Page 1

INSPIRED INNOVATION

u Magnetic Annealing Tool

Industry Leading Throughput

Featuring High Field Strength Magnet

Despatch’s Magnetic Annealing Tool provides process exibility and

improved yield, enabling recording head manufacturers to make signicant

advances in product performance. e product features a wide range of eld

strength options, including electromagnets up to 1.0 Tesla. Tight temperature uniformity of +/- 0.5°C across each wafer and within the wafer stack

maximize product yield. An aluminum brazed chamber provides even wafer

heating which is critical to the success of the magnetic annealing process.

Industry Leading Throughput

Despatch’s Magnetic Annealing Tool provides recording head manufacturers

with the best overall throughput in the industry, by combining large load

capability with uniform temperature ramp-up and cooldown rates. Standard

load size is up to 22 wafers per batch for the MT-300. Temperature ramp-up

and cool rates of over 5°C per minute allow for shortened cycle times and

increased throughput. Despatch Magnetic Annealing Tools maintain their

excellent temperature uniformity during the ramp phase of the process cycle.

Increased Yield

Despatch’s patented Magnetic Annealing Tool helps increase recording head

yield by maintaining tight tolerances throughout each batch. Temperature

tolerance within each wafer, and between wafers in a batch, is better than

±0.5% of soak temperature. e MT-300 maintains temperature uniformity of

±0.5°C. Precise magnetic eld uniformity is also maintained. Field uniformity

is better than ±2% throughout the work area. e maximum divergence angle

is 2 degrees in the plane of the wafers. ese tight tolerances lead to excellent

lot-to-lot consistency and superior product quality.

Greater Process Flexibility

Despatch’s Magnetic Annealing Tool oers exibility to recording head process

designers. With a wide range of temperatures, magnetic eld strengths, wafer

rotation, and a variety of material handling options, Despatch’s tools enable

head manufacturers to keep pace with rapidly changing technology.

FEATURES AT A GLANCE

u

Electro-magnet: Field strength

1.0 Tesla standard. Field uniformity ±2%

Divergence angle <1.5°

u

22 wafer levels per batch, plus 1 control

u

300°C maximum temperature

u

Automatic mass flow controlled backfill/

inert gas capability

u

Temperature uniformity: ±0.5°C

u

Standard vacuum system: 10-3 Torr

u

Ramp Rate: 5°C per minute

u

User friendly graphical interface,

featuring real time graphing, alarm

monitoring, and SECS/GEM compatibility

Minneapolis • shanghai • Berlin • singapore • hsinchu

Page 2

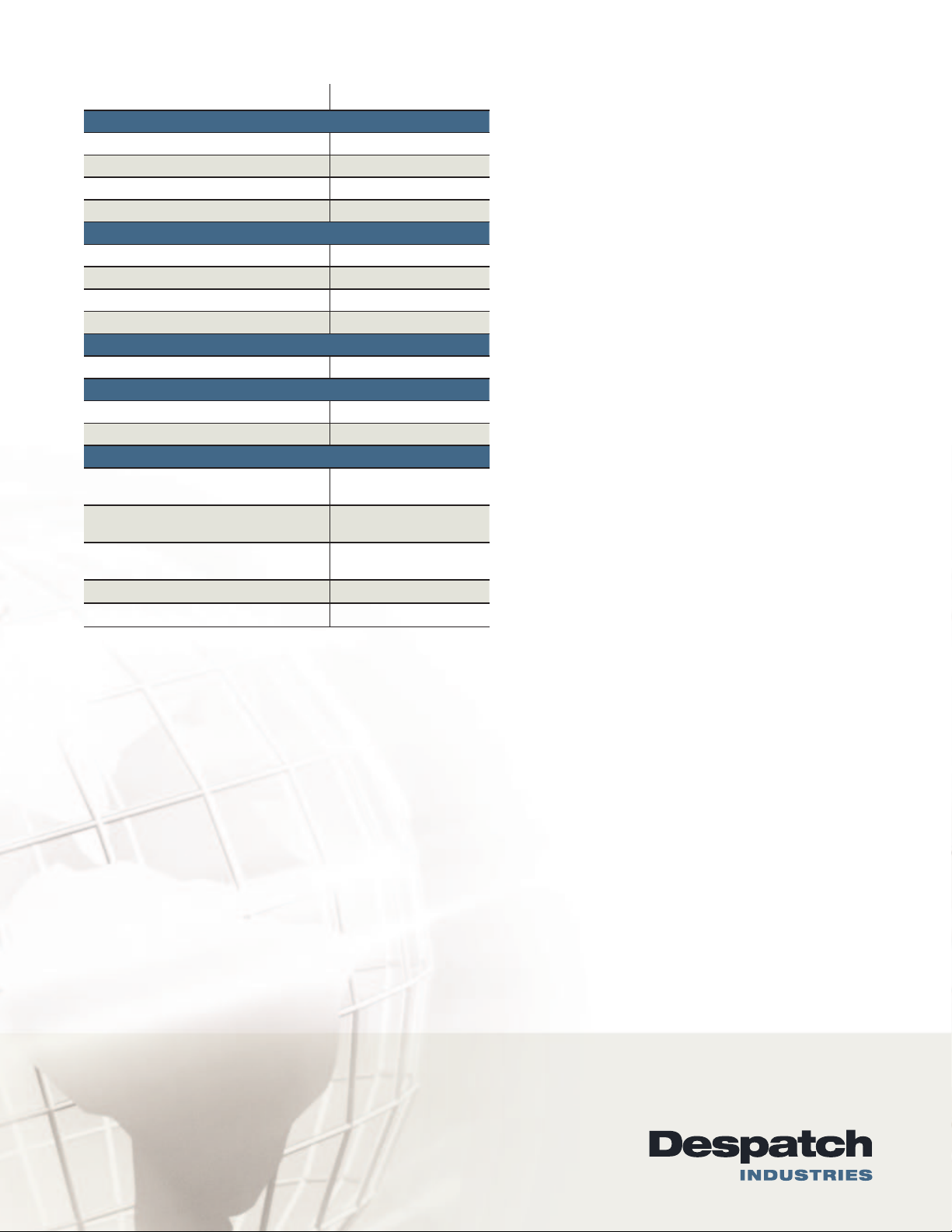

MODELS MT-300

TEMPERATURES

Maximum Temperature 300°C

Temperature Uniformity ±0.5°C

Ramp-Up Rate 5°C/Minute

Ramp-Down Rate 5°C/Minute

MAGNETIC OPTIONS

Permanent Magnet to 0.2 Tesla

Electro-Magnet to 1.0 Tesla

Maximum Divergence Angle 2°

Field Uniformity ±2%

VACUUM

Vacuum Base Pressure (Standard) 10

WAFERS

Wafer Size 200mm

Wafers Per Batch 22

other

Tool Overall Dimensions (WxDxH) 51 x 63 x 88 in

Control Cabinet Dimensions (WxDxH) 72.1 x 34.3 x 18.1 in

Electrical 208-3-50/60 65FLA 15KW

Tool Weight

Control Cabinet Weight

-3

Torr

129.5 x 160 x 223.5 cm

183.1 x 87.1 x 46 cm

(Other Options Available)

1,150 lbs (521.63 kg)

600 lbs (272.15 kg)

serVice anD technical support

Service Parts: 1-800-473-7373

International Service/Main: 1-952-469-8230

Service Fax: 1-952-469-8193

service@despatch.com

gloBal heaDQuarters

Phone: 1-888-DESPATCH (1-888-337-7282)

International Service/Main: 1-952-469-5424

Fax: 1-952-469-4513

sales@despatch.com

8860 207th Street West

Minneapolis, MN 55044 USA

www.despatch.com

© 2012 Despatch Industries. All rights reserved. Despatch is a registered trademark of Despatch Industries in the U.S. and other countries. Magnetic Annealing Tool 5-12

Loading...

Loading...