Page 1

Protocol Plus Owner’s Manual PREFACE

ULTRAFLEX DRYING AND FIRING

FURNACE

MODELS 1000, 3615, 3630, 3640

C-204

PROTOCOL

PLUS™

Controller

OWNER’S MANUAL

E-98

Version 2 1

PN 143895

VERSION 2

12/2010

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written perm ission of Despatch Industries, unless for purc haser's personal use.

Copyright © 2010 by Despatch Industries.

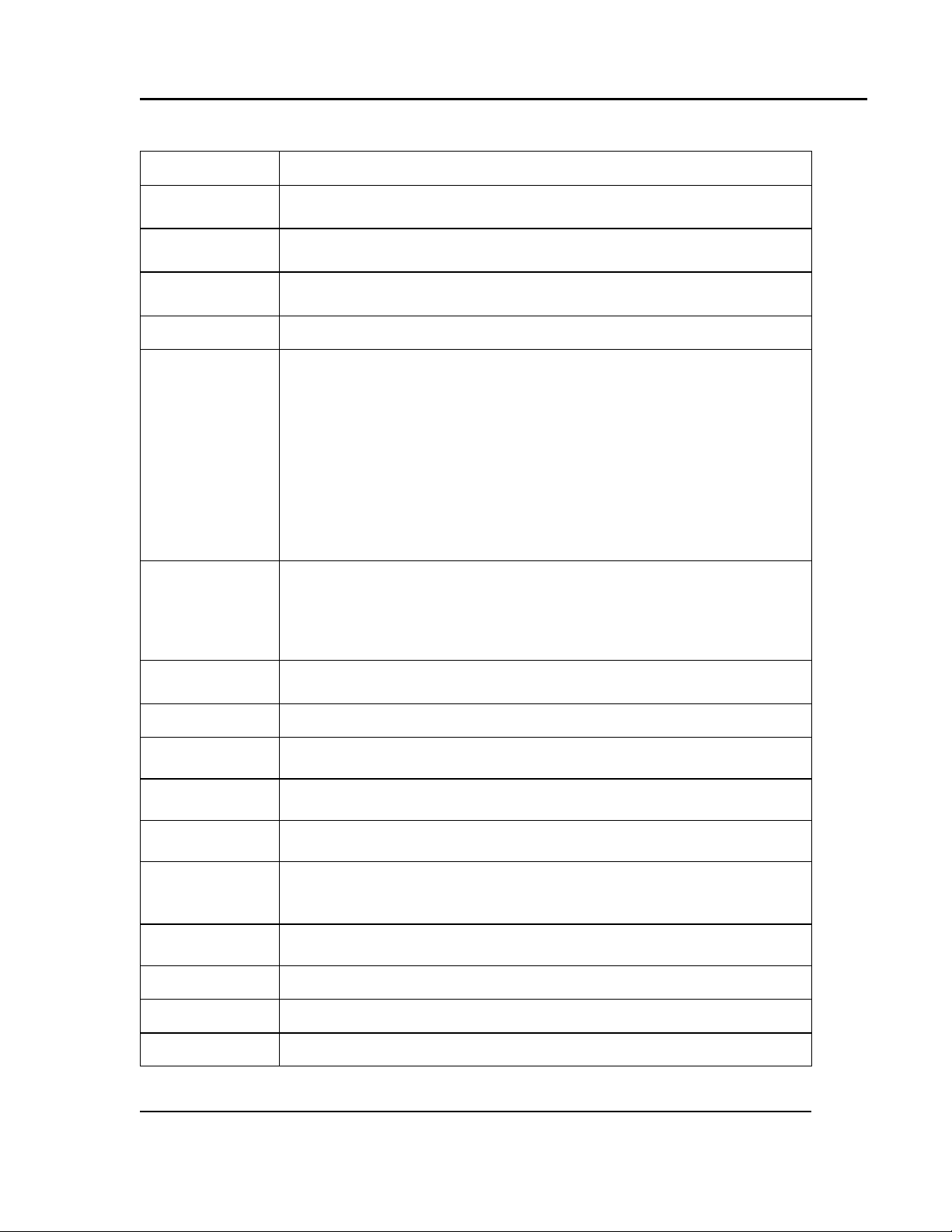

Page 2

PREFACE Protocol Plus Owner’s Manual

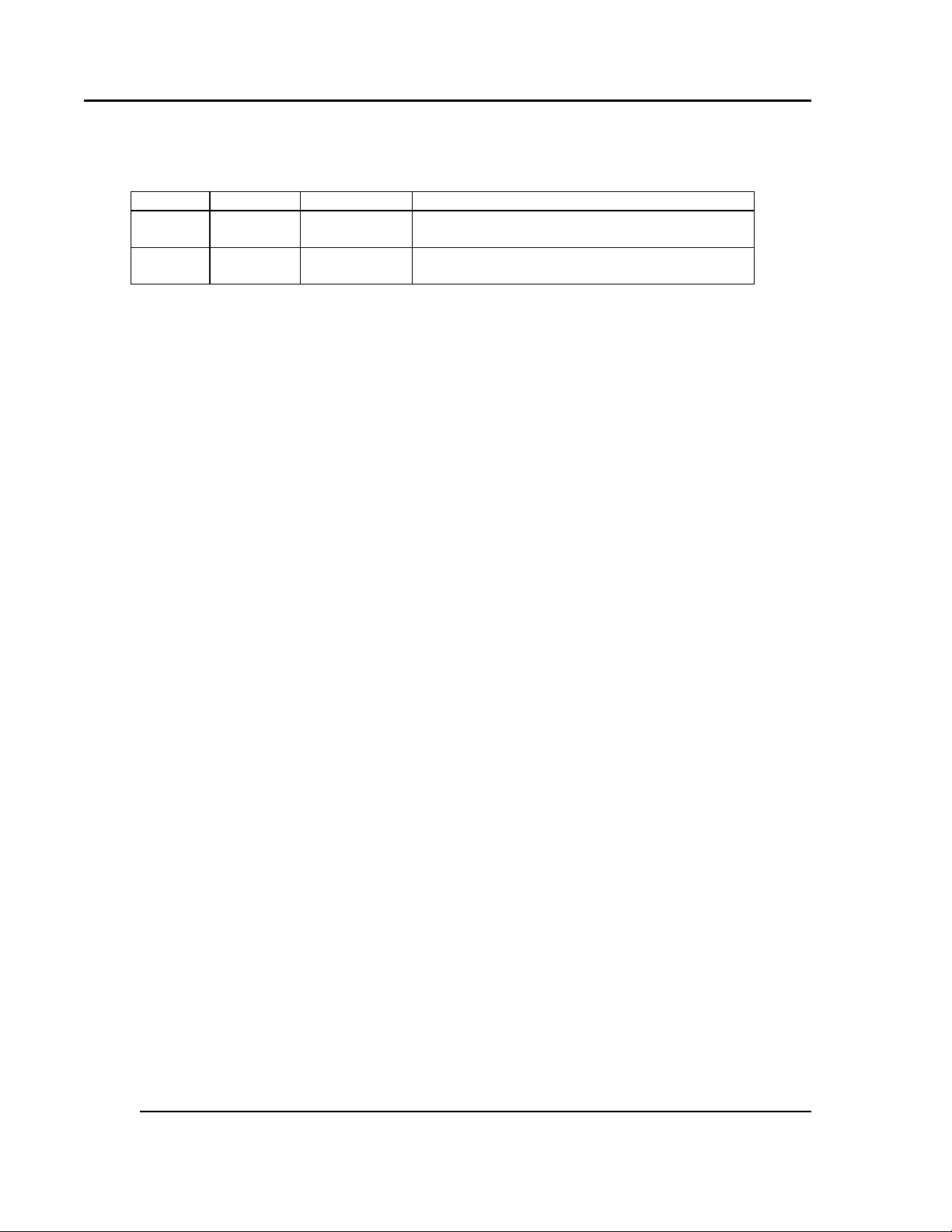

Revision

Date

Author

Description

P

C-195

7/10

K. Livingston

Revise format. Also based on E98 Rev P

(12/2008).

2.0

12/2010

K. Livingston

Remove Protocol Plus Controller to separate

Owner’s Manual

2 Version 2

Revision History

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written perm ission of Despatch Industries, unless for purc haser's personal use.

Copyright © 2010 by Despatch Industries.

Page 3

Protocol Plus Owner’s Manual PREFACE

Version 2 3

Table of Contents

1. Abo ut This Manua l .............................................................................................. 6

1.1. Important User Information ........................................................................ 6

1.2. Manufacturer & Service ............................................................................. 7

1.3. Organization of this Manual ....................................................................... 8

1.4. Conventions ............................................................................................... 8

1.5. Specifications ............................................................................................. 9

2. Safety ................................................................................................................ 10

2.1. Safety I nforma tio n ................................................................................... 10

2.1.1. Lockout ................................................................................................ 10

2.1.1.1. Lockout Requirements ...................................................................... 10

2.1.1.2. Lockout Pro cedu r e with Despatch Products ....................................... 10

2.2. Maintenance ............................................................................................. 11

2.3. Electrical Power ....................................................................................... 11

2.4. Fire .......................................................................................................... 11

2.5. Equipment Lockout Requirements............................................................ 11

3. Theory of Operation........................................................................................... 12

3.1. System Control—In General .................................................................... 13

3.1.1. High-L im it Fu nction ............................................................................. 13

3.1.2. Optiona l Serial Commu nications Hard ware .......................................... 13

3.2. Display Functions .................................................................................... 13

3.3. Modes and Menus .................................................................................... 15

3.4. Indicators ................................................................................................. 16

3.5. Key Fu nc tions .......................................................................................... 16

3.6. Outputs .................................................................................................... 16

4. Assembl y & Set up ............................................................................................. 18

4.1. Install the Protocol Plus Controller ........................................................... 18

4.2. MRC5000 Setup (Optional) ...................................................................... 19

5. Working with Operating Modes ......................................................................... 21

5.1. Start-up Basics ......................................................................................... 21

5.2. Manual Mod e ........................................................................................... 22

5.3. Timer Mode ............................................................................................. 23

5.4. Profi le Mode ............................................................................................ 24

5.5. Auto Start Mode ....................................................................................... 24

5.6. Setup Mode .............................................................................................. 25

5.6.1. Enter and Exit Setup Mode ................................................................... 25

5.6.2. Temperature S cale Conversio n ............................................................. 26

5.6.3. Program Page ....................................................................................... 26

5.6.3.1. Using the Progr am Page .................................................................... 27

5.6.3.2. Programming Optional Relay Outputs ............................................... 27

5.6.4. Sa mp le Profile ...................................................................................... 30

5.6.5. Setting Up Auto Start............................................................................ 31

5.6.5.1. Configure Auto Start ......................................................................... 32

5.6.5.2. Activate Auto Start............................................................................ 33

5.6.5.3. Deactivate Auto Start ........................................................................ 33

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written perm ission of Despatch Industries, unless for purc haser's personal use.

Page 4

PREFACE Protocol Plus Owner’s Manual

4 Version 2

5.6.6. Setting Up PID Page ............................................................................. 33

5.6.6.1. Access the PID Page ......................................................................... 33

5.6.6.2. Setting up Auto Tune ........................................................................ 34

5.6.7. Setting up the Control Page .................................................................. 34

5.6.7.1. Access Contro l Page ......................................................................... 34

5.6.8. Setting up the Communication Page ..................................................... 35

5.6.8.1. Access Communicat ion Page ............................................................ 35

5.6.8.2. Setting up the Real Time Clock Page ................................................ 36

5.6.8.3. Access Real Time Clock Page ........................................................... 36

5.6.9. Setting up the Relay Outputs Page ........................................................ 36

5.6.9.1. Access Relay Outputs Page ............................................................... 37

5.6.10. Setting up the Test Pag e .................................................................... 38

5.6.10.1. Access Relay Outputs Page ............................................................... 38

5.6.10.2. Set ting up the Zone Calibr a tion Page ................................................ 38

5.6.10.3. Access Zone Calibrat ion Page ........................................................... 39

5.6.10.4. Access Factor y Calibrat ion Recovery ................................................ 39

5.6.10.5. Adjusting Actua l Versus Displa yed Parameters................................. 40

5.6.10.6. Setting up the Sensor Calibration Page .............................................. 40

5.6.10.7. Access Sensor Calibration Page ........................................................ 40

5.6.11. Setting up the Enable Page ............................................................... 42

5.6.11.1. Access Enable Page .......................................................................... 42

5.6.12. Setting up Digital Inputs (Optional)................................................... 43

6. Maintenance ...................................................................................................... 45

6.1. Replacement Parts .................................................................................... 45

7. Troubleshooting: Error Messages and Alarm ..................................................... 45

8. Appendices ........................................................................................................ 47

8.1. Quick Reference and Default Values ........................................................ 47

8.1.1. Program Page Default Value s ............................................................... 47

8.1.2. Autostart Page Default Va lues .............................................................. 48

8.1.3. PID Page Default Values ...................................................................... 48

8.1.4. Programming Tab le Wo r ksheet ............................................................. 49

8.1.5. Control Page Default Values ................................................................. 50

8.1.6. Communication (Optional) Page Default Values ................................... 50

8.1.7. Real Time Clock Page Default Va lues .................................................. 51

8.1.8. Relay Outputs (Optional) Page Defau lt Values ..................................... 52

8.1.9. Test Page Default Values ...................................................................... 53

8.1.10. Zone Cal Page Default Values ........................................................... 53

8.1.11. Sensor Cal Page Default Values ........................................................ 53

8.1.12. Enable Page Default Values .............................................................. 54

8.2. Standard Pro du cts Warrant y ..................................................................... 55

Figures

Figure 1. Operato r Int er face. .......................................................................................... 12

Figure 2. Protocol Plus Displays and Control Buttons. ................................................... 14

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Page 5

Protocol Plus Owner’s Manual PREFACE

Version 2 5

Figure 3. Protocol Plus Controller Faceplate. ................................................................. 14

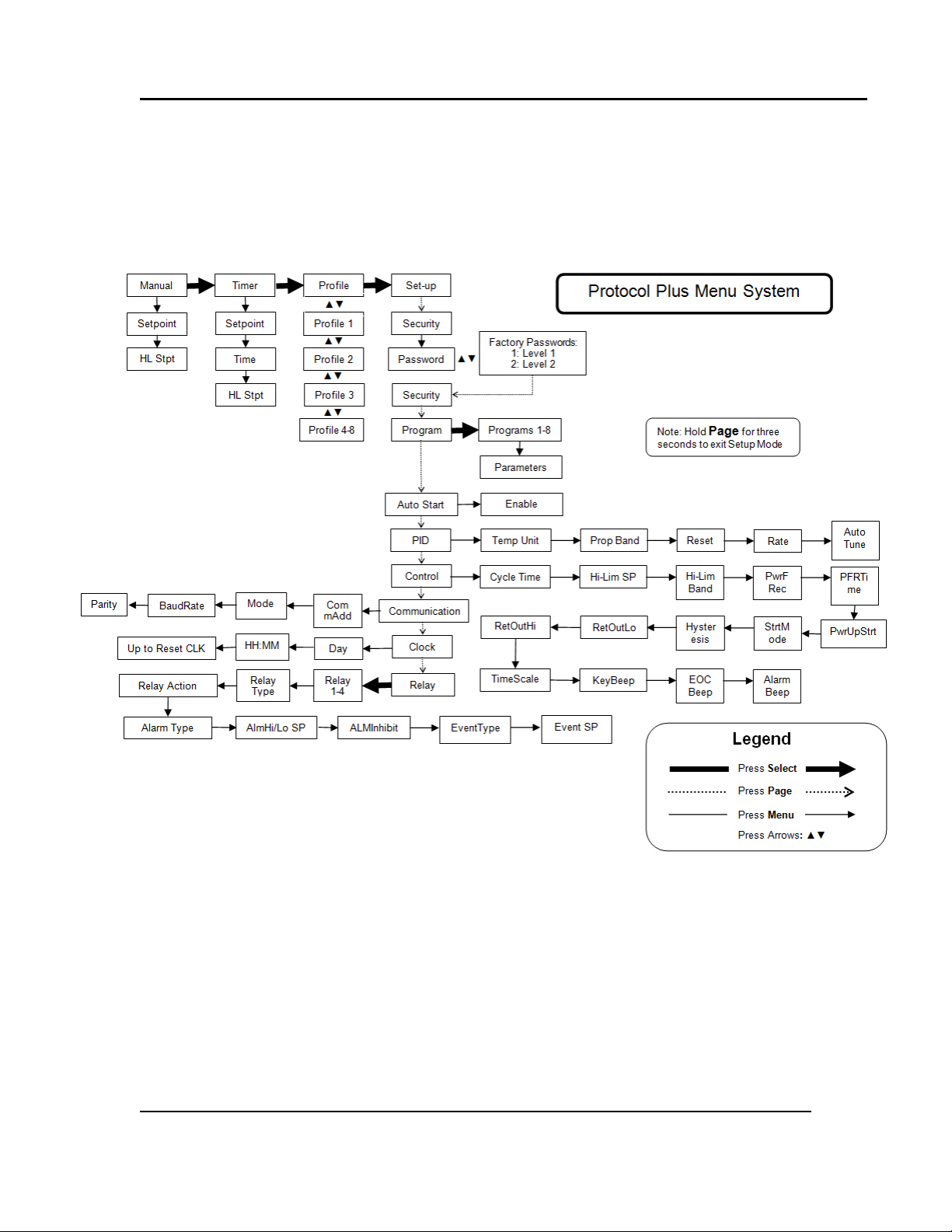

Figure 4. Protocol Plus Menu System—Setu p Det ail ..................................................... 15

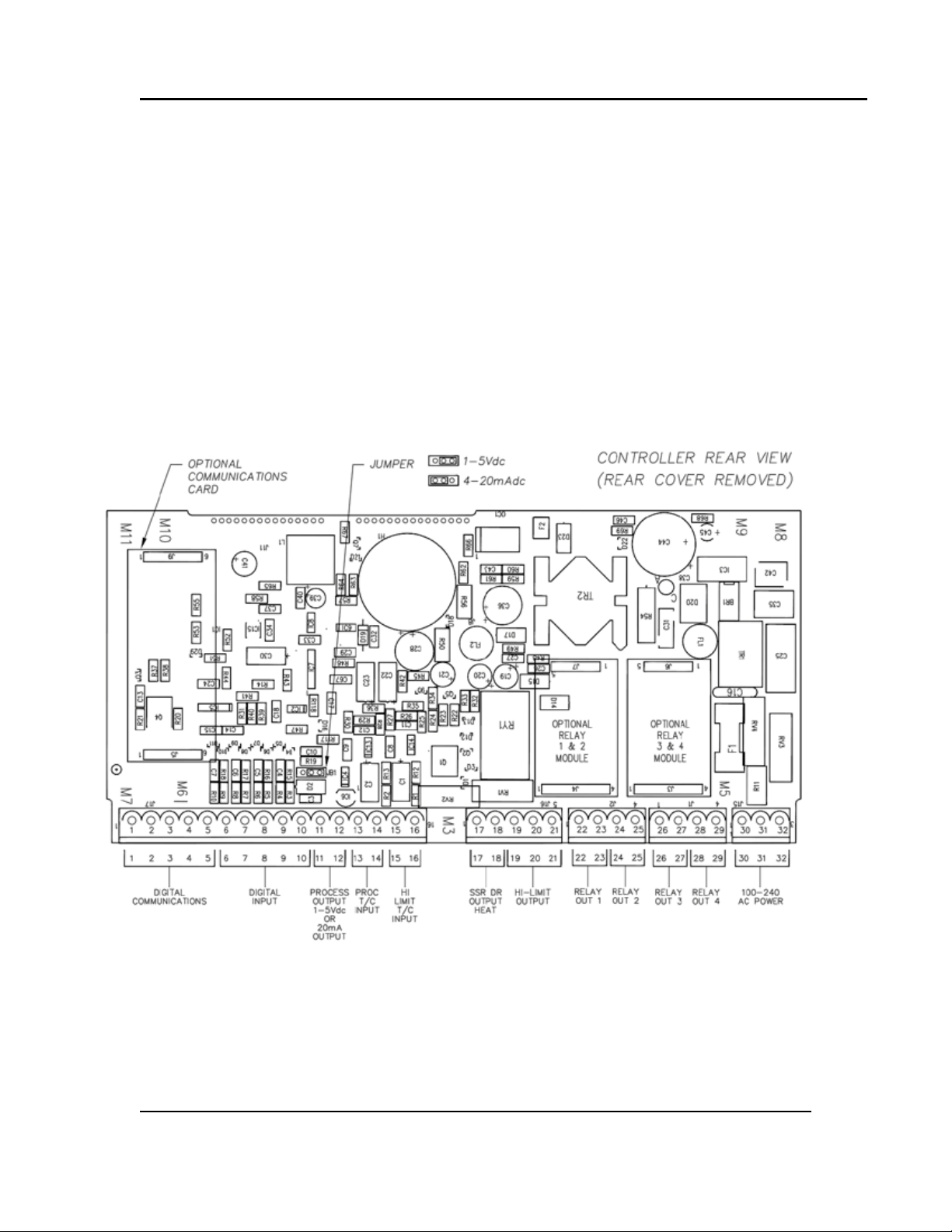

Figure 5. Protocol Plus Controller with Rear Cover Removed, Showing Locations for

Op tional c omponents . .................................................................................................... 17

Figure 6. Protocol Plus Wiring Diagram. ....................................................................... 19

Figu re 7. Samp le Profile. ............................................................................................... 30

Figu re 8. Samp le Profile Values. ................................................................................... 31

Figure 9. Digital Inputs. ................................................................................................. 44

Tables

Table 1. MRC 5000 Settings. ......................................................................................... 20

Table 2. Program Page Menu It ems and Exp lanation. .................................................... 28

Table 3. Parameter Definit io ns and/o r Ranges. .............................................................. 29

Table 4. Auto Start Menu Parameters and Values. ......................................................... 31

Table 5. PID Page Parameter s and Values. .................................................................... 33

Table 6. Control Page Para meter s and Values. ............................................................... 34

Table 7. Communication Page Par ameters and Values. .................................................. 36

Table 8. Real Time Clock Page Parameters and Values. ................................................ 36

Table 9. Relay Outputs P age P ar ameters and Va lues. .................................................... 37

Table 10. Access Relay Out put s Pag e Parameters and Values. ....................................... 38

Table 11. Zone Calibrat ion Page Parameters and Values. .............................................. 39

Table 12. Sensor Calibration Page Parameters and Values. ............................................ 42

Table 13. Enable Page Para meter s and Values. .............................................................. 43

Table 14. Digital Input Par amet ers and Values. ............................................................. 44

Table 15. Error Messages and Next St ep s. ..................................................................... 45

Table 16. Program Page Defau lt Va lues. ....................................................................... 47

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Page 6

ABOUT THIS MANUAL Protocol Plus Owner’s Manual

6 Version 2

1. About This Manual

1.1. Important User Information

Copyright © 2010 by Despatch Industries.

All rights reserved. No p art of the cont ent s of this manual may be reproduced, copied, or

transmitted in any form or by any means including graphic, electronic, or mechanical

methods or photocopying, recording, or info rmation storage and retrie val syst ems without

the written permission o f the publisher, unless it is for the purchaser's personal use.

Printed and bound in the United St at es of Amer ica.

The i nformation in this manual is su bject to chang e without notice and does not represent

a commitment on the part of Despatch Industries. Despatch Industries does not assume

any responsibility for any errors that may appear in this manual.

In no event will Despatch Industries be liable for technical or ed ito r ial omissio ns made

herein, nor for direct, i ndirec t, s pec ial, i ncidental, or co ns e quential damages resu lting

from the use or defect of this manual.

Values displayed on screens are examples only. Though

O

O

those values may be typical , cont act Despatch Industries for

the final value.

Users of this equipment must comply with operating

procedures and trainin g o f operation personnel as required

by the Occupational S af et y and Health Act (OS HA) of 1970,

Section 6 and relevant safety stand ards, as well as other

safety rules and regulations of state and local governments.

Refer to the relevant safety standards in OSHA and National

Fire Protection Associati on (NFPA), section 86 of 1990.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 7

Protocol Plus Owner’s Manual ABOUT THIS MANUAL

Danger!

Global Headquarters

Contact

Service & Technical

Support

Despatch Industries

International/Main: 1-952-469-5424

www.despatch.com

Service: 1-952-469-8230

Version 2 7

Only fully-trained and qualified personnel should setup and

maintain this equipment. Improper setup and operation of this

equipment could cause an explosion that may result in

equipme nt dama ge , pe rsonal injury or possible death.

The i nformation in this doc ument is not intend ed to co ve r all possi ble c ond itions and

situations that might o ccu r. The end user must exerc ise caut ion and common se ns e when

installing or maintaining Despatch Industries products. If any questions or problems

arise, call Despatch Industries at 1-888-DESPATCH or 1-952-469-5424.

1.2. Manufacturer & Service

The P r o tocol Plus™ controller is a proprietary controller designed by Despatch

Industries.

Despatch has specialized in thermal processing for over 100 years. Technical expertise

gained over those years helps pr ovide innovative solut ions to cr itical applications in

vertical markets and cutting edge technology worldw ide. Despat ch products are backed

by a drive for long-t er m custo mer satisfaction and a strong sense of responsib ilit y. T he

worldwide network of factory-trained Serv ice Pr ofes sionals is ava ilable to support your

Despatch equipment . From full service preventive mainte nanc e to ro ut ine repa ir and

certified calibration and uniformity, the Despatch ser vice net wor k is posit ioned to

respond to your business needs. O ur ser vice programs are customized to meet your

specific needs using o u r Advant age S er vice Assurance P r ogram (ASAP). For more

information on ASAP, visit www.despatch.com.

8860 207th Street

Lakeville, MN 55044

USA

US toll free: 1-888-337-7282

Fax: 1-952-469-4513

info@despatch.com

US toll free: 1-800-473-7373

Service @despatch.com

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 8

ABOUT THIS MANUAL Protocol Plus Owner’s Manual

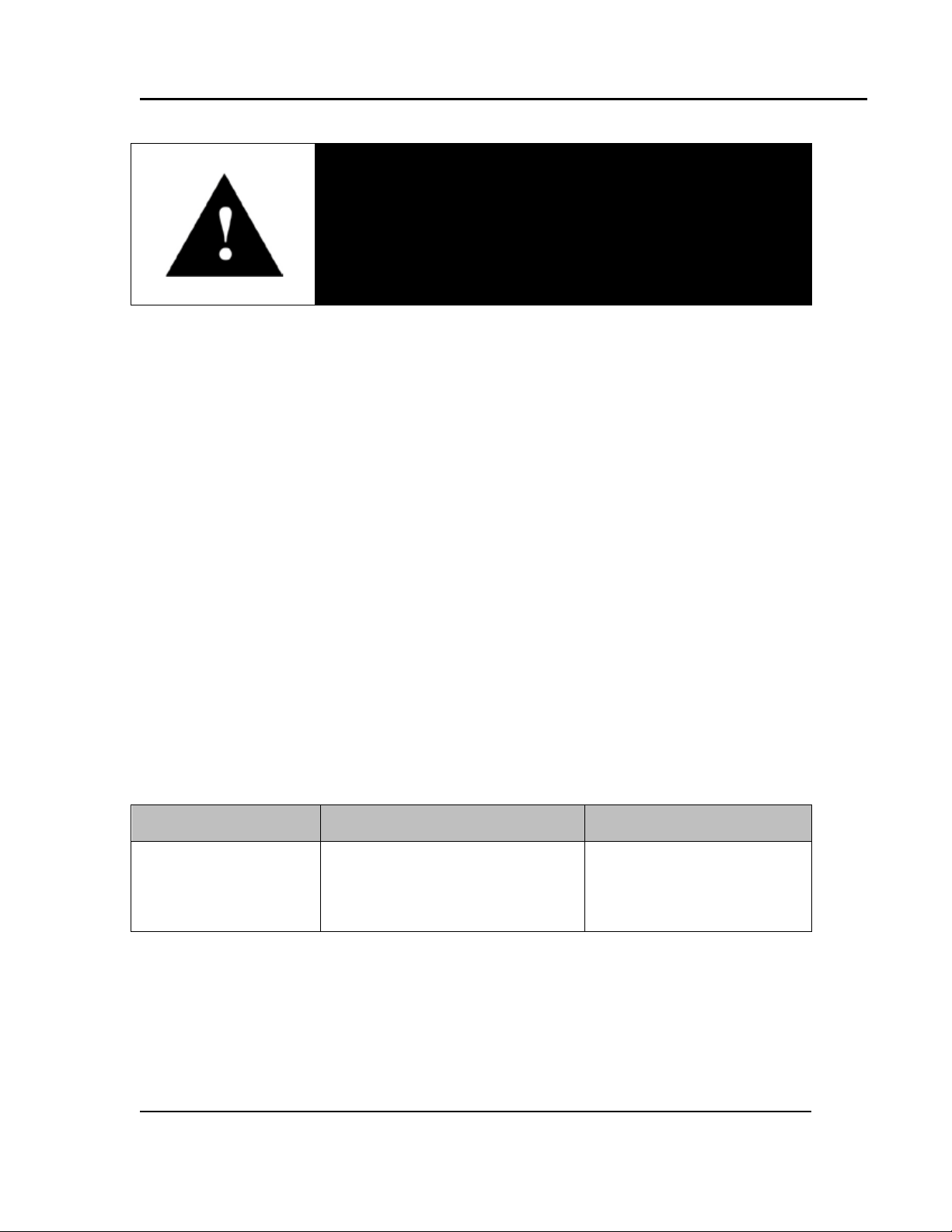

Danger!

This icon signifies information that descr ibes an uns afe condition

Danger!

A condition that may res ult in deat h, serious injury, or damage to

equipment.

Warning!

A condition that may res ult in ser ious injur y or dam age to

equipment.

Caution!

A condition that may res ult in damage to equipment or product.

LOG OUT

Reversed-out, Bold, 10pt Arial typeface indicates a s pecific k ey or

button on screen t o click.

8 Version 2

1.3. Organization of this Manual

This owner’s manual c ontains the most comprehensive s et of information for the

Despatch Protocol Plus controller, including installation instructions, theory of operation,

operating instructions, among other things.

Failure to heed warnings in this instruction manual and on the

oven could result in personal injury, property damage or death.

1.4. Conventions

This icon signifies im por tant information.

O

that may result in deat h, ser ious injur y , or damage to the

equipment.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 9

Protocol Plus Owner’s Manual ABOUT THIS MANUAL

UL, cUL listed:

UL file E136675

CE compliance

Low Voltage Direc tive 2006/95/EC

Power supply:

12 to 24 VAC/VDC +/-10%, DC to 60Hz, 30VA Maxim um

Temperature:

Operating 0 to 50°C

Humidity:

90% or less, non-condensing

Sensor inputs:

Temperature

Readout Stability (+/-1°F/10°F Change in ambient temperature)

Message display:

0.2 inches high ( 5mm)

Time base:

+/- 4 seconds accuracy in 24 hours

Heat control

output:

SSR Drive 24VDC nominal @ 70mA

Relay output:

(plug-in module)

Form A dry contact, rated 3 amps @ 24-264VAC

Retransmit

output:

1 to 5 VDC into > 100K ohm load

Communications:

• RS232 Single drop, isol ated

RS485 Multi-dr op, isolated

Remote inputs:

(plug-in module)

Dry-contact closure type with less than 250 ohm ON resistance

Front panel:

NEMA 4X (with gasket)

Dimensions:

3.57H x 7.24W x 2.84D inches (91H x 184W x 72D mm)

Panel opening:

3.63H x 7.30W inches (92H x 185W mm)

Version 2 9

1.5. Specifications

to:

display:

• EMC Directive 2004/108/ E C

•

• 100 to 240 VAC +10% -15%, 50-60Hz, 30VA Maximum

•

• Storage -20 to 60°C

•

• Type J thermocouple -73°C t o 760°C (-100° F t o 1400°F)

• Input impedance 1M ohm or great er

• Common mode noise rejection of 140db@60Hz

• Common mode input voltage of +/-12.0 VDC

• Sample rate of at least 1 sample per second

• Stability of +/- 0.5°C per 5°C change in ambient temperature

• Repeatability of +/- 0.5°C, or +/-0.1% of sensed temperature (whichever

is greater)

• Accuracy (@ 77°F + /-0.2 per c ent of span (+/-3°F)

• Supply Voltage Influence of +/-0.5°C per 10% change in nomi nal line

voltage

• 1 degree resolution ( C or F)

• Accuracy after calibration of +/- 1°C, or +/-0.2% of sensed temperature

(whichever is greater) @25°C

• Four-digi t seven-segment LCD, 0.43 inches high (11mm)

•

• Two-line, 16 alpha-numer ic 5x 7 dot matrix characters per line

•

(plug-in module)

• RS422 Multi-drop, isolated

•

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 10

SAFETY Protocol Plus Owner’s Manual

Danger!

10 Version 2

2. Safety

2.1. Safety Information

Do not wo rk on the Protocol Plus controller without reading and understanding this

section which contains important information and warnings. Ignoring these warnings can

result in death, serious injury or damage to the machine and product.

2.1.1. Lockout

Machine lockout places t he Protocol Plus controller into a zero energy state and prevents

accidenta l machine start up. Always follow the Lockout Proced ur e descr ibed in this

Section before cleaning, maintaining or repairing the Protocol Plus controller. An

accidenta l start-up, while working on the Protocol Plus cont roller, can result in serious

inju ry or death.

2.1.1.1. Lockout Requirements

1. Every power source that can energize any element o f the Protocol Plus controller

must be shut off at the closest po ss ible pow er source. This includes air, water and

electricity, includ ing the Disconnect Switch.

2. After energy sources ar e locked out, test to ensure circuits are de-energized.

2.1.1.2. Lockout Procedure with Despatch Products

Personnel author ized to lockout equipment must have the necessar y locks to perform the

lockout.

1. Physically disconnect all electrical power to the machine or lockout the appropriate

breaker or disconnects.

2. Close all valves and bleed off any pressure.

3. Test for power by attempting a start with the machine co nt ro ls.

4. Identify the Lockout Condition with a tag on the elect r ical disconnect and p neu matic

shut of f valve .

5. When work is complete, remove all tags and restore the machine to its wo r king state.

Electric a l pa ne ls contain high volt age. Disconnec t a nd loc k o ut

the power supply before working inside any electrical panels.

Failure to lock out the power supply can result in death or injury.

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Page 11

Protocol Plus Owner’s Manual SAFETY

Danger!

Danger!

Version 2 11

2.2. Maintenance

Only qualified and trained personnel should perform maintenance or repair.

2.3. Electrical Power

Only qualified and trained personnel should perform electrical maintenance or electrical

repair.

• Before performing maintenance, disconnect all electrical power from the machine.

Use a padlock and lockout all disco nnect s feeding power to the machine.

• Never clean or repair the controller whe n in op eration.

• Unauthorized alterat ions o r mod ifications to Protocol Plus controller are str ictly

forbidden. Never mod ify any electr ica l circu its. Unaut ho rized modifications can

impair the fu nction a nd sa fety of the Protocol P lus controller.

Contact with energized electrical sources may result in serio us

injury or death.

2.4. Fire

2.5. Equipment Lockout Requirements

Keep the Protocol Plus controller clean and free of scrap mat er ials, oil or solvents to

pre vent the p ossibility of fire . In the e vent of fire, us e a fir e extinguisher as follows.

1. De-energize the machine immediately by pushing an Emergency Stop push button

2. Turn off the remote main disconnect (customer supplied disconnect).

3. Extinguish the fire.

Always disconnect all power before extinguishing a fire.

Attempting to extinguish a fire in a machine connected to

electrical power can result in serious injury or death!

To prevent injury or equipment damage during inspection or repair, the Protocol Plus

controller must be locked out.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 12

THEORY OF OPERATION Protocol Plus Owner’s Manual

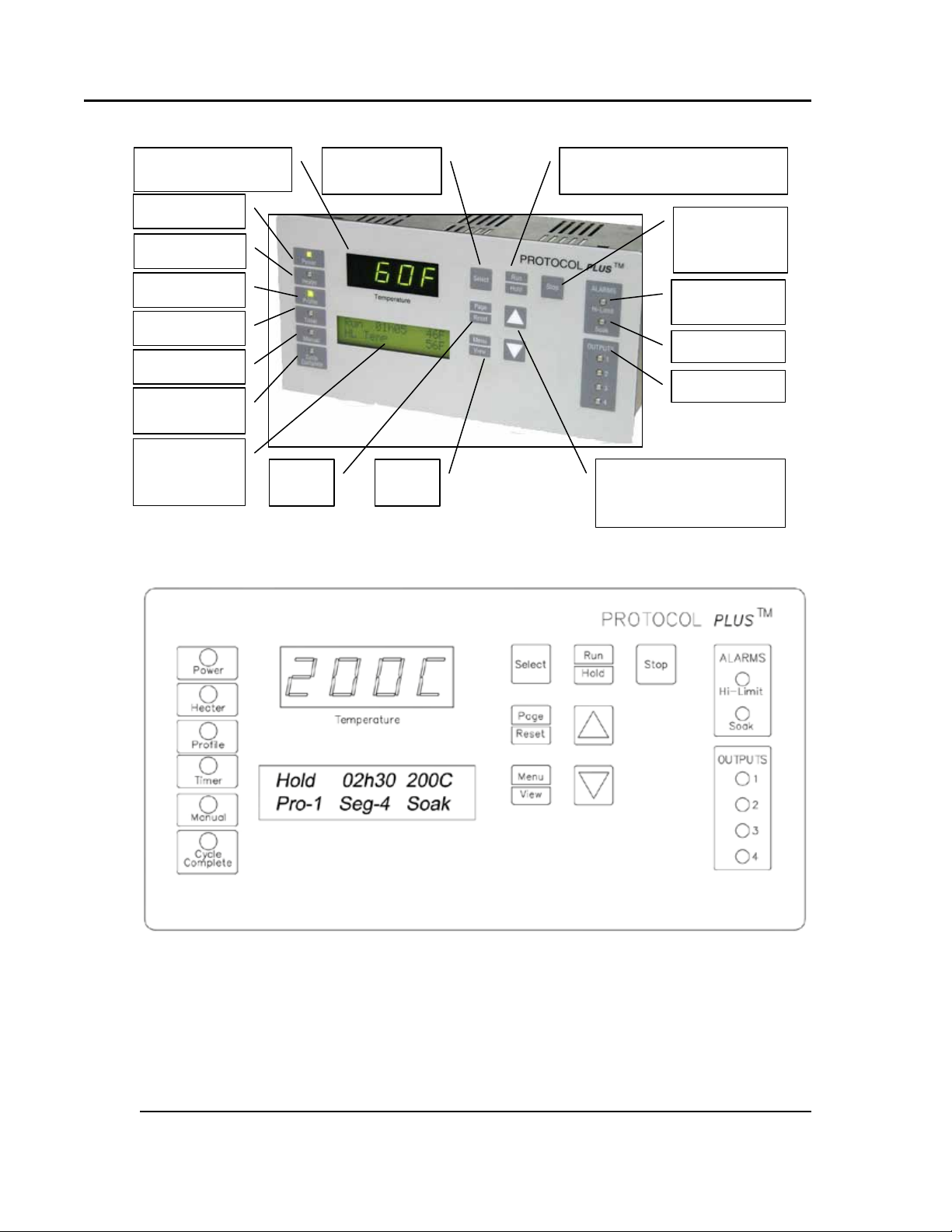

Figure 1. Operator Interface.

12 Version 2

3. Theory of Operation

The Protocol Plus is a modular micro pr ocessor based digital te mperatu r e cont roller

(Figure 1). The Protocol Plus controller operates as a dualfunc tioning controller/high limit instru ment. The control

po rtion u tiliz e s a time -pr oportioning voltage signal to

control heating devices with minimal tempe rature

fluctuations.

The h i gh limit portion protects the product and /or the oven

from overheat ing. If the product being processed has a

critical high te mperat ur e limit, t he high limit setpoint

should be set to a temperatur e somewhat below the

temperature at which the product could be damaged. If the product do es not ha ve a

critical high te mperat ur e limit, t he high limit set p oint s ho uld be set 5 to 15 degrees higher

tha n the maximum programmed setpoint at w hich the ove n will operate.

Th e Prot oc ol Plus controller provides three primary operat ing modes:

• Manual: Oven operates cont inuously at a fixed temperature until turned off.

• Timer: Oven operates at a fixed temperatu r e for a user-selected time period, then

automatically tu r ns off.

• Profile: Temperat u r es increase o r d ecr ease as defined by one of eight pre-

programmable ramp and soak profiles. Each pro file co nt ains up to eight r amp and

soak segments. The profiles can be linked to provide additional temperatur e

combinations.

In addition these primary operating modes, the Protocol Plus controller employs a

Stopped Mode, Auto Start Mode, Setup Mode and Fast Start Mode:

• Stopped Mode: All control and relay outputs are off. Stopped Mode is integrated

into each of the modes of operat ion.

• Aut o Start Mode: C ontrol may au tomat ic ally star t Manual, Timer, or Prof ile

mode based on a preset time and day. Optional event outputs can be util ized

during Manual, Timer, or Profile modes.

• Setup Mode: Provides access to control configuration and programming of

profiles. Set u p Mod e contains ten separate electronic “Pages” where con figuration

and programming para meter s (Menu items) are found and can be manipulated .

• Fast Start Mode: Pro vides for automatic startup of an operating mode w hen

po w er is applied. Use Fast St art Mo d e if the same mode of operation is used every

day. The user can turn on the power and the oven w ill start t he desired process

automatically. The Fast Start Mode is controlled by the Power-Up St a rt

parameters o n the Control page.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 13

Protocol Plus Owner’s Manual THEORY OF OPERATION

Version 2 13

3.1. System Control—In Ge ner a l

• T he Proto col Plus controller provides outputs for the cooling fan, door lock

switch/door release pus hbutton, and optional beacon lig ht

• As many as eight profiles for oven hea ting cycles are stored in the Proto col Plus

controller. Access profiles using the Protocol Plus keypad.

• The Prot oco l Plus cont r ols the solenoid valves in an in ert atmosphere oven for p urg e

and maint ain operat ion

3.1.1. High-Limit Function

The Protocol Plus controller has an integ rated h igh limit function which d is able s the

heater output when t ripped. Find High-Limit temperature readouts on LC D Line #2 in all

Modes (Stop, Run, Hold, and Standby) except Setup Mode. High-Limit temperature is

displayed for 10 seconds, alternating with current Mode and Status display for 10

seconds. The contro l will not allow t he high limit set point to be set below the current

setpo int value.

If the high limit trips, the Hi-Limit indicator w ill light and the relay must be ma nu a ll y

reset. Allow the o ven to cool several degrees (or increase t he high limit set point) and then

press Reset. The indic ator will turn of f.

3.1.2. Optional Serial Communications Hardware

Optional MODBUS RS422/485 serial communications hardware may be installed on the

Protoco l Plus controller, with a 9-pin communicatio ns port located on rear of oven. This

provide s the a bility to netwo rk the oven(s) with a host PC.

3.2.

Display Functions

The Protocol Plus contro ller has t wo displa ys. A dedicated LED upper display shows t he

oven temperatur e (Figure 2). A two line LCD lower display provides information on

control stat u s, high limit temperat ur e and a llows changes to be made to the control

settings. Figure 3 shows a schemat ic of the Protocol Plus face plate.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Page 14

THEORY OF OPERATION Protocol Plus Owner’s Manual

Power

Heater

Profile

Timer

Manual

Cycle

Complete

Oven Temperature

Information

Hi-Limit

Alarm

Outputs 1-4

Adjust parameter

Select mode

of operation

Page

Reset

Menu

View

Run/Hold:Pr ess to activate

mode of operation

Stop: Press

Mode

Figure 2. Protocol Plus Displays and Control Buttons.

Figure 3. Protocol Plus C ontroller Faceplate.

14 Version 2

to Stop any

Soak Alarm

on control

status

settings up or down as

necessary

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 15

Protocol Plus Owner’s Manual THEORY OF OPERATION

Figure 4. Protocol P lus Menu System—Set up Deta i l

Version 2 15

3.3. Modes and Menus

The Protocol Plus contro ller uses a menu system to display, setup and run the different

modes and configurations available fo r the LCC O ven (Figure 4).

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 16

THEORY OF OPERATION Protocol Plus Owner’s Manual

16 Version 2

3.4. Indicators

Refer to Figure 2:

• Power LED: Indicates power supplied to instrument

• Heater LED: Indicates heater output active

• Profile L ED: Indicates Pr ofile Mode is in operation

• Timer L ED: Indic a tes Timer Mode is in operat ion

• Manual LED: Indicat es Manual Mode is in operatio n

• Cycle Complete LED: Indicates co nt ro l is in Stopped or Standby modes.

• Hi-Limit Alarm LED: Indicates high limit r e lay has tripped (de-energized).

• S oak Alarm LED: Indicates the guarant eed soak deviation is in alarm condition.

• Outputs 1 through 4: Indicate that the optional relay outputs are in the ON state.

These output s may be configured as timed event outputs, process temperature trip

po int outputs, alar m outputs, or as an end of cycle relay ou tput. T he ON state can be

configured as energ ized or de-energized.

3.5. K ey Fun cti on s

Refer to Figure 2:

• Select: Press to select mode of operat ion. In Set u p Mode, to select profile number or

relay. In Profile/Run Mode, p r ess simulta neo usly with the UP key to advance a

segment.

• Run/Hold: Press to activate a mode of operation. If a Profile (or T imer) Mo d e is

running, pressing the Run/Hold key will place the Profile (or Timer ) in Hold status. A

subsequent press w ill resume the Pr ofile (Timer).

• Stop: Press to stop any mode of operation.

• Page/Reset: While in Setup Mo de, pr ess to access d ifferent P ages of configuration,

Press this key to silence an alarm if the instrument alarm sounds during operation. In

an operating mode, if an alarm or er ror cond it ion occurs, p r ess t his key to retur n the

instrument to normal oper ation once the condition is cleared.

• Menu/View: While running any operating mode, pressing this key will display the high

limit setpoint. While in Setup Mode, pressing this key will provide access to each

Menu parameter.

• ▲▼: Press to adjust parameter settings. In Profile/ Stopp ed Mode, press to select

profile to run. In Prof ile/R un Mode, pr ess ▲ sim ultane ous ly with Select to force the

program to advance one segment .

3.6. Outputs

The Protocol Plus contro ller comes standard with an out put s ignal that can transmit

temperature data to a user-supplied recording device. Opt ional output relays (four) can

also signal user-specified events or alarm to ext er nal devices (Figure 5).

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 17

Protocol Plus Owner’s Manual THEORY OF OPERATION

Figure 5. Protocol Plus C ontroller with Rear Cover Removed, Showing Locati ons for Opti onal

Version 2 17

• Heati ng output: The cont rol output is a DC voltage open-collector output which is

time-proport ioned and des igned to control a heat control device such as a solid stat e

relay.

• High limit: The high limit outpu t is a form C relay wh ic h is en erg ized un de r normal

operating condit ions. If t he co ntrol senses a tempe rature highe r t han t he high limit

se tpoint, or if there is a sensor e rr or, the high l imit relay will de-energize until the

condition is cleared and Reset is pressed. When the high limit relay is de-energized,

the he ate r is d is abled.

• Retransmission: The r etransm ission outp ut is a D C 1 to 5 volt or 4 to 20 ma (DC)

signal that is proport ional to the process temperature. The signal can be an input to

other devices such as a chart r eco r der.

• Relay (four optional outputs): T he four form A dry contact r elay output s can be

configured to funct ion as alar ms, event s, or end of cycle. The se o ut p ut s can be

ut ilized in Manual, Timer, or Pro file Modes.

components.

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Page 18

ASSEMBLY & SETUP Protocol Plus Owner’s Manual

Danger!

All grounding and safety equipment must be in compliance with

Warning!

18 Version 2

4. Assembly & Setup

applicable codes, ordinances and accepted safe practices.

Disconnect the main power swit ch or power cord before

attempting any rep air o r adjustment.

4.1. Install the Protocol Plus Controller

When replacing a Protocol Plus controller, follow the steps below. Tools required

for installation include ¼” socket set with #1 bit, #2 Philips screwdriver.

1. Disconnect the power.

2. Remove the screws from the sides of the control panel and slide it forward.

3. Unplug all terminals on the rear of the control, noting the proper

connections (

4. Remove the four retaining clips for the control.

5. Remove the control.

6. Insert the new control into the panel.

7. Fasten the four retaining clips.

8. Re-plug all terminals.

9. Fasten the control panel.

Figure 6).

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 19

Protocol Plus Owner’s Manual ASSEMBLY & SETUP

Figure 6. Protocol P lus Wi rin g D iagr am.

Version 2 19

4.2. MRC5000 Setup (Optional)

Refer to instruction s pro vid ed reco rder manufacturer for more

O

Temperature is retr ansmitt ed t o t he MRC5000 recorder from t he controller. Set up the

recorder by:

1. Ensure hardware jumper JU1 is in place for t he 5 VDC setting (Refer to MRC5000

Manual included).

2. Move Mode to PROG/TEST/CAL to display Prog.

3. Press ▼ twice to d is pla y Inps. Move to each Parameter Co d e using ▼or ▲. Adjust

each Parameter Code using the setti ngs in Table 1.

4. After adjusting a ll set ti n g s , mov e Mode to RUN. Disp lay on bot h the Recorder and

controller shou ld read t he same.

specific installation notes.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 20

ASSEMBLY & SETUP Protocol Plus Owner’s Manual

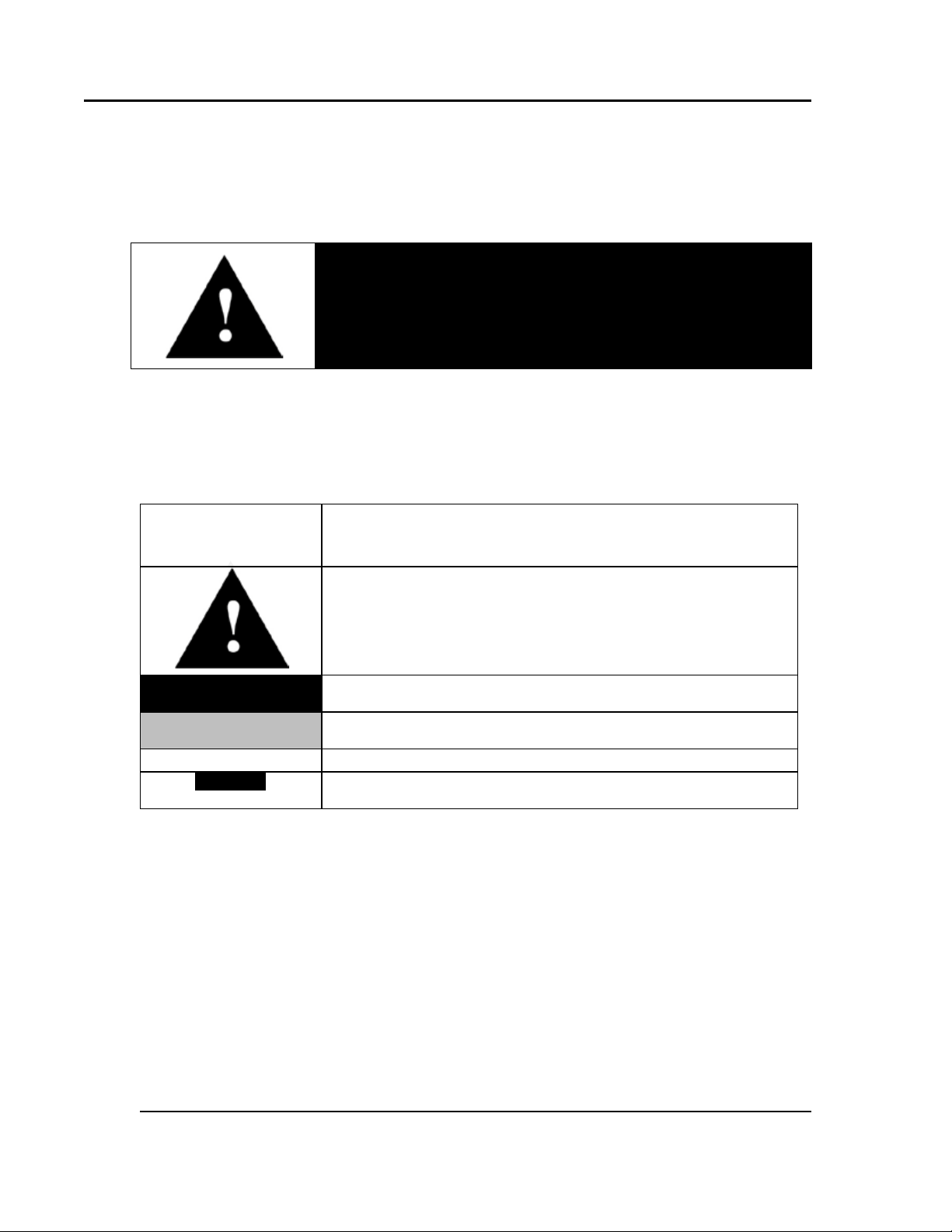

Parameter Code

Degrees C

Degrees F

Inps

18

18

Icor 0 0

diSP

On

On

dPOS

0 0 EUU

1

400 752

EUL1

0

32

ChUP

400

800

2

ChLO

0

0

DFF

1

1

20 Version 2

Table 1. MRC 5000 Settings.

1

These values must match the settings RetOutLo and RetOutHi on the Protocol Plus Contr ol page. For

example, if RetOutLo is 32, EUL must read 32.

2

Chang e 0 -400 chart paper to 0-800 chart paper. Depending on th e equipment used, 0-600 paper may be

used if the maximum temperature is 500 degrees F.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 21

Protocol Plus Owner’s Manual OPERATION

Version 2 21

5. Working wit h Oper at ing Modes

Users and operators of this controller must comply with

operating procedures and training of operating personnel as

required by the Occupatio nal Safety and Health Act (OSHA) of

O

5.1. Start-up Basics

1970, Section 5 and relevan t safety stand ards, and other safety

rules and regulations of state and local go vernments. Refer to

the relevant safety stand ards in OSHA and National Fire

Protection Associati on (NFPA), Section 86 of 1990.

Configuration controls may need to be changed depending on

O

At initial power -up, control is in Manual/Stopped Mode (unless the Autostart or Fast

Start Modes are active). To activate any o p er ating mode from Manual/Sto p ped Mod e,

press Select until the desired mode is displayed and then pres s Run. If the prop e r Profile

number is not displayed when t he Pro file Mod e is accessed, p r ess

desired Profile number is d ispla yed, then press

(displa y r ea ds None), no profiles ar e cur r ent ly progr ammed. Refer to Section 5.6 for

instructions about setting up profiles.

Note that:

• When the lower LCD display reads HL Temp, the Hi limit ther moco up le actua l

temperature read ing is displa yed. Note that the actual temperature reading is not an

error message.

• T he t emperat ur e setpoint can be adjusted while Manual or Timer Mode is running by

pressing ▲ or ▼.

• T o mo mentarily hold the Timer or Profile Mode, press Hold. To cont inue the Timer

or Profile Mode, press Run.

• To r eturn to St opped Mode at any time, press Stop and the Cycle Complete L ED wil l

illuminate.

Note that the control can be configured to automatically activate Manual, Timer or

Profile Mode when power is applied (power switch turned ON). See Contro l Page in the

Setup Mode to utilize the Fast St art mode (Section 5.6.7).

the mode used. Refer to the specifi c op erat in g instructions

below, for more information.

▲ or ▼ until the

Run. If no profile numbers are displayed

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 22

OPERATION Protocol Plus Owner’s Manual

22 Version 2

Control can be configu red to auto mat ically activate Manual,

O

5.2. Manual Mode

1. Press Select until Manual displays.

Timer or Profile Mode when po we r is ap plied (power swit c h ON).

Refer to Section 5.5.

Press Run at any time in the procedure to activate Manual Mode.

O

2. Press Menu to display the Pro cess Temperat u r e Setpoint (Setpt). Change Setpoint

(Setpt) by pressing ▲ or ▼.

If the SPChange on the Enable page in Setup Mode ha s been set

to DISABLED, it must be changed to ENABLED befo re any

O

3. Press

4. Optional feature: Press

5. To start Manual Mod e, press Run.

The display changes from Stop to Run. Return to Stopped Mode by pressing Stop. While

in operation, the process set p oint can be adjusted by using ▲ or ▼ to cha nge t he valu e

while the mode is running. Press Menu to display the High Limit Setpoint (HLSP)

setting.

Menu a second time to display curre nt h igh limit setp oint (HLSP). T he valu e

can be adjusted pressing

activated (see Cont rol page, Section 5.6.7) and the high limit cannot be adjusted.

event ON or ▼ to turn the even OFF. Repeat for all event s which are enab led (up to

four eve nts).

O

changes to the process temperature an d high limit setpoints can

be made.

▲ or ▼. If Band displays, the High Limit band feature is

Menu a third time to display Event1. Press ▲ to turn the

Changes to High Limit Setpoint or Eve n t Output Configuration

must be accomplished from the Stop Mode.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 23

Protocol Plus Owner’s Manual OPERATION

Version 2 23

5.3. Timer Mode

1. Press Select until Timer displays.

O

2. Press Menu to display the Pro cess Temperat u r e Setpoint (Setpt). C hange Set point

(Setpt) by using ▲ or ▼ to cha nge t he valu e.

O

Press Run at any time in the procedure to activate Timer Mode.

If the SPChange on the Enable page in Setup Mode ha s been set

to DISABLED, it must be changed to ENABLED befo re any

changes to the process temperature an d high limit setpoints can

be made.

3. Press Menu a second time to display current hig h limit set point (Hi-Lim SP). Change

Setpo int (Hi-Lim SP) using ▲ or ▼. If Band displays, the high limit band feature is

activated (see Cont rol page, Section 8.1.5) and the high limit cannot be adjusted.

4. Press

5. Optional Feature: Press

6. Press Menu a fifth time to display the current gu ar ant eed soak band (TmrGuarSoak)

7. To start Timer Mode, p r ess Run. The d ispla y changes from Stop to Run and the time

Pressing Run/Hold while in Time r Mo d e put s cont ro l in Hold status. The Time r LED will

flash to indicate Hold status. Press Run/Hold key again to continue timing. The Timer

LED will re turn to lit s tatus.

Menu a t hird t ime to display Time Set. Change the time se tting by using ▲ or ▼.

Menu a fourth time to display Event1. Press ▲ to turn the

event ON or ▼ to turn the even OFF. Repeat for all event s which are enab led (up to

four eve nts).

value. If the process temperat u r e deviates from the setpoint by more than this value,

the timer is placed in a Hold condition. T he timer continues whe n the process

temperature falls wit hin range. Reference the Quick Reference and Default Values

section (Section 8.1) for a vailable sett ings.

remaining displays. R eturn to Stopped Mode by pressing Stop. While in operation,

the process setpoint can be adjusted by using ▲ or ▼ to change the value while the

mode is running. Press Menu to disp l ay t he High Limit Setpoint.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 24

OPERATION Protocol Plus Owner’s Manual

24 Version 2

5.4. Profile Mode

1. Press Select until Profile is displayed. None may display if a profile has not been

selected or no profiles have bee n enter ed.

2. Press ▲ or ▼ to display the desired profile.

3. Start Profile Mode by pressing Run.

The display w ill chang e from Stop to Run and show segment time rema ining ,

Temperature S et po int, Pro file #, and the current segment number. To return to Stopped

Mode, pr ess Stop.

Press Run/Hold while in Profile Mode puts the cont r ol into Hold.

O

4. To advance to the next segment while running a profile, press Select and ▲ at the

same time.

If Link To is set to Standby in the Prog r am Page, at the End of Program/Pro file,

1. Cycle Complete LED indication goes ON.

2. Controller be e ps if

3. Heater/control output keeps cont ro lling oven t emperature at last Soak setpoint.

4. All events pr ogrammed (if relay cards are installed a nd progr ammed a s an event) fo r

the last Soak Segment st ays act ive.

Press Run/Hold again to continue in Profile Mode. The Profile

LED flashes to indicate Hold status.

End of Cycle beep is enabled.

Ramping down too fast may cause the high limi t relay to trip

unexpectedly if the high limit band feature is used. Avoid

O

trippin g the high limit relay by using a separate cooling profile

(one that does not use the high limit band) and then linking to

that profile to perform rapid cooling.

5.5. Auto Start Mode

Auto Start allows the operato r to start Manual, Timer, or Profile modes automatically at a

preset time and day. See Setting Up Auto Start (Section 5.6.5) for the time, day, and

operating mode sett ings.

If AutoStart is set to No in the Setup menu, AutoStart will not

O

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

display on the main Menu. If AutoStart is set to Yes in the Setup

menu, AutoStart will display on the main Menu.

Copyright © 2010 by Despatch Industries.

Page 25

Protocol Plus Owner’s Manual OPERATION

including the Enable page. The default security password values

Version 2 25

To activate Auto Start:

1. On Auto Start page, set Enable to Yes.

2. LCD displays Active, current dat e and time

To deactivate Auto Start, on Auto Start page, set Enable to No.

Once Auto Start is activat ed, co nt inue to u se all operat ing modes as you nor mally would.

If an operating mode is running at the time of a preset Auto Start function (provided Auto

Start is activated), the existing operating mode will overr ide the Auto Start function and

the Auto S tart will not turn on.

All processes set to run in Auto St art must be at least one

O

minute long for all Run Modes (Manual, Timer, and Profile) .

5.6. Setup Mode

Use Setup to configure a number of control parameter s. To access Set up , the cont roller

must read Stop.

5.6.1. Enter and Exit Setup Mode

Enter Setup from Stop by:

1. Press Select until Setup displays.

2. Press Page. Security displays.

3. Press Menu. Password displays. Use ▲ or ▼ to enter the proper password and press

Page.

Passwords Protection

The controller has two levels of password protected security.

Level one provides access only to those menu pages ena ble d on

the Enable page. Level two provides access to all menu pages,

O

are 1 for level one and 2 for level tw o.

If an improper password has been entered, the control will

remain at Security. To enter the proper password, press Menu.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 26

OPERATION Protocol Plus Owner’s Manual

including the Enable page. The default security password values

26 Version 2

Exit Setup by pressing Page and holding for three seconds.

Access each of individual Setup pages by pressing Page until the desired heading

displays. Press Menu to access Menu parameters. Press ▲ or ▼ to chang e Menu

parameter sett ings. Re fer to the Quick Reference and Default Values Appendix (S ection

8.1) for default a nd a vai lab le settings.

5.6.2. Temperature Scale Conversion

The Protocol Plus contro ller can be operated for either Centigrade or Fahrenheit. The

controller de faults to Centigrade. Chang from Centigrade to Fahre nheit by:

1. Enter Setu p M od e.

a. Press Select until Setup displays.

b. Press Page. Security displays.

c. Press Menu. Password displays. Use ▲ or ▼ to enter the proper password and

press Page.

Passwords Protection

The controller has two levels of password protected security.

Level one provides access only to those menu pages ena ble d on

the Enable page. Level two provides access to all menu pages,

O

are 1 for level one and 2 for level tw o.

If an improper password has been entered, the control will

remain at Security. To enter the proper password, press Menu.

2. Press Page until PID displays.

3. Press Menu. Temp Unit F or Temp Unit C displays.

4. Use ▲ or ▼ to toggle between and choose F and C.

5. Press a nd hold Page for approximately three seconds to exit Set up mode.

5.6.3. Program Page

Use the Program Page to prog r am the heat profiles. Table 16 show s t he me nu items

available. Eight profiles are available with up to eight ramp and soak segments per

profile. See Section 5.6.3.2 for infor mation on working with optional relay outputs.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 27

Protocol Plus Owner’s Manual OPERATION

Version 2 27

5.6.3.1. Using the Program Page

After entering the Pro gr am Page, pr ess Select to reach the pro file you desire to enter/edit.

Press Menu to select the profile. The first p ar ameter displays: Pr ofile #, Segment 1, Ramp

Time. Adjust the value by pressing ▲ or ▼. When the proper value is displayed, pr ess

Menu to continue to the next parameter. Continue using the Menu to view and adjust each

parameter.

If the current seg ment’s ra mp time value is left at 0:00, the next press of Menu advances

to the High Limit Setpoint parameter for that profile (Hi-Lim SP). Continue

entering/verif ying all par ameters until arriving at the last parameter: Guaranteed So ak

Band (Guar Band). After pro perly e ntering all parameter s, pr ess Page to r eturn to the to p

of the Profile Page. Press Select to enter/ edit anot her pro file, press Page to access another

page, or press and hold Page to exit Setup mode.

While editing any profile, press Select to advance the control to

the time value for the next segment , unt il the last segmen t has

O

been reached. This allow s faster edit ing of the profile rather than

pressing Menu to advance past each parameter.

If Link To Pro is set to Standby (Stby) in the Program Page at the end of running a Pro file,

1. Cycle Complete LED indication goes ON.

2. Controller be e ps if End of Cycle beep is enab led.

3. Heater/control output keeps cont ro lling oven t emperature at last Soak setpoint.

4. All events pr ogrammed (if relay cards are installed a nd progr ammed a s an event) fo r

the last Soak Segment st ays act ive.

Run a profile indefinitely by linking the profile to itself.

O

5.6.3.2. Programming Optional Relay Outputs

Optional relay outputs must be configured prior to use. If optiona l relay outp uts a re

installed, configure them as alarms or events on the Relay Outpu ts Page (Section 8.1.8)

before using. If configured as event outputs, these relays can be used as time or

temperature event s.

Check your schemat ic for relay use in your oven, but typical uses for optional rela ys

include:

• R elay 1: Cooling event

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 28

OPERATION Protocol Plus Owner’s Manual

Menu Item

Display

Description

28 Version 2

• Relay 2: End of cycle relay

• Re lay 3: Optional N2 purge event

• Re lay 4: Optional N2 maint ain e vent

Table 2. Program Page Menu Items and Explanation.

Ramp Time Seg 1

Event 1 Set Value

Event 2 Set Value3

Event 3 Set Value3

Event 4 Set Value3

Soak Temp Seg 1

Soak Time Seg 1

Event 1 Set Value3

Event 2 Set Value3

Event 3 Set Value3

Event 4 Set Value3

High Limit Setpoi nt

Loop From

Pro-1 Seg-1 Ramp Time

3

Pro-1 Seg-1 Ramp Event 1

Event 1 setting for segment 1 ramp of profile

Pro-1 Seg-1 Ramp Event 2

Pro-1 Seg-1 Ramp Event 3

Pro-1 Seg-1 Ramp Event 4

Pro-1 Seg 1 Soak Temp

Pro-1 Seg 1 Soak Time

Pro-1 Seg-1 Soak Even t 1

Pro-1 Seg-1 Soak Even t 2

Pro-1 Seg-1 Soak Even t 3

Pro-1 Seg-1 Soak Even t 4

Ramp time for segment 1 of profile

Event 2 setting for segment 1 ramp of profile

Event 3 setting for segment 1 ramp of profile

Event 4 setting for segment 1 ramp of profile

Soak temperatur e for segment 1 of profile

Soak time for segment 1 of profile

Event 1 setting for segment 1 soak of profile

Event 2 setting for segment 1 soak of profile

Event 3 setting for segment 1 soak of profile

Event 4 setting for segment 1 soak of profile

(Repeat for segments 2-8, until ramp = 00:00)

Profile-1 Hi-Lim SP

Profile-1 Loop From Seg

High limit setpoi nt f or pr ofile

To start a loop action in a profile

4

Loop To

Loop Count

Profile Link

Guaranteed Soak

Profile-1 Loop To S eg

Profile-1 Loop Number

Profile-1 Link To Pro

Profile-1 Guar Band

To end a loop action in a profile

Number of times to execute loop

To jump from this pr ofile to another

Guaranteed soak band f or pr ofile

3

Available only if optional relay outputs are installed (repeat all for Profiles 2-8).

4

Set to Band to use the high limit band feature.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 29

Protocol Plus Owner’s Manual OPERATION

Parameter

Definition and/or Range

Profile #

Eight profil es are available

Segment #

Program recipe segments one through eight. Give each segment its own set

Ramp Time

Time required to mov e ov en temper ature from one setpoint to another.

to the soak temperat ur e.

EV1 through 4

Program from one to four events into the ramp time portion of each segment.

install ed and is programmed for an event.

Soak Temp

Enter the temperat ur e setpoint of a particular segment . The setpoi nt can

range from -18 to 540 °C (0 to 1000 °F).

Soak Time

Enter the durati on of soak. S oak Time c an r ange from 0 to 99: 59.

EV1 through 4

Program from one to four events into the soak portion of each segment.

install ed and is programmed for an event.

Hi Limit SP

Enter the high limit setpoint. If the temperature exc eeds this value, hi-limit

will alarm and shut off the heater.

Loop From

Identify segm ent number to loop from.

Loop To

Identify segm ent number to loop to.

Loop Number

Enter value from 1-99 to preset the number of times to run the loop

established in “Loop From” and “Loop To.”

Link t o Pro

Enter value to instruc t profile in steps to take when the profil e ends. V alues

Val ue 1 – 8: Jump to specified profile

Guaranteed

Enter value that determines if the process temperature has deviated from the

Version 2 29

Table 3. Parameter Definitions and/or Ra ng e s.

of events, ramp and soak tim es and soak temperature.

Values between 0 and 99:59 are allowed.

The Protocol Plus cont r oller stores profile ramp and soak tim es without units.

Times are set as hours and minutes (HH: M M ) or minutes and seconds

(MM:SS). The setpoi nt aut om atically increments fr om the actual temperature

Events typic ally inv olv e ac tuating/disabli ng rel ay s to cl ose/open valves or

perform other r elay -controlled functions.

NOTE: Events actuate only when the controller has the optional relay cards

Soak Band

Events typic ally inv olv e ac tuating/disabli ng rel ay s to cl ose/open valves or

perform other r elay -controlled functions.

NOTE: Events actuate when the controller has the optional relay cards

include:

• STANDBY: Holds temperature setpoi nt while keeping event relay(s) at

last status, actuates cycle relay(s)

• STOP: Turns heater and all relays to OFF status

• HOLD: Holds temper ature setpoint and all relays at last status, at end of

profile

•

setpoint. If the proc ess temperature deviates from the setpoint by more than

the “Guaranteed S oak Band” value, the soak timer is placed in a hold

condition. The timer continues when the process tem peratur e falls within

range.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 30

OPERATION Protocol Plus Owner’s Manual

Figure 7. Sample Profile.

30 Version 2

5.6.4. Sample Profile

Figure 7 shows a graphic representation of the samp le profile, whi le Figure 8 s hows the

parameters entered to achieve that profile.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 31

Protocol Plus Owner’s Manual OPERATION

Enable

Autostart

Auto Start

Enable

Enable (yes) or disable (no)

the Autostart function

Sunday

mode

Auto Start Sun

Mode

Set mode on Sunday to

activate

Off, Manual, Timer , Pr o-1 to

Pro-8

Sunday

time

Auto Start Sun

Time

Set time on Sunday for mode

to activate

Monday

mode

Auto Start Mon

Mode

Set mode on Monday to

activate

Off, Manual, Timer , Pr o-1 to

Pro-8

Monday

time

Auto Start Mon

Time

Set time on Monday for mode

to activate

Tuesday

mode

Auto Start Tue

Mode

Set mode on Tuesday to

activate

Off, Manual, Timer , Pr o-1 to

Pro-8

Figure 8. Sample Profile Values.

Version 2 31

5.6.5. Setting Up Auto Start

Auto Start allows the operato r to start Manual, Timer, or Profile modes auto matical ly at a

preset time and day. Table 4 show s the menu items availa ble.

Table 4. Auto Start Menu Parameters and Values.

Menu Item Display Description Range

No, Yes

00:00 to 23:59

00:00 to 23:59

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 32

OPERATION Protocol Plus Owner’s Manual

Tuesday

time

Auto Start Tue

Time

Set time on Tuesday for mode

to activate

Wednesday

Auto Start Wed

Set mode on Wednesday to

Off, Manual, Timer , Pr o-1 to

Wednesday

time

Auto Start Wed

Time

Set time on Wednesday for

mode to activate

Thursday

mode

Auto Start Thu

Mode

Set mode on Thursday to

activate

Off, Manual, Timer , Pr o-1 to

Pro-8

Thursday

Auto Start Thu

Set time on Thursday for m ode

Friday

mode

Auto Star t Fri

Mode

Off, Manual, Timer , Pr o-1 to

Pro-8

Auto Star t Fri

Time

Set time on Friday for mode to

activate

Saturday

mode

Auto Start Sat

Mode

Set mode on Saturday to

activate

Off, Manual, Timer , Pr o-1 to

Pro-8

Saturday

Auto Start Sat

Set time on Saturday for m ode

32 Version 2

Menu Item Display Description Range

00:00 to 23:59

mode

time

Friday time

time

Mode

Time

Time

activate

to activate

Set mode on Friday to activate

to activate

5.6.5.1. Configure Auto Start

1. Access Setu p Mode.

2. Press Page until Auto Start displays.

3. Press

Menu.

Pro-8

00:00 to 23:59

00:00 to 23:59

00:00 to 23:59

00:00 to 23:59

If the display does not change, the controller may not have the

O

realtime clo ck option.

4. Set

Auto Start Enable to Yes.

5. Using Menu, sc r oll through the o ptions ava ilab l e and press ▲ or ▼ to set the desired

mode for each day of the week. Select from Manual, Timer or Profile 1 through 8.

6. After setting mode, press Menu.

7. Enter the time of day you wish the mode to activate.

8. Continue through the week by pressing Menu, or press Page if changes are complete.

a. One Auto Start mode can be set for each da y of the week.

b. Exit Setup by pressing Page and holding f or three seconds.

c. Press Select until Auto Start displays.

d. Make sure the correct time and day is displayed. If not correct, set time a nd

day to the Real Time Clock Page in the Setup mode.

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 33

Protocol Plus Owner’s Manual OPERATION

Proportional

band

Set proportional band for

tuning

Integral

PID

Derivative

Rate

PID Rate In

Sec

Version 2 33

5.6.5.2. Activate Auto Start

1. On Auto Start page, set Enable to Yes.

2. LCD displays Active, current d ate and time

5.6.5.3. Deactivate Auto Start

On Auto Start page, set Enable to No.

Once Auto Start is activat ed, co nt inue to u se all operat ing modes as you nor mally would.

If an operating mode is running at t he time of a preset Auto Start funct ion (pro vided Auto

Start is activated), t he exist ing op er ating mode w ill override the Auto Start function and

the Auto S tart will not turn on.

All processes set to run in Auto St art must be at least one

O

minute long for all Run Modes (Manual, Timer, and Profile).

5.6.6. Setting Up PID Page

The PID Page contains para meter s that control the response to t he setpo int and process

var ia ble inpu t . Table 5 show s the menu items ava ilab l e .

Table 5. PID Page Parameters and Values.

Menu Item Display Description Range

Display units PID Temp Unit Set display units to °C or °F °C or °F

PID Prop Band

reset

AutoTune PID AutoTune Enable auto tuning f unction Di sabl e, Enable

Reset/Rep/Min

Set integral reset for tuning 0.0 to 100 seconds/repeat

Set derivative rate for tuning 0.0 to 500 seconds

5.6.6.1. Access the PID Page

1. Enter Setu p M ode.

2. Press Page u ntil P ID displays.

3. Press Menu.

4. Change parameters by pressing Menu until the desired parameter is displayed. P ress

▲ or ▼ to set the desired value.

1 to 56°C (1 to 100°F)

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in an y form or b y an y

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 34

OPERATION Protocol Plus Owner’s Manual

Menu Item

Display

Description

Range

Cycle Time

Control Cycle

Time Sec

Set cycle time in seconds for

control out put

1 to 60 seconds

High limit

setpoint

Control Hi-Lim

SP

Maximum value for all high

limit setpoi nts

MinHiLimSP - MaxHiLimSP

6

High limit

Control Hi-Lim

If=0, high limit setpoint=

Band

Off, 3°C to 11°C (5°F to 20°F)

34 Version 2

5.6.6.2. Setting up Auto Tune

The AutoTune paramet er d isables o r enables the Aut oT u ne function. To use AutoTune:

1. Enter Setup M od e.

2. Press Page k ey until AutoTune displays.

3. Enable Autotune by pressing ▲ .

4. Press Page for three seconds to exit Setup Mode.

5. Cycl e power to the instrument.

6. Set Manual Mode to Run. The display will alternate betw een AutoTune and Manual.

If the Manual Mode setpoint is less tha n 50 degr ees hig her than the actual process

temperature, the AutoT une funct ion creat es an error cond ition. Clear t he error by cooling

the process temperatu r e or increas ing the setpoint until more than 50 degrees bet ween

them. After AutoTune has completed tuning, the AutoTune parameter will disable by

itself.

Cancel AutoTune by pressing STOP. Access the PID page in Setup Mode, and set the

AutoTune parameter to D isable.

5.6.7. Setting up the Control Page

The Control Page contains parameters that control miscellaneous functions. Table 6

shows the menu items available.

5.6.7.1. Access Control Page

1. Enter Setu p M od e.

2. Press Page until Control displays.

3. Press the Menu.

4. Change each parameter by pressing Menu unt il the desired parameter is displayed,

and then press ▲ or ▼ to change the value.

Table 6. Control Page Parameters and Values.

5

band

Band

Control Hi-Lim SP If>0, high

limit setpoi nt= Cont r ol SP6 +

5

High lim it setpo int is a read-on ly item wh ich is calculated on Enable page

6

Inc lude s ramping setpoints during profiles a nd controlled ramp s

All rig hts reserved. No part of the contents of this m an u al m ay b e r ep roduced, copied or t ransmitted in any for m or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the writ ten permission of Despatch Industrie s , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 35

Protocol Plus Owner’s Manual OPERATION

Menu Item

Display

Description

Range

Power fail

recovery

Control PwrFRec

Controls response to l oss of

power

Stop, Restart, H old, R esum e

Recovery

Control PFRTim e

Control abort s to Stopped

period longer then set value

00m00s to 99m59s

Powerup

ControlPwrUpStrt

Allows mode to automatically

Disabl e, Enable

Powerup

Start Mode

Control StrtMode

Operating mode for powerup

start

Off, Manual , Timer, Pro-1 to Pro-8

Hysteresis

Control

Hysteresis