Page 1

PROTOCOL™

DIGITAL OVEN CONTROLLER

INSTRUCTION MANUAL

P/N 116087

REV. 9/97

E-72

Prepared by:

Despatch Industries

P.O. Box 1320

Minneapolis, MN 55420-1320

Customer Service 800-473-7373

Page 2

Notice

Users of this equipment must comply with operating procedures and training of

operation personnel as required by the Occupational Safety and Health Act (OSHA)

of 1970, Section 6 and relevant safety standards, as well as other safety rules and

regulations of state and local governments. Refer to the relevant safety standards

in OSHA and National Fire Protection Association (NFPA), section 86 of 1990.

Caution

Setup and maintenance of the equipment should be performed by qualified

personnel who are experienced in handling all facets of this type of system.

Improper setup and operation of this equipment could cause an explosion that may

result in equipment damage, personal injury or possible death.

Thank you for choosing Despatch Industries. We appreciate

the opportunity to work with you and to meet your heat

processing needs. We believe that you have selected the

finest equipment available in the heat processing industry.

At Despatch, our service does not end after the purchase

and delivery of our equipment. For this reason we have

created the Service Products Division within Despatch. The

Service Products Division features our Response Center for

customer service. The Response Center will direct and

track your service call to ensure satisfaction.

Whenever you need service or replacement parts, contact

the Response Center at 1-800-473-7373: FAX 612-781-

5353.

Thank you for choosing Despatch.

Sincerely,

Despatch Industries

Page 3

Despatch Product Warranty

Parts, Materials and Labor

Despatch warrants all parts and materials to be free from defects in material and workmanship for a period of one (1) year from the

date of shipment unless otherwise mutually agreed upon in writing, or 2,000 hours of operation, whichever occurs first. (Note:

Laboratory oven electric heaters are warranted for a period of five [5] years from date of shipment.)

Despatch will repair or replace, at Despatch’s option, FOB Despatch’s factory, parts and materials covered by this warranty.

Despatch is not responsible for parts or material failures resulting from misuse, abuse, inadequate preventive maintenance, acts

of nature, or non-conforming utilities, including electrical, fuel supply, environmental and intake/exhaust provisions. This warranty

also does not cover normal wear or routine maintenance parts and materials expressly designed as expendable/consumable and

replaceable.

Labor services for parts and materials replacement and repair to support this warranty are available at Despatch’s normal service

fees. This service is provided worldwide by a network of factory trained professionals.

Terms and Conditions

The foregoing warranty shall be deemed valid and binding upon Despatch if and only if the Customer:

1. Installs, loads, operates and maintains the equipment supplied hereunder in accordance with the instruction manual

provided upon delivery and product labeling affixed to the subject equipment.

2. Agrees to follow the Emergency Procedure spelled out below.

Exclusions/Limitations of Liability

This warranty DOES NOT cover expenses incurred in the process of diagnosing and/or repairing equipment resulting from:

a) operator error, b) attempted service or modifications by other than Despatch authorized technicians, c) any use of the equipment

which is inconsistent with the operation manual or labeling, d) inadequate preventive maintenance, or e) acts of nature, such as

floods, fire, earthquake, or acts of war or civil emergency.

Despatch shall not, in any event, be liable for indirect, special, consequential or liquidated damages or penalties, including loss of

revenue, profits or business opportunities resulting from interruption of process or production. Despatch shall further be held

blameless for any damages or expenses resulting from delays in our attempts to diagnose and repair the equipment, unavailability

of spare parts or inaccessibility of the equipment. Specifically excluded from this warranty is responsibility for internal and external

corrosion damages to the equipment.

Non-Compliance

Despatch reserves the right to suspend and withhold service as provided under this warranty in the event of non-compliance by

the Customer to any terms and conditions of this warranty. Further, Despatch is held harmless for any loss of production, incurred

expenses, and other inconveniences due to suspension of service under this non-compliance provision.

Emergency Procedure

In an emergency situation, Customer agrees to: a) immediately shut off fuel or energy supply (gas and electricity), b) call 911 for

emergency assistance if needed, and c) call Despatch Service.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES

WHATSOEVER, AND SPECIFICALLY THERE ARE NOT IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR

A PARTICULAR PURPOSE.

THE FOREGOING WARRANTY IS NOT TRANSFERABLE IN SITUATIONS WHERE EQUIPMENT OWNERSHIP IS

TRANSFERRED TO ANOTHER PARTY.

Worldwide Phone 612-781-5363; Worldwide Fax 612-781-5185; North American Phone 800-473-7373

Despatch Service

Please see reverse side for other service offerings BB5 (5/97)

Page 4

Despatch

Service Support Programs

Despatch continues to deliver exceptional products backed by a strong sense of responsibility and drive for long term customer

satisfaction. Your partnership with Despatch can offer even higher value through your subscription to one of Despatch’s high value

service programs.

Warranty

Despatch’s exclusive, comprehensive service programs start with the warranty which is described on the other side of this

document. This warranty can be expanded immediately to meet your most stringent service needs. Despatch Service will be able

to answer your service questions and provide a quotation for the immediate expansion of your product warranty.

Immediate Service Response

The key to an effective service program is response. Wherever your location, Despatch is only a phone call away. Our North

American customers can reach Despatch at 1-800-473-7373. Worldwide customers can call 1-612-781-5363 or FAX

1-612-781-5485. Our Customer Service Technicians have over 200 years combined experience and access to detailed design and

manufacturing documentation specific to your Despatch unit(s). This exacting level of service is a benefit only Despatch can provide

and means that you can expect speedy, accurate and the most cost effective response.

Field Service Network

A worldwide network of factory trained Service Professionals is available to support your Despatch equipment. From routine repair

to certified instrument calibration, the Despatch service network is positioned to respond to your needs. As a manufacturer of custom

equipment, our service programs are customized to meet your specific needs regarding:

1. Service scope

2. Response time

3. Preventive maintenance frequency and content

4. Payment method

Sustained Service Support

At Despatch, long term customer satisfaction means more than just responding quickly and effectively to our customers’ service

needs. It means offering comprehensive customer support well beyond the scope and duration of our initial warranty. Despatch

offers two basic service packages which are customized to each individual customer’s need. These service packages are titled Full

Service and Preventive Maintenance Plus+ service agreement products. Each is unique in the industry and offer the following

benefits:

1. Priority response for minimum production interruption

2. Preventive maintenance for longer product life

3. Discounts on parts and services

4. Various payment plans to ease budgeting and recording expenses

5. Reduce purchase ordering costs

Worldwide Phone 612-781-5363; Worldwide Fax 612-781-5185; North American Phone 800-473-7373

Despatch Service

Page 5

TABLE OF CONTENTS

INTRODUCTION ..................................................... 1

THEORY OF OPERATION .............................................. 2

Protocol ....................................................... 2

Keypad Controls ................................................ 3

Status Indicator LEDs ............................................ 4

Operating Modes ................................................ 5

Manual Mode ............................................. 5

Timer Mode ............................................... 5

Program Mode ............................................ 5

Calibration Zero Offset ............................................ 6

Tune Setting ................................................... 7

Protocol Hi-Limit ................................................. 8

INSTRUCTIONS ...................................................... 9

Start-Up ....................................................... 9

Manual Mode .................................................. 10

Startup .................................................. 10

Run .................................................... 10

Stop .................................................... 11

Timer Mode ................................................... 12

Startup ................................................. 12

Run .................................................... 13

Manually Stop ............................................ 13

Program Mode ................................................. 15

Startup .................................................. 15

Run .................................................... 18

Manually Stop ............................................ 18

i

Page 6

APPENDIX ......................................................... 19

Special Instructions ............................................. 19

Control Instrument .............................................. 20

Tune Mode .............................................. 20

Tuning Worksheet ......................................... 22

Calibration Mode .................................... 23

Calibration Recovery ................................. 28

Diagnostics Mode .................................... 29

Power Failure ....................................... 30

Programming Examples and Outline ........................... 31

Example 1 - Manual Mode ............................. 31

Example 2 - Timer Mode .............................. 32

Program Mode ...................................... 33

Example 3 - Program Mode ............................ 36

Example 4 - Program Mode ............................ 37

Example 5 - Program Mode ............................ 38

Troubleshooting ................................................ 39

ii

Page 7

INTRODUCTION

The special features of the Protocol™ include:

C PID Tuning

C Programmable up to 48 segments

C Built-in manual reset hi-limit control

C Built-in process timer

C Self-diagnostics

C Digital display

C Three (3) event outputs

C RS422/RS485 bi-directional communications capability

C Recursive profile capability

1

Page 8

THEORY OF OPERATION

This section describes the Protocol installed in the LAC, LAD, LFD and LND Series

ovens.

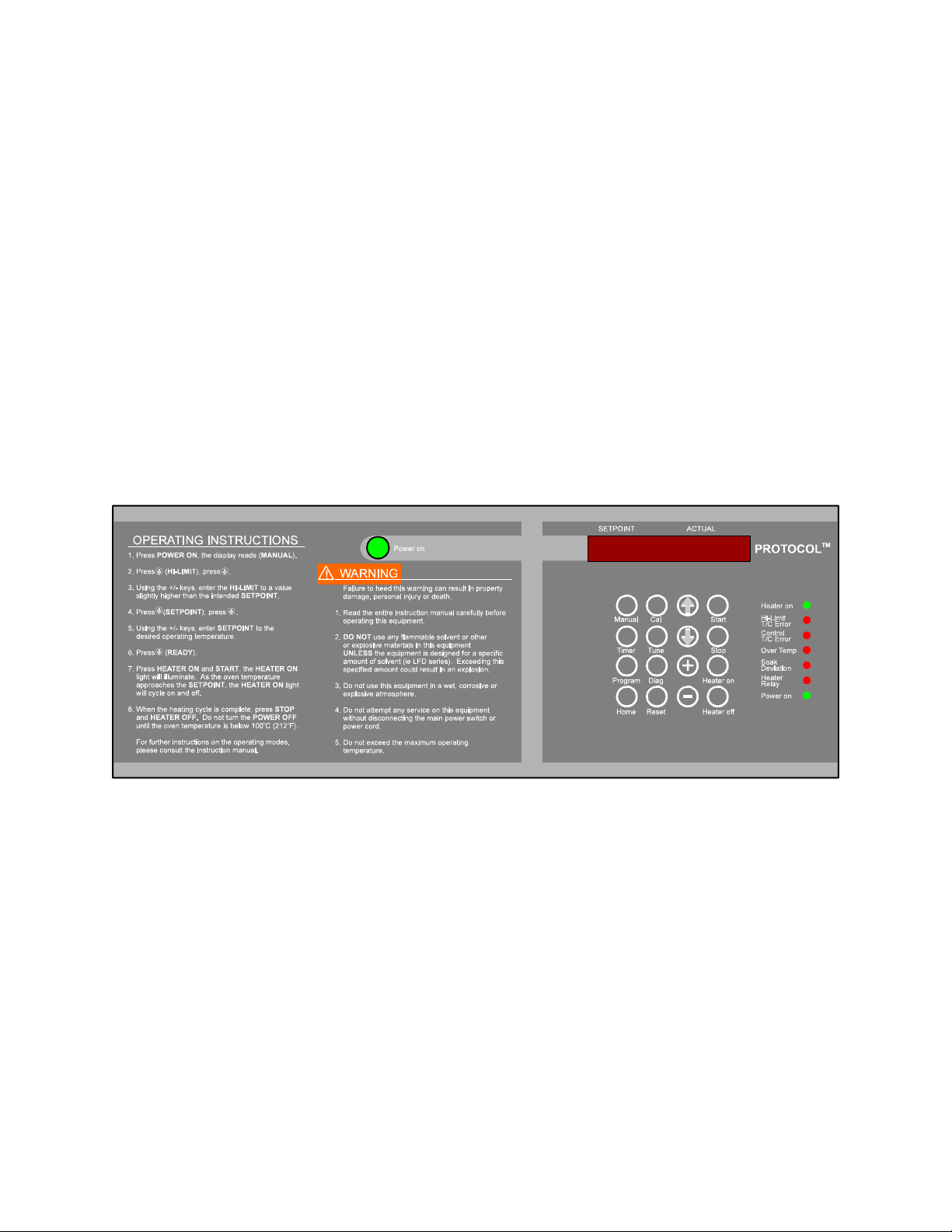

Protocol

The ovens are equipped with a modular microprocessor based digital temperature

controller.

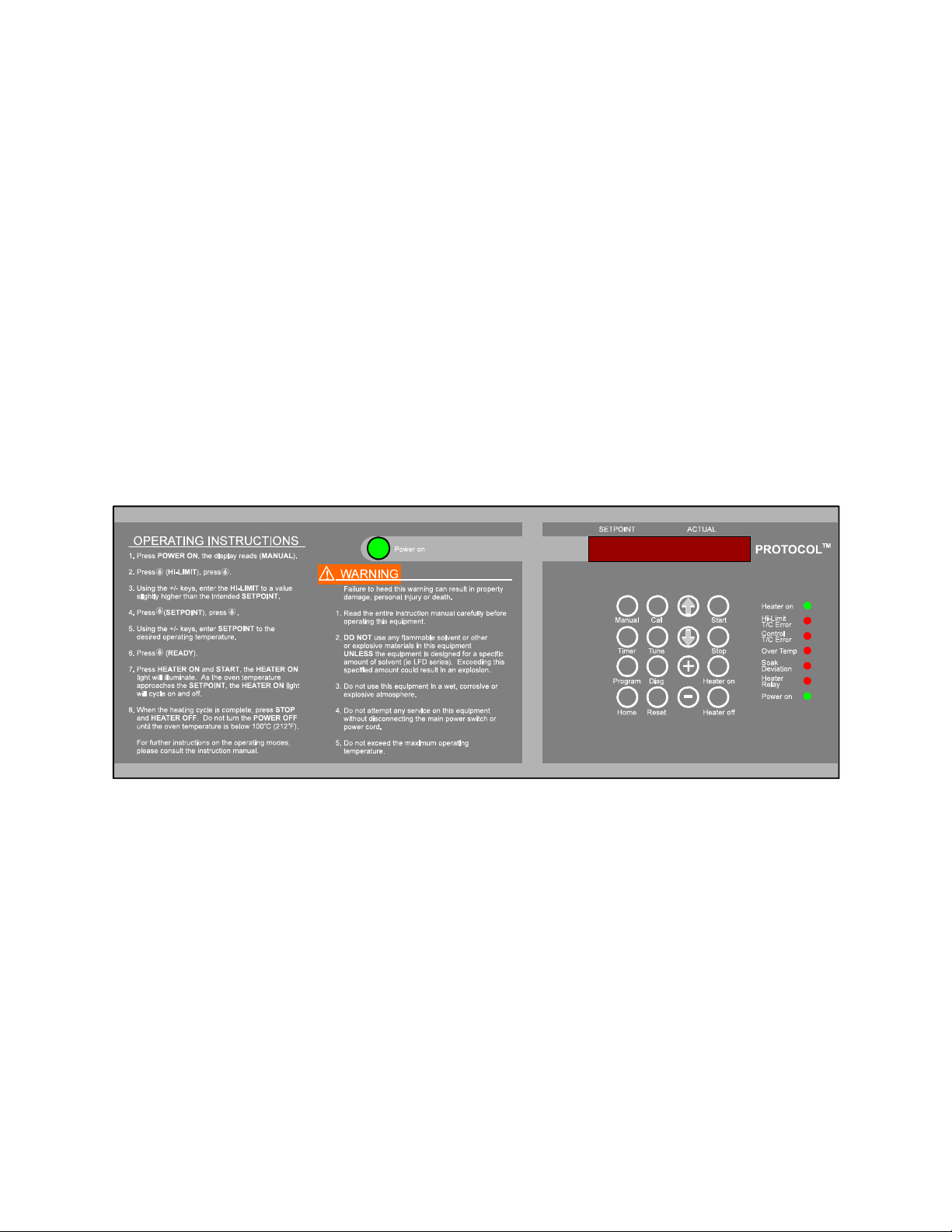

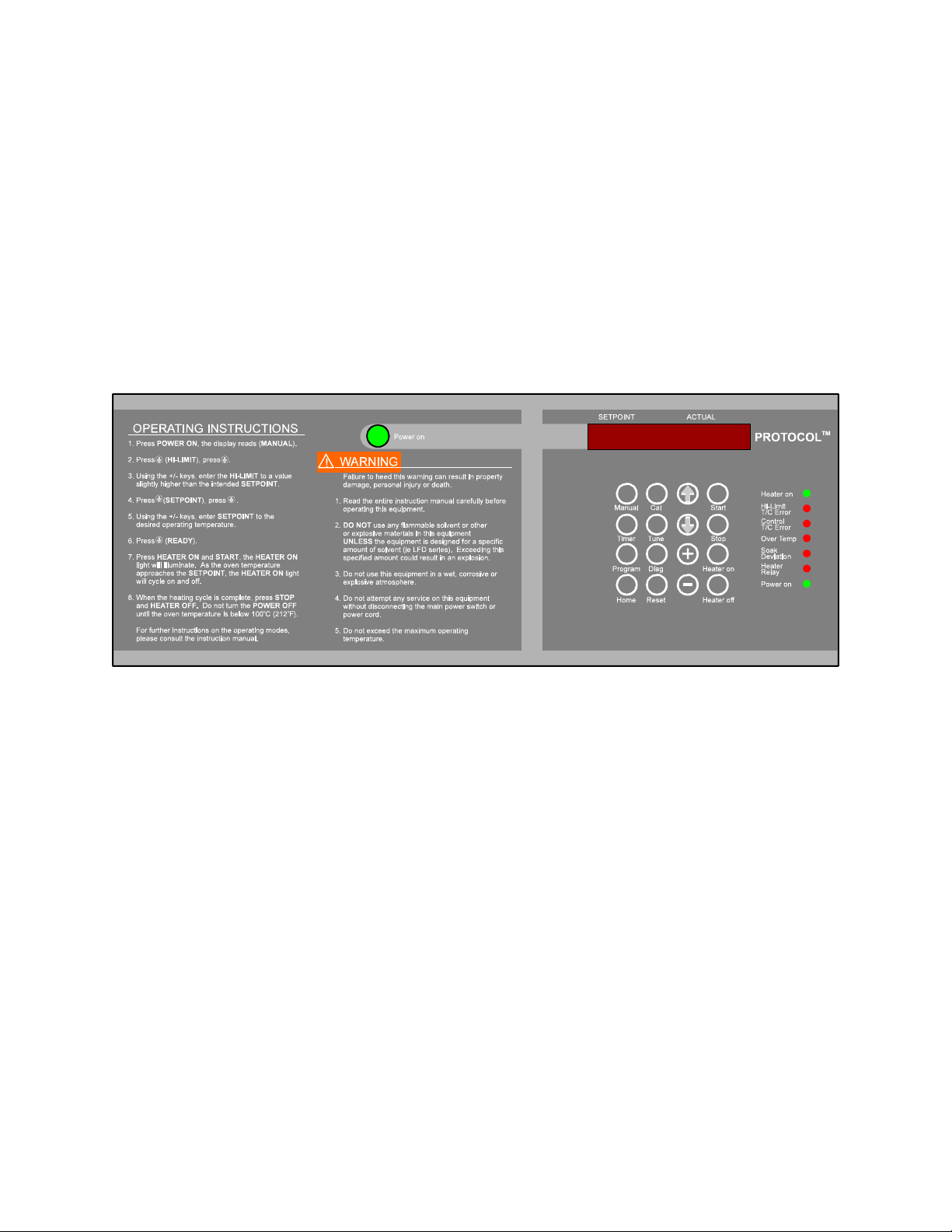

Figure 2. Main Display and Keypad on Protocol Control

The Despatch Protocol temperature controller is a dual functioning controller/high limit

instrument. The control portion of Protocol incorporates a microprocessor to digitally

control process variables with minimal temperature fluctuations.

The high limit portion of Protocol protects the product and/or the oven itself. If the

product being processed has a critical high temperature limit, the Hi-Limit parameter

should be set to a temperature somewhat below the temperature at which the product

could be damaged. If the product does not have a critical high temperature limit, the HiLimit parameter should be set to a value slightly higher than the highest programmed

setpoint to protect the oven equipment.

2

Page 9

Keypad Controls

Table 1 Protocol Keypad Controls

Mode Display Code Function Description

Manual MANUAL Operation Single setpoint control

Timer TIMER Operation Single setpoint control with process timer

Program PROGRAM Operation Programmable control with three event outputs

Tune TUNE Configure Set instrument parameters

Calibrate CAL-MODE Service Performs instrument calibration

Diagnostics DIAGNOSE Service Performs instrument thermocouple tests, SSR

power level and event output tests.

Table 2 Protocol Touchkeys

Key Description

• To move up through any mode

– To move down through any mode

+ To increase a setpoint or parameter

- To decrease a setpoint or parameter

Home To move to the beginning of any mode or segment

Reset To reset the control when an error has been corrected or to view the profile number,

segment number, and the number of loops (repeat times) remaining.

Heater

On

Heater

Off

Start To start an operating mode

Stop To stop an operating mode

To initiate heater relay

To disengage heater relay

3

Page 10

Status Indicator LEDs

Protocol has seven indicator LEDs that provide the following relevant information to the

user.

Table 3 Protocol Indicator LEDs

LED Function

Power on Lights when the power on pushbutton is pressed.

Heater relay Lights when a mode is ready for operation and the heater on key is pressed.

Soak Deviation Lights when the process temperature is not held within the user-specified soak

deviation limits. The light turns off when the temperature is within the soak

deviation limit.

Over Temp Lights when the process temperature exceeds the high limit value. The over

temperature light remains lit until the Reset is pressed.

Control T/C Error Lights when Lights when Protocol receives a control thermocouple error. the

Reset key clears the error upon corrective action.

Hi-Limit T/C

Error

Lights when Protocol receives a hi-limit thermocouple error. The Reset key

clears the error upon corrective action.

The Despatch Protocol temperature controller has been designed for ease of use while

maintaining elaborate and versatile control capabilities.

4

Page 11

Operating Modes

Protocol has three primary modes of operation: the Manual mode, the Timer mode and

the Program mode.

Manual Mode

The Manual mode is a single setpoint control mode that controls the process at the user

specified setpoint for an indefinite period of time. The Manual mode controls the oven

temperature within close limits as specified by the PID tuning parameters.

Timer Mode

The Timer mode is a single setpoint control mode with a built-in process timer that

starts timing either at the beginning of the process or at a user specified temperature.

As in the Manual mode, the Timer mode uses the PID parameters set in the tune mode.

Program Mode

The Program mode is a programmable ramp and soak control consisting of up to eight

profiles. Each profile consists of up to six segments for a total of 48 segments (8 x 6 =

48). Any one profile may be run recursively from two to 99 cycles or even continuously

if it is desired.

Each segment consists of a ramp and soak period. During the ramp period, the control

will track oven temperature. For example, a ramp is entered to heat from 100E C to

150E C in 50 minutes. Protocol will track the temperature 1E C every minute for 50

minutes. During the soak period, temperature is maintained as specified by the tuning

and soak deviation parameters.

Protocol will not allow a soak time to begin until the actual oven temperature is within

the soak deviation limit. This process is called assured soak. The ramp and soak

periods are adjustable from 0 to 99 hours, 59 minutes. Within each ramp and soak

period, up to three event outputs can be programmed either on or off.

The event relay is used for factory installed modifications, then disconnected before

shipping. Please consult the factory for information on connecting the event outputs.

When the events are connected, the user has the capability of controlling relays,

solenoid valves, etc., throughout the programming cycle.

5

Page 12

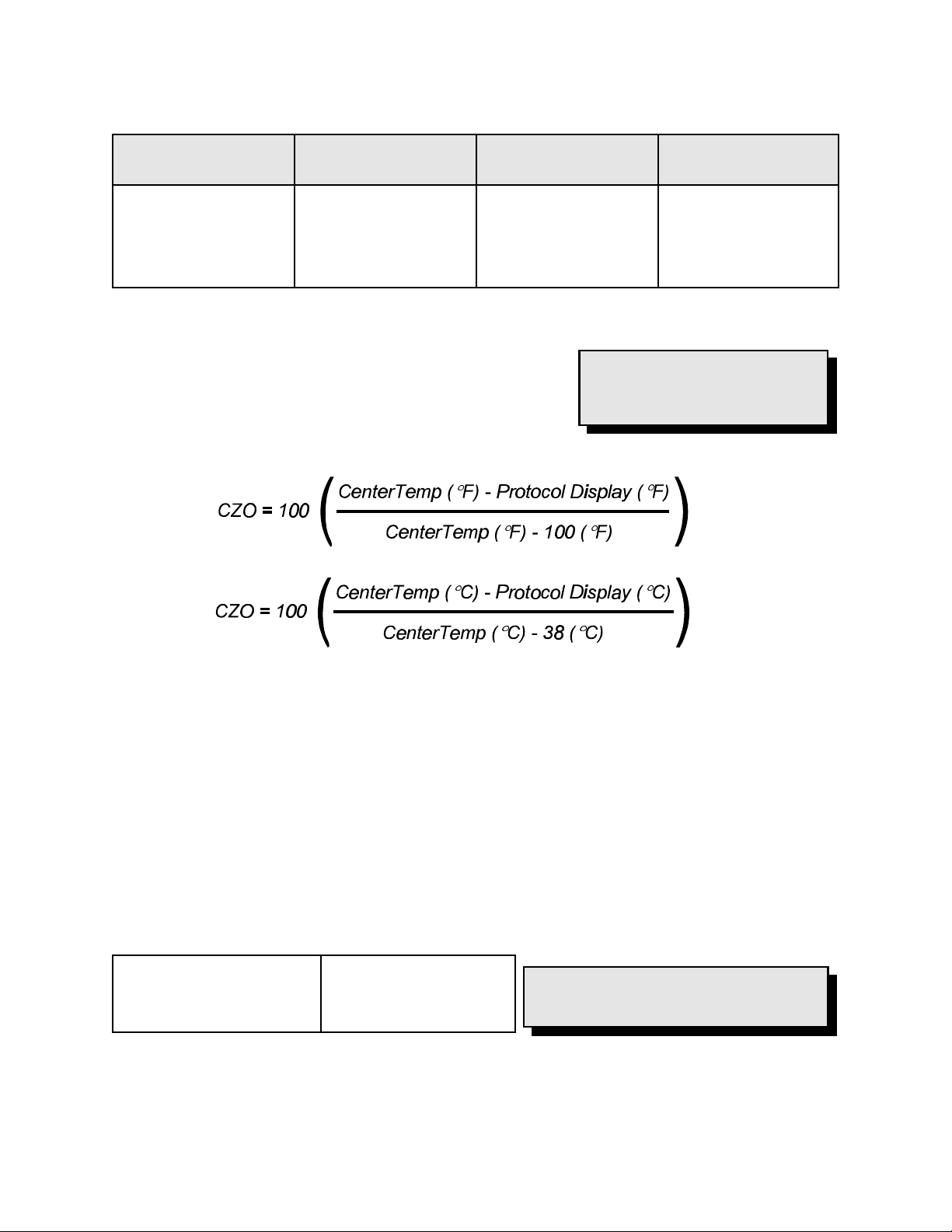

Calibration Zero Offset

The Calibration Zero Offset (CZO) of Protocol is factory preset and tested for the

specified operating conditions. Special instructions for accessing the tune mode to

change the CZO are referred to in the Appendix of this manual.

Figure 3. CZO Function in Tune Mode

The CZO may be useful to make the following small temperature corrections to the

control system.

C Correction of known sensor calibration errors.

C Correction of any known steady temperature offset between the heated

work-piece (load) and sensor. This is useful for applications where the sensor

cannot be located exactly at the work-piece.

C Alignment of temperature indications in a multi-zone/multi-controller application,

e.g., at ambient temperature.

Note that the CZO changes the value of the controlled temperature when used in

closed loop control. The CZO function can be represented by the equations:

Temp Indication (EF) = Sensor Temp (EF) - CZO% [100 (EF) - Sensor Temp (EF)]

Temp Indication (EC) = Sensor Temp (EC) - CZO% [38 (EC) - Sensor Temp (EC)]

The CZO function is a straight line pivoted around 100E F (38EC). Thus, the CZO

functions as an offset and has the ability to change the SLOPE of a temperature range.

6

Page 13

Table 4 Calibration Zero Offset Examples

CZO Display Temperature

measured by sensor

0.0

4.0

10.0

10.0

-10.0

100 EF

150 EF

150 EF

300 EF

300 EF

Offset EF Temperature Indication

-20 E

A more useful formula is one the user can use to

calibrate Protocol to match the center of the chamber.

This requires a temperature measuring device with its

thermocouple junction located at the center of the

chamber. CZO can be directly calculated by:

0 E

2 E

5 E

20 E

NOTE: The CZO function is

easily set for specific operating

conditions.

100 EF

152 EF

155 EF

320 EF

280 EF

Tune Setting

The Protocol has been preset and tested for normal operating conditions. Special

instructions for changing the tune setting are referenced in the Appendix of this manual.

The Protocol on the oven can be manually tuned. For your convenience the factory has

tested and preset the PID action to its optimum values. These values need not be

changed under normal operating conditions.

Table 5 Factory PID Settings

Proportional Band

Reset Time

Rate Time

5 degrees

30 seconds/repeat

0 degrees/second

7

NOTE: Reset times greater than 35

seconds/repeat are not recommended.

Page 14

Protocol Hi-Limit

Protocol will not let the high limit value drop below the setpoint value. In certain

situations, it may be necessary to change the setpoint first and then adjust the high limit

value.

It will be necessary to reset the hi-limit whenever it

has tripped. The hi-limit may be reset by first

allowing the oven chamber to cool slightly (or

increasing the parameter by several degrees) and

pushing the Reset key. During a high limit condition

the Over Temp LED will turn on thus deactivating

the heater.

WARNING: Never operate the

oven at a temperature in excess

of the maximum operating

temperature.

8

Page 15

INSTRUCTIONS

Start-Up

An outline and examples for the Manual mode, Timer mode and Program mode are

referenced in the Appendix. A completed typical program worksheet accompanies all

programmable event outputs installed at the factory.

1. Start Fan.

a. Press Power on pushbutton. You will hear the recirculating fan start.

b. Check that the green Power on LED is on.

Figure 5. Protocol Control Panel

9

Page 16

Manual Mode

Startup

The following are startup instructions for the Manual mode.

1. Select Manual mode.

a. Press the Manual key. MANUAL will be displayed.

2. Enter the high limit temperature.

a. Press – key. HI-LIMIT will

be displayed.

b. Press – key.

c. Using the +/- keys, enter the high limit temperature to a value slightly

higher than the intended SETPOINT.

3. Enter the Setpoint.

a. Press – key. SETPOINT

will be displayed.

b. Press – key.

c. Using the +/- keys, enter

the SETPOINT to the desired operating temperature.

Run

NOTE: For safety reasons, Protocol will not let

the operator set the Hi-limit below the setpoint.

It may be necessary to adjust the Protocol

setpoint first, then adjust the Hi-limit.

NOTE: During processing the

display shows the setpoint on the left and the

actual oven temperature on the right.

The following are run instructions for the

Manual mode.

NOTE: When Protocol is run in the Manual

1. Press – key. READY will be

displayed.

2. Press Heater on key. The Heater

relay LED will illuminate.

3. Press Start key. The Heater on LED will illuminate. As the oven temperature

approaches the setpoint, the Heater on LED will cycle on and off.

Mode, the setpoint can be adjusted without

stopping the operation. The setpoint is

adjusted by using the +/- keys.

10

Page 17

Stop

The following are stop instructions for the Manual mode.

1. Press the Heater off key. The Heater Relay LED will shut off.

2. Wait for oven temperature to fall below 100E C (212E F).

3. When the Manual mode is complete, press the Reset key to display the final

process temperatures.

4. Press the Stop key.

5. Press the Power on pushbutton to turn power off.

An example of the Manual mode is referenced in the Appendix.

11

Page 18

Timer Mode

Startup

The following are startup instructions for the Timer

mode.

1. Select Timer mode.

a. Press Timer key. TIMER will be

displayed.

2. Enter the high limit temperature.

a. Press – key. HI-LIMIT will be

displayed.

b. Press – key.

c. Using the +/- keys, enter the high limit temperature to a value slightly

higher than the intended setpoint.

3. Enter the Setpoint.

NOTE: During processing the

display shows the setpoint on the

left and the actual oven temperature on the right.

NOTE: For safety reasons, Protocol

will not let the operator set the Hilimit below the setpoint. It may be

necessary to adjust the Protocol

setpoint first, then adjust the Hi-limit.

a. Press – key. SETPOINT will be displayed.

b. Press – key.

c. Using the +/- keys, enter the SETPOINT to the desired operating

temperature.

4. Enter the process time.

a. Press – key. TIME will be displayed.

b. Using the +/- keys, enter the time of the process. (HHMM (hours/minutes)

or MMSS (minutes/ seconds) selected in the tune mode).

5. Enter timer starting temperature.

a. Press the – key. TEMP YES/NO will be displayed.

12

Page 19

b. Use the + or - keys to select either YES or NO.

C Press the - key to display NO and begin timing at ambient.

C Press the + key to display YES and begin timing at the following

input temperature.

c. Press the – key. TEMP and the begin timing temperature will be

displayed.

d. If YES was selected in step b, use the + or - keys to enter the temperature

at which the process timer begins timing.

If NO was selected in step b, this setpoint has no bearing on oven

operation.

Run

The following are run instructions for the Timer mode.

1. Press the – key. READY will be displayed.

NOTE: When the Timer mode is

2. Press the Heater on key. The Heater Relay

LED will illuminate.

3. Press the Start key. The Heater on LED will

illuminate and the setpoint and the actual

running, pressing the Start key will

display the time remaining in the

cycle. The display will show

TRHHMMSS which stands for the

time remaining, hours, minutes

and seconds.

temperature will be displayed. As the oven

temperature approaches the setpoint, the

Heater on LED will cycle on and off.

Manually Stop

The following are manual stop instructions for the Timer mode.

1. Press the Heater off key.

2. Wait for oven temperature to fall below 100E C (212E F).

3. When the Timer mode is complete, press the Reset key to display the final

process temperatures.

4. Press the Stop key.

13

Page 20

5. Press the Power on pushbutton to turn power off.

An example of the Timer mode is referenced in the Appendix of this manual.

14

Page 21

Program Mode

Startup

The following are startup instructions for the

Program mode.

NOTE: If all event relays are

disconnected or no modifications

involving event relays have been

made to your particular oven,

programming the events has no

effect on oven operation.

NOTE: All profiles entered can be

cleared by using the PROF CLR

function in the TUNE mode.

In any one segment, if the ramp and soak times are

zero, Protocol ignores the remaining segments of the profile. A soak period will not

begin until the actual oven temperature is within the soak deviation limit. During any

segment of a profile, if the actual oven temperature falls outside of the soak deviation

limit, the Soak Deviation LED will be illuminated.

1. Select Program mode.

a. Press Program key. PROGRAM will

be displayed.

2. Enter the high limit temperature.

a. Press – key. HI-LIMIT will be

NOTE: For safety reasons,

Protocol will not let the operator

set the Hi-Limit below the setpoint.

It may be necessary to adjust the

Protocol setpoint first, then adjust

the Hi-Limit.

displayed.

b. Press – key.

c. Use the + or - keys to enter the high limit temperature to a value higher

than the intended setpoints.

3. Enter the profile number.

a. Press – key. PROFILES will be displayed.

b. Press – key. PRO - 1 will be displayed.

c. Use the + or - keys to enter the profile number to program.

4. Program the profile.

a. Press – key. SEG - 1 will be

displayed.

b. Program the ramp rate.

1. Press – key. RAMP0001 will

be displayed.

NOTE: During processing the

display shows the setpoint on the

left and the actual oven

temperature on the right.

15

Page 22

2. Use the + or - keys to enter the ramp time.

c. Program the events desired during the ramp time.

1. Press – key. EVENTS will be displayed.

2. Press – key for each event.

3. Use the + or - keys to program the event outputs ON or OFF for the

ramp period.

d. Program the ramp ending temperature.

1. Press – key. TEMP and the ramp ending temperature will be

displayed.

2. Use the + or - keys to enter the desired ramp ending temperature.

e. Program the soak time.

1. Press – key. SOAK and the

WARNING: Never operate the oven

at a temperature in excess of the

maximum operating temperature.

soak time will be displayed.

2. Use the + or - keys to enter the soak time.

f. Program the events desired during the soak time.

1. Press – key. EVENTS will be displayed.

2. Press – for each event.

3. Use the + or - keys to program the event ON or OFF for the soak

period.

g. Enter the remaining segments 2-6 by following steps a through f.

16

Page 23

5. Enter the Soak-Deviation.

a. Press – key until SOAK-DEV is

displayed.

b. Press a key. The symbol +/- will be

displayed.

c. Use the + or - keys to enter the soak deviation limit.

6. Enter the next profile to continue to, or end profile.

a. Press – key. GOTO will be displayed.

b. Use the + or - keys to enter the profile number to continue to. Select End

to stop at the end of this profile. For continuous profiles enter the same

number of the profile that is currently being programmed.

7. Enter the number of profile recursions.

a. Press – key. REPEAT will be displayed.

NOTE: The SOAK-DEV limit is

also the assured soak limit. This

means that the soak times will not

begin until the process

temperature is within the SOAKDEV parameter.

b. Press – key. TIMES will be displayed.

c. Use the + or - keys to enter the number of times to complete the profile

being programmed (1 - 99).

8. Enter the profile end condition. The hold

command is contingent on the final segment

of the last profile to be run only.

a. Press – key. HOLD will be displayed.

b. Use the + or - keys to select YES or

NO.

C Selecting YES will hold at last setpoint. The event outputs will be

held at their last value.

C Selecting NO will not hold at last setpoint. The event outputs will

be turned off.

NOTE: If the Protocol is in a hold

condition, pressing the Reset key

will display that the control is in

segment 7 (HOLD).

17

Page 24

Run

The following are run instructions for the Program

mode.

1. Press Home key until PROGRAM is

displayed.

NOTE: When in the Program

mode, pressing the Start key will

display the time remaining in the

cycle (TRHHMMSS). Pressing the

Reset key will display the profile

number, segment number and the

loops (REPEAT TIMES)

remaining.

2. Press – key until PRO-1 is displayed.

3. Make sure the correct starting profile is entered by pressing + or -.

4. Press the • key until READY is displayed.

5. Press Heater on key. The Heater relay LED will illuminate.

6. Press Start key. The Heater on LED will illuminate. As the oven temperature

approaches the setpoint, the Heater on LED will cycle on and off. During

processing, the display shows the setpoint on the left and the actual oven

temperature on the right.

Manually Stop

The following are manual stop instructions for the Program mode.

1. Press Heater off key.

2. Wait for oven temperature to fall below 100EC (212EF).

3. Press the Reset key to display the final process temperature.

4. Press Stop key.

5. Press Power on pushbutton to turn power off.

Examples of the Program mode are referenced in the Appendix of this manual.

18

Page 25

APPENDIX

Special Instructions

The Protocol has been preset and tested at the factory for normal operating conditions.

In most applications, it will not be necessary to alter the oven's settings. This section

contains additional information and reference for special operating conditions.

19

Page 26

Control Instrument

Tune Mode

Various functions of the control instrument are set by parameters in the tune mode. To

access the tune mode, it is necessary to enter the proper code.

1. Press Tune key. The display reads TUNE.

2. Press – key. CODE *** will be displayed.

3. Enter +, -, -, +, -, +. PID TUNE will be displayed.

The PID tuning parameters may be entered. The units are listed below.

P = degrees

I = seconds/repeat

D = degrees/second

20

Page 27

Table 6 Tuning Outline

Display Description

TUNE

CODE

PID TUNE

P-1

I-1

D-1

DEG SPL CZO DIS

BEEP

PF-RECVR

DIG COMM

RECONFIG

PROF CLR

VARS CLR

CODE *E*

Selects tune mode.

Enter + - - + - +

Enter tuning parameters.

Proportional band in degrees (+/- keys).

Reset in seconds/repeat (+/- keys).

Rate in degrees/second keys).

Select EC or EF (+/- keys).

Setpoint limit, set to maximum temperature of oven (+/- keys)

Calibration zero offset -99.9 to 99.9 (+/- keys).

Time set in MMSS (minutes/seconds) or HHMM (hours/minutes).

Select beep on or off (+/- keys).

Power failure recovery mode. Use + or - keys to select from STOP, RESUME or

HOLD.

C STOP - Program terminates. must restart from the beginning of the program.

C RESUME - When power is restored, program resumes at the point where power

failure occurred.

C HOLD - Program waits for the operator. The operator has a choice of terminating

or resuming the program.

Digital communications option. Disregard unless Protocol is supplied with optional

digital communications interface. For proper setting, refer to the protocol software

manual or the Digital Communication User Guide. Select from NO COMM, CPIF or

ASCII (+ or - keys). Select from RS232C or RS422A (+ or - keys). Select address

(ADDR) from 1 to 999 (+ or - keys).

C NO COMM - No digital communication.

C CPIF - Computer interface mode communications (used for Protocol software)

C ASCII - ASCII line mode communications (used for user-created programs)

For saving changes to DIG COMM options in memory.

Entering code clears all profiles to default values.

Entering code clears the SRAM in Protocol. All parameters must be reset. Should be

done in EXTREME circumstances only. Recalibration is essential.

To turn events relays on in the profile mode. Do not change the code setting.

Experience and experimentation with tuning parameters will guide the user in

determining the proper settings when normal conditions are not present.

21

Page 28

Tuning Worksheet

In most applications it is not necessary to alter tuning parameters. To enter the tune

mode, press the Tune key. Tune will be displayed. Press – and enter +, -, -, +, -, +.

Using the – key and the +/- keys, enter the desired settings. Press Home when

finished.

Tuning Worksheet

Display Setting Factory Setting Units

P-1 5 degrees

I-1 30 seconds/repeat

D-1 0 degrees/second

DEG - C EF (EC)

SPL - Max Temp EF (EC)

CZO varies factor calibrated to center of the chamber

DIS - HHMM minutes/seconds (hours/minutes)

BEEP On off (on)

Notes:

1. The alternate is listed in ( ).

2. See Table 10, Tuning Outline, for further information regarding display codes.

3. Tuning parameters may change from those set at the factory. Load mass, fresh air

and exhaust damper settings will affect tuning parameters. Some experimentation is

required to determine optimum settings.

Reset times greater than 35 seconds/repeat are not recommended.

22

Page 29

Calibration Mode

Protocol has been tested and calibrated at the factory. Under normal operating

conditions recalibration should not be necessary. However, if the instrument does not

comply with known standards recalibration may be necessary.

Calibration Instructions

We recommend using a certified analog

thermocouple simulator/calibration source with less

than ±1E F noise. We have experienced signal

stability problems with some microprocessor based

thermocouple simulator/calibrators which induce an

error during the calibration procedure. This error

WARNING: Calibration

equipment without internal

ambient compensation provisions

requires subtracting the ambient

mV signal from the calibration

temperature mV signal to

calibrate Protocol properly.

generally results in a non-linear shift in the

controller's indicated temperature.

1. Disconnect AC power to the oven.

2. Remove Protocol controller to expose thermocouple input terminals.

3. Disconnect control and Hi-Limit thermocouples from controller thermocouple input

terminals (Control T/C, and Hi-Limit T/C).

Figure 6. Top View of J Type Thermocouple Inputs on Protocol

4. Mark thermocouple leads if not labeled.

5. Connect a 6 foot piece of type J thermocouple lead wire to each of the Control T/C

and Hi-Limit T/C terminals.

6. Twist together or jumper the lead wire end not connected to the Control T/C and

Hi-Limit T/C terminals. This creates a junction and prevents a control sensor error

[S-T/C ERR] and Hi-Limit sensor error [H-T/C ERR] caused by an open

thermocouple.

23

Page 30

All errors must be cleared to perform calibration. Any active error will inhibit the calibration function.

To clear a Hi-Limit control error [HL ERROR] caused by lost of calibration (Hi-Limit indication of

500E C or 932E F in the diagnostic mode):

1. Increase the Hi-Limit setpoint to 500E C or 932E F.

2. Press the Reset key.

7. Loosely fasten the Protocol controller to the oven.

8. Re-connect AC power to the oven.

9. Press the Power on pushbutton to energize oven.

10. Press the Tune key. The display reads [TUNE ].

11. Use the – and • keys to scroll through the tune mode configuration. The

controller must be configured to operate in EF (Fahrenheit) and CZO

should be set to zero (0.0).

a. Record initial tune mode parameters prior to making any changes.

b. Press the – key. The display reads [CODE ***].

c. Press the following key sequence: +, -, -, +, -, +.

The display reads [PID TUNE]. Protocol is in the tune mode.

d. Use the following table to change the tune mode parameters.

24

Page 31

Tune Mode Parameter Calibration

NOTE: ### or ##.# represents a numeric value or parameter.

Press Display Factory Default

Setting

– key P-1 ### 5 + or - keys 0E C to 500E C

– key I-1 ### 30 + or - keys 0 to 999

– key D-1 ### 0 + or - keys 0 to 999

– key DEG - C C + key for C or - key for F.

– key SPL - ### maximum designed

operating

temperature¹

– key CZO - ##.# can vary + or - keys to change

– key DIS

HHMM

– key BEEP ON ON + key for ON or the - key

HHMM + key for HHMM (hours

Actual

Setting

Press Adjustable Range

32E F to 932E F

seconds/repeat

degrees/second

+ or - keys 0E C to 500E C

32E F to 932E F

-99.9 to 99.9

parameter to 0.0

and minutes) or the - key

for MMSS (minutes and

seconds).

for OFF.

degrees

¹ 204E C/400E F, 260E C/500E F, 343E C/650E F

e. Press the Manual key. The display reads [MANUAL ].

f. Allow the controller a thirty (30) minute warm up time before proceeding to

the step #13 - CAL MODE.

12. Press the Cal key. The display reads [CAL--MODE].

13. Press the – key. The display reads [CODE ***].

14. Press the following key sequence: -, +, +, -, +, -.

The display reads [HCAL 250].

25

Page 32

15. Apply a 250E F signal to the high limit thermocouple input:

a. Connect the piece of type J thermocouple lead wire, wired to the High

Limit T/C terminals, to a thermocouple simulator.

b. Set the simulator to output a type J thermocouple signal.

c. Twist together or jumper the piece of type J thermocouple lead wire, wired

to the Control T/C terminals. This creates a junction and prevents a

Control sensor error [S-T/C ERR] caused by an open thermocouple.

Press the Reset key to clear a Control sensor error [S-T/C ERR] caused

by an open thermocouple.

d. Adjust the simulator to supply a 250E F signal. Wait for 30 seconds while

the control stabilizes.

16. Press the following key sequence: -, -, +. The display now reads HCAL

450.

17. Adjust the simulator to supply a 450E F signal. Wait for 30 seconds while

the control stabilizes.

18. Press the following key sequence: +, +, -. The display now reads HIL 450.

19. To verify proper calibration, adjust the simulator to supply a 350E F signal.

Within 30 seconds, the display should stabilize and read HIL 350.

20. To calibrate the control sensor, press the – key. The display reads

[SCAL 250].

21. Apply a 250E F signal to the control thermocouple input:

a. Connect the piece of type J thermocouple lead wire, wired to the Sensor

T/C terminals, to a thermocouple simulator.

b. The simulator should be set to output a type J thermocouple signal.

c. Twist together or jumper the piece of type J thermocouple lead wire to the

Hi-Limit T/C terminals. This creates a junction and prevents a hi-limit

sensor error [H-T/C ERR] caused by an open thermocouple. Press the

Reset key to clear a hi-limit sensor error [H-T/C ERR] caused by an

open thermocouple.

d. Adjust the simulator to supply a 250E F signal. Wait for 30 seconds while

the control stabilizes.

26

Page 33

22. Press the following key sequence: -, -, +. The display now reads SCAL

450.

23. Adjust the simulator to supply a 450E F signal. Wait for 30 seconds while

the control stabilizes.

24. Press the following key sequence: +, +, -. The display now reads SENS

450.

25. To verify proper calibration, adjust the simulator to supply a 350E F signal.

Within 30 seconds, the display should stabilize and read SENS 350.

26. Press the Manual key. The display reads [MANUAL]. If the control did

not calibrate properly repeat steps 12 - 25.

27. Press the Power on pushbutton to de-energize oven.

28. Disconnect AC power to the oven.

29. Remove Protocol controller to expose thermocouple inputs terminals.

30. Disconnect the two pieces of type J thermocouple lead wire connected to

the Control T/C and Hi-limit T/C terminals.

31. Re-connect control and Hi-Limit thermocouples to the controller

thermocouple terminals (Control T/C, and Hi-limit T/C).

32. Re-install the Protocol controller onto the oven.

33. Re-connect AC power to the oven.

34. Press the Power on pushbutton to energize oven.

35. Press the Tune key. The display reads [TUNE ].

36. Reset any tune mode parameters that were changed in step 12 to perform

calibration (examples: DEG = F and CZO = 0.0).

37. When changes have been completed, press the Manual key. The display

reads [MANUAL ].

The calibration procedure is complete.

27

Page 34

Calibration Recovery

The Protocol control has a factory calibration recovery feature. This feature allows the

operator to restore the Protocol to an operational condition should a calibration error

occur. The Factory Calibration Recovery feature should only be used as a temporary

fix until a proper calibration procedure utilizing a calibration source can be performed.

Only a complete calibration will restore the Protocol to an optimum performance level.

For proper calibration instructions refer to the calibration section of this manual.

Instructions

1. Select the Diagnose mode by pressing the DIAG key.

2. Press the – (down arrow) key until RCVR SEN is displayed.

3. To recover the control sensor calibration value, press the key sequence +, -, -, +, -,

+.

4. Press the – (down arrow) key until RCVR HIL is displayed.

5. To recover the high limit sensor calibration value, press the key sequence +, -, -, +, -,

+.

The calibration recovery is now complete.

28

Page 35

Diagnostics Mode

The diagnostics mode is provided to give certain relative information about Protocol.

The following table gives an outline of the diagnostics mode.

Display Description

DIAGNOSE Select Diagnostics mode.

SSR Protocol SSR output level.

EVENTS Events 1-3 follow

E-1 Event 1 output

E-2 Event 2 output

E-3 Event 3 output

SENS-T/C Control thermocouple display follows

GOOD Control thermocouple test and input reading

HL - T/C Hi-limit thermocouple display follows

GOOD Hi-limit thermocouple test and input reading

PWR % output

RCVR SEN Recover factory calibration for control sensor

RCVR HIL Recover factory calibration for high limit sensor

Items that can be adjusted by the user include SSR (ON or OFF), Events E-1, E-2 and

E-3(ON or OFF) and PWR. The SSR and PWR items can be used to test the solid

state relay for proper operation. The SSR item allows the SSR to output 100% (ON) or

0% (OFF). The PWR item allows for adjustable output from 0% to 100%. to

implement, adjust the PWR level with the +/- keys and turn on the heater relay.

RCVR SEN and RCVR HIL are used to restore the factory calibration should a

calibration error occur.

29

Page 36

Power Failure

In the event that the power supplied to Protocol is insufficient at any point during a

running mode, the display will read PWR-FAIL. In the tune mode the user can choose

the Power Fail Recovery mode from Stop, Resume and Hold. To restart after a power

failure in the hold mode, press the Start key to resume oven operation. Otherwise,

press the Reset key to clear the PWR-FAIL display. Do not shut off the power during a

running mode. This creates an error condition and PWR-FAIL will be displayed the

next time Protocol is powered up. Instead, press the Stop key and the Heater Off key.

This will power off Protocol without creating an error condition.

30

Page 37

Programming Examples and Outline

The following examples show a step by step procedure for

programming Protocol in the Manual, Timer and Program

modes. Example 1 covers the Manual mode and example 2

covers the Timer mode. A detailed outline covers the Program mode with a programming worksheet and examples 3-5

following the outline.

NOTE: Do not turn the

power off until the oven

temperature is below

100EC (212EF).

Example 1 - Manual Mode

Control the process at 250EF.

Manual Mode Example

Key DISPLAY Description

Manual

?

?

+

?

?

+

?

Heater On

MANUAL

Hi-Limit

HL 200

HL 275

SETPOINT

180 75

250 75

READY

READY

Select Manual mode

Enter the high limit temperature

High limit temperature currently set at 200EF

Increase high limit temperature to 275EF

Enter the setpoint

Setpoint at 180EF, actual oven temperature at 75EF

Increase setpoint to 250EF

Protocol is ready to run Manual mode

Heater relay initiated, heater ready for power

NOTE: EF is selected in the tune

mode.

Start

Stop

Heater Off

250 75

READY

READY

Setpoint = 250EF, actual oven temperature = 75EF

Stop Manual mode

Heater relay LED is off, heater secured off

31

Page 38

Example 2 - Timer Mode

Control the process at 200EC for three hours and 15

minutes with the timer beginning at 195EC. Protocol

will stop automatically when run in Timer mode.

Timer Mode Example

Key DISPLAY Description

Timer

?

?

-

?

?

-

?

+

TIMER

Hi-Limit

HL 225

HL 215

SETPOINT

210 25

200 25

TIME0010

TIME0315

Select timer mode

Enter the high limit temperature

Hi-Limit currently set at 225EC

Decrease high limit to 215EC

Enter the setpoint

Setpoint at 210EC, actual oven temperature at 25EC

Decrease setpoint to 200EC

Timer currently set for ten minutes

Increase timer to three hours and 15 minutes

NOTE: EC and HHMM

(hours/minutes) is selected in the

tune mode.

?

+

?

+

?

Heater On

Start

Stop

Heater Off

TEMP NO

TEMP YES

TEMP 79

TEMP 195

READY

READY

200 25

READY

READY

Timer currently set to begin timing at ambient

Timer set to begin timing at the following temperature

Timer currently set to begin timing at 79EC

Timer set to begin timing at 195EC

Protocol is ready to run Timer mode

Heater relay LED on, heater ready for power

Setpoint = 200EC, actual oven temperature = 25EC

Stop Timer mode

Heater relay LED is off, heater secured off

32

Page 39

Program Mode

Program Mode Outline

Display Description

PROGRAM

Select Program mode.

Hi-Limit

HL

PROFILES

PRO SEG RAMP

EVENTS

E-1

E-2

E-3

TEMP

SOAK

EVENTS

E-1

E-2

E-3

SOAK-DEV

+/-

Hi-Limit for Program mode

Enter high limit temperature (+ or - keys).

Enter profile number (1-8).

Segment number of profile (1-6)

Ramp time entered

Event status for ramp time

Event 1 status (ON or OFF)

Event 2 status (ON or OFF)

Event 3 status (ON or OFF)

Ramp ending temperature

Soak period of ramp ending temperature

Event status for soak period

Event 1 status (ON or OFF)

Event 2 status (ON or OFF)

Event 3 status (ON or OFF)

Soak-Deviation limit for profile (Also assured soak limit)

Enter soak-deviation limit.

GOTO

REPEAT

TIMES

HOLD

YES

NO

Enter profile to GOTO

End = Move to REPEAT TIMES command

1 = GOTO profile 1

2 = GOTO profile 2

:

8 = GOTO profile 8

Enter number of recursions (1-99)

1 = Execute profile 1 times

2 = Execute profile 2 times

:

99 = Execute profile 99 times

Hold at last setpoint?

Hold at last setpoint indefinitely.

Holds event outputs at last value.

No hold at last setpoint.

Event outputs turn OFF.

Notes on the Program mode:

33

Page 40

C The profile number is manually entered using the + or - keys.

C Six segments exist for each profile.

C If the ramp time and soak time for any one segment is zero, Protocol ignores the

remaining segments.

C The REPEAT TIMES command is the number of times to execute the profile being

programmed.

C The HOLD command is contingent on the final segment of the last profile to be run

only.

C A soak time will not begin until the actual temperature is within the soak-deviation

limit. (Assured soak limit).

C Make sure the proper starting profile number is displayed in the PRO- prompt before

executing the profile to be run.

While a program is being executed, pressing the Reset key will display the profile

number, segment number and the number of loops (REPEAT TIMES) remaining.

Pressing the Start key will display the appropriate ramp or soak time remaining (TR.)

If Protocol is in a HOLD condition, pressing the Reset key will display that the control is

in segment 7 (HOLD.)

34

Page 41

Program Worksheet

The program worksheet serves as a guide to the input parameters for the program

mode.

Figure 7. Sample Profile

Display Setting(s)

HL _____

PRO- _____

SEG- 1 2 3 4 5 6

RAMP _____ _____ _____ _____ _____ _____

E-1 _____ _____ _____ _____ _____ _____

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

TEMP _____ _____ _____ _____ _____ _____

SOAK _____ _____ _____ _____ _____ _____

E-1 _____ _____ _____ _____ _____ _____

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

SOAK-DEV _____

GOTO _____

REPEAT TIMES _____

HOLD _____

35

Page 42

Example 3 - Program Mode

Follow the characteristic curve listed below.

Figure 8. Example Temperature Profile

Display Setting(s)

NOTES: HHMM

(hours/minutes) and EC selected

in the tune mode. No event

outputs are being used. SoakDeviation limit = ±7EC (also

assured soak limit). Hold at last

setpoint. Ramp and soak times

of zero in any one segment

ignores remaining segments.

HL 150

PRO- 1

SEG- 1 2 3 4 5 6

RAMP 0020 0010 0010 0000 0000 0000

E-1 * _____ _____ _____ _____ _____ _____

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

TEMP 100 130 120 0000 0000 0000

SOAK 0010 0010 0001 0000 0000 0000

E-1 _____ _____ _____ _____ _____ _____

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

SOAK-DEV 7

GOTO End

REPEAT TIMES 1

HOLD Yes

* Events E-1, E-2, and E-3 will not be shown if they are not turned on.

36

Page 43

Example 4 - Program Mode

Autostart the oven after two hours and follow the characteristic curve below.

NOTES: MMSS

(minutes/seconds) and EF

selected in the tune mode. Event

1 wired properly for autostart,

events 2 - 3 are not used. No

hold at last setpoint.

Soak-Deviation = ±5EF (also

assured soak limit). Minimum

operating temperature is 70EF.

Figure 9. Example Temperature Profile

Display Setting(s)

HL 240

PRO- 1

SEG- 1 2 3 4 5 6

RAMP 0001 0100 0030 0100 0100 0030

E-1 * OFF ON ON ON ON ON

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

TEMP 70 130 160 130 220 100

SOAK 0200 0030 0100 0100 0200 0001

E-1 OFF ON ON ON ON OFF

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

SOAK-DEV 5

GOTO End

REPEAT TIMES 1____

HOLD NO

* Only E1 event is turned on.

37

Page 44

Example 5 - Program Mode

Complete characteristic curve five times.

Figure 10. Example Temperature Profile

NOTES: HHMM

(hours/minutes) and EC

selected in the tune mode.

No events used. SoakDeviation = 10EC (also

assured soak limit).

Minimum operating

temperature = 50EC. Ramp

and soak times of zero in

any one segment ignores

remaining segments.

Display Setting(s)

HL 115

PRO- 1

SEG- 1 2 3 4 5 6

RAMP 0100 0200 0000 0000 0000 0000

E-1 _____ _____ _____ _____ _____ _____

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

TEMP 100 0000 0000 0000 0000 0000

SOAK 0100 0001 0000 0000 0000 0000

E-1 _____ _____ _____ _____ _____ _____

E-2 _____ _____ _____ _____ _____ _____

E-3 _____ _____ _____ _____ _____ _____

SOAK-DEV 10

GOTO End

REPEAT TIMES 5

HOLD NO

38

Page 45

Troubleshooting

PROBLEM/

SYMPTOM

Erratic

temperature

control

Temperature will

not reach the

Setpoint

Display reads

“HL ERROR”

(blinking)

PROBABLE

CAUSE

The heater is not

turning ON

Defective SSR

The Hi-limit relay

does not click or

pull in when

pressing the

HEATER ON

pushbutton

The process

temperature has

exceeded the Hilimit temperature

setpoint.

SUGGESTED CORRECTIVE ACTION

The controller typically has a proportion band (PB) of 5°F.

• If the heater is not cycling ON when the process

displayed temperature is 3°F or more below the

setpoint temperature, check:

• Defective Controller (will not gate SSR)

• Open Heater Fuses

• Tripped Hi-limit controller

• Open Hi-limit relay

• If the heater is not cycling OFF when the process

displayed temperature is 3°F or more above the

setpoint temperature, check:

• Defective Controller (Temperature runaway)

• Shorted SSR

• Tuning parameters are incorrect (ex. CZO value

too large)

• Defective Controller (will not gate SSR)

• Open Heater Fuses

• Tripped Hi-limit controller

• Test SSR gate signal output.

• Check both the incoming and output wiring and

voltage.

• Check for loose wiring connector. Replace Protocol.

Set the hi-limit to a higher temperature and press the

RESET pushbutton.

Display reads

“S-TC ERR”

(blinking)

Display reads

“H-TC ERR

(blinking)

Controller

Calibration

The Control

thermocouple is

open

The Hi-limit

thermocouple is

open

Check DIAGNOSTICS MODE for actual temperature readout

of the Hi-limit (HL-T/C). If the reading is off by greater

than 2-3 degrees or displays 500°C (932°F), calibrate the

controller.

• Check for loose connections on the Control T/C

terminals (SEN).

• Defective T/C. Remove the T/C and short the

terminals with a jumper. The control should display

ambient temperature.

• Check for loose connections on the Hi-limit T/C

terminals (HIL)

• Defective T/C. Remove the T/C and short the

terminals with a jumper. The control should display

ambient temperature

39

Page 46

PROBLEM/

SYMPTOM

Temperature

runaway - heater

will not turn "OFF"

The center of the

chamber

temperature is

different from the

control

temperature

displayed

No digital display

with the power

LED ON

Test SSR gate

signal output

Keypad does not

work or only some

of the keys beep

Hi-limit relay does

not click or pull in

when pressing the

HEATER ON

pushbutton

PROBABLE

SUGGESTED CORRECTIVE ACTION

CAUSE

Shorted SSR

Relay

Defective

controller

The hot air

entering the

chamber will be

Disconnect the one of the SSR leads (SSR terminal #3 or

#4). If the heater stays "ON", Replace SSR.

If heater turns "OFF", controller may be defective

(check DIAGNOSTICS MODE).

Change the CZO value in the Tune Mode to shift the

controller’s displayed readout to the temperature in the

center of the chamber.

the hotter than

center of the

chamber.

The control power

Replace the Protocol controller.

supply is defective

Connect a VOM (set on 20vdc/higher scale) across the

SSR Relay input terminals (SSR terminal #3 and #4)

1) Adjust the setpoint temperature a minimum of 20°C

degrees above the process displayed temperature

(output should measure approximately (+)15vdc).

2) Adjust the setpoint temperature a minimum of 20°C

degrees below the process displayed temperature

(output should measure 0vdc).

3) Adjust the setpoint temperature at the process

displayed temperature (voltage output should pulse

somewhere between 0vdc & 15vdc).

4) If the controller output voltage does not follow the

levels listed above, replace controller.

Defective Protocol • Turn the power ON and OFF by cycling the Green

Power Pushbutton.

• Press the Reset key.

• Replace Protocol.

No power or

voltage to the

• Check the incoming wiring and voltage.

• Check for loose wiring connector.

Protocol to

energize the relay

(ex. airflow switch

is not closed).

No Events are

displayed in Profile

The Protocol hilimit is not

energizing relay

even if the Heater

Relay LED is ON or

faintly lighted.

Events not

enabled

• Check both the incoming and output wiring and

voltage.

• Check for loose wiring connector.

• Replace Protocol.

The CODE*E* is located under Tune Mode. Using the

same code as required for the Tune Mode, change the

number of relays to the number of events being used (ex.

Display indicates zero (0) relays used change the number

to one (1) for Event One).

40

Page 47

PROBLEM/

SYMPTOM

Control or Hi-limit

readout displays

500°C or 932°F

PROBABLE

CAUSE

Loss of calibration Perform calibration.

SUGGESTED CORRECTIVE ACTION

41

Loading...

Loading...