Delta Tau MACRO CPU BOARD 4Ax-602804-xHxx, 3U MACRO-CPU Board, 3A0-602804-10x Hardware Reference Manual

Page 1

^1 HARDWARE REFERENCE MANUAL

^2 MACRO CPU BOARD

^3 HRM for UMAC MACRO & MACRO Stack

^4 4Ax-602804-xHxx

^5 January 29, 2003

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Page 2

Page 3

MACRO-CPU Hardware Reference

CONTENTS

INTRODUCTION ....................................................................................................................... 1

3U Product Configurations (General Description) .................................................................................................................2

MACRO CPU Specifications ....................................................................................................................................................4

Physical Specifications............................................................................................................................................................4

Electrical Specifications ..........................................................................................................................................................4

3U MACRO-CPU CONFIGURATION........................................................................................ 5

3U MACRO CPU BOARD HARDWARE SETUP...................................................................... 7

3U MACRO CPU Board Jumper & Switch Setup .................................................................................................................7

MACRO CPU Board Connections...........................................................................................................................................8

3U MACRO-CPU JUMPER AND SWITCH CONFIGURATIONS ........................................... 11

3U MACRO-CPU Card Layout .............................................................................................................................................11

E1: Watchdog Timer Disable ...............................................................................................................................................12

E2: CPU Mode Operation ....................................................................................................................................................12

E3: Serial Port Baud Rate.....................................................................................................................................................12

E4: Power Supply-Loss Control (±15Vdc Supply Monitor) ................................................................................................12

E5: MACRO Received Signal Detect/Bypass Mode (rev -105 and 106 only). Does not exist on rev 107 and later models.

...............................................................................................................................................................................................13

E40: MACRO Input (Fiber/Wired) Selector ........................................................................................................................13

JP3: MACRO Loop back Test Select For Copper Only (rev -104 and earlier) ....................................................................13

JP4: Reserved for Future Use...............................................................................................................................................13

JP5-JP6: MACRO Copper EQ Select (rev -104 and earlier)................................................................................................14

Switch Configurations .............................................................................................................................................................15

SW1: MACRO Slave Node Configure.................................................................................................................................15

SW2: MACRO Master Number Select ................................................................................................................................15

Connector Summary ...............................................................................................................................................................16

MACRO STATION CHARACTER DISPLAY .......................................................................... 17

HARDWARE RE-INITIALIZATION ......................................................................................... 18

FIRMWARE UPDATES........................................................................................................... 20

3U MACRO-CPU BOARD CONNECTOR PIN-OUTS............................................................. 22

J6: (JTHW) Multiplexer Port Connector..............................................................................................................................22

J7: (JRS232) Serial Port Connector......................................................................................................................................24

J14, J17: MACRO COPPER I/O (OPT C)............................................................................................................................25

P1: UBUS Interface Connector .............................................................................................................................................26

TB1: (JPWR) 4-Pin Terminal Block.....................................................................................................................................27

U73: MACRO Fiber Optic Connector (OPT A)....................................................................................................................27

Contents i

Page 4

MACRO-CPU Hardware Reference

U MACRO-CPU HARDWARE MEMORY MAP ...................................................................... 28

ACCESSORIES ...................................................................................................................... 30

ii Contents

Page 5

MACRO-CPU Hardware Reference

INTRODUCTION

The 3U MACRO-CPU board is the processor and MACRO interface board that is used in a 3U MACRO Station

(in either UMAC MACRO or MACRO Stack configuration).

Note

There are 3 documents that describe the operation of Delta Tau Data Systems Inc. 3U MACRO

Station products:

•

UMAC System Manual (General Product Overview)

•

3U MACRO Station User’s Manual

•

3U MACRO Station Software Reference

This manual describes the interfaces and physical hardware that is used on the

3U MACRO CPU.

The UMAC MACRO and the MACRO Stack provide a remote interface for encoders, flags, direct-PWM digital

drives, analog drives, stepper drives, analog I/O, and digital I/O for Delta Tau Data's PMAC products that have a

MACRO interface.

The UMAC MACRO and MACRO Stack configurations communicate with PMAC2 Ultralites or Turbo PMAC2

Ultralites solely through the MACRO ring, interfacing to standard drives, encoders, flags, and I/O through onboard connectors. This MACRO Station integrated packaging and connectivity strategy provides revolutionary

flexibility and ease of use.

A 3U MACRO Station consists of a set of “3U” format Euro-cards (100 x 160 mm) that can be assembled in a

variety of configurations. When used in the rack configuration, connected through a backplane bus, the backplane

is UBUS format, designed by Delta Tau Data Systems Inc. for motion control and I/O interfaces.

When using the fiber optic MACRO interface, the 3U MACRO Station can be up to 3 kilometers (2 miles) away

from the PMAC2 controller or any other station on the ring. When using the RJ-45 copper electrical interface, it

can be up to 100 meters (~330 feet) away.

The 3U MACRO Station allows PMAC2 MACRO controllers to control servo axes and I/O just as if they were

directly connected to the PMAC2, even though they may be a great distance away. The only interface needed

from the PMAC2 is the electrically isolated MACRO ring.

Typically, a PMAC2 “Ultralite” board, one without any of its own servo interface circuitry, is used with the

MACRO Station to provide the most cost-effective solution.

Introduction

1

Page 6

MACRO-CPU Hardware Reference

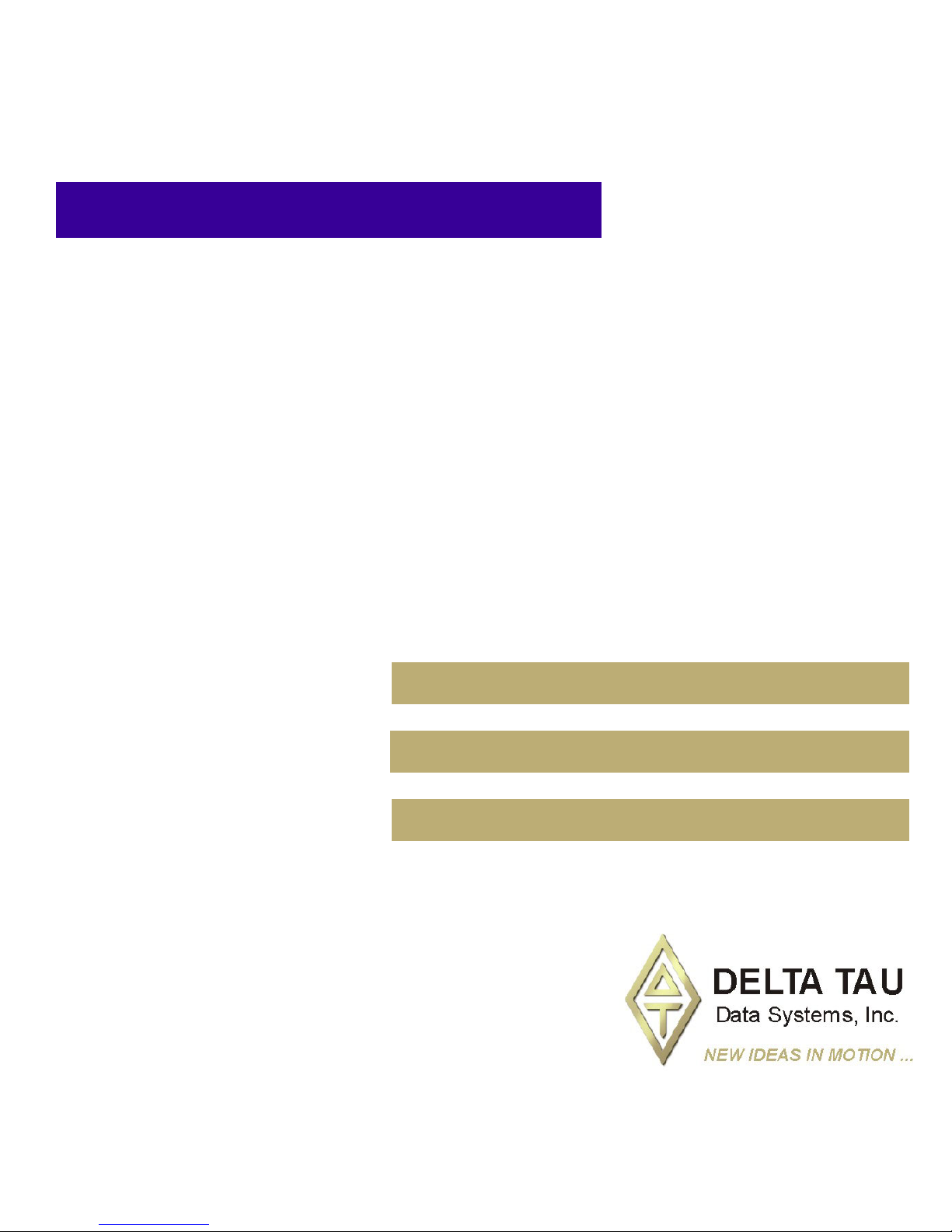

3U MACRO-CPU Board (3A0-602804-10x):

•

80MHz DSP56303 CPU

•

512k x 8 flash memory for user backup & firmware

•

Latest released firmware version

•

RS-232 serial interface for setup and debugging

•

Stack connectors for servo and I/O accessory boards

•

UBUS connector for backplane connection to servo

and I/O accessory boards

•

JTHW multiplexed I/O port with 26-pin IDC header

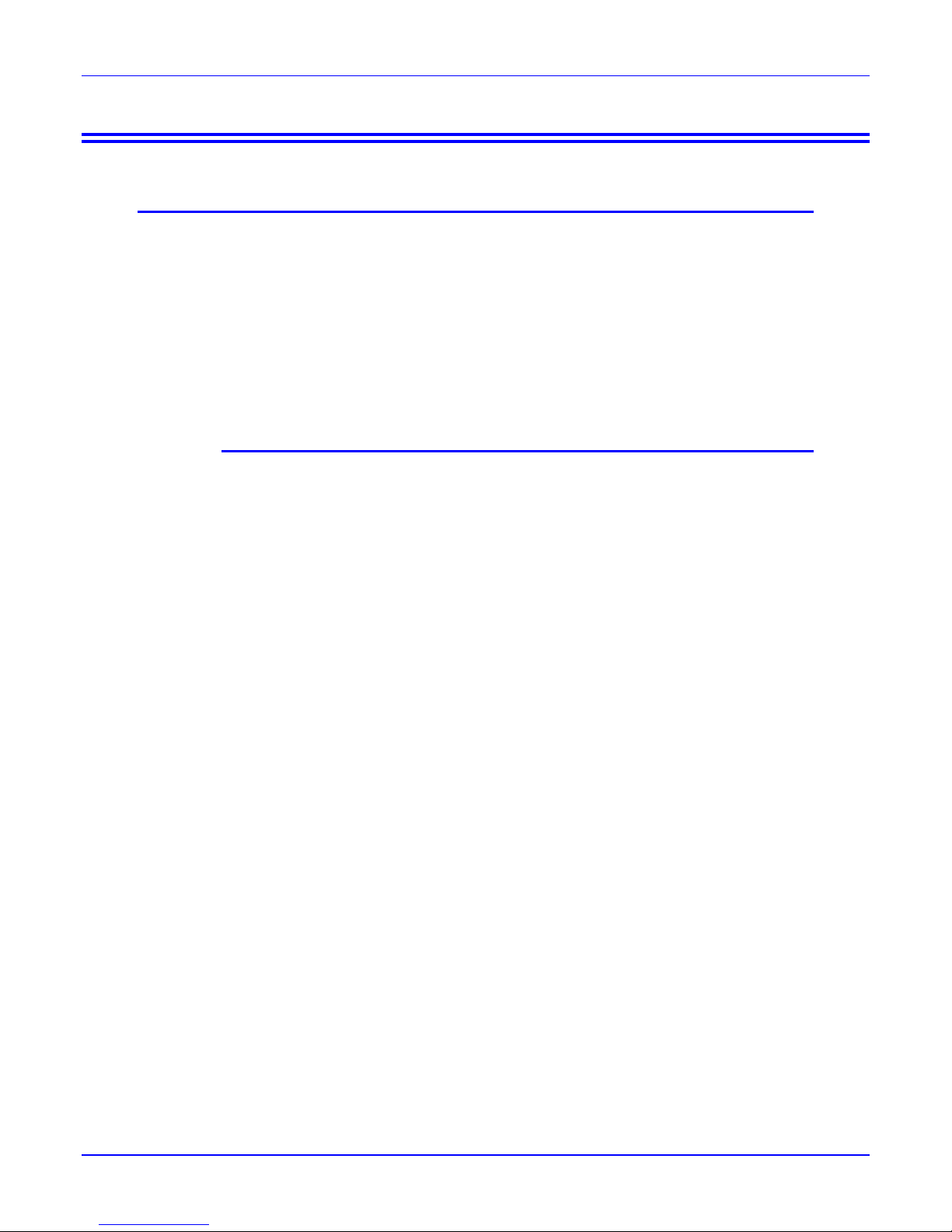

The 3U MACRO Station can be configured in either of two fundamental assemblies – “UMAC MACRO” and

“MACRO Stack”:

•

UMAC MACRO – In this configuration (once called

"Pack") the 3U-format boards are put together to

communicate through a backplane bus called the UBUS.

All boards are installed in a Euro-card rack. In this

configuration, all 3U-format boards or modules can be

installed or withdrawn from the pack individually,

providing ease of installation, debugging, and repair.

The photo at the upper right shows a UMAC rack with power

supply and I/O boards that are connected through a backplane.

This system allows for an easier integration of the 3U

MACRO-CPU for larger (up to 8 axes) applications.

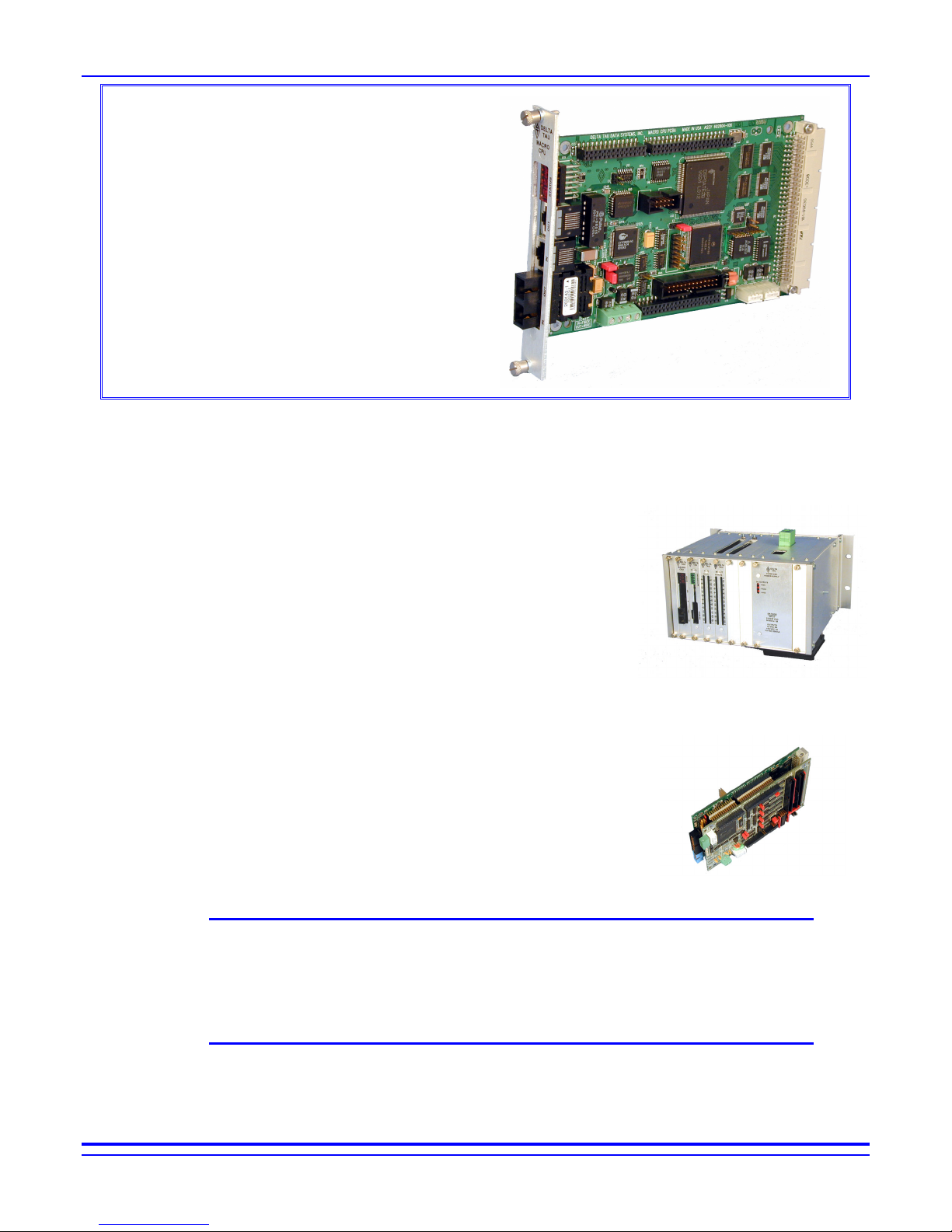

•

MACRO Stack – In the Stack configuration the 3U-format

boards are put together as a stack of piggyback boards,

(right, below). This configuration is ideal for compact,

cost-sensitive embedded applications.

UMAC MACRO Station

Configuration

4 Axis Stack Configuration

Note:

The Stack boards and related breakout boards can be installed in a Euro-card rack,

creating a hybrid “stack/pack” configuration. This requires a special backplane

configuration that makes removing stack boards difficult.

This hybrid configuration is now recommended for existing “legacy” systems only.

3U Product Configurations (General Description)

Introduction

2

Page 7

MACRO-CPU Hardware Reference

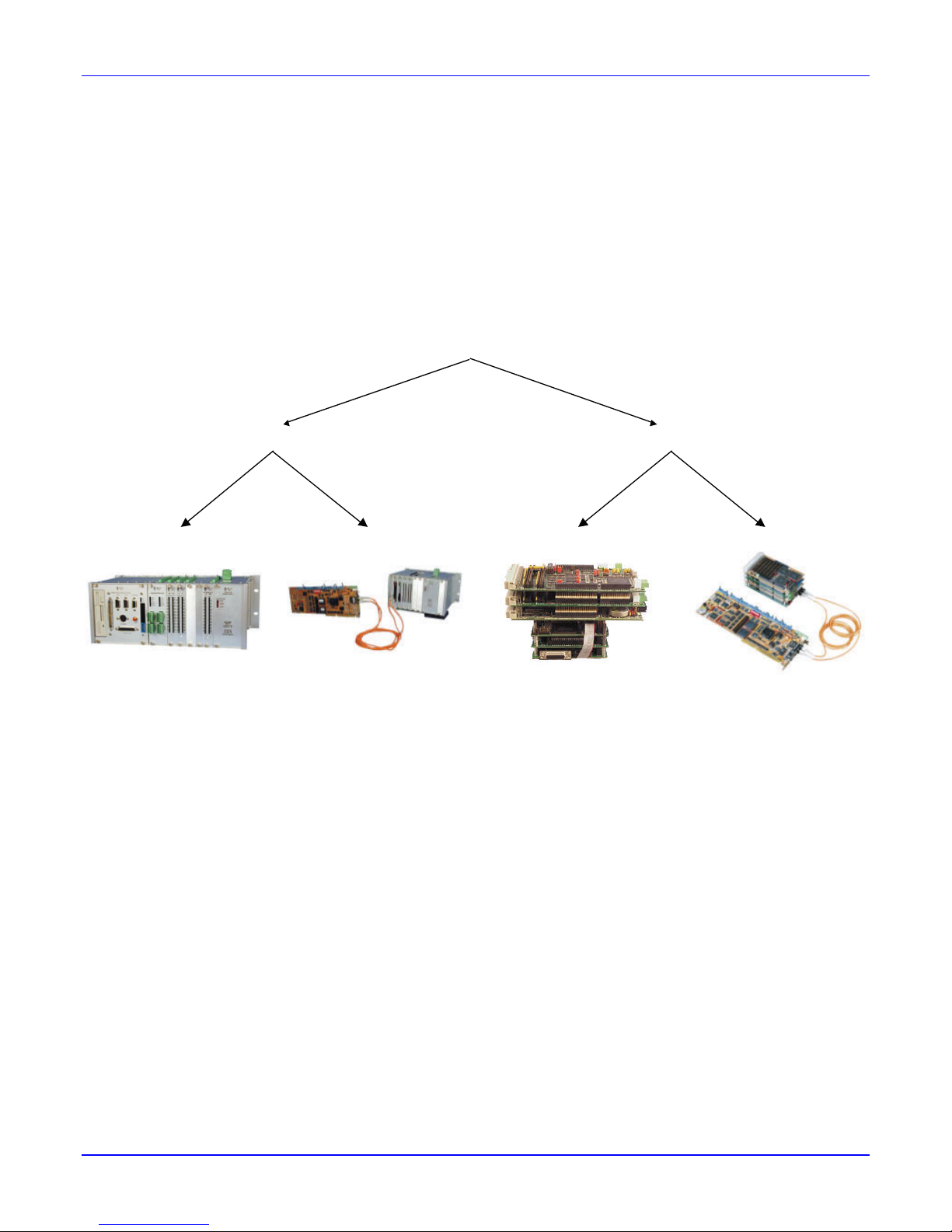

Assemblies of 3U-format boards can be made with either of two CPU processor boards – a 3U MACRO-CPU

board, or a 3U Turbo PMAC2 CPU board. Most other 3U-format boards, labeled “Accessory” boards, can be

used with either CPU board.

•

When the 3U MACRO-CPU board is used, the resulting assemblies are called “UMAC MACRO” or "3U

MACRO Stack."

•

When the 3U Turbo PMAC2 CPU board is used, the resulting assemblies are called “UMAC Turbo” or

"Turbo Stack."

Refer to the "UMAC & 3U Stack Products Selection Guide" for more detailed descriptions of how the rack and

stack products are integrated.

UMAC and 3U-Stack Products

UMAC Products Stack Products

UMAC Turbo UMAC MACRO Turbo Stack MACRO Stack

The UMAC Turbo is composed of

a 3U-format Turbo PMAC2 CPU

board and a set of accessory boards

in 3U-format, all plugged in a

common UBUS backplane and

installed inside a 3U format rack. A

PC/104 computer and several

optional communication

accessories (including all of the

major FieldBuses, MACRO and

Ethernet) can be inst alled inside the

UMAC system providing

convenient flexibility and virtually

unlimited expandability.

The UMAC MACRO is composed

of a MACRO Interface/CPU board

and a set of accessory boards in 3Uformat, all plugged in a common

UBUS backplane and installed

inside a 3U fo rmat rack. The UMAC

MACRO must receive commands

from an external MACRO

compatible device like a PMAC2

Ultralite or a UMAC Turbo system.

The UMAC MACRO does not

support a PC/104 or communication

accessories and it is preferred for

distributed control over a MACRO

ring connection.

The Turbo stack is composed of a

3U-format Turbo PMAC2 CPU

board and a set of ac cessory boards

in 3U-format plugged to it in a stack

configuration. The Turbo stack

configuration is less expensive than

the UMAC Turbo system but it is

limited to eight axes of motion

control versus 32 axes on a UMAC

Turbo system. The Turbo Stack is

selected over a UMAC Turbo

system because is more compact,

allowing its installation inside

already existing cabinets with some

space limitations.

The MACRO stack is composed of

a MACRO Interface/CPU board

and a set of accessory boards in

3U-format plugged to it in a stack

configuration. The UMAC

MACRO must receive commands

from an external MACRO

compatible device like a PMAC2

Ultralite or a UMAC Turbo

system. The MACRO Stack is

selected ove r a UMAC MACRO

sys te m because it is more compact,

allowing i ts installation inside

already existing cabinets with some

space limitations.

Introduction

3

Page 8

MACRO-CPU Hardware Reference

MACRO CPU Specifications

Physical Specifications

Size: 33.5cm x 9.9cm x 3.8cm (13.2" x 3.9" x 1.4")

Weight: ½ lb.

Temperature

Operating: 0°C to 60°C (32°)F to 140°F)

Storage: 12°C to 82°C (10°F to 180°F)

Humidity: 10% to 95%, noncondensing

Electrical Specifications

Power: 1.5A @ +5V (±5%) (7.5W) Pertains to 8-channel configuration, with a typical load of

encoders.

Introduction

4

Page 9

MACRO-CPU Hardware Reference

5

3U MACRO-CPU CONFIGURATION

The purchase of the 3U MACRO CPU board provides a 3U-format (100mm x 160mm) board with a DSP

processor, MACRO ring circuitry, “piggyback” connectors onto which “stack” accessory boards can be mounted,

and a backplane connector through which other 3U-format boards can be connected by means of a “UBUS”

passive-backplane board.

The MACRO CPU board went through an extensive redesign in the –105 revision, because key components on

the –104 and older revisions became obsolete. Both the older and the newer versions are described in this

manual. The only system change required is a slight change in the DIP-switch addressing of ACC-24E2x and

ACC-51E backplane axis boards when using the new MACRO CPU boards.

Note

It is recommended that only the new MACRO CPU boards, which have stronger backplane bus

drivers, be used in “UMAC” pack configurations.)

The 3U MACRO-CPU can be purchased in two physical configurations, distinguished by part number prefix:

• 300-602804-10x provides the 3U MACRO-CPU board without a front plate. This configuration is

recommended for “stack” assemblies.

• 3R0-602804-10x provides the 3U MACRO-CPU board with a front plate. This configuration is

recommended for “UMAC” rack assemblies. The top and bottom plates are provided with the ACC-Px

rack.

There are a few options available for the MACRO CPU board.

One of the Options A or C must be present on a MACRO CPU board to provide the actual MACRO ring interface

circuitry; both may be present:

Option A provides an SC-style fiber-optic transceiver to connect into the MACRO ring. Its main component is

the U73 transceiver.

Option C provides RJ-45 electrical input and output connectors for the MACRO ring. Its main components are

J14 and J17.

Option 10 permits a specified revision of the MACRO Station firmware to be installed in the flash memory in the

card. Without this option, the latest released revision is installed. A label on the flash memory IC indicates the

firmware revision installed at the factory (but not necessarily which revision is presently installed in the IC). The

presently installed revision can be ascertained by using the MSVER{node #} command.

3U MACRO-CPU Configuration

Page 10

MACRO-CPU Hardware Reference

6

3U MACRO-CPU Configuration

Page 11

MACRO-CPU Hardware Reference

7

3U MACRO CPU BOARD HARDWARE SETUP

The hardware setup of the 3U MACRO CPU Board consists of the setting of 2 rotary switches, the setting of

several E-point jumpers on each board, followed by power supply and signal connections.

Note

E-Point Jumper numbers are shown in white ink on the legend of each board. Pin numbers for

each number can be determined either from the legend on the component side on the board, or by

looking at the solder side of the board, where pin 1 has a square solder pad.

3U MACRO CPU Board Jumper & Switch Setup

The MACRO Station has two 16-way rotary switches on the MACRO CPU board that establish the station’s basic

configuration on the MACRO ring.

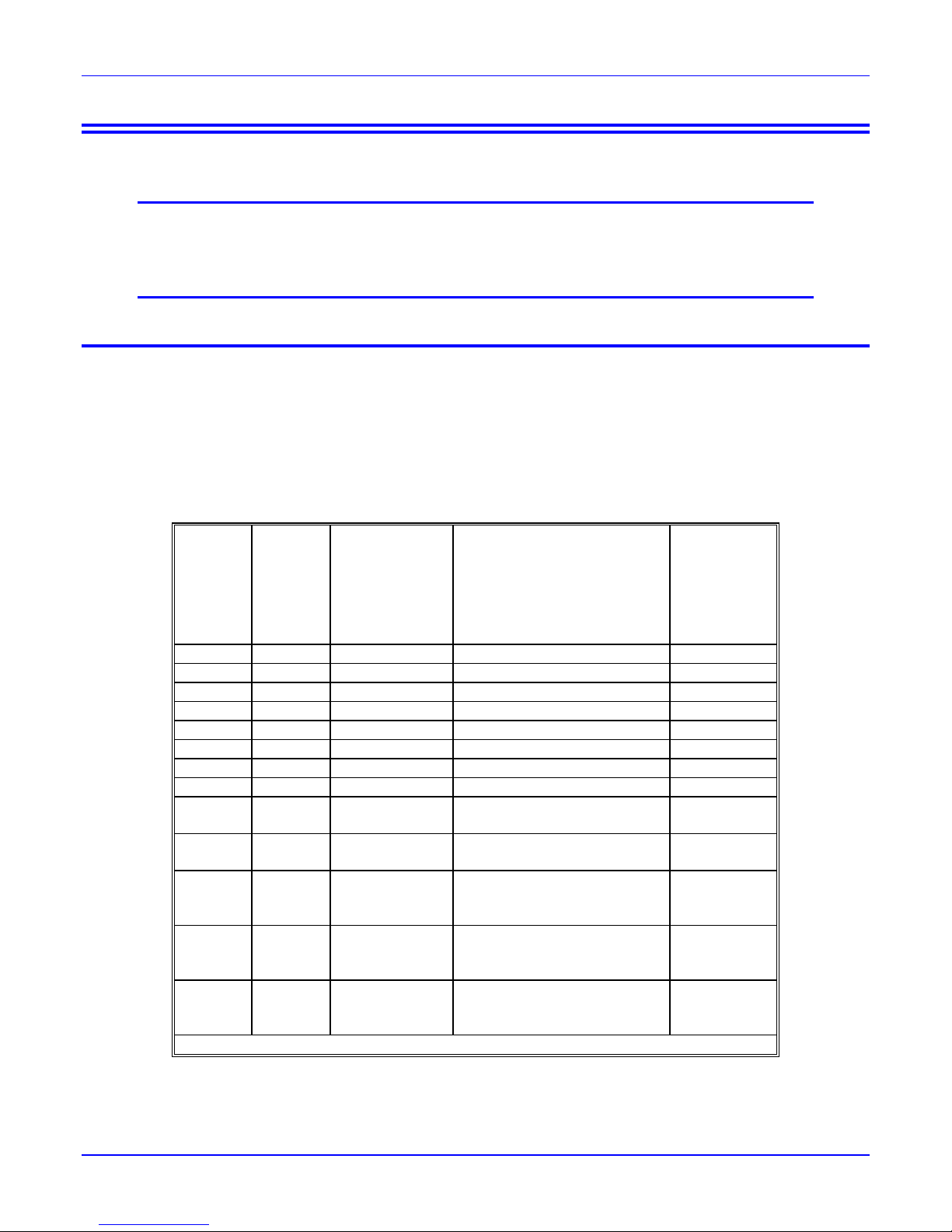

SW1 Rotary Switch Setting: SW1 establishes how many servo nodes, and which servo nodes, will be used on

the MACRO station. It also establishes the mapping of MACRO node numbers to MACRO Station channel

numbers. This mapping information will be important in establishing the software setup.

The following table shows possible MACRO Station axis configurations and the appropriate settings of SW1:

# of

Servo

Chan’s

&

Nodes

Which

MACR

O Servo

Nodes

Used

Used

2 0, 1 1x ACC-1E -- 8

2 4, 5 1x ACC-1E -- 9

2 8, 9 1x ACC-1E -- 10 ($A)

2 12, 13 1x ACC-1E -- 11 ($B)

2 0, 1 1x ACC-2E* 1x ACC-24E2x or 51E 2

2 4, 5 1x ACC-2E* 1x ACC-24E2x or 51E 3

2 8, 9 1x ACC-2E* 1x ACC-24E2x or 51E 4

2 12, 13 1x ACC-2E* 1x ACC-24E2x or 51E 5

4 0, 1, 4, 5 1x ACC-2E 1x ACC-24E2x w/ Opt 1x or 1x

4 8, 9, 12,

13

6 0, 1, 4, 5,

8, 9

6 0, 1, 4, 5,

8, 9

8 0, 1, 4, 5,

8, 9, 12,

13

More detailed information on the SW1 settings is presented in the Jumper/Switch description in the back of this

manual.

Stack Axis

Boards Used

1x ACC-2E 1x ACC-24E2x w/ Opt 1x or 1x

1x ACC-1E,

1x ACC-2E

2x ACC-2E* 1x ACC-24E2x w/ Opt 1x or 1x

2x ACC-2E 2x ACC-24E2x w/ Opt 1x /

Backplane (UMAC) Axis

Boards Used

ACC-51E w/ Opt 1

ACC-51E w/ Opt 1

1x ACC-24E2x w/ Opt 1x or 1x

ACC-51E w/ Opt 1;

plus 1x ACC-24E2x or 51E

ACC-51E w/ Opt 1;

plus 1x ACC-24E2x or 51E

ACC-51E w/ Opt 1

SW1 Setting

0

1

12 ($C)

6

7

3U MACRO CPU Board Hardware Setup

Page 12

MACRO-CPU Hardware Reference

SW2 Rotary Switch Setting: SW2 establishes the number of the master IC to which the MACRO station will

respond. The values of 0 to 15 correspond to Master numbers 0 to 15, respectively. For a non-Turbo PMAC2

master, this value must match the master number value in the first hexadecimal digit of PMAC2’s I996. For a

Turbo PMAC2, this value must match the master number value in the first hexadecimal digit of the Turbo

PMAC2’s I6840, I6890, I6940, or I6990, for MACRO ICs 0, 1, 2, or 3, respectively, on the Turbo PMAC2. The

default switch setting is 0, so the station will respond to Master 0.

Watchdog Timer Enable Jumper: For normal operation of the Compact MACRO Station, jumper E1 should be

OFF to enable the watchdog timer (an important safety feature).

Operational Mode Jumper: Jumper E2 should connect pins 2 and 3 to tell the CPU it is in normal operational

mode, not in “bootstrap” mode. It should only connect pins 1 and 2 if you desire to load new firmware into the

flash IC through the serial port.

Baud Rate Jumper: Jumper E3 must be ON if you are connecting an ACC-8D Option 9 Yaskawa absolute

encoder converter to the J7 serial port (most users will connect it to the JTHW port instead). This sets the baud

rate to 9600. If E3 is OFF, the baud rate is 38400.

Power Supply Check Jumper: Remove jumper E4 if you are not bringing a +/-12V to +/-15V supply into the

Compact MACRO Station itself (5V only). If you are bringing these analog circuit supplies into the Compact

MACRO Station, it is best to have jumper E4 on, so that the servo outputs are disabled if either of the analog

supplies is lost.

MACRO Input Select Jumper: Because the MACRO CPU board can potentially accept MACRO ring input

from either the RJ-45 electrical input or the fiber input, you must select which input is used (even if only one of

the ring interface options is present). Jumper E40 must be ON to use the fiber input; it must be OFF to use the

electrical input. (If both interface options A and C are present, either ring output may be used, regardless of the

setting of E40.)

MACRO Signal-Loss Detect Jumper: Jumper E5 (board revisions –105 and newer only) should connect pins 1

and 2 so that the MACRO receiver’s (fiber or electrical) loss-of-signal detect is reported automatically as a byte

“violation” error. Older revisions (-104 and before) of the board could not use the receiver’s signal-loss detect as

a “violation” error (relying on higher-level detection schemes), and connecting pins 2 and 3 makes operation of

the new revision completely compatible with the old. This is not recommended.

MACRO CPU Board Connections

The connection of Compact MACRO Station to other stations on the MACRO ring is achieved by connecting the

output connector of the Compact MACRO Station to the input connector of the next station, and by connecting

the output connector of the previous station to the input connector of the Compact MACRO Station. There must

be a completely connected ring, with all stations powered up, for any communications to occur on the ring.

Optical Fiber Ring Connection: The U73 integrated fiber optic transceiver is used for both the optical fiber

input and the optical fiber output connections to the MACRO ring. With the component side of the board up, and

the opening facing you, the input socket is on the right, and the output socket is on the left (these are marked on

the component).

RJ45 Electrical Ring Connection: The J14 connector is used for the input from the previous station on the

MACRO ring if electrical connection is used, and the J17 connector is used for the output to the next station on

the MACRO ring.

Multiplexer Port: The J6 26-pin header is used to connect to multiplexer port accessories such as the ACC-8D

Opt 7 resolver-to-digital converter board and the ACC-8D Opt. 9 Yaskawa absolute encoder interface board. This

port can be used alternately to provide 8 inputs and 8 outputs (non-multiplexed) at TTL levels.

Backplane “UBUS” Expansion Port: The P2 96-pin DIN header is used to connect to expansion port

accessories such as the ACC-9E, 10E, 11E, 12E, and 14E I/O boards, or the ACC-24E2x axis boards, through an

3U MACRO CPU Board Hardware Setup

8

Page 13

MACRO-CPU Hardware Reference

ACC-Ux “UBUS” backplane board. It can also be used to bring in 5V power, and optionally +/-15V power, from

a backplane or breakout board, to the entire MACRO Station.

Note

When interfacing to accessory boards across the UBUS backplane, it is strongly recommended to

use a new revision (-105 or higher) of the MACRO CPU board, and an ACC-Ux backplane board

(not an older ACC-Jx backplane board). The newer revision MACRO CPU boards have stronger

bus driver ICs, but they do not work well with the termination of the ACC-Jx backplane boards.

Power Terminal Block: The TB1 4-point terminal block can be used to bring in 5V power, and optionally

+/-15V power, to the entire MACRO Station. In a UMAC (pack) configuration, the power is more likely to be

brought in through the backplane.

3U MACRO CPU Board Hardware Setup

9

Page 14

MACRO-CPU Hardware Reference

0

3U MACRO CPU Board Hardware Setup

1

Page 15

MACRO-CPU Hardware Reference

3U MACRO-CPU JUMPER AND SWITCH CONFIGURATIONS

3U MACRO-CPU Card Layout

The "Location" columns of the ing s refe he ma locati hown in the drawings below: follow table r to t pped ons s

A

B

C

D

E

F

1

2

3

4

REV-105 and Later Revisions

Pin 1 of an E-point is masked by an "X" in white ink on the composite side, and by a square

solder pad on the solder side.

3U MACRO-CPU Jumper and Switch Configurations

REV-104 and Earlier Revisions

Note:

11

Page 16

MACRO-CPU Hardware Reference

E1: Watchdog Timer Disable

Rev -105

and Later

Location

B-1 F-1

Rev -104

and Earlier

Location

Jumper

Type

2-PIN

E2: CPU Mode Operation

Rev -105

and Later

Location

D-2 D-1

Rev -104

and Earlier

Location

Jumper

Type

3-PIN

E3: Serial Port Baud Rate

Rev -105

and Later

Location

E-3 E-2

Rev -104

and Earlier

Location

Jumper

Type

2-PIN

Description Default

Remove jumper to enable Watchdog Timer.

Jump pins 1 and 2 to disable Watchdog Timer (for test

purposes only)

Description Default

Jump pins 1 and 2 for firmware download through serial

port.

Jump pins 2 and 3 for normal operation.

Description Default

Jump pins 1 and 2 for 9600-baud serial port operation.

(Required for Yaskawa interface).

Remove jumper for 38400-baud serial port operation.

not jumpered

Pin 2-3

not jumpered

E4: Power Supply-Loss Control (±15Vdc Supply Monitor)

Rev -105

and Later

Location

E-3 E-2

Rev -104

and Earlier

Location

Jumper

Type

2-PIN

Description Default

Jump pins 1 and 2 to disable servo outputs on loss of +5V,

+15V, or –15V power supply.

Remove this jumper to monitor +5Vdc power supply only.

±15V supply monitoring is not usually required for

applications without DACs or A-D converters.

not jumpered

3U MACRO-CPU Jumper and Switch Configurations

12

Page 17

MACRO-CPU Hardware Reference

E5: MACRO Received Signal Detect/Bypass Mode (rev -105 and 106 only). Does

not exist on rev 107 and later models.

Rev -105

and Later

Location

B-3

Rev -104

and Earlier

Location

Jumper

Type

3-PIN

Description Default

Jump pins 1 and 2 to access the receiver’s signal detect operation.

Jump pins 2 and 3 to bypass the receiver’s signal detect

operation.

This jumper does not exist on MACRO-CPU versions -104

and earlier.

E40: MACRO Input (Fiber/Wired) Selector

Rev -105

and Later

Location

B-3 C-3

Rev -104

and Earlier

Location

Jumper

Type

2-PIN

Description Default

Remove jumper to select MACRO wired (RJ45) input from J14.

Jump pins 1 and 2 to select MACRO fiber optic input from U73.

(Option A)

(Option C)

JP3: MACRO Loop back Test Select For Copper Only (rev -104 and earlier)

Pin 1-2

Jumpered

Not

jumpered

Rev -105

and Later

Location

B-1

Rev -104

and Earlier

Location

Jumper

Type

2-PIN

Remove jumper to select loop back in the copper interface of

MACRO communications (for test purposes only).

Jump pins 1 and 2 for normal copper MACRO communications.

This jumper does not exist on MACRO-CPU versions -105

and greater.

JP4: Reserved for Future Use

Description Default

jumpered

3U MACRO-CPU Jumper and Switch Configurations

13

Page 18

MACRO-CPU Hardware Reference

4

JP5-JP6: MACRO Copper EQ Select (rev -104 and earlier)

Rev -105

and Later

Location

Rev -104

and Earlier

Location

B-1

Jumper

Type

2-PIN

Description Default

These jumpers are used to select different modes of

equalization when copper-based communications are used.

When not jumpered, adaptive equalization is used. JP5 and

JP6 are used for manufacturer's testing only.

These jumpers do not exist on MACRO-CPU versions -105

and greater.

not jumpered

3U MACRO-CPU Jumper and Switch Configurations

1

Page 19

MACRO-CPU Hardware Reference

5

Switch Configurations

SW1: MACRO Slave Node Configure

SW1

Setting

0

(default)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

***

# of Servo

Channels

& Nodes

Used

4 0, 1, 4, 5 1, 2, 3, 4 $C000, $C008,

4 8, 9, 12,

2 0, 1 1, 2 $C000, $C008* 4-axis None $F8003 $0003

2 4, 5 3, 4 $C010, $C018* 4-axis None $F8030 $0030

2 8, 9 1, 2 $C000, $C008* 4-axis None $F8300 $0300

2 12, 13 3, 4 $C010, $C018* 4-axis None $FB000 $3000

6 0, 1, 4, 5,

8 0, 1, 4, 5,

2 0, 1 9, 10 $C090, $C098 2-axis None $F8003 $0003

2 4, 5 9, 10 $C090, $C098 2-axis None $F8030 $0030

2 8, 9 9, 10 $C090, $C098 2-axis None $F8300 $0300

2 12. 13 9, 10 $C090, $C098 2-axis None $FB000 $3000

6 0, 1, 4, 5,

0

(I/O only)

(Reserved For Future Use)

0 11 - - - - $F8800 -

MACRO

Servo

Nodes

Specified

13

8, 9

8, 9, 12,

13

8, 9

None None None None None $F8000 $0000

Station

Channel

Nos.

$C010, $C018*

1, 2, 3, 4 $C000, $C008,

$C010, $C018*

1, 2, 3, 4,

5, 6

1, 2, 3, 4,

5, 6, 7, 8

1, 2, 3, 4,

9, 10

$C000, $C008,

$C010, $C018,

$C020, $C028*

$C000, $C008,

$C010, $C018,

$C020, $C028,

$C030, $C038*

$C000, $C008.

$C010, $C018,*

$C090, $C098

Station

Channel

Starting

Addresses

st

Axis

1

Board

Servo

IC

4-axis None $F8033 $0033

4-axis None $FB300 $3300

4-axis 4-axis $F8333 $0333

4-axis 4-axis $FB333 $3333

4-axis 2-axis $FB333 $0333

nd

Axis

2

Board

Servo

IC

PMAC2's I996

Value **

(Turbo

PMAC2’S

I6840, etc.

PMAC2's I1000,

I1002 Value

(Turbo

PMAC2’s I70,

I71, etc.)

* These addresses are for stack axis boards. Add $40 to these addresses for backplane axis boards.

** Other bits of this I-variable may also be set to enable I/O nodes or other slave stations it is commanding

*** A setting of 15 forces the station to use its factory default I-variables on power-up/reset.

SW2: MACRO Master Number Select

0: Commanded from Master IC # 0

1: Commanded from Master IC # 1

…

F: Commanded from Master IC # F (15)

3U MACRO-CPU Jumper and Switch Configurations

1

Page 20

MACRO-CPU Hardware Reference

6

Connector Summary

J1: ☼

☼

J2:

☼

J3:

☼

J4:

☼

J5:

J6:

J7:

J14, J17:

P1:

TB1:

U73:

JEXP_A: for interboard connection

JEXP_B: for interboard connection

JEXP_C: for interboard connection

JISP: Factory configuration header

JTAG/OnCE: Factory troubleshoot header

JTHW: Multiplexer Port Connector

JRS232: Serial Port Connector

RJ45: MACRO Copper I/O (OPT C)

JEXP: Backplane Expansion Port Connector

JPWR: 4-Pin Terminal Block

MACRO Fiber Optic Connector (OPT A)

☼

These connectors are not typically designated as end-user interfaces. The pinouts are not included in this hardware

reference manual. Consult the factory if pinout information is needed.

3U MACRO-CPU Jumper and Switch Configurations

1

Page 21

MACRO-CPU Hardware Reference

7

MACRO STATION CHARACTER DISPLAY

The Compact MACRO Station has a single hexadecimal character display on the CPU/Interface Board that

provides useful information as to the status of the station. The display can show the following values:

Value Meaning

(Blank) Ring not active

0-8 Operation OK; value is # of motors enabled

9 (reserved for future use)

A Amplifier fault

B Ring break fault

C CPU failure fault

D Ring data error

E Loss-of-encoder fault

F Other failure

MACRO Station Character Display

1

Page 22

MACRO-CPU Hardware Reference

HARDWARE RE-INITIALIZATION

MACRO hardware reinitialization to factory defaults is enabled when the SW1 setting is set to 15 or F

(hexidecimal) and the power is cycled at the MACRO Station. The only time the user would want to use a

hardware reinitialization to factory defaults with the MACRO Station would be if the MACRO Station always

powers up with a watchdog (typically if the ring clock at the Ultralite is different than the ring clock at the

MACRO Station). Node 11 will be the only MACRO Station node enabled. Therefore the user will have to enable

node 11 of the MACRO IC at the Ultralite to communicate to the MACRO Station.

Ultralite Example: Servo nodes 0,1,4,5 enabled at Ultralite (I996=$0F8033)

(A) The user would have to enable node 11, I996=$0F8833

(B) Then user can reistablish communications with MS11,(MIvar) commands

(C) Issue MS$$$***11 to ensure re-initialization

(D) Issue MSSAVE11 command to save the factory defaults to the Station

Turbo Ultralite Example: Servo nodes 0,1,4,5 enabled at Ultralite (I6841=$0F8033)

(A) The user would have to enable node 11, I996=$0F8833

(B) Then user can reistablish communications with MS11,(MIvar) commands

(C) Issue MS$$$***11 to ensure re-initialization

(D) Issue MSSAVE11 command to save the factory defaults to the Station

Hardware Re-initialization

18

Page 23

MACRO-CPU Hardware Reference

Hardware Re-initialization

19

Page 24

MACRO-CPU Hardware Reference

0

FIRMWARE UPDATES

Downloading new firmware to the MACRO Station is a simple process once the MACRO board is setup properly.

To download new firmware to the MACRO station, the user must have the following items:

5V power supply

2 jumpers

DB9 female to 10 pin header (any cable used for PMAC RS232 communications)

PC at the DOS prompt.

New firmware and necessary downloading batch files

Make sure to power down the MACRO Station

To download the software to the MACRO station, the user will first jumper the following E2 (1-2) and E1 (1-2).

Wire the 5V power to the appropriate terminal on the MACRO station or plug into 3U Rack.

Place the 10 pin header cable to the serial connection on the MACRO-station and place the other end to the

COM1 port on the PC (the batch files were written for COM1 but could be modified if necessary).

Goto the DOS prompt and create a directory called firmware and station (as an example).

C:\firmware\station

a:\copy *.* c:\firmware\station

Go back to the c drive and type the following command

c:\firmware\station\mcdwnld

The firmware will be down loaded to the MACRO station. Easy!

The PMAC Executive Software will soon have the capability of downloading the MACRO Station firmware in

the Windows Operating Environment.

(5) Place jumper E2 back to pins 2-3 and remove E1 jumper

Please call the factory if you have any questions.

Firmware Updates

2

Page 25

MACRO-CPU Hardware Reference

Firmware Updates

21

Page 26

MACRO-CPU Hardware Reference

3U MACRO-CPU BOARD CONNECTOR PIN-OUTS

The schematic circuits shown in this section are for interface reference only. Subtle differences may exist

between the circuits shown here and the actual hardware used.

J6: (JTHW) Multiplexer Port Connector

(26-pin Header at Location D-3)

Pin # Symbol Function Description Notes

1 GND Common PMAC Common

2 GND Common PMAC Common

3 DAT0 In/Out Data Byte Bit 0 Must be IN for MUX

4 SEL0 In/Out Select Byte Bit 0 Must be OUT for MUX

5 DAT1 In/Out Data Byte Bit 1 Must be IN for MUX

6 SEL1 In/Out Select Byte Bit 1 Must be OUT for MUX

7 DAT2 In/Out Data Byte Bit 2 Must be IN for MUX

8 SEL2 In/Out Select Byte Bit 2 Must be OUT for MUX

9 DAT3 In/Out Data Byte Bit 3 Must be IN for MUX

10 SEL3 In/Out Select Byte Bit 3 Must be OUT for MUX

11 DAT4 In/Out Data Byte Bit 4 Must be IN for MUX

12 SEL4 In/Out Select Byte Bit 4 Must be OUT for MUX

13 DAT5 In/Out Data Byte Bit 5 Must be IN for MUX

14 SEL5 In/Out Select Byte Bit 5 Must be OUT for MUX

15 DAT6 In/Out Data Byte Bit 6 Must be IN for MUX

16 SEL6 In/Out Select Byte Bit 6 Must be OUT for MUX

17 DAT7 In/Out Data Byte Bit 7 Must be IN for MUX

18 SEL7 In/Out Select Byte Bit 7 Must be OUT for MUX

19 N.C. N.C No Connection

20 GND Common PMAC Common

21 BRLD/ Output Buffer Request Low is “BUFFER REQ.”

22 GND Common PMAC Common

23 IPLD/ Output In Position Low is “IN POSITION”

24 GND Common PMAC Common

25 +5V Output +5VDC Supply Power Supply OUT

26 INIT/ Input PMAC RESET Low is “RESET”

Front View

3U MACRO-CPU Board Connector Pin-outs

22

Page 27

MACRO-CPU Hardware Reference

+5V

10

1

RP6

J6

(JTHW)

J6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

HEADER 26

DAT0

SEL0

DAT1

SEL1

DAT2

SEL2

DAT3

SEL3

DAT4

SEL4

DAT5

SEL5

DAT6

SEL6

DAT7

SEL7

INIT-

GND

3.3KSIP10C

9

8

7

6

5

4

3

2

DAT0

DAT1

DAT2

DAT3

DAT4

DAT5

DAT6

DAT7

SEL0

SEL1

SEL2

SEL3

SEL4

SEL5

SEL6

SEL7

+5V

10

1

RP7

3.3KSIP10C

9

8

7

6

5

4

3

2

+5V

U98

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

74FCT16245

(TSSOP)

GND

1

OE1

T/R1

A0

A1

GND

GND

A2

A3

VCC

VCC

A4

A5

GND

GND

A6

A7

A8

A9

GND

GND

A10

A11

VCC

VCC

A12

A13

GND

GND

A14

A15

OE2

T/R2

TI00

2

B0

3

B1

4

5

B2

6

B3

7

+5V

8

B4

9

B5

10

11

B6

12

B7

13

B8

14

B9

15

16

B10

17

B11

18

19

B12

20

B13

21

22

B14

23

B15

24

TI01

GND

Circuitry For J6- JTHW Interface

DISP0

DISP1

DISP2

DISP3

DISP4

DISP5

DISP6

DISP7

IO_24

IO_25

IO_26

IO_27

IO_28

IO_29

IO_30

IO_31

U12

VDD

1

VSS

2

FAULT_1 DATA_2

3

FAULT_2 DATA_3

4

EQU_1 DATA_4

5

EQU_2 DATA_5

6

AENA_1 DATA_6

7

8

AENA_2 DATA_7

9

A0

10

A1

11

A2

12

A3

13

A4

14

A5

15

A6

16

RD

17

WR

18

CS

19

ADC_STRB SEL_0

20

VSS2

21

ADC_CLK SEL_1

22

ADC_1 SEL_2

23

ADC_2 SEL_3

24

ADC_3 SEL_4

25

ADC_4 SEL_5

26

S_CLK SEL_6

27

S_CLKDIR SEL_7

28

SERVO

29

PHASE

30

DIN0

31

DIN1

32

DIN2

33

DIN3

34

DIN4

35

DIN5

36

DIN6

37

DIN7

38

DATA_STRB

39

VSS2

40

VDD2

41

VDD

42

CMD_IN

43

CMD_OUT

44

CMD_STROBE

45

DOUT0

46

DOUT1

47

DOUT2

48

DOUT3

49

DOUT4

50

DOUT5

51

DOUT6

52

DOUT7

53

VSS2

54

VLTN

55

STROBE_OUT

56

TCLK

57

CTRL0

58

CTRL1

59

CTRL2

60

VSS

61

VDD2

62

CTRL3

63

DISP0

64

DISP1

65

DISP2

66

DISP3

67

DISP4

68

VSS

69

DISP5

70

DISP6

71

DISP7

72

IO_24

73

IO_25

74

IO_26

75

IO_27

76

IO_28

77

IO_29

78

IO_30

79

IO_31

80

VDD2 VDD

DSPGATE2A

IO_00 FLAG_W1

IO_01 FLAG_V1

IO_02 FLAG_U1

IO_04 FLAG_D1

IO_05 FLAG_C1

IO_06 FLAG_B1

IO_07 FLAG_A1

DATA_0 ENC_C1

PUL_1 PWM_C_B1

DIR_1 PWM_C_T1

IO_08 PWM_B_B1

IO_09 PWM_B_T1

IO_10 PWM_A_B1

IO_11 PWM_A_T1

IO_12 PWM_A_T2

IO_13 PWM_A_B2

IO_14 PWM_B_T2

IO_15 PWM_B_B2

DIR_2 PWM_C_T2

PUL_2 PWM_C_B2

DATA_1 ENC_C2

IO_16 FLAG_A2

IO_17 FLAG_B2

IO_18 FLAG_C2

IO_19 FLAG_D2

IO_21 FLAG_U2

IO_22 FLAG_V2

IO_23 FLAG_W2

(TQFP160)

VDD2

IO_03 FLAG_T1

ENC_B1

ENC_A1

VSS2

VSS2

ENC_A2

ENC_B2

IO_20 FLAG_T2

VDD2

VSS2

DB10

DB11

TEST1

TEST_CLK

VDD2

PLLVDD

CLK20MHZ

PLLVSS

PLLAGND

VSS2

RESET

TESTOUT

DB12

DB13

DB14

DB15

DB16

DB17

DB18

DB19

DB20

DB21

DB22

DB23

160

159

158

157

156

155

154

153

152

151

150

149

148

VSS

147

146

145

144

143

142

141

140

VDD

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

VDD

120

119

118

DB0

117

DB1

116

DB2

115

DB3

114

DB4

113

DB5

112

DB6

111

DB7

110

DB8

109

DB9

108

107

106

105

104

103

102

101

100

LP1

99

LP2

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

VSS

81

3U MACRO-CPU Board Connector Pin-outs

23

Page 28

MACRO-CPU Hardware Reference

4

J7: (JRS232) Serial Port Connector

(10-pin Header at Location C-1)

Front View

Pin # Symbol Function Description Notes

1 N.C. No connection

2 DTR BIDIRECT Data Terminal Ready Just tied to “DSR”

3 TXD/ OUTPUT Send Data Transmit data to host

4 CTS INPUT Clear to Send Host Ready bit

5 RXD/ INPUT Receive Data Receive data from host

6 RTS OUTPUT Request to Send PMAC Ready bit

7 DSR BIDIRECT Data Set Ready Just tied to “DTR”

8 N.C. OUTPUT No Connection

9 GND COMMON PMAC Common

10 +5V OUTPUT +5VDC Supply Power supply out

C14

.1UF

C15

.1UF

CTS-

+5V

J7

(JRS232)

J7

N.C.

DTR

TXDCTS

RXDRTS

DSR

N.C.

GND

+5V

1

2

3

4

5

6

7

8

9

10

HEADER 10

C18

.1UF

C17

.1UF

C16

.1UF

TXD- TXD

CTS

RXD- RXD

RTS

+5V

6

4

5

14

13

7

8

V-

C2+

C2-

TXD

RXD

RTS

CTS

16

VCC

VSS

15

U5

2

+V

1

C1+

3

C1-

11

TXD

12

RXD

10

RTS

9

CTS

MAX202ECSE

(SOL16)

3U MACRO-CPU Board Connector Pin-outs

2

GND

Circuitry for J7- JRS232 Interface

Page 29

MACRO-CPU Hardware Reference

5

J14, J17: MACRO COPPER I/O (OPT C)

(8 pin RJ45)

Front View

Pin # Symbol Function Description Notes

1 DATA+ Data + Differential MACRO Signal. J17: DATA+ input.

J14: DATA+ output.

2 DATA- Data - Differential MACRO Signal J17: DATA- input.

J14: DATA- output.

3 unused Unused terminated pin See schematic below.

4 unused Unused terminated pin See schematic below.

5 unused Unused terminated pin See schematic below.

6 unused Unused terminated pin See schematic below.

7 unused Unused terminated pin See schematic below.

8 unused Unused terminated pin See schematic below.

The cable used for MACRO wired connections is CAT5 verified straight-through 8 conductor.

J14

tx+

tx-

50 50 50 50 50 50

50 50

U94

14

15

16

3

2

1

PE-68515

12

CMT

CT

11

TX-

TD-

10

TX+

TD+

5

CT

CT

6

RX-

RD-

7

RX+

RD+

7575

50 50 50 50 50 50

50 50

.01 mfd 2kv

Circuitry for J14 and J17- Copper MACRO I/O

50

J17

rx+

rx-

50

rj45

rj45

MTG HOLE

J14

1

2

3

4

5

6

7

8

CON8

J17

1

2

3

4

5

6

7

8

CON8

WIRED INPUT WIRED OUTPUT

M3

3U MACRO-CPU Board Connector Pin-outs

2

Page 30

MACRO-CPU Hardware Reference

6

P1: UBUS Interface Connector

(96 pin EURO-Connector at F-1, 2, 3, 4)

Front View on MACRO-CPU Card

Pin # Row A Row B Row C

1 +5Vdc +5Vdc +5Vdc

2 GND GND GND

3 BD01 DAT0 BD00

4 BD03 SEL0 BD02

5 BD05 DAT1 BD04

6 BD07 SEL1 BD06

7 BD09 DAT2 BD08

8 BD11 SEL2 BD10

9 BD13 DAT3 BD12

10 BD15 SEL3 BD14

11 BD17 DAT4 BD16

12 BD19 SEL4 BD18

13 BD21 DAT5 BD20

14 BD23 SEL5 BD22

15 BS1 (GND) DAT6 BS0 (GND)

16 BA01 SEL6 BA00

17 BA03 DAT7 BA02

18 BX/Y SEL7 BA04 (n.c.)

19 CS3- BA06 (n.c.) CS220 BA05 (CS7-) BA07 (n.c.) CS4- (CS6-)

21 CS12- BA08 (n.c.) CS1022 CS16- BA09 (n.c.) CS1423 BA13 (n.c.) BA10 (n.c.) BA12 (n.c.)

24 BRD- BA11 (n.c.) BWR25 BS3 (GND) MEMCS0- (n.c.) BS2 (GND)

26 n.c. MEMCS1- (n.c.) RESET

27 PHASE+ n.c. SERVO+

28 PHASE- (n.c.) n.c. SERVO- (n.c.)

29 GND n.c. GND

30 -15Vdc PWRGUD (n.c.) +15Vdc

31 GND GND GND

32 +5Vdc +5Vdc +5Vdc

1. Refer to the UBUS Specification for detailed signal descriptions. This interface is NOT VME bus compatible.

2. Items shown in parentheses represent pin descriptions for -104 and earlier revision MACRO-CPU boards.

3U MACRO-CPU Board Connector Pin-outs

2

Page 31

MACRO-CPU Hardware Reference

7

TB1: (JPWR) 4-Pin Terminal Block

(Location B-4)

Pin # Symbol Function Description Notes

1 GND Common Reference Voltage

2 +5V Input Positive Supply Voltage Supplies all PMAC digital circuits

3 +15V Input Positive Supply Voltage +12V to +15V; used for on-board analog

4 -15V Input Negative Supply Voltage -12 to –15V; used for on-board analog

U73: MACRO Fiber Optic Connector (OPT A)

(2 Socket SC-Style)

Front View

Pin # Symbol Function Description Notes

1 RX Fiber Input MACRO Ring Receiver

2 TX Fiber Output MACRO Ring Transmitter

A. The fiber optic version of MACRO uses 62.5/125 multi-mode glass fiber optic cable terminated in an SC-style

connector. The optical wavelength is 1,300nm.

B. It is possible to "adapt" wire to fiber operation when using OPT A & C on the same MACRO-CPU board.

3U MACRO-CPU Board Connector Pin-outs

2

Page 32

MACRO-CPU Hardware Reference

U MACRO-CPU HARDWARE MEMORY MAP

The values in this table represent the hardware locations associated with register-based transactions that occur in

the 3U MACRO-CPU.

Reference ADDR (hex) Description

CS00- $FFC0 Stack I/O select #1

CS02- $FFC8 Stack I/O select #2

CS04- $FFD0 Stack I/O select #3

CS06- $FFD8 Stack I/O select #4

CS0- $C000 Stack axis 1-4 select

CS1- $C020 Stack axis 5-8 select

CS2- $C040 UBUS backplane axis 1-8 select

CS3- $C060 UBUS backplane axis 5-8 select

CS4- $C080 On-board DSPGATE2 select

CS4X- $C0C0 UBUS backplane MACROgate or DSPgate2 select (CS4- on UBUS)

CS10- $FFE0 UBUS backplane I/O select #1

CS12- $FFE8 UBUS backplane I/O select #2

CS14- $FFF0 UBUS backplane I/O select #3

CS16- $FFF8 UBUS backplane I/O select #4

MEMCS0- $D000 UBUS hardware I/O field (was DPRCS-)

MEMCS1- $E000 UBUS hardware I/O field (was VMECS-)

The addressing field size is 16-bits in the 3U MACRO-CPU. The address table above is similar to the PMAC2

product line.

U MACRO-CPU Hardware Memory Map

28

Page 33

MACRO-CPU Hardware Reference

U MACRO-CPU Hardware Memory Map

29

Page 34

MACRO-CPU Hardware Reference

0

ACCESSORIES

Both the Turbo and the MACRO CPU boards can support either the Stack or the UMAC configuration. The

systems are configured modularly with the selection of a series of accessory boards, some appropriate for the

Stack, and some appropriate for the UMAC. These accessories are listed here. Each has its own manual for

detailed description.

The following table shows 3U products by function:

MACRO CPU Board

Options

“Stack” Piggyback

Accessory Boards

UMAC BackplaneMountable

Accessory Boards –

Axis

UMAC BackplaneMountable

Accessory Boards –

I/O

UMAC BackplaneMountable

Accessory Boards –

Communication

UMAC BackplaneMountable

Accessory Boards –

Miscellaneous

UBUS Backplane

Board must be ordered with

either Option A or Option C.

ACC-1E, 2-Axis Interface

Stack Board (UMAC

MACRO only), 3x0-60281010x

ACC-4E, Isolated 24-In/24Out Stack Board,

3x0-602872-10x

ACC-24E2, 2-Axis Digital

PWM, 3x0-603397-10x

Option 1A, Additional 2Axis Analog,

3A1-603398-10x

ACC-3E1, 48/96/144 I/O,

3x0-603359-10x

ACC-11E, Isolated 24-In/24Out Board, 3x0-603307-10x

ACC-55E, (UNET)

U

niversal Field Bus Adapter

work Card,

Net

3x0-603485-10x

ACC-28E, 16-Bit A/D,

3x0-603404-10x

ACC-53E, SSI,

3x0-603360-10x

ACC-58E, R/D Converter,

16 Bit, 3x0-603482-10x

ACC-U4, UBUS 4-Slot ACC-U6, UBUS 6-Slot ACC-U8, UBUS 8-Slot

Option A, fiber-optic

connectors

ACC-2E, 4-Axis Interface

Stack Board,

3x0-602805-10x

ACC-6E, 8/16-Channel 12Bit ADC Stack Board,

3x0-602810-10x

Option 1D, Additional 2Axis Digital PWM,

3D1-603397-10x

ACC-24E2S, 4-Axis

Stepper, 3x0-603441-10x

ACC-9E, 48 In,

3x0-603283-10x

ACC-12E, Isolated 24In/24-Hi-Power-Out Board,

3x0-603277-10x

ACC-36E, A/D, D/A

Converter, 3x0-603483-10x

ACC-56E, Extender Card,

300-603401-10x

Option C, RJ-45 electrical

MACRO connectors

ACC-3E, 48/96/144 TTL I/O

Stack Board,

3x0-602811-10x

ACC-24E2A, 2-Axis

Analog, 3x0-603398-10x

ACC-10E, Isolated 48Output Board,

3x0-603299-10x

ACC-14E, 48 I/O,

3x0-603472-10x

ACC-51E, X 4096

Interpolator,

3x0-603438-10x

ACC-57E, Yaskawa or

Mitsubishi ABS, Encoder

Unit, 3x0-603484-10x

Accessories

3

Page 35

MACRO-CPU Hardware Reference

Boards

Amplifiers – Analog

±10VDC Input

(Brush Motors)

Amplifiers – Digital

PWM Input

(brushless)

Power Supplies –

DC Input

Power Supplies –

AC Input

UMAC Chassis

Assemblies (Rack)

Backplane, 300-603462

ACC-U10, UBUS 10-Slot

Backplane,

300-603464-10x

ACC-U16, UBUS 16-Slot

Backplane,

300-603471-10x

4-Axis Analog ± 10V Input

Linear Amplifier, 24VDC,

0.5/1A,

300-603489-10x

Backplane, Double Analog

Amplifier, 300-603470-10x

2-Axis Digital PWM

Amplifier, 360VDC, 4/8A,

400-603391-10x

Single-Axis Digital PWM

Amplifier, 360VDC, 8/16A,

401-603492-10x

ACC-F, 3U DC to DC

Converter,10A,

30F-603216-OPT

ACC-E, 3U AC Power

Supply, 8A,

30E-603269-OPT

3U Rack, 10-1/2 Slot (42T)

542-602932-10x

3U Rack, Variable Width per

Customer Requirements

(custom design) ,

500-602932-10x

Backplane,

300-603403-10x

ACC-U12, UBUS 12-Slot

Backplane,

300-603465-10x

ACC-U18, UBUS 18-Slot

Backplane,

300-603491-10x

4-Axis Analog ± 10V Input

PWM Amplifier, 48VDC,

2/4A, 300-603443-10x

Backplane, Single Analog

Amplifier, 300-603490-10x

2-Axis Digital PWM/Macro

Amplifier, 360VDC, 8/16A,

400-603392-10x

Power Supply for 3U Digital

PWM Amplifiers,

400-603428-10x

ACC-E1, 3U AC Power

Supply, 14A,

31E-603269-OPT

3U Rack, 15-3/4 Slot (63T)

563-602932-10x

Backplane,

300-603463-10x

ACC-U14, UBUS 14-Slot

Backplane,

300-603466-10x

4-Axis Analog ± 10V Input

PWM Amplifier, 70VDC,

8/12A, 300-603486-10x

Single Axis Digital

PWM/Macro Amplifier,

360VDC, 8/16A,

401-603391-10x

Backplane, Digital PWM,

300-603435-10x

ACC-E2, AC Power Supply,

20A, 32E-603468-OPT

3U Rack, 21 Slot (84T)

584-602932-10x

ACC-8DE, 2-Axis 3U

Hybrid Stack/Pack

Accessories

(Legacy Systems

Only)

Analog-Output Breakout

Board, 3x0-603215-10x

ACC13A, Flag Terminal

Block Board,

300-603366-10x

Accessories

ACC-8FE, 2-Axis 3U

Digital-Output Breakout

Board, 3x0-603176-10x

ACC-13B, Amplifier

Terminal Block Board,

300-603367-10x

ACC-13, Encoder Terminal

Block Board,

300-603365-10x

ACC-15E, Isolated 12-In/12Out Opto22 Driver &

Breakout Board,

300-603488-10x

31

Loading...

Loading...