Page 1

INSPIRED INNOVATION

u PN Series Inert Atmosphere Ovens

Ideal for Wide Variety of Inert Atmosphere Applications

e PN Series Inert Atmosphere Ovens are designed to accommodate a wide

variety of processes where an inert atmosphere is required to prevent product

oxidation. Typical applications include curing, bonding and heat treating.

e PN Series contains a digital PID controller that is easy to use and

congure saving the operator time. It comes with two temperature ranges

and two sizes to meet your process needs. e stainless steel, continuously

welded interior is ideal for highly corrosive conditions or where interior

cleanliness is critical. It has adjustable recirculating air louvers that

allow “ne tuning” to assure uniform airow, even with varying load

congurations and consistent product heating. It also has a heat exchanger

for providing rapid cool-down or the ability to operate at low temperatures

within a sealed chamber – Air-to-water is used on 343°C models, air-to-air

for 538°C models.

Despatch provides the design integrity, manufacturing experience and

emphasis on quality necessary for dependable operation and excellent

process control.

FEATURES AT A GLANCE

u Horizontal airflow for superior

temperature uniformity

u Two maximum temperature ratings:

°C (650°F) and 538°C (1000°F)

343

u Two sizes: 9 cubic feet (255 liters) and

29 cubic feet (821 liters)

u Inert atmosphere capability

u Heat exchanger for rapid cool down

u Digital, easy to use, PID control

u Stainless Steel interior

u Adjustable recirculating air louvers

assure uniform airflow

u Chamber pressure gauge

u Positive sealing door for atmosphere

integrity

u UL and C-UL listed open industrial

control panel

Minneapolis • shanghai • Berlin • singapore • hsinchu • tokyo • seoul

Page 2

OPTIONS

u Programmable controls for controlling rate of temperature rise and

process timing functions.

u Recorders – 10 inch diameter round chart. Strip charts also available.

u Oxygen concentration management system to guarantee low oxygen

concentrations and prevent heating until desired oxygen level is

achieved, assuring optimal product results.

u Disconnect switch in control panel to completely disconnect power to

equipment. Disconnect switch must be opened before control cabinet

door can be opened.

u

Door switch to shut down the heater and/or blower when door is open.

u Door lock to prevent opening door during cycle to assure process

is not interrupted.

u Process timers to automatically shut down oven at end of process.

u Alarms, audible and visual to signal end of process or other events.

u Capped access ports for pass through of wires and piping

required for process.

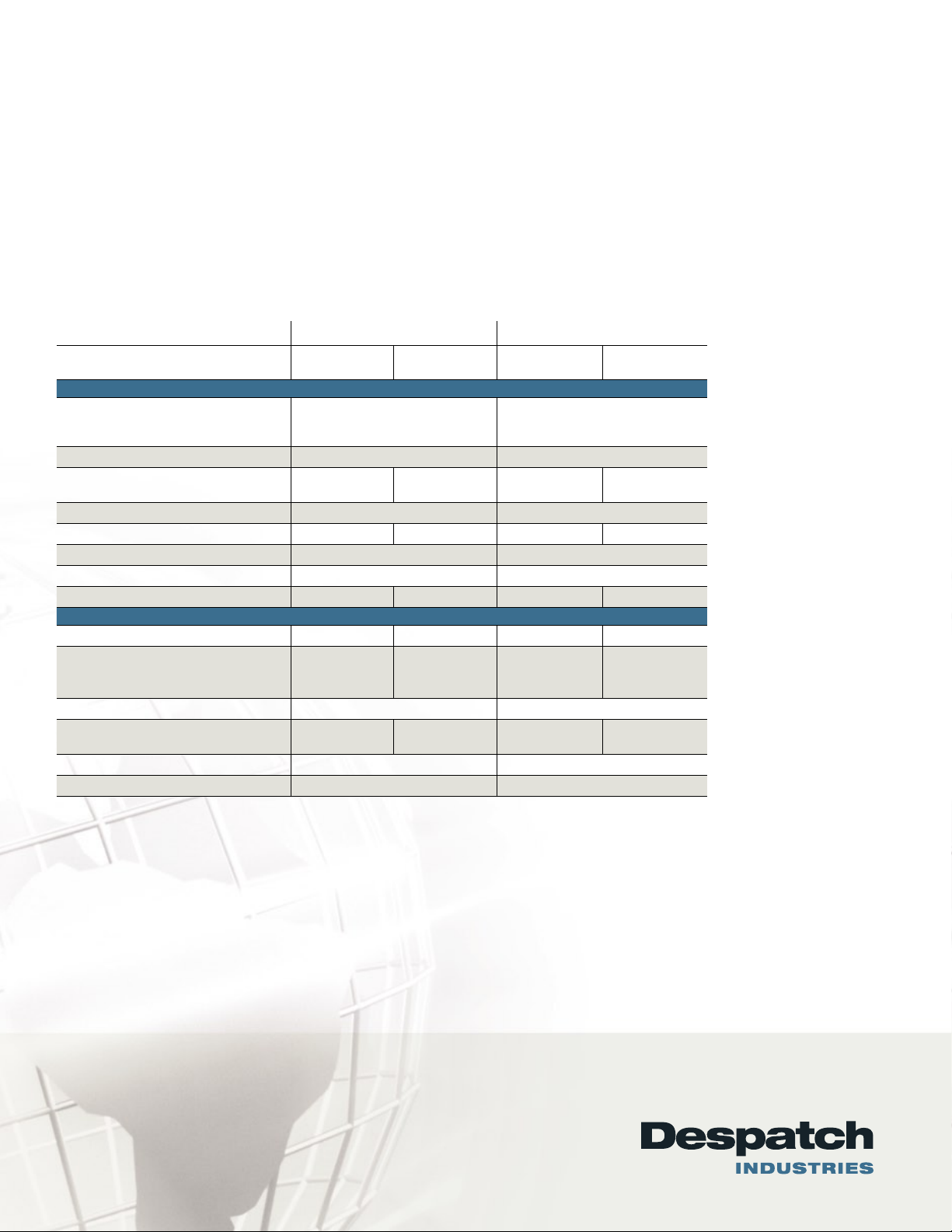

pn inert atMosphere oven PN 1-90 PN 2-29

D = 343OC (650OF)

F = 538OC (1000OF)

physical specifications

Chamber Size (width x depth x height) *Clear

opening width is reduced by 1.75 in (4.45 cm)

due to 7/8 in (2.2 cm) shelf supports on each side

Capacity 9 cu ft (255 liters) 29 cu ft (821 liters)

Overall Size (width x depth x height)

Distance from Floor to Work Opening 30 in (76 cm) 30 in (76 cm)

Insulation Thickness 5 in (12.7 cm) 6 in (15.2 cm) 5 in (12.7 cm) 6 in (15.2 cm)

Number of shelves provided 2 2

Maximum number of shelves 7 on 3 in (7.6 cm) centers 11 on 3 in (7.6 cm) centers

Approx. Weight 950 lbs. (431 kg) 2100 lbs. (952 kg) 2000 lbs. (907 kg) 3900 lbs. (1769 kg)

FUNCTIONAL SPECIFICATIONS

Heater Capacity 9 KW 20 KW 24 KW 40 KW

Recirculating System

Motor HP

CFM (LPS)

Time from Ambient to Maximum Temperature 60 Minutes (empty oven) 60 Minutes (empty oven)

Cool-Down Time from Maximum Temperature

Maximum Shelf Load 75 lbs. (34 kg) 130 lbs (59 kg)

Maximum Load Capacity 225 lbs. (102 kg) 350 lbs. (160 kg)

D F D F

25* x 25 x 25 in

63.5* x 63.5 x 63.5 cm

69 x 41 x 60 in

175 x 104 x 152 cm

1/3

575 CFM (271 LPS)11000 CFM (472 LPS)21700 CFM (802 LPS)21700 CFM (802 LPS)

45 Minutes to

o

100

C (212oF)

73 x 43 x 76 in

185 x 109 x 193 cm

105 Minutes to

125oC (257oF)

82 x 53 x 72 in

208 x 134 x 183 cm

45 Minutes to

100oC (212oF)

37* x 37 x 37 in

94* x 94 x 94 cm

85 x 55 x 88 in

216 x 139 x 223 cm

105 Minutes to

125oC (257oF)

Notes: PND ovens are not to be used with flammable solvents, combustible materials or enclosed containers. If your process involves flammable

solvents, consult the factory.

service and technical support

service parts: 1-800-473-7373

international service/main: 1-952-469-8230

service fax: 1-952-469-8193

service@despatch.com

gloBal headquarters

phone: 1-888-DESPATCH (1-888-337-7282)

international/main: 1-952-469-5424

fax: 1-952-469-4513

sales@despatch.com

8860 207th Street West

Minneapolis, MN 55044 USA

www.despatch.com

© 2010 Despatch Industries. All rights reserved. Despatch is a registered trademark of Despatch Industries in the U.S. and other countries. Ransco is a product line of Despatch Industries. PN 11-10

Loading...

Loading...