Page 1

e

SERVICE MANUAL

MODEL JP E3 E3B E2 EK EA E1 E1C

Ver. 3

Please refer to the

MODIFICATION NOTICE.

AVR-1311

AVR-391

MODEL JP E3 E3B E2 EK EA E1 E1C

DHT-1311XP

DHT-391XP

5.1CH HOME THEATER SYSTEM

33

33

AV SURROUND RECEIVER

3

33 3

s

For purposes of improvement, specifi cations and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

e

D&M Holdings Inc.

S0141-0V03DM/DG1010

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Please heed the points listed below during servicing and inspection.

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if fi ngers

are moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). For replacement

parts, be sure to use parts which have the same

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

◎Inspect for safety after servicing!

Check that all screws, parts and wires removed or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

conduct an inslation check on the external metal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ......Indicated by the z mark.

(2) Parts lists ......Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fi res

or other dangerous situations.

2

Page 3

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacture

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL

INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

r.

NOTE FOR PARTS LIST

Parts for which "nsp" is indicated on this table cannot be supplied.

1.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

2.

3.

Ordering part without stating its part number can not be supplied.

4.

Part indicated with the mark "★" is not illustrated in the exploded view.

5.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

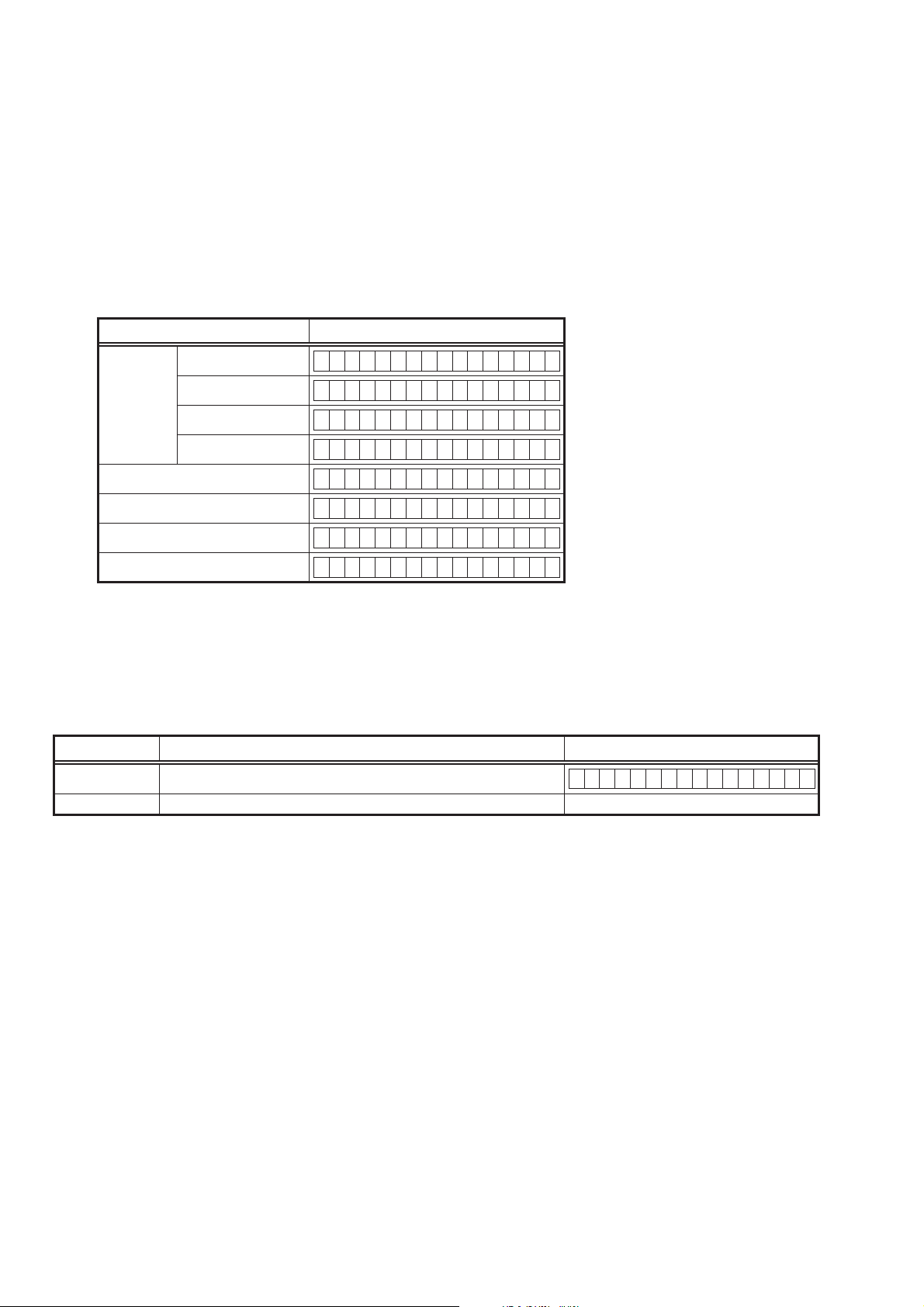

WARNING:

● Resistors

Ex.: RN

* Resistance

Capacitors

●

Ex.: CE

* Capacity (electrolyte only)

* Capacity (except electrolyte)

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

14K

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

: Units: ohm

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

・ Units:μF.

・ Units:pF

Shape

and performance

2

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

2

Indicates number of zeros after effective number.

2-digit effective number.

2

Indicates number of zeros after efective number. (More than 2)

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm1 8

1.2ohm1 R 2

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

2200μF2 2

2200pF=0.0022μF2 2

182

Resistance

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

3R2

CapacityMAllowable

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

error

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

Z:±80%

: - 20%

P : +100%

C:±0.25pF

D:±0.5pF

= : Others

FR

Others

BP

Others

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

1

・ Units:pF

2.2μF2 R

1-digit effective number.

2-digit effective number, decimal point indicated by R

220pF2 2

Indicates number of zeros after effective numver. (0 or 1)

2-digit effective number.

3

Page 4

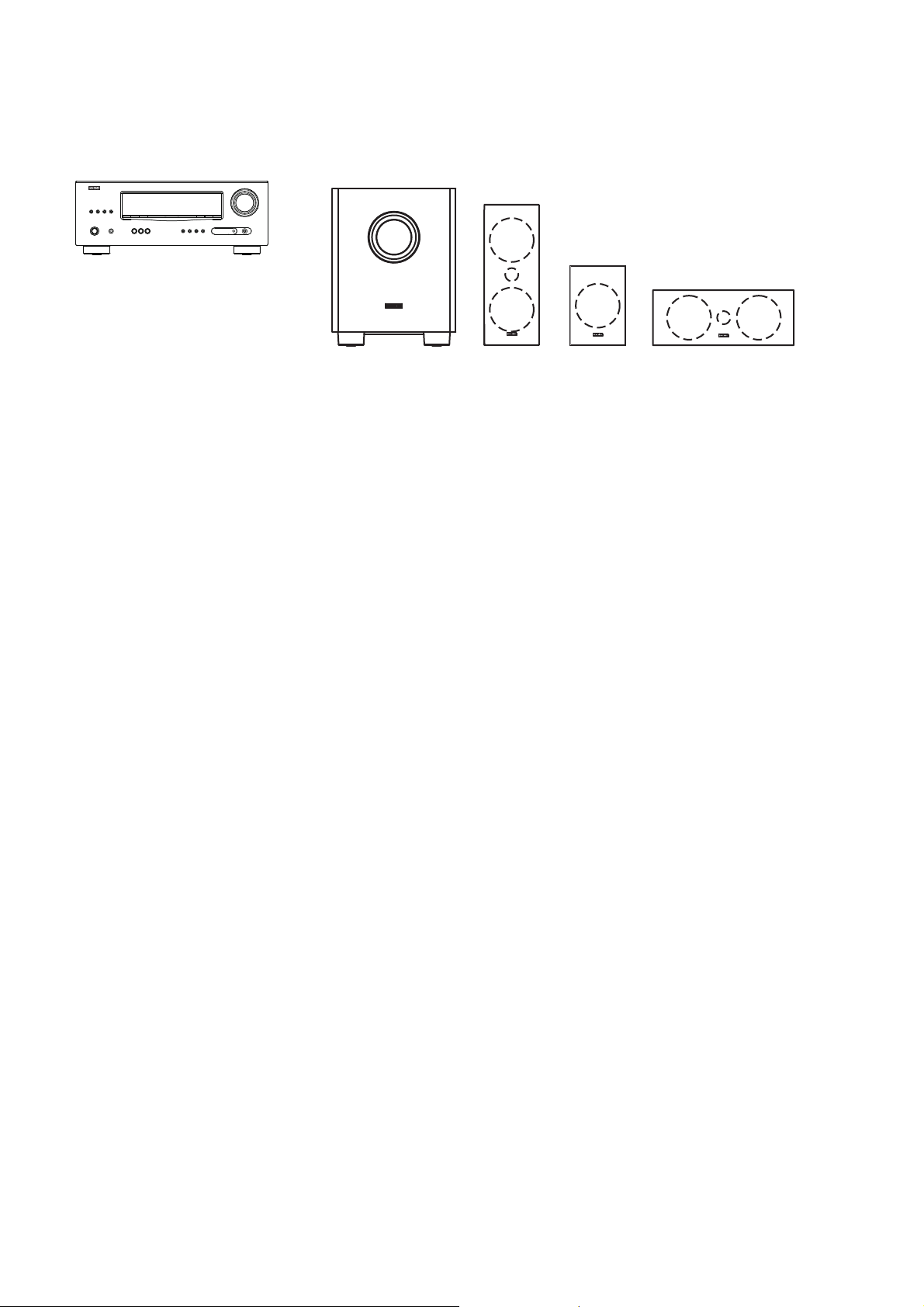

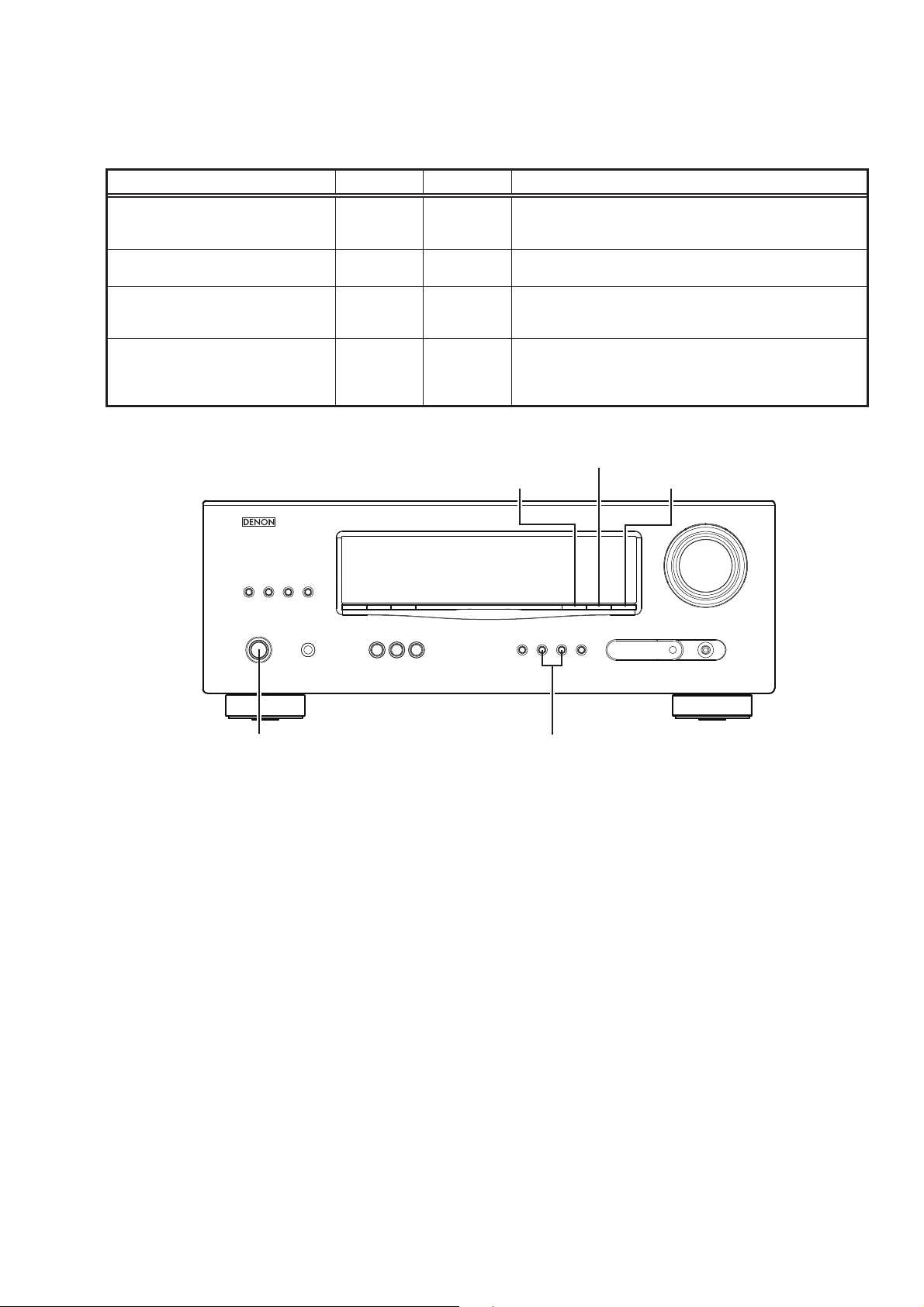

SYSTEM CONFIGURATION

• AVR-1311

• AVR-391

• DHT-1311XP (AVR-1311 + SYS-391HT)

• DHT-391XP (AVR-391 + SYS-391HT)

SYS-391HT : Refer to page 104-113 for the service manual.

TECHNICAL SPECIFICATIONS

n Audio Section

• Power amplifi er

Rated output :

Front :

75 W + 75 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

110 W + 110 W (6 Ω, 1 kHz with 0.7 % T.H.D.)

Center :

75 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

110 W (6 Ω, 1 kHz with 0.7 % T.H.D.)

Surround :

75 W + 75 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

110 W + 110 W (6 Ω, 1 kHz with 0.7 % T.H.D.)

Output connectors : 6 – 16 Ω

• Analog

Input sensitivity/Input impedance : 200 mV/47 kΩ

Frequency response: 10 Hz – 100 kHz — +1, –3 dB (DIRECT mode)

S/N : 98 dB (IHF–A weighted, DIRECT mode)

n Video Section

• Standard video connectors

Input/output level and impedance : 1 Vp-p, 75 Ω

Frequency response : 5 Hz – 10 MHz — +1, –3 dB

• Color component video connector

Input/output level and impedance :

Y (brightness) signal — 1 Vp-p, 75 Ω

B / CB signal — 0.7 Vp-p, 75 Ω

P

R / CR signal — 0.7 Vp-p, 75 Ω

P

Frequency response : 5 Hz – 10 MHz — +1, –3 dB

SYS-391HT

DSW-391 SC-C391SC-F391(x2) SC-R391(x2)

n Tuner section

[FM](Note: μV at 75 Ω, 0 dBf = 1 x 10

Receiving Range (for 391E3,391E3B) :

[FM] 87.5 MHz – 107.9 MHz

Receiving Range (for 1311E2,1311E1C,391EA) :

[FM] 87.5 MHz – 108.0 MHz

Usable Sensitivity :

[FM]1.2 μV (12.8 dBf)

50 dB Quieting Sensitivity :

[FM]MONO 2.8 μV (20.2 dBf)

S/N (IHF-A) :

[FM]MONO 70 dB

STEREO 67 dB

Total harmonic Distortion (at 1 kHz) :

[FM]MONO 0.7 %

STEREO 1.0 %

[AM]520 kHz – 1710 kHz

[AM]522 kHz – 1611 kHz

[AM]18 μV

n General

Power supply (for 391E3,391E3B) : AC 120 V, 60 Hz

(for 1311E2,391EA) : AC 230 V, 50 Hz

(for 1311E1C) : AC 220 V, 50 Hz

Power consumption :

330 W

Less than 0.5 W (Standby)

Maximum external dimensions :

435 (W) x 166 (H) x 381 (D) mm

Weight : 9.2 kg

n Remote Control Unit (RC-1149)

Batteries : R03/AAA Type (two batteries)

Maximum external dimensions : 50 (W) x 211 (H) x 22 (D) mm

Weight : 110 g (including batteries)

–15

W)

s

s

4

Page 5

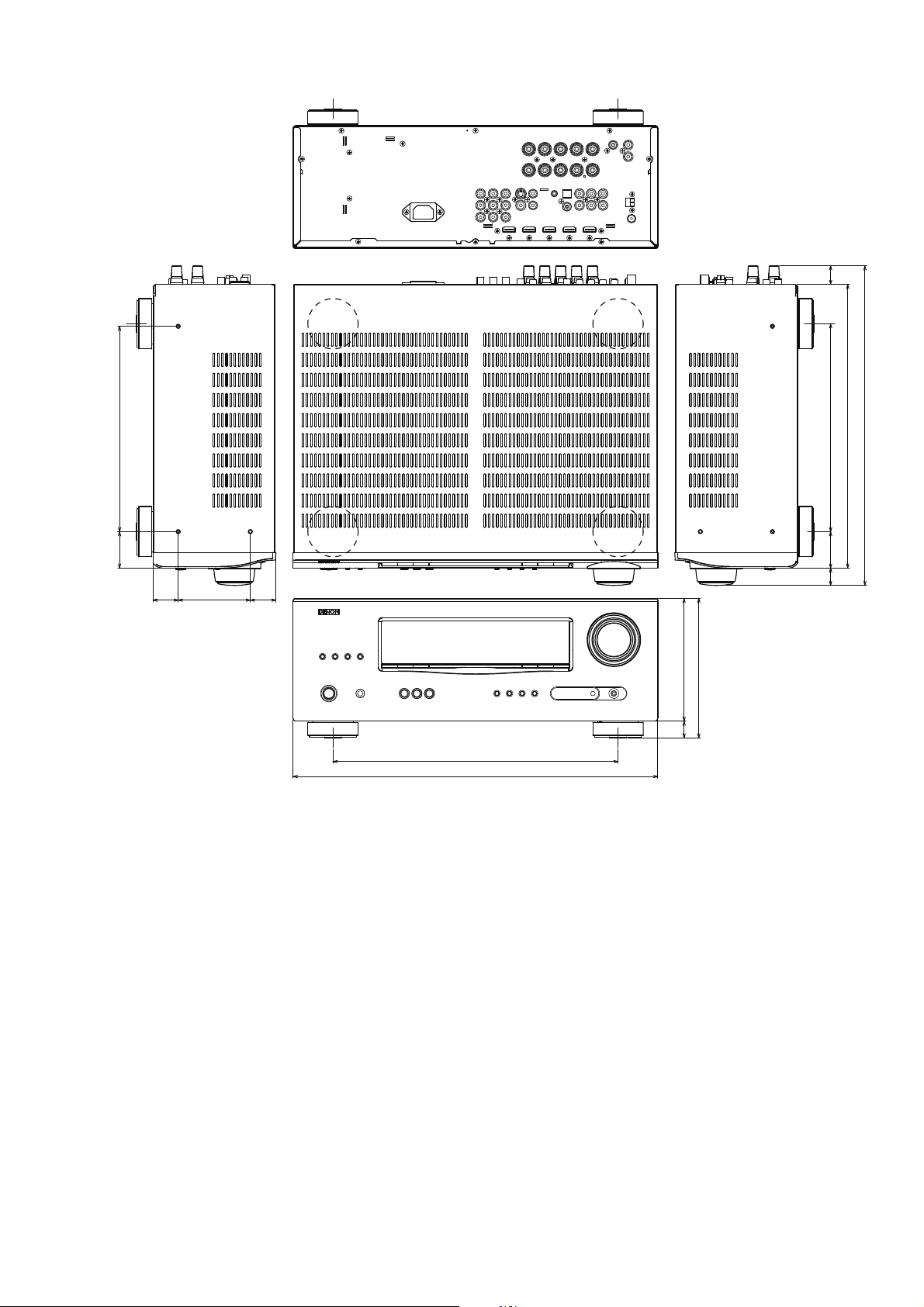

DIMENSION

22.2

245.0

43.5

30.0 30.5

86.0

340.0

435.0

248.0

43.5

20.7

146.5

166.5

20.0

The illustration is AVR-1311 model.

338.5

381.4

5

Page 6

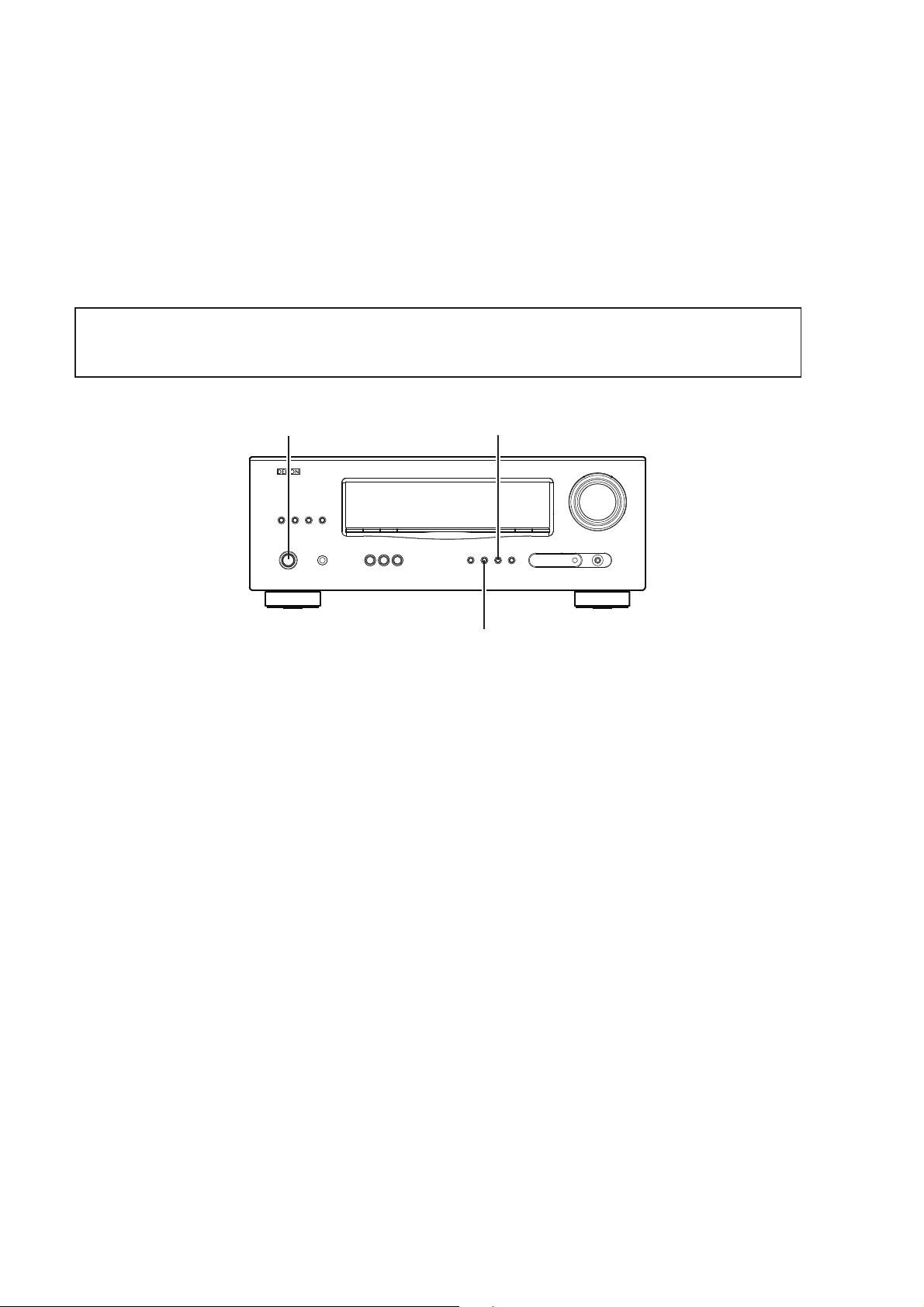

CAUTION IN SERVICING

Initializing AV SURROUND RECEIVER

AV SURROUND RECEIVER initialization should be performed when the μcom, peripheral parts of μcom, and Digital

P.W.B. are replaced.

1. Turn off the power using ON/STANDBY button.

2. Press ON/STANDBY button while simultaneously pressing SURROUND MODE 0 and SURROUND MODE

buttons.

3. Check that the entire display is fl ashing with an interval of about 1 second, and release your fi ngers from the 2

buttons and the microprocessor will be initialized.

Note: •If step 3 does not work, start over from step 1.

All user settings will be lost and this factory setting will be recovered when this initialization mode.

•

So make sure to memorize your setting for restoring after the initialization.

1

ON/STANDBY

SURROUND MODE 1

SURROUND MODE 0

Service Jigs

When you update the fi rmware, you can use the following

JIG (RS232C to internal connector conversion adapter with 4P FFC cable kit ).

Please order to Denon Offi cial Service Distributor in your region if necessary.

8U-210100S : WRITING KIT : 1 Set

606050028012P

(Refer to "VERSION UPGRADE PROCEDURE OF FIRMW

: 7P FFC(1.0) L-240 : 1 Set

ARE".)

6

Page 7

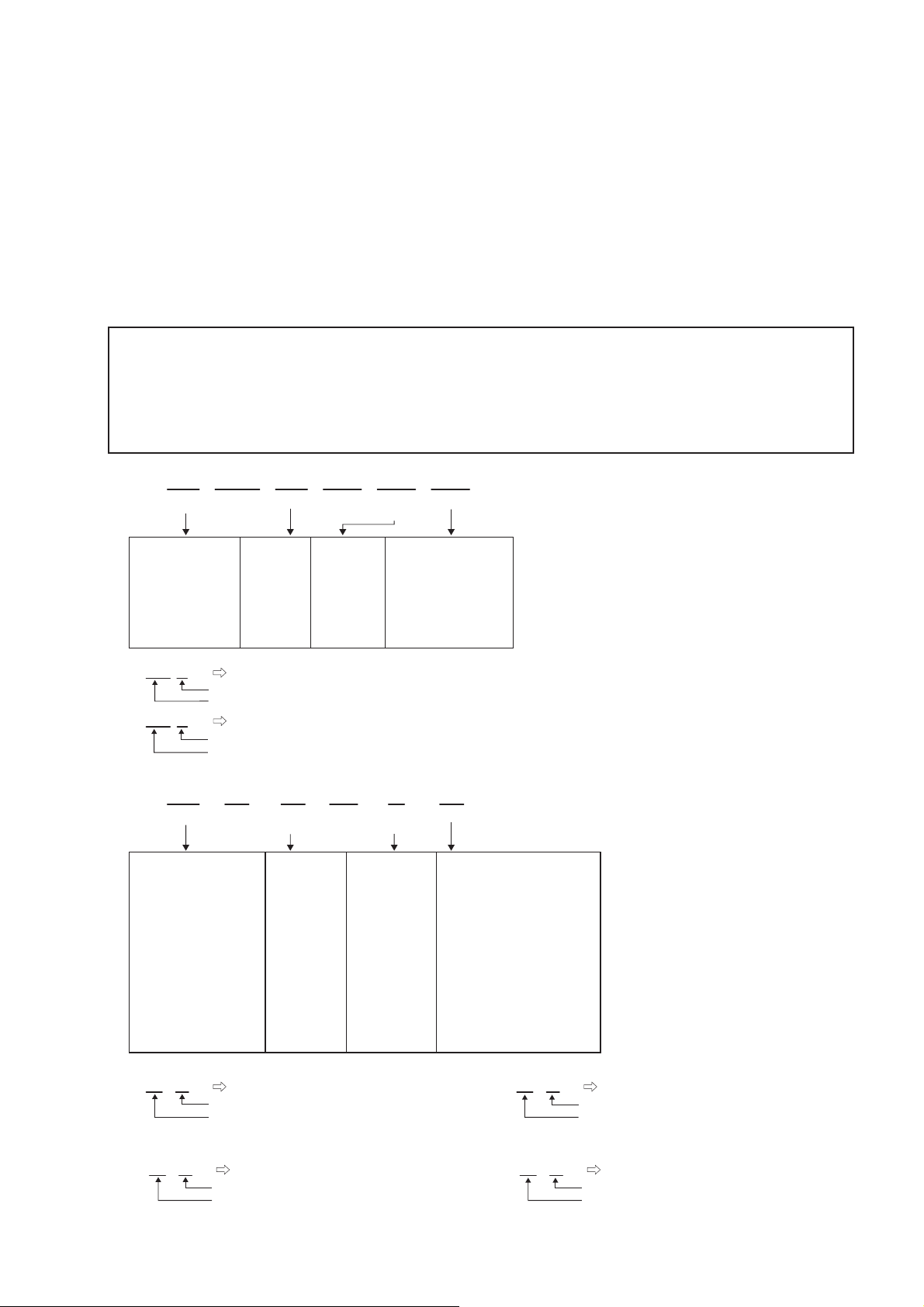

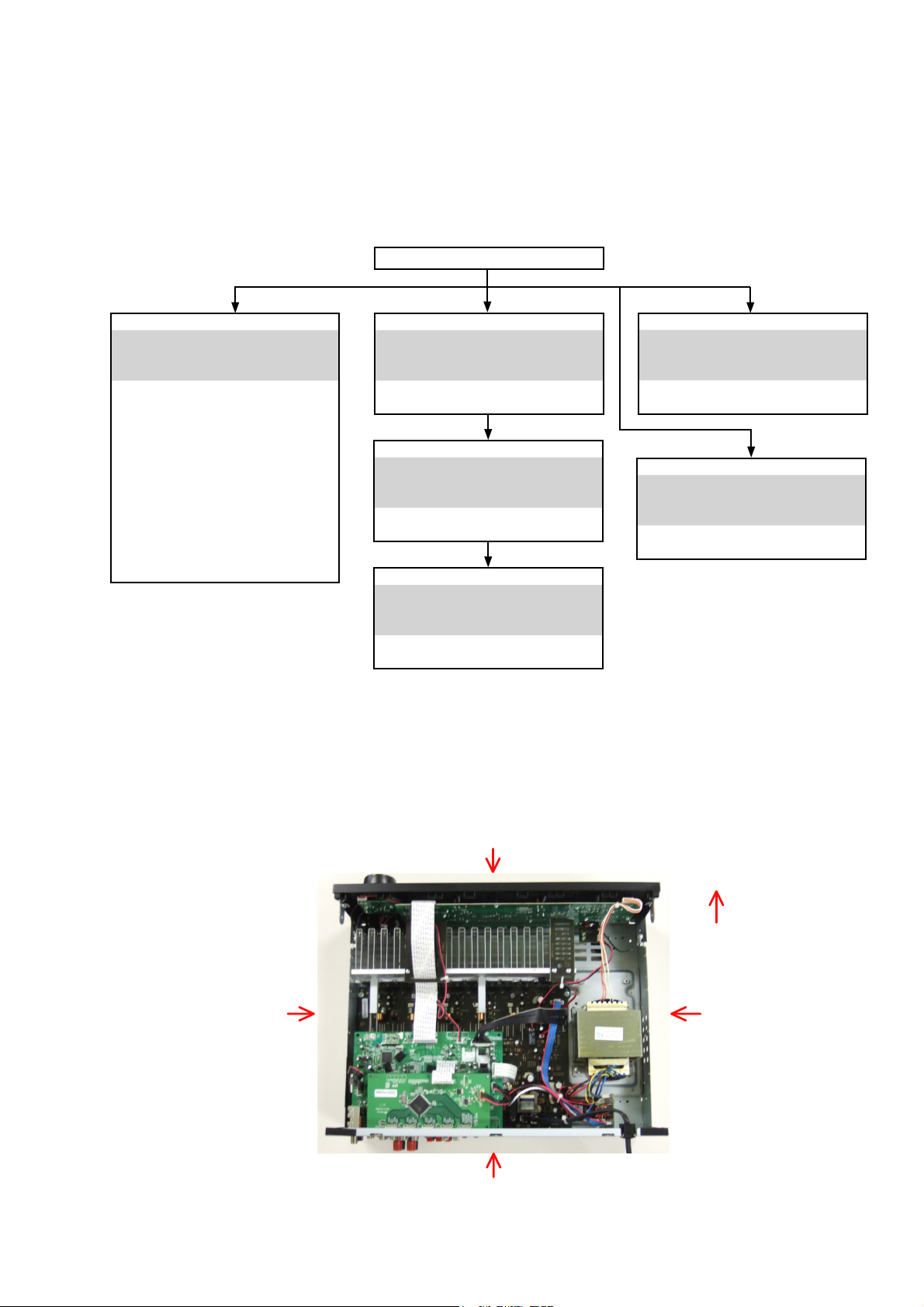

DISASSEMBLY

• Disassemble in order of the arrow of the fi gure of following fl ow.

• In the case of the re-assembling, assemble it in order of the reverse of the following fl ow.

• In the case of the re-assembling, observe "attention of assembling" it.

• If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly

as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

Refer to "DISASSEMBLY

1. FRONT PANEL ASSY"

and "EXPLODED VIEW"

AUX UNIT

(Ref. No. of EXPLODED VIEW : C1)

PHONE UNIT

(Ref. No. of EXPLODED VIEW : C2)

VOLUME UNIT

(Ref. No. of EXPLODED VIEW : C3)

HEADPHONE UNIT

(Ref. No. of EXPLODED VIEW : C8)

POWER UNIT

(Ref. No. of EXPLODED VIEW : C9)

FRONT UNIT

(Ref. No. of EXPLODED VIEW : C10)

HDMI UNIT

Refer to "DISASSEMBLY

2. HDMI UNIT"

and "EXPLODED VIEW"

HDMI UNIT

(Ref. No. of EXPLODED VIEW : C7)

INPUT UNIT

Refer to "DISASSEMBLY

3. INPUT UNIT"

and "EXPLODED VIEW"

INPUT UNIT

(Ref. No. of EXPLODED VIEW : C6)

RADIATOR ASSY

Refer to "DISASSEMBLY

4. RADIATOR ASSY"

and "EXPLODED VIEW"

MAIN UNIT

(Ref. No. of EXPLODED VIEW : C5)

REGULATOT UNIT

(Ref. No. of EXPLODED VIEW : C13)

POWER TRANS

(Ref. No. of EXPLODED VIEW : C14)

POWER UNIT

Refer to "DISASSEMBLY

5. POWER UNIT"

and "EXPLODED VIEW"

POWER TRANS

Refer to "DISASSEMBLY

6. POWER TRANS "

and "EXPLODED VIEW"

About the photos used for descriptions in the DISASSEMBLY" section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***"

at the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: C

Direction of photograph: B

Front side

Direction of photograph: D

Direction of photograph: A

7

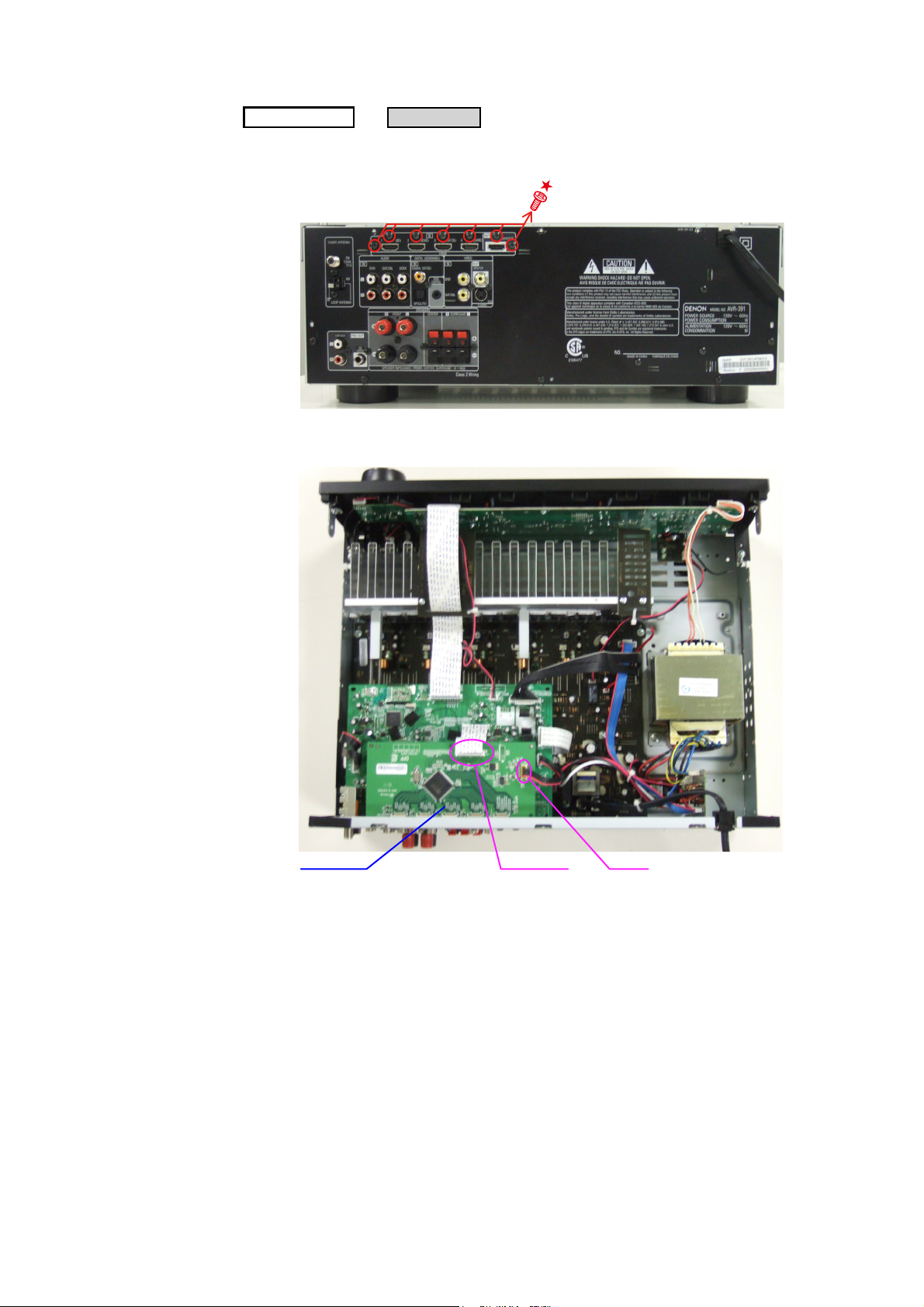

Page 8

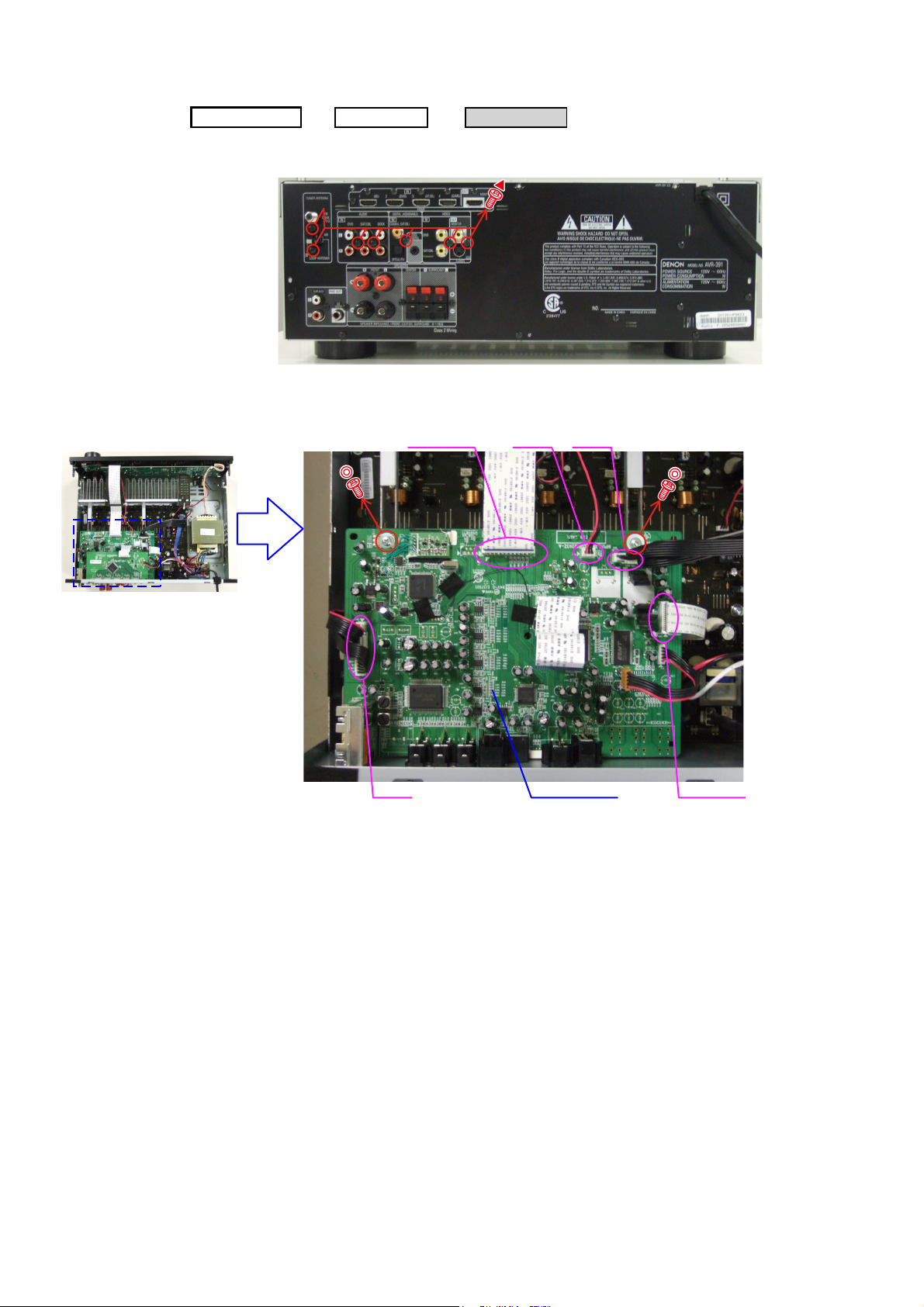

1. FRONT PANEL ASSY

Proceeding :

(1) Remove the screws.

View from bottom

(2) Cut the wire clamp band, then disconnect the connector wires and FFC cable. Remove the screws.

TOPCOVER

FRONT PANEL ASSY

FRONT PANEL ASSY

→

FFC cable

CN44

cut

CN209

cut

(3) Remove the screws.

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in FRONT PANEL ASSY.

CN71

8

WIRE SUPPORT UNIT

Page 9

2. HDMI UNIT

Proceeding :

(1) Remove the screws.

Direction of photograph: A

(2) Disconnect the connector wire and FFC cable.

TOPCOVER

HDMI UNIT

→

HDMI UNIT

CN12FFC cable

9

Page 10

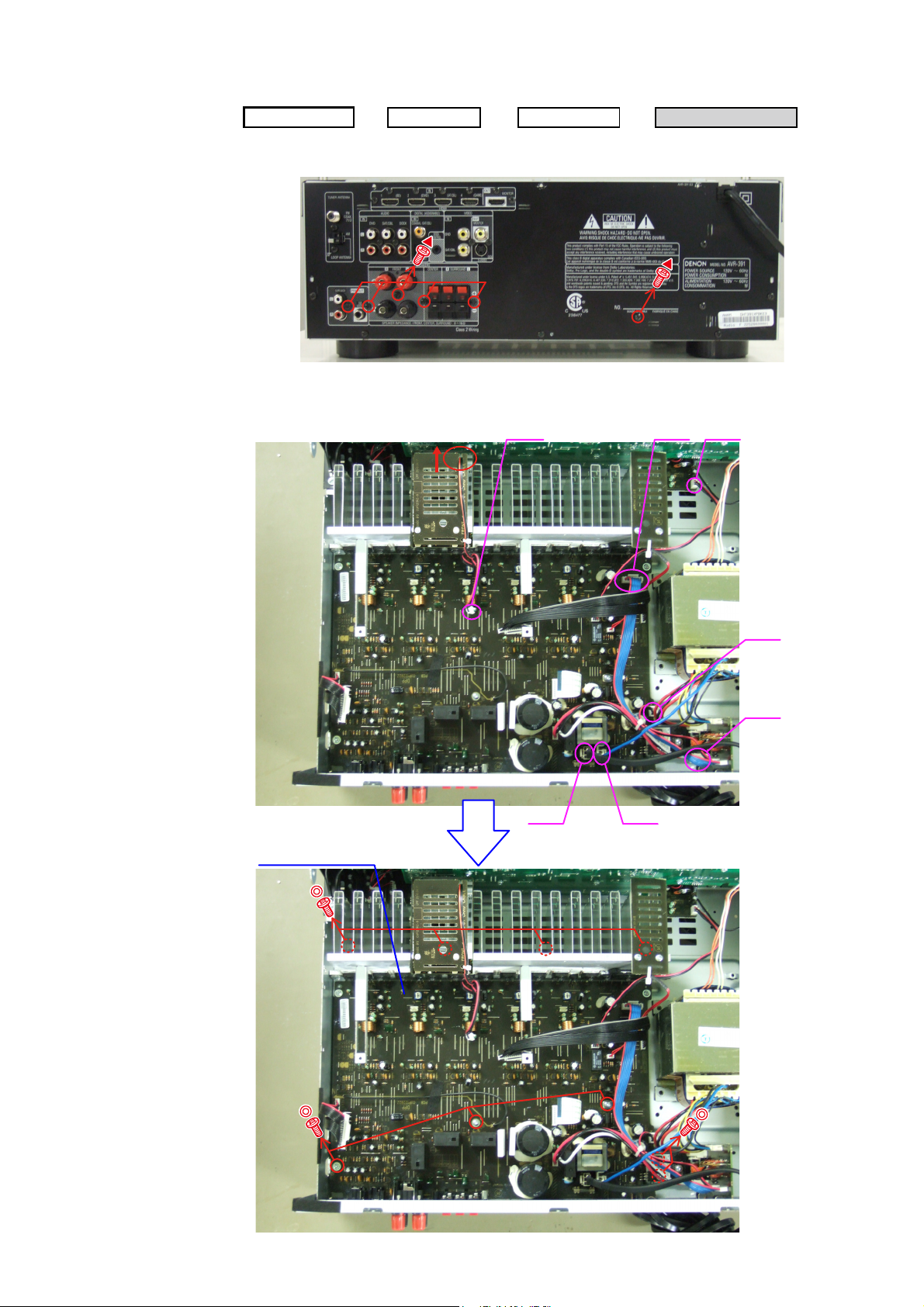

3. INPUT UNIT

Proceeding :

(1) Remove the screws.

Direction of photograph: A

(2) Disconnect the connector wires and FFC cables, then remove the screws.

TOPCOVER

HDMI UNIT

→

FFC cable

INPUT UNIT

→

CN71 CN43

CN42

INPUT UNIT

FFC cable

10

Page 11

4. RADIATOR ASSY

Proceeding :

(1) Remove the screws.

Direction of photograph: A

(2) Disconnect the connector wires, then remove the screws.

TOPCOVER

HDMI UNIT

→

→

INPUT UNIT

CN71 CN44

RADIATOR ASSY

→

CN46

RADIATOR ASSY

CN45

CN41

CN47 CN48

11

Page 12

(3) Remove the RADIATOR ASSY from the main unit.

Direction of photograph: C

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in RADIATOR ASSY.

5. POWER UNIT

Proceeding :

Please refer to "EXPLODED VIEW" for the disassembly method of POWER UNIT.

TOPCOVER

POWER UNIT

→

6. POWER TRANS

Proceeding :

Please refer to "EXPLODED VIEW" for the disassembly method of POWER TRANS.

CABINET TOP

TRANS MAIN

→

12

Page 13

SPECIAL MODE

Special mode setting button

Press the ON/STANDBY button to turn on while pressing both buttons A and B at the same time.

b

Mode Button A Button B Contents

Firmware versions such as Main, DSP are displayed in the FL

μcom/DSP Version display mode STATUS DIMMER

Initialization mode

Mode for switching tuner frequency step

Mode for preventing remote control

acceptance

SURROUND

MODE

SURROUND

MODE

SURROUND

MODE

0

0

0

SURROUND

MODE

RESTORER

STATUS

display. Errors are displayed when they occur.

(Refer to page 14.)

Backup data initialization is carried out. (Refer to page 6.)

1

---E2 model only--Change tuner frequency step to AM9k/FM50kHz STEP or

AM:10k/FM:200kHz.

Operations using remote control are rejected.

"REMOTE LOCK:ON" is displayed in FL display.

(Mode cancellation: Turn off power and execute the same

button operations as when performing setup.)

DIMMER

RESTORER STATUS

ON/STANDBY

SURROUND

0 MODE 1

13

Page 14

1. μcom/DSP Version display mode

1.1. Operation specifi cations

μcom/DSP version display mode:

When started up, the version information is displayed.

Starting up:

With the "DIMMER" and "STATUS" buttons pressed, press the "ON/STANDBY" button to turn the power on.

Now, press the "STATUS" button to the display the 2nd item information on the FL Display.

1.2. Display Order

Model name → Main-μcom version → DSP version → iPod Dock version (Connecting iPod Dock)

Display State

AVR-391 E3 model

AVR-1311 E2 model

Model name

AVR-391 EA model

AVR-1311 E1C model

Main-μcom version

DSP version

iPod Dock (ASD-1R/11R)

iPod Dock (ASD-3/51)

Cleared of mode:

Press the "ON/STANDBY" button to turn the power off.

AVR391 E3

AVR1311 E2

AVR391 EA

AVR1311 E1C

Main **.**

DSP.*.*.*

Dock Ver :**.**

Dock :I********

1.3. Error display

See the following table for each "Error information" display and its contents (status).

Condition - State

DSP NG When DSP boot, executing DSP reset makes to becomes error.

DSP OK (No error display, version display only)

DSP ERROR 01

14

Page 15

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE

When replaced of the U-PRO (Microprocessor) or the Flash ROM, conrm contents of the following.

PWB Name Ref. No. Description

DIGITAL IC91 T5CN5 B SOFTWARE: Main

DIGITAL IC82 ST25VF080B-50-4C-S2AF B SOFTWARE: DSP ROM

After

replaced

Remark

After replaced

A : Mask ROM (With software). No need write-in of software to the microprocessor.

B : Flash ROM (With software). Usually, no need write-in of software. But, when the software was updated, you should be

write-in of the new software to the microprocessor or ash ROM. Please check the software version.

C : Empty Flash ROM (Without software). You should be write-in of the software to the microprocessor or ash ROM.

Refer to "Update procedure" or "writing procedure", when you should be write-in the software.

VERSION UPGRADE PROCEDURE OF FIRMWARE

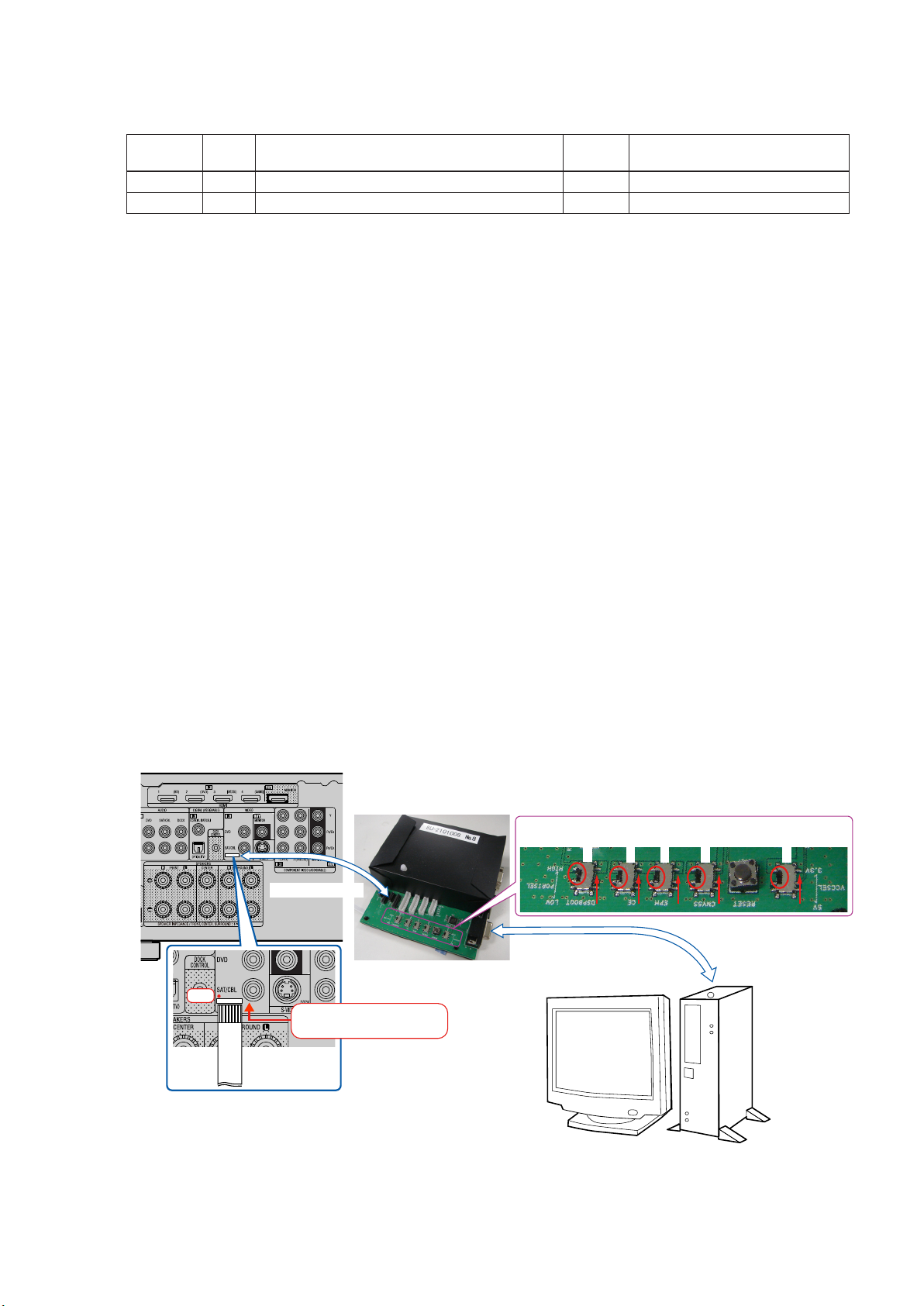

1. Preparations

-Before starting the operation-

(1) Personal Computer (Installed “BootTool_M330(Writing program).exe”).

(2) RS-232 cable (9P (Male), Straight).

(3) 8U-210100S Writing Kit.

(4) 606050028012P / 7P FFC(1.0) L=240.

-Connection of the AV receiver-

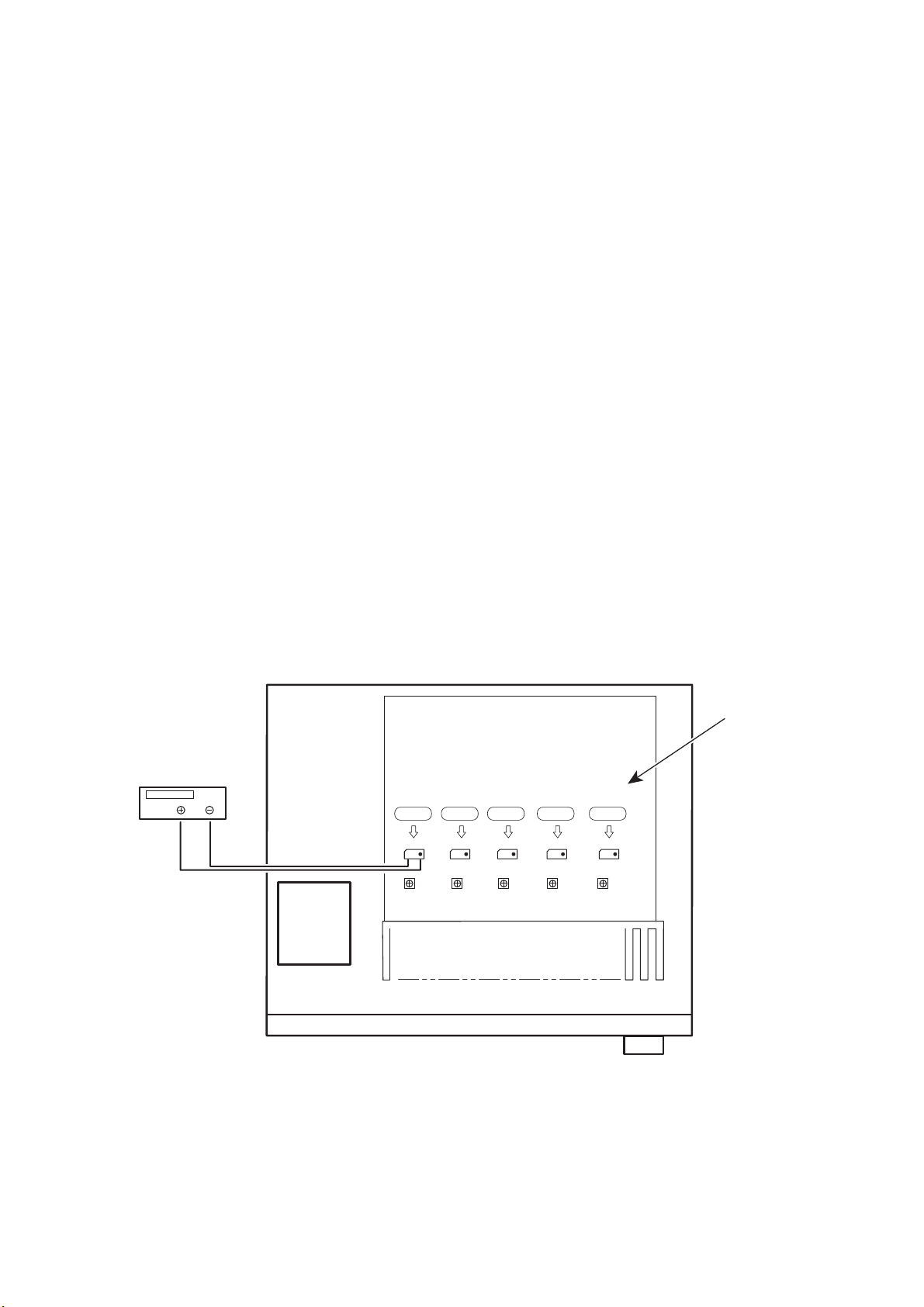

(1) Conrm the power on/off switch of the AV receiver is turning off.

(2) Connect the update terminal of AV receiver with the “Writing Kit”.

(Refer to gure below for the connection of the 7P FFC cable.)

(3) Connect the RS-232C cable from PC with the “Writing Kit”.

7P FFC Cable

Writing Kit

1 pin

This side is contacts of

7P FFC Cable.

7P FFC Cable

S706-709 : HIGE

S709

S708

RS-232C Cable

S707

S706

S702 : 3.3V

S702

PC

15

Page 16

2. UPDATE FIRMWARE

(1) Connect the update terminal of AV receiver with the “Writing Kit”.

(2) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(3) Press the "ON/STANDBY" button to turn the power on of AV receiver.

(4) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H L H

(5) Press the "RESET" switch of “Writing Kit".

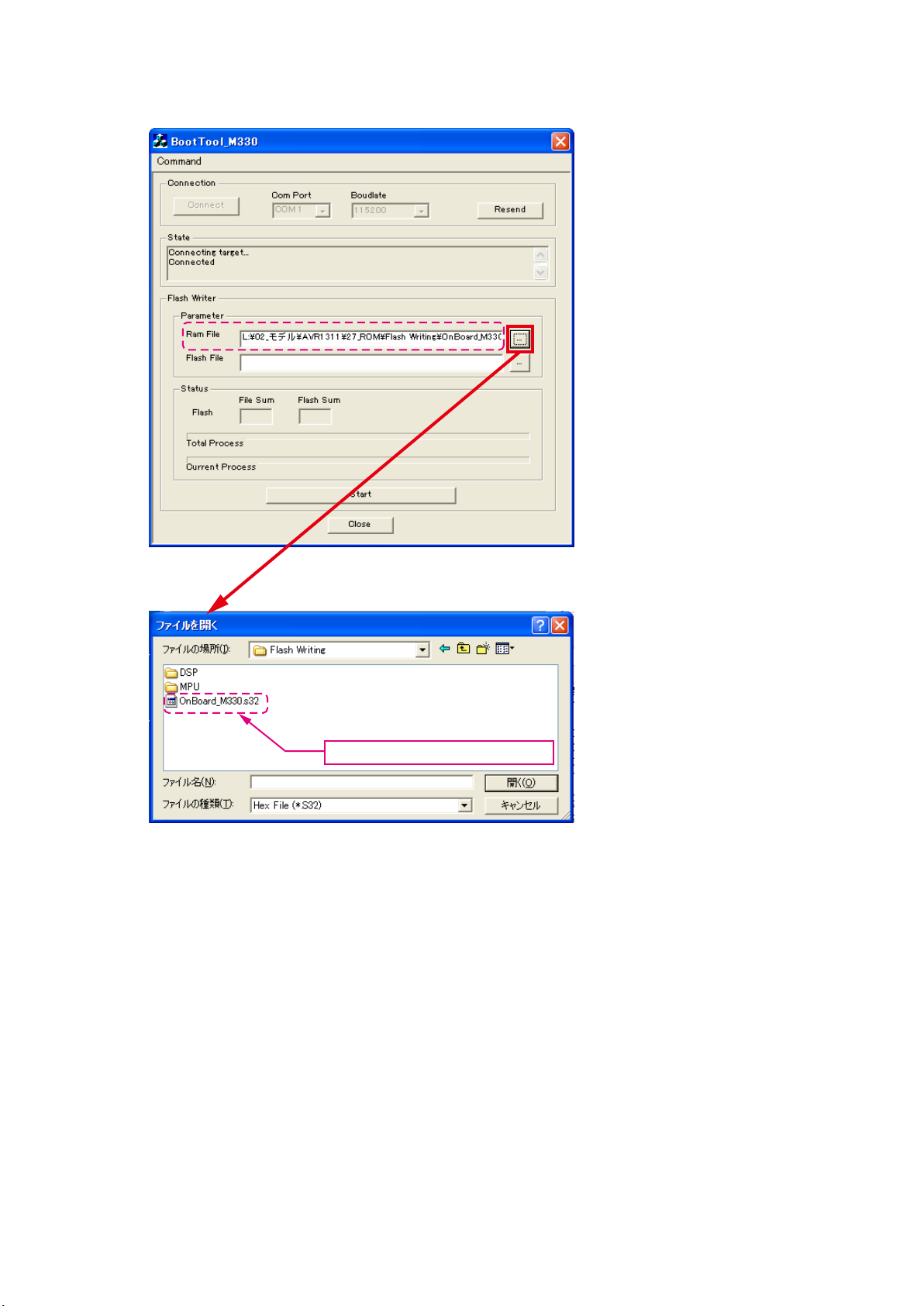

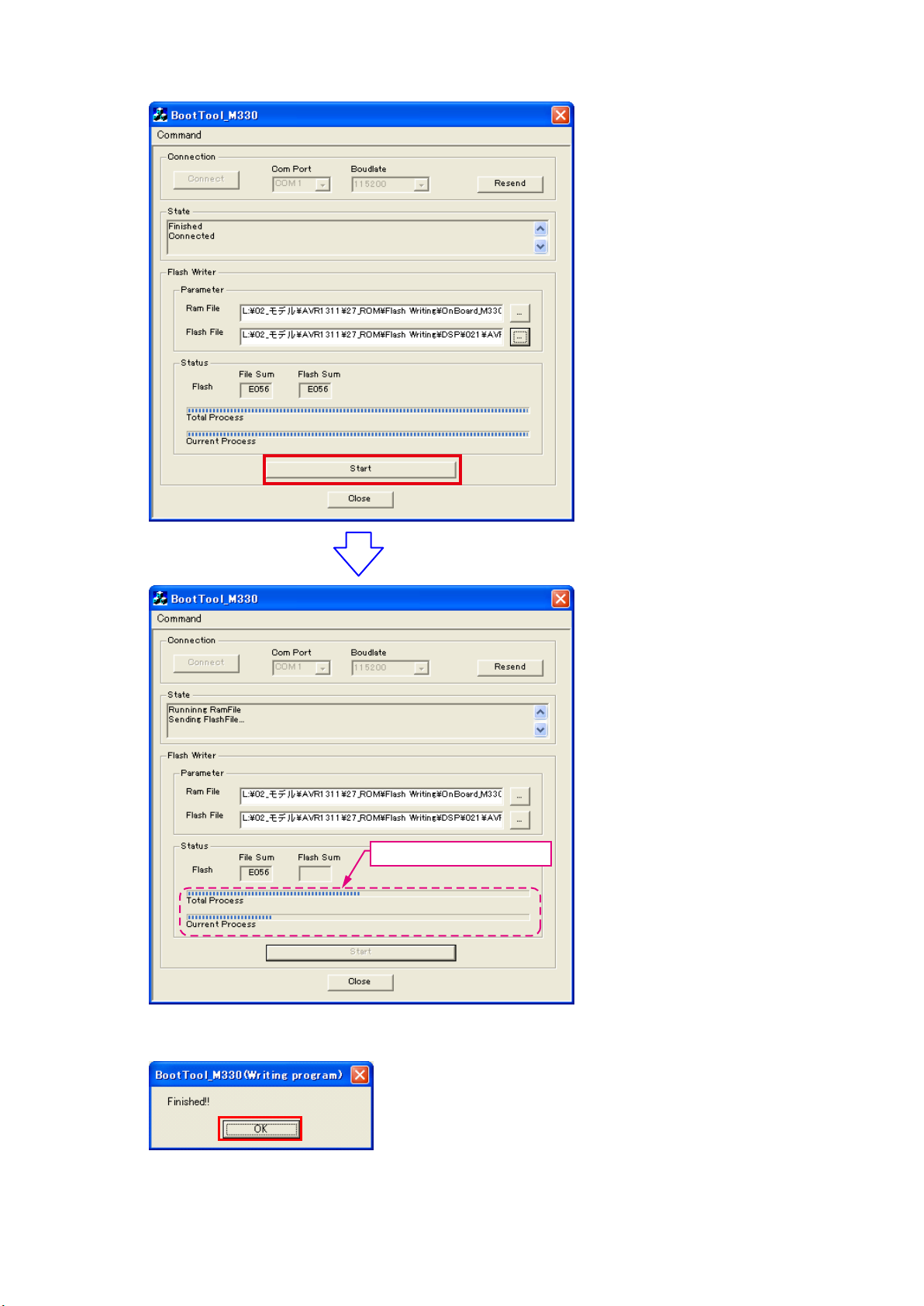

(6) Run the “BootTool_M330(Writing program).exe” on desktop of PC.

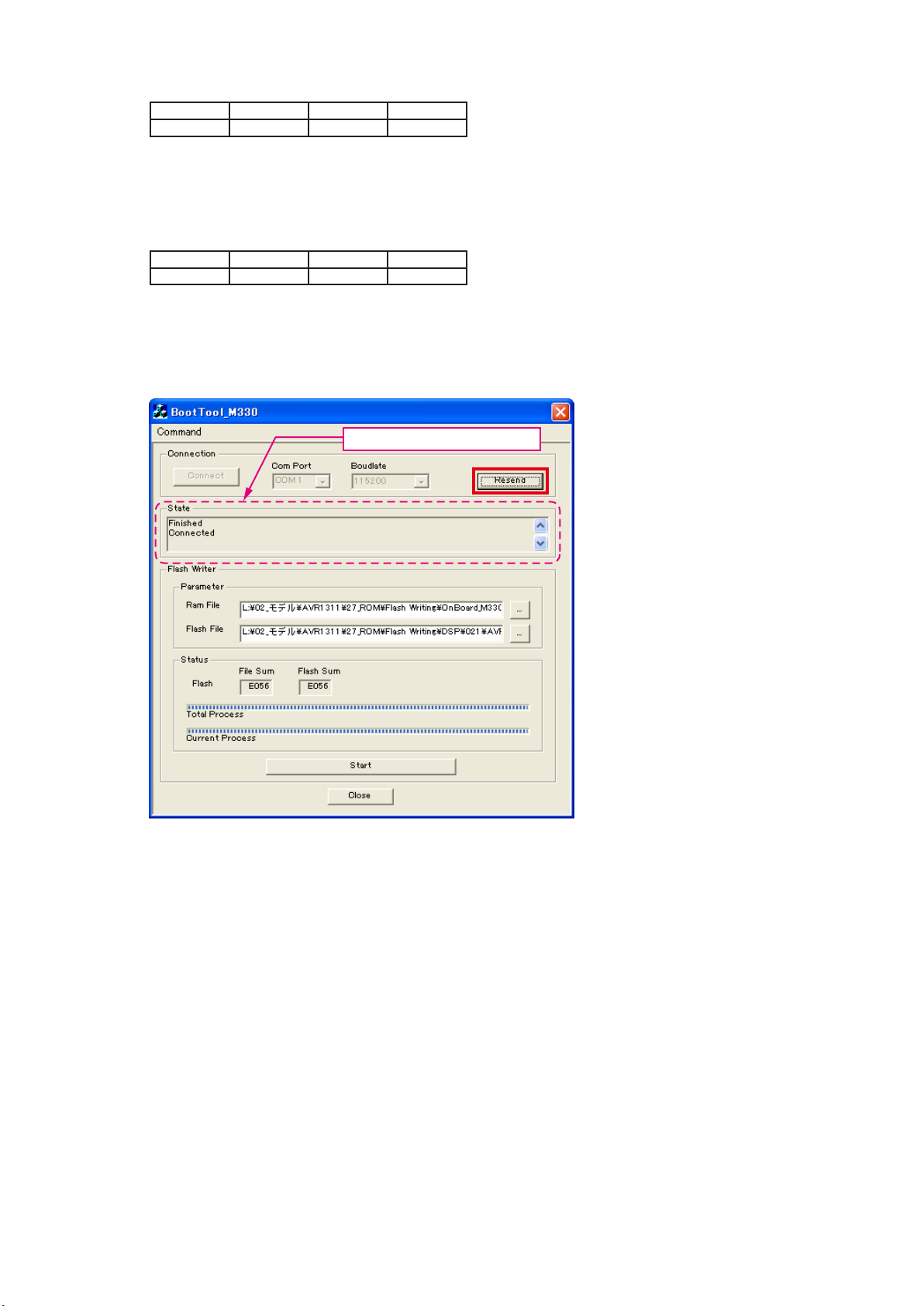

(7) Click the “Connect” button.

"Connected" is displayed, it is OK.

16

Page 17

DSP SF1

(8) Choose Ram File(OnBoard_M330.s32).

Choose Ram File(OnBoard_M330.s32).

17

Page 18

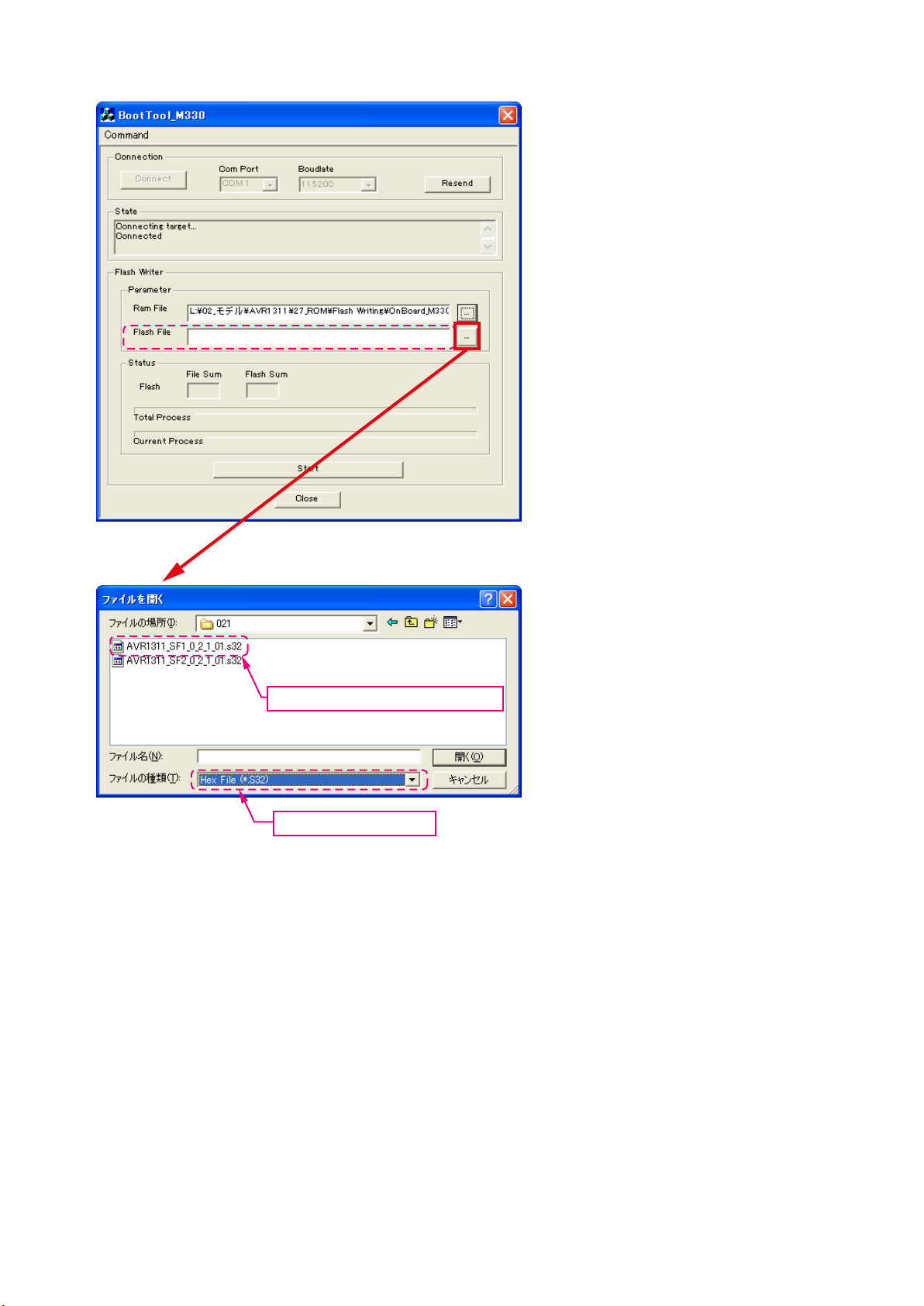

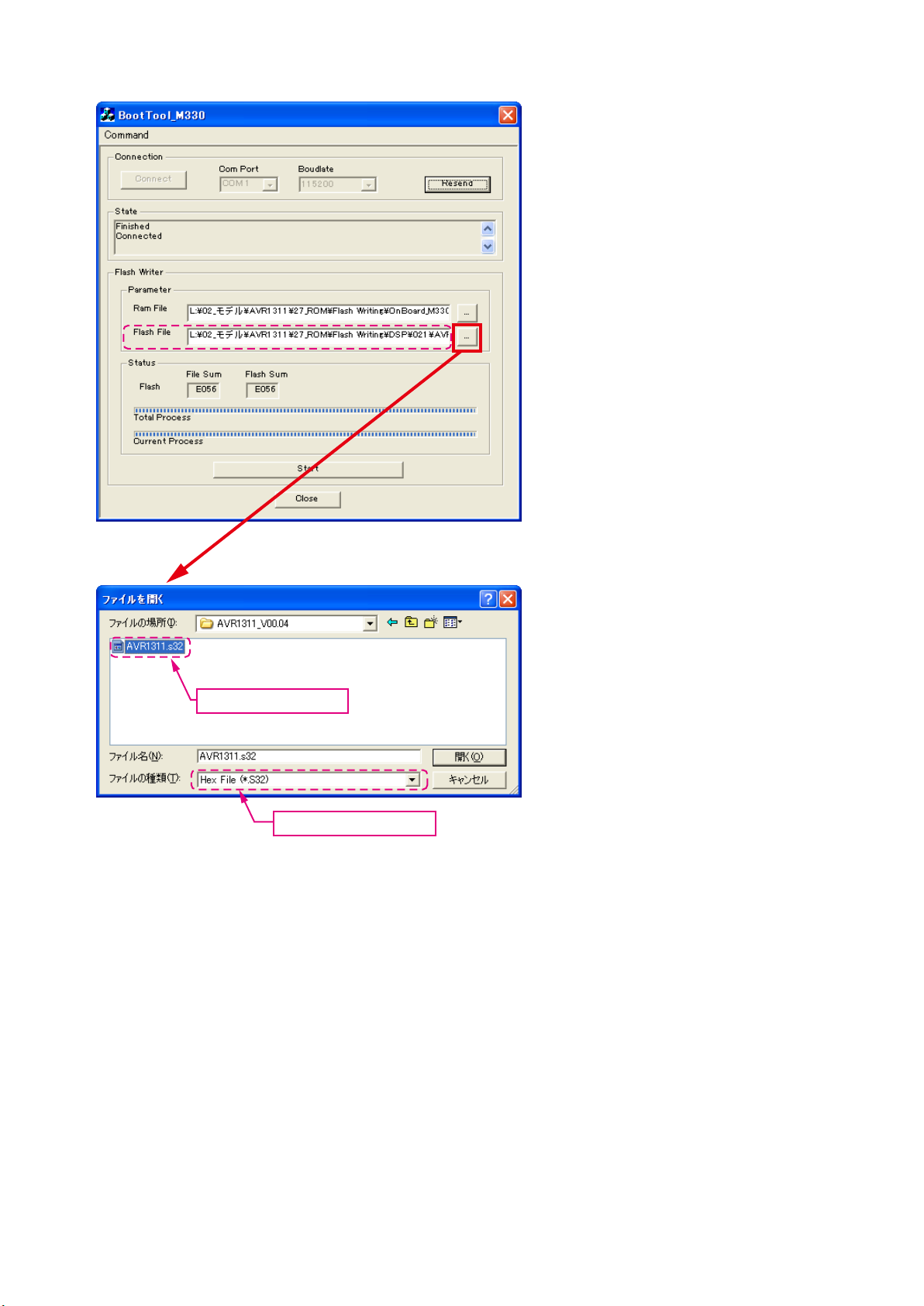

(9) Choose Flash File(DSP : SF1).

Choose "AVR1311_SF1_*_*_*_01.s32".

Choose "Hex File (*.S32)".

18

Page 19

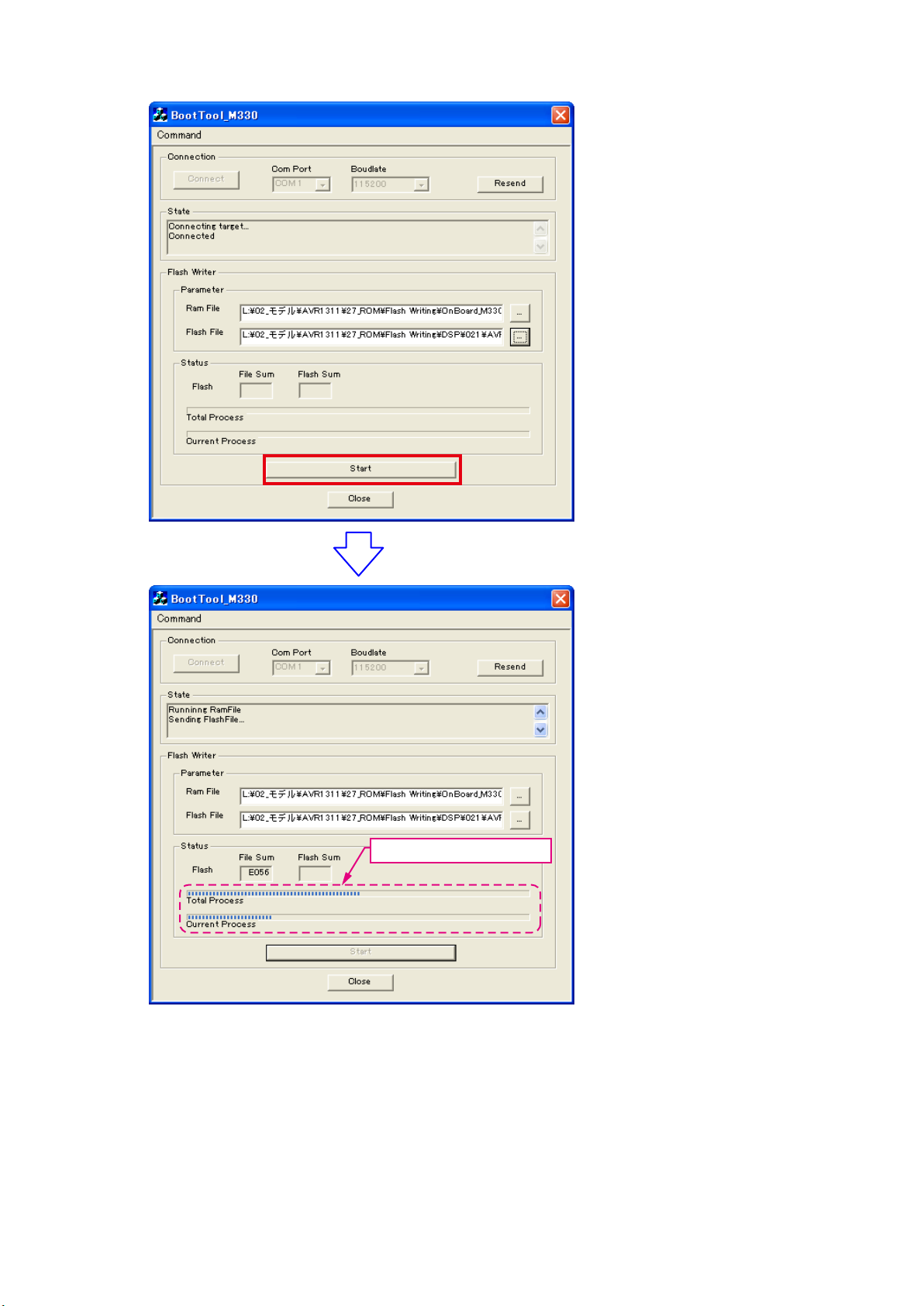

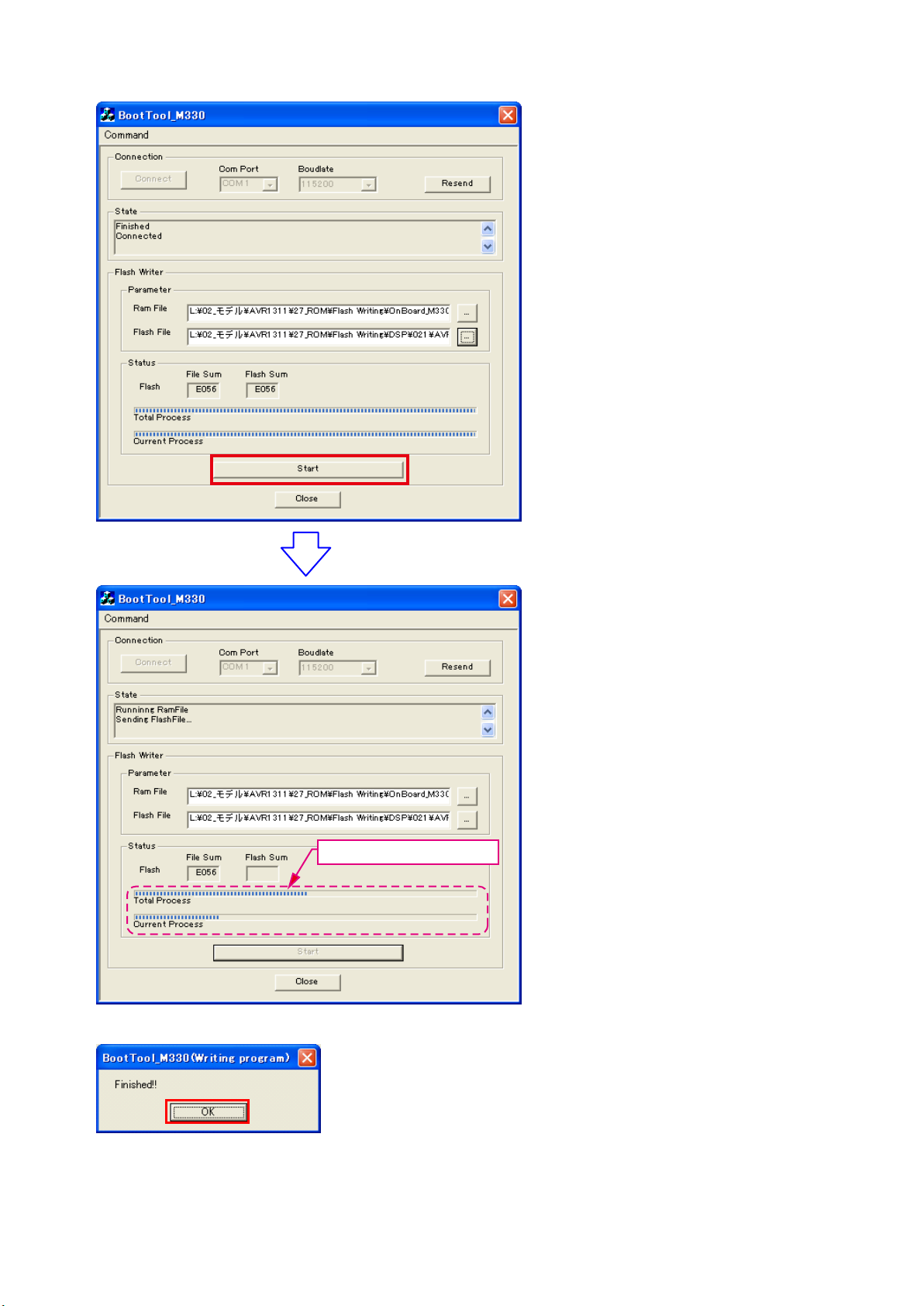

(10) Click the “Start” button.

The Setup Status bar appears.

19

Page 20

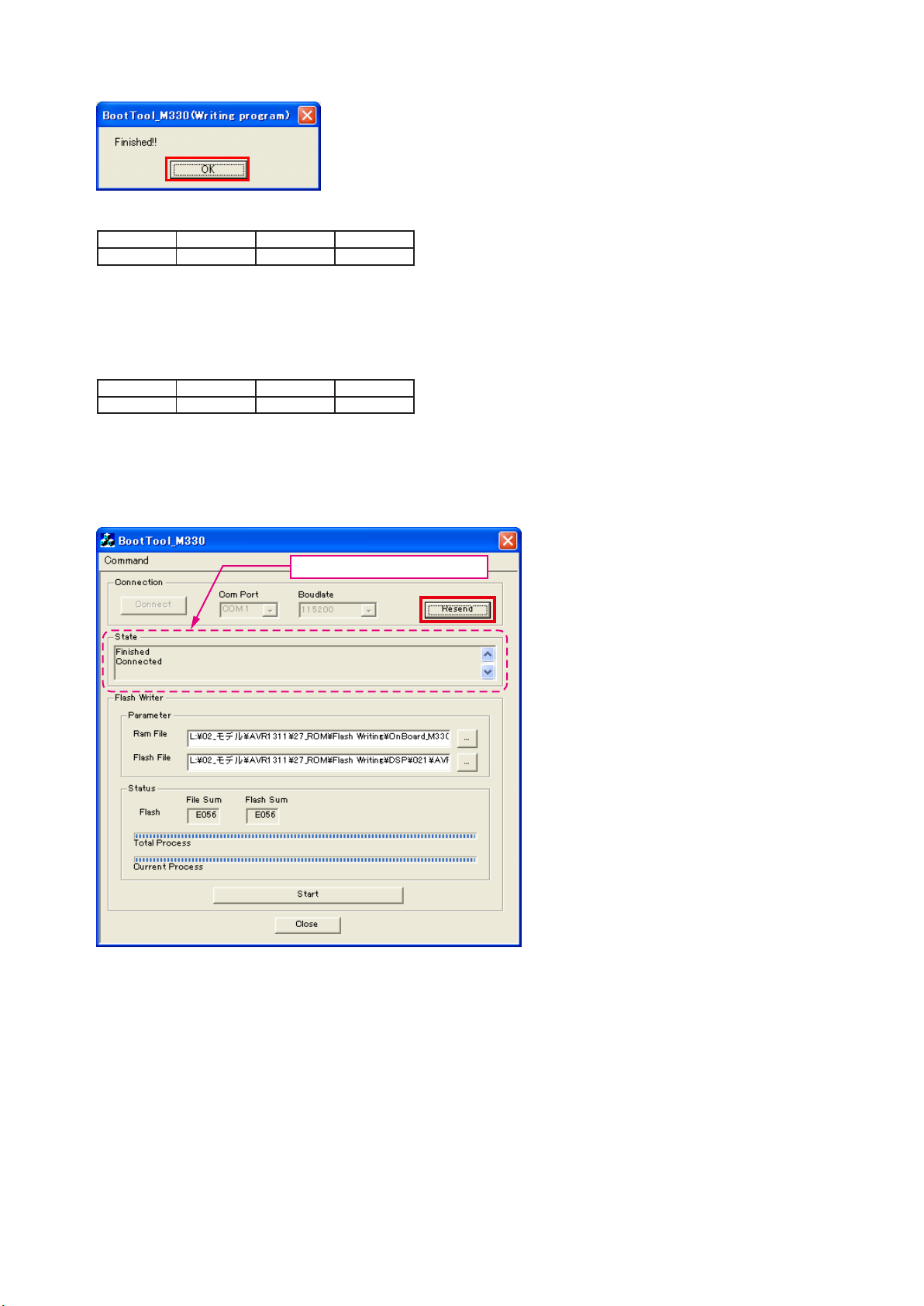

(11) "Finished!!" is displayed. Click the "OK"” button.

(12) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(13) Press the "RESET" switch of “Writing Kit".

(14) AV receiver is power on and starts update of DSP1.

(15) "Write Comleted" is displayed in the FL tube.

(16) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H L H

(17) Press the "RESET" switch of “Writing Kit".

DSP SF2

(18) Click the “Resend” button.

"Connected" is displayed, it is OK.

20

Page 21

(19) Choose Flash File(DSP : SF2).

Choose "AVR1311_SF2_*_*_*_01.s32".

Choose "Hex File (*.S32)".

21

Page 22

(20) Click the “Start” button.

The Setup Status bar appears.

(21) "Finished!!" is displayed. Click the "OK"” button.

22

Page 23

(22) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(23) Press the "RESET" switch of “Writing Kit".

(24) AV receiver is power on and starts update of DSP2.

(25) "Write Comleted" is displayed in the FL tube.

(26) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H L H

(27) Press the "RESET" switch of “Writing Kit".

MAIN

(28) Click the “Resend” button.

"Connected" is displayed, it is OK.

23

Page 24

(29) Choose Flash File(MAIN).

Choose "AVR1311.s32".

Choose "Hex File (*.S32)".

24

Page 25

(30) Click the “Start” button.

The Setup Status bar appears.

(31) "Finished!!" is displayed. Click the "OK"” button.

25

Page 26

(32) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(33) Press the "RESET" switch of “Writing Kit".

(34) Initializing.

1. Turn off the power using ON/STANDBY button.

2. Press ON/STANDBY button while simultaneously pressing SURROUND MODE

and SURROUND MODE

0

buttons.

3. Check that the entire display is ashing with an interval of about 1 second, and release your ngers from the 2

buttons and the microprocessor will be initialized.

Note: •If step 3 does not work, start over from step 1.

All user settings will be lost and this factory setting will be recovered when this initialization mode.

•

So make sure to memorize your setting for restoring after the initialization.

3. Notice:

Please keep the following notice for rmware update.

(a) Keep the PC environment

(b) Avoid the communication cable from the electrical noise source.

(e.g. telephone cable, AC line, a uorescent light)

(c) Don’t remove cable during update.

(d) Don’t turn off the power during update.

(e) Don’t run other PC application during update.

(f) Stop the resident program on PC (Virus checker and System check utilitu, etc)

(g) Stop the screen saver on PC.

(h) Stop the power save ability on PC.

(i) In case of laptop PC, Use the AC adaptor.

1

Conrming the rmware’s number after upgraded

After completion of the updating operation, the new version number can conrmed by starting up the AVR1311 or AVR391

according to the following procedure.

With the following operation, the AVR1311 or AVR391 can be set to the Flash ROM Version-Number Conemation mode.

Turn on power switch while simultaneously pressing "DIMMER" and "STATUS" buttons on the front panel. Every time the

"STATUS" button is pressed, version number of the Model, Main, DSP, … are indicated on the front panel section in the

following order.

Depression Button Name Remarks

1 STATUS Model Name AVR1311 or AVR391 **

2 STATUS Main CPU Main: **.**

3 STATUS DSP ROM DSP.*.*.*

26

Page 27

ADJUSTMENT

Audio Section

Idling Current

Required measurement equipment: DC Voltmeter

1. Preparation

(1) Avoid direct blow from an air conditioner or an electric fan, and adjust the unit at normal room temperature

15 °C ~ 30 °C.

(2) Presetting

• POWER (Power source switch) OFF

• SPEAKER (Speaker terminal) No load

(Do not connect speaker, dummy resistor, etc.)

2. Adjustment

(1) emoved top cover and set VR41(FL),VR45(FR),VR42(C),VR44(SL),VR43(SR), on Main Amp. Unit at fully

counterclockwise position.

(2) Connect DC Voltmeter to test points (Front-Lch:CN51,Front-Rch:CN55,CENTERch:CN53,

Surround-Lch:CN52,Surround-Rch:CN54).

(3) Connect power cord to AC Line, and turn power switch "ON".

(4) Presetting.

MASTER VOLUME : "---" counterclockwise (c min.)

SPEAKER (Speaker terminal) : No load

(Do not connect speaker, dummy resistor, etc.)

FUNCTION : DVD

(5) Within 2 minutes after the power on, turn VR41 clockwise (x) to adjust the TEST POINT voltage to

1.5 mV ± 0.5 mV DC.

(6) After 10 minutes from the preset above, turn VR401 to set the voltage to 2.0 mV ± 0.5 mV DC.

(7) Adjust the Variable Resisters of other channels (VR42-VR45) in the same way.

DC Voltmeter

S Lch

F Lch

CN51

VR41 VR44 VR42 VR43 VR45

CN52

C ch

CN53

S Rch

CN54

F Rch

CN55

MAIN UNIT ASS'Y

27

Page 28

SURROUND MODES AND PARAMETERS

SS

D. Comp z3 DRCz4 LFE z5

z2

DSSS

z1

Channel output Surround Parameter

SS

z2

SDD D DSSS

SDD D D S S

SDD D D S S

SDD D D S

SDD D D S S

SDD D D S S

SDD D D S S

SDD D D S S

SDD D D S S

SDD D D S

S DSSS

SDD D

S D

Front L/R Center Surround L/R Surround Back L/R Subwoofer Mode

Surround mode

DTS NEO:6

DOLBY DIGITAL

DOLBY DIGITAL Plus

DOLBY TrueHD

DTS SURROUND

DTS 96/24

MULTI CH IN

DOLBY PRO LOGIC gx SDD D DSSS

STEREO

DIRECT (Multi-channel)

Symbols in the table

S This indicates the audio output channels or surround parameters that can be set.

D This indicates the audio output channels. The output channels depend on the settings of “Speaker Config.”.

DIRECT (2channel)

DOLBY PRO LOGIC g S D D DSSS

DTS-HD

S D

DTS Express

MULTI CH STEREO

VIRTUAL

z1 A signal for each channel contained in an input signal is output as audio.

z2 Only when “Mode” is set to “LFE+Main”, sound is output from the subwoofer.

z3 This item can be selected when a Dolby Digital or DTS signal is played.

z4 This item can be selected when a Dolby TrueHD signal is played.

z5 This item can be selected when a Dolby Digital or DTS signal or DVD-Audio is played.

28

Page 29

RESTORER z7

Tone

NEO:6 Music mode only

PRO LOGIC g/gx Music mode only

Panorama Dimension Center Width Center Image

Surround Parameter

SS

SS

z2

S

S.Back Subwoofer

AFDM z6

Surround mode

DIRECT (2 channel)

SS S

DIRECT (Multi-channel)

STEREO

MULTI CH IN

DOLBY PRO LOGIC gx S SSS SS

DOLBY PRO LOGIC g S SSS SS

S SSS

SS S

SS S

SS

SS S

SS S

DOLBY DIGITAL

DOLBY DIGITAL Plus

DOLBY TrueHD

DTS SURROUND

DTS NEO:6

DTS 96/24

S SS

SS

SS S

z2 Only when “Mode” is set to “LFE+Main”, sound is output from the subwoofer.

z6 This item can be selected when a Dolby Digital or DTS or DVD-Audio signal is played.

z7 This item can be set when the input signal is analog, PCM 48 kHz or 44.1 kHz.

DTS-HD

DTS Express

MULTI CH STEREO

VIRTUAL

29

Page 30

DOLBY

DIGITAL

DOLBY

DIGITAL

(2ch)

(4/3ch)

DOLBY

DIGITAL

(5.1/5/4ch)

Flag)

DOLBY

(With no

DIGITAL EX

DOLBY

(With Flag)

DIGITAL EX

DOLBY

DIGITAL Plus

DOLBY

TrueHD

DTS 96/24

DTS

(5.1ch)

Input signal types and formats

MTRX

DTS ES

DSCRT

DTS ES

(With Flag)

(With Flag)

F

SSF

S S

DS

SFFF

F

DTS

EXPRESS

High

DTS-HD

Resolution

Audio

Master

DTS-HD

(2ch)

LINEAR PCM

PCM DTS-HD DTS DOLBY DOLBY DIGITAL

(multi ch)

LINEAR PCM

ANALOG

Audio

F

F

F

SS S

SS S

z F D

z F D

z SSS

z SSSS

SS S

z If “Speaker Config.“ – “S.B(Pre)“ is set to “None”, this surround mode cannot be selected.

Surround mode NOTE

DTS NEO:6 CINEMA

DTS NEO:6 MUSIC

DTS-HD MSTR

DTS-HD HI RES

DTS ES DSCRT6.1

DTS ES MTRX6.1

DTS SURROUND

DTS 96/24FDTS + PLgx CINEMA z SSSS

DTS + PLgx MUSIC z SSSS

DTS EXPRESS

DTS + NEO:6

Symbols in the table

F This indicates the default surround mode.

D This indicates the surround mode that is fixed when “AFDM” is set to “ON”.

S This indicates the selectable surround mode.

DTS SURROUND

DOLBY TrueHD

DOLBY SURROUND

30

DOLBY DIGITAL+

DOLBY DIGITAL EX

DOLBY DIGITAL

DOLBY (D) +PLgx CINEMA z F

DOLBY (D) +PLgx MUSIC z SSSS

DOLBY PRO LOGIC gx CINEMA zS S S

DOLBY PRO LOGIC gx MUSIC zS S S

DOLBY PRO LOGIC gx GAME zS S S

DOLBY PRO LOGIC g CINEMA SS S

DOLBY PRO LOGIC g MUSIC SS S

DOLBY PRO LOGIC g GAME SS S

DOLBY PRO LOGIC

Page 31

DOLBY

DIGITAL

DOLBY

DIGITAL

DOLBY

DIGITAL

DOLBY

DIGITAL EX

DOLBY

DIGITAL EX

DOLBY

DOLBY

DTS 96/24

DTS

(2ch)

(4/3ch)

(5.1/5/4ch)

Flag)

(With no

(With Flag)

DIGITAL Plus

TrueHD

(5.1ch)

Input signal types and formats

MTRX

DTS ES

(With Flag)

DSCRT

DTS ES

(With Flag)

DTS

EXPRESS

High

DTS-HD

Resolution

Audio

Master

DTS-HD

(2ch)

LINEAR PCM

PCM DTS-HD DTS DOLBY DOLBY DIGITAL

(multi ch)

LINEAR PCM

ANALOG

Audio

F

F D (7.1)

SS S SSSSSSSSSSSSSS

SS S SSSS SSSSS

SS S SSSS SSSSS

FS F SSSSSSSSSSSSSS

z If “Speaker Config.“ – “S.B(Pre)“ is set to “None”, this surround mode cannot be selected.

Surround mode NOTE

MULTI CH IN

MULTI CH IN + PLgx CINEMA zS

MULTI CH IN + PLgx MUSIC zS

MULTI CH IN 7.1

DIRECT

MULTI CH STEREO

VIRTUAL

STEREO

MULTI CH IN

DIRECT

DSP SIMULATION

STEREO

31

Page 32

TROUBLE SHOOTING

1. POWER

1.1. Power not turn on

Power not turn on.

Is the ON/STANDBY

indicator on the front panel

fl ashing red?

YES

Are there any incomplete

connections in the

connectors connecting

between the various circuit

boards?

Is there a short circuit

NO

between the speaker

terminals and the ground?

Correct the short

YES

circuit between the

speaker and ground.

NO

Is the fuse blown?

NO

Does the power turn on

when the POWER switch is

turned off then back on?

YES YES YES

Check the primary ciruitry

parts including the POWER

switch(for poor contacts,

etc.), and replace any

defective parts.

YES

Connect the connectors

property.

YES

Refer to Fuse is blown.

Is a DC 5V voltage being

NO NO

supplied from the MAIN B'd

to the microprocessors?

Check the microprocessor

periphery circuitry and

replace any degective parts.

NO

Check for damage in the

power amplifi er circuitry

parts and replace any

defective parts.

Is a DC5V voltage output

when the cord supplying the

power from the MAIN B'd to

the microprocessor(BN43)

is unplugged?

Check the circuitry and parts

from BN43 on the MAIN

B'd to the microprocessor

for damage and shortcircuits,and replace any

defective parts.

Check the parts from

NO

IC45 to the primary

circuitry and replace

any defective parts.

1.2. Fuse is blown

Check for leaks or short

circuits in the primary side

parts,and replace any

defective parts.

Fuse is blown

Check for short circuits in the

rectifi er diodes and circuitry of

the secondary side rectifying

circuits,and replace any

defective parts.

After repairing, also replace the fuse.

32

Check for short circuits in

the power stabilizer unit's

regulator output terminal and

the ground,and replace any

defective parts.

Page 33

2. Analog video

MONITOR OUT(CVBS) Output NG

Check ±5V

+5V : C755

-5V : C754

OK

Check output

Output V : IC71-1pin

OK

Check cable between main unit and monitor

or Check monitor.

AVR-1311 model only

MONITOR OUT(COMPONENT) Output NG

Check ±5V

+5V : C797

-5V : C799

OK

Check output

Output Y : C785

Output Pb : C787

Output Pr : C789

NG

The power supply circuitry is defective.

NG

The IC71 and surrounding circuitry is defective.

NG

The power supply circuitry is defective.

NG

The IC73 and surrounding circuitry is defective.

OK

Check cable between main unit and monitor

or Check monitor.

33

Page 34

3. HDMI/DVI

3.1. No picture or sound is output

No picture or sound is output.

Check HDMI/DVI cable connection.

(1) Is the HDMI/DVI cable properly connected?

YES

(2) Are you using an HDMI/DVI selector, repeater or a device for

improving picture quality?

YES

(3) Are you using a certifi ed HDMI cable (one with the HDMI stamp)?

YES

(3) Are you using an HDMI/DVI cable less than 5 meters in length?

YES

(4) Are the picture and sound output when another HDMI/DVI cable

is used?

NO

NO

There may be a problem with the HDMI/DVI

cable. Check connection.

YES

Disconnect everything and connect only the

HDMI/DVI cable to check

NO

Use a certifi ed HDMI cable (one with the

HDMI stamp).

Replace the HDMI/DVI cable with one that

NO

is less than 5 meters in length (2 meters

recommended) to check.

YES

The HDMI/DVI cable is defective.

Check BD/DVD player.

YES

(5) Is the BD/DVD player's HDMI output setting correct?

YES

(6) When using a DENON BD/DVD player's, is the fl uorescent

display tube's "HDMI" indicator lit? If using a non-DENON BD/

DVD player's, proceed to

NO

(8) Is sound output from the set's speaker terminals when the TV's

power is turned off or the connection cable between the TV and

the set is disconnected?

"YES".

YES

(7)

Are the picture and sound output

when the BD/DVD player's

resolution is changed?

NO

NO

(9) Are the picture and sound

output when a different BD/

DVD player's is used?

NO

YES

Check HDMI output setting, referring to the

BD/DVD player's operating instructions.

YES

Set the BD/DVD player's output resolution to

a resolution with which the TV is compatible.

YES

The BD/DVD player's may not be compatible

with HDCP repeaters. Ask the BD/DVD

player's manufacturer.

YES

The BD/DVD player's is defective.

34

Page 35

Check TV

(10) Is the TV HDCP-compatible?

YES

(11) Is the TV compatible with resolutions of 1080P?

YES

(12) Is the TV's input set to HDMI?

YES

(13) Are the picture and sound output when a different TV is used?

Check set (AVR-1311, 391)

(14) Is the set's input set to HDMI?

YES

YES

NO

Use an HDCP-compatible TV. PC TVs

cannot be used.

If the TV is not compatible with resolutions

NO

of 1080P, no picture will be output, even

if the BD/DVD player's resolution is set to

1080P.

NO

Check TV's input setting, referring to the

TV's operating instructions.

NO

The TV is defective.

NO

Check set's input setting, referring to the

set's operating instructions.

The set does not recognize the TV.

(15) Is the "H"(3V-5V) signal outputted of IC11 (41pin)?

With the TV connected, Check voltage of the IC on the side on

which the TV is connected.

Is communication waveform confi rmed in 15pin(DDC_

CLK)/16pin(DDC_DATA)

Is terminate the TMDS signal

6pin/7pin/9pin/10pin/12pin of HDMI connector (JK15)?

YES

(16)

When using a DENON

BD/DVD player, is the FL

display's "HDMI" indicator lit?

If using a non-DENON BD/

DVD player, proceed to

"NO".

YES

of HDMI connector (JK15)

is

3.3V

confi rmed in

The BD/DVD player does not recognize the

connection with the set.

(17)

Is the "H"(3V-5V) signal outputted of HDMI

connector (JK11/JK12/JK13/JK14 : 19pin)?

NO NO

With the BD/DVD player connected, Check

voltage of the HDMI connector for the input

on the side on which the BD/DVD player is

connected.

Is communication waveform confi rmed in

15pin(DDC_CLK)/16pin(DDC_DATA)

HDMI connector

Is terminate the TMDS signal

1pin/3pin/4pin/6pin/7pin/9pin/10pin/12pin of each

HDMI connector?

?

1pin/3pin/4pin/

YES

YES

The pattern and circuit from the HDMI

NO

connector (JK15) to the IC11 is defective, or

HDMI output circuitry is defective (IC11 and

surrounding circuitry).

The pattern and circuit

from the HDMI connector

(JK11/JK12/JK13/JK14)

to the IC11 is defective.

of each

?

is

3.3V

confi rmed in

Check operation of IC11.

(Video input 480P from BD/DVD players / Connect the TV.)

(18) Check power supply.

Are 1.8V or 3.3V supplied to IC11 (each power supply pin)?

YES

NO

The power supply circuitry is defective.

35

Page 36

(19) Check xtal oscillator.

Is there 28.6363MHz oscillation of X101?

NO

The X101 or IC11 is defective.

YES

(20) Check RESET.

Is RESET waveform confi rmed in IC11 (97pin), when power is

turned on? (If continued to "H" or " L", proceed to "NO".)

YES

(21) Check control signal(I2C).

Is waveform confi rmed in IC11 78pin(SDATA)/79pin(SCL). (If not

continued to " L", proceed to "YES".)

YES

HDMI output circuitry is defective (IC11 and surrounding circuitry).

NO

The RESET pattern or IC11 is defective.

NO

The SDATA/SCL line pattern is defective.

36

Page 37

3.2. HDMI test point and waveforms

Detail

+5V

A

D

A

TMDS D2+ HPD

TMDS D0+

TMDS D2-

TMDS D0-

B

C

B

Detail

TMDS D2- TMDS D0-

TMDS D2+ TMDS D0+ HPD

C

Detail

43pin㧦DDC_DATA

44pin㧦DDC_CLK

TMDS D1+ TMDS D1+

TMDS D1- TMDS D1-

DDC_DATA DDC_CLK

TMDS D1+ +5VTMDS CK+

TMDS D1- TMDS CK-

D

Detail

HDMI_SCL HDMI_SDA

37

Page 38

DDC_CLK/DDC_DATA/TMDS : Check item (15),(17)

0.9V

DDC_CLK

TMDS SIGNAL

2.48V

IPINDE/IPINVSYNC/IPINHSYNC/IPINPCK : Check item (21)

HDMI_SDA

HDMI_SCL

DDC_DATA

38

Page 39

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK

䇭

㩿㪏㪎㪀㪘㪧㪇㪶㪦㪬㪫

㩿㪏㪏㪀㪘㪧㪈㪶㪦㪬㪫

㩿㪏㪐㪀㪘㪧㪉㪶㪦㪬㪫

㩿㪐㪇㪀㪘㪧㪊㪶㪦㪬㪫

㩿㪐㪈㪀㪘㪧㪋㪶㪦㪬㪫

㩿㪐㪋㪀㪘㪧㪌㪶㪦㪬㪫

㩿㪐㪌㪀㪪㪚㪣㪢㪶㪦㪬㪫

㩿㪐㪍㪀㪤㪚㪣㪢㪶㪦㪬㪫

㪛㪘㪠㪈㪶㪛㪘㪫㪘㪇㪃㪛㪪㪛㪇㩿㪉㪎㪀

㪛㪘㪠㪈㪶㪛㪘㪫㪘㪈㪃㪛㪪㪛㪈㩿㪉㪍㪀

㪛㪘㪠㪈㪶㪛㪘㪫㪘㪉㪃㪛㪪㪛㪉㩿㪉㪋㪀

㪛㪘㪠㪈㪶㪛㪘㪫㪘㪊㪃㪛㪪㪛㪊㩿㪉㪊㪀

㪛㪘㪠㪈㪶㪣㪩㪚㪢㪃㪛㪪㪛㪋㩿㪊㪇㪀

㪛㪘㪠㪈㪶㪪㪚㪣㪢㪃㪛㪪㪛㪄㪚㪣㪢㩿㪉㪐

㪀

㪛㪘㪦㪶㪤㪚㪣㪢㩿㪋㪇㪀

㩿㪋㪎㪀㪛㪘㪦㪈㪶㪛㪊

㩿㪋㪏㪀㪛㪘㪦㪈㪶㪛㪉㪃㪟㪪㪉

㩿㪋㪐㪀㪛㪘㪦㪈㪶㪛㪘㪫㪘㪈㪃㪟㪪㪈

㩿㪌㪈㪀㪛㪘㪦㪈㪶㪛㪘㪫㪘㪇㪃㪟㪪㪇

㩿㪌㪉㪀㪛㪘㪦㪈㪶㪪㪚㪣㪢

㩿㪌㪋㪀㪛㪘㪦㪈㪶㪣㪩㪚㪣㪢

㩿㪈㪍㪀㪯㪫㪘㪣㪶㪦㪬㪫

㩿㪊㪉㪀㪛㪘㪠㪉㪶㪣㪩㪚㪢

㩿㪊㪊㪀㪛㪘㪠㪉㪶㪪㪚㪣㪢

㩿㪊㪋㪀㪛㪘㪠㪉㪶㪛㪘㪫㪘㪃㪛㪪㪛㪌

㪪㪘㪠㪶㪚㪣㪢㩿㪍㪈㪀

㪪㪘㪠㪶㪣㪩㪚㪢㩿㪍㪇㪀

㪪㪘㪠㪶㪪㪛㪦㪬㪫㩿㪌㪋㪀

㪩㪤㪚㪢㩿㪌㪌㪀

㩿㪈㪀㪚㪯㪶㪪㪛㪠㪥㪈

㩿㪍㪋㪀㪚㪯㪶㪪㪛㪠㪥㪉

㩿㪍㪊㪀㪚㪯㪶㪪㪛㪠㪥㪊

㩿㪍㪉㪀㪚㪯㪶㪪㪛㪠㪥㪋

㩿㪉㪀㪚㪯㪶㪪㪚㪣㪢

㩿㪊㪀㪚㪯㪶㪣㪩㪚㪢

㩿㪌㪐㪀㪦㪤㪚㪢

㩿㪋㪎㪀㪩㪯㪧㪉㪆㪞㪧㪦㪉

㩿㪋㪐㪀㪩㪯㪧㪇

㪚㫆㪸㫏㫀㪸㫃㪈

㪦㫇㫋㫀㪺㪸㫃㪈

㪠㫅㫇㫌㫋

㽳

㪠㪚㪏㪈

㪚㪪㪋㪐㪎㪇㪉㪋㪚㪭㪱

䋨㪘㪬㪛㪠㪦㩷㪛㪪㪧䋩

㪠㪚㪏㪋

㪚㪪㪋㪉㪌㪉㪏

䋨㪛㪠㪩㪂㪚㪦㪛㪜㪚䋩

㪠㪚㪈㪈

㪘㪛㪭㪎㪍㪉㪉㪙㪪㪫㪱

㽴

㽲

CH1: D-DATA

1

CH1: DATA

CH2: fs

CH3: 64fs

CH4: 256fs

3

CH1: DATA

CH2: fs

CH3: 64fs

2

Wave form

39

Page 40

40

BLOCK DIAGRAM

Page 41

414243

Page 42

Page 43

Page 44

44

LAEVEL DIAGRAM

Page 45

45

Page 46

46

181716151413121110987654321

G

F

E

D

C

B

A

PRINTED WIRING BOARDS

FRONT (COMPONENT SIDE)

d

PHONE (COMPONENT SIDE)

d

HEADPHONE (COMPONENT SIDE)

d

REGULATOT (COMPONENT SIDE)

d

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

321

D

C

B

A

54321

7654321

A

A

B

B

C

C

D

Page 47

47

123456789101112131415161718

G

F

E

D

C

B

A

FRONT (FOIL SIDE)

d

PHONE (FOIL SIDE)

d

HEADPHONE (FOIL SIDE)

d

REGULATOT (FOIL SIDE)

d

123

D

C

B

A

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

12345

A

B

C

1234567

A

B

C

D

Page 48

48

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

POWER (COMPONENT SIDE)

d

POWER (FOIL SIDE)

d

VOLUME (COMPONENT SIDE)

d

VOLUME (FOIL SIDE)

d

AUX (COMPONENT SIDE)

d

AUX (FOIL SIDE)

d

4321

C

B

A

1234

C

B

A

4321

A

B

C

D

321

A

B

C

D

1234

A

B

C

D

123

A

B

C

D

Page 49

49

MAIN (COMPONENT SIDE)

d

Bar code

1716151413121110987654321

M

L

K

J

I

H

G

F

E

D

C

B

A

鉛フリー半田

半田付けには、鉛フリー

半田 (Sn-Ag-Cu) を使用

してください。

Lead-free Solder

When soldering, use

the Lead-free Solder

(Sn-Ag-Cu).

Page 50

50

INPUT (COMPONENT SIDE)

d

1716151413121110987654321

M

L

K

J

I

H

G

F

E

D

C

B

A

鉛フリー半田

半田付けには、

鉛フリー半田

(Sn-Ag-Cu) を使

用してください。

Lead-free

Solder

When soldering,

use the Lead-

free Solder

(Sn-Ag-Cu).

Page 51

51

INPUT (FOIL SIDE)

d

1234567891011121314151617

M

L

K

J

I

H

G

F

E

D

C

B

A

鉛フリー半田

半田付けには、

鉛フリー半田

(Sn-Ag-Cu) を使

用してください。

Lead-free

Solder

When soldering,

use the Lead-

free Solder

(Sn-Ag-Cu).

Page 52

52

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

13121110987654321

G

F

E

D

C

B

A

HDMI (COMPONENT SIDE)

Page 53

53

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

HDMI (FOIL SIDE)

12345678910111213

G

F

E

D

C

B

A

Page 54

54

87654321

A

B

C

D

E

F

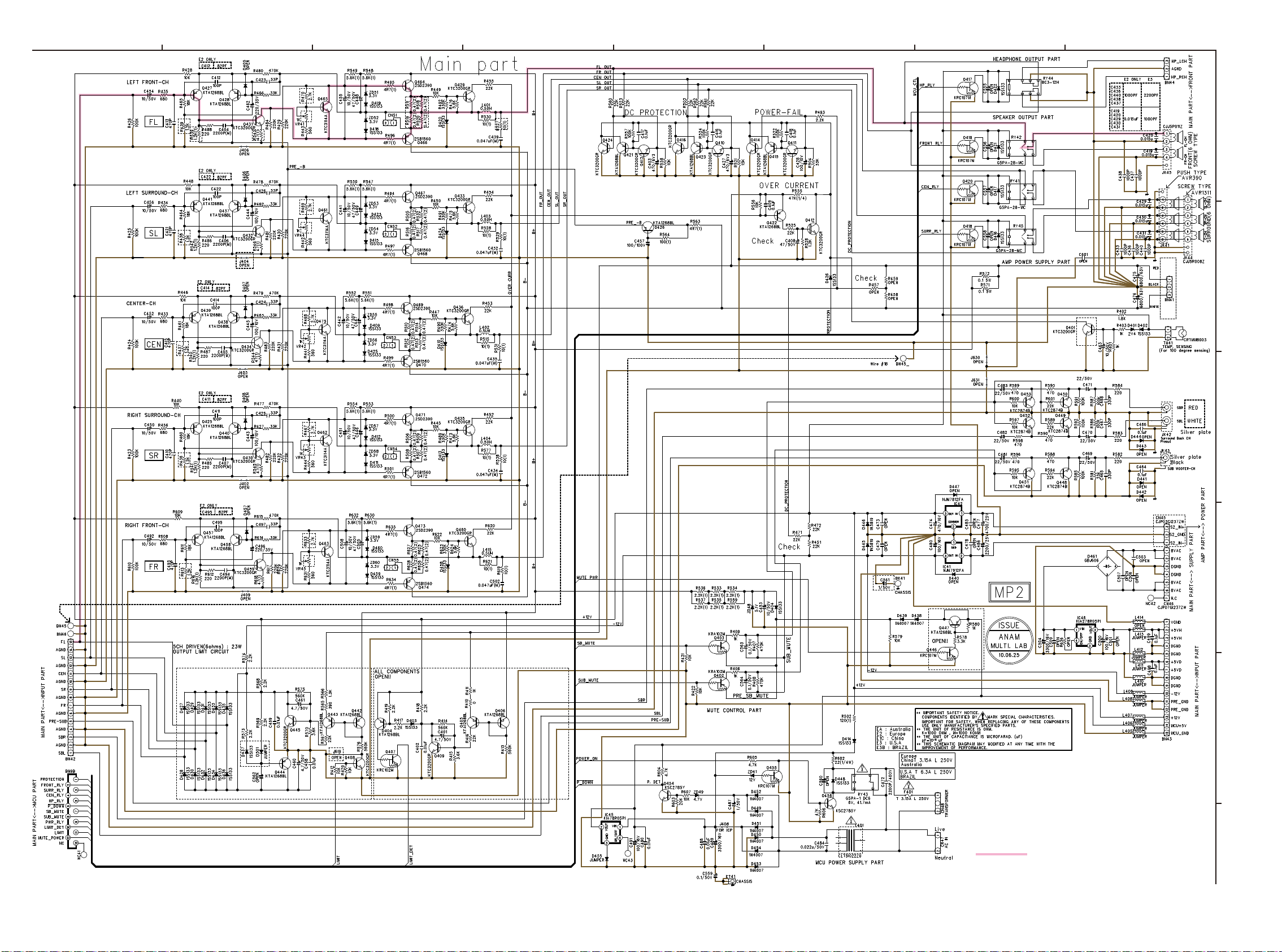

SCHEMATIC DIAGRAMS (1/7)

d

Page 55

55

HDMI/TMDS SIGNAL LINE

D2+

D2 SHIELD

D2-

D1+

D2 SHIELD

D1-

D1 SHIELD

D0+

D0-

CK+

D1 SHIELD

CK-

CE REMOTE

NC

DDC CLK

DDC DATA

GND

+5V

HP DET

INPUT-4

D2+

D2 SHIELD

D2-

D1+

D2 SHIELD

D1-

D1 SHIELD

D0+

D0-

CK+

D1 SHIELD

CK-

CE REMOTE

NC

DDC CLK

DDC DATA

GND

+5V

HP DET

INPUT-3

D2+

D2 SHIELD

D2-

D1+

D2 SHIELD

D1-

D1 SHIELD

D0+

D0-

CK+

D1 SHIELD

CK-

CE REMOTE

NC

DDC CLK

DDC DATA

GND

+5V

HP DET

INPUT-2

D2+

D2 SHIELD

D2D1+

D2 SHIELD

D1-

D1 SHIELD

D0+

D0CK+

D1 SHIELD

CK-

CE REMOTE

DDC CLK

DDC DATA

GND

+5V

DDCC_SCL

CVDD

CGND

RXC_C-

RXC_C+

TVDD

RXC_0-

RXC_0+

CGND

RXC_1-

RXC_1+

TVDD

RXC_2-

RXC_2+

HP_CTRLD

5V_DETD

DGND

DVDD

DDCD_SDA

DDCD_SCL

CVDD

CGND

RXD_C-

RXD_C+

TVDD

RXD_0-

RXD_0+

CGND

RXD_1-

RXD_1+

TVDD

RXD_2-

RXD_2+

CVDD

CGND

TXPVDD

TXPLGND

EXT_SWING

HP_ARC-

ARC+

TXDDC_SDA

TXDDC_SCL

TXAVDD

TXGND

TXC-

TXC+

TXGND

TX0-

TX0+

TXGND

TX1-

TX1+

TXAVDD

TX2-

TX2+

TXGND

CEC

DGND

DVDD

ALSB

CSB

EP_SCK

EP_CS

EP_MOSI

EP_MISO

MCLK_I N

SCLK_IN

AP5_IN

AP4_IN

DGNDIO

AP1_IN

AP0_IN

SDATA

SCL

DGND

DVDD

INT

INT2

INT_TX

DGNDDIO

DVDDIO

AP0_OUT

AP2_IN

AP3_IN

DVDDIO

TXPGND

<TXPLVDD_1V8>

AP1_OUT

AP2_OUT

AP3_OUT

AP4_OUT

DGND

DVDD

AP5_OUT

SCLK_OUT

MCLK_O UT

RESETB

PWRDNB

PGND

PVDD

XTAL

XTAL1

PVDD

PGND

HP_CTRLA

5V_DETA

RTERM

DDCA_SDA

DDCA_SCL

CVDD

CGND

RXA_CRXA_C+

TVDD

RXA_0RXA_0+

CGND

RXA_1RXA_1+

TVDD

RXA_2RXA_2+

HP_CTRLB

5V_DETB

DGND

DVDD

DDCB_SDA

DDCB_SCL

CVDD

CGND

RXB_CRXB_C+

TVDD

RXB_0RXB_0+

CGND

RXB_1RXB_1+

TVDD

RXB_2RXB_2+

HP_CTRLC

5V_DETC

DDCC_SDA

D2+

D2 SHIELD

D2-

D1+

D2 SHIELD

D1-

D1 SHIELD

D0+

D0-

CK+

D1 SHIELD

CK-

CE REMOTE

NC

DDC CLK

DDC DATA

GND

+5V

HP DET

Recommended

about 891.3 ohm

INPUT-1

OUTPUT

500 ohm

RXD_C-

RXD_C+

RXD_0-

RXD_0+

RXD_1-

RXD_1+

RXD_2-

RXD_2+

RXC_C-

RXC_C+

RXC_0-

RXC_0+

RXC_1-

RXC_1+

RXC_2-

RXC_2+

RXB_CRXB_C+

RXB_0RXB_0+

RXB_1RXB_1+

RXB_2RXB_2+

RXA_CRXA_C+

RXA_0RXA_0+

RXA_1RXA_1+

RXA_2RXA_2+

: 887 ohm(1%)

place R122 & R123 & C137

as clos e as possi ble

to pin40 on the bot of PCB

TXC-

TXC+

TX0-

TX0+

TX1-

TX1+

TX2-

TX2+

<PVDD_1V8>

<DVDD_1V8>

<DVDDIO_3V3 >

<TXAVDD_1V8>

<TVDD_3V3 >

<CVDD_1V8>

<TXPVDD_1V8>

HDMI_MCLK

HDMI_SCLK

HDMI_LRCLK

HDMI_SDATA 3

HDMI_SDATA 2

HDMI_SDATA 1

HDMI_SDATA 0

GND

PWRDNB

HDMI_RESET

HDMI_SCL

HDMI_SDA

INT_TX

INT2

INT1

OPEN

NC

HPD

+5VH

FROM/TO INPUT PART

GND

36.7mA

332.4mA

1.5mA

15mA

5.2mA

24.8mA

292.2mA

503.6mA

HDMI_SCL

HDMI_SDA

+5VH

GND

OPEN

OPEN

OPEN

OPEN

OPEN

OPEN

HDMI_MCLK

HDMI_SCLK

HDMI_LRCLK

HDMI_SDATA 3

HDMI_SDATA 2

HDMI_SDATA 1

HDMI_SDATA 0

HDMI_SPDIF

DEBUG

CSSOWP

GND

SI

SCK

HOLD

VCC

OPEN

NOT USED

SPI_HOLD

SPI_WP

GND

DC/DC CONVERTER

+5VH

ASQS12U020R2

ESD suppressor

ASQS12U020R2

ESD suppressor

ASQS12U020R2

ESD suppressor

ASQS12U020R2

ESD suppressor

ASQS12U020R2

ESD suppressor

+1V8H

NC(SW)

NC(SW)

NC

NC

VOUT

VOUT

NC

PVIN

NC(SW)

NC(SW)

NC(SW)

NC(SW)

NC(SW)

AVIN

NC(SW)

PGND

VOUT

VOUT

VOUT

VOUT

VOUT

PGND

PGND

PGND

PVIN

NC

NC

NC

PGND

PGND

PVIN

NC

AGND

XFB

SS

EAOUT

POK

ENABLE

GND

OPEN

GND

PWRDNB

HDMI_RESET

HDMI_SCL

HDMI_SDA

INT_TX

INT2

INT1

ARC

OPEN

OPEN

CHASSIS

+5VH

+5VH+5VH+5VH

+5VH

+5VH

+5VH

+5VH

+5VH

+5VH

+8VH

+8VH

+1V8H

+1V8H

+1V8H

+1V8H

+1V8H

+1V8H

+3V3H

+3V3H

+3V3H

FROM/TO DSP & U-COM PART

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JK11

YKF45-7074N

Q101

KRA102S

Q102

KRC103S

R102

22K

R101

1K

C101

0.1uF

R105

100

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JK12

YKF45-7074N

Q103

KRA102S

Q104

KRC103S

R108

22K

R107

1K

C102

0.1uF

R110

100

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JK13

YKF45-7074N

Q105

KRA102S

Q106

KRC103S

R113

22K

R112

1K

C103

0.1uF

R115

100

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JK15

YKF45-7074N

R147

47K

144

143

142

141

140

139

138

137

136

135

133

134

132

131

130

129

128

127

126

125

124

122

123

121

120

119

118

117

116

115

114

113

112

111

110

109

108107106105104103102101100999897969594939291908988878685848382818079787776757473

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

363534333231302928272625242322212019181716151413121110987654321

IC11

ADV7622BSTZ

R123

8.2K(1%)

R122

1K(1%)

R130

4.7K

R131

4.7K

R140

10K

R139

OPEN

R128

OPEN

R125

47K

R126

OPEN

R138

0

C145

47P

C146

47P

X101

28.6363M

R144

1K(1%)

R143

1K(1%)

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JK14

YKF45-7074N

Q107

KRA102S

Q108

KRC103S

R118

22K

R117

1K

C104

0.1uF

R120

100

R119

47K

R114

47K

R109

47K

R104

47K

R148

100

C161

1uF

C162

0.1uF

C160

OPEN

13

2

5

Vin

Cont

GND

Vout

NC

4

IC13

OPEN

NJU7754F05TE1

C105

0.1uF

C106

0.1uF

C107

0.1uF

C108

0.1uF

C109

0.1uF

C110

0.1uF

C111

0.1uF

C112

0.1uF

C113

0.1uF

C114

0.1uF

C115

0.1uF

C128

0.1uF

C127

0.1uF

C126

0.1uF

C125

0.1uF

C124

0.1uF

C123

0.1uF

C122

0.1uF

C131

0.1uF

C132

10uF/6.3V

C133

0.1uF

C134

10uF/6.3V

L101

9R005Z

L102

9R005Z

C135

0.1uF

C136

10uF/6.3V

L104

9R005Z

C129

0.1uF

C130

10uF/6.3V

L103

9R005Z

C147

0.1uF

C150

10uF/6.3V

L107

9R005Z

L108

9R005Z

C149

0.1uF

C148

10uF/6.3V

C140

0.1uF

C141

10uF/6.3V

L105

9R005Z

L106

9R005Z

C138

0.1uF

C139

10uF/6.3V

C121

0.1uF

C120

0.1uF

C119

0.1uF

C118

0.1uF

C117

0.1uF

C116

0.1uF

C152

OPEN

C153

OPEN

C154

OPEN

C155

OPEN

C156

OPEN

C157

OPEN

C158

OPEN

C159

OPEN

C137

OPEN

R127

47K

R1360R1350R134

0

1234

5678

RN11

33ohm (1005SIZE X 4),1/16W

1234

5678

RN12

33ohm (1005SIZE X 4),1/16W

R137

1K

R142

0

R141

OPEN

C144

0.1uF

C163

0.1uF

C164

10uF/6.3V

L109 9Z014Z

C165

0.1uF

4321

CN11

L114

9R005Z

L113

OPEN

AA

D131

OPEN

AA

D132

OPEN

A A

D133

OPEN

AA

D134

OPEN

AA

D135

OPEN

A A

D136

OPEN

AA

D137

OPEN

A A

D138

OPEN

AA

D121

OPEN

A A

D122

OPEN

AA

D123

OPEN

AA

D124

OPEN

A A

D125

OPEN

AA

D126

OPEN

A A

D127

OPEN

A A

D128

OPEN

AA

D111

OPEN

AA

D112

OPEN

A A

D113

OPEN

AA

D114

OPEN

AA

D115

OPEN

AA

D116

OPEN

AA

D117

OPEN

A A

D118

OPEN

AA

D101

OPEN

A A

D102

OPEN

AA

D103

OPEN

AA

D104

OPEN

AA

D105

OPEN

AA

D106

OPEN

AA

D107

OPEN

A A

D108

OPEN

AA

D148

OPEN

AA

D147

OPEN

AA

D146

OPEN

AA

D145

OPEN

AA

D144

OPEN

AA

D143

OPEN

AA

D142

OPEN

AA

D141

OPEN

R106

47K

AA

D139

OPEN

AA

D140

OPEN

R121

47K

R116

47K

AA

D129

OPEN

AA

D130

OPEN

R111

47K

A A

D119

OPEN

AA

D120

OPEN

AA

D109

OPEN

AA

D110

OPEN

R145

1.8K

R146

1.8K

AA

D150

OPEN

A A

D149

OPEN

C142

OPEN

R133

100

R132

100

C143

OPEN

R124

OPEN

8765

4321

IC14

OPEN

R165

OPEN

R162

OPEN

R163

OPEN

R166

OPEN

R164

OPEN

C180

OPEN

C166

0.22uF

C167

10uF/6.3V

3837 36 35 3433 32 3130 29 2827 26

25

24

23

22

21

20

19181716151413121110987

6

5

4

3

2

1

IC16

EX3AV

C173

22uF

T101

AGND

T102

EAOUT

R167

4.7K

T103

POK

R170

150K

C170

OPEN

L110 OPEN

C168

OPEN

C174

10uF/6.3V

C169

OPEN

C175

0.1uF

C176

10uF/6.3V

C172

0.1uF

C171

10uF/6.3V

R169

39K

R168

68K

R175

OPEN

R176

OPEN

R177

OPEN

R178

OPEN

R174

OPEN

R173

OPEN

R172

OPEN

R171

OPEN

54321

CN12

T104

GND

T105

+8V

R156

10K

R155

10K

R154

10K

R153

10K

R152

10K

R151

10K

R150

10K

R149

10K

R157

0

C178

15n

C179

15p

C181

OPEN

C182

OPEN

R179

OPEN

R180

OPEN

R181

OPEN

3

2

1

D151

OPEN

R182

OPEN

R183

OPEN

R129

4.7K

2

31

OUT

GND

IN

IC15

NJM2845DL133

R184

4.7K

R185

4.7K

R186

4.7K

R187

4.7K

R189

OPEN

R188

OPEN

R190

OPEN

R194

OPEN

R192

OPEN

R191

OPEN

R193

OPEN

R195

OPEN

R196

OPEN

19

1816

1715

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN8B

R197

4.7K

SPI_WP

SPI_HOLD

SPI_HOLD

SPI_WP

D_GND

87654321

A

B

C

D

E

F

SCHEMATIC DIAGRAMS (2/7)

Page 56

56

ANALOG AUDIO SIGNAL LINE

87654321

A

B

C

D

E

F

SCHEMATIC DIAGRAMS (3/7)

d

Page 57

57

VIDEO SIGINAL LINE

COMPONENT (Y) SIGNAL LINE

87654321

A

B

C

D

E

F

SCHEMATIC DIAGRAMS (4/7)

d

Page 58

58

ANALOG AUDIO SIGNAL LINE

DIGITAL AUDIO SIGINAL LINE

87654321

A

B

C

D

E

F

SCHEMATIC DIAGRAMS (5/7)

d

Page 59

59

87654321

A

B

C

D

E

F

SCHEMATIC DIAGRAMS (6/7)

d

Page 60

60

ANALOG AUDIO SIGNAL LINE

87654321

A

B

C

D

E

F

SCHEMATIC DIAGRAMS (7/7)

d

Page 61

WIRING DIAGRAM

61

Page 62

EXPLODED VIEW

C8

C9

C10

C1

C2

C3

C11

C12

C4

C5

C6

C7

C13

C14

C16

S11

X5

S6

X6

S12

X3

S4

S4

S4

X17

S4

S2

S2

S7

S5

X17

S7

X2

X10

S1

X17

S8

X4

S8

X3

S8

S8

AVR1311

AVR1311

AVR391

AVR391

X3

S9

S8

X2

S3

S3

S3

S8

X2

S3

X4

S5

X2

S3

S10

X4

X2

X2

X2

X2

X2

X2

X2

X2

S3

X4

S3

S3

C15

S7

S5

X17

S7

X2

X10

P1

P9

P2

P3

P4

P6

P10

P11

P4

P6

P5

P8

P7

P7

P8

P13

P12

M1

M6

M1

M2

M9

M8

M3

M3

M4

M5

M10

M7

M11

M11

M11

M11

M4

M12

M5

z

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by

the manufacturer.

WARNING:

62

Page 63

PARTS LIST OF EXPLODED VIEW

zParts for which "nsp" is indicated on this table cannot be supplied.

z

P.W.B. ASS'Y for which "nsp" is indicated on this table cannot be supplied. When repairing the P.W.B. ASS'Y, check the board parts table and order replacement parts.

zPart indicated with the mark " ★ " is not illustrated in the exploded view.

zThe parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

1311E2 : Europe model 1311E1C : China model

391E3 : U.S.A. & Canada model 391E3B : Brazil model s 391EA : Australia model

BK : Black model SP : Premium Silver model

Ref.No. Part No. Part Name Remarks Q'ty New

C10' nsp FRONT P.W.B. UNIT ASS'Y COP12291U *

C10 nsp FRONT UNIT

C1 - AUX UNIT

C2 - PHONE UNIT

C3 - VOLUME UNIT

C9 - POWER UNIT

C8 - HEADPHONE UNIT

C13 - REGULATOT UNIT

C5' nsp MAIN P.W.B. UNIT ASS'Y 1311E2 COP12292E *

C5' nsp MAIN P.W.B. UNIT ASS'Y 1311E1C COP12292C *

C5' nsp MAIN P.W.B. UNIT ASS'Y 391E3,391E3B COP12292L *

C5' nsp MAIN P.W.B. UNIT ASS'Y 391EA COP12292N *

C5 - MAIN UNIT

C11 - WIRE SUPPORT UNIT

s

C6 nsp INPUT P.W.B. UNIT ASS'Y 1311E2 COP12293E *

C6 nsp INPUT P.W.B. UNIT ASS'Y 1311E1C COP12293C *

C6 nsp INPUT P.W.B. UNIT ASS'Y 391E3,391E3B COP12293L *

C6 nsp INPUT P.W.B. UNIT ASS'Y 391EA COP12293N *

C7 943189009470D HDMI P.W.B. UNIT ASS'Y COP12294U *

P1 943412009840D VOLUME KNOB BK CBN1A249 1 *

P1 943412009850D VOLUME KNOB SP CBN1A249C73 1 *

P2 963419010060D RCA COVER BK CGR1A510ZB28 1

P2 963419011380D RCA COVER SP CGR1A510YG45 1

P3 943402009680D FRONT PANEL 1311BKE2 CGW1A500B28Z 1 *

P3 943402009690D FRONT PANEL 1311SPE2,1311SPE1C CGW1A500RGG45Z 1 *

P3 943402009670D FRONT PANEL 391BKE3,391BKE3B,391BKEA CGW1A499B28Z 1 *

P4 963411002810S 4KEY BUTTON BK CBT1A1138B28 2

P4 963411002930S 4KEY BUTTON SP CBT1A1138G45 2

P5 963411001410D 3KEYB BUTTON BK CBT1A1139B28Z 1

P5 963411011340D 3KEYB BUTTON SP CBT1A1139G45Z 1

P6 00D9630365002 WINE 3KEY BUTTON BK CBT1A1140B28 2

P6 00D9630365301 WINE 3KEY BUTTON SP CBT1A1140G45 2

P7 nsp FOOT CUSHION CHG2A289 4

P8 943416009700D FOOT CKL2A093 4

P9 943407009710D FL WINDOW CGU1A451Z 1

P10 943411009860D BUTTON STANDBY ASS'Y BK CBT1A1141ZA 1 *

P10 943411009870D BUTTON STANDBY ASS'Y SP CBT1A1141YA 1 *

P11 00D9630137807 STANDBY LENS CGL1A289 1

P12 nsp RUBBER CHG1A113 1

s

s

63

Page 64

Ref.No. Part No. Part Name Remarks Q'ty New

P13 nsp PCB HOLDER CHE170 2

M1 nsp TOP BRACKET CMD1A355 2

M2 nsp BOTTOM CHASSIS CUA4A302 1

M3 nsp PCB BRACKET CMD1A417 2

M4 nsp PCB BRACKET CMD1A774 2

M5 nsp REAR PANEL 1311SPE2,1311BKE2 CKF4A437Z 1 *

M5 nsp REAR PANEL 1311SPE1C CKF3A437Y 1 *

M5 nsp REAR PANEL 391BKE3 CKF1A437Z 1 *

M5 nsp REAR PANEL 391BKEA CKF1A437Y 1 *

M5 nsp REAR PANEL 391BKE3B CKF1A437X 1 *

M6 00D1310158007 DENON BADGE(BLACK049) BK CGB1A140U 1

M6 00D1310158010 DENON BADGE(SILVER052) SP CGB1A140T 1

M7 nsp FIP BRACKET CMD1A572 2

M8 00M07BW257010 TOP CABINET BK CKC2A155K117 1

M8 943403002040M TOP CABINET SP CKC1A155D11 1

M9 nsp HEAT SINK CMY8A161 1

M10 nsp TRANS BRACKET CMD2A675 1

M11 nsp PCB BRACKET CMD1A569 4

M12 nsp PCB BRACKET CMD1A188 1

s

C12 943252010310S POSISTOR ASS'Y (100) CRTDHTS100180W 1

C14 943101009650D POWER TRANS

z

C14 943101009660D POWER TRANS 1311SPE1C CLT5U042ZH 1 *

z

C14 943101009640D POWER TRANS 391BKE3,391BKE3B CLT5U042ZU 1 *

z

C15 nsp CORD BUSHING KHR1A028 1

C16 00MYJ04002640 AC RECEPTACLE(15A/250V,R-301,B21) 1311BKE2,1311SPE2 CJJ8A006ZW

H1 nsp WIRE ASS'Y 2P(100MM) 1311SPE2,1311BKE2 CWZPM5003TW91A 1

★

H2 943606009880D CARD CABLE CWC4C4A13B120B 1 *

★

H3 943606009890D CARD CABLE(Shield,105C)

★

H4 943606009900D CARD CABLE CWC6C4A19B100B10 1 *

★

H5 nsp FERRITE RING CLZ9W003Z 1

★

H6 nsp FERRITE CORE RINGTYPE CLZ9Z004Y 1

★

H7 nsp FERRITE CORE CLZ9Z071Z 1

★

H8 nsp CLAMPER CHR301 7

★

H9 nsp TAPE HEMELON CHS1A032 3

★

H10 606050028012P (7)P FFC(1.0) 606050028012P 1

★

SCREWS

S1 nsp SPECIAL SCREW CHD1A012R 17

S2 nsp SCREW CTWS3+10GR 2

S3 nsp SCREW CTB3+6JR 18

S4 nsp SCREW CTBD3+10JR 23

S5 nsp SCREW

S5 nsp SCREW 391BKE3,391BKE3B,391BKEA CTBD3+8JFZR 17

S6 nsp SCREW BK CTWD4+6FFZR 6

S6 nsp SCREW SP CTWD4+6FFN 6

S7 nsp SCREW CTB3+6FFZR 12

S8 nsp SCREW CTW3+8JR 15

1311SPE2,1311BKE2,

391BKEA

1311BKE2,1311SPE2,

1311SPE1C

CLT5U042ZE 1 *

CWC4C4A23B220B08S

CTBD3+8JFZR 19

s

1*

s

64

Page 65

Ref.No. Part No. Part Name Remarks Q'ty New

S9 nsp SCREW CTW3+12JR 2

S10 nsp SPECIAL SCREW CHD1A023R 4

S11 nsp SCREW BK CTB3+8JFZR 5

S11 nsp SCREW SP CTB3+8JFN 5

S12 nsp SCREW BK CTBD3+8JFZR 3

S12 nsp SCREW SP CTBD3+8JFN 3

65

Page 66

PACKING VIEW (for AVR-1311, 391)

5-1

67

3

8910

1

2

z

5-2

13

12

11

14

PARTS LIST OF PACKING & ACCESSORIES (for AVR-1311, 391)

zParts for which "nsp" is indicated on this table cannot be supplied.

zPart indicated with the mark " ★ " is not illustrated in the exploded view.

zThe parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

14

11

12

13

4

Note: The symbols in the column "Remarks" indicate the following destinations.

1311E2 : Europe model 1311E1C : China model

391E3 : U.S.A. & Canada model 391EA : Australia model

BK : Black model SP : Premium Silver model

Ref.No. Part No. Part Name Remarks Q'ty New

1 nsp POLYSET BAG CPP1A081Z 1

2 90M-ZC000320R POWER CORD 1311SPE2,1311BKE2 CJA2B054Z 1

z

2 90M-YC000790R POWER CORD 1311SPE1C CJA2N047ZA 1

z

2 90M-YC000780R POWER CORD 391BKE3 CJA523FBYA 1

z

2 943611010020S POWER CORD 391BKEA CJA2H116Z 1

z

3 943533009560D SNOW PAD(L) CPS1A880 1 *

4 943533009570D SNOW PAD(R) CPS1A881 1 *

5-1 541110486002D INSTRUCTION MANUAL A 1311SPE2,1311BKE2 CQX1A1538Z 1 *

5-2 541110603005D INSTRUCTION MANUAL B 1311SPE2,1311BKE2 CQX1A1538Y 1 *

5-1 541110488008D INSTRUCTION MANUAL 1311SPE1C CQX1A1540Z 1 *

5-1 541110484006D INSTRUCTION MANUAL 391BKE3 CQX1A1537Z 1 *

5-1 541110489001D INSTRUCTION MANUAL 391BKEA CQX1A1541Z 1 *

6 307010085006D REMOCON TRANSMITER ASS'Y CARTAVR1311 1 *

7 nsp BATTERY (SIZE 'AAA') CABR03PPB 2

66

Page 67

Ref.No. Part No. Part Name Remarks Q'ty New

8 00D9430113403 FM 1 POLE ANT.

8 90M-ZA000230R FM 1 POLANT(UL) 391BKE3 CSA1A019Z 1

9 943116009500S AM LOOP ANT CSA1A032Z 1

10 nsp POLY BAG CPB1061W 1

11 943531009950D OUTCARTON BOX 1311SPE2,1311BKE2 CPG1A924X 1 *

11 943531009960D OUTCARTON BOX 1311SPE1C CPG1A924V 1 *

11 943531009520D OUTCARTON BOX 391BKE3,391BKEA CPG1A924Z 1 *

12 nsp CONTROL LABEL CQB1A993Z 2

13 nsp COLOR LABEL 1311SPE2,1311SPE1C CQB1A 676 2

14 nsp PHOTO LABEL B 391BKE3 CQB1A1010Z 2

1311SPE2,1311BKE2,

1311SPE1C,391BKEA

CSA1A018Z 1

67

Page 68

PACKING VIEW (for DHT-1311XP, 391XP)

3

5-1

67

8910

1

13

z

2

4

14

11

SYS-391HT

5-2

(Refer to page 109,110.)

13

12

PARTS LIST OF PACKING & ACCESSORIES (for DHT-1311XP, 391XP)

zParts for which "nsp" is indicated on this table cannot be supplied.

zPart indicated with the mark " ★ " is not illustrated in the exploded view.

zThe parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

1311E2 : Europe model

391E3 : U.S.A. & Canada model 391E3B : Brazil model s 391EA : Australia model

BK : Black model

Ref.No. Part No. Part Name Remarks Q'ty New

1 nsp POLYSET BAG CPP1A081Z 1

2 90M-ZC000320R POWER CORD 1311BKE2 CJA2B054Z 1

z

2 90M-YC000780R POWER CORD 391BKE3 CJA523FBYA 1

z

2 943611010020S POWER CORD 391BKEA CJA2H116Z 1

z

2 943611011130D POWER CORD 391BKE3B CJA2F118Z 1

z

3 943533009930D SNOW PAD(L) CPS1A882 1 *

s

68

Page 69

Ref.No. Part No. Part Name Remarks Q'ty New

4 943533009940D SNOW PAD(R) CPS1A883 1 *

5-1 541110486002D INSTRUCTION MANUAL A 1311SPE2,1311BKE2 CQX1A1538Z 1 *

5-2 541110603005D INSTRUCTION MANUAL B 1311SPE2,1311BKE2 CQX1A1538Y 1 *

5-1 541110484006D INSTRUCTION MANUAL 391BKE3,391BKE3B CQX1A1537Z 1 *

5-1 541110489001D INSTRUCTION MANUAL 391BKEA CQX1A1541Z 1 *

6 307010085006D REMOCON TRANSMITER ASS'Y CARTAVR1311 1 *

7 nsp BATTERY (SIZE 'AAA') CABR03PPB 2

8 00D9430113403 FM 1 POLE ANT. 1311BKE2,391BKEA CSA1A018Z 1

8 90M-ZA000230R FM 1 POLANT(UL) 391BKE3,391BKE3B CSA1A019Z 1

9 943116009500S AM LOOP ANT CSA1A032Z 1

10 nsp POLY BAG CPB1061W 1

11 943537009980D OUTCARTON BOX CPG1A929 1 *

12 943531009990D OUTCARTON BOX 1311BKE2 CPG1A925X 1 *

12 943531010000D OUTCARTON BOX 391BKE3,391BKE3B,391BKEA CPG1A925Z 1

13 nsp COLOR LABEL CQB1A993Z 2

14 nsp PHOTO LABEL A 391BKE3,391BKE3B CQB1A1000Z 2

*

s

s

s

s

69

Page 70

SEMICONDUCTORS

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC's

R2A15218FP (INPUT :IC61)

FLIN2

DATA

CLOCK

DGND

SUBR

SUBL

SBLCIN

FRIN2

SBRCIN

50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31

SRIN2

SLIN2

SWIN2

CIN2

SBRIN2

SBLIN2

N.C.

TRER

BASSR2

N.C.

BASSR1

MUTE

AVEE

N.C.

ADCL

ADCR

AGND

N.C.

INR1

INL1

INR2

INL2

INR3

INL3

INR4

INL4

INR5

INL5

INR6

INL6

INR7

INL7

INR8

INL8

N.C.

INRA/RECR1

INLA/RECL1

N.C.

INR9

INL9

N.C.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

AVEE

0/-6/-12/-18dB

ATT

MAIN

MCU

I/F

SUB

REC

SUB

AVCC

-f

-f

Bass/ Treble

-14~+14dB

(2dB step)

Tone

Tone

Bass/ Treble

-14~+14dB

(2dB step)

Bypass

Tone+MIX

Tone+MIX

Bypass

+42~-95dB,

-f(0.5dBstep)

+42~-95dB,

-f(0.5dBstep)

+42~-95dB,

-f(0.5dBstep)

+42~-95dB,

-f(0.5dBstep)

+42~-95dB,

-f(0.5dBstep)

+42~-95dB,

-f(0.5dBstep)

Tone

Tone

+42~0dB

(0.5dBstep)

+42~0dB

(0.5dBstep)

CMIX

SWMIX

0~-95dB,

(0.5dBstep)

MAIN

MAIN

0~-95dB,

(0.5dBstep)

SUB

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

AVCC

N.C.

TREL