Page 1

ADVANCING SOLAR TECHNOLOGY

u 60MW Infrared

Drying/Firing Furnace

Maximize your throughput

e Despatch 60MW infrared drying/ring furnace is designed for

maximum throughput, consistent process repeatability and maximum

equipment up-time resulting in consistently high yields, superior product

quality and reduced cost of ownership.

In addition to these exceptional performance capabilities, this model

features a touchscreen graphical user interface, eye-level electronics

access, and the rst of its kind push-button chamber access. ese

innovations make it easy to use, maximize performance and up time and

allow you to continually improve your results.

FEATURES AT A GLANCE

u

Rapid thermal ramping (>100°C/sec)

u

Enhanced thermal cooling (>100°C/sec)

u

Closed loop temperature controls

u

Enhanced software recipe management

u

Touchscreen graphical user interface

u

Master production control interface

u

Data logging

u

Redundant over-temperature shutdown

u

Minimized wafer shadowing design

u

Safe, simple chamber accessibility

u

Eye-level electronics for easy maintainability

OPTIONS

u

Water-cooled heat exchanger

u

Failed element monitor

u

Profiling systems

u

VOC thermal oxidizer

u

Water filter bypass

u

Ultrasonic belt cleaner

u

Uninterruptible power supply

u

Custom belt widths

u

Mesh belt with stand-off (dimple) supports

u

Integration to wafer automation equipment

Patented technology

Minneapolis • shanghai • Berlin • singapore • hsinchu • tokyo

Page 2

60MW DRYING/FIRING FURNACE CDF 7224 CDF 9024

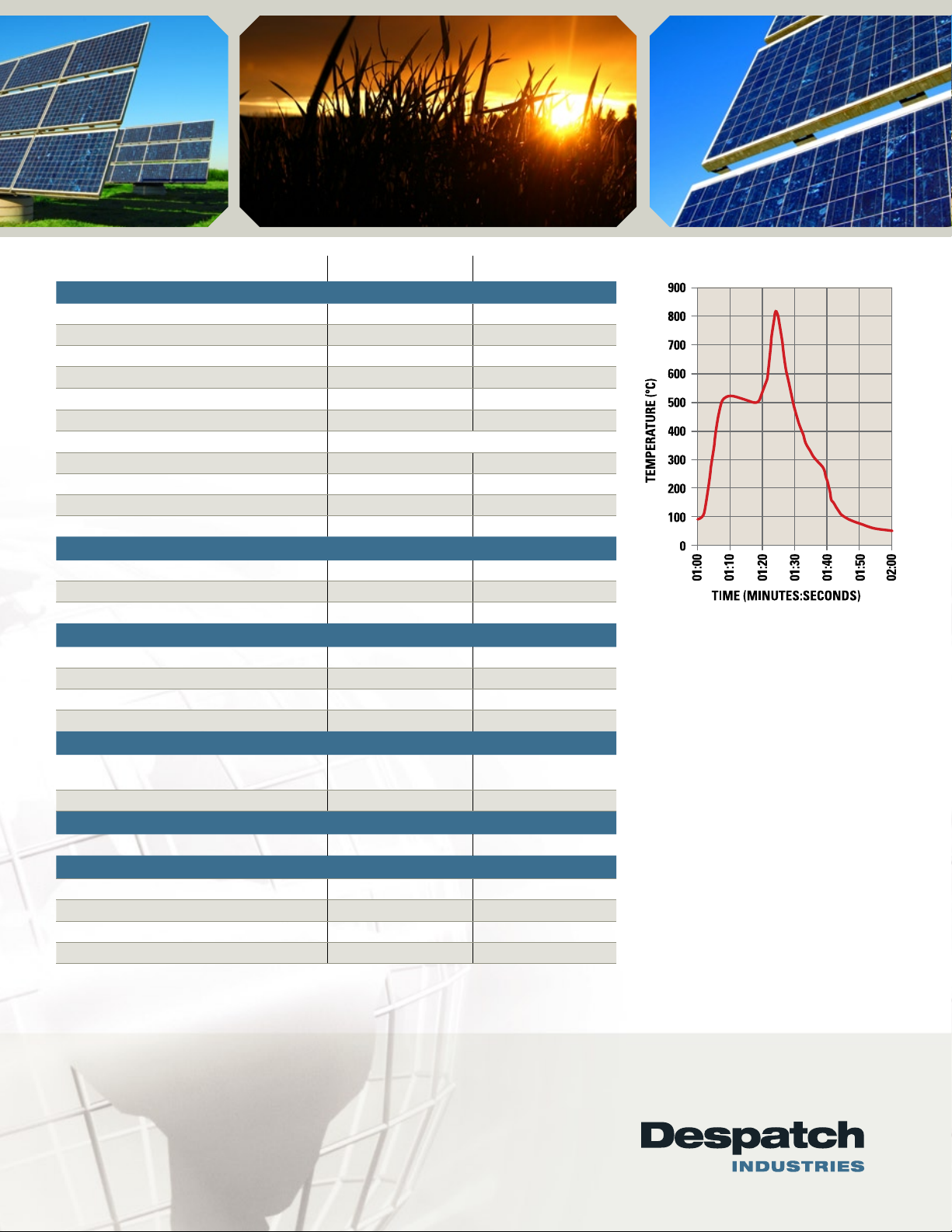

Max cool rate = 121ºC/Sec

Heating and cooling rate >100ºC/sec Time above 600ºC <6 sec

Max heat rate = 113ºC/Sec

PRODUCT CONFIGURATION

Overall length 1191 cm (469 in) 1283 cm (505 in)

Overall width 1186 cm (73 in) 160 cm (63 in)

Overall height 179 cm (70 in) 201 cm (79 in)

Standard entrance table 48 cm (19 in) 92 cm (36 in)

Inspection area

Standard exit table 94 cm (37 in) 92 cm (36 in)

Conveyor type Lightweight balance spiral weave, Nichrome V, friction drive

Conveyor height above floor 110 cm ± 3.8 cm (43.3 in ± 1.5 in) 100 cm ± 3.81 cm (39 in ± 1.5 in)

Conveyor width (custom up to 24 in /61 cm wide) 45.7 cm (18 in) 45.7 cm (18 in)

Net weight 5,675 kg (12,500 lbs) 4,535 kg (10,000 lbs)

Shipping weight 6,356 kg (14,000 lbs) 5,215 kg (11,500 lbs)

ELECTRICAL REQUIREMENTS

Voltage 208–480V/3 phase/50–60 Hz 208–480V/3 phase/50–60 Hz

Maximum load ~306 Amps ~294 Amps

Nominal load ~122 Amps ~118 Amps

WATER REQUIREMENTS

Typical flow 11 lpm (3 gpm) 11 lpm (3 gpm)

Pressure (maximum) 827 370 pascal (120 psi) 827 370 pascal (120 psi)

pH level 7.2–7.6 7.2–7.6

Recommended inlet temperature 15°C (59°F) 15°C (59°F)

EXHAUST

Process exhaust venturi assist

*hood required, no direct connection

Cabinet exhaust 1,700 m

PROCESS ATMOSPHERE

Clean dry air (CDA) 68 m3/h (2,400 scfh) typical 119 m3/h (4,200 scfh) minimum

process capaBilities

Maximum temperature (drying/firing) 400°C/1,000°C 400°C/1,000°C

Conveyor speed range 64–635 cm/min (25–250 ipm) 64–635 cm/min (25–250 ipm)

Conveyor speed accuracy ± 0.5% ± 0.5%

Throughput (6x6 in/156x156 mm wafers with 250 ipm belt speed) 3,400 wafers per hour 3,400 wafers per hour

46 cm (18 in) 46 cm (18 in)

5 sets 5 sets

3

/h (60,000 scfh) 2,550 m3/h (90,000 scfh)

Rapid ramp up and cool down

capabilities enable you to

optimize your ring proles for

high eciency cell production.

Notes: Specifications are subject to change without notice. Contact Despatch for most updated specification.

SERVICE AND TECHNICAL SUPPORT

service parts: 1-800-473-7373

international service/main: 1-952-469-8230

service fax: 1-952-469-8193

service@despatch.com

gloBal headquarters

phone: 1-888-DESPATCH (1-888-337-7282)

international/main: 1-952-469-5424

fax: 1-952-469-4513

sales@despatch.com

8860 207th Street West

Minneapolis, MN 55044 USA

www.despatch.com

© 2009 Despatch Industries. All rights reserved. Despatch is a registered trademark of Despatch Industries in the U.S. and other countries. 60MWCDF-12-09

Loading...

Loading...