Page 1

O-ADC DEMA

SANITIZER PUMP

Overview

The O-ADC is an auxiliary 24 VDC powered pump designed to be used in conjunction with the

Nitro and Nitro Express Ware Wash Dispensers. The O-ADC has convenient female spade

connectors to connect to the control boards of these units. It comes with 10 feet of wire so that

the pump can be mounted close to the sanitizer injection point.

Warnings

Installation of DEMA products must meet all applicable electrical codes and

regulations established by national, city, county, parish, provincial or other

agencies. It is possible that electrical codes and regulations require that a certified

electrical contract or or engineer perform the electrical installat ion. For questions,

contact a certified electrician.

ALL ELECTRICAL POWER MUST BE TURNED OFF TO THE

DISPENSER AND TO THE APPLIED MACHINE.

All installations must conform to local plumbing codes and use approved

backflow prevention devices. A pressure indicating tee is to be installed with

existing faucets acco rd ing to loca l plumbing codes in the state of Wisconsin and

any other state that requires the use of a pressure indicting tee.

ALWAYS WEAR PROTECTIVE CLOTHING AND EYEWEAR WHEN

WORKING WITH CHEMICAL PRODUCTS.

I-969 Page 1 of 4

Rev. A-35763 6/10/10

Page 2

Specifications

Packing List

Part Number Description

81.290.1 0-ADC PUMP L/ACC

904.8KY RINSE CHECK VALVE ¼” COMP X 1/8” NPT KYNAR

30.41 SCREW AND ANCHOR KIT

81.312.2 SPLIT PICK UP TUBE STIFFENER

100.12.SV1 VINYL RINSE TUBING (16’)

81.16.3 TIE WRAPS 8” LONG (4)

81.183.5 STRAIN RELIEF

I969 INST. SHEET

Operational Requirements

Main Power 24 VDC

Enclosure Mater ial ABS

Environmental Temp. 0-40°C 32-104°F

Produ ct Weight .45 kg 1.0 lbs

The integrity and operational characteristics of this unit are not guaranteed outside the above

mentioned parameters. Use of this unit outside of these parameters nullifies warranty.

Size

For indoor use only

Other Replacement Kits of Interest

KIT NO. DESCRIPTION

81.316.1

81.316.2 CONTROL BOARD NITRO EXPRESS FOR 2 PRODUCT (DETERGENT/RINSE)

81.316.3 CONTROL BOARD NITRO EXPRESS WITH SANITIZER (3 PRODUCT)

81.316.4 NITRO/NITRO EXPRESS DETERGENT PUMP CONVERSION OR REPLACEMENT KIT

81.316.10 NITRO/NITRO EXPRESS DETERGENT MOTOR ONLY REPLACEMENT KIT

81.316.6 NITRO/NITRO EXPRESS DETERGENT VALVE CONVERSION AND REPLACEMENT KIT

81.316.5 NITRO/NITRO EXPRESS RINSE PUMP REPLACEMENT KIT

81.316.11 NITRO/NITRO EXPRESS RINSE MOTOR ONLY REPLACEMENT KIT

81.316.7 NITRO/NITRO EXPRESS DETERGENT PUMP ONLY REPLACEMENT KIT

81.316.8 NITRO/NITRO EXPRESS RINSE PUMP ONLY REPLACEMENT KIT

L1115

81.223.1

NITRO/NITRO EXPRESS POWER SUPPLY REPLACEMENT KIT

MEMBRANE LABEL

MOUNTING BRACKET

I-969 Page 2 of 4

Rev. A-35763 6/10/10

Page 3

Installation

WARNING: INSTALLATION OF DEMA PRODUCTS MUST MEET ALL APPLICABLE

ELECTRICAL CODES AND REGULATIONS ESTABLISHED BY NATIONAL, CITY,

COUNTY, PARISH, PROVINCIAL OR OTHER AGENCIES. IT IS POSSIBLE THAT

ELECTRICAL CODES AND REGULATIONS REQUIRE THAT A CERTIFIED

ELECTRICAL CONTRACTOR OR ENGINEER PERFORM THE ELECTRICAL

INSTALLATION. FOR QUESTIO NS, CONTACT A CERTIFIED ELECT RICIAN.

ALL ELECTRICAL POWER MUST BE TURNED OFF TO THE HEATING ELEMENTS AND DISH

MACHINE PRIOR TO BEGINNING INSTALLATION

Mounting the Pump

1. Remove mounting bracket from the pump.

2. Mount the bracket in an appropriate place on a wall.

3. Slide the pump onto the bracket.

Connecting the Chemical Tubing t o the Pump

1. After mounting the pu mp, measure the length of tubing needed to go from the pump to the chemical

containers. The sanitizer tubing (100.12.SV1) is clear in color and has a small inside diameter.

2. Cut the tubing to the length required and, if desired, place the pickup tube on the tubing before placing in

the ch emical conta iner.

3. Measure the len gth of tubing needed t o go from the pump to the chemical injection point on the machine.

4. Cut the tubing to the length required to reach the chemical injection point on the machine.

Setting up the Pump and the Nitro/Nitr o Expre ss

1. Remove one of the hole plugs from th e bottom of th e Nitro or Nitro Express.

2. Run the wiring from the pump through the hole and use the strain reli ef in the pa ckagin g kit of the unit to

hold the wire in place in the unit. Make s ure enough wire is in the unit to hook the pump to the control

board.

3. There is a dedicated place to connect the pump to the control board. Use the two female quick conn ects to

conn ect to the spad e connecti ons labeled sanitizer. The black wi re shoul d be connected on the left or

negative terminal and the red should be connected on the right or positive terminal.

4. For programming and setup, please refer to the instruction sheets for the Nitro Express (I974) or the Nitro

(I980).

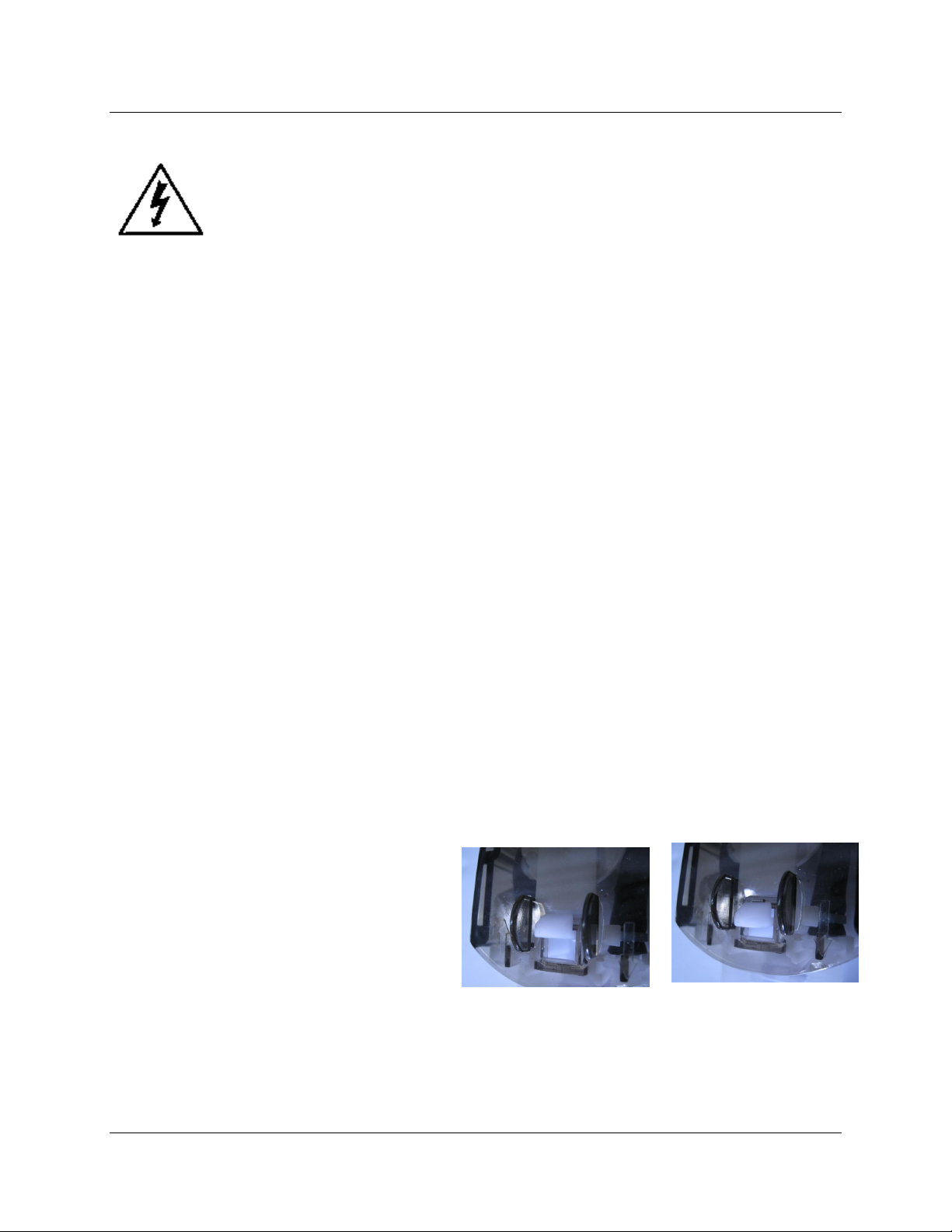

Clasp Close Pump Heads

The pump heads have an added feature which will

help to ensure the pump head is installed properly.

When pushing the pump head on be sure to see the

clip is fully covering the notch as seen in the first

picture. If the tab is not fully engaged, there is a

possibility of it popping off the pump head as se en in

the secon d pictur e.

I-969 Page 3 of 4

Rev. A-35763 6/10/10

Page 4

Troubleshooting

Symptom Probable Cause Remedy

No power is being supplied

to the unit

Pumps are not priming like

they should be or not

holding a prime

Rinse/Sanitizer pump not

running

1. Power is not cycling on the machine

properly.

1. Hole in the tubing from the chemical

container to the pump head.

2. Hole in the squeeze tube in the p ump

head.

3. Fitting is not tight on the tubing

1. Speed turned off. 1. Check the program ming to see th e speed sett ing

1. Check with the di sh machine manufacturer if all

power should have been restored to the unit to see

if there is an issue with the machine.

1. Check the tubin g from the chemical container to

the pump head for leak s by feel ing the tubing for

chemical that has leaked out. Replace the tube if

necessary.

2. Replace the squeeze tube aft er inspecting it for a

possible hole or leak.

3. Check both the inlet and outlet fitting and tighten if

necessary to create a good sea l.

and make sure it is on the proper setting.

Warranty

Merchandise Returns

No Merchandise will be Ret urned for Credit Without DEMA’S Written Permissi on. Re turned

Merchandise Authorization Number is Required in Advance of Return.

Product Warranty

DEMA products are warranted against defective material and workmanship under normal use and service

for one year from the date of manufacture. This limited warranty does not apply to any products that have

a norma l life shorter than one year or failure and damage caused by chem icals, corr osion, physical abuse,

or misapplication. Rubber and synthetic rubber parts such as “o”-rings, diaphragms, PVC tubing, and

gaskets are considered expendable and are not covered under warranty. This warranty is extended only to

the original buyer of DEMA pr oducts . If pr oducts are alter ed or repaired withou t prior approval of DEMA,

this warranty is void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection shows

them t o be de fect ive, th ey wil l be rep aired or r epla ced with out ch ar ge, F. O. B. fact or y. DEMA assum es n o

lia bility for dam ages. Retu rn merchan dise auth orization n umber mu st be grant ed in advan ce of return ed

unit s for repair or replacement (See “Merchandise Return s” above).

I-969 Page 4 of 4

Rev. A-35763 6/10/10

Loading...

Loading...