CORETM Delivery Unit

Magellan Mount

User Manual

Table of Contents

DentalEZ

®

Equipment

Section I Introduction

Product Overview ............................................... 1

Magellan Unit Features ......................................2

Dimensions ........................................................ 3

Speci cations .................................................... 4

Classi cations ................................................... 5

Explanation of Symbols & Signs ...................... 5

Safety Precautions ............................................ 6

Section II Preinstallation

Packaging .......................................................... 9

Unit Placement ................................................. 10

Utility Service Center (USC) ............................. 10

Section III Installation

Magellan Unit Support ..................................... 13

Umbilical Assembly .......................................... 15

Finalizing USC Installation ............................... 17

Magellan Unit Post ............................................ 19

Delivery Head ................................................... 20

USC Base ........................................................... 21

Rear Assistant .................................................. 21

Assistant’s Arm (Optional) .............................. 22

Assistant’s Instrumentation (Optional) ......... 23

Fiber Optic Tubing (Optional).......................... 24

Fiber Optic Electrical (Optional) ..................... 24

Light or Monitor Pole (Optional) ..................... 25

Power Module (Optional)................................. 26

Section VI Care

Cleaning ........................................................... 37

Disinfecting ...................................................... 38

Section VII User Service Information

Troubleshooting .............................................. 39

Service Instruction .......................................... 42

Disposal of Equipment .................................... 42

Section VIII Parts Lists/Diagrams

Utility Service Center ...................................... 43

Pivot/Mounting Hardware ............................... 43

Simplicity Assistant’s Arm (Optional) ............ 44

Galaxy Assistant’s Arm (Optional) ................. 45

CORE Assistant’s Arm (Optional) ................... 46

CORE Delivery Head ........................................ 47

Touch Pads ....................................................... 48

Clean Water System ........................................ 49

Foot Control ..................................................... 49

Air/Water Syringe ............................................ 50

HVE Nozzle ....................................................... 50

Saliva Ejector Nozzle ....................................... 50

EMC Information .............................................. 53

Limited Warranty ............................................. 55

Section IV Testing

Delivery System ............................................... 29

Syringe ............................................................. 30

Foot Control and Handpieces ......................... 30

Other Optional Features.................................. 32

Section V Operation

Delivery Head ................................................... 33

Syringe ............................................................. 34

Foot Control ..................................................... 34

Assistant’s Vacuum Accessories ................... 35

Clean Water System ........................................ 35

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

i

i

CORETM Magellan Unit

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

ii

Section I Introduction

DentalEZ

®

Equipment

Product Overview

This manual contains installation, operation and

care instructions, and user service information for

the DentalEZ® CORE™ Magellan Dental Delivery

Unit.

The CORE Magellan unit is intended to be used

by trained professional dental care personnel

only as an interface device to connect the dental

operatory hand instruments to the appropriate

supply utility such as air, water, vacuum, drain and

electrical. It functions as a system management

device that provides a method of operating the

hand instruments from a single control input

device.

The CORE Magellan unit is manufactured to be

used with a dental chair that supports a patient

in a reclined seated position. Operators will be

positioned around the patient’s head as required

for optimum access for the speci c procedure

being performed. The delivery unit positions the

handpieces for the optimum presentation to the

operator.

NOTICE

• Installation by an authorized

DentalEZ dealer service technician is

recommended.

• For any questions about an order, please

contact a DentalEZ Equipment customer

service representative at 866-DTE-INFO.

Light Post

(Optional)

Adjustable

Rear Assistant’s

Arm & Mount

(Optional

Delivery

Head

Magellan

Unit Post

Arm

The CORE Magellan unit is designed to provide

trouble-free service when installed, operated and

cared for according to the procedures set forth in

this manual.

To ensure proper installation, carefully

read all of the instructions contained in

this manual, paying close attention to all

warnings, cautions and notes.

Before starting installation procedures, review

the illustration to become familiar with the

components of the CORE Magellan unit (Figure 1).

After the CORE Magellan unit is installed, review

the features, operation procedures, and care

guidelines with the doctor’s sta .

Leave this manual in the doctor’s o ice.

Clean

Water

System

Magellan

Unit

Support

Figure 1. Main components of the CORE Magellan unit

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

1

1

Section I Introduction

CORETM Magellan Unit

Magellan Unit Features

Designed with simplicity in mind, the CORE product line provides a straightforward, easy-to-use delivery

unit with common components, simple integrated holders and an easy-to-read pressure gauge. The

left/right Magellan-style mount unit positions StarDental® handpieces and ancillaries within easy,

comfortable reach.

Standard Features

• Secure tray placement.

• Air gauge for easy pressure

monitoring.

• Break release handle.

• Easy access control block and

internals for easy maintenance.

• Aluminum ex arm for stability and

ease of positioning.

• Built standard with BioFreeTM tubing.

Optional Features

• Optional integrated dual access touchpad controls.

• Rear assistant’s arm/instrumentation with centrally located solids collector and tubing.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

2

Section I Introduction

Dimensions

DentalEZ

®

Equipment

24¼"

16"

20¾"

15¼"

23½"

R23"

21¼"

R26¾"

1½"

19"

15¾"

17½"

Figure 2. Top and side view dimensions for the CORE Magellan-mount delivery unit

www.DentalEZ.com

PN: 2717-267C

3

3

57"

41"

10½"

10½-23⅞"

6¼"

866-DTE-INFO

Section I Introduction

CORETM Magellan Unit

Speci cations

Power Supply

• 115V AC, 50/60 Hz, as applicable

Air Pressure

• 551.6 kPa (80 PSI) (at regulator in USC)

Water Pressure

• 275.8 kPa (40 PSI) (at regulator in USC or clean

water manifold)

Clean Water System

• Reservoir capacity: 2.0 L

Shipping (Package) Weight

• CORE Traditional Delivery Head and Arms:

24.5 lb. (11.1 kg)

Recommended Environmental Conditions

Transportation and Storage

• Temperature range: -20°F to 165°F

(-29°C to 74°C)

• Relative humidity range: 0% to 95%

Operation

• Temperature range: 59°F to 80°F (15°C to 27°C)

• Relative humidity range: 0% to 95%

• Atmospheric pressure range: 50 to 105 kPa

• Magellan Delivery Unit Post: 13 lb. (5.8 kg)

• Magellan Delivery Unit Support: 20 lb. (9 kg)

• Utility Service Center (USC): 15 lb. (6.8 kg)

• Assistant’s Arm: 16 lb. (7.2 kg)

• Light Post (Optional): 15 lb. (6.8 kg)

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

4

Section I Introduction

DentalEZ

®

Equipment

Classi cations

Medical-General Medical Equipment

Certi ed as to electrical shock, re

E355890

For the purposes of this user manual, the UL

approval is for the unit (head/arm assembly) and

power supply. All other regulatory markings are

provided in their respective manuals.

• Type of Protection Against Electric Shock:

Class 1 Equipment.

• Degree of Protection Against Electric Shock:

Type B Applied Parts. The handpiece is

considered an applied part.

and mechanical hazards only in

53HN

accordance with:

ANSI/AAMI ES60601-1:2005

CAN/CSA C22.2 NO. 60601-1-08

IEC 80601-2-60:2012

Explanation of Symbols & Signs

= Caution

= Warning

= Biohazard

= Warning - Dangerous Voltage

= General Mandatory Action

= Refer to Manual (Follow Instructions)

= Alternating Current

= Direct Current

= Protective Earth (Ground)

= Type B Applied Part

• Degree of Protection Against Ingress of Water:

Ordinary

• Flammable Gases: Equipment not suitable for

use in the presence of a ammable anesthetic

mixture with air, oxygen or nitrous oxide.

• Not intended for use in an oxygen rich

environment.

• Mode of Operation: Continuous

The authorized European representative is:

Dental Hygienics & Decontamination (DHD)

41 Blackwell Drive, Braintree Business Park

Braintree Essex, CM7 2PU, UK

Phone: +44 01787 877877 (ext. 200)

= European Certi cation

= Serial Number

= Manufacture Date

= Manufacturer

= Electromagnetic Radiation

= Do Not Trash

= Box Must Remain Upright

= Do Not Place Box on Unlevel Surface

= Do Not Stack Box

= Box Contents Safe Temperature Range

= Box Contents Safe Humidity Range

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

5

5

Section I Introduction

CORETMMagellan Unit

Safety Precautions

WARNING

Before proceeding with electrical

installation, all wiring must be in

accordance with NEC and local electrical

codes.

To avoid the risk of electrical shock, this

equipment must only be connected to a

supply mains with protective earth.

• Do not modify this equipment without

permission from DentalEZ. Unauthorized

modi cation will void the warranty and

could result in serious injury. If this

equipment is modi ed, appropriate

inspection and testing must be conducted

to ensure continued safe use of

equipment.

• Property damage and/or personal injury

may result if directions are not followed or

OEM parts are not used.

CAUTION

To satisfy FCC RF exposure requirements

for mobile and base station transmission

devices, a separation distance of 20 cm or

more should be maintained between the

antenna of this device and persons during the

operation. To ensure compliance, operation at

closer that this distance is not recommended.

The antenna(s) used for this transmitter must

not be co-located or operating in conjunction

with any other antenna or transmitter.

NOTICE

• Some illustrations and instructions in

this user manual include installation of

optional city water. If optional city water

is wanted, purchase kit PN 3658-484 for

units with a cuspidor or PN 3658-485 for

units without a cuspidor.

• The use of ACCESSORY equipment not

complying with the equivalent safety

requirements of this equipment may lead

to a reduced level of safety of the resulting

system. Consideration relating to the

choice shall include:

• Use of the accessory in the PATIENT

VICINITY

• Evidence that the safety certi cation

of the ACCESSORY has been

performed in accordance to the

appropriate IEC 60601-1 harmonized

standard.

• Always turn o unit and remove power

from unit when servicing. (Turn o power

at disconnect or service breaker.

• Never leave children unattended when

unit is in use.

• Isolating the unit from the supply mains is

accomplished by unplugging the unit from

the power receptacle.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

6

Section I Introduction

Safety Precautions (Continued)

DentalEZ

®

Equipment

NOTICE

• Medical electrical equipment needs

special precautions regarding

electromagnetic (EMC) compatibility

and needs to be installed according to

EMC information. (See EMC Information

provided in this manual.)

• In accordance with Part 15 of FCC rules,

this equipment was tested and complies

with Class A digital device limits. These

limits are designed to give equipment

reasonable protection against

detrimental interference when operated

in a commercial environment.

• Mobile radio frequency (RF)

communications equipment can a ect

medical electrical equipment.

• Accessory equipment not complying with

the Medical Device Safety standard IEC

60601-1 may contribute to a reduced level

of safety of the CORE Delivery Unit. It is

necessary for all accessory equipment

and attachments to comply with IEC

80601-2-60 Medical Electrical Equipment.

NOTICE

This equipment has been tested and found

to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful

interference in a residential installation.

This equipment generates, uses and

can radiate radio frequency energy, and

if not installed and used in accordance

with the instructions, may cause harmful

interference to radio communications;

however, there is no guarantee that

interference will not occur in a particular

installation. If this equipment does cause

harmful interference to radio or television

reception (which can be determined by

turning the equipment o and on) the

user is encouraged to try to correct the

interference by one or more of the following

measures:

• Reorient or relocate the receiving

antenna.

• Increase the separation between the

equipment and receiver.

www.DentalEZ.com

PN: 2717-267C

• Connect the equipment to an outlet on

a circuit di erent from that to which the

receiver is connected.

• Consult the dealer or an experienced

radio/TV technician for help.

7

7

866-DTE-INFO

CORETM Magellan Unit

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

8

Section II Preinstallation

Packaging

DentalEZ

®

Equipment

Unpacking Unit Cartons

The CORE Magellan unit components are packaged

and shipped according to the carton diagrams

shown (Figure 3 and Figure 4).

Verify the components packaging contents against

the packing list. All parts supplied are necessary for

proper installation; DO NOT discard any hardware

or components until installation is complete.

NOTE: Cartons may contain empty packing inserts

(even if optional components were ordered).

Magellan Unit Carton Contents

NOTE: If a pre-tubed chair was ordered, items

marked with an asterisk (*) will be on the chair.

• Magellan Unit Support*

• Umbilical*

• Clean Water System

CAUTION

To avoid damage to the carton contents, do

not use a knife or sharp object to open the

packaging.

Unit Post Carton Contents

NOTE: If light post was ordered, entire contents

will be inside light post box.

• Magellan Unit Post

• Installation Hardware

CORE Unit Light

Post (If Ordered)

Installation

Hardware

Magellan

Unit Post

Spacer

• Tray Package

• Utility Service Center

• Foot Control

Clean

Water

Package

Umbilical*

Magellan

Unit

Support*

Figure 3. CORE Magellan unit carton contents

Foot

Control

Tray

Package

Utility

Service

Center

(USC)

Figure 4. CORE Magellan unit post carton contents

Installation Hardware

Pole Pivot Supply Bag Magellan Light Supply Bag

(Optional)

Post Pivot Pin Spacer

Two Thrust Bearings

Four Thrust Washers Two #10 Internal Tooth Lock

3/8" x 2¼" Hex-head Bolt Two 5/6" Heavy Duty Electrical

.382/.393 ID × .683 OD Washer #10-32 × 3/8" Pan-head Screw

13/32" ID × 13/16" OD Washer

Socket Set Screw Light Adapter Cord Assembly

1/4-20 × 3/8" Set Screw

Rubber Pivot Cover

#10-32 × 1" Pan-head Screw

Washers

Clamps

7-1/2" Nylon Cable Tie

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

9

9

Section II Preinstallation

CORETM Magellan Unit

Unit Placement

WARNING

• DO NOT position equipment any place

where it would interfere with unplugging

the power cord from the receptacle.

• The plug cannot be located in a position

that requires tools to access.

Utility Service Center (USC)

Parts Included

• Utility Service Center (USC)

• USC Cover

• USC Template

• Bag of Supplies

NOTICE

• Set the USC cover aside until all

installation and testing of the delivery

system is complete.

• DO NOT DISCARD the USC template after

use. Neatly refold it and place in it the

back of this user manual.

Tools Required

• Drill

USC Site Preparation

1. Remove and unfold the full-size USC template

found in the USC carton.

2. Position the USC template according to the

exact layout indicated, making certain correct

distance from base to chair is maintained.

3. Using the USC template, drill four corner

mounting holes for the USC base. DO NOT

secure the base to the oor at this time.

NOTE: For wood or metal oors, drill 5/32" holes.

For concrete oors, drill 1/4" holes and install

plastic anchors.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

10

Section II Preinstallation

Utility Service Center (USC) (Continued)

DentalEZ

®

Equipment

Plumbing Contractor’s Procedure

WARNING

• Before proceeding with plumbing

installation, comply with and maintain all

applicable utility codes and regulations.

NOTICE

• If use of the optional city water system

is planned for in the future, it is highly

recommended to install necessary

components now.

• For reference, a color-coded tubing

diagram is included with this user manual.

Tools Required

• 5/8" Open-end Wrench

USC Installation

NOTE: Items marked with an asterisk (*) are

optional components.

Chair Side

Vacuum

Fitting (Not

Supplied)

(Optional

City Water

Installation

Shown)

Figure 5. Utility service center with optional city water

Air Fitting

Assembly

Drain

Fitting (Not

Supplied)

*Water

Actuator

Valve

Assembly

7. Flush the air and *water lines to remove trash

and debris.

8. Connect the air tting assembly to the air stop

valve as shown in the template. Using a 5/8"

open-end wrench, tighten the nut securely.

9. Connect the *water actuator valve assembly to

the water stop valve as shown in the template.

Using a 5/8" open-end wrench, tighten the nut

securely.

1. Open the USC bag of supplies.

2. Orient the utilities as described in the USC

template and stub through the oor. Vacuum

and drain ttings not supplied; refer to the USC

template for requirements. (Figure 5)

NOTE: Pay close attention to the orientation of the

template to the chair.

3. Sweat the valve adapters to the air and *water

stubs.

4. Apply the appropriate thread sealant to the

valve adapter(s) and install the stop valve(s).

5. Sweat the vacuum elbow to the stub.

6. Sweat the hose connector to the elbow as

applicable and orient as shown in the template.

www.DentalEZ.com

PN: 2717-267C

Electrical Contractor’s Procedure

The electrical contractor is to provide a covered

115V AC receptacle that meets all applicable utility

codes and regulations. For the recommended

location of the 115V AC receptacle, refer to the

USC template.

NOTE: Electrical contractor’s parts are NOT

supplied.

CAUTION

Rating of main circuit breakers should be

20 Amps maximum.

866-DTE-INFO

11

11

CORETM Magellan Unit

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

12

Section III Installation

Magellan Unit Support

DentalEZ

®

Equipment

Parts Included

• Magellan Unit Support

• Three Leveling Set Screws

• M16 Bolt

NOTE: If support is preinstalled, proceed to

Pinch Bolt &

Washer

Leveling Set

Screw Holes (3)

Figure 6. Magellan unit support

Step 6

CORE Chair

1. Raise the chair base and back to full UP

position.

2. Disconnect the chair from the power supply.

3. Take o the chair seat upholstery by removing

the ve Phillips-head screws from underneath

the chair (Figure 7).

4. Position the Magellan unit support so that

the lip of the chair rests underneath the lip of

the washer. The mount will hold itself in place

(Figure 8 and Figure 9).

.

Unit Support

Figure 8. Position the unit support under the chair

Figure 9. Slide lip of washer onto lip of chair

5. Install the M16 bolt loosely into the back of the

mount and into the chair.

6. If support is preinstalled, loosen (but do not

remove) M16 bolt to allow for leveling

(Figure 10).

Phillips-head Screws (5)

Figure 7. Remove ve (5) Phillips-head screws

www.DentalEZ.com

PN: 2717-267C

Figure 10. M16 bolt

13

13

Leveling

Set

Screws

M16 Bolt

866-DTE-INFO

Section III Installation

Magellan Unit Support (Continued)

CORETM Magellan Unit

7. Place a level on the Magellan unit support,

parallel with and perpendicular to the chair

center line, then check the level of the unit

support.

NOTE: If leveling is neces

screws until the unit support is level.

8. Tighten M16 bolt (55 foot-pounds).

NOTE: If necessary, repeat steps 5, 6 and 7 after

unit and light are added to re-level.

sary, adjust the 3/16" set

NuSimplicity Chair

1. Raise the base and back to full UP position.

2. Disconnect the chair from the power supply.

3. Take o the chair’s seat by removing the

1/4-20 thumb screw from underneath the seat.

Push the seat toward the back of the chair to

clear the substrate from the slide bosses, then

set the seat aside with all related hardware

(Figure 11).

Substrate 1/4-20 Thumb

Screw

4. Select the following items from the Magellan

unit support hardware package:

• Three 1/2" × 1½" Bolts

• Three 1/2" Lock Washers

• Four 1/2" Flat Washers

• Four 1/2" Shims

• Two 3/8" × 1/2" Set Screws

5. Determine if the two outside 1/2" threaded

hole mounting pads and the Magellan unit

support are level. If the mounting pads or unit

support are not level, select the necessary

amount of 1/2" shims needed to provide a level

condition across the two pads.

6. Position the Magellan unit support so that

the three 1/2" through holes align with the

corresponding threaded holes of the chair

mount casting.

7. Install the two outside 1/2" bolts and lock

washers and the number of 1/2" shims

determined in step 5 through the Magellan

unit support and thread into the chair mount

casting.

Figure 11. Remove the chair seat

NOTE: If inst

DentalEZ chair that is not pre-tubed, continue with

the following instructions. If installing on a pretubed chair,

www.DentalEZ.com

PN: 2717-267C

alling the CORE delivery unit on a

skip steps 4 through 10

.

8. Tighten both outside 1/2" bolts to allow a 3/16"

clearance at the middle 1/2" bolt location.

9. Install the middle 3/8" set screws in the

bottom of the Magellan unit support.

10. Install the middle 1/2" lock washer and 1/2"

bolt, but

14

do not

fully tighten.

866-DTE-INFO

Section III Installation

DentalEZ

®

Equipment

Magellan Unit Support (Continued)

11. Place a level on the Magellan unit support,

parallel with and perpendicular to the chair

center line, then check the level of the unit

support.

NOTE: If leveling is neces

screws until the unit support is level

Leveling Set Screws

Figure 12. Adjust 3/8" set screws if leveling is necessary

sary, adjust the 3/8" set

(Figure 12)

1/2" Bolts

Umbilical Assembly

CORE Chair

NOTE: Provide su icient slack in the umbilical

assembly to avoid stretching when the chair is in

its full UP position.

.

1. From the umbilical bag of supplies, select

the umbilical assembly with the supplied

L-bracket.

2. Route the umbilical between the hydraulic

pump and the control board, then under the

cantilever arm.

3. Route the remainder of the umbilical through

the pivot and up into the chair casting, using

tie wraps to secure.

NOTICE

For tubing connections, see the tubing

diagram in the back of this user manual.

12. Tighten all hardware (55 foot-pounds for 1/2"

bolt).

NuSimplicity Chair

1. From the umbilical bag of supplies, select

the umbilical assembly with the supplied

L-bracket.

2. Route the umbilical between the hydraulic

pump and the control board, then under the

cantilever arm.

3. Tie wrap the umbilical to the bracket

(Figure 13).

L-bracket

Tie Wrap

Figure 13. Tie wrap umbilical to L-bracket

www.DentalEZ.com

PN: 2717-267C

15

15

866-DTE-INFO

Section III Installation

Umbilical Assembly

4. Route the umbilical through the brackets on

the cantilever and secure using tie wraps

(Figure 14).

5. Route the remainder of the umbilical through

the pivot and up into the chair casting using

tie wraps to secure (Figure 15).

6. Using the two 10-32 screws provided, secure

the L-bracket.

7. Leave the base cover o until the foot control

has been installed.

CORETM Magellan Unit

Tie

Wraps

Figure 14. Route umbilical through cantilever brackets

Tie Wraps

Figure 15. Route remainder of umbilical through pivot

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

16

Section III Installation

DentalEZ

Finalizing USC Installation

®

Equipment

NOTE: The following instructions for nalizing Utility

Service Center (USC) connections include optional city

water installation.

system only, omit steps 10* through 14*

If installing standard clean water

.

NOTICE

Pictures for the following steps are located on

the next page (Figure 16 - Figure 18).

NOTE: Refer to the tubing diagram (PN: 2662-304)

in the literature packet for all connections.

1. Select the following hardware items:

• Six 1/8" Tubing Clamps

• Three 1/4" Tubing Clamps

2. Remove the cable wrap to expose the tubing

connections of the umbilical assembly

NOTE: If the pump cover and the chair’s lower

cantilever cover are not already removed, take

them o now.

3. Route the foot control tubing into base of the

chair.

4. Find the foot control leads of the chair’s

umbilical assembly numbered 1, 2, 3 and 4

located toward the rear of the chair’s pump

motor assembly.

5. Attach the 1, 2, 3 and 4 leads with the

corresponding numbered connectors of the

foot control tubing.

6. In the USC, attach the hard, red air line

to the air valve tting using the supplied

compression tting (Figure 16, connection A).

7. Connect the 1/8" red tube from the umbilical

to the poppet valve connection opposite the

existing barb assembled to the 1/4" red tube

(Figure 17, connection C).

8. Connect the 1/8" yellow tube from the

umbilical to the poppet valve connection

opposite the existing barb assembled to the

1/8" yellow tube (Figure 17, connection D).

9. Connect the 1/4" red tube, numbered 1, to the

middle barb of the poppet valve in the USC.

Then secure the connection using a 1/4" tubing

clamp. (This is the drive air line for the foot

control) (Figure 17, connection E).

10. *Attach a 1/4" tubing clamp to the rigid 1/4"

green water line of the water regulator.

11. *Use soap to lubricate the 1/4" barb, then

connect the water line to the water valve

actuator (Figure 16, connection B).

12. *Connect the 1/4" green tube of the umbilical

to the connector from the 1/4" green tube of

the water regulator (Figure 18, connection F).

13. *Attach a 1/8" tubing clamp to the 1/8" yellow

air line of the poppet valve.

14. *Use soap to lubricate the barb of the water

valve actuator. Attach the 1/8" yellow line of

the poppet valve to this barb and secure using

a 1/8" tubing clamp (Figure 18, connection G).

15. If a rear assistant’s arm is installed, slip the

vacuum hose from the chair over the vacuum

elbow in the USC (Figure 18, connection H).

16. If an optional ber optic electrical system

is installed, attach the electrical leads of

the power pack transformer to the adapter

harness. Attach the electrical leads to the

matching connector on the main harness.

17. Route the main harness through the 5' × 1¾"

corrugated ducting hose to the inside of the

chair pump cover (for future connections if

necessary).

18. In the USC, open the air/water stop valves and

check for leaks.

www.DentalEZ.com

PN: 2717-267C

17

17

866-DTE-INFO

Section III Installation

Finalizing USC Installation (Continued)

*B

CORETM Magellan Unit

*Water Regulator

A

Vacuum

Elbow

Figure 16. Optional city water layout

C

D

E

Figure 17. Typical installation

Air

Regulator

*F

www.DentalEZ.com

PN: 2717-267C

*G

H

Figure 18. Typical installation

866-DTE-INFO

18

Section III Installation

Magellan Unit Post

Pivot Cover

Pivot Cover

DentalEZ

®

Equipment

3/8" Hex-head Bolt

3/8" Lock Washer

Magellan Unit Post

Tools Required

• 1/8" Hex Key

1. Select the following hardware package items

(Figure 19):

• 1/4" x 3/4" Set Screw

• 1/4" x 3/8" Set Screw

• 3/8-16" × 2-14" Hex Head Screw

• 3/8" Flat Washer

• 3/8" Lock Washer

3/8" Flat Washer

Post Pivot Pin

Slot

Unit Pole

Thrust Bearing

Unit Support

1/4-20 × 3.8"

Set Screw

Figure 19. Magellan unit post hardware

Thrust Washers

1/4-20 × 3.8"

Set Screw

Post Stop

(Ground Point)

5. Position a thrust washer onto the at member

of the Magellan unit pole and post pivot pin.

• Four Thrust Washers

• Two Thrust Bearings

• Pivot Cover

• Post Pivot Pin

• Post Stop

2. Place a thrust washer on the bearing surface

of the post pivot pin.

3. Apply lubricant to a thrust bearing and install the

bearing, followed by a second thrust washer.

4. Insert post pivot pin and bearing stack into

unit pole.

www.DentalEZ.com

PN: 2717-267C

6. Apply lubricant to the second thrust bearing

and install followed by a thrust washer.

7. Insert the post pivot pin and unit pole with thrust

bearing and washers into the unit support.

NOTE: Engagement is a slip

t, provided the

Magellan unit post is held in alignment.

CAUTION

To avoid damage to the pivot bushing, do not

use force when installing the pivot pin into the

Magellan unit post.

866-DTE-INFO

19

19

Section III Installation

CORETM Magellan Unit

Magellan Unit Post (Continued)

8. Make sure the pivot pin slot faces the side of

the unit support having the tapped hole.

9. Seat the pivot mount until its head is in full

contact with the bottom and sides of the

Magellan unit support.

10. Use 3/8-16" × 2-1/4" hex head screw,

lockwasher and at washer to secure post

pivot pin to unit support.

11. Locate the 1/4-20 × 3/4" long set screw in the

threaded hole on the Magellan unit support.

Then tighten the set screw to prevent the

pivot pin from rotating.

12. Place a 1/4-20 × 3/8" long set screw into

the threaded hole in the at member of the

Magellan unit post.

13. Engage the 1/4-20 × 3/8" set screw with a 1/8"

hex key to deform the internal bushing against

the pivot mount until a 3-lb force is required to

rotate the unit post.

14. Install the pivot cover over the bolt head.

Delivery Head

Delivery

Head

Tools Required

• 5/64" Hex Key

1. Remove the packaging from the delivery

head along with the adjustable arm and the

umbilical assembly.

2. Feed the umbilical assembly into the unit post,

ensuring that the leading end of the

umbilical assembly (with the protective spiral

end) does not catch on the open access slot

or weld seam of the unit post’s at joint.

www.DentalEZ.com

PN: 2717-267C

3. After the umbilical assembly is completely

installed in the unit post, insert ex arm into

unit post.

4. Secure the bearing arm support with a set

screw using 5/64" hex key.

5. Match and connect the tubes and wires

from the Magellan arm umbilical assembly

to the tubes and wires of the chair umbilical

assembly. Refer to tubing diagram (PN: 2662-

304).

6. For touchpad control equipped, route harness

through chair, connect terminal to main

control board, and coil excess harness.

866-DTE-INFO

20

Section III Installation

USC Base Rear Assistant

1. Position the USC base over the four corner holes

that were drilled during preinstallation.

2. Secure the base using four #10 screws.

NOTICE

If previous utilities interfere with the USC

base internal bracing, modi cation may be

necessary.

DentalEZ

Rear

Assistant

CORE Chair

Tools Required

®

Equipment

• 1/4" Hex Key

• 9/16" Socket

NOTE: Remove seat cushion, if necessary.

1. Place the chair in its full upright position.

2. Attach the rear assistant mount to the

platform below the chair brake with two

shoulder screws. Tighten in place with 1/4" hex

key (Figure 20).

NOTE: Recessed holes must be facing upward.

www.DentalEZ.com

PN: 2717-267C

Figure 20. Attach rear assistant mount to platform

21

21

866-DTE-INFO

Section III Installation

Rear Assistant (Continued) Assistant’s Arm (Optional)

3. Remove the cap and nut from the shoulder

bolt located in the link of the rear assistant’s

arm (Figure 21).

4. Place the link of the rear assistant’s arm on

Cap

plastic washer. (Be sure to keep the

Shoulder Bolt

washer/ spring washers in the

same orientation.)

Figure 21. Remove cap and nut from shoulder bolt

5. Thread the shoulder bolt into the bracket and

tighten the bolt securely using 1/4" hex key.

T

est that the arm rotates without the bolt

head turning.

top of the bracket and

Bracket

Link

Washer

CORETM Magellan Unit

Rear

Assistant’s

Arm & Mount

Tools Required

• 1/4" Hex Key

6. From the underside of the bracket, install the

nut on the shoulder bolt and tighten securely

with 9/16" socket.

7. Replace the cap in the link.

8. Pass the tubing and wires from the assistant’s

arm through the strain relief bushing in the

cantilever cover.

9. Pass the tubing wires through the wire

bracket.

10. Connect the 5/8" ID vacuum hose of the rear

assistant’s arm to the 5/8" ID vacuum hose of

the chair by sliding it over the connector of the

chair’s ducting hose.

11. Cut o excess vacuum tubing, if necessary.

• 9/16" Socket

NOTE: Remove seat cushion, if necessary.

1. Place the chair in its full upright position.

2. Remove the cap and nut from the shoulder bolt

located in the link of the rear assistant’s arm

(Figure 22).

Cap

Bracket

Shoulder Bolt

Figure 22. Remove cap and nut from shoulder bolt

Link

Washer

3. Place the link of the rear assistant’s arm on

top of the bracket and plastic washer. (Be

sure to keep the washer/spring washers in the

same orientation.)

www.DentalEZ.com

PN: 2717-267C

4. Thread the shoulder bolt into the bracket and

tighten the bolt securely with 1/4" hex key.

Test that the arm rotates without the bolt

head turning.

866-DTE-INFO

22

Section III Installation

DentalEZ

®

Equipment

Assistant’s Arm (Opt) (Continued) Assistant’s Instrumentation

5. From the underside of the bracket, install the

nut on the shoulder bolt and tighten securely

with 9/16" socket.

6. Replace the cap in the link.

7. Pass the tubing and wires from the assistant’s

arm through the strain relief bushing in the

cantilever cover.

8. Pass the tubing and wires through the wire

bracket.

9. Connect the 5/8" ID vacuum hose of the rear

assistant’s arm to the 5/8" ID vacuum hose of

the chair by sliding it over the connector of the

chair's ducting hose.

10. Cut o excess vacuum tubing, if necessary.

11. Refer to tubing diagram (PN: 2662-304) for

air/water connections.

12. For touchpad control equipped, route harness

through chair, connect terminal to main

control board, and coil excess harness.

Saliva Ejector (SE)

1. Connect the SE valve to the 5/16" OD SE tubing

(Figure 23).

SE Valve

5/16" OD SE Tubing

Figure 23. Connect SE tubing and SE valve

2. Hang the SE valve in the instrument holder.

3. Connect the SE tubing to the open 1/4" port

under the solids collector in the assistant’s

arm.

High Volume Evacuator (SE)

1. Connect the HVE valve to the 5/8" OD tubing

(Figure 24).

HVE Valve

www.DentalEZ.com

PN: 2717-267C

5/8" OD Tubing

Figure 24. Connect HVE valve and OD tubing

2. Hang the HVE valve in the instrument holder.

3. Connect the tubing to an open 1/2" port under

the solids collector in the assistant’s arm.

4. If an optional second high volume evacuator

valve is used, remove plug.

Air/Water Syringe

NOTE: The syringe for the delivery head is factory

installed.

866-DTE-INFO

23

23

Section III Installation

CORETM Magellan Unit

Fiber Optic Tubing (Optional) Fiber Optic Electrical (Optional)

NOTE: The ber optic tubing is factory installed. NOTE: The ber optic electrical wiring is factory

installed. To complete installation, connect the

ber optic wires from the unit head/arm to the

ber optic transformer in the utility service center

(USC). Plug in the ber optic transformer.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

24

Section III Installation

Light or Monitor Post (Optional)

DentalEZ

®

Equipment

Light

Post

Tools Required

• 1/8" Hex Key

1. Select the following hardware package items

(Figure 25):

• 1/4" × 3/4" Set Screw

• 1/4" × 3/8" Set Screw

• 3/8-16" × 2¼" Hex Head Bolt

• 3/8" Flat Washer

• 3/8" Lock Washer

Post Stop

Thrust

Washers

1/4" × 3/8"

Set Screw

1¼" Brass Bushing

Thrust

Washers

Slot

3/8" Flat Washer

3/8"-16 × 2¼"

Hex Head Bolt

Pivot Cover

1/4" × 3/4"

Set Screw

Counter Bore

Thrust Bearing

Light Arm or

Monitor Arm

Thrust

Bearing

Post Pivot Pin

3/8" Lock

Washer

• Four Thrust Washers

• Two Thrust Bearings

• Pivot Cover

• Post Pivot Pin

• Post Stop

2. Raise the chair base to its upper travel limit

and disconnect the chair power.

3. Apply lubricant to both sides of all thrust

washers and thrust bearings.

4. Place a thrust washer, bearing and another

thrust washer onto the pivot pin. Then insert

www.DentalEZ.com

PN: 2717-267C

Figure 25. Light/monitor post hardware

the pivot pin and bearing stack through the

1-1/4" brass bushing at the end of the light/

monitor post. Place another thrust washer,

bearing and thrust washer onto the pin.

5. While holding the bearings and pin in the post,

align the machined hole in the pivot pin with

the pin in the chair support’s bottom counter

bore. Then adjust the unit post and pin so the

pin will slide into the counter bore.

NOTE: Engagement is a slip

t, provided the

Magellan light/monitor post is held in alignment.

866-DTE-INFO

25

25

Section III Installation

CORETM Magellan Unit

Light or Monitor Pole (Opt) (Cont)

CAUTION

To avoid damage to the pivot bushing, do not

use force when installing the pivot mount into

the light/monitor post.

6. Seat the pivot mount until its head is in full

contact with the bottom and sides of the

Magellan unit support.

7. Make sure the pivot pin slot faces the side of

the unit support having the tapped hole.

8. While holding the unit post in position, install

the 3/8"-16 × 2¼" hex head bolt with 3/8" lock

and at washers through the pin so that it

threads into the chair support, then tighten

the bolt enough to remove most clearances

between the bearings.

9. Install the 1/4" × 3/4" set screw into the

threaded hole on the Magellan unit support,

then tighten the set screws to prevent the

pivot pin from rotating.

Power Module (Optional)

1. Unplug all cords from the receptacle in the

USC.

NOTE: See the power module system wiring

diagram provided with this user manual for

connections.

2. Connect the main wiring harness to the power

module (Figure 26).

1/8"

Barb

Main

Harness

1/8" Yellow

Line

Figure 26. Connect main harness to power module

Power

Module

1/8" Yellow

Line “T”

Umbilical

10. Finish tightening the bolt in the pin until all the

clearance between the bearings is removed

and the post moves freely, then re-tighten the

set screw.

11. Place a 1/4" × 3/8" set screw into the threaded hole

in the at member of the Magellan unit post.

12. Engage the set screw with a 1/8" hex key to

deform the internal bushing against the pivot

mount until a 3-lb force is required to rotate

the unit post.

13. Install the pivot cover over the bolt head.

www.DentalEZ.com

PN: 2717-267C

3. A “T” must be spliced into the 1/8" yellow

air line near the poppet valve. Then connect

the open end of the “T” to the barb of the

power module using a section of 1/8" yellow

air line and two tubing clamps. If necessary,

cut a section of 1/8" yellow air line out of the

umbilical to make connection.

4. After checking all the plug connections,

reconnect the power plug and surge protector

into the receptacle in the USC.

866-DTE-INFO

26

Section III Installation

Power Module (Opt) (Cont)

CAUTION

To avoid damage to the unit, the surge

protector supplied with the power module

must be used at all times.

5. Pass the green wire of the main harness

through the umbilical and ground it to the

power module, USC base or chair (Figure 27).

NOTE: It may be necessary to remove an existing

screw and reinsert the screw with the green

ground wire attached.

NOTE: Make sure the air valve in the USC is open.

DentalEZ

®

Equipment

Green

Ground

of Main

Harness

Figure 27. Pass green wire of harness through umbilical

6. At the delivery head, turn master switch to

ON and ensure power is available at power

module.

NOTICE

For power supply options, the Power Module

or the XP Power Supply must be chosen.

www.DentalEZ.com

PN: 2717-267C

27

27

866-DTE-INFO

CORETM Magellan Unit

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

28

Section IV Testing

Delivery System

DentalEZ

®

Equipment

NOTICE

• Before testing the delivery system, make

sure the shipping tie wrap is removed

from the adjustable arm pivot area at the

delivery head.

• The air regulator is factory preset to

delivery 551.5 kPa (80 PSI). The water

regulator is preset to deliver 275.8 kPa

(40 PSI).

Tools Required

• Phillips-head Screwdriver

• 1/16" Hex Key

• 1/4" Hex Key

Utility Service Center

Air and Water Filter/Regulators

If the regulators are not set, do the following

adjustment process:

1. Pull the locking knob.

2. Turn the adjustment knob on each regulator

until the correct pressure reading is reached

(clockwise to increase or counterclockwise to

decrease).

3. When nished, push the locking knob down.

Adjustable Arm

To check the maneuverability of the CORE

adjustable arm, do the following:

1. Depress and hold the brake release button.

2. Lift the adjustable arm or lower it into the

desired position.

1. Turn ON all services supplying the USC.

2. Open the air and water manual stop valves by

turning the knobs counterclockwise.

3. Inspect all joints and connections for leaks.

4. Plug in any transformers in the USC into an

electrical outlet.

5. Flip the master switch forward to turn ON unit

(Figure 28).

OFF ON

Master

Switch

Figure 28. Turn master switch to ON position

6. Inspect for leaks in the service console,

cuspidor and delivery head.

3. Release the brake release button (Figure 29).

Brake

Release

Button

Brake

Release

Handle

Figure 29. Delivery head brake release

4. To adjust ex arm drift, remove ex arm

cap near the post using a Phillips-head

screwdriver and 1/16" hex key. With cover

removed, push unit in the furthest downward

position to gain access to the adjustment

screw. Using a 1/4" hex key, adjust drift by

rotating this screw. Once adjustment is

complete, reassemble ex arm cap.

www.DentalEZ.com

PN: 2717-267C

29

29

866-DTE-INFO

Section IV Testing

CORETM Magellan Unit

Syringe

If the unit is equipped with a syringe, rst depress

the air button and then the water button to test

the ow.

Foot Control & Handpieces (Opt)

Coolant Water Lines

1. At the foot control, ip the toggle to WET

(Figure 30).

WET/DRY

Toggle

Figure 30. Flip toggle switch to WET position

• Before connecting handpieces, all air must

be purged from the coolant water lines to

allow the system to function properly.

Dry Wet

Chip Air

CAUTION

Valve

2. Purge air from the coolant water lines on each

handpiece as follows:

a. Turn the water coolant valve

counterclockwise to its full, open position.

b. Remove the handpiece tubing from holder.

Water Adjustment Valves

Figure 31. Adjustment valves

c. While facing the deliver head, start with the

handpiece tubing on the far left, then fully

depress the foot control to allow water to

ow into a sink or other container.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

30

Section IV Testing

Foot Control & Handpieces (Opt) (Continued)

DentalEZ

®

Equipment

d. As the water is owing, continue the

purging operation of the remaining tubings

(moving from the left tubing to the right

tubing).

e. Allow water to ow freely from all tubings

until all air has escaped.

3. Attach the handpieces to the tubing as follows:

a. Slide the connector nut down along the

tubing to expose the handpiece adapter.

b. Carefully align and insert the handpiece

swivel base into the adapter.

c. Replace and tighten the connector nut to

complete installation.

Air Pressure

1. Flip the toggle to DRY at the foot control.

2. To adjust the individual handpiece drive air

pressure to the manufacturer’s speci cations,

do the following procedure:

a. Remove the handpiece from its holder.

c. Hold the handpiece, fully depress the foot

control, and observe the amount of air

pressure delivered to the handpiece.

d. Locate the air pressure adjustment screws

on the bottom of the delivery head chassis

(Figure 33).

Air Pressure Adjustment

Figure 33. Air pressure adjustment screws

e. Turn the air pressure adjustment screw

on the control valve of the appropriate

handpiece (counterclockwise to increase

pressure, clockwise to decrease pressure)

until the handpiece manufacturer’s correct

speci cation registers on the pressure

gauge.

b. Insert an air pressure gauge as indicated

(Figure 32).

Handpiece

Adapter

Tubing

(Insert

Nut

Figure 32. Insert air pressure gauge

www.DentalEZ.com

PN: 2717-267C

Air Pressure

Gauge Here)

3. Repeat step 2 (a-e) to set the pressure for

each handpiece.

Chip Air Foot Control (If Equipped)

If the handpiece utilizes coolant air, a burst of air

should be delivered to the handpiece when the

chip air valve is depressed.

866-DTE-INFO

31

31

Section IV Testing

CORETM Magellan Unit

Foot Control & Handpieces (Opt)

Flush Valve

1. Remove the handpiece from its holder.

2. Activate the ush valve (Figure 34).

3. Operate each handpiece for 30 seconds into a

cuspidor, sink or open vacuum line.

Flush Valve

Figure 34. Flush valve

Other Optional Features

Fiber Optics

Follow the test procedures outlined in the

instructions included in each ber optic

handpiece package.

Assistant’s Vacuum Accessories

Evacuate one cup of water (8 oz. each) through

the saliva ejector and the high-volume evacuator.

NOTICE

After all nal testing is complete, install the

USC cover.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

32

Section V Operation

Delivery Head

DentalEZ

®

Equipment

WARNING

• To prevent possible injury due to

accidental operation, do not leave young

children unattended.

• Do not place objects weighing more than

10 pounds on the delivery head/tray.

Master Switch Control

The master switch (located on the underside of

the delivery unit) controls the ON/OFF functions

of air, water and electricity to the entire unit. Flip

the master switch forward to turn ON unit

(Figure 35).

OFF ON

Master Switch

Figure 35. Flip master switch to ON

Delivery Head Positioning

The horizontal and vertical location of the delivery

head can be varied by doing the following:

• To vary the horizontal location, push or pull the

brake handle (Figure 37).

• To raise the delivery head, lift up the brake

handle with the brake button pressed.

• To lower the delivery head, make sure the

brake is o and pull the head down.

• When positioned correctly, release the brake

button.

Brake Release

Button

Brake

Release

Handle

Figure 37. Delivery head brake release

NOTICE

• IMPORTANT: At the end of each workday

and anytime the unit is unattended, make

sure the master switch is in OFF position.

Oil Collector/Filter

The oil collector/ lter is designed to collect oil

from the handpiece exhaust air. Periodically check

the lter for cleaning or replacement by removing

the cover and inspecting the lter (Figure 36).

Oil Filter Housing

Figure 36. Oil lter housing

www.DentalEZ.com

PN: 2717-267C

33

33

866-DTE-INFO

Section V Operation

Syringe Foot Control

CORETM Magellan Unit

The syringe is designed to deliver air or water, or a

mixture of air and water, as required.

• To deliver water only, press the button on the

syringe marked with a water drop symbol.

• For air only, press the button on the syringe

with no marking.

• To get a spray mixture of air and water, press

both buttons simultaneously.

The speed of the handpiece is controlled by

depressing the disc located on the foot control

(Figure 38).

WET/DRY

Toggle

Figure 38. Foot control disc

• A light pressure on the foot control disc

causes a slow speed.

• Full pressure on the disc causes the

handpiece to operate at full speed.

Dry Wet

Chip Air

Valve

NOTE: The optional coolant water spray ON/OFF

function is also controlled by using the toggle

located on the foot control as described above.

Chipblower

If the handpiece utilizes coolant air, the

chipblower is used to blow debris away from the

cutting site by creating an air blast through the

handpiece without causing the bur to rotate. To

operate the chip blower, depress and hold down

the valve on the upper right of the foot control.

Optional Fiber Optics

The ber optics control is automatically activated

by operating the handpiece using the foot control.

NOTE: When the foot control is released, the ber

optics light will stay on for approximately ten (10)

seconds to allow inspection of the cutting site.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

34

Section V Operation

DentalEZ

®

Equipment

Assistant’s Vacuum Accessories Clean Water System

WARNING

Do not hang objects weighing more than

5 pounds on the assistant’s arm.

The standard instrumentation for an assistant’s

arm is one High Volume Evacuator (HVE), one

Saliva Ejector (SE) and a three-way syringe.

(Syringe operating instructions on p. 34.) Optional

features include an additional HVE.

NOTE: The assistant’s arm pivots to allow

positioning of the instruments for easy access.

HVE and SE

The ow of vacuum through the HVE and SE is

controlled by a lever valve (Figure 39).

• Pushing the lever forward toward the tip

opens the vacuum.

Operation of the clean water system is as follows:

• Flip the toggle switch to the ON position (Figure

40).

• If optional city water is in use, ip the toggle

switch to change usage from city water to

bottle water.

• To remove the bottle, rst ip the toggle

switch to the OFF position, then unscrew it

from the assembly.

Toggle

Switch

• Moving the lever toward the hose end

decreases the vacuum ow.

• To close the valve, move the lever all the way

toward the hose end.

HVE Lever Valve

Close Open

SE Lever Valve

Close Open

Figure 39. HVE and SE lever valves

Bottle

Figure 40. Clean water system

NOTICE

This dental water delivery system is equipped

with BioFree

properties built in to protect it.

TM

tubing containing antimicrobial

www.DentalEZ.com

PN: 2717-267C

35

35

866-DTE-INFO

CORETM Magellan Unit

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

36

Section VI Care

Cleaning

DentalEZ

®

Equipment

CAUTION

Do not use abrasive cleaning agents.

The CORE delivery unit should be cleaned as

follows:

• Wipe frequently with a damp, lint-free cloth.

• Use a neutral detergent to clean stains.

• At the end of the day, turn the master

ON/OFF valve to the OFF position and clean

instrumentation.

• Each morning, turn the master valve ON and

check the air and water systems for proper

operation using the three-way syringe.

NOTE: It is recommended that puncture-resistant

nitrile gloves be worn for the following procedures.

High-Volume Evacuator (HVE)

With the high-volume evacuator vacuum valve

in the OFF position, disconnect the valve. Using

a brush, clean the interior of the valve under a

faucet, and rinse thoroughly.

Solids Collector

To clean the solids collector located at the

instrument end of the assistant’s arm, do the

following:

1. Push the lever on the saliva ejector upward to

equalize pressure.

2. Remove the lid by lifting it straight up.

3. Grasp the stem on the basket and lift the

basket straight up.

4. Throw away and replace with new basket.

Clean Water System

Empty the bottle at the end of each day, then

before the day’s rst procedure, ll it with fresh

water.

Water Lines

To prevent contamination, maintain clean water

lines and regenerate the BioFreeTM tubing. (Refer

to the included packet.)

Air/Water Pressure Regulator Filter

Saliva Ejector (SE)

Disconnect the saliva ejector valve from the

tubing and repeat the procedure described for the

HVE.

NOTE: After cleaning the HVE, SE and solids

collector, evacuate two cups of SlugBusterTM

vacuum line cleaning solution (one cup each)

through the HVE and SE to sanitize the system.

NOTICE

Cleaning brushes and SlugBusterTM can be

ordered through DentalEZ dealers.

www.DentalEZ.com

PN: 2717-267C

The lter element in the air pressure regulator is

intended to keep moisture out of the unit and the

lter element in the water pressure regulator is

intended to keep contaminants out of the unit. It

is recommended to replace these lters at least

once a year. If the lter element is clogged, it will

visibly look dirty, causing a pressure and ow

drop. In this case, the element should be replaced.

866-DTE-INFO

37

37

Section VI Care

Disinfecting

CAUTION

• Use extreme caution when selecting the

proper chemical disinfectant for the CORE

Magellan unit.

• Avoid using disinfectants in spray

containers because they may cause

premature staining, discoloration and/or

damage to the unit.

• Do not use disinfectants that contain:

▪ Iodophors

▪ Glutaraldehydes

▪ Phenols

CORETM Magellan Unit

▪ Sodium Hypochlorites

▪ Alcohol (on plastic surfaces)

Liquid disinfectants are recommended for use on

the delivery system external surfaces and should

be applied using a soft, clean cloth.

TM

Cavicide

Cavicide is the recommended disinfectant for

use on all ext

from MetrexTM Research

ernal surfaces. Cavicide1

TM

is not

recommended for use.

Cavicide and CaviCide1 are trademarks of Metrex Research, LLC.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

38

Section VII User Service Information

Troubleshooting

DentalEZ

®

Equipment

A full color, fold-out tubing diagram of the CORE

WARNING

Magellan unit is provided with this manual.

• Before servicing, always disconnect the

The following charts should be used when

troubleshooting CORE Magellan unit problems.

If these suggested troubleshooting procedures

do not resolve the problem, refer to the Service

Instruction section that follows.

external power by unplugging the unit

from the power receptacle.

• Exercise extreme caution when

troubleshooting the electrical

components of the CORE Magellan unit.

When testing, always disconnect the

external power. When electrical power

NOTICE

The DentalEZ Technical Service Department is

available to supply service personnel with any

additional information or instructions needed to

repair or maintain the dental delivery system.

is required, safety precautions must be

followed.

• Do not modify this equipment without

authorization from the manufacturer.

• The power module power cord is not

replaceable by service personnel.

Delivery Head

Symptom Possible Cause(s) Solution

Unit will not

turn on

Unit has no

electric power

Unit has no air Unit is not turned on Ensure master toggle valve is in ON position.

No water

(handpiece and

syringe)

Air in coolant

water

No air to master switch Open stop valve in oor utility box.

Open and adjust air regulator to 80 PSI.

Check for pinched red 1/8" tubing in arms.

Faulty master switch Turn switch on and verify air ow.

Faulty air pilot valve Verify on air supply to top tting of valve.

If air is present at top tting of valve, verify air to foot control tubing. If

no air at tubing, valve is defective.

No building power Check main circuit supply.

Faulty electric switch Contact electrician.

Improper outlet voltage Verify proper outlet voltage in USC.

Air stop valve is closed Turn stop valve on and verify 80 PSI on air gauge.

Pinched air line Check for pinched or restricted 1/8" red tubing from oor utility box to

the master switch.

Faulty air pilot valve Check barbs for blockage. If none, replace valve.

Water toggle is in OFF position Place the CMU switch plate toggle in ON position.

No water in clean water bottle Fill bottle.

Pressure regulator not adjusted Ensure clean water system gauge reads 40 PSI.

No air to bottle water system Check for pinched or restricted airline.

Slide clamp is clamping line Move clamp to allow water ow through line.

Unit has not been purged Purge water lines (Section IV Testing, Foot Control & Handpieces)

Faulty water control valve If unit was purged, replace water control valve.

www.DentalEZ.com

PN: 2717-267C

39

39

866-DTE-INFO

Section VII User Service Information

Troubleshooting (Continued)

Handpiece

Symptom Possible Cause(s) Solution

No drive air Drive air ow adjustments on pinch valves

are closed

Faulty handpiece holder valve If valve does not release with handpiece out of holder and tubing to

Faulty foot control Depress foot control if no air is present, repair or replace foot control.

Pinched or restricted tubing Straighten or replace the 1/4" red tubing.

No ber-optic light

at handpiece

No coolant water

at any handpiece

Water dribbles

from handpiece

while in holder

Water dribbles

from handpiece

after foot control

is released

No coolant air to

handpiece

Power transformer is not plugged in Plug transformer into designated receptacle in USC.

Internal wires in control head and

post-mounted console are not connected

No signal air to ber optic lamp control Check pinched or restricted tubing.

Faulty transformer Check output for 22-23 VAC.

Faulty ber optic control Fiber optic controls have a calibration range of 2.5 to 6.0V DC. Check

Faulty bulb Replace bulb.

No signal air to receptacles in the USC Check for pinched or restricted tubing.

Coolant water adjustment valve closed. Turn valve counterclockwise to open valve.

Water toggle on foot control is in the OFF

position

Water toggle on clean water system is in the

OFF position

Slide clamp is in clamped position Slide clamp so it moves freely on tubing.

Water bottle empty Fill water bottle.

Pressure too low on clean water system Verify clean water system pressure gauge reads 40 PSI and adjust

Pinched or restricted tubing Straighten or replace tubing.

Faulty handpiece holder Repair or replace holder.

Pinched or restricted tubing to holder Straighten or replace tubing.

Pinch valve diaphragm is leaking Replace diaphragm.

Low air pressure Ensure air regulator gauge in oor box reads 80 PSI.

Low air pressure Ensure air regulator gauge in oor box reads 80 PSI.

Faulty water control valve Depress foot control then release. Remove black tubing from water

Faulty water relay in foot control Turn unit o . Open foot control and inspect water relay block. If piston

Pinched or restricted tubing from foot control Straighten or replace tubing.

Slide clamp is in clamped position Reposition slide clamp so it moves freely on tubing.

Pinched or restricted tubing Straighten or replace tubing.

Turn adjustments screw counterclockwise to adjust drive air pressure.

Set to manufacturer's recommended pressure.

holder is not restricted, replace hanger valve.

Check connections in control head and post-mounted console.

for proper voltage according to the handpiece manufacturer’s

recommendations.

Flip toggle to the right for the ON position.

Flip toggle to the ON position.

accordingly.

control valve. If dribble continues, replace valve.

is not damaged and is moving freely, stretch the spring. Reassemble

and retry foot control.

CORETM Magellan Unit

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

40

Section VII User Service Information

DentalEZ

Troubleshooting (Continued)

Arm System

Symptom Possible Cause(s) Solution

Horizontal arms

drift left or right

Unit head is not

level from front

to back.

Adjustable arm

does not hold

position.

Symptom Possible Cause(s) Solution

Bowl rinse has no

water

Bowl rinse runs

continuously

Bowl does not

drain or drains

slowly

No water ows

from cup to ll

Unit is not properly leveled Verify unit is level. Also, verify arms are properly seated. Adjust

tension or set screws as needed.

Pivot is not properly adjusted Remove end cap cover and adjust bolt as necessary.

Improper adjustment With nothing on delivery head, adjust bolt at the rear of the ex arm so

unit stays in place.

Faulty brake switch Make sure air is running through the brake toggle when the brake is on.

No air to brake switch Ensure unit master toggle is in ON position.

Cuspidor (Optional)

Delivery HeadDelivery Head

Stop valve closed Open stop valve inside USC compartment.

Pinched or restricted 1/4" green tubing from

oor utility box to post-mounted console

Water actuator valve in oor utility box is not

activated

Bowl rinse button not working Verify air signal is present at the bowl rinse poppet valve on the

Bowl rinse actuator valve in cuspidor is not

opening

Water pressure is too high Set water pressure gauge at 40 PSI.

Bowl rinse actuator valve is stuck open Check the valve in the cuspidor for air signal. If air is present, check

Restricted or pinched drain line Examine drain line and free and obstructions

Restricted or pinched vent line Examine vent line and free any obstructions.

Cup ll button is not working Check actuator valve in cuspidor for air signal at cup ll actuator valve

Cup ll actuator valve in cuspidor is not open Verify signal is present at actuator when cup ll button is depressed. If

Check for restricted or obstructions and free accordingly.

Verify unit master switch is turned ON.

Verify air signal is present at valve on water line.

Verify regulator is open and pressure is at 40 PSI.

cuspidor when the bowl rinse button is depressed.

Verify air signal is present at actuator valve when button is depressed.

At actuator valve in cuspidor, check for water supply from oor utility

box. Also, ensure water passes through the valve when the rinse

button is depressed.

bowl rinse poppet valve. If air is not present, replace actuator valve.

in post-mounted console when button is depressed.

Check for pinched airlines.

air and water are present, replace valve.

®

Equipment

www.DentalEZ.com

PN: 2717-267C

41

41

866-DTE-INFO

Section VII User Service Information

Service Instruction Disposal of Equipment

CORETM Magellan Unit

If the area of concern is not addressed in this

manual, contact your local DentalEZ full-service

dealership at 866-DTE-INFO (866-383-4636). See

Limited Warranty.

Please have the following product information

available. Information may be found on the

product model/serial number label (Figure 41):

• Model Name:

• Model Number:

• Serial Number:

• Date of Installation:

• Dealer:

Model/Serial

Number Label

Disposal and Decommissioning of

DentalEZ Products

NOTE: All local regulatory requirements for

disposal and decommissioning of equipment

apply.

• Electrical Salvage

Remove all circuit board and electrical cabling

for recycle as electrical salvage.

• Metal Salvage

Remove all aluminum and steel components

for recycle as metal salvage.

• Plastic Salvage

Remove all plastic components for recycle as

plastic salvage.

• Biologically Contaminated Salvage

Figure 41. Model/serial number on CORE delivery head

Cuspidor, waste lines from the cuspidor, and

the oral extraction lines should be handled

with precaution and disposed of appropriately.

• Non-Salvage Components

All other material unsuitable for recycling

should be disposed of properly.

For speci c questions regarding material

type, contact DentalEZ customer service. For

decommissioning information on associated

equipment from other manufacturers, refer to the

documentation from the manufacturer.

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

42

Section VIII Parts Lists/Diagrams

DentalEZ

®

Equipment

Utility Service Center

# Part/Kit Name Part/Kit No.

1* Water Actuator Valve 3801-637

2 Stop Valve 3800-960

3 Air Regulator 3801-638

4 Air Regulator Gauge Repl. Kit, Watts 3802-266

5* Water Regulator Gauge Repl. Kit, Watts 3802-269

6* Water Pressure Gauge 3800-533

7 Air Regulator Bowl, Watts 3802-267

8* Water Regulator Bowl, Watts 3802-268

9* Water & Air Regulator Repair Kit, Watts 3802-273

10* Water Regulator Filter, Watts 3802-270

11 Air Regulator Filter, Watts 3802-271

12 Regulator Retainer, Watts 3802-272

13 Poppet Valve 3801-649

*Optional Equipment

*1

3

2

*5

Pivot/Mounting Hardware

# Part/Kit Name Part/Kit No.

14 Pivot Hardware Kit, Unit or Light Pole 3801-866

14

4

7

*8

*9

*10 11

12

*6

13

www.DentalEZ.com

PN: 2717-267C

43

43

866-DTE-INFO

Section VIII Parts Lists/Diagrams

Simplicity Assistant’s Arm (Optional)

# Part/Kit Name Part/Kit No.

1 Instrument Holder 3801-710

2 Touch Pad PCB 3801-761

3 Touch Pad Cover 3801-708

4 Switch, J Membrane 3801-790

4a Switch, Simplicity Membrane 3802-356

5 Lid 3801-707

6 O-Ring 3801-720

7 Solids Collector Trap (3) 3625-338

8 Bottom Housing 3801-709

CORETM Magellan Unit

5

4

4a

6

7

3

2

8

1

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

44

Section VIII Parts Lists/Diagrams

DentalEZ

®

Equipment

Galaxy Assistant’s Arm (Optional)

# Part/Kit Name Part/Kit No.

9 Instrument Holder Housing 3801-963

9a Instrument Housing w/Electrical Switches 3802-327

10 Solids Collector Trap (3) 3625-338

11 Lid 3801-964

12 O-Ring 3801-720

13 Inside Cover 3801-965

14 Bottom Housing 3801-966

12

14

11

10

13

9 9a

www.DentalEZ.com

PN: 2717-267C

45

45

866-DTE-INFO

Section VIII Parts Lists/Diagrams

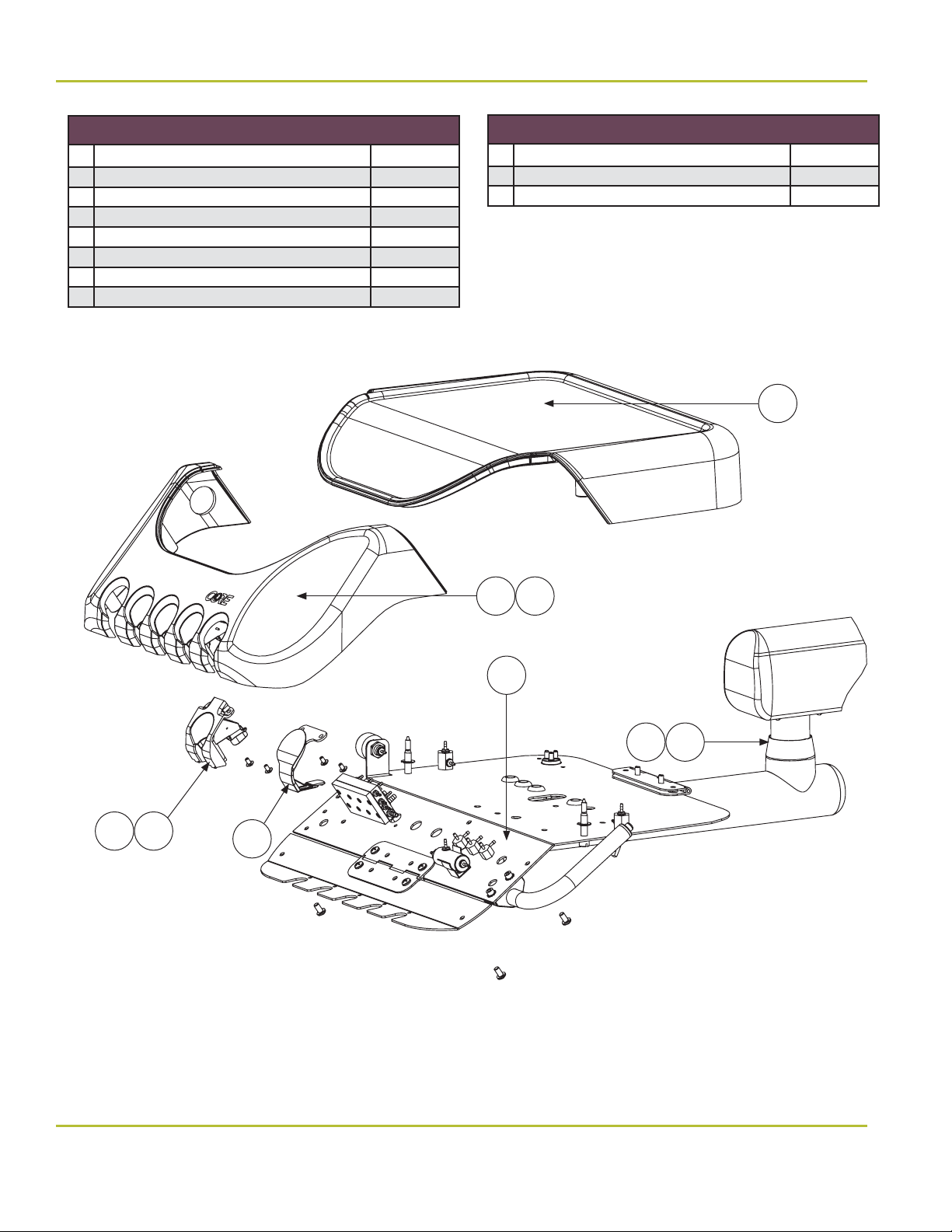

CORE Assistant’s Arm (Optional)

# Part/Kit Name Part/Kit No.

1 Core Rear Assist Solids Cap 3802-556

2 O-Ring 3801-720

3 Core Rear Assist HVE Insert 3802-557

4 Core Rear Assist SE Insert 3802-558

5 Core Rear Assist Solids Bowl 3802-559

6 Core Rear Assist Pivot Pin 3802-560

7 Core Rear Assist BTM Cover 3802-561

8 Core Rear Assist TP, Blank 3802-562

9 Core Rear Assist TP, Core Chair 3802-563

10 Core Rear Assist TP, NuSimplicity Chair 3802-564

11 Solids Collector Plug 3802-565

12 Solids Collector Basket 3625-927

12

CORETM Magellan Unit

1

2

8 9 10

4

3

5

11

6

7

www.DentalEZ.com

PN: 2717-267C

866-DTE-INFO

46

Section VIII Parts Lists/Diagrams

2

DentalEZ

®

Equipment

CORE Delivery Head

# Part/Kit Name Part/Kit No.

1 CORE Rigid Arm Cap 3802-553

2 CORE Flex Arm Cap 3802-554

3 CORE Flex Arm Cover 3802-555

4 Master ON/OFF Toggle 3802-063

5 Flush Toggle 3802-064

6 Air Pressure Gauge 3801-695

7 Repair Kit for Control Block 3802-386

8 Water Retraction Valve 3800-417

9 Brake Handle and Valve 3802-249

10 Lid Screw 3802-387

11 CORE Unit Oil Collector 3802-550

3

1

4

6

11

5

7

10

9

8

www.DentalEZ.com

PN: 2717-267C

47

47

866-DTE-INFO

Section VIII Parts Lists/Diagrams

CORETM Magellan Unit

CORE Delivery Head (Continued)

# Part/Kit Name Part/Kit No.

12 CORE HP Holder w/o Valve 3802-545

13 CORE HP Holder w/ Valve 3802-546

14 CORE HP Blank 3802-547

15 CORE Unit Cover 3802-548

16 CORE Unit Water Adjustment Valve 3802-549

17 CORE Head to Flex Arm Cap 3802-551

18 CORE Head to Flex Arm Key 3802-552

Touch Pads

# Part/Kit Name Part/Kit No.

19 CORE Chair 3802-573

20 NuSimplicity Chair 3802-580