UNVENTED (VENT-FREE) SOLAR FUSION GAS HEATER

SAFETY INFORMATION AND INSTALLATION MANUAL

RESIDENTIAL MODELS

SF20NT, SF20PT,

LSF20NT, LSF20PT,

VSF20NT, VSF20PT,

SF30NT, SF30PT,

LSF30NT, LSF30PT,

VSF30NT, VSF30PT

GARAGE MODELS

LSFG20NT, LSFG20PT,

REM20NT, REM20PT,

SFG20NT, SFG20PT,

SPC20NT, SPC20PT,

VSFG20NT, VSFG20PT

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

•

Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

Save this manual for future reference.

For more information, visit www.desatech.com

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual for correct installation

and operational procedures. For assistance or additional information consult a qualified installer, service

agency or the gas supplier.

WARNING: This is an unvented gas-fired heater. It uses

air (oxygen) from the room in which it is installed. Provisions for adequate combustion and ventilation air must

be provided. Refer to Air for Combustion and Ventilation

section on page 5 of this manual.

This appliance may be installed in an aftermarket,* permanently located, manufactured (mobile) home, where

not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use with other gases.

* Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

State of Massachusetts: The installation must be made by a licensed plumber or gas fitter in the

Commonwealth of Massachusetts.

Sellers of unvented propane or natural gas-fired supplemental room heaters shall provide to each

purchaser a copy of 527 CMR 30 upon sale of the unit.

Vent-free gas products are prohibited for bedroom and bathroom installation in the Common

wealth of Massachusetts.

-

TABLE OF CONTENTS

Safety Information ............................................... 3

Local Codes ........................................................ 4

Product Identification ........................................... 4

Unpacking ........................................................... 4

Product Features ................................................. 4

Air For Combustion and Ventilation .....................

Installation ........................................................... 7

Operating Heater ............................................... 12

Inspecting Heater .............................................. 14

Cleaning and Maintenance ................................ 15

2

www.desatech.com

Troubleshooting .................................................

Technical Service .............................................. 19

Service Publications .......................................... 19

Service Hints ..................................................... 19

Specifications ....................................................

5

Accessories ....................................................... 21

Replacement Parts ............................................ 21

Parts Central ..................................................... 21

Illustrated Parts Breakdown and Parts List ....... 22

Warranty Information .........................................

16

20

24

116307-01A

SAFETY INFORMATION

WARNING: This product contains and/or generates chemicals

known to the State of California

to cause cancer or birth defects

or other reproductive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble,

operate or service this heater.

Improper use of this heater can

cause serious injury or death

from burns, fire, explosion,

electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of carbon

monoxide poisoning resemble the flu, with head

aches, dizziness or nausea. If you have these signs,

the heater may not be working properly. Get fresh

air at once! Have heater serviced. Some people

are more affected by carbon monoxide than others.

These include pregnant women, people with heart

or lung disease or anemia, those under the influ

ence of alcohol and those at high altitudes.

Natural and Propane/LP Gas: Natural and Propane/

LP gases are odorless. An odor-making agent is

added to these gases. The odor helps you detect a gas

leak. However, the odor added to the gas can fade.

Gas may be present even though no odor exists.

Make certain you read and understand all warnings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

WARNING: Any change to

this heater or its controls can

be dangerous.

WARNING: Do not use a

blower insert, heat exchanger

insert or other accessory not approved for use with this heater.

Due to high temperatures, the

appliance should be located out

of traffic and away from furniture

and draperies.

Do not place clothing or other

flammable material on or near

the appliance. Never place any

objects on the heater.

Surface of heater becomes very

hot when running heater. Keep

children and adults away from

hot surface to avoid burns or

clothing ignition. Heater will

remain hot for a time after shut

down. Allow surface to cool

before touching.

Carefully supervise young children when they are in the same

room with heater.

-

Make sure grill guard is in place

before running heater.

Keep the appliance area clear

-

and free from combustible ma

terials, gasoline and other flammable vapors and liquids.

1. This appliance is only for use with the type

of gas indicated on the rating plate. This ap

pliance is not convertible for use with other

gases.

2. Do not place propane/LP supply tank(s) in

side any structure. Locate propane/LP supply

tank(s) outdoors.

3. This heater shall not be installed in a bedroom

or bathroom.

4. If you smell gas

• Shut off gas supply

• Do not try to light any appliance

• Do not touch any electrical switch; do not

use any phone in your building

• Immediately call your gas supplier from a

neighborʼs phone. Follow the gas supplierʼs

instructions

• If you cannot reach your gas supplier, call

the fire department

-

-

-

-

www.desatech.com

3116307-01A

SAFETY INFORMATION

Continued

5. This heater needs fresh, outside air ventilation

to run properly. This heater has an Oxygen

Depletion Sensing (ODS) safety shutoff

system. The ODS shuts down the heater if

not enough fresh air is available. See Air for

Combustion and Ventilation, page 5.

6. Keep all air openings in front and bottom of

heater clear and free of debris. This will insure

enough air for proper combustion.

7. If heater shuts off, do not relight until you

provide fresh, outside air. If heater keeps

shutting off, have it serviced.

8. Do not run heater

• where flammable liquids or vapors are used

or stored

• under dusty conditions

9. Do not use heater if any part has been under

water. Immediately call a qualified service

technician to inspect the room heater and to

replace any part of the control system and any

gas control which has been under water.

10. Turn off and unplug (if using electricity)

heater and let cool before servicing. Only a

qualified service person should service and

repair heater.

11. Operating heater above elevations of 4,500

feet (1,371 m) could cause pilot outage.

12.

To prevent performance problems, do not use

propane/LP fuel tank of less than 100 lbs. (45 kg)

capacity.

13. Before using furniture polish, wax, carpet

cleaner or similar products, turn heater off. If

heated, the vapors from these products may

create a white powder residue within burner

box or on adjacent walls or furniture.

14. Provide adequate clearances around air

openings.

LOCAL CODES

Install and use heater with care. Follow all local codes. In

the absence of local codes, use the latest edition of The

National Fuel Gas Code, ANSI Z223.1/NFPA 54*.

*Available from:

American National Standards Institute, Inc.

National Fire Protection Association, Inc.

1430 Broadway

New York, NY 10018

Batterymarch Park

Quincy, MA 02269

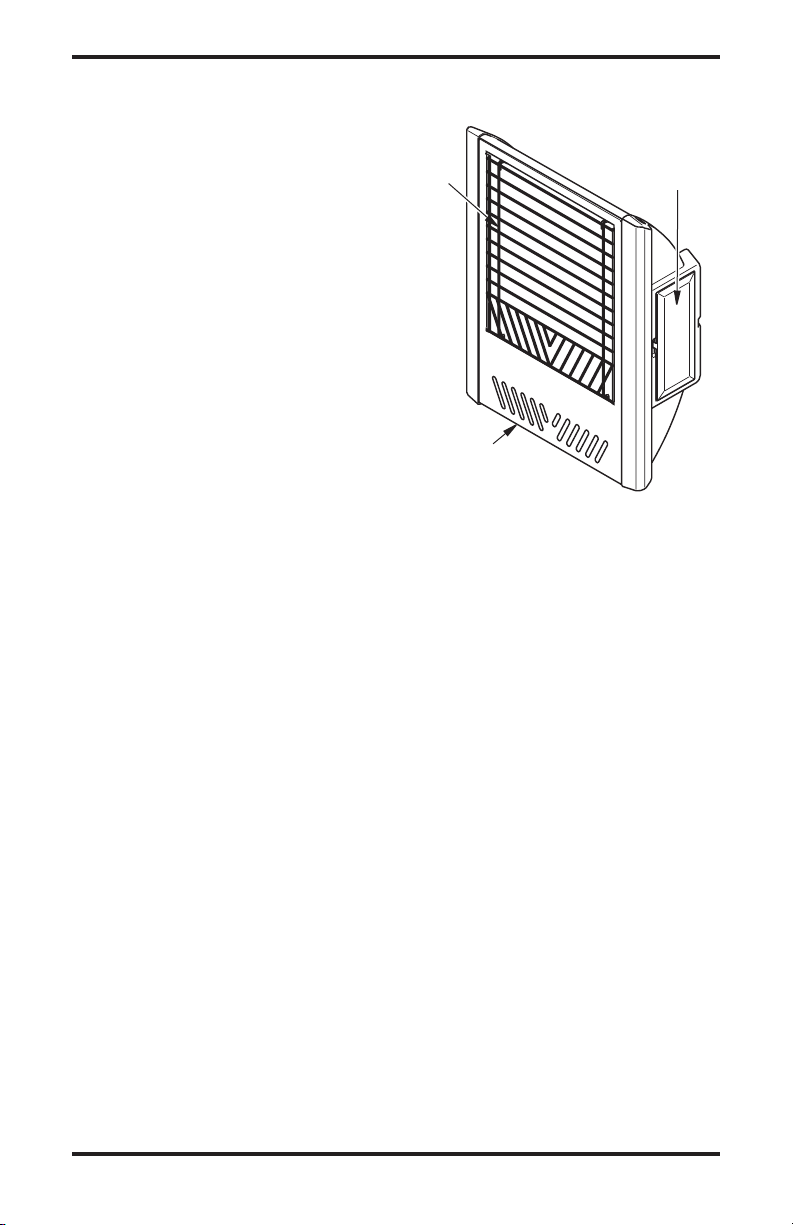

PRODUCT

IDENTIFICATION

Grill

Guard

Front Panel

Figure 1 - Vent-Free Gas Heater

Control Knob &

Ignitor Button

(inside door)

UNPACKING

1. Remove heater, front panel and grill from

carton. Set aside in a safe location.

2. Carefully remove refractory from heater and

remove packing material. Check refractory

for any damage. If the refractory is damaged

do not use. See Replacement Parts, page 21.

Set aside in a safe location.

3. Check heater for any damage. If heater is dam

aged, promptly return to where you bought

heater.

PRODUCT FEATURES

SAFETY DEVICE

This heater has a pilot with an Oxygen Depletion Sensing (ODS) safety shutoff system. The

ODS/pilot is a required feature for vent-free room

heaters. The ODS/pilot shuts off the heater if there

is not enough fresh air.

IGNITION SYSTEM

This heater has either a piezo ignitor or electronic

ignitor to light heater fuel supply.

THERMOSTATIC HEAT CONTROL

Thermostat models have a thermostat sensing

bulb and a control valve. This results in the great

est heater comfort. This can also result in lower

gas bills.

-

-

4

www.desatech.com

116307-01A

AIR FOR COMBUSTION

AND VENTILATION

WARNING: This heater shall

not be installed in a confined

space or unusually tight construction unless provisions are

provided for adequate combustion and ventilation air. Read the

following instructions to insure

proper fresh air for this and

other fuel-burning appliances

in your home.

Todayʼs homes are built more energy efficient

than ever. New materials, increased insulation and

new construction methods help reduce heat loss

in homes. Home owners weather strip and caulk

around windows and doors to keep the cold air out

and the warm air in. During heating months, home

owners want their homes as airtight as possible.

While it is good to make your home energy effi

cient, your home needs to breathe. Fresh air must

enter your home. All fuel-burning appliances need

fresh air for proper combustion and ventilation.

Exhaust fans, fireplaces, clothes dryers and fuel

burning appliances draw air from the house to

operate. You must provide adequate fresh air for

these appliances. This will insure proper venting

of vented fuel-burning appliances.

PROVIDING ADEQUATE

VENTILATION

The following are excerpts from National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Section 5.3,

Air for Combustion and Ventilation.

All spaces in homes fall into one of the three fol

lowing ventilation classifications:

1. Unusually Tight Construction

2. Unconfined Space

3. Confined Space

The information on pages 5 through 7 will help

you classify your space and provide adequate

ventilation.

Unusually Tight Construction

The air that leaks around doors and windows

may provide enough fresh air for combustion and

ventilation. However, in buildings of unusually

tight construction, you must provide additional

fresh air.

Unusually tight construction is defined as

construction where:

a. walls and ceilings exposed to the out

side atmosphere have a continuous

water vapor retarder with a rating of

one perm (6 x 10

less with openings gasketed or sealed

and

b. weather stripping has been added on

openable windows and doors and

c. caulking or sealants are applied to

areas such as joints around window

and door frames, between sole plates

and floors, between wall-ceiling joints,

between wall panels, at penetrations

for plumbing, electrical and gas lines

and at other openings.

If your home meets all of these three cri

teria, you must provide additional fresh

air. See Ventilation Air From Outdoors,

page 7.

If your home does not meet all of the three

criteria above, proceed to Determining

-

Fresh-Air Flow For Heater Location.

Confined and Unconfined Space

The National Fuel Gas Code, ANSI Z223.1/NFPA

54 defines a confined space as a space whose

volume is less than 50 cubic feet per 1,000 Btu

per hour (4.8 m

rating of all appliances installed in that space and

an unconfined space as a space whose volume is

not less than 50 cubic feet per 1,000 Btu per hour

3

(4.8 m

per kw) of the aggregate input rating of

all appliances installed in that space. Rooms com

municating directly with the space in which the

appliances are installed*, through openings not

furnished with doors, are considered a part of the

unconfined space.

* Adjoining rooms are communicating only if

there are doorless passageways or ventilation grills

between them.

-11

kg per pa-sec-m2) or

3

per kw) of the aggregate input

DETERMINING FRESH-AIR FLOW

FOR HEATER LOCATION

Determining if You Have a Confined or

Unconfined Space

Use this work sheet to determine if you have a

confined or unconfined space.

Space: Includes the room in which you will install

heater plus any adjoining rooms with doorless passageways or ventilation grills between the rooms.

-

-

-

www.desatech.com

5116307-01A

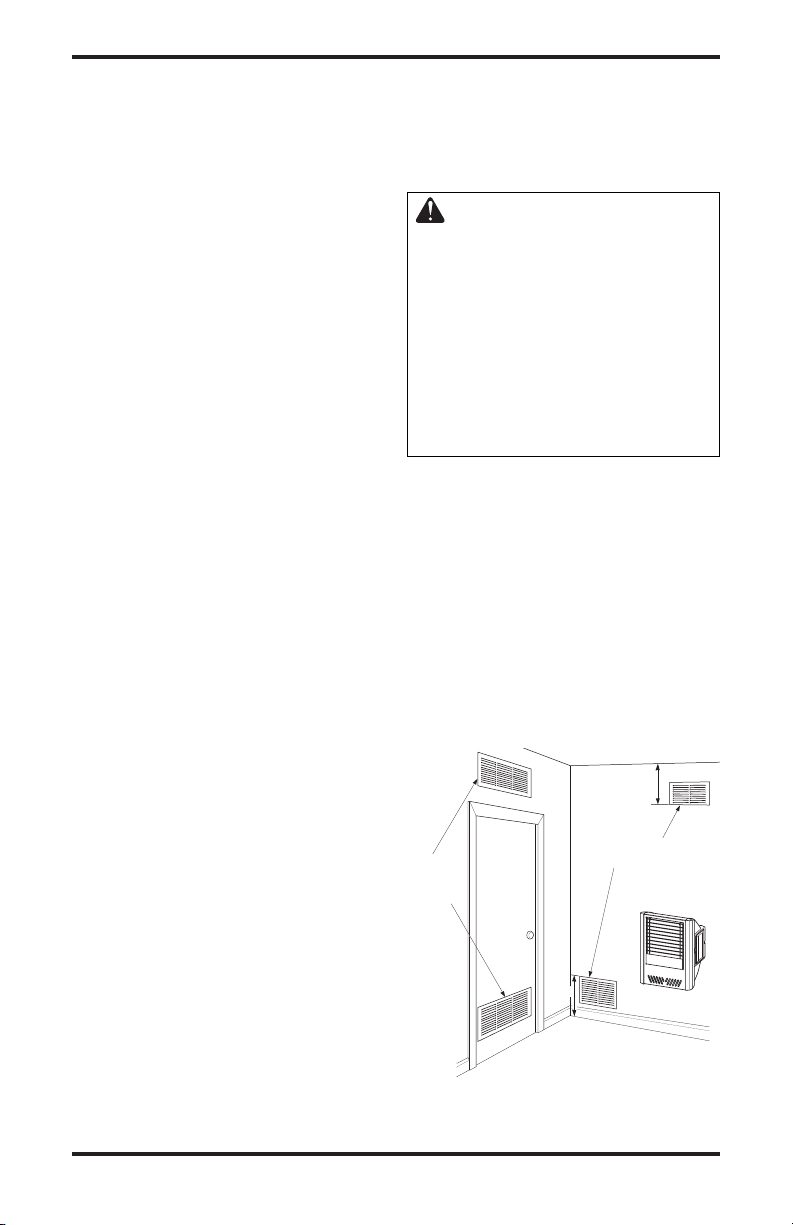

Or

Remove

Door into

Adjoining

Room,

Option 3

Ventilation Grills

Into Adjoining Room,

Option

2

12"

12"

Ventilation

Grills

into Adjoining

Room,

Option 1

AIR FOR COMBUSTION

AND VENTILATION

Continued

1. Determine the volume of the space (length x

width x height).

Length x Width x Height =__________cu. ft.

(volume of space)

Example: Space size 20 ft. (6.1 m) (length) x

16 ft. (4.88 m) (width) x 8 ft. (2.44 m) (ceiling

height) = 2560 cu. ft. (volume of space)

If additional ventilation to adjoining room is

supplied with grills or openings, add the volume

of these rooms to the total volume of the space.

2. Multiply the space volume by 20 to determine

the maximum Btu/Hr the space can support.

__________ (volume of space) x 20 = (Maxi-

mum Btu/Hr the space can support)

Example: 2560 cu. ft. (72.4 m3) (volume of space) x 20

= 51,200 (maximum Btu/Hr the space can support)

3. Add the Btu/Hr of all fuel burning appliances in

the space.

Vent-free heater _____________

Gas water heater* _____________

Gas furnace _____________

Vented gas heater _____________

Gas fireplace logs _____________

Other gas appliances* + ____________

Total = ____________

* Do not include direct-vent gas appliances. Di

rect-vent draws combustion air from the outdoors

and vents to the outdoors.

Example:

Gas water heater _____________

Vent-free heater + ____________

Total = ____________

40,000

20,000

60,000

4. Compare the maximum Btu/Hr the space can

support with the actual amount of Btu/Hr used.

_________

_________

Btu/Hr (maximum the space can support)

Btu/Hr (actual amount of Btu/Hr used)

Example: 51,200 Btu/Hr (maximum the space

can support)

60,000 Btu/Hr (actual amount of

Btu/Hr used)

The space in the above example is a confined space

because the actual Btu/Hr used is more than the maxi

mum Btu/Hr the space can support. You must provide

additional fresh air. Your options are as follows:

A. Rework worksheet, adding the space of an adjoin

ing room. If the extra space provides an unconfined

space, remove door to adjoining room or add

ventilation grills between rooms. See Ventilation

Air From Inside Building.

B. Vent room directly to the outdoors. See Ventila

tion Air From Outdoors, page 7.

6

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

Btu/Hr

www.desatech.com

C. Install a lower Btu/Hr heater, if lower Btu/Hr size

makes room unconfined.

If the actual Btu/Hr used is less than the maximum

Btu/Hr the space can support,

the space is an un-

confined space. You will need no additional fresh

air ventilation.

WARNING: If the area in

which the heater may be oper

ated is smaller than that defined

as an unconfined space or if the

building is of unusually tight

construction, provide adequate

combustion and ventilation air

by one of the methods described

in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 Section 5.3

or applicable local codes.

VENTILATION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining un

confined space. When ventilating to an adjoining

unconfined space, you must provide two permanent openings: one within 12" (30.4 cm) of the

ceiling and one within 12" (30.4 cm) of the floor

on the wall connecting the two spaces (see options

1 and 2, Figure 2). You can also remove door into

-

adjoining room (see option 3, Figure 2). Follow the

National Fuel Gas Code, ANSI Z223.1/NFPA 54,

Section 5.3, Air for Combustion and Ventilation for

required size of ventilation grills or ducts.

-

-

Figure 2 - Ventilation Air from Inside

-

Building

116307-01A

-

-

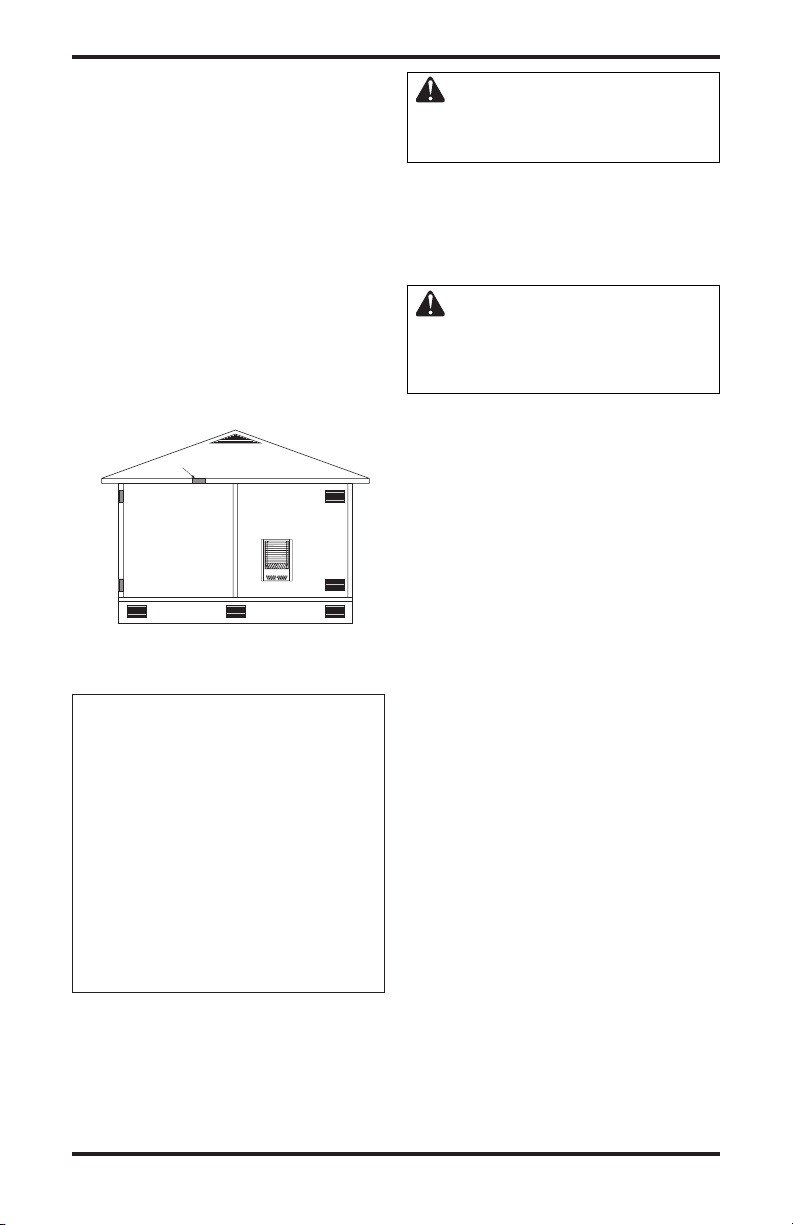

AIR FOR COMBUSTION

Outlet

Air

Ventilated

Attic

Outlet

A

ir

Inlet

Air

Inlet Air

Ventilated

Crawl Space

To

Crawl

Space

To Attic

AND VENTILATION

Continued

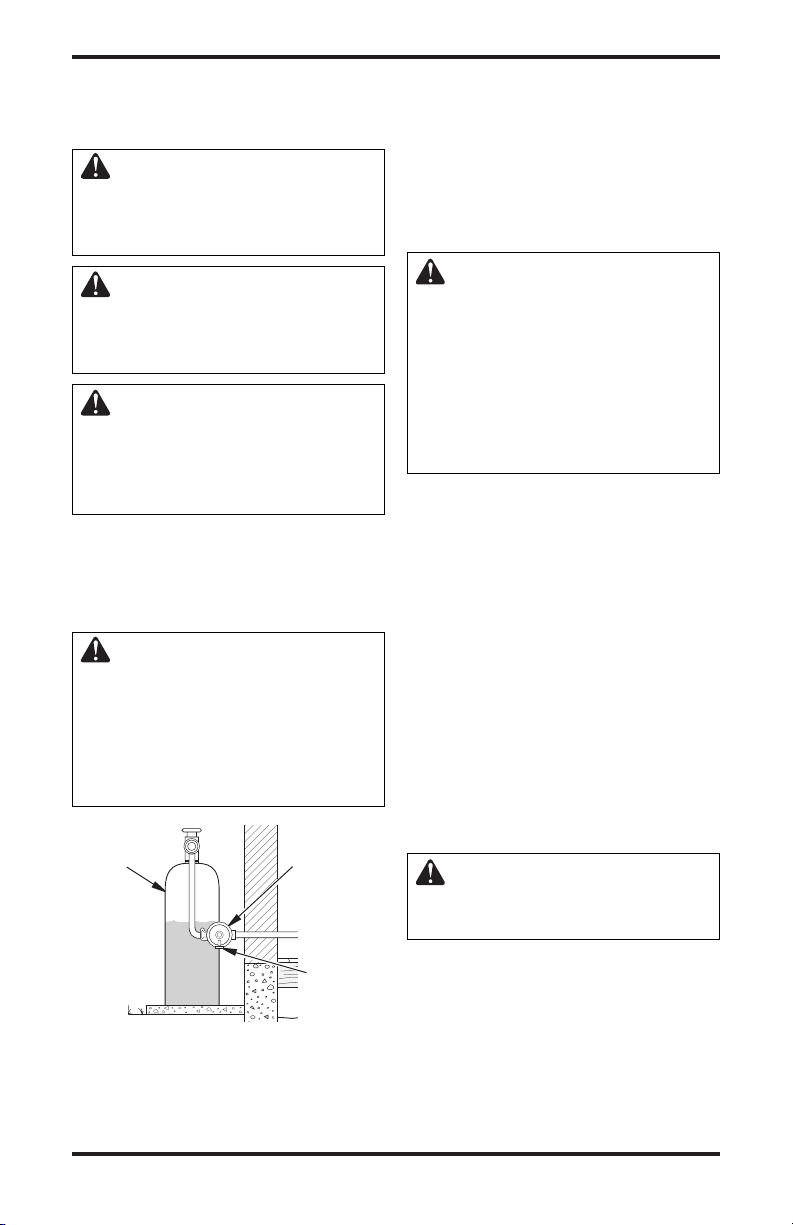

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation grills

or ducts. You must provide two permanent open

ings: one within 12" (30.4 cm) of the ceiling and

one within 12" (30.4 cm) of the floor. Connect

these items directly to the outdoors or spaces

open to the outdoors. These spaces include attics

and crawl spaces. Follow the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, Section 5.3, Air for

Combustion and Ventilation for required size of

ventilation grills or ducts.

IMPORTANT: Do not provide openings for inlet

or outlet air into attic if attic has a thermostatcontrolled power vent. Heated air entering the attic

will activate the power vent.

Figure 3 - Ventilation Air from Outdoors

INSTALLATION

NOTICE: This heater is intended

for use as supplemental heat.

Use this heater along with your

primary heating system. Do not

install this heater as your pri

mary heat source. If you have a

central heating system, you may

run system’s circulating blower

while using heater. This will help

circulate the heat throughout the

house. In the event of a power

outage, you can use this heater

as your primary heat source.

-

WARNING: A qualified service person must install heater.

Follow all local codes.

CHECK GAS TYPE

Use only the correct type of gas (natural or pro-

pane/LP). If your gas supply is not the correct gas

type, do not install heater. Call dealer where you

bought heater for proper type heater.

WARNING: This appliance

is equipped for (natural or propane/LP) gas. Field conversion

is not permitted.

INSTALLATION ITEMS

Before installing heater, make sure you have the

items listed below.

• for propane/LP gas, external regulator (supplied

by installer)

• piping from gas supply (check local codes)

• flex gas tubing

• sealant (resistant to propane/LP gas)

• equipment shutoff valve*

• flex gas line with 3/8" NPT tap

• ground joint union

• sediment trap

• tee joint

• pipe wrench

• for natural gas, test gauge connection*

* A CSA design-certified equipment shutoff valve

with 1/8" NPT tap is an acceptable alternative to

test gauge connection. The optional CSA designcertified equipment shutoff valve can be purchased

from your dealer. See

Accessories, page 21.

www.desatech.com

7116307-01A

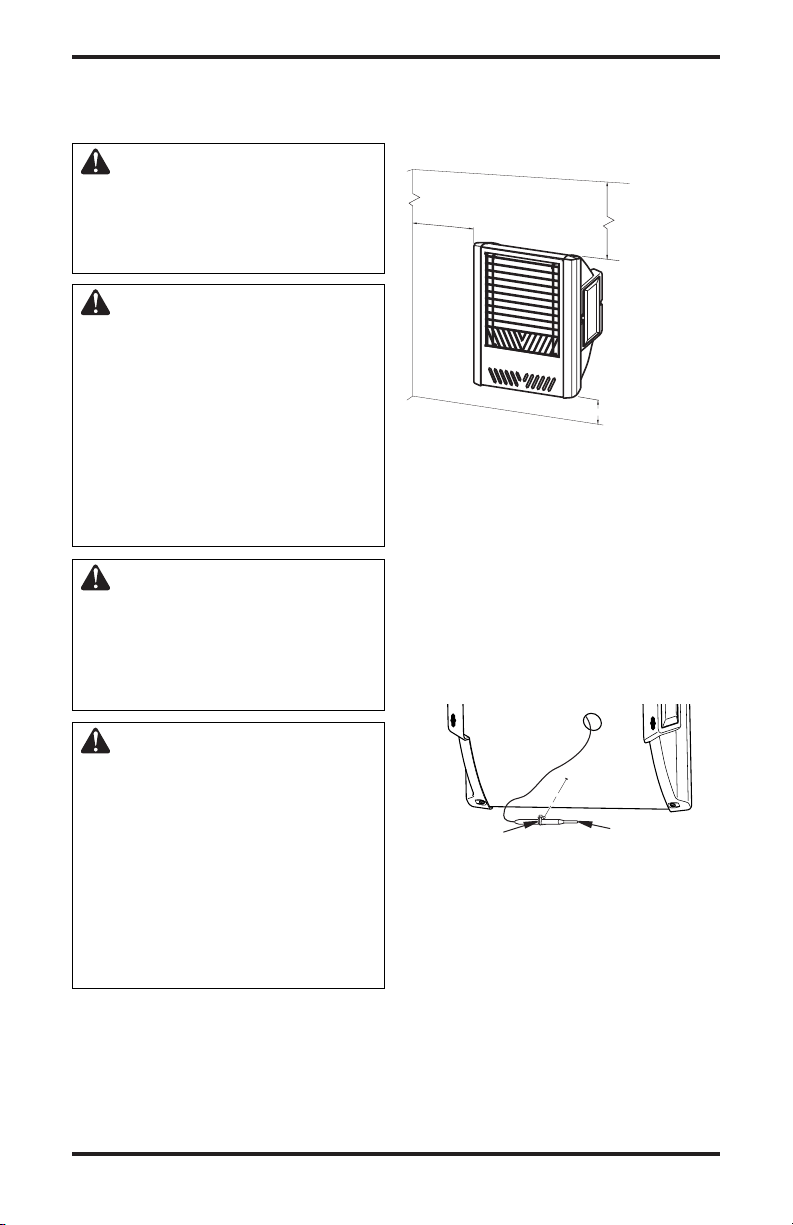

INSTALLATION

Minimum

From

Sides Of

Heater

36"

FLOOR

CEILING

Minimum

Residential Heaters:

2" Minimum To Top

Surface Of Carpeting,

Tile Or Other

Combustible Material

Garage Heaters:

18" Minimum To

Garage Floor

Left

Side

Right

Side

6" (15.2 cm)

Continued

LOCATING HEATER

WARNING: Maintain the

minimum clearances shown

in Figure 4. If you can, provide

greater clearances from floor,

ceiling and joining wall.

WARNING: Never install the

heater

• in a bedroom or bathroom

• in a recreational vehicle

• where curtains, furniture, cloth

ing or other flammable objects

are less than 36" from the front,

top or sides of the heater

• as a fireplace insert

• in high traffic areas

• in windy or drafty areas

CAUTION: If you install the

heater in a home garage

• heater pilot and burner must be

at least 18" above floor

• locate heater where moving

vehicle will not hit it

For convenience and efficiency, install heater

• where there is easy access for operation, inspec

tion and service

• in coldest part of room

-

Figure 4 - Mounting Clearances As

Viewed From Front of Heater

THERMOSTAT SENSING BULB

The thermostat sensing bulb is located on the lower

rear panel of heater.

1. Place clamp on thermostat sensing bulb as

shown in Figure 5. Clamp is provided in

hardware package.

2. Snap clamp into mounting hole as shown in

Figure 5. Mounting hole is located in the center

of lower back panel of heater. Make sure the

thermostat sensing bulb is horizontal.

-

CAUTION: This heater creates

warm air currents. These currents

move heat to wall surfaces next

to heater. Installing heater next

to vinyl or cloth wall coverings

or operating heater where impurities (such as, but not limited to,

tobacco smoke, aromatic candles,

cleaning fluids, oil or kerosene

lamps, etc.) in the air exist, may

discolor walls or cause odors.

IMPORTANT: Vent-free heaters add moisture to

the air. Although this is beneficial, installing heater

in rooms without enough ventilation air may cause

mildew to form from too much moisture. See Air for

Combustion and Ventilation, page 5. If high humid

ity is experienced, a dehumidifier may be used to

help lower the water vapor content in the air.

8

www.desatech.com

Clamp

Figure 5 - Attaching Thermostat Sensing

Bulb

Thermostat

Sensing Bulb

INSTALLING HEATER TO WALL

Methods For Attaching Heater To Wall

Attach heater to wall in one of two ways:

1. Attaching to wall stud

2. Attaching to wall anchor

Attaching to Wall Stud: This method provides

the strongest hold. Insert mounting screws into

wall studs.

Attaching to Wall Anchor: This method allows you

to attach mounting screws to hollow walls (wall

areas between studs) or to solid walls (concrete

or masonry).

116307-01A

INSTALLATION

18 3/4"

Min.

7"

Min.

20,000 Btu Heaters

16 7/8"

30,000 Btu Heaters

24 5/16"

Ad j o ini n g Wa l l

Insert Mounting

Screws

Floor

Continued

Decide which method better suits your needs.

Either method will provide a secure hold for the

heater.

Marking Screw Locations

WARNING: Maintain minimum clearances shown in

Figure 5. If you can, provide

greater clearances from floor

and joining wall.

Mark two screw locations on wall as shown in

Figure 6).

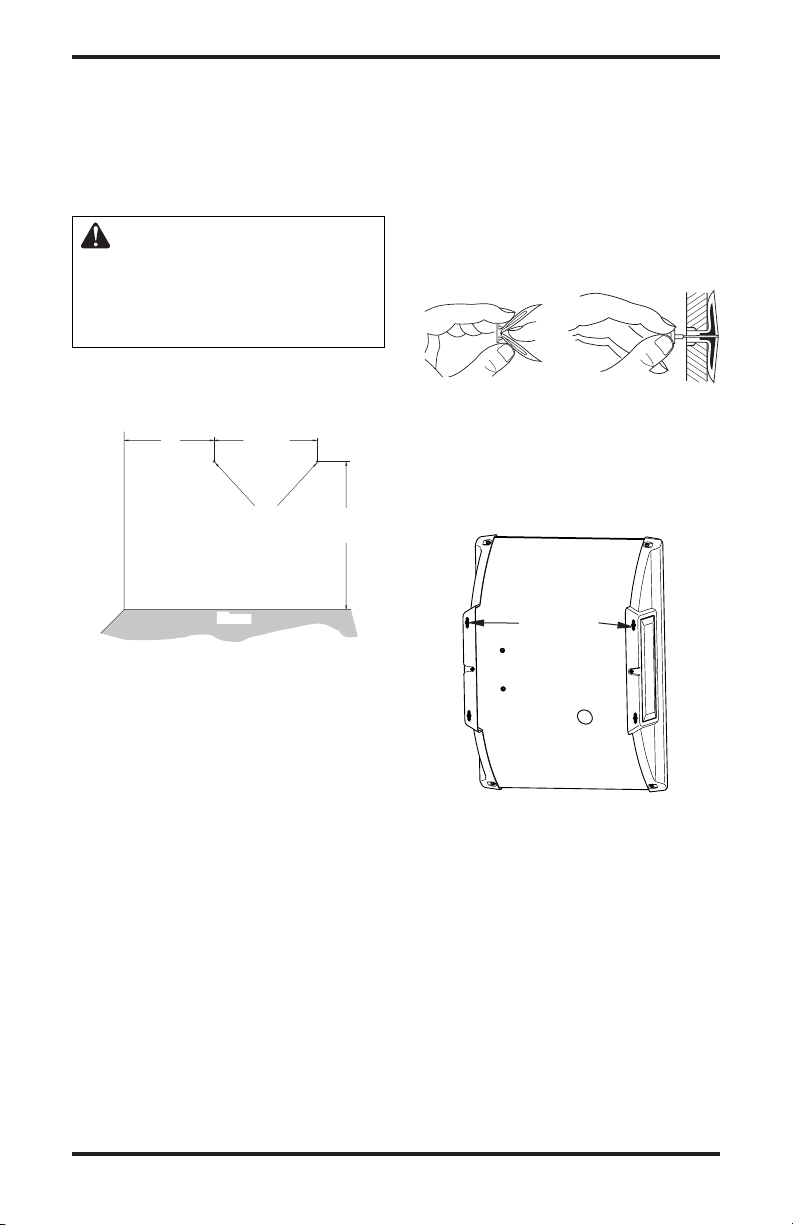

2. Fold wall anchor as shown in Figure 7.

3. Insert wall anchor (wings first) into hole. Tap

anchor flush to wall.

4. For thin walls (1/2" or less), insert red key

into wall anchor. Push red key to “pop” open

anchor wings. IMPORTANT:

Do not hammer

key! For thick walls (over 1/2" thick) or solid

walls, do not pop open wings.

5. Insert mounting screws into wall anchors.

6. Tighten screws until screw head is 1/8" away

from wall.

Figure 7 - Folding

Anchor

Figure 8 - Popping

Open Anchor Wings

For Thin Walls

Placing Heater On Mounting Screws

1. Locate two top vertical key slots on back end

panels of heater.

2. Place heater onto mounting screws.

Vertical

Key Slots

Figure 6 - Wall Mounting Clearances

Locate hardware packet behind left side door

of heater.

Attaching To Wall Stud Method

For attaching heater to wall studs

1. Drill holes at marked locations using 9/64"

drill bit.

2. Tighten screws until screw head is 1/8" away

from wall.

Attaching To Wall Anchor Method

For attaching heater to hollow walls (wall areas be

tween studs) or solid walls (concrete or masonry).

1. Drill holes at marked locations using 5/16"

drill bit. For solid walls (concrete or masonry),

drill at least 1" deep.

Figure 9 - Vertical Key Slots for Mounting

-

www.desatech.com

Heater to Wall

9116307-01A

INSTALLATION

Continued

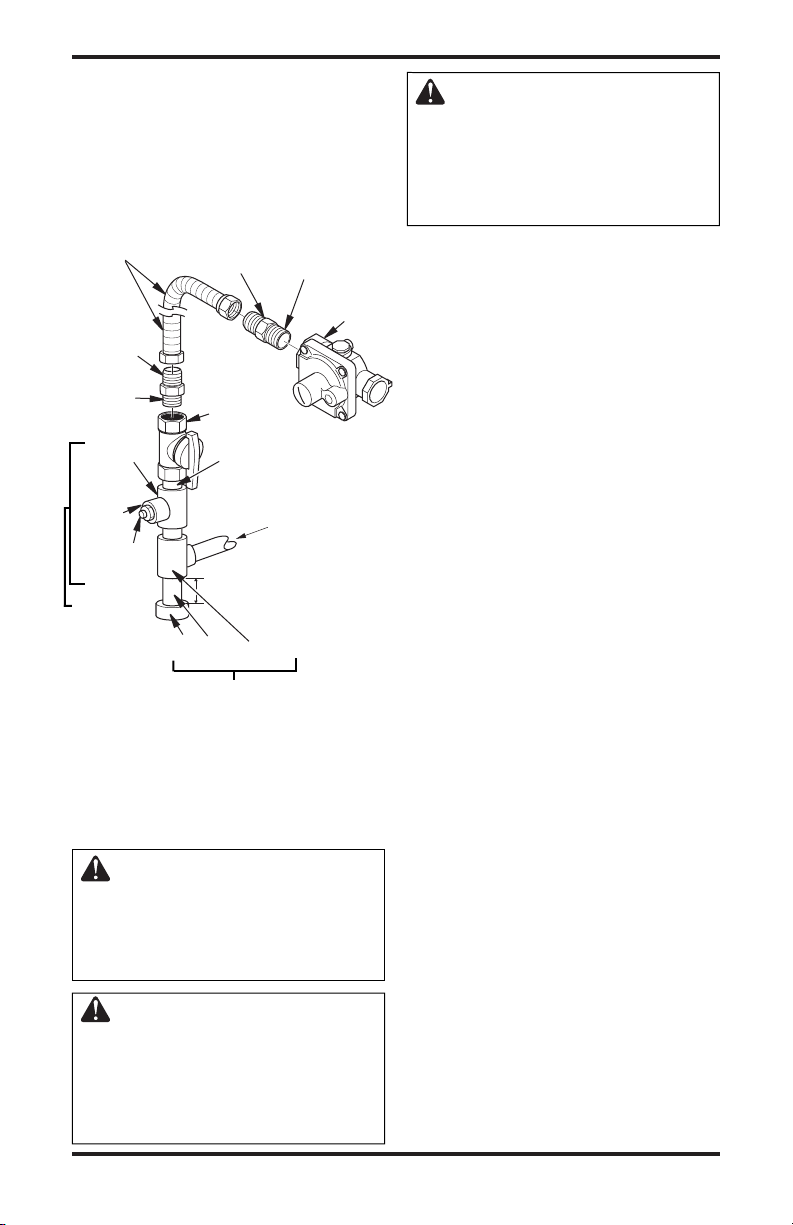

CONNECTING TO GAS SUPPLY

WARNING: This appliance

requires a 3/8" NPT (National

Pipe Thread) inlet connection to

the pressure regulator.

For propane/LP gas, the installer must supply an

external regulator. The external regulator will

reduce incoming gas pressure. You must reduce

incoming gas pressure to between 11" and 14" of

water. If you do not reduce incoming gas pressure,

heater regulator damage could occur. Install the

external regulator with the vent pointing down

as shown in Figure 10. Pointing the vent down

protects it from freezing rain or sleet.

WARNING: A qualified service person must connect heater

to gas supply. Follow all local

codes.

WARNING: For natural

gas, never connect heater to

private (non-utility) gas wells.

This gas is commonly known

as wellhead gas.

IMPORTANT: For natural gas, check gas line

pressure before connecting heater to gas line. Gas

line pressure must be no greater than 10.5" of wa

ter. If gas line pressure is higher, heater regulator

damage could occur.

CAUTION: For propane/LP

gas, never connect heater directly to the propane/LP supply.

This heater requires an external

regulator (not supplied). Install

the external regulator between the

heater and propane/LP supply.

Propane/LP

Supply Tank

Figure 10 - External Regulator With Vent

Pointing Down

10

External

Regulator

Vent

Pointing

Down

www.desatech.com

CAUTION: Use only new,

black iron or steel pipe. Internally-tinned copper tubing may

be used in certain areas. Check

your local codes. Use pipe of

large enough diameter to allow

proper gas volume to heater. If

pipe is too small, undue loss of

volume will occur.

Typical Inlet Pipe Diameters

20,000 Btu/Hr Models - 3/8" or greater

30,000 Btu/Hr Models - 1/2" or greater

Installation must include equipment shutoff valve,

-

union and plugged 1/8" NPT tap. Locate NPT

tap within reach for test gauge hook up. NPT

tap must be upstream from heater (see Figure

11, page 11).

IMPORTANT: Install an equipment shutoff valve

in an accessible location. The equipment shutoff

valve is for turning on or shutting off the gas to

the appliance.

Apply pipe joint sealant lightly to male NPT

threads. This will prevent excess sealant from

going into pipe. Sealant in pipe could result in

clogged heater valves. Most flex gas tubing does

not require sealant. Read instructions supplied

with flex gas tubing.

WARNING: Use pipe joint

sealant that is resistant to liquid

petroleum (LP) gas.

Install sediment trap in supply line as shown in

Figure 11, page 11. Locate sediment trap where

it is within reach for cleaning. Locate sediment

trap where trapped matter is not likely to freeze.

A sediment trap traps moisture and contaminants.

This keeps them from going into heater controls. If

sediment trap is not installed or is installed wrong,

heater may not run properly.

Install male connector and flex gas line to equipment

shutoff valve as shown in Figure 11, page 11.

116307-01A

INSTALLATION

Continued

IMPORTANT: Hold the pressure regulator and

connector with wrench when connecting it to gas

piping and/or fittings. Do not over tighten pipe

connection to regulator. The regulator body could

be damaged.

Flex Gas

Line

3/8" Male

Flare

to NPT

Connector

Pipe Joint

Sealant

Required

(NPT End)

Tee Joint

Reducer

Bushing

to 1/8"

NPT

1/8" NPT

Plug Tap

Test Gauge

Connection*

* A CSA design-certified equipment shutoff valve

with 1/8" NPT tap is an acceptable alternative to

test gauge connection. Purchase the optional CSA

design-certified equipment shutoff valve from your

dealer. See Accessories, page 21.

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping

and connections, internal and

external to unit, for leaks after

installing or servicing. Correct

all leaks at once.

WARNING: Never use an

open flame to check for a leak.

Apply a noncorrosive leak detec

tion fluid to all joints. Bubbles

forming show a leak. Correct all

leaks at once.

116307-01A

3/8" Male

Flare to NPT

Connector

Equipment

Shutoff

Figure 11 - Gas Connection

Valve*

3" Min

Cap Tee Pipe

Joint Nipple

Sediment Trap

Pipe Joint

Sealant Required

(NPT End)

3/8" NPT

Pipe Nipple

Natural Gas

From Gas Meter

(4" W.C. to 10.5"

W.C. Pressure)

Propane/LP

From External

Regulator

(11" W.C. to 14"

W.C. Pressure)

Pressure

Regulator

-

www.desatech.com

CAUTION: For propane/LP

gas, make sure external regulator has been installed between

propane/LP supply and heater.

See guidelines under Connect-

ing to Gas Supply, page 10.

PRESSURE TESTING GAS SUPPLY

PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance main

gas valve (control valve) and equipment

shutoff valve from gas supply piping system.

Pressures in excess of 1/2 psig will damage

heater regulator.

2. Cap off open end of gas pipe where equipment

shutoff valve was connected.

3. Pressurize supply piping system by either

opening propane/LP supply tank valve for

propane/LP gas or opening main gas valve

located on or near gas meter for natural gas

or using compressed air.

4. Check all joints of gas supply piping system.

Apply a noncorrosive leak detection fluid to

all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Reconnect heater and equipment shutoff valve

to gas supply. Check reconnected fittings for

leaks.

Test Pressures Equal To or Less Than 1/2

PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Figure 12,

page 12).

2. Pressurize supply piping system by either

opening propane/LP supply tank valve for

propane/LP gas or opening main gas valve

located on or near gas meter for natural gas

or using compressed air.

3.

Check all joints from gas meter for natural gas

or propane/LP supply tank for propane/LP gas,

to equipment shutoff valve (see Figure 13 or 14,

page 12). Apply a noncorrosive leak detection

fluid to all joints. Bubbles forming show a leak.

4. Correct all leaks at once.

PRESSURE TESTING HEATER GAS

CONNECTIONS

1. Open equipment shutoff valve (see Figure 12,

page 12).

2. For natural gas open main gas valve located

on or near gas meter. For propane/LP gas open

propane/LP supply tank valve.

11

INSTALLATION

Continued

3. Make sure control knob of heater is in the OFF

position.

4. Check all joints from equipment shutoff valve

to thermostat gas valve (see Figure 13 or 14).

Apply a noncorrosive leak detection fluid to

all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Light heater (see Operating Heater, this page).

Check all other internal joints for leaks.

7. Turn off heater (see To Turn Off Gas to Appli

ance, page 14).

8. Install refractory and front panel.

Equipment

Shutoff Valve

Figure 12 - Equipment Shutoff Valve

Gas

Meter

Open

Closed

Thermostat

Gas Valve

Equipment

Shutoff

Valve

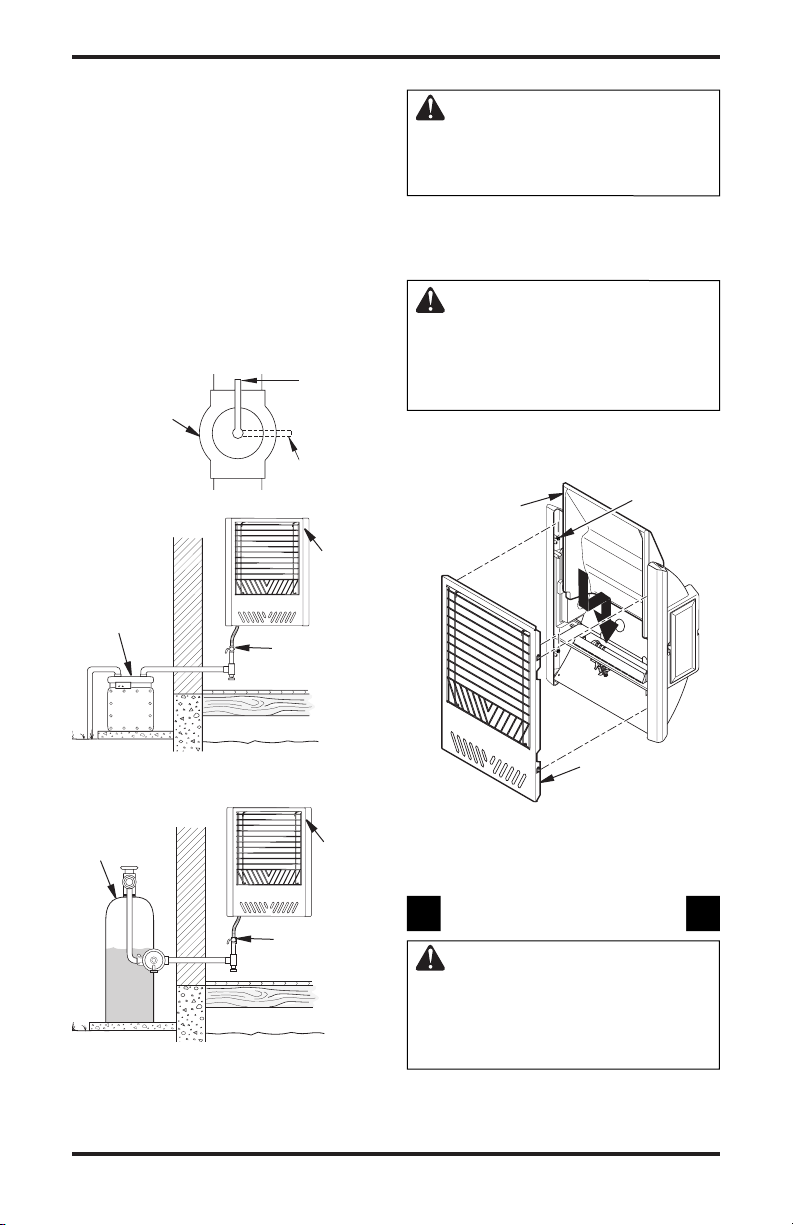

Installing Refractory and Front Panel

WARNING: Examine refractory panel. If damaged, do not

operate heater. See Replace

ment Parts, page 21.

1.

Gently lift refractory and position into heater. Take

care not to damage refractory (see Figure 15).

If refractory is damaged call the phone number

found under Replacement Parts, page 21.

-

CAUTION: Refractory may

shift inside heater. When install

ing or removing front panel, use

caution to prevent refractory

from falling.

2. Install front panel of heater by placing slots on

each side over and down onto shoulder screws

(see Figure 15).

Refractory

Shoulder

Screw

-

-

Figure 13 - Checking Gas Joints for

Natural Gas

Propane/LP

Supply Tank

Equipment

Shutoff

Valve

Figure 14 - Checking Gas Joints for

Propane/LP Gas

12

Figure 15 - Installing Front Panel and

Thermostat

Gas Valve

OPERATING HEATER

low these instructions exactly,

a fire or explosion may result

causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be

lighted by hand. When lighting the pilot,

follow these instructions exactly.

www.desatech.com

Front Panel

Refractory

FOR YOUR SAFETY READ

BEFORE LIGHTING

WARNING: If you do not fol-

116307-01A

O

F

F

P

I

L

O

T

OPERATING HEATER

Continued

B. BEFORE LIGHTING smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighborʼs phone. Follow the gas

supplierʼs instructions.

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in or turn the

gas control knob. Never use tools. If the

knob will not push in or turn by hand,

donʼt try to repair it, call a qualified service

technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control which

has been under water.

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information starting

on page 12.

2. Make sure equipment shutoff valve is

fully open.

3. Turn off any electric power to the appliance

if service is to be performed.

4. Turn control knob clockwise

OFF position.

5. Wait five minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety

information starting on page 12. If you donʼt

smell gas, go to the next step.

6. Turn control knob counterclockwise

to the PILOT position. Press in control knob

for five (5) seconds.

7. With control knob pressed in, push down

and release ignitor button. This will light

pilot. The pilot is attached to the front of

to the

burner. Note: You may be running this

heater for the first time after hooking up to

gas supply. If so, you may need to press in

control knob for 30 seconds or more. This

will allow air to bleed from the gas system.

If needed, keep pressing ignitor button until

pilot lights. If ignitor does not light pilot,

refer to Troubleshooting, page 16 or contact

a qualified service person or gas supplier for

repairs. Until repairs are made, light pilot

with match. To light pilot with match, see

Manual Lighting Procedure, page 14.

8. Keep control knob pressed in for 30 seconds

after lighting pilot. After 30 seconds, release

control knob.

• If control knob does not pop up when

released, contact a qualified service person

or gas supplier for repairs.

Note: If pilot goes out, repeat steps 4 thru 7.

Thermostat models have a safety interlock

system. Wait one (1) minute before lighting

pilot again.

9. Turn control knob counterclockwise

to desired heating level. The main burner

should light.

CAUTION: Do not try to adjust heating levels by using the

equipment shutoff valve.

Ignitor Button

(Actual Ignitor may vary)

Figure 16 - Control Knob In The OFF

Position

Thermocouple

Figure 17 - Pilot

Control Knob

Ignitor

Electrode

Pilot

Burner

www.desatech.com

13116307-01A

OPERATING HEATER

Continued

TO TURN OFF GAS

TO APPLIANCE

Shutting Off Heater

1. Turn control knob clockwise to the

OFF position.

2. Turn off all electric power to the appliance

if service is to be performed.

Shutting Off Burner Only (pilot stays lit)

Turn control knob clockwise

PILOT position.

THERMOSTAT CONTROL

OPERATION

The thermostatic control used on these models

differs from standard thermostats. Standard

thermostats simply turn on and off the burner.

The thermostat used on this heater senses the

room temperature. At times the room may

exceed the set temperature. If so, the burner

will shut off. The burner will cycle back on

when room temperature drops below the set

temperature. The control knob can be set to

any heat level between 1 and 5.

amount of gas flow to the burner that increases

or decreases the burner flame height.

Note: The thermostat sensing bulb measures

the temperature of air near the heater cabinet.

This may not always agree with room temperature (depending on housing construction,

installation location, room size, open air tem

peratures, etc.) Frequent use of your heater will

let you determine your own comfort levels.

MANUAL LIGHTING

PROCEDURE

1.

Remove front panel (see Figure 10, page 9).

2. Follow steps 1 through 7 under Lighting

Instructions, page 13.

3. With control knob pressed in, strike match.

Hold match to pilot until pilot lights.

4. Keep control knob pressed in for 30 seconds

after lighting pilot. After 30 seconds, release

control knob. Now follow step 9, under

Lighting Instructions, page 13.

5. Replace front panel.

to the

This adjusts the

INSPECTING HEATER

Check pilot flame pattern and burner flame pattern often.

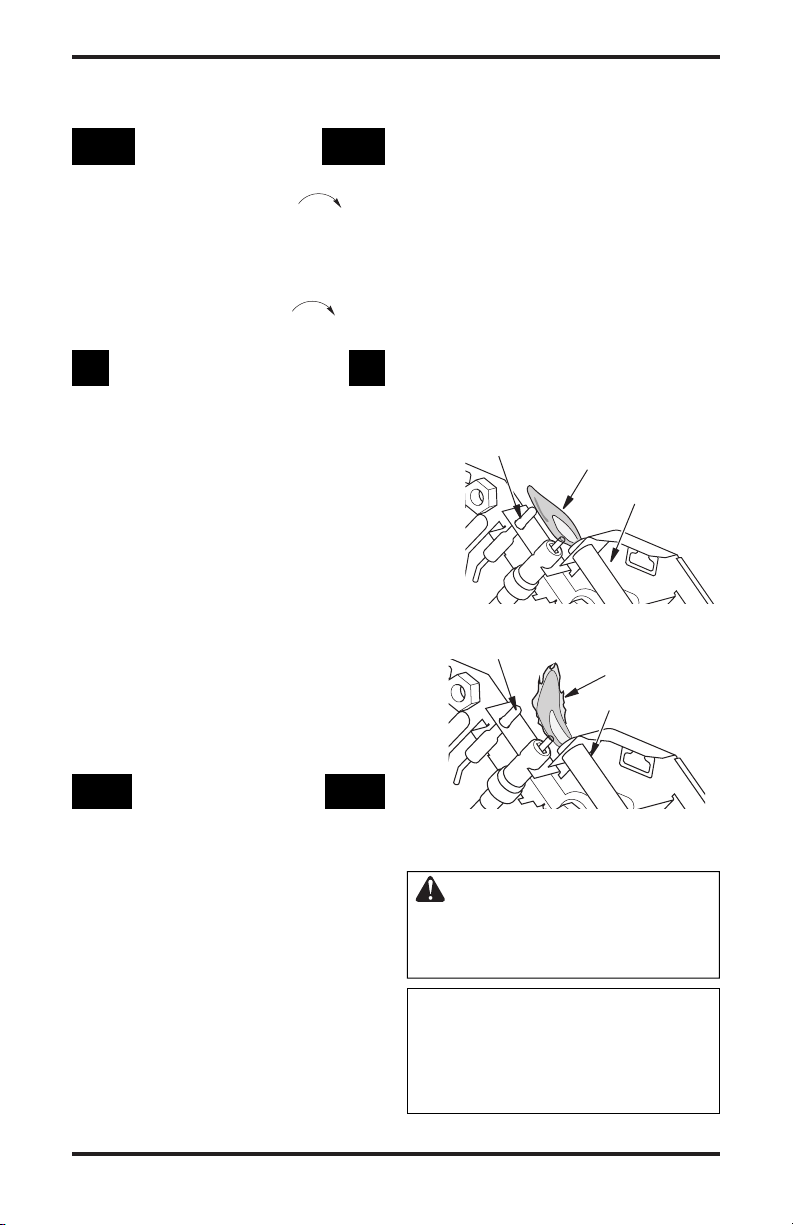

PILOT FLAME PATTERN

Figure 18 shows a correct pilot flame pattern. Figure

19 shows an incorrect pilot flame pattern. The incor

rect pilot flame is not touching the thermocouple.

This will cause the thermocouple to cool. When the

thermocouple cools, the heater will shut down.

If pilot flame pattern is incorrect, as shown in

Figure 19

•

turn heater off (see To Turn Off Gas to Ap-

pliance

)

• see Troubleshooting, page 16

Note: The pilot flame on natural gas units will

have a slight curve, but flame should be blue and

have no yellow or orange color.

Thermocouple

Figure 18 - Correct Pilot Flame Pattern

Thermocouple

-

Figure 19 - Incorrect Pilot Flame Pattern

BURNER FLAME PATTERN

WARNING: If yellow tipping

occurs, your heater could produce increased levels of carbon

monoxide.

NOTICE: Do not mistake orange

flames with yellow tipping. Dirt

or other fine particles enter the

heater and burn causing brief

patches of orange flame.

Blue Pilot Flame

Pilot Burner

Yellow Pilot Flame

Pilot Burner

-

14

www.desatech.com

116307-01A

INSPECTING HEATER

Continued

Figure 20 shows a correct burner flame pattern.

Figure 21 shows an incorrect burner flame pattern.

The incorrect burner flame pattern shows yellow

tipping of the flame.

If burner flame pattern is incorrect, as shown in

Figure 21

• turn heater off (see To Turn Off Gas to Appli

ance, page 14)

• see Troubleshooting

Figure 20 - Correct Burner Flame Pattern

Figure 21 - Incorrect Burner Flame Pattern

, page 16

Blue

Flame

Yellow

Tipping

CLEANING AND

MAINTENANCE

WARNING: Turn off heater

and let cool before cleaning.

CAUTION: You must keep

control areas, burner and circu

lating air passageways of heater

clean. Inspect these areas of

heater before each use. Have

heater inspected yearly by a

qualified service person. Heater

may need more frequent cleaning due to excessive lint from

carpeting, bedding material, pet

hair, etc.

WARNING: Failure to keep

the primary air opening(s) of

the burner(s) clean may result in

sooting and property damage.

-

www.desatech.com

ODS/PILOT AND BURNER

Use a vacuum cleaner, pressurized air or small,

soft bristled brush to clean.

BURNER PILOT AIR INLET

The primary air inlet holes allow the proper

amount of air to mix with the gas. This provides a

clean burning flame. Keep these holes clear of dust,

dirt and lint. Clean these air inlet holes prior to each

heating season. Blocked air holes will create soot.

-

We recommend that you clean the unit every three

months during operation and have heater inspected

yearly by a qualified service person.

We also recommend that you keep the burner

tube and pilot assembly clean and free of dust and

dirt. To clean these parts we recommend using

compressed air no greater than 30 PSI. Your local

computer store, hardware store or home center

may carry compressed air in a can. You can use a

vacuum cleaner in the blow position. If using com

pressed air in a can, please follow the directions on

the can. If you donʼt follow directions on the can,

you could damage the pilot assembly.

1. Shut off the unit, including the pilot. Allow

the unit to cool for at least thirty minutes.

2. Inspect burner, pilot for dust and dirt.

3. Blow air across the ports/slots and holes in the

burner.

4. Never insert objects into the pilot tube.

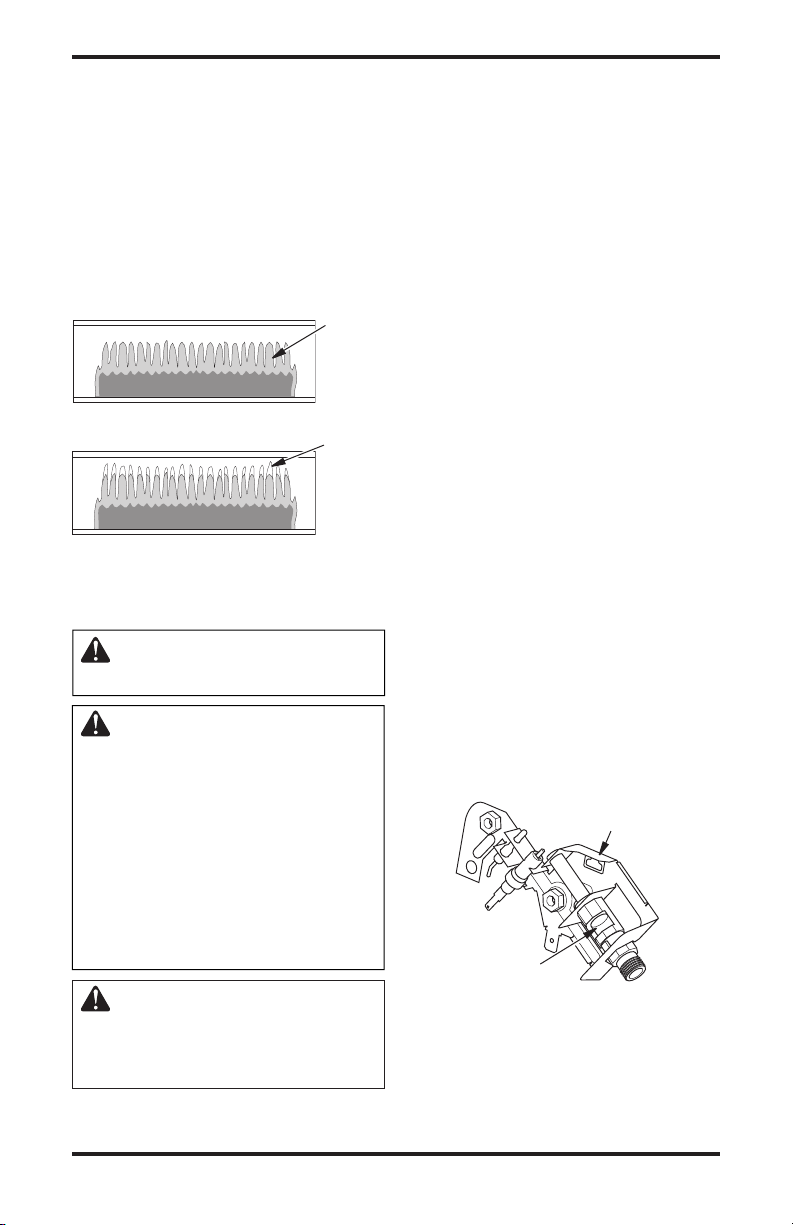

Clean the pilot assembly also. A yellow tip on the

pilot flame indicates dust and dirt in the pilot as

sembly. There is a small pilot air inlet about two

inches from where the pilot flame comes out of

the pilot assembly (see Figure 22). With the heater

off, lightly blow air through the air inlet. You may

blow through a drinking straw if compressed air

is not available.

Pilot Assembly

Pilot Air Inlet

Figure 22 - Pilot Air Inlet

CABINET

Air Passageways

Use a vacuum cleaner or pressurized air to clean.

Exterior

Use a soft cloth dampened with a mild soap and

water mixture. Wipe the cabinet to remove dust.

-

-

15116307-01A

Loading...

Loading...