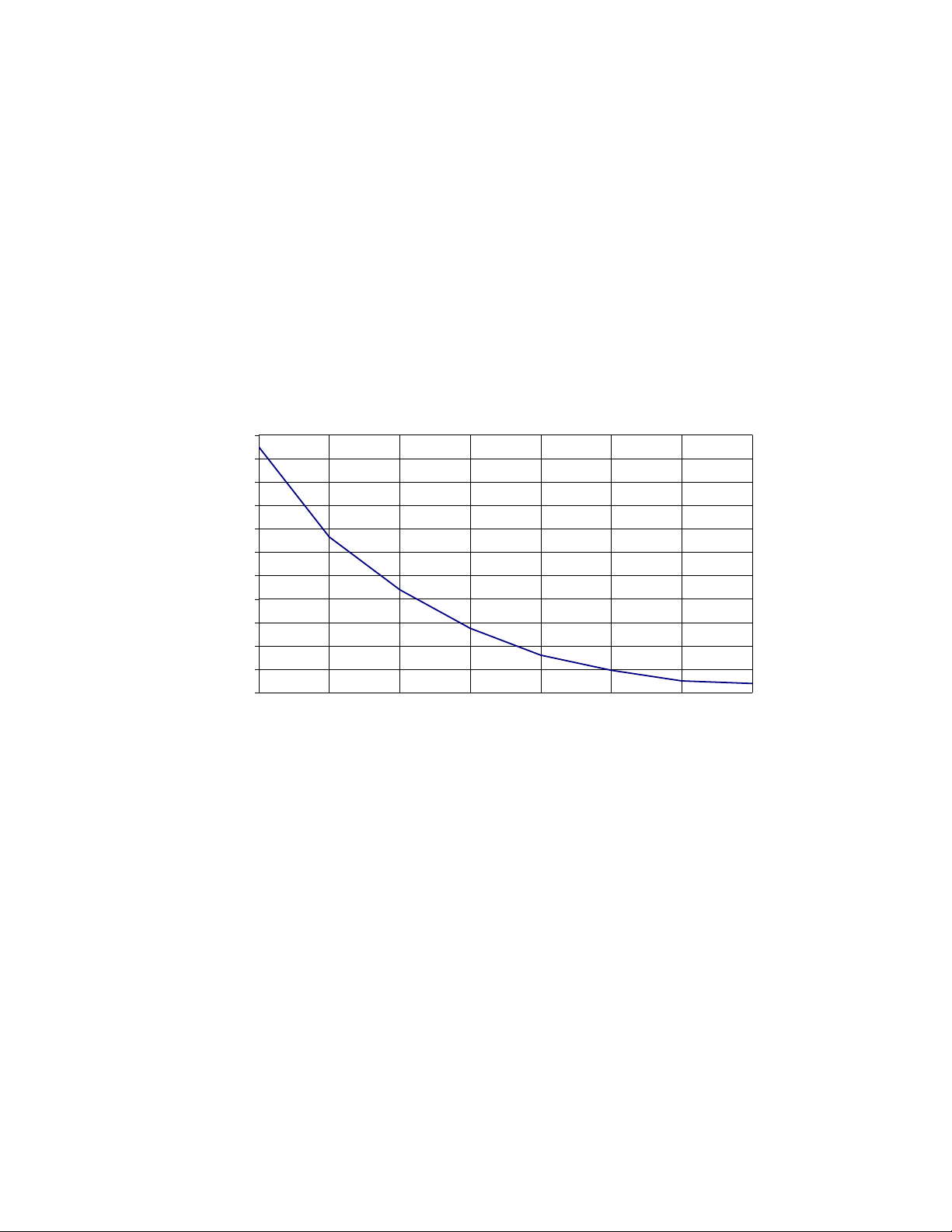

The chart below shows the time required to reduce the oxygen content to different

percentages of concentration. At a flow rate of 100 SCFH in the RBC1-50 Burn-In

oven, oxygen concentration from 21% in room air down to 6% in the closed oven takes

approximately 11 minutes.

Flow Rate Time Versus Oxygen Content

22

20

18

16

14

12

% O2

10

8

6

4

2

0

0 4 8 12 16 20 24 26

Time in Minutes

31

Page 36

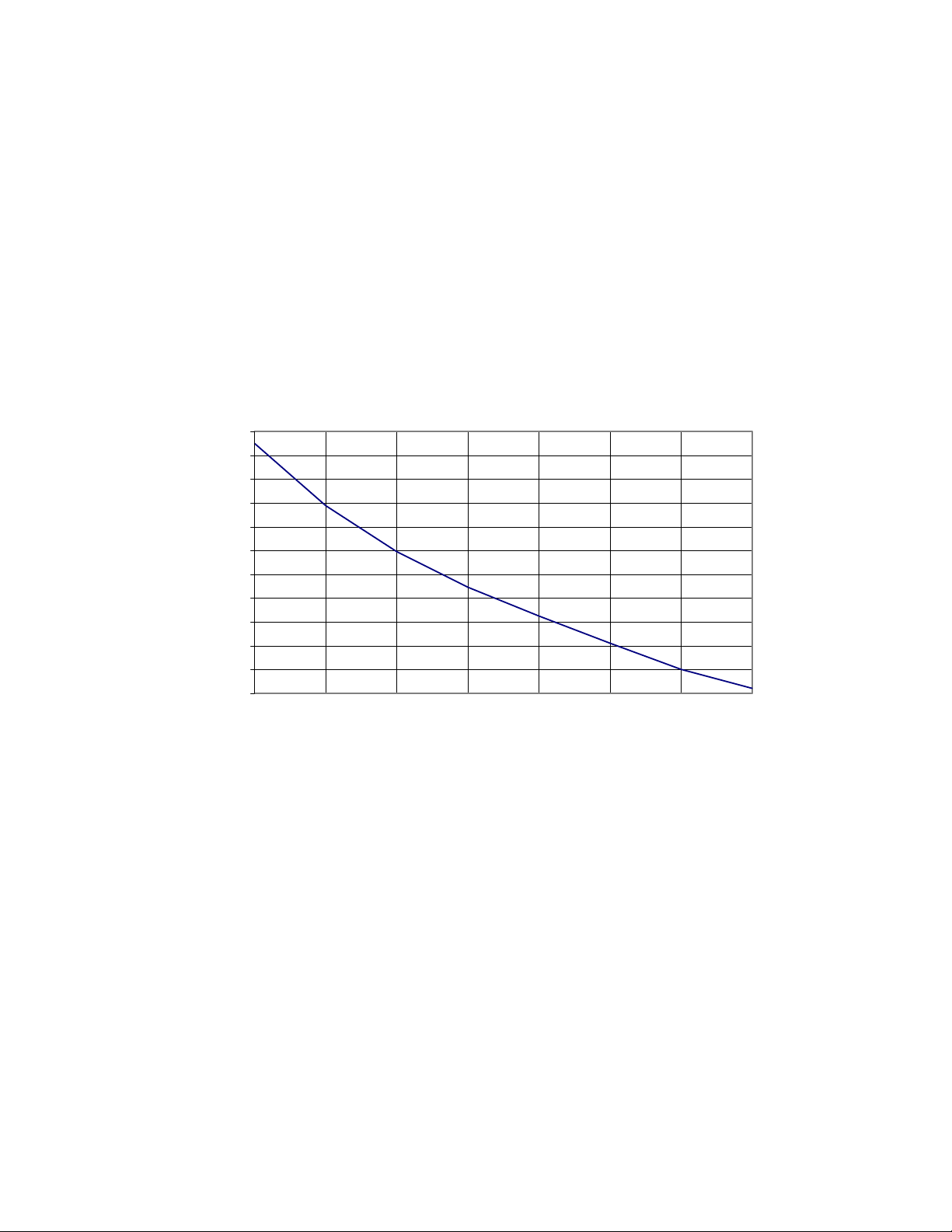

Maintain Rate

The chart below shows typical flow rate required to maintain the oxygen content at

different percentages of concentration in the RBC1-50 Burn-In oven with nitrogen

atmosphere option installed. For example, it requires 36SCFH to keep the oxygen

concentration down to 6½ percent in the closed oven chamber. The preliminary

settings can be determined from this graph. If the oxygen concentration must be

determined more accurately, use an oxygen monitor.

Oxygen Stabilization vs. Flow of N2

22

20

18

16

14

12

%O2

10

8

6

4

2

0

0 9 18 27 36 45 54 63

SCFH-N2

32

Page 37

Troubleshooting

Equipment, which operates for extended lengths

of time, may develop problems. Below are

possible problems and suggested solutions. If

you have a problem not listed and do not know

WARNING

Disconnect the main power switch

or power cord before attempting any

repair or adjustment.

what to do, contact Despatch Industries at our toll free Help Line 800-473-7373.

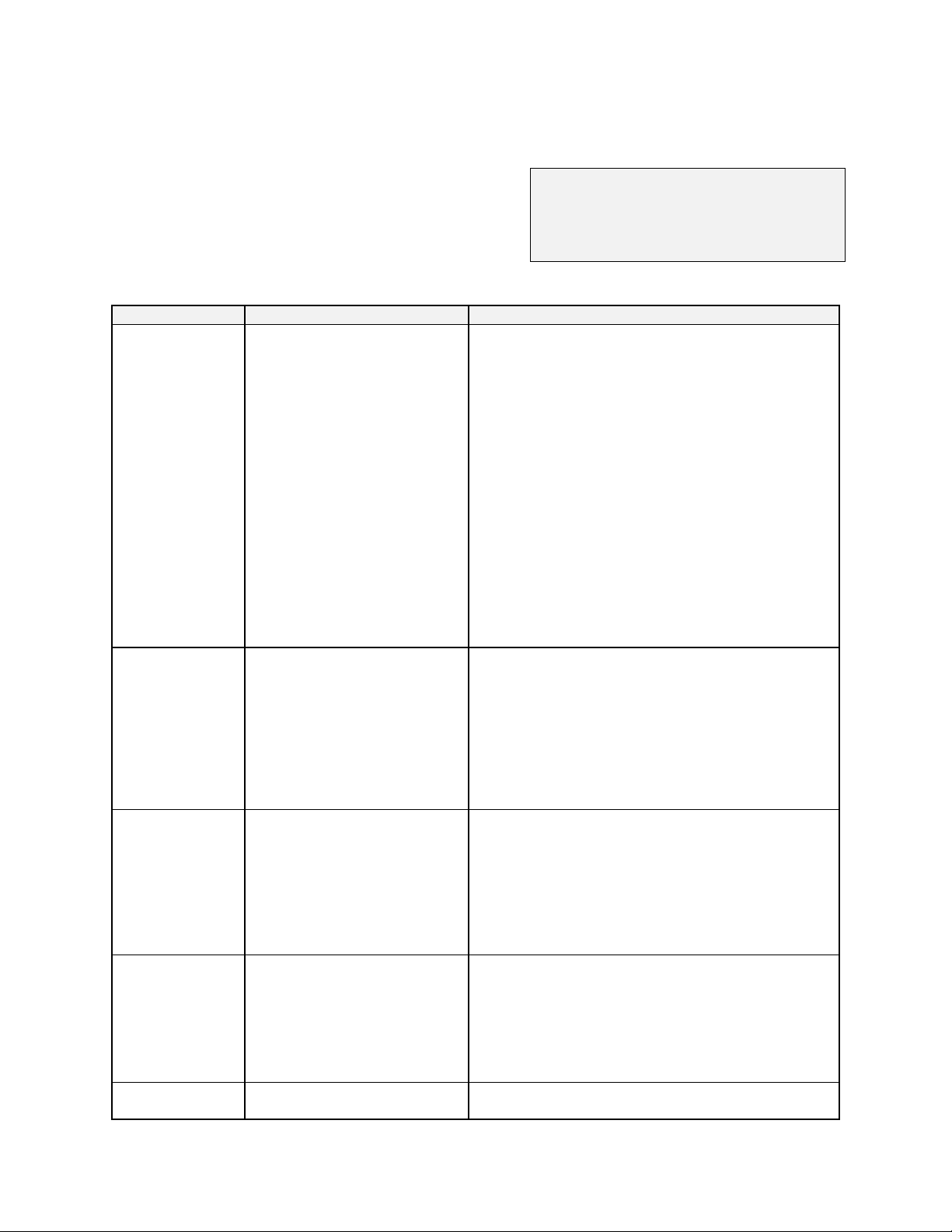

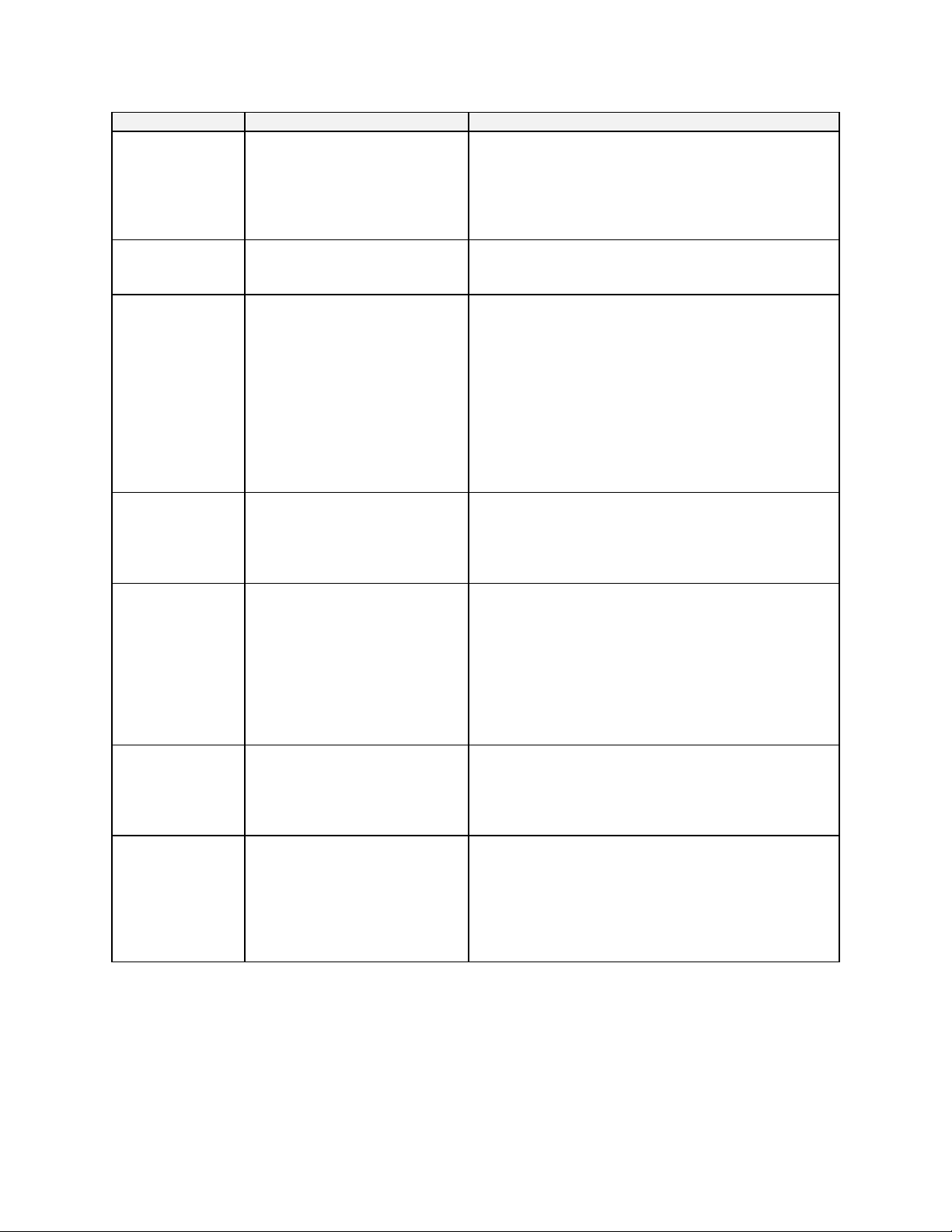

Difficulty Probable Cause Suggested Remedy

Failure to heat No power

Burned out heater

Control malfunction

Loose wire connections

Heater relay failure

No power to the heater

Airflow switch open

Door switch failure

(if installed)

Slow heat up Improperly loaded

Low line voltage

Heating element(s) are

burned out

Fan motor failure

Frequent heater

element burnout

Erratic temp. or

inaccurate temp.

Excess surface

or door temp.

Harmful fumes generated by

load

Spillage or splattering of

material on heater elements

Overheating oven

Control malfunction

Improper tuning parameters

High limit setting

Improper offset

Door seal deterioration Replace door seal.

Check power source and/or oven and wall fuses.

Replace heater (see warranty.)

Replace control.

Disconnect power and check connections behind

control panel.

Replace circuit board.

Reset High limit(s). Make sure control is calling for

heat. Check controller. Check SSR.

Check airflow switch.

Replace door switch.

Reduce load or redistribute load in chamber.

Supply sufficient power and proper connections.

Check for circuit overload.

Replace heater (see warranty statement.)

Replace fan motor.

Increase vent opening or discontinue process.

Disconnect power and clean oven chamber and

elements.

Check the High limit. Do not operate oven over

260°C (500°F).

Replace control.

Check tuning parameters.

High limit should be 10-25°C higher than setpoint.

Check zone calibration.

:

33

Page 38

Difficulty Probable Cause Suggested Remedy

Improper airflow Fan motor failure

Fan wheel seated too low on

fan shaft

Unbalanced fan wheel

Excessive

vibration

Oven will not

control at

setpoint

Damper motor

(exhaust) not

responding

Liquid nitrogen

(LN2) not cooling

Heater does not

shut down until

temp. reaches

the High limit

setting

Nitrogen (N2) not

flowing correctly

Dirty fan wheel

Unbalanced fan wheel

High limit set too low

Control malfunction

SSR malfunction

Air friction of recirculation fan

Damper motor (exhaust) not

responding

Linkage binding

Motor not working

Improper tuning parameters

Solenoid valve not responding

Improper tuning parameters

Tank empty or valve is to the

OFF position

Pressure regulator set too low

Control malfunction

SSR malfunction

Tank empty or valve is to the

OFF position

Pressure regulator set too low

Flowmeter incorrectly set

Replace fan motor.

Adjust fan wheel for 3/16" clearance between

wheel and inlet ring.

Replace fan wheel.

Clean fan.

Replace fan wheel.

Set the high limit higher

Replace control.

Replace SSR and/or check control output voltage.

Open fresh air vent. Unit will not control below

minimum operating temperature with vent closed.

Check tuning parameters.

Observe and correct linkage.

Check supply and signal voltage.

Check tuning parameters.

Check supply voltage and control output. Replace

valve.

Check tuning parameters.

Check liquid nitrogen (LN2) supply and valve

position.

Adjust regulator to 35PSIG maximum.

Replace control

Replace SSR

Check nitrogen supply and valve position.

Adjust regulator within the acceptable range of the

flowmeter.

Adjust flowmeter to the desired flow rate.

34

Page 39

Circuit Board Check

The circuit board mounted on the control panel has three status LED indicators to help

troubleshoot if the oven is not heating.

• If LED 1 is not lit, check 2F and 3F (control fuses), or power switch.

• If LED 1 and LED 3 are lit but not LED 2, check high limit (and optional door

switch, if installed).

If all three LEDs are lit, check 1F and 4F (heater relay fuses), SSR, heater, heater

fuses, and heater relay.

35

Loading...

Loading...