Dent-X Endos AC-ACP Service manual

ENDOS AC / ACP  0051

0051

(120V version)

Service Manual

Release 17 July 2013 (Rev. 7)

SERVICE MANUAL

Revision history

Revision history Manual code 6961902103

Rev. |

Date |

Page/s |

Modification description |

|

|

|

|

0 |

02.04.03 |

- |

Document approval. |

|

|

|

|

1 |

25.09.03 |

All |

Remote timer version release. |

|

|

|

ETL certification. |

|

|

|

Spare Parts update. |

|

|

|

(Ref. RDM 5641, RDM 5644) |

|

|

|

|

2 |

10.11.03 |

7, 8 |

Addition of "X-MIND" identification on main label. |

|

|

|

(Ref. RDM 5693) |

|

|

|

|

3 |

26.03.04 |

8 |

Notify body change for CE mark. |

|

|

|

(Ref. RDM 5781) |

|

|

|

|

4 |

15.03.05 |

8, 18, 72, 73 |

Editorial correction on Enabling/Disabling the |

|

|

|

"Ready" key. |

|

|

|

Modified the DP arm label. |

|

|

|

(Ref. RDM 5938, RDM 6052) |

|

|

|

|

5 |

10.01.06 |

28 |

Dose linearity reference measurement time updated. |

|

|

|

(Ref. RDM 6164) |

|

|

|

|

6 |

13.07.07 |

30, 31, 45, |

Removed optional chemical screws. |

|

|

104, 108, 110 |

Added NOTE with indication that the device is |

|

|

|

supplied as unit to be installed permanently |

|

|

|

(EN60601-1 – paragraph 19). |

|

|

|

Spare Parts update. |

|

|

|

(Ref. RDM 6568, RDM 6620) |

|

|

|

|

7 |

17.07.13 |

6, 8, 31, 34, |

New scissor arm assembling procedure. |

|

|

from 39 to 43, |

Added note on spacer insertion during stand arm set |

|

|

58, 59, 96, |

assembling. |

|

|

98, 100 |

Identification label update. |

|

|

|

Mains plug on mobile stand version no more |

|

|

|

supplied. |

|

|

|

Schematics and drawing update. |

|

|

|

Spare Parts update. |

|

|

|

(Ref. RDM 7302, RDM 7532, RDM 7710, RDM 7723, RDM 7763, |

|

|

|

RDM 7797) |

|

|

|

|

(Rev. 7) |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Revision history

THIS PAGE IS INTENTIONALLY LEFT BLANK

ENDOS AC/ACP (120V) |

(Rev. 7) |

SERVICE MANUAL

Contents

|

|

|

Contents |

|

1. |

INTRODUCTION |

1 |

||

|

1.1 |

Icons in the manual................................................................................ |

1 |

|

2. |

SAFETY ASPECTS |

2 |

||

|

2.1 |

Warnings................................................................................................ |

3 |

|

|

2.2 |

Protection from X-rays............................................................................ |

4 |

|

|

2.3 |

Environmental risks and disposal .......................................................... |

5 |

|

|

2.4 |

Symbols in use ....................................................................................... |

6 |

|

3. |

DESCRIPTION |

7 |

||

|

3.1 |

Identification labels ................................................................................ |

7 |

|

|

3.2 |

Functions, Models and Versions............................................................. |

9 |

|

|

|

3.2.1 Extension arm and scissors arm.......................................................... |

9 |

|

|

|

3.2.2 |

Tubehead............................................................................................ |

9 |

|

|

3.2.3 |

Timer................................................................................................ |

10 |

|

3.3 |

Configurations...................................................................................... |

11 |

|

|

|

3.3.1 |

Standard configuration...................................................................... |

11 |

|

|

3.3.2 |

Remote timer configuration ............................................................... |

12 |

|

|

3.3.3 |

Mobile stand configuration ................................................................ |

13 |

|

|

3.3.4 Remote X-ray button configuration .................................................... |

14 |

|

4. |

TECHNICAL DATA |

15 |

||

|

4.1 |

Method for correcting exposure times................................................... |

18 |

|

|

4.2 |

Method for measuring technical factors................................................ |

20 |

|

|

4.3 |

Correct use of dosimeters to measure exposure times .......................... |

21 |

|

|

4.4 |

Curves tube features ............................................................................ |

23 |

|

|

4.5 |

Reference standard............................................................................... |

27 |

|

|

4.6 |

Overall dimensions............................................................................... |

29 |

|

5. |

PRE-INSTALLATION |

30 |

||

|

5.1 |

Mounting methods ............................................................................... |

30 |

|

|

5.2 |

Electric pre-setting ............................................................................... |

31 |

|

6. |

INSTALLATION |

32 |

||

|

6.1 |

Wall installation ................................................................................... |

32 |

|

|

|

6.1.1 Timer set up (standard configuration) ................................................ |

33 |

|

|

|

6.1.2 Wall support set-up (Remote Timer configuration) .............................. |

35 |

|

|

|

6.1.3 Timer set up (Remote Timer configuration)......................................... |

36 |

|

|

|

6.1.4 Assembling the mobile stand and timer installation............................ |

37 |

|

|

|

6.1.5 |

X-ray button ..................................................................................... |

38 |

|

6.2 |

Assembling the scissors arm ................................................................ |

39 |

|

|

|

6.2.1 Assembling the scissors arm (DP arm) ............................................... |

39 |

|

|

|

6.2.2 Assembling the stand arms set .......................................................... |

43 |

|

|

|

|

|

|

(Rev. 7) |

i |

ENDOS AC/ACP (120V) |

|

|

|

SERVICE MANUAL |

|

|

|

|

|

Contents |

|

6.3 |

Tubehead assembly .............................................................................. |

44 |

|

|

6.4 |

Installation of the optional parts........................................................... |

45 |

|

|

|

6.4.1 |

Counterplate..................................................................................... |

45 |

|

|

6.4.2 |

Remote X-ray button......................................................................... |

46 |

|

|

6.4.3 Installation of chemical screws .......................................................... |

47 |

|

|

6.5 |

Electrical connection ............................................................................ |

48 |

|

|

|

6.5.1 Electrical connection for standard versions........................................ |

49 |

|

|

|

6.5.2 Electrical connection for versions equipped with Remote Timer .......... |

50 |

|

|

6.6 |

Final working tests ............................................................................... |

51 |

|

|

|

6.6.1 |

"ENDOS ACP" timer .......................................................................... |

51 |

|

|

6.6.2 |

"ENDOS AC" timer ............................................................................ |

54 |

7. |

MAINTENANCE |

56 |

||

|

7.1 |

Generalities .......................................................................................... |

56 |

|

|

7.2 |

Arm adjustment.................................................................................... |

57 |

|

|

|

7.2.1 Adjusting the extension arm support frictioning mechanism .............. |

58 |

|

|

|

7.2.2 Adjusting the extension arm frictioning mechanism ........................... |

59 |

|

|

|

7.2.3 Adjusting the balance scissors arm.................................................... |

60 |

|

8. |

SET-UP |

|

62 |

|

|

8.1 |

Display and modification of parameters................................................ |

66 |

|

9. |

ERROR MESSAGES AND TROUBLESHOOTING |

76 |

||

|

9.1 |

Functional messages ............................................................................ |

77 |

|

|

9.2 |

Errors during start-up phase................................................................ |

80 |

|

|

9.3 |

Errors that can be reset during the start-up phase............................... |

82 |

|

|

9.4 |

Errors during X-ray exposure ............................................................... |

83 |

|

|

9.5 |

Faults not signalled .............................................................................. |

84 |

|

|

|

9.5.1 The timer does not work.................................................................... |

84 |

|

10. |

REPLACING PARTS |

87 |

||

|

10.1 |

Replacing the tubehead ........................................................................ |

87 |

|

|

10.2 |

Replacement timer boards .................................................................... |

88 |

|

|

10.3 |

Replacing the keyboard ........................................................................ |

88 |

|

|

10.4 |

Replacing the scissors arm ................................................................... |

88 |

|

11. |

SCHEMATICS AND DRAWINGS |

89 |

||

12. |

SPARE PARTS |

97 |

||

13. |

FIXING TEMPLATES |

109 |

||

This publication can only be reproduced, transmitted, transcribed or translated into any human or computer language with the written consent of Manufacturer.

This Manual in English is the original version.

ENDOS AC/ACP (120V) |

ii |

(Rev. 7) |

SERVICE MANUAL

Introduction

1.INTRODUCTION

NOTE:

This manual is updated to the product status it is sold with, to guarantee the user an adequate reference for equipment use and any aspect connected with use safety. The manual may not reflect any product variation without impact on operating procedures and use safety.

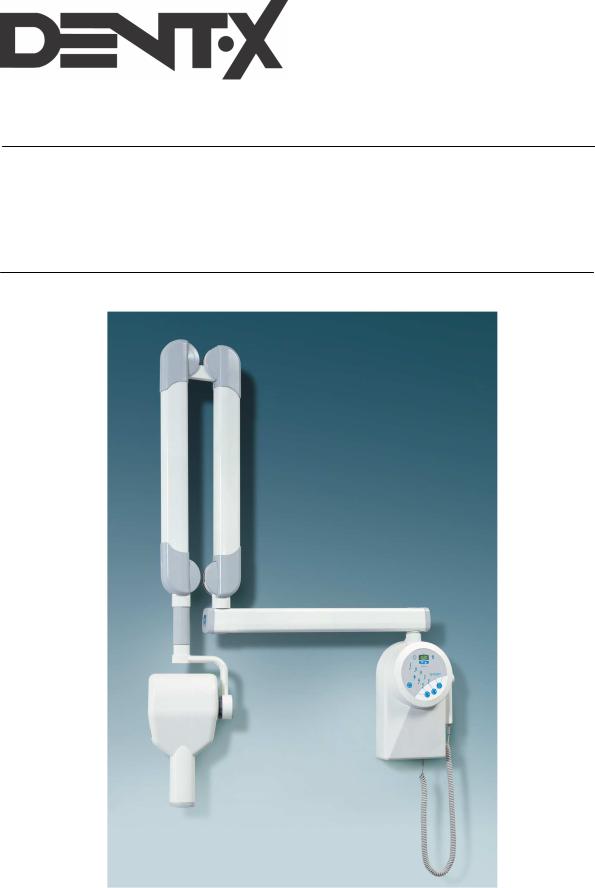

The intraoral radiographic ENDOS AC/ACP, produces high quality intraoral X-rays, thanks to reduced exposure times and the small dimensions of the focal spot.

ENDOS AC/ACP is exclusively intended for the execution of intraoral X-rays.

The equipment has the following features:

∙Very good quality X-rays pictures

∙user friendly

∙ergonomic design.

The equipment is controlled by a microprocessor that makes it possible to reproduce exposure times and is composed of the following parts:

∙Timer: ENDOS AC or ENDOS ACP equipped with wall plate

∙Extension arm (30 cm, 60 cm or 80 cm for wall version)

∙Scissors arm (DP)

∙Tubehead 70 kV 8 mA – X-ray tube with grid.

The purpose of this manual is to provide the user with instructions that will allow him to run the equipment safely and efficiently.

The equipment must be used according to the procedures in the manual and never for different purposes from the ones for which it has been designed.

1.1Icons in the manual

|

Indicates a “NOTE”; we recommend particular attention in reading the |

subjects identified with this icon. |

Indicates a “WARNING”; subjects identified with this icon concern safety aspects regarding the patient and/or the operator.

(Rev. 7) |

1 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Safety aspects

2.SAFETY ASPECTS

WARNING:

Read this chapter very carefully.

Villa Sistemi Medicali designs and makes their equipment according to safety requirements; moreover, they supply all necessary information for appropriate use and warnings relating to dangers connected with X-ray generators.

The manufacturer does not accept any responsibility for:

∙Use of ENDOS AC/ACP equipment for purposes other than those for which it has been designed,

∙damages to the equipment, the operator, the patient caused both by wrong installations and maintenance that do not follow the procedures contained in the user manuals and the installation provided with the equipment, and by wrong operating techniques,

∙mechanical and / or electrical changes , made during and after installation, that differ from the ones in the Service Manual.

Only personnel authorised by the Manufacturer may carry out technical work on the equipment.

Only authorised personnel can remove the tubehead from its support and/or gain access to live parts.

ENDOS AC/ACP (120V) |

2 |

(Rev. 7) |

SERVICE MANUAL

Safety aspects

2.1Warnings

The equipment must be used according to the procedures in this manual and never for different purposes from the ones for which it has been designed.

Before carrying out any maintenance disconnect the equipment from the power line using the circuit breaker provided.

The utmost attention must be paid during the installation and calibration phase with the equipment connected to the line, since components directly supplied by the input line are accessible.

ENDOS AC/ACP is an electro-medical device and for this reason can be used only under the supervision of highly qualified medical staff in possession of all the necessary knowledge about X-ray protection.

The user is responsible for fulfilling all the legal requirements connected with the possession, installation and use of the equipment itself.

ENDOS AC/ACP is built for continuous running with intermittent load; for this reason the planned duty cycle must be observed.

Although the equipment is designed to provide a reasonable degree of protection from electromagnetic interference, according to IEC International regulations, it must be installed at an adequate distance from electricity transformer rooms, static continuity units, from two-way amateur radios and cellular phones. The latter can be used only at a minimum distance of 1.5m from any part of the equipment.

Any instrumentation or equipment for professional use located near ENDOS AC/ACP must conform to Electromagnetic Compatibility regulations. Non conforming equipment, with known poor immunity to electromagnetic fields, must be installed at a distance of at least 3m from ENDOS AC/ACP and supplied by a dedicated electric line.

ENDOS AC/ACP must be turned off when using electro-cautery or similar equipment in the vicinity of the equipment itself.

The equipment is not designed to be used in the presence of anaesthetic mixtures inflammable with air, oxygen or nitrous oxide.

WARNING:

For safety reasons, it is forbidden to overload the extension arm or the scissors arm in an anomalous way, for instance by leaning on it.

(Rev. 7) |

3 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Safety aspects

2.2Protection from X-rays

Although dosage given by modern X-ray equipment is low on average, during the execution of the exposure, the operator must take all precautions to protect the patient and himself in compliance with the regulations in force.

WARNING:

Protection from X-ray radiation is regulated by law. The equipment must be used by specialised personnel only.

a)The film (or the digital sensor) must be put into the patient’s mouth manually or using the appropriate supports. If possible it must be held by the patient himself.

b)During X-ray exposure, the operator must not come into contact with the tubehead or the collimator cone.

c)During exposure, the operator must be at a certain distance from the X-ray source (at least 2 metres), in the opposite direction to X-ray beam.

d)During exposure, the operator and the patient are the only people allowed in the room.

e)The lead aprons should be used to reduce the undesirable effect of secondary radiation on the patient.

ENDOS AC/ACP (120V) |

4 |

(Rev. 7) |

SERVICE MANUAL

Safety aspects

2.3Environmental risks and disposal

Some parts of the equipment contain material and fluids which must be disposed of in special areas designated by the local health authorities at the end of the equipment’s life cycle.

In particular the equipment contains the following materials and / or components:

∙Tubehead: hard plastic materials, metal materials, glass, dielectric oil, lead, tungsten

∙Other parts of the equipment: hard plastic materials, metal materials, printed circuits, iron-plastic materials.

(Rev. 7) |

5 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Safety aspects

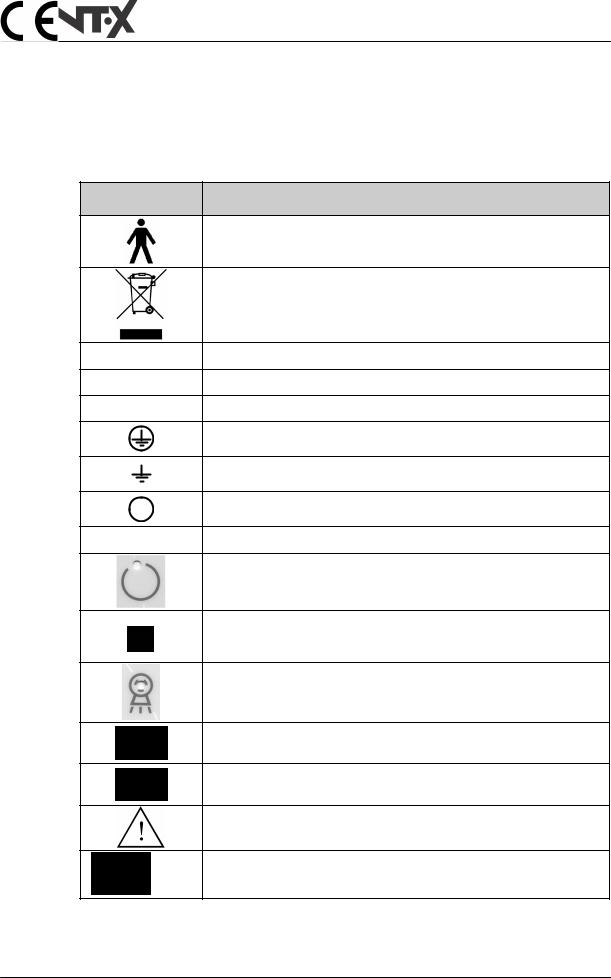

2.4Symbols in use

The following symbols are used in this manual and in ENDOS AC/ACP, besides the symbols on the keyboard (see chapter 6 of User's Manual):

Symbol Description

Equipment with applied parts Type B

A number of machine parts contain materials and liquids that upon completion of the machine’s life cycle must be disposed of at recovery centers established by the local health units

~Alternate current

NConnecting point to neutral conductor

LConnecting point to live conductor

Protection ground

Functional ground

OFF ; equipment not connected to electricity line

½ON ; equipment connected to electricity line

Permission key to exposure; the permitted exposure status is displayed by switching on the corresponding green symbol

Focal spot according to IEC 336

X-ray emission

Product identification code

Serial number

Warning: see the accompanying documentation

Conformity to the EC 93/42 Directive and subsequent 0051 amendments and additions

ENDOS AC/ACP (120V) |

6 |

(Rev. 7) |

SERVICE MANUAL

Description

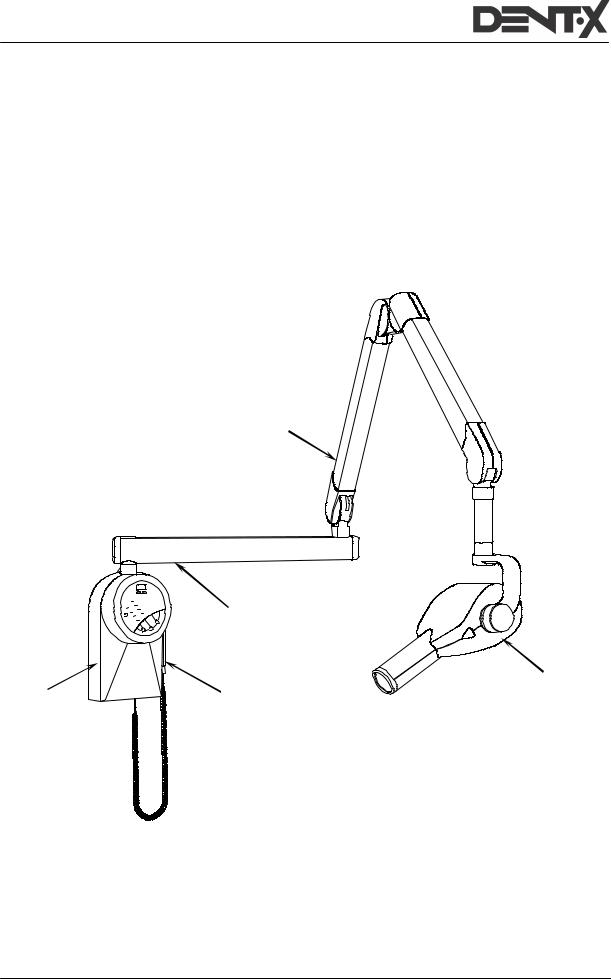

3.DESCRIPTION

3.1Identification labels

4

|

5 |

|

3 |

1 |

2 |

(Rev. 7) |

7 |

ENDOS AC/ACP (120V) |

|

|

|

SERVICE MANUAL |

|

|

|

|

|

Description |

|

1a |

|

1b |

|

|

ENDOS AC/ACP |

|

ETL certification |

|

|

label |

|

label |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

WARNING label

|

|

|

|

|

3a |

|

|

3b |

|

Tubehead label |

|

Tubehead label |

||

(X-ray tube type CEI) |

|

(X-ray tube type KAILONG) |

||

|

|

|

|

|

|

|

|

|

|

|

4 |

5 |

|

6 |

|

|

|

DP arm label |

Extension arm label |

Collimator 30 cm (optional) label |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENDOS AC/ACP (120V) |

8 |

(Rev. 7) |

SERVICE MANUAL

Description

3.2Functions, Models and Versions

ENDOS AC/ACP intraoral radiographic equipment is composed of the following parts:

3.2.1Extension arm and scissors arm

It is composed of a double articulated joint arm, enabling extension horizontally and vertically. The tubehead is balanced in all positions.

NOTE:

The scissors arm is designed to work correctly at a max. angle of 160°; so its use requires a flare angle of less than 160°.

Moreover, a horizontal extension arm can be added, available in various sizes, to meet all requirements.

3.2.2Tubehead

The 70 kVp voltage, the 8 mA current and the use of a tube with grid reduce exposure times and the quantities of X-rays absorbed by the patient. The radiogenic equipment is provided with a collimator with 20 cm focus skin distance and a 6 cm X-ray emission diameter at the exit of the cone. The tubehead is connected to the arm by a guide, which allows 360° horizontal rotation and 290° vertical rotation.

Two alternate X-ray tubes can be used: both have the same characteristics and provide the same performance.

The tubehead, assembled with different X-ray tubes, are interchangeable so long as pre-heating time is set to the proper value indicated on the tubehead label (see chapter 8).

(Rev. 7) |

9 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Description

3.2.3Timer

The name of ENDOS AC/ACP depends on the type of timer in use:

∙ENDOS ACP

ENDOS ACP is a digital timer with microprocessor where exposure times can be selected both manually and automatically.

With automatic selection there is a choice of 30 pre-set times depending on the patient’s size (small, medium or large) and the type of tooth and acquisition mode (film, digital).

There are 33 fixed manual selection times that vary from a minimum of 0.02 seconds to a maximum of 3.20 seconds.

The main feature of this timer is that it has an automatic exposure time compensation for drift of nominal voltage within ± 10%.

∙ENDOS AC

ENDOS AC has the same features as the ENDOS ACP timer, excluding automatic and digital anatomic selection.

It has manual exposure time selection only.

NOTE:

A remote X-ray button configuration can be made, outside the exam room. This can be a pure door bell X-ray button or a device which also show status of the unit ("Ready" and "Exposure in progress").

ENDOS AC/ACP (120V) |

10 |

(Rev. 7) |

SERVICE MANUAL

Description

3.3Configurations

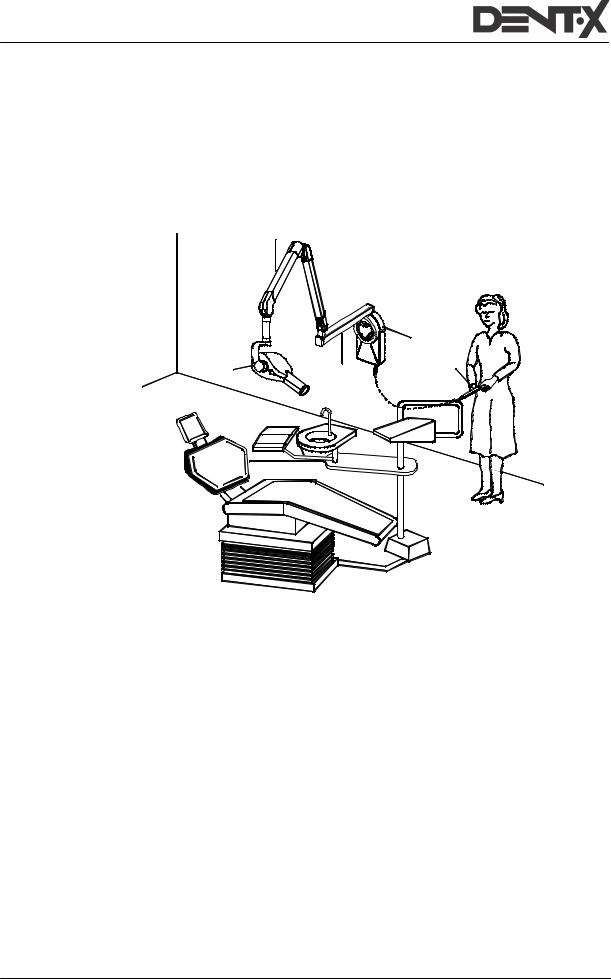

3.3.1Standard configuration

2

|

4 |

|

1 |

5 |

|

3 |

||

|

Figure 3-1

1Tubehead

2Scissors arm

3Extension arm

4Timer

5X-ray button

(Rev. 7) |

11 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Description

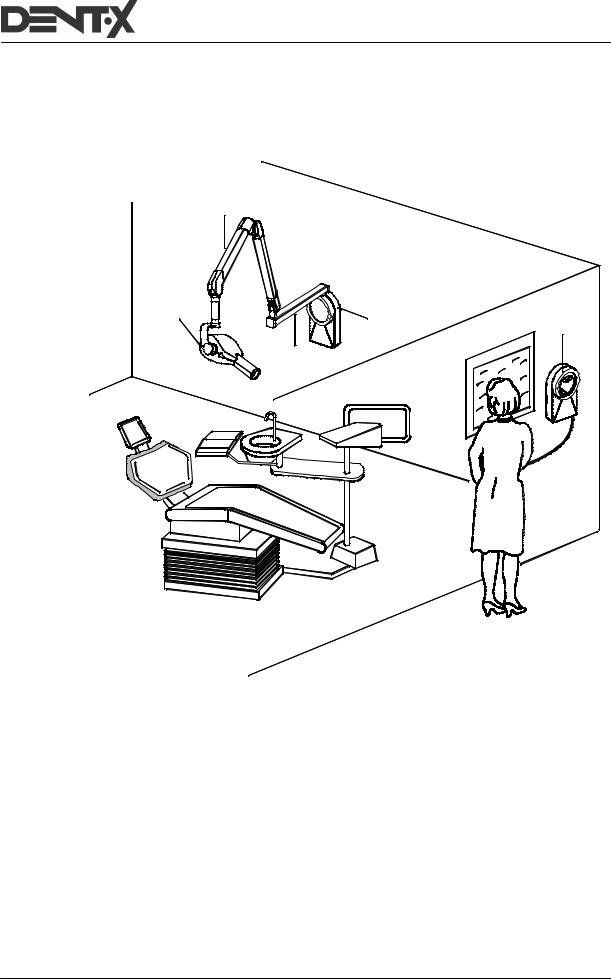

3.3.2Remote timer configuration

2

1 |

4 |

5 |

|

||

|

3 |

|

6

6

Figure 3-2

1Tubehead

2Scissors arm

3Extension arm

4Wall support (kit code 8161301002)

5Remote timer

6X-ray button

ENDOS AC/ACP (120V) |

12 |

(Rev. 7) |

SERVICE MANUAL

Description

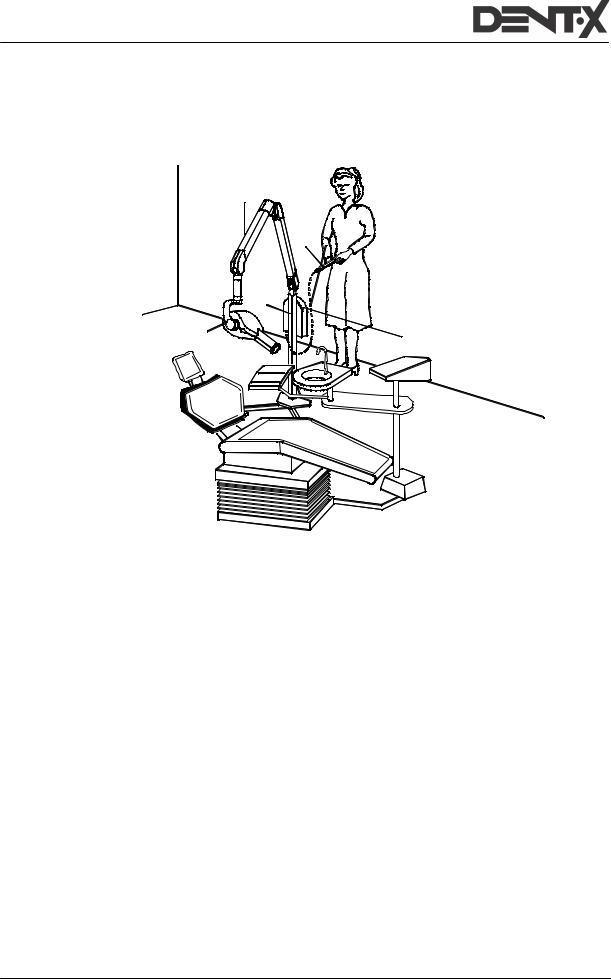

3.3.3Mobile stand configuration

|

2 |

|

5 |

|

3 |

1 |

4 |

|

Figure 3-3

1 Tubehead

2 Scissors arm

3 Mobile stand

4 Timer

5 X-ray button

(Rev. 7) |

13 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Description

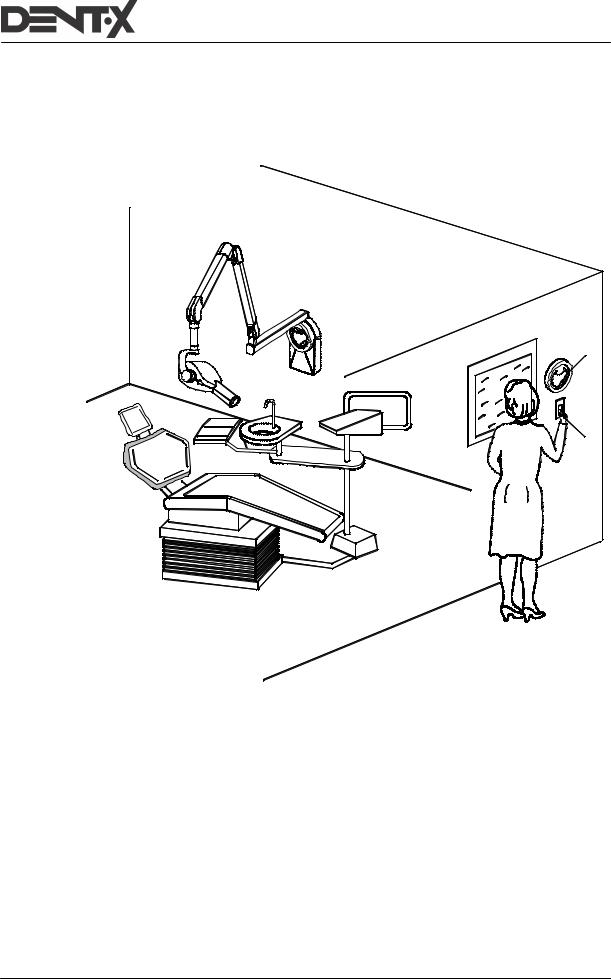

3.3.4Remote X-ray button configuration

2

1

Figure 3-4

Alternative 1:

1X-ray button (not supplied)

Alternative 2:

2X-ray button + light signalling of "Ready" or "Exposure in progress" (supplied as kit P/N 6661309500)

ENDOS AC/ACP (120V) |

14 |

(Rev. 7) |

SERVICE MANUAL

Technical data

4.TECHNICAL DATA

Technical features

Equipment |

ENDOS AC/ACP |

|

|

Manufacturer |

VILLA SISTEMI MEDICALI |

|

Via delle Azalee 3 |

|

20090 Buccinasco (MI) - ITALY |

|

|

Class |

Class I° with type B applied parts |

|

|

|

(EN 60601-1 classification) |

|

|

Protection level |

Standard Apparatus IP20 |

|

|

Line voltage |

120 V ± 10% |

|

|

Line frequency |

60 Hz |

|

|

Max absorbed current |

7.8 A rms impulsive @ 132 V |

|

|

Power consumption |

920 VA impulsive @ 120 V |

|

|

Line voltage regulation |

< 3 % |

|

|

Main fuse |

10 AF |

|

|

Pre-set exposure times |

from 0.02 to 3.2 s in 33 steps |

|

|

Automatic selection |

30 pre-set times |

(only for ENDOS ACP) |

|

|

|

Exposure time accuracy of corrected |

± 10% or ± 32 ms |

time (*) (see paragraph 4.1) |

(whichever is greater - see note |

|

paragraph 4.5) |

|

|

Pre-selected exposure time accuracy |

The absolute maximum deviation can be |

(this is the value of timer setting |

–100% +150% when line voltage changes |

pre-selected by the operator) |

within rated voltage range: it includes |

|

inaccuracy and correction due to line |

|

voltage changes (see paragraph 4.1) |

|

|

Circuit type |

Single phase self-rectifying with grid |

|

control |

|

|

kV selection (high voltage value) |

70 kVp |

|

|

Tubehead current |

8 mA |

|

|

KV accuracy |

± 15 % |

|

|

Tubehead (anode) current accuracy |

± 2 mA |

|

|

Max. exposure time |

3.2 s |

|

|

Timer dimension |

345×195×100 mm |

|

|

(*)This is the actual exposure time, pre-indicated on the timer during the enabled status and during exposure and determined by the internal algorithm as a function of line voltage.

(Rev. 7) |

15 |

ENDOS AC/ACP (120V) |

|

|

|

SERVICE MANUAL |

|

|

|

|

Technical data |

|

|

|

|

|

|

|

Tubehead features |

|

|

|

|

|

|

|

|

|

Manufacturer |

VILLA SISTEMI MEDICALI |

||

|

|

Buccinasco (MI) |

|

|

|

|

|

|

|

|

Rated voltage |

70 kVp |

|

|

|

|

|

|

|

|

Tubehead power |

430 W |

|

|

|

|

|

|

|

|

Pre-heating time |

100 ms |

|

|

|

|

|

|

|

|

Total filtration |

³ 2 mm Al eq. @ 70 kV |

||

|

|

|

|

|

|

HVL (Half Value Layer) |

> 1.5 mm Al eq. |

|

|

|

|

|

|

|

|

Transformer insulation |

Oil bath |

|

|

|

|

|

|

|

|

Interval between exposures / |

32 times X–ray time / |

||

|

duty cycle |

1 : 32 |

|

|

|

|

|

|

|

|

Focal spot |

0.8 (IEC 336) |

|

|

|

|

|

|

|

|

Minimum focus to skin distance |

20 cm (optional 30 cm cone) |

||

|

|

|

|

|

|

X-ray beam diameter (@ 20cm focus) |

£ 6 cm (optional 35x45 mm) |

||

|

|

|

|

|

|

Cooling |

Convection |

|

|

|

|

|

|

|

|

Radiation leakage at 1 m |

< 0.1 mGy/h |

|

|

|

|

|

|

|

|

Technical factors for radiation leakage |

70 kV, 8 mA, 1 s duty cycle |

||

|

|

1 exposure each 32 seconds |

||

|

|

|

|

|

|

X-ray tube features |

|

|

|

|

|

|

|

|

|

Manufacturer |

CEI Bologna |

KAILONG Electronic |

|

|

|

(Italy) |

(China) |

|

|

|

|

|

|

|

Type |

OCX/ 70-G |

KL16 - 0.8 - 70G |

|

|

|

with grid |

|

|

|

|

|

|

|

|

Inherent filtration |

0.5 mm Al |

0.4 mm Al |

|

|

|

equivalent to 70 kV |

equivalent to 70 kV |

|

|

|

|

|

|

|

Anode tilt |

19° |

19° |

|

|

|

|

|

|

|

Anode material |

Tungsten |

Tungsten |

|

|

|

|

|

|

|

Rated voltage |

70 kV |

70 kV |

|

|

|

|

|

|

|

Maximum filament current |

2.8 A |

2.8 A |

|

|

|

|

|

|

|

Maximum filament voltage |

4 V |

4.1 V |

|

|

|

|

|

|

|

Anode thermal capacity |

6 kJ |

7 kJ |

|

|

|

|

|

|

ENDOS AC/ACP (120V) |

16 |

(Rev. 7) |

SERVICE MANUAL

Technical data

Environmental conditions

Operating temperature range |

+10°C ÷ +40°C |

|

|

Operating relative humidity range |

30% ÷ 75% |

|

|

Temperature range for transport and |

-20°C ÷ +70°C |

storage |

|

|

|

Max. relative humidity for transport and |

<95 % non condensing |

storage |

|

|

|

Min. atmospheric pressure for storage |

630hPa |

and transport |

|

|

|

Apparatus and detachable parts weight |

|

|

|

Gross weight including packing |

30.4 kg |

|

|

Net apparatus weight in standard |

25.4 kg |

configuration |

|

|

|

60 cm extension arm (standard) |

2.9 kg |

|

|

80 cm extension arm |

3.5 kg |

|

|

30 cm extension arm |

1.9 kg |

|

|

Scissors arm |

9 kg |

|

|

Timer plus wall plate |

5 kg |

|

|

Tubehead |

8.5 kg |

|

|

(Rev. 7) |

17 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Technical data

4.1Method for correcting exposure times

This RX intraoral equipment features a special function called Computer Controlled Density which makes it possible to correct exposure time automatically when line voltage is different from its nominal voltage.

A change in the line voltage affects the peak voltage applied to the RX tube and the high voltage value affects the Rx spectrum very significantly. This, in turn, affects the optical density of the image on the film. The task of the correction is to achieve the same optical image density irrespective of the variations in line voltage, within its permitted variation range of ± 10%. In short, this feature makes it possible to obtain the same quality of image without having to be concerned about possible line variations which occur frequently in many areas and which are almost impossible to prevent without resorting to costly equipment.

Automatic exposure time correction works with the following sequence: inside the timer there is a voltmeter which takes a constant reading of the line voltage, while the user selects the desired exposure time. After the user has chosen the exposure time he knows from experience to be the best for the type of X-ray he is going to take, the user himself presses the key enabling exposure and the timer shows on the screen the correct time that will be used for the exposure in progress, time that the timer itself has calculated according to the value of the line voltage measured an instant before pressing the key of the exposure permission.

NOTE:

ENDOS AC and ENDOS ACP timers work in step with the line frequency, so the calculated time is always rounded off to the multiple of the line frequency itself.

The correct exposure time shown once the timer has been enabled by the "Ready" key and during the execution of the X-ray is the time actually used by the equipment: it is calculated applying a correction factor to the time selected by the user, based on the empirical law relating to the optical density of the film with the high voltage peak value and consequently with the line voltage.

NOTE:

If the "Ready" key has been disabled in system configuration, the display will show the "corrected" exposure time only during exposure or holding the X-ray button pressed at the end of it.

ENDOS AC/ACP (120V) |

18 |

(Rev. 7) |

SERVICE MANUAL

Technical data

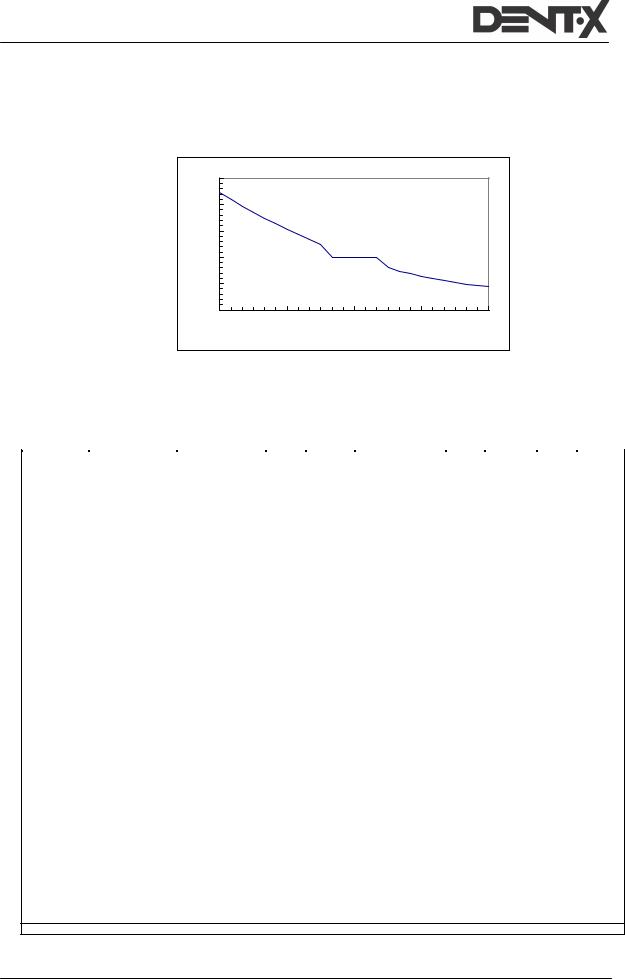

The qualitative relation between the multiplication factor and the line voltage is shown in the following picture (for equipment configured to work at 120V):

Multiplication factor of exposure time to the variation of line voltage

1,75 |

|

|

|

|

1,5 |

|

|

|

|

1,25 |

|

|

|

|

1 |

|

|

|

|

0,75 |

|

|

|

|

0,5 |

|

|

|

|

108 |

114 |

120 |

126 |

132 |

Line voltage

The following table allows to establish pre-indicated times and final real exposure times as a function of pre-selected time and line voltage variation.

line voltage |

108V |

112V |

116V |

124V |

128V |

132V |

||||||

|

corrected |

|

corrected |

|

corrected |

|

corrected |

|

corrected |

|

corrected |

|

|

exposure |

|

exposure |

|

exposure |

|

exposure |

|

exposure |

|

exposure |

|

|

time (on |

max/min |

time (on |

max/min |

time (on |

max/min |

time (on |

max/min |

time (on |

max/min |

time (on |

max/min |

|

the basis |

exposure |

the basis |

exposure |

the basis |

exposure |

the basis |

exposure |

the basis |

exposure |

the basis |

exposure |

|

of current |

time due to |

of current |

time due to |

of current |

time due to |

of current |

time due to |

of current |

time due to |

of current |

time due to |

|

line |

intrinsic |

line |

intrinsic |

line |

intrinsic |

line |

intrinsic |

line |

intrinsic |

line |

intrinsic |

|

voltage) |

inaccuracy |

voltage) |

inaccuracy |

voltage) |

inaccuracy |

voltage) |

inaccuracy |

voltage) |

inaccuracy |

voltage) |

inaccuracy |

line voltage |

1,61 |

|

1,37 |

|

1,17 |

|

0,87 |

|

0,78 |

|

0,72 |

|

correction factor: |

|

|

|

|

|

|

||||||

preselected time |

|

|

|

|

|

|

|

|

|

|

|

|

(ms) |

|

|

|

|

|

|

|

|

|

|

|

|

20 |

32 |

64 |

27 |

59 |

23 |

55 |

17 |

49 |

16 |

48 |

14 |

46 |

|

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

40 |

64 |

96 |

55 |

87 |

47 |

79 |

35 |

67 |

31 |

63 |

29 |

61 |

|

|

32 |

|

23 |

|

15 |

|

3 |

|

0 |

|

0 |

60 |

97 |

129 |

82 |

114 |

70 |

102 |

52 |

84 |

47 |

79 |

43 |

75 |

|

|

65 |

|

50 |

|

38 |

|

20 |

|

15 |

|

11 |

100 |

161 |

193 |

137 |

169 |

117 |

149 |

87 |

119 |

78 |

110 |

72 |

104 |

|

|

129 |

|

105 |

|

85 |

|

55 |

|

46 |

|

40 |

200 |

322 |

354 |

274 |

306 |

234 |

266 |

174 |

206 |

156 |

188 |

144 |

176 |

|

|

290 |

|

242 |

|

202 |

|

142 |

|

124 |

|

112 |

400 |

644 |

676 |

548 |

580 |

468 |

500 |

348 |

380 |

312 |

344 |

288 |

320 |

|

|

612 |

|

516 |

|

436 |

|

316 |

|

280 |

|

256 |

800 |

1288 |

1320 |

1096 |

1128 |

936 |

968 |

696 |

728 |

624 |

656 |

576 |

608 |

|

|

1256 |

|

1064 |

|

904 |

|

664 |

|

592 |

|

544 |

1000 |

1610 |

1642 |

1370 |

1402 |

1170 |

1202 |

870 |

902 |

780 |

812 |

720 |

752 |

|

|

1578 |

|

1338 |

|

1138 |

|

838 |

|

748 |

|

688 |

1200 |

1932 |

1964 |

1644 |

1676 |

1404 |

1436 |

1044 |

1076 |

936 |

968 |

864 |

896 |

|

|

1900 |

|

1612 |

|

1372 |

|

1012 |

|

904 |

|

832 |

1500 |

2415 |

2447 |

2055 |

2087 |

1755 |

1787 |

1305 |

1337 |

1170 |

1202 |

1080 |

1112 |

|

|

2383 |

|

2023 |

|

1723 |

|

1273 |

|

1138 |

|

1048 |

2000 |

3220 |

3252 |

2740 |

2772 |

2340 |

2372 |

1740 |

1772 |

1560 |

1592 |

1440 |

1472 |

|

|

3188 |

|

2708 |

|

2308 |

|

1708 |

|

1528 |

|

1408 |

2500 |

4025 |

no exposure |

3425 |

3457 |

2925 |

2957 |

2175 |

2207 |

1950 |

1982 |

1800 |

1832 |

|

|

no exposure |

|

3393 |

|

2893 |

|

2143 |

|

1918 |

|

1768 |

3000 |

4830 |

no exposure |

4110 |

no exposure |

3510 |

3542 |

2610 |

2642 |

2340 |

2372 |

2160 |

2192 |

|

|

no exposure |

|

no exposure |

|

3478 |

|

2578 |

|

2308 |

|

2128 |

|

|

|

|

|

|

|

|

|

|

|

|

|

no exposure = the timer does not allow exposure times longer than 4 sec

(Rev. 7) |

19 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Technical data

4.2Method for measuring technical factors

kVp KVp value is defined as the stationary value of high voltage applied to the tube which settles on load after preheating time.

KVp value is measured by a non-invasive instrument, with accuracy of over 2%, to the nominal value of line voltage.

A direct high voltage measurement can be made only by disassembling the tubehead. This operation can be executed only in the factory.

mA The anodic current value is defined as the average value of stationary current which settles on load after pre-switching time.

The anodic current value is measured using a digital voltmeter measuring the voltage drop at the ends of the resistance from 1 kΩ, 1% assembled on the tubehead. To take this measurement, remove the side plastic plug of the tube support; connect the ground voltmeter terminal on the yellow/green cable clamp screw and insert the positive terminal into the contact at the end of the grey cable. The digital voltmeter must be selected on DC, and the relation of transformation is given by 1 mA = 1V. Execute an exposure of at least 1 sec.

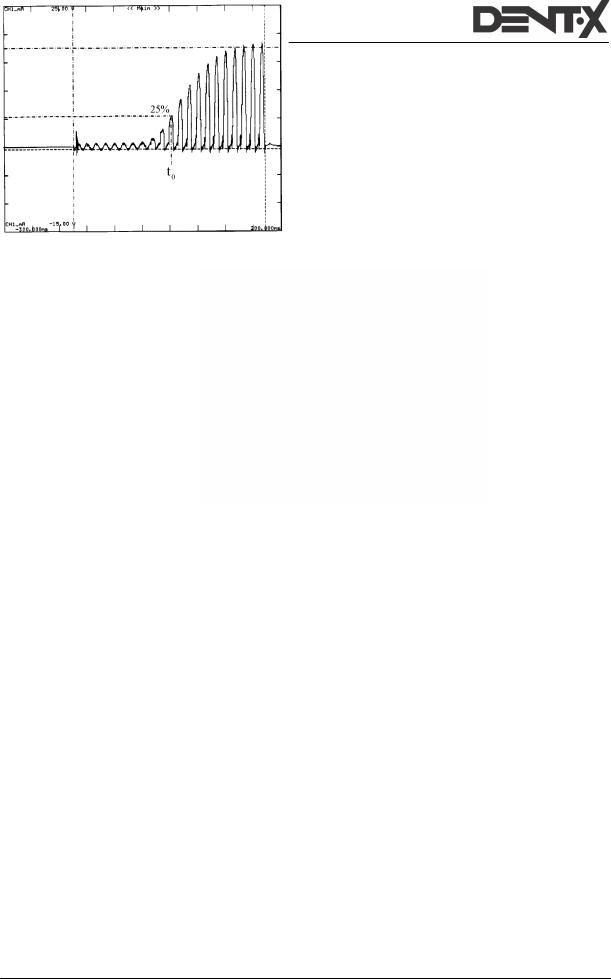

tThe exposure time value is the time during which the value of the anodic peak current exceeds 25% of the steady state value. The time taken to reach this condition is called "pre-heating time".

The measurement must be taken at nominal line voltage, measuring the anodic current wave-form on the 1kΩ resistance and using a memory oscilloscope.

Exposure time measurements using non-invasive equipment can lead to systematic errors in exposure time measurements which cannot be quantified and which depend on the equipment used for measuring (see paragraph 4.3).

ENDOS AC/ACP (120V) |

20 |

(Rev. 7) |

SERVICE MANUAL

Technical data

4.3Correct use of dosimeters to measure exposure times

The spread of non-invasive equipment to measure the functional parameters of RX equipment has introduced a series of interpretation problems when measuring exposure times.

The source of the problem is in the characteristic rise curve of the RX tube’s anodic current which is represented in the picture:

Anodic current

Time

According to IEC60601-2-7 (1998) regulations, "in equipment where the filament is switched on and high voltage is applied simultaneously, the exposure time is calculated as the interval between the instant when the anodic current exceeds 25% of the nominal value and the instant when it goes below such value".

This method is defined as invasive because it requires that the anodic current flowing through a resistance inside the tubehead must be measured.

Non-invasive methods are definitely easier and faster compared with the invasive method, but they are prone to errors which can be considerable when determining exposure time. In fact some of these devices start counting exposure time as soon as a small quantity of radiation reaches the measuring chamber with the result that they take longer times than the ones determined by the invasive method applied by the manufacturer.

Consequently, calculations obtained by these non-invasive methods can erroneously lead to the conclusion that the equipment timer is not accurate. Actually the difference is connected to the method adopted in measuring the exposure time.

(Rev. 7) |

21 |

ENDOS AC/ACP (120V) |

SERVICE MANUAL

Technical data

By using a tube with grid it is possible to reduce to the minimum the time required for the anodic current, and as a consequence, the dose adjustment to reach the steady state, so there is very little difference between the exposure time measurement using the invasive and the non invasive method.

Corrective actions

A practical method can be applied to get round the problem which can be described this way:

∙In a graph you report the values of times measured using the equipment compared with the ones displayed by the timer (automatically corrected for the line variations): the dots of the graph are interpolated with a straight line (if possible by the least square method or more simply in a graphic way).

∙You determine the intercept on the Y axis of this straight line: this can be assumed as the time value that the non-invasive device adds to each measurement due to the radiation which reaches the device before the anodic current is 25% of its maximum value.

∙Then you subtract this "offset" time from all the device measurements and you proceed with comparing the time measurements displayed by the timer.

ENDOS AC/ACP (120V) |

22 |

(Rev. 7) |

SERVICE MANUAL

Technical data

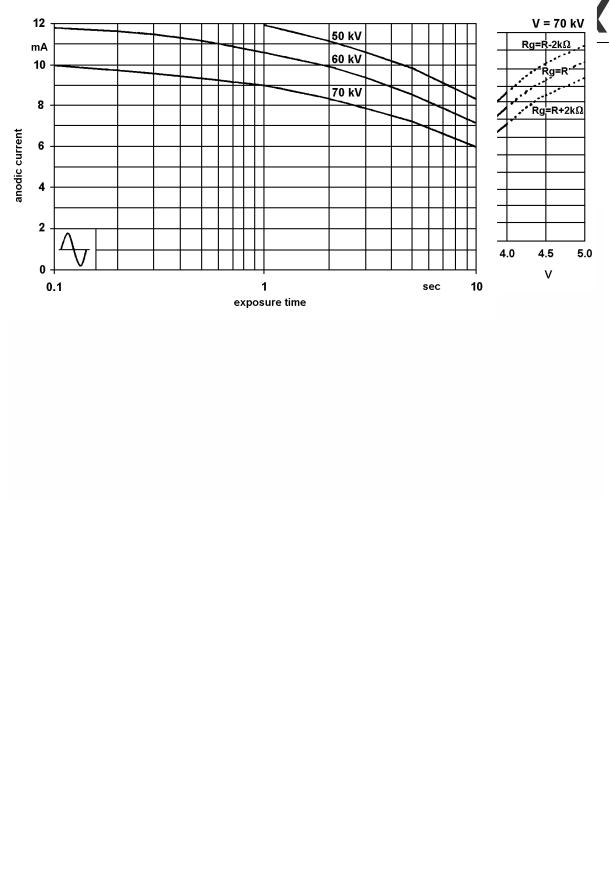

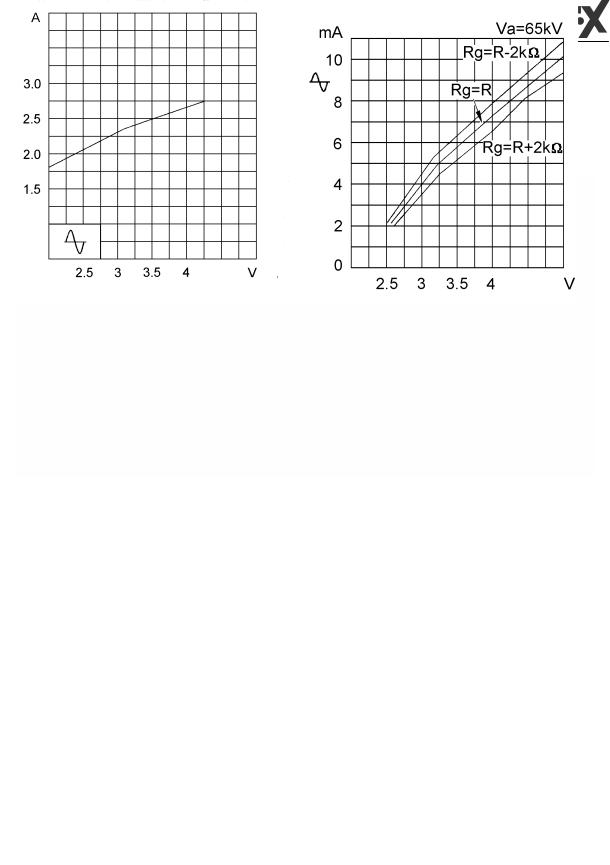

4.4Curves tube features

OCX / 70-G

Feature of emission

Load

|

|

|

|

|

|

|

|

(Rev. 7) |

23 |

ENDOS AC/ACP (120V) |

|

SERVICE MANUAL

Technical data

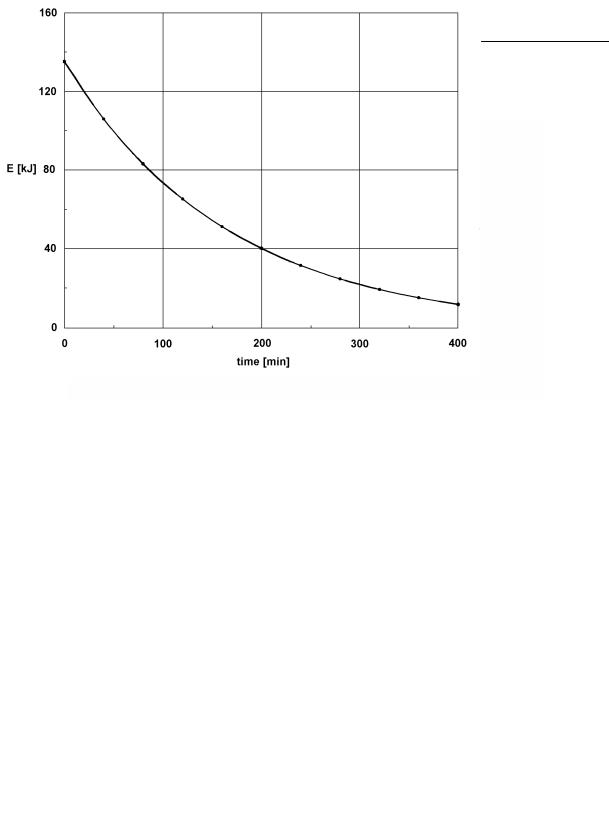

Curve anode cooling

Curve tubehead cooling

|

|

|

|

|

|

|

|

ENDOS AC/ACP (120V) |

24 |

(Rev. 7) |

|

SERVICE MANUAL

Technical data

KL16 – 0.8 – 70G

Feature of emission

Filament characteristics

|

|

|

|

|

|

(Rev. 7) |

25 |

ENDOS AC/ACP (120V) |

Loading...

Loading...