Page 1

Protocol 3 Owner’s Manual PREFACE

PROTOCOL 3™ Controller

OWNER’S MANUAL

E-105

PN 313327

VERSION 1.2

6/2013

Version 1.2 1

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 2

PREFACE Protocol 3 Controller Owner’s Manual

Revision

Date

Author

Description

1.0

1/2012

K. Livingston

Initial release

1.1

3/2013

K. Livingston

Modified instructions for delayed start and remote

communication. Modbus User’s Programming Manual

added (E-106/ PN320813, Version 3/2013, Updated for

Engineering Issue 8).

1.2

6/2013

K. Livingston

Minor edits

2 Version 1.2

Revision History

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 3

Protocol 3 Owner’s Manual PREFACE

Version 1.2 3

Table of Contents

1. About This Manual ................................................................................................. 6

1.1. Important User Information .......................................................................... 6

1.2. Manufacturer & Service ................................................................................ 7

1.3. Organization of this Manual ......................................................................... 8

1.4. Conventions .................................................................................................. 8

1.5. Specifications ................................................................................................ 9

2. Safety .................................................................................................................... 13

2.1. Safety Information ...................................................................................... 13

2.1.1. Lockout.................................................................................................... 13

2.1.1.1. Lockout Requirements ......................................................................... 13

2.1.1.2. Lockout Procedure with Despatch Products ........................................ 13

2.2. Maintenance ................................................................................................ 13

2.3. Electrical Power .......................................................................................... 14

2.4. Fire .............................................................................................................. 14

2.5. Equipment Lockout Requirements ............................................................. 14

3. Theory of Operation .............................................................................................. 15

3.1. System Control—In General....................................................................... 15

3.1.1. High-Limit Function ............................................................................... 15

3.1.2. Outputs .................................................................................................... 16

3.2. Remote Communication ............................................................................. 16

4. Assembly & Setup ................................................................................................ 18

4.1. Install the Protocol 3 Controller .................................................................. 18

4.2. Protocol 3 Controller Conversion with NO Options................................... 18

4.3. Setting Up Remote Communication ........................................................... 19

5. Working with Operating Modes ........................................................................... 20

5.1. User Controls .............................................................................................. 20

5.2. First Screens ................................................................................................ 23

5.2.1. Manual Mode .......................................................................................... 24

5.2.1.1. Display Manual Mode ......................................................................... 24

5.2.1.2. Start Manual Mode .............................................................................. 24

5.2.2. Timer Mode ............................................................................................. 25

5.2.3. Profile Mode ............................................................................................ 26

5.2.4. Main Menu .............................................................................................. 27

5.3. Setting up a Profile...................................................................................... 29

5.3.1. Prepare for Profile Setup ......................................................................... 33

5.3.2. Sample Profile ......................................................................................... 35

5.3.3. Key In the Sample Profile Setup ............................................................. 37

5.4. Recorder Control ......................................................................................... 40

5.5. USB Menu .................................................................................................. 41

5.5.1. Working with USB Memory Stick Folders and Files ............................. 43

5.5.2. File Naming Conventions........................................................................ 44

5.5.3. Create a New Name Before Writing to the USB Device ........................ 44

5.6. Configuration Menu .................................................................................... 45

5.6.1. Alarm Configuration ............................................................................... 49

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2013 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 4

PREFACE Protocol 3 Controller Owner’s Manual

4 Version 1.2

5.6.1.1. Access the Configuration Menu .......................................................... 49

5.6.1.2. Work with the Alarm Menu ................................................................. 49

5.6.1.3. Using Alarms to Switch Relay Outputs ............................................... 50

5.6.1.4. Alarm Application Example ................................................................ 51

5.6.1.5. Glossary of Alarm Terms .................................................................... 52

5.6.2. Working with Calibration Offsets ........................................................... 54

5.6.2.1. Access the Configuration Menu .......................................................... 54

5.6.2.2. Working with Input Configuration ...................................................... 54

5.6.2.3. Factory Calibration .............................................................................. 55

5.6.2.4. Single Point Calibration....................................................................... 55

5.6.2.5. Two Point Calibration ......................................................................... 55

5.6.3. Setting Up Remote Communication ....................................................... 56

5.7. Automatic Tuning ....................................................................................... 56

5.8. Product Information .................................................................................... 57

5.9. Service Information .................................................................................... 57

5.10. Remote Operation ................................................................................... 58

5.11. Setting Up Digital Inputs......................................................................... 59

6. Maintenance .......................................................................................................... 61

6.1. Replacement Parts ....................................................................................... 61

7. Troubleshooting .................................................................................................... 62

7.1. Error Messages and Alarm.......................................................................... 62

7.2. Controller Firmware Revision .................................................................... 62

7.3. Troubleshoot Protocol Manager/Protocol 3 Controller Communication.... 62

8. Appendices ............................................................................................................ 67

8.1. Standard Products Warranty ....................................................................... 67

8.2. Modbus Programming ................................................................................ 68

8.3. Programming Worksheet ............................................................................ 68

Figures

Figure 1. Operator Interface. ............................................................................................. 15

Figure 2. Typical Controller Output Sticker. .................................................................... 17

Figure 3. Protocol Plus to Protocol 3 Connection Conversions........................................ 17

Figure 5. Select a Mode Display. ...................................................................................... 20

Figure 6. Manual Mode Display Screen. .......................................................................... 24

Figure 7. Timer Mode Display Screen. ............................................................................. 25

Figure 8. Profile Mode. ..................................................................................................... 27

Figure 9. Main Menu. ....................................................................................................... 28

Figure 10. Profile Setup. ................................................................................................... 29

Figure 11. Profile Setup Menu. ......................................................................................... 31

Figure 12. Sample Profile. ................................................................................................ 35

Figure 13. Sample Profile Values. .................................................................................... 36

Figure 14. Recorder Control. ............................................................................................ 40

Figure 15. Recorder Status. ............................................................................................... 40

Figure 16. USB Menu. ...................................................................................................... 41

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 5

Protocol 3 Owner’s Manual PREFACE

Version 1.2 5

Figure 17. USB Port on Front Panel. ................................................................................ 43

Figure 18. USB Files and Folders Requirements (as seen from Windows Explorer). ..... 43

Figure 19. Configuration Menu (see also Table 16 for more information). ..................... 46

Figure 4. How High, Low and Band process alarms are implemented. ........................... 53

Figure 20. Service Information Screen. ............................................................................ 58

Figure 21. Standard Digital Input Wiring. ........................................................................ 59

Figure 22. Check Cabling. ................................................................................................ 63

Figure 23. Older model serial converter schematic. ......................................................... 64

Figure 24. Newer model serial converter schematic. ....................................................... 65

Figure 25. USB Converter Schematic. .............................................................................. 66

Tables

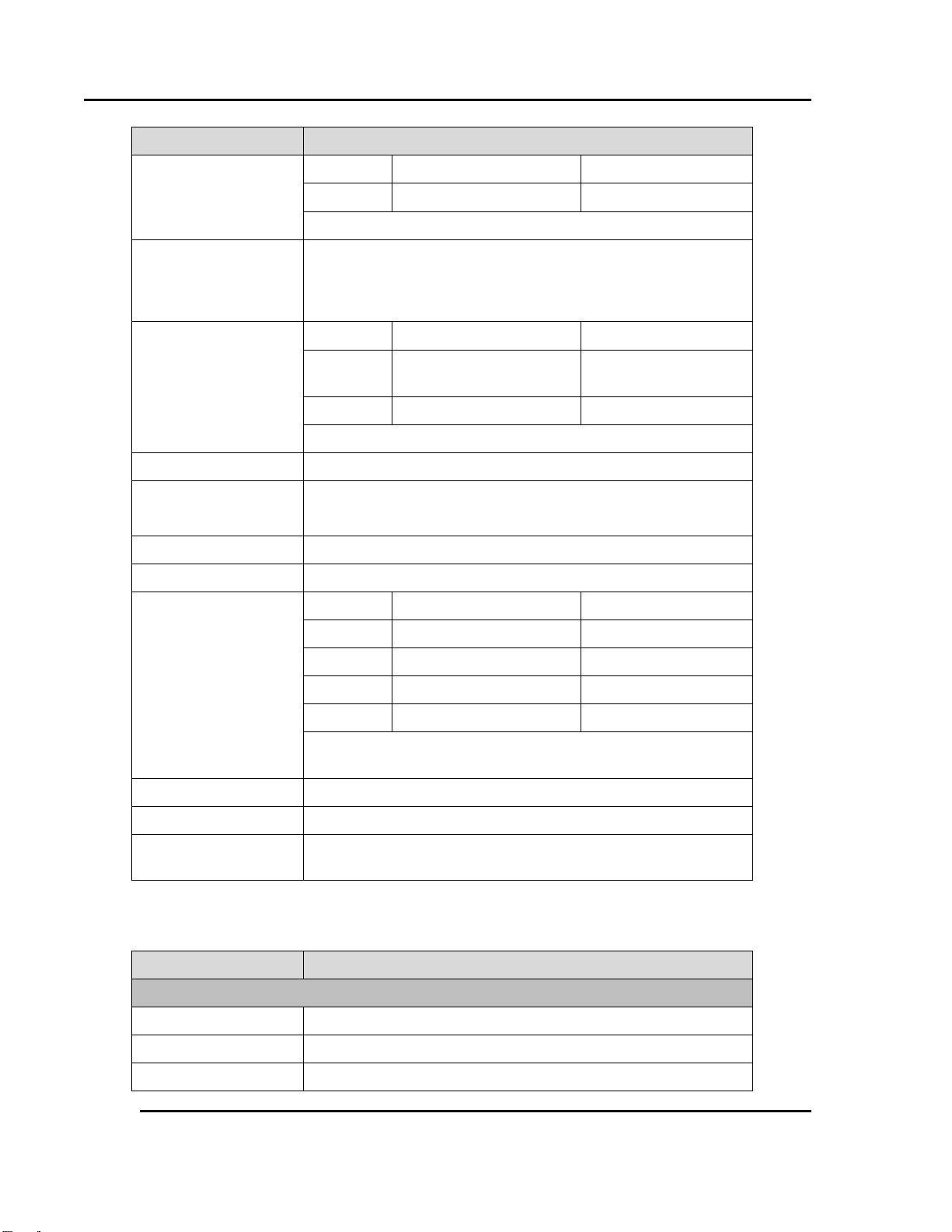

Table 1. Process Input. ........................................................................................................ 9

Table 2. Outputs. ............................................................................................................... 10

Table 3. Operating Conditions (For indoor use). .............................................................. 11

Table 4. Conformance Norms. .......................................................................................... 11

Table 5. Display. ............................................................................................................... 11

Table 6. Data Recorder. .................................................................................................... 12

Table 7. Protocol Plus to Protocol 3 Controller Conversion. ........................................... 18

Table 9. Keypad Buttons and Functions. .......................................................................... 20

Table 10. LEDs and Functions.......................................................................................... 22

Table 11. Sub Menu Descriptions ..................................................................................... 28

Table 12. Profile Setup Options. ....................................................................................... 30

Table 13. Profile Setup Steps, Options and Descriptions. ................................................ 32

Table 14. Profile Parameter Options. ................................................................................ 39

Table 15. USB Menu Options. .......................................................................................... 42

Table 16. Configuration Menu in Tabular Format............................................................ 47

Table 8. Protocol 3 Possible Alarm Settings. ................................................................... 49

Table 17. Automatic Tuning Options. .............................................................................. 56

Table 18. Product Information Details. ............................................................................. 57

Table 19. Input settings. .................................................................................................... 59

Table 20. Error Messages and Next Steps. ....................................................................... 62

Table 21. Programming Worksheet. ................................................................................. 68

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2013 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 6

ABOUT THIS MANUAL Protocol 3 Controller Owner’s Manual

Values displayed on screens are examples only. Though

those values may be typical, contact Despatch Industries for

the final value.

Users of this equipment must comply with operating

procedures and training of operation personnel as required

by the Occupational Safety and Health Act (OSHA) of 1970,

Section 6 and relevant safety standards, as well as other

safety rules and regulations of state and local governments.

Refer to the relevant safety standards in OSHA and National

Fire Protection Association (NFPA), section 86 of 1990.

6 Version 1.2

1. About This Manual

1.1. Important User Information

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied, or

transmitted in any form or by any means including graphic, electronic, or mechanical methods or

photocopying, recording, or information storage and retrieval systems without the written

permission of the publisher, unless it is for the purchaser's personal use.

Printed and bound in the United States of America.

The information in this manual is subject to change without notice and does not represent a

commitment on the part of Despatch Industries. Despatch Industries does not assume any

responsibility for any errors that may appear in this manual.

In no event will Despatch Industries be liable for technical or editorial omissions made herein,

nor for direct, indirect, special, incidental, or consequential damages resulting from the use or

defect of this manual.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 7

Protocol 3 Controller Owner’s Manual ABOUT THIS MANUAL

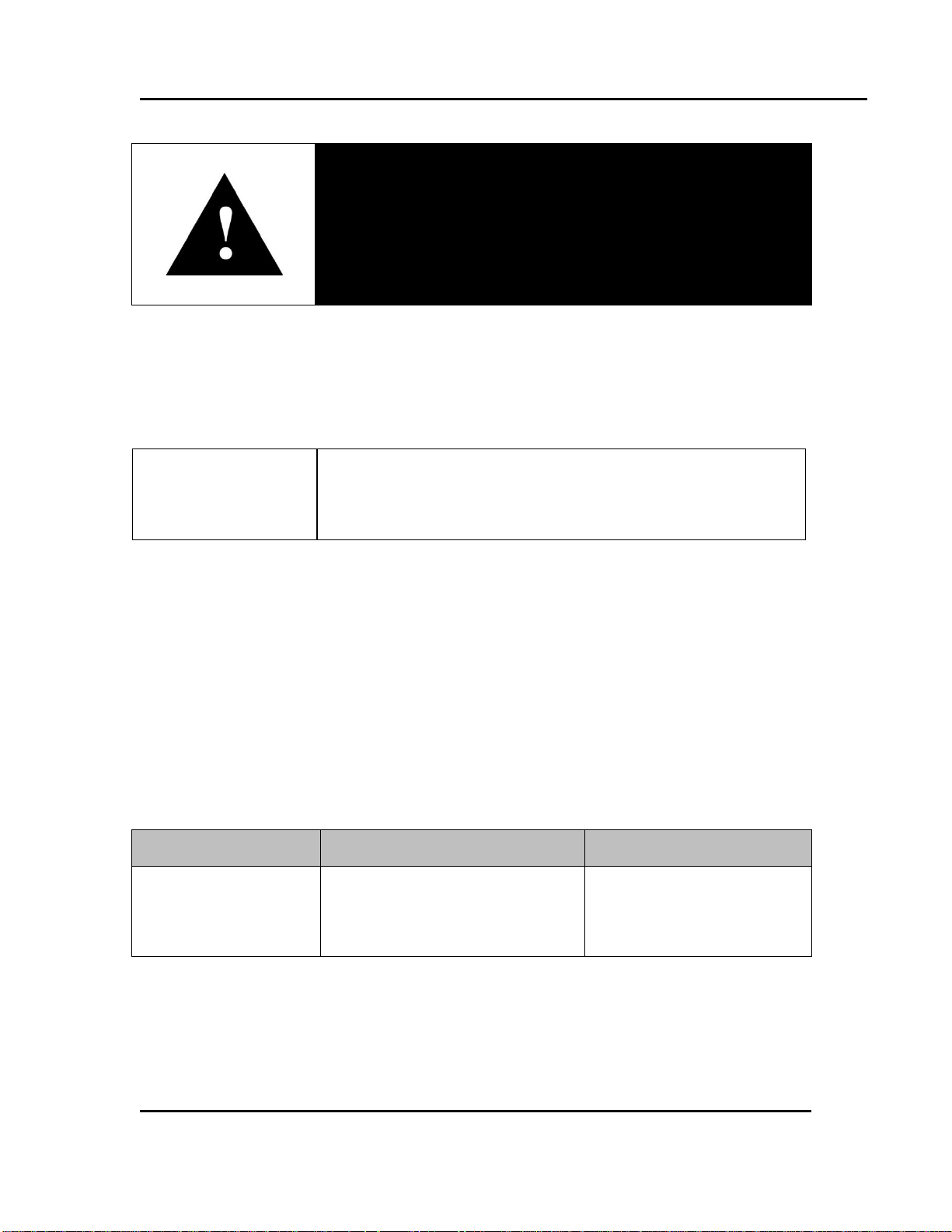

Danger!

Only fully-trained and qualified personnel should setup and

maintain this equipment. Improper setup and operation of this

equipment could cause an explosion that may result in

equipment damage, personal injury or possible death.

Modbus communication protocols require the Protocol 3

controller be updated to version 2.3 or higher.

Global Headquarters

Contact

Service & Technical

Support

Despatch Industries

8860 207th Street

Lakeville, MN 55044

USA

International/Main: 1-952-469-5424

US toll free: 1-888-337-7282

Fax: 1-952-469-4513

info@despatch.com

www.despatch.com

Service: 1-952-469-8230

US toll free: 1-800-473-7373

Service @despatch.com

Version 1.2 7

The information in this document is not intended to cover all possible conditions and situations

that might occur. The end user must exercise caution and common sense when installing or

maintaining Despatch Industries products. If any questions or problems arise, call Despatch

Industries at 1-888-DESPATCH or 1-952-469-5424.

1.2. Manufacturer & Service

Despatch has specialized in thermal processing for over 100 years. Technical expertise gained

over those years helps provide innovative solutions to critical applications in vertical markets and

cutting edge technology worldwide. Despatch products are backed by a drive for long-term

customer satisfaction and a strong sense of responsibility. The worldwide network of factorytrained Service Professionals is available to support your Despatch equipment. From full service

preventive maintenance to routine repair and certified calibration and uniformity, the Despatch

service network is positioned to respond to your business needs. Our service programs are

customized to meet your specific needs using our Advantage Service Assurance Program

(ASAP). For more information on ASAP, visit www.despatch.com.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 8

ABOUT THIS MANUAL Protocol 3 Controller Owner’s Manual

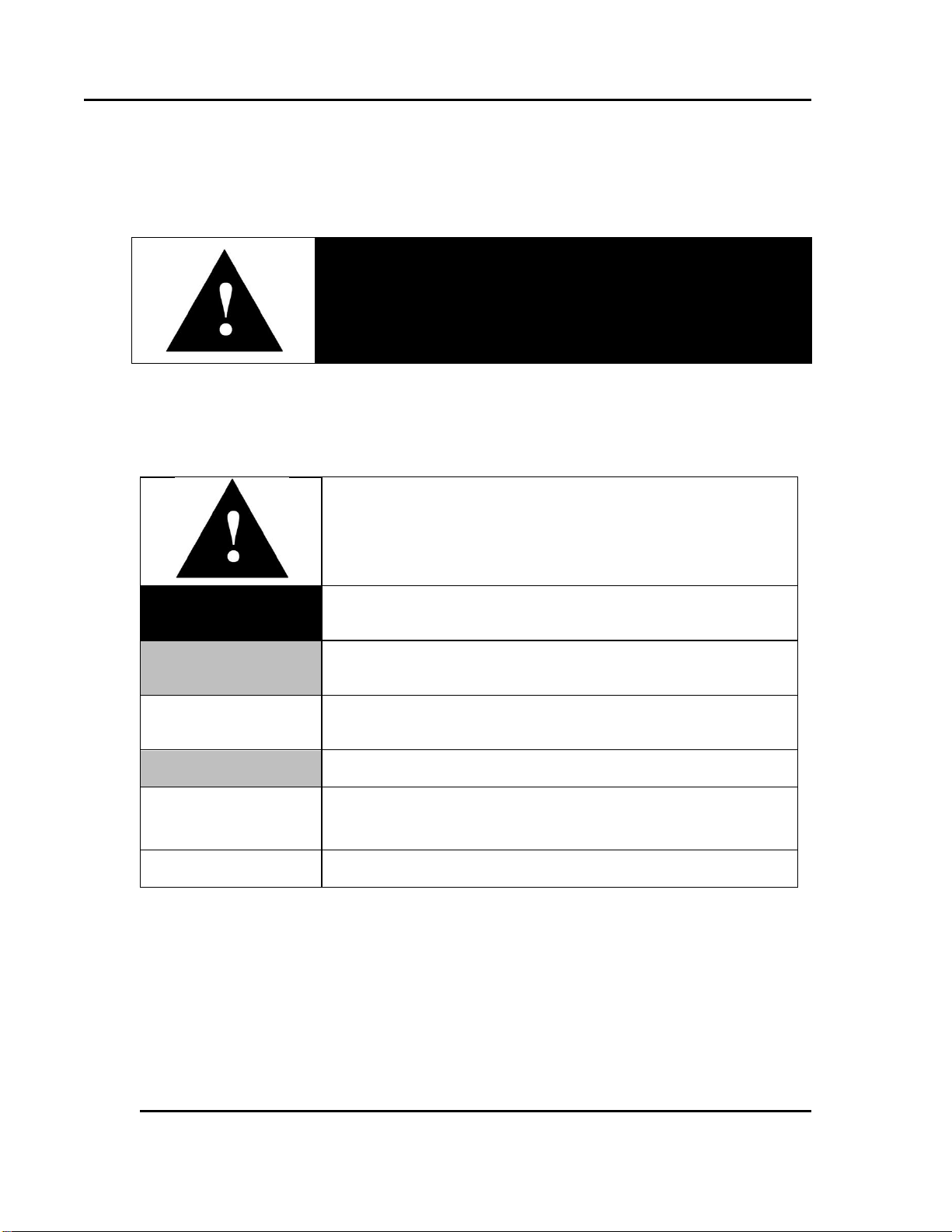

Danger!

Failure to heed warnings in this instruction manual and on the

oven could result in personal injury, property damage or death.

This icon signifies information that describes an unsafe

condition that may result in death, serious injury, or damage

to the equipment.

Danger!

Danger is the signal word used to indicate a hazardous

situation that, if not avoided, will result in death or severe

injury.

Warning!

Warning is the signal word used to indicate a hazardous

situation that, if not avoided, could result in death or severe

injury.

Caution!

Caution is the signal word used to indicate a hazardous

situation that, if not avoided, could result in moderate or

minor injury.

Notice

Notice is the signal word used to indicate a hazardous

situation that, if not avoided, could result in property damage.

This icon signifies supplemental important information.

LOG OUT

Bold, 10 point sans-serif typeface indicates a specific key or

button on screen to click.

8 Version 1.2

1.3. Organization of this Manual

This owner’s manual contains the most comprehensive set of information for the Despatch

Protocol 3™ controller, including installation instructions, theory of operation, operating

instructions, among other things.

1.4. Conventions

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 9

Protocol 3 Controller Owner’s Manual ABOUT THIS MANUAL

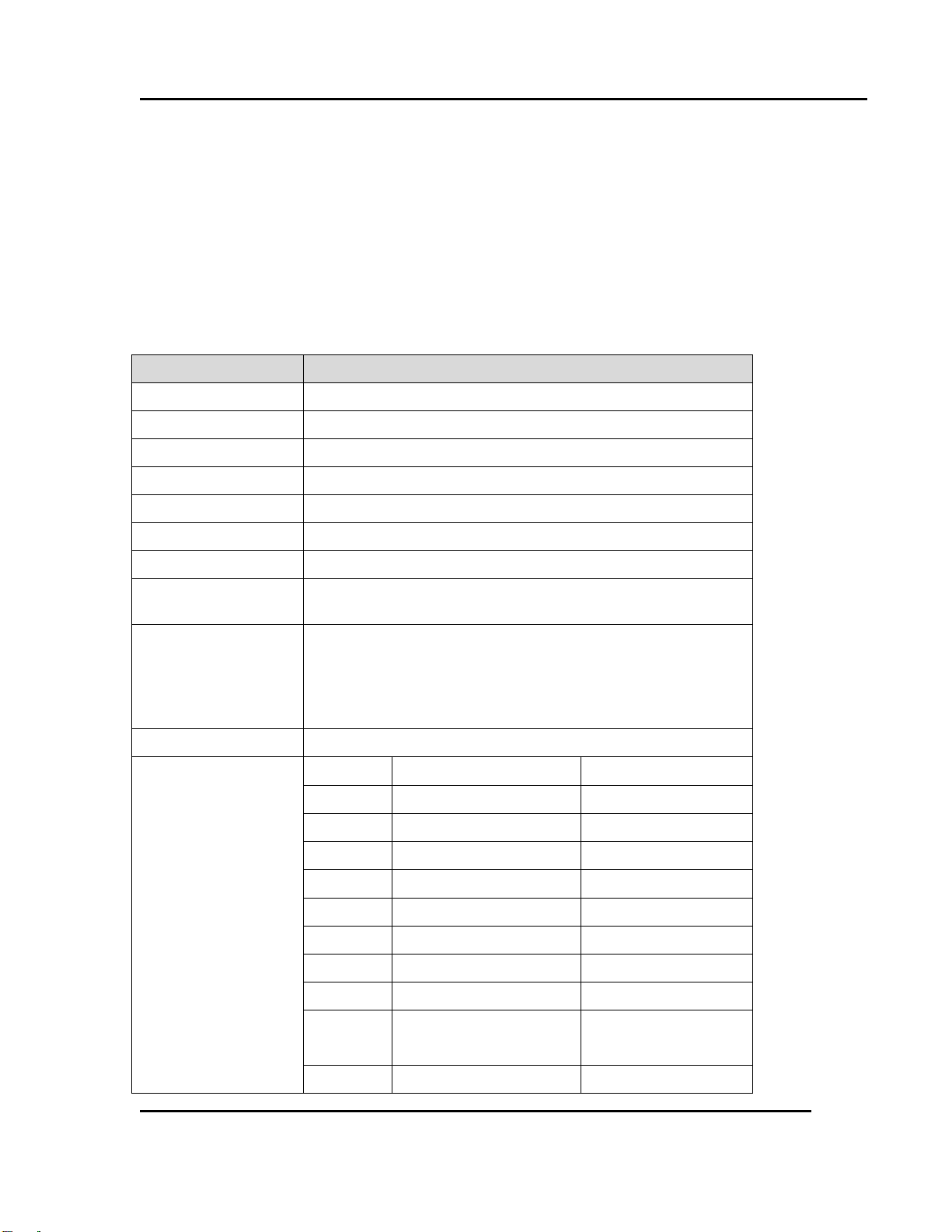

Item

Description

Sampling Rate:

4 per second

Resolution:

16 bits. Always four times better than display resolution.

Impedance:

>10MΩresistive, except DC mA (5Ω) and V (47kΩ)

Temp Stability:

Error <0.01% of span per °C change in ambient temperature

Supply Variation:

Supply voltage influence negligible within supply limits

Humidity Influence:

Negligible if non‐condensing

Process Display:

Displays up to 5% over and 5% under span limits

Process Variable

Input Offset:

Reading adjustable ± Controller Span. Values added to

Process Variable, Values subtracted from Process Variable.

Sensor Break

Detection:

Thermocouple & RTD—SSR output goes to 0

High Limit Sensor Break alarms activate

Linear (4 to 20mA, 2 to 10V and 1 to 5V only)—SSR

output goes to 0

Isolation:

Isolated from all outputs (except SSR driver) at 240V AC

Supported

Thermocouple Types

& Ranges:

Type

Range °C

Range °F

B

+100 to 1824°C

+211 to 3315°F

C

0 to 2320°C

32 to 4208°F

D

0 to 2315°C

32 to 4199°F

E

-240 to 1000°C

‐400 to 1832°F

J

-200 to 1200°C

-328 to 2192°F *

K

‐200 to 1200°C

‐328 to 2192°F *

L

0 to 762°C

32 to 1402°F *

N

0 to 1399°C

32 to 2551°F *

PtRh

20%: 40%

0 to 1850°C

32 to 3362°F

R

0 to 1759°C

32 to 3198°F

Version 1.2 9

1.5. Specifications

Specifications for the Protocol 3 controller include six sets of information:

Process Input (Table 1)

Outputs (Table 2)

Operating Conditions (Table 3)

Conformance Norms (Table 4)

Display (Table 5)

Data Recorder (Table 6)

Table 1. Process Input.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 10

ABOUT THIS MANUAL Protocol 3 Controller Owner’s Manual

Item

Description

S

0 to 1762°C

32 to 3204°F

T

‐240 to 400°C

‐400 to 752°F *

Optional decimal place can be displayed up to 999.9°C/F

Thermocouple

Calibration:

±0.1% of full range, ±1LSD (±1°C for internal CJC if enabled).

Linearization better than better ±0.2°C (±0.05 typical) on

ranges marked * in the table above. Linearization for other

ranges is better than ±0.5°C. BS4937, NBS125 & IEC584.

Supported RTD Types

& Ranges:

Type

Range °C

Range °F

3‐Wire

PT100

‐199 to 800°C

‐328 to 1472°F

NI120

‐80 to 240°C

‐112 to 464°F

Optional decimal place can be displayed up to 999.9°C/F

RTD Calibration:

0.1% of full range, ±1LSD

Linearization:

Linearization better than ±0.2°C (±0.05 typical).

PT100 input to BS1904 & DIN43760 (0.00385Ω/Ω/°C).

RTD Excitation:

Sensor current 150μA ±10%

Lead Resistance:

<0.5% of span error for max 50Ωper lead, balanced

Supported Linear

Types & Ranges:

Type

Range

Offset Range

mA DC

0 to 20mA DC

4 to 20mA DC

mV DC

0 to 50mV DC

10 to 50mV DC

V DC

0 to 5V DC

1 to 5V DC

V DC

0 to 10V DC

2 to 10V DC

Scalable from ‐9999 to 10000. Decimal point selectable from 0

to 3 places, but limited to 5 display digits (e.g. 9999.9)

Maximum Overload:

1A on mA input terminals, 30V on voltage input terminals

DC Calibration:

±0.1% of full range, ±1LSD

DC Input Multi‐Point:

Linearization:

Up to 15 scaling values can be defined anywhere between 0.1

and 100% of input

Item

Description

Relays

Type & Rating:

Single pole single throw (SPST); 2A resistive at 120/240VAC

Lifetime:

>200,000 operations at rated voltage/current

Isolation:

Basic Isolation

10 Version 1.2

Table 2. Outputs.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 11

Protocol 3 Controller Owner’s Manual ABOUT THIS MANUAL

Item

Description

Linear DC

Resolution:

8 bits in 250mS (10 bits in 1s typical, >10 bits in >1s typical)

Accuracy:

±0.25% of range, (mA @ 250W, V @ 2kW). Degrades linearly

to ±0.5% for increasing burden (to specification limits)

Isolation:

Basic Isolation

Item

Description

Temperature:

Operating: 0°C to 55°C (32°F to 131°F)

Storage: –20°C to 80°C (-4°F to 176°F)

Relative Humidity:

20% to 95% non‐condensing

Supply Voltage and

Power:

100 to 240VAC ±10%, 50/60Hz, 20VA

Item

Description

EMI:

CE: Complies with EN61326

Safety Considerations:

CE: Complies with EN61010‐1. UL, cUL to UL61010C‐1.

Pollution Degree 2, Installation Category II

Front Panel Sealing:

IP65 rating. IP20 behind the panel. (IP rating not recognized /

approved by UL)

Front Panel Cleaning:

Wash with warm soapy water and dry immediately. Close the

USB cover (if fitted) before cleaning.

Item

Description

Display Type:

160 x 80 pixel, monochrome graphic LCD with a dual color

(red/green) backlight

Display Area:

66.54mm (W) x 37.42mm (H)

Display Characters:

0 to 9, a to z, A to Z, plus ( ) ‐ and _

Version 1.2 11

Table 3. Operating Conditions (For indoor use).

Table 4. Conformance Norms.

Table 5. Display.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 12

ABOUT THIS MANUAL Protocol 3 Controller Owner’s Manual

Item

Description

Recording Memory:

1Mb non‐volatile flash memory. Data retained when power is

turned off

Recording Interval:

1; 2; 5; 10; 15; 30 seconds or 1; 2; 5; 10; 15; 30 minutes

Recording Capacity:

Dependent on sample rate and number of values recorded.

Two values can be recorded for up to 7 days at 10s intervals.

More values or faster sample rates deduce the maximum

duration.

RTC Battery Type:

VARTA CR 1616 3V Lithium. Clock runs for >1 year without

power (Part # 274030)

RTC accuracy:

Real Time Clock error <1 second per day

12 Version 1.2

Table 6. Data Recorder.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 13

Protocol 3 Controller Owner’s Manual SAFETY

Danger!

Electrical panels contain high voltage. Disconnect and lock out the

power supply before working inside any electrical panels. Failure to

lock out the power supply will result in death or injury.

Version 1.2 13

2. Safety

2.1. Safety Information

Do not work on the Protocol 3 controller without reading and understanding this section which

contains important information and warnings. Ignoring these warnings can result in death, serious

injury or damage to the machine and product.

2.1.1. Lockout

Machine lockout places the Protocol 3 controller into a zero energy state and prevents accidental

machine start up. Always follow the Lockout Procedure described in this Section before cleaning,

maintaining or repairing the Protocol 3 controller. An accidental start-up, while working on the

Protocol 3 controller, can result in serious injury or death.

2.1.1.1. Lockout Requirements

1. Every power source that can energize any element of the Protocol 3 controller must be shut

off at the closest possible power source. This includes air, water, nitrogen and electricity,

including the Disconnect Switch.

2. After energy sources are locked out, test to ensure circuits are de-energized.

2.1.1.2. Lockout Procedure with Despatch Products

Personnel authorized to lockout equipment must have the necessary locks to perform the lockout.

1. Physically disconnect all electrical power to the machine or lockout (with a padlock) the

appropriate breaker or disconnects.

2. Close all valves and bleed off any pressure.

3. Test for power by attempting a start with the machine controls.

4. Identify the Lockout Condition with a tag on the electrical disconnect and pneumatic shut off

valves.

5. When work is complete, remove all tags and restore the machine to its working state.

2.2. Maintenance

Only qualified and trained personnel should perform maintenance or repair.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 14

SAFETY Protocol 3 Controller Owner’s Manual

Danger!

Contact with energized electrical sources will result in serious

injury or death.

Danger!

Always disconnect all power before extinguishing a fire.

Attempting to extinguish a fire in a machine connected to

electrical power will result in serious injury or death.

14 Version 1.2

2.3. Electrical Power

Only qualified and trained personnel should perform electrical maintenance or electrical repair.

Before performing maintenance, disconnect all electrical power from the machine. Use a

padlock and lockout all disconnects feeding power to the machine.

Never clean or repair the controller when in operation.

Unauthorized alterations or modifications to Protocol 3 controller are strictly forbidden.

Never modify any electrical circuits. Unauthorized modifications can impair the function and

safety of the Protocol 3 controller.

2.4. Fire

Keep the Protocol 3 controller clean and free of scrap materials, oil or solvents to prevent the

possibility of fire. In the event of fire, use a fire extinguisher as follows.

1. De-energize the machine immediately by pushing an Emergency Stop push button (if

supplied).

2. Turn off the remote main disconnect (customer supplied disconnect).

3. If the fire is in the workspace, keep the door closed.

4. Extinguish the fire.

2.5. Equipment Lockout Requirements

To prevent injury or equipment damage during inspection or repair, the Protocol 3

controller must be locked out.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 15

Protocol 3 Controller Owner’s Manual THEORY OF OPERATION

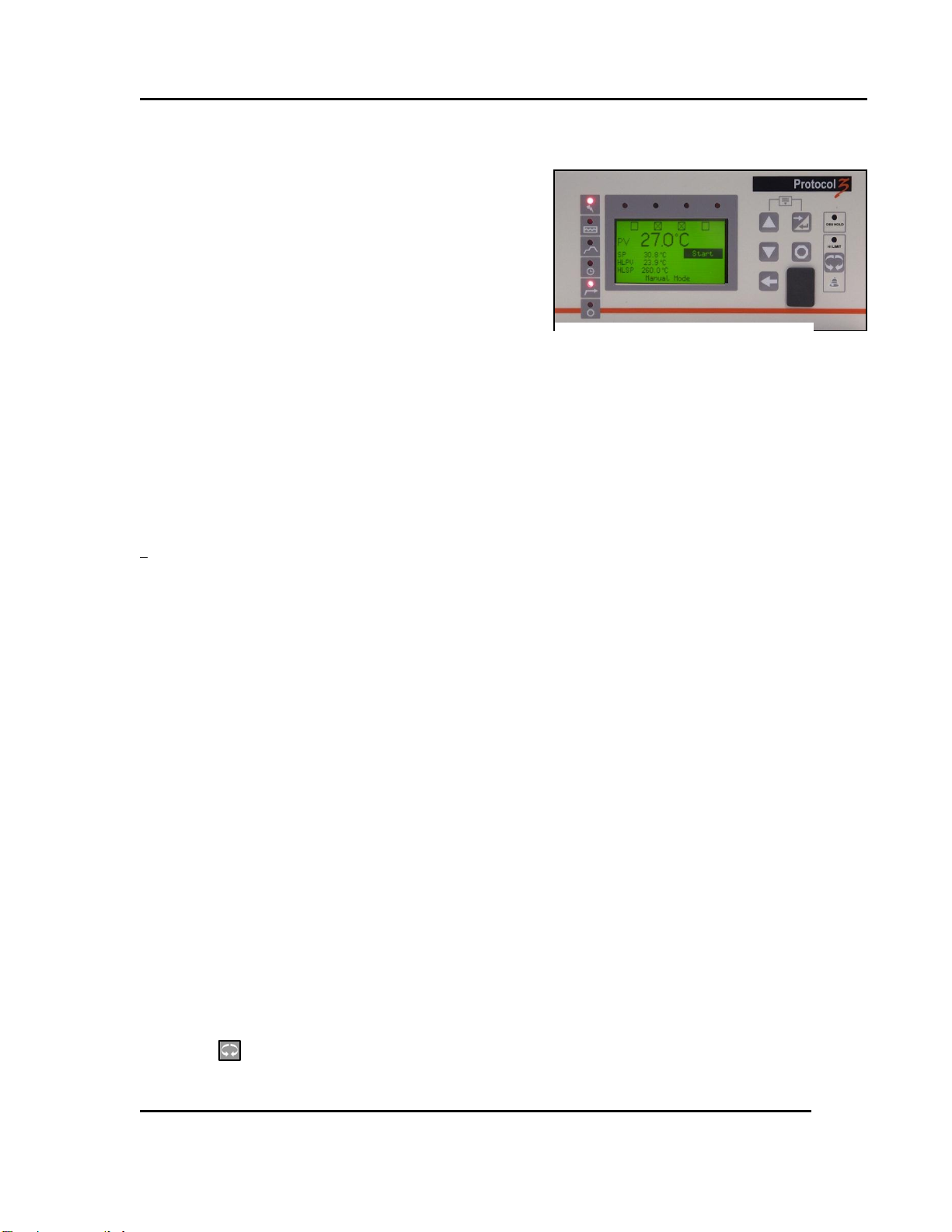

Figure 1. Operator Interface.

Version 1.2 15

3. Theory of Operation

The Protocol 3 is a microprocessor based digital

temperature controller designed for simple and flexible

oven operation (Figure 1). The Protocol 3 controller

operates as a dual-functioning controller/high limit

instrument. The control portion utilizes a

time-proportioning voltage signal to control heating

devices with minimal temperature fluctuations.

The high limit portion protects the product and/or the

oven from overheating. If the product being processed has a critical high temperature limit, the

high limit setpoint should be set to a temperature somewhat below the temperature at which the

product could be damaged. If the product does not have a critical high temperature limit, the high

limit setpoint should be set 5 to 15 degrees higher than the maximum programmed setpoint at

which the oven will operate.

The Protocol 3 controller provides three primary operating modes:

Manual: Oven operates continuously at a fixed temperature until turned off.

Timer: Oven operates at a fixed temperature for a user-selected time period, and then

automatically turns off.

Profile: Temperatures increase or decrease as defined by 255 segments that can be allocated

to 64 ramp and soak profiles. The profiles can be linked to provide additional temperature

combinations.

The Protocol 3 controlled is equipped to allow a ramp/soak temperature control, which maintains

oven temperature with either a fixed setpoint or a ramp/soak profile.

3.1. System Control—In General

The Protocol 3 controller provides outputs for the cooling fan, door lock switch/door release

pushbutton, and optional beacon light

A number of profiles for oven heating cycles are stored in the Protocol 3 controller. Access

profiles using the Protocol 3 keypad

The Protocol 3 controls the solenoid valves in an inert atmosphere oven for purge, maintain

and water cooling operation

The Protocol 3 can also be operated remotely with a PC running Protocol Manager software.

3.1.1. High-Limit Function

The Protocol 3 controller has an integrated high limit function which disables the heater output

when tripped. The High-Limit temperature is displayed as HLPV (Manual Mode only).

If the high limit trips, the Hi-Limit indicator will light and the relay must be manually reset.

Allow the oven to cool several degrees below the setpoint (or increase the high limit setpoint) and

then press . The indicator will turn off.

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 16

THEORY OF OPERATION Protocol 3 Controller Owner’s Manual

16 Version 1.2

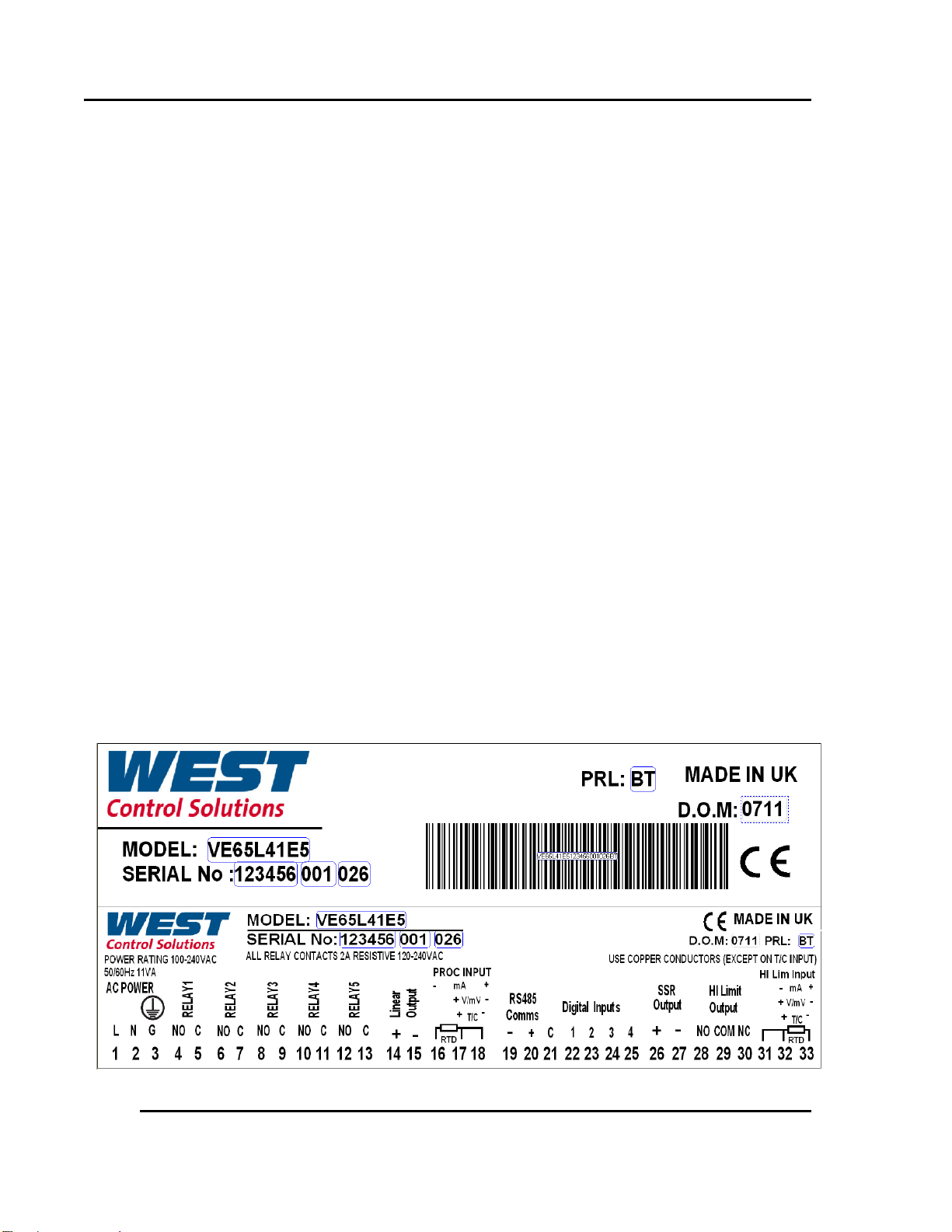

3.1.2. Outputs

The Protocol 3 controller comes standard with an output signal that can transmit temperature

data, setpoint data or control power to a user-supplied recording device. Output relays (five) can

also signal user-specified events or alarm to external devices (Figure 2 and Figure 3).

Heating output: The control output is a DC voltage open-collector output which is

time-proportioned and designed to control a heat control device such as a solid state relay.

High limit: The high limit output is a SPDT relay which is energized under normal operating

conditions. If the control senses a temperature higher than the high limit setpoint, or if there is

a sensor error, the high limit relay will de-energize until the condition is cleared and Reset is

pressed. When the high limit relay is de-energized, the heater is disabled.

Retransmission: The retransmission output is a signal that is proportional to the process

temperature, setpoint or control power:

o 0-5V

o 0-10V

o 2-10V

o 020 ma

o 4-20 ma

o 0-10VDC Power Supply

The signal can be an input to other devices such as a chart recorder.

Relays: The five SPST dry contact relay outputs can be configured to function as alarms,

events, or end of cycle. These outputs can be utilized in Manual, Timer or Profile Modes.

3.2. Remote Communication

When used with a PC running Protocol Manager™ software, the Protocol 3 controller allows an

operator to remotely control the oven, download recipes and log data.

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 17

Protocol 3 Controller Owner’s Manual THEORY OF OPERATION

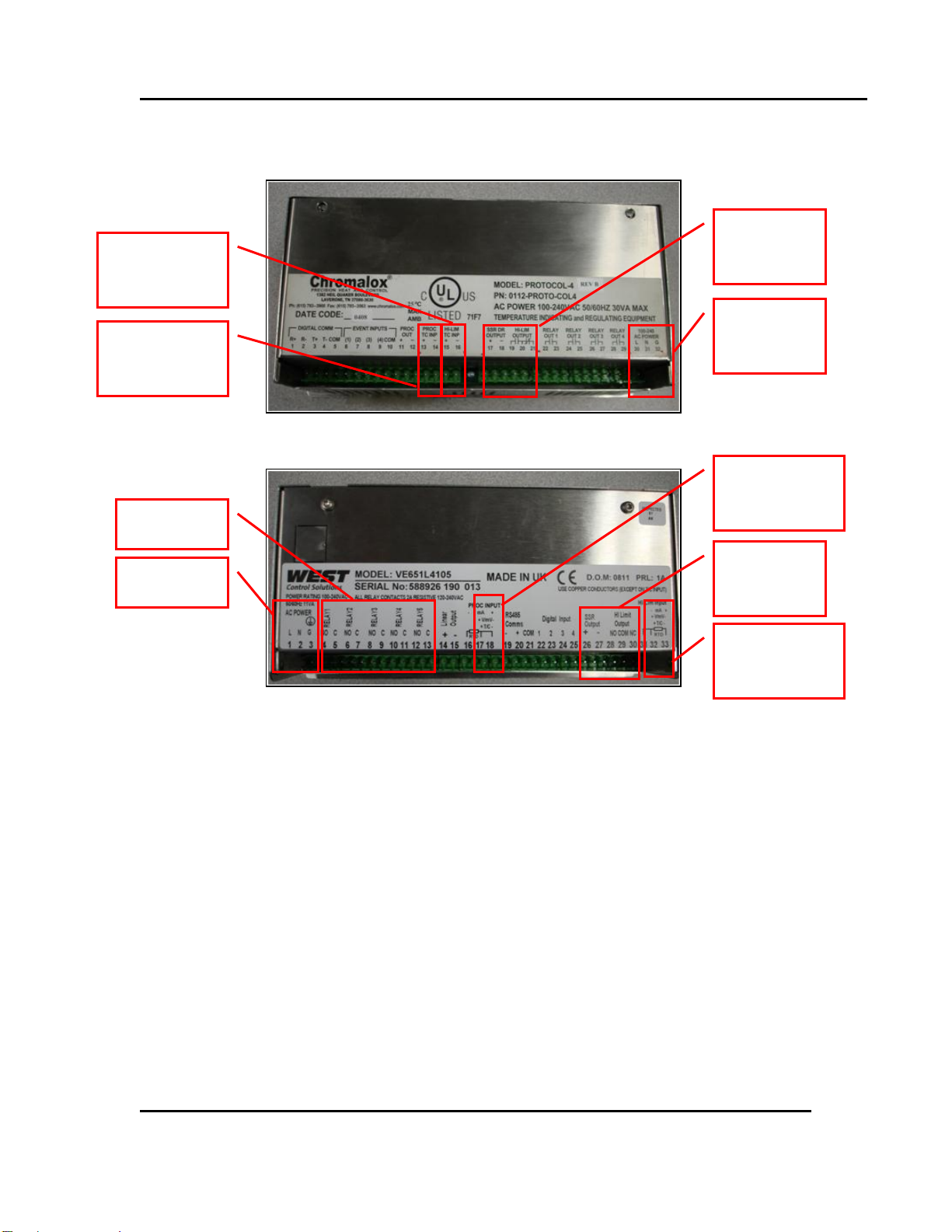

Protocol Plus Rear Panel

Protocol 3 Rear Panel

Former

Connections

New Power

Connections

Former SSR

Connections

New SSR

Connections

Former Control

Connections

Former Hi-limit

Connections

New Control

Connections

New Hi-limit

Connections

Relays

Figure 3. Protocol Plus to Protocol 3 Connection Conversions.

Figure 2. Typical Controller Output Sticker.

Version 1.2 17

and Hi-Limit

Thermocouple

Power

Thermocouple

Thermocouple

and Hi-Limit

Thermocouple

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 18

ASSEMBLY & SETUP Protocol 3 Controller Owner’s Manual

Danger!

All grounding and safety equipment must be in compliance with

applicable codes, ordinances and accepted safe practices.

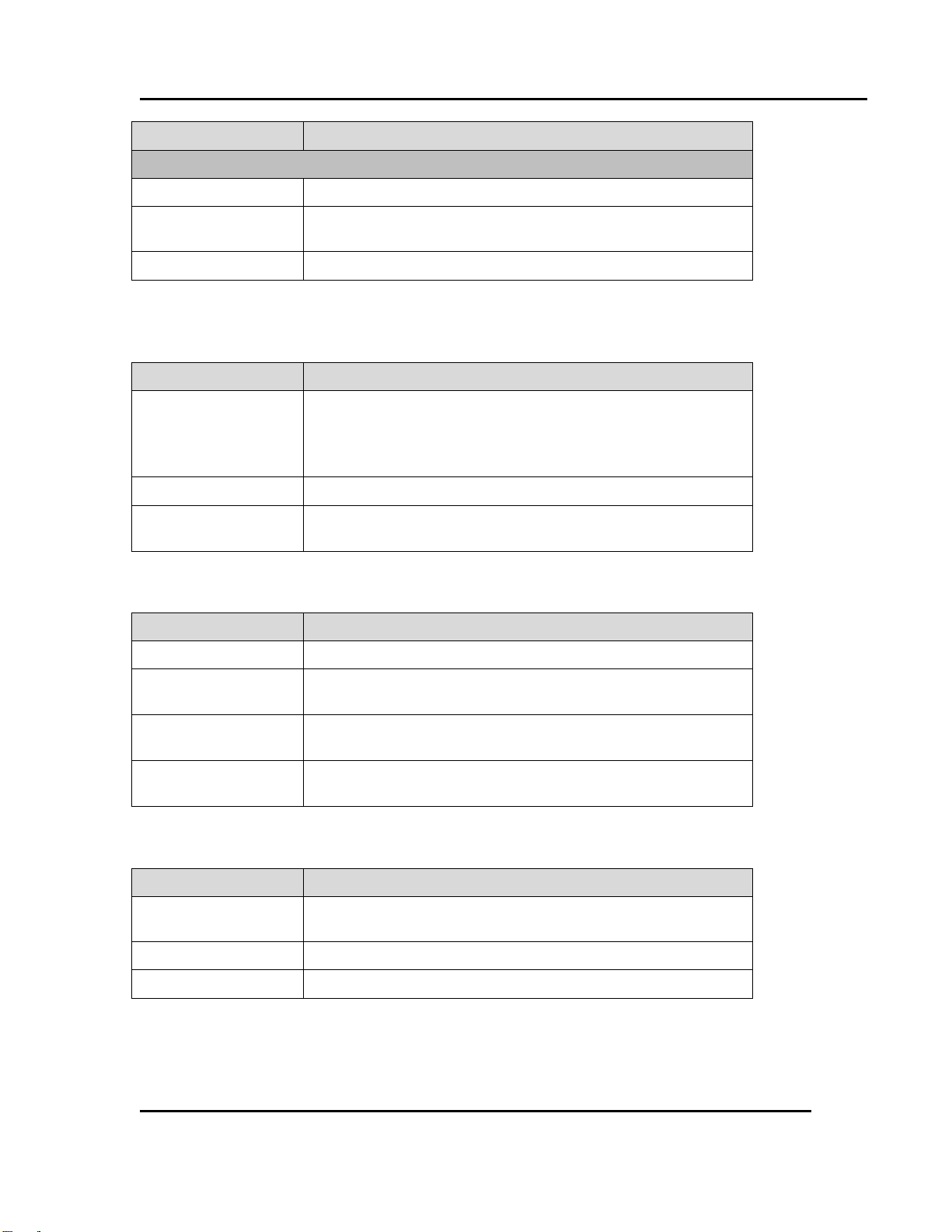

Terminal Block

Former

Protocol Plus Connections

New

Protocol 3 Connections

Three pin terminal block for

power leads

Terminals 30, 31, 32

Terminals 1, 2, 3

Five pin terminal block for

SSR and Hi-limit

Terminals 17, 18, 19, 20, 21

Terminals 26, 27, 28, 29, 30

Remove the four-pin terminal

block from thermocouples and

rewire with two three-pin

blocks.

Control Thermocouple

Terminals 13, 14

Control Thermocouple

Terminals 17, 18

Hi-limit Thermocouple

Terminals 15, 16

Hi-limit Thermocouple

Terminals 32, 33

Warning!

Disconnect the main power switch or power cord before

attempting any repair or adjustment.

18 Version 1.2

4. Assembly & Setup

4.1. Install the Protocol 3 Controller

When replacing a Protocol 3 controller, follow the steps below. Tools required for installation

include ¼” socket set with #1 bit, #2 Philips screwdriver.

1. Disconnect the power.

2. Unplug all terminals on the rear of the control, noting the proper connections (Figure 3).

3. Remove the retaining clips for the controller.

4. Remove the controller.

5. Insert the new controller into the panel.

6. Fasten the retaining clips.

7. Re-plug all terminals.

8. Secure the control panel.

4.2. Protocol 3 Controller Conversion with NO Options

To replace the older model Protocol Plus controller with the newer Protocol 3 controller, connect

terminal blocks as indicated in Table 7 and Figure 3.

Table 7. Protocol Plus to Protocol 3 Controller Conversion.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 19

Protocol 3 Controller Owner’s Manual ASSEMBLY & SETUP

Version 1.2 19

4.3. Setting Up Remote Communication

Remote communication between the Protocol 3 controller and a PC running the Despatch

Protocol Manager software involves providing each controller with a unique address and

following the communication protocol procedures. Up to 32 separate controllers can be run from

a PC running the Despatch Protocol Manager software. See the Protocol Manager Instruction

Manual for the complete set-up procedure.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2013 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 20

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Users and operators of this controller must comply with

operating procedures and training of operating personnel as

required by the Occupational Safety and Health Act (OSHA) of

1970, Section 5 and relevant safety standards, and other safety

rules and regulations of state and local governments. Refer to

the relevant safety standards in OSHA and National Fire

Protection Association (NFPA), Section 86 of 1990.

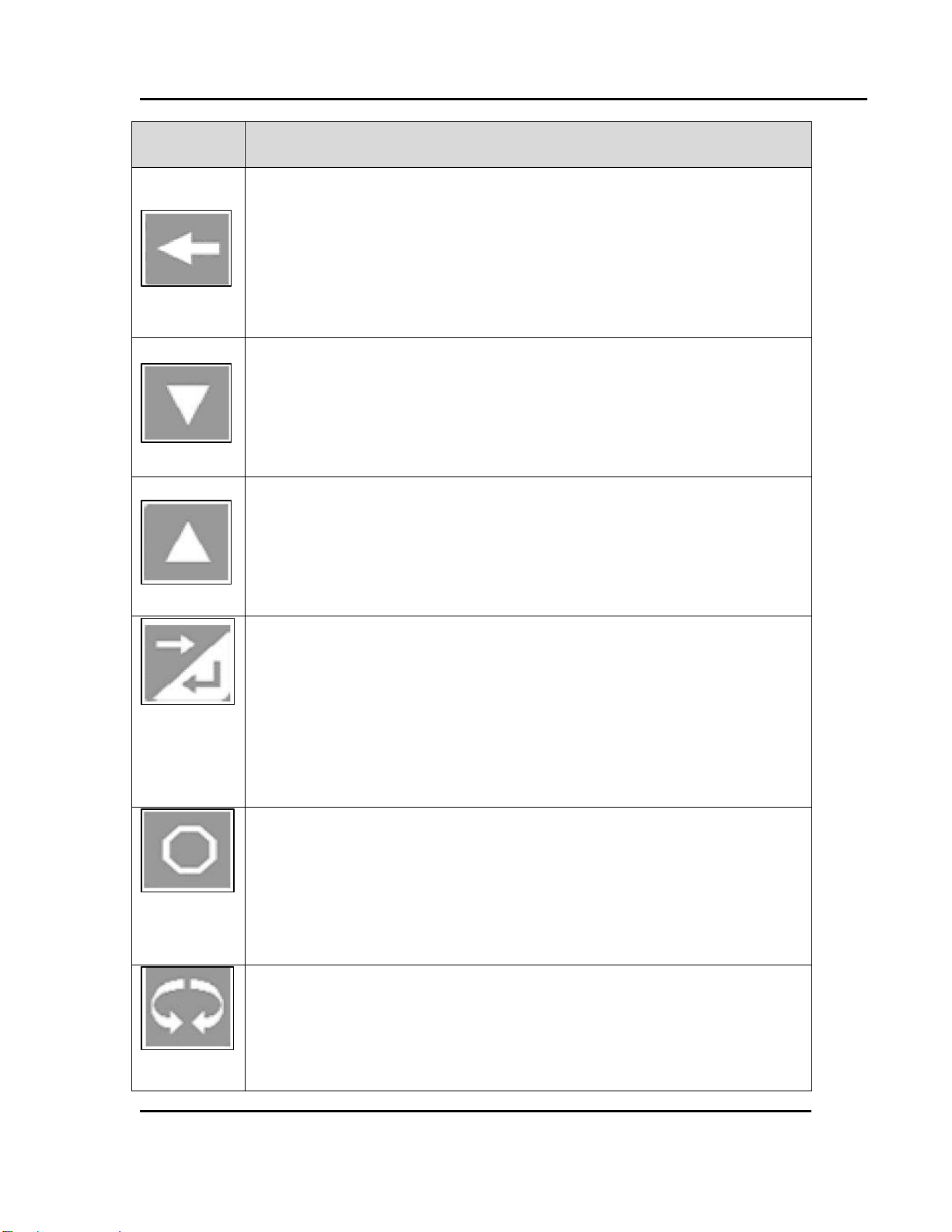

Keypad

Button

Function

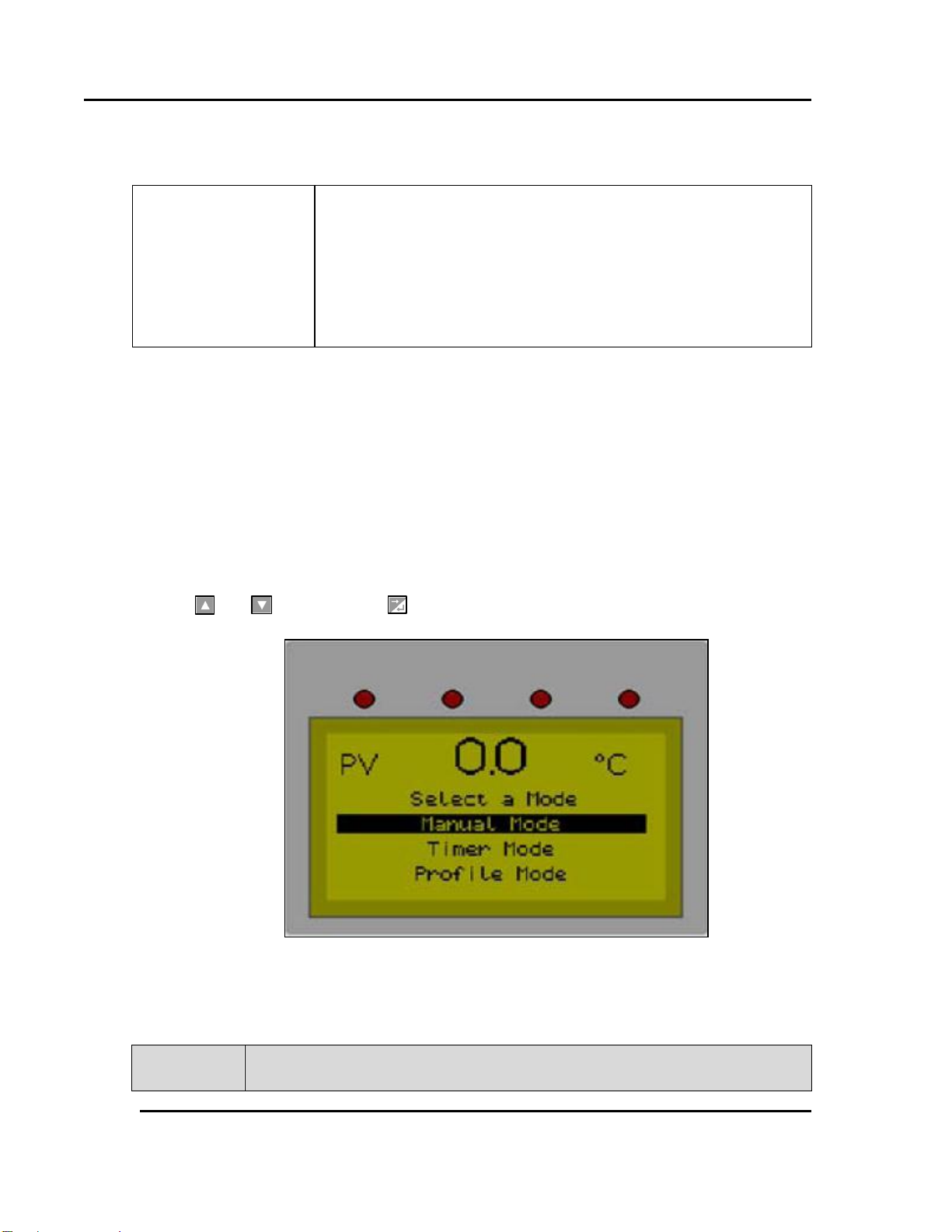

Figure 4. Select a Mode Display.

20 Version 1.2

5. Working with Operating Modes

5.1. User Controls

Each Protocol 3 Controller has six keypad switches (Table 8). Use the buttons to navigate user

menus, adjust parameter values and control outputs. In configuration screens, a context sensitive

scrolling help-text displays user-guides about the function of the keys across the bottom of the

screen.

The Protocol 3 Controller has nine LEDs which indicate a variety of instrument functions (Table

9).

When the Protocol 3 Controller is first powered ON, the screen displays Select a Mode (Figure

4). Use and to navigate and to select the highlighted mode.

Table 8. Keypad Buttons and Functions.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 21

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Keypad

Button

Function

Navigate to previous screen

Press to move back to the previous parameter or screen in the current

mode.

NOTE: Pressing this switch updates the instrument to the value

displayed. If editing a parameter, ensure the current (highlighted)

parameter value is correct before pressing.

Navigate down through menu/parameter lists

Menus and configuration choice screens: Press to move to the next item on

the list.

Editable values: Press to decrease. Press and hold to speed the change.

Trend View: press to move the Cursor Line back through stored data

points.

Navigate up through menu/parameter lists

Menus and configuration choice screens: Press to move to the previous

item on the list.

Editable values: Press to increase. Press and hold to speed the change.

Trend View: press to move the Cursor Line forward through stored data

points.

Navigate to next item on a screen or to next screen

Press to move forward to the next parameter or screen in the current mode.

Enables Edit on parameters in the Main Mode selections.

NOTE: Pressing this switch updates the instrument to the value

displayed. If editing a parameter, ensure the current (highlighted)

parameter value is correct before pressing.

Manual, Timer and Profile Mode: press to stop current process

In Manual Mode, pressing switch disables the controlling output

In Timer Mode, pressing switch stops timer and disables controlling output

In Profile Mode, pressing switch stops current profile and disables

controlling output

Reset Latched High Limit relay if below alarm condition

If High Limit alarm is active, press to release the High Limit relay.

NOTE: This switch releases the High Limit relay only if the controller is

Version 1.2 21

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 22

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Keypad

Button

Function

not in the High Alarm State (LED indicator turned OFF).

and to move up one menu level:

Simultaneously press

From Select a Mode, pressing both moves to the main menu.

From Sub-menus, press both several times to reach the main menu.

NOTE: Simultaneously pressing these switches updates the instrument to

the value displayed. If editing a parameter, ensure the current

(highlighted) parameter value is correct before pressing.

LED

Function

Power LED: When lit, indicates power to the device.

Heater LED: When lit, indicates primary heating output is active.

Profile LED: When lit, indicates a profile is currently running.

Timer LED: When lit, indicates a timer is currently running.

Manual LED: When lit, indicates the controller is in Manual Mode.

22 Version 1.2

Table 9. LEDs and Functions.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 23

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

LED

Function

Cycle Complete LED: When lit, indicates the controller is currently stopped.

When lit during a profile or Timer Mode, indicates process value has deviated

from the soak value indicated by the controller. Set Soak Deviation value in the

Profile Configuration mode or in the Timer Mode from the Main Menu. See

Troubleshooting Section 7 for more information.

When lit indicates the controller has exceeded the High Limit Value. Set High

Limit Alarm Value and Hysteresis in the Alarm Configuration menu.

(Four LEDs

located above

LCD display)

When lit, indicates relays 1-4 are active. Relay can be assigned as an Event,

Alarm or Cycle.

Change configuration controls depending on the mode used.

Refer to the specific operating instructions below, for more

information.

Regularly backup critical system data according to your

company policies. Be sure to back up configuration and profiles

to a removable memory device. Refer to Section 5.5.1 for more

information.

Version 1.2 23

5.2. First Screens

At initial power-up, control is in Select a Mode. This screen allows the choice of manual mode,

timer mode or profile mode.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 24

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Four relay LEDs

Relay navigational boxes

Figure 5. Manual Mode Display Screen.

24 Version 1.2

5.2.1. Manual Mode

Manual Mode allows the oven to operate continuously at a fixed temperature until turned off. Use

Manual Mode (Figure 5) to control Set Point, High Limit Value and four relays.

Better explanation:

5.2.1.1. Display Manual Mode

From the Select a Mode screen, press or to navigate to Manual Mode. Press to select

the highlighted option. Press to exit from Manual Mode and to stop all outputs.

5.2.1.2. Start Manual Mode

1. Navigate to and highlight Manual Mode.

2. Press to display the Manual Mode screen.

3. Manual Mode allows you to set the setpoint (SP), and the High Limit set point (HLSP).

a. Press or to navigate through the menu.

b. Select and highlight the menu item.

c. Press .

d. Press or to change values.

e. Press to select the value.

4. Manual Mode allows you to set event relay status

a. Press or to navigate to and select the appropriate relay (Figure 5).

b. Press to toggle the relay on and off.

5. Once all parameters are set, press or to navigate to and highlight Start.

6. Press to start the process.

a. Press to abort the process.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 25

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Hours

Seconds

Figure 6. Timer Mode Display Screen.

Version 1.2 25

b. After pressing , press to return to Select a Mode screen

7. Adjust the temperature setpoint while running in Manual or Timer Mode by:

a. Press .

b. Press or to select mode of operation.

c. Press .

d. Press or to change the SP value.

e. Press .

f. Press to return to normal display.

8. Return to Stopped Mode at any time, press and the Cycle Complete LED will illuminate

Press to select a mode screen.

5.2.2. Timer Mode

Use Timer Mode to control Time Set Point: when

the time expires, the control output is turned OFF

(Figure 6).

1. Navigate to and highlight Timer Mode.

2. Press or to navigate to the desired

time or temperature units.

3. Press to select the value to change.

4. Press or to change value.

5. Press to enter the desired value.

6. Timer Mode allows you to set event relay status:

a. Press or to navigate to and select

the appropriate relay (Figure 5).

b. Press to toggle the relay ON and OFF.

7. Set all parameters then press or to navigate to and highlight Start.

8. Press to start the process.

a. Press to abort the process

b. Press to return to Select a Mode screen.

9. Adjust the temperature setpoint while running in Manual Mode or Timer Mode by:

a. Press .

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 26

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

26 Version 1.2

b. Press or to navigate to the desired time or temperature units.

c. Press .

d. Press or to change the SP value.

e. Press .

f. Press to return to normal display.

10. To return to Stopped Mode at any time, press and the Cycle Complete LED will

illuminate.

11. Press to return to Select A Mode screen.

5.2.3. Profile Mode

Navigate to HLSP to set the High Limit Setpoint before running a profile. Use Profile Mode to

select and run profiles that are programmed into the unit (Figure 7). Press or to

navigate, to select the highlighted profile. Press to start profile. Press to stop the

profile and to exit Profile Mode (profile must be stopped to exit Profile Mode).

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2013 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 27

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Status bar shows status of profile and segment.

If you are unable to select a desired profile, verify that Remote

Profile Control is Disabled. When Remote Profile Control is

Disabled, the Select Profile to Start reads “Digital”

Figure 7. Profile Mode.

Version 1.2 27

5.2.4. Main Menu

The Main Menu (Figure 8) provides access to a number of useful sub menus (Table 10). Access

the Main Menu from the Select a Mode screen (Figure 4) by:

1. Simultaneously press and .

2. Press or to navigate, to select the highlighted option.

3. Press to enter that mode.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 28

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Menu Item

Description

Mode Selection

Return to Select a Mode screen

Timer Mode

See Timer Mode Option (Section 5.2.2)

Profile Setup

Create, edit and delete profiles

Recorder Control

Start, stop and delete recordings on unit.

USB Menu

Access all read/write options to USB device

Configuration Menu

Program all input and output settings

Automatic Tuning

Opens selection for Auto and Self Tune features

Product Information

Display information about unit

Service Information

Display name and address of service department

Figure 8. Main Menu.

28 Version 1.2

Table 10. Sub Menu Descriptions

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 29

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Regularly backup critical system data according to your

company policies. Be sure to back up configuration and profiles

to a removable memory device. Refer to Section 5.5.1 for more

information.

Find General Configuration Parameters in Section 5.6. Find

Profile Setup in Section 5.3

Note that other options are not visible until a profile is created.

Figure 9. Profile Setup.

Version 1.2 29

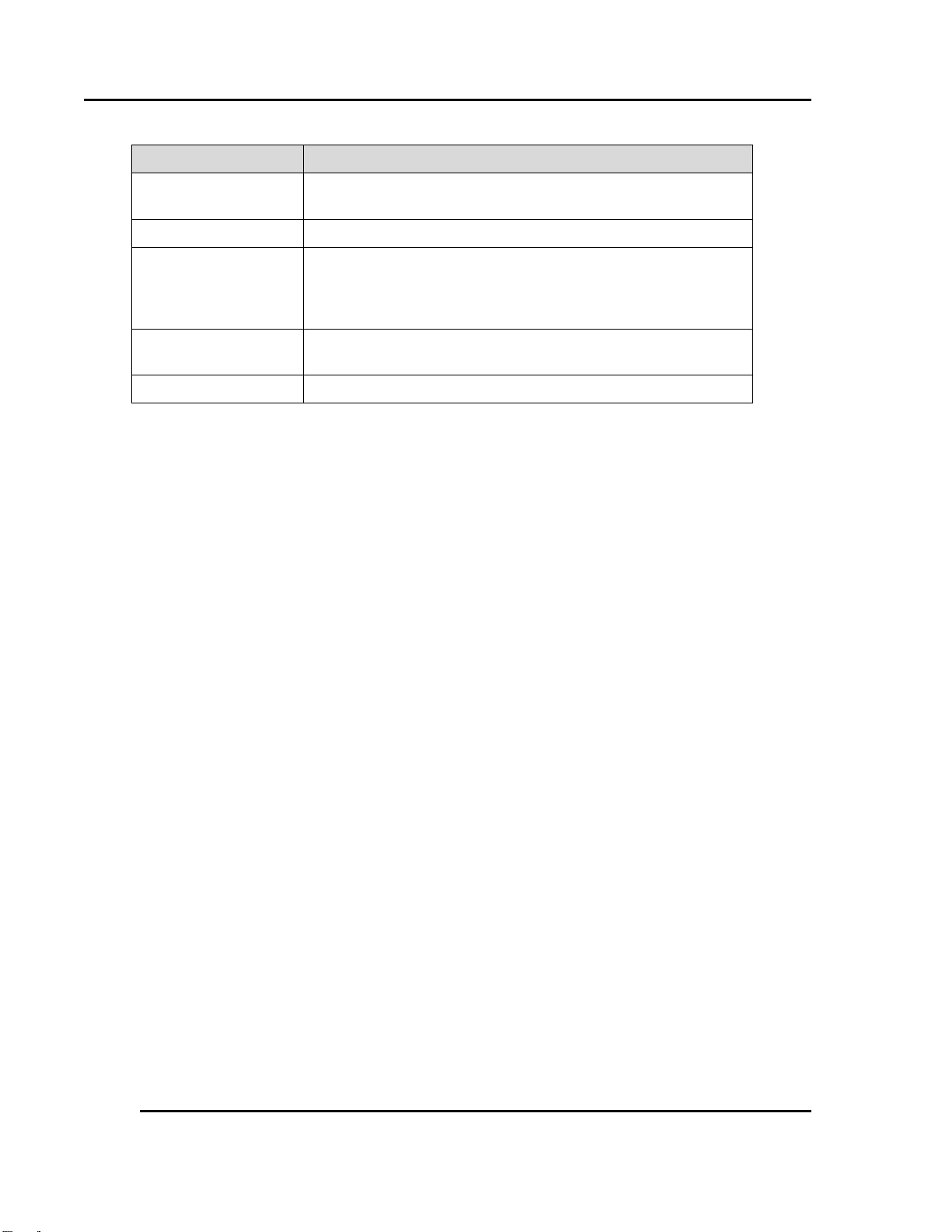

5.3. Setting up a Profile

Use Profile Setup to create, edit and delete profiles (Figure 9). Access the Profile Setup from the

Main Menu screen. The Profiler option allows storage of up to 255 profile segments, shared

between a maximum of 64 Profiles. Each profile controls the value of the setpoint over time;

increasing, decreasing or holding its value as required. See Table 11 for Profile Setup options.

Figure 10 (Table 12) shows the Protocol 3 Controller configuration options. Table 13 shows the

full list of Profile Parameter options.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 30

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Menu Item

Description

General Configuration

Enable remote Profile control and Profile automatic start

Create a Profile

Create profile

Edit a Profile Header

Change the name of any created profile

Edit a Profile Segment

Change the settings of a specific segment in a profile

Insert a Segment

Create a new segment in an existing profile

Delete a Segment

Delete a segment in an existing profile

Delete a Profile

Delete an existing profile

Delete all Profiles

Delete all profiles in the unit

30 Version 1.2

Table 11. Profile Setup Options.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 31

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Figure 10. Profile Setup Menu.

Version 1.2 31

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 32

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Step #

Protocol 3 Descriptor

Option

Description

General Configuration

1.

Remote Profile Control

Disabled

Disallow a remote source to run a profile

Enabled

Allow a remote source to run a profile

2.

Automatic Start

Disabled

Disallow use of delayed start time

Enabled

Allow controller to start at a later time with

programmed delay

Create a Profile

3.

Enter a Profile Name

Unique name for each profile using up to 8

characters

4.

Profile Start Trigger

None

Profile start not delayed

After Delay

Set hours and minutes to delay before

starting the profile

Day and Time

Set time of day (hour and minutes) and day

of week to start profile. Options include

each day of the week and combinations of

days.

5.

Profile Recovery

Method

If power-down occurs while this profile is

running, specify the action for the controller

to take during power-up:

Control Off

Controller goes to OFF

Restart Profile

Controller restarts current profile

Maintain Last

Profile SP

Controller maintains previous profile

setpoint

Continue

Profile

Controller continues (for specified time) the

profile from where it was when power

failed.

Profile Abort Action

If program aborts, profile should:

Control Off

Controller goes off

6.

Maintain Last

Profile SP

Choose the number of times to cycle the

program, up to an infinite number of times.

Edit a Profile Segment

7.

Edit Segment Number

Ramp Time

Set target setpoint (degrees centigrade)

Set the segment ramp time (hh:mm:ss)

Set the Auto-Hold Type: None, Above

Setpoint, Below Setpoint, Band.

Set Events 1-5: Press or to

toggle between Active and Inactive.

8.

Ramp Rate

Set the target setpoint (degrees

centigrade)

Set the segment ramp rate in units per

hour

Set the Auto-Hold Type: None, Above

Setpoint, Below Setpoint, Band.

Set Events 1-5: Press or to

toggle between Active and Inactive.

9.

Step

Set the target setpoint (degrees centigrade)

10.

Dwell

Choose time to dwell at setpoint.

Specify Auto-Hold type: None, Above

setpoint, Below setpoint, Band

32 Version 1.2

Table 12. Profile Setup Steps, Options and Descriptions.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 33

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Step #

Protocol 3 Descriptor

Option

Description

Set Events 1-5: Press or to

toggle between Active and Inactive

11.

Hold

Choose when to release Hold: Operator

Key Press or Time of Day

Set Events 1-5: Press or to

toggle between Active and Inactive

12.

Loop

Set the number of times to loop current

segment

Specify how to move back to the host

segment after specified loops: Ramp

time, hold

Set Events 1-5: Press or to

toggle between Active and Inactive

13.

Join

Joins one profile to another: specified

profile immediately follows first profile

Navigate to and highlight to select from

among the current profiles

Set Events 1-5: Press or to

toggle between Active and Inactive

14.

End

Ends the segment and creates the profile.

Choose segment type from: Control Off,

Maintain Last Profile SP, Control Off with

Events

15.

Repeat

Sequence

Then End

Repeats sequence specified number of

times and then ends the segment and

creates the profile. Along with enter

numbering of times to repeat sequence,

choose from: Control Off, Maintain Last

Profile SP, Control Off with Events

Version 1.2 33

5.3.1. Prepare for Profile Setup

From the Select a Mode screen, simultaneously press and to display the Main Menu

(Figure 8):

1. Navigate to and highlight Profile Setup.

2. Press to display Profile Setup Enter Profiler Mode Unlock Code screen.

3. Press to enter Unlock Code 0010.

4. Press to display the Profile Setup screen.

5. Press to move right and to move left. Press or navigate through

numbers, uppercase letters and lower case letters.

6. After entering the profile name, press as often as necessary to move to the next

screen.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 34

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Before initiating the Profile Setup, use the programming

worksheet (Section 8.3) to work out all parameters. Once the

Profile Setup is begun, setup must continue to the end or lose

all entered values.

When programming an oven with a gas-fired heater, note that

the burner can be started manually or by programming a profile

using the Protocol 3 controller.

34 Version 1.2

Table 12 will serve as a useful guide for both general configuration and setting up a profile.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 35

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Figure 11. Sample Profile.

Version 1.2 35

5.3.2. Sample Profile

Figure 11shows a graphic representation of the sample profile, while Figure 12 shows the

parameters entered to achieve that profile. Section 5.3.3 shows how to enter the profile.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 36

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Figure 12. Sample Profile Values.

36 Version 1.2

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 37

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Version 1.2 37

5.3.3. Key In the Sample Profile Setup

To help show the process of setting up a profile, this section uses the sample profile as an

example (from Figure 11 and Figure 12). Figure 10 shows the overall flowchart for working with

Profile Setup. For entering sample values, we choose the default values.

Navigate to and Enter Profile Setup

From Select a Mode screen, simultaneously press and to display the Main Menu:

1. Navigate to and highlight Profile Setup.

2. Press to display Profile Setup Enter Profiler Mode Unlock Code screen.

3. Press to enter Factory Unlock Code 0010.

4. Press to display the Profile Setup screen.

5. Press to select Create a Profile.

6. Press to enter mode.

7. Input unique Profile name: press to move right and to move left. Press or

to navigate through numbers, uppercase letters and lower case letters.

8. After entering the profile name, press as often as necessary to move to the next

screen.

9. For Profile Start Trigger, when None is highlighted, press to complete the entry.

10. For Profile Recovery Method, when Control Off is highlighted, press to

complete the entry.

11. For Profile Abort Action, when Control Off is highlighted, press to complete the

entry.

12. For How Many Time to Cycle Program, press and navigate to the desired

number of cycles.

a. Press to complete the entry.

Program Segment 1 according the Sample Profile (Figure 11 and Figure 12):

13. When Segment Number 1 displays, press .

14. Highlight Ramp Time and press .

15. For Target Setpoint,

a. Press or navigate to 100°C (212°F).

b. Press to complete the entry.

16. For Segment Ramp Time,

a. Press or navigate to 1 hour (01:00:00).

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 38

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Note: Last segment must be an End segment to exit Profile Entry

Mode.

38 Version 1.2

b. Press as needed to complete the entry.

17. For Auto-Hold Type, when None is highlighted, press to complete the entry.

18. For Event 1-5, press as needed to accept Inactive.

Program Segment 2 according the Sample Profile:

19. When Segment Number 2 displays, press .

20. Highlight Dwell and press .

21. For Dwell at 100.0°C (212 °F),

a. Press or navigate to 1 hour (01:00:00).

b. Press as needed to complete the entry.

22. For Auto-Hold Type, when None is highlighted, press to complete the entry.

23. For Event 1-5, press as needed to accept Inactive.

Program Segment 3 according the Sample Profile:

24. When Segment Number 3 displays, press .

25. Highlight Ramp Time and press .

26. For Target Setpoint,

a. Press or navigate to 20°C (68°F).

b. Press to complete the entry.

27. For Segment Ramp Time,

a. Press or navigate to 2 hours (02:00:00).

b. Press as needed to complete the entry.

28. For Auto-Hold Type, when None is highlighted, press to complete the entry.

29. For Event 1-5, press as needed to accept Inactive.

Finish Profile Creation:

30. When Segment Number 4 displays, press .

31. Highlight End and press .

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 39

Protocol 3 Controller Owner’s Manual WORKING WITH OPERATING MODES

Profile Parameter

Options

Profile Limits

Number of profiles = 64 maximum.

Total number of segments (all programs) = 255 maximum.

Loop Back Segments

1 to 9999 loops back to specified segment.

Profile Cycling

1 to 9999 or Infinite repeats per profile.

Sequence Repeats

1 to 9999 or Infinite repeats of joined profile sequences.

Segment Types

Ramp Up/Down over time, Ramp Rate Up/Down, Step, Dwell, Hold,

Join A Profile, End or Repeat Sequence Then End.

Time-base

All times specified in hh:mm:ss (Hours, Minutes & Seconds).

Segment Time

Maximum segment time 99:59:59 hh:mm:ss. Use loop-back for

longer segments (e.g. 24:00:00 x 100 loops = 100 days).

Ramp Rate

0.001 to 9999.9 display units per hour.

Hold Segment

Release

Release With Key-press, At Time Of Day or via a Digital Input.

Start From Value

1st segment starts from current setpoint or current PV input value.

Delayed Start

After 0 to 99:59 (hh:mm) time delay, or at specified day(s) & time.

Note: Enable Automatic Start in the Profile Setup: General

Configuration Menu. Delayed start will not operate unless

Automatic Start has been enabled.

Profile End Action

Selectable from: Control Off, Maintain Last Profile SP, Control

Off with Events. Use Controller Setpoint or Control Outputs Off.

Profile Abort Action

Selectable from: Keep Last Profile Setpoint, Use Controller Setpoint

or Control Outputs Off.

Power/signal Loss

Recovery Action

Selectable from: Continue Profile, Restart Profile, Keep Last Profile

Setpoint, Use Controller Setpoint or Control Outputs Off.

Auto-Hold

Off or Hold if input >Band above and/or below SP for each

segment.

Profile Control

Run, Manual Hold/Release, Abort or jump to next segment.

Profile Timing

Accuracy

0.02% Basic Profile Timing Accuracy.

± <0.5 second per Loop, End or Join segment.

Segment Events

Events turn on for the duration of the segment. For End Segments,

the event state persists until another profile starts, the user exits

from profiler mode, or the unit is powered down.

Version 1.2 39

a. For Segment End Type, with Control Off highlighted, press .

32. For Profile Created, press .

33. Press and to display the Main Menu. Press or to select Mode Selection

and press .

Table 13. Profile Parameter Options.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2013 by Despatch Industries.

Page 40

WORKING WITH OPERATING MODES Protocol 3 Controller Owner’s Manual

Figure 13. Recorder Control.

Figure 14. Recorder Status.

All recordings in the unit can be downloaded to a USB device

using the USB port and the USB Menu.

40 Version 1.2

5.4. Recorder Control

Use Recorder Control to start, stop and clear

recordings (Figure 13). Access the Recorder

Control from the Main Manu.

1. Navigate to and highlight Recorder