Denon DVM-1845 Service Manual

Ver. 1

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E1C E1K EUT

DVM-1845/745

DVD VIDEO AUTO CHANGER

3

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

Denon Brand Company, D&M Holdings lnc.

●

本機の仕様は性能改良のため、予告なく変更すること

があります。

●

補修用性能部品の保有期間は、製造打切後 8 年です。

●

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

●

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

TOKYO, JAPAN

X0336V.01 DE/CDM 0704

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Caution - Class 1M visible and invisible laser radiation when open.

Do not view directly with optical instruments.

DVM-1845/745

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子、マイク端子、入力端子など]と

の間で、絶縁抵抗値が1 MΩ 以上であることを確認してく

ださい。この値以下のときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…!マークで表示しています。

(2) 部品表…!マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

DVM-1845/745

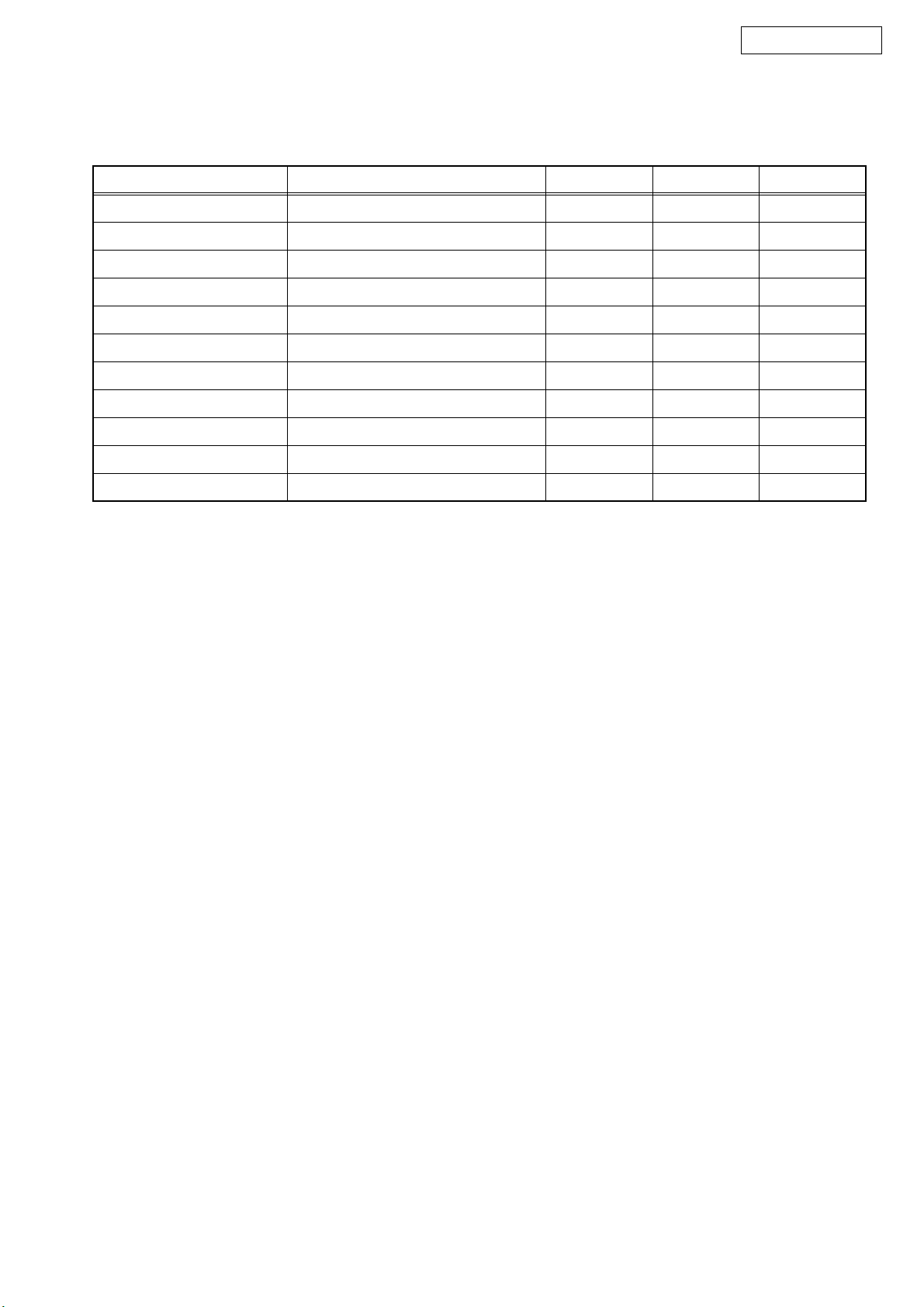

SPECIFICATIONS

Item Conditions Unit Nominal Limit

1. Video Output 75 load Vpp 1.0 ± 0.1

2. Optical Digital Out dBm -18

3. Audio (PCM)

3-1. Output Level 1 kHz, 0 dB Vrms 2.0

3-2. S/N dB 120

3-3. Freq. Response

DVD fs = 48 kHz, 20 Hz ~ 22 kHz dB ± 1.0

CD fs = 44.1 kHz, 20 Hz ~ 20 kHz dB ± 1.0

3-4. THD+N

DVD 1 kHz, 0 dB % 0.004

CD 1 kHz, 0 dB % 0.004

Notes:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply: AC 120 V, 60 Hz

3. Load Impedance: 100 k load (Audio Output)

4. Room Ambient: 5 °C - 40 °C

3

DVM-1845/745

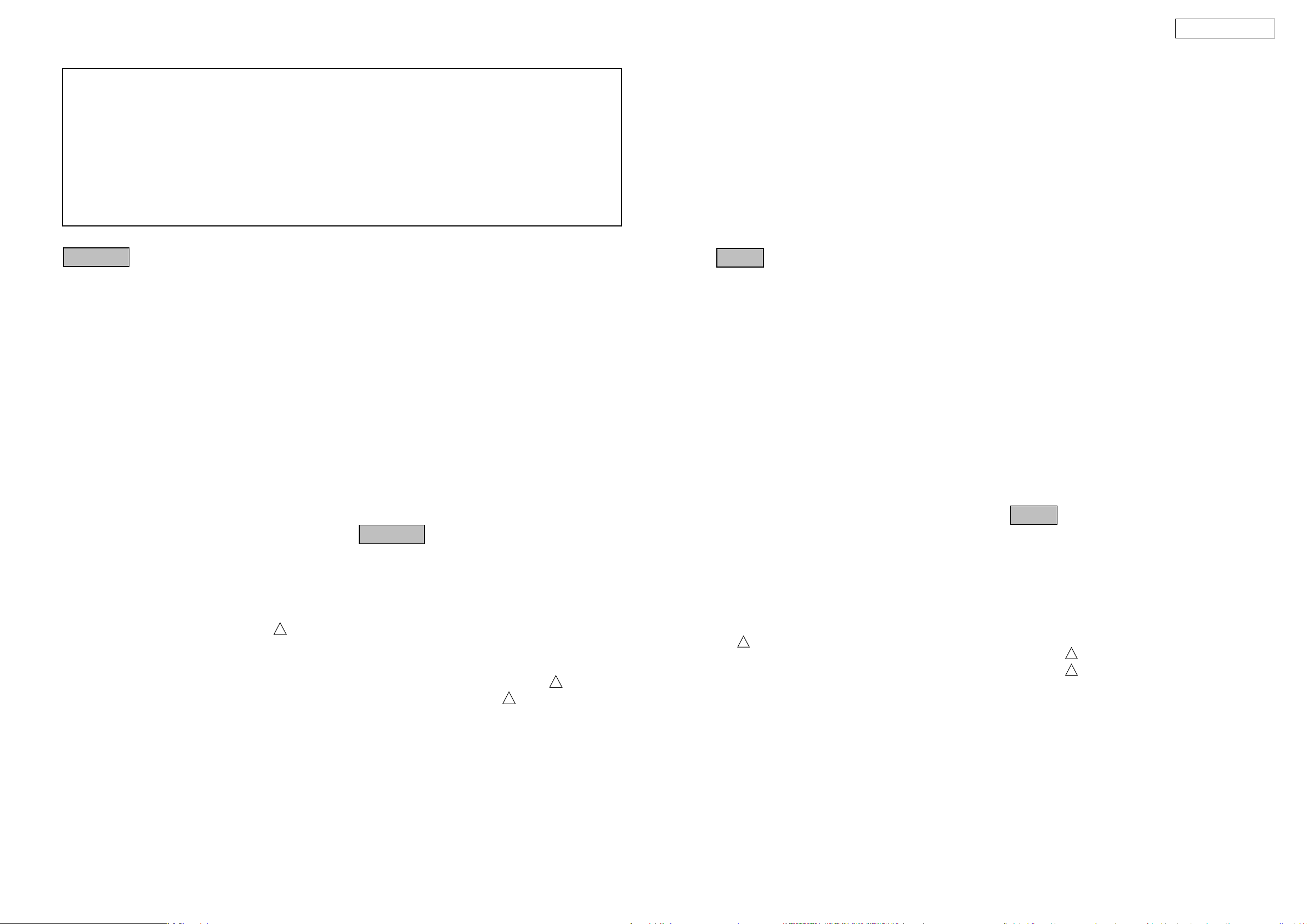

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

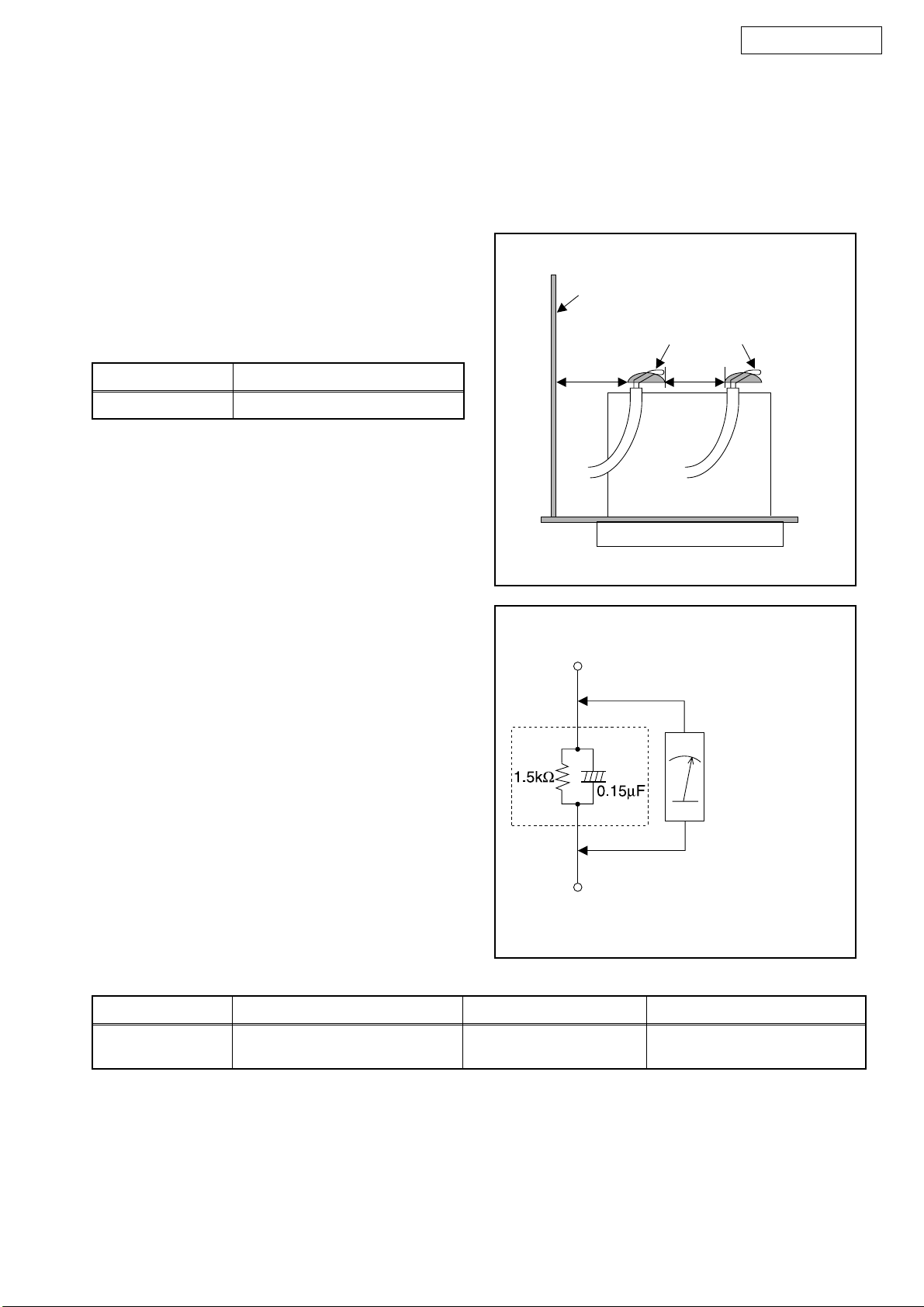

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d’)

120 V ≥ 3.2 mm (0.126 inches)

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

d' d

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

0.15 µF CAP. & 1.5 kΩ RES.

Connected in parallel

i ≤ 0.5 mA Peak Exposed accessible parts

4

Fig. 2

STANDARD NOTES FOR SERVICING

DVM-1845/745

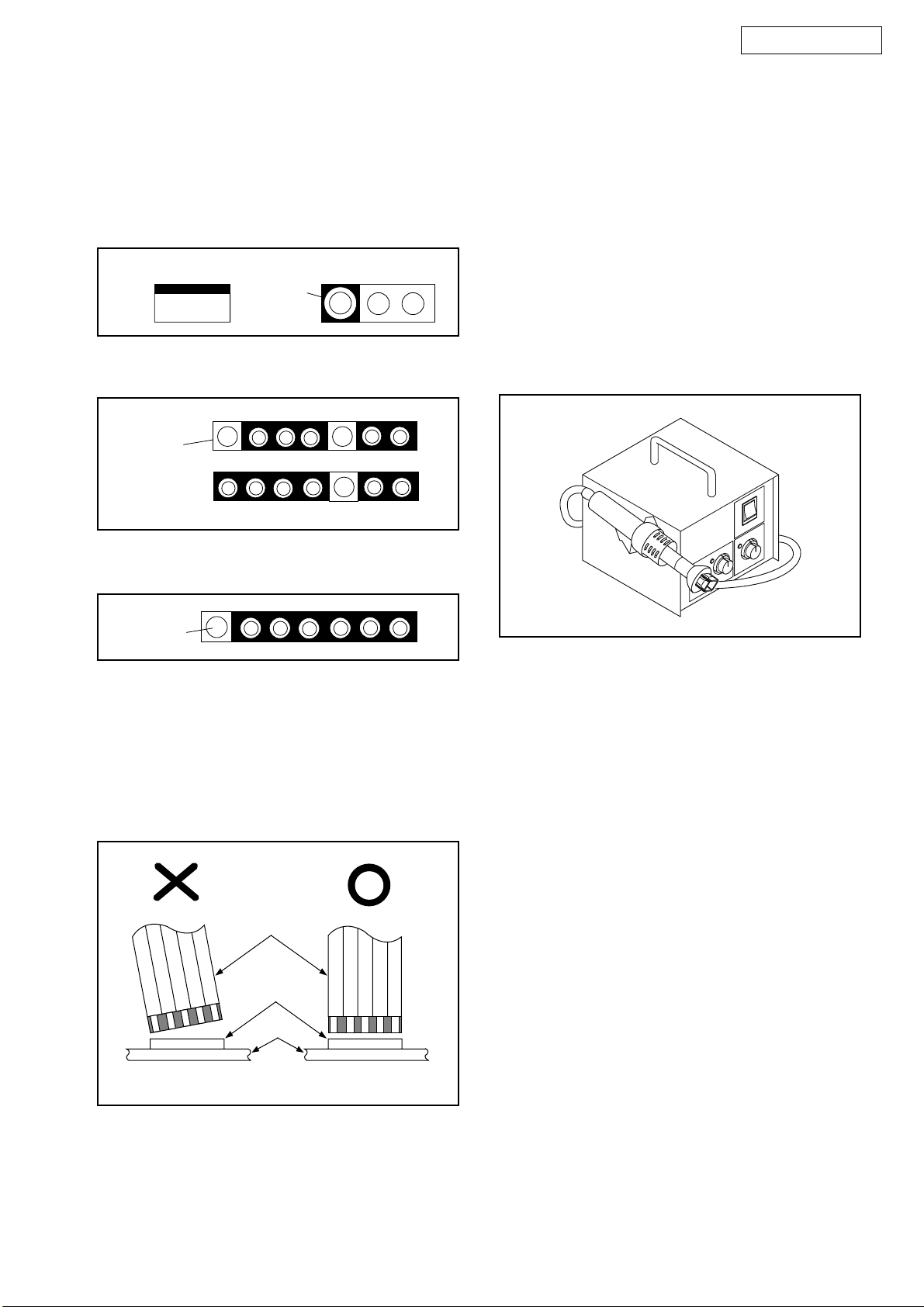

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

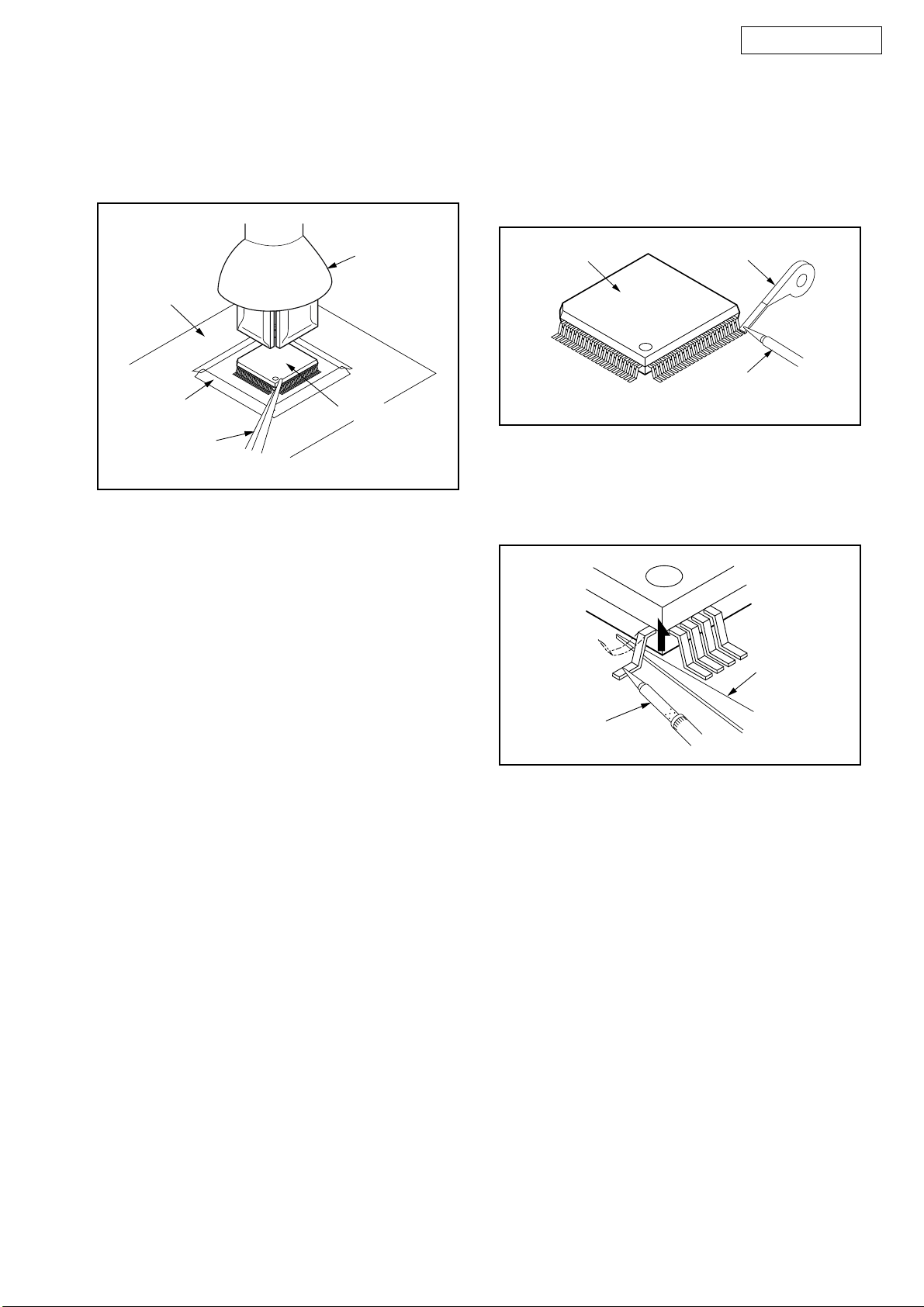

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

5

DVM-1845/745

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

Machine

Flat Pack-IC

Fig. S-1-2

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

Flat Pack-IC

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Desoldering Braid

Soldering Iron

Fig. S-1-3

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

6

DVM-1845/745

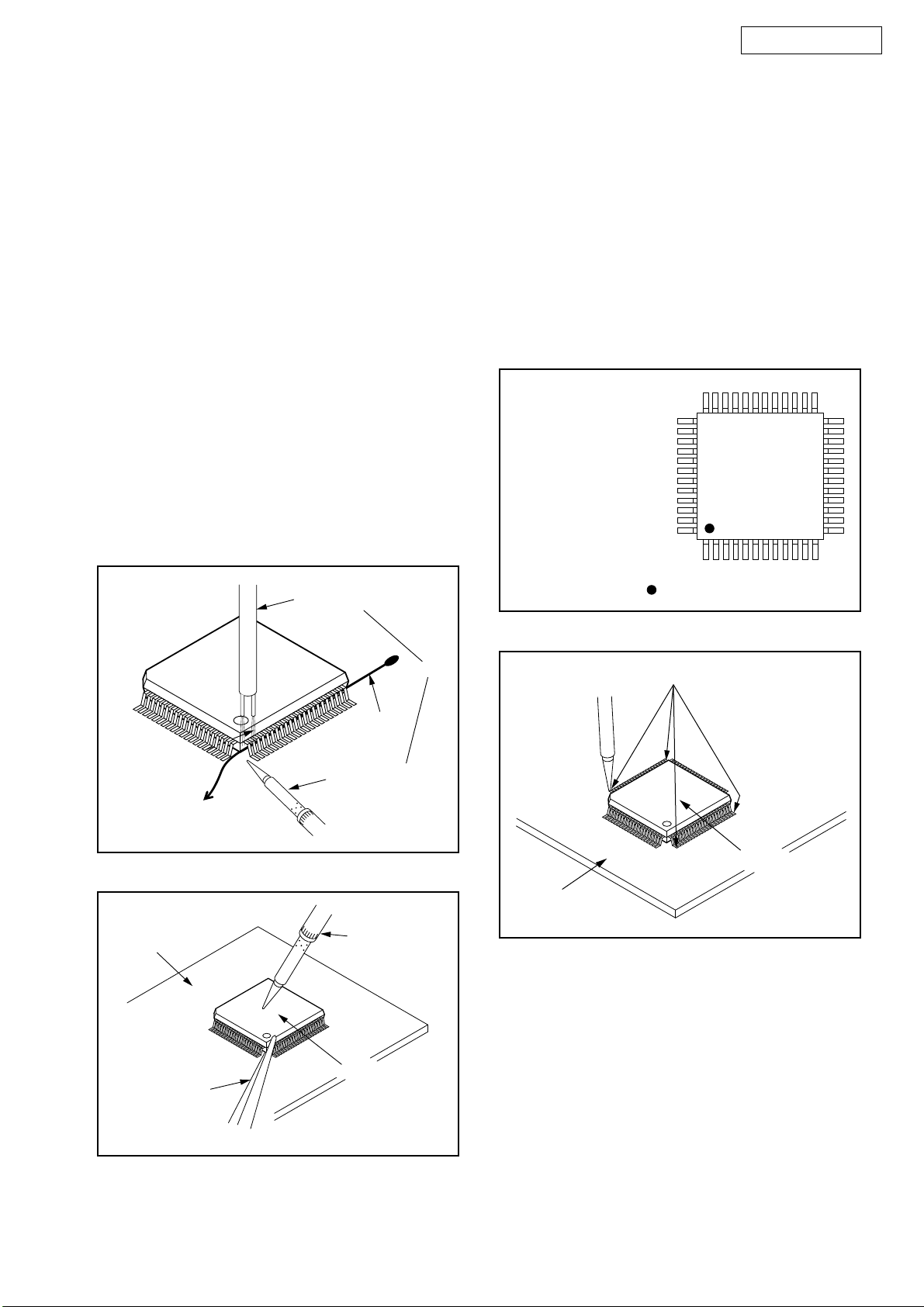

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

7

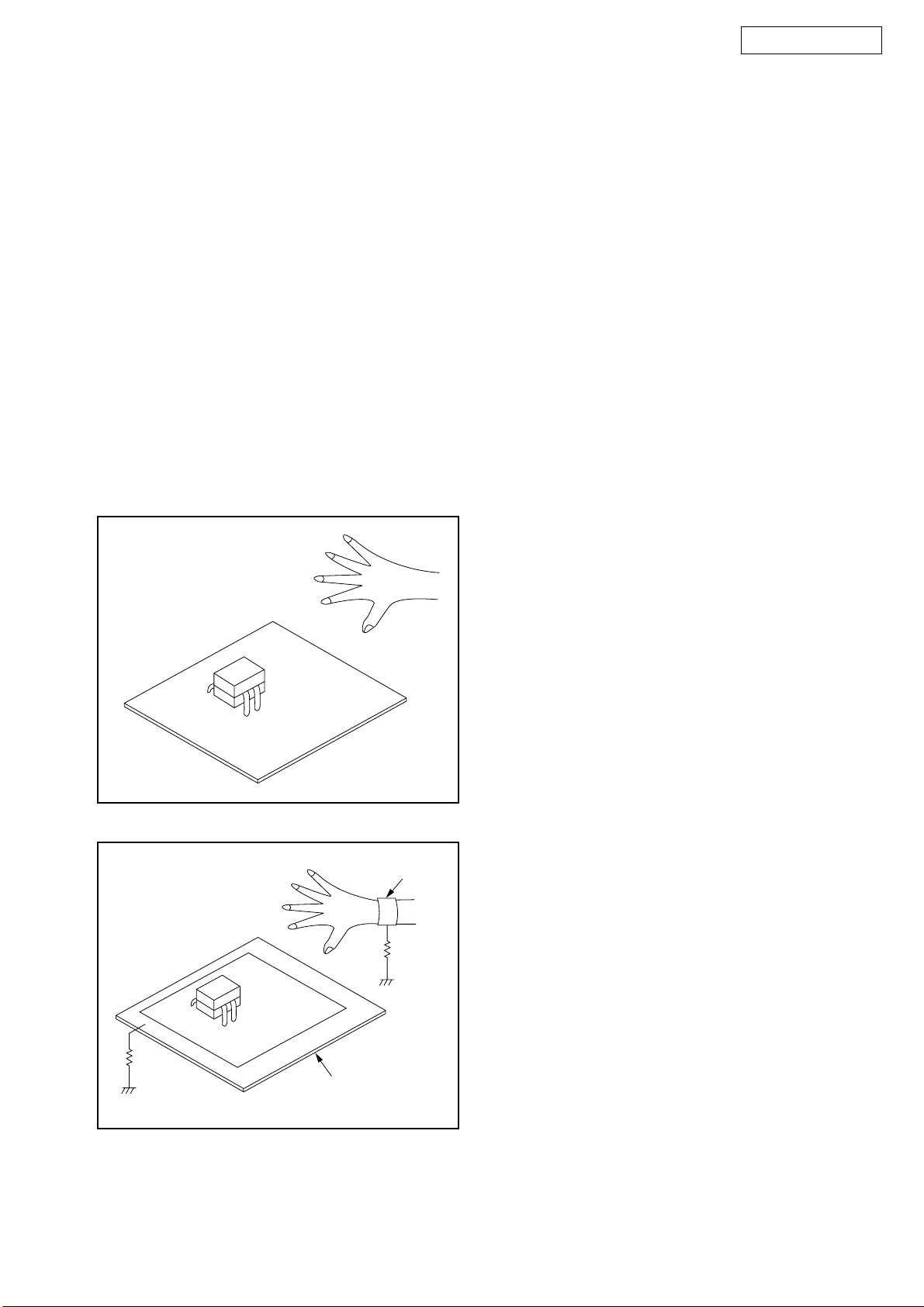

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

DVM-1845/745

<Incorrect>

<Correct>

CBA

Grounding Band

1MΩ

1MΩ

CBA

Conductive Sheet or

Copper Plate

8

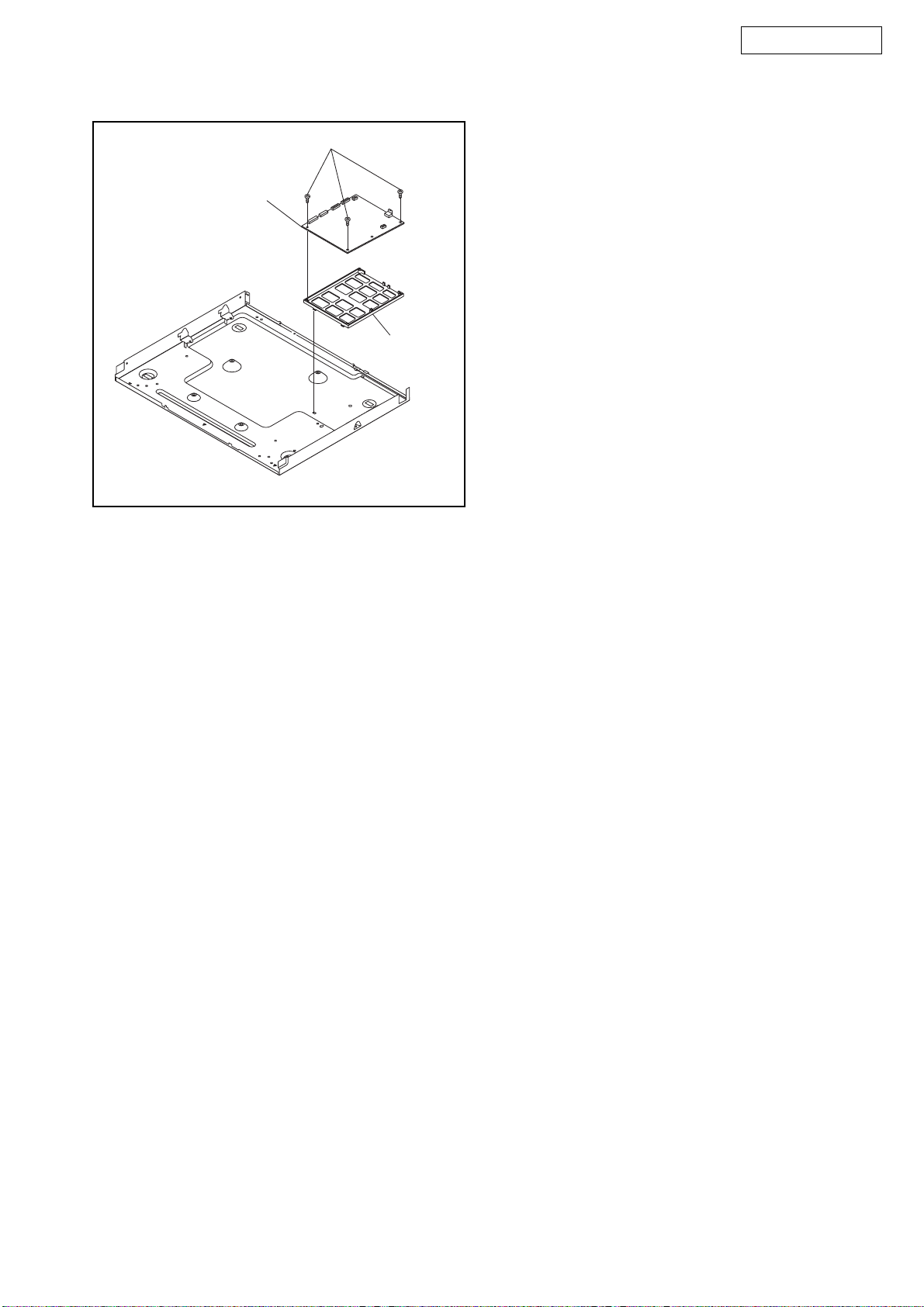

CABINET DISASSEMBLY INSTRUCTIONS

DVM-1845/745

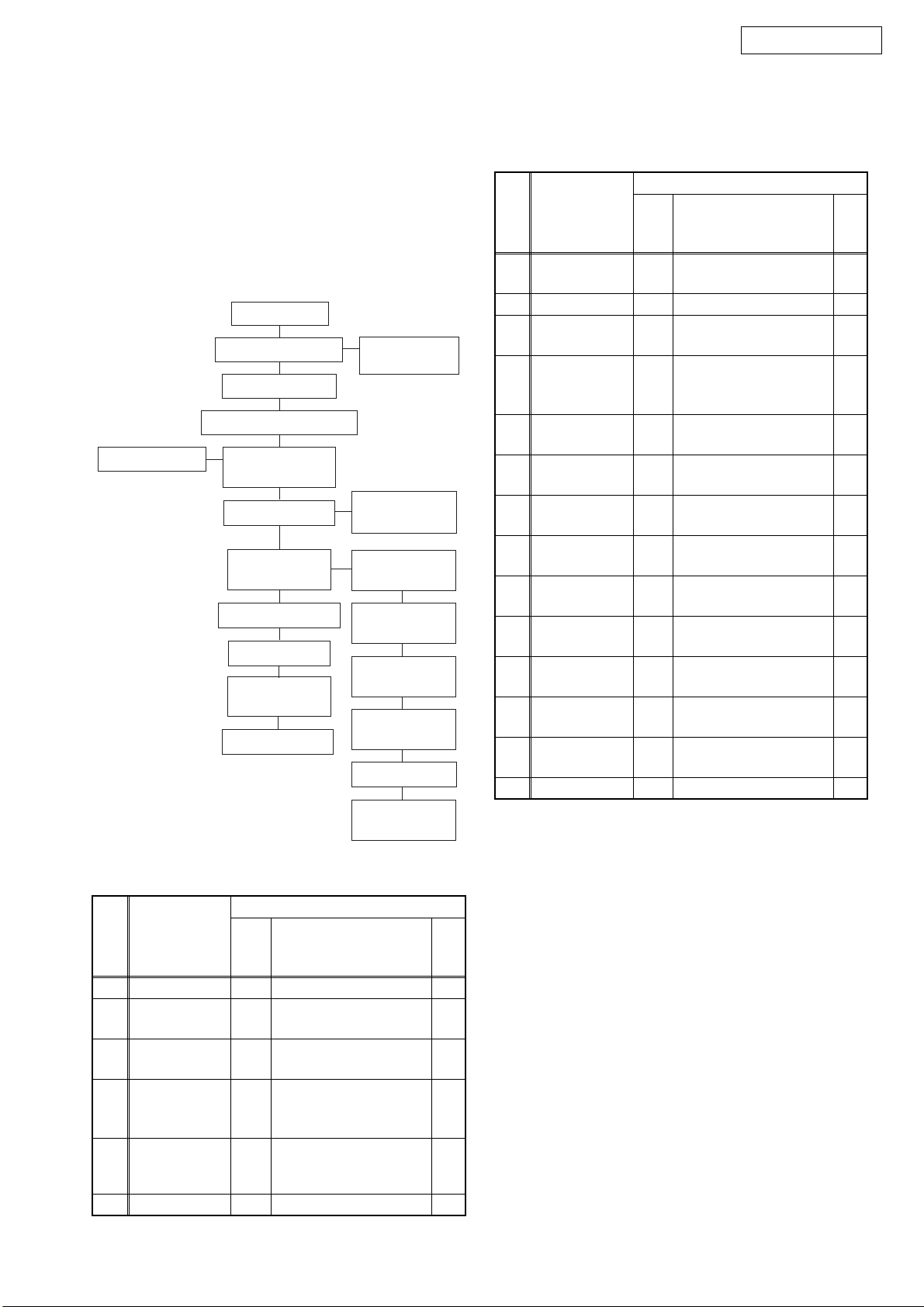

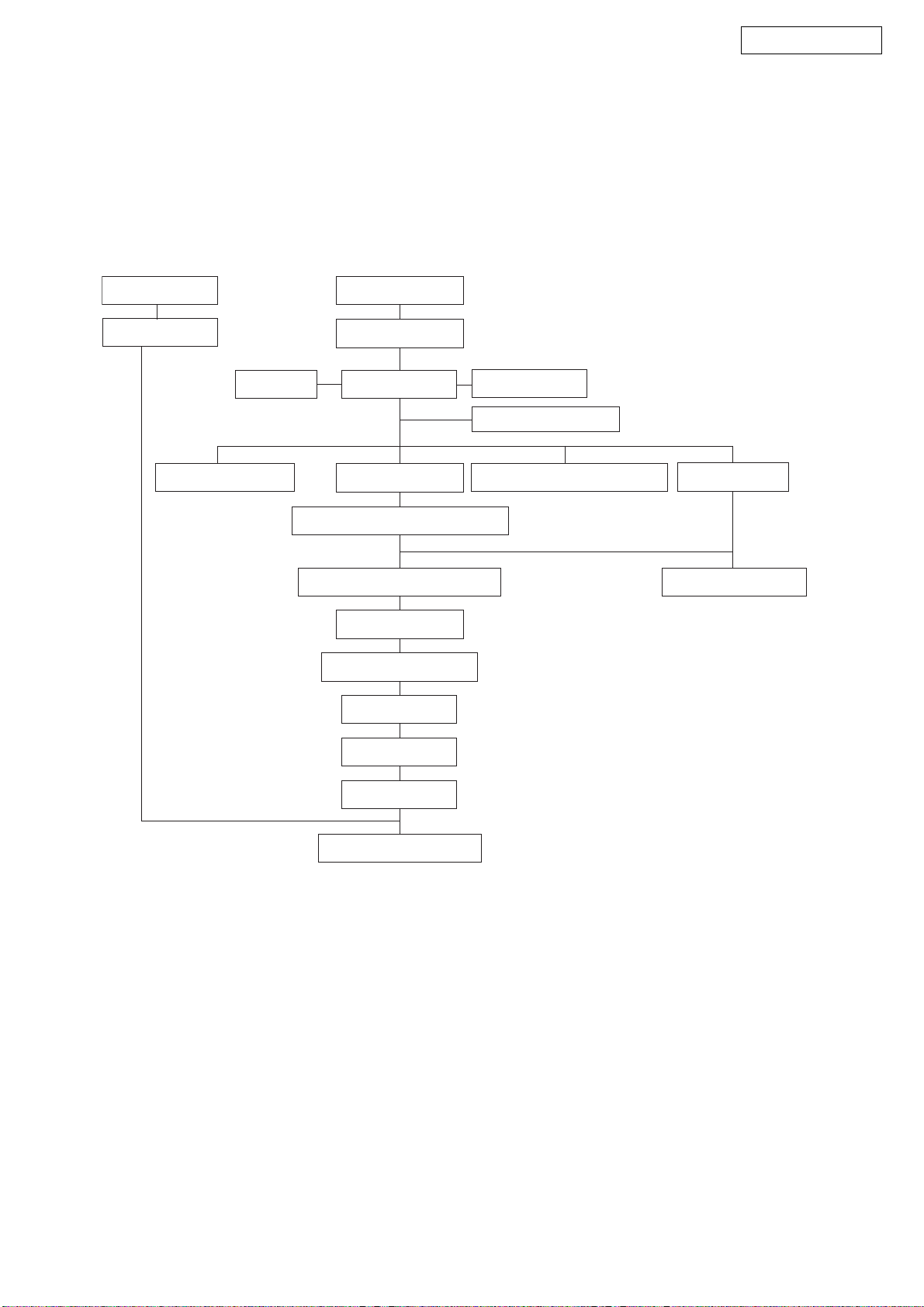

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] Top Cover

[7] Power

Switch CBA

[9] Tray

Guide (L)

[11] Loading

Pulley

[12] Slide Tray

Gear (B)

[13] Slide Tray

Gear (A)

[14] Motor

Assembly

[15] Switch CBA

[16] Tray

Guide (R)

[6] Function CBA

[2] Front Assembly

[3] Bracket (Top)

[4] Stopper Bracket L, R

[5] Slide Tray

Assembly

[8] Rear Panel

[10] Tray Guide

(R) Unit

[17] Changer CBA

[18] AV CBA

[19] DVD Main

CBA Unit

[20] PCB Holder

ID/

LOC.

No.

Power Switch

[7]

CBA

PAR T

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

D4 CN2103, (S-4) -

[8] Rear Panel D6 4(S-5), 11(S-6), (S-7) -

REMOVAL

Tr ay

[9]

Guide (L)

Tr ay

[10]

Guide (R)

Unit

Loading

[11]

Pulley

Slide Tray

[12]

Gear (B)

Slide Tray

[13]

Gear (A)

Motor

[14]

Assembly

Switch

[15]

CBA

Tr ay

[16]

Guide (R)

[17] Changer CBA D9

[18 AV CBA D9

DVD Main

[19]

CBA Unit

D7 (S-8) -

2(S-9), CN3003,

D7

CN3004

D8 (S-10), Belt L -

D8 (S-11), *(P-1) -

D8 ---------- -

D8 (S-12) -

D8 *2(L-4) -

D8 ---------- -

CN3102, CN3301,

2(S-13)

5(S-14), CN1001,

CN1601

D10 3(S-15) -

[20] PCB Holder D10 ---------- -

↓

(1)

↓

(2)

↓

(3)

↓

(4)

Note

-

-

-

↓

(5)

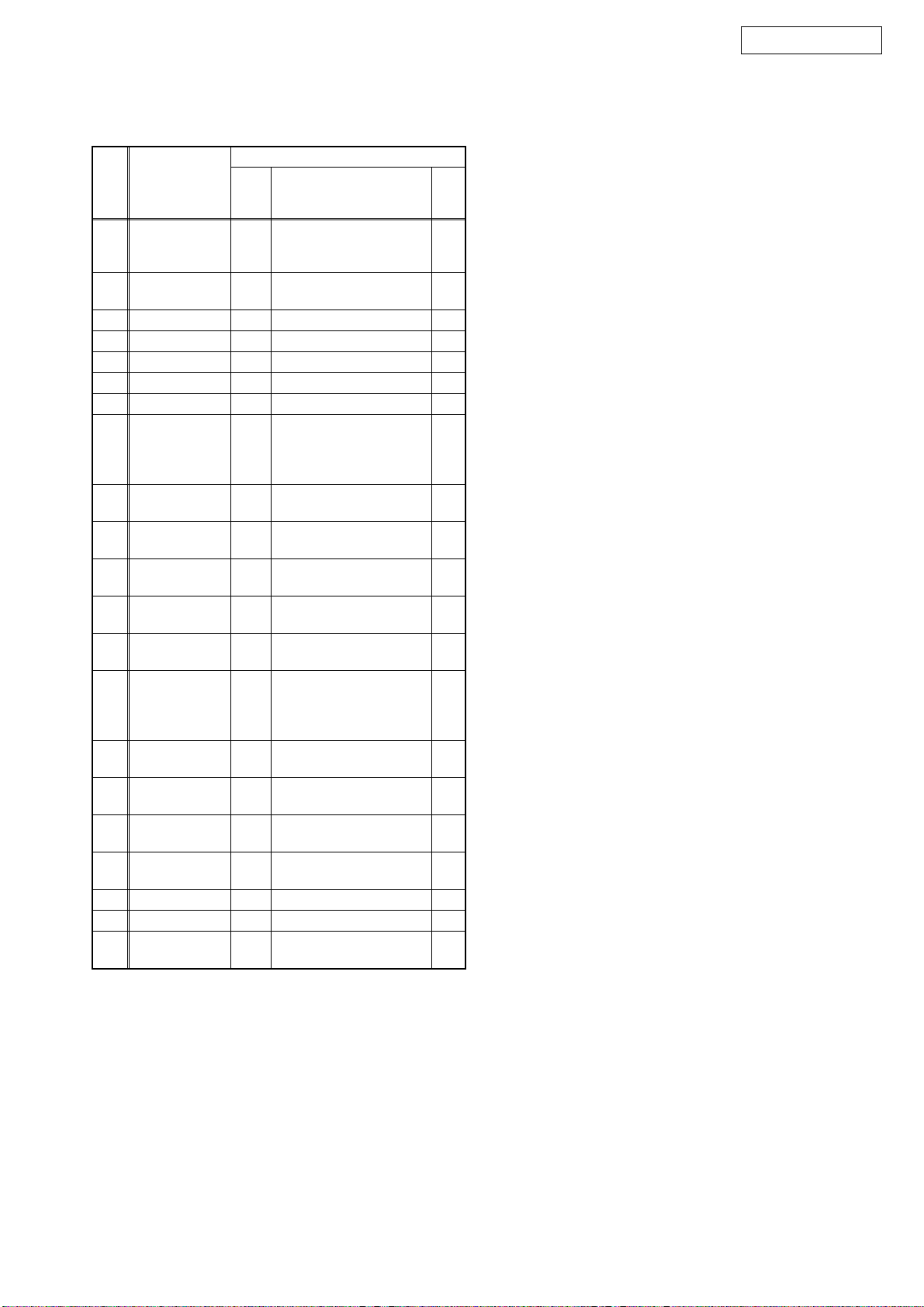

2. Disassembly Method

ID/

LOC.

No.

PAR T

Fig.

No.

[1] Top Cover D1 6(S-1) -

Front

[2]

[3]

Assembly

Bracket

(Top)

D2 *8(L-1) 1

D3 2(S-2) -

Stopper

[4]

Bracket

D3 4(S-3) -

L, R

Slide Tray

[5]

Assembly

D4

D5

[6] Function CBA D4 *2(L-2), CN2201 -

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

CN5001, CN5004

Note

2

3

4

(1): Identification (location) No. of parts in the figures

(2): Name of the part

(3): Figure Number for reference

(4): Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5): Refer to “Reference Notes.”

9

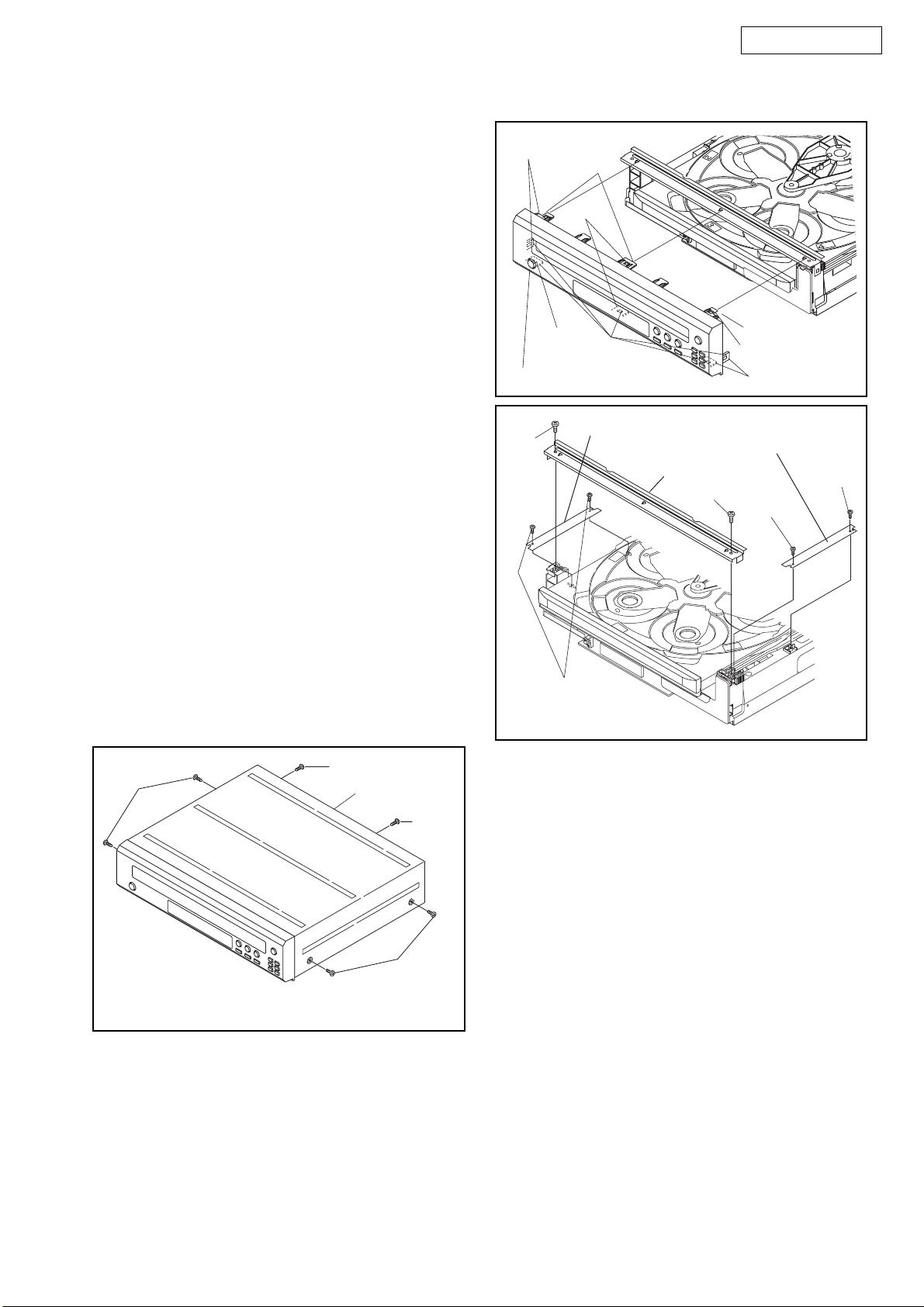

Reference Notes

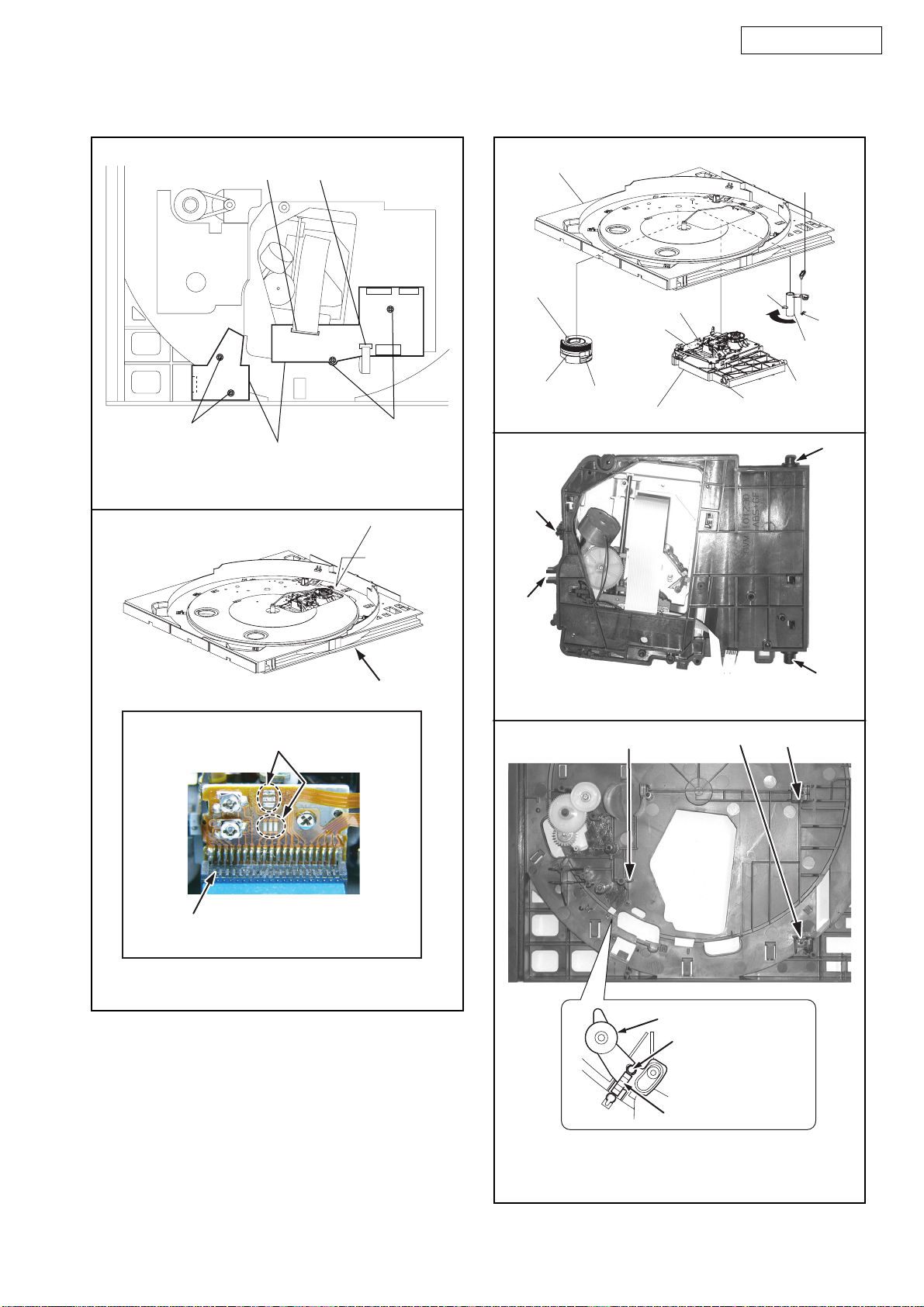

CAUTION 1: Locking Tabs (L-1) are fragile. Be careful

not to break them.

1-1. To release eight Locking Tabs (L-1), first release

five Locking Tabs (A), and then three Locking

Tabs (B). (Fig. D2)

CAUTION 2: Electrostatic breakdown of the laser

diode in the optical system block may occur as a

potential difference caused by electrostatic charge

accumulated on cloth, human body etc., during

unpacking or repair work.

To avoid damage of pickup follow next procedures.

2-1. To remove the Chuck Arm, remove the Screw A,

two Rotary Tray Washers and Rotary Tray

Spring. (Fig. D5)

2-2. Short the three short lands of FPC cable with sol-

der before removing the FFC cable (CN5004 on

the Relay CBA). If you disconnect the FFC cable

without shorting them, the laser diode of pickup

will be destroyed. (Fig. D5)

2-3. Disconnect the Connector (CN5001). Remove

the Slide Tray Assembly carefully. (Fig. D5)

CAUTION 3: When reassembling, confirm the three

short lands of FPC cable is solderd, and connect the

FFC cable (CN5004 on the Relay CBA) completely.

Then remove the solder from the three short lands of

FPC cable. (Fig. D5)

CAUTION 4: Before reinstalling, turn the Slide Tray

Gear (B) fully clockwise. (Fig. D4)

(L-1)

[2] Front Assembly

(S-2)

(B)

(L-1)

(L-1)

(A)

[4] Stopper Bracket L

(S-3)

(L-1)

(B)

(L-1)

[4] Stopper Bracket R

[3] Bracket (Top)

(S-2)

(S-3)

DVM-1845/745

Fig. D2

(S-3)

Fig. D3

(S-1)

(S-1)

[1] Top Cover

(S-1)

(S-1)

Fig. D1

10

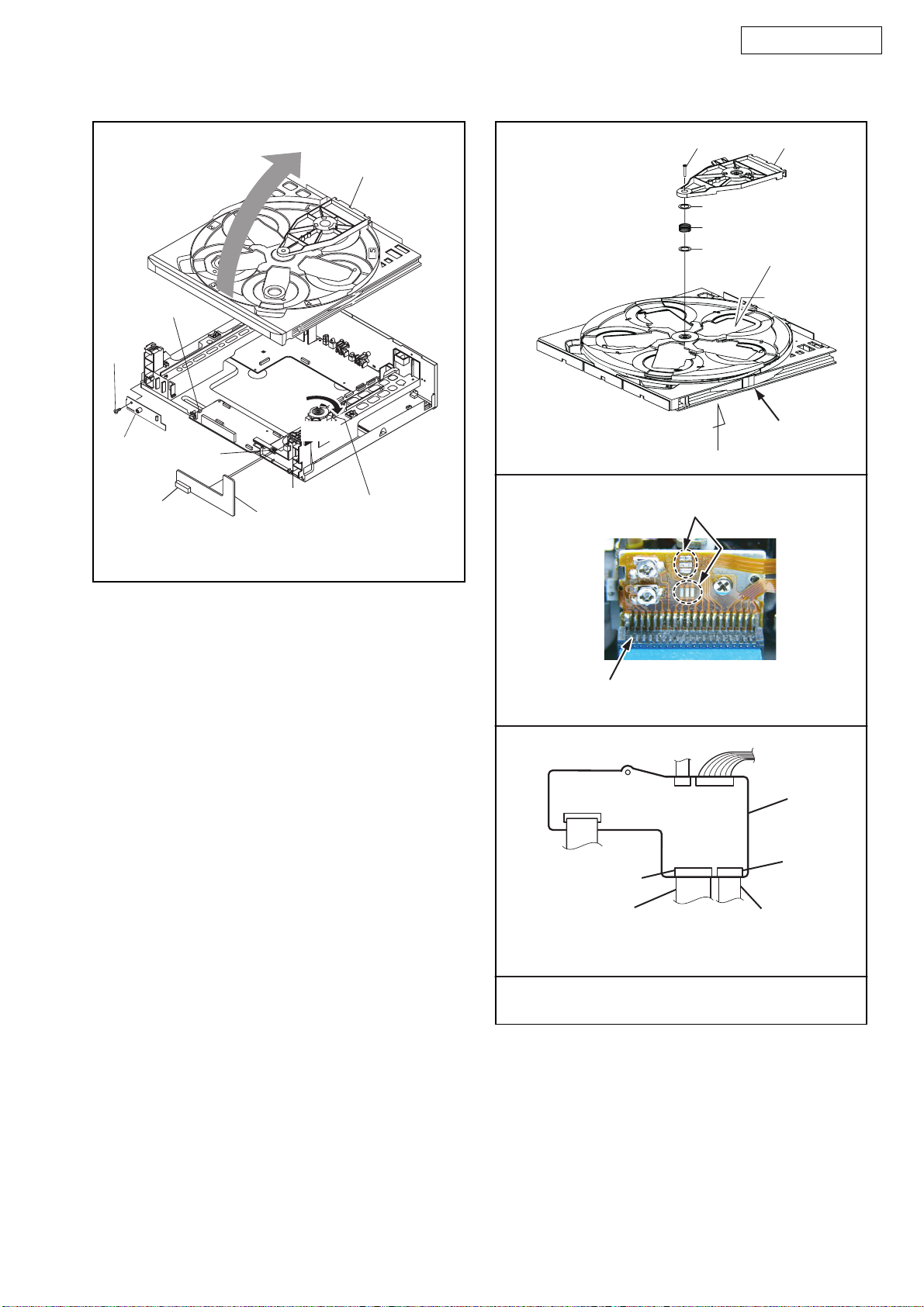

DVM-1845/745

CN2103

(S-4)

[7] Power

Switch CBA

CN2201

(L-2)

[5] Slide Tray

Assembly

Turn

(L-2)

[6] Function CBA

Slide Tray

Gear (B)

Fig. D4

Screw A

Rotary tray washer

Rotary tray spring

Rotary tray washer

Chuck arm

A

B

Short the three short lands by soldering.

(Either of two places.)

Slide Tray

Assembly

FPC Cable

CN5004

FFC cable from

the DVD Main

CBA Unit

View for B (Relay CBA)

View for A

Relay CBA

CN5001

FFC cable from

the Changer CBA

Fig. D5

11

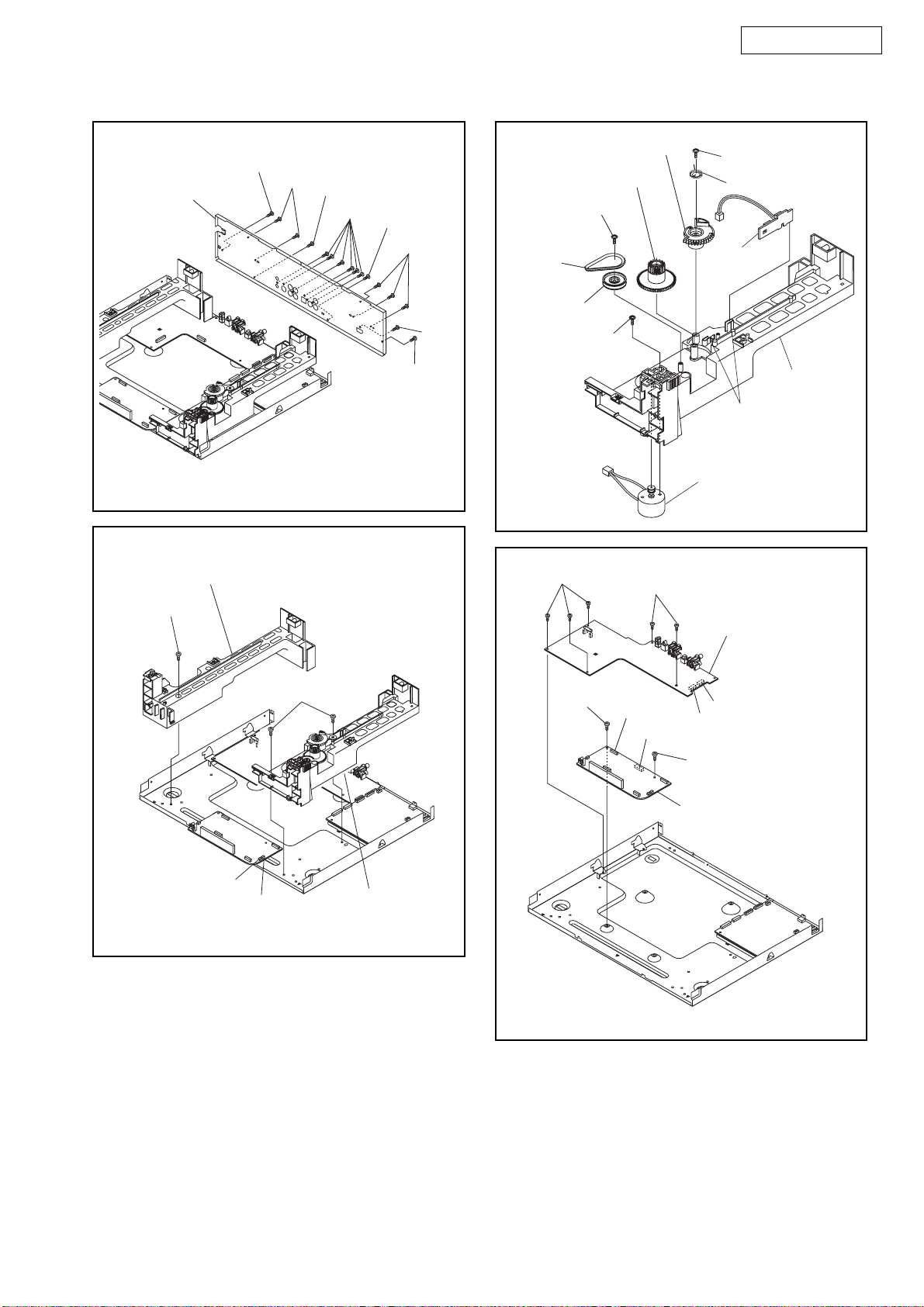

DVM-1845/745

[8] Rear Panel

[9] Tray Guide (L)

(S-8)

(S-5)

(S-6)

(S-5)

(S-6)

(S-5)

(S-6)

(S-7)

(S-5)

Fig. D6

[12] Slide Tray Gear (B)

[13] Slide Tray Gear (A)

(S-10)

Belt L

[11] Loading

Pulley

(S-14)

(S-12)

(S-14)

(S-11)

(P-1)

[15] Switch

CBA

[16] Tray

Guide (R)

(L-4)

[14] Motor Assembly

Fig. D8

[18] AV CBA

CN3003

CN3004

(S-9)

[10] Tray Guide

(R) Unit

Fig. D7

(S-13)

CN3102

CN3301

CN1601

CN1001

(S-13)

[17] Changer CBA

Fig. D9

12

[19]

DVD Main

CBA Unit

DVM-1845/745

(S-15)

[20] PCB Holder

Fig. D10

13

DVM-1845/745

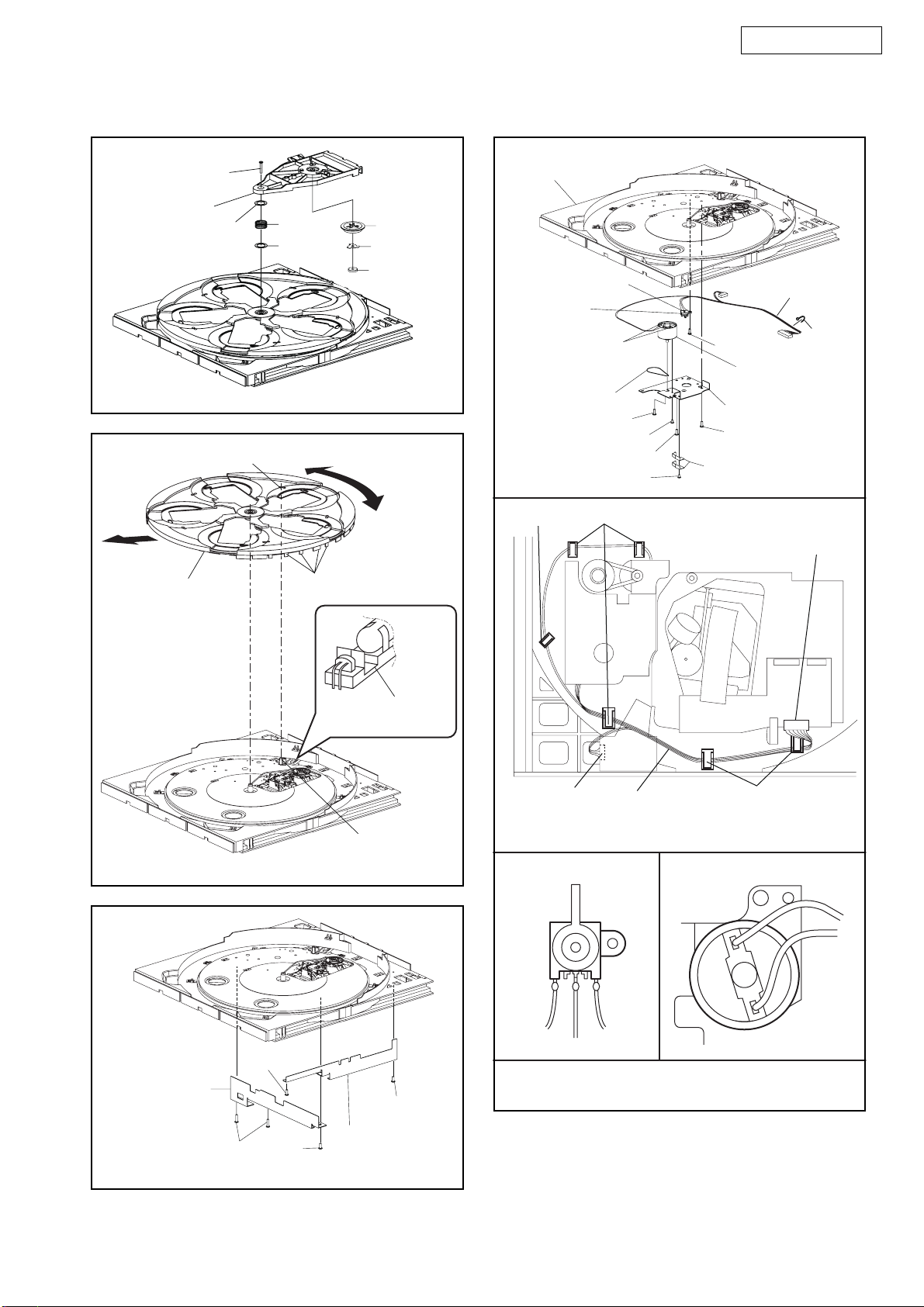

SLIDE TRAY ASSEMBLY DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain access to item(s) to be serviced. When Reassembly, follow

the steps in reverse order. Bend, route, and dress the cables as they were originally.

[1] Chuck Arm

[2] Rotary Tray

[9] Detector Switch

[6] Belt L

[3] Plate Holder 2

[4] Plate Holder 3

[7] Gear Plate

[8] Mecha Cable

[11] Relay CBA + Sensor CBA

[14] Mecha Holder Assembly

[15] Motion Gear

[17] Rotary Tray Gear

[18] Idler Gear

[5] Plate Spring

[16] Loading Pulley

[10] Rotary Motor Assembly

[12] Slot Lever

[13] Rotary Stopper

[19] Idler Pad

[20] Idler Arm

[21] Slide Tray Chassis

14

DVM-1845/745

2. Disassembly Method

ID/

LOC

.No.

[1] Chuck Arm MD1

[2] Rotary Tray MD2 ----------

[3] Plate Holder 2 MD3 2(S-2), (S-3) [4] Plate Holder 3 MD3 2(S-4) [5] Plate Spring MD4 (S-5) [6] Belt L MD4 ---------- [7] Gear Plate MD4 3(S-6), (S-7) -

[8] Mecha Cable MD4

[9]

[10]

[11]

[12] Slot Lever MD6 *(P-2)

[13]

[14]

[15] Motion Gear MD6 ----------

[16]

[17]

[18] Idler Gear MD7

[19] Idler Pad MD7 ---------- [20] Idler Arm MD7 ---------- -

[21]

↓

(1)

(1): Identification (location) No. of parts in the figures

(2): Name of the part

(3): Figure Number for reference

(4): Identification of parts to be removed, unhooked,

(5): Refer to “Reference Notes.”

PAR T

Detector

Switch

Rotary Motor

Assembly

Relay CBA +

Sensor CBA

Rotary

Stopper

Mecha Holder

Assembly

Loading

Pulley

Rotary Tray

Gear

Slide Tray

Chassis

↓

(2)

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw, CN=Connector,

W=Washer

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

Fig.

No.

MD4 Desolder 3

MD4 Desolder 3

MD5

MD6 ----------

MD5

MD6

MD7 (S-10), (W-2) -

MD7 ---------- -

MD7 ---------- -

↓

(3)

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

(S-1), 2(W-1), (P-1),

Magnet, Yoke,

Clamper

6(L-1), *CN5002,

*CN5101, (S-8)

Lead clamper,

Desolder

4(S-9), *CN5003,

*CN5005

----------

*(P-3), (S-11), (W-3),

(W-4)

↓

(4)

Note

1

2

4

5

6

7

6

7

4

5

8

9

8

9

↓

(5)

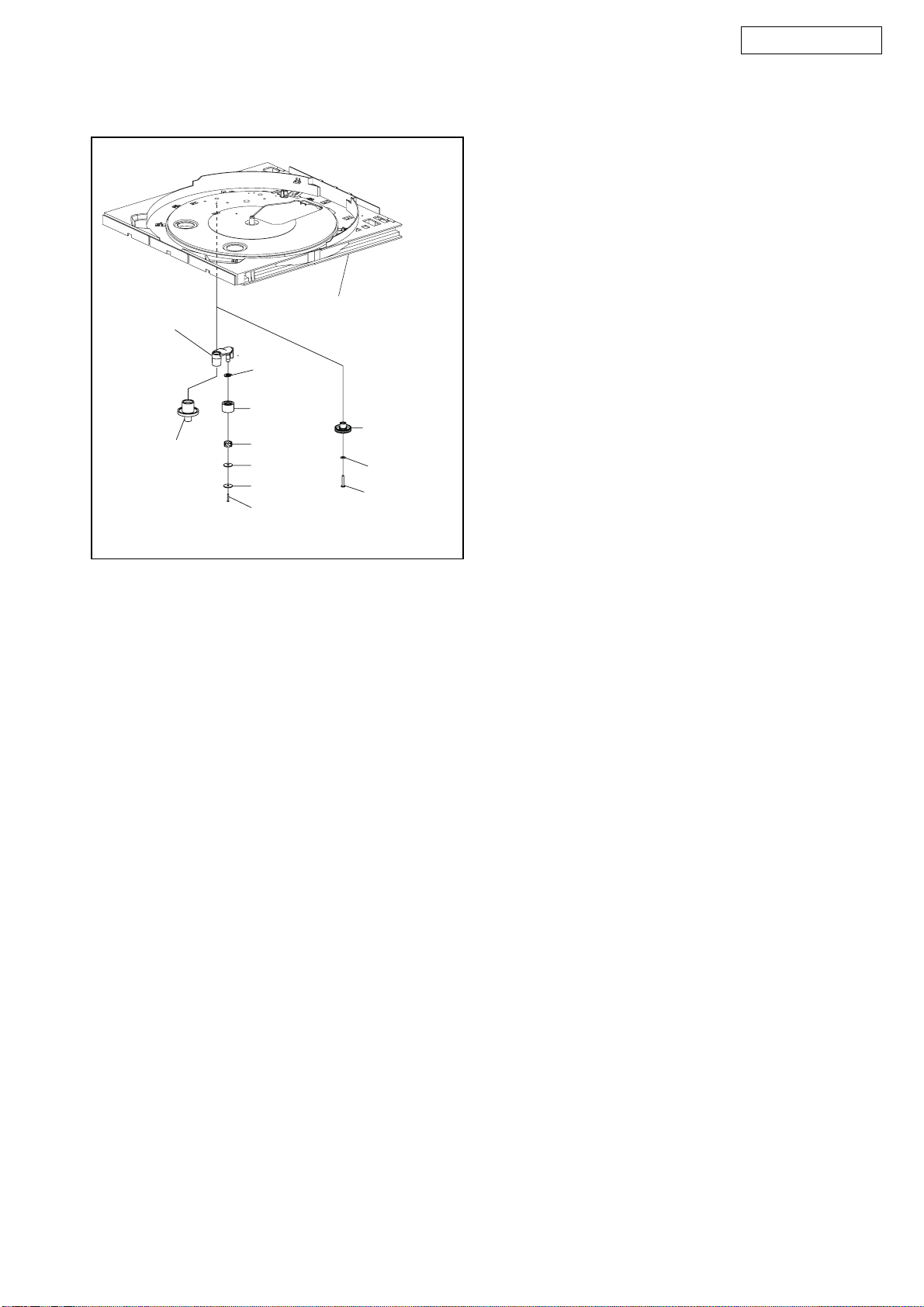

Reference Notes

1. Disassembly note

Slide the Rotary Tray slowly in the direction of the

front while rotating it.

2. Reassembly note

Align the rails on the Rotary Tray with the slot on

-

-

-

the sensor and align pin A with hole A on the

Rotary Tray.

3. Reassembly note

Re-solder the leads on the Rotary Motor Assembly

or the Detector Switch as shown in Fig. MD4.

4. CAUTION: Electrostatic breakdown of the laser

diode in the optical system block may occur as a

potential difference caused by electrostatic charge

accumulated on cloth, human body, etc., during

unpacking or repair work.

To avoid damage of pickup:

a. Short the three short lands of the FPC cable

with solder before removing the FFC cable

(CN5005). If you disconnect the FFC cable

(CN5005) without shorting them, the laser diode

of the pickup will be destroyed. (“View for A” in

Fig. MD5)

b. Disconnect the two connectors (CN5003 and

CN5005) on the Relay CBA.

5. CAUTION: When Reassembly, confirm the FFC

cable (CN5005) is connected completely. Then

remove the solder from the three short lands of the

FPC cable. (“View for A” in Fig. MD5)

6. Disassembly note

Remove the spring (P-2). Then remove the Slot

Lever with the Rotary Stopper while turning the

Slot Lever in the direction of the arrow as shown in

Fig. MD6.

7. Reassembly note

a. Install the Slot Lever and the Rotary Stopper

with spring (P-2) as shown in “Bottom View of

the Slide Tray” of Fig. MD6.

b. Align pin B on the Slot Lever with slot B on the

Motion Gear.

8. Disassembly note

The Mecha Holder Assembly and the Motion Gear

should be removed together.

9. Reassembly note

The pins, slots or holes on the Mecha Holder

Assembly, the Motion Gear and the Slide Tray align

as follows:

• Pin C on the Mecha Holder Assembly with hole B

on the Slide Tray Chassis

• Pin D on the Mecha Holder Assembly with slot C

on the Motion Gear

• Pin E on the Mecha Holder Assembly with

cavity A on the Slide Tray Chassis

• Slot A on the Mecha Holder Assembly with rib A

on the Slide Tray Chassis

15

DVM-1845/745

(S-1)

[1] Chuck Arm

2

[2] Rotary Tray

(W-1)

Hole A

(P-1) Clamper

(W-1)

Yoke

Magnet

Fig. MD1

1

Rails on the Rotary Tray

Slide Tray

Desolder

[9] Detector

Switch

Desolder

[6] Belt L

(L-1)

(S-6)

(S-7)

(L-1)

(S-6)

(S-5)

[8] Mecha

Cable

(S-8)

[10] Rotary Motor

Assembly

[7] Gear Plate

(S-6)

[5] Plate Spring

Lead

clamper

CN5002

[3] Plate

Holder 2

(S-2)

(S-4)

(S-3)

Slot on

the sensor

Pin A

(S-4)

[4] Plate

Holder 3

Fig. MD2

Fig. MD3

CN5101

[8] Mecha Cable

(L-1)

Bottom View of the Slide Tray

Detector Switch DC Mini Motor

yellow

black

blue

red

brown

Fig. MD4

16

DVM-1845/745

CN5003CN5005

(S-9)

[11] Relay CBA + Sensor CBA

(S-9)

Bottom View of the Slide Tray

A

Slide Tray

[15] Motion

Gear

Slot B

Pin D

Slot A

Slot C

[13] Rotary

Stopper

Slot A

Pin D

[14] Mecha Holder Assembly

Pin B

turn

[12] Slot

Lever

Pin C

Pin E

(P-2)

Pin E

Slide Tray

Short the three short lands by soldering.

(Either of two places.)

FPC Cable

View for A

Fig. MD5

Pin C

Bottom View of the Mecha Holder Assembly

Rib A

Hole B

[12] Slot Lever

[13] Rotary Stopper

(P-2)

Cavity A

17

Bottom View of the Slide Tray

Fig. MD6

DVM-1845/745

[20] Idler

Arm

[17] Rotary

Tray Gear

[21] Slide Tray Chassis

[19] Idler

Pad

[18] Idler

Gear

(P-3)

(W-3)

(W-4)

(S-11)

[16] Loading

Pulley

(W-2)

(S-10)

Fig. MD7

18