Page 1

E-101

P. N. 157427

REVISION B

6/2002

PROTOCOL PLUS™ CONTROL

(HEAT/COOL VERSION)

INSTRUCTION MANUAL

SOFTWARE VERSION 3.1

Prepared by:

Despatch Industries

P.O. Box 1320

Minneapolis, MN 55440-1320

Customer Service 800-473-7373

Page 2

NOTICE

CAUTION

Users of this equipment must comply with operating procedures and training of

operation personnel as required by the Occupational Safety and Health Act (OSHA) of

1970, Section 6 and relevant safety standards, as well as other safety rules and

regulations of state and local governments. Refer to the relevant safety standards in

OSHA and National Fire Protection Association (NFPA), section 86 of 1990.

Setup and maintenance of the equipment should be performed by qualified personnel

who are experienced in handling all facets of this type of system. Improper setup and

operation of this equipment could cause an explosion that may result in equipment

damage, personal injury or possible death.

Dear Customer,

Thank you for choosing Despatch Industries. We appreciate the

opportunity to work with you and to meet your heat processing needs. We

believe that you have selected the finest equipment available in the heat

processing industry.

At Despatch, our service does not end after the purchase and delivery of

our equipment. For this reason we have created the Service Products

Division within Despatch. The Service Products Division features our

Response Center for customer service. The Response Center will direct

and track your service call to ensure satisfaction.

Whenever you need service or replacement parts, contact the Response

Center at 1-800-473-7373: FAX 612-781-5353.

Sincerely,

Despatch Industries

Page 3

Despatch Industries

Product Warranty

See separate warranty for Benchtop and Laboratory Ovens (Form BB7)

Parts, Materials and Labor

Seller warrants the equipment manufactured by Seller and not by others, to be free

from defects in workmanship and material under normal use and service for a

period of (1) year from the date of delivery or the period of two thousand (2,000)

accumulated hours of use, whichever period is shorter. Use or service with

corrosive or abrasive chemicals or materials is not deemed normal. The period of

the foregoing warranty, in the case of furnaces, shall be ninety (90) days or five

hundred twenty-five (525) accumulated hours of use, whichever period is shorter.

Components manufactured by others, including expendable items, are warranted

only in accordance with the warranty, if any, issued by such other manufacturer.

Buyer shall give Seller written notice of any defects with 14 days after discovery

thereof, specifying each particular defect discovered. If such notice is properly

given, Seller will correct without charge any workmanship that is demonstrated to

Seller's satisfaction to have been defective at the time of installation, and will repair

or replace, at Seller's option, without charge, f.o.b. Seller's factory, parts covered by

this warranty that upon inspection are found defective under normal use within the

warranty period above stated. All work of removal and reinstallation, whether or not

found defective, and shipping charges for defective or replacement parts shall be at

the sole expense of Buyer.

The foregoing warranty shall not apply to (i) work done or materials furnished by

others in connection with installation work performed without supervision by Seller's

installation supervisors, or (ii) equipment repaired or altered by others unless such

repairs or alterations were specifically agreed to in writing by an Officer of Seller.

Seller shall not be liable for consequential damages of any kind which occur during

the course of installation of equipment, or which result from the use or misuse by

Buyer, its employees or others of the equipment supplied hereunder, and Buyer's

sole and exclusive remedy against Seller for any breach of the foregoing warranty

or otherwise shall be for the repair or replacement of the equipment or parts thereof

affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if and only if Buyer

loads, operates and maintains the equipment supplied hereunder in accordance

with the instruction manual to be provided upon delivery of the equipment. Seller

does not guarantee the process of manufacture by Buyer or the quality of product to

be produced by the equipment supplied hereunder, and Seller shall not be liable for

prospective profits.

Despatch will repair or replace, at Despatch's option, FOB Despatch's factory, parts

and materials covered by this warranty. Despatch is not responsible for parts or

material failures resulting from misuse, abuse, inadequate preventive maintenance,

acts of nature, or non-conforming utilities, including electrical, fuel supply,

environmental and intake/exhaust provisions. This warranty also does not cover

normal wear or routine maintenance parts and materials expressly designed as

expendable/consumable and replaceable. (Note: Laboratory oven electric heaters

are warranted for a period of five [5] years from date of shipment; three [3] years

from date of shipment for Protocol Plus and DES 2000 temperature controllers.)

Labor services for parts and materials replacement and repair to support this

warranty are available at Despatch's normal service fees. This service is provided

worldwide by a network of factory trained professionals.

Transportation Costs

All transportation costs to transport defective parts or materials to Despatch, and to

transport repaired or replacement parts or materials to Customer, shall be the

responsibility of the Customer.

Terms and Conditions

This Warranty shall be deemed valid and binding upon Despatch if and only if the

Customer:

1. installs, loads, operates, and maintains the covered product supplied hereunder

in accordance with the instruction manual provided upon delivery and product

labeling affixed to the subject equipment:

THE REPRESENTATION AND WARRANTIES SET FORTH HEREIN ARE EXCLUSIVE AND IN LIEU OF, AND CUSTOMER HEREBY WAIVES AND DISCLAIMS

RELIANCE UPON, ALL OTHER REPRESENTATIONS AND WARRANTIES OF EVERY KIND WHATSOEVER, WHETHER EXPRESS OR IMPLIED, OR ARISING BY

OPERATION OF LAW OR IN EQUITY, OR BY COURSE OF PERFORMANCE OR DEALING OR USAGE OF TRADE, INCLUDING, WITHOUT LIMITATION, ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE.

THIS WARRANTY IS PERSONAL TO THE CUSTOMER AND MAY NOT BE TRANSFERRED OR ASSIGNED. ALL LIMITATIONS HEREUNDER, HOWEVER, SHALL BE

BINDING ON ALL SUCCESSORS AND ASSIGNS OF CUSTOMER.

2. if applicable, follows the Emergency Procedure set forth in this Warranty; and

3. contacts Despatch's Helpline at 1-800-473-7373 for assistance in diagnosing

and troubleshooting the problem immediately upon discovering any damage or

malfunction.

Despatch's reasonable determination as to whether a repair, replacement, or

service is covered by this Warranty shall be final and binding.

Exclusions

This Warranty DOES NOT cover:

1. damage or malfunctions, or expenses incurred in the process of diagnosing

and/or repairing damage or malfunctions, resulting from any of the following:

operator error, misuse, abuse, inadequate preventive maintenance, normal wear

and tear, service or modifications by other than Despatch authorized technicians,

use of the covered product that is inconsistent with the operation manual or

labeling, acts of nature (including, without limitation, floods, fire, earthquake, or

acts of war or civil emergency), internal or external corrosion, or non-conforming

utilities (including, without limitation, electrical, fuel supply, environmental and

intake/exhaust installations);

2. repair or replacement of parts or materials designed and intended to be

expendable or consumable;

3. routine maintenance; or

4. labor costs incurred for troubleshooting, diagnostics, or testing (except for testing

required to verify that a covered defective part or material has been repaired).

Limitations of Liability

Despatch shall not, in any event, be liable for indirect, special, consequential,

incidental, or punitive damages or penalties of any kind, including, without limitation

loss of revenue, profits or business opportunities resulting from interruption of

process or production. In no event shall Despatch be liable for damages in excess

of the amounts paid by Customer to Despatch with respect to the applicable

product(s). This Warranty does not cover, and Despatch shall not be liable for any

losses, costs, damages or expenses resulting from delays in diagnosing or

repairing the products, supplying or obtaining replacement parts or materials,

strikes, labor stoppages or shortages, fires, accidents, government acts or

regulations, or any other causes beyond the control of Despatch.

Non-Compliance By Customer

Despatch reserves the right to suspend and withhold service under this Warranty in

the event of non-compliance by the Customer to any terms and conditions of this

Warranty or the applicable purchase order or invoice. Further, Despatch shall not

be liable for any loss of production, expenses, and inconveniences incurred due to

such suspension.

Customer Furnished Equipment Warranty Limitation

This Warranty does not cover diagnosis or repairs of defects in or caused by, lack

of performance of, or fitness for purpose of customer-supplied parts or equipment

unless specifically noted in the Despatch written order acceptance confirmation.

Performance Commitment

Despatch provides no guarantee of process performance or fitness for purpose,

unless specifically noted otherwise in Despatch written order acceptance

confirmation. Despatch is providing equipment with design parameters specific only

to its equipment.

Procedure Upon Discovery of Defects and Emergencies

In the event Customer becomes aware of any defect in the applicable products,

Customer must immediately: (a) shut off fuel or energy supply (gas and electricity),

(b) call for emergency assistance, if needed, and (c) notify Despatch Service.

Worldwide Phone 612-781-5356; Worldwide Fax 612-781-5485; North American Phone 800-473-7373

Service

e-mail info@despatch.com; www.despatch.com

Please see reverse side for other service offerings BB5 (5/28/02)

Page 4

Despatch Industries

Advantage Service Assurance Program (ASAP)

CONTACT: DESPATCH SERVICE AGREEMENTS SPECIALIST at 800-473-7373 or 612-781-5356

or e-mail: info@despatch.com

Despatch continues to deliver exceptional products backed by a strong sense of responsibility and drive for long term customer

satisfaction. Your partnership with Despatch can offer even higher value through your subscription to one of Despatch's Advantage

Service Assurance Program (ASAP).

Warranty

Despatch's exclusive, comprehensive service programs start with the 1 year parts only warranty which is described on the other

side of this document. This warranty can be expanded immediately to meet your most stringent service needs. Despatch Service

Products Group will be able to answer your service questions and provide a quotation for the immediate expansion of your product

warranty. Call 800-473-7373 or 612-781-5356; or e-mail info@despatch.com.

Immediate Service Response

The key to an effective service program is response. Wherever your location, Despatch is only a phone call away. Our U.S. and

Canadian customers can reach Despatch at 1-800-473-7373. Worldwide customers can call 1-612-781-5356 or FAX

1-612-781-5485. Our Customer Service Technicians have over 150 years combined experience and access to detailed design and

manufacturing documentation specific to your Despatch unit(s). This exacting level of service is a benefit only Despatch can provide

and means that you can expect speedy, accurate and the most cost effective response.

Field Service Network

A worldwide network of factory trained Service Professionals is available to support your Despatch equipment. From routine repair

to certified instrument calibration, the Despatch service network is positioned to respond to your needs. As a manufacturer of

custom equipment, our service programs are customized to meet your specific needs regarding:

1. Service scope

2. Response time

3. Preventive maintenance frequency and content

4. Payment method

Sustained Service Support

At Despatch, long term customer satisfaction means more than just responding quickly and effectively to our customers' service

needs. It means offering comprehensive customer support well beyond the scope and duration of our initial warranty. Despatch

offers two basic service packages which are customized to each individual customer's need. These service packages are titled Full

Service and Preventive Maintenance Plus+ service agreement products. Each is unique in the industry and offer the following

benefits:

1. Priority response for minimum production interruption

2. Preventive maintenance for longer product life

3. Discounts on parts and services

4. Various payment plans to ease budgeting and recording expenses

5. Reduce purchase ordering costs

Worldwide Phone 612-781-5356; Worldwide Fax 612-781-5485; North American Phone 800-473-7373

e-mail info@despatch.com; www.despatch.com

Service

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS................................................................................................... i

INTRODUCTION.............................................................................................................1

Theory of Control Operation........................................................................................1

Operating Modes......................................................................................................3

Setup Mode..............................................................................................................3

Fast Start Mode........................................................................................................3

High Limit.................................................................................................................4

Indicators .................................................................................................................4

Displays ...................................................................................................................5

Key Functions..........................................................................................................5

Outputs ....................................................................................................................6

Relay (Continued)....................................................................................................7

Communication........................................................................................................7

Optional Software.....................................................................................................7

INSTRUCTIONS .............................................................................................................8

Start-Up.......................................................................................................................8

Operation.....................................................................................................................9

Manual Mode...........................................................................................................9

Timer Mode............................................................................................................10

Profile Mode...........................................................................................................11

Auto Start Mode.....................................................................................................11

Setup Mode............................................................................................................12

Instructions for Setup Mode Pages............................................................................13

Program Page........................................................................................................13

Profile # ..............................................................................................................15

Sample Profile........................................................................................................16

Auto Start Page (optional)......................................................................................17

Control Page..........................................................................................................20

Communication Page (optional).............................................................................21

Real Time Clock Page (optional)............................................................................21

Relay Outputs Page (optional)...............................................................................22

Test Page...............................................................................................................23

Zone Calibration Page ...........................................................................................24

Sensor Calibration Page........................................................................................26

Enable Page...........................................................................................................28

Digital Inputs (optional) ..........................................................................................29

Error Messages and Alarms ......................................................................................30

Quick Reference and Default Values.........................................................................31

Technical Specifications............................................................................................38

APPENDIX: Temperature Scale Conversion and Optional MRC5000 Setup................39

Temperature Scale Conversion (C/F)........................................................................39

i

Page 6

ii

Page 7

INTRODUCTION

The special features of the Protocol PlusTM control include:

• PID tuning

• Ramp/Soak programming of up to 64 segments

• Segment looping and profile linking

• Built-in manual reset high limit control

• Built-in process timer

• Dedicated LED display for process temperature

• Multi-purpose two-line LCD display with backlight

• Auto-tuning

• Security access

• Digital inputs for remote profile control

• Optional relay outputs for events, alarms, or end-of-cycle signal

• Optional real-time-clock

• Optional RS232/RS422/RS485 MODBUS communications

Theory of Control Operation

The Protocol Plus is a modular microprocessor based digital temperature controller. The

Protocol Plus operates as a dual functioning controller/high limit instrument. The control

portion utilizes a time-proportioning voltage signal to control heating devices with

minimal temperature fluctuations.

The high limit portion protects the product and/or the oven from overheating. If the

product being processed has a critical high temperature limit, the high limit setpoint

should be set to a temperature somewhat below the temperature at which the product

could be damaged. If the product does not have a critical high temperature limit, the

high limit setpoint should be set 5 to 15 degrees higher than the maximum programmed

setpoint at which the oven will operate.

1

Page 8

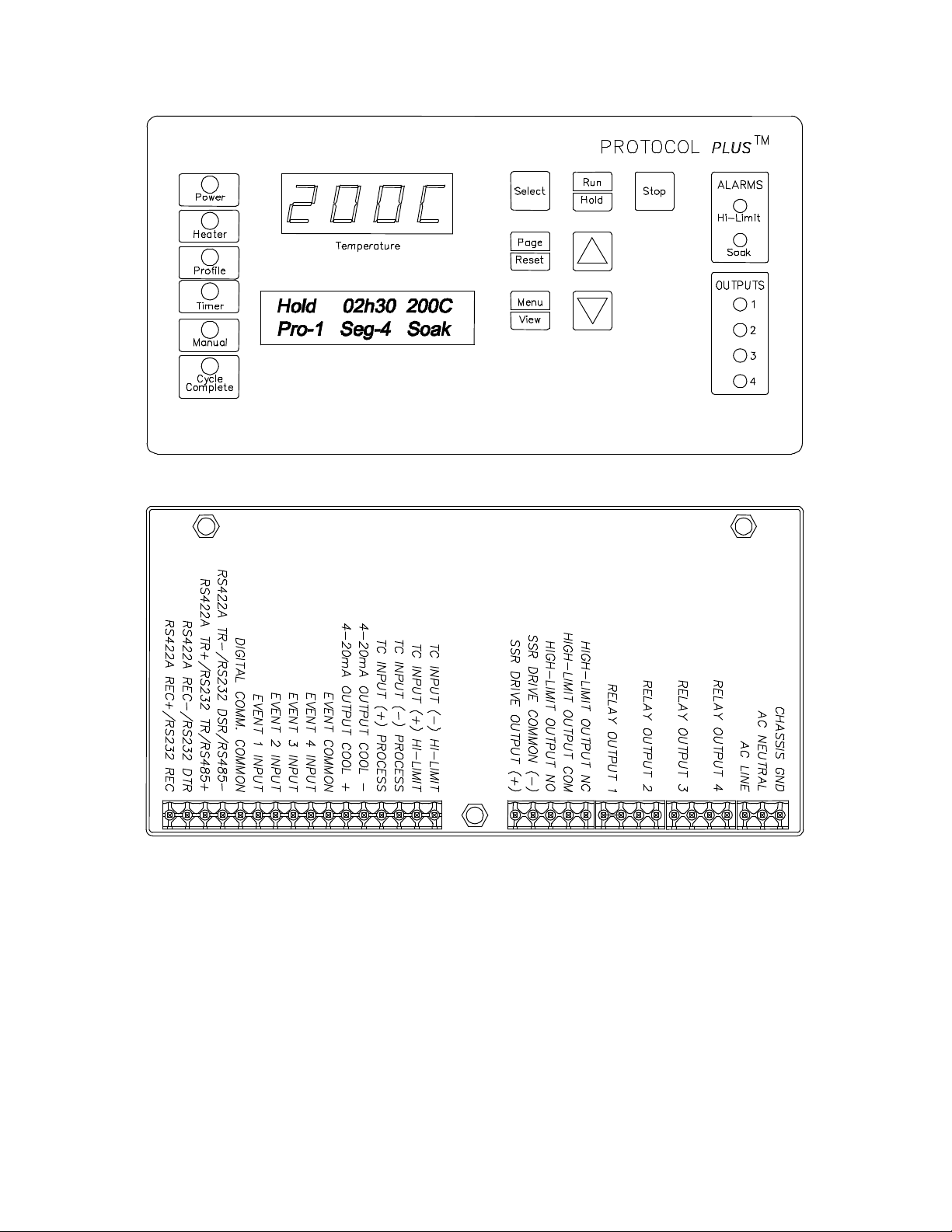

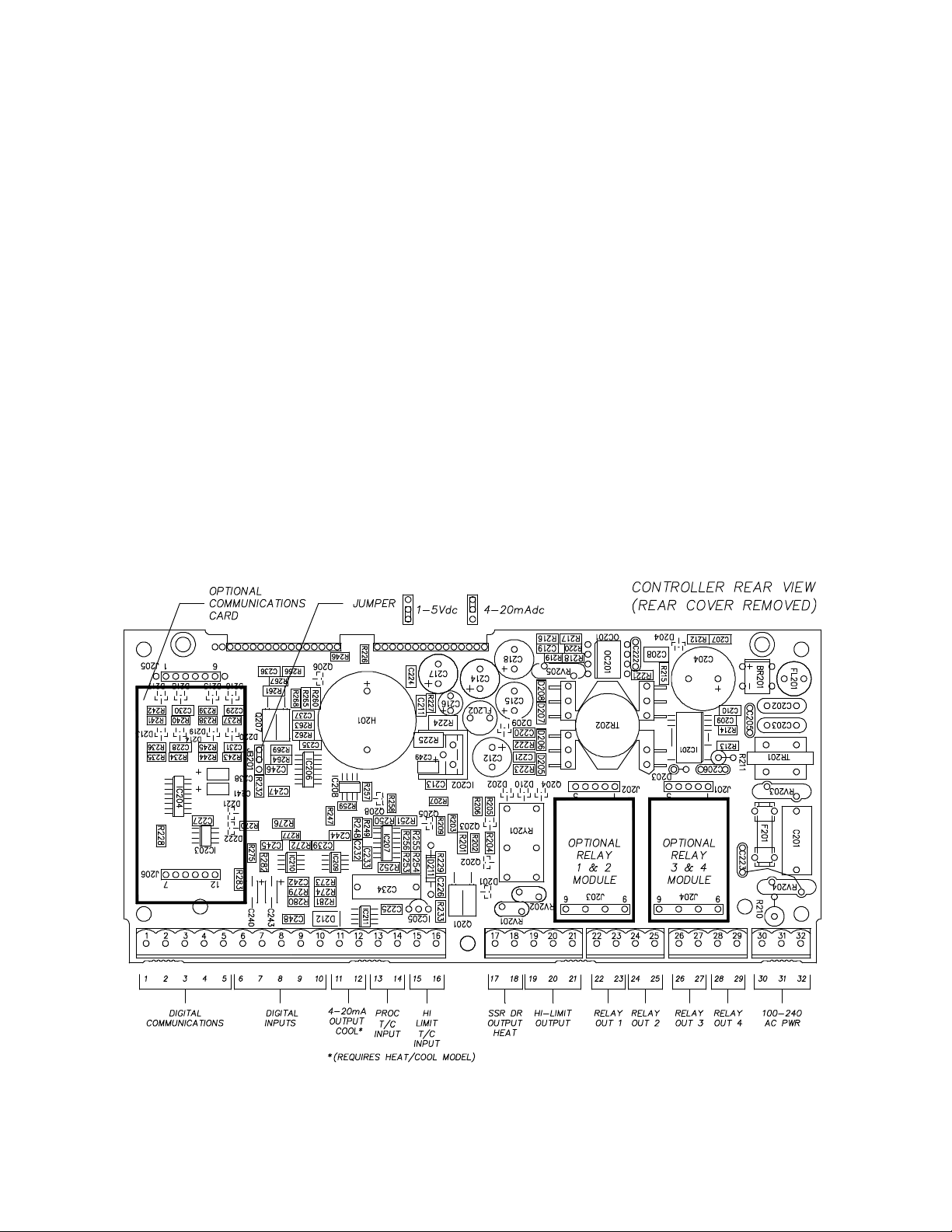

Protocol Plus Faceplate and Wiring Diagram

2

Page 9

Operating Modes

The Protocol Plus control has five modes of operation available:

Stopped Mode: All control and relay outputs are off. Stopped Mode is integrated

into each of the following four modes of operation.

Manual Mode: Control operates as a single setpoint control until Stopped mode is

accessed

Timer Mode: Control operates as a single setpoint control until preset time period

has expired.

Profile Mode: Control operates as a ramp/soak profiling control until the end of

the profile. 8 profiles are available with up to 8 ramp/soak segments

in each profile.

Auto Start Mode (optional): Control may automatically start Manual, Timer, or

Profile mode based on a preset time and day.

Requires the optional real-time clock feature.

The optional event outputs can be utilized during Manual, Timer, or Profile modes.

Setup Mode

The control has a Setup Mode which provides access to control configuration and

programming of profiles. The Setup Mode contains ten separate electronic Pages where

the configuration and programming parameters (Menu items) are found. The Setup

Mode Pages are described in detail elsewhere in this manual.

Fast Start Mode

The Protocol Plus control has the ability to automatically start an operating mode when

power is applied. This feature may be useful if the same mode of operation is used

everyday. The user can turn on the power and the oven will start the desired process

automatically. The Fast Start Mode is controlled by the Power-Up Start parameters on

the Control page (see Setup Mode).

3

Page 10

High Limit

The control has an integrated high limit function which will disable the heater output

when tripped. If the high limit does trip, the relay will need to be manually reset. When

the high limit relay is tripped, the Hi-Limit indicator will be lit. Allow the oven to cool

several degrees (or increase the high limit setpoint) and then press the Reset key. The

indicator will turn off.

The control will not allow the high limit setpoint to be set below the current setpoint

value.

Indicators

The Protocol Plus control has 12 indicating LEDs that provide operational information to

the user.

C Power LED: Indicates that power is supplied to the instrument.

C Heater LED: Indicates that the heater output is active.

C Profile LED: Indicates that the Profile Mode is in operation.

C Timer LED: Indicates that the Timer Mode is in operation.

C Manual LED: Indicates that the Manual Mode is in operation.

C Cycle Complete LED: Indicates that the control is in Stopped mode.

C Hi-Limit Alarm LED: Indicates that the high limit relay has tripped (de-energized).

C Soak Alarm LED: Indicates that the guaranteed soak deviation is in alarm

condition.

C Outputs 1 through 4: Indicate that the optional relay outputs are in the ON state.

These outputs may be configured as timed event outputs, process temperature trip

point outputs, alarm outputs, or as an end of cycle relay output. The ON state can

be configured as energized or de-energized.

4

Page 11

Displays

The Protocol Plus control has two displays. A dedicated LED upper display shows the

oven temperature. A two-line LCD lower display provides information on control status

and allows changes to be made to the control settings.

Key Functions

The Protocol Plus control has seven keys that provide operation.

• Select key: Press to select mode of operation. In Setup Mode, to select profile

number or relay. In Profile/Run Mode, press simultaneously with the UP key to

advance a segment.

• Run/Hold key: Press to activate a mode of operation. If a Profile (or Timer)

Mode is running, pressing the Run/Hold key will place the Profile (or Timer) in

Hold status. A subsequent press will resume the Profile (Timer).

• Stop key: Press to stop any mode of operation.

• Page/Reset key: While in Setup Mode, press to access different Pages of

configuration, Press this key to silence an alarm if the instrument alarm sounds

during operation. In an operating mode, if an alarm or error condition occurs,

press this key to return the instrument to normal operation once the condition is

cleared.

• Menu/View key: While running any operating mode, pressing this key will

display the high limit setpoint. While in Setup Mode, pressing this key will provide

access to each Menu parameter.

• keys: Press these keys to adjust parameter settings. In Profile/Stopped

Mode, press to select profile to run. In Profile/Run Mode, press key

simultaneously with the Select key to force the program to advance one

segment.

5

Page 12

Outputs

The Protocol Plus control has seven different outputs available.

• Heating output: The control output is a DC voltage open-collector output which

is time-proportioned and designed to control a heat control device such as a solid

state relay.

• Cooling output: The cooling output is a 4 to 20 ma DC output which is designed

to control a cooling device such as a damper motor.

• High limit: The high limit output is a form C relay which is energized under

normal operating conditions. If the control senses a temperature higher than the

high limit setpoint, or if there is a sensor error, the high limit relay will de-energize

until the condition is cleared and the Reset key is pressed. When the high limit

relay is de-energized, the heater is disabled.

• Relay (four optional outputs): The four form A dry contact relay outputs can be

configured to function as alarms, events, or end of cycle. These outputs can be

utilized in Manual, Timer, or Profile Mode.

Layout for Optional Components

6

Page 13

Relay (Continued)

Use the Relay Card Optional Ay p/n 144562 to add relays to the standard controller.

Each relay card contains two relays (maximum of two cards Ay’s allowed).

Communication

The Protocol Plus control has optional MODBUS communication available which can

communicate via RS232, RS422, or RS485 to a computer. See communications option

assembly p/n 161957 for board and cable assembly. Please refer to the MODBUS

communications manual which comes with this option.

Optional Software

The Protocol Manager program allows the operator to start/stop multiple ovens (32

maximum) from a personal computer. A data log can also be used to record process

information (p.n. 140008).

7

Page 14

INSTRUCTIONS

Start-Up

These instructions are provided as a quick reference for operating the Protocol Plus

control. If the Profile Mode is to be used, or the configuration of the control needs to be

changed, please refer to the Setup Mode instructions before operating the control. For

more detailed operating instructions refer to the Operation instructions for the mode you

wish to use.

Upon initial power-up the control is in Manual/Stopped Mode (unless the Autostart or

Fast Start Modes are active). To activate any operating mode from Stopped Mode,

press the Select key until the desired mode is displayed, then press the Run key. If the

proper Profile number is not displayed when the Profile Mode is accessed, press the

or keys until the desired Profile number is displayed, then press the Run key. If no

profile numbers can be displayed (display only reads NONE) then no profiles are

currently programmed (see Setup Mode).

The temperature setpoint can be adjusted while Manual or Timer Mode is running by

pressing the UP or DOWN key.

To momentarily hold the Timer or Profile Mode, press the Hold key. To continue the

Timer or Profile Mode, press the Run key.

To return to Stopped Mode at any time, press the Stop key and the cycle complete LED

will illuminate.

Note that the control can be configured to automatically activate Manual, Timer or

Profile Mode when power is applied (power switch turned on). See Control Page in the

Setup Mode to utilize the Fast Start mode.

8

Page 15

Operation

Manual Mode

Press the Select key until Manual is displayed (note you can press the Run key at any

time to activate Manual Mode).

1. Press the Menu key to display the Process Temperature Setpoint (setpt). You

can change the Setpoint with the keys.

Note: If the SPChange parameter on the Enable page in Setup Mode has been

set to DISABLED, it must be changed to ENABLED before any changes to the

process temperature and high limit setpoints can be made.

2. Press the Menu key a second time to display current high limit setpoint (Hi-Lim

SP). The value can be adjusted by pressing the keys. If Band is displayed,

the high limit band feature is activated (see Control page) and the high limit can

not be adjusted.

3. (optional feature) Press the Menu key a third time to display Event1. Press the

key to turn on the event or to turn off the event. Repeat for all events which

are enabled (up to 4).

4. To start Manual Mode, press the Run key.

The display will change from Stop to Run. To return to Stopped Mode, press the

Stop key. While in operation, the process setpoint can be adjusted by using the

keys to change the value while the mode is running. Pressing the Menu key

will display the High Limit Setpoint (HLSP) setting.

If changes to the high limit setpoint or event output configuration are needed, they must

be done from the stopped mode.

9

Page 16

Timer Mode

1. Press the Select key until Timer is displayed (note you can press the Run key at

any time to activate Timer Mode).

2. Press the Menu key to display the Process Temperature Setpoint (Setpt). You

can change the Setpoint with the keys.

Note that if the SPChange parameter on the Enable page in Setup Mode has

been set to DISABLED, it must be changed to ENABLED before any changes to

the process temperature and high limit setpoints can be made.

3. Press the Menu key a second time to display current high limit setpoint (Hi-lim

SP). The value can be adjusted by pressing the keys. If Band is displayed,

the high limit band feature is activated (see Control page) and the high limit can

not be adjusted.

4. Press the Menu key a third time to display Time Set. You can change the time

setting with the keys.

5. (optional feature) Press the Menu key a fourth time to display Event1. Press the

key to turn on the event or to turn off the event. Repeat for all events which

are enabled (up to 4).

6. Press the Menu key a fifth time to display the current guaranteed soak band

(TmrGuarSoak) value. If the process temperature deviates from the setpoint by

more than this value, the timer is placed in a hold condition. The timer continues

when the process temperature falls within range. Reference the Quick

Reference and Default Values section for available settings.

7. To start Timer Mode, press the Run key.

The display will change from Stop to Run and the time remaining will be

displayed. To return to Stopped Mode, press the Stop key. While in operation,

the process setpoint can be adjusted by using the keys to change the value

while the mode is running. Pressing the Menu key will display the High Limit

Setpoint.

Pressing the Run/Hold key while the Timer Mode is in operation will put the control in

Hold status. The Timer LED will flash to indicate the held status. Press the Run/Hold

key again to continue timing. The Timer LED will return to lit status.

10

Page 17

Profile Mode

1. Press the Select key until Profile is displayed. “None” may be displayed if a

profile has not been selected or no profiles entered.

2. Press the key to display the desired profile to run.

3. To start Profile Mode, press the Run key.

The display will change from Stop to Run and the segment time remaining,

Temperature Setpoint, Profile #, along with the current segment number, will be

displayed. To return to Stopped Mode, press the Stop key.

Pressing the Run/Hold key while the Profile Mode is in operation will put the control in

Hold status. Press the Run/Hold key again to continue the mode. The Profile LED will

flash to indicate the hold status.

To advance to the next segment while running a profile, press the Select and UP arrow

keys at the same time.

Note that ramping down too fast may cause the high limit relay to trip unexpectedly if

the high limit band feature is used. This can be avoided by using a separate cooling

profile that does not utilized the high limit band and then jumping to that profile to

perform rapid cooling.

Auto Start Mode

The Auto Start Mode allows the control to start Manual, Timer, or Profile mode

automatically at a preset time and day. See the Auto Start Page in Setup Mode for the

time, day, and operating mode settings. The Auto Start Mode requires the optional Real

Time Clock feature for operation.

To activate the Auto Start Mode, the control must first be in Stopped Mode.

1. Press the Select key until Auto Start is displayed.

2. Press the Menu key.

3. Press the keys to activate or deactivate the Auto Start feature.

Note that once you activate Auto Start, you can continue to use all operating modes as

normal. If an operating mode is running at the time of a preset Auto Start function, and

Auto Start is activated, the existing operating mode will override the auto Start function

and the Auto Start will not turn on.

To use the Auto Start for the next day, the auto start must show in the LCD display that

it is active.

11

Page 18

Setup Mode

Configuration of the control and programming of the ramp/soak profiles must be done in

the Setup Mode. To access Setup Mode, the control must first be in Stopped Mode.

1. Press the Select key until Setup is displayed.

2. Press the Page key and Security will be displayed.

3. Press the Menu key and Password will also be displayed. Use the keys to

enter the proper password.

4. Once the proper password is displayed, press the Page key twice to enter the

Setup Mode.

To exit Setup Mode, press and hold the Page key for three seconds.

The control has two levels of password-protected security. Level one provides access

only to those menu pages that are enabled on the Enable page. Level two provides

access to all menu pages, including the Enable page. The default security password

values are 1 for level one and 2 for level two.

If an improper password has been entered, the control will remain at the Security

display. To enter the proper password, press the Menu key. To exit Setup Mode, press

and hold the Page key for three seconds.

Mapping of the Setup Mode is provided in the following sections. To access each

parameter Page, which are described in detail in the following sections, press the Page

key until the desired page heading is displayed. Press the Menu key to access each

Menu parameter. Press the keys to change Menu parameter settings.

Refer to the Quick Reference and Default Values section for available settings for each

Menu parameter.

Press the Page key to continue with each Page, or press and hold the Page key for

three seconds to exit Setup Mode.

12

Page 19

Instructions for Setup Mode Pages

Program Page

Programming of the profiles is provided on the Program Page. Eight profiles are

available with up to eight ramp and soak segments per profile.

If the optional relay outputs are installed, they must be configured as alarms or events

on the Relay Outputs Page before they can be utilized. If configured as event outputs,

these relays can be used as time or temperature events.

When entering the Program Page, press the Select key to select the profile you wish to

enter/edit, then press the Menu key. The first parameter (Profile #, Segment 1, Ramp

Time) will display. Adjust the time value with the keys. Once the proper value is

displayed, press the Menu key to continue. Continue with the Menu key to adjust/view

each parameter.

If the ramp time value of the current segment is left at 0:00, the next press of the Menu

key will advance the control to the High Limit Setpoint parameter for that profile.

Continue entering / verifying all parameters until you get to the last parameter

(Guaranteed Soak Band). Once all parameters have been properly entered, press the

Page key to return to the top of the Profile Page. You can press the Select key to

enter/edit another profile, press the Page key to access another page, or press and hold

the Page key to exit Setup mode.

While editing any profile, pressing the Select key will advance the control to the time

value for the next segment, until the last segment has been reached. This allows faster

editing of the profile rather than pressing the Menu key to advance past each

parameter.

To run a profile indefinitely, link the profile to itself.

13

Page 20

Menu Item Display Description

Ramp Time Seg 1 Pro-1 Seg-1 Ramp Time Ramp time for segment 1 of profile

Event 1 Set Value* Pro-1 Seg-1 Ramp Event 1 Event 1 setting for segment 1 ramp of profile

Event 2 Set Value* Pro-1 Seg-1 Ramp Event 2 Event 2 setting for segment 1 ramp of profile

Event 3 Set Value* Pro-1 Seg-1 Ramp Event 3 Event 3 setting for segment 1 ramp of profile

Event 4 Set Value* Pro-1 Seg-1 Ramp Event 4 Event 4 setting for segment 1 ramp of profile

Soak Temp Seg 1 Pro-1 Seg 1 Soak Temp Soak temperature for segment 1 of profile

Soak Time Seg 1 Pro-1 Seg 1 Soak Time Soak time for segment 1 of profile

Event 1 Set Value* Pro-1 Seg-1 Soak Event 1 Event 1 setting for segment 1 soak of profile

Event 2 Set Value* Pro-1 Seg-1 Soak Event 2 Event 2 setting for segment 1 soak of profile

Event 3 Set Value* Pro-1 Seg-1 Soak Event 3 Event 3 setting for segment 1 soak of profile

Event 4 Set Value* Pro-1 Seg-1 Soak Event 4 Event 4 setting for segment 1 soak of profile

(repeat for segments 2-8, until ramp or soak time = 00:00)

High Limit Setpoint Pro-1 Hi-Lim SP High limit setpoint for profile**

Loop From Pro-1 Loop From Seq To start a loop action in a profile

Loop To Pro-1 Loop To Seq To end a loop action in a profile

Loop Count Pro-1 Loop Number Number of times to execute loop

Profile Link Pro-1 Link To Pro To jump from this profile to another

Guaranteed Soak Pro-1 Guar Band Guaranteed soak band for profile

See the definitions on the following pages for parameter ranges.

* only available if optional relay outputs are installed (repeat all for profiles 2-8)

** Set to Band to use the high limit band feature

14

Page 21

Profile #

There are eight profiles available.

Segment#

Ramp Time

EV1 through 4

Soak Temp.

Soak Time

EV1 through 4

Recipe segments 1 through 8 may be programmed, each with its own

set of events, ramp and soak times, and soak temperature.

The time required to ramp from one setpoint up to another setpoint.

Values between 0 and 59:59 are allowable. In the Protocol Plus

controller, the profile ramp and soak times are stored without units.

Units are set as either hours and minutes (HH:MM) or minutes and

seconds (MM:SS). The setpoint will automatically increment from the

actual temperature to the soak temperature.

From 1 to 4 events may be programmed into the ramp time portion of

each segment here. These typically involve actuating/disabling relays

to close/open valves or perform other relay-controlled functions.

NOTE: These will only actuate when the controller has the relay cards

installed and programmed for an event.

The temperature setpoint of a particular segment is entered here; it

can range from -18 to 540 degrees C (0 to 1000 degrees F).

The duration of soak is entered here; the value can range from 0 to

59:59.

From 1 to 4 events may be programmed into the soak portion of each

segment here. These typically involve actuating/disabling relays to

close/open valves or perform other relay-controlled functions. NOTE:

These will only actuate when the controller has the relay cards

installed and programmed for an event.

Hi Limit SP

Loop From

Loop To

Loop Number

Profile Link

Guaranteed

Soak Band

The high limit setpoint may be entered here; if the temperature

exceeds this value, the hi-limit will alarm and shut off the heater.

Values are No, Seq-1 to Seq-8.

Values are No, Seq-1 to Seq-8.

Values are 0 - 99.

These values enable the operator to jump from a certain step to

another step of the recipe a preset number of times.

Values are STOP/HOLD/1 - 8. When the profile ends, the profile can

turn the heater off, hold the temperature setpoint at the end of the

profile, or jump to another specified profile.

If the process temperature deviates from the setpoint by more than

this value, the soak timer is placed in a hold condition. The timer

continues when the process temperature falls within range.

15

Page 22

Sample Profile

Programming Table

Profile Number____1______ Profile Name__________

Segment

Time

Ramp Soak

Events Events

1 2 3 4

Temp-

erature

Time

1 2 3 4

1 01h00 100 01h00

2 02h00 50 00h01

3 00h00

4

5

6

7

8

High Limit Setpoint 115

Loop From Seq No

Loop To Seq No

Loop Number 0

Link To Pro No

Guar Soak Band 10

16

Page 23

Auto Start Page (optional)

If the optional real time clock has been installed, the Auto Start Page can be configured

to automatically start Manual, Timer or Profile Mode at a specified time and day. Note

that if Auto Start Enable is set to Yes in the Setup Mode, the Auto Start feature is not

turned on - it is available to the operator to be activated in Stopped Mode.

To configure the Auto Start feature:

1. Access the Setup Mode.

2. Press the Page key until Auto Start is displayed.

3. Press the Menu key. If there is no change in the display, the controller may not

have the realtime clock option.

4. Set Auto Start Enable to Yes.

5. Using the Menu key, scroll through the options available and use the keys

to set the mode desired for each day of the week. You may select from Manual,

Timer, or Profile 1 through 8.

6. When the mode is set press the Menu key.

7. Enter the time of day you wish the mode to activate.

8. Continue through the rest of the week by pressing the Menu key, or press the

Page key when done.

One Auto Start mode can be set for each day of the week. Exit the Setup mode by

pressing and holding the Page key for three seconds. Press the Select key until Auto

Start is displayed. Make sure the correct time and day is displayed. If not proper, set it

to the correct time on the Real Time Clock Page in the Setup mode. Press the Run key

to activate Auto Start. The display will change from Stop to Active. When the preset time

and day occurs, the appropriate operating mode will start. You can de-activate Auto

Start by pressing the Select key until Auto Start is displayed, then pressing the Stop

key.

Note that once you activate Auto Start, you can continue to use all operating modes as

normal. If an operating mode is running at the time of a preset Auto Start function, and

Auto Start is activated, the existing operating mode will override the Auto Start function

and the Auto Start will not turn on.

17

Page 24

Menu Item Display Description Range

Enable

Autostart

Sunday

mode

Sunday

time

Monday

mode

Monday

time

Tuesday

mode

Tuesday

time

Wednesday

mode

Wednesday

time

Thursday

mode

Thursday

time

Friday

mode

Friday time Auto Start Fri

Saturday

mode

Saturday

time

Auto Start Enable Enable (yes) or disable (no) the

Auto Start Sun

Mode

Auto Start Sun

Time

Auto Start Mon

Mode

Auto Start Mon

Time

Auto Start Tue

Mode

Auto Start Tue

Time

Auto Start Wed

Mode

Auto Start Wed

Time

Auto Start Thu

Mode

Auto Start Thu

Time

Auto Start Fri

Mode

Time

Auto Start Sat

Mode

Auto Start Sat

Time

No, Yes

Autostart function

Set mode on Sunday to activate Off, Manual, Timer, Pro-1 to Pro-8

Set time on Sunday for mode to

activate

Set mode on Monday to activate Off, Manual, Timer, Pro-1 to Pro-8

Set time on Monday for mode to

activate

Set mode on Tuesday to activate Off, Manual, Timer, Pro-1 to Pro-8

Set time on Tuesday for mode to

activate

Set mode on Wednesday to

activate

Set time on Wednesday for mode

to activate

Set mode on Thursday to activate Off, Manual, Timer, Pro-1 to Pro-8

Set time on Thursday for mode to

activate

Set mode on Friday to activate Off, Manual, Timer, Pro-1 to Pro-8

Set time on Friday for mode to

activate

Set mode on Saturday to activate Off, Manual, Timer, Pro-1 to Pro-8

Set time on Saturday for mode to

activate

00:00 to 23:59

00:00 to 23:59

00:00 to 23:59

Off, Manual, Timer, Pro-1 to Pro-8

00:00 to 23:59

00:00 to 23:59

00:00 to 23:59

00:00 to 23:59

18

Page 25

PID Page

The PID Page contains parameters which control the response to the setpoint and

process variable input. To access the PID Page, enter the Setup Mode. Press the Page

key until PID is displayed. Press the Menu key. Each parameter can be changed by

pressing the Menu key until the desired parameter is displayed, and then pressing the

keys to change the value.

Menu Item Display Description Range

Display units PID Temp Unit Set display units to °C or °F

Proportional band PID PB(H) Set proportional band for tuning

Integral reset PID I(H) Rep/min Set integral reset for tuning 0 to 100 Sec/repeat

Derivative Rate PID D(H) in sec Set derivative rate for tuning 0 to 500 Sec.

AutoTune PID AutoTune Enable auto tuning function DIS EN

Proportional band PID PB(C) Set proportional band for tuning

Integral reset PID I(C) Rep/min Set integral reset for tuning 0 to 100 Sec/repeat

Derivative Rate PID D (C) in sec Set derivative rate for tuning 0 to 500 Sec.

Heat Offset PID Heat Offset Set PB up or down from Setpoint

Cool Offset PID Cool Offset Set PB up or down from Setpoint

°C or °F

1 to 56°C (1 to 100°F)

1 to 56°C (1 to 100°F)

-6 to 6°C (-11 to 11°F)

-6 to 6°C (-11 to 11°F)

The AutoTune parameter disables or enables the AutoTune function. To utilize

AutoTuning:

1. Access the Setup Mode.

2. Press the Page key until the display reads AutoTune. Press the key to enable

the AutoTune.

3. Press the Page key for three seconds to exit Setup Mode.

4. Cycle power to the instrument.

5. Set Manual Mode to run. The display will alternately display AutoTune and

Manual.

If the Manual Mode setpoint is less than 50 degrees higher than the actual process

temperature, the AutoTune function will create an error condition. This can be cleared

by either cooling off the process temperature or increasing the setpoint until there is

more than 50 degrees between them. Once the AutoTune function is allowed to

complete tuning, the AutoTune parameter will disable by itself.

If you wish to cancel the AutoTune function, press the STOP key, access the PID page

in Setup Mode, and set the AutoTune parameter to Disable.

19

Page 26

Control Page

The Control Page contains various parameters which control miscellaneous functions.

To access the Control Page, enter the Setup Mode. Press the Page key until Control is

displayed. Press the Menu key. Each parameter can be changed by pressing the Menu

key until the desired parameter is displayed, and then pressing the keys to change

the value.

Menu Item Display Description Range

Cycle Time Control Cycle

Time Sec

High limit

setpoint

High limit

band

Power fail

recovery

Recovery

time limit

Powerup

start enable

Powerup

Start Mode

Hysteresis Control

Process out

low

Process out

high

Time scale Control

Key press

beep

End of cycle

beep

Alarm beep Control

Control type Control

Control Hi-Lim

SP***

Control Hi-Lim

Band

Control PwrFRec Controls response to loss of

Control

PFRTime****

ControlPwrUpStrt Allows mode to automatically

Control StrtMode Operating mode for powerup start

Hysteresis

Control

RetOutLo

Control RetOutHi Process value for retransmit

TimeScale

Control KeyBeep Internal beeper sounds when key

Control

EOCBeep

AlarmBeep

Ctrl Heat/Cool

Set cycle time in seconds for

control output

Maximum value for all high limit

setpoints

If=0, high limit setpoint= Control

Hi-Lim SP If>0, high limit

setpoint= Control SP* + Band

power

Control aborts to Stopped mode if

power is lost for time period

longer then set value

start when power is first applied

Hysteresis for all alarms and

temperature events

Process value for retransmit

output = 1VDC

output = 5VDC

Time scale setting for program

and timer mode**

is pressed

Internal beeper sounds at end of

cycle

Internal beeper sounds for alarms

Set control type

1 to 60 seconds

MinHiLimSP - MaxHiLimSP*

Off, 3°C to 11°C (5°F to 20°F)

Stop, Restart, Hold, Resume

00m00s to 99m59s

Disable, Enable

Off, Manual, Timer, Pro-1 to Pro-8

1°C to 56°C (1°F to 100°F)

hh:mm or mm:ss

On or Off

On or Off

On or Off

Heat, cool, heat/cool

* includes ramping setpoints during profiles and controlled ramps

** power fail recovery time limit is always MM:SS regardless of time scale setting

*** high limit setpoint is a read-only item which is calculated on Enable page

**** requires real-time-clock feature

20

Page 27

Communication Page (optional)

The Communication Page contains parameters for the communications feature. To

access the Communications Page, enter the Setup Mode (see description earlier in this

manual). Press the Page key until Communication is displayed. Press the Menu key.

Each parameter can be changed by pressing the Menu key until the desired parameter

is displayed, and then pressing the keys to change the value.

Menu Item Display Description Range

Address Communication CommAddr Sets address node for

control

Mode Communication Mode Turns on/off

communications

Baud Rate Communication BaudRate Sets interface speed 2400, 4800, 9600, 19.2K,

Parity Communication Parity Sets parity for interface None, Odd, Even

1 to 255

OFF, Modbus

38.4K

Real Time Clock Page (optional)

The Real Time Clock Page allows the control to be configured to have an operating

mode begin automatically at a specific time on a specific day of the week. The real time

clock feature is required for using the Power Failure Recovery mode Time Limit feature

(see Control Page). The real-time-clock is a seven day, 24 hour clock with battery

backup.

To access the Real Time Clock Page, enter the Setup Mode. Press the Page key until

Clock is displayed. Press the Menu key. (If there is no change in the display, the

controller may not have the realtime clock option.) Each parameter can be changed by

pressing the Menu key until the desired parameter is displayed, and then pressing the

keys to change the value.

Menu Item Display Description Range

Day of the

week

Time of

day

Reset

clock

Clock Day Setting for current day of the week Sun, Mon, Tue, Wed, Thu, Fri, Sat

Clock HH:MM Setting for current time of the day 00:00 to 23:59

Clock UP to

Reset CLK*

Press the key to set the clock

to entered values

Ready, Done

* If the key is not pressed, the clock values will retain their original values. The

display will change to Done if the clock is reset

21

Page 28

Relay Outputs Page (optional)

The Relay Outputs Page configures the four alarm/event outputs. Each output has a

dedicated indicator light and can be configured as a temperature alarm, profile event, or

end of cycle output. Temperature alarms can be of type process high, process low,

deviation high, deviation low, or deviation band.

To access the Relay Page, enter the Setup Mode (see description earlier in this

manual). Press the Page key until Relay is displayed. Press the Select key until the

desired relay output is selected. Press the Menu key. Each parameter can be changed

by pressing the Menu key until the desired parameter is displayed, and then pressing

the keys to change the value. To configure a specific relay, press the Select key

until the desired relay appears.

NOTE: If Relay 0 appears, then no relays are installed (see relay kit assembly p.n.

144562).

Menu Item Display Description Range

Type of relay Relay 1

RelayType

Action of relay Relay 1

RelayAction

Type of

alarm*

Alarm

setpoint*

Alarm

deviation*

Inhibit alarm* Relay 1

Type of

event**

Event

setpoint***

Relay 1

AlarmType

Relay 1 AlmHi/Lo

SP

Relay 1

AlmDevBand

ALMInhibit

Relay 1

EventType

Relay 1 Event SP Setpoint for temperature event SPLoLim to SPUpLim****

(repeat for relay outputs 2-4, if available)

* appears only for alarm types

** appears only for time or temperature event types

*** appears only for temperature event types

Turning on the Alarm Inhibit function disables the alarm output on power up until the

process temperature has reached a non-alarming condition ("safe").

If the relay output has been configured as latching, the RESET key must be pressed to

return the output to the non-alarm state once the alarm condition has cleared.

Set function of relay Off, Alarm, Cycl, Ev1 to Ev4

Set coil and contact state of

relay

Set alarm type for relay High, Low, Plus, Minus, Band

Setpoint for alarm

Deviation band for alarm 1 to 56°C (1 to 100°F)

Inhibits alarm until "safe"

condition is reached

Set event type for relay Time or Temp

NDE, NE, NDEL, NEL*****

-73°C to 760°C (-100°F to 1400°F)

En or Dis

22

Page 29

Test Page

The Test Page contains parameters which allow manual control of the heat control and

optional relay outputs and should be used only for testing the functionality of the control

instrument. Do not operate the oven for processes using the Test Page.

To access the Test Page, enter the Setup Mode (see description earlier in this manual).

Press the Page key until Test is displayed. Press the Menu key. Each parameter can be

changed by pressing the Menu key until the desired parameter is displayed, and then

pressing the keys to change the value.

Menu Item Display Description Range

Heater

output

High limit

relay

Relay 1

output

Relay 2

output

Relay 3

output

Relay 4

output

HiLim

Sensor

Test HeatOut Activate SSR output 100%

Test HiLimOut Activate high limit alarm

(de-energize relay)

Test Rly1 Out Energize relay output 1

Test Rly2 Out Energize relay output 2

Test Rly3 Out Energize relay output 3

Test Rly4 Out Energize relay output 4

Test HL Temp

(push and hold up)

Displays sensor reading*

*Push key to refresh display

When the Test Page is entered, all outputs are automatically set to off. When exiting

the Test Page, all outputs will return to their previous condition regardless of the Test

Page settings.

On

On

On

On

On

On

23

Page 30

Zone Calibration Page

The Zone Calibration Page allows adjustment of the displayed temperature versus the

actual temperature measured by the control thermocouple. This may be desirable in

certain conditions where the center of the oven chamber is not the same temperature as

the control thermocouple. This may occur when the oven is not allowed to soak at a

constant temperature for long periods of time, or the oven is being used at high

temperature.

There is also a Factory Calibration Recovery which will restore the factory calibration

values when the control was first shipped by the manufacturer. This may be helpful if

the calibration has been lost and a calibration instrument is not readily available. To use

the Factory Calibration Recovery feature only, bypass the Zone 1 and Zone 2

calibration parameters by pressing the Menu key.

To access the Zone Calibration Page, enter the Setup Mode (see description earlier in

this manual). Press the Page key until Zone Cal is displayed. Press the Menu key. Each

parameter can be changed by pressing the Menu key until the desired parameter is

displayed, and then pressing the keys to change the value.

Menu Item Display Description Range

Zone 1

actual

Zone1

displayed

Zone 2

actual

Zone2

displayed

Factory

calibration*

Zone Cal

Zone1Act

Zone Cal

Zone1Dis

Zone Cal

Zone2Act

Zone Cal

Zone2Dis

Zone Cal

FactCal

Point at which Zone 1 is set (center

of chamber)

Desired displayed value for Zone 1

setting

Point at which Zone 2 is set (center

of chamber)

Desired displayed value for Zone 2

setting

Restores the factory calibration

values

*Only use when no calibration instrument is available, push key to restore factory

values.

Press the Page key to exit the Zone Calibration Page.

Two points of display calibration (temperature offset) are available. The Zone 1 Actual

and Zone 2 Actual parameters are the two temperature points where the offset is to take

effect. These values are adjustable. The Zone 1 and Zone 2 Displayed parameters are

the values the user wishes to have displayed at the Actual temperatures, and are also

adjustable.

-73°C to 760°C (-100°F to 1400°F)

-73°C to 760°C (-100°F to 1400°F)

-73°C to 760°C (-100°F to 1400°F)

-73°C to 760°C (-100°F to 1400°F)

Ready or Done (push- key)

24

Page 31

As an example, the control is displaying 400°F with the setpoint being 400°F, but the

center of the oven chamber is actually 395°F. This can occur due to oven wall losses

and product loading variations. The operator may change the zone calibration so that

the center of the oven is 400°F when the display reads 400°F. In this case operate the

oven in manual mode with a setpoint of 400°F. Record the center of the chamber (as

measured with an independent sensor). Access the Zone Calibration Page and enter

this measured value as the Zone 2 Actual value, with 400° as the Zone 2 Displayed

value.

Zone 1 can be adjusted using the same method at a lower temperature. The instrument

will then create a linear offset based on the Zone1 and Zone 2 Actual temperature

values. Note that the oven does not have to be heated to adjust the zone parameters if

the zone values are known based on prior experience.

25

Page 32

Sensor Calibration Page

The Sensor Calibration Page has parameters which can change the internal calibration

of the temperature sensor input signal. There is a low and high calibration point for both

the control sensor and the high limit sensor. To calibrate the instrument, allow the

control to warm up for at least 30 minutes.

To access the Sensor Calibration Page, enter the Setup Mode (see description earlier in

this manual). Press the Page key until Control Sensor is displayed. Press the Menu

key.

The control may have the optional process value retransmission output feature. The

output is a 1 to 5VDC signal. To calibrate the retransmit signal, the RetOutLo and

RetOutHi values from the Control Page must be known. You may bypass calibrating

the control and high limit sensor input to access only the retransmit calibration by

pressing the Menu key until RetCalLo is displayed (skip steps 4-17).

To re-calibrate the instrument:

1. Disconnect the control and high limit sensor thermocouples.

2. Connect a calibration instrument with a type J thermocouple output to the

control sensor input. Allow the control to warm up at least 30 minutes.

3. Access Setup Mode.

4. Press Page key until -100F is displayed.

5. Press Menu key until Ctrl Sens -100F is displayed.

6. With Ctrl Sens -100F displayed, adjust the calibration instrument to Type J

thermocouple, -100 degrees Fahrenheit output.

7. Wait 30 seconds. Press the key.

8. With Ctrl Sens 1400F displayed, adjust the calibration instrument to 1400

degrees Fahrenheit output (Type J thermocouple).

9. Wait 30 seconds. Press the key.

10. When the control displays Ctrl Sens Done, disconnect the calibration

instrument from the control sensor input and connect it to the high limit sensor

input. Reconnect the control sensor thermocouple.

11. Press the Menu key until HL Sens -100F is displayed.

12. With the control displaying HL Sens -100F, adjust the calibration instrument

to -100 degrees Fahrenheit output (Type J thermocouple).

13. Wait 30 seconds. Press the key.

14. With the control displaying HL Sens 1400F, adjust the calibration instrument

to 1400 degrees Fahrenheit output (Type J thermocouple).

15. Wait 30 seconds. Press the key.

16. When the control displays HL Sens Done, disconnect the calibration

instrument from the high limit sensor input. Re-connect the high limit sensor

thermocouple.

17. To skip calibration of the retransmit signal, press the Page key twice to exit the

Sensor Calibration Page.

18. To calibrate the retransmit signal, press the Menu key until RetCalLo is

displayed.

26

Page 33

19. Connect a calibration instrument with a type J thermocouple output to the

control sensor input.

20. Connect a voltage measurement device to the retransmit output terminals.

21. Set the calibration instrument output to the temperature value of the RetOutLo

parameter from the Control Page.

22. Adjust the RetCalLo * value using the keys until the voltage measurement

device reads 1VDC.

23. Press the Menu key.

24. Set the calibration instrument output to the temperature value of the RetOutHi

parameter from the Control Page.

25. Adjust the RetCalHi * value using the keys until the voltage measurement

device reads 5VDC.

26. Press the Menu key.

27. Press the Page key to exit the Sensor Calibration Page.

28. Calibration is now complete. Disconnect the calibration instrument and voltage

measurement device (if used).

29. Verify that the control and high limit sensor thermocouples are connected.

Menu Item Display Description Range

Control Sensor

Cal

HiLim Sensor

Cal

Retransmit Cal RetCalLo XXXX *

Ctrl Sens -100F

Ctrl Sens 1400F

Ctrl Sens Done

HL Sens -100F

HL Sens 1400F

HL Sens Done

RetCalHi XXXX *

Calibrate Sensor Low End

Calibrate Sensor High End

Control Sensor Cal Complete

Calibrate HiLim Sensor Low

End

Calibrate HiLim Sensor High

End

HiLim Sensor Cal Complete

Calibrate Retransmit Output

Low

Calibrate Retransmit Output

High

-100 to 1400°F

-100 to 1400°F

(read only)

-100 to 1400°F

-100 to 1400°F

(read only)

0 to 4096**

0 to 4096***

*Note that the actual RetCalLo and RetCalHi values displayed are of no importance.

27

Page 34

Enable Page

The Enable Page controls access to the other Setup Pages. The setpoint minimum and

maximum values, and the security passwords are also set on the Enable Page.

To access the Enable Page, enter the Setup Mode using a level 2 access code (see

description earlier in this manual). Press the Page key until Enable is displayed. Press

the Menu key. Each parameter can be changed by pressing the Menu key until the

desired parameter is displayed, and then pressing the keys to change the value.

NOTE: Changing the enable to “yes” for each page will allow access to the page in

Level 1 security.

Menu Item Display Description Range

Profiles Enable Profile

1-8

Autostart Enable Auto

Start

PID Enable PID Controls access to PID Page Yes or No

Control Enable Control Controls access to Control Page Yes or No

Controls access to Program Page Yes or No

Controls access to AutoStart

Page

Yes or No

Communication Enable

Communication

Real Time

Clock

Relay outputs Enable Relay

Test Enable Test Controls access to Test Page Yes or No

Zone

Calibration

Sensor

Calibration

Setpoint lower

limit

Setpoint upper

limit

High limit

overhead

Password level 1 Enable

Password level 2 Enable

Setpoint

Change

Analog Output

Type

Enable Clock Controls access to Real Time

1-4

Enable Zone

Cal

Enable Sensor

Cal

Enable

SPLowerLim

Enable

SPUpperLim

Enable

HiLimOH

Password 1

Password 2

Enable

SPChange

Enable Analog

Type

Controls access to

Communication Page

Clock Page

Controls access to Relay Page Yes or No

Controls access to Zone

Calibration Page

Controls access to Sensor

Calibration Page

Sets minimum setpoint allowed

Sets maximum setpoint allowed

Sets maximum high limit setpoint

allowed*

Sets password for access level 1 0 to 1000

Sets password for access level 2 0 to 1000

Set to DISABLE to lock out

setpoint and high limit setpoint

changes in Manual and Timer

Modes

Sets Analog Output type Ctrl or Proc

Yes or No

Yes or No

Yes or No

Yes or No

-73°C to 760°C (-100°F to 1400°F)

-73°C to 760°C (-100°F to 1400°F)

3 to 11°C (5 to 20°F)*

Yes or No

* Maximum high limit setpoint = SPUpperLim + HiLimOH

28

Page 35

Digital Inputs (optional)

The Protocol Plus control can be run by external inputs wired to the control from an

external source such as a PLC or control panel switches. The external run operation

can Run, Hold or Stop profiles 1 through 7 (profile 8 can not be operated externally).

Refer to the table below for the inputs required for the desired operation. NOTE: A

profile must be created in the program page before trying to run a profile number.

Input 1 Input 2 Input 3 Profile Selected

ON OFF OFF 1

OFF ON OFF 2

ON ON OFF 3

OFF OFF ON 4

ON OFF ON 5

OFF ON ON 6

ON ON ON 7

OFF OFF OFF none

To start the selected profile, set Input 1, 2, 3 or 4 to ON.

To hold a profile, set Input 4 to OFF.

To stop a profile, set all inputs to OFF.

Digital Inputs

29

Page 36

Error Messages and Alarms

The Alarm Status Hi-limit LED is flashing. This indicates a problem with the

thermocouple, or the Hi-limit setpoint has been exceeded. Once the problem has

corrected, press the Reset pushbutton.

The Alarm Status Soak LED is flashing. This indicates that the oven temperature has

not entered or dropped out of the soak band and the soak timer has stopped.

The top LED Display reads OPEN. This indicates that either the Control or the Hi-limit

thermocouple is disconnected or broken. The lower LCD display should indicate which

thermocouple is the problem. Repair or replace the thermocouple.

The lower LCD display reads CONTROL SENS ERR. This indicates that the Control

thermocouple is disconnected or broken. The upper LED display should indicate OPEN

showing a thermocouple problem. Repair or replace the thermocouple.

The lower LCD display reads HI-LIM SENS ERR. This indicates that the Hi-limit

thermocouple is disconnected or broken. Repair or replace the thermocouple.

The lower LCD display reads HIGH LIMIT ALARM. This indicates that the Hi-limit

temperature setpoint has been exceeded. Determine if the setting is set too close to the

setpoint, the SSR is defective, or the calibration is incorrect.

30

Page 37

Quick Reference and Default Values

Program Page

Menu Item Display Default Range Setting

Ramp Time Seg 1 Pro-1 Seg-1 Ramp Time 00:00 00m00s to

99h59s

Event 1 Set Value Pro-1 Seg-1 Ramp Event 1 Off Off, On

Event 2 Set Value Pro-1 Seg-1 Ramp Event 2 Off Off, On

Event 3 Set Value Pro-1 Seg-1 Ramp Event 3 Off Off, On

Event 4 Set Value Pro-1 Seg-1 Ramp Event 4 Off Off, On

Soak Temp Seg 1 Pro-1 Seg 1 Soak Temp 68°F SPLowerLim to

SPUpperLim *

Soak Time Seg 1 Pro-1 Seg 1 Soak Time 00:00 00m00s to

99h59s

Event 1 Set Value Pro-1 Seg-1 Soak Event 1 Off Off, On

Event 2 Set Value Pro-1 Seg-1 Soak Event 2 Off Off, On

Event 3 Set Value Pro-1 Seg-1 Soak Event 3 Off Off, On

Event 4 Set Value Pro-1 Seg-1 Soak Event 4 Off Off, On

(repeat for segments 2-8)

High Limit Setpoint Pro-1 Hi-Lim SP Max

HiLimSP

Loop From Pro-1 Loop From XX No No, Seg-1 to

Loop To Pro-1 Loop To XX No No, Seg-1 to

Loop Count Pro-1 Loop Number 0 0 to 99

Profile Link Pro-1 Link To XX Stop Stop, Hold,

Guaranteed Soak Pro-1 Guar Band Off Off, 1 to 760°C

(repeat for profiles 2-8)

MinHiLimSP to

MaxHiLimSP *,

Band **

Seg-8

Seg-8

Pro-1 to Pro-8

(1400°F)

* See Enable Page

** Band value is set on Control Page

31

Page 38

Programming Table

Profile Number__________

Profile Name__________

Segment

Time

Ramp Soak

Events Events

1 2 3 4

Temp-

erature

Time

1 2 3 4

1

2

3

4

5

6

7

8

High Limit Setpoint

Loop From Seq

Loop To Seq

Loop Number

Link To Pro

Guar Soak Band

32

Page 39

Autostart

Menu Item Display Default Range Setting

Enable Autostart Auto Start Enable No No, Yes

Sunday mode Auto Start Sun Mode Off Off, Manual, Timer, Pro-1 to Pro-8

Sunday time Auto Start Sun Time 00:00 00:00 to 23:59

Monday mode Auto Start Mon Mode Off Off, Manual, Timer, Pro-1 to Pro-8

Monday time Auto Start Mon Time 00:00 00:00 to 23:59

Tuesday mode Auto Start Tue Mode Off Off, Manual, Timer, Pro-1 to Pro-8

Tuesday time Auto Start Tue Time 00:00 00:00 to 23:59

Wednesday mode Auto Start Wed Mode Off Off, Manual, Timer, Pro-1 to Pro-8

Wednesday time Auto Start Wed Time 00:00 00:00 to 23:59

Thursday mode Auto Start Thu Mode Off Off, Manual, Timer, Pro-1 to Pro-8

Thursday time Auto Start Thu Time 00:00 00:00 to 23:59

Friday mode Auto Start Fri Mode Off Off, Manual, Timer, Pro-1 to Pro-8

Friday time Auto Start Fri Time 00:00 00:00 to 23:59

Saturday mode Auto Start Sat Mode Off Off, Manual, Timer, Pro-1 to Pro-8

Saturday time Auto Start Sat Time 00:00 00:00 to 23:59

PID

Menu Item Display Default Range Setting

Display units PID Temp Unit °C °C or °F

Proportional band PID PB(H) 6°C 1 to 56°C (1 to 100°F)

Integral reset PID I(H) Rep/min 2 0 to 100 seconds/repeat

Derivative Rate PID D(H) in sec 0 0 to 500 seconds

AutoTune PID AutoTune Disable Disable, Enable

Proportional Band PID PB(C) 6°C 1 to 56°C (1 to 100°F)

Integral reset PID I(C) Rep/min 2 0 to 100 seconds/repeat

Derivative Rate PID D(C) in sec 0 0 to 500 seconds

Heat Offset PID Heat Offset 0°C

Cool Offset PID Cool Offset 0°C

-6 to 6°C (-11 to 11°F)

-6 to 6°C (-11 to 11°F)

33

Page 40

Control

Menu Item Display Default Range Setting

Cycle Time Control Cycle Time 1 1 to 60 seconds

High limit setpoint Control Hi-Lim SP Max HiLimSP MinHiLimSP - MaxHiLimSP*

High limit band Control Hi-Lim Band Off Off, 3°C to 11°C (5°F to 20°F)

Power fail recovery Control PwrFRec Stop Stop, Restart, Hold, Resume

Recovery time limit Control PwrFTime 00m00s 00m00s to 99m59s

Powerup start enable Control EPwrStrt Dis Dis, En

Powerup Start Mode Control StrtMode Off Off, Manual, Timer, Pro-1 to Pro-8

Hysteresis Control Hyst 3°C 1°C to 56°C (1°F to 100°F)

Process out low Control RetOutLo 80°C -73°C to 760°C (-100°F to 1400°F)

Process out high Control RetOutHi 400°C -73°C to 760°C (-100°F to 1400°F)

Time scale Control TimeScale hh:mm hh:mm or mm:ss

Key press beep Control KeyBeep On On or Off

End of cycle beep Control EOCBeep Off On or Off

Alarm beep Control AlarmBeep Off On or Off

Control Type Control Ctrl Heat/Cool Heat, Cool, Heat/Cool

*see Enable Page

Communication (optional)

Menu Item Display Default Range Setting

Address Communication CommAddr 1 1 to 255

Mode Communication CommMode OFF OFF, Modbus

Baud rate Communication Baud Rate 19.2K 2400, 4800, 9600,

19.2K, 38.4K

Parity Communication Parity None None, Odd, Even

34

Page 41

Real Time Clock

Menu Item Display Default Range Setting

Day of the week Clock Day Mon Sun, Mon, Tue,

Wed, Thu, Fri, Sat

Time of day Clock HH:MM 00:00 00:00 to 23:59

Reset clock Clock UP to Reset CLK* Ready Ready, Done

* if the key is not pressed, the clock values will retain their original values, the display

will change to Done if the clock is reset

Relay Outputs (optional)

Push Select key to select relay. If Relay 0 appears, no relays are installed

Menu Item Display Default Range

Type of relay Relay 1 RelayType Off Off, Alarm, Cycl, Ev1 to Ev4

Action of relay Relay 1 RelayAction NDE NDE, NE, NDEL, NEL*****

Type of alarm* Relay 1 AlarmType High High, Low, Plus, Minus, Band

Alarm setpoint* Relay 1 AlmHi/Lo SP 538°C -73°C to 760°C (-100°F to 1400°F)

Alarm deviation* Relay 1 AlmDevBand 3°C 1 to 56°C (1 to 100°F)

Inhibit alarm* Relay 1 ALMInhibit On En or Dis

Type of event** Relay 1 EventType Time Time or Temp

Event setpoint *** Relay 1 Event SP SPUpLim SPLoLim to SPUpLim****

(repeat for relay outputs 2-4, if available)

* appears only for alarm types

** appears only for time or temperature event types

*** appears only for temperature event types

**** see enable page

***** Normally de-energized and non-latching, normally energized and non-latching, normally de-energized and

latching, normally energized and latching

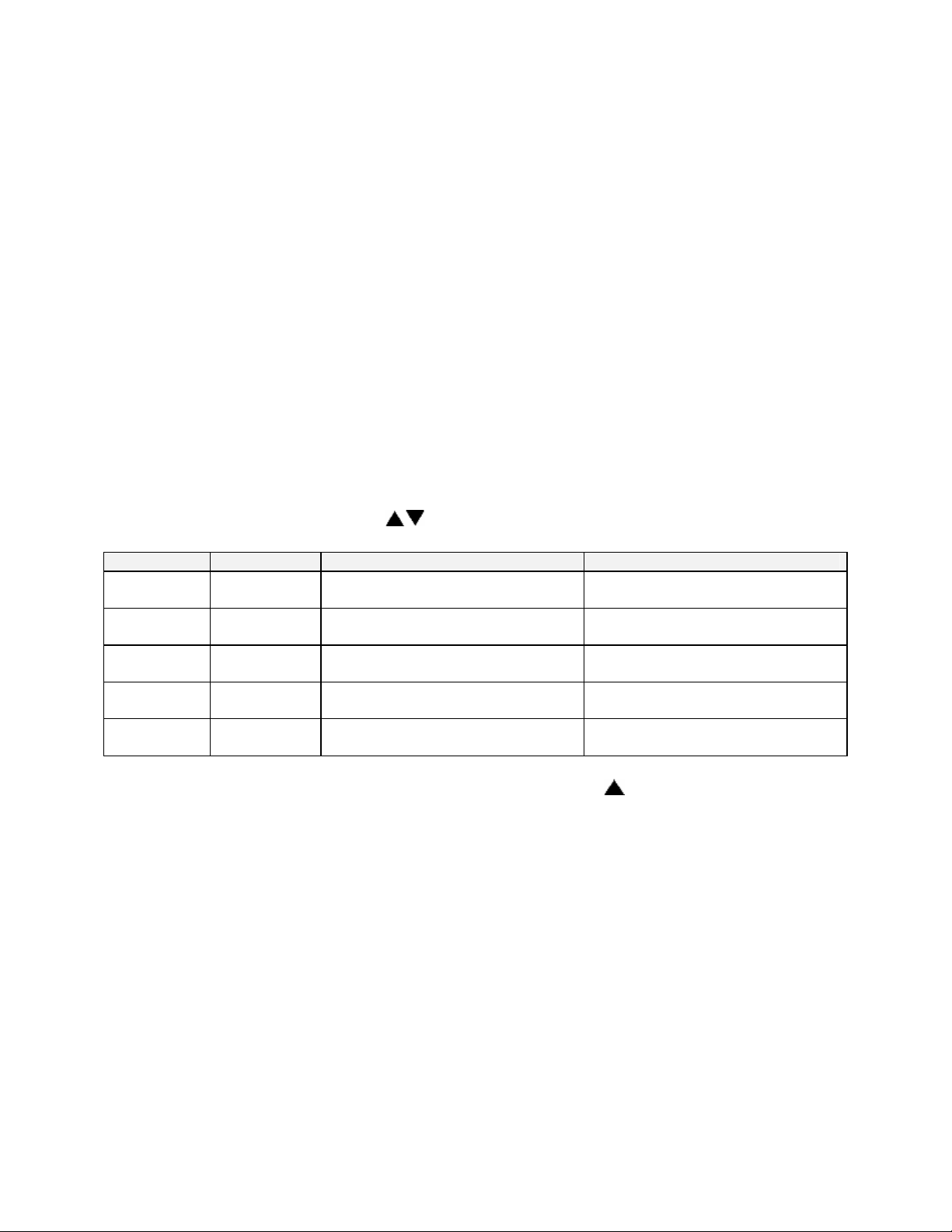

Table of Settings

Relay Type Action Alarm/

Event Type

Setpoint Alarm

Deviation

Alarm

Inhibit

35

Page 42

Test

Menu Item Display Default Range Setting

Heater output Test HeatOut Off On

High limit relay Test HiLimOut Off On

Relay 1 output Test Rly1 Out Off On

Relay 2 output Test Rly2 Out Off On

Relay 3 output Test Rly3 Out Off On