Page 1

Modbus Programming Manual PREFACE

ULTRAFLEX DRYING AND FIRING

FURNACE

MODELS 1000, 3615, 3630, 3640

C-204

VERSION 1

10/2008

Modbus User’s Programming

Manual for Protocol 3™

E-106

PN 320813

VERSION 2

7/2012

Version 2 1

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 2

PREFACE Modbus Programming Manual

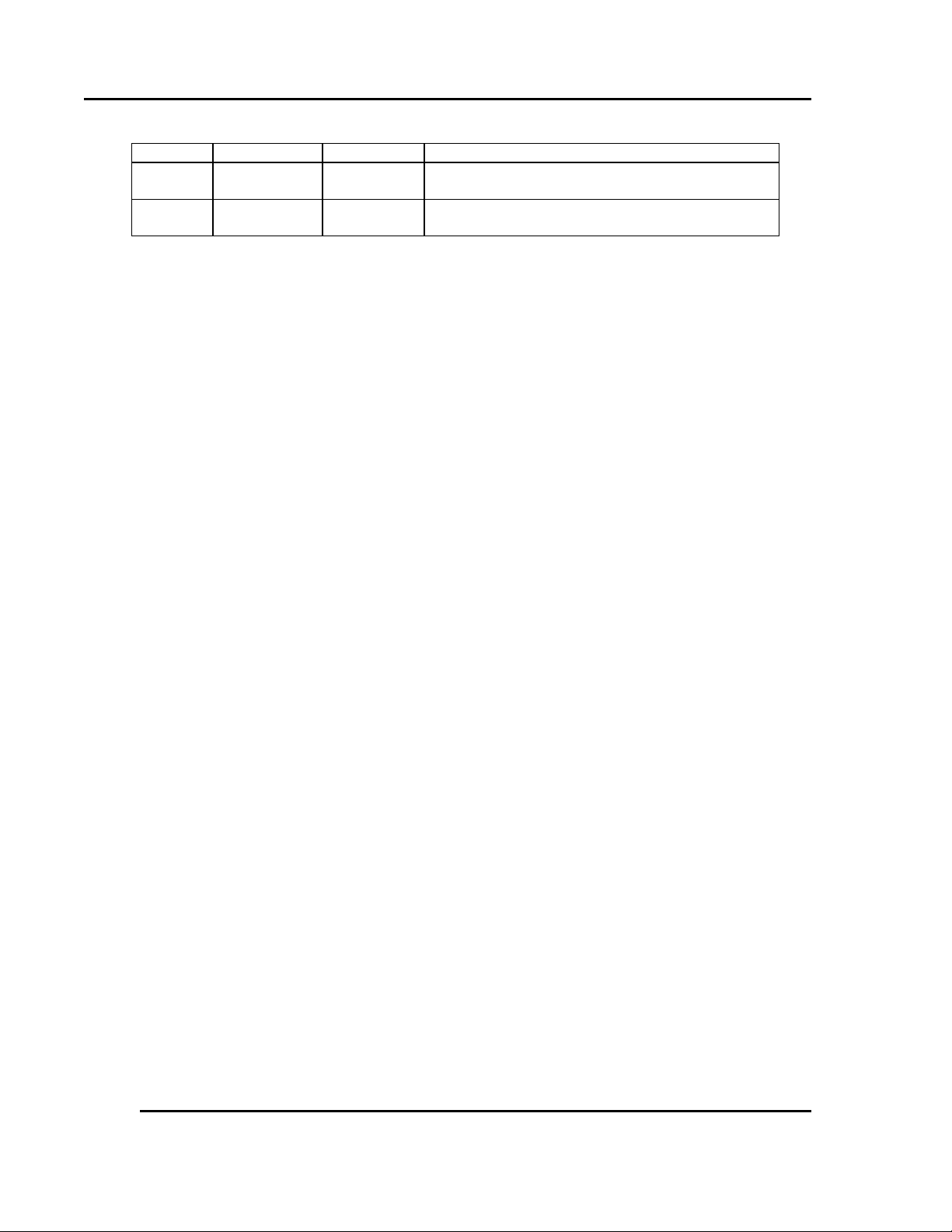

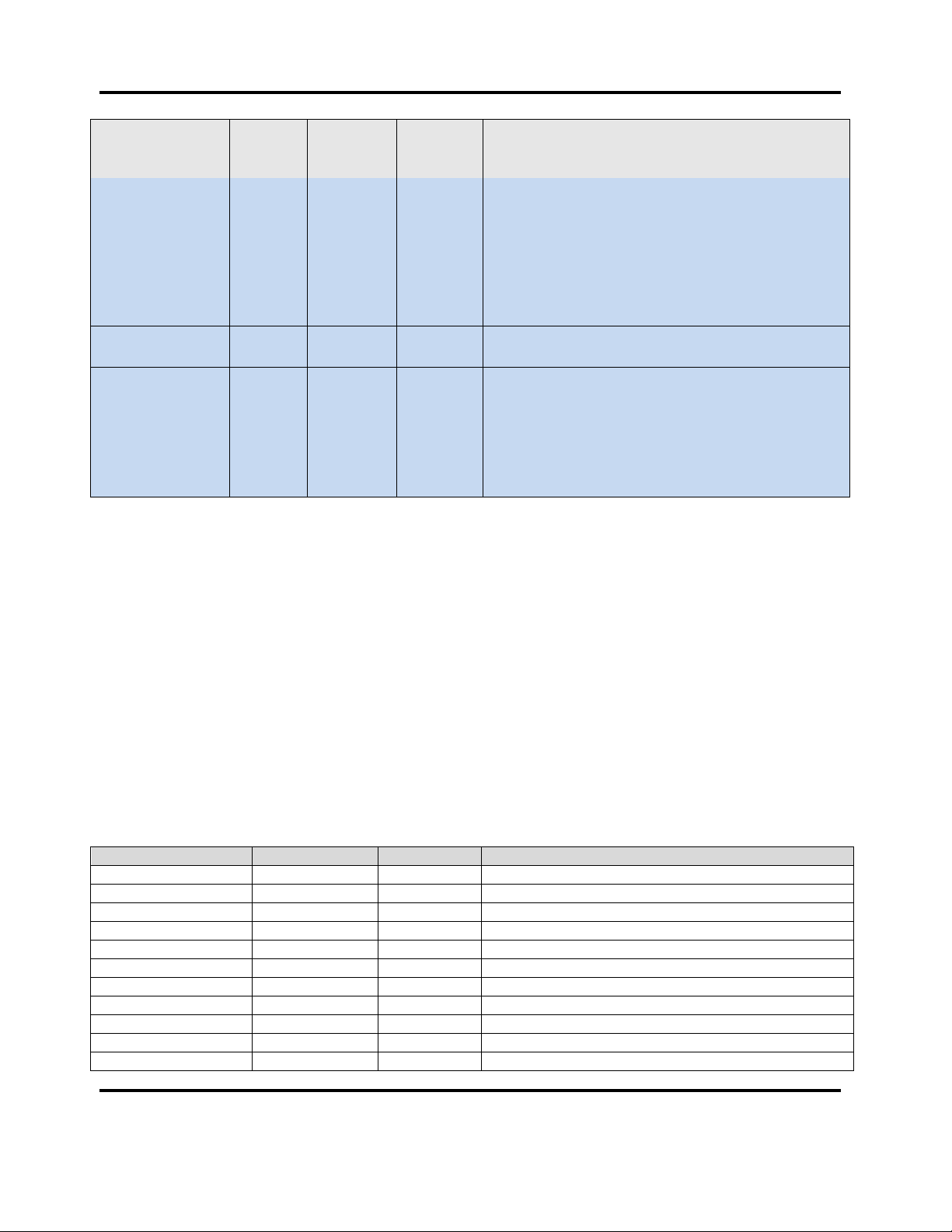

Revision

Date

Author

Description

1

6/2012

Livingston

Original Release - Revised for Protocol 3 and

formatting

2

7/2012

Livingston

Updated Register tables for new Protocol 3

Firmware release 2.0

2 Version 2

Revision History

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 3

Modbus Programming Manual PREFACE

Version 2 3

Table of Contents

1. About This Manual ............................................................................................................. 5

1.1. Important User Information ..................................................................................... 5

1.2. Manufacturer & Service .......................................................................................... 5

1.3. Organization of this Manual .................................................................................... 6

1.3.1. Reference Documents .......................................................................................... 6

1.4. Serial Communications ........................................................................................... 6

1.4.1. Supported Protocols ............................................................................................. 6

1.4.2. RS485 Configuration ........................................................................................... 6

1.4.3. RS485 Device Addressing ................................................................................... 7

1.4.4. Ethernet Configuration ........................................................................................ 7

1.4.5. Link Layer ........................................................................................................... 8

1.4.6. Supported Modbus Functions .............................................................................. 9

1.4.7. Function Descriptions .......................................................................................... 9

1.4.8. Data Formats ..................................................................................................... 12

2. Modbus Address List ........................................................................................................ 13

2.1. Input Parameters .................................................................................................... 13

2.1.1. Process Input Parameters ................................................................................... 13

2.1.2. High Limit Input Parameters ............................................................................. 14

2.1.3. Digital Inputs ..................................................................................................... 16

2.2. Output Parameters ................................................................................................. 16

2.2.1. Relay Output 1 Parameters ................................................................................ 16

2.2.2. Relay Output 2 Parameters ................................................................................ 17

2.2.3. Relay Output 3 Parameters ................................................................................ 18

2.2.4. Relay Output 4 Parameters ................................................................................ 18

2.2.5. Relay Output 5 Parameters ................................................................................ 19

2.2.6. Linear Output Parameters .................................................................................. 20

2.3. Setpoint Parameters ............................................................................................... 21

2.4. Control Parameters ................................................................................................ 22

2.5. Alarm Parameters .................................................................................................. 24

2.5.1. Alarm 1 .............................................................................................................. 24

2.5.2. Alarm 2 .............................................................................................................. 24

2.5.3. Alarm 3 .............................................................................................................. 25

2.5.4. Alarm 4 .............................................................................................................. 25

2.5.5. Alarm 5 .............................................................................................................. 26

2.5.6. High Limit Alarm Parameters ........................................................................... 26

2.6. Logger parameters (Data Logger) ......................................................................... 28

2.6.1. Data Recorder .................................................................................................... 28

2.6.2. Real Time Clock ................................................................................................ 28

2.7. Display Parameters ................................................................................................ 29

2.7.1. Keys ................................................................................................................... 29

2.7.2. LEDs .................................................................................................................. 29

2.7.3. HMI ................................................................................................................... 29

2.7.4. System Data ....................................................................................................... 30

2.8. Mode Controls ....................................................................................................... 32

2.8.1. General Mode Control ....................................................................................... 32

2.8.2. Manual Mode Parameters .................................................................................. 32

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2012 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 4

PREFACE Modbus Programming Manual

4 Version 2

2.8.3. Timer Mode Parameters .................................................................................... 33

2.8.4. Profile Mode Parameters ................................................................................... 34

2.9. Uploading and Downloading of Profiles ............................................................... 35

2.9.1. Instruction Sequence to create a profile at the next available position .............. 36

2.9.2. Instruction Sequence to create a profile at a specified profile position ............. 36

2.9.3. Instruction Sequence to edit an existing Profile Header .................................... 37

2.9.4. Instruction Sequence to read a profile ............................................................... 37

2.9.5. Profile Command Code Descriptions ................................................................ 37

2.9.5.1. Creating a profile header (Command Code CP) ............................................ 37

2.9.5.2. Editing/Creating a profile header at a location (Command Code EP or WP) 39

2.9.5.3. Creating a Segment (Command Code WS) ................................................... 40

2.9.5.4. Editing or Inserting a Segment (Command Codes IS and ES) ...................... 41

2.9.5.5. Segment Info A, B Information ..................................................................... 42

2.9.5.6. Deleting Profiles (Command Code DP and DA) ........................................... 43

2.9.5.7. Deleting a Segment (Command Code DS) .................................................... 44

2.9.5.8. Getting the Number of Segments Remaining (Command Code SR) ............ 44

2.9.5.9. Edit Response Message ................................................................................. 45

2.9.5.10. Reading a Profile Header (Command Code RP) ........................................... 46

2.9.5.11. Read a Segment (Command Code RS) .......................................................... 47

2.9.5.12. Read a profile Name (Command Code PN) .................................................. 49

2.9.5.13. Read Profile Memory Status (Command Code PS) ...................................... 51

Figures

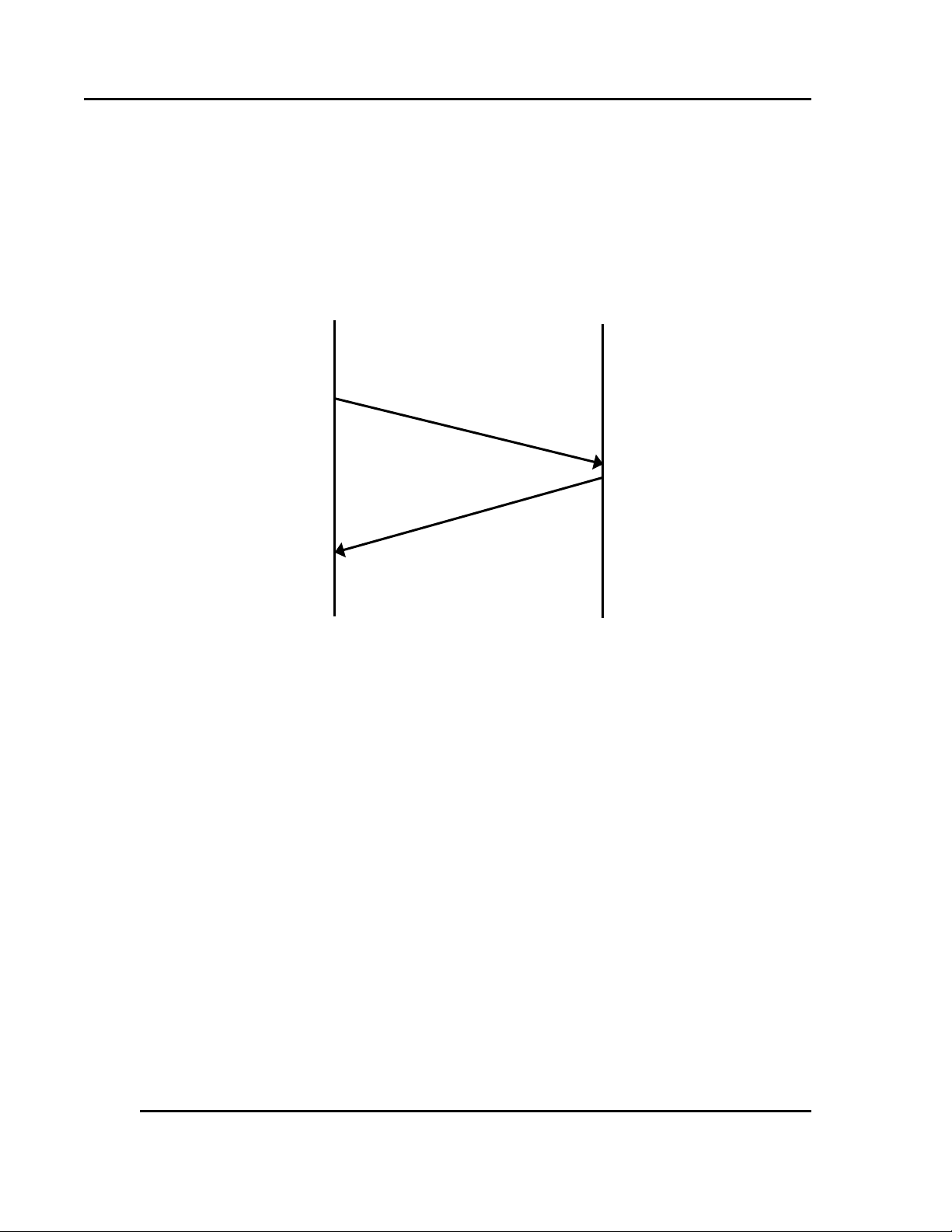

Figure 1. Modbus Link Layer. ......................................................................................................... 8

Copyright © 2012 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 5

Modbus Programming Manual ABOUT THIS MANUAL

Values displayed on screens are examples only. Though

those values may be typical, contact Despatch Industries for

the final value.

Version 2 5

1. About This Manual

1.1. Important User Information

Copyright © 2012 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied, or

transmitted in any form or by any means including graphic, electronic, or mechanical methods or

photocopying, recording, or information storage and retrieval systems without the written

permission of the publisher, unless it is for the purchaser's personal use.

Printed and bound in the United States of America.

The information in this manual is subject to change without notice and does not represent a

commitment on the part of Despatch Industries. Despatch Industries does not assume any

responsibility for any errors that may appear in this manual.

In no event will Despatch Industries be liable for technical or editorial omissions made herein,

nor for direct, indirect, special, incidental, or consequential damages resulting from the use or

defect of this manual.

The information in this document is not intended to cover all possible conditions and situations

that might occur. The end user must exercise caution and common sense when installing or

maintaining Despatch Industries products. If any questions or problems arise, call Despatch

Industries at 1-888-DESPATCH or 1-952-469-5424.

1.2. Manufacturer & Service

Despatch has specialized in thermal processing for over 100 years. Technical expertise gained

over those years helps provide innovative solutions to critical applications in vertical markets and

cutting edge technology worldwide. Despatch products are backed by a drive for long-term

customer satisfaction and a strong sense of responsibility. The worldwide network of factorytrained Service Professionals is available to support your Despatch equipment. From full service

preventive maintenance to routine repair and certified calibration and uniformity, the Despatch

service network is positioned to respond to your business needs. Our service programs are

customized to meet your specific needs using our Advantage Service Assurance Program

(ASAP). For more information on ASAP, visit www.despatch.com.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 6

ABOUT THIS MANUAL Modbus Programming Manual

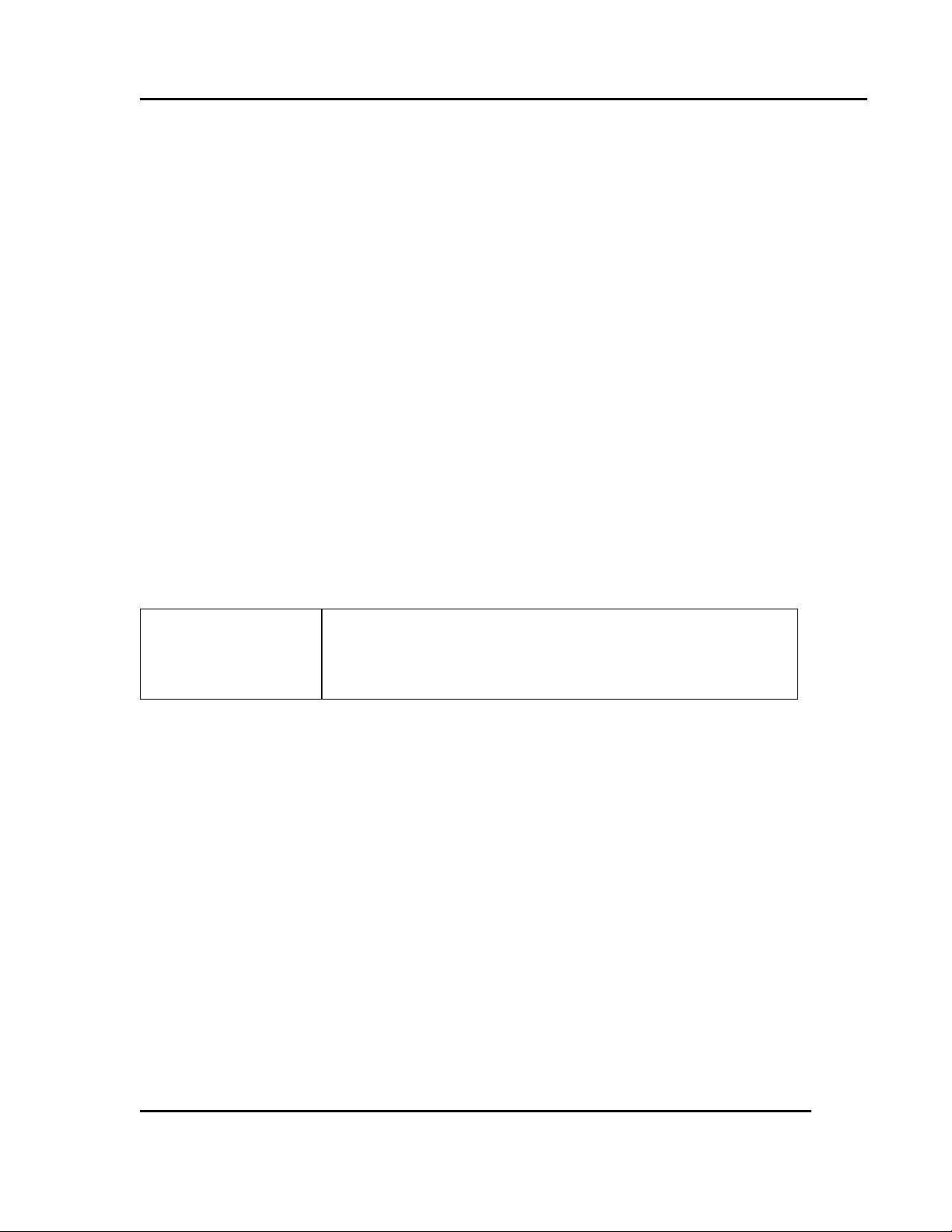

Global Headquarters

Contact

Service & Technical

Support

Despatch Industries

8860 207th Street

Lakeville, MN 55044

USA

International/Main: 1-952-469-5424

US toll free: 1-888-337-7282

Fax: 1-952-469-4513

info@despatch.com

www.despatch.com

Service: 1-952-469-8230

US toll free: 1-800-473-7373

Service @despatch.com

This programming manual assumes an intermediate

understanding of the Modbus Protocol. Only limited

information is presented here regarding the Modbus Protocol

specifications.

6 Version 2

1.3. Organization of this Manual

This document provides all application-specific information necessary for developing a Modbus

Master application program for interfacing with the Protocol 3™ slave controller.

1.3.1. Reference Documents

The following Modbus Protocol documents should also be helpful and relevant:

For a complete description of the Modbus protocol refer to the description provided at

http://www.modicon.com/ or http://www.modbus.org/.

1.4. Serial Communications

1.4.1. Supported Protocols

The unit supports two communication interfaces Modbus RTU and Modbus TCP. Modbus RTU

is supported through the RS485 interface and Modbus TCP is supported through the optional

Ethernet Module.

For a complete description of the Modbus protocol refer to the description provided at

http://www.modbus.org/.

1.4.2. RS485 Configuration

The RS485 address, bit rate and character format are configured via the front panel from the

Comms Configuration menu.

Physical layer configuration settings possible are:

Data rate: 4800, 9600, 19200, 38400, 57600 or 115200 bps

Parity: None (default), Even, Odd

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 7

Modbus Programming Manual ABOUT THIS MANUAL

Version 2 7

Character format: Always 8 bits per character.

Device Address: See below.

1.4.3. RS485 Device Addressing

The instrument must be assigned a unique device address in the range 1 to 255. This address is

used to recognize Modbus Queries intended for this instrument. With the exception of globally

addressed broadcast messages, the instrument ignores Modbus Queries that do not match the

address that has been assigned to it.

The instrument will accept broadcast messages (global queries) using device address 0 no matter

what device address is assigned. No response messages are returned for globally addressed

Queries.

1.4.4. Ethernet Configuration

For Modbus TCP communications (Modbus over Ethernet), the IP address can either be assigned

by a Dynamic Host Configuration Protocol (DHCP), BootP or AutoIP server on the network, or

manually assigned using the IP address allocation software tool.

The supported data rates 10/100BASE-T (10 or 100 Mbps) are automatically detected.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2012 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 8

ABOUT THIS MANUAL Modbus Programming Manual

MODBUS

SLAVE

QUERY

RESPONSE

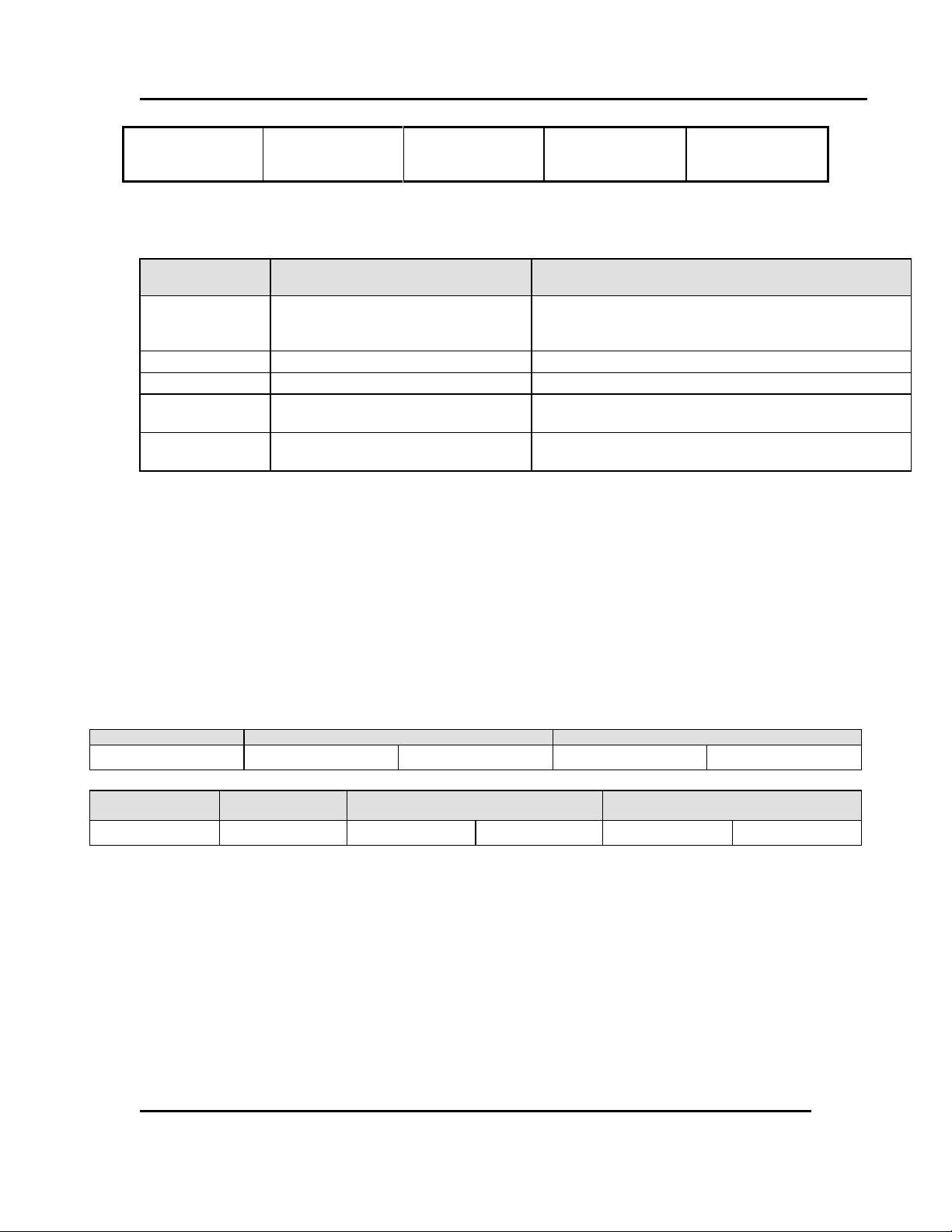

Figure 1. Modbus Link Layer.

8 Version 2

1.4.5. Link Layer

A Query (or command) is transmitted from the Modbus Master to the Modbus Slave. The slave

instrument assembles the reply to the master (see Figure 1).

MASTER

INSTRUMENT

A message for either a QUERY or RESPONSE is made up of an inter-message gap followed by a

sequence of data characters. The inter-message gap is at least 3.5 data character times - the

transmitter must not start transmission until 3 character times have elapsed since reception of the

last character in a message, and must release the transmission line within 3 character times of the

last character in a message.

Note:

Three character times is approximately 0.25ms at 115200 bps, 0.51ms at 57600 bps, 0.75ms at

38400 bps, 1.5ms at 19200 bps, 3ms at 9600 bps and 6ms at 4800bps.

Data is encoded for each character as binary data, transmitted LSB first.

For a QUERY the address field contains the address of the slave destination. The slave address is

given together with the Function and Data fields by the Application layer. The CRC is generated

from the given address, function and data characters.

For a RESPONSE the address field contains the address of the responding slave. The Function

and Data fields are generated by the slave application. The CRC is generated from the address,

function and data characters.

The standard MODBUS RTU CRC-16 calculation employing the polynomial 216+215+22+1 is

used.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 9

Modbus Programming Manual ABOUT THIS MANUAL

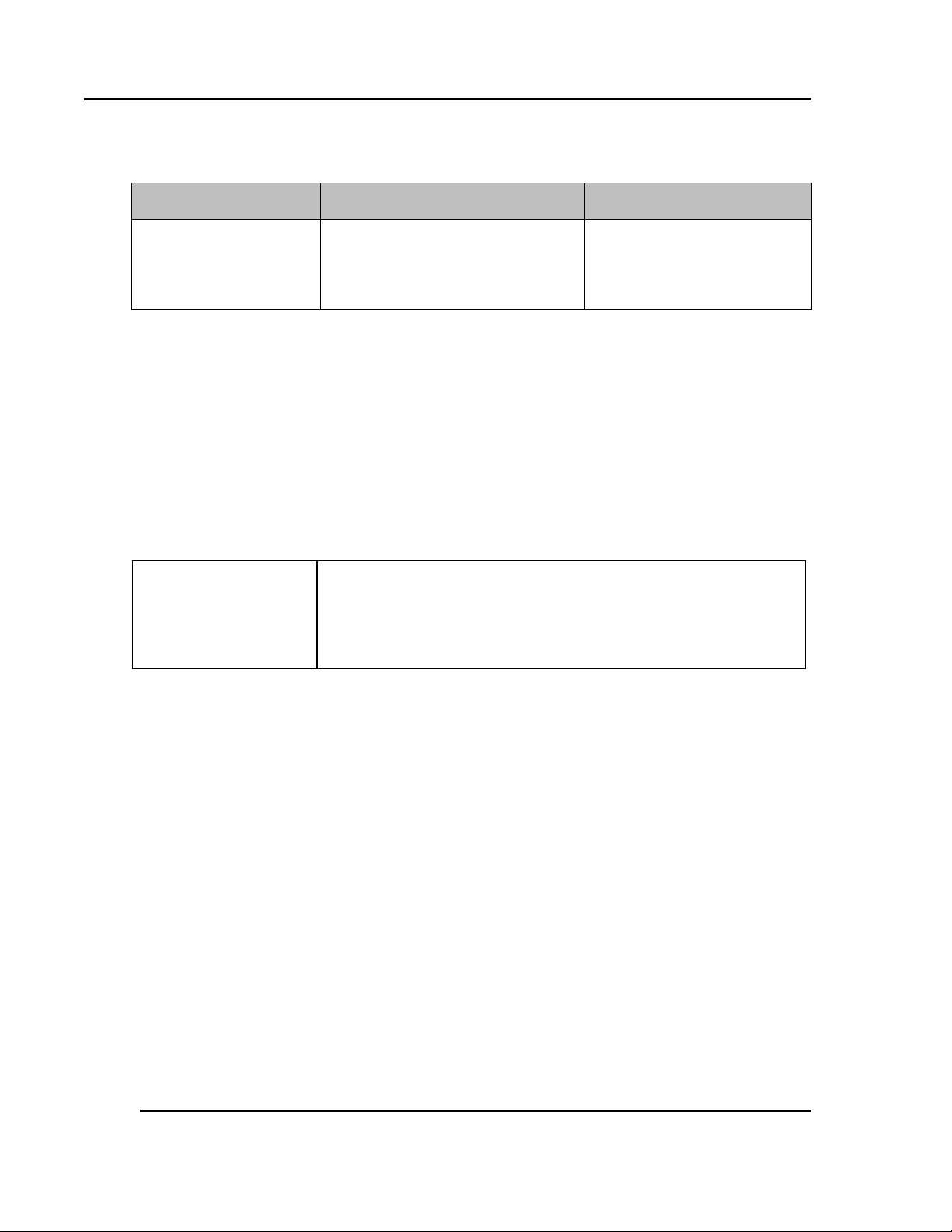

Inter-message

gap

Address

1 character

Function

1 character

Data

n characters

CRC Check

2 characters

Function Code

(decimal)

Modbus Meaning

Description

03 / 04

Read Holding/Input registers

Read current binary value of specified number of

parameters at given address. Up to 64 parameters

can be accessed with one Query.

06

Write Single Register

Writes two bytes to a specified word address.

08

Diagnostics

Used for loopback test only.

16 (0x10 hex)

Write Multiple Registers

Writes up to 253 bytes of data to the specified

address range.

23 (0x17 hex)

Read/Write Multiple Registers

Reads and Writes 253 bytes of data to the specified

address ranges.

QUERY

Function

Address of 1st Word

Number of Words

03 / 04

HI

LO

HI

LO

RESPONSE

Function

Number of Bytes

First Word

Last Word

03 / 04 HI

LO

HI

LO

Version 2 9

1.4.6. Supported Modbus Functions

Modbus defines several function types. The following types are supported by this instrument:

1.4.7. Function Descriptions

The following is interpreted from the Modbus Protocol Description obtainable from

http://www.modbus.org/. Refer to that document if clarification is required.

In the function descriptions below, the preceding device address value is assumed, as is the

correctly formed two-byte CRC value at the end of the QUERY and RESPONSE frames.

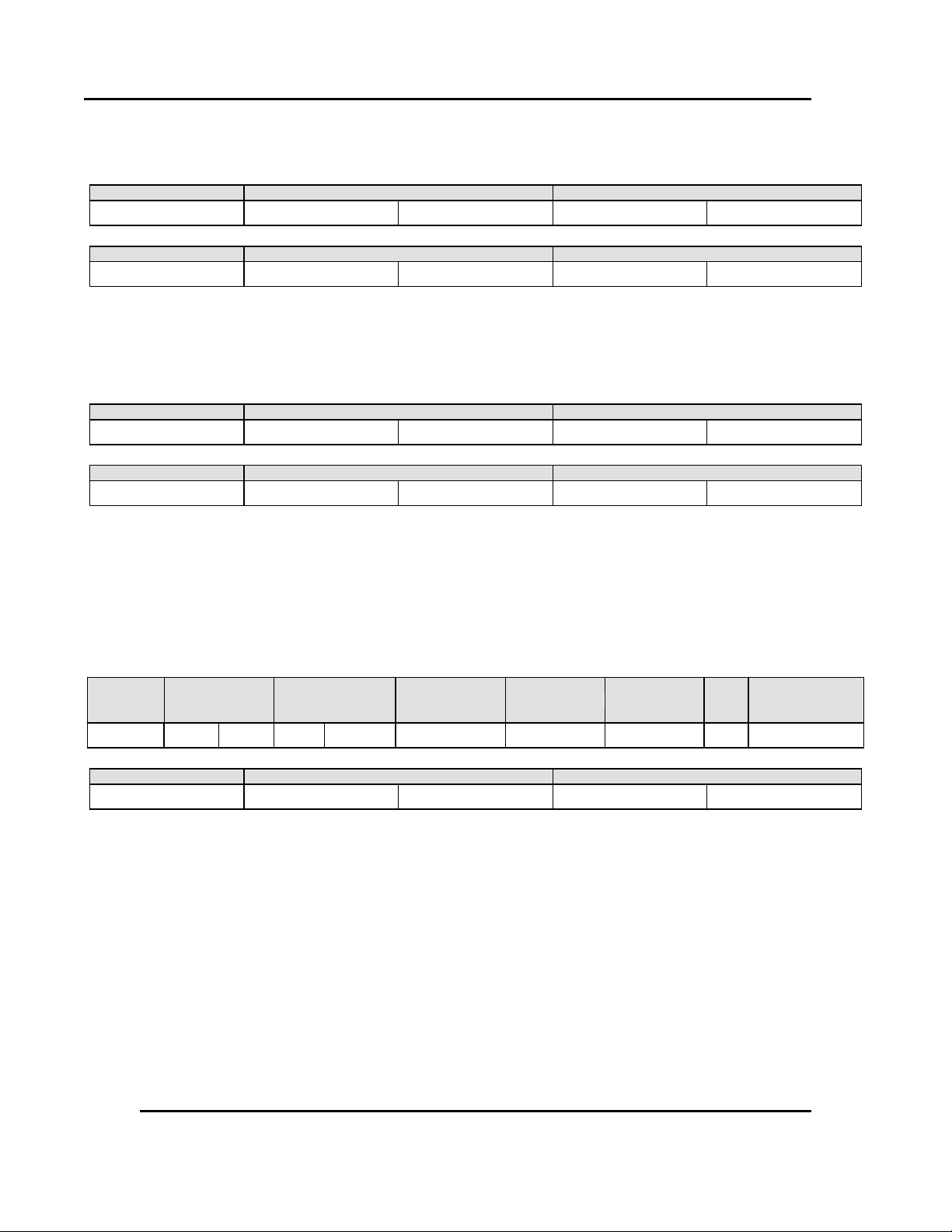

Function 03 / 04 - Read Holding/Input Registers

Reads current binary value of data at the specified word addresses.

In the response the “Number of Bytes” indicates the number of data bytes read from the

instrument. E.g. if 5 words are read, the count will be 10 (A hex). The maximum number of

words that can be read is 64. If a parameter does not exist at one of the addresses read, then a

value of 0000h is returned for that word.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 10

ABOUT THIS MANUAL Modbus Programming Manual

QUERY

Function

Address of Word

Value to write

06

HI

LO

HI

LO

RESPONSE

Function

Address of Word

Value written

06

HI

LO

HI

LO

QUERY

Function

Diagnostic Code

Value

08

HI =00

LO=00

HI

LO

RESPONSE

Function

Sub-function

Value

08

HI=00

LO=00

HI

LO

QUERY

Function

1st Write

Address

Number of Words

to Write

Number of

Query Bytes

1st Query Byte

2nd Query

Byte

etc

Last Query Byte

10

HI

LO

HI

LO

→

RESPONSE

Function

1st Word Address

Number of Words

10

HI

LO

HI

LO

10 Version 2

Function 06 - Write Single Register

Writes two bytes to a specified word address.

Note:

The Response normally returns the same data as the Query.

Function 08 - Loopback Diagnostic Test

Note:

The Response normally returns the same data as the loopback Query. Other Diagnostic

Codes are not supported.

Function 16 - Write Multiple Registers (0x10 Hex)

Writes consecutive word (two-byte) values starting at the specified address.

Note:

The number of data bytes that can be written in one message is 253 bytes.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 11

Modbus Programming Manual ABOUT THIS MANUAL

QUERY

Function

1st Read

Address

Number of

Words to

Read

1st Write

Address

Number of

Words to Write

Values to Write

1st Word

2nd Word

etc

Last Word

17

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO → HI

LO

RESPONSE

Function

Number of Bytes

Read Data

1st Word

2nd Word

etc

Last Word

17

HI

LO

HI

LO → HI

LO

Exception Code

Error Condition

Interpretation

00

Unused

None.

01

Illegal function

Function number out of range.

02

Illegal Data Address

Write functions: Parameter number out of range or not

supported. (for write functions only).

Read Functions: Start parameter does not exist or end

parameter greater than 65536.

03

Illegal Data Value

Attempt to write invalid data / required action not executed.

RESPONSE

Function

Exception Code

Original Function code with its Most

Significant Bit (MSB) set.

as detailed above

Version 2 11

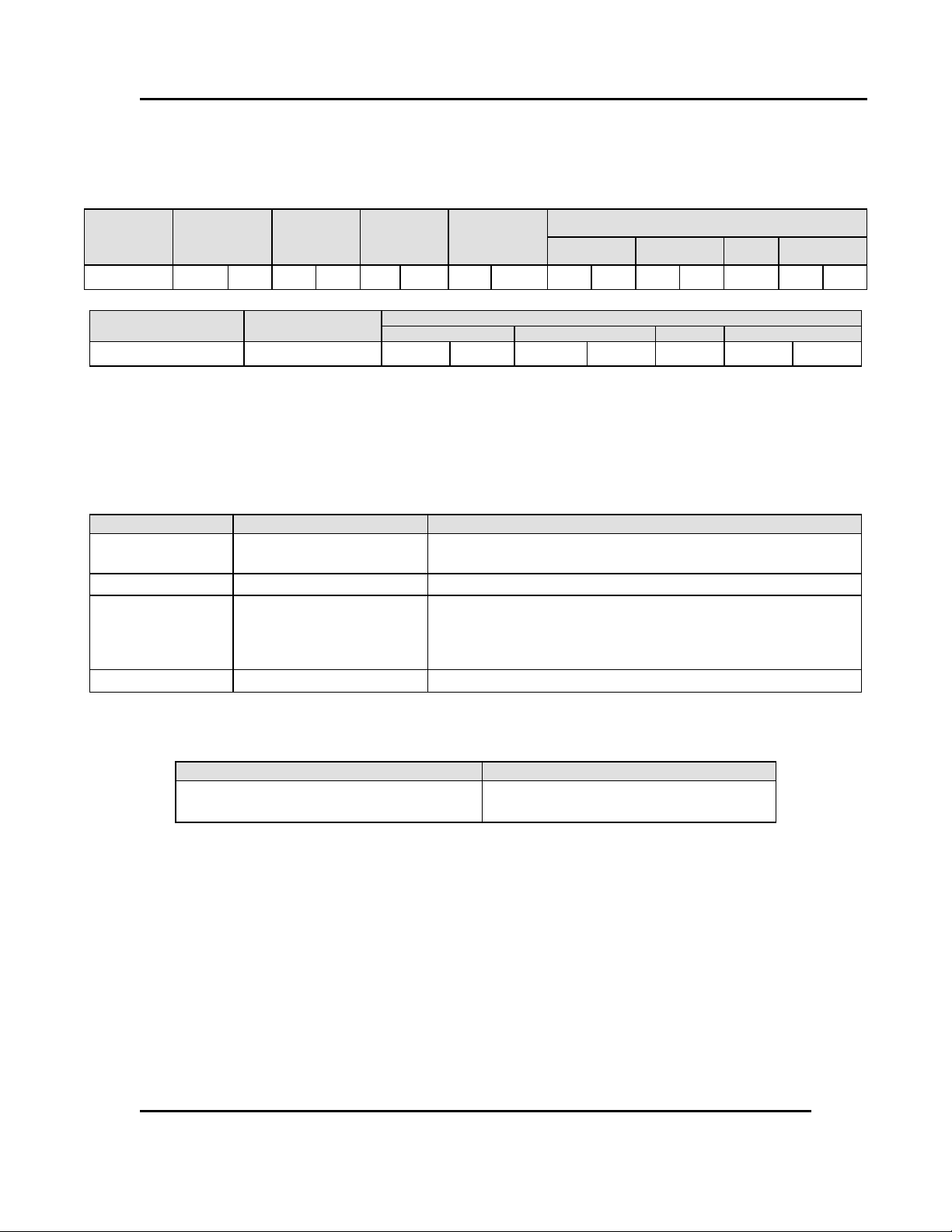

Function 23 Hex - Read / Write Multiple Registers (0x17 hex)

Reads and writes the requested number of consecutive words (two-bytes) starting at the specified

addresses.

Note:

The number of data bytes that can be read and written in one message is 253 bytes.

Exception Responses

When a QUERY is sent that the instrument cannot interpret, an Exception RESPONSE is

returned. Possible exception responses are:

The format of an exception response is:

Note:

In the case of multiple exception codes for a single QUERY the Exception code returned is

the one corresponding to the first parameter in error.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 12

ABOUT THIS MANUAL Modbus Programming Manual

Calculating Parameter Register Addresses

Integer Only

Integer+1

Floating Point

Register Address

Calculation

(hex)

Address

Address + 0x4000

Address x 2 + 0x8000

(dec)

Address

Address + 16384

Address x 2 + 32768

Address Example:

(For Process Variable)

(hex)

0x0407

0x4407

0x880E

(dec)

1031

17415

34830

Data Value Returned:

If actual Value = 23.9 decimal

(hex)

0x00, 0x17

0x00, 0xEF

0x41, 0xBF, 0x33, 0x33

(dec)

23

239

23.9 as floating decimal

Address Example:

(For Selected Setpoint)

(hex)

0x101F

0x501F

0xA03E

(dec)

4127

20511

41022

Data Value Returned:

If Value = 1 (Alternative SP)

(hex)

0x00, 0x01

0x00, 0x0A

0x3F, 0x80, 0x00, 0x00

(dec) 1 10

1.0

as floating decimal

12 Version 2

The Modbus parameter register addresses are detailed in the following sections.

The Access column indicates if a parameter is read only (RO) or if it can also be written to

(R/W).

Note:

Some parameters that do not apply for a particular configuration will accept reads and

writes. Read only parameters will return an exception if an attempt is made to write values

to them.

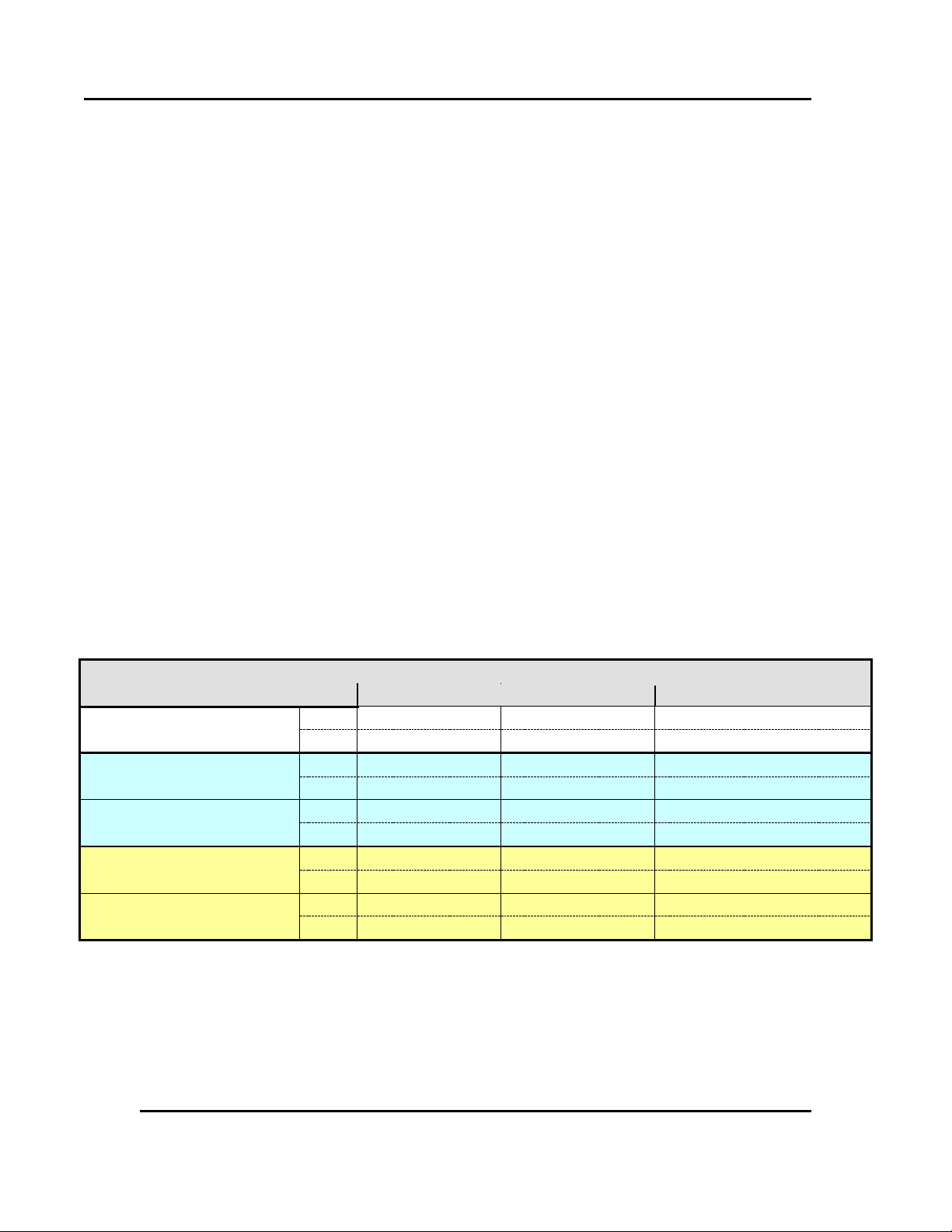

1.4.8. Data Formats

Data can be read or written in three formats: Integer Only, Integer with 1 Decimal Place and

Floating Point Number.

The Modbus Address column shows the register address for each parameter in integer format.

Other formats can be calculated from the Integer Only address.

When working in Hexadecimal, the format calculations are:

Address for Integer with 1 Decimal Place = Integer address plus 0x4000

Address for Floating Point = Integer address multiplied by 2, plus 0x8000

When working in Decimal, the format calculations are:

Address for Integer with 1 Decimal Place = Integer address plus 16384

Address for Floating Point = Integer address multiplied by 2, plus 32768

Example Register Address Calculations

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 13

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

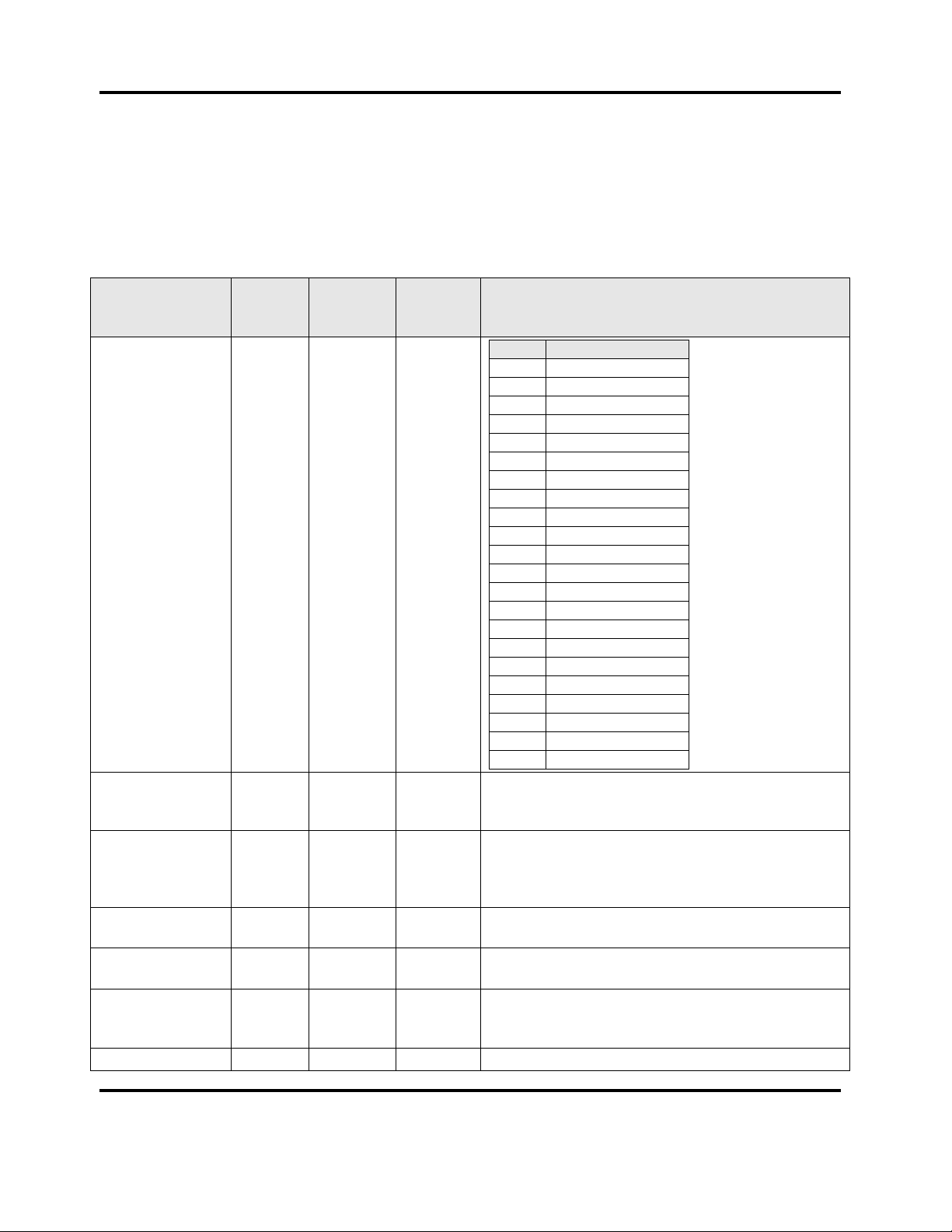

Input Range

1024

0x0400

R/W

Value

Range

0

B TC

2

C TC

4

D TC

6

E TC

8

J TC

10

K TC

12

L TC

14

N TC

16

R TC

18

S TC

20

T TC

22

P24

24

Pt100

26

NI120

28

0_20mA

29

4_20mA

30

0_50mV

31

10_50mV

32

0_5V

33

1_5V

34

0_10V

35

2_10V

Engineering units

1025

0x0401

R/W

0 = None

1 = Degrees C

2 = Degrees F

Decimal Place

1026

0x0402

R/W

0 = 1234

1 = 123.4

2 = 12.34

3 = 1.234

Process Input

Range Minimum

1027

0x0403

R/W

Process Input

Range Maximum

1028

0x0404

R/W

Process Input

Process variable

offset

1029

0x0405

R/W

Span of the input range

Process Input

1030

0x0406

R/W

Any value between 0.0 and 512.0

13 Version 2

2. Modbus Address List

2.1. Input Parameters

2.1.1. Process Input Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 14

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Filter time

constant

Process Input

Process Variable

1031

0x0407

R

Process Input

Sensor Break

Flag

1032

0x0408

R

0 = Inactive

1 = Active

Process Input

Under Range

Flag

1033

0x0409

R

0 = Inactive

1 = Active

Process Input

Over Range Flag

1034

0x040A

R

0 = Inactive

1 = Active

Process Input

CJC Enable

1035

0x040B

R/W

0 = Enable

1 = Disabled

Process Input

User Calibration

Type

1085

0x043D

R/W

0 = No User Calibration

1 = Single Point Calibration

2 = Two Point Calibration

Process Input

Low Temperature

Calibration Point

1086

0x043E

R/W

Process Input

Low Calibration

Offset

1087

0x043F

R/W

Process Input

High

Temperature

Calibration Point

1088

0x0440

R/W

Process Input

High Calibration

Offset

1089

0x0441

R/W

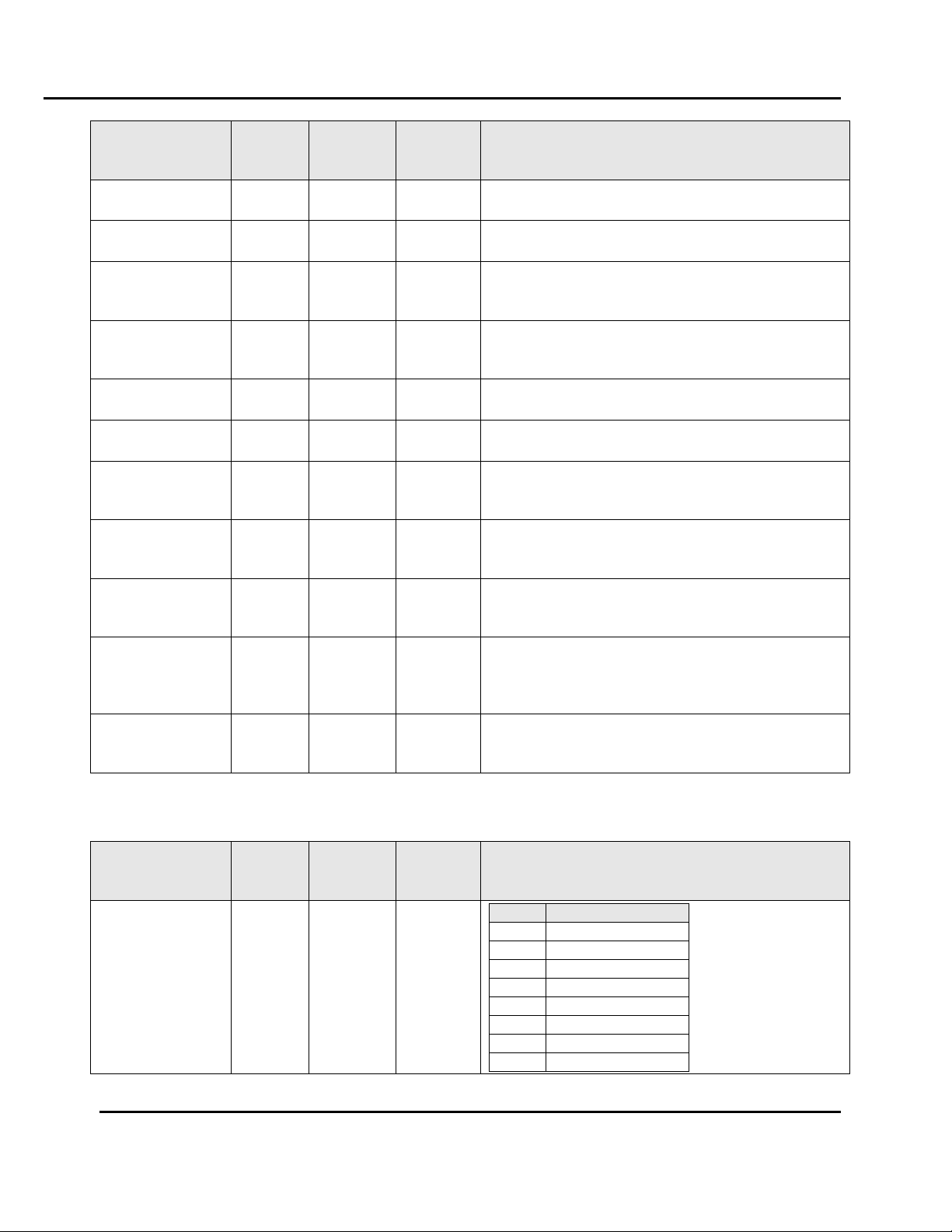

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

High Limit Input

Range

9000

0x2328

R/W

Value

Range

0

B TC

2

C TC

4

D TC

6

J TC

10

K TC

14

L TC

18

N TC

20

R TC

14 Version 2

2.1.2. High Limit Input Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 15

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

22

S TC

24

T TC

28

P24

30

Pt100 RTD

34

0_20mA

35

4_20mA

36

0_50mV

37

10_50mV

38

0_5V

39

1_5V

40

0_10V

41

2_10V

High Limit Input

Engineering units

9001

0x2329

R/W

0 = None

1 = Degrees C

2 = Degrees F

High Limit Input

Decimal Place

9002

0x232C

R/W

0 = 1234

1 = 123.4

2 = 12.34

3 = 1.234

High Limit Input

Range Minimum

9003

0x232A

R/W

High Limit Input

Range Maximum

9004

0x232B

R/W

High Limit User

Calibration Type

9008

0x2330

R/W

0 = No User Calibration

1 = Single Point Calibration

2 = Two Point Calibration

High Limit Input

Process variable

offset

9009

0x2331

R/W

Span of the input range

Process Input

Low Calibration

Offset

9010

0x2332

R/W

Process Input

Low Temperature

Calibration Point

9011

0x2333

R/W

Process Input

High Calibration

Offset

9012

0x2334

R/W

Process Input

High

Temperature

Calibration Point

9013

0x2335

R/W

High Limit Input

Process Variable

9006

0x232E

R

High Limit Input

9007

0x232F

R

Bit 0 = OPEN

15 Version 2

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 16

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

status

Bit 1 = Low

Bit 2 = High

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Digital input

states

2001

0x7D1

R

Bit Position

Digital input

0 1 1 2 2 3 3

4

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

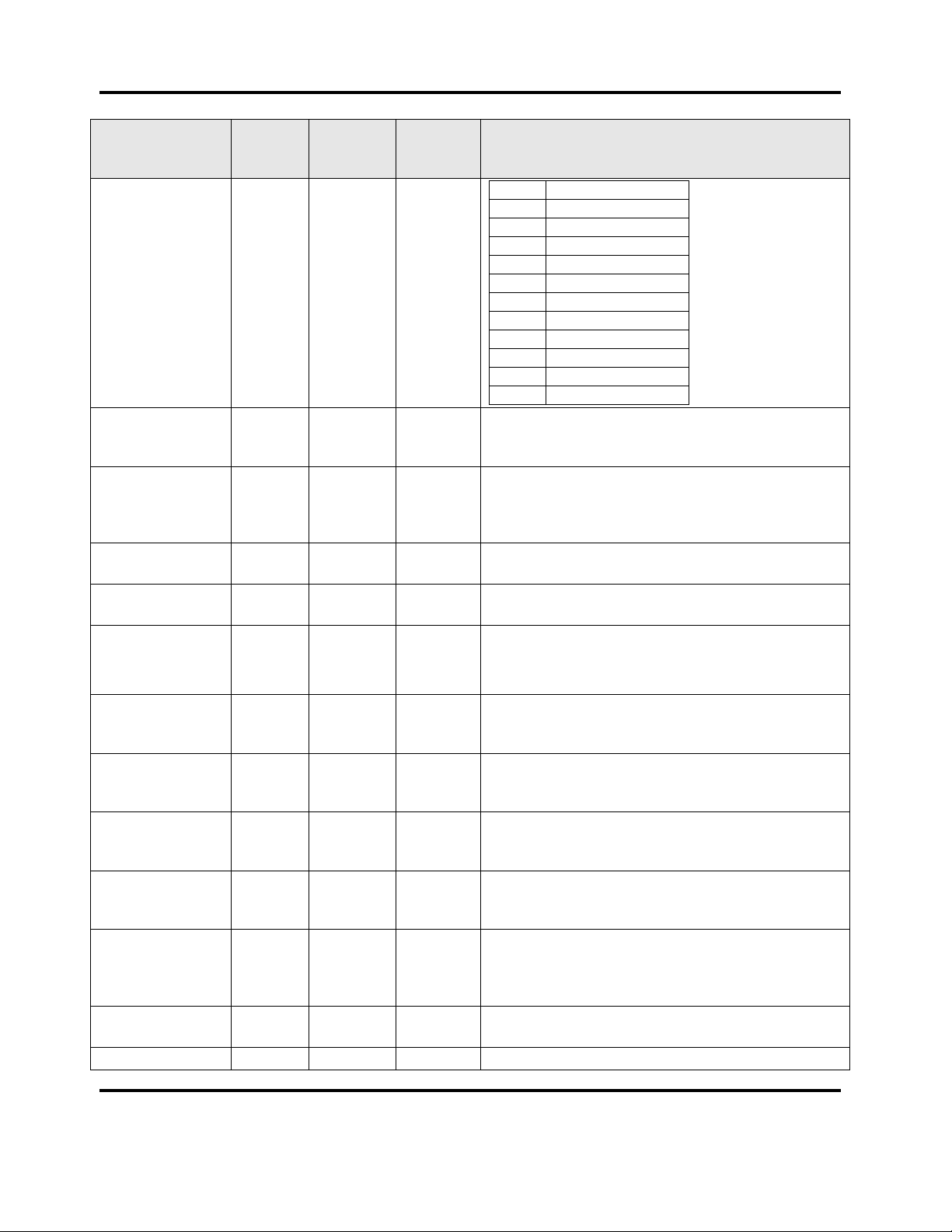

Usage

2146

0x0862

R/W

Value

Usage

0

None

1

Alarm 1

2

Alarm 2

3

Alarm 3

4

Alarm 4

5

Alarm 5

6

Event 1

7

Event 2

8

Event 3

9

Event 4

10

Event 5

11

Cycle Complete

12

Profile Running

13

Or of Alarms

14

Alarm and Events

Alarm Selection

2148

0x0864

R/W

Value

Selection

0

Alarm 1 or Alarm 2

1

Alarm 1 or Alarm 2 or Alarm 3

2

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4

16 Version 2

2.1.3. Digital Inputs

2.2. Output Parameters

2.2.1. Relay Output 1 Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 17

ADDRESS LIST Modbus Programming Manual

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

3

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4 or Alarm 5

Event Alarm

Selection

2150

0x0866

R/W

Value

Selection

0

Alarm 1 or Event 1

1

Alarm 2 or Event 2

2

Alarm 3 or Event 3

3

Alarm 4 or Event 4

4

Alarm 5 or Event 5

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Usage

2176

0x0880

R/W

Value

Usage

0

None

1

Alarm 1

2

Alarm 2

3

Alarm 3

4

Alarm 4

5

Alarm 5

6

Event 1

7

Event 2

8

Event 3

9

Event 4

10

Event 5

11

Cycle Complete

12

Profile Running

13

Or of Alarms

14

Alarm and Events

Alarm Selection

2178

0x0882

R/W

Value

Selection

0

Alarm 1 or Alarm 2

1

Alarm 1 or Alarm 2 or Alarm 3

2

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4

3

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4 or Alarm 5

Event Alarm

Selection

2180

0x0884

R/W

Value

Selection

0

Alarm 1 or Event 1

1

Alarm 2 or Event 2

2

Alarm 3 or Event 3

3

Alarm 4 or Event 4

4

Alarm 5 or Event 5

17 Version 2

2.2.2. Relay Output 2 Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 18

ABOUT THIS MANUAL Modbus Programming Manual

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Usage

2186

0x088A

R/W

Value

Usage

0

None

1

Alarm 1

2

Alarm 2

3

Alarm 3

4

Alarm 4

5

Alarm 5

6

Event 1

7

Event 2

8

Event 3

9

Event 4

10

Event 5

11

Cycle Complete

12

Profile Running

13

Or of Alarms

14

Alarm and Events

Alarm Selection

2188

0x088C

R/W

Value

Selection

0

Alarm 1 or Alarm 2

1

Alarm 1 or Alarm 2 or Alarm 3

2

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4

3

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4 or Alarm 5

Event Alarm

Selection

2190

0x088E

R/W

Value

Selection

0

Alarm 1 or Event 1

1

Alarm 2 or Event 2

2

Alarm 3 or Event 3

3

Alarm 4 or Event 4

4

Alarm 5 or Event 5

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Usage

2205

0x89D

R/W

Value

Usage

0

None

18 Version 2

2.2.3. Relay Output 3 Parameters

2.2.4. Relay Output 4 Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 19

ADDRESS LIST Modbus Programming Manual

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

1

Alarm 1

2

Alarm 2

3

Alarm 3

4

Alarm 4

5

Alarm 5

6

Event 1

7

Event 2

8

Event 3

9

Event 4

10

Event 5

11

Cycle Complete

12

Profile Running

13

Or of Alarms

14

Alarm and Events

Alarm Selection

2207

0x089F

R/W

Value

Selection

0

Alarm 1 or Alarm 2

1

Alarm 1 or Alarm 2 or Alarm 3

2

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4

3

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4 or Alarm 5

Event Alarm

Selection

2209

0x08A1

R/W

Value

Selection

0

Alarm 1 or Event 1

1

Alarm 2 or Event 2

2

Alarm 3 or Event 3

3

Alarm 4 or Event 4

4

Alarm 5 or Event 5

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Usage

2216

0x08A8

R/W

Value

Usage

0

None

1

Alarm 1

2

Alarm 2

3

Alarm 3

4

Alarm 4

5

Alarm 5

6

Event 1

7

Event 2

8

Event 3

9

Event 4

10

Event 5

19 Version 2

2.2.5. Relay Output 5 Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 20

ABOUT THIS MANUAL Modbus Programming Manual

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

11

Cycle Complete

12

Profile Running

13

Or of Alarms

14

Alarm and Events

Alarm Selection

2218

0x08AA

R/W

Value

Selection

0

Alarm 1 or Alarm 2

1

Alarm 1 or Alarm 2 or Alarm 3

2

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4

3

Alarm 1 or Alarm 2 or Alarm 3 or

Alarm 4 or Alarm 5

Event Alarm

Selection

2220

0x08AC

R/W

Value

Selection

0

Alarm 1 or Event 1

1

Alarm 2 or Event 2

2

Alarm 3 or Event 3

3

Alarm 4 or Event 4

4

Alarm 5 or Event 5

Parameter

Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Linear Output

Usage

2144

0x0860

R/W

Value

Usage

0

None

1

Retransmit PV

2

Retransmit SP

3

Primary (Heat) Control Power

4

Cool Control Power (Only available on

Heat Cool model)

Linear output

range

2223

0x08AF

R/W

Value

Range

0

0 – 5V

1

0 – 10V

2

2 – 10V

3

0 – 20mA

4

4 – 20mA

Retransmit

Minimum

2152

0x0868

R/W

Retransmit

Maximum

2153

0x0869

R/W

20 Version 2

2.2.6. Linear Output Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 21

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Setpoint Minimum

3944

0x0F68

R/W

Limited by input range maximum/minimum

Setpoint

Maximum

3945

0x0F69

R/W

Limited by input range maximum/minimum

Manual/Timer

Mode Setpoint

Value

3960

0x0F78

R/W

Limited by Setpoint maximum/minimum

21 Version 2

2.3. Setpoint Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 22

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Cycle time

4301

0x10CD

R/W

0.5 to 512.0

Control Type

4310

0x10D6

R/W

0 = Single (Heat Only)

1 = Dual (Heat/Cool)

(Only available on Heat Cool Variant)

Control Action

4311

0x10D7

R/W

0 = Direct

1 = Reverse

Proportional Band 1

4312

0x10D8

R/W

0.0 to 999.9

Secondary (Cool)

Proportional Band

4313

0x10D9

R/W

0.0 to 999.9

(Only available on Heat Cool Variant)

Integral/Reset

4314

0x10DA

R/W

0.0 to 5999

Derivative/Rate

4315

0x10DB

R/W

0.0 to 5999

Bias

4316

0x10DC

R/W

For single control 0 to 100, for Duel control -100

to 100

Overlap/DeadBand

4317

0x10DD

R/W

20% of the proportional band

(Only available on Heat Cool Variant)

On/Off Differential

4320

0x10E0

R/W

0.1 to 100

Heat/Primary Power

Upper limit

4321

0x10E1

R/W

10 to 100% Can not be made smaller than

Heat/Primary Lower limit + 10

Heat/Primary Power

Lower limit

4322

0x10E2

R/W

0 to 90% Can not be made larger than

Heat/Primary Upper limit – 10

Cool/Secondary

Power Upper limit

4323

0x10E3

R/W

10 to 100% Can not be made smaller than

Cool/Secondary Lower limit + 10

Cool/Secondary

Power Lower limit

4324

0x10E4

R/W

0 to 90% Can not be made larger than

Cool/Secondary Upper limit – 10

Pretune Enable

4325

0x10E5

R/W

0 = Disabled

1 = Enabled

Self tune Enable

4326

0x10E6

R/W

0 = Disabled

1 = Enabled

Loop Alarm Type

4327

0x10E7

R/W

1 = Time

2 = Auto

Loop Alarm time

4328

0x10E8

R/W

1 to 5999

Primary Power

4329

0x10E9

R

0 to 100%

Pretune Status

4332

0x10EC

R

0 = Inactive

1 = Active

Self tune Status

4333

0x10ED

R

0 = Inactive

1 = Active

Loop Alarm status

4334

0x10EE

R

0 = Inactive

1 = Active

Preset Power

4335

0x10EF

R/W

0% to 100%

22 Version 2

2.4. Control Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 23

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Auto Pre-tune

4336

0x10F0

R/W

0 = Disabled

1 = Enabled

23 Version 2

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 24

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm Type

6144

0x1800

R/W

0 = High Alarm

1 = Low Alarm

2 = Deviation Alarm

3 = Band Alarm

4 = Loop Alarm

5 = Sensor Break Alarm

Alarm Value

6145

0x1801

R/W

Limited by the input range maximum and minimum

for Alarm types 0 and 1. Limited by the span of the

input range for alarm types 2 and 3. Not used for

alarms 4 and 5.

Alarm Hysteresis

6146

0x1802

R/W

Limited by the span of the input range

Alarm inhibit

6147

0x1803

R/W

0 = Disabled

1 = Enabled

Alarm status

6148

0x1804

R

0 = Inactive

1 = Active

Alarm inhibit

status

6149

0x1805

R

0 = Not inhibited

1 = Inhibited

Rate Minimum

Time Alarm

Value

6150

0x1806

R/W

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm Type

6160

0x1810

R/W

0 = High Alarm

1 = Low Alarm

2 = Deviation Alarm

3 = Band Alarm

4 = Loop Alarm

5 = Sensor Break Alarm

Alarm Value

6161

0x1811

R/W

Limited by the input range maximum and minimum

for Alarm types 0 and 1. Limited by the span of the

input range for alarm types 2 and 3. Not used for

alarms 4 and 5.

Alarm Hysteresis

6162

0x1812

R/W

Limited by the span of the input range

Alarm inhibit

6163

0x1813

R/W

0 = Disabled

1 = Enabled

Alarm status

6164

0x1814

R

0 = Inactive

1 = Active

24 Version 2

2.5. Alarm Parameters

2.5.1. Alarm 1

2.5.2. Alarm 2

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 25

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm inhibit

status

6165

0x1815

R

0 = Not inhibited

1 = Inhibited

Rate Minimum

Time Alarm

Value

6166

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm Type

6176

0x1820

R/W

0 = High Alarm

1 = Low Alarm

2 = Deviation Alarm

3 = Band Alarm

4 = Loop Alarm

5 = Sensor Break Alarm

Alarm Value

6177

0x1821

R/W

Limited by the input range maximum and minimum

for Alarm types 0 and 1. Limited by the span of the

input range for alarm types 2 and 3. Not used for

alarms 4 and 5.

Alarm Hysteresis

6178

0x1822

R/W

Limited by the span of the input range

Alarm inhibit

6179

0x1823

R/W

0 = Disabled

1 = Enabled

Alarm status

6180

0x1824

R

0 = Inactive

1 = Active

Alarm inhibit

status

6181

0x1825

R

0 = Not inhibited

1 = Inhibited

Rate Minimum

Time Alarm

Value

6182

0x1826

R/W

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm Type

6192

0x1830

R/W

0 = High Alarm

1 = Low Alarm

2 = Deviation Alarm

3 = Band Alarm

4 = Loop Alarm

5 = Sensor Break Alarm

Alarm Value

6193

0x1831

R/W

Limited by the input range maximum and minimum

for Alarm types 0 and 1. Limited by the span of the

input range for alarm types 2 and 3. Not used for

25 Version 2

2.5.3. Alarm 3

2.5.4. Alarm 4

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 26

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

alarms 4 and 5.

Alarm Hysteresis

6194

0x1832

R/W

Limited by the span of the input range

Alarm inhibit

6195

0x1833

R/W

0 = Disabled

1 = Enabled

Alarm status

6196

0x1834

R

0 = Inactive

1 = Active

Alarm inhibit

status

6197

0x1835

R

0 = Not inhibited

1 = Inhibited

Rate Minimum

Time Alarm

Value

6198

0x1836

R/W

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm Type

6208

0x1840

R/W

0 = High Alarm

1 = Low Alarm

2 = Deviation Alarm

3 = Band Alarm

4 = Loop Alarm

5 = Sensor Break Alarm

Alarm Value

6209

0x1841

R/W

Limited by the input range maximum and minimum

for Alarm types 0 and 1. Limited by the span of the

input range for alarm types 2 and 3. Not used for

alarms 4 and 5.

Alarm Hysteresis

6210

0x1842

R/W

Limited by the span of the input range

Alarm inhibit

6211

0x1843

R/W

0 = Disabled

1 = Enabled

Alarm status

6212

0x1844

R

0 = Inactive

1 = Active

Alarm inhibit

status

6213

0x1845

R

0 = Not inhibited

1 = Inhibited

Rate Minimum

Time Alarm

Value

6214

0x1846

R/W

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm Value

9022

0x233E

R/W

26 Version 2

2.5.5. Alarm 5

2.5.6. High Limit Alarm Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 27

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Alarm Hysteresis

9023

0x233F

R/W

Limited by the span of the input range

Alarm status

9007

0x232F

R

0 = Inactive

1 = Active

27 Version 2

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 28

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Log Interval

7550

0x1D7E

R/W

0 = Every second

1 = Every 2 seconds

2 = Every 5 seconds

3 = Every 10 seconds

4 = Every 15 seconds

5 = Every 30 seconds

6 = Every Minute

7 = Every 2 Minutes

8 = Every 5 Minutes

9 = Every 10 Minutes

10 = Every 15 Minutes

11 = Every 30 Minutes

12 = Every 60 Minutes

Log Mode

7551

0x1D7F

R/W

0 = Record until memory used

1 = Continues FIFO

Memory

Remaining

7554

0x1D82

R

In Bytes

Time Remaining

7555

0x1D83

R

In seconds

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Date format

7868

0x1EBC

R

0 = dd/mm/yyyy (European Default)

1 = mm/dd/yyyy (USA Default)

Time

7869

0x1EBD

R/W

In seconds from midnight

Date

7870

0x1EBE

R/W

Day of the week

7872

0x1EC0

R/W

1 = Monday

2 = Tuesday

3 = Wednesday

4 = Thursday

5 = Friday

6 = Saturday

7 = Sunday

28 Version 2

2.6. Logger parameters (Data Logger)

2.6.1. Data Recorder

2.6.2. Real Time Clock

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 29

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Key State

7669

0x1DF5

R

Current state of the keys

Key Debounce

7670

0x1DF6

R/W

Not currently supported

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

LED 1 Label

7660

0x1DEC

R/W

LED 2 Label

7661

0x1DED

R/W

LED 3 Label

7662

0x1DEE

R/W

LED 4 Label

7663

0x1DEF

R/W

Backlight Colour

7668

0x1DF4

R/W

0 = Green to Red on Alarm

1 = Red to Green on Alarm

2 = Green

3 = Red

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Language

7675

0x1DFB

R/W

0 = Downloaded Language

1 = English

LCD Contrast

7676

0x1DFC

R/W

0 to 100

Invert LCD

7677

0x1DFD

R/W

0 = Normal

1 = Inverted

Setup Lock Code

7678

0x1DFE

R/W

Default 10

Configuration

Lock Code

7679

0x1DFF

R/W

Default 10

Tune Lock Code

7680

0x1E00

R/W

Default 10

USB Lock Code

7683

0x1E03

R/W

Default 10

Recorder Lock

Code

7684

0x1E04

R/W

Default 10

Profile Lock Code

7682

0x1E02

R/W

Default 10

29 Version 2

2.7. Display Parameters

2.7.1. Keys

2.7.2. LEDs

2.7.3. HMI

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 30

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Serial number hi

210

0x00D2

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Serial number lo

211

0x00D3

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Serial number line

212

0x00D4

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Serial number qty

213

0x00D5

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Date of

manufacture (Day)

370

0x0172

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Date of

manufacture

(Month)

371

0x0173

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Date of

manufacture (Year)

372

0x0174

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Software PRL

208

0x00D0

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Hardware PRL

207

0x00CF

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Software version

201

0x00C9

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Hardware option

200

0x00C8

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Manufactures ID

216

0x00D8

R

Can only be set through diagnostics mode,

Refer to document ENG2491

Unit ID

203

0x00CB

R

Should never be set by automatic test

equipment

Version Major

217

0x00D9

R

Should never be set by automatic test

equipment

Version Minor

218

0x00DA

R

Should never be set by automatic test

equipment

OP Version

202

0x00CA

R

Should never be set by automatic test

equipment

Sub Version

204

0x00CC

R

Should never be set by automatic test

equipment

Software type

206

0x00CE

R

Should never be set by automatic test

equipment

OEM Code hi

373

0x0175

R

Should never be set by automatic test

equipment

OEM Code lo

374

0x0176

R

Should never be set by automatic test

30 Version 2

2.7.4. System Data

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 31

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

equipment

Contact Details line

1

400

0x0190

R/W

26 characters of text

Contact Details line

2

401

0x0191

R/W

26 characters of text

Contact Details line

3

402

0x0192

R/W

26 characters of text

Contact Details line

4

403

0x0193

R/W

26 characters of text

Contact Details line

5

404

0x0194

R/W

26 characters of text

Contact Details line

6

405

0x0195

R/W

26 characters of text

Contact Details line

7

406

0x0196

R/W

26 characters of text

Communications

Address

413

0x019D

R/W

Communications

Baud rate

414

0x019E

R/W

Communications

Parity

415

0x019F

R/W

31 Version 2

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 32

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Mode Selection

8285

0x205D

R/W

0 = Do Nothing

1 = Manual Mode

2 = Timer Mode

3 = Profile Mode

4 = Mode Selection

Digital input

Profile Selection

control Enable

8273

0x2051

R/W

0 = HMI or Comms selection

1 = Digital input profile selection

Current Mode

Selected

8280

0x2058

RO

0 = Mode Selection

1 = Configuration

2 = Manual

3 = Timer

4 = Profile

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Manual Mode

Recovery

8278

0x2056

R/W

0 = Control Off

1 = Recover to Mode

Manual Mode

recovery Time

8279

0x2057

R/W

Value in seconds

Manual Mode

Status

8281

0x2059

RO

0 = Mode Stopped

1 = Mode Running

Manual Mode

Relay Status

2170

0x087A

RO

Bit 0 = Relay 1

Bit 1 = Relay 2

Bit 2 = Relay 3

Bit 3 = Relay 4

Bit 4 = Relay 5

Manual Mode

Control

8283

0x205B

R/W

0 = Stop Manual Mode

1 = Start Manual Mode

3 = Waiting for Command

Manual Mode

Control Setpoint

3960

0x0F78

R/W

Manual Mode

Relay 1

8249

0x2039

R/W

0 = Off

1 = On

Manual Mode

Relay 2

8250

0x203A

R/W

0 = Off

1 = On

Manual Mode

Relay 3

8251

0x203B

R/W

0 = Off

1 = On

32 Version 2

2.8. Mode Controls

2.8.1. General Mode Control

2.8.2. Manual Mode Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 33

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Manual Mode

Relay 4

8252

0x203C

R/W

0 = Off

1 = On

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Timer Mode

Recovery

8275

0x2053

R/W

0 = Control Off

1 = Restart Timer

2 = Continue Timer

Timer Mode

Recovery Time

8276

0x2054

R/W

Value in seconds

Timer Mode Auto

Hold Value

8272

0x2050

R/W

Timer Mode

Status

8282

0x205A

RO

0 = Mode Stopped

1 = Mode Running

Timer Mode

Relay Status

2170

0x087A

RO

Bit 0 = Relay 1

Bit 1 = Relay 2

Bit 2 = Relay 3

Bit 3 = Relay 4

Bit 4 = Relay 5

Timer Mode

Control

8284

0x205C

R/W

0 = Stop Timer

1 = Start Timer

3 = Waiting for Command

Timer Time

8270

0x204E

R/W

Time in seconds

Current

Remaining Time

of timer

8238

0x202E

RO

Value in seconds. The amount of time remaining

for the active segment.

Timer Mode

Control Setpoint

3960

0x0F78

R/W

Timer Mode

Relay 1

8249

0x2039

R/W

0 = Off

1 = On

Timer Mode

Relay 2

8250

0x203A

R/W

0 = Off

1 = On

Timer Mode

Relay 3

8251

0x203B

R/W

0 = Off

1 = On

Timer Mode

Relay 4

8252

0x203C

R/W

0 = Off

1 = On

33 Version 2

2.8.3. Timer Mode Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 34

ABOUT THIS MANUAL Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Currently

Selected Profile

8243

0x2033

R/W

Value between 0 and 63

Currently Active

Segment

8244

0x2034

RO

Value between 0 and 255

Current Setpoint

8256

0x2040

RO

Currently

Running

Segment Type

8258

0x2042

RO

0 = None

1 = Ramp Up

2 = Step

3 = Dwell

4 = Hold

5 = Loop

6 = Join

7 = End

8 = Ramp Down

Start Delay Time

8233

0x2029

RO

Value in seconds. The current start delay time

remaining

Current Time of

the active

segment

8237

0x202D

RO

Value in seconds. The amount of time the

segment has been running

Current

Remaining Time

of segment

8238

0x202E

RO

Value in seconds. The amount of time remaining

for the active segment.

Current Time of

the running

Profile

8235

0x202B

RO

Value in seconds. The amount of time the profile

has been running.

Current

Remaining

Profile Time

8236

0x202C

RO

Value in seconds. The amount of time remaining

for the complete profile.

Total Hold Time

8239

0x202F

RO

Value in seconds. The total amount of time the

profile has been held for.

Profile Mode

Relay Status

2170

0x087A

RO

Bit 0 = Relay 1

Bit 1 = Relay 2

Bit 2 = Relay 3

Bit 3 = Relay 4

Bit 4 = Relay 5

Event 1 Status

8249

0x2039

RO

0 = Inactive

1 = Active

Event 2 Status

8250

0x203A

RO

0 = Inactive

1 = Active

Event 3 Status

8251

0x203B

RO

0 = Inactive

1 = Active

Event 4 Status

8252

0x203C

RO

0 = Inactive

1 = Active

Profile Selection

8243

0x2033

R/W

Value between 0 and 63 to select the profile to run

34 Version 2

2.8.4. Profile Mode Parameters

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 35

ADDRESS LIST Modbus Programming Manual

Parameter Name

Modbus

Address

(Dec)

Modbus

Address

(Hex)

Access

R/W

Notes

Profile Control

8245

0x2035

R/W

0 = Do Nothing

1 = Run the selected profile

2 = Hold the currently running profile

3 = Abort the currently running profile

4 = Jump to the next segment

5 = Release a held profile

6 = Exit the profile control once the profile has

completed and is holding the last setpoint

Active Profile

Name

8259

0x2043

R

The currently selected profile name

Profile Status

8241

0x2031

R

0 = Stopped

1 = Running

2 = Held

3 = Delayed

4 = Error

5 = Aborted

6 = Ended

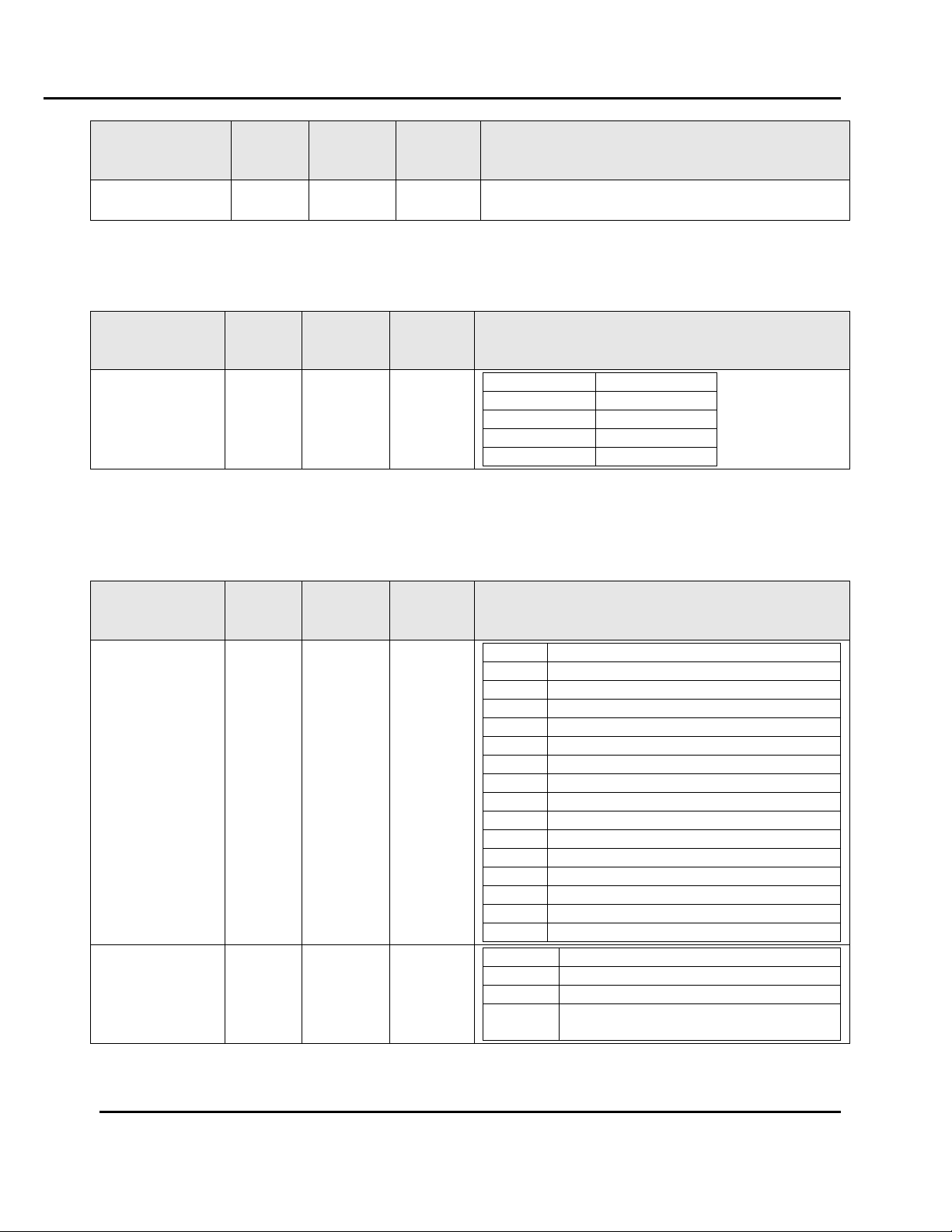

Command Code

Value Decimal

Value Hex

Function

CP

17232

0x4350

Create Profile

EP

17744

0x4550

Edit Profile

WP

22352

0x5750

Write Profile

WS

22355

0x5753

Create Segment

IS

18771

0x4953

Insert Segment

ES

17747

0x4553

Edit a Segment

DP

17488

0x4450

Delete a Profile

DA

17473

0x4441

Delete all profiles

DS

17491

0x4453

Delete a Segment

SR

21330

0x5352

Get the number of segments remaining

RP

21072

0x5250

Read Profile Header

35 Version 2

2.9. Uploading and Downloading of Profiles

The information in this section is intended for advanced users writing their own software code.

Most users will create or edit profiles using the instrument keypad or via BlueControl. Either

method allows quick and easy editing of profiles.

Advanced users can setup or edit profiles by writing to the Profile Configuration parameter at

address 8198 (0x2006). This can only be accessed by using Modbus function code 23 (0x17). The

instrument replies with a status message.

When creating a new profile the steps below must be followed exactly, either to create a profile at

the next available position, or at a position that you specify.

Each message in the sequence includes a 2 byte Command Code that tells the instrument the

purpose of the message, and therefore the meaning of the data contained in it.

The command codes support by this instrument are:

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any means

including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and retrieval systems without

the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2012 by Despatch Industries.

Page 36

ADDRESS LIST Modbus Programming Manual

Command Code

Value Decimal

Value Hex

Function

RS

21075

0x5253

Read Segment

PN

20558

0x504E

Read Profile Name

PS

20563

0x5053

Read the profiler memory status

36 Version 2

The following rules apply when creating a profile over communications:

Profiles must always be terminated with an end segment.