Page 1

E-100

P. N. 208711

REVISION G

8/2006

DESPATCH PROTOCOL MANAGER

NETWORK UTILITY SOFTWARE

INSTALLATION AND OPERATION MANUAL

Prepared by:

Despatch Industries

8860 207th St. West

Lakeville, MN 55044

Customer Service 800-473-7373

Page 2

Thank you for choosing Despatch Industries. We appreciate

the opportunity to work with you and to meet your heat

processing needs. We believe that you have selected the

finest equipment available in the heat processing industry.

At Despatch, our service does not end after the purchase

and delivery of our equipment. For this reason we have

created the Service Products Group within Despatch. The

Service Products Group features our Response Center for

customer service. The Response Center will direct and track

your service call to ensure satisfaction.

Whenever you need service or replacement parts, contact

the Response Center at 1-800-473-7373: FAX 952-469-

8193.

Sincerely,

Despatch Industries

Page 3

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................1

INSTALLATION...............................................................................................................2

Host Computer Requirements..............................................................................2

Installing the Software ..........................................................................................2

Software Setup.....................................................................................................6

Configuring the Controllers........................................................................6

Startup and Login ......................................................................................7

Setup ......................................................................................................... 9

Network Setup .........................................................................................12

Configuring a Recipe ...............................................................................21

Recipe Selection Setup ........................................................................... 27

Datalog Functions....................................................................................28

STARTING THE CONTROLLER ..................................................................................33

Run Time Window..............................................................................................34

Manual Mode...........................................................................................34

Timer Mode..............................................................................................35

Profile Mode.............................................................................................36

COMMUNICATION CARD INSTALLATION AND JUMPER SETTINGS ......................38

Wiring Diagrams.................................................................................................38

Communication Card Installation........................................................................39

Communication Card Jumper Settings...............................................................41

Connecting Protocol Plus Controller(s) to a Communications Host PC .............42

Single Oven.............................................................................................42

Multiple Ovens.........................................................................................42

TROUBLESHOOTING THE COMMUNICATIONS OPTION.........................................46

Controller Parameters..............................................................................46

Protocol Manager Parameters.................................................................46

Controller Hardware and Cabling.............................................................48

i

Page 4

INTRODUCTION

The Despatch Protocol Manager network utility software enables the operation of

multiple Protocol Plus controllers from a remote PC. As many as 32 Protocol Plus units

may be operated.

The software performs the following functions:

• Remote access and operation of one or more Protocol Plus controllers

• Allows use of a centralized PC to store and edit profiles

• Allows the same profiles to be downloaded to multiple controllers

• Allows a profile to be uploaded from a particular controller to the central PC,

so it can be passed to the other controllers

• Allows centralized data logging from all controllers connected to the central

PC

NOTE: Use this document in conjunction with Despatch publication E98 (p.n.

143895), Protocol Plus Control Instruction Manual.

1

Page 5

INSTALLATION

Host Computer Requirements

The host computer must be Pentium-class or equivalent, running Windows 95,

Windows 98, Windows NT, Windows 2000 or Windows XP.

An RS-232 serial port, COM1 – COM4, must be available.

Installing the Software

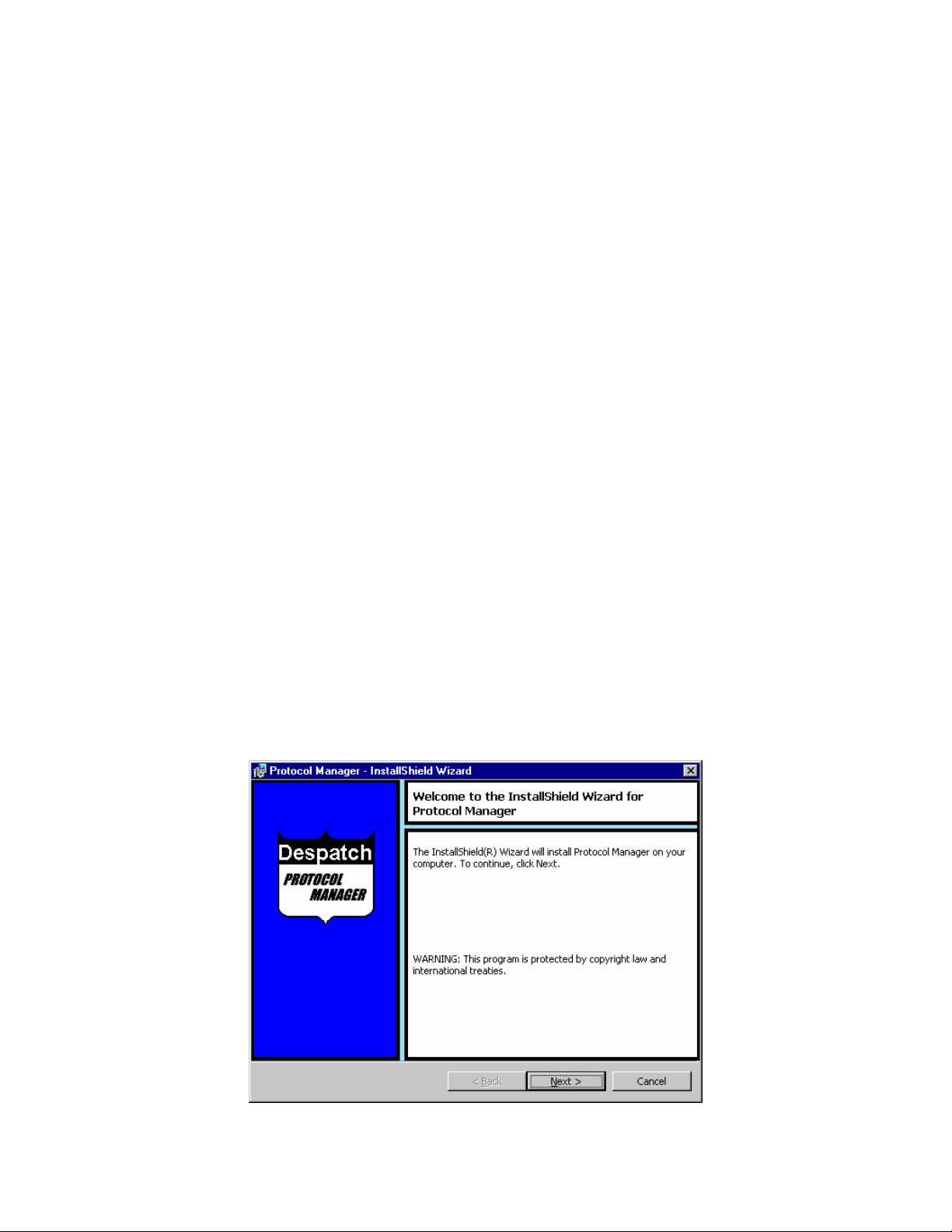

NOTE: Close all open applications before installing Protocol Manager software.

1. Insert the Protocol Manager software CD-ROM into the CD drive of the

control computer.

2. Click on the start button in the lower left corner of the screen.

3. Click on the "Run" button from the menu that appears.

4. Click on the Browse button. Change the Look In box at the top of the window

to the drive letter for your CD drive.

5. Double-click on the Setup.exe file. The following screen will appear:

Figure 1 Protocol Manager Installer

2

Page 6

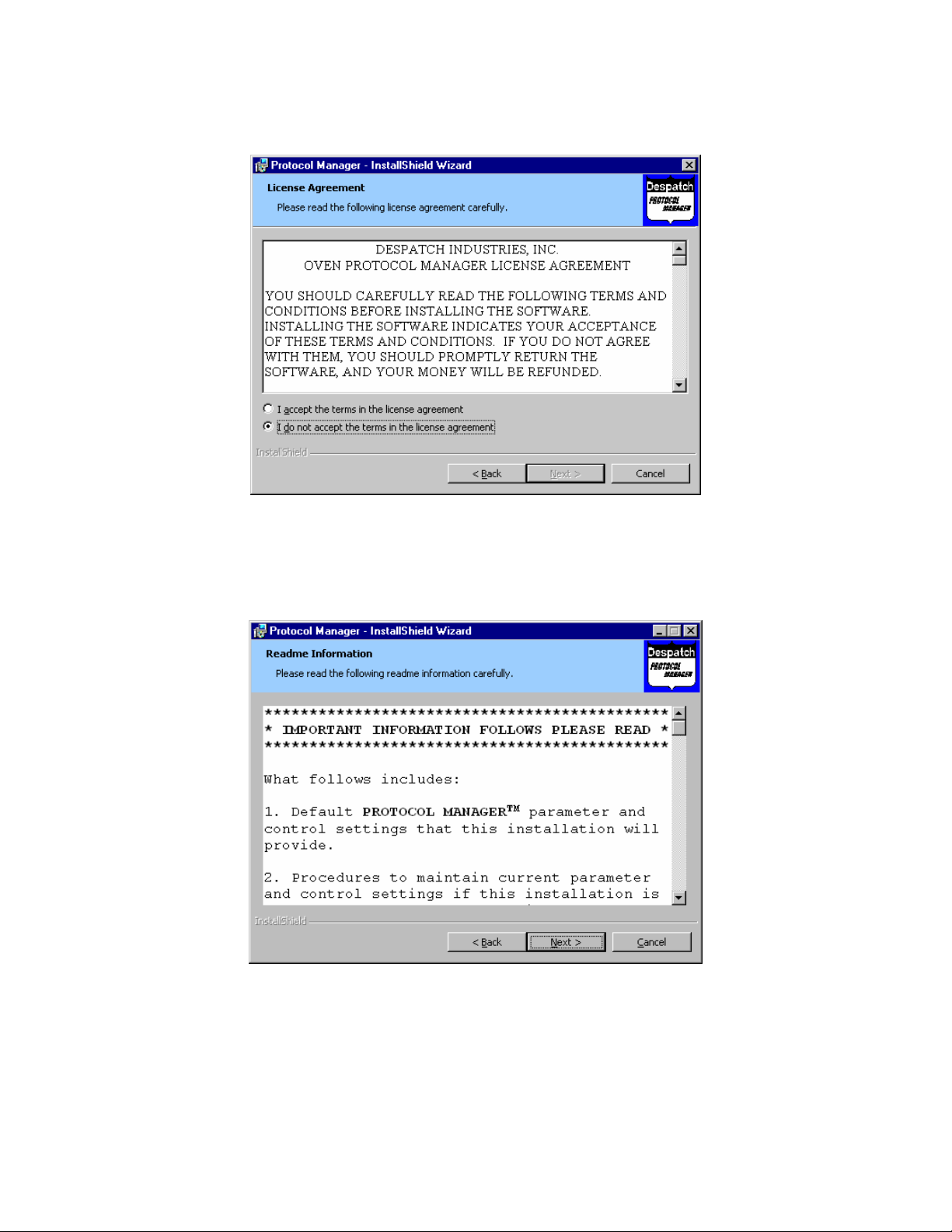

6. Click on the Next button. The following screen will appear:

Figure 2 License Agreement

7. Scroll the window to read the license agreement, then click on the "I accept

the terms" button and click Next to continue. The following screen will appear.

Figure 3 Initial Setup Parameters ReadMe

3

Page 7

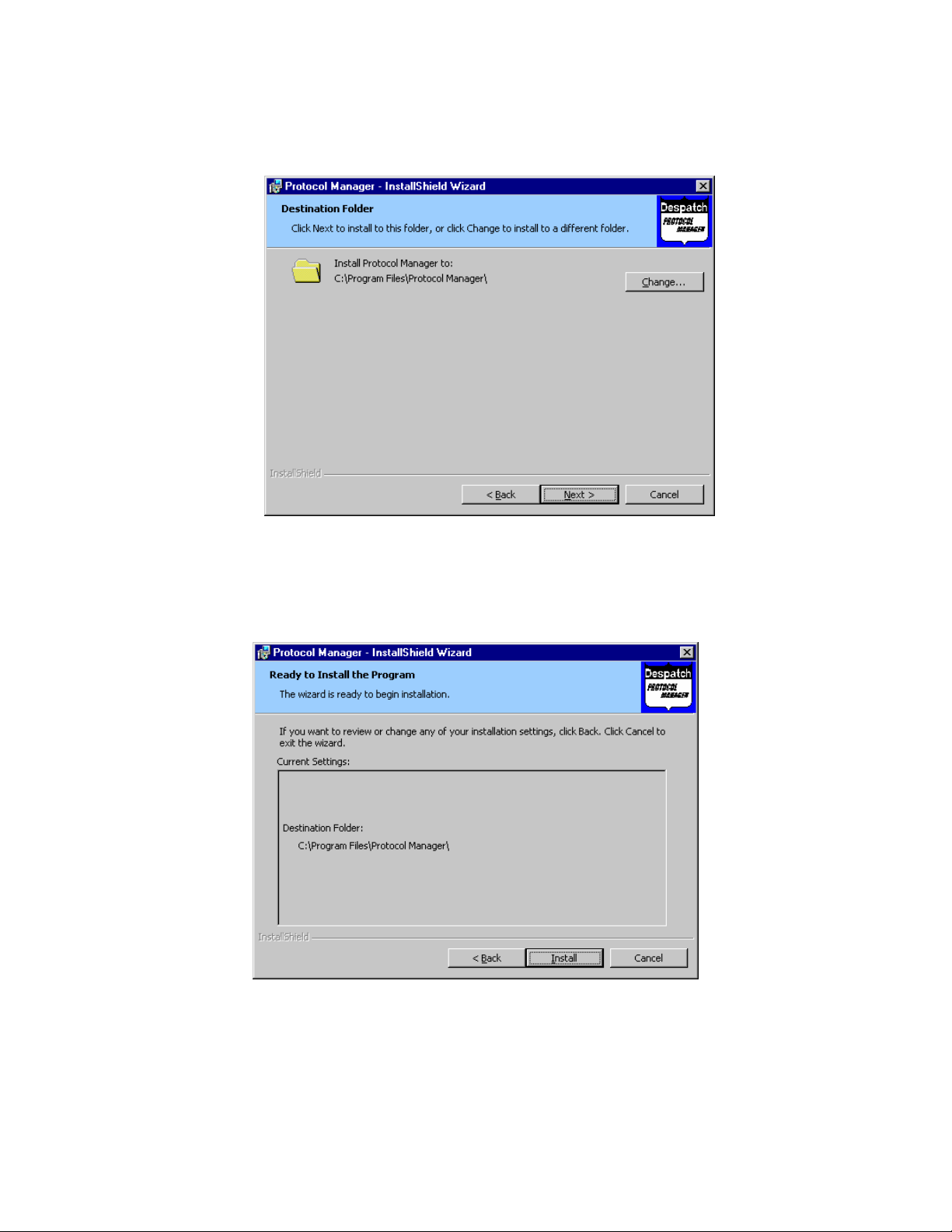

8. Scroll the window to read all the information, then click Next. The following

screen will appear.

Figure 4 Destination Folder Selection

9. Either accept the directory shown and click Next, or select a new directory

using the Change button, then click Next. The following screen will appear.

Figure 5 Install Screen

4

Page 8

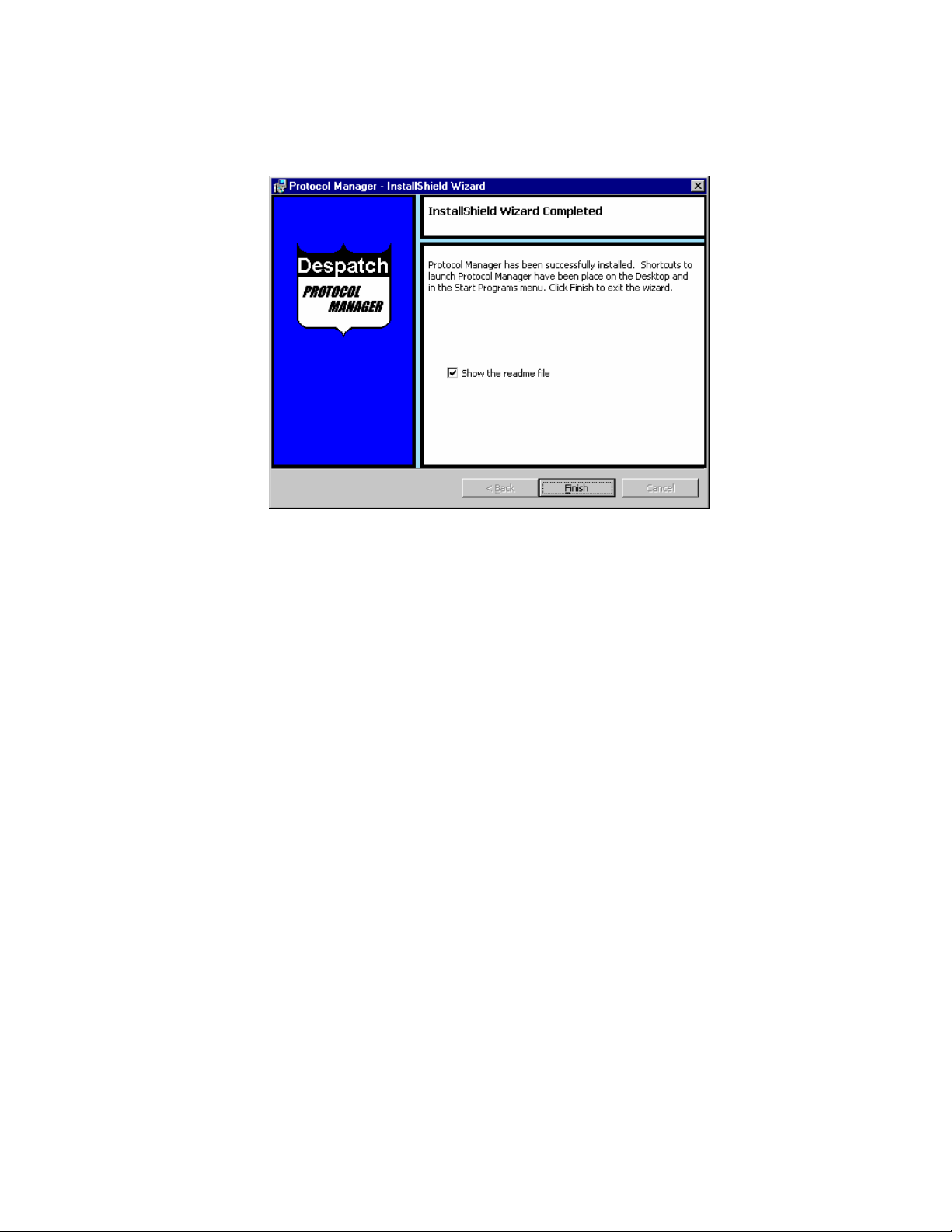

10. If all is in order, click the Install button to install the software. When the

installation is complete, the following screen will appear.

Figure 6 Completion Screen

11. If the “Show the readme file” box is checked, the ReadMe file displayed in

Figure 3 above will be opened for reading again, if necessary. Uncheck the

box to skip reading the file again. Click on Finish to complete the installation.

5

Page 9

Software Setup

Configuring the Controllers

1. Use the keys on the faceplate of each Protocol Plus controller to set these

parameters. Consult Despatch Manual E98 for information on this process.

2. On each of the controllers, the following parameters must be defined in order

for the new control software to communicate with the controllers. Normal

conditions use the settings listed in parentheses in the Communication

Page in the Setup Mode of the controller.

• Address (1 - 247) - A unique address must be assigned to each controller.

Make certain that controller addresses are known when setting up the

software.

• NOTE that each of the multiple controllers must have a different address.

• Communication mode (MUST be Modbus)

• Baud rate (19.2 K)

• Parity (none)

6

Page 10

Startup and Login

1. Start the application by clicking the Windows taskbar's Start button, then

clicking Programs from the menu that appears, then clicking the Protocol

Manager option from the list that appears.

a. NOTE: The very first time this is done, a prompt may appear that there is

no setup information yet, and that the password is despatch.

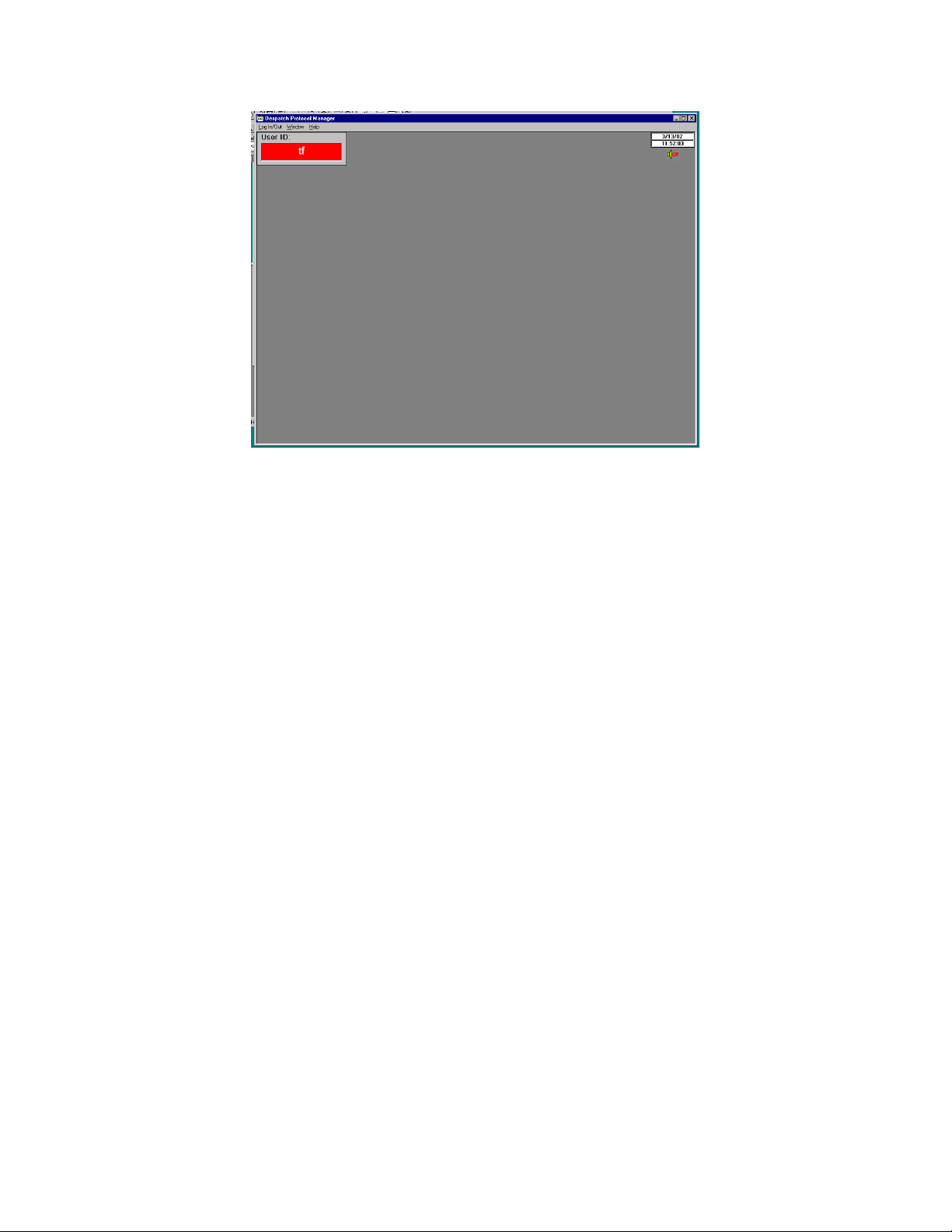

2. From the main screen that appears, select Login from the pulldown menu (or

double-click where it says (logged out) to log in. Note that an Operator ID

must be typed in, to log into the software. Type despatch into the Password

space. See Figure 7. NOTE that the Operator ID can be up to 16 characters

long.

Figure 7 ID and Password Entry

When login is successful, the User ID will appear in the upper left corner of the

screen. NOTE that different operator levels have different colors behind the User

ID: Level 2 is black, Level 3 is green, and Level 4 is red. See Figure 8.

7

Page 11

Figure 8 User ID After Login

8

Page 12

Setup

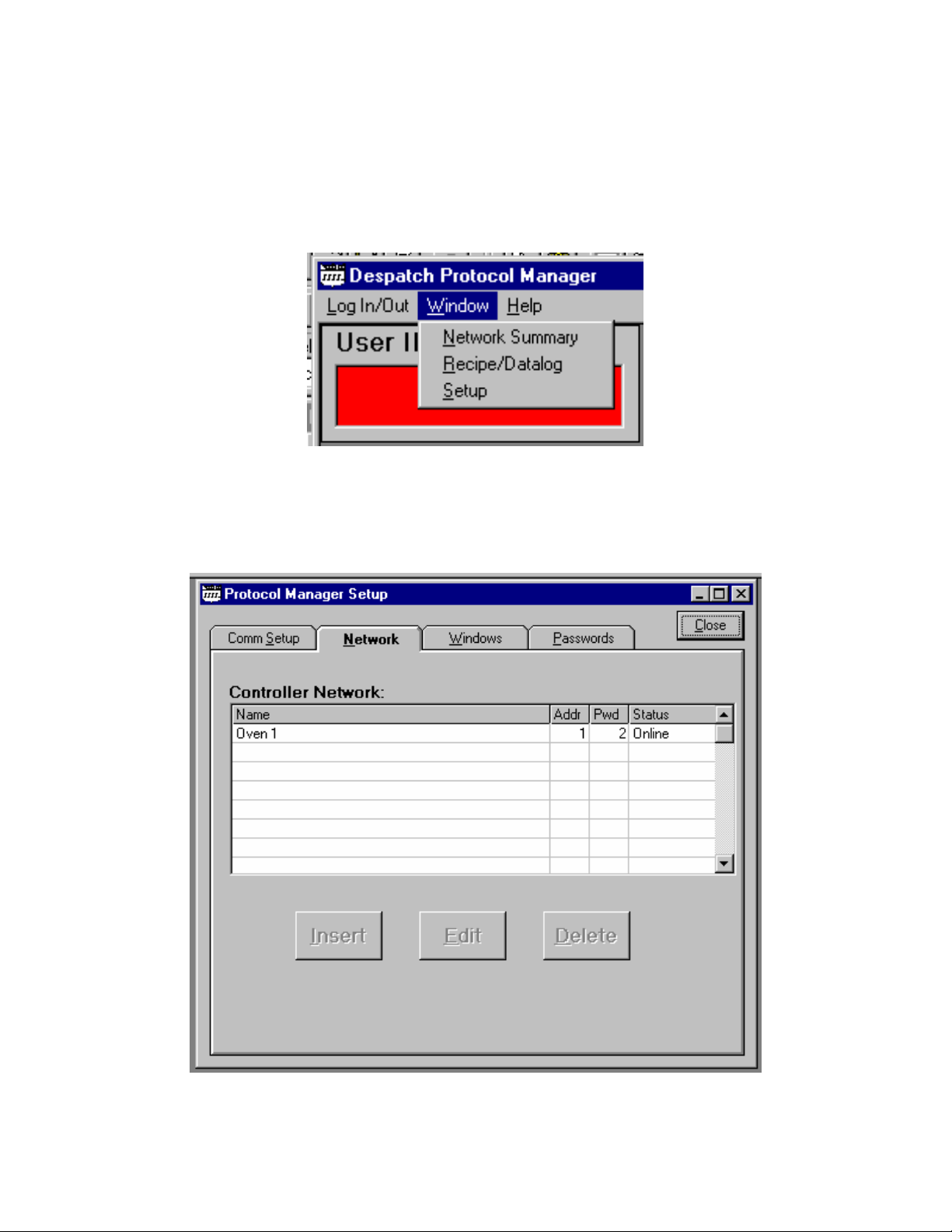

1. At this point the system must be set up. Move the cursor to the top of the

screen and click on the Window prompt to reach the Setup pulldown. See

Figure 9.

Figure 9 Setup Pulldown

2. Click on the Setup prompt, and the Software Setup window will pop up. See

Figure 10.

Figure 10 Software Setup Window

9

Page 13

Comm Setup

The first tab on the left is the Comm Setup tab. Use the cursor to make selections to

allow the computer and Protocol Plus controllers to communicate.

Figure 11 Protocol Manager Setup: Comm Setup Tab

1. Port Selection

• COM 1

• COM 2

• COM 3

• COM 4

Select the communication port that matches your host computer hardware.

2. Baud Rate

• 2400

• 4800

• 9600

• 19.2 K

• 38.4 K

10

Page 14

Select the baud rate that corresponds to the rate programmed into the Protocol Plus

controller(s). 38.4 K provides fastest communication. If the controller(s) will not go

on line, try a lower speed.

3. Parity Option

• None

• Odd

• Even

Select the parity that corresponds to that which is programmed into the Protocol

Plus controller(s).

4. Use Long Timeout Delay checkbox

The software uses a timer to check Protocol controller response time. The software

calculates acceptable response time - especially critical when using multiple

controllers. If an unexpected communication failure occurs, checking this box will

increase the communication timeout period. NOTE: For normal operation, leave this

box unchecked: don't check this box unless a communication failure occurs.

5. Press the Accept button to save the selected parameters. Press the Restore

button to return to the previously saved parameters.

NOTE that changes will not take effect until the Accept button is pressed.

6. Click on the OK button to save settings.

11

Page 15

Network Setup

1. The second tab from the left on the Software Setup window is the Network

tab. Select this tab to add controllers to the system. See Figure 12. Note that

if all the buttons are not active, click on the space below the Name to activate

the insert button.

Figure 12 Protocol Manager Setup: Network Tab

2. Use this screen to add as many controllers as are connected to the host PC.

Click on the first blank line to select it, then click the Insert button and press it

to add a new controller to the software. The Controller Setup window will

pop up. See Figure 13.

Figure 13 Controller Setup Window

12

Page 16

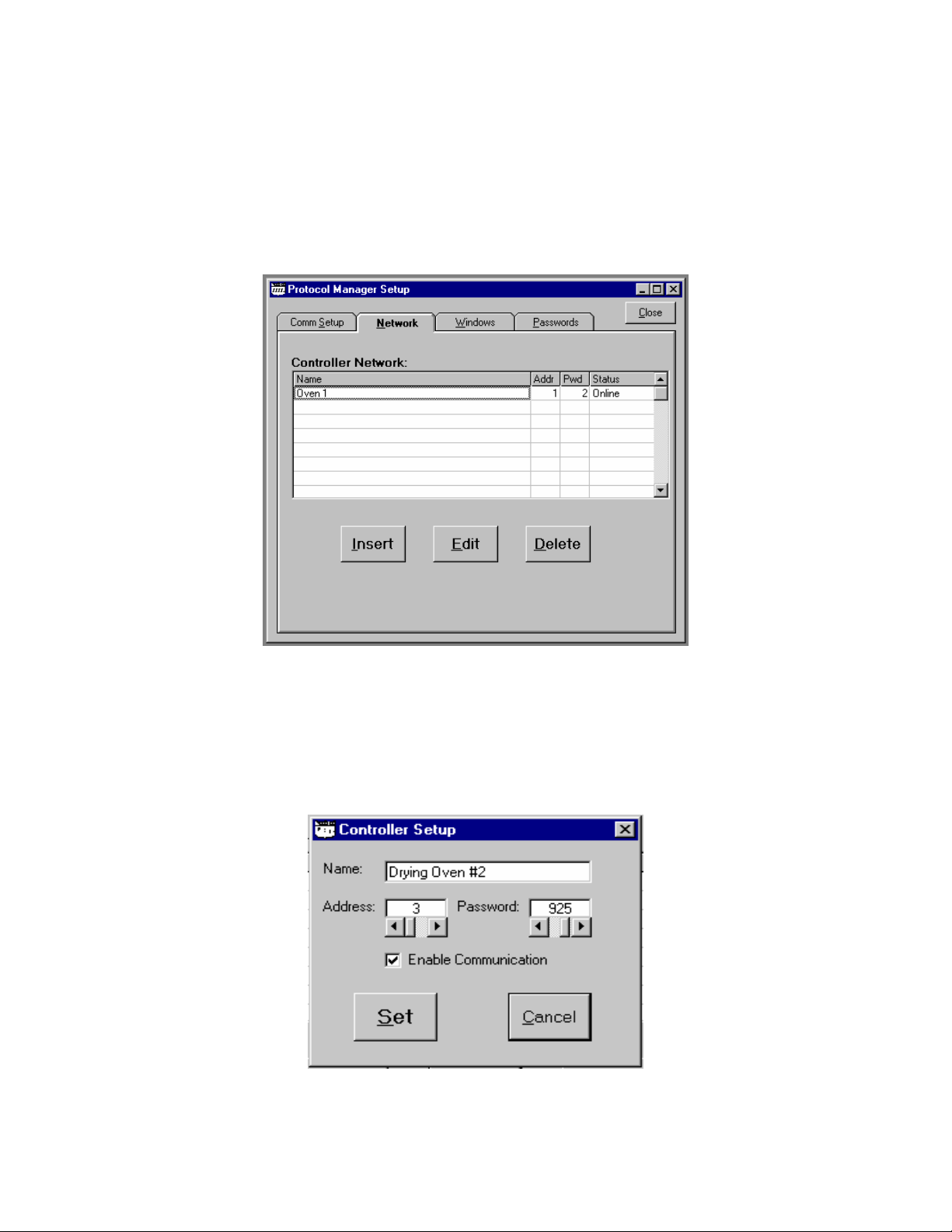

Name Field: Designate and type in the name of the oven or controller, up to 24

characters long, maximum.

Address Field: Type the address or move the slide bar of the Address field to

enter the address of the controller. (This field must correspond with the address

programmed into the controller on the Communication Page; see Manual E-98

for directions.) Values 1 through 247 are accepted.

Password Field: Type the password or move the slide bar of the Password

field to enter the password Level 2 of the controller. (This field must correspond

with the Level 2 password programmed into the controller on the Enable Page;

see Manual E-98 for directions.) Values from 1 to 1000 are accepted. Default is

2.

Enable Communication Checkbox: Use the cursor to check this box to add it

to the list of controllers working under the software. If the status for the controller

shows DISABLED in the Status column of the Network tab of the Software

Setup window (see Figure 12), this box must be rechecked.

A controller can be disabled by leaving this box unchecked. Communication will

not be attempted with disabled controllers, which may be desirable if an oven is

shut off (not used) for a long period of time.

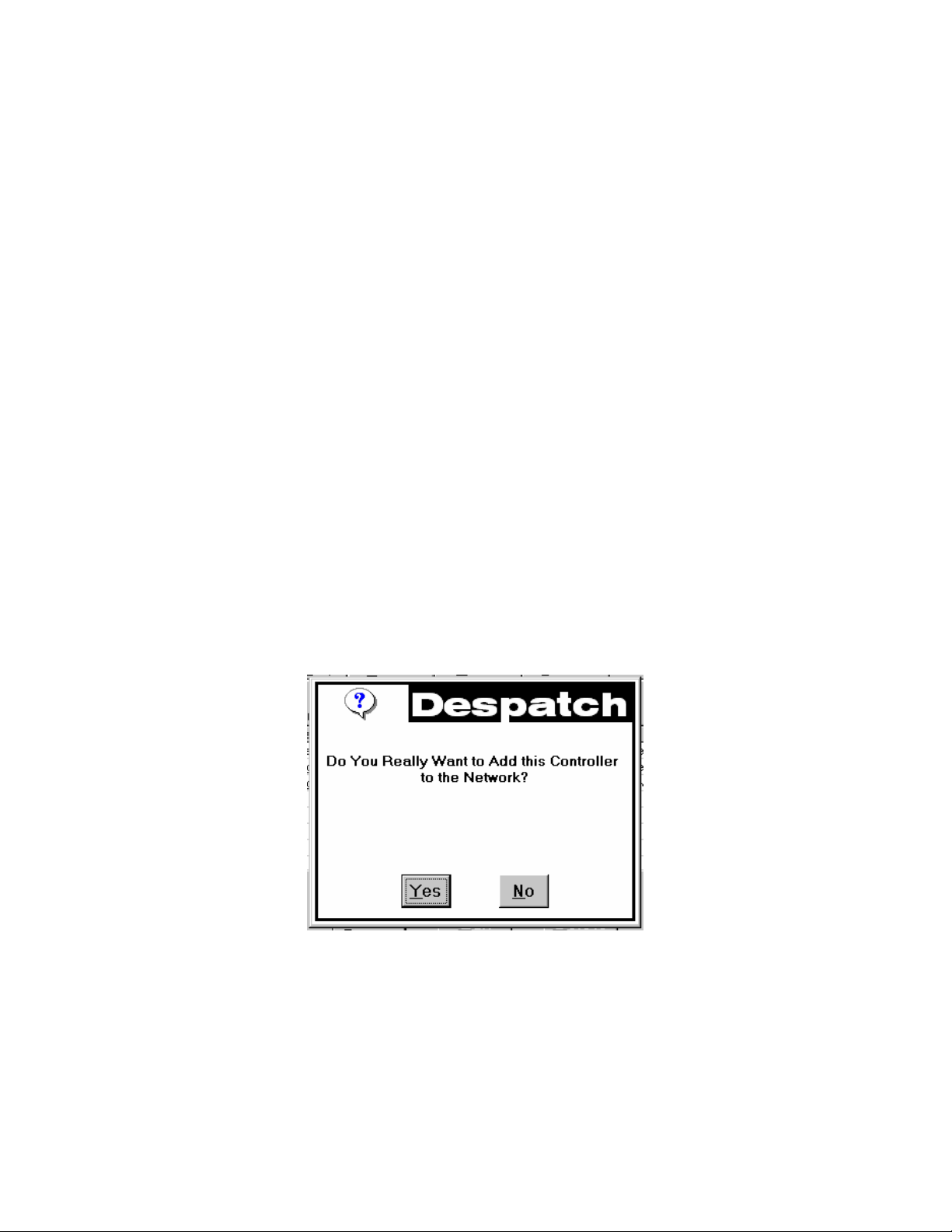

3. When the chosen parameters have been entered, press the Set button on

the popup. A question box will pop up (see Figure 14).

Figure 14 Controller Question Popup

4. Click Yes to add the controller to the network.

13

Page 17

Windows Setup

1. The third tab from the left on the Software Setup window is the Windows

tab. This allows the operator to select the parameters that may be viewed

from the Network Summary Window and the Controller Run Time window.

Press this tab to bring up its screen. See Figure 15.

Figure 15 Protocol Manager Setup: Windows Tab

Use the checkboxes on the left side of the screen to select which parameters

to display when viewing the Network Summary Window and Controller

Run Time Window (both described below). Press the Accept button to save

the selected parameters . Press the Restore button to return to the

previously saved parameters.

On the right side of the screen, select the alarm sound from one of five preset

sounds for high limit trip, and for soak deviation from guaranteed soak band.

(If no sound card is detected, the Alarm Sounds field is grayed out.)

2. Click Yes to save settings.

14

Page 18

Software Setup: Passwords Setup

The fourth tab from the left on the Software Setup window is the Passwords tab.

Press this tab to bring up its screen. See Figure 16.

Three levels of passwords may be set at this screen, which controls the software login

level. The highest level, Level 4, enables the user to change communication settings,

add/delete controllers from the network, change passwords, and perform all lower-level

operations.

The next highest login level, Level 3, enables the user to edit/write recipes, configure

data log settings, and perform all lower-level operations.

The next login level, Level 2, enables the user to change controller modes, select

profiles, change set points, start data logging, and perform Level 1 operations.

The lowest login level, Level 1, allows the user to view run-time status, and start, stop

or hold controller operation. No password is required.

Figure 16 Protocol Manager Setup: Passwords Screen

15

Page 19

Values from 0 minutes to 60 minutes may be set in the Auto Logoff Time window,

which will automatically log the operator off the system after this predetermined period

of time. Setting this value to zero disables this feature and the system will not

automatically log off. Press the Accept button to save the selected parameters. Press

the Restore button to return to the previously saved parameters.

The 'Can Exit if Not Logged In' option can be checked to allow Protocol Manager to

be stopped at any time. If this option is left unchecked, Protocol Manager can only be

stopped if a user has successfully logged in at any level.

Exit the Setup Mode by clicking the X box at the upper right-hand corner of the

Software Setup box.

16

Page 20

Network Summary Window

Figure 17 Network Summary Window

To view the Network Summary Window, click on the Windows prompt to reach Network

Summary. Click on the Network Summary prompt, and the Network Summary Window

will pop up. See Figure 17.

The Network Summary Window simultaneously displays parameters for all the

controllers connected in the system. Parameters that may be displayed in the Network

Summary Window are:

Χ Controller Name and Address

Χ Temperature Setpoint and Value

Χ Alarms and Events Status

Χ Cycle Complete and Buzzer Status

Χ Operating Mode

Χ Run/Stop/Hold Status

Χ Controller Online/Offline Status

Use the check boxes in the Windows tab (Software Setup page) to select how many

of these parameters will be shown. Figure 17 shows the Network Summary Window

with all of the parameters available.

Double-click on a Controller ID in the Name column to display the associated

Controller Run Time Window (see Figure 18).

17

Page 21

Controller Run Time Window

Figure 18 Controller Run Time Window

The Controller Run Time Window displays current status of an individual controller.

Parameters that may be displayed in the Controller Run Time Window are:

Χ Controller Name and Address

Χ Temperature Setpoint and Value

Χ Alarms and Events Status

Χ Cycle Complete and Buzzer Status

Χ Operating Mode

Χ Run/Stop/Hold Status

Χ Controller Online/Offline Status

Χ High Limit Setpoint and Value

Χ Time Remaining in Timer Mode

Χ Profile, Segment, and Time in Profile Mode

Χ Operator ID

Χ Lot Information

Recipes are started, run, and stopped from this window. This window may be used to

remotely control the controller's operating mode and state. If this window disappears,

click on the Network Summary window and double click on the controller name. If the

Network Summary window does not appear in the main menu, click on windows on

the task bar and then click on Network Summary on the pulldown menu.

18

Page 22

The Controller Run Time Window initially appears “collapsed” as shown below:

Figure 19 Collapsed Controller Run Time Window

Double-Clicking the “Cycle COMPLETE” indicator will alternately expand or collapse the

Controller Run Time Window.

The expanded window appears as shown below if Lot Datalogs have not been enabled

(see “Datalog functions”):

Figure 20 Expanded Controller Run Time Window

19

Page 23

The expanded window appears as shown below if Lot Datalogs have been enabled

(see “Datalog functions”):

Figure 21 Expanded Controller Run Time Window with Lot Datalogs Enabled

20

Page 24

Configuring a Recipe

To create a recipe, go to the bar at the top of the screen and pull down to Recipe/

Datalog from the Window designation. The Recipe Editor Window will appear. See

Figures 22 and 23.

Figure 22 Recipe/Datalog Pulldown

Figure 23 Recipe Editor Screen

21

Page 25

Double-click on the fields in the center of the Recipe/Datalog window to bring up a

window box to access and change the value shown. Move the slider to change the

value quickly. Click on the arrow at either end to change the value by 1. Click in the

white space to the left and right of the slider to change the value by 10. Click OK to lock

in the change. See Figure 24.

Figure 24 Value Change Window

Parameters on the Recipe screen include:

Recipe Name

Type the name of the new recipe being created.

Seg#

Ramp Time

EV1 through 4

Soak Temp.

Recipe segments 1 through 8 may be programmed, each with its

own set of events, ramp and soak times, and soak temperature.

The time required to ramp setpoint up to temperature may be

programmed here. Values between 0 and 99:59 are allowable. As in

the Protocol Plus controller, profile ramp and soak times are stored

without units. Units are independently set locally, in the actual

controller, as either hours and minutes (HH:MM) or minutes and

seconds (MM:SS).

From 1 to 4 events may be programmed into the ramp time portion

of each segment here. These typically involve actuating/disabling

relays to close/open valves or perform other relay-controlled

functions. NOTE: These will only actuate when the controller has the

relay cards installed and programmed for an event. Recipes may

contain four Ramp and four Soak event choices, although only those

relays actually supplied in a Protocol Plus controller and configured

for events will be affected by recipe settings, when used to run a

profile.

The temperature of a particular segment is entered here; it can

range from -18 to 540 degrees C (0 to 1000 degrees F). See Notes

on Soak Temp and Hi Limit SP, below.

Soak Time

The duration of soak is entered here; the value can range from 0 to

99:59.

22

Page 26

EV1 through 4

From 1 to 4 events may be programmed into the soak portion of

each segment here. These typically involve actuating/disabling

relays to close/open valves or perform other relay-controlled

functions. NOTE: These will only actuate when the controller has the

relay cards installed and programmed for an event.

Guaranteed

Soak Band

Hi Limit SP

Loop from

Segment ___

to Segment

___ ___ times

Link to Profile

Temp. Units

If the process temperature deviates from the setpoint by more than

this value, the timer is placed in a hold condition. The timer

continues when the process temperature falls within range.

The high limit setpoint may be entered here; if the temperature

exceeds this value, the hi-limit will alarm and shut off the heater. See

Notes on Soak Temp and Hi Limit SP, below.

These values enable the profile or controller to jump from a certain

step to another step of the recipe a preset number of times.

Values for the end of profile option are:

STOP Stop oven operation

HOLD Hold setpoint

1 – 8 Jump to selected profile number

STBY Enter standby mode. See note on Standby Mode below.

Selects degrees Fahrenheit or Centigrade, for the recipe display

only. Recipes stored on the host PC, like profiles in the Protocol

Plus, are always stored with temperatures in degrees Fahrenheit,

regardless of the selected viewing units. Note that changing the

display units converts displayed recipe temperatures accordingly.

OPEN/SAVE

(to Folder)

READ/WRITE

(to Controller)

Profile

Number

These buttons enable the operator to open a new recipe, or save the

current one to a predetermined folder.

These buttons enable the operator to upload a recipe from one of

the Protocol Plus controllers in the system, or to write the current

recipe to one of the controllers.

Selects which of the Controller's eight profiles is used when reading

or writing recipes.

Notes on Soak Temp. and Hi Limit SP Values

In the recipe editor screen, Soak Temp and Hi Limit SP values can be adjusted in the

range of -18 to 538 °C (0 - 1000 °F). Errors may occur attempting to download a recipe

to a Controller's profile if one of the recipe's ramp times, soak temperatures, or the high

limit setpoint value is incompatible with the range set internally for the target controller.

In this case, an error message similar to Figure 25 will be displayed, and no changes

will be made to the Controller's profile.

23

Page 27

Figure 25 MODBUS Comm Error Message

Note on Standby Mode

In the recipe editor screen, the Link to Profile value “STBY” option (Standby mode)

can only be used with Protocol Plus controller version 4 or higher. If a recipe with the

Standby mode selected is chosen for download to an earlier version controller, a popup

message will be displayed by Protocol Manager, and the downloaded profile will set the

Link to Profile value to the “HOLD” option for that controller.

Figure 26 Standby mode Message

Creating a New Recipe

1. Pull down from the Windows/Recipe/Datalog position on the menu bar to

Recipe.

2. Press the NEW button.

24

Page 28

3. Enter the values desired.

4. Press SAVE to save the recipe.

Opening an Existing Recipe

1. Press the OPEN button at the bottom of the Recipe Editor screen.

2. Select the recipe from the popup list.

25

Page 29

Reading/Writing a Recipe to/from a Controller

1. Select the controller from the box at the bottom right corner of the Recipe

Editor screen. See Figure 27. Only controllers that are currently enabled and

Online will be listed in the box.

Figure 277 Read/Write Area, Recipe Editor Screen

2. Select a profile (1 through 8) to be read/written from/to the controller.

3. Press the READ or WRITE button to either call up the recipe from the

selected controller, or write the current recipe to the selected controller.

NOTE: Reading the parameters from a controller will overwrite any information stored in

the displayed recipe.

26

Page 30

Recipe Selection Setup

1. Go to the second tab from the left at the top of the Recipe Editor screen.

2. Click on this tab and the Recipe Selection screen will pop up. See Figure 28.

Figure 288 Recipe Selection Screen

The Selectable Recipe Files list indicates which recipes can be selected by name

when starting a profile run remotely. Recipes can be added to this list by clicking the

"Add" button and selecting a recipe from the list box that pops up.

Profiles can be started remotely by profile number only if the "Start Profile by Number"

option is chosen as shown above. If the "Start Profile by Recipe Name" option is

chosen in this window, starting a profile will require selection of a recipe, by name, from

the "Selectable Recipe Files" list that will be displayed in the controller start window

(see "Starting the Controller").

27

Page 31

Datalog Functions

Datalog files are maintained to periodically record controller data to a disk file for future

analysis. Protocol Manager can maintain two different types of datalog files from

networked controllers.

Profile Datalogs – are initiated automatically when a controller is remotely started

running, and are closed automatically when the controller stops running. Profile

datalogs are useful for jobs that are based on a specific process run.

Log Datalogs – are initiated, and subsequently closed, manually, using the Controller

Run Time Window, regardless of the controller's running status. Log Datalogs are

useful for jobs that are not related strictly to an entire, single process run.

Both types of datalog files will contain header information, followed by periodic data

records. Header information and record data are set for both types of datalogs in the

Profile Datalog Window. Both types of files will be stored in the Log File Folder path

indicated in the Profile Datalog window.

The Profile Datalog window also allows setting file naming options and log entry interval

options for Profile Datalogs.

The Lot Datalog window is used to enable Lot Datalogs, and set the Log Entry interval

specifically for Lot Datalogs.

28

Page 32

The Profile Datalog and Lot Datalog screens are accessed from the tabs at the right

side of the initial Recipe Editor screen, off the Recipe/Datalog Window. See Figures

29 and 30.

Figure 299 Profile Datalog Window

Select the parameters to be written to the datalog by checking the boxes on the Profile

Datalog Window screen.

Log File Header Information

Check the following boxes to select the types of data to be written into the log file

header:

Χ Controller Name

Χ Start Date and Time

Χ Operator ID

Χ Lot Information

29

Page 33

Log File Record Data

Check the following boxes to select the types of data to be written into the log file itself:

Χ Elapsed Time

Χ Entry Date and Time

Χ Temperature Setpoint

Χ Temperature Value

Χ Alarms and Events Status

Χ Recipe Name

Log File Folder

This field displays the folder used to store datalog files.

Log At Intervals/Log at Profile Change

These buttons determine whether data will be logged at a certain time interval (see Log

Entry Interval, below), or if data will be logged at every change point programmed into

the recipe (start point, beginning of ramp, beginning of soak, etc.). Select one of these

logging options depending on the detail level required, and the amount of disk space

available for log records. Typically, a short run with few steps might use the time interval

option, and a long run with many steps might use the profile change option.

Log Entry Interval: This value controls how often data is logged into a local disk file

when selected for a running controller. For example, if two minutes is selected, data will

be logged from each running controller approximately every two minutes; it does not

mean that all controllers will be polled for data within a two minute period.

The minimum usable interval depends on the number of controllers in the network.

Typically, the minimum interval, in seconds, can be approximated by Tmin = 4 + N,

where N = number of Controllers on the network.

Datalog files take up storage space. Typically, a log file's header contains from 10 to up

to about 250 bytes, plus Lot Information (Lot Information contains from 0 to 576

bytes), depending on which header information is selected. Each logged data entry

contains up to 50 bytes, depending on which data is selected. One running controller,

logging data every 15 seconds, would produce a datalog growing at a rate of about 11

Kbytes per hour. 11 Controllers running at this rate would consume about 1 Mbyte of

storage every 8 hours.

The datalog is enabled by the Enable Datalog checkbox in the Run Time Window

(described later in this manual).

30

Page 34

Log File Naming Options

Log file names consist of a Controller ID and Time Stamp, created when a data log is

started.

Controller ID

Identifies the controller by address (three digits with leading zeroes) or name. If name is

selected, blank spaces and characters not legal for use in a Windows file name are

converted to underscore characters.

Time Stamp

Select the time format used for the log entries.

Notes on Log File Naming Options

The Controller ID and Time Stamp are combined, but separated by an underscore

character, to create a datalog file name prefix. The file name is automatically appended

with a ".log" extension.

For a controller named "East Fab #1" with an address of 2, a datalog file name would

either begin with "002" (if Address selected) or "East_Fab_#1" (if Name selected).

For a run started on February 4th, 2000, at 2:13:45 pm, the Time Stamp would be

either "000204" (if YYMMDD selected), "00020414" (if YYMMDDhh selected),

"0002041413" (if YYMMDDhhmm selected), or "000204141345" (if YYMMDDhhmmss

selected).

If "Name" and "YYMMDDhh" were selected, the complete file name prefix would be

"East_Fab_#1_00020414", and the new datalog filename would be

"East_Fab_#1_00020414.log". If a file with that name already existed, however, the

new file would be renamed "East_Fab_#1_00020414_1.log".

When a datalog is started, and a filename is created, duplicate filenames are checked

for; if a file with the created name already exists, the new filename's prefix has an

underscore and a numerical value appended to it to create a unique filename.

31

Page 35

Figure 30 Lot Datalog Window

The Lot Datalog screen enables datalog functions to be selected on a per-job basis

rather than for all jobs.

32

Page 36

STARTING THE CONTROLLER

The controller is started by using the Controller Run Time Window(s) which are

accessed from the Window pulldown off the main screen.

Start the profile by pressing the RUN/HOLD button at the top right portion of the

Controller Run Time window. The Start Running screen will appear. See Figure 31.

Figure 301 Controller Run Time Window

NOTE that the operator need not be logged in to start or run the controller from the Run

Time Window. However, the Start Running screen requires a login.

33

Page 37

Run Time Window

Three different modes of operation are available as tabs from the Start Running

screen:

Χ Manual mode

Χ Timer mode

Χ Profile Mode

Manual Mode

Figure 32 illustrates the Manual operating mode. The process run is held at a single

setpoint temperature until the STOP button is pressed at the Controller Run Time

Window. Process setpoint, hi-limit setpoint and event status may be entered in the

appropriate fields.

Figure 312 Start Running Screen: Manual Mode

34

Page 38

Timer Mode

Figure 33 illustrates Timer Mode. This mode allows the operator to start and stop the

process for a preset length of time.

Figure 33 Start Running Screen: Timer Mode

The timer mode is similar to the manual mode except that the time at temperature is

added.

If the soak band temperature deviates from this setting, the timer is placed in a hold

condition.

35

Page 39

Profile Mode

Figure 34 illustrates Profile Startup Mode with the "Start Profile by Number" option

selected (see "Recipe Selection Setup"). In this mode, one of eight separate profiles

(recipes) may be run. Profiles are created or added to the system at the Recipe Editor

Screen (Figure 23). NOTE that if a profile number is selected here, but was not created

and stored, the profile will not start.

Figure 324 Start Running Screen: Profile Mode

36

Page 40

Figure 35 illustrates Profile Mode startup with the “Start Profile by Recipe Name” option

selected (see “Recipe Selection Setup").

Figure 335 Profile Mode Startup with "Start Profile by Recipe Name"

NOTE: The list of recipes shown is created from the collection of recipes that have

been stored locally. Selecting to start a profile using a recipe from this list will first cause

the recipe to be downloaded to the controller as Profile 8, then Profile 8 will be started.

37

Page 41

COMMUNICATION CARD INSTALLATION

AND JUMPER SETTINGS

Wiring Diagrams

Figure 346 RS232 Wiring

Figure 357 RS422A Wiring (4 wire)

Figure 368 RS485 Wiring (2 wire)

38

Page 42

WARNING

Electronic components are extremely sensitive to static electricity. Before opening

the controller case, read and follow the precautions below to prevent damage from

static electricity.

1. Turn off power to the controller.

2. Touch a bare metal surface on the exterior of the controller.

3. Disconnect the power connection from the controller or unplug from the

power source.

Also follow these static electricity precautions:

• Avoid static-causing surfaces while working with electronic components.

• Remove parts from their anti-static bags only when ready for use. Do not lay parts

on the outside of the anti-static bag because only the inside provides protection.

• Hold circuit boards by their edges or any metal mounting hardware. Avoid touching

components or connectors on the circuit boards.

Communication Card Installation

1. Turn off power to the controller.

2. Remove the back cover of the controller by removing the two screws at the

top of the unit.

3. Looking into the back of the controller with the connector terminal strips at the

bottom, install the communication card onto the two 5 pin headers on the rear

circuit board. Be sure the jumper blocks on the communication card are

positioned toward the bottom of the controller. See Figure 39, Controller Rear

View with Communication Card (left). Be sure the card is seated firmly onto

the headers.

4. Set the jumpers on the communication card for the desired serial

communication interface based on Figure 40, Communication Card Jumper

Settings.

5. Reinstall the back cover.

6. Wire the communication connections on the rear of the unit for the desired

serial communication interface based on Figure 36, RS232 Wiring, Figure 37

RS422A Wiring (4 wire), or Figure 38, RS485 Wiring (2 wire).

7. Reapply all power connections to the controller.

39

Page 43

Figure 39 Controller Rear View with Communication Card (left)

40

Page 44

Communication Card Jumper Settings

1. Turn off power to the controller.

2. Remove the back cover of the controller (if it is not already removed) by

removing the two screws at the top of the unit.

3. Set the jumpers on the communication card for the desired serial

communication interface based on Figure 40, Communication Card Jumper

Settings, below.

4. Reinstall the back cover.

5. Reapply power to the controller.

Figure 40 Communication Card Jumper Settings

41

Page 45

Connecting Protocol Plus Controller(s)

to a Communications Host PC

Single Oven

If the oven purchased was not supplied with communication option, order Despatch RS232 communication kit P/N 161968. This kit contains all the parts required for one oven

to host PC via RS-232 including: Protocol Plus add-on communications board, oven

internal cabling, 25 foot null modem cable and Modbus protocol instruction manual.

For single oven communication, the Protocol Plus controller should be configured for

RS-232 connection. Connect the host PC’s RS-232 COM port to the oven’s

communication port using a null-modem cable. Despatch P/N 161971 provides a 25

foot null-modem cable. Refer to Protocol Plus Manual for communication card jumper

and controller configuration settings.

Multiple Ovens

If the ovens purchased were not supplied with communication option, order Despatch

P/Ns 141820, add on Protocol Plus communication board, and 161950 (the internal

cabling) to make the ovens communication-ready including DB9 external cable

connections. Order Despatch P/N 161955 for the components required to network two

ovens to a host PC. This kit includes RS-232 to RS-422/RS-485 bi-directional adapter,

cabling, and Protocol-specific termination plugs.

Generically speaking, the following description details the steps necessary to network

multiple Protocol Plus controllers:

The host PC must have its assigned RS-232 COM port connected to a RS-422/RS-485

bi-directional adapter, for example a “B&B Electronics” adapter Despatch P/N 161938-

40. These P/Ns provide the adapter, power supply and PC-to-adapter serial cable.

The following wiring description refers specifically to the B&B device, but may be

applied to acceptable substitute devices.

The Protocol Plus controller’s optional communication card should be configured for

RS-422A 4-wire connection. Set the dipswitches and jumpers on the adapter to match

the communication from the host PC RS-232 COM port to the adapter. Wiring from the

B&B adapter’s RS-422A RS-485 terminals is daisy-chained to each of the Protocol Plus

controllers. Connect the power supply pigtail leads from the adapter wall mount

transformer into the +12V and GND on the adapter. Plug the transformer into a

standard 120V / 60 Hz supply outlet.

It is important to note that the communication ready ovens are supplied with two DB9

42

Page 46

network ports; “Communication In” and “Communication Out”. For shorter networking

runs, standard serial communication rated cables are available in a variety of lengths.

For example; Despatch P/N 161970 is a 25 foot serial cable. DB9 termination plugs are

also available from Despatch including P/N 161969; the required termination for a RS422 4-wire network. See remaining information if longer network cable lengths are

required.

Typically, RS-422A/RS-485A cables consist of three individually shielded twisted pairs;

one pair transmits data from the Host PC to the ovens, one pair transmits data from the

ovens to the host PC, and one conductor from the third pair is the signal common. The

remaining conductor of the third pair is unused. Cable such as Belden type 9843 should

be used.

The network requires a cable breakout junction box near each oven. 120 ohm

terminating resistors must be installed at each end of the RS-422/RS-485 network.

Refer to the following page for a simplified network wiring diagram. In this case, "To

Host PC" actually indicates a cable connection to the B&B adapter. The "PC Rcv" and

"PC Xmit" terminals refer to the B&B adapter's RD and TD terminals respectively.

Install the 120 ohm resistor between the RD+ and RD- terminals. Connect the GND

wire to the 422/485 GND terminal. The remaining termination resistor is applied at the

RD+ and RD- terminals of the “last in line” networked oven.

RS-422/RS-485 allows communication over wires up to 1000 meters in length. It is

important to note that the associated runs from the oven’s Protocol Plus controller to

the breakout junction box be limited to 5 meters maximum. The junction boxes provide

a drop from the network cable to each oven. The cables marked “to Oven Controller”

are terminated with 9-pin male subminiature “D” plug for mating with the oven

controller’s Communication In” serial data receptacle.

Wire drop the cable according to the following table:

Oven signal Junction box terminal 9-pin plug pin number

Rcv+

Rcv-

Xmit+

Xmit-

GND

5 2

4 7

1 3

2 4

3 5

The daisy chain drop cables may use shielded pairs. Cable shields should be

connected as follows:

• At each junction box - to the box interior chassis.

• At each drop cable 9-in plug-to the lug shell if conductive.

If a non-conductive shell is used, no connection is required.

43

Page 47

Figure

37

. Junction Box Wiring

44

Page 48

The junction boxes are used to provide a drop from the network cable to each Oven.

The cables marked "To Oven Controller" are each terminated with a 9-pin Male

subminiature "D" plug, for mating with the Oven Controller's serial data receptacle. Wire

the drop cable according to the following table:

Oven

Signal

Junction Box

Terminal

9-Pin Plug

Pin Number

Rcv +

Rcv -

Xmit +

Xmit -

Gnd

The daisy-chain and drop cables may use shielded pairs. Cable shields should be

connected as follows:

• At the B&B adapter B to the earth ground terminal

• At each junction box B to the box interior chassis

• At each drop cable 9-pin plug B to the plug shell, if conductive; do not

connect to anything if a non-conductive shell is used

5 2

4 7

1 3

2 4

3 5

45

Page 49

TROUBLESHOOTING THE

COMMUNICATIONS OPTION

Controller Parameters

(see Protocol Plus manual to enter Communications Page)

• Address (Default = 1) This setting must be different on each control/oven if using

RS422/RS485 interface.

• Mode (Default = OFF) This must be set to Modbus.

• Baud Rate (Default = 19.2K) If you are having problems going to a lower baud

rate may help, but do not change to start with.

• Parity (Default = None) This should remain the default.

Protocol Manager Parameters

1. Log on the highest level security (Level 4). The default password initially is

“despatch”.

2. Click on the Windows pulldown menu at the top of the screen.

3. Click on Setup menu.

4. Click on the Comm Setup tab and verify the settings match the controller

parameters set above. Click on the OK button when finished.

46

Page 50

5. Click on the Network tab and highlight the oven you are trying to setup. Click on

the Edit button.

6. Make sure the address matches and the password is set to the level 2 password

of the controller (Default = 2). The enable communications box should be

checked. Click on OK when finished.

47

Page 51

The software should now show a green ON-LINE. If not, check the hardware and

cabling.

Controller Hardware and Cabling

Check the communications card

• The card needs to be installed correctly (jumpers are on the bottom of the card

and should be facing the green terminals)

• The jumpers need to be setup for RS232 or RS422, depending on the interface

being used. See Modbus User’s Programming manual (E102) for proper

settings.

Check cabling between the controller and outside of oven

• The R+ should be connected to terminal #1 on the back of the controller. Check

with an ohm meter that pin #2 on the 9 pin connector on the outside of the oven

is connected to this terminal.

• The R- should be connected to terminal #2 on the back of the controller. Check

with an ohm meter that pin #7 on the 9 pin connector connected to this terminal.

• The T+ should be connected to terminal #3 on the back of the controller. Check

48

Page 52

with an ohm meter that pin #3 on the 9 pin connector connected to this terminal.

• The T- should be connected to terminal #4 on the back of the controller. Check

with an ohm meter that pin #4 on the 9 pin connector connected to this terminal.

• The SG should be connected to terminal #5 on the back of the controller. Check

with an ohm meter that pin #5 on the 9 pin connector connected to this terminal.

Check cabling between the computer and outside of oven

RS232 INTERFACE

The cable running from the Oven’s 9 Pin connector and the computer should be a null

modem cable (for a PC with a 9 pin connector, pin 2 at each end connects to pin 3 at

the other end, and the cable requires a female 9 pin plug at the PC end and a male 9

pin plug at the Oven end).

Despatch kit p/n 161968 includes all parts required to make one oven communicationready. The kit also contains a 25-foot cable (p/n 161971) for PC-to-oven

communication.

RS422/485 INTERFACE

The typical wiring scheme is shown on the next page using wiring kit p/n 161955.

Additional ovens (maximum of 32 ovens) can be added using wiring kit p/n 161956.

49

Page 53

50

Loading...

Loading...