Page 1

E-102

p.n. 143896

Modbus User's Programming Manual

For

Despatch ProtocolTM Plus

A-51643 Rev. 6 10/06/03

Page 2

Chromalox Instruments and Controls

Revision History

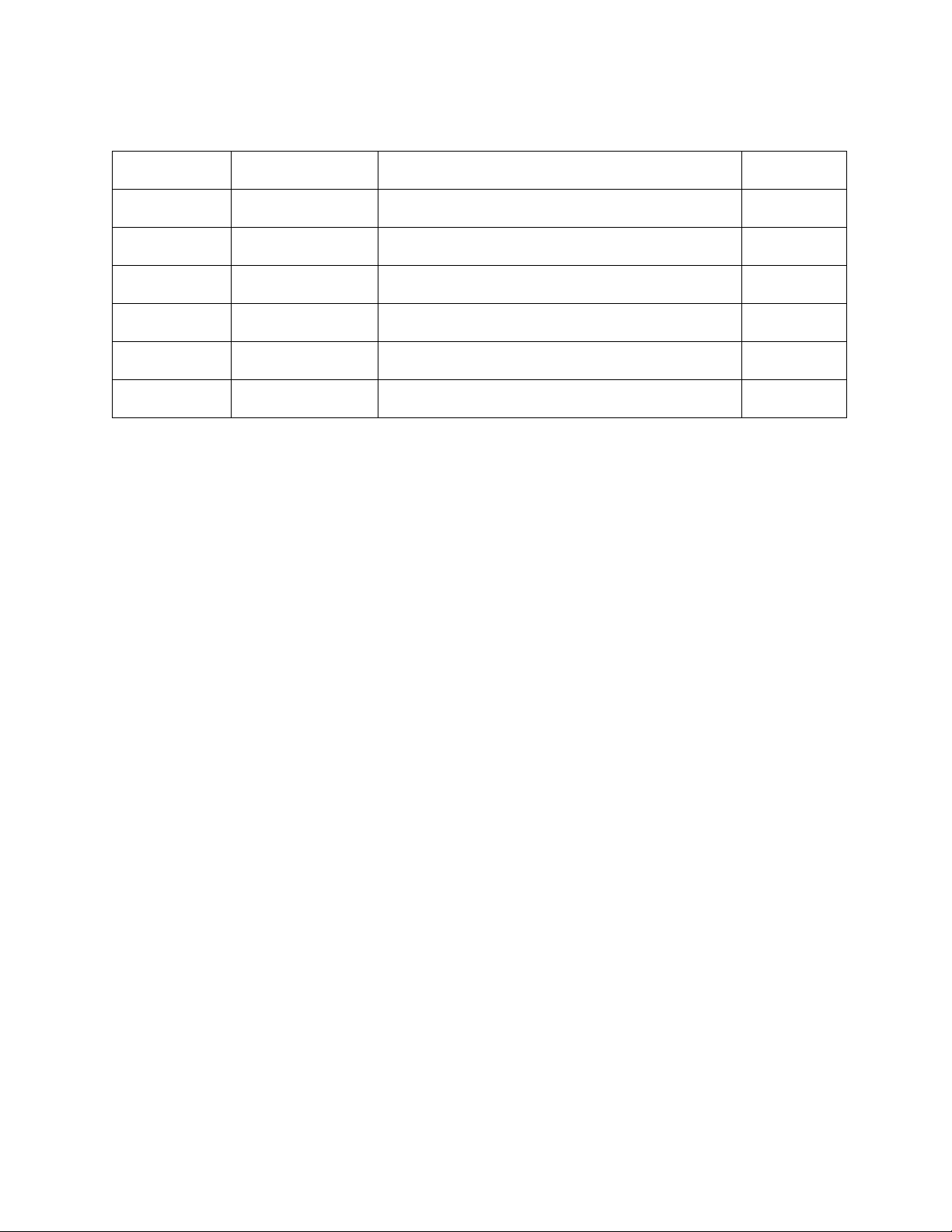

Rev. Date Description

0 10/6/1998 Original Release

1 01/25/1999 Major revisions to match tested software.

2 02/12/1999

3 03/22/1999 Corrected figure references in communication card setup sections. Added text

4 01/24/2002 Added holding register address references for new menus for software version 3.0

5 06/10/2002 Added section 7, Programming Example and General Hints

6 10/6/2003 Section 3.6, change data address information in register 449.

Corrected temperature readout descriptions to 1 °F from 0.1 °F. Corrected misc.

typos. Removed front panel security code holding register. Moved

communication security code holding register to address 0.

concerning level 1 & 2 password holding registers.

and 3.1(Heat/Cool).

Approvals

Project Manager Bhupesh Gandhi

Design Engineer Bhupesh Gandhi

Engineering Manager Al Roman

Sales Manager Gus Guthrie

Customer Rich Johnson

Customer Brian Hajder

A-51643 Rev. 6 10/06/03 i

Page 3

Chromalox Instruments and Controls

Table of Contents

1 OVERVIEW................................................................................................................................................ 2

1.1 PURPOSE................................................................................................................................................2

1.2 CONVENTIONS AND DEFINITIONS ............................................................................................................2

2 COMMUNICATIONS SPECIFICATIONS................................................................................................2

2.1 SUPPORT SPECIFICATIONS ......................................................................................................................2

2.2 TIMING SPECIFICATIONS ......................................................................................................................... 2

2.3 WIRING .................................................................................................................................................2

2.4 COMMUNICATION CARD INSTALLATION AND JUMPER SETTINGS ..............................................................2

2.4.1 Communication Card (0113-10175) Installation ................................................................................2

2.4.2 Communication Card Jumper Settings............................................................................................... 2

3 REGISTER AND I/O MAPPING................................................................................................................2

3.1 UNMAPPED AND RESERVED REGISTERS...................................................................................................2

3.2 REGISTER QUANTITY LIMITATIONS......................................................................................................... 2

3.3 DISCRETE INPUT ASSIGNMENTS..............................................................................................................2

3.4 DISCRETE OUTPUT ASSIGNMENTS........................................................................................................... 2

3.5 INPUT REGISTER ASSIGNMENTS..............................................................................................................2

3.6 HOLDING REGISTER ASSIGNMENTS ......................................................................................................... 2

4 APPLICATION OPERATIONS.................................................................................................................2

4.1 SECURITY LEVEL AND DISCRETE INPUTS, DISCRETE OUTPUTS, AND REGISTER ACCESS ............................ 2

4.2 MULTIPLE REGISTER WRITE LIMITATIONS .............................................................................................. 2

4.3 CONTROL OPERATION AND RUN/HOLD/STOP FUNCTIONS........................................................................2

4.4 CONTROLLER MODE AND DATA ACCESS................................................................................................. 2

4.5 MONITORING AND ACKNOWLEDGEMENT OF ALARMS, EVENTS, AND CYCLE COMPLETE, DISCRETE INPUTS,

AND DISCRETE OUTPUTS..................................................................................................................................... 2

4.6 EVENT SETUP VALUES ...........................................................................................................................2

4.7 KEYPAD LOCKOUT.................................................................................................................................2

4.8 TEMPERATURE VALUES..........................................................................................................................2

4.9 TIME VALUES ........................................................................................................................................ 2

4.10 HIGH LIMIT SETPOINT AND BAND REGISTERS.......................................................................................... 2

4.11 BROADCASTING WITH GUARANTEED DELIVERY ......................................................................................2

4.12 COMMUNICATION PARAMETER ADJUSTMENTS........................................................................................2

5 FUNCTION SET DETAILS ........................................................................................................................ 2

A-51643 Rev. 6 10/06/03 ii

Page 4

Chromalox Instruments and Controls

5.1 FUNCTION SET OVERVIEW......................................................................................................................2

5.2 REGISTER AND I/O FUNCTION SET DESCRIPTION FOR PROTOCOL

5.2.1 [01] Read Outputs.............................................................................................................................2

5.2.2 [02] Read Input Discretes.................................................................................................................. 2

5.2.3 [03] Read Holding Registers (Read Multiple Registers) .....................................................................2

5.2.4 [04] Read Input Registers..................................................................................................................2

5.2.5 [06] Write Single Register................................................................................................................. 2

5.2.6 [16] Write Multiple Registers ............................................................................................................2

5.3 DIAGNOSTICS AND SUPPORT DESCRIPTION FOR PROTOCOL

5.3.1 [08] Diagnostics ............................................................................................................................... 2

5.3.1.1 [08 00] Return Query Data........................................................................................................................ 2

5.3.1.2 [08 01] Restart Communications Option....................................................................................................2

5.3.1.3 [08 02] Return Diagnostic Register...........................................................................................................2

5.3.1.4 [08 04] Force Listen Mode Only............................................................................................................... 2

5.3.1.5 [08 10] Clear Communication Counters ....................................................................................................2

5.3.1.6 [08 12] Return Bus Communication Error Count....................................................................................... 2

5.3.1.7 [08 13] Return Bus Exception Error Count................................................................................................ 2

5.3.1.8 [08 14] Return Slave Message Count ........................................................................................................2

5.3.1.9 [08 15] Return Slave No Response Count..................................................................................................2

5.3.1.10 [08 18] Return Bus Character Overrun Count ............................................................................................2

5.3.2 [17] Report Slave ID .........................................................................................................................2

TM

PLUS .................................................2

TM

PLUS.......................................................... 2

5.4 EXCEPTION RESPONSE DESCRIPTION.......................................................................................................2

5.4.1 [01] Illegal Function......................................................................................................................... 2

5.4.2 [02] Illegal Data Address.................................................................................................................. 2

5.4.3 [03] Illegal Data Value .....................................................................................................................2

6 MODBUS PROTOCOL QUICK REFERENCE........................................................................................ 2

6.1 PROTOCOL FORMAT ...............................................................................................................................2

6.2 RTU TRANSMISSION MODE....................................................................................................................2

6.2.1 Coding System................................................................................................................................... 2

6.2.2 Serial Byte Setup ...............................................................................................................................2

6.2.3 Error Checking Field ........................................................................................................................ 2

6.2.4 Message Framing..............................................................................................................................2

6.3 ADDRESS FIELD .....................................................................................................................................2

6.4 FUNCTION FIELD....................................................................................................................................2

6.5 DATA FIELD...........................................................................................................................................2

6.6 ERROR CHECKING FIELD ........................................................................................................................ 2

6.7 FIELD CONTENTS IN MODBUS MESSAGES................................................................................................ 2

A-51643 Rev. 6 10/06/03 iii

Page 5

Chromalox Instruments and Controls

6.7.1 The Byte Count Field......................................................................................................................... 2

7 PROGRAMMING EXAMPLE AND GENERAL HINTS..........................................................................2

7.1 CODE EXAMPLE .....................................................................................................................................2

7.2 ADDITIONAL COMMUNICATIONS TROUBLESHOOTING HINTS.................................................................... 2

List of Figures and Tables

TABLE 1: MODBUS REFERENCES .............................................................................................................................2

TABLE 2: PROTOCOL

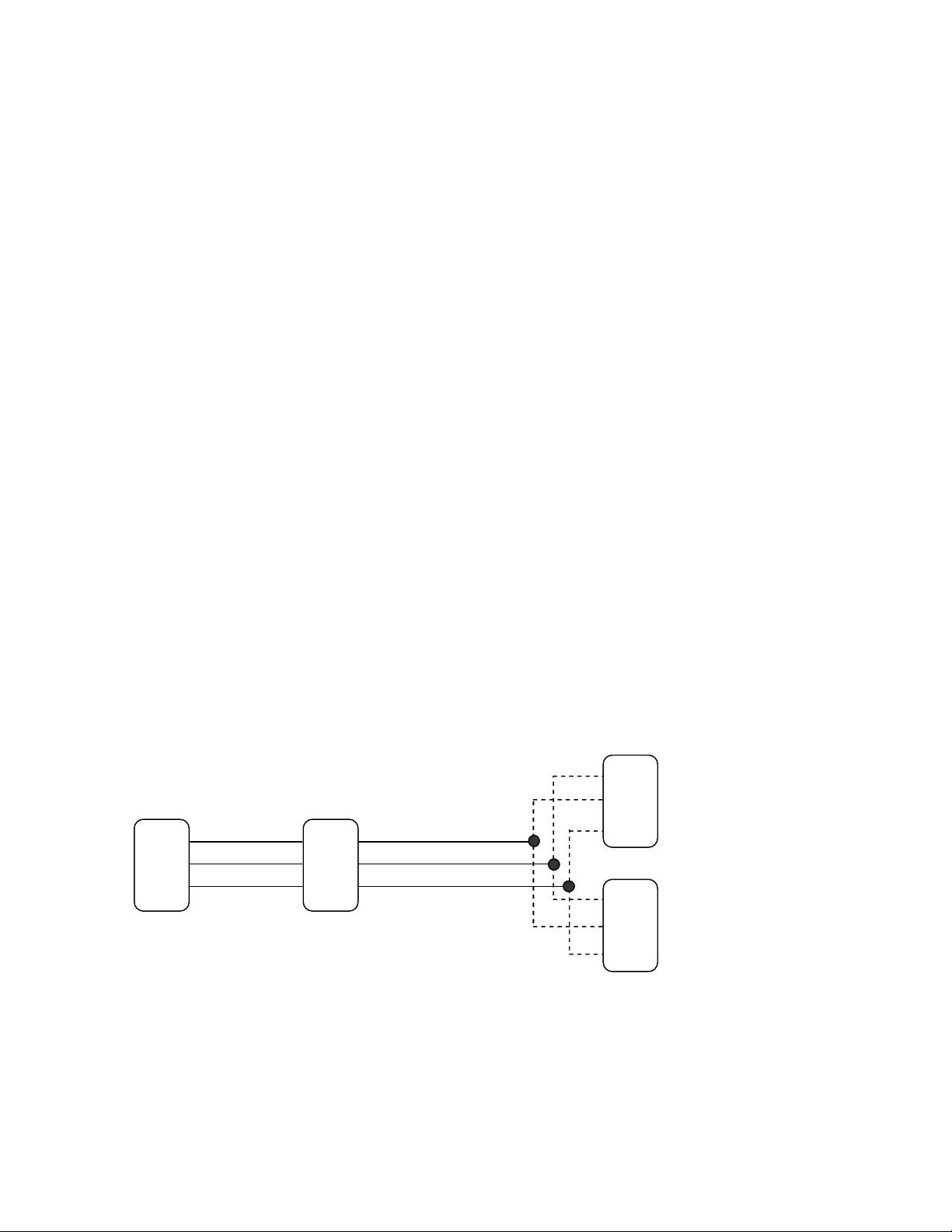

FIGURE 1: RS232 WIRING ...................................................................................................................................... 2

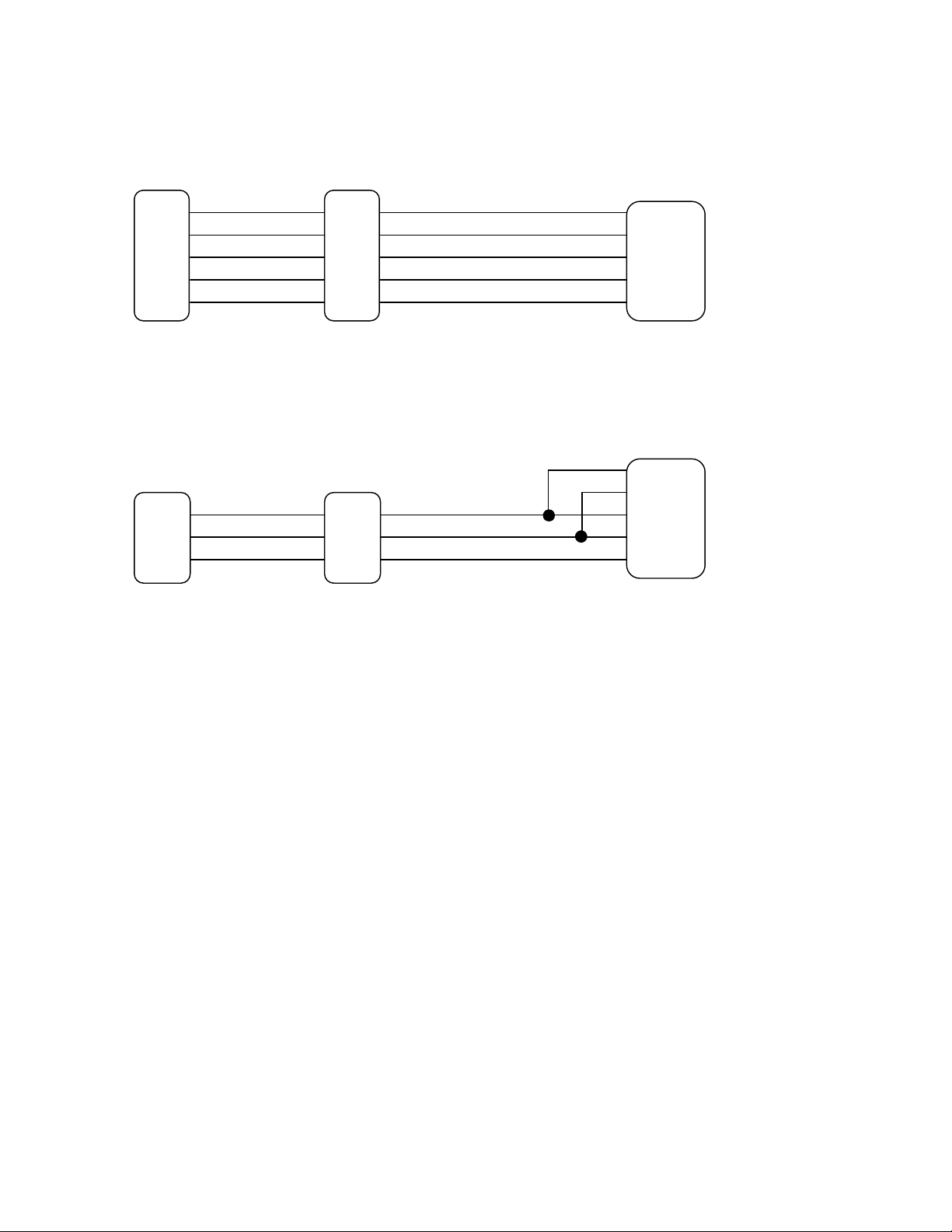

FIGURE 2: RS422A WIRING (4 WIRE)...................................................................................................................... 2

FIGURE 3: RS485 WIRING (2 WIRE).........................................................................................................................2

FIGURE 4: CONTROLLER REAR VIEW WITH COMMUNICATION CARD (LEFT).............................................................. 2

FIGURE 5: COMMUNICATION CARD (0113-10175) JUMPER SETTINGS ........................................................................ 2

TABLE 3: PROTOCOL

TABLE 4: PROTOCOL

TABLE 5: PROTOCOL

TABLE 6: PROTOCOL

TM

PLUS REFERENCES...............................................................................................................2

TM

PLUS DISCRETE INPUT ADDRESS MAP..................................................................................2

TM

PLUS DISCRETE OUTPUT ADDRESS MAP............................................................................... 2

TM

PLUS INPUT REGISTER ADDRESS MAP.................................................................................. 2

TM

PLUS HOLDING REGISTER ADDRESS MAP.............................................................................2

TABLE 7: COMMUNICATION SECURITY LEVELS........................................................................................................ 2

TABLE 8 PROTOCOL

TABLE 9 PROTOCOL

TABLE 10 PROTOCOL

TABLE 11: PROTOCOL

TM

PLUS FUNCTION AND EXCEPTION CODE SET ........................................................................2

TM

PLUS DIAGNOSTIC (FUNCTION CODE 08) SUB-FUNCTION SET ...............................................2

TM

PLUS EXCEPTION CODE SET .............................................................................................. 2

TM

PLUS DIAGNOSTIC REGISTER BIT ASSIGNMENT ..................................................................2

FIGURE 6 CRC FLOWCHART ..................................................................................................................................2

A-51643 Rev. 6 10/06/03 iv

Page 6

Chromalox Instruments and Controls

A-51643 Rev. 6 10/06/03 v

Page 7

Chromalox Instruments and Controls

1 Overview

1.1 Purpose

This document provides all application specific information necessary for developing a Modbus Master

application program for interfacing with the ProtocolTM Plus slave controller. The assumption is made

that the programmer has at least an intermediate understanding of the Modbus Protocol. Only limited

information is presented here regarding the Modbus Protocol specifications. Below is a list of relevant

Modbus Protocol documents. A quick reference section is provided in this document (see section 6

Modbus Protocol Quick Reference). A programming guideline section provides a programming

example and general communications hints (see section 7 Programming Example and General Hints

for programming help).

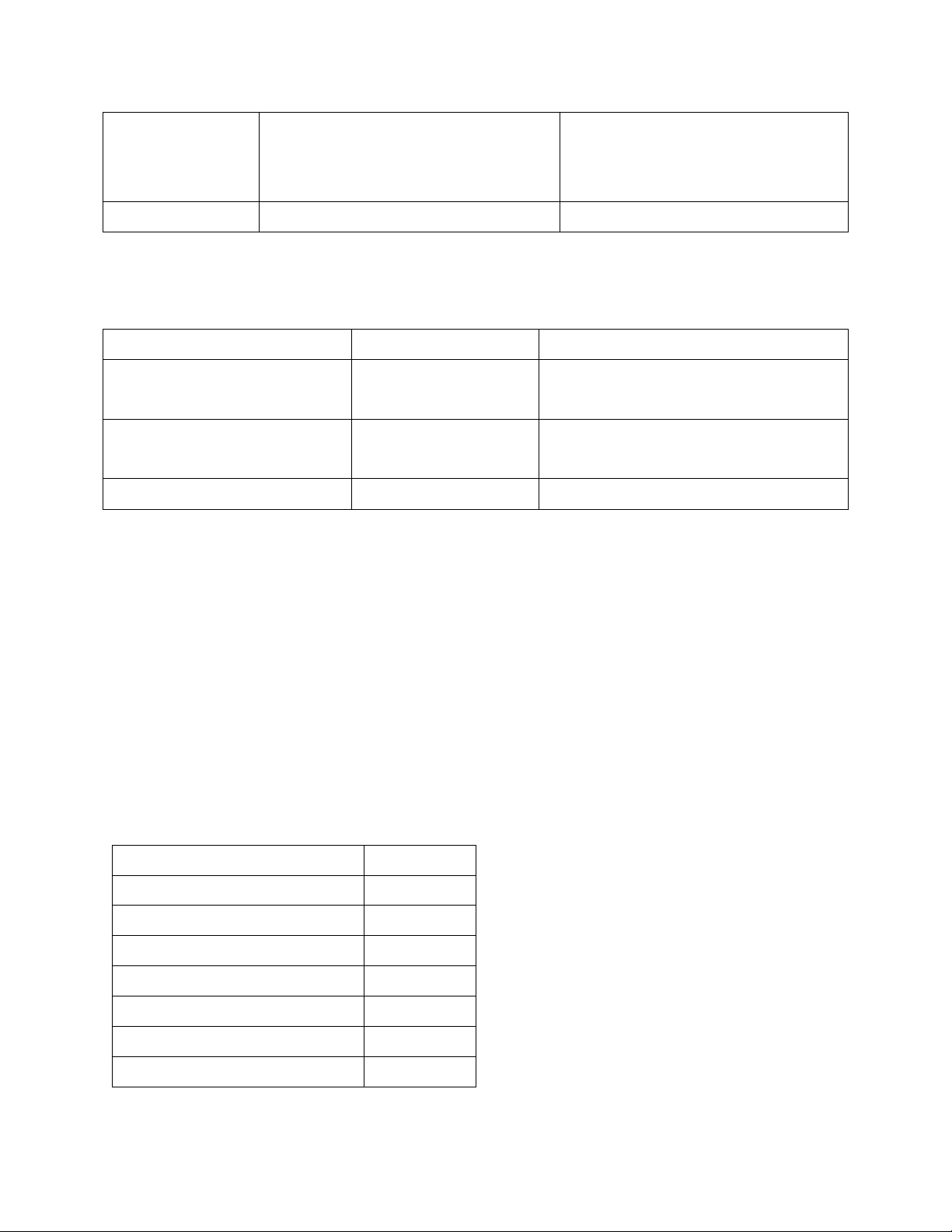

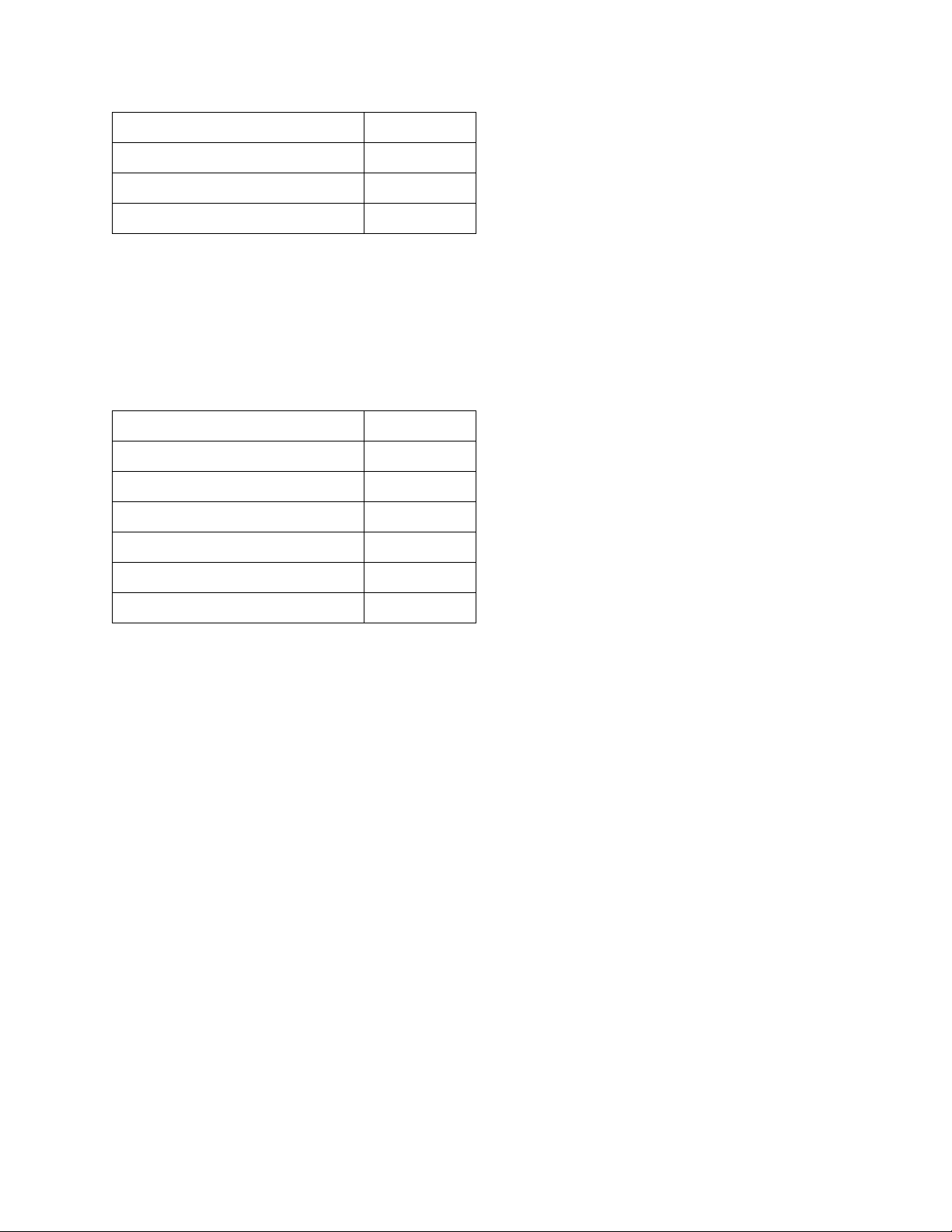

Table 1: Modbus References

Modicon Modbus Protocol http://www.modicon.com/techpubs/intr7.html

Schneider Automation Open Modbus/TCP

Specification

http://www.modicon.com/openmbus.html/

Table 2: ProtocolTM Plus References

Engineering Specification for Despatch ProtocolTM Plus A-50778

1.2 Conventions and definitions

RTU: Remote Terminal Unit

CRC: Cyclical Redundancy Check

$: Represents a hexadecimal number

XOR: Exclusive OR logic operation

LSB: Least Significant Bit

MSB: Most Significant Bit

XX: Don’t Care when used in a hex number

--: Field contents are data dependent

NA: Not Applicable

TBD: To Be Determined or To Be Defined

A-51643 Rev. 6 10/06/03 1

Page 8

Chromalox Instruments and Controls

Master Device

2 1

Protocol™ Plus DB

-

9 Connector

3 5 2 3 7

Protocol™ Plus Connector

5 5

2 Communications Specifications

2.1 Support Specifications

Device Support: Slave only.

Slave ID Code (Identifies Product Line): 1.

Transmission Mode: RTU mode only.

Communication Medium: RS232, RS422, or RS485.

Address Support: 1 – 247.

Baud Rate: 2400, 4800, 9600, 19.2K, 38.4K

Parity: None, Even, or Odd.

2.2 Timing Specifications

Message Framing: Silent period of at least 3.5 character times before the first character and after the last

character of the message.

Character Framing: No more than 1.5 character times of silence between received and transmitted

characters.

Message Timeout (Query Response Time): Response to queries will be made within 1 sec.

2.3 Wiring

Figure 1: RS232 Wiring

DB-9

2

Rcv

Xmit

Gnd

Rcv

Xmit

Gnd

3

Rcv

Xmit

Gnd

3

Rcv

Xmit

Gnd

DB-25

A-51643 Rev. 6 10/06/03 2

Page 9

Chromalox Instruments and Controls

2 5

Protocol™ Plus DB

-

9 Connector

Master Device

3 7

1 5

Protocol™ Plus Connector

5

Protocol™ Plus DB

-

9 Connector

5

Protocol™ Plus Connector

Master Device

3 7

Figure 2: RS422A Wiring (4 wire)

Rcv +

Rcv Xmit +

Xmit - 4

Gnd

T/R +

T/R Gnd

Rcv +

2

3

Rcv -

Xmit +

Xmit - 4

Gnd

7

3

14

2

16

Xmit + (b)

Xmit – (a)

Rcv + (b)

Rcv – (a)

Gnd

DB-25

(Pin #’s based on RS-530

standard; may vary by

device)

Figure 3: RS485 Wiring (2 wire)

14

Xmit + (b)

2

3

4

T/R +

T/R Gnd

3

4

16

Xmit – (a)

Rcv + (b)

Rcv – (a)

Gnd

DB-25

(Pin #’s based on RS-530

standard; may vary by

device)

2.4 Communication Card Installation and Jumper Settings

WARNING

Electronic Components are extremely sensitive to static electricity. Before opening the controller

case, read and follow the precautions below to prevent damage from static electricity.

1. Turn off power to the controller.

2. Touch a bare metal surface on the exterior of the controller.

3. Disconnect the power connection from the controller or unplug from the power source.

Also follow these static electricity precautions:

v Avoid static-causing surfaces while working with electronic components.

v Remove parts from their anti-static bags only when ready for use. Do not lay parts on the outside of

the anti-static bag because only the inside provides protection.

v Hold circuit boards by their edges or any metal mounting hardware. Avoid touching components or

connectors on the circuit boards.

2.4.1 Communication Card (0113-10175) Installation

1. Turn off power to the controller.

2. Remove the back cover of the controller by removing the two screws at the top of the unit.

A-51643 Rev. 6 10/06/03 3

Page 10

Chromalox Instruments and Controls

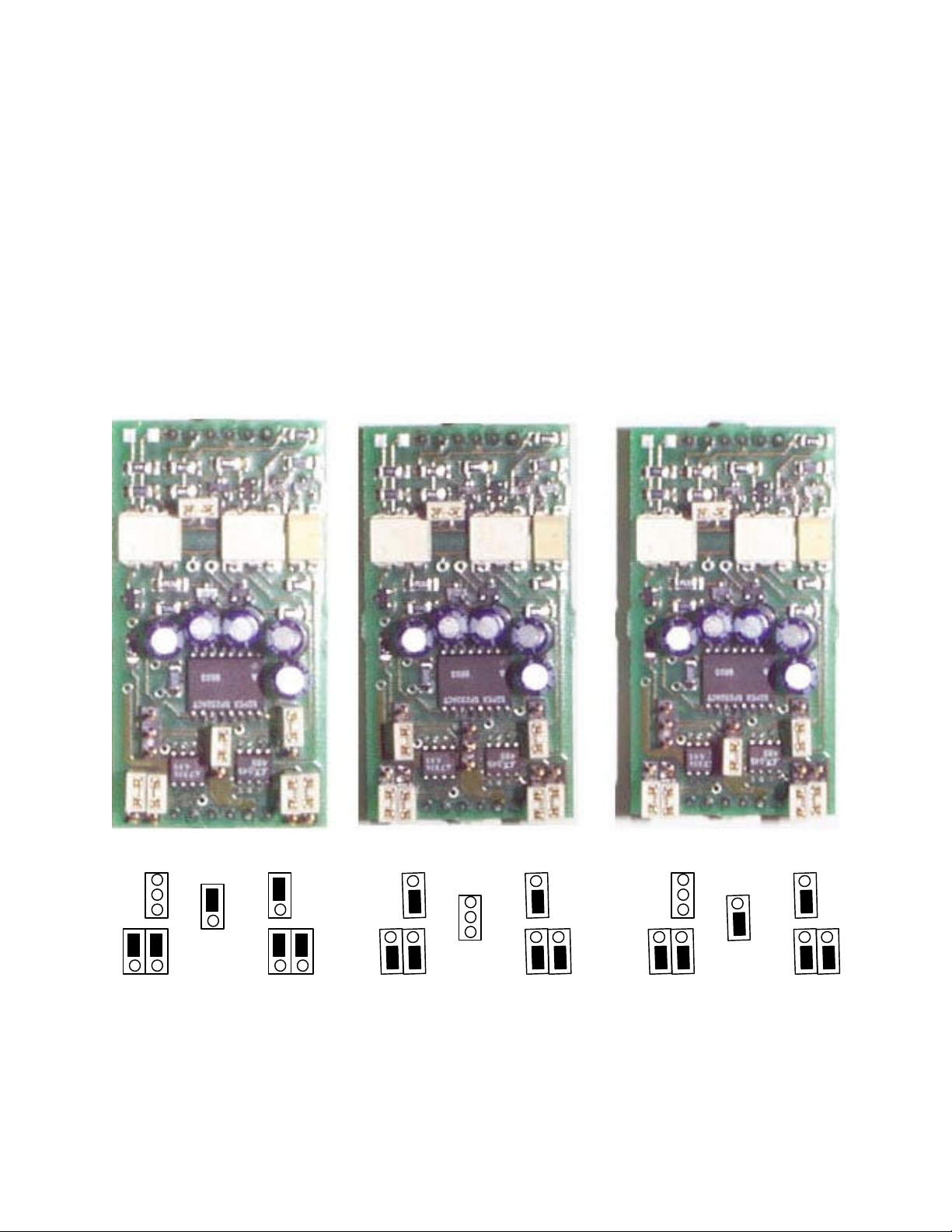

3. Looking into the back of the controller with the connector terminal strips at the bottom, install the

communication card onto the two 5 pin headers on the rear circuit board. Be sure the jumper blocks

on the communication card are positioned toward the bottom of the controller. See Figure 4:

Controller Rear View with Communication Card (Left). Be sure the card is seated firmly onto the

headers.

4. Set the jumpers on the communication card for the desired serial communication interface based on

Figure 5: Communication Card (0113-10175) Jumper Settings.

5. Reinstall the back cover.

6. Wire the communication connections on the rear of the unit for the desired serial communication

interface based on Figure 1: RS232 Wiring, Figure 2: RS422A Wiring (4 wire), or Figure 3:

RS485 Wiring (2 wire).

7. Reapply all power connections to the controller.

Figure 4: Controller Rear View with Communication Card (Left)

A-51643 Rev. 6 10/06/03 4

Page 11

Chromalox Instruments and Controls

RS232 Jumper Settings

RS422 Jumper Settings

RS485 Jumper Settings

2.4.2 Communication Card Jumper Settings

1. Turn off power to the controller.

2. Remove the back cover of the controller (if it is not already removed) by removing the two screws at

the top of the unit.

3. Set the jumpers on the communication card for the desired serial communication interface based on

Figure 5: Communication Card (0113-10175) Jumper Settings.

4. Reinstall the back cover.

5. Reapply power to the controller.

Figure 5: Communication Card (0113-10175) Jumper Settings

A-51643 Rev. 6 10/06/03 5

Page 12

Chromalox Instruments and Controls

3 Register and I/O Mapping

3.1 Unmapped and Reserved Registers

Reserved and NA registers will be read as zero with no exception error being generated. Thus, the host

can request data from multiple addresses with gaps between and still receive a valid response. Illegal and

undefined register address blocks will always generate an illegal data address exception.

Reserved and NA registers may be written without generating an exception, however the data is ignored

for these registers and no write takes place. Illegal and undefined register address blocks will always

generate an illegal data address exception.

3.2 Register Quantity Limitations

The number of registers that can be accessed in one query is limited to 50.

3.3 Discrete Input Assignments

The status of the four event inputs can be read as discrete inputs in Modbus format.

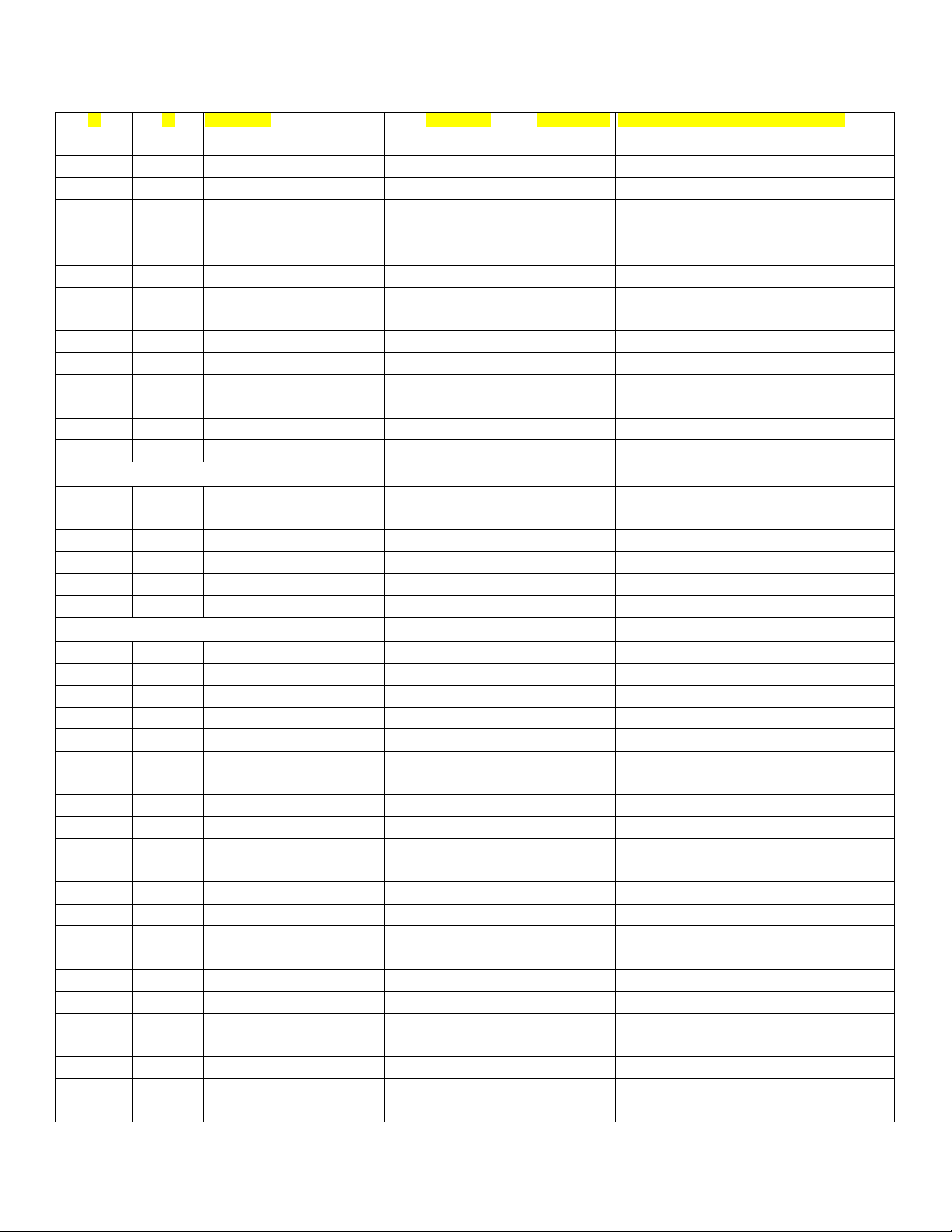

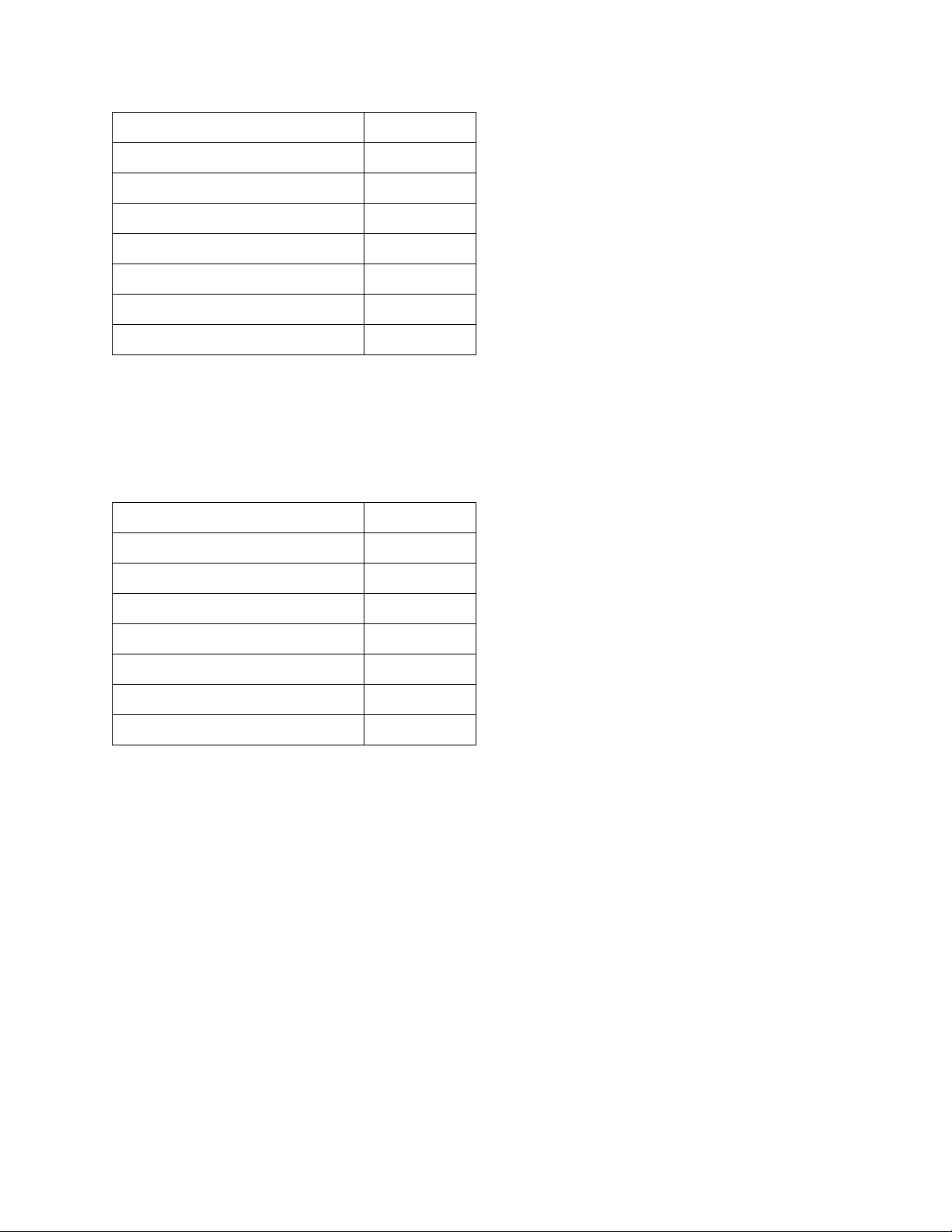

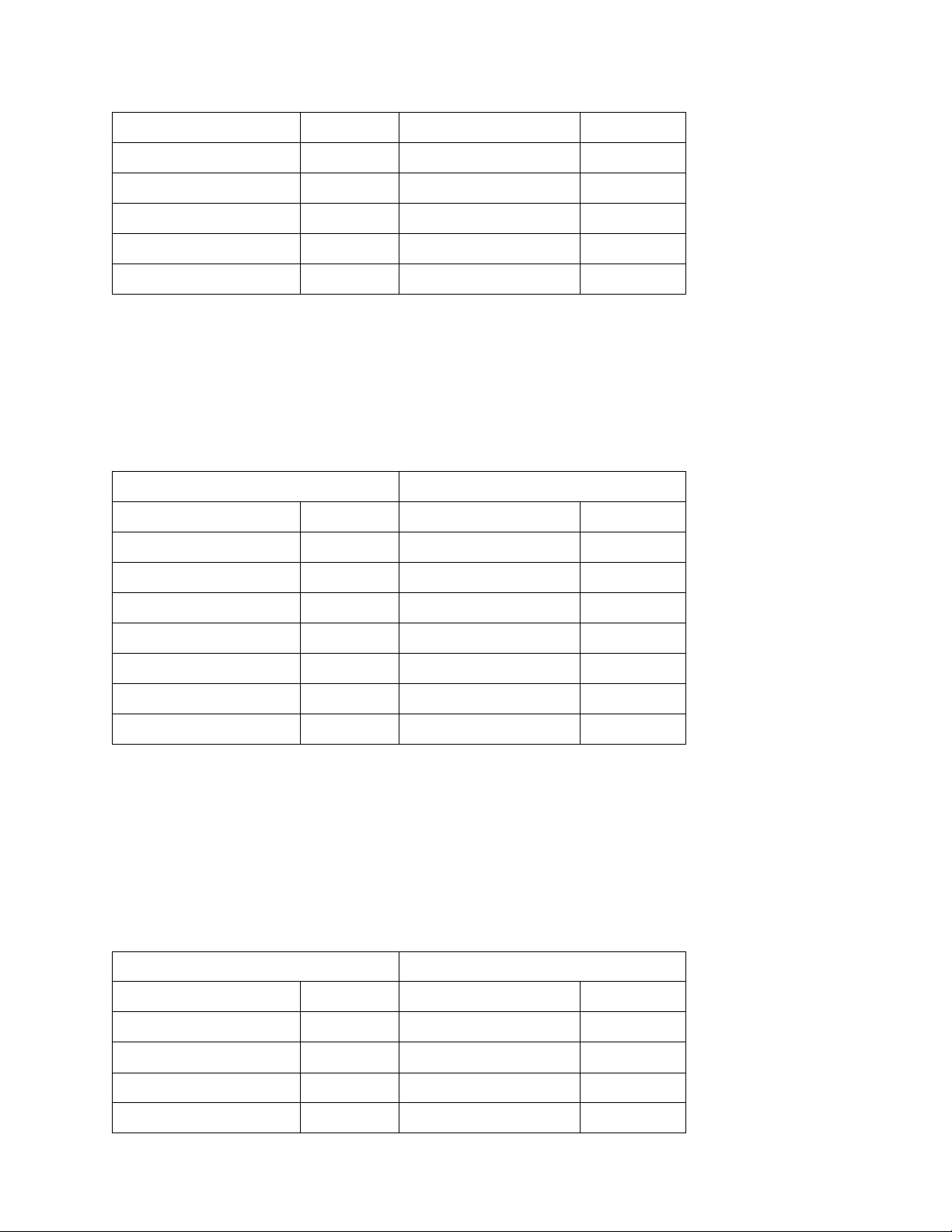

Table 3: ProtocolTM Plus Discrete Input Address Map

Data Address Hex Address Description Security

8 -- 65535

0

1

2

3

4 -- 7

$0000 Event Input 1

$0001 Event Input 2

$0002 Event Input 3

$0003 Event Input 4

$0004 -- $0007 Illegal, Reserved for future inputs

$0008 - $FFFF Undefined, available for application assignment

0

0

0

0

0

0

3.4 Discrete Output Assignments

The status of the four relay outputs can be read as discrete outputs in Modbus format. Writes to the

outputs are not supported, that is, the functions “Write Single Output” (06) and “Write Multiple Outputs”

(15) are not implemented.

A-51643 Rev. 6 10/06/03 6

Page 13

Chromalox Instruments and Controls

Table 4: ProtocolTM Plus Discrete Output Address Map

Data Address Hex Address Description Security

8 -- 65535

0

1

2

3

4 -- 7

$0000 Relay Output 1

$0001 Relay Output 2

$0002 Relay Output 3

$0003 Relay Output 4

$0004 -- $0007 Illegal, Reserved for future inputs

$0008 - $FFFF Undefined, available for application assignment

0

0

0

0

0

0

A-51643 Rev. 6 10/06/03 7

Page 14

Chromalox Instruments and Controls

Timer/Ramp/Soak Interval Time

0 = ramp interval of segment, 1 = soak interval of

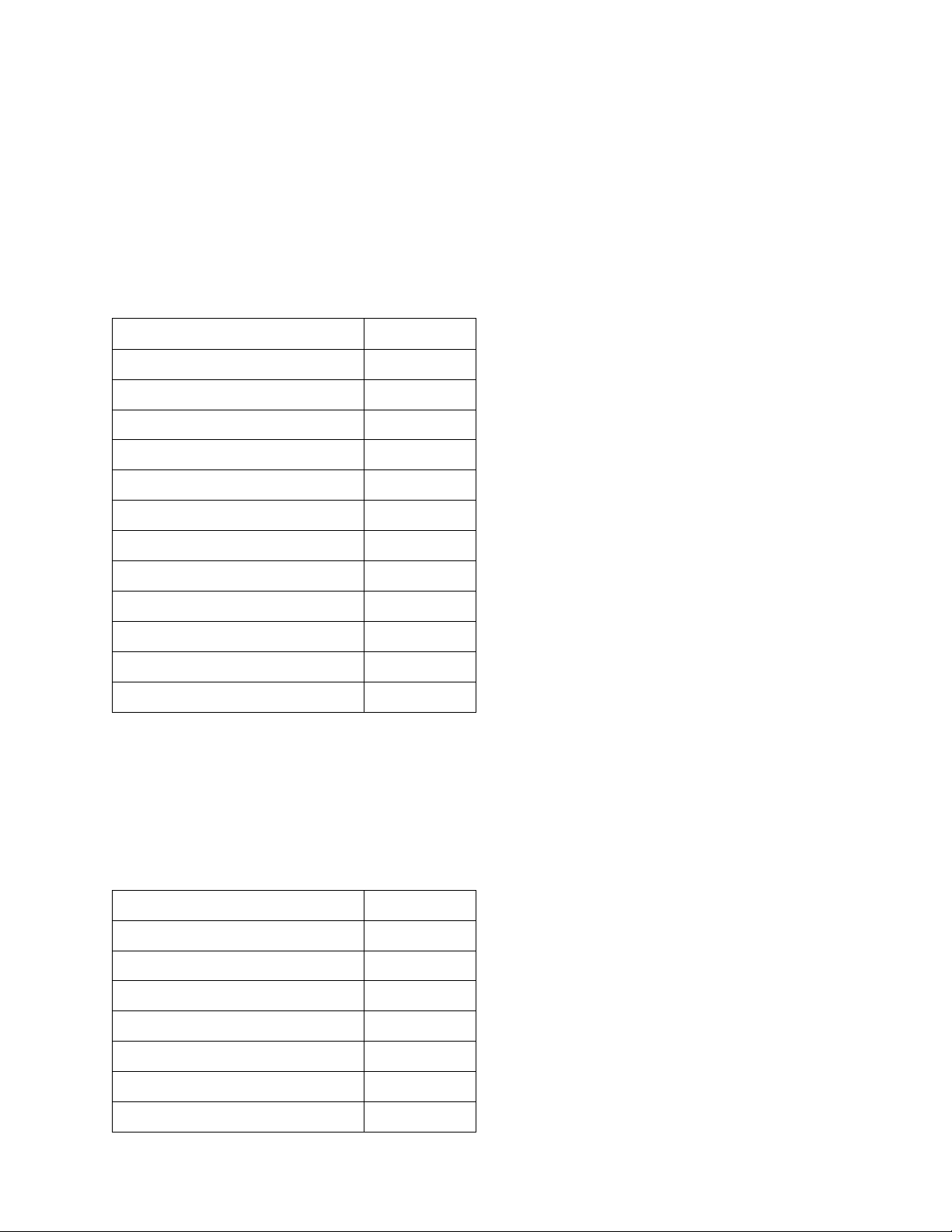

3.5 Input Register Assignments

Input registers are intended for read only information and functions that cannot or should not be

controlled remotely. Much status information is mapped as holding registers so that operations can be

controlled remotely. Examples are control output commands, ramp/soak status (run, hold, stop), and

ramp/soak program number.

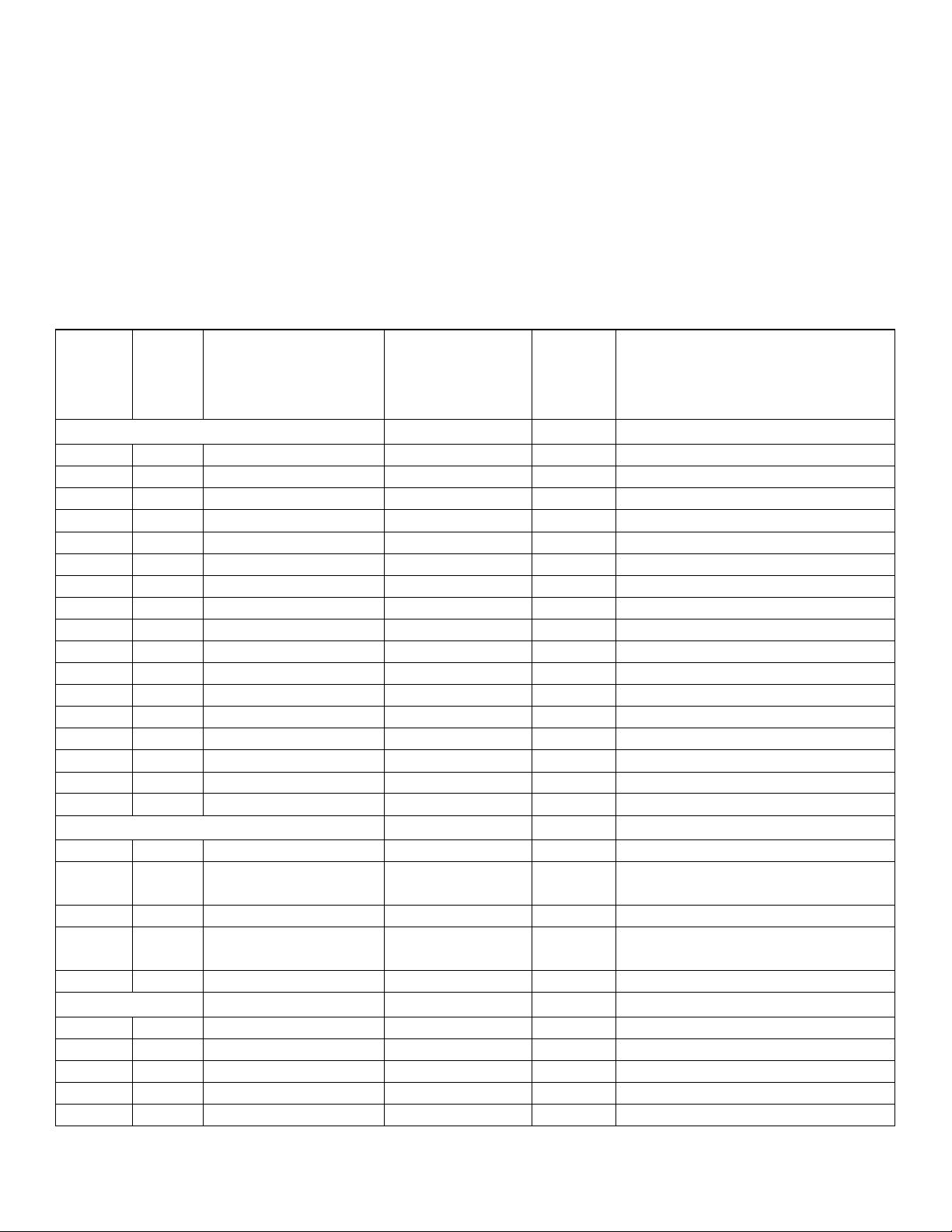

Table 5: ProtocolTM Plus Input Register Address Map

Page[menu]

Data

Address

Hex

Address

Description

Association or

Range

Security

Level Comments

Control Loop Input Registers

0 0 PV Sensor range 0 read as xxxx deg. F

1 1 Active SP Sensor range 0 read as xxxx deg. F

2 2 Active Hi Limit SP Sensor range 0 read as xxxx deg. F

3 3 PV Status -1, 0, 1 0 -1 = underrange, 0 = in range, 1 = overrange

4 4 NA 0 0

5 5 Hi Limit PV Sensor Range 0 read as xxxx deg. F

6 6 Hi Limit PV Status -1, 0, 1 0 -1 = underrange, 0 = in range, 1 = overrange

7 7 Control Output Command 0 - 100.0 0 value has an implied decimal pt. of 1

8 8 Hi Limit Output 0, 1 0 0 = Off, 1 = On

9 9 Max Hi Limit SP Control[Hi-Lim SP] 0 read as xxxx deg. F

10 A NA 0 0

11 B PV Max Sensor Range 0 read as xxxx deg. F

12 C PV Min Sensor Range 0 read as xxxx deg. F

13 D Reserved for factory use

14 E Reserved for factory use

15 F Reserved for factory use

16 -- 127 10 -- 7F Illegal, Reserved standard reg.

Timer/Profile Input Registers

128 80 Segment Number 1-99 0 Current segment number

129 81

130 82 Segment Loops Remaining 0 - 99 0 Number of loops remaining in the ramp/soak program.

131 83 Ramp/Soak Interval Indicator 0, 1 0

132 -- 143 84 -- 8F Illegal, Available to application

Remaining

Global Input Registers

144 90 Terminal Temp (CJC) Ambient Range 0 read as xxx.x deg. F

145 91 N/A 0 0

146 92 Reset Counter 0 - $FFFF 0 Number of processor resets.

147 93 Power Down Counter 0 - $FFFF 0 Number of power down interrupts.

148 94 Alarms Status 0 - $F 0 Bits 0-3 = Alarms 1-4. Bit value: 0 = Off, 1 = On

00:00 - 99:59 0 Time remaining in ramp/soak interval

segment

A-51643 Rev. 6 10/06/03 8

Page 15

Chromalox Instruments and Controls

149 95 Events Status 0 - $F 0 Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

150 96 Cycle Complete Status 0, 1 0 0 = Off, 1 = On

151 97 Audible Annunciator Status 0, 1 0 0 = Off, 1 = On

152 -- 155 98 -- 9B Reserved, available to application 0 0

156 – 157 9C – 9D Reserved for factory use

158 -- 159 9E – 9F N/A 0 0

A/D Input Registers

160 -- 165 A0 -- A5 Reserved for factory use

166 -- 167 A6 -- A7 Illegal, Reserved standard reg.

168 -- 175 A8 -- AF Illegal, Available to application

Allocated

Blocks

176 -- 255 B0 -- FF Illegal, Reserved standard reg.

256 -- 65535 100 -- FFFF Undefined

A-51643 Rev. 6 10/06/03 9

Page 16

Chromalox Instruments and Controls

3.6 Holding Register Assignments

Holding registers are intended for information and functions that can be read or written. Each holding

register has a corresponding internal memory variable in the slave device. This association is shown in

the address map table.

Table 6: ProtocolTM Plus Holding Register Address Map

Page[menu]

Association or

Data

Address

Hex

Address

Description

Global Holding Registers

0 0 Communications Security Code 0-999 (0) 0 Security code setting for remote interface.

1 1 Temperature Display Units PID[Temp Unit] 1 or 2 (Note 1) 0 = deg. F, 1 = deg. C.

2 2 Reserved for factory use

3 3 Reserved for factory use

4 4 Reserved for factory use

5 5 Keypad Lockout 0 = normal, 1 = locked (0) 2 Disables front panel keypad

6 6 Controller Mode

7 7 Alarm Acknowledge 0 - $FFF F 0 0 = No Action, >0 = Alarm Acknowledge

8 8 Level 1 Password Enable[Password 1] 2 0 – 999 (Write not allowed while in setup mode)

9 9 Level 2 Password Enable[Password 2] 2 0 – 999 (Write not allowed while in setup mode)

10 A Key Press Beep Control[Key Beep] 1 or 2 (Note 1) 0 = off, 1 = on

11 B End of Cycle Beep Control[EOC Beep] 1 or 2 (Note 1) 0 = off, 1 = on

12 C Alarm Beep Control[Alarm Beep] 1 or 2 (Note 1) 0 = off, 1 = on

13 D Setpoint Change Enable Enable[SPChange] 2 0 = no, 1 = yes

14 E Analog output type Enable[Aout] 2 0 = Control (Default), 1 = Process

15 F Reserved, Available to application 0 0

Control Loop Holding Registers

16 10 Manual SP Manual[setpt] 0 read/written as xxxx deg. F.

17 11 Manual High Limit SP Manual[Hi-Lim SP] 0 read/written as xxxx deg. F.

18 12 Manual Event 1-4 Setup $0 - $F ($0) 0 Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

19 13 NA 0 0

20 14 Proportional Band (Heat) PID[P (H)] 1 or 2 (Note 1) read/written as xxxx deg. F.

21 15 Integral Reset (Heat) PID[I (H) Rep/Min] 1 or 2 (Note 1) value is in repeats/min

22 16 Derivative Rate (Heat) PID[I (H) in sec] 1 or 2 (Note 1) value is in seconds

23 17 Hysteresis Control[Hysteresis] 1 or 2 (Note 1) read/written as xxxx deg. F.

24 18 High Limit Band Control[Hi-Lim Band] 1 or 2 (Note 1) read/written as xxxx deg. F. 4 = Off.

25 19 Cycle Time Control[Cycle Time Sec] 1 or 2 (Note 1) value is in seconds

26 1A Proportional Band (Cool) PID[P(C)] 1 or 2 (Note 1) read/written as xxxx deg. F. (H/C Version 3.1 Only)

27 1B Integral Reset (Cool) PID[I (C) Rep/Min] 1 or 2 (Note 1) value is in repeats/min. (H/C Version 3.1 Only)

28 1C Derivative Rate (Cool) PID[D(C) in Sec] 1 or 2 (Note 1) Value is in Seconds. (H/C Version 3.1 Only)

29 1D Heat Offset PID[Heat Offset] 1 or 2 (Note 1) read/written as xxxx deg. F. (+/- P Band H) H/C Only

30 1E Cool Offset PID[Cool Offset] 1 or 2 (Note 1) read/written as xxxx deg. F. (+/- P Band H) H/C Only

Range (default

value)

Read: 1 – 5

Write: 1 - 4

Security

Level Comments

0 1=Manual, 2=Timer, 3=Profile, 4=Autostart, 5=Setup

A-51643 Rev. 6 10/06/03 10

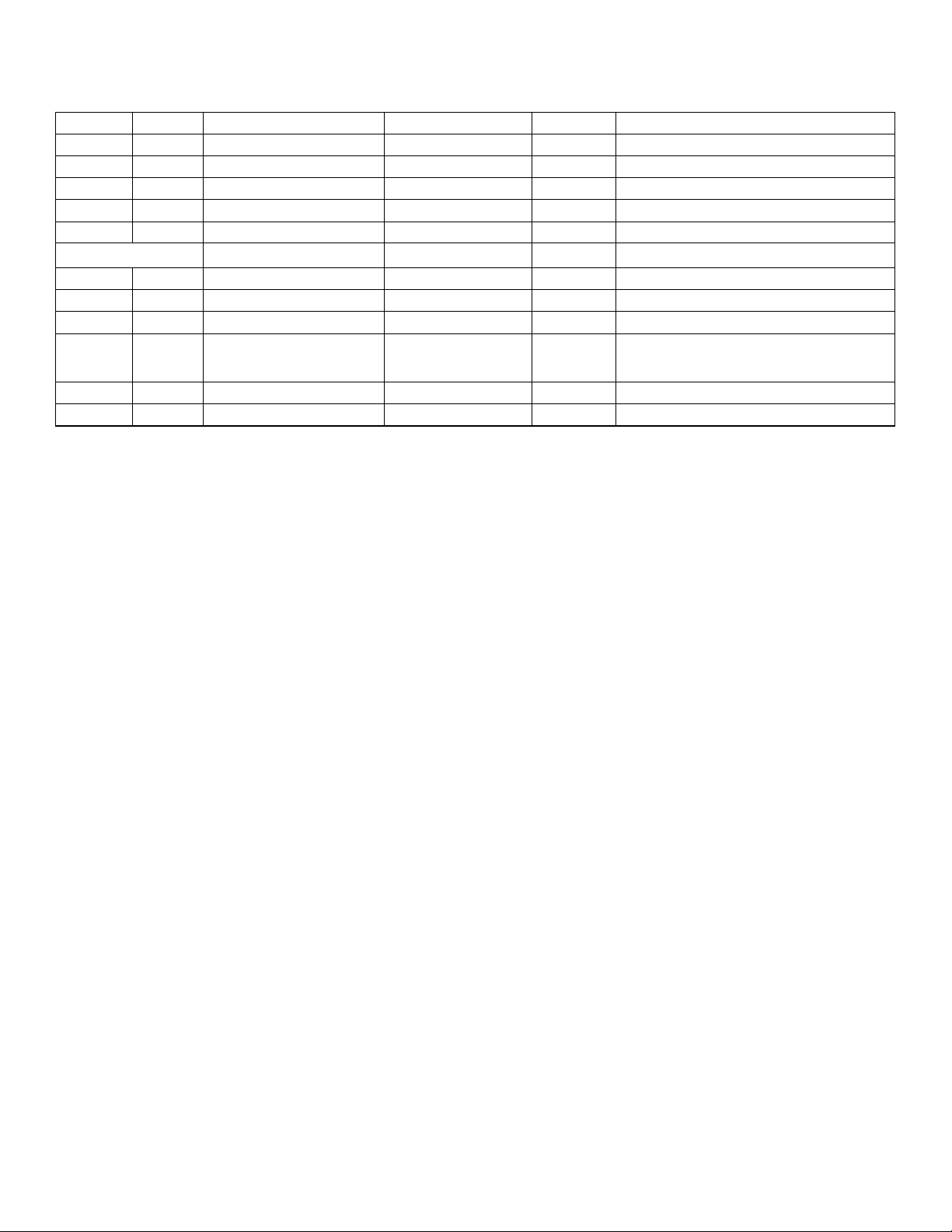

Page 17

Chromalox Instruments and Controls

31 1F Control Type Control[Ctrl] 1 or 2 (Note 1) 0 = Heat, 1 = Cool, 2 = Heat/Cool. H/C Only

32 – 34 20 – 22 NA 0 0

35 23 Auto Tune Enable PID[Auto Tune] 1 or 2 (Note 1) 0 = Disabled, 1 = Enabled

36 24 Power Up Start Enable Control[PwrUpStrt] 1 or 2 (Note 1) 0 = Disabled, 1 = Enabled

37 25 Power Up Start Mode Control[StrtMode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

38 – 39 26 – 27 NA 0 0

40 28 Power Fail Recovery Control[PwrFRec] 1 or 2 (Note 1) 0=Stop, 1=Restart, 2=Hold, 3=Resume

41 29 Recovery Time Limit Control[PFRTime] 1 or 2 (Note 1) 00h00m to 99h59m

42 – 44 2A – 2C NA 0 0

45 2D SP Low Limit Enable[SPLowerLim] 2 read/written as xxxx deg. F.

46 2E SP Upper Limit Enable[SPUpperLim] 2 read/written as xxxx deg. F.

47 2F High Limit Over Head Enable[HiLimOH] 2 read/written as xxxx deg. F.

48 – 53 30 – 35 NA 0 0

54 36 Process Out Scale Low Control[RetOutLo] 1 or 2 (Note 1) read/written as xxxx deg. F.

55 37 Process Out Scale High Control[RetOutHi] 1 or 2 (Note 1) read/written as xxxx deg. F.

56 – 63 38 – 3F Illegal, Available to application

Timer Holding Registers

64 40 Timer SP Timer[Setpt] 0 read/written as xxxx deg. F.

65 41 Timer High Limit SP Timer[Hi-Lim SP] 0 read/written as xxxx deg. F.

66 42 Timer Event 1-4 Setup $0 - $F ($0) 0 Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

67 43 Timer Value Timer[Time Set] 0 read/written as xx:xx hrs:min or min:sec

68 44 Timer Guaranteed Soak Band Timer[TmrGuarSoak] 0 read/written as xxxx deg. F. 0 = Off.

69 -- 399 45 -- 18F Illegal, Reserved standard reg.

Control Operation and Profile Holding Registers

400 190 NA 0 0

401 191 Profile Number 0 - 8 0 Current Profile number; 0= none;

402 192 Run/Hold/Stop Control 0 - 2 0 0 = Stop key, 1 or 2 = Run/Hold key

403 193 Time Scale Control[TimeScale] 1 or 2 (Note 1) 0 = mm:ss, 1 = hh:mm

404 194 Segment Advance 0 - $FFFF 0 0=no action; >0 = advance to next segment

Profile 1

405 195 Segment 1 Ramp Time Seg-1 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

406 196 Segment 1 Ramp Event 1-4 Setup Seg-1 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

407 197 Segment 1 Soak Temp Seg-1 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

408 198 Segment 1 Soak Time Seg-1 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

409 199 Segment 1 Soak Event 1-4 Setup Seg-1 Soak[Event1 -4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

410 19A Segment 2 Ramp Time Seg-2 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

411 19B Segment 2 Ramp Event 1-4 Setup Seg-2 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

412 19C Segment 2 Soak Temp Seg-2 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

413 19D Segment 2 Soak Time Seg-2 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

414 19E Segment 2 Soak Event 1-4 Setup Seg-2 Soak[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

415 19F Segment 3 Ramp Time Seg-3 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

416 1A0 Segment 3 Ramp Event 1-4 Setup Seg-3 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

417 1A1 Segment 3 Soak Temp Seg-3 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

418 1A2 Segment 3 Soak Time Seg-3 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

419 1A3 Segment 3 Soak Event 1-4 Setup Seg-3 Soak[Event1 -4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

420 1A4 Segment 4 Ramp Time Seg-4 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

A-51643 Rev. 6 10/06/03 11

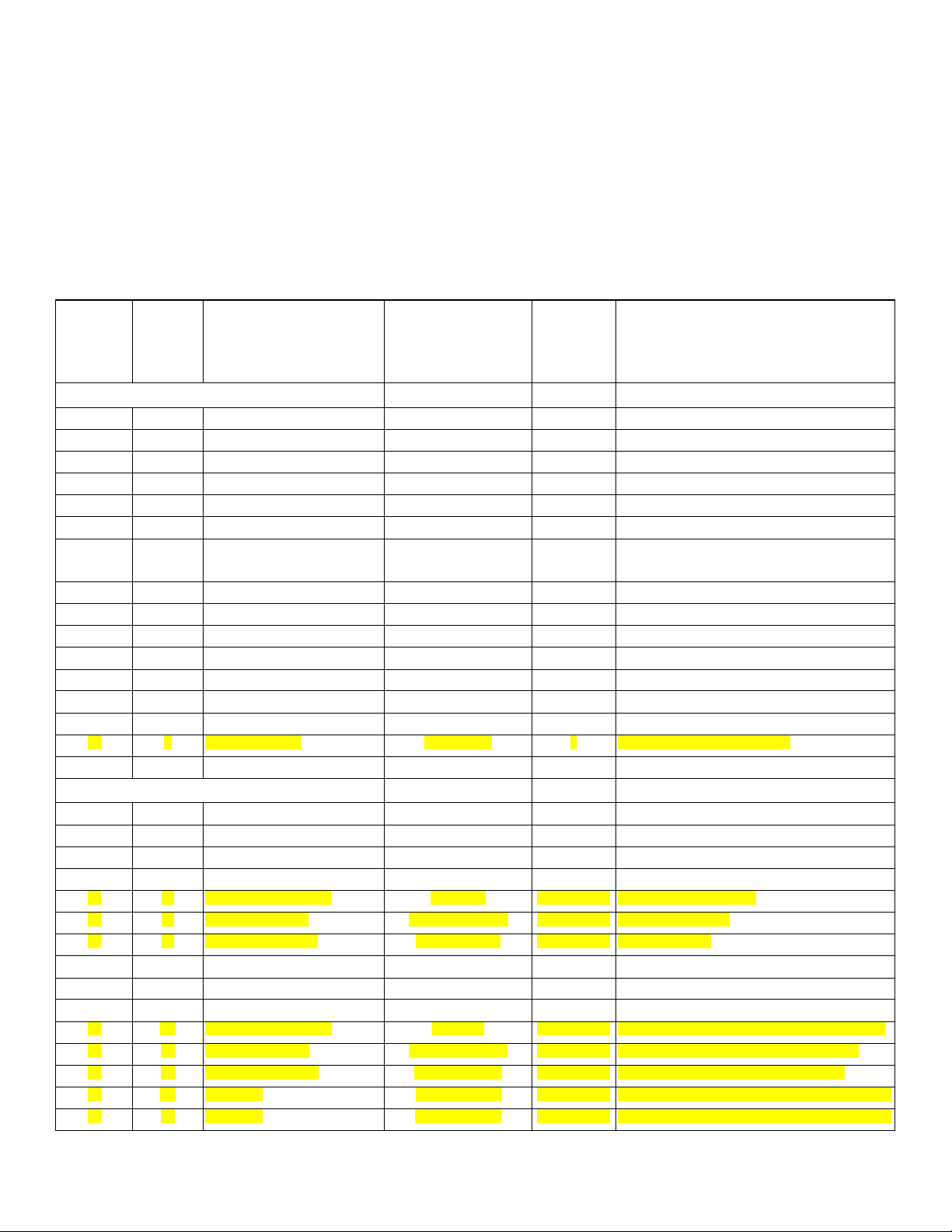

Page 18

Chromalox Instruments and Controls

421 1A5 Segment 4 Ramp Event 1-4 Setup Seg-4 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

422 1A6 Segment 4 Soak Temp Seg-4 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

423 1A7 Segment 4 Soak Time Seg-4 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

424 1A8 Segment 4 Soak Event 1-4 Setup Seg-4 Soak[Event1 -4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

425 1A9 Segment 5 Ramp Time Seg-5 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

426 1AA Segment 5 Ramp Event 1-4 Setup Seg-5 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

427 1AB Segment 5 Soak Temp Seg-5 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

428 1AC Segment 5 Soak Time Seg-5 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

429 1AD Segment 5 Soak Event 1-4 Setup Seg-5 Soak[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

430 1AE Segment 6 Ramp Time Seg-6 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

431 1AF Segment 6 Ramp Event 1-4 Setup Seg-6 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

432 1B0 Segment 6 Soak Temp Seg-6 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

433 1B1 Segment 6 Soak Time Seg-6 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

434 1B2 Segment 6 Soak Event 1-4 Setup Seg-6 Soak[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

435 1B3 Segment 7 Ramp Time Seg-7 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

436 1B4 Segment 7 Ramp Event 1-4 Setup Seg-7 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

437 1B5 Segment 7 Soak Temp Seg-7 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

438 1B6 Segment 7 Soak Time Seg-7 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

439 1B7 Segment 7 Soak Event 1-4 Setup Seg-7 Soak[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

440 1B8 Segment 8 Ramp Time Seg-8 Ramp[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

441 1B9 Segment 8 Ramp Event 1-4 Setup Seg-8 Ramp[Event1-4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

442 1BA Segment 8 Soak Temp Seg-8 Soak[Temp] 1 or 2 (Note 1) read/written as xxxx deg. F.

443 1BB Segment 8 Soak Time Seg-8 Soak[Time] 1 or 2 (Note 1) read/written as xx:xx hrs:min or min:sec

444 1BC Segment 8 Soak Event 1-4 Setup Seg-8 Soak[Event1 -4] 1 or 2 (Note 1) Bits 0-3 = Events 1-4. Bit value: 0 = Off, 1 = On

445 1BD High Limit SP [Hi-Lim SP] 1 or 2 (Note 1) read/written as xxxx deg. F.

446 1BE Loop From Segment # [Loop From Seg No] 1 or 2 (Note 1) 0 = None; 1-8 = Loop from segement.

447 1BF Loop to Segment # [Loop To Seg No] 1 or 2 (Note 1) 0 = None; 1-8 = Loop to segement.

448 1C0 Loop # of Times [Loop Number] 1 or 2 (Note 1) 0-99

449 1C1 Link to Profile [Link To Pro] 1 or 2 (Note 1) -1=Stop, 0=Hold, 1-8=Profile 1-8, -2=Standby.

450 1C2 Guaranteed Soak Band [Guar Band] 1 or 2 (Note 1) read/written as xxxx deg. F. 0 = Off.

Profile 2

451 -- 496 1C3 -- 1F0 Profile 2 Holding Registers (same as Profile 1) 1 or 2 (Note 1)

Profile 3

497 -- 542 1F1 -- 21E Profile 3 Holding Registers (same as Profile 1) 1 or 2 (Note 1)

Profile 4

543 -- 588 21F -- 24C Profile 4 Holding Registers (same as Profile 1) 1 or 2 (Note 1)

Profile 5

589 -- 634 24D -- 27A Profile 5 Holding Registers (same as Profile 1) 1 or 2 (Note 1)

Profile 6

635 -- 680 27B -- 2A8 Profile 6 Holding Registers (same as Profile 1) 1 or 2 (Note 1)

Profile 7

681 -- 726 2A9 -- 2D6 Profile 7 Holding Registers (same as Profile 1) 1 or 2 (Note 1)

Profile 8

727 -- 772 2D7 -- 304 Profile 8 Holding Registers (same as Profile 1) 1 or 2 (Note 1)

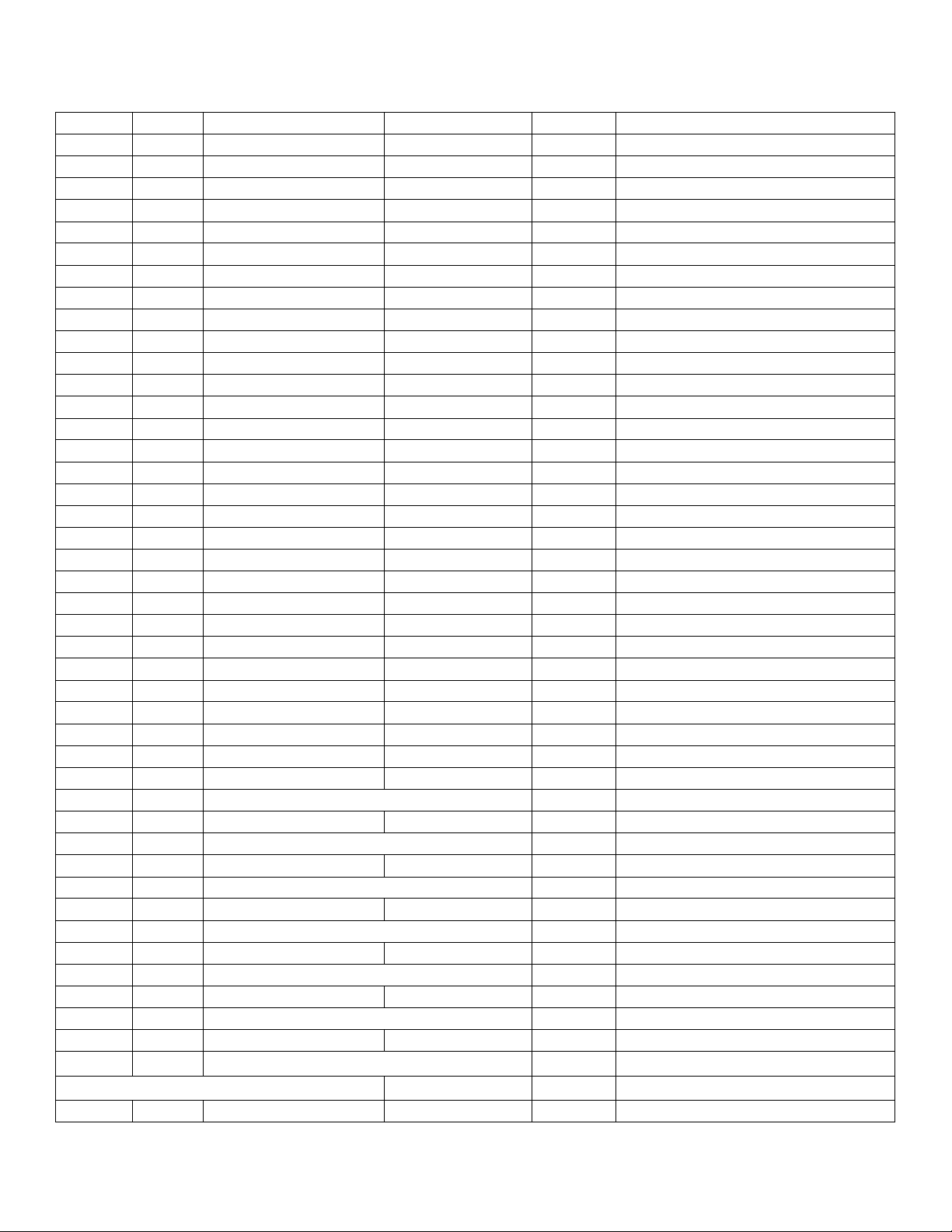

Auto Start Holding Registers

773 305 Auto Start Enable Auto Start[Enable] 1 or 2 (Note 1) 0 = Disabled, 1 = Enabled

A-51643 Rev. 6 10/06/03 12

Page 19

Chromalox Instruments and Controls

774 306 Sunday Run Mode Auto Start Sun[Mode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

775 307 Sunday Run Time Auto Start Sun[Time] 1 or 2 (Note 1) 00h00m to 23h59m

776 308 Monday Run Mode Auto Start Mon[Mode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

777 309 Monday Run Time Auto Start Mon[Time] 1 or 2 (Note 1) 00h00m to 23h59m

778 30A Tuesday Run Mode Auto Start Tue[Mode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

779 30B Tuesday Run Time Auto Start Tue[Time] 1 or 2 (Note 1) 00h00m to 23h59m

780 30C Wednesday Run Mode Auto Start Wed[Mode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

781 30D Wednesday Run Time Auto Start Wed[Time] 1 or 2 (Note 1) 00h00m to 23h59m

782 30E Thursday Run Mode Auto Start Thu[Mode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

783 30F Thursday Run Time Auto Start Thu[Time] 1 or 2 (Note 1) 00h00m to 23h59m

784 310 Friday Run Mode Auto Start Fri[Mode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

785 311 Friday Run Time Auto Start Fri[Time] 1 or 2 (Note 1) 00h00m to 23h59m

786 312 Saturday Run Mode Auto Start Sat[Mode] 1 or 2 (Note 1) 0=Off, 1=Manual, 2=Timer, 3-10=Profile 1-8

787 313 Saturday Run Time Auto Start Sat[Time] 1 or 2 (Note 1) 00h00m to 23h59m

788 -- 1023 314 -- 3FF Illegal, Available to application

Relay Outputs Holding Registers

Relay Output 1

1024 400 Output 1 Type Relay 1[Relay Type] 1 or 2 (Note 1) 0=Off, 1=Alarm, 2=Cycle, 3=Event

1025 401 Relay 1 Action Relay 1[Relay Action] 1 or 2 (Note 1) 0=NDE, 1=NE, 2=NDEL, 3=NEL

1026 402 Alarm 1 Type Relay 1[Alarm Type] 1 or 2 (Note 1) 0 = High, 1 = Low, 2 = +Dev, 3 = -Dev, 4 = +/-Dev

1027 403 Alarm 1 Setpoint Relay 1[AlmHi/LoSP] 1 or 2 (Note 1) read/written as xxxx deg. F.

1028 404 Alarm 1 Deviation Setpoint Relay 1[AlmDevBand] 1 or 2 (Note 1) read/written as xxxx deg. F.

1029 405 Alarm 1 Inhibit Relay 1[AlmInhibit] 1 or 2 (Note 1) 0=Disabled, 1=Enabled

1030 406 Event 1 Type Relay 1[Event Type] 1 or 2 (Note 1) 0=Time, 1=Temp

1031 407 Event 1 Setpoint Relay 1[Event SP] 1 or 2 (Note 1) read/written as xxxx deg. F.

Relay Output 2

1032 -- 1039 408 -- 40F Output 2 Holding Registers (same as Output 1) 1 or 2 (Note 1)

Relay Output 3

1040 -- 1047 410 -- 417 Output 3 Holding Registers (same as Output 1) 1 or 2 (Note 1)

Relay Output 4

1048 -- 1055 418 -- 41F Output 4 Holding Registers (same as Output 1) 1 or 2 (Note 1)

Test Mode Holding Registers

1056 -- 1062 420 -- 426 Reserved for factory use

1063 -- 1135 427 -- 46F Illegal, Available to application

Communication Holding Registers

1136 470 Controller Address Communication[Unit Addr] 1 or 2 (Note 1) 1-247

1137 471 Communications Mode Communication[Enable] 1 or 2 (Note 1) 0=Disabled, 1=Enabled

1138 472 Baud Rate Communication[BaudRate] 1 or 2 (Note 1) 0=2400, 1=4800, 2=9600, 3=19.2K, 4=38.4K

1139 473 Parity Communication[Parity] 1 or 2 (Note 1) 0=None, 1=Odd, 2=Even

1140 474 Reserved, Available to application 0 0

Real Time Clock Holding Registers

1141 475 Week Day Clock[Day] 1 or 2 (Note 1) 1=Sunday, 2=Monday, . . . 7=Saturday

1142 476 Time Clock[hh:mm] 1 or 2 (Note 1) 00h00m to 23h59m

1143 477 Enter Clock[UP to Reset CLK] 1 or 2 (Note 1) 0 = No action, >0 = Set Clock

1144 -- 1151 478 -- 47F Illegal, Reserved for standard reg.

Calibration Holding Registers

A-51643 Rev. 6 10/06/03 13

Page 20

Chromalox Instruments and Controls

1152 -- 1159 480 -- 487 Reserved for factory use

1160 -- 1183 488 -- 49F Illegal, Available to application

1184 -- 1188 4A0 -- 4A4 Reserved for factory use

1189 -- 1199 4A5 -- 4AF Illegal, Available to application

1200 -- 1279 4B0 -- 4FF Illegal, Reserved for standard reg. Reserved for future standard assignments.

Page Enable Holding Registers

1280 500 Program Page 1-8 Enable[Profile 1-8] 2 1 = Yes (security level 1); 0 = No (security level 2)

1281 501 Auto Start Page Enable[Auto Start] 2 1 = Yes (security level 1); 0 = No (security level 2)

1282 502 PID Parameters Page Enable[PID] 2 1 = Yes (security level 1); 0 = No (security level 2)

1283 503 Control Page Enable[Control] 2 1 = Yes (security level 1); 0 = No (security level 2)

1284 504 Communications Page Enable[Communication] 2 1 = Yes (security level 1); 0 = No (security level 2)

1285 505 Real Time Clock Page Enable[Clock] 2 1 = Yes (security level 1); 0 = No (security level 2)

1286 506 Relay Output Page 1-4 Enable[Relay 1-4] 2 1 = Yes (security level 1); 0 = No (security level 2)

1287 507 Test Page Enable[Test] 2 1 = Yes (security level 1); 0 = No (security level 2)

1288 508 Zone Calibration Enable[Zone Cal] 2 1 = Yes (security level 1); 0 = No (security level 2)

1289 509 Sensor Calibration Enable[Sensor Cal] 2 1 = Yes (security level 1); 0 = No (security level 2)

Allocated Blocks

1290 -- 65535 50A -- FFFF Undefined Available for application assignment.

Dependent on enable page setting

NOTES

1

A-51643 Rev. 6 10/06/03 14

Page 21

Chromalox Instruments and Controls

4 Application Operations

This section defines application operations in ProtocolTM Plus controller and how they are achieved

through Modbus.

4.1 Security Level and Discrete Inputs, Discrete Outputs, and Register Access

Access to discrete I/O and registers addresses are guarded via a security level. The communications

security code holding register ($0000) contains the current security setting for accessing data in the

controller through the communications port. Each I/O or register address has an associated preset security

level that controls access. If the current communication security code does not match the register’s

security level, access is denied. An illegal data address exception is generated and data is not changed.

For multiple reads and writes, if any address is inaccessible, an exception response occurs and data is not

affected in the slave.

The communications security operation mirrors the security operation for adjusting parameters through

the front panel keypad. Security levels for each I/O and register address are shown in the I/O and register

mapping tables. The access passwords for security levels 1 and 2 are set via the security level holding

registers ($0008, $0009). The communications security code is set to 0 whenever the controller is

powered up or reset. The access password registers ($0008, $0009) cannot be written to while the

controller is in setup mode to protect adjustments in progress via the front panel keypad.

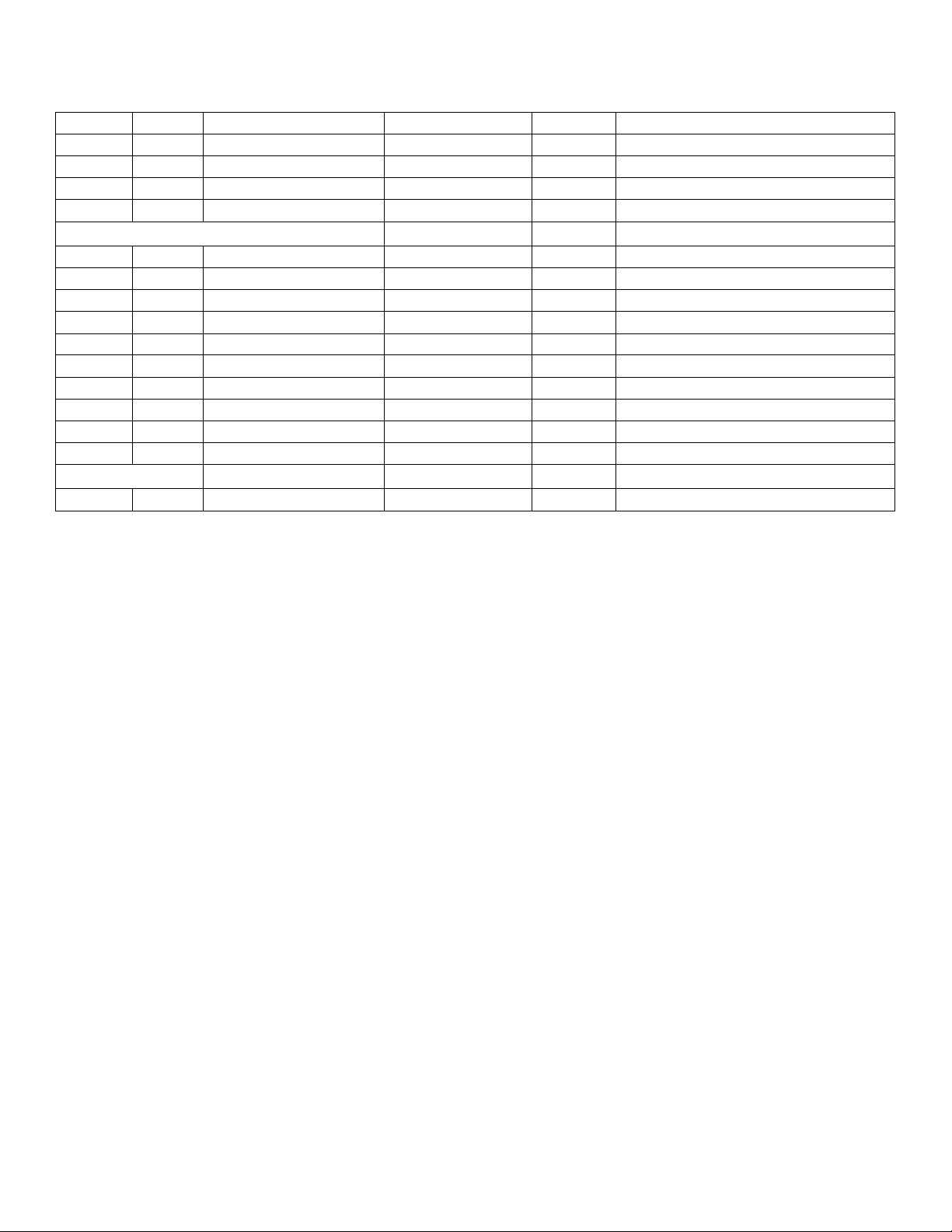

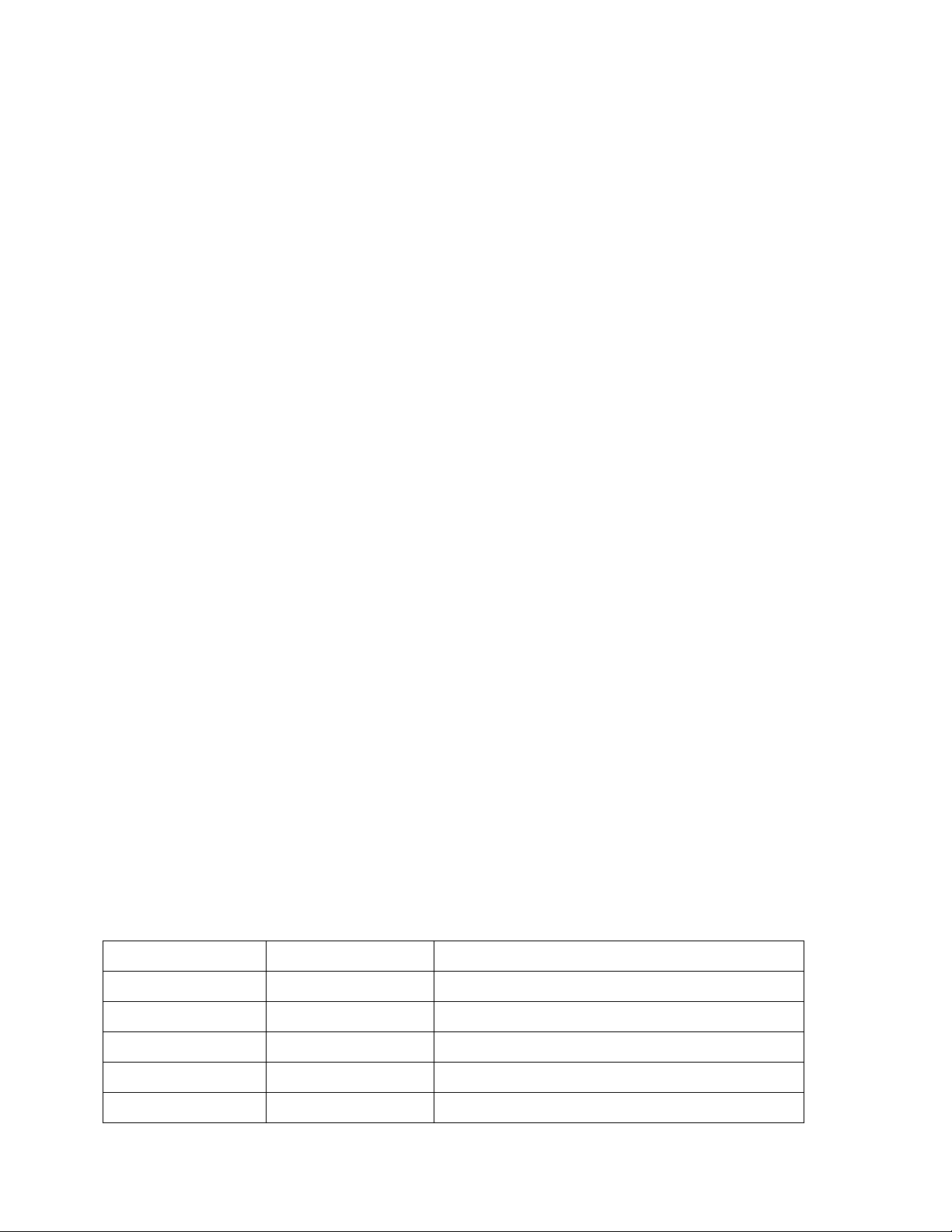

Table 7: Communication Security Levels

Security Level Description Access Code

0 Global Access Any

1 User Access Level 1 Password Level 1 Menu

2 User Access Level 2 Password Level 2 Menu

3 Factory Only Access ---

4.2 Multiple Register Write Limitations

The Modbus Protocol requires all addresses and all data in a multiple write to be valid for any write to

occur. If an exception response occurs none of the registers are modified. Because all addresses and data

must be verified before the data is actually written, a limitation exists for multiple writes to registers

whose values are interdependent. The verification of data may fail because data to be written to one

register is invalid until data for another register is actually written. In these cases, successive single

register writes must be performed.

A-51643 Rev. 6 10/06/03 15

Page 22

Chromalox Instruments and Controls

An example is the Manual Setpoint and Manual High Limit Setpoint holding registers. If the registers are

currently set to 500 °F and 509 °F respectively, then a multiple write of 300 °F and 350 °F respectively

will fail. During data verification, the high limit value of 350 °F is invalid because the setpoint is set to

500 °F. A single write of 300 °F to Manual Setpoint followed by a single write of 350 °F to Manual High

Limit Setpoint will work.

4.3 Control Operation and Run/Hold/Stop Functions

The 4 control states of the controller (Manual, Timer, Profile, and Autostart) can be set via the Controller

Mode holding register ($0006). The controller mode cannot be changed unless the controller is stopped.

Before changing modes, the STOP value must be written to the Run/Hold/Stop holding register ($0192),

then the desired mode value can be written to the Controller Mode holding register. When reading the

Controller Mode holding register ($0006), a fifth mode (Setup) can be detected. The user cannot place

the controller into setup mode via Modbus because the setup mode applies only to adjusting parameters

via the front panel keypad.

When the controller is in Manual, Timer, or Profile control mode, the Run/Hold/Stop register ($0192) is

used to Run, Hold, or Stop the controller. A value of 0 simulates the STOP key; a value of 1 or 2

simulates the RUN/HOLD key. When in Profile control mode, the Profile Number ($0191) and the

Segment Advance ($0194) holding registers control which profile and segment are being executed. The

Profile Number holding register can only be written when the controller is stopped. A value of 0 sets the

desired profile to none. Writing any non-zero value to the Segment Advance register simulates pressing

the Select/Up Arrow combination while running a profile to advance to the next profile segment.

The Profile Number holding register, along with the Profile Input Registers $0080-$0083 can be read to

monitor the status of the controller. The Segment Number input register ($0080) provides the current

segment number. Input register $0081 provides the time remaining in the current interval and input

register $0082 the number of segment loops remaining. The Ramp/Soak Interval Indicator ($0083) input

register indicates whether the current interval is a ramp or soak interval (0=ramp, 1=soak).

4.4 Controller Mode and Data Access

Most holding registers can only be written to if the controller is stopped. The exceptions are listed below.

All registers can be read in any mode as long as the communications security code is set to the proper

level. An illegal data address response is generated if the controller is not in the correct state to access a

register. The following registers can be written while the controller is running.

A-51643 Rev. 6 10/06/03 16

Page 23

Chromalox Instruments and Controls

REGISTER ADDRESS REGISTER DESCRIPTION

$0000 COMMUNICATIONS ACCESS CODE

$0005 KEYPAD LOCKOUT

$0007 ALARM ACKNOWLEDGE

$0008 LEVEL 1 PASSWORD (write not allowed while in setup mode)

$0009 LEVEL 2 PASSWORD (write not allowed while in setup mode)

$0010 MANUAL SETPOINT

$0040 TIMER SETPOINT

$0192 RUN/HOLD/STOP

$0194 SEGMENT ADVANCE

4.5 Monitoring and Acknowledgement of Alarms, Events, and Cycle Complete, Discrete

Inputs, and Discrete Outputs

Two input registers allow monitoring of the alarm ($0094) and event ($0095) functions associated with

relay outputs 1-4. The corresponding input register represents a binary pattern that indicates the state of

each function. Bits 0-3 of the holding register value represent item 1-4 respectively. A bit value of 0

indicates off, while a bit value of 1 indicates on. Example: A read of holding register $0098 returns a

value of $0006. This would indicate that alarms 2 and 3 are active.

The cycle complete status is monitored by reading input register $0096. A value of 0 indicates the cycle

is active, while a value of 1 indicates the cycle is complete.

Reading the discrete input addresses-$0000 - $00003 monitors the hardware states of the external inputs

Event 1-4. For details on the return values see 5.2.2 [02] Read Input Discretes. Since these inputs are

active low switch inputs, a returned value of 1 (or on) means the input is active (electrically pulled low).

Reading the discrete output addresses-$0000 - $00003 monit ors the hardware states of relays 1-4. For

details on the return values see 5.2.1 [01] Read Outputs.

The audible annunciator can be monitored via input register $0097. A value of 0 indicates the audible

annunciator is off, while a value of 1 indicates on. Acknowledgement of alarms and cycle complete

audible annunciation is handled through the alarm acknowledge holding register ($0007). Writing any

non-zero value to this register will acknowledge the alarm. This register emulates the pressing of the

Page/Reset key during an audible alarm condition.

A-51643 Rev. 6 10/06/03 17

Page 24

Chromalox Instruments and Controls

4.6 Event Setup Values

For Manual, Timer, and Profile events setup, the corresponding holding register represents a binary

pattern that determines each event output state. Bits 0-3 of the holding register value represent Event

outputs 1-4 respectively. A bit value of 0 sets the event output to be off, while a bit value of 1 sets the

output to be on.

4.7 Keypad Lockout

The front panel keypad can be disabled (locked out) by writing the value 1 to the Keypad Lockout

holding register ($0005). A write of 0 will unlock the keypad. The keypad lockout register is always set

to 0 during a power-up or reset of the controller to ensure that the keypad can never be permanently

locked out.

4.8 Temperature Values

Temperature values read from input and holding registers and written to holding registers are always in °F

and assume no decimal place. An exception is the ambient temperature input register ($0090) which

assumes 1 decimal place. A value read or written as 750 would represent 75.0 °F.

4.9 Time Values

Time values are read and written in a format that adheres to the to Modbus standard of two bytes per data

item. The high byte is a hex number representing hours or minutes while the low byte is a hex number

representing minutes or seconds. The units of the two bytes (hhmm or mmss) are dependent of the format

of the specific register being accessed. Example: 12h00m ⇒ $0C00; 36m42s ⇒ $242A.

4.10 High Limit Setpoint and Band Registers

The Despatch Protocol Plus has several special cases involving the adjustment and display of high limit

parameters. Since only values can be returned via Modbus (no special strings), the read/write of these

parameters has been implemented in the simplest manner that still allows for complete functionality.

All high limit setpoint and band registers read and write directly to the parameter associated with the

register address—regardless of whether that value is active due to the setting of another high limit register

(as in the high limit band holding register $0018). To determine the high limit setpoint currently being

used for control, read the Active High Limit Setpoint register $0002.

4.11 Broadcasting with Guaranteed Delivery

Broadcast messages are processed by all slaves and do not generate a response. In order to verify the

delivery, acceptance, and processing of broadcast messages the following procedure can be used.

A-51643 Rev. 6 10/06/03 18

Page 25

Chromalox Instruments and Controls

1. Send an individual function code 08, sub-function 10 queries (clear communication counters) to each

slave on the network.

2. Perform desired broadcast functions.

3. Send an individual function code 08, sub-function 14 queries (return slave message count) to each

slave on the network.

4. If the number of processed messages in each slave matches the number of broadcasts sent then the

broadcast messages were sent reliably.

4.12 Communication Parameter Adjustments

If the communication parameters (slave address, mode, baud rate, or parity) are changed through the front

panel or through the Modbus link, the controller need not be reset. The new parameters (in the controller)

will become effective on the next query/response cycle. However, in some cases, the first query after

changing the settings may not generate a response as this query is used to reset the communication setup.

The user is responsible for setting the master device to the proper settings.

Setting the communications mode to “disabled” will immediately disable communications.

Communications can only be re-enabled through the front panel keypad. Use the force listen mode

command (5.3.1.4 [08 04] Force Listen Mode Only) to temporarily disable communications.

A-51643 Rev. 6 10/06/03 19

Page 26

Chromalox Instruments and Controls

slave and successfully processed.

5 Function Set Details

This section details the Modbus functions supported in the ProtocolTM Plus controller.

5.1 Function Set Overview

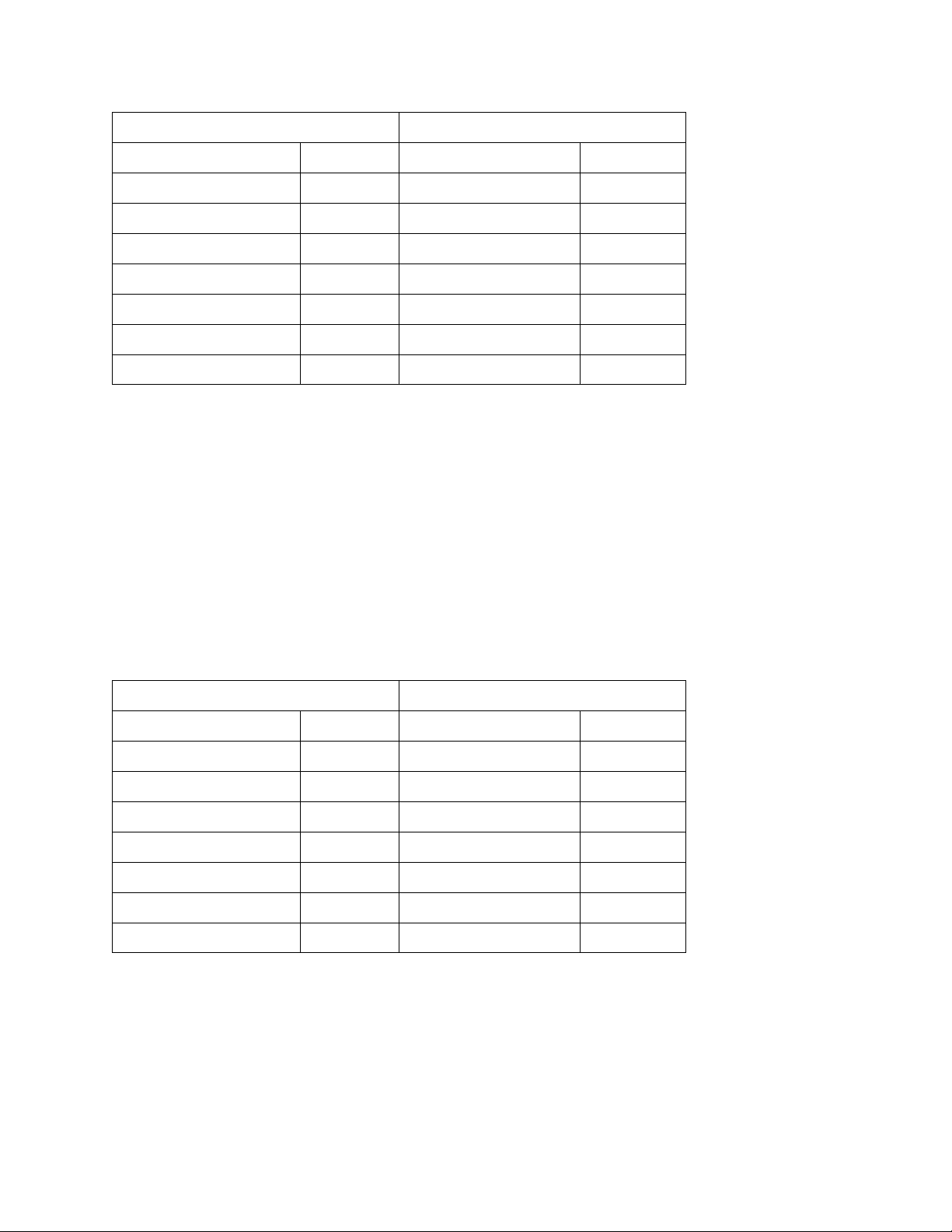

Table 8 ProtocolTM Plus Function and Exception Code Set

Function Code Function Name

01 Read Outputs

02 Read Input Discretes

03 Read Holding Register (Read Multiple Registers)

04 Read Input Registers

06 Write Single Register

08 Diagnostics

16 Write Multiple Registers

17 Report Slave ID

Table 9 ProtocolTM Plus Diagnostic (Function Code 08) Sub-function Set

Sub-function Code Sub-function Name Comments

00 Return Query Data Loop Back

01 Restart Communications Options Reset the slave. Cancels Listen Only

Mode.

02 Return Diagnostic Register Contents of slave’s 16-bit diagnostic

register.

04 Force Listen Only Mode Reset by Restart Communications

Option

10 Clear Counters and Diagnostic Register Also cleared at power up. Clears only

the counters

12 Return Bus Communication Error Count Slave CRC errors only.

13 Return Bus Exception Error Count Slave Exception Response count.

14 Return Slave Message Count Number of messages addressed to the

Includes broadcast messages.

A-51643 Rev. 6 10/06/03 20

Page 27

Chromalox Instruments and Controls

15 Return Slave No Response Count Number of messages addressed to the

18 Return Bus Character Overrun Count Number of overrun and framing errors.

Table 10 ProtocolTM Plus Exception Code Set

Exception Code Description Comments

01 Illegal Function The function code received is not valid or

02 Illegal Data Address The data address received is invalid or is

03 Illegal Data Value The data value received is invalid.

slave for which no response was

returned.

is not supported.

not accessible due to security setting.

5.2 Register and I/O Function Set Description for ProtocolTM Plus

5.2.1 [01] Read Outputs

Class 1 command. Reads the On/Off status of discrete outputs in the slave. Broadcast is not supported.

Query

The query message specifies the starting output and quantity of outputs to be read. Outputs are addressed

starting at 0.

Example: Query to read outputs 20 . . . 56 from slave address 17.

Field Name Data

Slave address $11

Function $01

Starting address hi $00

Starting address lo $13

Number of outputs hi $00

Number of outputs lo $25

CRC $----

A-51643 Rev. 6 10/06/03 21

Page 28

Chromalox Instruments and Controls

Response

The output status in the response is packed as one output per bit of the data field. Status is indicated as 0

= Off, 1 = On. The LSB of the first data byte contains the output addressed in the query. The other

outputs follow toward the high order end of this byte, and from low order to high order in subsequent

bytes. If the returned output quantity is not a multiple of eight, the remaining bits in the final data byte

will be padded with zero (toward the high order end). The Byte Count field specifics the quantity of

complete bytes of data.

Example response:

Field Name Data

Slave address $11

Function $01

Byte count $05

Data (outputs 27 . . . 20) $CD

Data (outputs 35 . . . 28) $A0

Data (outputs 43 . . . 36) $36

Data (outputs 51 . . . 44) $FB

Data (outputs 56 . . . 52) $05

CRC $----

5.2.2 [02] Read Input Discretes

Class 1 command. Reads the On/Off status of discrete inputs in the slave. Broadcast is not supported.

Query

The query message specifies the starting input and quantity of inputs to be read. Inputs are addressed

starting at 0.

Example: Request to read inputs 1 . . . 7 from slave address 8.

Field Name Data

Slave address $08

Function $02

Starting address hi $00

Starting address lo $00

A-51643 Rev. 6 10/06/03 22

Page 29

Chromalox Instruments and Controls

Number of outputs hi $00

Number of outputs lo $07

CRC $----

Response

The input status in the response message is packed as one input per bit of the data field. Status is

indicated as 0 = Off, 1 = On. The LSB of the first data byte contains the input addressed in the query.

The other inputs follow toward the high order end of this byte, and from low order to high order in

subsequent bytes. If the returned input quantity is not a multiple of eight, the remaining bits in the final

data byte will be padded with zero (toward the high order end). The Byte Count field specifics the

quantity of complete bytes of data.

Example response:

Field Name Data

Slave address $08

Function $02

Byte count $01

Data (inputs 7 . . . 1) $74

CRC $----

5.2.3 [03] Read Holding Registers (Read Multiple Registers)

Class 0 command. Reads the contents of holding registers in the slave. Broadcast is not supported.

Query

The query message specifies the starting register and quantity of registers to be read. Registers are

addressed starting at 0.

Example: Request to read registers 108 . . . 110 from slave address 1.

Field Name Data

Slave address $01

Function $03

Starting address hi $00

Starting address lo $6B

A-51643 Rev. 6 10/06/03 23

Page 30

Chromalox Instruments and Controls

Number of registers hi $00

Number of registers lo $03

CRC $----

Response

The register data in the response message are packed as two bytes per register (one word). For each

register, the first byte contains the high order bits and the second contains the low order bits.

Example response:

Field Name Data

Slave address $01

Function $03

Byte count $06

Data (register 108 hi) $00

Data (register 108 lo) $1E

Data (register 109 hi) $10

Data (register 109 lo) $26

Data (register 110 hi) $02

Data (register 110 lo) $AC

CRC $----

5.2.4 [04] Read Input Registers

Class 1 command. Read the contents of input registers in the slave. Broadcast is not supported.

Query

The query message specifies the starting register and quantity of registers to be read. Registers are

addressed starting at 0.

Example: Request to read input register 10 from slave device 17.

Field Name Data

Slave address $11

Function $04

Starting address hi $00

A-51643 Rev. 6 10/06/03 24

Page 31

Chromalox Instruments and Controls

Starting address lo $09

Number of registers hi $00

Number of registers lo $01

CRC $----

Response

The register data in the response are packed as two bytes per register (one word). For each register, the

first byte contains the high order bits and the second contains the low order bits.

Example response:

Field Name Data

Slave address $11

Function $04

Byte count $02

Data (register 10 hi) $00

Data (register 10 lo) $23

CRC $----

5.2.5 [06] Write Single Register

Class 1 command. Writes a value into a single holding register. When broadcast, the value is written to

the same register reference in all slaves on the network. Use of broadcast with this command should be

used with caution as the register addressed may differ in function on each slave device in the network.

Note: The written value will remain valid until the controller’s next write to the register through its

keypad or internal logic.

Query

The query message specifies the register reference to be written. Registers are addressed starting at zero.

The requested value is specified in the query data field in two bytes (one word). The first byte represents

the high order bits and the second byte represents the low order bits.

Example: Request to preset register 2 to the value 3 in slave device 14.

A-51643 Rev. 6 10/06/03 25

Page 32

Chromalox Instruments and Controls

Field Name Data

Slave address $0E

Function $06

Register address hi $00

Register address lo $01

Data hi $00

Data lo $03

CRC $----

Response

The normal response is an echo of the query, returned after the register has been written.

Example response:

Field Name Data

Slave address $0E

Function $06

Register address hi $00

Register address lo $01

Data hi $00

Data lo $03

CRC $----

5.2.6 [16] Write Multiple Registers

Class 0 command. Write values into a sequence of holding registers. When broadcast, the values are

written to the same register references in all slaves on the network. Use of broadcast with this command

should be used with caution as the registers addressed may differ in function on each slave device in the

network.

Note: The written values will remain valid until the controller’s next write to the register through its

keypad or internal logic.

Query

The query message specifies the register references to be written. Registers are addressed starting at zero.

The number of registers to be written are transmitted in two bytes (one word) with the first byte being the

A-51643 Rev. 6 10/06/03 26

Page 33

Chromalox Instruments and Controls

high order bits and the second byte the low order bits. Next, the actual number of data bytes is

transmitted (one byte). The requested values are specified in the query data field in two bytes (one word)

per register. The first byte represents the high order bits and the second byte represents the low order bits

of the register value.

Example: Request to preset two registers starting at register 5 to the values of 10 and 258 respectively in

slave device 14.

Field Name Data

Slave address $0E

Function $10

Starting register address hi $00

Starting register address lo $04

Number of registers hi $00

Number of registers lo $02

Byte count $04

Data hi (register 5) $00

Data lo (register 5) $0A

Data hi (register 6) $01

Data lo (register 6) $02

CRC $----

Response

The normal response returns the slave address, function code, starting address, and quantity of registers

written.

Example response:

Field Name Data

Slave address $0E

Function $10

Starting register address hi $00

Starting register address lo $04

Number of registers hi $00

Number of registers lo $02

CRC $----

A-51643 Rev. 6 10/06/03 27

Page 34

Chromalox Instruments and Controls

5.3 Diagnostics and Support Description for ProtocolTM Plus

All of the diagnostic and support functions are unclassified commands that tend to be application

dependent. The Modbus diagnostic function provides a series of tests and information exchange for

checking the integrity of the controller, the communication link, and the status of the controller.

Broadcast is not supported.

5.3.1 [08] Diagnostics

The function uses a two-byte sub-function code field in the query to define the type of test to be

performed. Most of the diagnostic queries use a two-byte data field to send diagnostic data or control

information to the slave. In sub-functions where the data is not required, $0000 is transmitted as data and

is ignored by the slave.

The slave echoes both the function code and sub-function code in a normal response as well as returning

any requested data. The diagnostic query form is shown below. The response is sub-function dependent

and may be application dependent. In cases where no return data is required and the data field was

included in the query, the query data field is echoed in the slave response.

Diagnostic Query Form

Field Name Data

Slave address $XX

Function $08

Sub-function hi $XX

Sub-function lo $XX

Data hi $XX

Data lo $XX

CRC $----

5.3.1.1 [08 00] Return Query Data

The data passed in the query data field is to be returned (looped back) in the response. The entire

response message should be identical to the query.

Example: Return Query Data $AA55 from slave device 2.

A-51643 Rev. 6 10/06/03 28

Page 35

Chromalox Instruments and Controls

Query Response

Field Name Data Field Name Data

Slave address $02 Slave address $02

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $00 Sub-function lo $00

Data hi $AA Data hi $AA

Data lo $55 Data lo $55

CRC $---- CRC $----

5.3.1.2 [08 01] Restart Communications Option

The slave is reset, its communication port initialized and restarted, and all of its communications event

counters cleared. If the slave is currently in Listen Only mode, no response is returned. This function is

the only one that brings the port out of Listen Only mode. If the port is not currently in Listen Only

mode, a normal response is returned. This occurs before the reset is executed. When the slave receives

the query, it attempts a restart and executes its power-up confidence tests. Successful completion of the

tests will bring the port online.

Example: Restart Communications on slave device 2.

Query Response

Field Name Data Field Name Data

Slave address $02 Slave address $02

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $01 Sub-function lo $01

Data hi $00 Data hi $00

Data lo $00 Data lo $00

CRC $---- CRC $----

5.3.1.3 [08 02] Return Diagnostic Register

The contents of the slave’s 16 bit diagnostic register are returned in the response. The assignment of

diagnostic register bits in ProtocolTM Plus controllers is shown below. In the register, bit 15 is the highorder bit. The description is TRUE when the corresponding bit is set to logic 1.

A-51643 Rev. 6 10/06/03 29

Page 36

Chromalox Instruments and Controls

Table 11: ProtocolTM Plus Diagnostic Register Bit Assignment

Bit # Description

0 NA

1 NA

2 EEPROM Data Error

3 NA

4 NA

5 NA

6 NA

7 A/D

8 Not Used – Loop Error

9 Not Used – Tune Error

10 Not Used -- Available for Application Specific Support

11 Not Used -- Available for Application Specific Support

12 Not Used -- Available for Application Specific Support

13 Not Used -- Available for Application Specific Support

14 Not Used -- Available for Application Specific Support

15 Not Used -- Available for Application Specific Support

Example: Return the diagnostic register from slave device 2 (with an EEPROM error).

Query Response

Field Name Data Field Name Data

Slave address $02 Slave address $02

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $02 Sub-function lo $02

Data hi $00 Data hi $00

Data lo $00 Data lo $04

CRC $---- CRC $----

5.3.1.4 [08 04] Force Listen Mode Only

Forces the slave into Listen Only Mode. This isolates it from the other devices on the network, allowing

them to continue communicating without interruption form the addressed slave. No response is returned.

When the slave enters this mode, all active communications are turned off. All messages broadcast or

A-51643 Rev. 6 10/06/03 30

Page 37

Chromalox Instruments and Controls

addressed to the slave are monitored, but no action is taken and no responses sent. The Restart

Communications Option function is the only command that will bring the slave out of Listen Only Mode.

Example: Force slave device 23 into Listen Only Mode.

Query No Response

Field Name Data

Slave address $17

Function $08

Sub-function hi $00

Sub-function lo $04

Data hi $00

Data lo $00

CRC $----

5.3.1.5 [08 10] Clear Communication Counters

Clears all communication diagnostic counters. Counters are also cleared upon a controller reset.

Example: Clear communication counters in slave device 23.

Query Response

Field Name Data Field Name Data

Slave address $17 Slave address $17

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $0A Sub-function lo $0A

Data hi $00 Data hi $00

Data lo $00 Data lo $00

CRC $---- CRC $----

5.3.1.6 [08 12] Return Bus Communication Error Count

The response data field returns the quantity of CRC errors encountered by the slave since its last reset or

clear counters command.

Example: Return bus communication error count in slave device 9.

A-51643 Rev. 6 10/06/03 31

Page 38

Chromalox Instruments and Controls

Query Response

Field Name Data Field Name Data

Slave address $09 Slave address $09

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $0C Sub-function lo $0C

Data hi $00 Data hi $00

Data lo $00 Data lo $07

CRC $---- CRC $----

5.3.1.7 [08 13] Return Bus Exception Error Count

The response data field returns the quantity of Modbus exception responses returned by the slave since its

last reset or clear counters command. For a description of exception responses see 5.4 Exception

Response Description.

Example: Return bus exception count in slave device 3.

Query Response

Field Name Data Field Name Data

Slave address $03 Slave address $03

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $0D Sub-function lo $0D

Data hi $00 Data hi $00

Data lo $00 Data lo $02

CRC $---- CRC $----

5.3.1.8 [08 14] Return Slave Message Count

The response data field returns the quantity of messages addressed to the slave, or broadcast, that the

slave has successfully processed since its last reset or clear counters command.

Example: Return slave message count in slave device 5.

Query Response

Field Name Data Field Name Data

Slave address $05 Slave address $05

A-51643 Rev. 6 10/06/03 32

Page 39

Chromalox Instruments and Controls

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $0E Sub-function lo $0E

Data hi $00 Data hi $00

Data lo $00 Data lo $6C

CRC $---- CRC $----

5.3.1.9 [08 15] Return Slave No Response Count

The response data field returns the quantity of messages addressed to the slave for which it returned no

response since its last reset or clear counters command. No response due to errors are not counted.

Example: Return slave no response count in slave device 9.

Query Response

Field Name Data Field Name Data

Slave address $09 Slave address $09

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $0F Sub-function lo $0F

Data hi $00 Data hi $00

Data lo $00 Data lo $02

CRC $---- CRC $----

5.3.1.10 [08 18] Return Bus Character Overrun Count

The response data field returns the quantity of messages addressed to the slave that it could not handle

because of communication port overrun, framing errors, or parity errors since its reset or clear counters

command.

Example: Return bus character overrun count in slave device 1.

Query Response

Field Name Data Field Name Data

Slave address $01 Slave address $01

Function $08 Function $08

Sub-function hi $00 Sub-function hi $00

Sub-function lo $12 Sub-function lo $12

A-51643 Rev. 6 10/06/03 33

Page 40

Chromalox Instruments and Controls

Data hi $00 Data hi $00

Data lo $00 Data lo $03

CRC $---- CRC $----

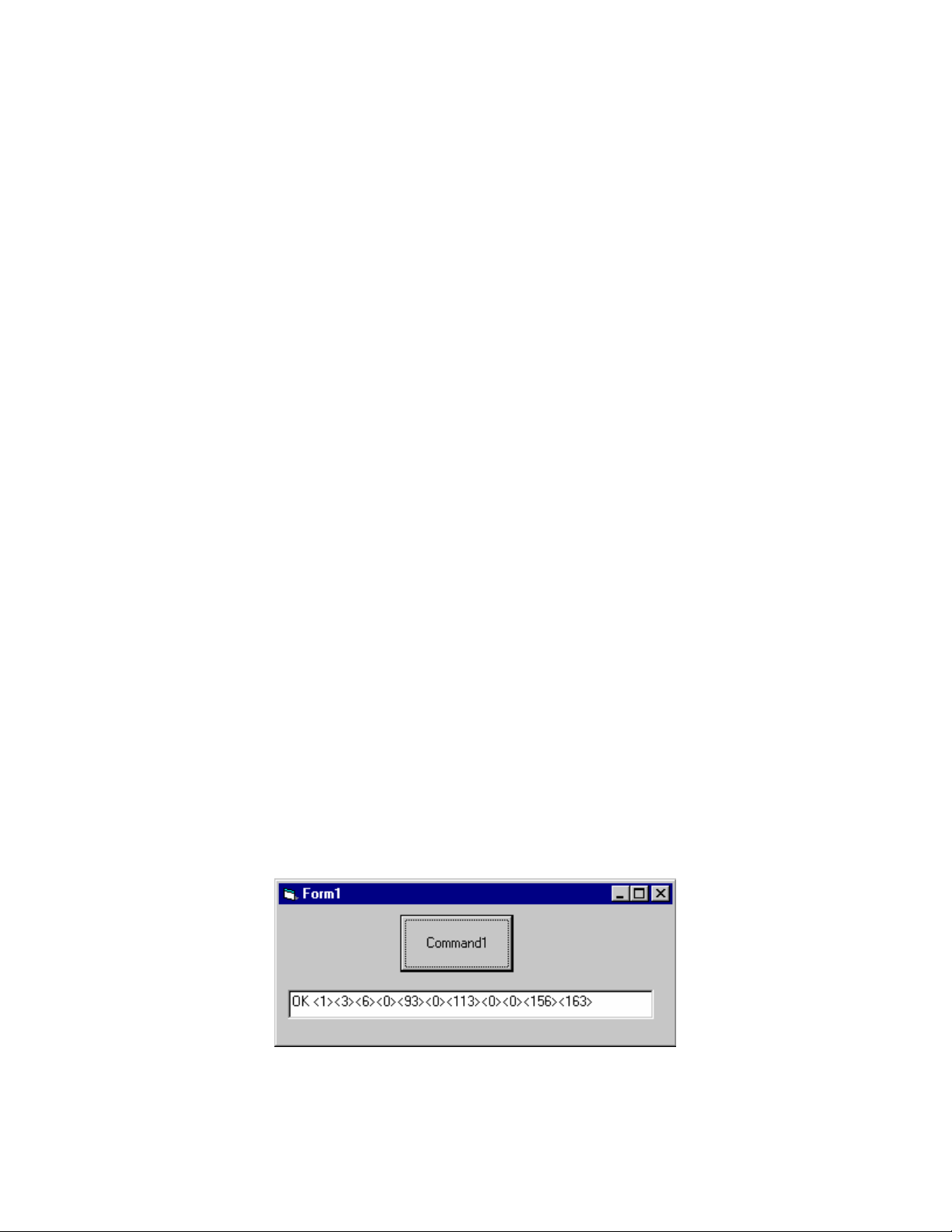

5.3.2 [17] Report Slave ID

Requests the slave to return its ID code. The ID code identifies the product line of which the slave is a

member. The Slave ID for ProtocolTM Plus is 1. Besides the ID code, the slave’s software version

number is also returned as an ASCII string. The version number will be sent in the format “VXX.X”.

Query

Example: Report Slave ID from slave address 15 whose software version is 5.0.

Field Name Data

Slave address $0F

Function $11

CRC $----

Response

The normal response is to echo the slave address and function code, supply a data byte count, return the

slave ID code, and return the software version number string.

Example: Response.

Field Name Data Comment

Slave address $0F

Function $11

Byte Count $06

Slave ID $01 ProtocolTM Plus ID code

Version number hi byte $56 ‘V’

$30 ‘0’

. $35 ‘5’

. $2E ‘.’

Version number lo byte $30 ‘0’

CRC $----

A-51643 Rev. 6 10/06/03 34

Page 41

Chromalox Instruments and Controls

5.4 Exception Response Description

Except for broadcast messages, when a master device sends a query to a slave it expects a normal

response. One of four possible events can occur from the master query:

1. If the slave device receives the query without a communication error, and can handle the query

normally, it returns a normal response.

2. If the slave does not receive the query due to a communication error, no response is returned. The

master program will eventually process a timeout condition for the query.

3. If the slave receives the query, but detects a communication error (parity, CRC), no response is

returned. The master program will eventually process a timeout condition for the query.

4. If the slave receives the query without a communication error, but cannot handle it (for example, if

the request is to read a nonexistent output or register), the slave will return an exception response

informing the master of the nature of the error.

The master device’s application program has the responsibility of handling exception responses. Typical

processes are to post subsequent retries of the message, to try diagnostic messages to the slave, and to

notify operators. The exception codes supported in the ProtocolTM Plus controller are summarized in

Table 10 ProtocolTM Plus Exception Code Set.

In an exception response, the slave sets the MSB of the function code to 1. This makes the function code

value in an exception response exactly $80 higher than the value in the query. With function code’s MSB

set, the master’s application program can recognize the exception response and can examine the data field

for the exception code.