DEMA Chemaster DM-813-PLLL-1T, Chemaster DM-813-PDLL-2T, Chemaster DM-813-PLLL-2T, Chemaster DM-813-PDLL-1T Installation Instructions Manual

DEMA 813 PROBELESS DEMAMaster

INSTALLATION INSTRUCTIONS

TM

I-729 Pg 1 of 15

Rev D 11/01

Models:

DM-813-PLLL-1T

DM-813-PDLL-1T

DM-813-PLLL-2T

DM-813-PDLL-2T

System Overview

The DEMA DEMAMaster probeless series is designed for long reliable use with simplicity in mind for both

the installer and user. The system is based on the reliable DEMA peristaltic pump. The pumps are installed

in a heavy plastic housing with a sealed cover that uses a Lexan label with visible function indicators.

Pumps are available with three different motor/gear box speeds, 15, 60, and 105 RPM.

There are micro controllers housed in the unit that control the operation of the pumps. The detergent pump

is controlled by a set of DIP switches that can be arranged to supply a selected amount of detergent based on

door counts or time depending on the application. The rinse aid is set by a potentiometer that controls the

speed of pump and can be delayed up to 12 seconds. In addition, the probeless detergent board has the

ability to keep track of time and deliver a new initial charge when in the door mode.

The DEMAMaster is supplied with a transformer mounted in housing that allows primary voltage hook up of

120, 208 or 240 at 50/60Hz.

Please read all instructions before proceeding with the DEMAMaster installation.

Dishroom Room Survey

A complete survey of the dish machine sight should be completed before the DEMAMaster installation.

1. Locate the power connection points on the dish machine. This power must be 120, 208 or 240 volts

50/60Hz.

Note: When installing a DEMAMaster probeless on a door operated dish machine, keep in

mind that the detergent control will need to recognize door openings based on power

“on” and “off” to the DEMAMaster. In addition, all installations will require that the

rinse control recognize the dish machine rinse cycle.

2. Select location to mount the DEMAMaster on a wall that will allow access to the chemical product

containers and the chemical product feeds points on the dish machine. The DEMAMaster should be

kept away from moisture releasing machinery and from water being splashed directly on the unit.

3. Mount the DEMAMaster on a wall by use of the supplied hanger. Use appropriate wall anchors

when mounting on dry wall.

I-729 Pg 2 of 15

Rev D 11/01

Electrical Installation

1. BEFORE GOING ANY FURTHER, ALL ELECTRICAL POWER MUST BE TURNED OFF TO

2. Connect the power to the DEMAMaster. The DEMAMaster will accept 120VAC, 208VAC or

This product is designed only to be used as described in this instruction sheet. Adhere to all warnings an d

cautions identified in this document.

WARNING: Electrical and grounding installation of DEMA products must comply with

electrical codes and regulations established by national, city, county, parish, provincial or

other agencies. It is possible that electrical codes and regulations require that a certified

electrical contractor or engineer perform the electrical installation.

For questions, contact a certified electrician.

DISCONNECT ALL ELECTRICAL POWER TO THE DISPENSER AND THE APPLIED

MACHINE WHEN SERVICING- FOLLOW LOCKOUT / TAGOUT PROCEDURES.

WARNING: Installations must conform to all local and national plumbing codes and use

approved backflow prevention and pressure relief devices where required.

ALWAYS DISCONNECT DISPENSER FROM WATER SOURCE WHEN DISPENSER

IS NOT IN USE.

Always read SDS for all chemicals used and follow personal protective guidelines.

THE DISH MACHINE AND ANY OTHER CIRCUIT THAT IS TO BE USED FOR THIS

INSTALLATION. LOCKOUT AND TAG PROCEDURES SHOULD BE OBSERVED WHEN

INSTALLING THIS DEVICE. NEVER OPEN THE DEMAMASTER UNLESS POWER HAS

BEEN TURNED OFF. SIGNALS MAY BE PRESENT FROM DISH MACHINE, EVEN WITH

THE POWER TURNED OFF. ONLY USE ELECTRICAL CODE APPROVED INSULATED

WIRING AND ELECTRICAL FIXTURES WITH THIS INSTALLATION.

Note: The DEMAMaster is equipped with 1 or 2 transformers depending on the model. If

there are 2 transformers, the detergent control will be powered by one while the rinse

aid control, will be powered by the other.

If the DEMAMaster is equipped with 1 transformer, both the detergent and rinse

control, will be powered by the same transformer. In this case it will be necessary to

wire the unit so that the rinse aid control will only run during the rinse cycle. This can

be done via a pressure switch, which should be wired to the DEMAMaster terminal

block connections labeled “pressure switch”.

240VAC 50/60Hz. The detergent control is normally wired to something that is common to the

pump operation, thus signaling a wash cycle. The rinse control is normally wired to something that is

common to the rinse solenoid valve, thus signaling a rinse cycle. Some dish machines may have a

terminal block setup for power for both detergent and rinse, see schematic or owners manual of the

dish machine to determine if this option is available.

I-729 Pg 3 of 15

Rev D 11/01

3. Locate the power terminal block inside the DEMAMaster enclosure. There will be 2 when there are

2 transformers. Connect “hot” or “live” wire to the terminal labeled “line”. Connect the “return

line” to the appropriate terminal block position based on supply voltage. The “earth ground” wire

must be connected to the terminal block by use of the grounding clip (supplied in installation kit).

The power line should be secured by use of a proper electrical fitting through access hole in

DEMAMaster enclosure. The power line must also be secured properly between the dish machine or

power source and DEMAMaster.

Note: When wiring is completed the DEMAMaster should feed detergent based on door counts or

time depending on type of machine (door or conveyor). The rinse aid should feed only during the

rinse cycle. It may be necessary to use a pressure switch to signal the rinse aid feed. Evaluate the

application for requirements to assure proper operation.

I-729 Pg 4 of 15

Rev D 11/01

80-77-1

CONTROL BOARD

PROBLESS DETERGENT

X20753-7 (81-32-7) VALVE

(SEE DRAWING FOR PART NO.)

24VDC OUT

BLACK

RED

X20753-2 (81-32-2) MOTOR

MOTOR OR

VALVE

SOLENOID

RINSE CONTROL BOARD

80-69-6

24VDC RINSE OUT

24VDC SANI OUT

24VAC OUT

24VAC IN

X20753-2

(81-32-2)

(SEE DRAWING FOR PART NO.)

X20753-1 (81-32-1) MOTOR

X20753-6 (81-32-6) VALVE

20758-1 (81-35) FUSE HOLDER

MOTOR

25457-16 (81-34-16) FUSE

ORANGE

ORANGE

TRANSFORMER

40 VA

80-70

(81-36-2)

DETERGENT

20759-2

X20753-1

(81-32-1)

SANI

24VAC IN

UNUSED

+

++

BLACK

RED

X20753-1

(81-32-1)

BLACK

ORANGE

X20753-2

(81-36-2)

20759-2

(81-32-2)

FOR PART NO.)

ORANGE

(SEE DRAWING

TRANSFORMER

80-70

25457-16 (81-34-16) FUSE

20758-1 (81-35) FUSE HOLDER

RED

MOTOR

RINSE

40 VA

FUSE

1A. 250V

RED

BLUE

RED

(SEE DRAWING FOR PART NO.)

TERMINAL BLOCK &

BRACKET ASSY.

240VAC RETURN

208VAC RETURN

120VAC RETURN

BLACK

WHITE

(SEE DRAWING FOR PART NO.)

TERMINAL BLOCK &

BRACKET ASSY.

LINE

240VAC RETURN

BLUE

208VAC RETURN

FUSE

1A. 250V

BLACK

WHITE

LINE

120VAC RETURN

I-729 Pg 5 of 15

Rev D 11/01

PROBLESS DETERGENT

CONTROL BOARD

80-77-1

80-69-6

RINSE CONTROL BOARD

24VDC SANI OUT

24VDC RINSE OUT

X20753-2 (81-32-2) MOTOR

X20753-7 (81-32-7) VALVE

24VDC OUT

+

RED

X20753-1 (81-32-1) MOTOR

X20753-6 (81-32-6) VALVE

BLACK

(81-94-2)

24VAC IN

24VAC OUT

20774-2

(81-94-1)

24VAC IN

+

RED

(81-32-2)

X20753-2

(81-32-1)

X20753-1

+

BLACK

RED

BLACK

ORANGE

ORANGE

UNUSED

20774-1

(81-94-1)

ORANGE

(SEE DRAWING FOR PART NO.)

MOTOR

SANI

TRANSFORMER

40 VA

80-70

(81-32-1)

X20753-1

20774-1

(81-32-2)

X20753-2

(81-36-2)

20759-2

25457-16 (81-34-16) FUSE

20758-1 (81-35) FUSE HOLDER

(SEE DRAWING FOR PART NO.)

MOTOR OR

VALVE

SOLENOID

DETERGENT

ORANGE

2

SWITCH

I-729 Pg 6 of 15

Rev D 11/01

ORANGE

1

PRESSURE

RED

240VAC RETURN

BLUE

208VAC RETURN

120VAC RETURN

WHITE

FUSE

1A. 250V

BLACK

(SEE DRAWING FOR PART NO.)

LINE

BRACKET ASSY.

TERMINAL BLOCK &

(SEE DRAWING FOR PART NO.)

MOTOR

RINSE

Tubing Connections

Included in the installation kit is a roll of low-density polyethylene (LDPE) tubing that can be used to

connect from the chemical container, to the pump, and from the pump to the injection fittings on the

machine.

Measure the length of the tubing needed on the suction side from the chemical container to the pump and cut

the tubing to proper length. Install the tubing into the pickup tubes (Grey PVC) through the compression nut,

and tighten the nut. Route the tubing to the suction side of the pump. An arrow on the faceplate indicates

the flow direction. Push the tubing into the pump squeeze tube approximately1/2-3/4”(15-20mm). Secure

the tubing with a tie wrap around the squeeze tube. Use the same procedure on the outlet of the squeeze

tubing and route the LDPE tubing to the injection point of the machine. Cut off all excess tubing and keep

tubing away from hot surfaces and sharp edges to prevent damage or leakage.

See Detergent and Rinse Tubing Connections below for specific information concerning discharge tube

connection.

Detergent Tubing Connections

Included with the kit is a bulkhead fitting that will accept the discharge of the detergent at the machine.

There are two fittings depending on the model. If the DEMAMaster has a detergent pump, then the fitting

will have a ¼” compression fitting that will accept the ¼” LDPE pump discharge tubing. It the unit has a

solenoid valve then the fitting will have a barb fitting designed for a 5/8” I.D. tube. A 7/8” diameter hole

will need to be cut above the waterline in the side of the dish machine wash tank to accommodate the

bulkhead fitting. The bulkhead fitting should not be located above the concentration probe.

When using the detergent pump simply run the tubing from the outlet of the pump to the ¼” compression

fitting on the bulkhead fitting.

When using the solenoid valve run the ¼” LDPE tubing from the ¼” compression fitting on the outlet of the

valve to the siphon breaker for the solid bowl or powder feeder.

Rinse Tubing Connections

Note: A check valve is included in the installation kit. The procedure below describes the installation of this

check valve. Other hardware may be needed to complete the installation properly.

Install ¼” compression by 1/8” NPT rinse injection check valve into the rinse input water between the

vacuum breaker and the final rinse arm. Drill an 11/32” hole and tap to 1/8” NPT. When installing to

copper pipe or tubing use saddle clamps.

Connect the ¼” OD poly tubing between the ¼” rinse check valve and the discharge side of the peristaltic

rinse squeeze tubing. Use a plastic tie to hold the ¼” polypropylene tubing into the peristaltic squeeze tube.

Detergent and Rinse Calibration

Detergent

Prior to calibration the system must be primed. The system is primed when the chemical is dispensing from

the injection point into the dish machine tank. This can only be done while power is being supplied to the

probeless detergent board. By pressing the button on the front cover labeled “detergent prime” the pump

will run. Simply press and hold until the pump and tubing has been primed.

Note: If Detergent Prime button is held less than 5 seconds, the pump will run for the amount time

that has been set for initial charge or until button is pushed again.

I-729 Pg 7 of 15

Rev D 11/01

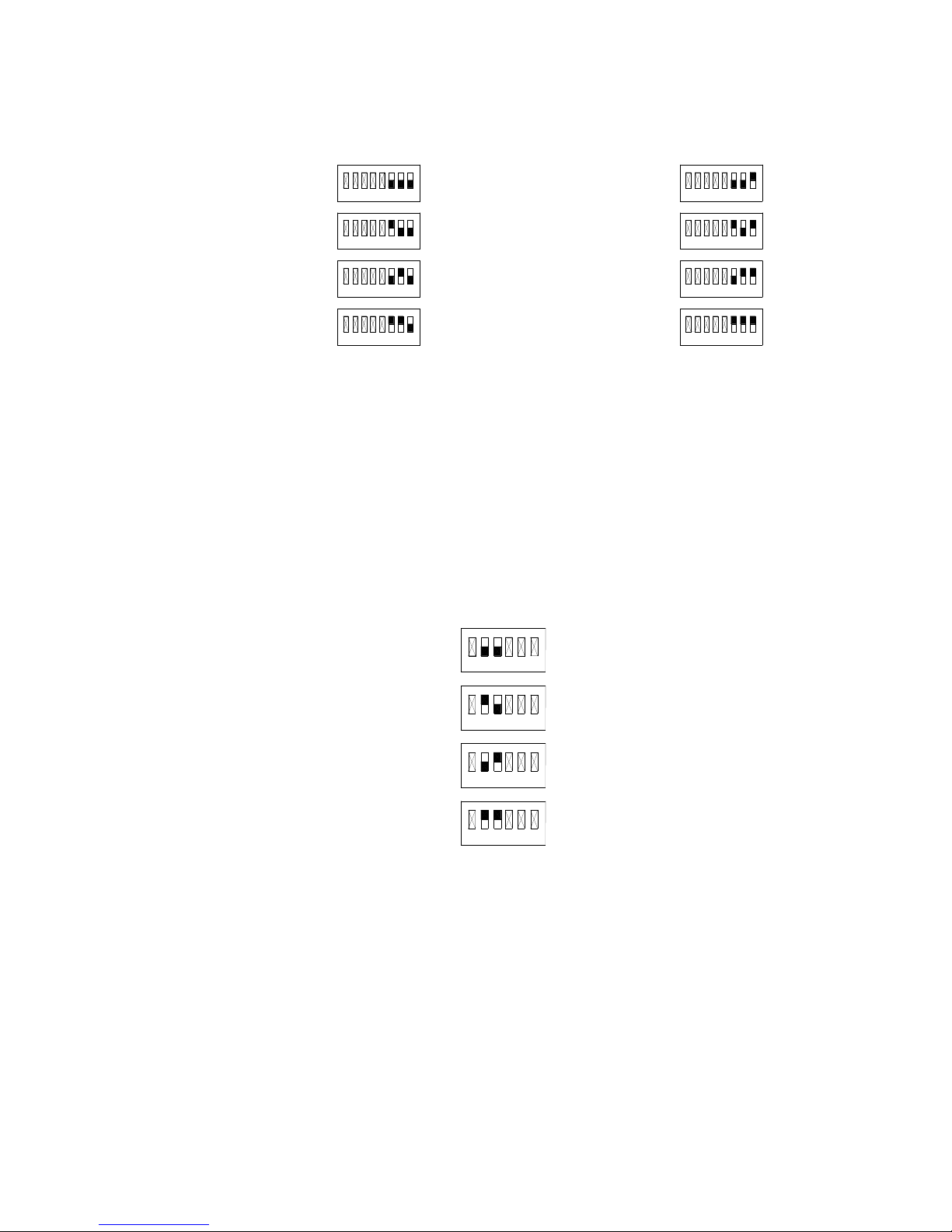

The detergent set up involves the use of the DIP switches on the pro-bless detergent control board. There are

a bank of 6 and a bank of 8 switches located directly on the control board. The detergent concentration

should be setup so that the desired level of concentration is maintained while the dish machine is being used.

The concentration can be tested by use of a titration test kit (DEMA P/N 81-53), not included.

1. Door or Conveyor mode: 6 DIP Switch Bank, Switch 1

12345 6 421 356

2. Initial Charge Time: Sets the amount of Initial Charge based on time. See table below for the P switch

configuration.

0

5 SEC

10 SEC

15 SEC

20 SEC

25 SEC

30 SEC

35 SEC

213

213

213

213

321

213

213

213

4

4

4

4

4

4

4

4

56

56

56

56

5

6

567

567

56

7

8

7

8

7

8

7

8

7

8

8

8

7

8

1 MIN

1 MIN 5 SEC

1 MIN 10 SEC

1 MIN 15 SEC

1 MIN 20 SEC

1 MIN 25 SEC

1 MIN 30 SEC

1 MIN 35 SEC

1234576

1234

2143

56

1234 765

54321

1234 765

1234

1234

1 MIN 50 SEC

8

8

8

8

8

8

8

8

1 MIN 55 SEC

2 MIN

2 MIN 5 SEC

2 MIN 10 SEC

2 MIN 15 SEC

2 MIN 20 SEC

2 MIN 25 SEC

65

7

7

6

7

756

65

7

1234

1234

1234

1234

1234

21

1234

4321

586

56

56

56

576

567

43

5687

56

7

7

8

7

8

7

8

8

8

7

8

40 SEC

45 SEC

50 SEC

55 SEC

321

123

213

213

I-729 Pg 8 of 15

Rev D 11/01

4

4

4

4

5

6

576

56

5687

7

8

8

7

8

1 MIN 40 SEC

1 MIN 45 SEC

1234576

5123476

8

8

2 MIN 30 SEC

2 MIN 35 SEC

1234

576

54321

8

6

7

8

3A. Dead Cycle Count – Door Mode Only

Sets the amount of wash cycles (door operations) that will take place before a recharge will occur.

See table below for DIP switch configuration. Example: If the Dead Cycle Count is set to 3, there

will be three wash cycles where no detergent will be added. On the 4

th

cycle a recharge will occur.

0 CYCLES

1 CYCLE

2 CYCLES

3 CYCLES

614325

652341

652341

6

14325

3B. Dwell Time Setting – Conveyor Mode Only

Sets the amount of time between a charge and a recharge and recharges. See table below for DIP

switch configuration. Example: Dwell Time is set for 1 min 30 sec. After the probeless control

supplies an initial charge or a recharge, 1 minute and 30 seconds must expire before the next

recharge will occur.

0

15 SEC

30 SEC

2143

123 4

65

56

4123

65

3 MIN

3 MIN 15 SEC

3 MIN 30 SEC

4 CYCLES

5 CYCLES

6 CYCLES

7 CYCLES

123

132

132

652341

1

6

4325

6

1423 5

61423 5

645

654

654

5 MIN 30 SEC

5 MIN 45 SEC

6 MIN

321456

3

12

3

21

456

564

45 SEC

1 MIN

1 MIN 15 SEC

1 MIN 30 SEC

1 MIN 45 SEC

2 MIN

2 MIN 15 SEC

2 MIN 30 SEC

2 MIN 45 SEC

312 4

123 4

2143

123 4

1324

123 4

2143

123 4

312 4

56

56

56

56

56

56

3 MIN 45 SEC

4 MIN

65

4 MIN 15 SEC

4 MIN 30 SEC

65

4 MIN 45 SEC

5 MIN

65

5 MIN 15 SEC

123

3

12

3

21

312

3

31221546

645

546

456

564

654231

456

6 MIN 15 SEC

6 MIN 30 SEC

6 MIN 45 SEC

7 MIN

7 MIN 15 SEC

7 MIN 30 SEC

7 MIN 45 SEC

12

12

312

546

3

21

456

321

546

3

21

456

546

3

3

546

321

456

I-729 Pg 9 of 15

Rev D 11/01

4. Recharge Time: Sets the amount of recharge based on time. See table below for DIP switch

configuration.

1 SEC

2 SEC

3 SEC

4 SEC

5. Initial Charge Clock

This feature is adjustable as shown below while in door mode only. When the unit is in the

conveyor mode the initial charge clock defaults to 1 hour.

This feature is used to provide an initial charge after a set amount of time expired without

using the DEMAMaster. See the table below for the DIP switch configuration. Example:

Initial Charge Clock is set for 2 hours. If no power has been supplied to the probeless control

for at least 2 hours, the pro-bless control will provide an initial charge the next time power is

supplied.

421356

7

8

1

5432

786

6

54321

7

8

5123476

8

5 SEC

6 SEC

7 SEC

8 SEC

1

234

1234

54321

6

7

8

5

76

8

5

6

7

8

54321

6

7

8

15 MIN

2 HOURS

3 HOURS

4 HOURS

421356

65312 4

65312 4

65312 4

Note: The DEMAMaster probeless board is designed with a 5 second delay when powered up. This

means that the detergent pump or valve will not operate until continuous power is supplied to

the board for at least 5 seconds.

I-729 Pg 10 of 15

Rev D 11/01

Rinse Aid Calibration

Prior to calibration the system must be primed. The system is primed when the chemical has filled the

tubing up to the injection point. On the rinse side this can only be done during the time the rinse solenoid is

active. On the front cover there is a button called prime. By depressing this, the pump will run at maximum

speed. This may have to be done several times to ensure the chemical has filled up the entire tubing system.

1. Put the pick up tube into a measuring cylinder and fill with chemical to an easily read level.

2. Set the pump speed according to the chemical manufacturer’s recommendations e.g. (2 oz/10

seconds). Calculation = 2oz x 6= 12oz/min. 12 oz divided by the capacity of the pump per

revolution (1.5)=8 revolutions per minute or 8/6=1.4 revolutions per 10 seconds (the rinse cycle).

3. Check level again and fill to mark if necessary and let pump run for at least five cycles and check

the amount being injected. This will automatically compensate for back pressure, (pressure loss in

tubing and etc.).

4. At this point the system is ready for operation.

5. The rinse delay may be set, by adjusting the potentiometer labeled “rinse delay” on the rinse

board. A 0-12 second delay may be set.

6. There are 18 seconds of rinse limit available when the “rinse limit” jumper is in the on position.

When the jumper is in the off position, there is no rinse limit. This means that the rinse pump

will run through the entire rinse cycle, when jumper is in the off position.

Sanitizer Calibration

Prior to calibration the system must be primed. The system is primed when the chemical has filled the

tubing up to the injection point. On the rinse side this can only be done during the time the rinse solenoid is

active. On the front cover there is a button labeled “Sani Prime”. By depressing this, the pump will run at

maximum speed. This may have to be done several times to ensure the chemical has filled up the entire

tubing system.

1. Put the pick up tube into a measuring cylinder and fill with chemical to an easily read level.

2. Set the pump speed according to the chemical manufacturer’s recommendations e.g. (2 oz/10

seconds). Calculation = 2oz x 6= 12oz/min. 12 oz divided by the capacity of the pump per

revolution (1.5)=8 revolutions per minute or 8/6=1.4 revolutions per 10 seconds (the rinse cycle).

3. Check level again and fill to mark if necessary and let pump run for at least five cycles and check

the amount being injected. This will automatically compensate for back pressure, (pressure loss in

tubing and etc.).

4. At this point the system is ready for operation.

DEMAMaster Operation

The user of the DEMAMaster only needs to perform the following:

- Monitor the level of the detergent and rinse aid products.

- When changing the detergent or rinse aid products, prime the pump by pressing and holding the

“Detergent Prime” or “Rinse Prime” button until the pump and lines or primed.

- If dish machine tank is emptied and refilled, an initial charge can be delivered by pressing the

“Detergent Prime” button for less than 5 seconds.

- The clock will deliver an initial charge if the unit is not powered up for the amount of time that

has been programmed into the initial charge clock. Example: The dish machine is turned off at

the end of a shift, at the start of a next shift the DEMAMaster will deliver an initial charge when

powered up, providing that the initial charge clock has expired.

I-729 Pg 11 of 15

Rev D 11/01

30

28

29

OPTIONAL SOLENOID VALVE

31 32 33

14

34

35

13

1

14

34

5

7

(DETERGENT UNITS WITH 2 TRANSFORMERS)

6

(UNITS WITH 1 TRANSFORMER)

8

9

9

3

2

21

(FOR 812 MODELS)

(FOR 813 MODELS)

16

17

18

I-729 Pg 12 of 15

Rev D 11/01

15

20

19

18

24

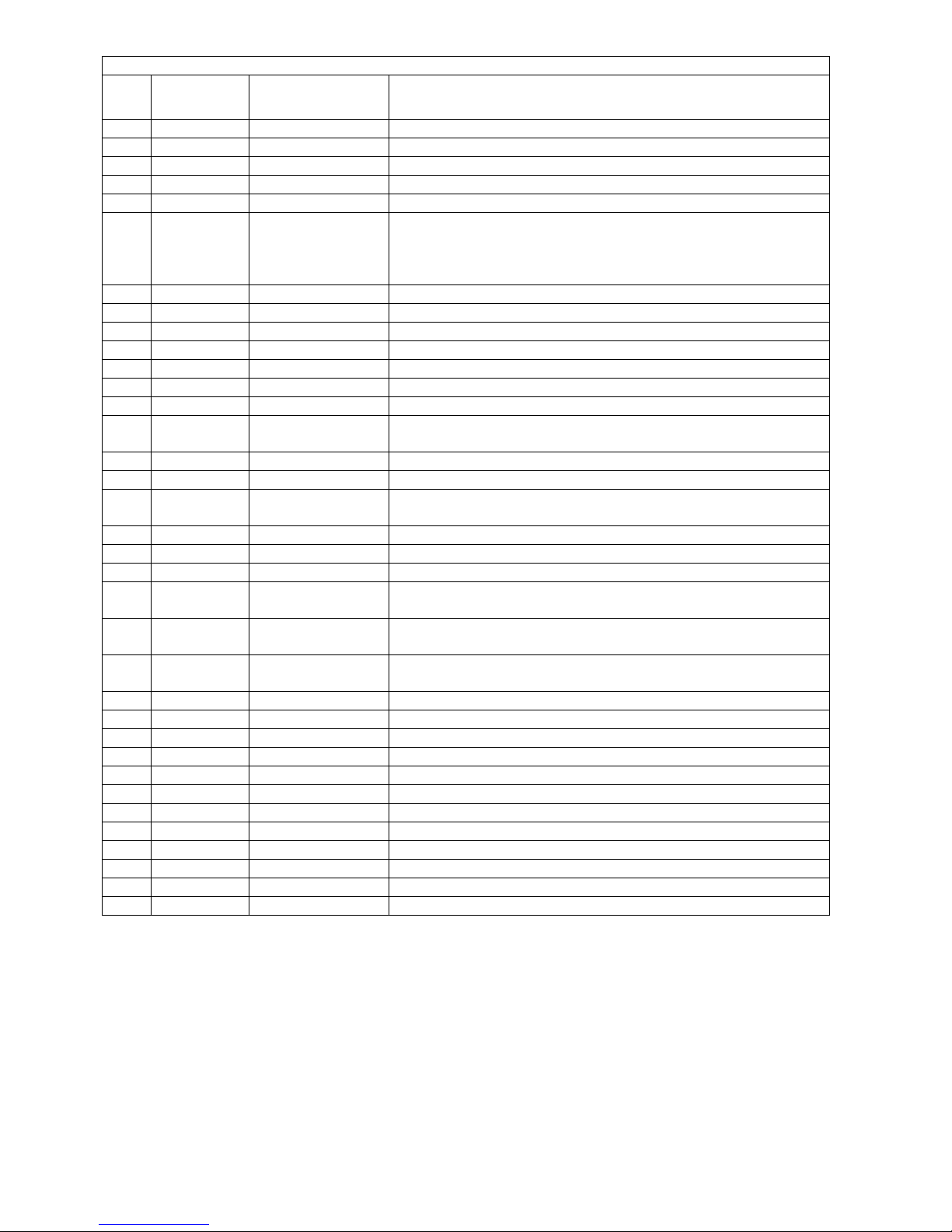

Replacement Parts

Item

DEMA Part

No.

1 81-2 1 DEMAMaster Double Control Box

2 81-5 1 DEMAMaster Double Control Box Lid

3 81-6 1 Hinge and Screw Kit

4 81-1 1 Mounting Bracket Kit

5 80-70 1 Transformer 40VA

6 81-10-1

7 81-10-2 1 Terminal Block & Bracket Assy. (Rinse, units with 2 transformers)

8 81-10-5 1 Terminal Block & Bracket Assy. (units with 1 transformer)

9 44-116-1 2 / Transformer # 8 x ½ HI-LO Screw (mounting transformer)

10 81-35 1 / Transformer Fuse Holder

11 81-34-16 1 / Transformer Fuse 1A, 250V

12 81-36-2 1 / Transformer Blue Wire Nut

13 80-59-60 1 60 RPM Gear/motor

14 80-59-15

15 80-77-1 1 Pro-bless Detergent Control (circuit board for controlling detergent)

16 80-69-5 1 (for 812 Models) Rinse Control Board (circuit board for controlling rinse)

17 80-69-6 1 (for 813 Models)

18 81-20-2 3 / control board # 4 HI-LO Screw (mounting circuit boards)

19 80-99 1 Coin Cell Battery (CR2032)

20 81-13-6 1 Modular Connector 6 pole (for Pro-bless Detergent Control Board)

21 81-13-8 1

22 81-94-1

23 81-94-2

24 81-29-2 2 Captive Screw

25 81-47-1 1 Hole Plug

26 L604 1 Caution Label – Electrical

27 L605 1 Caution Label - Chemical

28 44-125 1 Solenoid Cover

29 44-116-1 1 Cover Screw

30 44-123-4 1 Solenoid Valve-Detergent (Dry Feed Models)

31 44-124-2 2 Solenoid Mounting Screw

32 44-29 2 Lock Washer

33 44-90 2 Hex Nut

34 25-65RE-11 2 Squeeze Tube - Rinse

35 25-65CE-11 1 Squeeze Tube - Detergent

No.

Qty Required Description

1-Qty Model No.

ends 1T

2 Qty Model No.

ends 2T

1 / Rinse and

1 / Sanitizer

2 (1 transformer

units)

1 (1 transformer

units)

Terminal Block & Bracket Assy. (Detergent, units with 2

transformers)

15 RPM Gear/motor

Rinse & Sanitizer Control Board (circuit for controlling rinse and

sanitizer)

Modular Connector 8 pole (for Rinse and/or Sanitizer Control

Board)

18 AWG Orange Wire – 8” long

18 AWG Orange Wire – 10” long

I-729 Pg 13 of 15

Rev D 11/01

25-67C2-2

25-85S

25-84C2

25-83C2-2

25-85L

25-91-C2

SQUEEZE TUBE

C2 PUMP ASSEMBLY

C2 Pump Parts

Part No. Description

25-91-C2 C2 Pump Head Gasket

25-67C2-2 C2 Pump Head

25-84C2 C2 Roller Block (2 roller)

25-83C2-2 C2 Face Plate

25-85S #10-32 X 1 ¾” Machine Screw

25-85L #10-32 X 2 ¼” Machine Screw

25-C2D C2 Pump Head Kit (kit includes C2 Pump parts listed above)

I-729 Pg 14 of 15

Rev D 11/01

Return Policy

No merchandise may be returned for credit without DEMA Engineering Company’s written permission. Return Merchandise

Authorization (RMA) number required in advance of return.

Warranty

DEMA products are warranted against defective material and workmanship under normal use and service for one year from the

date of manufacture. This limited warranty does not apply to products that have a normal life shorter than one year or failure and

damage caused by chemicals, corrosion, improper voltage supply, physical abuse or misapplication. Rubber and synthetic parts

such as “O”-rings, diaphragms, squeeze tubing and gaskets are considered expendable and are not covered under warranty. This

warranty is extended only to the original buyer of DEMA products. If products are altered or repaired without prior approval of

DEMA, this warranty will be void.

Defective units or parts should be returned to the factory with transportation prepaid . If inspection shows them to be defective,

they will be repaired or replaced without charge. F.O.B. factory DEMA assumes no liability for damages. Return merchandise

authorization number to return units for repair or replacement must be granted in advance of return.

I-729 Pg 15 of 15

Rev D 11/01

Loading...

Loading...