Denon DVM-4800 Service Manual

SERVICE MANUAL

For U.S.A. & Canada model

Digital Player

MODEL

DVD VIDEO AUTO CHANGER

DVM-4800

Some illustrations using in this service manual are slightly different from the actual set.

14-14, AKASAKA 4-CHOME, MINATO-KU, TOKYO 107-8011 JAPAN

Telephone: 03 (3584) 8111

X0124 205 NC 0110

DVM-4800

SPECIFICATIONS

Signal system: NTSC

Applicable discs: (1) DVD-video/audio discs

1-layer 12 cm single-sided discs, 2-layer 12 cm single-sided discs,

2-layer 12 cm double-sided discs (1 layer per side)

1-layer 8 cm single-sided discs, 2-layer 8 cm single-sided discs,

2-layer 8 cm double-sided discs (1 layer per side)

(2) Compact discs (CD-DA, Video CD)

12 cm discs, 8 cm discs

S-Video output: Y output level: 1 Vp-p (75 Ω/ohms) C output level: 0.286 Vp-p

Output connectors: S connectors, two sets

Video output: Output level: 1 Vp-p (75 W/ohms) Output connector: Pin-plug jacks, two sets

Component output: Y output level: 1 Vp-p (75 Ω/ohms)

C

B/CR output level: 0.650 Vp-p (75 Ω/ohms) PB/PR output level: 0.700 Vp-p (75 Ω/ohms)

Output connector: Pin jack, 1 set

Audio output: Fixed output level: 2 Vrms (1 kHz, 0 dB)

Number of connectors: 1 set (2 ch mixed output)

1 set (6 ch discrete output)

Audio output properties: (1) Frequency response

• DVDs (linear PCM) : 2 Hz to 22 kHz (48 kHz sampling)

: 2 Hz to 44 kHz (96 kHz sampling)

: 2 Hz to 88 kHz (192 kHz sampling)

• CDs : 2 Hz to 20 kHz

(2) S/N ratio

• DVDs : 115 dB

• CDs : 115 dB

(3) Total harmonic distortion

• DVDs : 0.0025 %

• CDs : 0.0030 %

(4) Dynamic range

• DVDs : 108 dB

• CDs : 100 dB

Digital audio output: Optical digital output: Optical connector, 1 set

Coaxial digital output: Pin jack, 1 set

Power supply: AC 120 V, 60 Hz

Power consumption: 22 W

Maximum external

dimensions: 434 (width) x 131 (height) x 415 (depth) mm (not including protruding parts)

Mass: 7.2 kg

■ Remote Control Unit: RC-548

Type: Infrared pulse

Power Supply: DC 3 V, two batteries ("AAA" (R03))

2

DVM-4800

3

DVM-4800

1. COUNTERMEASURES AGAINST ELECTROSTATIC DISCHARGE (ESD)

The laser diode in the traverse unit (laser pickup) may be damaged by static electricity charged in your cloth or body. Be

careful not to damage it by ESD when handling for servicing.

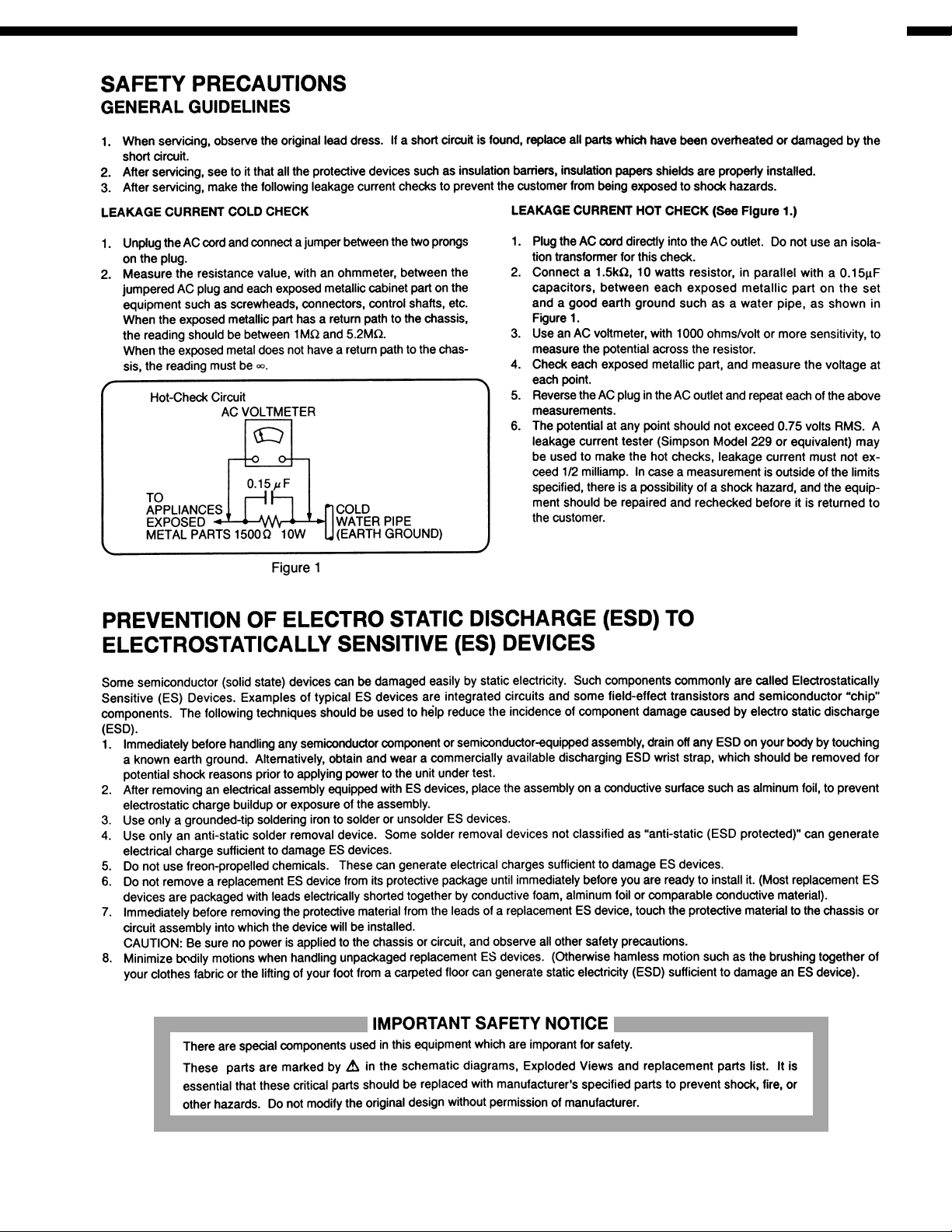

1.1 Grounding for Electrostatic Breakdown Prevention

Components using an optical pickup (laser diode) such as DVD players etc. are liable to breakdown by static electricity under

the working environment.

Perform repair work in the working condition having proper grounding for preventing static electricity.

1.1.1 Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the optical pickup is placed and ground the sheet.

1.1.2 Human body grounding

Use an anti-static wrist strap to discharge the static electricity from your body.

1.1.3 Handling of optical pickup

1) The optical pickup for spare parts is supplied with its laser diode shorted to ensure quality during transportation.

After the parts replacement, return to normal by proper procedures. (refer to the pages related)

2) Do not use a tester or etc. for checking the laser diode since the laser diode may be damaged easily by the voltage

of the tester inside battery.

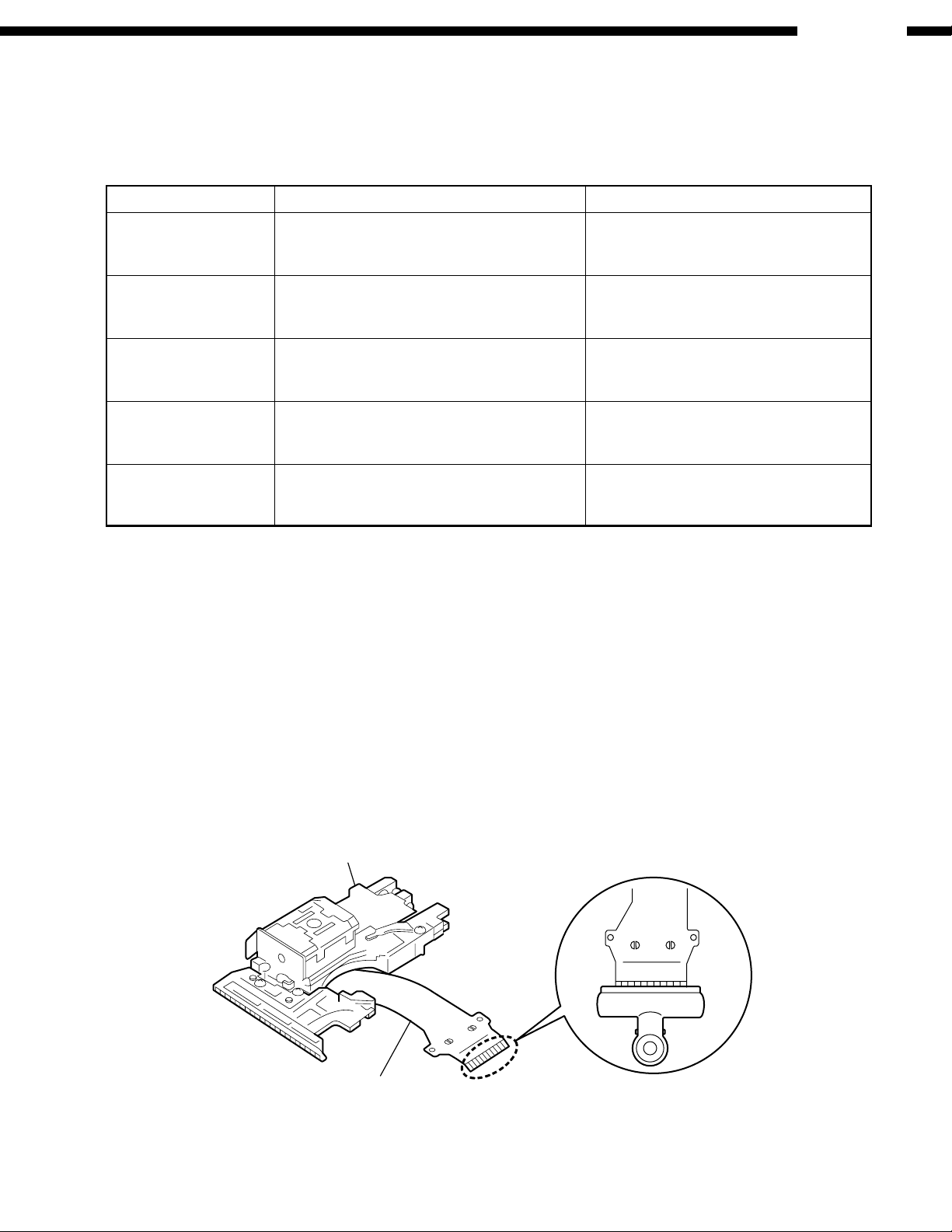

Wrist strap

(Anti-static bracelet)

Iron plate or some metals

to conduct electricity

1.2 Handling of Traverse Unit (laser pickup)

1.2.1 Do not apply a strong shock to the traverse unit (laser pickup) since it is made of precise structure.

1.2.2 To prevent the breakdown of the laser diode, install the flexible cable after removing the short pin for preventing a

electrical charge. When removing or connecting the short pin, finish the job in as short time as possible.

Also, cut out the short land of the flexible cable using nippers and etc. after replacing the optical pickup. Refer to

TRAVERSE UNIT DISASSEMBLY” in this manual for the handling of the traverse unit.

1.2.3 Be careful not to apply excessive stress to the flexible board (FPC Board) since it may cause cutting.

1.2.4 Do not turn the variable resistor of the laser power since it is not adjustable.

4

DVM-4800

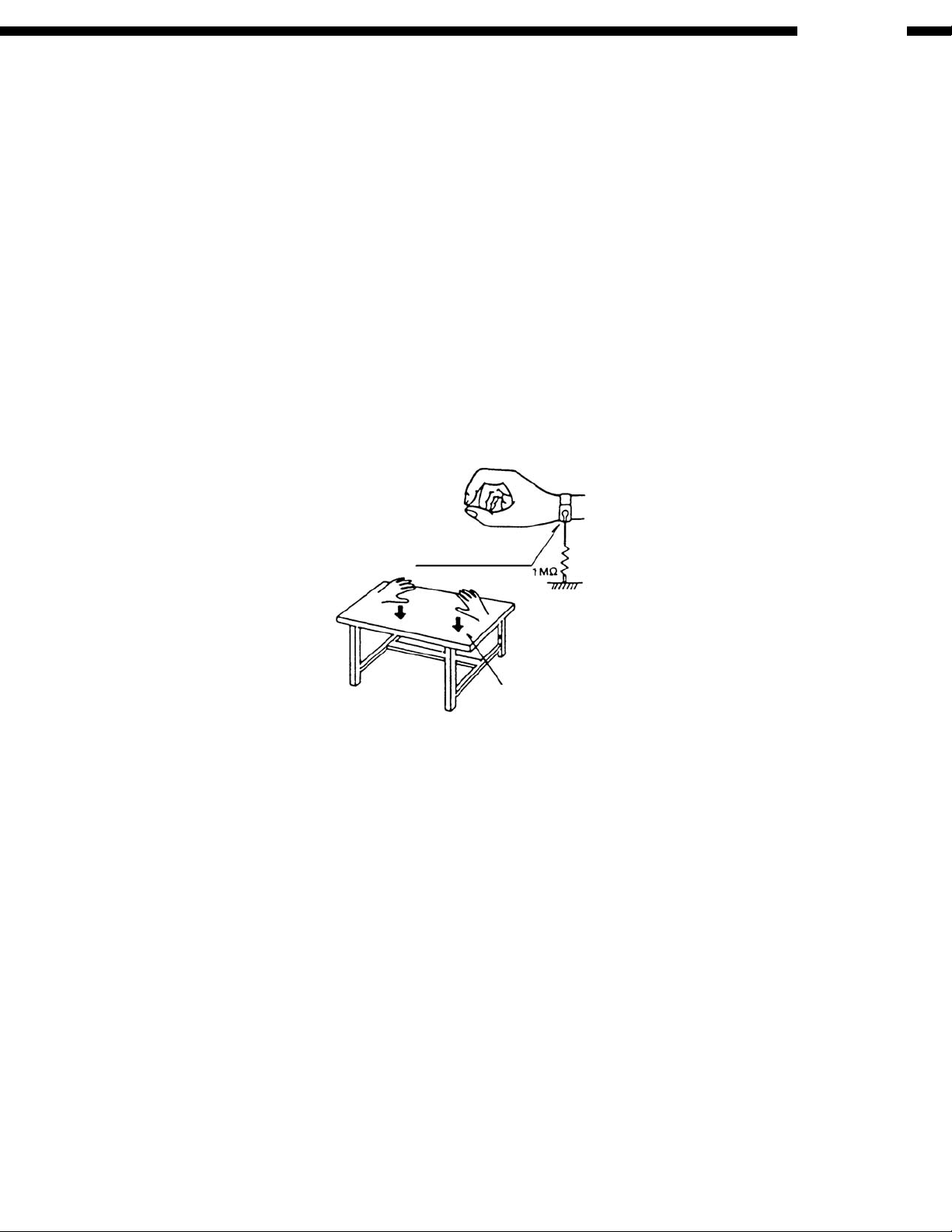

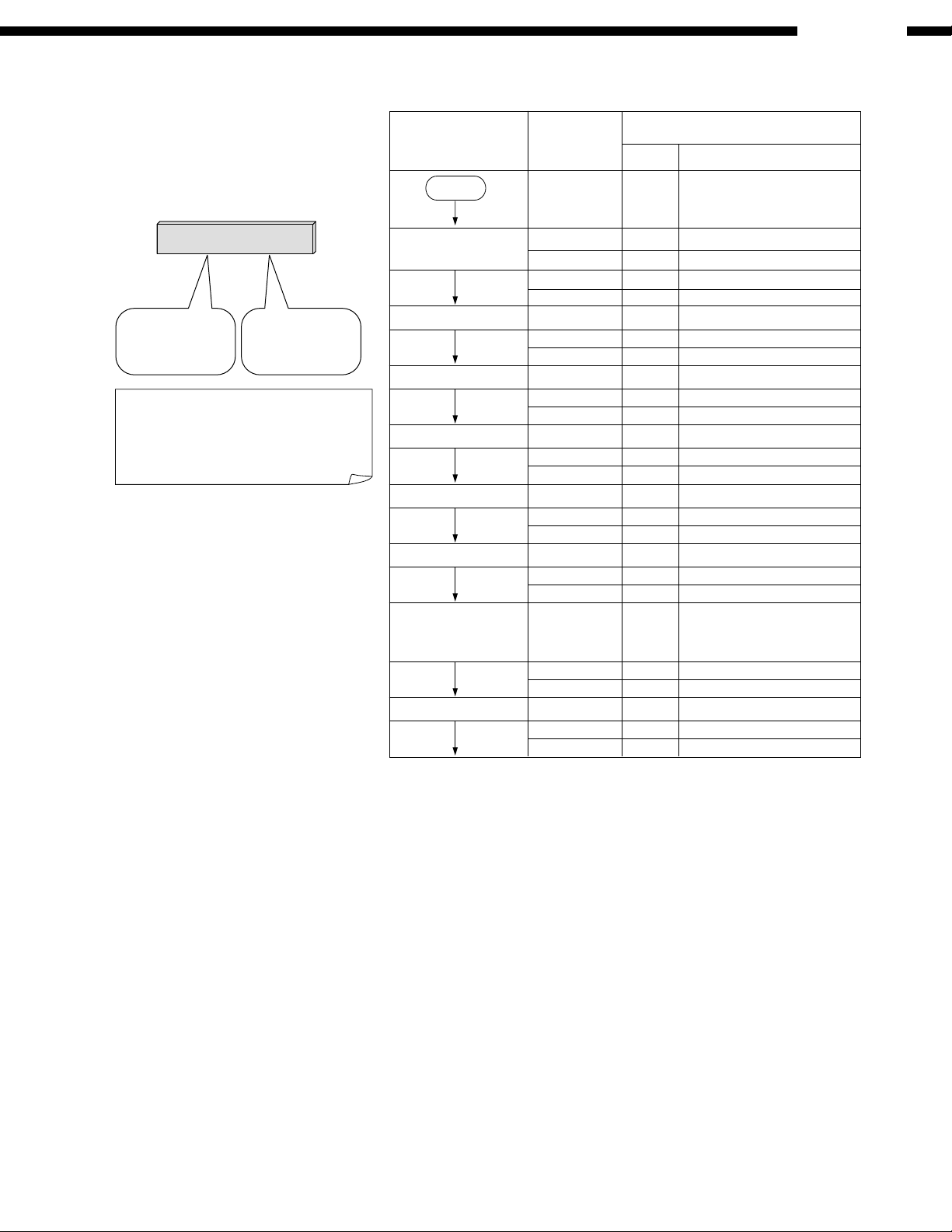

2. OPTICAL PICKUP SELF-DIAGNOSIS AND REPLACEMENT PROCEDURE

2.1 Self-diagnosis

The optical pickup self-diagnosis function and tilt adjustment check function have been included in this unit. When repairing,

use the following procedure for effective Self-diagnosis and tilt adjustment. Be sure to use the self-diagnosis function before

replacing the optical pickup when "NO DISC" is displayed. As a guideline, you should replace the optical pickup when the

value of the laser drive current is more than 55.

Note:

Press the power button to turn on the power, and check the value within three minutes before the unit warms up.

(Otherwise, the result will be incorrect.)

"NO DISC" is displayed, unit does

not play smoothly, etc.

Use the optical pickup self-diagnosis function.

Method: With no disc in the player:

• Press the "DISPLAY" button on the

remote control unit while pressing the

Check the laser drive current.

"PAUSE" and "OPEN/CLOSE" buttons on

the player.

[Display content]

Value is 70 (DVD),

55 (CD) or less

Replace the optical pickup (Refer

to the section "OPTICAL PICKUP

REPLACEMENT PROCEDURE"

in this Guide.)

Check the laser drive current after

replacement.

Write the present value into the

unit if it is 60 (DVD), 45 (CD) or

less.

Do the optical pickup tilt adjustment. (Refer to the section "TILT

ADJUSTMENT" in this Guide.)

Value is more than

70 (DVD), 55 (CD)

Use the tilt

adjustment check

function.

Factory setting Present value

Replace with a new optical pickup if the present

value is more than 60 (DVD), 45 (CD).

Cause: Damage due to static electricity during

replacement.

Method: With no disc in the player:

• Press the "DISPLAY" button on the remote

control unit while pressing the "PAUSE" and

"OPEN/CLOSE" buttons on the player.

Write the present value

into the player if it is 45

or less.

Writing Method:

• Press the "PAUSE" button on the remote

control unit while pressing the "PAUSE" and

"OPEN/CLOSE" buttons on the player.

Initialize the player.

5

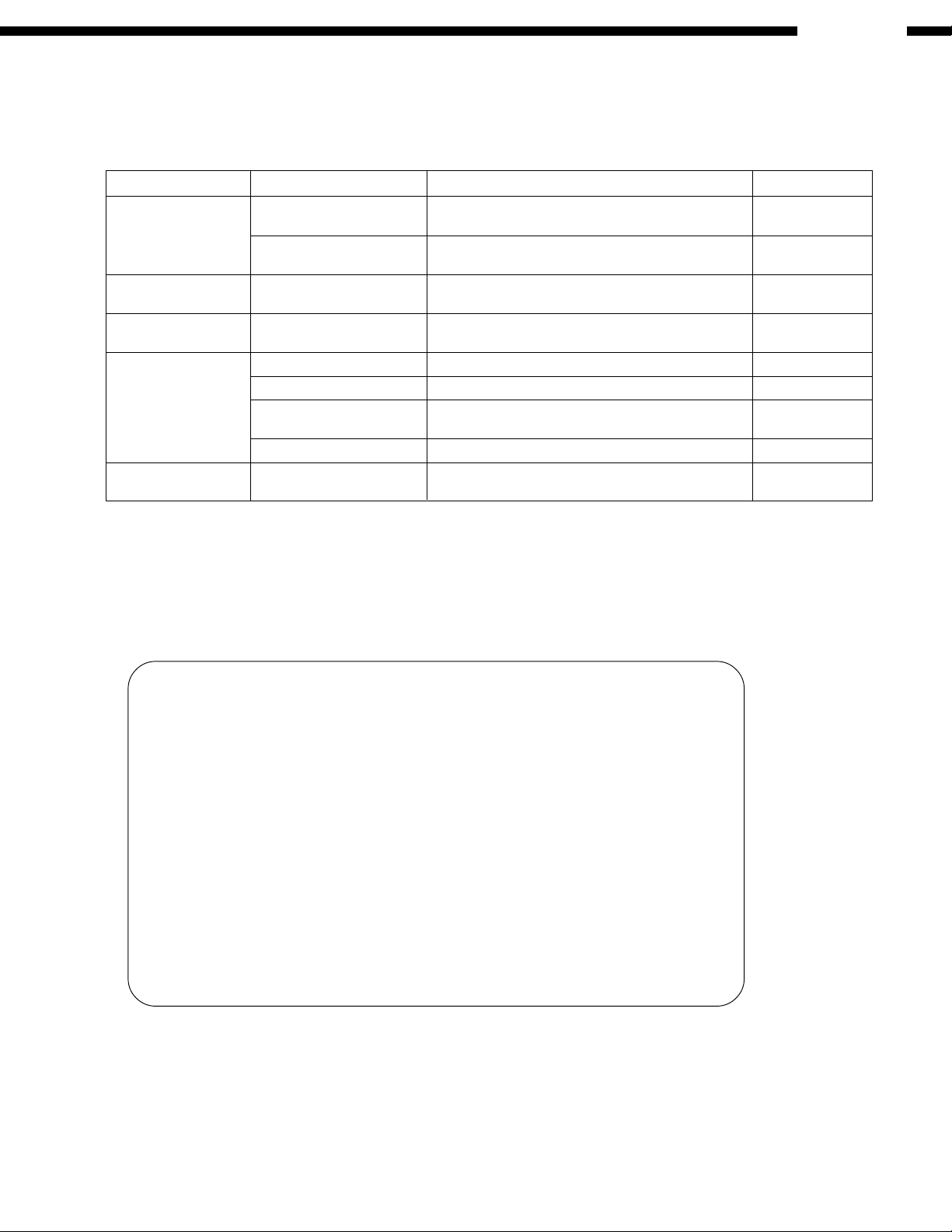

2.2 Cautions to Be Used Before Replacing the Optical Pickup Unit

and Spindle Motor Assembly

Before replacing the optical pickup unit and spindle motor assembly, check the total using hours for each of them.

The checking method is as follow:

Operating state & Key operation Display

Using hours of CD laser Press "PAUSE, FWD-SKIP" and "5" on the T1_xxxx_yyyy: total hours are

remote control in this order while the unit displayed by 4-digit figures (unit: 10 hours).

is stopped yyyy: CD laser Time

Using hours of DVD laser Press "PAUSE, FWD-SKIP" and "5" on the T1_xxxx_yyyy: total hours are

remote control in this order while the unit displayed by 4-digit figures (unit: 10 hours).

is stopped xxxx: DVD laser Time

Using hours of SP motor Press "PAUSE, FWD-SKIP" and "6" on the T2_xxxx: total hours are

remote control in this order while the unit displayed by 4-digit figures

is stopped (unit: 10 hours).

Resetting using hours While displaying Timer 1 data, press STOP T1_0000_0000

of CD and DVD lasers and FWD-SKIP buttons on the player, and

(Simultaneous resetting) "5" button on the remote control unit

Resetting using hours While displaying Timer 2 data, press STOP T2_0000

of the motor and FWD-SKIP buttons on the player, and

"6" button on the remote control unit

DVM-4800

Cautions to be taken when replacing the optical pickup

The optical pickup may break down due to the static electricity of human body. Take proper protection measures against static

electricity before repairing the parts around the optical pickup. (See the page describing the PREVENTION OF STATIC

ELECTRICITY DISCHARGE.)

1. Do not touch the areas around the laser diode and actuator.

2. Do not judge the laser diode with a tester. (The tester will be damaged easily.)

3. It is recommended to use a destaticized soldering iron for short-circuiting or removing the laser diode.

(Recommended soldering iron) HAKKO ESD Product.

4. Solder the land of the flexible cable in the optical pickup.

Note:

• When using a soldering iron which is not destaticized, short-circuit the terminal face of the flexible case with a clip.

After that, short-circuit the land.

• After the repairing work is completed, remove the solder according to the correct procedure shown in this Technical

Guide.

Optical pickup unit

Flexible cable

Ground with a clip.

6

3. SELF-DIAGNOSIS FUNCTION AND SERVICE MODES

3.1 Self-diagnosis Function and Service Modes

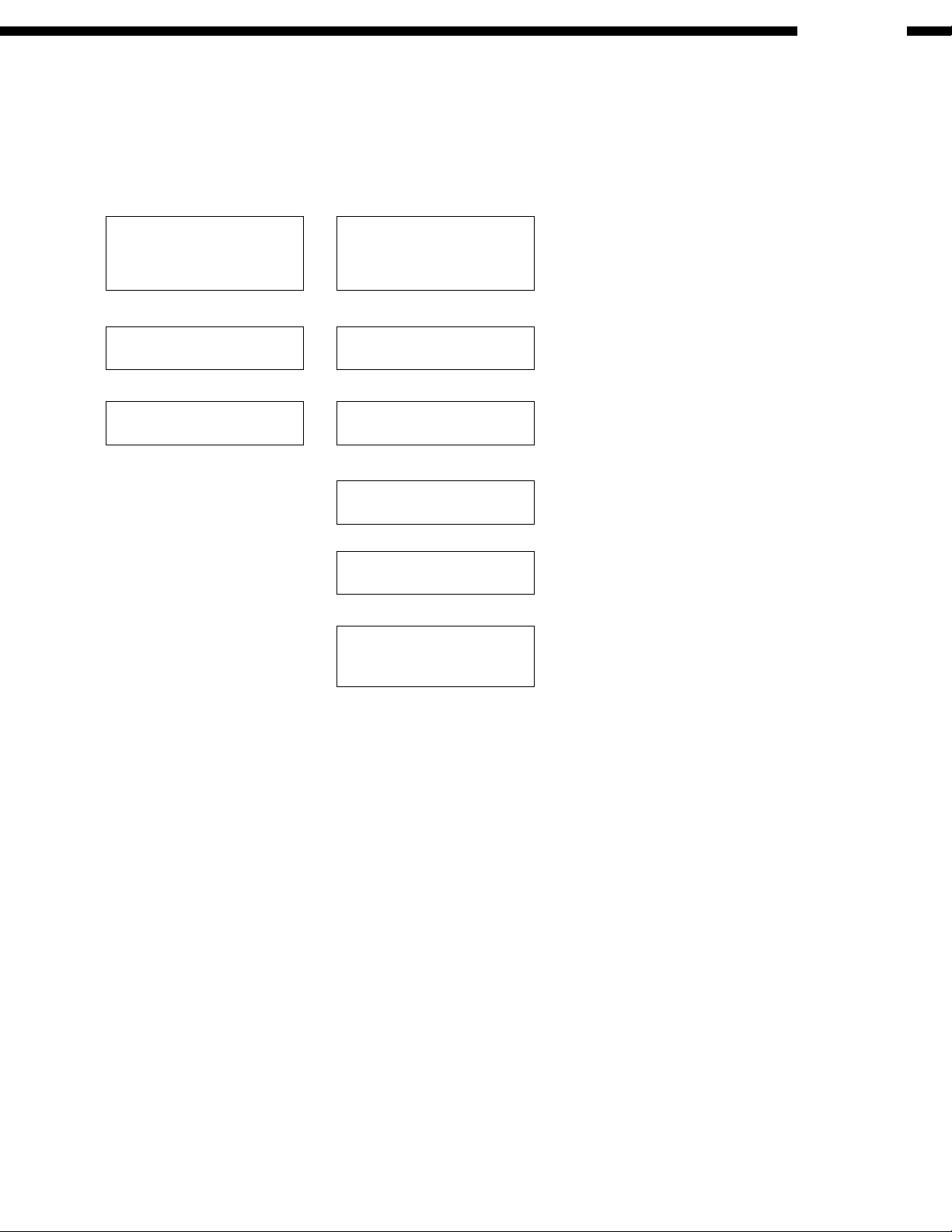

Improving the self-diagnosis function

The self-diagnosis function in our DVD player currently in use is improved as follows:

DVM-4800

Our DVD player currently

in use

UHF error display

The latest error storage

function

n=1

Jitter/read error display

Laser drive current display

For DVD

Our new DVD

UHF error display

The latest error storage

n=20

Jitter/read error display

Focus drive value display

laser drive current display

For DVD/CD

ADSC internal RAM data

display

Servo process display

Total operation time

display SP motor

Laser (DVD/CD)

The storage capacity is increased.

The focus drive current value can be displayed.

The servo learning value stored in the RAM data

inside the ADSC (servo controller) IC is displayed.

Mainly in the initial starting operation period of the

player, a number is allotted to the servo process

of each step, and the process of the starting

operation can be displayed.

The operation times of SP motor and the laser

(both for the DVD and CD) can be displayed.

7

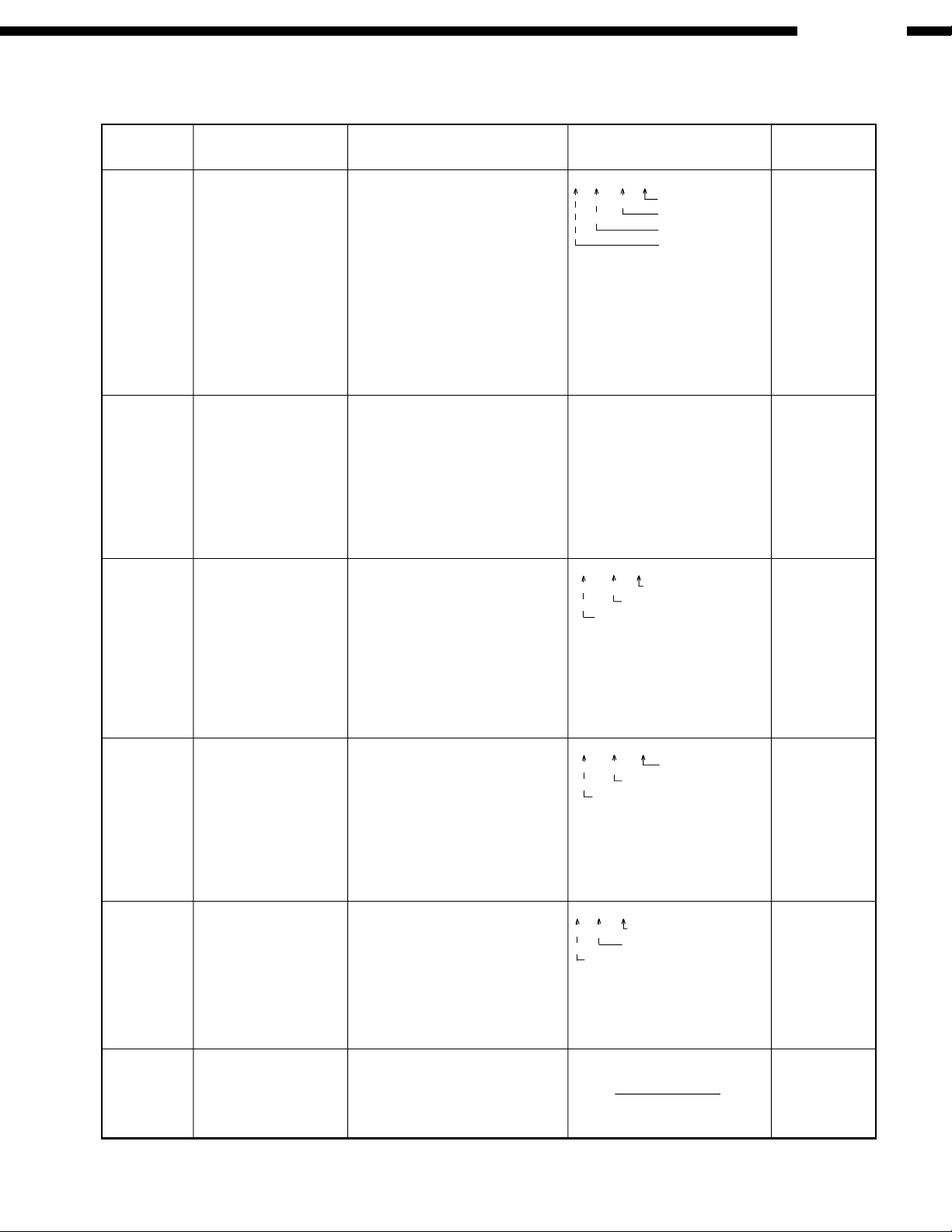

3.2 Service mode table

Pressing various button combinations on the player and remote control unit can activate the service modes.

DVM-4800

Item

Jitter check In PLAY mode, press Jitter check J_xxx_yyy_zz Press STOP

Error code In ** mode, press PAUSE Error code check Error code (play_err) is expressed Cancelled

check and OPEN buttons on the The latest error code stored in in the following convention. automatically

Initial setting In STOP mode, press Initial setting of laser drive current LDO_034_028 Cancelled

of laser drive PAUSE and OPEN buttons lnitial current value for each of DVD

current on the player, and PAUSE laser and CD laser is separately

DVD laser In STOP mode, press DVD laser drive current measurement LDD_034_032 Cancelled

drive current PAUSE and OPEN buttons DVD laser drive current is measured Measured current automatically

measurement on the player, and and the result is displayed together

ADSC internal In ** mode, press PAUSE ADSC internal RAM data check A_DFA_6901 Press STOP

RAM data and OPEN buttons on the ADSC internal RAM data is read out

check player, and RETURN and displayed. Address

Servo process In STOP mode, press Servo process display Turn off the

display PAUSE and FWD-SKIP The servo process from STOP to primary power.

button combination method

PAUSE and OPEN buttons Jitter rate is measured and displayed. Focus drive value or OPEN button.

on the player, and "5" Measurement is repeatedly done in Read error counter

button on the remote the cycle of one second. Read error Jitter rate

control unit. counter starts from zero upon mode Jitter check mode

setting, When target block data failed

to be read out, the counter advances Jitter rate is shown in decimal

by one increment. When the failure is notation to one place of decimal.

caused by minor error, it may be Focus drive value is shown in

corrected when retried to enable hexadecimal notation.

successful reading. In this case, the

counter advances by one. When the

error persists even after retry, the

counter may jump by two or more.

player, and "0" button on EEPROM is displayed.

the remote control unit.

* With pointing of cursor

up and down on diaplay,

panel controller switches * "nn" denotes the serial number

the serial number of of history.

history and sends out the

command accordingly.

button on the remote saved in EEPROM.

control unit.

DISPLAY button on the with the initial value stored in

remote control unit. EEPROM.

After the measurement, DVD laser The value denotes the current in

emission is kept on. It is turned off decimal notation. The above

when POWER key is switched off. (It example shows the initial current

is also turned off when the primary is 34mA and the measured value

power is switched off.) is 32mA.

button on the remote Change the address with CLEAR key

control unit. operation to show the data for 11

addresses. The value is shown in hexadecimal

buttons on the player, and ACCESS is displayed.

"7" button on the remote

control unit.

Function Display

Error code=0 x DAXX is expressed: ➔ nn UXX

Error code=0 x DBXX is expressed: ➔ nn HXX

Error code=0 x DXXX is expressed: ➔ nn FXX

Error code=0 x 0000 is expressed: ➔ nn F--

DVD laser current measurement

Laser current measurement mode

The value denotes the current in

decimal notation. The above

example shows the initial current

is 34mA and 28mA for DVD laser

and CD laser respectively when

the laser is switched on.

Initial current stored in EEPROM

DVD laser current measurement mode

ADSC internal RAM data check mode

notation. The above example

shows the data in ADSC address

DFAh is 6901h.

CD laser current measurement

RAM data for specified address

Player mode and

Cancellation

5 seconds later.

automatically

5 seconds later.

5 seconds later.

or OPEN button.

8

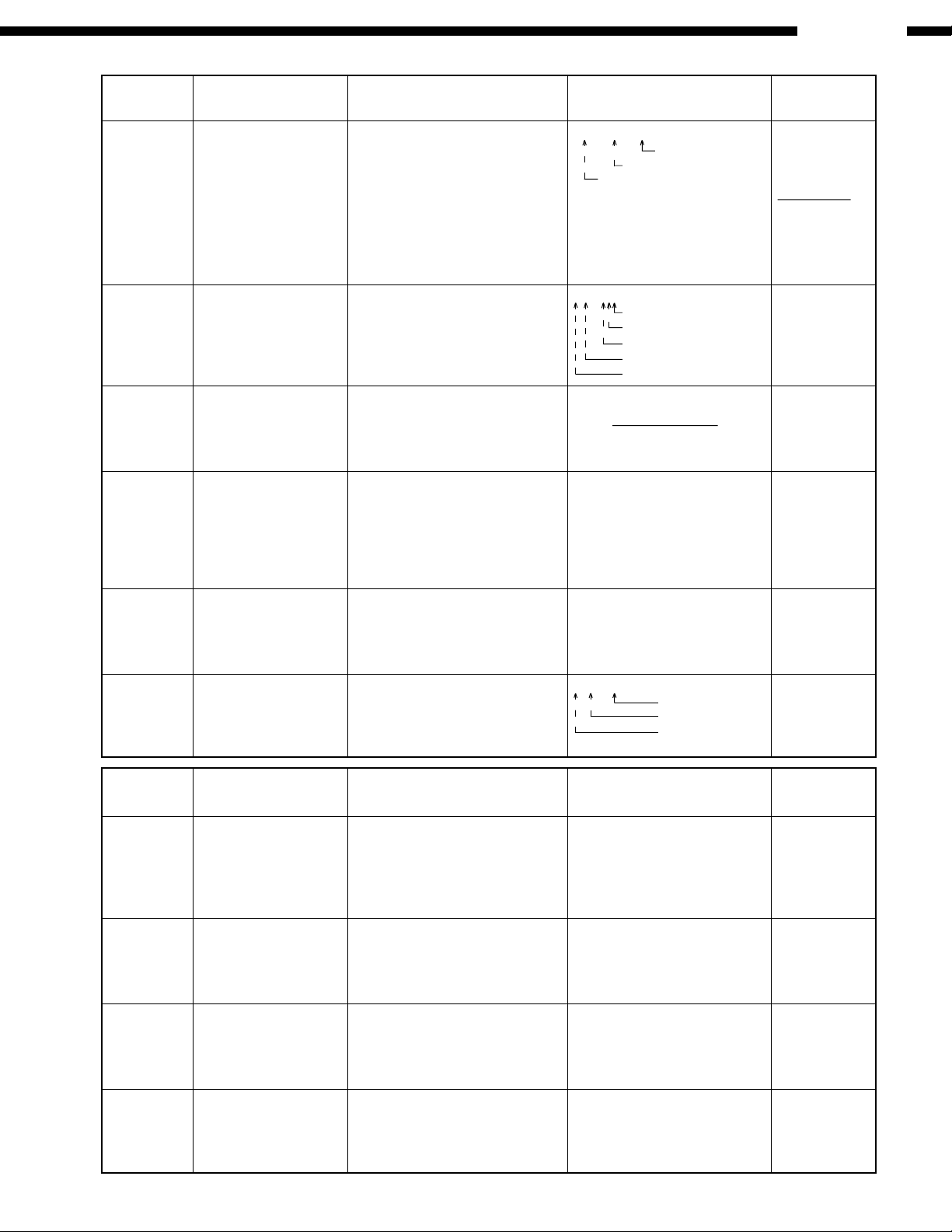

DVM-4800

Item

CD laser drive In STOP mode, press CD laser drive current measurement LDC_028_026

current PAUSE and FWD-SKIP CD laser drive current is measured

measurement buttons on the player, and and the result is displayed together

Version In STOP mode, press Version display srrr_xyzzz Cancelled

display PAUSE and OPEN buttons

Lighting of In ** mode, press Lighting of display tube Press STOP

display tube PAUSE and OPEN buttons or OPEN button.

Dealer's lock In STOP mode, press Dealer's lock "LOCKED" sign appears when Repeat the

Initializaition In STOP mode, press Initialization "INITIALIZED"

Region display In STOP mode, press Region display x_yy_zzz Cancelled

button combination method

DISPLAY button on the with the initial value stored in

remote control unit. EEPROM.

After the measurement, CD laser The value denotes the current in

emission is kept on. It is turned off decimal notation

when POWER key is switched off. (It The above example shows the

is also turned off when the primary initial current is 28mA and the

power is switched off.) measured value is 26mA.

on the player, and "7"

button on the remote

control unit.

on the player, and "9"

button on the remote

control unit.

STOP button on the The lock is switched ON or OFF. dealer's lock is switched on, or same operation.

player, and POWER button When dealer's lock is ON, it prohibits when secondary power key or tray

on the remote control unit. switching off of the secondary power opening key is pressed while the

and tray opening. lock is on.

When the lock is switched, its ON/OFF "UNLOCKED" sign appears when

status is stored in EEPROM. dealer's lock is switched off.

PAUSE, BWD-SKIP and User settings are cancelled and player

OPEN buttons on the is initialized to factory setting.

player for 3 seconds or

longer.

PAUSE and OPEN buttons N: NTSC/6: PAL60 automatically

on the player, and "6" N: noPAL/P: PAL 5 seconds later.

button on the remote Region No.

control unit.

Function Display

Measured current

Initial current stored in EEPROM

CD laser current measurement mode

System controller release number

System controller model number

System controller generation

Panel controller release number

Panel controller model number

Player mode and

Cancellation

automatically

5 seconds later.

Item

Timer 1 check In STOP mode, press Timer 1 check T1_1234_5678 Cancelled

Timer 1 reset While displaying Timer 1 Timer 1 reset T1_0000_0000 Cancelled

Timer 2 check In STOP mode, press Timer 2 check T2_1234 Cancelled

Timer 2 reset While displaying Timer 2 Timer 2 reset T2_0000 Cancelled

button combination method

PAUSE and FWD-SKIP Laser operation timer Operation time is

buttons on the player, and measured separately for DVD laser and to the right CD laser time. 5 seconds later.

"5" button on the remote and CD laser.

control unit. notation in a unit of 10 hours.

data, press STOP and Laser operation timer Operation time automatically

FWD-SKIP buttons on the of both DVD laser and CD laser is 5 seconds later.

player, and "5" button on reset all at once.

the remote control unit.

PAUSE and FWD-SKIP Spindle motor operation timer

buttons on the player, and

"6" button on the remote notation in a unit of 10 hours.

control unit. "0000" will follow "9999".

data, press STOP and Spindle motor operation timer automatically

FWD-SKIP buttons on the 5 seconds later.

player, and "6" button on

the remote control unit.

Function Display

Shown to the left is DVD laser time,

Time is shown in 4 digits of decimal

"0000" will follow "9999".

Time is shown in 4 digits of decimal

Player mode and

Cancellation

automatically

automatically

5 seconds later.

9

3.3 Servo Process Flow

DVM-4800

Specification of the servo process

display in the starting flow

1 2 0 9

Servo process

that has stopped

(Restrictions)

All processes that are under operation

cannot be displayed due to the limit of

the processing time.

Servo process

that is under

operation

Starting flow

START

Initial setting

Tray control

TRV initial movement

Disc detection

Disc type distinction

Focus servo

Tracking servo

Range of the

servo process

numbers

00 00 Each initial setting

01 01 TRV initial movement

02~08 02 Initial setting in FE system

02~08 02 Initial setting in FE system

10~13 12 Focus ON

14~15 15 Tracking ON

Processing items

Contents of each processNumber

05 Detecting LD ON HALF

08 Detecting CD LD ON

13 FBAL adjustment

Gain learning

ID read

17 17 Gain adjustment in ADSC

focus system

18~1A 19 DBAL/equalizer adjustment

1A ID read

10

DVM-4800

3.4 Servo Process Display Mode

In starting operation of the player, a number is allotted to each servo process so that the operation of each step can be seen.

The relation between the process and the displayed number are as follows:

Number allotment to the servo process

Process classification Each processing item Description Process number

Initial start process Initial start The process starts after the tray is loaded. (The state 0~40

is changed to "READY" or "PREPARE".)

Secondary learning Servos for the DVD-DL 1st layer and the CD-DA double 50~7F

Restart process Restart When a user operates in the "READY" state, each servo 80~9F

Seek process Seek The optical pickup is moved to the disc destination in A0~BF

Repair process Recover

(Error check) An error is searched in the PLAY/SEEK state. C1~C3

(Attention) An error is recovered following the attention error C4~C6

(Q code read) If any Q code is improperly read, reset and retry. C7~C9

Stop process Stop A servo is controlled in response to the user's operation F0~FF

speed are learned in this step.

is turned on.

this process.

interrupt from the S-ODC.

to stop the disc completely.

3.5 ADSC Internal Ram Data Display

The servo learning value in the RAM data inside the servo processor ADSC is displayed.

The value is useful for the servo operation/disc quality judge including the OPU.

The concrete contents are shown below:

Address

Contents of display

4B4 Focus gain learning value for DVD-S, DVD-D(L0), CD, and VCD

4BC Focus gain learning value for DVD-D(L1)

4B6 Focus balance learning value for DVD-S, DVD-D(L0), CD, and VCD

4BE Focus balance learning value for DVD-D(L1)

4B5 Tracking gain value for DVD-S, DVD-D(L0), CD, and VCD

4BD Tracking gain value for DVD-D(L1)

TB0 Tracking balance value for DVD-S, DVD-D(L0), CD, and VCD

TB1 Tracking balance value for DVD-D(L1)

DBD DSL offset learning value for DVD-S and DVD-D

DBC DSL offset learning value for CD and VCD

FC0 Equalizer FC value for DVD-S, DVD-D(L0), CD, and VCD

BT0 Equalizer BOOST value for DVD-S, DVD-D(L0), CD, and VCD

FC1 Equalizer FC value for DVD-D(L1)

BT1 Equalizer BOOST value for DVD-D(L1)

11

DVM-4800

3.6 Sales demonstration lock function

This function prevents discs from being lost when the unit is used for sales demonstrations by disabling the disc eject

function. "LOCKED" is displayed on the unit, and ordinary operation is disabled.

Setting

The sales demonstration lock is set by simultaneously pressing STOP button on the player and POWER button on the

remote control unit.

Cancellation

The lock can be cancelled by the same procedure as used in setting. ("UNLOCKED" is displayed on cancellation.

Disconnecting the power cable from power outlet does not cancel the lock.)

3.7 Service Precautions

3.7.1 Recovery after the DVD player is repaired

When an FROM or an EEPROM in and on the module P.C.B. has replaced, carry out the recovery disc processing to

optimize the drive.

Playback the disc above to process the recovery automatically.

Recovery disc (Product number: RFKZD5TR001)

Note:

This unit requires no initialization process carried out after the traditional DVD players were repaired.

When the recovery measures are taken, the customer setting will return to the factory setting as same as the procedure

described in item of "Initialization" in 2.2 is carried out. Write down the contents of the setting before recovery processing,

and reset the player.

3.7.2 Firmware version-up of the DVD player

The firmware of the DVD player may be renewed to improve the quality including operationability and playerbility to the

substandard discs processing to optimize the drive.

The version-up disc has also a recovery function so that you don't need use the recovery disc again.

Note:

If the AC power supply is shut out during version-up due to a power failure, the version-up is improperly carried out.

In such a case, replace the FROM and carry out the version-up again.

The product number of the version-up disc will be noticed when it is supplied.

3.7.3 Initialization of DVD Player

Initialize the DVD player when replacing CPU and its peripheral parts, and Mother P.W.B., etc.

How to Initialize

Pressing the "STILL/PAUSE" + "SKIP REW" + "OPEN/CLOSE" buttons at once makes DVD player initialization (factory

setting condition). "INITIALIZED" is indicated on the screen and "INITIALIZE" on the display of the main unit.

Note

When the initialization has been made, the contents of user setting is lost.

Therefore, memorize the contents of user setting prior to the initialization and re-set them again after the initialization.

3.7.4 Setting after Repair

After finishing the repair work, follow the steps below.

Setting Condition

At the power on state,

1) Press the "OPEN/CLOSE" button to close the tray.

2) Turn the power off.

3) Unplug the power cord from the wall outlet.

Note

Do not close the tray manually after disconnecting the power cord from the wall outlet in tray open condition.

12

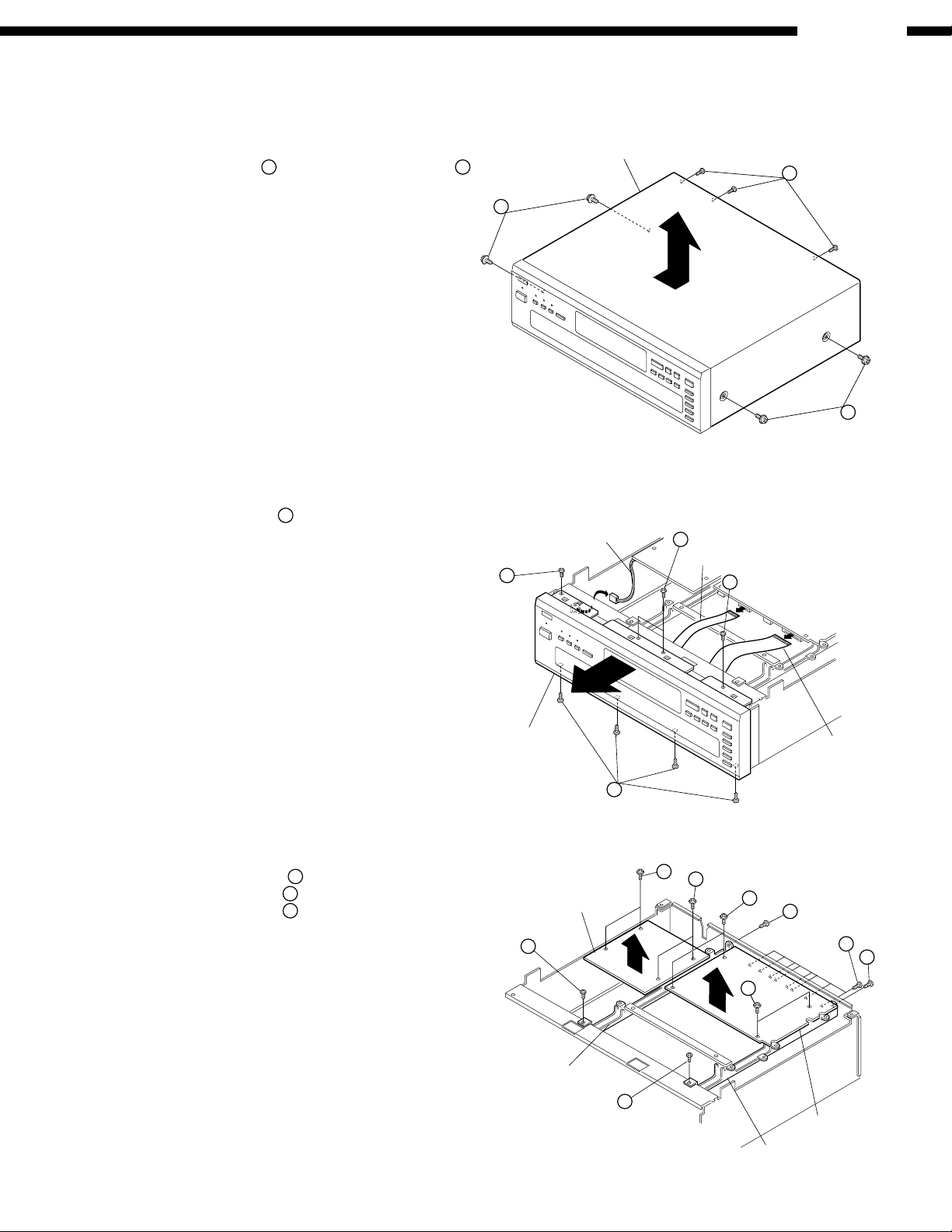

4. DISASSEMBLY

(Follow the procedure below in reverse order when reassembling)

DVM-4800

4.1 Top Cover

Remove 4 screws 1 on both sides and 3 screws

on the rear, then detach the Top Cover as shown to

the arrow direction.

4.2 Front Panel

(1) Remove 8 screws 3 from the top and bottom edges

of the Front Panel.

(2) Detach the Front Panel to the arrow direction,

together with its Inner Panel.

Top Cover

2

1

Connector

3

2

1

Flexible Wire

3

3

4.3 Mother & Power P.W.B., Stay

(1) Remove 12 screws 4 to detach the Mother P.W.B.

(2) Remove 4 screws 5, to detach the Power P.W.B.

(3) Remove 4 screws

6

to detach 2 Stays.

Front Panel

Power P.W.B.

6

Stay

Flexible Wire

3

5

5

4

6

4

6

4

6

Mother P.W.B.

Stay

13

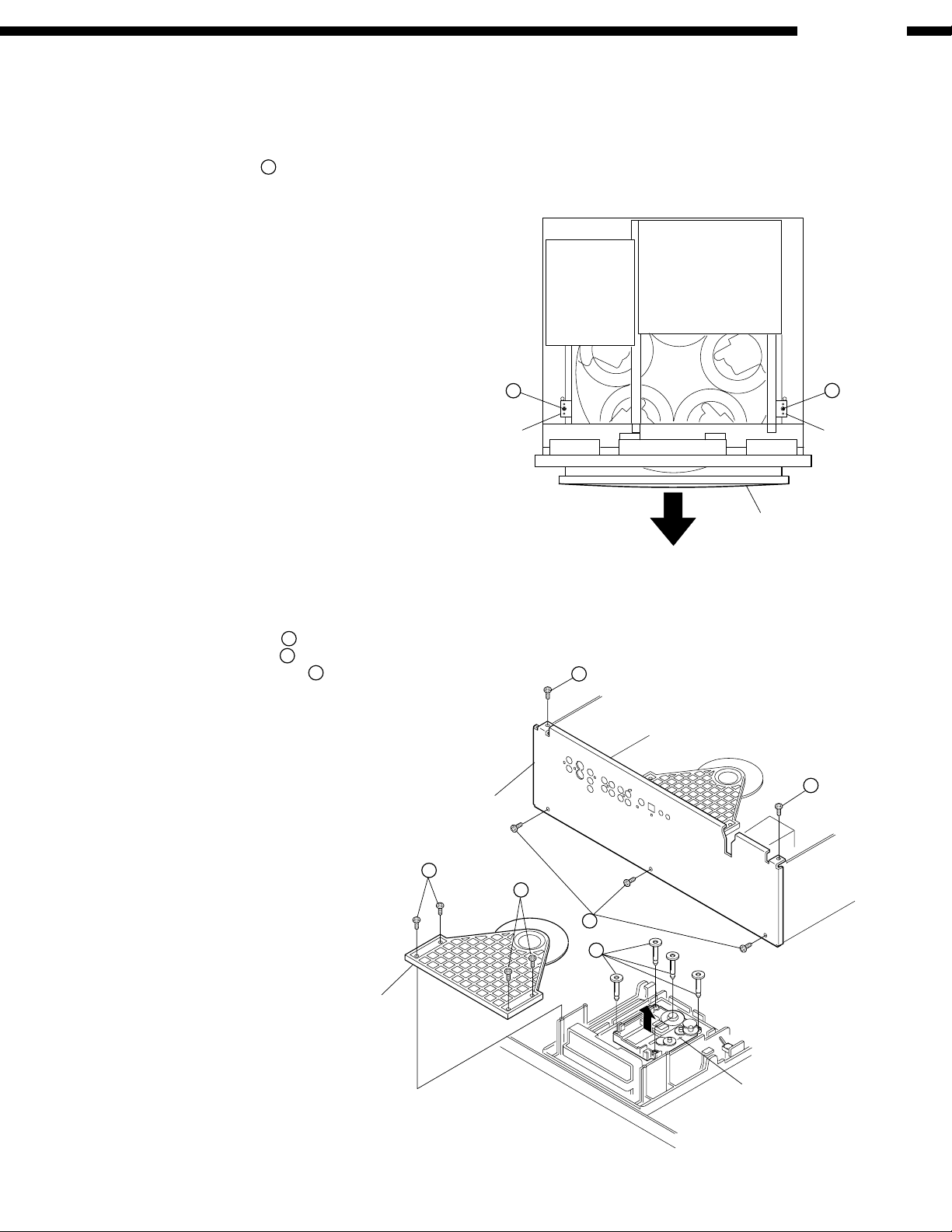

4.4 Loader Frame Ass'y

Remove 2 screws 7 to detach 2 Side Plates, then pull

out the Loader Frame in the arrow direction.

Note: Draw out the Loader Frame 1 ~ 2 cm and

turn the power off, before performing this step.

DVM-4800

4.5 DVD Mecha.

(1) Remove 5 screws 8 to detach the Rear Panel.

(2) Remove 4 screws 9 to detach the Clamp Base.

(3) Remove 4 fixed pin

Traverse Unit.

to detach the DVD

Side Plate

Rear Panel

7

Loader Frame

8

7

Side Plate

8

Clamp Base

9

9

8

DVD Traverse Unit

14

5. ADJUSTMENT PROCEDURES

5.1. Service Tools and Equipment

Application Name Number

Tilt adjustment DVD test disc DVDT-S15 or DVDT-S01

Hex wrench

Inspection Extension cable (module P.W.B. to mother P.W.B.) JGS0098

Extension cable (module P.W.B. to mother P.W.B.) VUC8026

Extension cable (module P.W.B. to mother P.W.B.) RFKZ0097

Extension cable (module P.W.B. to mother P.W.B.) VUC8026

Others Screw lock RZZ0L01

Grease RFKXGAK152

Oil RFKXGA1280, JZS0648

Confirmation CD test disc PVCD-K06 or any other commercially

available disc

VCD test disc PVCD-K06 or any other commercially

available disc

Recovery disc RFKZD5TR001

5.2. Important points in adjustment

5.2.1. Important points in optical adjustment

· Before starting optical adjustment, be sure to take anti-static measures.

· Optical pickup tilt adjustment is needed after replacement of the following components.

1. Optical pickup unit

2. Spindle motor unit

3. Optical pickup peripheral parts (such as rail)

Notes

Adjustment is generally unnecessary after replacing other parts of the traverse unit. However, make adjustment if there is a

noticeable degradation in picture quality. Optical adjustments cannot be made inside the optical pickup. Adjustment is generally

unnecessary after replacing the traverse unit.

5.2.2. Important points in electrical adjustment

· Follow the adjustment procedures described in this Manual.

5.3. Storing and Handling Test Discs

· Surface precision is vital for DVD test discs. Be sure to store and handle them carefully.

1. Do not place discs directly onto the workbench, etc., after use.

2. Handle discs carefully in order to maintain their flatness. Place them into their case after use and store them vertically. Store

discs in a cool place where they are not exposed to direct sunlight or air from air conditioners.

3. Accurate adjustment will not be possible if the disc is warped when placed on a surface made of glass, etc. If this happens, use

a new test disc to make optical adjustments.

4. If adjustment is done using a warped disc, the adjustment will be incorrect and some discs will not be playable.

DVM-4800

15

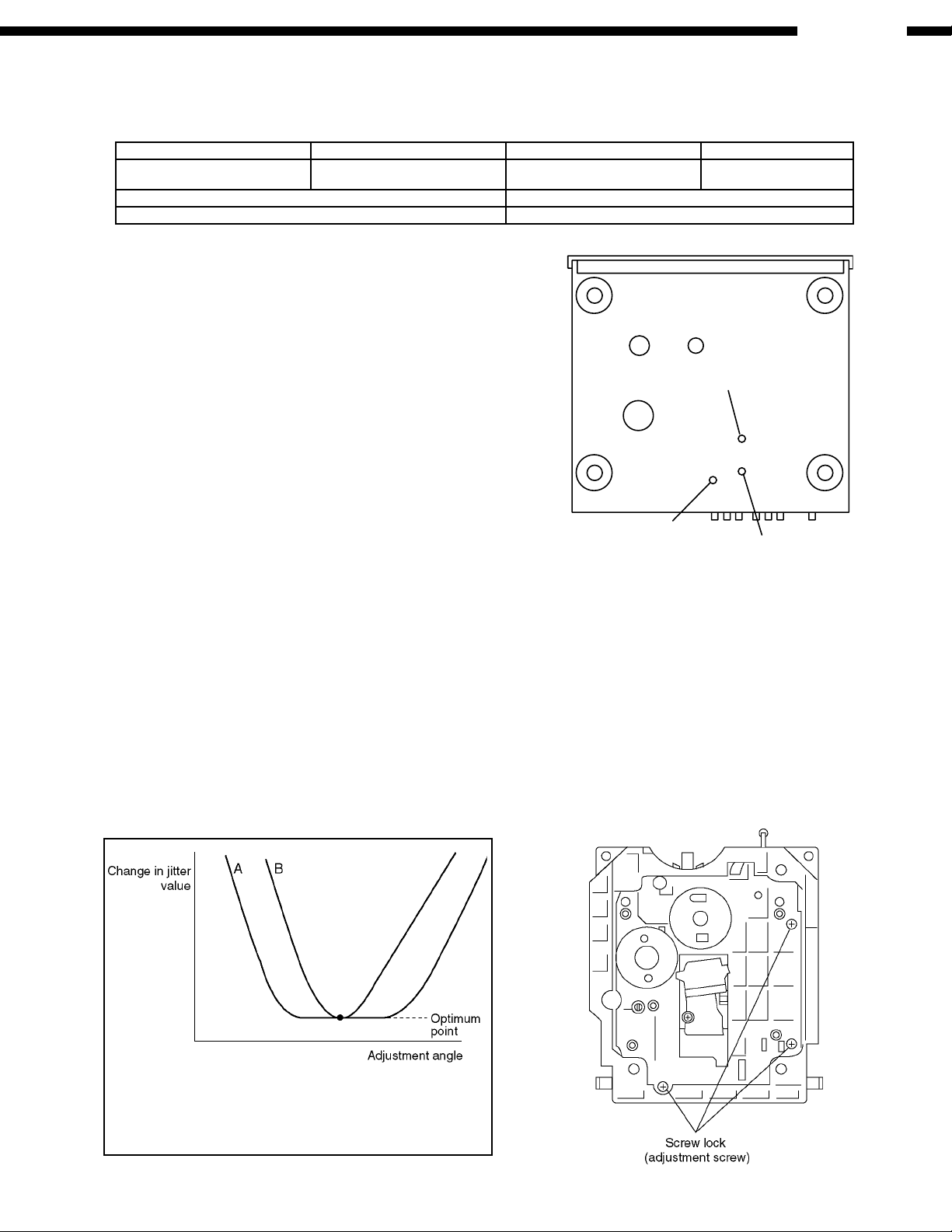

5.4.1.1. Adjustment procedure

1. While pressing PAUSE and OPEN/CLOSE buttons on the

Tangential Adjust Screw

Tilt Adjust Screw 2

Tilt Adjust Screw 1

main unit, press "5" on the remote control unit.

2. Confirm that "J_xxx_yyy_zz" is shown on the front display.

For your information:

"yyy" and "zz" shown to the right have nothing to do with

the jitter value. "yyy" is the error counter, while "zz" is

the focus drive value.

Note:

Jitter value appears on the front display.

3. Play test disc T01 (inner periphery).

4. Adjust tangential adjustment screw so that the jitter value is

minimized.

5. Play test disc T43 (outer periphery).

6. Adjust tilt adjustment screw 1 so that the jitter value is

minimized.

7. Play test disc T43 (outer periphery).

8. Adjust tilt adjustment screw 2 so that the jitter value is

minimized.

9. Repeat adjusting tilt adjustment screws 1 and 2 alternately

until the jitter value is minimized.

5.4.1.2. Important points

1. Make tangential adjustment first, and then make tilt

adjustment.

2. Repeat adjusting two or three times to find the optimum

point.

3. Finish the procedure with tilt adjustment.

Jitter value depends on the model:

1. If the jitter value changes like B, the optimum point is easy to

find.

2. If the jitter value changes like A, set the optimum point near the

middle.

5.4.1.3. Check after adjustment

Play test disc or any other disc to make sure there is no picture

degradation in the inner, middle and outer peripheries, and no

audio skipping. After adjustment is finished, lock each

adjustment screw in position using screw lock.

5.4.1.4. Procedure for screw lock

1. After adjustment, remove top cover, tray, clamper base and

traverse unit in this sequence.

2. Lay the traverse unit upside down, and fix adjustment screw

with screw lock.

3. After fixing, reassemble traverse unit, clamper base, tray

and top cover.

5.4. Optical adjustment

5.4.1. Optical pickup tilt adjustment

Measurement point Adjustment point Mode Disc

Tangential adjustment screw

Tilt adjustment screw

T01 (inner periphery) play

T43 (outer periphery) play

DVDR-S15 or DVDT-S01

Measuring equipment Adjustment value

None (Main unit display for servicing is used.) Adjust to the minimum jitter value.

Front Side

DVM-4800

16

DVM-4800

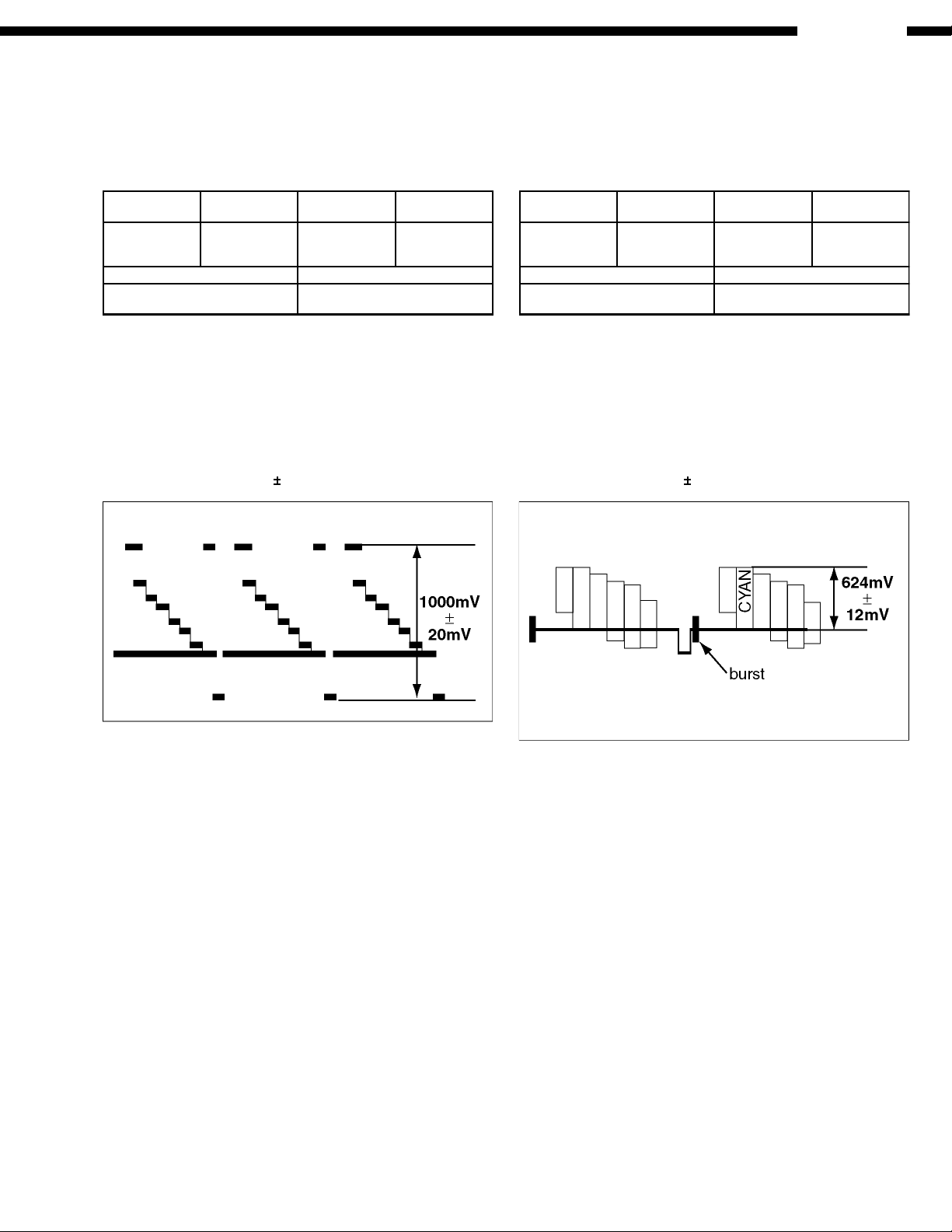

Do this confirmation after replacing a P.W.B.

5.5.1. Video Output (Luminance Signal)

Adjustment

Measurement

Point

Adjustment

Point

Mode Disc

Video Output

Pin Terminal

GND: Chassis

VR3225 Playback

(Color Bar)

DVDT-S20

(title 9)

Measuring Device Adjustment Value

Oscilloscope

500 mV/div, 10 µs/div

1000 ± 20mV p-p

For compatibility of video signal output.

1. Connect the monitor TV to the video output terminal and

terminate at 75 Ohms.

2. Play back the color bar part title 9 (DVDT-S20) of the DVD

Test Disc title.

3. Adjust the VR3225 so that the luminance signal output is as

shown below.

Adjustment Value = 1000 20 mV p-p

Fig. 5-5-1 Luminance Signal Output

5.5.2. Video Output (Chrominance

Signal) Adjustment

Measurement

Point

Adjustment

Point

Mode Disc

Video Output

Pin Terminal

GND: Chassis

VR3221 Playback

(Color Bar)

DVDT-S20

(title 9)

Measuring Device Adjustment Value

Oscilloscope

500 mV/div, 10 µs/div

624 ± 12mV p-p

For compatibility of video signal output.

1. Connect the monitor TV to the video output terminal and

terminate at 75 Ohms.

2. Play back the color bar part title 9 (DVDT-S20) of the DVD

Test Disc title.

3. Adjust the VR3221 so that the chrominance (CYAN) signal

output is as shown below.

Adjustment Value = 624 12 mV p-p

Fig. 5-5-2 Chrominance Signal Output

5.5. Electrical Adjustment

17

DVM-4800

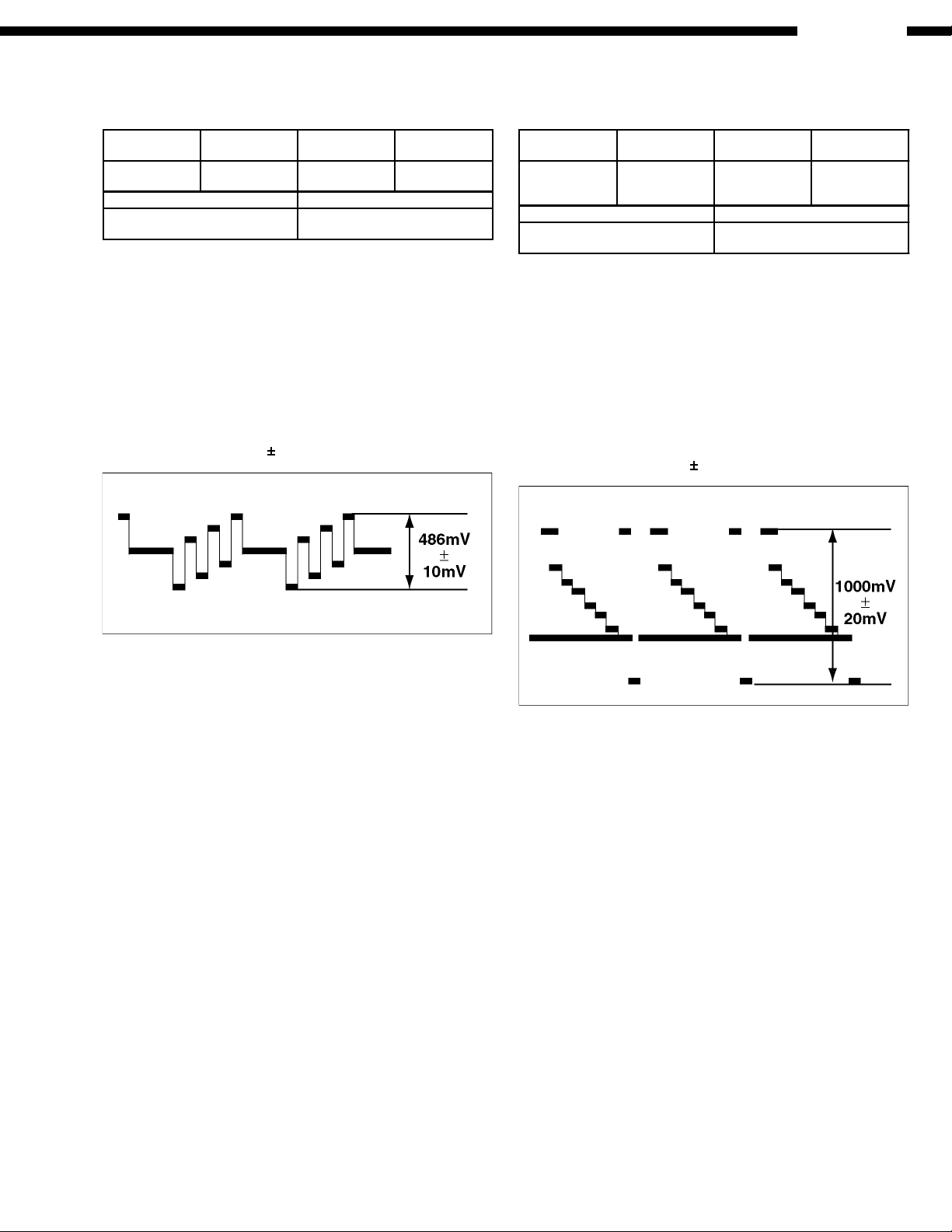

5.5.3. Video Output (CB Signal)

Adjustment

Measurement

Point

Adjustment

Point

Mode Disc

CB Output Pin

Terminal

VR3201 Playback

(Color Bar)

DVDT-S20

(title 9)

Measuring Device Adjustment Value

Oscilloscope

200 mV/div, 10 µs/div

486 ± 10mV p-p

NOTE:

CB/CR Output should be 75Ω terminate.

For compatibility of video signal output.

1. Connect the monitor TV to the video output terminal and

terminate at 75 Ohms.

2. Play back the color bar part title 9 (DVDT-S20) of the DVD

Test Disc title.

3. Adjust the VR3201 so that the CB signal output is as shown

below.

Adjustment Value = 486 10 mV p-p

Fig. 5-5-3 CB Signal Output

5.5.4. Progressive Video Output

(Y Signal) Adjustment

Measurement

Point

Adjustment

Point

Mode Disc

Progressive

Terminal

GND: Chassis

VR3771 Playback

(Color Bar)

DVDT-S20

(title 9)

Measuring Device Adjustment Value

Oscilloscope

200 mV/div, 5 µs/div

1000 ± 20mV p-p

NOTE:

Progressive Output should be 75Ω terminate.

For compatibility of video signal output.

1. Connect the monitor TV to the Y (Progressive) output

terminal and terminate at 75 Ohms.

2. Play back the color bar part title 9 (DVDT-S20) of the DVD

Test Disc title.

3. Adjust the VR3771 so that the Y (Progressive) signal output

is as shown below.

Adjustment Value = 1000 20 mV p-p

Fig. 5-5-4 Y Signal Output

18

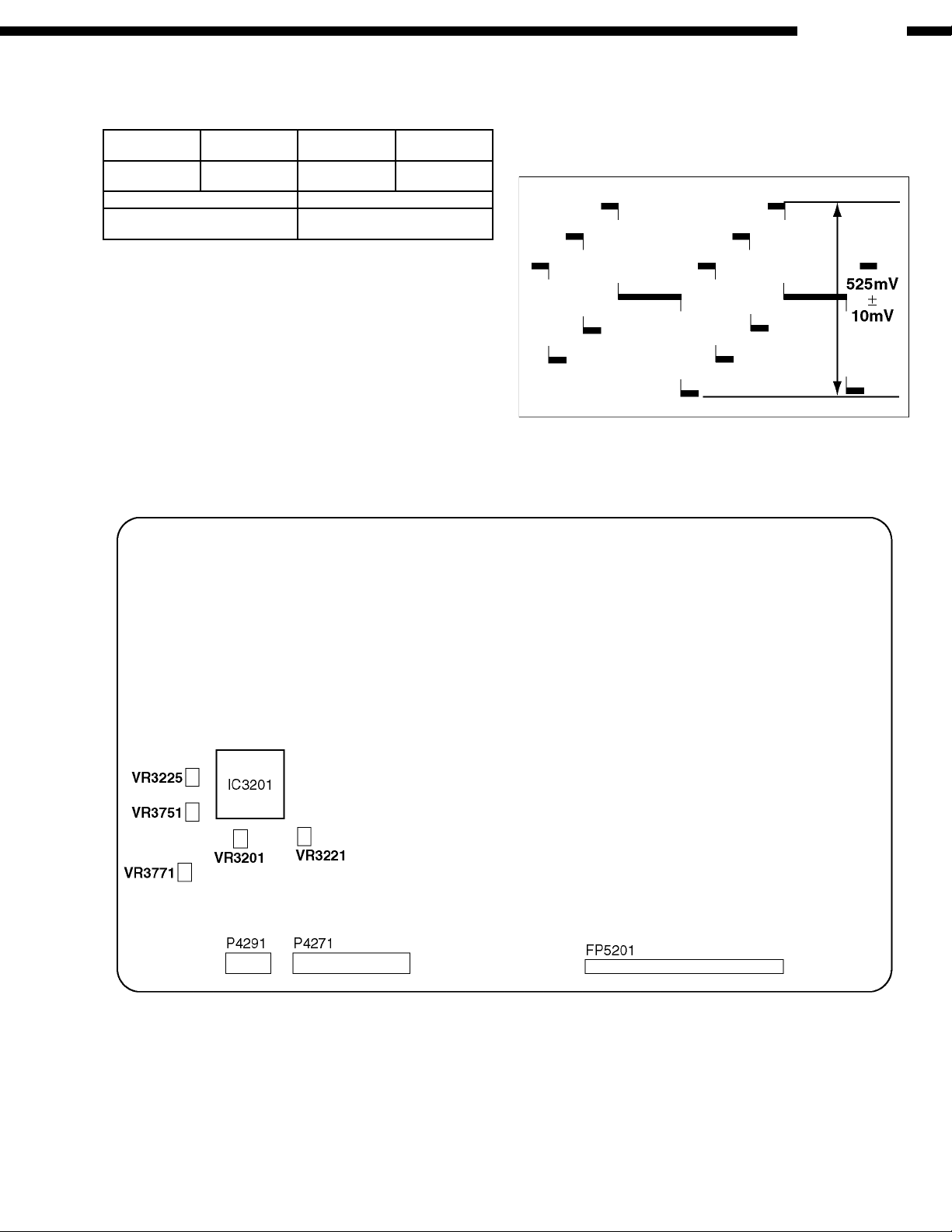

5.5.5. Progressive Video Output

(PB Signal) Adjustment

Measurement

Point

Adjustment

Point

Mode Disc

Progressive

Terminal

VR3751 Playback

(Color Bar)

DVDT-S20

(title 9)

Measuring Device Adjustment Value

Oscilloscope

100 mV/div, 5 µs/div

525 ± 10mV p-p

NOTE:

Progressive Output should be 75Ω terminate.

For compatibility of video signal output.

1. Connect the monitor TV to the video output terminal and

terminate at 75 Ohms.

2. Play back the color bar part title 9 (DVDT-S20) of the DVD

Test Disc title.

3. Adjust the VR3751 so that the PB signal output is as shown

below.

Fig. 5-5-5 PB Signal Output

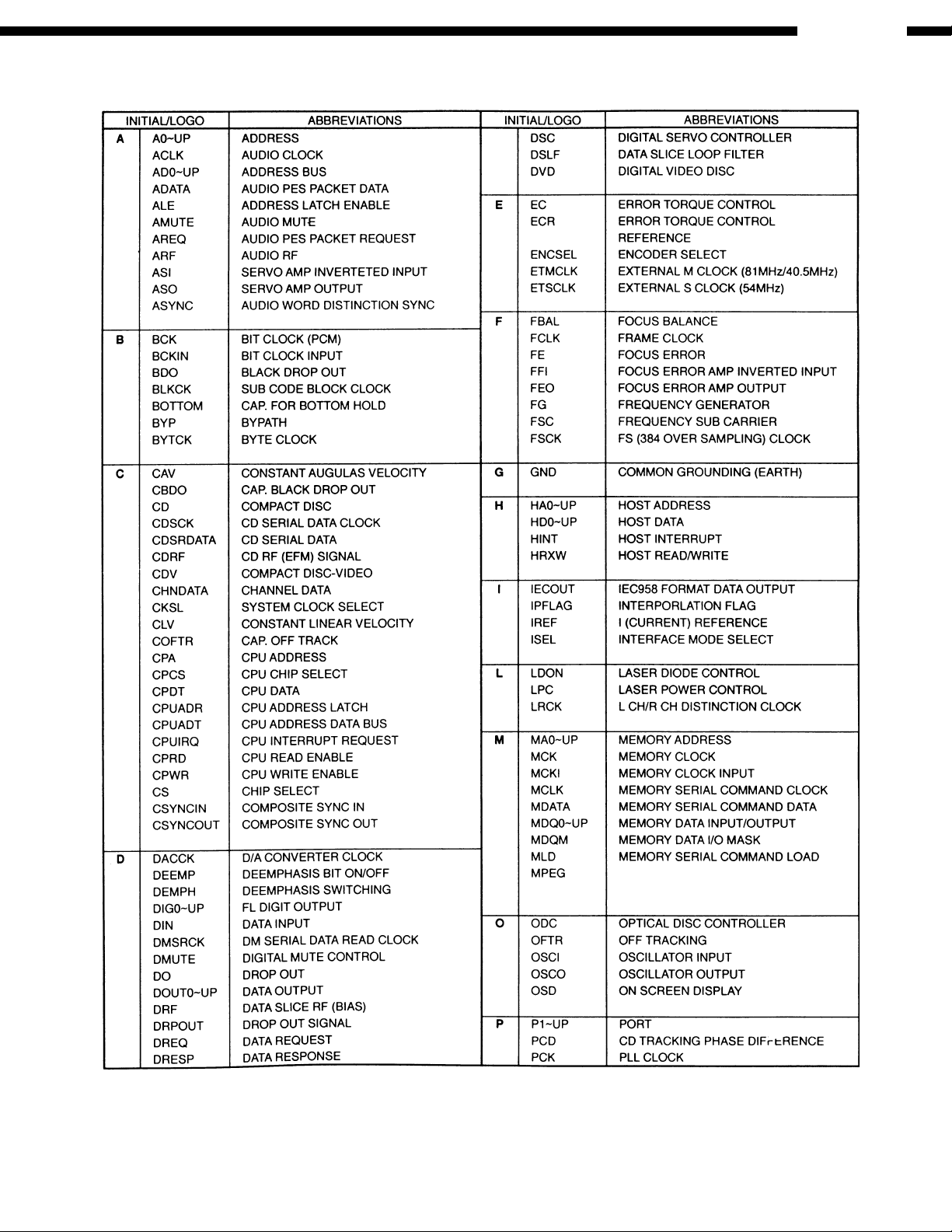

5.5.6. Test Point & Controls Location

MODULE P.W.B. (COMPONENT SIDE)

DVM-4800

19

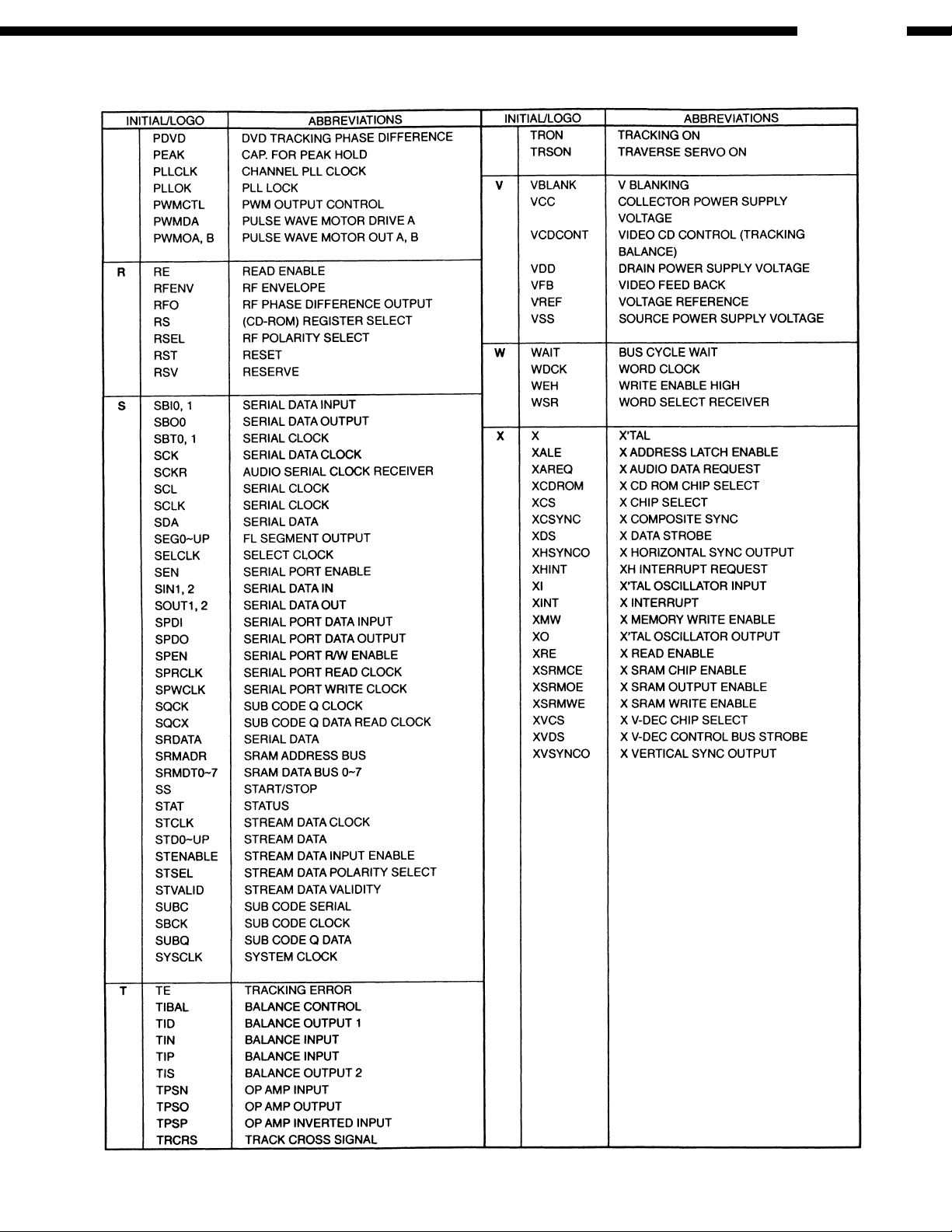

6. ABBREVIATIONS

DVM-4800

MOVING PICTURE EXPERTS GROUP

20

DVM-4800

21

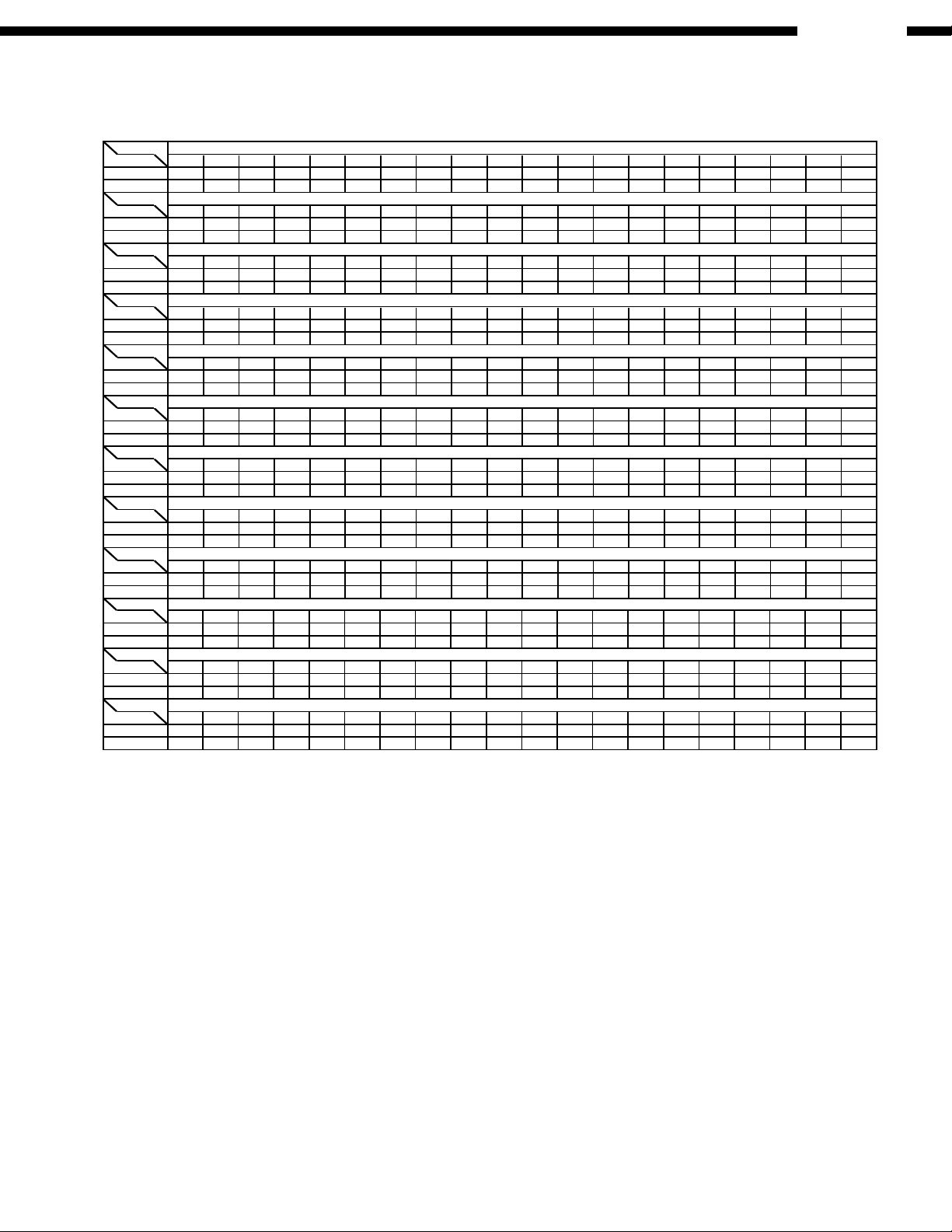

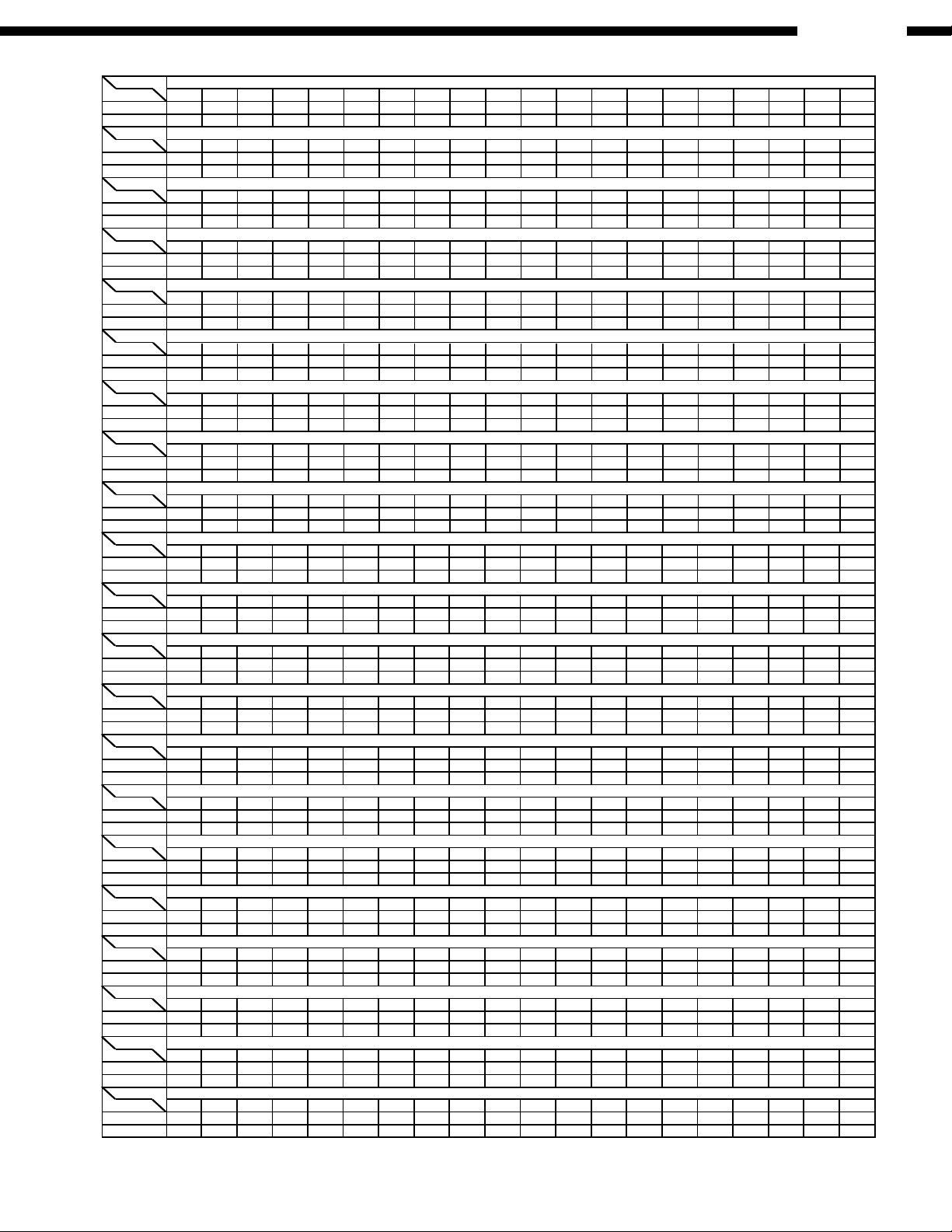

7. VOLTAGE CHART

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

IC2001

IC2001

IC2001

IC2001

1 2 3 4 5 6 7 8 9 1011121314 151617181920

0 3.3 3.3 0 3.3 3.3 0 0

0 3.3 3.3 0 3.3 3.3 0 0 1.9 2.1 0 0 0 0 3.3

1.9 2.3 2.2 2.2 2.3 2.4 2.3 2.2 2.4 1.8 0 1.8

1.8 2.2 1.8 0 1.8

IC2501

12345678 91011121314151617181920

1.7 1.7 1.7 1.7 1.7 0.1 0 5.0 0 0

1.7 1.7 1.7 1.7 1.7

IC2502

12345

1.7 1.7 0 0 4.9

004.91.7 1.7

0.1 0 5.0 3.3 0

2.9 2.9 2.9 2.9 4.4 4.4 4.4 4.4 0 3.1

2.9 2.9 2.9 2.9 3.6 4.4 5.9 2.5 0 3.1

37 38 39 40

3.2 3.2 3.2 3.2

2.8 2.8 2.7 2.7

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

0 2.3 2.2 3.0 2.5 3.0 2.6 3.3 3.3 3.3 3.3

0 1.9 2.0 2.7 2.2 2.6 2.6 1.7 2.5 1.4 3.3

0 3.3 3.3

0 3.3 3.3

3.3 3.3

3.3 3.3

57 58 59 60

3.3 1.8 0 0

3.3 1.8 0 0

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

3.2 3.2 3.2 2.0 1.5 0 3.2 0

2.6 2.7 2.6 2.6 1.5 0 3.2 0

3.3 3.3 3.3

3.3 3.3 0

0 3.3 3.3

0 3.3 0

00

00

77 78 79 80

0 3.3 1.5 1.5

70 71 72 73 74 75 7661 62 63 64 65 66 67 68 69

3.2 3.3 0 0 1.8 2.0 1.6 1.6

3.2 3.3 3.3 0 2.1 1.0 1.6 2.2

3.3 0 0

1.3 3.3 3.3

001.8

0

3.3 3.3

0 3.3 1.5 1.501.83.3 3.3

IC2001

97 98 99 100

1.4 1.6 3.3 1.4

90 91 92 93 94 95 9681 82 83 84 85 86 87 88 89

0 0 0 1.6 0 1.7 1.7 3.3 0 1.6

0 0 0 1.6 0 1.7 1.7 3.3 0 1.6

1.6 0 1.7 1.600

1.4 1.6 3.3 1.41.6 0 1.7 1.600

IC2001

117 118 119 120

1.7 1.6 1.7 1.7

110 111 112 113 114 115 116101 102 103 104 105 106 107 108 109

1.4 0 1.5 2.1 2.8 1.7 1.6 1.5 3.3

1.4 0 1.5 2.1 2.8 1.7 1.6 1.5 3.3

1.6

1.6

1.6 2.7 1.7 3.301.7

1.7 1.6 2.1 2.51.7 3.31.71.6 2.2 0

IC2001

137 138 139 140

3.3 0 3.3 0

130 131 132 133 134 135 136121 122 123 124 125 126 127 128 129

2.3 1.7 1.7 0 3.3 0 1.2 1.3 1.3

2.1

1.3

1.7 1.7 0 3.3 0 1.4 1.3 1.3 1.3

3.3 3.3 3.3 1.703.3

3.3 0 3.3 03.3 3.3 3.3 1.703.3

IC2001

157 158 159 160

0003.3

150 151 152 153 154 155 156141 142 143 144 145 146 147 148 149

0 3.3 3.3 0 0 1.6 3.3 3.3 0

0.403.3 3.3 0 0 1.6 3.3 3.3 0.9 0

3.3 1.8 0 3.300

0 1.0 01.8 0 3.300 0.90.6

IC2001

170 171 172 173 174 175 176161 162 163 164 165 166 167 168 169

0 3.3 0 0 0 3.3 0 3.3 3.3

0 3.3 0 0.8 0 0.7 0 1.0 3.300

00 3.33.303.3

3.33.30.8 3.300

IC2501

21 22 23 24 25 26 27 28

9.2 9.2 1.7 1.6 1.6 1.7 0

9.2 9.2 1.9 1.6 1.6 1.7 3.3

3.1

3.1

Main P.W.B.

DVM-4800

22

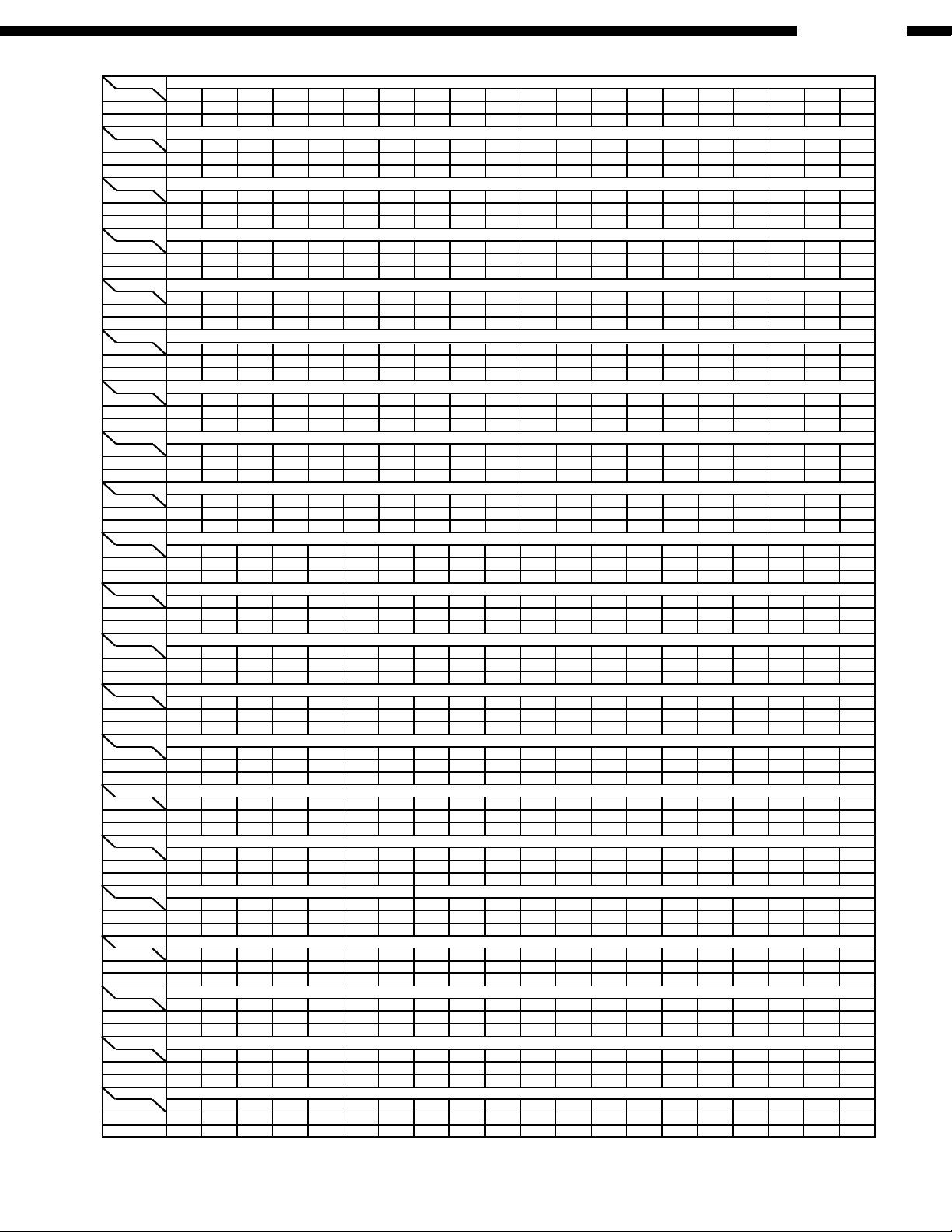

DVM-4800

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

IC3001

IC3001

IC3001

IC3001

1 2 3 4 5 6 7 8 9 1011121314 151617181920

3.3 0 1.2 0.1 1.8 1.2 0.1 1.0 0 1.2 3.3 3.4 3.3 0 1.7 1.8 3.3 3.4 2.3

3.3 0 1.6 0.1 1.8 1.7 0.1 1.6 0 1.6 3.3 3.4 3.3 0 0 1.8 2.8 3.4 000

37 38 39 40

1.8 2.3 2.3 3.3

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

0 0 3.3 0 3.4 1.4 3.3 3.3 0 1.5 0

3.3

2.5 2.3 2.43.5 2.2

1.8 1.9 1.8 2.13.3 3.1 3.3 3.4 1.4 0.2 2.6 1.7 3.3 0 2.1 1.9 2.22.7 2.2

57 58 59 60

1.8 3.1 3.2 3.1

1.8 2.6 2.6 2.7

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

3.3 3.3 0 2.2 2.3 2.1 2.9 3.3

1.8 1.7 0 2.0 2.1 1.9 2.8 3.3

3.1 3.1 3.1

2.6 2.8 2.8

3.1 3.1 3.1

2.8 2.8 2.8

03.1

02.8

IC3061

IC3061

IC3061

1 2 3 4 5 6 7 8 9 1011121314 151617181920

3.3 2.8 0 2.7 2.8 0 2.7 3.0 3.3

2.6 3.1 2.7 2.8 0 2.9 3.0 3.3

2.7 2.8 0 2.8 3.3 2.5 0 3.2 3.3 3.1

3.3

IC3091

12345678

1.6 1.9 1.9 0 1.5 1.5 2.1 4.8

1.9 1.9 0 1.5 1.5 2.1 4.81.6

2.9

1.0

2.8 0 2.8 3.3 2.5 3.3 3.2 3.3 3.1 0

37 38 39 40

3.3 1.7 2.4 0

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

0 0 0 0 0 1.1 3.3 0 1.0 1.1

0 0 0 0.3 1.6 3.3 0 1.4 1.6

1.1

0.3

1.1 1.4 000

3.3 1.7 1.9 01.6 1.4 1.4 000

50 51 52 53 5441 42 43 44 45 46 47 48 49

0 2.9 3.3 2.6 2.6 0 2.6 3.003.3 2.4 2.4 0 2.9 0

2.9 3.3 2.8 2.7 0 2.8 2.8 3.3 2.9 2.9 0 2.2 0

77 78 79 80

1.8 3.3 3.3 3.3

70 71 72 73 74 75 7661 62 63 64 65 66 67 68 69

3.4 3.1 3.1 0 3.2 3.1 3.2 3.4

3.4 2.8 2.8 0 2.9 2.9 2.9 3.3

0 1.7 3.4

0.5 1.7 3.4

003.3

0

03.3

1.8 1.1 1.0 1.00.8 1.60.8 0.8

IC3001

97 98 99 100

1.8 0 1.8 1.5

90 91 92 93 94 95 9681 82 83 84 85 86 87 88 89

3.3 0 1.7 0 3.4 1.6 1.7 1.7 0 0

0.8 0 1.7 0.8 3.3 1.8 1.7 1.7 0 0.8

00 1.61.73.4 0

1.8 0 1.8 1.500 01.73.4 0

IC3001

117 118 119 120

3.4 0 0.1 3.0

110 111 112 113 114 115 116101 102 103 104 105 106 107 108 109

3.4 0 0 0 3.4 1.6 1.8 0 3.3

3.4 0 0.2

0 0 3.3 2.9 000

3.3 0 0 3.30 3.4 1.6 1.8 0 3.3 0 0 3.3 2.9 000

IC3001

137 138 139 140

000 0

130 131 132 133 134 135 136121 122 123 124 125 126 127 128 129

0 3.4 0 0.1 3.4 0 0 0 0 3.3 0 0 0 1.600

0000 0 0 0.1 3.4 0 3.3 0 0 2.9 0 0 0 1.600 0

IC3001

157 158 159 160

0 2.8 2.9 3.3

150 151 152 153 154 155 156141 142 143 144 145 146 147 148 149

3.4 0 0 3.3 3.1 1.8 1.3 0.6 0.7 0.7 0 2.0 1.3 00.3 0.3

0 2.2 2.93.4 0 0 3.3 3.1 1.8 1.3 1.2 1.3 1.3 0 1.6 1.2 3.31.1 1.5 3.3

IC3001

170 171 172 173 174 175 176161 162 163 164 165 166 167 168 169

2.6 2.8 0 2.7 2.7 3.3 3.0 2.8 0

3.1

2.8 3.1 3.3 2.9 02.7 1.8

177 178 179 180

3.3 2.92.8 2.7

IC3001

190 191 192 193 194 195 196181 182 183 184 185 186 187 188 189

2.8 0 1.7 1.8 1.7 0 3.4 3.4 2.6

2.8

IC3001

201 202 203 204 205 206 207 208

0 1.8 1.2 0 0 1.1 0 0

1.8 1.4 0 3.3 0 1.5 00

0.1

0 1.7 1.8 1.7 0 3.4 3.4 2.2 0.2

1.8 2.5 3.2 3.23.3 0

197 198 199 200

3.0 03.3 1.5

1.8 1.9 3.2 3.23.3 0 3.0 03.3 1.3

2.8 0 0 2.7 3.3 3.0 - 0 - 2.6 3.3 2.6 00 1.8 3.3 2.62.8 -

IC3201

IC3201

IC3201

IC3201

12345678 91011121314151617181920

1.4 0.6 0.7 0.7 2.0 0.3 0.3 1.4 3.3 3.3

1.4 1.3 1.3 1.1 1.6 1.2 1.6 1.2 3.3 3.3

3.3 0

3.3

3.3

3.3

3.3

3.3

3.3

3.3

3.3

3.3

3.3

3.3

IC3261

12345678 910111213141516

1.3 1.5 1.3 1.5 1.5 0 0 0 0 0

1.3

IC3251

123456

4.8 0 4.8 1.3 0 3.3

0 4.8 1.3 0 3.34.8

0 1.0 1.2 1.0 1.5 4.8

1.5 1.3 1.5 1.5 0 0 0 0 0 0 1.2 1.4 1.2 1.5 4.8

3.3

3.3

3.3

3.3

3.3

3.30

37 38 39 40

0.4 3.3 0 0

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

3.3 0 0 0 3.0 3.0 0 0 1.3 1.6

0 0 0 3.3 0 1.6 0 3.3 3.0

0.5

3.3

0.4 0 0.83.3 0

0.6 3.3 0 03.0 0 0.5 0.501.3

57 58 59 60

000 0

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

0.8 0 3.3 0.8 0 1.6 1.3 1.3 3.2 3.1

0.8 0 3.3 0.8 0 1.6 1.3 1.3 3.2 3.1

3.3 0 0 003.3

000 03.3 0 0 003.3

61 62 63 64

003.3

003.300

23

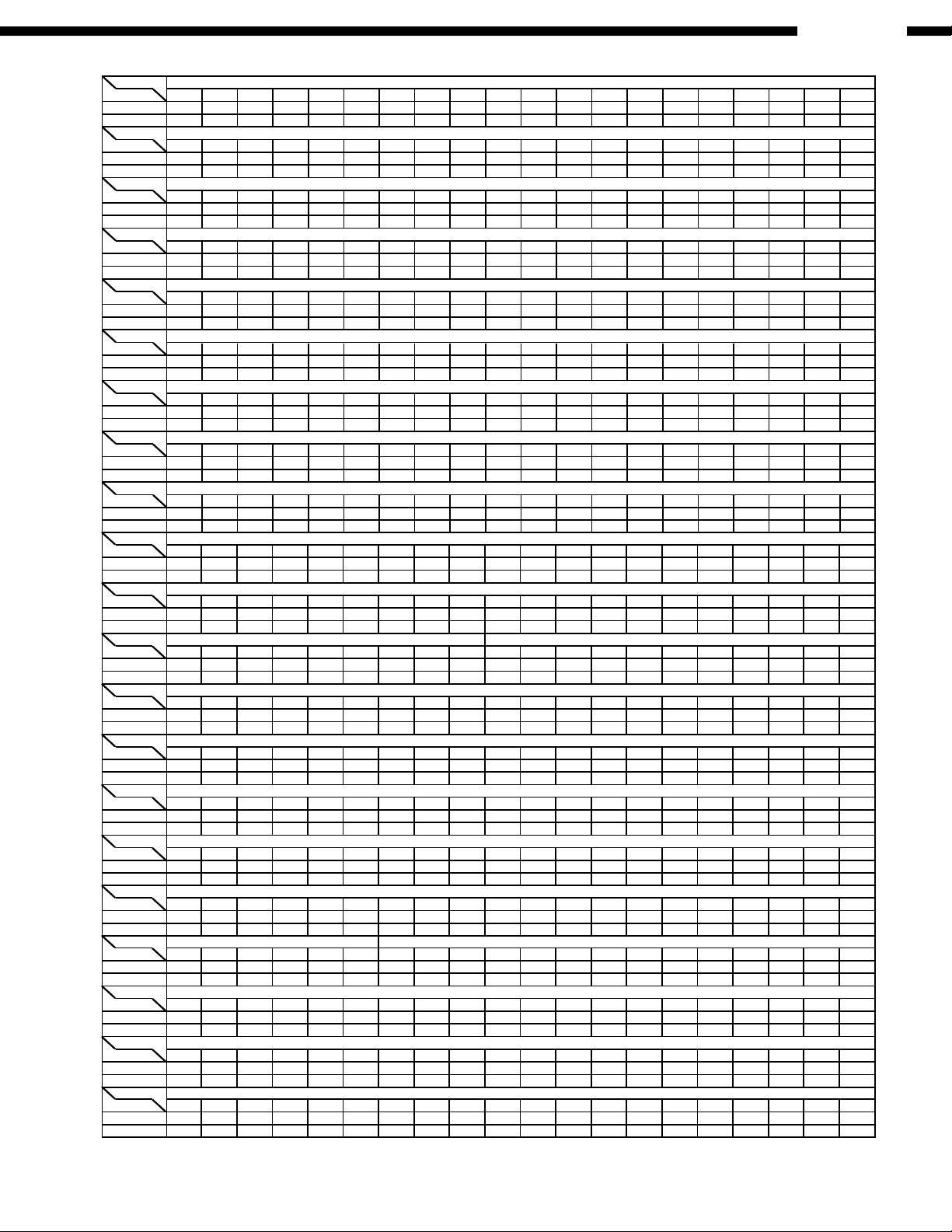

DVM-4800

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

IC3701

IC3701

IC3701

IC3701

1 2 3 4 5 6 7 8 9 1011121314 151617181920

3.4 0 3.4 0 0 0 3.4 3.4 3.1 3.4

3.4 0 3.4 0 0 0 3.4 3.4 3.1 3.4

0 2.8 3.3 3.1 0.8 0 0 0 0 0

0 0.6 3.3 3.1 2.8 0 0 0 1.3 1.3

37 38 39 40

0.9 0.6 0.6 3.4

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

0 0 3.3 0 0 0 3.3 2.3 0

1.0 0.6 3.3 2.2 1.9 2.4 1.4 0 0

0 3.4 0 0.9 0.91.9 0.6

0.5 0.5 3.3 3.43.4 0 1.3 1.31.2 1.10

57 58 59 60

003.40

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

2.7 0 0 0 0.9 0.5 0.5 0.5 3.4 1.6

3.3 0 0 0 1.2 1.2 1.2 1.2 3.4 1.6

00 003.3 0

003.4000 2.10.22.0 0.9

77 78 79 80

0 1.7 1.7 1.7

70 71 72 73 74 75 7661 62 63 64 65 66 67 68 69

1.6 3.4 0 0 3.4 0 3.3 3.3 0 1.6

1.6 3.4 0 0 3.4 0 3.3 3.3 0 1.6

3.4 3.3 1.5 1.70.7 0

0 1.7 1.7 1.73.4 3.3 0.6 1.70.7 0

IC3701

97 98 99 100

0.9 1.4 0 0

90 91 92 93 94 95 9681 82 83 84 85 86 87 88 89

3.4 1.7 1.6 1.7 1.8 2.2 0 0 3.3 1.1

3.4 1.7 1.6 1.7 2.1 2.2 3.3 0 0 1.1

0.9 2.1 0.9 3.42.1 2.1

1.3 1.2 0 01.7 2.4 1.3 3.42.2 2.3

IC3731

IC3731

IC3731

IC3731

1 2 3 4 5 6 7 8 9 1011121314 151617181920

1.4 3.3 1.4 1.2 0 1.2 2.3 3.3 2.6 1.7

1.2 3.3 1.6 1.6 0 1.6 1.9 3.3 2.2 2.2

0 1.9 1.9 3.3 3.3 0 1.9 1.8 0 1.7

3.3 3.3 0 2.2 1.8 0 2.10 2.0 2.0

37 38 39 40

000 0

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

2.8 3.3 0.6 0.6 3.3 3.3 3.3 0 2.2

2.5 3.3 0.6 0.6 3.3 3.3 3.3 0 2.2

0 1.6 1.6 3.3 01.6 1.6

000 01.6 1.6 3.3 01.6 1.60

57 58 59 60

0 1.7 3.3 1.0

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

0 0 0 0 0 0 1.6 1.7 1.7 1.7

0 0 0 0 0 0 1.6 1.7 1.7 1.7

2.1 0 0 0.603.3

0 1.7 3.3 1.62.1 0 1.6 0.603.3

IC3751

IC3751

IC3751

1 2 3 4 5 6 7 8 9 1011121314 151617181920

0 0 0 0.9 0.5 0.5 0.5 3.3 0.1 0.1

3.3 0 0 1.2 1.2 1.2 1.3 2.2 1.3 2.1

IC4201IC3781

123456

4.8 0 4.8 1.3 0 3.3

4.8 0 4.8 1.3 0 3.3

123

0 3.3 4.7

0 3.3 4.7

0 3.5 0 0 0 1.8 0.8 1.1 1.8 0

3.5 0 0 0 1.3 1.3 1.3 1.2 0.50.2

37 38 39 40

1.7 1.6 1.6 3.2

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

1.2 1.2 1.2 3.3 1.6 0 2.6 3.3 3.1 3.0

0.5 0.5 3.2 3.3 1.6 0 2.6 3.3 3.1 3.0

3.0 0.6 3.3 0.600.4

1.7 1.6 1.6 3.23.0 0.5 3.3 0.600.7

IC4211

IC4211

1 2 3 4 5 6 7 8 9 1011121314 151617181920

1.7 0 1.6 0 1.5 0 3.3 0 0 4.7

1.7 0.8 1.6 0 1.5 0 3.3 0 0 4.7

0 2.3 2.4 0 4.7 2.4 2.3 0 4.7 0

0 2.3 2.4 0 4.7 2.4 2.3 0 4.7 0

21 22 23 24 25 26 27 28

0 3.2 3.3 3.3 0 3.3 2.8 3.3

3.2 0 0 0 3.3 2.8 3.30

IC4221

IC4221

1 2 3 4 5 6 7 8 9 1011121314 151617181920

1.7 0 1.6 1.9 1.5 3.7 0 4.7 4.7 0

1.7 0.8 1.6 1.9 1.5 3.7 0 4.7 4.7 0

2.3 0 2.3 0 4.7 2.4 0 2.3 0 4.7

2.3 0 2.3 0 4.7 2.4 0 2.3 0 4.7

21 22 23 24 25 26 27 28

0 3.2 0 4.7 4.8 3.3 2.8 3.3

3.2 0 4.7 4.6 3.3 2.8 3.34.9

50 51 5241 42 43 44 45 46 47 48 49

3.3 3.3 0 0.1 0.3 0.6 0.7 0.5 0 0 0

3.3 0 0 0.1 0 0 0.1 0 0 0 0

0.1

0.1

77 78 79 80

003.33.1

70 71 72 73 74 75 7661 62 63 64 65 66 67 68 69

0 0 0.9 0.9 3.3 0 3.3 0 0 0

1.6 0 1.6 1.6 3.3 0 3.3 1.9 1.7 0

00.9 1.703.3 0

2.2 2.2 3.3 2.42.3 0.9 2.2 03.3 2.2

IC3731

97 98 99 100

1.4 0.9 0 2.2

90 91 92 93 94 95 9681 82 83 84 85 86 87 88 89

1.5 0 1.5 1.4 0 0 0 0 0 0

2.2 0 2.9 1.7 0 0 0 0 0 3.3

00 03.300

1.6 1.7 0 1.73.3 0 0 3.300

IC3701

117 118 119 120

1.8 1.6 3.0 2.2

110 111 112 113 114 115 116101 102 103 104 105 106 107 108 109

3.4 1.0 0.9 0.9 0.9 1.6 1.9 1.9 1.8 2.7

3.4 1.2 1.2 1.2 1.2 1.3 2.4 2.6 1.1 2.2

0 1.8 3.4 2.02.1 2.0

2.5 2.6 1.9 2.20 2.2 3.4 2.82.4 2.0

IC3701

137 138 139 140

000 0

130 131 132 133 134 135 136121 122 123 124 125 126 127 128 129

1.8 0 1.8 1.8 1.7 1.6 1.6 1.5 2.0 3.4 0 0 0 000

0002.2 0 2.2 2.2 2.4 2.6 2.6 1.7 2.0 3.4 0 0 0 000 0

IC3701

157 158 159 160

1.6 2.9 2.9 2.9

150 151 152 153 154 155 156141 142 143 144 145 146 147 148 149

0 0 0 0 0 0.6 0.7 0.6 0 0 0 0 0 1.3 1.1 1.2 1.6

0 3.4 0.3 0 3.40.3 -

1.6 2.9 2.9 2.3.4 1.3 0 3.41.4 1.20

24

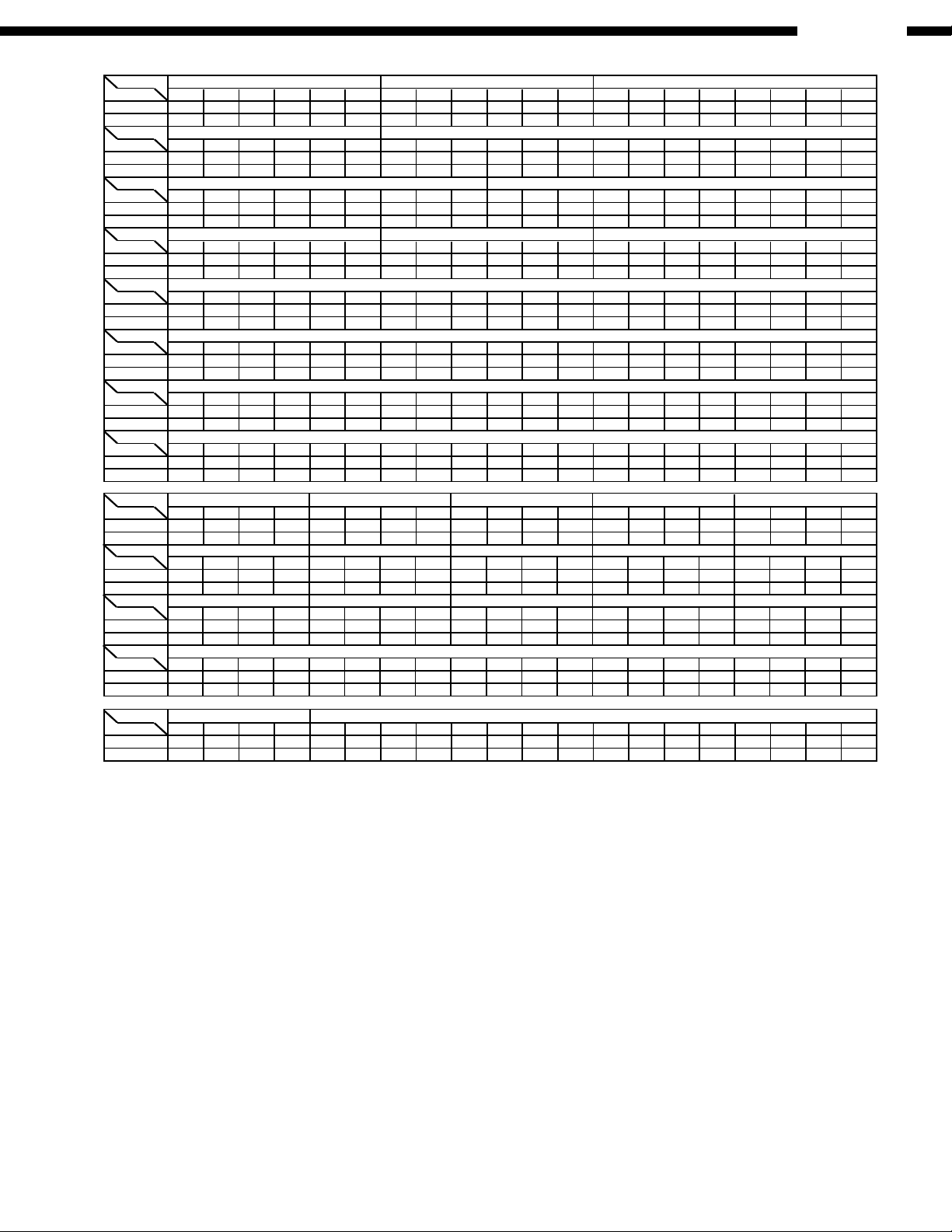

DVM-4800

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

IC4231

IC4231

1 2 3 4 5 6 7 8 9 101112 1314 1516171819 20

1.7 0 1.6 1.9 1.5 3.6 0 4.7 4.7 0

1.7 0 1.6 1.9 1.5 3.6 0 4.7 4.7 0

2.3 0 2.4 0 4.7 2.4 0 2.3 0 4.7

2.3 0 2.4 0 4.7 2.4 0 2.3 0 4.7

21 22 23 24 25 26 27 28

0 3.2 0 4.7 4.7 3.3 2.8 3.3

0 3.2 0 4.7 4.7 3.3 2.8 3.3

IC4241

IC4241

1 2 3 4 5 6 7 8 9 101112 1314 1516171819 20

1.7 0 1.6 1.9 1.5 3.6 0 4.7 4.7 0

1.7 0 1.6 1.9 1.5 3.6 0 4.7

IC4261

12345678

00000005.0

4.9 0 4.9 0 0 4.9 4.9 4.9

IC5262

12345678

2.2 2.2 2.2 0 2.2 2.2 2.2

2.2 2.2 2.2 0 2.2 2.2 2.2

4.9

IC5266

12345678

1.7 4.2 0 0 1.1 0 004.8

0000 0 04.8

IC5267

12345678

1.7 0 0 0 1.0 0 0

01.9

4.9

1.8 0 0 0 0 0

IC6211

12345

0 0 0 3.3 3.3

0 0 0 3.3 3.3

IC6221

12345678

0 0 0 0 3.0 3.0 0 3.3

0 0 0 0 3.0 3.0 0 3.3

4.9

4.7 0

2.3 0 2.4 0 4.7 2.4 0 2.3 0 4.7

2.3 0 2.4 0 4.7 2.4 0 2.3 0 4.7

21 22 23 24 25 26 27 28

0 3.2 0 4.7 4.7 3.3 2.8 3.3

0 3.2 0 4.7 4.7 3.3 2.8 3.3

IC5201

IC5201

IC5201

IC5201

1 2 3 4 5 6 7 8 9 101112 1314 1516171819 20

0 4.4 0 4.4 0 1.7 1.7 1.7 3.3 0

0.5 3.2 0 4.4 0 1.7 1.7 2.0 3.3 0

3.2 3.3 0 0 1.2 1.7 1.7 1.7 1.7 1.7

3.2 3.3 0 0 1.2 1.7 1.7 1.7 1.7 2.1

37 38 39 40

1.2 0 3.3 0

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

1.7 1.7 2.7 0 1.7 0 2.2 4.8 1.7 1.8

1.7 1.7 2.7 0 1.7 0 2.2 4.8 1.7 1.8

1.8 2.1 1.5 3.302.1

1.2 0 0 01.8 2.1 1.5 3.302.1

57 58 59 60

2.2 2.2 2.2 2.2

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

1.7 1.6 1.6 1.1 1.7 2.2 2.2 2.2 2.2 2.1

2.5 1.4 1.8 2.2 1.9 2.2 2.2 2.2 2.2 2.1

2.2 2.1 4.8 2.22.2 2.3

2.2 2.2 2.2 2.22.2 2.1 4.8 2.22.2 2.3

IC5263

12345678 910111213141516

0 1.7 2.2 2.2 2.2 0 0 0 3.3 0 0.2 1.1 1.1 1.7 4.9

0 0 0 0 0 0 0 0 3.3 0 0 2.2 0.1 2.2 2.0

4.9

4.9

61 62 63 64

0 2.2 2.2

0 2.2 2.200

IC6201

IC6201

IC6201

IC6201

12345678 91011121314151617181920

3.3 3.1 3.3 3.3 3.3 3.3 3.3 3.0 3.3 0

3.3 2.7 3.3 3.3 3.3 3.3 3.3 2.5 0 0

0 3.3 2.1 3.0 3.0 2.8 3.3 3.3 0 0

0 0.1 1.4 2.6 1.7 1.4 3.3 3.3 0 0

37 38 39 40

1.7 0 0 0

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

3.3 3.3 1.5 1.8 3.3 3.0 2.5 3.0 2.2 2.3

3.3 3.3 1.5 1.8 3.3 2.6 2.1 0 0 1.9

2.4 2.2 2.4 2.22.2 3.3

1.7 2.0 2.1 1.92.4 1.9 2.2 1.82.0 3.3

57 58 59 60

3.3 0 0 3.3

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

000.500000 03.3

1.8 1.4 0.5 0 1.4 0 0 0 0 3.0

3.3 3.3 3.3 3.33.3 2.1

3.3 0 0 3.32.8 3.3 3.03.0 1.91.1

IC6301

IC6301

IC6301

12345678 91011121314151617181920

2.2 2.2 2.1 2.2 2.4 2.2 2.2 2.5 2.0 2.0

2.2 2.0 1.7 1.7 2.1 1.9 1.9 2.2 1.4 1.4

3.3 3.3 0 3.3 2.0 2.0 2.3 2.3 2.2 3.0

2.6 3.3 0 3.3 3.3 1.3 1.7 1.9 2.2 2.7

37 38 39 40

3.3 3.0 3.1 3.0

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

2.5 3.0 2.8 3.0 3.0 3.0 0 3.0 3.0 3.0

2.1 2.6 2.6 2.5 2.5 2.8 0 2.7 2.7 2.6

3.0 3.1 3.1 3.03.1 3.1

3.3 2.7 2.8 2.62.6 2.6 2.7 2.72.7 2.7

41 42 43 44 45 46 47 48

3.0 3.0 3.1 3.1 3.1 0 3.3 2.0

2.6 2.7 2.8 2.8 2.8 0 3.3 1.9

77 78 79 80

3.3 0.1 0 0

70 71 72 73 74 75 7661 62 63 64 65 66 67 68 69

0 0 0 0 0 3.3 3.3 3.3 0 0

0 0 0 0 0 3.3 3.3 0 0 2.8

3.3 3.3 3.3 3.33.3 3.3

3.3 2.9 3.3 3.33.3 3.3 3.3 3.33.3 3.3

IC6201

97 98 99 100

3.3 3.3 3.3 3.3

90 91 92 93 94 95 9681 82 83 84 85 86 87 88 89

3.3 3.3 3.3 3.4 3.3 3.3 3.3 3.3 3.3 3.3

3.3 3.3 3.3 3.4 0.4 0.4 0 1.2 0.4 0.4

3.3 0 3.3 3.303.3

3.3 3.3 3.3 3.30.3 0 3.3 3.303.3

25

DVM-4800

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

Ref No.

MODE

STOP

PLAY

IC6501

12345

0 1.6 0 1.6 3.2

1.6 0 1.6 3.20

Q2001

ECB

1.5 2.1 4.8

1.5 2.1 4.8

Q3221

ECB

1.1 0.5 0

1.1 0.5 0

Q3226

ECB

1.0 0.4 0

1.2 0.6 0

Q3231

ECB

1.5 0.8 0

1.5 0.8 0

Q3236

ECB

1.5 0.8 0

Q3761

ECB

1.3 0.6 0

0.6 01.3

Q3766

ECB

1.3 0.6 0

1.3 0.6 0

Q3771

ECB

1.2 0.4 0

1.4 0.6 0

Q5211

123

4.3 4.8 1.7

3.2 3.8 2.2

Q5215

123

4.4 4.8 1.1

4.4 4.8 1.1

Q5261

ECB

1.1 1.8 4.8

1.1 1.8 4.8

Q6215

ECB

003.2

003.2

1.1 1.8 4.8

1.1 1.8 4.8

Q5262

ECB

Q5263

ECB

1.6 0.9 0

1.8 1.1 0

Q5264

ECB

0.5 1.1 4.8

0.3 1.1 4.8

Q5271

123

0 3.3 0

0 3.3 0

QR5221

123

3.3 3.3 0.4

3.3 0.1 3.3

QR5241

123

3.3 3.3 0

3.3 0.1 3.3

1.5 0.8 0

IC6531

12345

0 1.6 0 1.6 3.2

1.6 0 1.6 3.20

IC6561

12345

0 1.6 0 1.6 3.2

1.6 0 1.6 3.20

IC6541

12345

1.5 1.5 1.5 0 1.5

678

3.2 3.2 3.2

1.5 1.5 0 1.5 3.2 3.2 3.21.5

IC6551

12345

1.5 1.5 1.6 0 1.4

678

003.2

1.5 1.6 0 1.4 0 0 3.21.5

IC6511

12345

0 1.6 0 1.6 3.2

1.6 0 1.6 3.20

IC6521

12345

0 1.6 0 1.6 3.2

1.6 0 1.6 3.20

IC6571

12345

0 1.6 0 1.6 3.2

1.6 0 1.6 3.20

IC6581

12345

0 1.6 0 1.6 3.2

1.6 0 1.6 3.20

IC6591

12345

0 1.6 0 1.5 3.2

1.6 0 1.5 3.20

IC6801

IC6801

IC6801

IC6801

1 2 3 4 5 6 7 8 9 101112 1314 151617181920

3.4 2.5 1.6 0 0 3.3 0 0 3.1 3.0

3.4 2.5 1.5 0 0 3.3 0 0 2.7 2.7

0 0 3.4 3.1 3.4 0 3.3 3.4 0 0

0 0 2.7 3.4 0 3.3 3.4 0 00

37 38 39 40

3.3 0 3.3 3.4

30 31 32 33 34 35 3621 22 23 24 25 26 27 28 29

3.1 0 3.1 3.4 3.4 3.1 3.2 2.1 3.3 2.5

2.8 0 2.8 3.4 3.4 2.8 2.2 1.6 2.6 2.5

3.2 1.7 3.3 3.41.6 0

3.3 0 0.8 3.42.0 1.7 1.7 3.41.6 0

57 58 59 60

003.41.6

50 51 52 53 54 55 5641 42 43 44 45 46 47 48 49

3.1 3.3 3.3 0 0 3.4 3.3 0 0 0

0.6 3.3 3.3 0 0 3.4 0.8 0 0 0

1.6 0 0 2.51.7 1.7

003.41.61.6 0 0 2.51.7 1.7

77 78 79 80

03.40 0

70 71 72 73 74 75 7661 62 63 64 65 66 67 68 69

3.4 0 0 0 3.4 0 0 0 0 0

3.4 0 0 0 3.4 0 0 0 0 0

3.4 3.4 0 000

03.41.400003.3 3.33.4

26

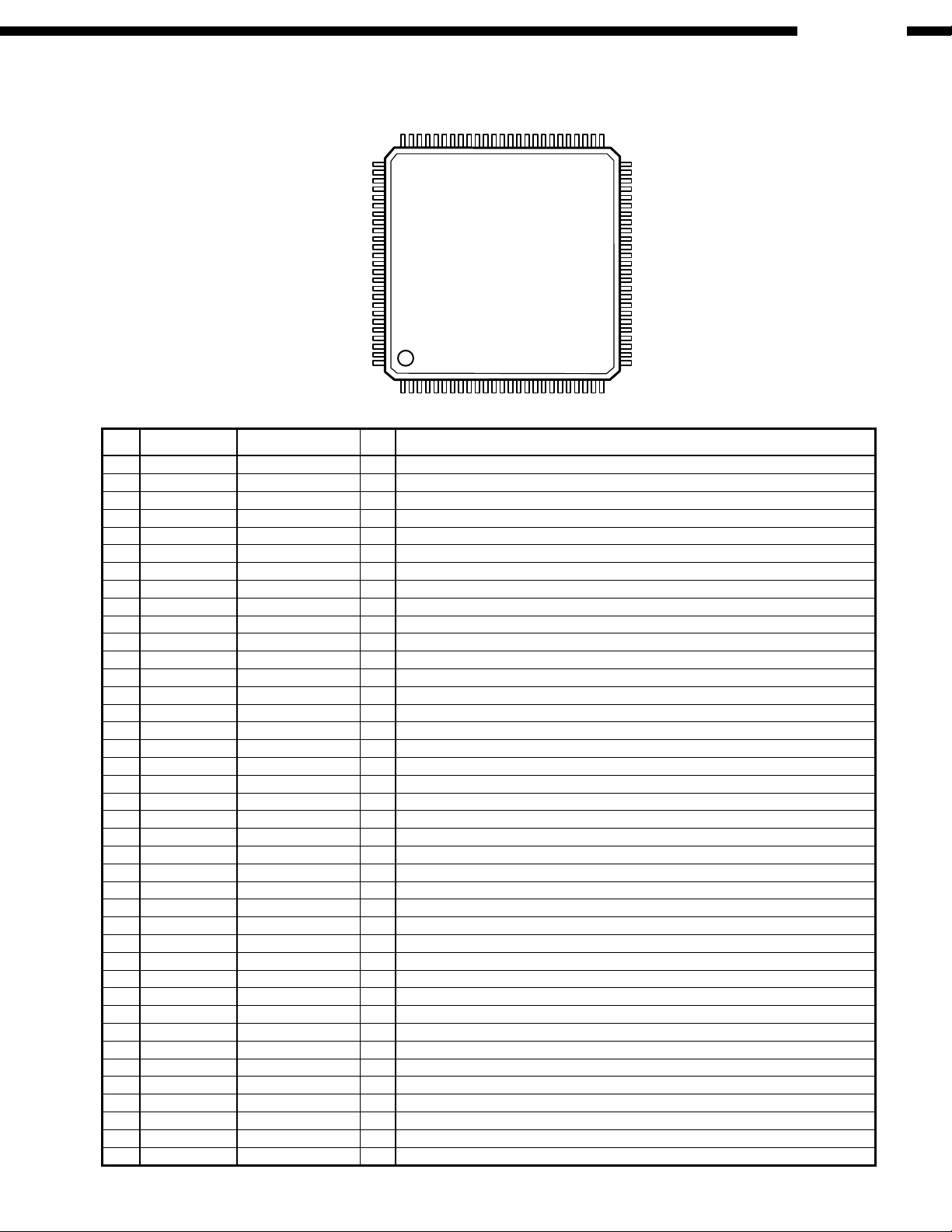

8. SEMICONDUCTORS

IC's

MN101C35DCA (IC601)

76

75

DVM-4800

51

50

100

1

MN101C35DCA Terminal Function

Pin

No.

10 OSC1 XO I Clock

11 VSS GND GND

12 XI GND I Not used

13 XO NC O Not used

14 MMOD GND I Memory mode

15 VREF- GND I A/D reference L

16 PA0 KEYIN0 I A/D key input

17 PA1 KEYIN1 I A/D key input

18 PA2 KEYIN2 I A/D key input

19 PA3 SWOP I Tray open detect, L: Open

20 PA4 SWCL I Tray close detect, L: Close

21 PA5 PA5 I Model set jumper 1

22 PA6 PA6 I Model set jumper 2

23 PA7 PA7 I Model set jumper 3

24 VREF+ 5V I A/D reference H

25 P07 POWERMUT O Power mute, H: Mute

26 P27 /RST I Reset

27 P10 SWDN I Chucking down detect, L: Down

28 P11 SWUP I Chucking up detect, L: Up

29 P12 OPEN O Tray open, H: Open

30 P13 CLOSE O Tray close, H: Close

31 P14 ROULETTE-L O Roulette left-turn, H: Left-turn

32 P15 ROULETTE-R O Roulette right turn, H: Right turn

33 P20 (IRQ0) REM I Remote-control input

34 P21 VSYNC I V-Sync (IRQ)

35 P22 W.REMIN I Wired remote-control input

36 P23 RFF I RFF

37 P24 R.SENS I Roulette sensor, H: detect slit

38 P25 D.SENS I Disc sensor, L: detect disc

39 P30 SDA O I2C SDA

40 P31 POWER-OFF O Main power control, L: On

Pin Name FunctionI/OSymbol

1 P00 ST-BY LED O ST-BY LED

2 P01 R-SPEED O Roulette rotation slow down, H: Down

3 P02 FL DRIVE O FL light off, L: Off

4 P03 CMD O Serial output

5 P04 STATUS I Serial input

6 P05 DSPCLK I Serial clock

7 P06 AUDIO ONLY LED O Audio Only LED

8VDD 5V +5V

9 OSC2 XI O Clock

26

25

27

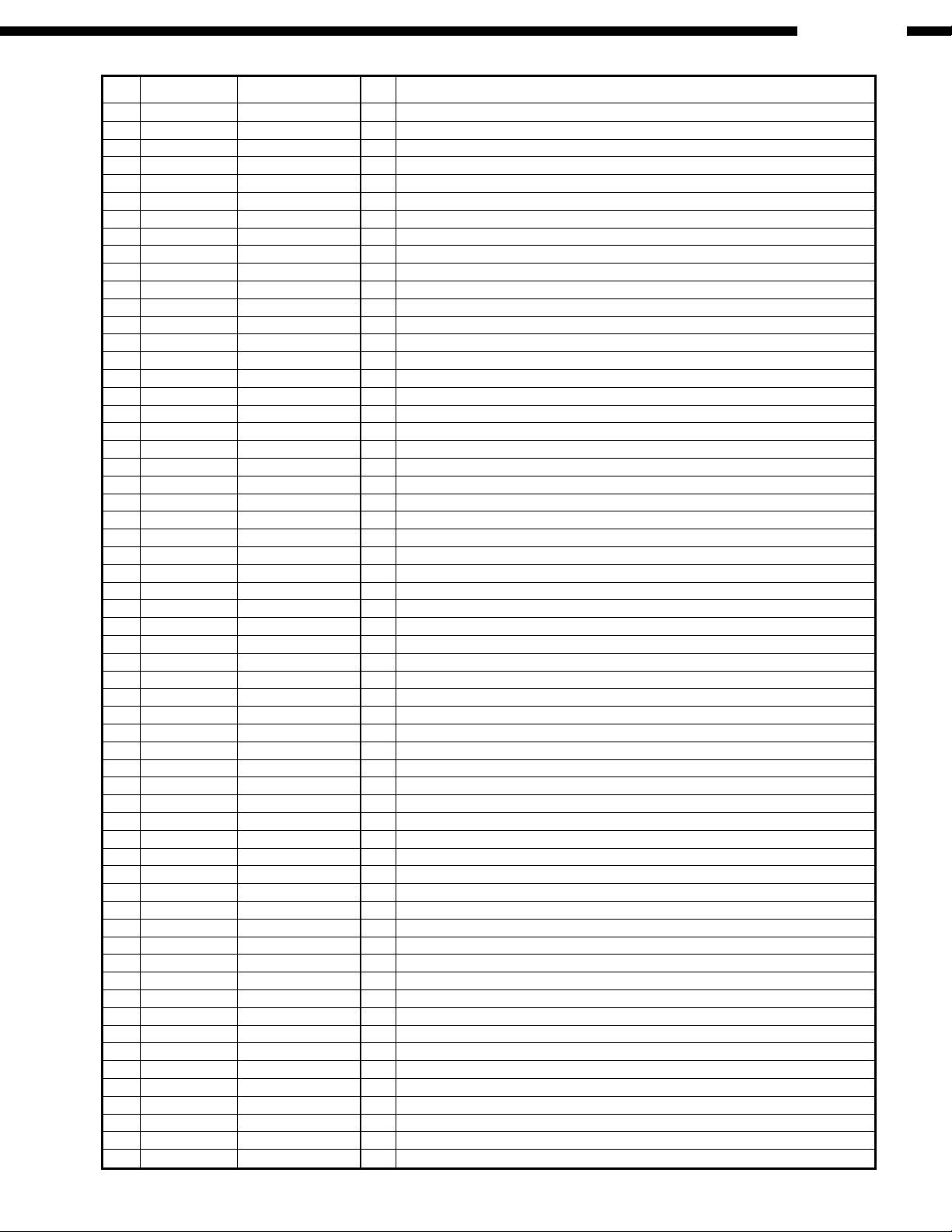

DVM-4800

Pin

No.

41 P32 SCV O I2C SCL

42 P50 D.F.2.I I D.F.2 detect

43 P51 DEEMPH O Emphasis control

44 P52 RSTN O Reset output for D.F.1, L: Reset

45 P53 CKDV1 O Master clock switching sig.1

46 P54 CKDV2 O Master clock switching sig.2

47 P67 G17 O FL-DGT

48 P66 G16 O FL-DGT

49 P65 G15 O FL-DGT

50 P64 G14 O FL-DGT

51 P63 G13 O FL-DGT

52 P62 G12 O FL-DGT

53 P61 G11 O FL-DGT

54 P60 G10 O FL-DGT

55 P41 G9 O FL-DGT

56 P40 G8 O FL-DGT

57 P77 G7 O FL-DGT

58 P76 G6 O FL-DGT

59 P75 G5 O FL-DGT

60 P74 G4 O FL-DGT

61 P73 G3 O FL-DGT

62 P72 G2 O FL-DGT

63 P71 G1 O FL-DGT

64 P70 S1 O FL-SEG

65 P87 S2 O FL-SEG

66 P86 S3 O FL-SEG

67 P85 S4 O FL-SEG

68 P84 S5 O FL-SEG

69 P83 S6 O FL-SEG

70 P82 S7 O FL-SEG

71 P81 S8 O FL-SEG

72 P80 S8 O FL-SEG

73 P97 S10 O FL-SEG

74 P96 S11 O FL-SEG

75 P95 S12 O FL-SEG

76 P94 S13 O FL-SEG

77 P93 S14 O FL-SEG

78 P92 S15 O FL-SEG

79 P91 S16 O FL-SEG

80 P90 S17 O FL-SEG

81 PC2 S18 O FL-SEG

82 PC1 S19 O FL-SEG

83 PC0 S20 O FL-SEG

84 PB7 S21 O FL-SEG

85 PB6 S22 O FL-SEG

86 PB5 S23 O FL-SEG

87 PB4 S24 O FL-SEG

88 PB3 S25 O FL-SEG

89 PB2 S26 O FL-SEG

90 PB1 S27 O FL-SEG

91 PB0 S28 O FL-SEG

92 PD7 S29 O FL-SEG

93 PD6 S30 O FL-SEG

94 PD5 S31 O FL-SEG

95 PD4 S32 O FL-SEG

96 PD3 S33 O FL-SEG

97 PD2 S34 O FL-SEG

98 PD1 S35 O FL-SEG

99 PD0 S36 O FL-SEG

100 VPP -29V I -29V

Pin Name FunctionI/OSymbol

28

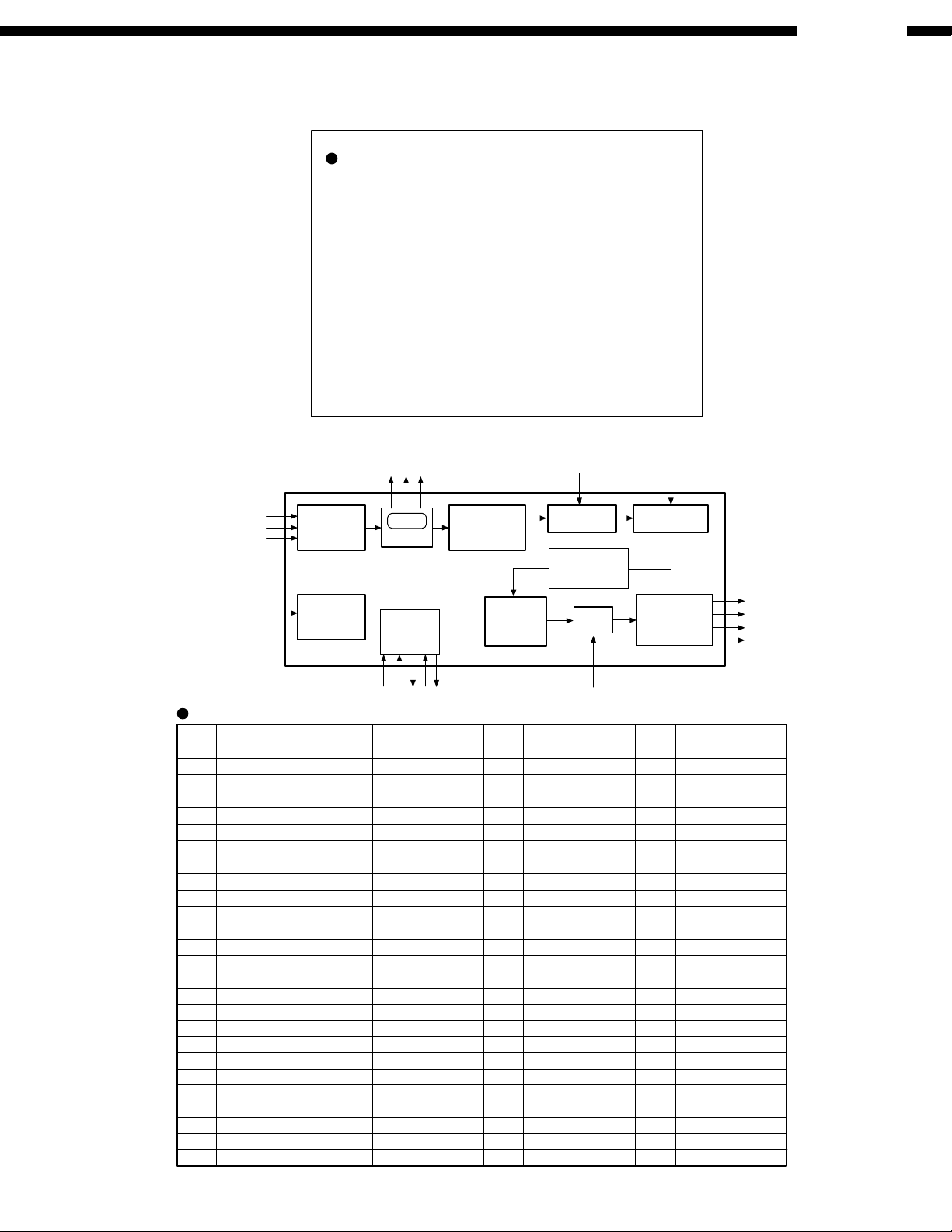

PMD200 (IC101)

DVM-4800

MODD

MODB

MODA

WCKO

BCKO

VCCS

GNDS

GNDG

VCCLQ

GNDQ

SMUTE

DOUT/DOL

VCCHQ

HMUTE

SPI/I2C

DEEMP

VCCS

GNDS

SS/HA2

MOSI/HA0

MISO/SDA

LRCI

BCKI

DIN

EXTAL

LRCI

BCKI

DOR

DIN

Input Data

Interface

Generator

NCNCNCNCGAIN

9998979695949392919089888786858483828180797877

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26272829303132333435363738394041424344454647484950

HREQ

SCK/SCL

Timing

PINIT

NC

RESET

HDCD

HDCD

Detect

Control

Interface

VCCG

VCCP

ZERO

ZERO

PCAP

GAIN

GNDS

VCCS

GNDP

EXTAL

Interpolation

GNDQ

HDCDNCVCCHQ

GNDQ

GNDG

VCCLQ

VCCHQ

2xFs

Filter

Dither

Generator

VCCLQNCNC

GNDG

GNDG

GNDG

GNDG

NCNCNC

NCNCNC

VCCC

GNDC

SMUTE

Attenuator Deemphasls

Interpolation

Filter

Mute

GNDD

VCCD

GNDG

GNDG

NC

VCCA

GNDA

DEEMP

Output Data

Interface

GNDG

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

NC

GNDG

NC

NC

GNDA

VCCA

NC

NC

NC

NC

VCCLQ

GNDQ

GNDA

VCCA

NC

VCCHQ

NC

NC

NC

NC

GNDA

VCCA

NC

NC

NC

NC

DOL

DOR

WCKO

BCKO

PMD200 Terminal Function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Signal Name

MODD

MODB

MODA

WCKO

LRCI

BCKO

BCKI

VCCS

GNDS

GNDG

VCCLQ

GNDQ

SMUTE

DOUT/DOL

VCCHQ

DOR

HMUTE

SPI/I2C

DEEMP

DIN

VCCS

GNDS

SS/HA2

MOSI/HA0

MISO/SDA

Pin

No.

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

SCK

MISO

MOSI

I2C/SPI

HREQ

Signal Name

SCK/SCL

HREQ

PINIT

RESET

NC

VCCP

PCAP

GNDP

EXTAL

VCCHQ

GNDQ

VCCLQ

GNDG

NC

NC

NC

VCCC

GNDC

NC

NC

NC

NC

VCCA

GNDA

NC

Pin

No.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

HMUTE

Signal Name

NC26

NC

NC

NC

VCCA

GNDA

NC

NC

NC

NC

VCCHQ

NC

VCCA

GNDA

GNDQ

VCCLQ

NC

NC

NC

NC

VCCA

GNDA

NC

NC

GNDG

Pin

No.

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Signal Name

GNDG

GNDG

GNDG

VCCD

GNDD

GNDG

GNDG

GNDG

GNDG

NC

NC

VCCLQ

GNDQ

VCCHQ

NC

HDCD

VCCS

GNDS

ZERO

VCCG

GAIN

NC

NC

NC

NC

29

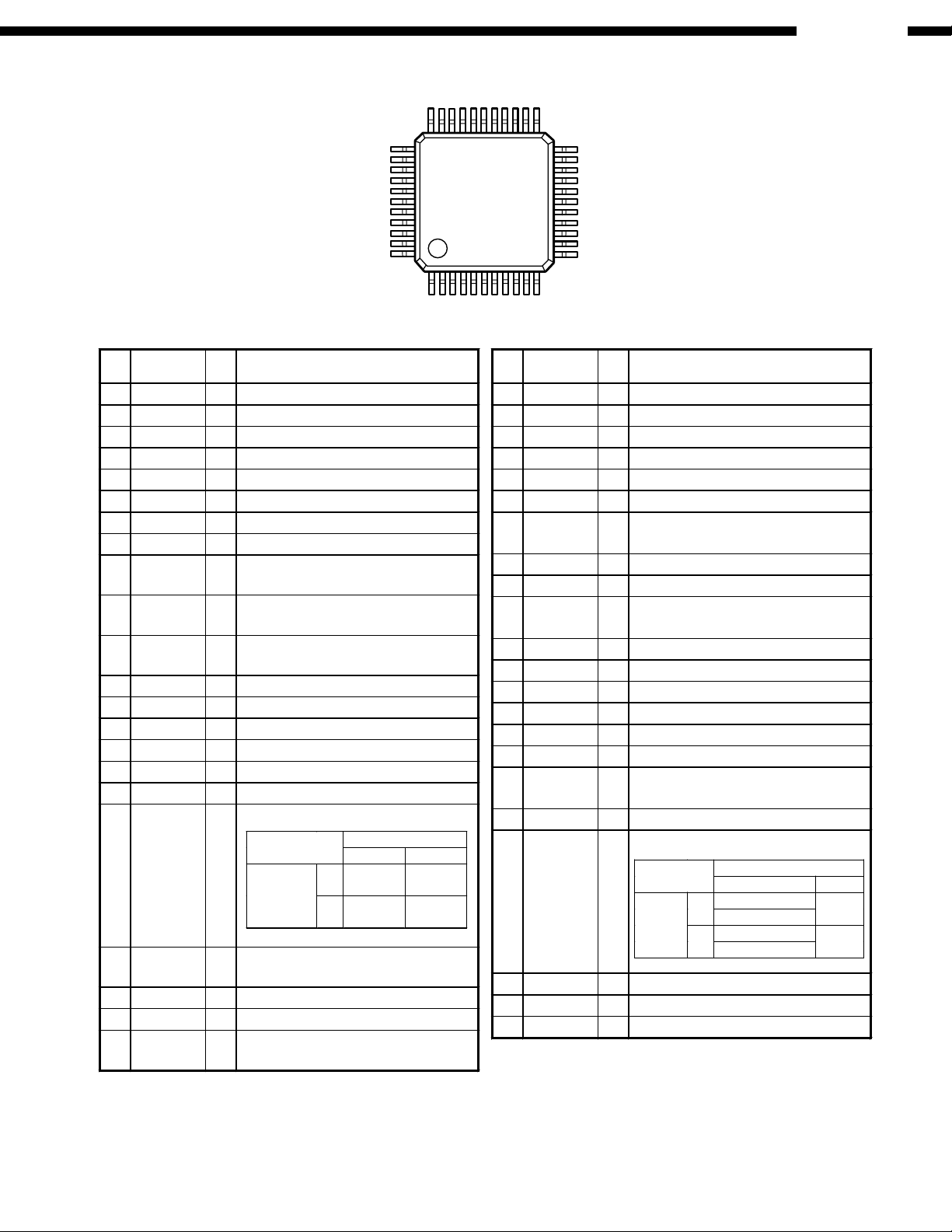

DVM-4800

DXP7001AF (IC201)

33

34

44

1

DXP7001AF Terminal Function

Pin

Pin Name I/O Description

No.

1 MDT Ip Microcomputer Interface Data

2 MCK Ip Microcomputer Interface Clock

3 MLEN Ip Microcomputer Interface Latch Enable

4 RSTN Ip Reset Terminal

5 DLRCK Ip Audio Serial Input Data L/R Clock

6 VSS

7 DBCK Ip Audio Serial Input Bit Clock

8 DDT Ip Audio Serial Input Data

9 TEST2N Ip

10 TEST3N Ip

11 TEST4N Ip

12 DFBCK Ip Lambda-processor Input Bit Clock

13 DFWCK Ip Lambda-processor Input Word Clock

14 DOL Ip Lambda-processor Input Data L-channel

15 DOR Ip Lambda-processor Input Data R-channel

16 LMOD Ip Lambda-processor Operation Mode Set

17 OMOD1 Ip Output Mode Setting Terminal 1

18 OMOD2 Ip

19 INVIN Ip

20 BCKO O Lambda-processor Output Bit Clock

21 WCKO O Lambda-processor Output Word Clock

22 WCKO2 O

Ground Terminal

−

Test Setting Terminal 2 (Alpha-processor 1

Output shifts 12-bit.)

Test Setting Terminal 3 (Alpha-processor 2

Output stops.)

Test Setting Terminal 4 (Lambda-processor

Output stops.)

Output Mode Setting Terminal 2

OMOD1

LH

18bit

L

H

Alternate

20bit

Parallel

OMOD2

Lambda-processor Input Reversed

Polarity Terminal

Lambda-processor Output Word Clock 2

(for Canceling OFFSET on 1DAC

24bit

Alternate

24bit

Parallel

23

22

12

11

Pin

Pin Name I/O Description

No.

23−P24L O−/Lambda-processor Lch 24th bit Output *1, *2

24−P23L O−/Lambda-processor Lch 23rd bit Output *1, *2

25−P22L O−/Lambda-processor Lch 22nd bit Output *1, *2

26−P21L O−/Lambda-processor Lch 21st bit Output *1

27−P20L O−/Lambda-processor Lch 20th bit Output *1

28 VDD

29 SO2L/P19L O

30 SO1L O Lambda-processor Lch(+) Output

31 SO1R O Lambda-processor Rch(+) Output

32 SO2R/P19R O

33−P20R O−/Lambda-processor Rch 20th bit Output *1

34−P21R O−/Lambda-processor Rch 21st bit Output *1, *2

35−P22R O−/Lambda-processor Rch 22nd bit Output *1, *2

36−P23R O−/Lambda-processor Rch 23rd bit Output *1, *2

37−P24R O−/Lambda-processor Rch 24th bit Output *1, *2

38 TEST1N Ip Test Terminal 1 (Alpha-processor 1 stops)

39 CKSLN Ip System Clock Select (384fs system /

40 CKDV1 Ip System Clock Divider Select Terminal 1

41 CKDV2 Ip

42 XTI I X-TAL Oscillator Input Terminal

43 XTO O X-TAL Oscillator Output Terminal

44 CKO O Clock Output Terminal

Power Supply Terminal

−

Lambda-processor Lch(−) Output /19

Output *1

Lambda-processor Rch(−) Output/19

Output *1

256fs system)

System Clock Divider Select Terminal 2

CKDV1

LH

192fs (CKSLN=H)

L

CKDV2

256fs (CKSLN=H)

192fs (CKSLN=H)

H

256fs (CKSLN=H)

th

th

768fs

384fs

bit

bit

(Ip = Input Terminal with pull-up)

*1: Outputted on OMOD1=L (18-bit Alternate Output or 20

-

bit Parallel Output)

*2: Internal Signal is outputted on OMOD1=H (24-bit Alternate Output or 24

or TEST4N is set to L.

-

bit Parallel Output) and one of TEST1N, TEST2N, TEST3N

30

Loading...

Loading...