Page 1

^1USER MANUAL

^2 AMP 1

^3 40W 4-Channel Linear Brush Motor

^4 3Ax-603489-xUxx

^5 August 22, 2006

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Page 2

Copyright Information

© 2003 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained in

this manual may be updated from time-to-time due to product improvements, etc., and may not

conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain

static sensitive components that can be damaged by incorrect handling. When installing or handling

Delta Tau Data Systems, Inc. products, avoid contact with highly insulated materials. Only

qualified personnel should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial environment,

install them into an industrial electrical cabinet or industrial PC to protect them from excessive or

corrosive moisture, abnormal ambient temperatures, and conductive materials. If Delta Tau Data

Systems, Inc. products are exposed to hazardous or conductive materials and/or environments, we

cannot guarantee their operation.

Page 3

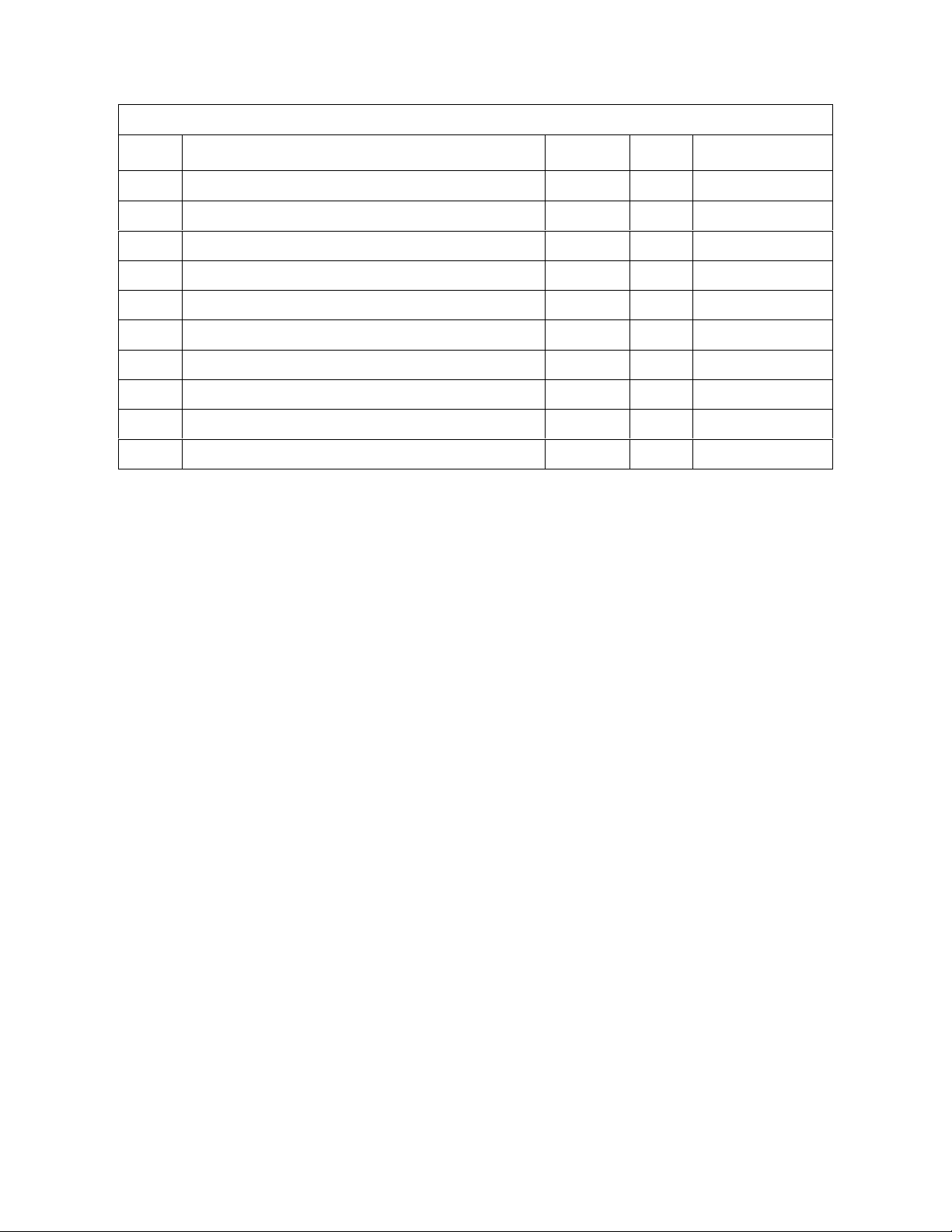

REV. DESCRIPTION DATE CHG APPVD

1 E-POINT JUMPER & AMP SPEC REVISIONS 08/22/06 CP R. UNADKAT

REVISION HISTORY

Page 4

Page 5

Amp 1

Table of Contents

INTRODUCTION ........................................................................................................................................ 1

Power Supply Considerations .................................................................................................................... 1

Selecting Current vs. Voltage Mode .......................................................................................................... 1

Maximum Current Output E-Point Jumpers..........................................................................................1

Amplifier-Enable/Fault Polarity Selection ............................................................................................ 2

Torque/Velocity Control ............................................................................................................................ 2

HARDWARE DESCRIPTION ................................................................................................................... 3

TB1: 8-Pin PMAC Interface Terminal Block ............................................................................................ 3

TB2: 13-Pin Motor Amplifier Output Terminal Block .............................................................................. 3

TB3: External Power Ground..................................................................................................................... 3

TB4: External Power.................................................................................................................................. 3

TB5: External Logic Power........................................................................................................................ 4

P1: 96 Pin Power Input Connector............................................................................................................. 4

Amplifier Specifications ............................................................................................................................ 5

Power Stage Specifications.................................................................................................................... 5

Mechanical Specifications..................................................................................................................... 5

Environmental ....................................................................................................................................... 5

Amplifier User Components Description................................................................................................... 5

Fuses...................................................................................................................................................... 5

LEDs...................................................................................................................................................... 5

Offset Pots ............................................................................................................................................. 6

SAMPLE WIRING DIAGRAM.................................................................................................................. 7

ANALOG AMPLIFIER BACKPLANE BOARD ..................................................................................... 9

Single Quad H-Bridge Amplifier Backplane Layout .................................................................................9

Dual Quad H-Bridge Amplifier Backplane Layout.................................................................................. 10

Table of Contents i

Page 6

Page 7

Amp 1

INTRODUCTION

The Amp 1 Linear Amplifier is a 3U-size amplifier designed to drive small DC brushed type motors or

proportional hydraulic valve actuators. This amplifier provides four 40W continuous (60W intermittent)

linear amplifiers. The Amp 1 Linear Amplifier may be interfaced conveniently to the PMAC controller

via Acc-24E2A. The maximum bus voltage for this amplifier is 24VDC and the continuous rating for

each drive is 0.5A.

The amplifiers on this product will output a current or voltage that is proportional to the voltage input.

The amplifier can receive its logic power supply (_15V) from the 3U-power supply and the bus voltage is

supplied from a separate supply.

Power Supply Considerations

The Amp 1 Linear Amplifier requires a single power supply of +12V to +24V max. The current

requirement can vary depending on the load, but should not exceed 4A (1A per channel) continuous and

8A peak (2A per channel) for a one-second period. A slow blow 5A fuse is installed to protect the shunt

and a fast acting 8A fuse to protect the main bus.

If the amplifier is driven beyond its rated power, driver overheating may occur. In this event, the driver

will output a fault signal on the corresponding pin of Terminal Block 2 (TB2) and turn on the

corresponding red LED next to Terminal Block 1, TB1, shown in the Amplifier Layout Diagram.

Selecting Current vs. Voltage Mode

The Amp 1 Linear Amplifier can be configured in either current or voltage mode. This is configured by

setting the following E-point jumpers.

Maximum Current Output E-Point Jumpers

Each of the amplifiers has an E-point jumper that allows changing the transconductance factor of the

amplifier.

Jumper Description Default

E1A Jumper 1-2 Current Mode with gain of 0.2 A/V

E1B Jumper 1-2 Current Mode with gain of 0.04 A/V E1A & E2 Jumper 1-2 Voltage Mode with gain of 1V in = 2.6V out No jumper Jumper 1-2 Current Mode with gain of 0.02 A/V

E3A Jumper 1-2 Current Mode with gain of 0.2 A/V

E3B Jumper 1-2 Current Mode with gain of 0.04 A/V

E3A & E4 Jumper 1-2 Voltage Mode with gain of 1V in = 2.6V out

No jumper Jumper 1-2 Current Mode with gain of 0.02 A/V

E5A Jumper 1-2 Current Mode with gain of 0.2 A/V

E5B Jumper 1-2 Current Mode with gain of 0.04 A/V

E5A & E6 Jumper 1-2 Voltage Mode with gain of 1V in = 2.6V out

No jumper Jumper 1-2 Current Mode with gain of 0.02 A/V

E7A Jumper 1-2 Current Mode with gain of 0.2 A/V

E7B Jumper 1-2 Current Mode with gain of 0.04 A/V

E7A & E8 Jumper 1-2 Voltage Mode with gain of 1V = 2.6V out

No jumper Jumper 1-2 Current Mode with gain of 0.02 A/V

Channel 1 Setup

Channel 2 Setup

Channel 3 Setup

Channel 4 Setup

X

X

X

X

Introduction 1

Page 8

Amp 1

Jumpers are provided to lower the current output rating either 200 or 400mA, for motors with smaller

current needs. Effectively, this cuts the amplifier transconductance factor in half, allowing use of the full

+10V from PMAC’s DAC outputs rather than scaling the system to output +2V via Ix69.

Note:

If the amplifier is driving a DC motor at high speeds, the current supply to the

motor may be reduced if the back EMF voltage of the motor is sufficiently large

(refer to the motor manufacture’s data sheet).

Amplifier-Enable/Fault Polarity Selection

The controller (PMAC or UMAC) should be configured for low-true amplifier-enable signals. A green

LED next to Terminal Block 1 (TB1) for each amplifier on the 3U linear amplifier is lit when the board is

receiving power and that amplifier is enabled.

Also, if the amplifier fault signal is fed back to PMAC, bit 23 (the most significant bit) of Ix25 (PMAC)

or bit 23 of Ix24 for Turbo PMAC should be set to zero for Low True fault input. The red LED for each

channel is lit when the amplifier faults (overheats).

Torque/Velocity Control

For direct torque or velocity control, the following I-variables may be adjusted as part of the motor

software setup (Example for PMAC2-Turbo):

Ixx00

Ixx02

Ixx03

Ixx04

Ixx24

Ixx25

Ixx69

Set to 1 to activate motor.

Motor xx Command Output Address. For example:

I102=$078003 to use DAC1 with motor 1.

Motor xx Position Loop Feedback Address. For

example: I103=$3501 to use Encoder 1.

Motor xx Velocity Loop Feedback Address. For

example: I104=$3501 to use Encoder 1.

Set motor xx Flag Mode Control. For example:

I124=$100001 to specify high true fault input.

Set motor xx Flag Address. For example:

I125=$078000 to specify channel 1 flags.

Set motor xx Output Command Limit.

Refer to the Turbo PMAC/PMAC2 Software Reference Manual for full descriptions of these I-variables.

2 Introduction

Page 9

Amp 1

HARDWARE DESCRIPTION

There are six connectors on the QUAD H-Bridge Amplifier board:

TB1: 8-Pin PMAC Interface Terminal Block •

•

TB2: 13-Pin Motor Amplifier Output Terminal Block

•

TB3: External Power Ground

•

TB4: External Bus Power

•

TB5: External logic power

•

P1: 96-Pin Power Input Connector

TB1: 8-Pin PMAC Interface Terminal Block

This terminal block provides the actual connection to the motors.

Pin Symbol Function Description

1 AMPOUT1 Output First Motor + Lead

2 AMPOUT1/ Output First Motor - Lead

3 AMPOUT2 Output Second Motor + Lead

4 AMPOUT2/ Output Second Motor - Lead

5 AMPOUT3 Output Third Motor + Lead

6 AMPOUT3/ Output Third Motor - Lead

7 AMPOUT4 Output Fourth Motor + Lead

8 AMPOUT4/ Output Fourth Motor - Lead

TB2: 13-Pin Motor Amplifier Output Terminal Block

This connector brings in up to four analog command signals and amplifier-enable lines. It also sends the

amplifier fault signal back to the controller.

Pin Symbol Function Description Notes

1 DAC1+ Input Command Signal 1 Reference to AGND

2 AENA1- Input Amplifier Enable 1 Reference to AGND

3 FAULT1- Output Amplifier Fault 1 Reference to AGND

4 DAC2 Input Command Signal 2 Reference to AGND

5 AENA2- Input Amplifier Enable 2 Reference to AGND

6 FAULT2- Output Amplifier Fault 2 Reference to AGND

7 AGND Analog Ground

8 DAC3 Input Command Signal 3 Reference to AGND

9 AENA3- Input Amplifier Enable 3 Reference to AGND

10 FAULT3- Output Amplifier Fault 3 Reference to AGND

11 DAC4 Input Command Signal 4 Reference to AGND

12 AENA4- Input Amplifier Enable 4 Reference to AGND

13 FAULT4- Output Amplifier Fault 4 Reference to AGND

TB3: External Power Ground

Pin Symbol Function Description

1 PGND Input Bus power reference

TB4: External Power

Pin Symbol Function Description

1 A+24V Input Bus power reference

Hardware Description 3

Page 10

Amp 1

TB5: External Logic Power

Pin Symbol Function Description

1 AGND Input/Output Reference for logic supply

2 A+15V Input For logic power (usually from backplane)

3 AGND Input/Output Reference for logic supply

4 A-15V Input For logic power (usually from backplane)

P1: 96 Pin Power Input Connector

Pin# Row A Row B Row C

1 PGND PGND PGND 2 PGND PGND PGND 3 PGND PGND PGND 4 PGND PGND PGND 5 PGND PGND PGND 6 PGND PGND PGND 7 PGND PGND PGND 8 PGND PGND PGND

9 NC NC NC 10 +24V (bus) +24V (bus) +24V (bus) 11 +24V (bus) +24V (bus) +24V (bus) 12 +24V (bus) +24V (bus) +24V (bus) 13 +24V (bus) +24V (bus) +24V (bus) 14 +24V (bus) +24V (bus) +24V (bus) 15 +24V (bus) +24V (bus) +24V (bus) 16 +24V (bus) +24V (bus) +24V (bus) 17 +24V (bus) +24V (bus) +24V (bus) 18 NC NC NC 19 DB R+ DB R+ DB R+ 20 DB R+ DB R+ DB R+ 21 DB R+ DB R+ DB R+ 22 DB R+ DB R+ DB R+ 23 NC NC NC 24 DB R- DB R- DB R25 DB R- DB R- DB R26 DB R- DB R- DB R27 DB R- DB R- DB R28 NC NC NC 29 AGND AGND AGND 30 A+15V A+15V A+15V 31 AGND AGND AGND 32 A-15V A-15V A-15V

4 Hardware Description

Page 11

Amp 1

Amplifier Specifications

Power Stage Specifications

Description Specification

V+ input voltage 12V minimum, 24V maximum

Logic power 15V @ 100mA, -15V @ 50mA

Transconductance factor 0.2 A/V, 0.04 A/V, or 0.02 A/V

Max continuous current 4A (1A per channel)

Peak current 8A (2A per channel)

Command input voltage

Mechanical Specifications

Size & Dimension See Diagram

TB1 Connector 8-pin Screw Terminal

TB2 Connector 13-pin Phoenix

TB3 Connector 1-pin Screw Terminal

TB5 Connector 1-pin Screw Terminal

TB4 Connector 4-pin Screw Terminal

P1 Connector 96-pin 3U back plane

+/- 10V

Environmental

Operating Temperature 0 C to 55 C (32 F to 135 F)

Storage temperature -12 C to 82 C (10 F to 180 F) Humidity 0% to 95%, non-condensing

Amplifier User Components Description

Fuses

Label Type Description

F1 8A Fast Blow for BUS

LEDs

Label Function

LD1 Channel 1 Enable LD2 Channel 1 Fault LD3 Channel 2 Enable LD4 Channel 2 Fault LD5 Channel 3 Enable LD6 Channel 3 Fault LD7 Channel 4 Enable LD8 Channel 4 Fault LD10 Over Temperature Fault

Hardware Description 5

Page 12

Amp 1

Offset Pots

Name Label Function

A

B

C

D

R6 Channel 1 Current Offset R46 Channel 2 Current Offset R86 Channel 3 Current Offset

R126 Channel 4 Current Offset

6 Hardware Description

Page 13

Amp 1

SAMPLE WIRING DIAGRAM

Sample Wiring Diagram 7

Page 14

Amp 1

8 Sample Wiring Diagram

Page 15

Amp 1

ANALOG AMPLIFIER BACKPLANE BOARD

The analog amplifier backplane board allows easy access to power the Quad H-Bridge amplifier units

when placed in the 3U racks. The amplifier backplane boards come in two options: single amplifier 2-slot

assemblies or dual amplifier 4-slot assemblies. The board itself has terminal screws for the external bus,

external shunt resistors, a Molex connector for the logic power, and another Molex connector for the

cooling fans.

Backplane Board Part Number 3U Slots used

Single Amplifier 603490-10x

Dual Amplifier 603470-10x

Single Quad H-Bridge Amplifier Backplane Layout

2

4

Analog Amplifier Backplane Board 9

Page 16

Amp 1

Dual Quad H-Bridge Amplifier Backplane Layout

10 Analog Amplifier Backplane Board

Loading...

Loading...