Page 1

NATURAL GAS LOG

VENTED DECORATIVE APPLIANCES

OWNER’S OPERATION AND INSTALLATION MANUAL

RGA 2-72

APPROVED

TESTED AND

LISTED BY

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury, or

loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

— Installation and service must be performed by

a qualified installer, service agency, or the

gas supplier.

Burner Models

HFVMR18 and

HFVMR24

WARNING: Improper installation, adjustment, alteration, service, or maintenance can cause

injury or property damage. Refer to this manual for correct

installation and operational

procedures. For assistance or

additional information consult

a qualified installer, service

agency, or the gas supplier.

WARNING: This appliance is

for installation only in a solidfuel burning masonry or UL127

factory-built fireplace, constructed of noncombustible

material, and connected to a

working flue. (See page 4 for

minimum flue opening.)

WARNING: This is a gas-fired appliance. It uses air (oxygen) from the room in which

it is installed. Provisions for adequate combustion and ventilation air must be

provided. Refer to

This appliance may be installed in an aftermarket* manufactured (mobile) home,

where not prohibited by state or local codes.

* Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

Air for Combustion and Ventilation

Save this manual for future reference.

section on page 4 of this manual.

Page 2

VENTED NATURAL GAS LOGS

SAFETY

INFORMATION

WARNINGS

WARNING ICON G 001

WARNING: Keep flue open

when operating unit.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate, or service this log set. Improper use of this log set can cause

serious injury or death from burns,

fire, explosion, electrical shock,

and carbon monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs

of carbon monoxide poisoning resemble the

flu, with headaches, dizziness, or nausea. If

you have these signs, the log set may not be

working properly. Get fresh air at once!

Have log set serviced. Some people are

more affected by carbon monoxide than

others. These include pregnant women,

people with heart or lung disease or anemia,

those under the influence of alcohol, and

those at high altitudes.

Natural Gas: Natural gas is odorless. An

odor-making agent is added to the gas. The

odor helps you detect a gas leak. However,

the odor added to the gas can fade. Gas may

be present even though no odor exists.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this log set.

WARNING: Any change to this

log set or its controls can be

dangerous.

1. This appliance, as supplied, is only for

use with the type of gas indicated on

the rating plate. This appliance is convertible for use with propane/LP, using

the GA9050 or GA9150 pilot kit.

2. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do

not use any phone in your building

• immediately call your gas supplier

from a neighbor’s phone. F ollow the

gas supplier’s instructions

• if you cannot reach your gas supplier ,

call the fire department

3. Never install the log set

• in a recreational vehicle

• where curtains, furniture, clothing, or

other flammable objects are less than

42 inches from the front, top, or sides

of the log set

• in high traffic areas

• in windy or drafty areas

4. Before installing in a solid fuel burning fireplace, the chimney flue and firebox must be cleaned of soot, creosote,

ashes, and loose paint by a qualified

chimney cleaner. Creosote will ignite

if highly heated. Inspect chimney flue

for damage.

5. Y ou must operate this log set with a fireplace screen in place. Make sure fireplace

screen is closed before running log set.

If the fireplace has glass doors, they

must remain fully OPEN while this log

set is in operation.

6. This log set is designed to be smokeless. If logs ever appear to smoke, turn

off appliance and call a qualified service person.

eration, slight smoking could occur due

to log curing and the burning of manufacturing residues. Y ou ma y wish to add

more ventilation by opening a window .

7. To reduce the creation of soot, follow

the instructions in Cleaning and Main-

tenance, page 7.

8. Do not allow fans to blow directly into

the fireplace. Avoid any drafts that alter burner flame patterns. Ceiling fans

can create drafts that alter burner flame

patterns. Altered burner patterns can

increase sooting.

Note:

During initial op-

9. Do not use a blower insert, heat exchanger insert or other accessory not

approved for use with this log set.

10. This log set needs fresh, outside air ventilation to run properly. See Air for

Combustion and Ventilation, page 4.

11. Do not run log set

• where flammable liquids or vapors

are used or stored

• under dusty conditions

12. Do not burn solid fuel in the fireplace

after installing the log set. Do not use

this log set to cook food or burn paper

or other objects.

13. Log set becomes v ery hot when in use.

Keep children and adults away from hot

surface to avoid burns or clothing ignition. Log set will remain hot for a time

after shutdown. Allow surface to cool

before touching.

14. Carefully supervise young children

when they are in the room with log set.

15. Do not use appliance if any part has been

exposed to or under water . Immediately

call a qualified service technician to inspect the room appliance and to replace

any part of the control system (if using

GA9050 or GA9150) and any gas control which has been under water.

16. To help prevent breakage, new logs

must be broken-in (see Curing Logs,

page 7).

17. Turn log set off and let cool before servicing, installing, or repairing. Only a

qualified service person should install,

service, or repair log set.

2

901915

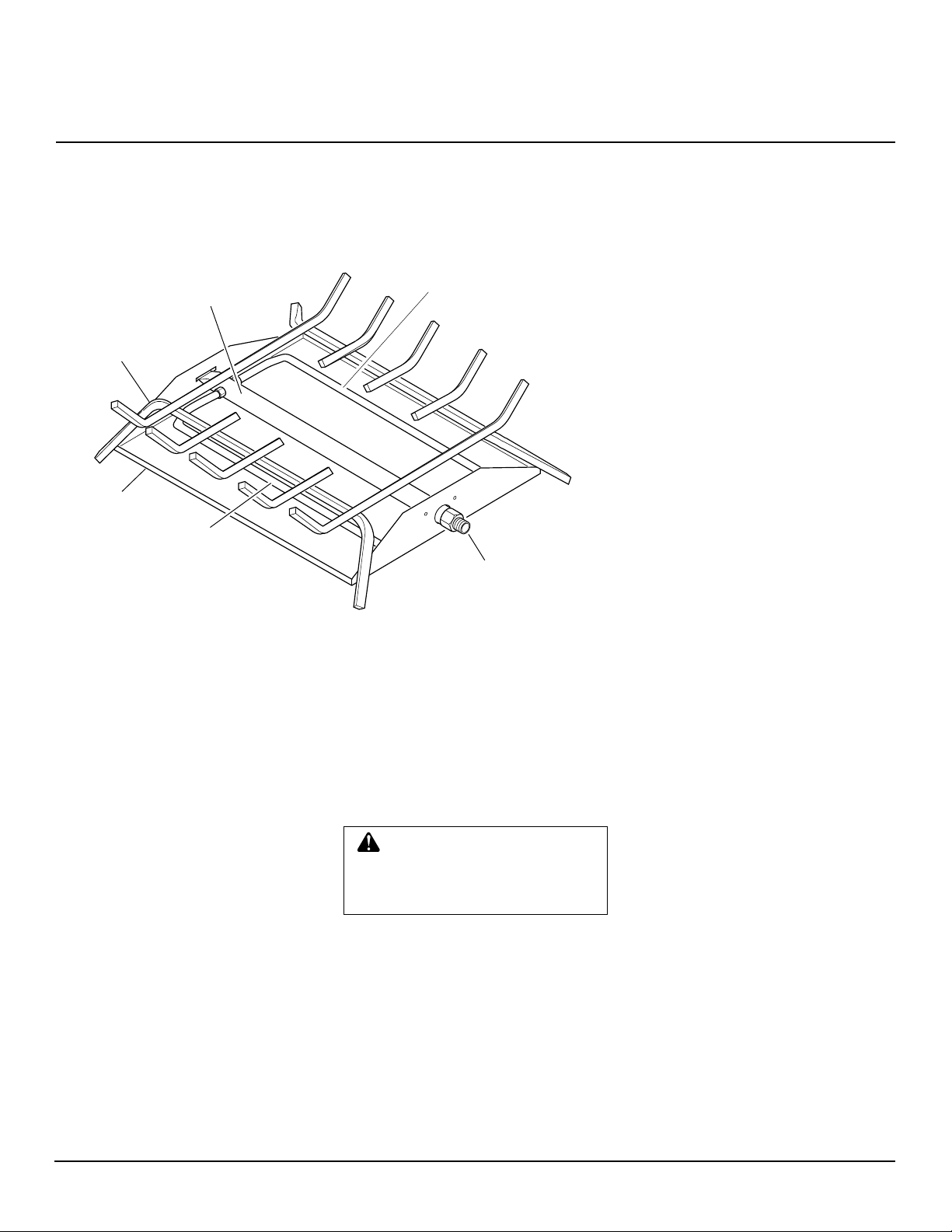

Page 3

OWNER’S MANUAL

PRODUCT

IDENTIFICATION

Burner

Manifold

Grate

Burner

Pan

Left

Side

Burner

Figure 1 - Product Identification (HFVMR24 Shown)

Hearth Kit Model: _____________________________________

Serial Number: _______________________________________

Log Set Model: HFVMR18 or HFVMR24

LOCAL CODES

Install and use log set with care. Follow all

local codes. In the absence of local codes, use

the latest edition of The National Fuel Gas

Code, ANS Z223.1, also known as NFPA 54*.

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

UNPACKING

CAUTION: Do not remove the

metal data plates from the burner

pan. The d ata plates contain important product information.

1. Remove logs, hearth kit, pan materials,

and hardware from carton.

2. Remove all protective packaging applied to logs and base for shipment.

3. Check all items for any shipping damage. If damaged, promptly inform

dealer where you bought the product.

Right Side

Burner

Burner Inlet

Fitting

OPTIONAL

PRODUCT

FEATURES

ON/OFF SAFETY VALVE/

PILOT KIT AND PROPANE/LP

CONVERSION

An optional valve/safety pilot kit with a

piezo ignitor is available for this appliance.

This system requires no matches, batteries,

or other sources to light. You must use this

optional system for LP conversion. See Ac-

cessories, page 13.

REMOTE CONTROL READY

(MILLIVOLT) SAFETY VALVE/

PILOT KIT

An optional millivolt valve/safety pilot kit

with a piezo ignitor is available for this

appliance. This system requires no matches,

batteries, or other sources to light. This

system may be connected to a wall switch or

hand-held wireless remote control. See Ac-

cessories, page 13.

REMOTE CONTROL

ACCESSORIES

There is an optional hand-held ON/OFF

remote control that can be purchased separately for this log set. You must use the

millivolt valve/safety pilot kit to use remote

accessories with this appliance. See Acces-

sories, page 13.

A wall switch is also available for this

appliance. You must use the millivolt valve/

safety pilot kit to use the wall switch with

this appliance. See Accessories, page 13.

901915

3

Page 4

VENTED NATURAL GAS LOGS

AIR FOR

COMBUSTION AND

VENTILATION

WARNING: This appliance

shall not be installed in a confined space or unusually tight

construction unless provisions

are provided for adequate combustion and ventilation air. Read

the following instructions to insure proper fresh air for this and

other fuel-burning appliances in

your home.

Today’s homes are built more energy efficient than ever. New materials, increased

insulation, and new construction methods

help reduce heat loss in homes. Home owners

weather strip and caulk around windows and

doors to keep the cold air out and the warm air

in. During heating months, home owners

want their homes as airtight as possible.

While it is good to make your home energy

efficient, your home needs to breathe. Fresh

air must enter your home. All fuel-burning

appliances need fresh air for proper combustion and ventilation.

Exhaust fans, fireplaces, clothes dryers, and

fuel burning appliances draw air from the

house to operate. You must provide adequate fresh air for these appliances. This

will insure proper venting of vented fuelburning appliances.

INSTALLATION

NOTICE: Installation, service, and

repair of this appliance must be

performed by a qualified installer,

service agency, company or gas

supplier experienced with this

type of gas appliance. Only factory authorized components listed

in these instructions may be used

in accordance with the

manufacturer’s instructions and

all codes and requirements of the

authority having jurisdiction. Any

modifications to this kit, or use of

unauthorized components or accessory items will void the

manufacturer’s warranty, and may

result in a hazardous condition.

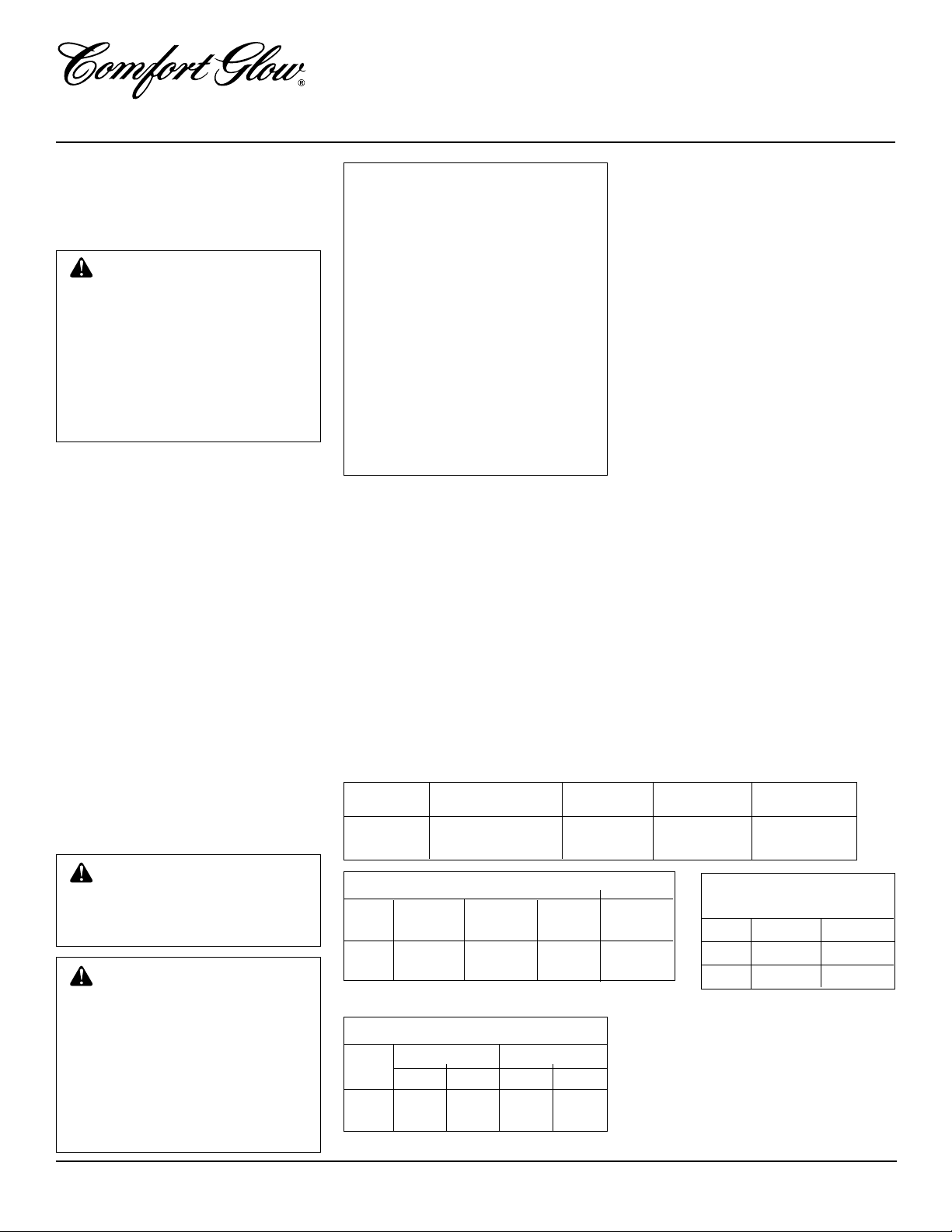

FLUE OPENING

SPECIFICATIONS

Note:

This vented appliance must be installed only in a solid-fuel burning fireplace

with a working flue and constructed of noncombustible material.

The charts in Figure 2 indicate technical

information regarding the installation of

your gas log set. Please make sure that all of

the specifications shown are applicable before installation is attempted.

The fireplace must include a working flue

and venting system with the minimum openings shown in the Figure 2.

MODEL DESCRIPTION

HFVMR18 18" Multi-Side 55,000 45,000 8" dia.

HFVMR24 24" Multi-Side 65,000 55,000 8" dia.

Btu Input

Natural Gas

CHECK GAS TYPE

Use only natural gas. If your gas supply is not

natural gas, you must install ON/OFF Safety

Valve/Pilot Kit (see Accessories, page 13).

Call dealer where you bought log set.

If the fireplace does not have a gas supply

shut-off valve, one must be installed.

VENTING SPECIFICATIONS

FOR INSTALLATION

The fireplace chimney flue and vent must be

drafting properly. To check the vent for

proper drafting: Light a tightly rolled newspaper on one end and place it at the inside

front edge of the fireplace. Observe the

smoke and be sure the vent is properly

drawing it up the chimney. If the smoke

spills out into the room, extinguish the flame

and remove any obstruction until proper

venting is achieved.

The chimney flue must remain open a minimum of 3" at all times during the operation

of this log set.

Btu Input

Propane Gas

Minimum

Vent Opening

CAUTION: Do not remove the

metal data plates attached to the

burner pan. The data plates contain

important warranty information.

WARNING: Before installing

in a solid fuel burning fireplace,

the chimney flue and firebox must

be cleaned of soot, creosote,

ashes, and loose paint by a qualified chimney cleaner. Creosote

will ignite if highly heated. A dirty

chimney flue may create and distribute soot within the house. Inspect chimney flue for damage.

MINIMUM FIREBOX SIZES

LOG FRONT BACK

SIZE WIDTH* WIDTH** DEPTH HEIGHT

18" 28" 28" 16" 18"

24" 29 3/4" 29 3/4" 16" 18"

* Add 6" if safety valve/pilot is used

**At depth indicated

BURNER ORIFICE

LOG NATURAL PROPANE/LP

SIZE IN. NUM. IN. NUM.

18" .111 34 .073 49

24" .129 30 .086 44

Figure 2 - Technical Information Charts

4

FUEL INLET PRESSURE

SPECIFICATIONS (W.C.)

Min. Max.

NG 5.5" 10.5"

LP 11" 13"

901915

Page 5

OWNER’S MANUAL

INSTALLATION

Continued

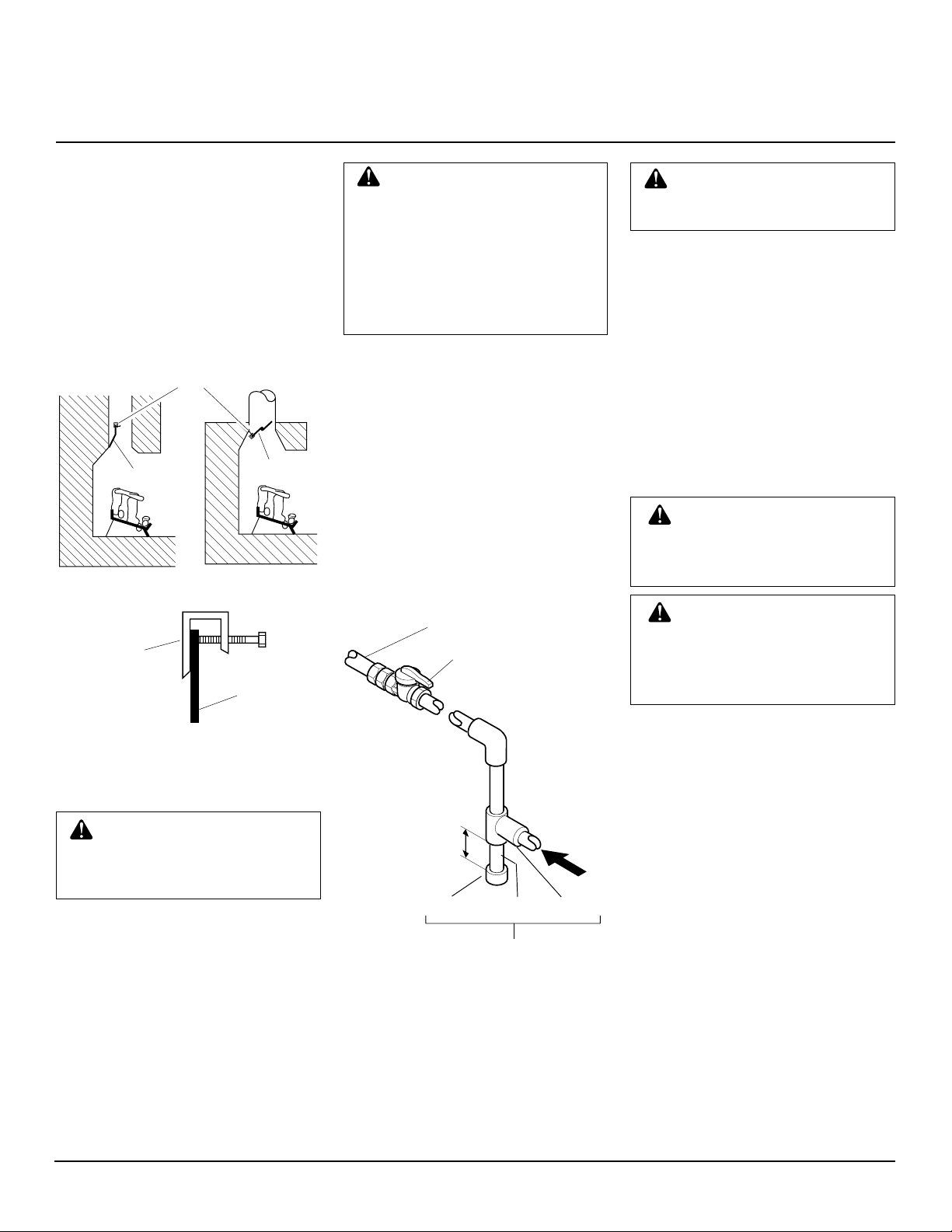

INSTALLING DAMPER

CLAMP

Secure the damper stop clamp provided to

the leading edge of the damper as shown in

Figure 3. If for any reason this clamp doesn't

work on your fireplace, another suitable

clamp or permanent stop must be installed,

or the damper blade must be cut or removed.

Damper Clamp

Damper

Masonry Fireplace

Damper

Clamp

Figure 3 - Attaching Damper Clamp

Manufactured

Fireplace

CONNECTING TO GAS

SUPPLY

WARNING: A qualified service person must connect log set

to gas supply. Follow all local

codes.

Installation Items Needed

Before installing log set, make sure you

have the items listed below.

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve

• test gauge connection

• adjustable (crescent) wrench or pliers

• sediment trap

• tee joint

• pipe wrench

Damper

Damper

CAUTION: Use only new,

black iron or steel pipe. Internally-tinned copper tubing may

be used in certain areas. Check

your local codes. Use pipe of 1/2"

diameter or greater to allow

proper gas volume to log set. If

pipe is too small, undue loss of

pressure will occur.

Installation must include an equipment

shutoff valve, union, and plugged 1/8" NPT

tap. Locate NPT tap within reach for test

gauge hook up. NPT tap must be upstream

from log set (see Figure 4).

IMPORTANT:

Install equipment shutoff

valve in an accessible location. The equipment shutoff valve is for turning on or

shutting off the gas to the appliance.

Apply pipe joint sealant lightly to male

threads. This will prevent excess sealant

from going into pipe. Excess sealant in pipe

could result in a clogged burner injector.

Approved

Gas Hose

CSA Design-Certified

Equipment Shutoff

Valve With 1/8" NPT

Tap*

From Gas

Meter (5"

W.C.** to

10.5" W.C.

3" Minimum

Cap

Pipe Nipple

Sediment Trap

Figure 4 - Gas Connection

Pressure)

Tee Joint

* Purchase the optional CSA design-certified equipment shutoff valve from your

dealer. See Accessories, page 13.

** Minimum inlet pressure for purpose of

input adjustment.

CAUTION: Use pipe joint sealant that is resistant to liquid petroleum (LP) gas.

We recommend that you install a sediment

trap in supply line as shown in Figure 4.

Locate sediment trap where it is within

reach for cleaning. Install in piping system

between fuel supply and heater. Locate sediment trap where trapped matter is not likely

to freeze. A sediment trap traps moisture

and contaminants. This keeps them from

going into log set controls. If sediment trap

is not installed or is installed wrong, log set

may not run properly.

CHECKING GAS

CONNECTIONS

WARNING: Test all gas piping and connections for leaks

after installing or servicing. Correct all leaks at once.

WARNING: Never use an open

flame to check for a leak. Apply a

mixture of liquid soap and water

to all joints. Bubbles forming show

a leak. Correct all leaks at once.

Pressure Testing Gas Supply

Piping System

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance

main gas valve (control valve) and equipment shutoff valv e from gas supply piping system. Pressures in excess of 1/2 psig

will damage heater regulator .

2. Cap off open end of gas pipe where

equipment shutoff valve w as connected.

3. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

4. Check all joints of gas supply piping

system. Apply mixture of liquid soap

and water to gas joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Reconnect log set and equipment

shutoff valve to gas supply. Check reconnected fittings for leaks.

Continued

901915

5

Page 6

VENTED NATURAL GAS LOGS

INSTALLATION

Continued

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Figure 5).

2. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

3. Check all joints from gas meter to equipment shutoff valve (see Figure 5). Apply

mixture of liquid soap and water to gas

joints. Bubbles forming show a leak.

4. Correct all leaks at once.

Equipment Shutoff

Valve

Gas Meter

Figure 5 - Checking Gas Joints

HEARTH KIT ASSEMBLY

AND INSTALLATION

Kit Assembly

1. Unscrew burner inlet fitting from

burner manifold.

2. Place burner manifold in pan with

threaded opening facing open knockout plug (see Figure 6). Make sure the

burner ports face downward.

3. Using thread sealant (resistant to the action of propane/LP gas) on larger end

of fitting, screw the burner inlet fitting

through hole and into burner manifold.

Tighten using a wrench. If using propane/LP gas, follow instructions included in optional GA9050 valve kit

or GA9150 valve kit for installation and

operation.

4. Using thread sealant on the male

threads, install the burner connection

fittings into the 1/8" NPT holes on each

side of the burner manifold.

5. Press the right and left side burners onto

the burner connection fittings. The

burner porting should face downward

(see Figure 6).

Burner

Connection

Fittings

Figure 6 - Installing Burner

Burner Manifold

Side

Burners

Burner Inlet

Fitting

Installation and Gas Connection

1. Place the burner pan assembly in the center of the fireplace floor. Make sure the

inlet end of the pan faces the gas supply .

2. Thread the gas supply fitting to the

fireplace gas supply pipe. Use thread

sealant.

3. Install adapter fitting onto the burner

inlet fitting using thread sealant on

male threads of burner inlet fitting

(see Figure 7). Adjust to most convenient position.

4. Install the gas connector tube to the gas

supply fitting. Carefully shape tube to

attach to adapter fitting. Be careful not

to cause kinks in tube.

5. Using the 1/4" x #8 provided, install

the cover over the inlet fitting.

Gas

Connector

Tube

Burner Pan

Assembly

Adapter Fitting

TESTING BURNER FOR

LEAKS

1. Generously apply soapy solution to all

connections.

WARNING: Never check for

gas leaks with open flame.

2. Light the burner with the shutoff valv e

no more than half open and holding a

match slightly in front of the pan (see

Lighting Instructions, page 7).

3. Inspect all connections for bubbles, raw

gas odor, or flame from any area other

than the burner (leaks). If leaks are detected, shut off the gas valve immediately. Tighten, or reassemble the loose

connection(s) using pipe joint compound until burner system is leak free.

4. When the burner is tested and leak free,

observe the individual tongues of flame

on the burner .

includes more ports on the outside of the

bar. Make sure that all ports are clear

and producing flame evenly across the

burner . If any ports appear blocked, clear

them by removing the burner manifold

and reaming the ports with a modified

paper clip or other suitable tool.

5. When finished testing, turn the gas

shutoff valve OFF to extinguish all

flames.

Note:

The burner design

ADDING PAN MATERIAL

1. Open the bags of ash bed material (vermiculite) and spread it evenly across the

burner pan to the top. You may overflow the front and sides of the pan to

cover the entire pan and connecting

hardware. If using optional GA9050 or

GA9150 valve, do not cover valve with

pan material.

2. Open the glowing embers and evenly

cover the ash bed material (vermiculite) in the burner pan.

Figure 7 - Connecting Gas to Appliance

6

901915

Page 7

OWNER’S MANUAL

INSTALLATION

Continued

INSTALLING THE GRATE

AND LOGS

1. Place the grate over the burner pan. The

grate should “lock” into place over the

corners of the pan (see Figure 8).

2. Place one of the bottom logs on the

grate and slide forward against the front

grate bars. Repeat for other side (see

Figure 9).

5. Place the smaller top logs onto the bottom logs (see Figure 10). Leave as

much open space between logs as possible to minimize flame impingement

and sooting.

they are handled roughly or if hit together while being placed.

Grate

Burner

Pan

Figure 8 - Installing Grate (Pan Material

Not Shown)

Note:

Logs may chip if

OPERATING

APPLIANCE

FOR YOUR SAFETY

READ BEFORE

LIGHTING

WARNING: Keep flue open

when operating unit.

WARNING: If you do not follow these instructions exactly, a

fire or explosion may result causing property damage, personal

injury or loss of life.

BEFORE LIGHTING smell all around

the appliance area for gas. Be sure to

smell next to the floor because some gas is

heavier than air and will settle on the

floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach y our gas supplier,

call the fire department.

GAS SHUTOFF

VALVE OPERATION

Flame Adjustment

Adjust the flame ON/OFF by turning the

gas shutoff valve counterclockwise

to open or clockwise to

close, as necessary.

Shutting Off Appliance

Turn gas shutoff valve clockwise

to the OFF position.

CURING LOGS

During the 2-3 hour appliance break-in

period, you may detect an odor from the

appliance as the various paints and compounds used in the manufacturing of this

log set cure. This is a normal and temporary situation that is not cause for alarm.

However, you may want to provide extra

ventilation to the room during this time.

To ensure proper curing of the logs:

• Ignite a 2" flame and maintain it for 1

hour.

• Burn the logs in consecutive 1 hour periods raising the flame an additional

2" to full flame height for a total of

three hours.

Figure 9 - Placement of Bottom Logs

Figure 10 - Placement of Top Logs

901915

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information,

above.

2. Turn the gas shutoff valve to OFF.

3. Wait f ive (5) minutes to clear out any

gas. If you then smell gas STOP! Follow the safety information above. If

you don‘t smell gas, go on to the next

step.

4. Light a match and lay it on top of

the pan material about 2" from the

end of the supply side of the pan

5. Slowly turn the gas shutoff valve ON

until the burner ignites. If the bur ner

doesn’t ignite within 10 seconds with

the match burning, turn the shutoff

valve OFF and repeat steps 1 through

4 again.

7

CLEANING AND

MAINTENANCE

• Keep the area around the log set clean

and clear of debris.

• Occasionally, you may use a soft bristle

brush to clean logs.

• Once every year a qualified agency or

certified chimney sweep should examine and clean the venting system of the

fireplace.

Page 8

VENTED NATURAL GAS LOGS

TROUBLESHOOTING

Note:

For additional help, visit DESA

International’s technical service web site

at www.desatech.com.

Note:

All troubleshooting items are listed in

order of operation.

WARNING: Turn off log set

and let cool before servicing. Only

a qualified service person should

service and repair log set.

OBSERVED PROBLEM

Log set is smoking/sooting excessively

(

Note:

It is natural and unavoidable for

vented gas log sets to produce moderate

levels of carbon (soot) where flames

contact the logs. This is especially true

with propane/LP gas.)

Burner is excessively noisy

(

Note:

The movement and combustion of

gas will create low, unavoidable levels of

noise.)

Burner flame is too low or too high

POSSIBLE CAUSE REMEDY

1. Poor fuel quality

2. Fireplace venting system not drafting

properly

3. Excessive flame impingement or

blockage

4. Improper fuel/air mixture

5. Excessive gas supply/pressure

1. Passage of air/gas across irregular surfaces

1. Incorrect gas supply or pressure

2. Blocked burner orifice or burner manifold ports

3. Improper burner orifice size

1. Contact local natural or propane/LP gas

company

2. Adjust damper wide open and/or have

fireplace and venting professionally

cleaned and checked

3. Separate the logs to allow more flame

passage

4. Remove any foreign items from the

flame pattern and/or check for proper

orifice sizing

5. Preheat flue in very cold weather

1. Relieve any tight bends or kinks in gas

supply line

1. Check for proper gas supply pressure

2. Free burner orifice and manifold ports

of any burrs, paint, or other blockage

3. Verify proper burner orifice sizing (see

Figure 2, page 4)

www.desatech.com

8

901915

Page 9

TROUBLESHOOTING

Continued

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

OWNER’S MANUAL

IMPORTANT:

Cleaning supplies, paint, paint remover, cigarette smoke, cements and glues, new

carpet or textiles, etc., create fumes. These fumes may mix with combustion air

and create odors. These odors will disappear over time.

OBSERVED PROBLEM

Log Set produces a clicking/ticking noise

just after burner is lit or shut off

Log Set produces unwanted odors

Gas odor even when control knob is in OFF

position

Gas odor during combustion

Operating log set where impurities in air exist may create odors.

POSSIBLE CAUSE

1. Metal expanding while heating or contracting while cooling

1. Log set burning vapors from paint, hair

spray, glues, cleaners, chemicals, new

carpet, etc. (See

ment above)

2. Gas leak. See W arning statement at

top of page

1. Gas leak. See W arning statement at

top of page

2. Control valve defective

1. Gas leak. See W arning statement at

top of page

IMPORTANT

state-

REMEDY

1. This is common with most log sets. If

noise is excessive, contact qualif ied service person

1. Open flue to maximum. Stop using odor

causing products while log set is running

2. Locate and correct all leaks (see Check-

ing Gas Connections, pages 5 and 6)

1. Locate and correct all leaks (see Check-

ing Gas Connections, pages 5 and 6)

2. Replace control valve

2. Locate and correct all leaks (see Check-

ing Gas Connections, pages 5 and 6)

901915

www.desatech.com

9

Page 10

VENTED NATURAL GAS LOGS

3

6

12

10

11

10

4

7

9

5

1

8

2

ILLUSTRATED

PARTS

BREAKDOWN

HFVMR18

HFVMR24

10

901915

Page 11

OWNER’S MANUAL

PARTS LIST

HFVMR18

HFVMR24

This list contains replaceable parts used in your log set. When ordering parts, follow the

instructions listed under Replacement Parts on page 13 of this manual.

KEY PART NUMBER FOR

NO. HFVMR18 HFVMR24 DESCRIPTION QTY.

1 901058-01 901058-01 Brass 3/8 FLR x 1/2 FPT Adapter 1

2 901059-01 901059-01 Brass 3/8 FLR x 3/8 FPT Adapter 1

3 901066-01 901066-01 Brass Air Mixer - Natural Gas 1

4 901064-10 901064-03 Natural Gas Injector 1

5 901763-02 901763-01 Burner Manifold 1

6 901767-02 901767-01 Burner Pan 1

7 901242-01 901242-01 Damper Clamp - Std. Assembly 1

8 901232-01 901232-01 Gas Line - 10" Flex 1

9 901800-01 901757-01 Log Grate 1

10 901060-01 901060-01 Burner Connection Fitting 2

11 901765-03 901765-01 Right Side Burner 1

12 901765-04 901765-02 Left Side Burner 1

PARTS AVAILABLE — NOT SHOWN

901156-01 901156-01 .125# Bag Embers 1

901155-01 – 1.5# Bag Ash Bed Material

– (Vermiculite) 1

901155-01 901155-01 1.5# Bag Ash Bed Material

(Vermiculite) 2

901036-01 901036-01 Aluminum Rating Plate-Generic 1

901915

11

Page 12

VENTED NATURAL GAS LOGS

ILLUSTRATED

PARTS

BREAKDOWN

LOG SET

This list contains replaceable parts used in your log set. When ordering parts, follow the

instructions listed under Replacement Parts on page 13 of this manual.

KEY PART NUMBER FOR

NO. 18" 24" DESCRIPTION QTY.

1 901656-01 901657-01 Bottom Front 1 2

2 901666-01 901667-01 Bottom Front 2 2

3 901619-01 901619-01 FS-12Y Top Log 1

4 901617-01 901617-01 FS-16 Top Log 1

5 901612-01 901612-01 FS-17 Top Log 1

6 901620-02 901620-02 FR12L Top Log 1

7 — 901614-01 FS15 Top Log 1

7

6

3

2

Manchester Split Oak Logs

5

4

1

12

901915

Page 13

OWNER’S MANUAL

REPLACEMENT

PARTS

Note:

Use only original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product or

Parts Dealers (page 14) . If they can’t supply

original replacement part(s), call DESA

International’s Technical Service Department

at 1-800-DESA LOG (1-800-337-2564).

When calling DESA International, have

ready

• your name

• your address

• model and serial numbers of your log set

• how log set was malfunctioning

• type of gas used (propane/LP or natural gas)

• purchase date

Usually, we will ask you to return the defec-

tive part to the factory.

PARTS NOT UNDER

WARRANTY

Contact authorized dealers of this product

or Parts Dealers on page 14. When calling,

have ready

• model number of your log set

• the replacement part number

ACCESSORIES

Contact authorized dealers of this product

or Parts Dealers on page 14.

RECEIVER AND HANDHELD REMOTE CONTROL

KIT - CGHRC Series

For all models. Allows the gas log set to be

turned on and off by using a hand-held

remote control. Valve/Pilot Kit GA9150-1

must be used with this remote.

WALL-MOUNT ON/OFF

SWITCH - GWMS2

(Not Shown)

For all models. Allows the gas log set to be

turned on and off with a wall switch when

used with GA9150.

ON/OFF SAFETY VALVE/

PILOT KIT - GA9050-1

(Not Shown)

For all models. Required for propane/LP

installation.

REMOTE READY VALVE/

PILOT KIT - GA9150-1

(Not Shown)

For all models.

INDIVIDUAL ROUND LOG

GA9450

(Not Shown)

For all models. Use when more logs are

desired. Carton of 6

INDIVIDUAL SPLIT LOG

GA9550

(Not Shown)

For all models. Carton of 6.

ASH BED MATERIAL

(Vermiculite) - GA9750

(Not Shown)

For all models. Carton of 6.

GLOWING EMBERS - GA9950

(Not Shown)

For all models. Use for firebox decoration

ßnly.

SILICA SAND - GA9850

(Not Shown)

For all models. Use for firebox decoration

only. Carton of 6.

LAVA ROCK - GA6067

(Not Shown)

For all models. Use for firebox decoration

only.

DECORATIVE ASH BED

CONTROL COVER - CDABK

(Not Shown)

An attractive way to cover control knob

and piezo ignitor.

18" ORNAMENTAL GRATE

ENHANCER - GA9350

(Not Shown)

For 18" models only. Additional decoration

for front grate.

24" ORNAMENTAL GRATE

ENHANCER - GA9360

(Not Shown)

For 24" models only. Additional decoration

for front grate.

EQUIPMENT SHUTOFF

VALVE - GA5010

For all models. Equipment shutoff valve with

1/8" NPT tap. Fits 1/2" NPT pipe.

901915

PINE CONES - GA9650

(Not Shown)

For all models. Use for additional decoration only. Carton of 6 Boxes (3 pine cones

per box).

13

Page 14

VENTED NATURAL GAS LOGS

PARTS DEALERS

Baltimore Electric

1348 Dixwell Avenue

Hamden, CT 06514-0322

1-800-397-7553

203-248-7553

Parts Department

Portable Heater Parts

342 N. County Rd. 400 East

Valparaiso, IN 46383-9704

All States

219-462-7441

1-800-362-6951

sales@portableheaterparts.com

techservice@portableheaterparts.com

FBD

1349 Adams Street

Bowling Green, KY 42103-3414

270-846-1199

1-800-654-8534

Fax: 1-800-846-0090

franktalk@aol.com

Master Parts Dist.

1251 Mound Ave NW

Grand Rapids, MI 49504-2672

616-791-0505

1-800-446-1446

Fax: 616-791-8270

www.nbmc.com

These Parts Dealers are privately-owned businesses. They have agreed to support our

customer’s needs by providing original replacement parts and accessories.

Washer Equipment Co.

1715 Main Street

Kansas City, MO 64108-2195

KS, MO, AR

816-842-3911

www.washerparts.com

Laporte’s Parts & Service

2444 N. 5th Street

Hartsville, SC 29550-7704

803-332-0191

Parts Department

Cans Unlimited, Inc.

East Coast Energy Products

707 Broadway

W. Long Branch, NJ 07764-1542

732-870-8809

1-800-755-8809

www.njplaza.com/ecep

P.O. Box 645

Taylor, SC 29687-0013

All States

803-879-3009

1-800-845-5301

cuisales@aol.com

Dayton Hardware

P.O. Box 275

North Dayton Station

Dayton, OH 45404-0275

All States

937-258-3721

OH 1-800-762-3426

Halco Enterprises

208 Carter Drive, Unit 21

West Chester, PA 19382-4500

610-430-7717

1-800-368-0803

www.halcoenterprises.com

14

901915

Page 15

OWNER’S MANUAL

NOTES

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

901915

15

Page 16

WARRANTY INFORMATION

KEEP THIS WARRANTY

Model

Serial No.

Date Purchased

Always specify model and serial numbers when communicating with the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written

warranty. We make no other warranty, expressed or implied.

LIMITED WARRANTY

COMFORT GLOW VENTED GAS LOGS

DESA International warrants this product to be free from defects on burner system for three (3) years and logs for a lifetime from

the date of first purchase, provided that the product has been properly installed, operated and maintained in accordance with all

applicable instructions. To make a claim under this warranty the Bill of Sale or cancelled check must be presented.

This warranty is extended only to the original retail purchaser. This warranty covers the cost of part(s) required to restore this log set

to proper operating condition and an allowance for labor when provided by a DESA International Authorized Service Center. Warranty

part(s) MUST be obtained through authorized dealers of this product and/or DESA International who will provide original factory

replacement parts. Failure to use original factory replacement parts voids this warranty. The log set MUST be installed by a qualified

installer in accordance with all local codes and instructions furnished with the unit.

This warranty does not apply to parts that are not in original condition because of normal wear and tear, or parts that fail or become

damaged as a result of misuse, accidents, lack of proper maintenance or defects caused by improper installation. Travel, diagnostic cost,

labor, transportation and any and all such other costs related to repairing a defective log set will be the responsibility of the owner.

TO THE FULL EXTENT ALLOWED BY THE LAW OF THE JURISDICTION THAT GOVERNS THE SALE OF THE PRODUCT;

THIS EXPRESS WARRANTY EXCLUDES ANY AND ALL OTHER EXPRESSED WARRANTIES AND LIMITS THE DURATION OF ANY AND ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE TO THREE (3) YEARS ON BURNER SYSTEM AND A LIFETIME ON LOGS FROM THE

DATE OF FIRST PURCHASE; AND DESA INTERNATIONAL’S LIABILITY IS HEREBY LIMITED TO THE PURCHASE

PRICE OF THE PRODUCT AND DESA INTERNATIONAL SHALL NOT BE LIABLE FOR ANY OTHER DAMAGES

WHATSOEVER INCLUDING INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow a limitation on how long an implied warranty lasts or an exclusion or limitation of incidental or consequential

damages, so the above limitation on implied warranties, or exclusion or limitation on damages may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights that vary from state to state.

For information about this warranty write:

INTERNATIONAL

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

www.desatech.com

901915 01

NOT A UPC

901915-01

Rev. A

12/00

Loading...

Loading...