Page 1

ELECTRIC FIREPLACE/INSERT

SAFETY INFORMATION AND INSTALLATION MANUAL

Patent No. 7,219,456 B1

MODELS EL36L, EL36LD AND VE36LBHB

PLEASE READ THIS MANUAL BEFORE INSTALLING

AND USING APPLIANCE.

WARNING: If the information in this manual is not followed exactly, an electrical shock or re may result causing property damage, personal injury or loss of life.

FOR YOUR SAFETY

— Do not store or use gasoline or other ammable va-

pors and liquids in the vicinity of this or any other

appliance.

— Installation and service must be performed by a

qualied service agency.

This replace meets the construction and safety stan-

dards of H.U.D. for application in manufactured homes

when installed according to these instructions.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

For more information, visit www.desatech.com

Page 2

Safety .................................................................. 2

TABLE OF CONTENTS

Listing Approvals ................................................. 3

Product Dimensions ............................................ 3

Product Identication ........................................... 4

Unpacking and Testing ........................................ 4

Locating Fireplace ............................................... 4

Installation ........................................................... 6

Operation ............................................................. 7

Accessory Installation .......................................... 8

SAFETY

WARNING: Improper installa-

tion, adjustment, alteration, ser-

vice or maintenance can cause

injury or property damage. Refer

to this manual. For assistance or

additional information, consult

a qualied installer.

CAUTION: Do not expose the

heater to the elements (such as

rain, etc).

Do not place clothing or other

ammable material on or near

rebox. Never place any objects

on the replace.

Carefully supervise young chil-

dren when they are in the room

with replace.

Fireplace becomes very hot

when running. Keep children and

adults away from hot surfaces to

avoid burns or clothing ignition.

Fireplace will remain hot for a

time after shutdown. Allow sur-

faces to cool before touching.

Do not install replace directly

on carpet or similar surface

which may restrict air circulation

beneath unit.

When using electrical heaters, basic precautions should always be followed to reduce

the risk of re, electric shock and injury to

persons, including the following:

www.desatech.com

Cleaning .............................................................. 9

Servicing .............................................................. 9

Wiring Diagram .................................................. 14

Troubleshooting ................................................. 15

Replacement Parts ............................................ 16

Technical Service............................................... 16

Accessories ....................................................... 17

Parts .................................................................. 18

Warranty ..............................................Back Cover

1. Read all instructions before using this

heater.

2. Keep combustible materials, such as

furniture, pillows, bedding, papers, clothes

and curtains at least 3 feet (0.9 m) from

front of heater.

3. This heater is hot when in use. To avoid

burns, do not let bare skin touch hot surfaces. The grill directly in front of heater outlet

becomes hot during heater operation.

4. Extreme caution is necessary when any

heater is used by or near children or invalids and whenever heater is left operating

and unattended.

5. Always unplug heater when not in use.

6. Do not operate any heater with a damaged

cord or plug or if heater malfunctions or

has been dropped or damaged in any way.

Return heater to authorized service facility

for examination, electrical or mechanical

adjustment or repair.

7. Do not use outdoors.

8. This heater is not intended for use in

bathrooms, laundry areas and similar

indoor locations. Never locate heater

where it may fall into a bathtub or other

water container.

9. Do not run cord under carpeting. Do not

cover cord with throw rugs, runners or the

like. Arrange cord away from trafc area

and where it will not be tripped over.

10. To disconnect heater, turn controls to the

OFF before removing plug from outlet

(turn off power to unit).

11. Do not insert or allow foreign objects to

enter any ventilation or exhaust opening

as this may cause an electric shock or re

or damage the heater.

12. To prevent possible re, do not block air

intakes in any manner. Do not use on soft

surfaces, like a bed, where openings may

become blocked.

13.

Connect to properly grounded circuits only.

122663-01D2

Page 3

SAFETY

17 1/4"

17

5

/8"

24

1

/4"

35"

8"

21"

37"

43"

42

1

/8" To Nail Location

36

1

/

2

"

31

7

/

8

"

36

3

/

4

" To Nail Location

41"

2

1

/8"

5/8"

TOP

FRONT

LEFT SIDE RIGHT SIDE

36

1

/

8

"

15 1/8"

Continued

14. A heater has hot and arcing or sparking

parts inside. Do not use it in areas where

gasoline, paint or ammable liquids or

vapors are used or stored.

15. Use this heater only as described in this

manual. Any other use not recommended

by the manufacturer may cause re, electric shock or injury to persons.

16. Avoid the use of an extension cord because the extension cord may overheat

and cause a risk of re. However, if you

have to use an extension cord, the cord

should be No. 14 AWG minimum size and

rated not less than 1875 WATTS.

17. Always use ground fault protection where

required by electrical codes.

LISTINg APPROVALS

This heater has been tested in accordance

with the CSA Standards for xed and location-dedicated electric room heaters in the

United States. All components are UL or CSA

safety certied.

If you need assistance during installation,

please contact your local dealer or the DESA

Heating, LLC at 1-866-672-6040.

Please have the distributor’s model and serial

numbers when you call.

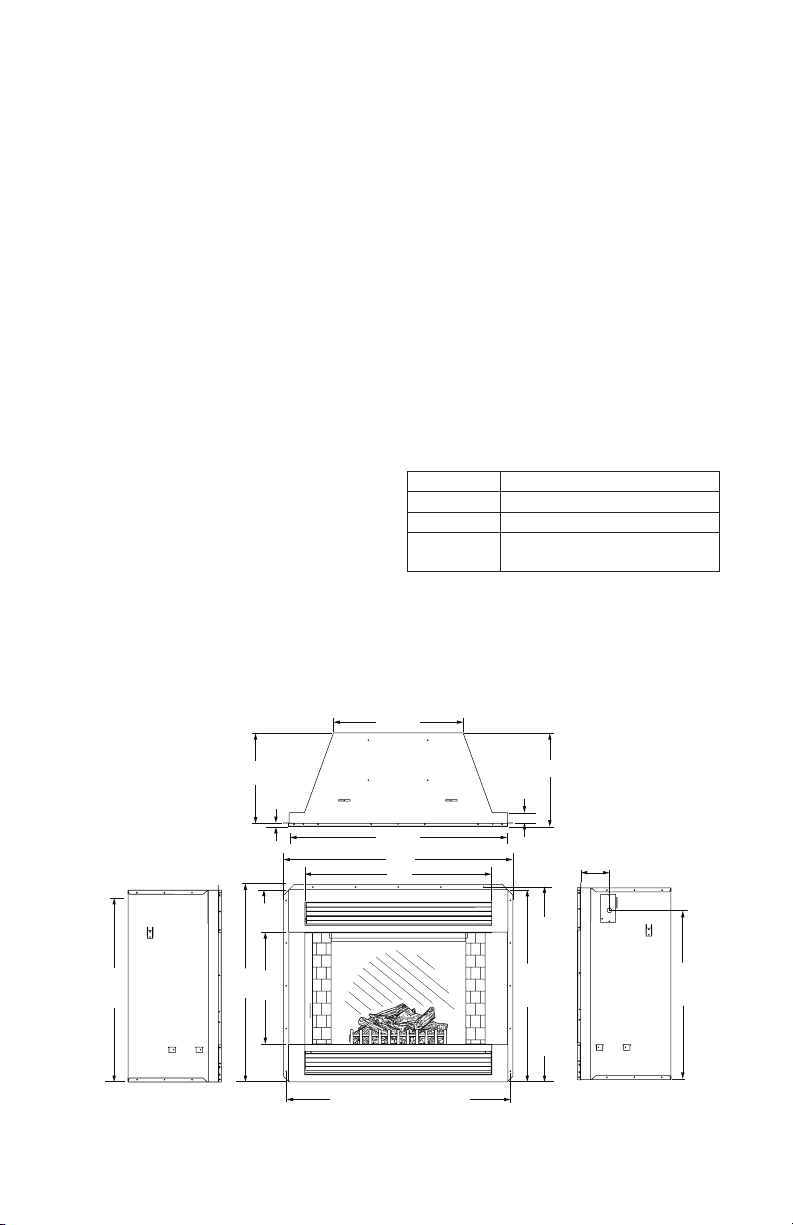

PRODUCT DIMENSIONS

18. Always disconnect power before performing any cleaning, maintenance or relocation of heater.

19. To prevent a possible re, do not burn

wood or other materials in this heater.

20. To prevent electric shock or re, always

use a certified electrician should new

circuits or outlets be required.

21. When transporting or storing heater, keep

in a dry place.

22. Control panel door gets hot during heater

operation. To open control panel door,

gently pull on left and right outer edges.

Do not open from center of control panel

door.

Description: 36" Fireplace

Voltage: 120 / 240

Watts: 1500 / 3000

Amps: 15 Amp / 20 Amp

Grounded Circuit

Note: This heater must be electrically wired and

grounded in accordance with local codes or, in

the absence of local codes, with National Electric

Code ANSI/NFPA 70-latest edition or the Canadian Electric Code, CSA C22.1 as appropriate.

Figure 1 - Heater Dimensions

122663-01D 3

www.desatech.com

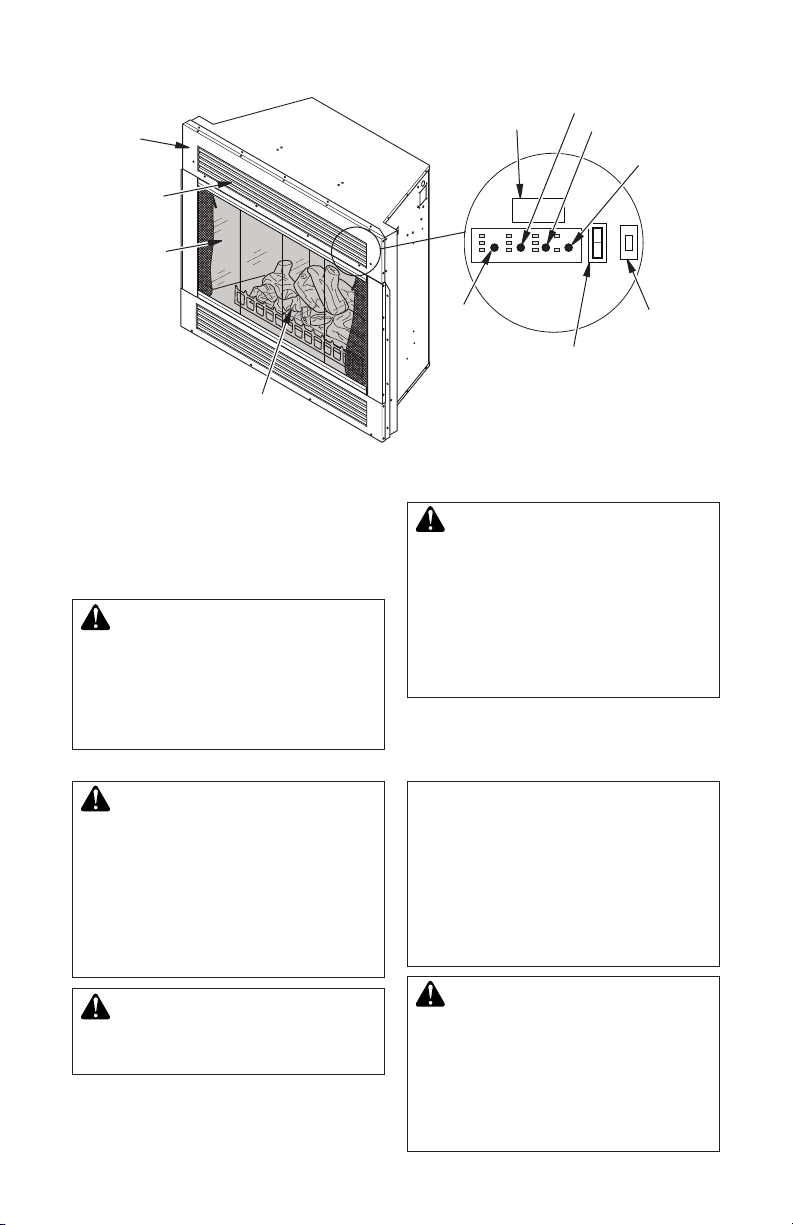

Page 4

Heater FlameEmber Backlight

Power

Control

Panel

Door

Heat Vents

(Behind Door)

Front Glass

PRODUCT IDENTIFICATION

Remote Hide

Flame Control

Ember Control

Backlight

Control

Log Set

Figure 2 - Product Identication

UNPACkINg AND TESTINg

Carefully remove unit from box. Prior to permanently installing unit, test to make sure unit

operates properly. Unit does not come with a

power cord installed. Unit must be hard wired

to either a 120/60 or 240/60 volt supply.

CAUTION; The unit must

be connected to a properly

grounded and protected 120/240

volt circuits. Always use ground

fault protection where required

by the electrical code.

LOCATINg FIREPLACE

WARNING: Due to high tem-

peratures, this heater should

be located out of trafc. Keep

combustible materials such

as furniture, pillows, bedding,

papers, clothes and curtains at

least 3 feet (0.9 m) from the front

of the heater.

Heater

Control

ON/OFF

Power

Button

Magnetic

Catch

WARNING: Do not operate

the unit if it is damaged or has

malfunctioned. If you suspect

the unit is damaged, return the

unit to an authorized service

facility for examination, electrical or mechanical adjustment

or repair.

NOTICE: Minimum and maximum

clearances must be maintained at

all times. Illustrations throughout

these instructions reect typical

installations and are for design

purposes only. Actual installa-

tions may vary slightly due to

individual preferences.

WARNING: Never locate this

heater where it may fall into a bathtub or other water container.

WARNING: To prevent

contact with sagging or loose

insulation, the heater must not

be installed against vapor barrier

or exposed insulation. Localized

overheating could occur and a

re could result.

www.desatech.com

122663-01D4

Page 5

LOCATINg FIREPLACE

Internal Wall

Installation

Full Projection

Installation

Flush

Installation

Corner

Installation

Facing Material May

Be Noncombustible

Wa ll Treatments or

Combustible Wood

Combustible Wood

Mantels and Tr ims

May Extend Above

Profile Shown when

Maintained within

30° Parameter

Shown

Framed

Material

T o p of Cabinet

Note: All Mantel Clearances

are Measured from Top of

Fireplace Opening

30°

23"

12" Ref.

21"

4

1

/2"

1

1

/2"

15" Min.

17"

10

1

/2"

To p View of Fireplace

5"

3"

30°

1

3

/4" Max.

Minimum 10"

from Perpendicular

Side Wall

Edge of

Firebox

Opening

Combustible

Material Must

Not Overlap

Front Face

Safe Zone

heater to the elements (such as

rain, etc.)

safety glasses for protection

during installation and maintenance.

Plan where to locate and frame replace.

Before installation consider the following:

1. Fireplace location must allow for wall and

ceiling clearances (see Installation Clear-

ances).

2. Fireplace screen should not be exposed

to direct sunlight from windows or doors.

3. Unit can be wired for either 120/60 (15

amp circuit) or 240/60 (20 amp circuit).

A dedicated circuit should be provided

to avoid circuit breaker trips or blown

fuses.

Flush Installations are recommended where

living space is limited or at a premium. Since

space required to enclose replace would

be located beyond an outside wall, this in-

stallation would require additional planning

and construction. Check local codes for any

restrictions.

Projected Installations can extend any dis-

tance into room. A projection may be ideal for

a new addition on an existing, nished wall.

Corner Installations make use of space

that may not normally be used and provides

a wider and more efcient viewing angle and

heat distribution.

Internal Wall Installations provide a discrete

option for room separation and can also be an

ideal addition to an existing wall.

Figure 3 - Possible Installation Locations

122663-01D 5

Continued

CAUTION: Do not expose the

CAUTION: Wear gloves and

www.desatech.com

INSTALLATION

INSTALLATION CLEARANCES

Minimum clearances to combustible construction are:

Top, Back and Sides of Recessed Cabinet 0" Min.

Drywall to Sides of Front Face 0" Min.

Framing at Nailing Flanges 0" Min.

Ceiling to Opening 36" Min.

Floor 0" Min.

Front 36" Min.

Perpendicular Side Wall 10" Min.

M

antel Clearances

For mantel clearances see Figures 4 and 5.

Figure 4 - Mantel Clearances

Figure 5 - Mantel Side Clearances

Page 6

41 1/4"

7

1

/2"

36

1

/2"

Platform/Subflooring

42 3/8"

29

3

/8"

58

1

/4"

1 1

5

/8"

These Dimensions

Allow for 1 1

5

/8" of

Clearance to Side

Wa ll of Fireplace

and 10' Clearance

to Perpendicular

Side Walls

INSTALLATION

Continued

WARNING - RISK OF FIRE!

Wiring to power source must not

be pinched or against a sharp

edge.

WARNING - RISK OF FIRE!

To prevent a possible re, do

not block air intake or exhaust

in any manner. Do not use on

soft surfaces where openings

may become blocked.

WARNING - RISK OF FIRE!

Do not blow or place insulation

against the rebox.

WARNING: If the informa-

tion in these instructions is

not followed exactly, a re or

explosion may result causing

property damage, personal injury or death.

Do not store or use gasoline or

other ammable vapors in the vicinity of this or any other heater.

A junction box is provided to hard wire unit to

either a 15 amp (120/60) or 20 amp (240/60),

120 Volt 60 Hz grounded circuit.

Tools and building suppli es required for

installation:

• Saw • Square

• Pliers • Gloves

• Hammer • Level

• Phillips screwdriver • Surround

• Framing materials • Electric drill/bits

• Tape measure

• Wall-nishing materials

• Caulking material

CAUTION: Provide adequate

clearances around the air open-

ings and adequate accessibility

clearances for servicing and

proper operations.

www.desatech.com

WARNING: Control panel

door on this heater cannot, in

any way, be covered as it may

create a re hazard.

BUILT-IN INSTALLATION

Built-in installations require a framed enclosure constructed of 2" x 4" or heavier lumber

and sized in accordance with Figure 6. This

allows unit to slide into opening and be nailed

to stud at sides and top nailing anges. These

anges accept 5/8" drywall or plywood board

to nish unit ush to face. Optional trim ac-

cessories are available that will extend 1/2"

over rough edge of wall opening (see Acces-

sories, page 17).

IMPORTANT: If installing a perimeter trim kit,

you must install shoulder screws before insert-

ing replace into opening. See instructions

included with trim kit. If installing a mantel,

you must follow clearance instructions (see

Installation Clearances, page 5).

Figure 6 - Framing Dimensions

Figure 7 - Corner Dimensions

122663-01D6

Page 7

INSTALLATION

Heater Flame EmberBacklight

Power

Continued

A hearth extension is suggested for a more

pleasing appearance. The replace may be

raised on a wood or non-combustible platform

supporting its entire width and depth and

extending in front of the replace as long as

louvers are not obstructed.

Note: When installing replace in cold climates against a non-insulated exterior wall,

wall must be fully insulated in accordance with

local building code.

ELECTRICAL INSTALLATION

WARNING: Any electrical re-

wiring of this appliance must be

done by a qualied electrician.

This wiring must be done in ac-

cordance with local codes and/or

in the U.S.A. with the current, N a -

tional Electrical Code ANSI/NFPA

No 70 and in Canada with CSA

C22.1 Canadian Electric code.

OPERATION

The controls (see Figure 8) are located behind

hinged control panel door. If using heater, control panel door will be hot during and immediately after operation. Open door by pulling

control panel door on left and right side.

1. Connect replace to power source. Turn

on lighted power switch (see Figure 8).

2. Adjust Flame/Ember/Backlight/Heater

to desired settings using the control pad

on replace (Figure 8) or remote control

(Figure 9). Figure 10, page 8, shows re-

place settings available. Default settings

are circled. Press control pad or remote

control buttons once and release to adjust

settings.

Note: When on, ember bed will lighten

and darken automatically to simulate real

embers.

This replace should be connected to a dedicated 15 amp

(120/60) or 20 amp (240/60),

circuit as other appliances may

cause the circuit breaker to trip

or fuse to blow when replace

is in operation.

A junction box is provided to hard wire unit to

either a 15 amp (120/60) or 20 amp (240/60),

120 Volt 60 Hz grounded circuit.

Heater

Control

Figure 8 - Controls For Electric Fireplace

Flame

Control

Ember

Control

Lighted Power Switch

Backlight

Control

Figure 9 - Remote Control For Electric

122663-01D 7

www.desatech.com

Fireplace

Page 8

OPERATION

Continued

The heater is pre-set to the following

temperatures:

HIGH will shut off when room reaches

approximately 86° F (30° C).

MEDIUM will shut off when room reaches

approximately 79° F (26° C).

LOW will shut off when room reaches

approximately 72° F (22° C).

Note: Fan on heater will continue to run for 5-7

seconds after heater has been turned off.

3. When using remote control, aim remote

at sensor located in center of unit just

above log set. IMPORTANT: This remote

ACCESSORY INSTALLATION

OPTIONAL GLASS DOORS

(Model EL36L only. Doors are included

with models EL36LD and VE36LBHB)

Model EL36L will accept bifold glass doors

that are fully operable

Installing Bifold Glass Doors

Follow these steps to install left and right

operable panels:

1. With handle down, completely fold panel

on its hinges.

2. With handle facing center of rebox opening insert lower pivot pin on door panel

into hole in bottom outer edge of rebox

opening (see Figure 11).

3. Keep folded door tilted and slide upper two

pins into guide track below upper facial

edge of rebox opening.

4. Tilt glass assembly fully vertical until outer

pivot pin snaps into mounting hole in upper spring clip.

5. Once top and bottom pins are secured,

unfold door into closed position.

6. Repeat steps 1 through 5 for opposite

door assembly.

7. To adjust doors, slide partially open. Using

a Phillips screwdriver, loosen hold-down

screws on spring clips (see Figure 12).

8. Close both doors until evenly joined at

middle and note gap as measured to outer

edges of front face.

9. Reopen each door one at a time and

retighten the hold-down screw while preserving noted gap at each edge.

10. Repeat process until both doors are even-

ly joined, spaced and working freely.

www.desatech.com

control must remain within 20 feet (6 m)

of replace to be effective.

4.

When power switch is turned off, replace

settings go back to default (see Figure 10).

HEATER Off Low Medium High

FLAME Off Low Medium High

EMBER Off Low Medium High

BACKLIGHT Off Low High

Figure 10 - Fireplace Settings (Default

Figure 11 - Installing/Removing Glass

Partially

Opened

Door

Settings are Circled)

Spring Clip

Press Spring Clip

to Release Pivot

Pin

Fold Bifold Door

After Releasing

Spring Clip to

Slide Door Out of

Upper Track

Remove Pivot Pin

From Bottom Face

While Sliding Door

Out of Upper Track

Pivot Pin

Doors

Side Front

Face

Figure 12 - Adjust Glass Door

Spring Clip

122663-01D8

Page 9

ACCESSORY INSTALLATION

Continued

Removing Bifold Glass Doors

Bifold doors may be removed for replacing

or cleaning.

1. Partially open each door and press up on

upper spring clip with a screw driver until

outer top pivot pin is free of the clip.

CLEANINg

WARNING: Always discon-

nect power and allow the heater

to cool before performing any

cleaning, maintenance or relocation of this heater. Turn controls

to OFF and remove plug from

outlet or turn off circuit breaker

to heater.

CLEANING FIREBOX

1. Open bi-fold doors and screens.

2. Using a brush vacuum attachment, gently

clean compartment.

3. Close screens and doors.

2. Fully fold frame assembly and slide upper

edge towards center of rebox opening

until the guide pins are free of the frame

rail (see Figure 11, page 8).

CLEANING BACK SCREEN (GLASS)

1. The glass is cleaned in the factory during

assembly. During shipment, installation,

handling, etc. glass surface may collect

dust particles. These can be removed

by bufng lightly with a clean damp cloth

(water only). Glass should be completely

dried with a lint free cloth or paper towel.

2. To access glass to clean, follow steps

1 through 5 under Service Preparation,

page 10.

3. Using gloves, gently remove glass panel

by sliding it toward you. There is a rubber

bumper on each corner of glass.

4. Clean glass as instructed in step 1.

5. Follow steps 8 through 13 under Service

Preparation, page 10.

SERVICINg

WARNING: Turn off appliance

and let cool before servicing.

Only a qualied service person should service and repair

heater.

For questions regarding replacing parts, see

page 13.

Note: All service procedures are performed

through front face opening of replace.

REPLACING LOG

1. Turn off power to unit (circuit breaker).

2. Open upper control panel door. Turn

power switch off.

3. Open bi-fold doors (if equipped) and

screens.

4. Remove screws securing each side of log

to brackets (see Figure 13).

5. Carefully remove old log.

122663-01D 9

www.desatech.com

6. Install new log.

7. Reinstall screws into brackets to secure

new log.

8. Close screens and doors.

Screw

Log

Figure 13 - Removing Log and Ember LED

Ember LED Strip

with Standoffs

Page 10

SERVICINg

Continued

REPLACING SCREENS

1. Open upper control panel door. Turn

power switch off.

2. Open bi-fold doors (if equipped).

3. Remove 2 screws securing screen rods

(see Figure 14).

4. Tilt rod down and remove from bracket.

5. Remove old screen from rod and discard.

Install new screen onto rod.

6. Reinstall rod into bracket and replace

screws.

7. Close doors.

Mounting

Holes

Screen

Rod

Retaining

Screw

Figure 14 - Removing Screen/Rod Assembly

REPLACING EMBER STRIP

1. Follow steps 1 and 4 under Replacing Log,

page 9.

2. Locate ember LED strip (see Figure 13,

page 9). Disconnect wire (right side).

3. Remove ember LED strip by squeezing

top of standoffs and discard.

4. Being careful not to break LED strip, press

new ember LED strip onto standoffs.

5. Reconnect wire to LED strip.

6. Follow steps 5 through 7 under Replacing

Log, page 9.

SERVICE PREPARATION

Perform steps 1 through 4 below, then locate

part that needs replacing in the instructions

that follow.

1. Open control panel door. Turn off power

to unit (circuit breaker).

www.desatech.com

2. Open bi-fold doors (if equipped) and

screens.

3. Remove screws securing each side of log

to brackets (see Figure 13, page 9).

4. Carefully remove log.

5. Remove screws from back corners and

front of top panel (see Figure 15). Remove

top panel and set aside.

Note: For LED drum and motor, only

remove back screws. Top panel does not

have to be completely removed. Carefully push top panel up to remove screen

glass.

6. Using gloves, gently remove glass panel

by sliding it toward you. There is a rubber

bumper on each corner of glass. Set aside

in a safe location.

7. Follow instructions on pages 11 thru 13 to

replace part.

8. Using gloves, install glass by gently slid-

ing, smooth side toward replace front,

into brackets on either side that hold glass

in place.

9. Reinstall top panel. Pull top panel down

so that screen glass seats into glass

retainer.

10. Reinstall screws from step 5.

11. Reinstall log.

12. Reinstall screws into brackets to secure

log.

13. Close screens and doors.

14. Turn on power to unit (circuit breaker).

Control

Panel

Door

Top Panel

Screen Glass

Figure 15 - Removing Screen Glass (all

parts not shown for clarity)

122663-01D10

Page 11

SERVICINg

Continued

SCREEN GLASS

1. In the event of glass breakage, vacuum all

remaining glass pieces with a shop vac. DO

NOT VACUUM WHILE PIECES ARE HOT.

Replace glass only with replacement part

specically for this heater. Never substitute

material. Only fully tempered soda lime

safety glass may be used on this heater.

2. Remove and replace glass, follow steps

1 through 13 (skip step 7) under Service

Preparation, page 10.

LED DRUM AND MOTOR (FLAME

GENERATION)

1. Follow steps 1 through 6 under Service

Preparation, page 10.

2. Disconnect wires from motor and LED

drum assembly.

3. Remove screws from bottom panel to

remove assembly (see Figure 16).

4. If motor on assembly fails, loosen clamps

(see Figure 16). Remove screws from

motor. Hold universal joint while removing

motor and discard.

5. Install new motor. Slide motor shaft into

universal joint and tighten clamps.

6. Hold LED drum assembly in place on

bottom panel and replace screws.

White

Wire

Red

Wire

Screws

7. Reattach wires to motor and LED drum.

Note: LED drum wires are polarity sensitive and must be connected correctly.

White wire plugs onto left terminal and red

wire plugs onto right terminal. Motor wires

can be connected to either terminal.

8. Follow steps 8 through 13 under Service

Preparation, page 10.

MAIN CONTROL BOARD

1. Follow steps 1 through 6 under Service

Preparation, page 10.

2. Disconnect wires to main control board.

3. Squeeze top of standoffs to remove main

control board and discard.

4. Install new control board by gently pushing

onto standoffs.

5. Reconnect wires to main control board

(see Wiring Diagram, page 14).

6. Follow steps 8 through 13 under Service

Preparation, page 10.

Transformer

Main Control

Board

Standoffs

LED Drum

Assembly

Clamps

Figure 16 - Flame Generation LED Drum

Assembly

122663-01D 11

Motor

Figure 17 - Control Board

www.desatech.com

Page 12

SERVICINg

Continued

TRANSFORMER

1. Follow steps 1 through 6 under Service

Preparation, page 10.

2. Disconnect transformer wires from control

board.

3. Remove 2 screws from rebox surround

to remove transformer (see Figure 18).

4. Remove and discard transformer.

5. Place new transformer against inside

of rebox surround and replace screws

removed in step 3.

6. Reconnect transformer wires to control

board (see Wiring Diagram, page 14).

6. Follow steps 8 through 13 under Service

Preparation, page 10.

Screws

Transformer

Nuts

Figure 18 - Removing Transformer

HEATER

1. Follow steps 1 through 6 under Service

Preparation, page 10.

2. Disconnect wires from heater.

3. Remove 4 screws from side of heater, see

(Figure 19).

4. Install new heater.

5. Connect wires to new heater (see Wiring

Diagram, page 14)

6. Follow steps 8 through 13 under Service

Preparation, page 10.

Blower

Heater

Figure 19 - Removing Heater from

Blower

BLOWER ASSEMBLY

1. Follow steps 1 through 6 under Service

Preparation, page 10.

2. Disconnect wires from heater/blower assembly.

3. Remove 4 screws holding blower/heater

and brackets to replace top (see Figure

20).

4. Remove 4 screws securing heater to

blower (see Figure 19).

5. Install old heater onto new blower with

screws removed in step 4.

6. Install new blower/heater assembly to top

panel with screws removed in step 3.

7. Reconnect wires to blower/heater assembly (see Wiring Diagram, page 14).

8. Follow steps 8 through 13 under Service

Preparation, page 10.

Brackets

Figure 20 - Removing Blower/Blower

www.desatech.com

Assembly

122663-01D12

Page 13

SERVICINg

Continued

BACKLIGHT LED STRIP

1. Follow steps 1 through 4 under Service

Preparation, page 10.

2. Disconnect wires from backlight LED

strip.

3. Squeeze top of standoffs to remove backlight LED strip and discard.

4. Place new backlight LED strip onto standoffs and push gently.

5. Connect wires to backlight LED strip (see

Wiring Diagram, page 14).

6. Follow steps 11 through 13 under Service

Preparation, page 10.

Backlight

LED Strip

Standoffs

Figure 21 - Replacing Backlight LED

REMOTE CONTROL SENSOR

1. Follow steps 1 through 6 under Service

Preparation, page 10.

2. Disconnect wire from remote control sensor board.

Strip

Remote Control Sensor

3. Squee ze top of standoffs t o remove

board.

4. Gently push new board onto standoffs.

5. Connect wires to remote sensor board.

6. Follow steps 8 through 13 under Service

Preparation, page 10.

SETTINGS CONTROL BOARD

1. Follow steps 1 through 6 under Service

Preparation, page 10.

2. Disconnect wire from settings control

board.

3. Remove screws from bracket to remove

settings control board (see Figure 23).

4. Place new settings control board into position making sure each control is aligned

with slot in panel. Install using screws

from step 3. DO NOT overtighten. This

will damage control board.

5. Reconnect wire to settings control board

(see Wiring Diagram, page 14).

6. Follow steps 8 through 13 under Service

Preparation, page 10.

Settings

Control

Board

Screw

Figure 23 - Replacing Settings Control

Figure 22 - Replacing Remote Control

122663-01D 13

Sensor

www.desatech.com

Board

Page 14

WIRINg DIAgRAM

Junction Box

Voltage 120V AC

32" and 36" BUILDER ELECTRIC FIREPLACE CONTROL DIAGRAM

PCB BOARD AND FUNCTION CONTROL ASSEMBLY

P/N F904-0036-9000 (Rev A)

DPST

Rocker Switch

Purple

Yellow

Brown

Dark Green

Gray

Blue

Red

Black

Purple

Ye llow

Brown

Gray

Blue

Red

Black

4

Note:

YLW: Yellow

CYA: Cyan

BRW: Brown

WHT: White

BLK: Black

ORG: Orange

GRE: Dark Green

WHT

WHT

YLWYLW YLW

BRW

ORGORG GRECYA

FAN

LESLBS LDA

+

+

-

-

MTR RCS

SCB

TF1

THM

M

Gray

Heater

Heater

Fuse

Heating Element

Assembly

Blower

LED Ember Strip

LED Backlight Strip

Remote Control

Sensor (Infrared)

LED Drum/

Motor Assembly

Settings

Control

Board

1

99

1

Transformer

Thermostat

Blue

Cyan

White

Black

White

Black

Yellow

White

Red

Junction Box

Voltage 240V AC

WARNING

Cover all unused

wires with tape

and install wire

nuts. Unplug unit

before servicing.

Purple

Yellow

Brown

Dark Green

Gray

Blue

Red

Black

White

Electrical

Outlet

Black

Green

White

Black

Green

1

2

5

M

www.desatech.com

122663-01D14

Page 15

TROUBLESHOOTINg

WARNING: Turn off appliance and let cool before servicing. Only

a qualied service person should service and repair heater.

OBSERVED PROBLEM

Fireplace turns off and will

not turn on

Flame is not moving

Flame is not visible

Log set and/or ember is not

glowing

Flame sputters/ashes

Rem ote c ontrol does not

work

Fireplace will not come on

when switch is ipped to ON

Heater does not provide heat

when turned on

122663-01D 15

POSSIBLE CAUSE REMEDY

1. Fireplace has overheated

and safe ty device has

caused thermal switch to

disconnect or home circuit

breaker has opened

1. Loose wiring

2. Flame motor defective

1. Wiring is loose

1. Wiring is loose

1. Flame motor is defective

2. Flame generation contacts

dirty/obstructed

1. Low batteries

2. Not aiming control correctly

3. Defective remote control

and/or sensor

1. Control failure

2. Breaker tripped

1. Thermal switch has been

tripped

2. Circuit breaker has been

tripped

3. Wiring is loose

4. Heater is defective

5. Thermostat cycled off

www.desatech.com

1. Reset swit ch by tur ning

main power switch off and

waiting 5 minutes then turning it back on or reset circuit

breaker

1. Inspect wiring for l oo se

connections

2.

Call a qualied service technician to replace ame motor

1. Di sconn ect fro m power

source and inspect wiring for

loose connections and repair

or replace if necessary

1. Di sconn ect fro m power

source and inspect wiring for

loose connections and repair

or replace if necessary

1.

Call a qualied service techni-

cian to replace ame motor

2. Di sco nnect pow er. Fol-

low steps to replace ame

ge ner ati on LE D. Cl ean

contacts with dry cloth.

1. Replace AAA batteries in

remote control

2. Aim control at sensor located directly behind glass

screen in center of unit just

above logs

3. Re pl ac e remote cont rol

and/or sensor

1. Call a qualied service technician to replace control

2. Reset breaker

1. Turn unit off. Turn off power

to unit for 5 minutes. Turn

power and unit on.

2. Turn off circuit breaker that

supplies electricity to unit.

Wait 5 minutes then flip

circuit breaker back on

3. Di sconn ect fro m power

source and inspect wiring for

loose connections and repair

or replace if necessary

4. Replace heater

5. Change to higher setting

Page 16

REPLACEMENT PARTS

Note: Use only original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If

they can’t supply original replacement part(s),

call DESA Heating, LLC at 1-866-672-6040.

When calling DESA Heating, LLC, have

ready:

• your name

• your address

• model and serial numbers of your heater

• how heater was malfunctioning

• purchase date

TECHNICAL SERVICE

You may have further questions about installation, operation, or troubleshooting. If so, con-

tact DESA Heating, LLC at 1-866-672-6040.

When calling please have your model and

serial numbers of your heater ready.

You can also visit DESA Heating, LLC’s web

site at www.desatech.com.

Usually, we will ask you to return the part to

the factory.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If

they can’t supply original replacement part(s),

call DESA Heating, LLC at 1-866-672-6040 for

referral information. A list of authorized dealers

can be found by visiting www.desatech.com.

When calling DESA Heating, LLC, have

ready:

• model and serial numbers of your heater

• the replacement part number

www.desatech.com

122663-01D16

Page 17

ACCESSORIES

Purc hase thes e acce ssori es fro m your

local dealer. If they can not supply these

accessories, either contact your nearest

Parts Central or call DESA Heating, LLC at

1-866-672-6040 for information. You can also

write to the address listed on the back page

of this manual.

36" PERIMETER TRIM KITS

PT36 - Black

PT36B - Brushed Brass

PT36PB - Polished Brass

PT36P - Platinum

36" BIFOLD GLASS DOOR KITS

BD36 - Black

BD36B - Brushed Brass

BD36PB - Polished Brass

BD36P - Platinum

122663-01D 17

www.desatech.com

Page 18

MODEL EL36L, EL36LD, VE36LBHB

23

6

28

15

29

19

19

14

24

5

7

22

16

17

18

4

8

21

32

30

2

27

25

26

3

13

10

11

20

12

1

9

31

PARTS

www.desatech.com

122663-01D18

Page 19

PARTS

MODELS EL36L, EL36LD, VE36LBHB

This list contains replaceable parts used in your replace. When ordering parts, follow the

instructions listed under Replacement Parts on page 16 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

1 120929-01 Door Handles * 2

2 120929-02 LED Ember Strip 1

3 120929-03 Log Set 1

4 120929-04 Rear Glass (Screen) 1

5 120929-05 Flame Effect Mirror 1

6 120928-46 Heater/Blower Bracket 2

7 120928-44 Flame Effect Mirror Bracket 2

8 120927-16 Back Light Strip 1

9 120929-09 Top 1

10 120929-10 Glass Door, Left * 1

11 120929-11 Glass Door, Right * 1

12 120929-12 Control Panel Door 1

13 120929-13 Front Panel 1

14 120929-14 Mesh Screens 2

15 120929-15 Screen Rods 2

16 120929-16 Back Panel, Left Side 1

17 120929-17 Back Panel, Center 1

18 120929-18 Back Panel, Right Side 1

19 120929-19 Magnetic Catch 2

20 120929-20 Bottom Panel 1

21 120928-40 Grate 1

22 120927-08 Handles 2

23 120928-42 Heater 1

24 120928-43 Blower 1

25 120928-27 Transformer 1

26 120928-26 Main Control Board and Standoffs 1

27 120927-21 Remote Control Sensor 1

28 120927-12 Settings Control Board 1

29 120927-24 ON/OFF Switch 1

30 120929-21 LED Drum Assembly 1

31 120927-14 Motor 1

32 120927-20 Remote Control 1

* Optional for model EL36L.

PARTS AVAILABLE - NOT SHOWN

120929-06 Wire (Flame Effect) 1

120929-07 Wire (Ember Bed) 1

120929-08 Wire (Backlight) 1

120927-23 Thermocouple 1

122663-01D 19

www.desatech.com

Page 20

122663 01

WARRANTY

kEEP THIS WARRANTY

Model (

located on product or identication tag

Serial No. (

located on product or identication tag

Date Purchased __________________________

Keep receipt for warranty verication.

DESA HEATINg, LLC LIMITED WARRANTIES

Standard Warranty: DESA Heating, LLC warrants this new product and any parts thereof to be free from

defects in material and workmanship for a period of one (1) year from the date of rst purchase from an

authorized dealer provided the product has been installed, maintained and operated in accordance with

DESA Heating, LLC’s warnings and instructions.

For products purchased for commercial, industrial or rental usage, this warranty is limited to 90 days from

the date of rst purchase.

Factory Reconditioned Products

Limited Warranty: DESA Heating, LLC warrants factory reconditioned products and any parts thereof

to be free from defects in material and workmanship for 30 days from the date of rst purchase from an

authorized dealer provided the product has been installed, maintained and operated in accordance with

DESA Heating, LLC’s warnings and instructions.

Terms Common to All Warranties

The following terms apply to all of the above warranties:

Always specify model number and serial number when contacting the manufacturer. To make a claim under

this warranty the bill of sale or other proof of purchase must be presented.

This warranty is extended only to the original retail purchaser when purchased from an authorized dealer,

and only when installed by a qualied installer in accordance with all local codes and instructions furnished

with this product.

This warranty covers the cost of part(s) required to restore this product to proper operating condition and

an allowance for labor when provided by a DESA Heating, LLC Authorized Service Center or a provider

approved by DESA Heating, LLC. Warranty parts must be obtained through authorized dealers of this product and/or DESA Heating, LLC who will provide original factory replacement parts. Failure to use original

factory replacement parts voids this warranty.

Travel, handling, transportation, diagnostic, material, labor and incidental costs associated with warranty

repairs, unless expressly covered by this warranty, are not reimbursable under this warranty and are the

responsibility of the owner.

Excluded from this warranty are products or parts that fail or become damaged due to misuse, accidents,

improper installation, lack of proper maintenance, tampering, or alteration(s).

This is DESA Heating, LLC’s exclusive warranty, and to the full extent allowed by law; this express warranty

excludes any and all other warranties, express or implied, written or verbal and limits the duration of any

and all implied warranties, including warranties of merchantability and tness for a particular purpose to one

(1) year on new products and 30 days on factory reconditioned products from the date of rst purchase.

DESA Heating, LLC makes no other warranties regarding this product.

DESA Heating, LLC’s liability is limited to the purchase price of the product, and DESA Heating, LLC shall

not be liable for any other damages whatsoever under any circumstances including indirect, incidental, or

consequential damages.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

For information about this warranty contact:

New Products

) _____________________________

) __________________________

NOT A UPC

DESA Heating, LLC

2701 Industrial Drive

Bowling Green, KY 42101

www.desatech.com

1-866-672-6040

122663-01

Rev. D

06/08

Loading...

Loading...