Desa VDVF36 TPNA, DVF36 TPNPA, VDVF36 TPNPA, VDVF36 TPNEA, VDVF36 TPNPEA Installation Instructions Manual

...

PENINSULA MODELS (V)DVF36

TPNA/TPNPA/TPNEA/TPNPEA

SEE THROUGH MODELS (V)DVF36

GRAVITY DIRECT VENT GAS FIREPLACE

TSTA/TSTPA/TSTEA/TSTPEA

INSTALLATION INSTRUCTIONS

SAVE THIS BOOK

This book is valuable. In addition to instructing you on how to install and maintain your appliance, it also contains information that will

enable you to obtain replacement parts or accessory items when needed. Keep it with your other important papers.

G

I

S

E

N

D

PENINSULA MODEL

SHOWN

C

E

D

R

E

I

T

F

This appliance may be installed in an aftermarket* permanently, manufactured (mobile) home, where not prohibited by state or local

codes. This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use with

other gases, unless a certified kit is used and installed by a qualified technician.

*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer.

I

DESA INTERNATIONAL

2701 INDUSTRIAL DRIVE P/N 56131

P.O. BOX 90024 REV C

BOWLING GREEN, KY 42101-9004 8/02

www.desatech.com

CONTENTS

• DIMENSIONS ---------------------------------------------------------------------------------------- PG. 2

• INTRODUCTION ---------------------------------------------------------------------------------------- PG. 3

• CLEARANCES ---------------------------------------------------------------------------------------- PG. 4

• FRAMING ---------------------------------------------------------------------------------------- PG. 5

• GENERAL VENTING ---------------------------------------------------------------------------------------- PG. 6

• VENTING INSTALLATION ---------------------------------------------------------------------------------------- PG. 7

• HORIZONTAL TERMINATION ---------------------------------------------------------------------------------------- PG. 11

• VERTICAL TERMINATION ---------------------------------------------------------------------------------------- PG. 12

• TERMINATION CLEARANCES ---------------------------------------------------------------------------------------- PG. 15

• WIRING CONNECTIONS ---------------------------------------------------------------------------------------- PG. 16

• REMOTE CONTROL ---------------------------------------------------------------------------------------- PG. 17

• GAS LINE HOOK-UP ---------------------------------------------------------------------------------------- PG. 18

• INSTALLING LOG SET ---------------------------------------------------------------------------------------- PG. 19

• GLASS DOORS ---------------------------------------------------------------------------------------- PG. 20

• LIGHTING INSTRUCTIONS ---------------------------------------------------------------------------------------- PG. 24

• TROUBLE SHOOTING GUIDE ---------------------------------------------------------------------------------------- PG. 26

• REPLACEMENT AND ACCESSORIES -------------------------------------------------------------------------------------- PG. 28

• WARRANTY ---------------------------------------------------------------------------------------- PG. 29

- 1 - For more information, visit www.desatech.com

D

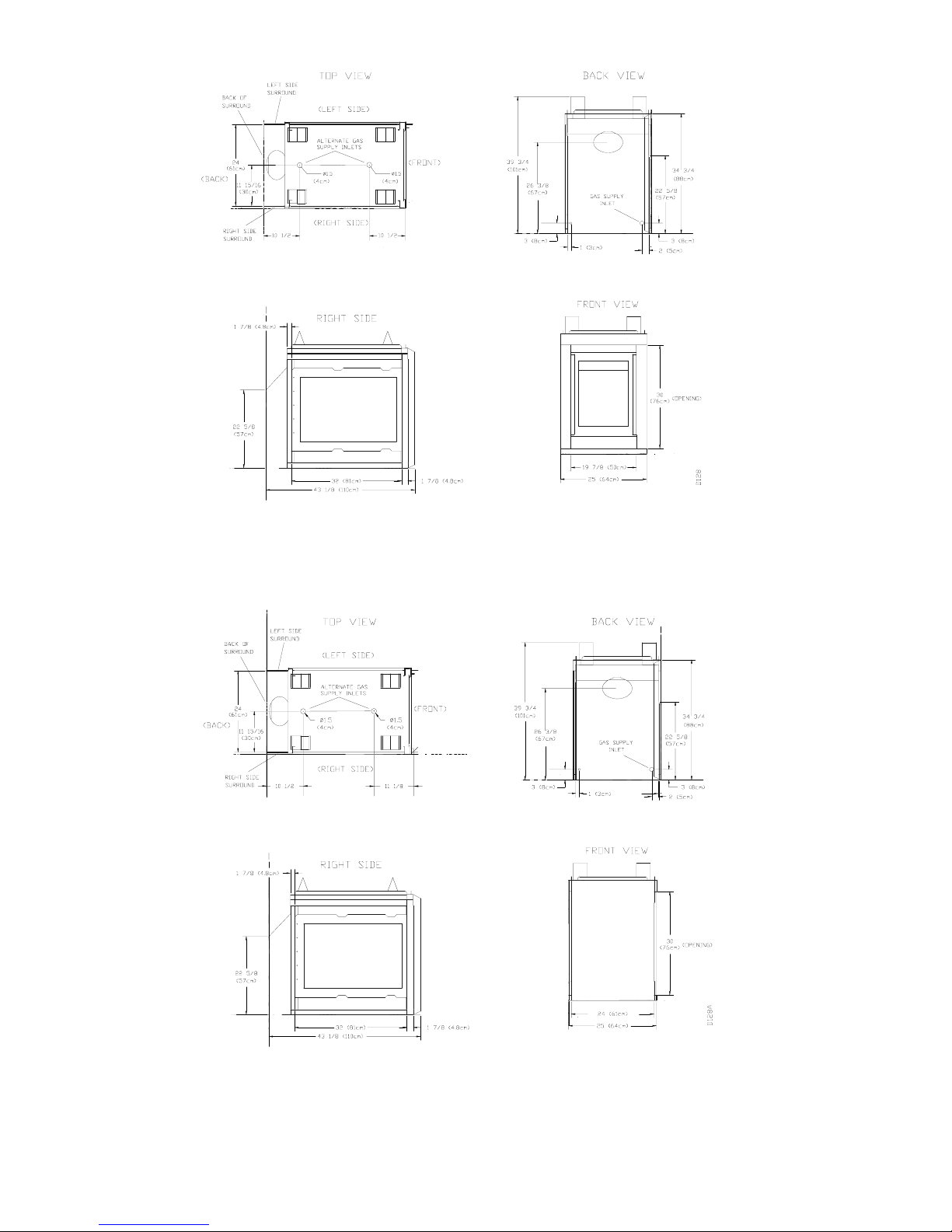

Figure 1 PENINSULA DIMENSIONS

Figure 2 SEE -THROUGH DIMENSIONS

- 2 - For more information, visit www.desatech.com

r

d

n

N

p

r

d

a

a

d

• Do not store or use gasoline or any other flammable

vapors or liquids in the vicinity of this or any othe

appliance.

• Due to high temperatures, the appliance should be

located out of traffic and away from furniture an

draperies.

• Do not place clothing or other flammable materials o

or near the appliance.

EVER leave children unattended when a fire is

•

burning in the fireplace.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause injury,

roperty damage, or loss of life. Refer to this manual fo

assistance or additional information. Consult a qualifie

installer or local distributor.

CHECK LOCAL CODES BEFORE

INSTALLING THIS FIREPLACE.

FOR YOUR SAFETY

FOR YOUR SAFETY

INTRODUCTION

Models (V) DVF36TPNA/TPNPA series are three-sided direct

vent gas fireplaces and models (V) DVF36TSTA/TSTPA are

two-sided direct vent gas fireplace heaters with sealed

combustion chambers. Both use a millivolt gas control valve

with a millivolt ignition system.

Models (V) DVF36TPNEA/TPNPEA and (V) DVF36

STEA/TSTPEA use a direct spark ignition with a 24 VAC

control module. All models have HI/LO valve that controls

the flame height. These units can be equipped with louvers

for circulating or with panels for non-circulating operation.

Fan Kit models DVFFBK and DVFFBKT are available for

these units as an option. If you are uncertain as to what gas

your unit is equipped for, please check the rating plate located

in the interior of the appliance opening or consult your local

distributor of DESA products.

BEFORE BEGINNING THE INSTALLATION OF THE

FIREPLACE, READ THESE INSTRUCTIONS THROUGH,

COMPLETELY.

♦ This DESA fireplace and its components are safe

when installed according to this installation manual.

Unless you use DESA components, which has been

designed and tested for this appliance, you may cause

a fire hazard.

♦ The DESA warranty will be voided by and DESA

disclaims any responsibility for the following actions:

a) Modification of the fireplace, components, doors, blower,

fans, air inlet system and damper control.

b) Use of any component part not manufactured or approved

by DESA in combination with a DESA fireplace system.

c) Installation and/or operation in a manner other than

instructed in this manual.

d) Burning of anything other than the type of gas approved for

use in this gas appliance.

This appliance, when installed, must be electrically grounded

in accordance with local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70 or

CSA C22.1 Canadian Electrical Code for Canada.

The installation must conform to local codes, or in the

absence of local codes, with the National Fuel Gas Code ANSI

Z223.1 (CAN B149. in CANADA)

This appliance complies with ANSI Z21.50, and CGA

2.22M98 as a VENTED GAS FIREPLACE and is listed and

tested by the Canadian Standards Association.

NOTICE: Installation and repair should be done by

qualified service person. The appliance should be

inspected before use and at least annually thereafter by

qualified service person. More frequent cleaning may be

required due to excessive lint from carpeting, bedding etc.

It is important that the control compartments, burners an

circulating air systems be kept clean.

SELECTING LOCATION

To determine the safest and most efficient location for your

appliance, consider the following guidelines:

1. The location must allow for all the proper clearances (see

section on Clearances and Mantle Clearances).

2. Consider a location where drafts, air conditioning ducts,

windows, or doors would not affect the heat output.

3. A location that avoids the cutting of joists or roof rafters

makes installation easier.

-3 - For more information, visit www.desatech.com

f

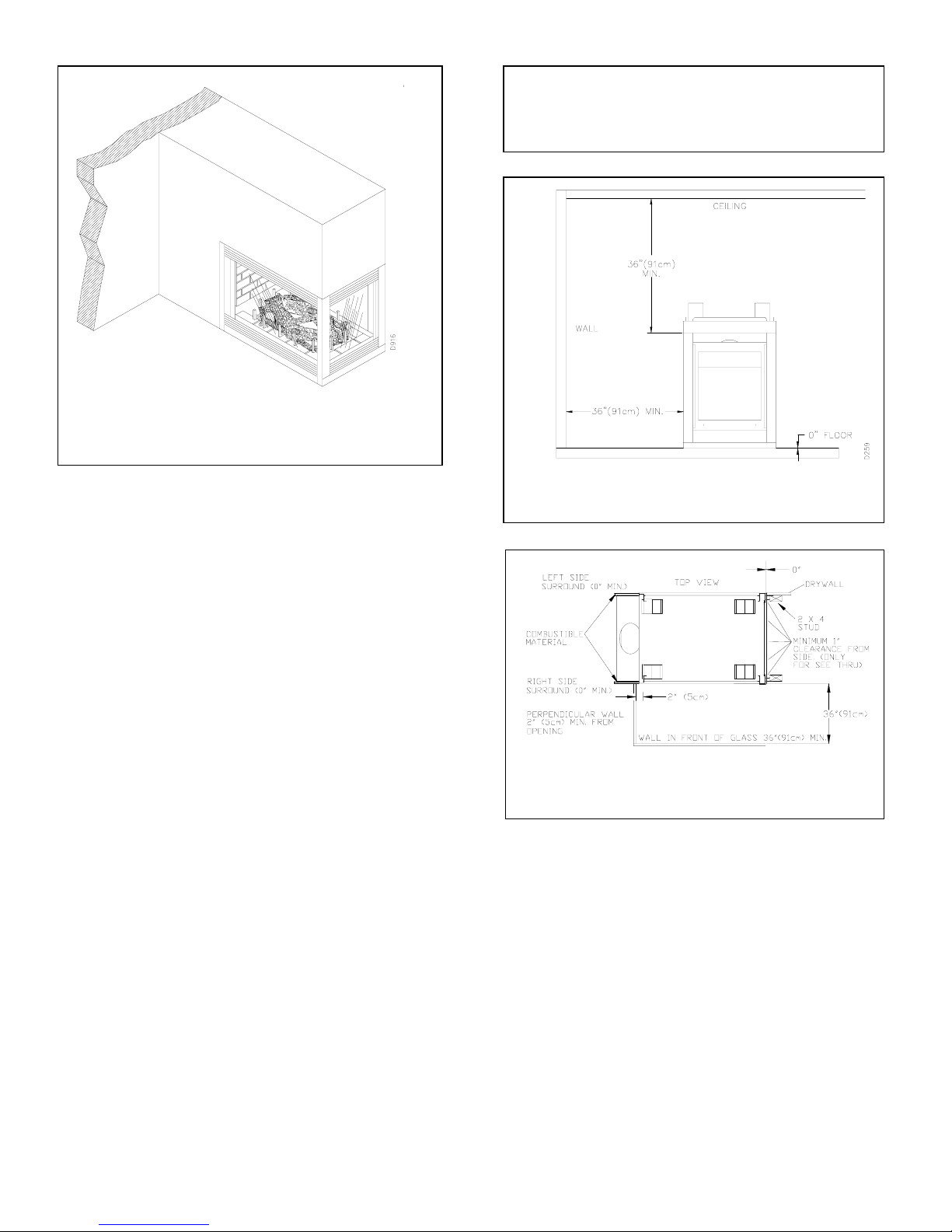

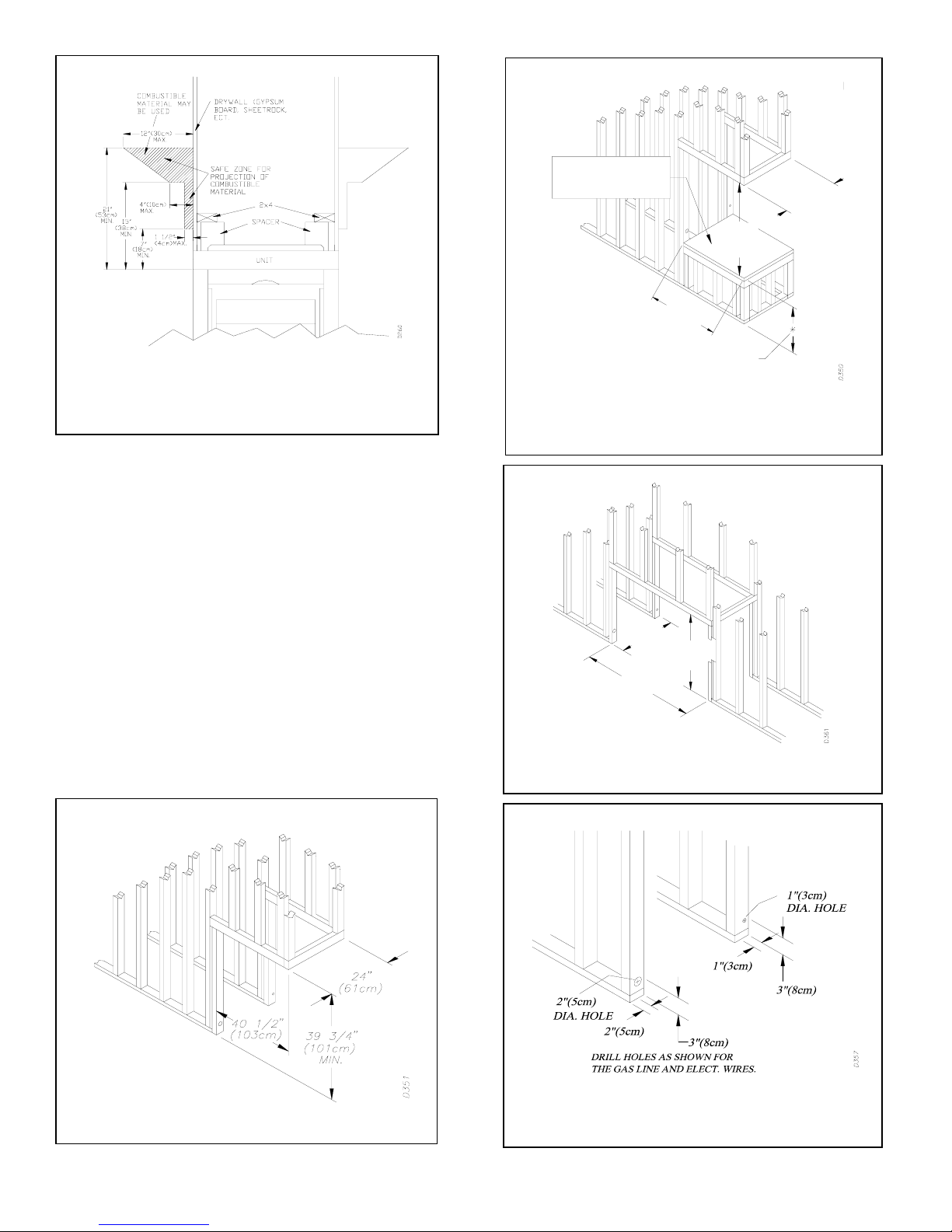

Figure 3 FIREPLACE INSTALLATION OF

PENINSULA MODEL SHOWN

IN SELECTING A LOCATION, THE FOLLOWING

PRECAUTIONS MUST BE OBSERVED:

1. A projection may be ideal for a new addition on an

existing finished wall. Refer to horizontal termination

configurations on page 11 or vertical termination

configurations on page 12.

2. Do not connect this appliance to a chimney system used

for a solid fuel-burning fireplace.

3. Due to high temperatures, do not locate this

appliance in high traffic areas or near furniture and

draperies.

4. Never obstruct the front opening of the appliance or the

flow of combustion and ventilation air. Keep control

compartments accessible.

5. Do not locate close to where gasoline or other flammable

liquids may be stored. The appliance must be kept clear

and free from combustible materials.

CLEARANCES

Minimum clearances to combustibles are:

• Back and side of surround …………… 0”

• Vent Surfaces (side and bottom) ………. 1”

• Top Vent Surface (horizontal run) ……… 2”

• Ceiling to Opening ………………………... 36”

MANTEL CLEARANCES

Woodwork, such as wood trims, mantles, and other

combustible materials should not be placed within 7 inches

(178 mm) of the opening of this fireplace (see figure 6).

Combustible material above projecting more than 1-1/2 inches

(38 mm) from the appliance's front face must not be placed

less the 15 inches (381 mm) from the opening of the

appliance, (ref. NFPA Standard 211 Sec.7-3.3.3).

• Floor ………………………………………. 0”

• Wall to Front of Glass …………………….. 36”

• Perpendicular Wall to Opening of Unit …… 2”

• Top Spacer …………………………. 0”

CAUTION: Do not block required air spaces with

insulation or any other materials. Do not obstruct the

effective opening of the appliance with any type o

facing material.

Figure 4 MINIMUM CLEARANCES

PENINSULA MODEL

Figure 5 MINIMUM CLEARANCES

SEE-THROUGH MODEL

-4 - For more information, visit www.desatech.com

g

g

ure 6 MANTEL CLEARANCES FOR

Fi

PENINSULA AND SEE-THROUGH MODELS

(PENINSULA SHOWN)

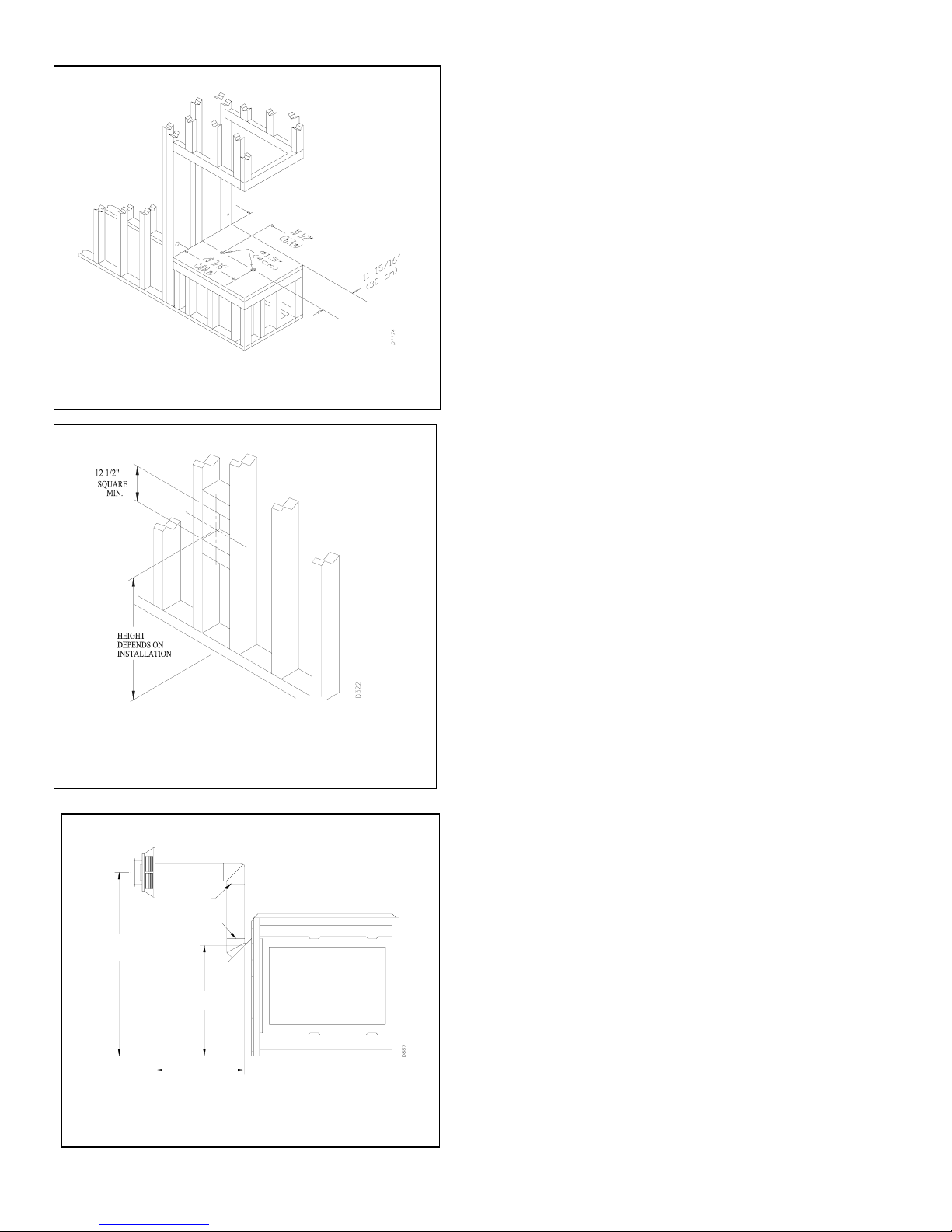

FRAMING

Once the final location has been determined, observing

clearances for the vent termination, you may construct framing

using dimensions shown in figures 7, 8 and 9 depending on

your particular installation. If the appliance is to be installed

directly on carpeting, tile (other than ceramic), or any

combustible material other than wood flooring, the appliance

must be installed upon a metal or wood panel extending the

full width and depth of the appliance. There are three holes on

each side of the bottom of the unit where screws can be used

to secure the unit to the floor.

The gas supply line may be connected through the side

framing or alternately through the lower sub-flooring or a

platform base if provided (see figures 10 and 11). Depending

on the installation, refer to the appropriate illustration.

Figure 7 ROUGH OPENING (PENINSULA)

PLATFORM MUST BE

SOLID, FLAT, AND

FULLY SUPPORTED

39 3/4"

(101cm)

MIN.

24"

(61cm)

40 1/2"

(103cm)

AS REQUIRED BY DESIGN

AS LONG AS CEILING

CLEARANCE IS MAINTAINED

ure 8 ROUGH OPENING ON PLATFORM

Fi

(PENINSULA)

24"

(61 cm)

43 1/4"

(110 cm)

39 3/4"

(101 cm)

MIN.

Figure 9 ROUGH OPENING (SEE-THROUGH)

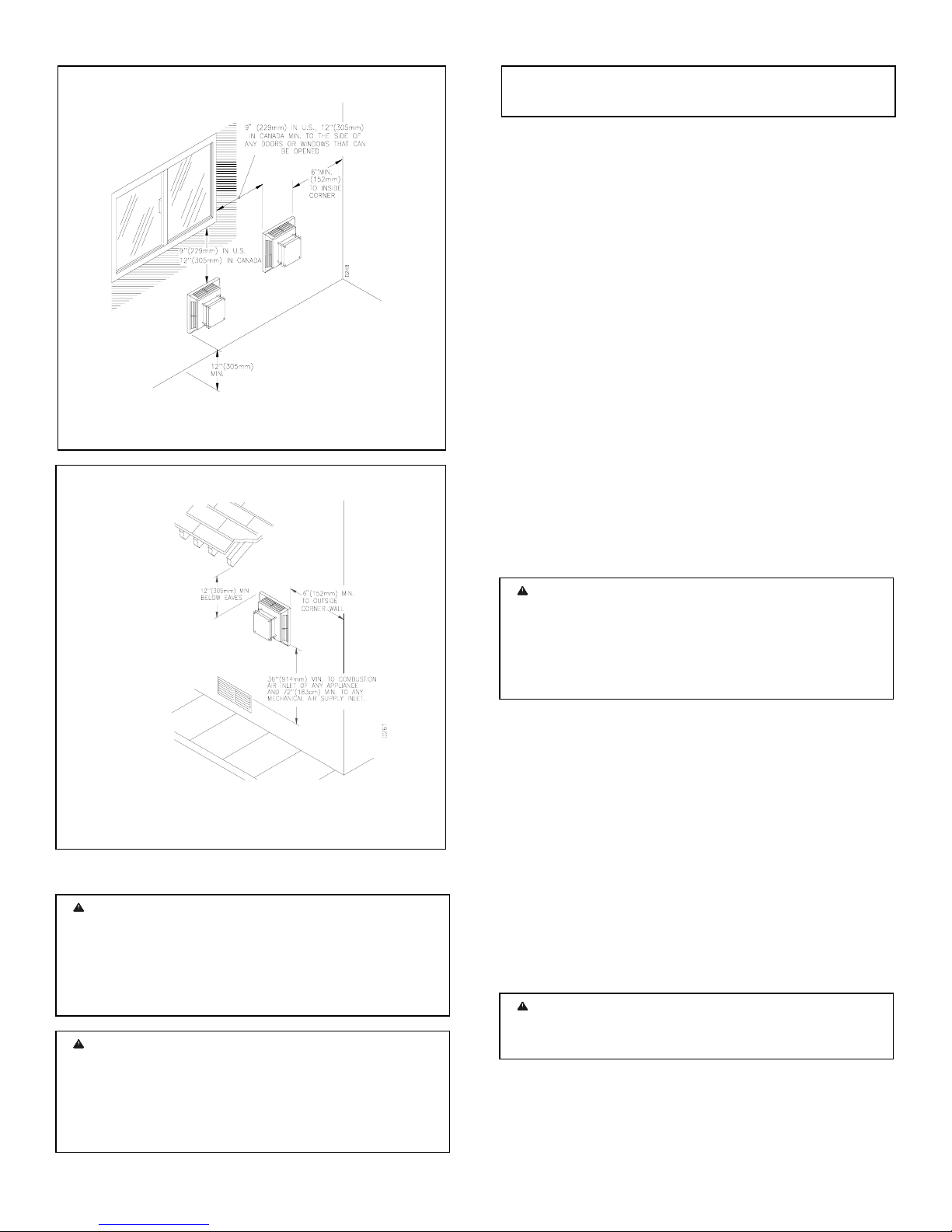

Figure 10

AND ELECTRICAL WIRES FOR BOTH MODELS

HOLE LOCATIONS FOR GAS LINE

-5 - For more information, visit www.desatech.com

Figure 11

ALTERNATE GAS SUPPLY LOCATION

Figure 12 ROUGH OPENING FOR

INSTALLATION OF EXTERIOR VENT

TERMINAL

TERMINATION CAP

VERTICAL

HEIGHT DEPENDS

ON INSTALLATION

90 DEG.

ELBOW

45 DEG. ELBOW

26 3/8"

(67cm)

HORIZONTAL

LENGTH DEPENDS

ON INSTALLATION

Figure 13 VENT OPENING HEIGHT

FIREPLACE

GENERAL VENTING

These models are approved for use with Simpson, DuraVent®, rigid type direct vent pipe as supplied by DESA or

may be used with approved types of flexible vent pipe (i.e.

ECCO-FLEX™ or ZFlex™) when appropriately sized for a 8"

outer and 5" inner diameter application.

Your Fireplace is approved for venting either horizontally

through a sidewall, or vertically through a roofline using the

following guidelines:

• Only use DESA supplied or approved types of venting

components or venting kits. Do not mix different types of vent

components, modify vent components, or custom fabricate

vent components for use in any one installation.

• Minimum clearances between vent pipes and combustible

material is 1" (25mm), except where stated otherwise.

• Combustible material may be flush with the top front of the

fireplace with a maximum thickness of 3/4".

• Do not recess venting terminals into a wall or siding.

• Do not install vent terminals below grade level maintain a

minimum height of 12" above snow line.

• Do not terminate the venting system into an attic or garage.

• Install horizontal venting with a 1/4" rise for every 12" of

run towards the termination.

• There must not be any obstruction such as bushes, garden

sheds, fences, decks, or utility buildings within 24" from the

front of the termination cap.

• Do not locate termination cap where excessive snow or ice

build up may occur. Be sure to clear vent termination area

after snow falls to prevent accidental blockage of the venting

system. When using snow blowers, do not direct snow towards

vent termination area.

VENT TERMINATION CLEARANCES

The final position of your appliance depends on the location of

the vent termination in relation to the clearances that must be

observed as shown in figures 14 and 15.

You may avoid extra framing by positioning your fireplace

against an already existing framing member. The back of the

fireplace may be positioned directly against a combustible

wall.

* Check with local codes or with the current CAN/CGA B149

(.1 or .2) Installation Codes for Canada for Installations in the

USA follow the current National Fuel Gas Code, ANS Z223.1

also known as NFPA 54.

-6 - For more information, visit www.desatech.com

d

f

d

y

h

h

w

N

y

m

a

n

a

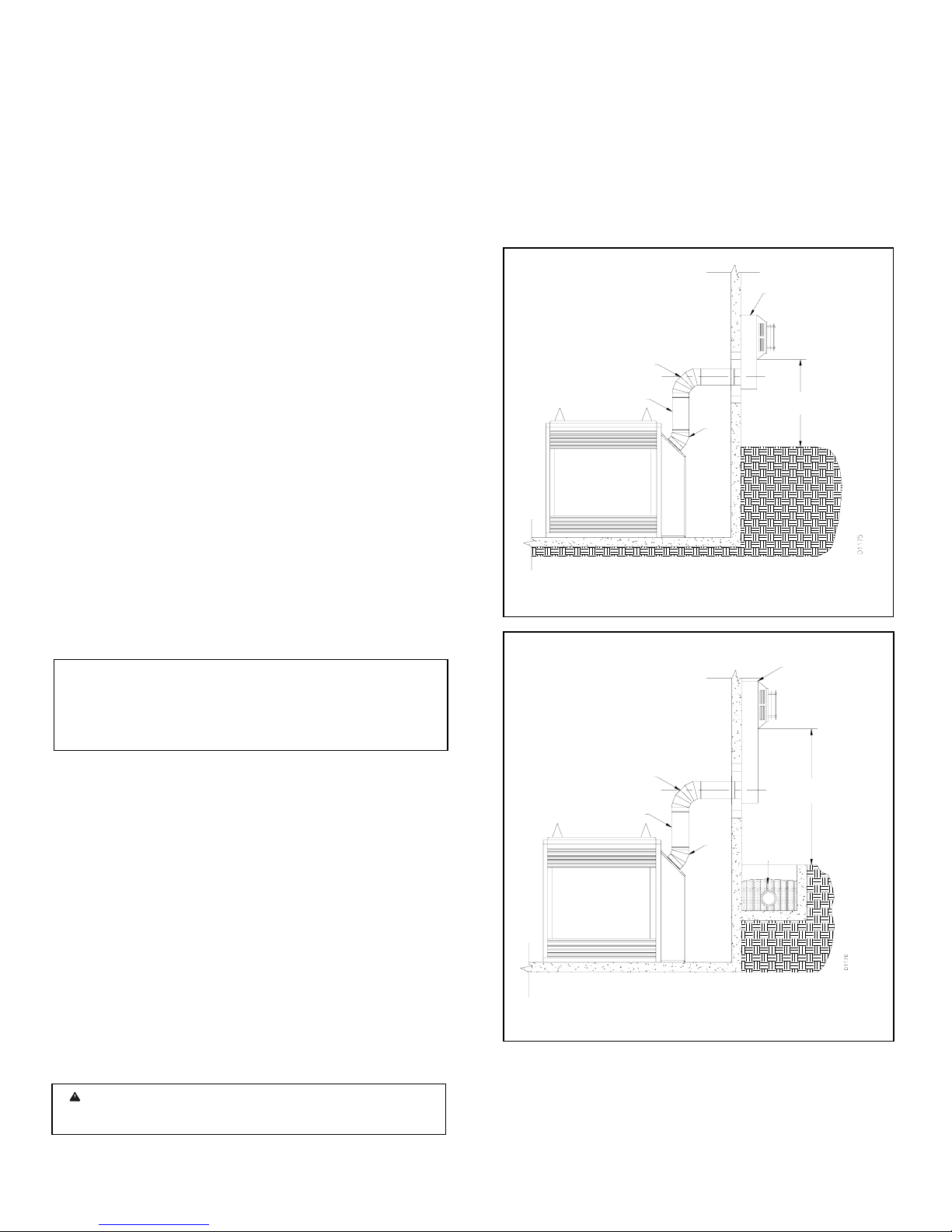

Figure 14 VENT CLEARANCES

Figure 15 VENT CLEARANCES

VENTING INSTALLATION

WARNING: Read all instructions completely an

thoroughly before attempting installation. Failure to do so

could result in serious injury, property damage or loss o

life. Operation of an improperly installed and maintaine

venting system could result in serious injury, propert

damage or loss of life.

WARNING: Seal all connections with hig

temperature silicone every time a vent connection is made.

Before joining elbows or pipes, apply a bead of hig

temperature silicone sealant to the male end of the elbo

or pipe. High temperature silicone must also be used to reseal any connections after maintenance to venting system.

OTICE: Failure to follow these instructions will void the

warranty.

INSTALLATION PRECAUTIONS

Consult local building codes before beginning the installation.

The installer must make sure to select the proper vent system

for installation. Before installing a vent kit, the installer must

read this fireplace manual and any vent kit instructions.

Only a qualified installer or service person should install a

venting system. The installer must follow these safety rules:

• Wear gloves and safety glasses for protection.

• Use extreme caution when using ladders or when working

on top of roofs.

• Be aware if electrical wiring locations in walls and

ceilings.

The following actions will void the warranty on your venting

system:

• Installation of any damaged venting component.

• Unauthorized modification of the venting system.

• Installation of any component part not manufactured or

approved by DESA. Installation other than as instructed

by these instructions.

WARNING: This gas fireplace and its vent assembl

must be vented directly to the outside. The venting syste

must NEVER be attached to the chimney serving

separate solid fuel-burning appliance. Each gas appliance

must use a separate vent system. Do not use in commo

vent system.

INSTALLATION PLANNING

There are two basic types of direct-vent installations:

• Horizontal Termination

• Vertical Termination (Rigid Vent Pipe Only)

It is important to select the proper length of vent pipe for the

type of termination you choose. It is also important to note the

wall thickness.

For Horizontal Termination: Select the amount of vertical

rise desired. The horizontal run of venting must have 1/4" rise

for every 12" of run towards the termination.

WARNING: Never run the vent downward as this

may cause excessive temperatures, which could cause

fire.

Up to two 90° elbows may be used in this vent configuration.

See Horizontal Termination Configurations page 11.

-7 - For more information, visit www.desatech.com

For Vertical Terminations: Measure the distance from the

N

fireplace flue outlet to the ceiling. Add the ceiling thickness,

the vertical rise in an attic or second story, and allow for

sufficient vent height above the roofline.

You may use up to two 90° elbows in this configuration. See

Vertical Termination Configurations on pages xx and xx.

Note: You may use two 45° elbows in place of a 90° elbow.

You must follow rise to run ratios when using 45° elbows.

For two-story applications, fire stops are required at each floor

level. If an offset is needed in the attic, additional pipe and

elbows will be required.

You may use a chase with a vent termination having exposed

pipe on the exterior of the house. See Installing Vent System

in a chase.

Your DESA direct-vent fireplace has been tested for a

minimum of 3 feet of vertical rise with accommodation for a

maximum of 11" wall thickness. Any horizontal application

longer than 12" must provide a minimum of one (1) foot of

vertical rise for every three (3) feet of horizontal run. The

maximum amount of horizontal run is 20' with 8' of vertical

rise (see Installation for Horizontal Termination, page 11).

The maximum vertical run is 30' (see Installation for Vertical

Termination, page 12).

INSTALLING VENT SYSTEM IN A CHASE

A chase is a vertical box-like structure built to enclose venting

that runs along the outside of a building.

OTICE: Treatment of firestops and construction of the

chase may vary from building type to building type. These

instructions are not substitutes for the requirements of local

building codes. You must follow all local building codes.

NOTE: When installing in a chase, you should insulate the

chase as you would the outside walls of your home. This is

especially important in cold climates. A minimum clearance

between vent pipes and combustible materials such as

insulation is 1".

After framing the chase install the venting system by

following the installation instructions for vertical installations

on page xx.

INSTALLATION FOR HORIZONTAL TERMINATION

1. Determine the route your horizontal venting will

take.

NOTE: The location of the horizontal vent termination on the

exterior wall must meet all local and national building codes

and must not be easily blocked or obstructed.

WARNING: Do not recess a vent terminal into a wall

or a siding. This will cause a fire hazard.

Snorkel terminations are available for terminations requiring a

vertical rise on the exterior of the building (see figures 16 and

17). Snorkel kits are available for rigid pipe applications only

to provide for a 14" rise and a 36" rise (see page 14). Follow

the same installation procedures used for standard horizontal

terminations. If installing the snorkel termination to raise the

vent termination from below grade level such as in a basement

installation, you must provide proper drainage to prevent

water from entering the snorkel termination (see figure 17).

Do not back fill around the snorkel termination.

SNORKEL

1' MINIMUM

90°

12" MIN.

45°

Figure 16 SNORKEL TERMINATION

36" SNORKEL

1' MINIMUM

90°

45°

12" MIN.

DRAINAGE

Figure 17 SNORKEL TERMINATION W/ DRAIN PIPE

2. Rigid vent-pipes and fittings have special twist-lock

connections. Assemble the desired combinations of pipe and

elbows to the appliance adapter with pipe seams oriented

towards the wall or floor.

-8 - For more information, visit www.desatech.com

Loading...

Loading...