Page 1

NanoTrace

Moisture Analyzer

DF-745

EnterNextMenuESC

Instruction Manual

Firmware Version 3.1.5

DELTA F CORPORATION

4 Constitution Way, Woburn, MA 01801-1087

Telephone: (781) 935-4600 FAX: (781) 938-0531

P/N 99000041

082510

Page 2

The Delta F Difference

Your NanoTrace Moisture Analyzer has been designed, manufactured and is

supported under the tightest of controls, thus helping to insure the highest

possible standards of quality.

Every analyzer that Delta F manufactures is tested and operated on a variety of

gas concentrations to insure that it functions properly when you receive it.

The certificate of calibration assures your analyzer has been calibrated on gases

that are traceable to NIST standards. With proper maintenance, your analyzer

should remain calibrated for years.

For a fast and successful startup, please read this manual carefully. There are

important cautions and a number of helpful hints to help you to optimize the

operation of your analyzer.

If you have questions, please do not hesitate to call the Delta F Service Line at

(781) 935-5808, use our Service FAX Line at (781) 932-0053 or e-mail us at

Service@Delta-F.com.

Copyright 2004 - 2010 by Delta F Corporation

No part of this publication may be reproduced, stored in a retrieval system or transmitted in

any form, or by any means including electronic, mechanical, photocopying, recording or

otherwise without prior written permission of Delta F Corporation.

NanoTrace Moisture Analyzer is a trademark of Delta F Corporation. VCR is a

registered trademark of the Cajon Company.

Page 3

Read Me First…

Unpacking Procedure

Follow the procedure below to unpack your NanoTrace Moisture Analyzer

1. Examine the condition of the packaging and its contents. If any damage is

apparent, immediately notify the carrier and Delta F. Do not proceed with

the installation.

2. Check the contents against the packing slip to make sure the shipment is

complete. Unattached equipment may be shipped with the analyzer in

supplemental packaging. Shortages should be reported to Delta F

immediately.

3. All NanoTrace Moisture Analyzers are shipped with the following:

Item Delta F Part

Number

Power cord with 115 VAC connector

NOTE: No power cord is supplied with 220 VAC units

USB Memory Stick, Flash Drive (SONY USM512J) P/N 49600512

VCR Filter Gasket P/N 60300268

Aspirator P/N 14241410

Instruction Manual P/N 99000041

P/N 59017237

4. Open the analyzer door, remove any shipping materials and verify that

nothing has come loose during transit.

5. The analyzer is set at the factory to operate on 120 VAC or 240 VAC.

Examine the voltage indicator on the rear panel to verify that the voltage is

set as ordered.

6. Save the original container in the event you may need to ship the analyzer

to another location or back to the factory (see Shipping in the Service

section).

Installation and Maintenance

The NanoTrace Moisture Analyzer provides years of accurate and dependable

service if it is set up, operated and maintained properly. It is essential to make

a careful and complete installation as outlined in the Installation and Start Up

section of this manual. It is assumed that NanoTrace Moisture Analyzer users

are familiar with the techniques and precautions associated with Ultra-High

Purity (UHP) gas, its plumbing, and devices such as UHP regulators and gas

purifiers, and that the analyzer is used as designed and intended.

Page 4

Unlike much UHP analytical equipment, NanoTrace Moisture Analyzer does

not require constant maintenance. However the maintenance intervals for zero

and span calibrations, must be determined and followed carefully.

Thank You

Thank you for selecting the NanoTrace Moisture Analyzer. Delta F designs,

manufactures, exhaustively tests, and supports every analyzer under the

tightest quality controls. You should expect every Delta F analyzer to arrive in

perfect working order and, with good maintenance, provide years of troublefree service. Please call the Service Phone Line at (781) 935-5808 if you need

assistance or if you have suggestions, or use our Service Fax Line at (781)

932-0053 or e-mail us at Service@Delta-F.com.

Page 5

1 Table of Contents

1 Table of Contents ....................................................................1

1.1 Table of Figures...................................................................................................... 3

2 Cautions.................................................................................... 7

2.1 Symbols and Explanations......................................................................................7

2.2 Important Warnings ...............................................................................................7

3 Specifications ..........................................................................9

3.1 Moisture.................................................................................................................9

3.2 General................................................................................................................... 9

4 Installation, Start Up and Shut Down ................................... 13

4.1 Analyzer Installation ............................................................................................ 14

4.1.1 Vacuum Source ....................................................................................... 14

4.1.2 Pneumatic Pressure Line Connection - Optional ...................................... 15

4.1.3 Sample Gas Connections ......................................................................... 15

4.1.4 Electrical Connections ............................................................................. 17

4.1.5 Hydrogen Service Safety System .............................................................. 17

4.2 Analyzer Start Up................................................................................................. 19

4.2.1 Gas Delivery System ................................................................................ 19

4.2.2 Gas Pressure and Flow Settings ............................................................... 20

4.2.3 Download System Data............................................................................ 21

4.3 Analyzer Shut Down ............................................................................................21

5 Options ................................................................................... 25

5.1 Key Lock .............................................................................................................. 25

5.2 Operating Voltage ................................................................................................ 25

5.3 Serial Communications......................................................................................... 25

5.4 Analog Voltage Output.........................................................................................25

5.5 Hydrogen Service Safety System ...........................................................................25

5.6 Vacuum Pump...................................................................................................... 25

5.6.1 Installation of the Vacuum Pump ............................................................. 26

5.6.2 Moisture Sample Gas Outlet Connection to Vacuum Pump ...................... 28

5.6.3 Electrical Connections ............................................................................. 28

6 Connecting to External Devices ........................................... 31

6.1 Serial Communication Port – J5 ........................................................................... 31

6.2 Analog Signal Outputs – J4 ..................................................................................32

6.3 4-20 mA Outputs – J4........................................................................................... 32

6.4 Relay Ports – J8, J9............................................................................................... 33

7 User Interface ......................................................................... 35

7.1 Data Display Screen .............................................................................................35

7.2 Keypad ................................................................................................................. 35

7.3 Menu Structure..................................................................................................... 36

7.4 Main Menu........................................................................................................... 36

7.4.1 Isolate Analyzer – Optional ..................................................................... 37

7.4.2 Restore Sample Gas Flow – Optional ....................................................... 38

Table of Contents DF-745 1

Page 6

7.4.3 Calibrate Menu........................................................................................ 38

7.4.4 Data History Routine ............................................................................... 42

7.4.5 Data Downloader Routine........................................................................ 44

7.4.6 View Logs Menu ..................................................................................... 46

7.4.7 Analyzer Setup ........................................................................................ 49

7.4.8 Analog Output Setup ............................................................................... 55

7.4.9 Graph Setup ............................................................................................ 56

7.4.10 Diagnostics Menu ................................................................................ 56

7.4.11 Adjust Contrast.................................................................................... 62

7.4.12 Power Up Default – Optional ............................................................... 63

7.4.13 Date/Time............................................................................................ 64

7.4.14 Communications.................................................................................. 65

7.4.15 Download System Data ........................................................................ 65

7.4.16 System Info.......................................................................................... 67

8 Sample Gas Preparation and Delivery................................. 69

8.1 Introduction.......................................................................................................... 69

8.2 Sample Flow Rate and Pressure ............................................................................ 69

8.3 Flow Rate Effects on Sensor Performance............................................................. 69

8.4 Sample Gas Scale Factor ...................................................................................... 69

8.4.1 Background Gas Effects on Indicated Flow Rate ...................................... 69

8.5 Flammable Sample Gas ........................................................................................ 70

9 Service.................................................................................... 71

9.1 Return Material Authorization number ................................................................. 71

9.2 Maintenance......................................................................................................... 71

9.2.1 Storage Conditions .................................................................................. 71

9.2.2 Moisture Cell Maintenance...................................................................... 71

9.2.3 Vacuum Pump Maintenance .................................................................... 71

9.3 Replaceable Parts List........................................................................................... 73

9.4 Troubleshooting the DF–745 NanoTrace Analyzer ............................................... 75

10 Theory of Operation .............................................................. 77

10.1 The Moisture Measurement................................................................................. 77

10.1.1 Moisture and the IR Spectrum.............................................................. 77

10.1.2 Absorption Spectroscopy...................................................................... 78

11 Safety...................................................................................... 79

11.1 General Warnings............................................................................................... 79

12 Warranty ................................................................................. 81

13 Index ....................................................................................... 83

14 Appendix A – User Menu Screens........................................ 85

15 Appendix B – Hydrogen Service Safety System................. 89

15.1 Instrument .......................................................................................................... 89

15.2 Vacuum Pump ....................................................................................................89

15.3 Installation.......................................................................................................... 89

15.4 Operation............................................................................................................ 90

2 DF-745 Table of Contents

Page 7

1.1 Table of Figures

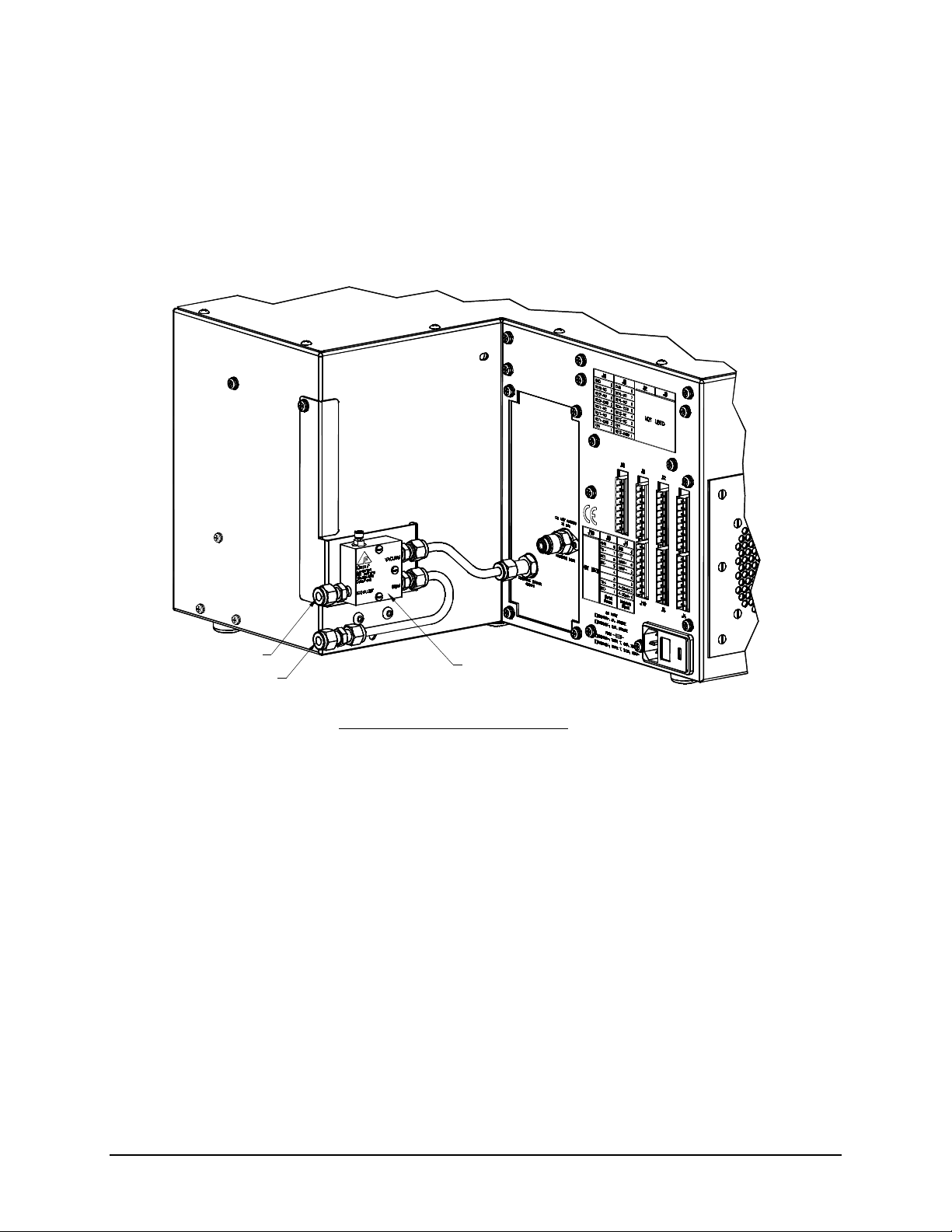

Figure 1: Overall View.............................................................................................................................. 11

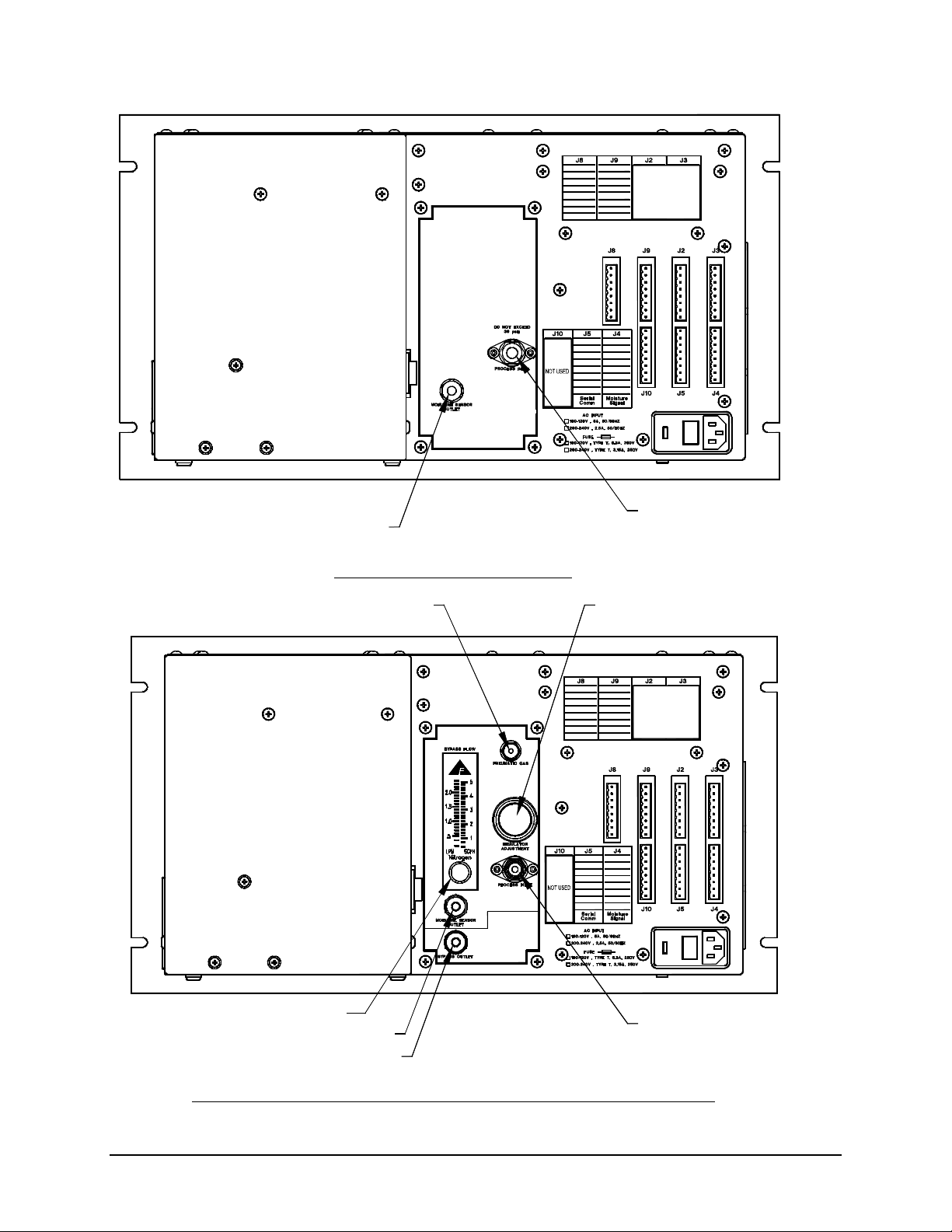

Figure 2: Major Internal Components........................................................................................................ 13

Figure 3: Aspirator Installation ................................................................................................................. 14

Figure 4: Rear Gas Connections ................................................................................................................ 16

Figure 5: Rear Gas Connections and Controls with Optional Gas Panel..................................................... 16

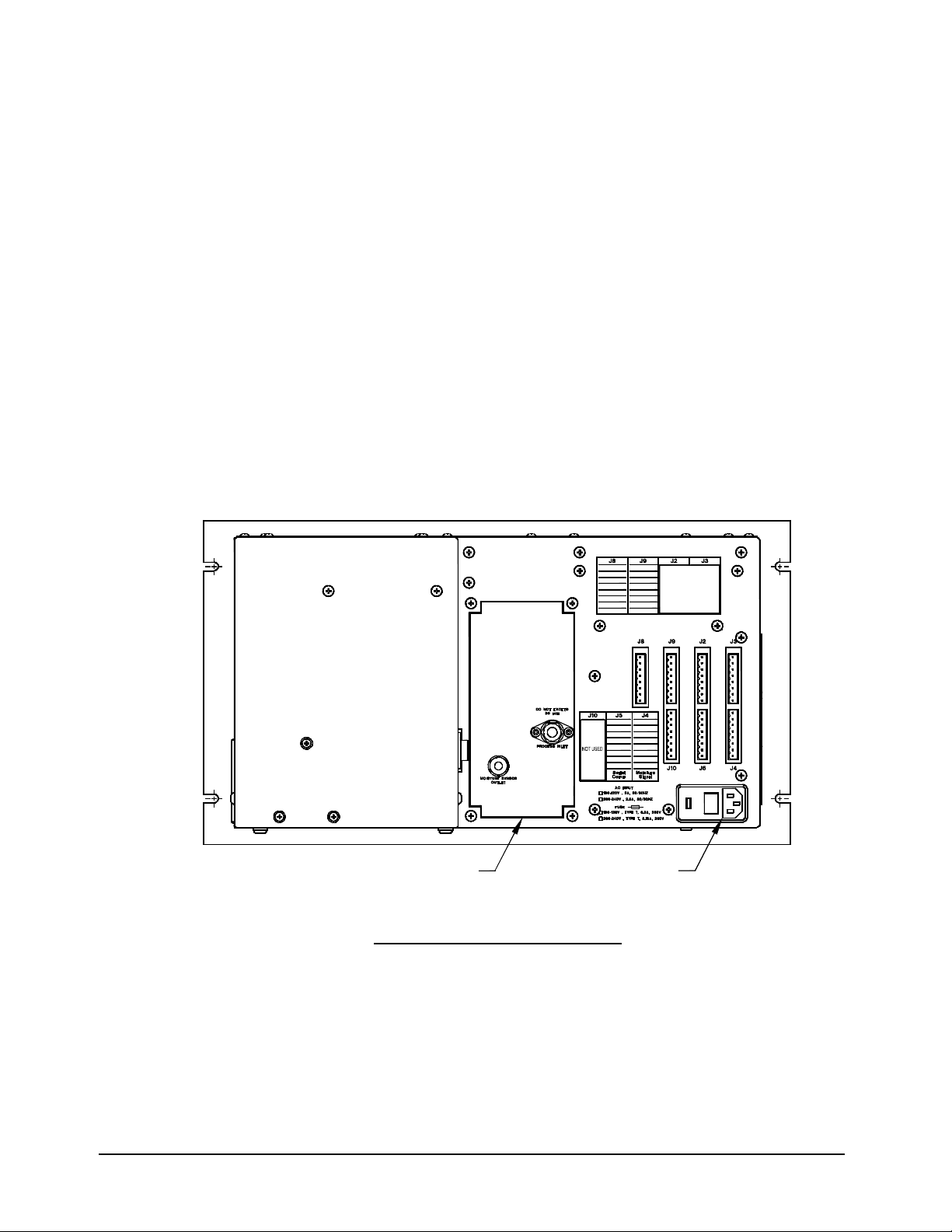

Figure 6: AC Power Connections .............................................................................................................. 17

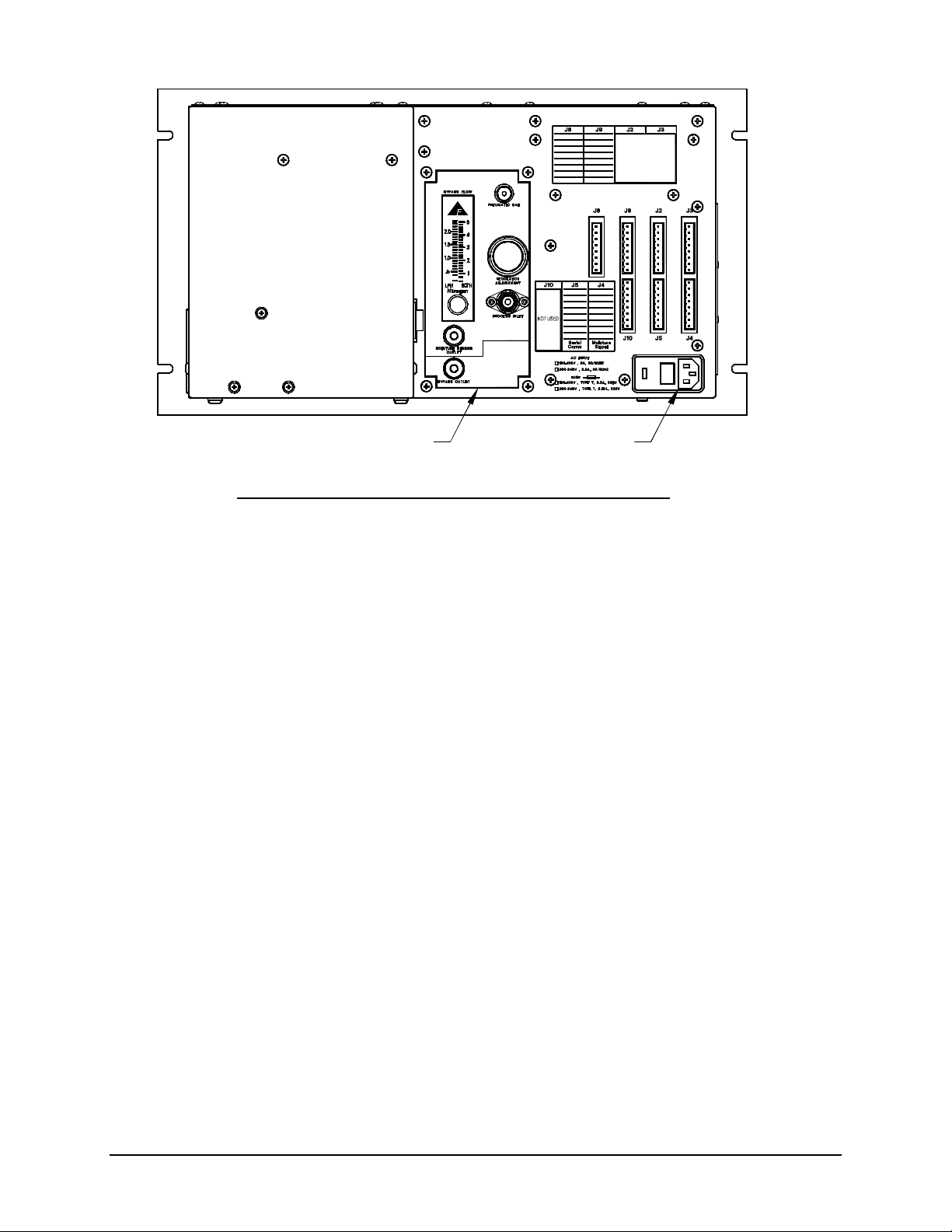

Figure 7: AC Power Connections with Optional Gas Panel........................................................................ 18

Figure 8: Data Display Screen................................................................................................................... 19

Figure 9: Block Diagram of Gas Flow Path and Aspriator ......................................................................... 22

Figure 10: Block Diagram of Gas Flow Path with Optional Valves and Aspirator...................................... 23

Figure 11: Vacuum Pump Assembly.......................................................................................................... 26

Figure 12: Vacuum Pump Mount Dimensions ........................................................................................... 27

Figure 13: Vacuum Pump Dimensions ......................................................................................................27

Figure 14: Vacuum Pump Power Connections and Controls ...................................................................... 28

Figure 15: Block Diagram of Gas Flow Path and Optional Vacuum Pump................................................. 29

Figure 16: Block Diagram of Gas Flow Path with Optional Valves and Vacuum Pump .............................29

Figure 17: Rear Panel Electrical Connectors.............................................................................................. 31

Figure 18: Data Display Screen ................................................................................................................. 35

Figure 19: Keypad..................................................................................................................................... 36

Figure 20: Main Menu ..............................................................................................................................36

Figure 21: Main Menu (without valve option) ...........................................................................................37

Figure 22: Isolate Analyzer ....................................................................................................................... 37

Figure 23: Isolate Warning........................................................................................................................ 38

Figure 24: Restore Sample Gas Flow......................................................................................................... 38

Figure 25: Calibrate Menu ........................................................................................................................ 39

Figure 26: Check/Adjust Zero Menu.......................................................................................................... 39

Figure 27: Check/Adjust Zero Screen ........................................................................................................ 40

Figure 28: User Zero Offset ....................................................................................................................... 40

Figure 29: Manual Zero Screen .................................................................................................................41

Figure 30: Data History Menu................................................................................................................... 42

Figure 31: Data History Screen.................................................................................................................. 43

Figure 32: Install Media ............................................................................................................................ 43

Figure 33: Example of Data Download......................................................................................................43

Figure 34: Data Downloader Menu............................................................................................................ 44

Figure 35: Data Downloader Screen .......................................................................................................... 44

Figure 36: View Location Screen............................................................................................................... 45

Figure 37: Keyboard Display..................................................................................................................... 45

Figure 38: Delete Selection........................................................................................................................ 46

Figure 39: View Zero Log Menu ............................................................................................................... 46

Figure 40: Zero Log Screen ....................................................................................................................... 47

Figure 41: View System Error Code Log Menu .........................................................................................47

Figure 42: System Error Code Screen........................................................................................................48

Figure 43: Pump Capacity Test Log Menu................................................................................................. 48

Figure 44: Pump Capacity Test Log...........................................................................................................49

Figure 45: Sample GSF Menu ................................................................................................................... 49

Figure 46: Sample GSF Setup Screen ........................................................................................................ 50

Figure 47: GSF Pressure Setting................................................................................................................ 50

Figure 48: Fan Failure Alarm....................................................................................................................50

Table of Contents DF-745 3

Page 8

Figure 49: Alarm Setup Menu................................................................................................................... 51

Figure 50: Alarm Setup Screen ................................................................................................................. 52

Figure 51: Temperature Alarm Setup ........................................................................................................ 53

Figure 52: Pressure Alarm Setup............................................................................................................... 53

Figure 53: System Alarm Setup................................................................................................................. 54

Figure 54: Analog Output Setup Menu...................................................................................................... 55

Figure 55: Analog Output Setup Screen .................................................................................................... 55

Figure 56: Graph Setup Menu ................................................................................................................... 56

Figure 57: Graph Setup Screen.................................................................................................................. 56

Figure 58: Active Zero On/Off Menu ........................................................................................................ 57

Figure 59: Test Relays Menu..................................................................................................................... 58

Figure 60: Test Alarm Relays Screen ........................................................................................................ 58

Figure 61: Test Analog Outputs Menu....................................................................................................... 59

Figure 62: Test Analog Voltage Output Screen.......................................................................................... 59

Figure 63: Signal Monitor Menu ............................................................................................................... 60

Figure 64: Signal Monitor Screen.............................................................................................................. 60

Figure 65: Pump Capacity Test Menu........................................................................................................61

Figure 66: Pump Capacity Test Screen ...................................................................................................... 61

Figure 67: Pump Pressure Failure.............................................................................................................. 61

Figure 68: Pump Capacity Test Log ..........................................................................................................62

Figure 69: Adjust Contrast Menu ..............................................................................................................62

Figure 70: Adjust Display Contrast Screen ................................................................................................ 62

Figure 71: Power Up Default Menu ........................................................................................................... 63

Figure 72: Power Up Default Screen.......................................................................................................... 63

Figure 73: Date/Time Menu ...................................................................................................................... 64

Figure 74: Date/Time Setup Screen ........................................................................................................... 64

Figure 75: Communications Menu ............................................................................................................65

Figure 76: Communications Setup Screen ................................................................................................. 65

Figure 77: Download System Data Menu .................................................................................................. 66

Figure 78: Insert Media............................................................................................................................. 66

Figure 79: Media Warning ........................................................................................................................ 66

Figure 80: Download Time Line................................................................................................................ 67

Figure 81: System Info Menu .................................................................................................................... 67

Figure 82: System Info Screen................................................................................................................... 68

Figure 83: Software Upgrade Screen ......................................................................................................... 68

Figure 84: Schematic of Moisture Cell ...................................................................................................... 77

Figure 85: Hydrogen Service Safety System............................................................................................... 93

Figure 86: Pump Purge Option .................................................................................................................. 94

4 DF-745 Table of Contents

Page 9

Table of Tables

Table 1: Recommended Sample Outlet Vacuum Pressure .......................................................................... 21

Table 2: Pin-out of Serial Comm Connector J5.......................................................................................... 32

Table 3: Serial Communications Connections ........................................................................................... 32

Table 4: Pin-Out of Moisture Signal Output Connector J4 ......................................................................... 32

Table 5: Pin-Out of Relay Connectors J8 and J9 ........................................................................................ 33

Table 6: Alarm Codes ............................................................................................................................... 51

Table 7: Sample Outlet Pressure................................................................................................................ 69

Table 8: Replaceable Parts List.................................................................................................................. 73

Table of Contents DF-745 5

Page 10

Page 11

2 Cautions

There are a number of warnings and cautions that must be observed to avoid damage to the

analyzer as well to insure the safety of its users. The analyzer must be operated in a manner

specified in this manual. Delta F cannot be responsible for direct or consequential damages

that result from installing or operating the analyzer in a manner not described in this manual.

Importantly, the analyzer has been designed for use with inert, non-toxic, non-combustible

sample gases only. Delta F cannot be responsible for direct or consequential damages that

result from using the analyzer with these gases.

2.1 Symbols and Explanations

Following is a list of the various symbols used throughout this manual and their definitions.

CAUTION

This symbol alerts the user to the presence of physically hazardous

conditions that may be dangerous to individuals or equipment.

This symbol alerts the user to the presence of important operations

and/or maintenance information.

2.2 Important Warnings

Potentially hazardous AC voltages are present

within this instrument. Leave all servicing to

qualified personnel. Disconnect the AC power

source when installing or removing: external

connections, the sensor, or the electronics.

NOTE

CAUTION

Cautions DF-745 7

Page 12

CAUTION

Do not setup or operate this analyzer without a

complete understanding of the instructions in this

manual. Do not connect this Analyzer to a power

source until all signal and plumbing connections

are made.

CAUTION

This analyzer must be operated in a manner consistent with its

intended use and as specified in this manual.

EMI DISCLAIMER

This Analyzer generates and uses small amounts of radio frequency

energy. There is no guarantee that interference to radio or

television signals will not occur in a particular installation. If

interference is experienced, turn-off the analyzer. If the

interference disappears, try one or more of the following methods

to correct the problem:

Reorient the receiving antenna.

Move the instrument with respect to the receiver.

Place the analyzer and receiver on different AC circuits.

8 DF-745 Cautions

Page 13

3 Specifications

3.1 Moisture

Lowest Detection Level (LDL): 2 ppb @ Constant Conditions

Resolution: Analytical (Smallest Detectable Change): .5 ppb

Display: 100 ppt

Accuracy: Greater of ±3% of reading or ±1 ppb @ Constant Conditions

Speed of Response: Typically 10 minutes to reach 90 percent of an upward step change

Upset Recovery Time: Typically less than 5 minutes from a high ppb upset to within 10

ppb of the previously stable reading.

Range: 0-20 ppm

Background Gas Compatibility: All inert and passive gases including N2, H2, He, Ar

and O

2

3.2 General

Warranty: One year from ship date on the entire instrument. See Warranty section on

page 81.

Power Requirements: 100 to 120 VAC, 50/60 Hz, standard, 5 Amps

200 to 240 VAC, 50/60 Hz (optional), 2.5 Amps

Display: 7.4 inch VGA Color (640X480)

Ambient Operating Temperature: 10° C to 40° C (50° F to 105° F)

Output Signals:

Analog Output: User Scalable: 0-2 ppb to 0-20 ppm Moisture

0-1, 0-2, 0-5, or 0-10 VDC (minimum load resistance 1K)

Isolated 4-20 mADC, 1K ohm loop resistance max (28V Compliance voltage provided)

Digital Communications: Two-way RS-232 or RS-485 set at the time of order

Operating Inlet Pressure: 5 to 30 psig (0.3 to 2 bar)

Flow Rate: 0.5 – 4.0 slpm N

Sample Temperature: 10° C to 80°C (50° F to 176° F)

EMI Sensitivity: Tested to standards EN61000-3-3 and EN61326-1

2

Specifications DF-745 9

Page 14

Audible/Visual Alarm Status Indicators: Four Moisture levels, Temperature,

Moisture cell Diagnostic, Zero Verification or Calibration in Process, Moisture Analyzer

off-line, Analog output freeze during calibration.

Alarm Relays: Four non-latching, independently assignable to moisture alarms or to

moisture calibration-in-process indicator. SPDT contacts rated at 1 Amp @ 30 VDC. Fail

safe action upon loss of power to alarm condition. Not designed to switch AC power.

Storage Temperature: Not to exceed 50° C (122° F)

Construction: NEMA 1, 19 inch rack mount

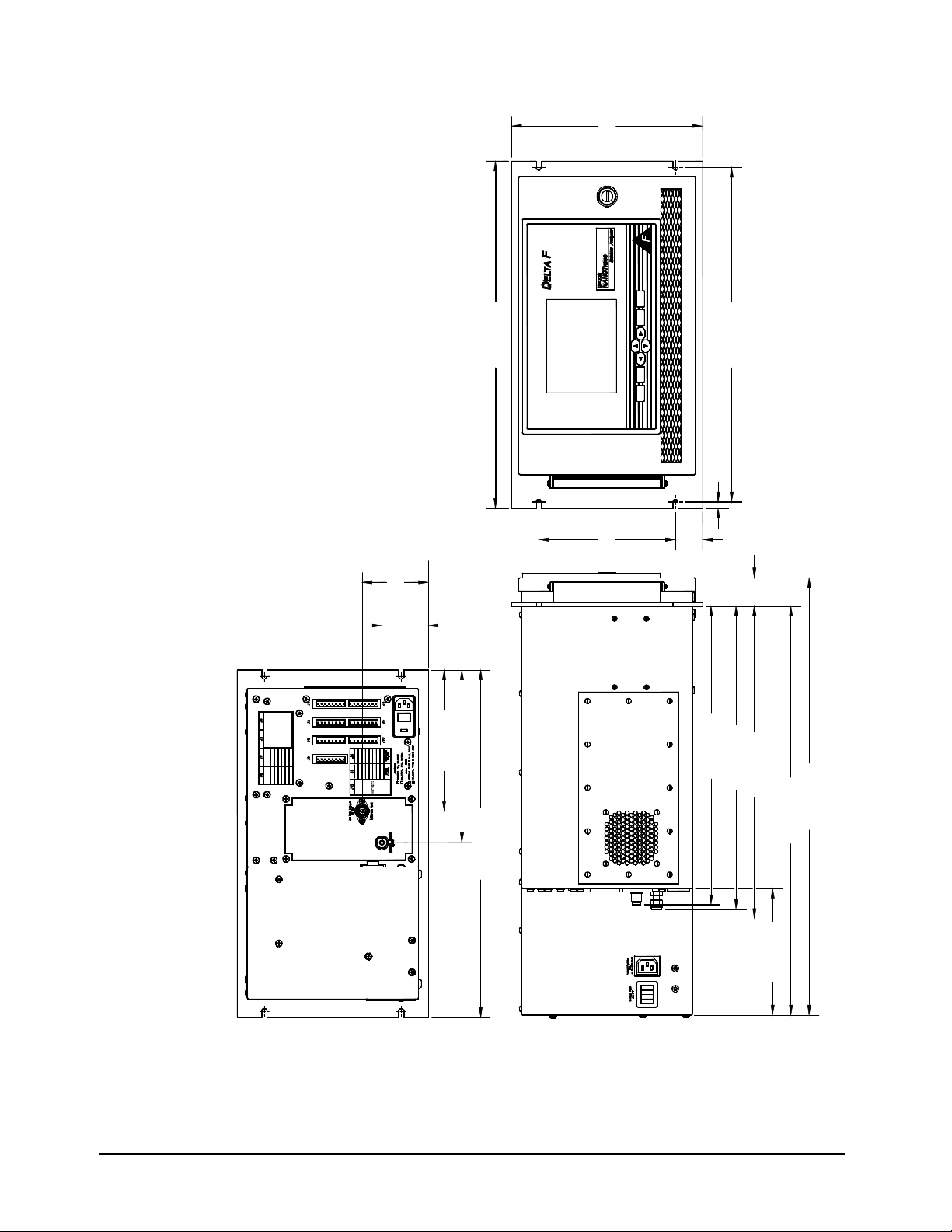

Dimensions: 19 inch (48.3cm) wide x 10.5 inch (26.7 cm) high x 22.5 inch (57.2 cm)

deep

Weight: 70 pounds (31.8 kg)

Gas Path Construction Materials:

300 series stainless steel electro-polished

1/4-inch VCR-type compatible sample inlet fitting

1/8-inch compression sample outlet fitting

1/4-inch compression vacuum fitting

Kel-f valve seats

PTFE Vacuum tubing

10 DF-745 Specifications

Page 15

EnterNextMenuESC

19.00 [482.60]

18.31 [465.12]

.34 [8.74]

7.50 [190.50] 10.47 [265.94]

1.49 [37.72]

1.55 [39.25]

3.63 [92.08]

2.54 [64.44]

NOT USED

55 RLY4-COMRLY2-COM

44 RLY3-NC12

3

6

7

KEY

RLY3-NO

GND8

RLY4-NC

321 RLY3-COM

7

6 RLY4-NO

RLY1-COM

RLY1-NO

RLY1-NC

KEY

RLY2-NO

RLY2-NC

GND 8

87645

KEY

GND8

764

TX-

GND

~

3312

4-20mA-

4-20mA+

AOUT+

1

2

5 AOUT-

~~~

RX+

TX+

RX-

KEY

~ ~

7.71 [195.77]

9.45 [239.90]

16.33 [414.78]

16.58 [421.01]

17.08 [433.71]

23.93 [607.70]

22.38 [568.45]

(19.00 [482.60])

6.94 [176.28]

Figure 1: Overall View

Specifications DF-745 11

Page 16

Page 17

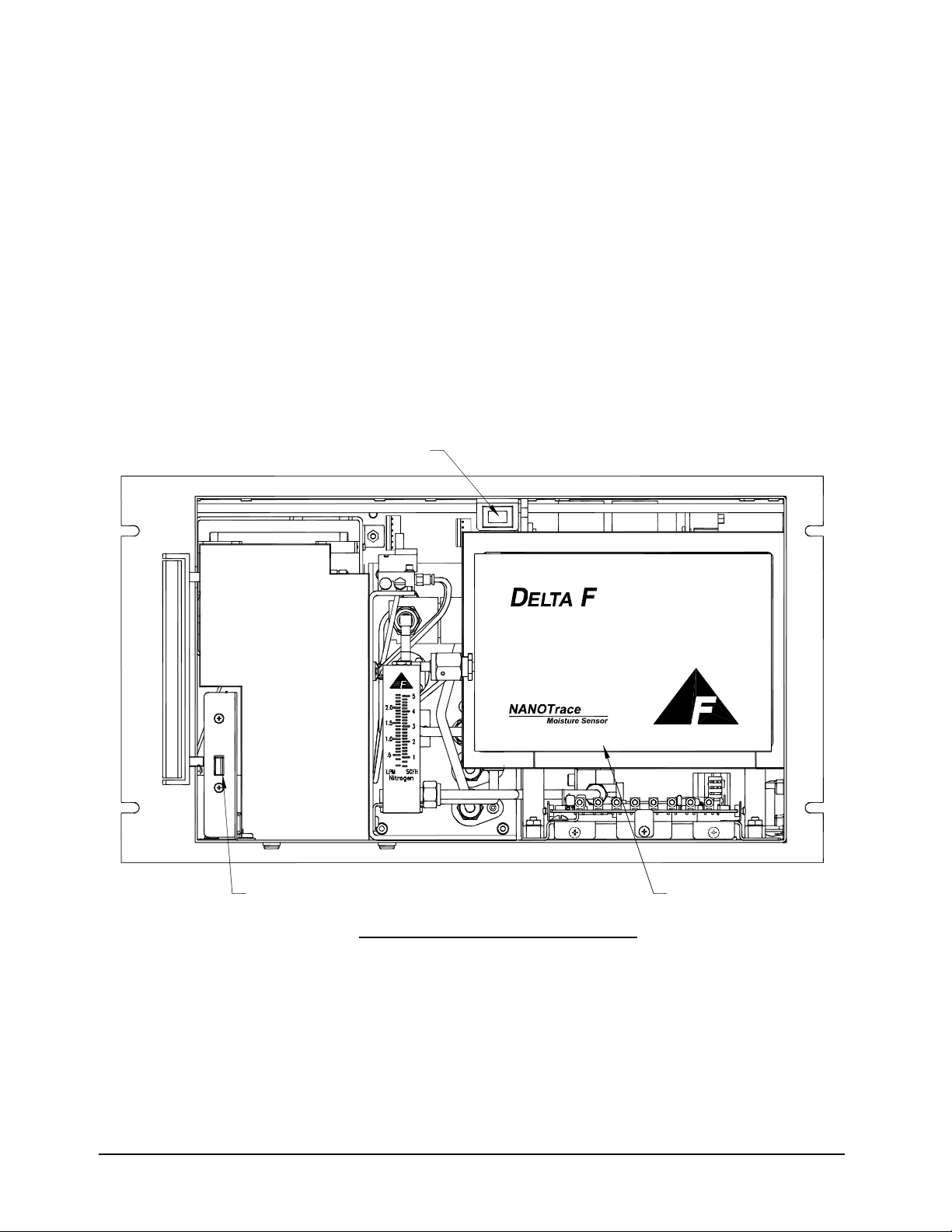

4 Installation, Start Up and Shut Down

2

Installation of the analyzer requires the following steps be followed:

Connecting the N2/Air supply to the aspirator

Connecting an exhaust tube to the aspirator outlet, if needed

Connecting the pneumatic pressure service to the pneumatic inlet fitting

Connecting the sample gas line to the analyzer inlet fitting

Making the power connection to the analyzer

POWER SWITCH

USB PORT H O SENSOR

Figure 2: Major Internal Components

Installation, Start Up and Shut Down DF-745 13

Page 18

4.1 Analyzer Installation

4.1.1 Vacuum Source

4.1.1.1 Aspirator

The standard vacuum source provided with the DF-745 analyzer is a factory installed

aspirator as shown in Figure 3. Aspirator installation with the optional gas panel is identical.

SAMPLE VENT

80 psi IN

ASPIRATOR

Figure 3: Aspirator Installation

A regulated source of dry compressed gas (either N2 or air) is required at 80psi and a flow

rate of approximately 15 slpm. Connection is made to the aspirator by way of a ¼ inch

compression fitting labeled “80 psi IN”. It is very important to note that the diameter of the

gas supply line must be a minimum of ¼ inch to provide sufficient flow. If operation in

Helium background is anticipated, a shut off valve should be installed at the inlet to the

aspirator.

For ease of installation, the aspirator source can also supply the pneumatic gas inlet by way

of a 1/8 inch adapter.

The gas at the sample vent port is comprised of the analyzer sample gas and the compressed

gas, and any noise can be mitigated by simply installing a ¼ inch tube of approximately 3 ft

in length. Backpressure should be minimized at this port (max 2.0 psi) and if the exhaust

must be vented for safety reasons it must be done to a header of greater diameter.

The aspirator needle valve should be opened (CCW) completely.

14 DF-745 Installation, Start Up and Shut Down

Page 19

Be sure to use a backup wrench when making all connections to the

aspirator.

4.1.1.2 Vacuum Pump

An optional vacuum pump can be purchased for those cases where there is insufficient gas

pressure or flow to operate the aspirator, or when the analyzer is installed in a portable cart

and connection to a continuous gas supply is inconvenient. See page 25 for information on

the installation of the optional vacuum pump.

4.1.2 Pneumatic Pressure Line Connection - Optional

The pneumatic gas connection (required for the optional gas panel) is a 1/8 inch

compression fitting as shown in Figure 5 and requires 70 – 125 psig air or N2 pressure. For

ease of installation, the pneumatic feed line can be connected directly to the ¼ inch aspirator

source by way of a 1/8 inch adapter.

4.1.3 Sample Gas Connections

4.1.3.1 Sample Gas Inlet Connection

Sample gas is connected to the analyzer via a ¼ inch male swivel VCR fitting labeled

Process Inlet at the rear of the instrument as shown in Figure 4. Sample pressure of 30 –

150 psig is required and is regulated internally.

Pre-purge the line by connecting to the analyzer (with a new VCR filter gasket) only finger

tight and flowing gas for 15 minutes. Then tighten the inlet fitting.

NOTE: A VCR filter gasket (supplied) should always be used to protect the gas delivery

system from any particulate matter that may have collected in the line.

When power is applied to the analyzer, the internal gas control valves will automatically go

to a state as determined by the user. See the section on Power Up Defaults on page 63 for

additional information.

NOTE: When received from the factory, if equipped with internal gas valves, the moisture

cell will be isolated with pressure in the system. See the sections on Moisture Gas Valves

Control on pages 38 for instructions on starting the gas flow through either sensor.

See Figure 9 for an overview of the gas flow through the analyzer.

See the section on Gas Pressure and Flow Settings on page 20 for important information on

plumbing and powering up the analyzer.

4.1.3.2 Sample Gas Outlet Connection

The sample gas outlet connection is a ¼ inch compression fitting labeled Moisture Sensor

Outlet as shown in Figure 4. A ¼ inch stainless tube is connected from the analyzer sample

outlet to the Aspirator assembly. See Figure 3. Open the needle control valve (CCW) on

the top of the aspirator assembly completely. NOTE: If the Hydrogen Service Safety

System is included, the sample outlet line must be made of steel. See page 89 for additional

information.

Installation, Start Up and Shut Down DF-745 15

Page 20

See page 25 for information on the installation of the optional vacuum pump.

PROCESS OUTLET

REGULATOR ADJUST

BYPASS OUTLET

GND 8

GND8

RLY2-NC

RLY2-NO

RLY1-NC

RLY1-NO

RLY1-COM

KEY

7

RLY4-NC

6 RLY4-NO

RLY3-NO

1 RLY3-COM

7

6

55 RLY4-COMRLY2-COM

NOT USED

44 RLY3-NC

23KEY32

1

Figure 4: Rear Gas Connections

PNEUMATIC GAS INLET

GND

GND8

TX-

KEY

7

KEY

6

AOUT+

RX-

5 AOUT-

4

TX+

4-20mA+

RX+

124-20mA-

~

~

~

~

GND 8

GND8

RLY2-NC

7

RLY4-NC

RLY2-NO

6 RLY4-NO

RLY1-NC

RLY1-NO

RLY3-NO

RLY1-COM

KEY

1 RLY3-COM

8

7

6

5

4

33

2

1

~

~

PROCESS INLET

7

6

55 RLY4-COMRLY2-COM

NOT USED

44 RLY3-NC

23KEY32

1

BYPASS FLOW ADJUST

GND

TX-

KEY

RX-

TX+

RX+

8

GND8

7

KEY

7

6

6

AOUT+

5

5 AOUT-

4

4

33

4-20mA+

12124-20mA-

~

~

~

~

~

~

PROCESS INLET

PROCESS OUTLET

Figure 5: Rear Gas Connections and Controls with Optional Gas Panel

16 DF-745 Installation, Start Up and Shut Down

Page 21

4.1.4 Electrical Connections

Open the door and locate the power switch in the center of the upper rail. Be sure it is in

the OFF position. Plug the line cord (supplied with 110VAC units only) into the receptacle

at the back of the analyzer. Verify the operating voltage is proper according to the label on

the rear and connect the line cord to the power source. See Figure 6 and Figure 7.

4.1.5 Hydrogen Service Safety System

This optional system is designed to safeguard the DF-745 from explosion hazards when

operating on hydrogen sample gas under normal pressure and flow conditions as detailed in

the Operating Instruction Manual. The instrument chassis and the remote pump, if

equipped, are both protected by maintaining a safe condition within their respective

enclosures. If installed, this option impacts the electrical wiring, gas plumbing and operation

of the analyzer. See page 89 for additional installation and operation information.

NOTE, if equipped with the Hydrogen Safety Service System, when shipped from the

factory the analyzer will be configured through the GSF screen to measure hydrogen. As a

result, the Hydrogen Safety Service System will be enabled out of the box.

STANDARD GAS PANEL SHOWN

Figure 6: AC Power Connections

GND 8

GND8

RLY2-NC

7

RLY4-NC

RLY2-NO

6 RLY4-NO

RLY1-NC

RLY1-NO

RLY3-NO

RLY1-COM

KEY

1 RLY3-COM

GND

GND8

TX-

KEY

7

KEY

6

AOUT+

RX-

5 AOUT-

4

TX+

2

4-20mA+

RX+

4-20mA-

~

~

~

~

AC INLET

7

6

55 RLY4-COMRLY2-COM

NOT USED

44 RLY3-NC

23KEY32

1

8

7

6

5

4

33

121

~

~

Installation, Start Up and Shut Down DF-745 17

Page 22

GND

8

GND

RLY2-NC

RLY2-NO

RLY2-COM

RLY1-NC

RLY1-NO

RLY1-COM

KEY

TX-67

KEY

TX+42

RX+ 1

8

RLY4-NC

7

7

RLY4-NO

6

6

RLY4-COM

5

5

RLY3-NC

4

4

RLY3-NO

3

3

KEY

2

2

RLY3-COM

1

1

8GND

GND 8

KEY67

AOUT+

5RX-

AOUT- 5

3

3

4-20mA+42

4-20mA- 1

~

~

~

~

ISOLATION GAS PANEL SHOWN AC INLET

Figure 7: AC Power Connections with Optional Gas Panel

~

NOT USED

~

18 DF-745 Installation, Start Up and Shut Down

Page 23

4.2 Analyzer Start Up

It is important to note that, if equipped with automatic gas valves, the moisture cell is

isolated from gas flow while the analyzer is off power.

Open the door and turn on the power using the main power switch inside the analyzer. See

Figure 2. The pump, if equipped, should turn on (see page 17) and the analyzer will

undergo a series of Diagnostic Procedures while the various startup screens are displayed.

Next, the Delta F Corporation logo is briefly displayed and then the data display appears

with the “Warming Up” screen flashing. The warm up process takes approximately six to

ninety minutes after which the display will look similar to Figure 8 (values shown are only

representative).

During the Warm Up process the gas valves (if equipped) can be opened and gas flow

started. See the section on Gas Pressure and Flow Settings on page 20 for important

information on the gas delivery system and setting proper pressures and flow rates.

During the warm up period all analog and digital outputs are held to an

artificial 0.011ppb reading to avoid the reporting of false readings.

NOTE

Figure 8: Data Display Screen

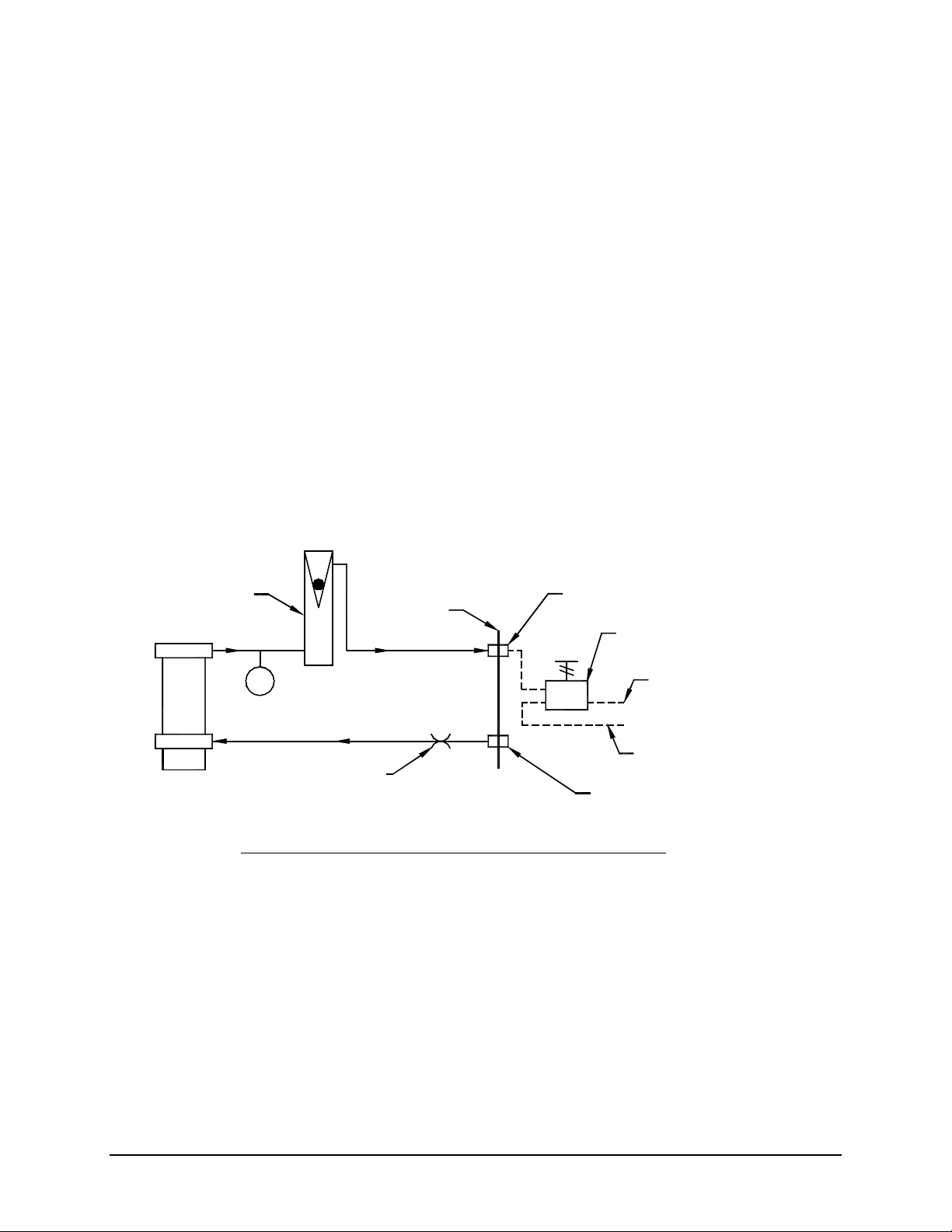

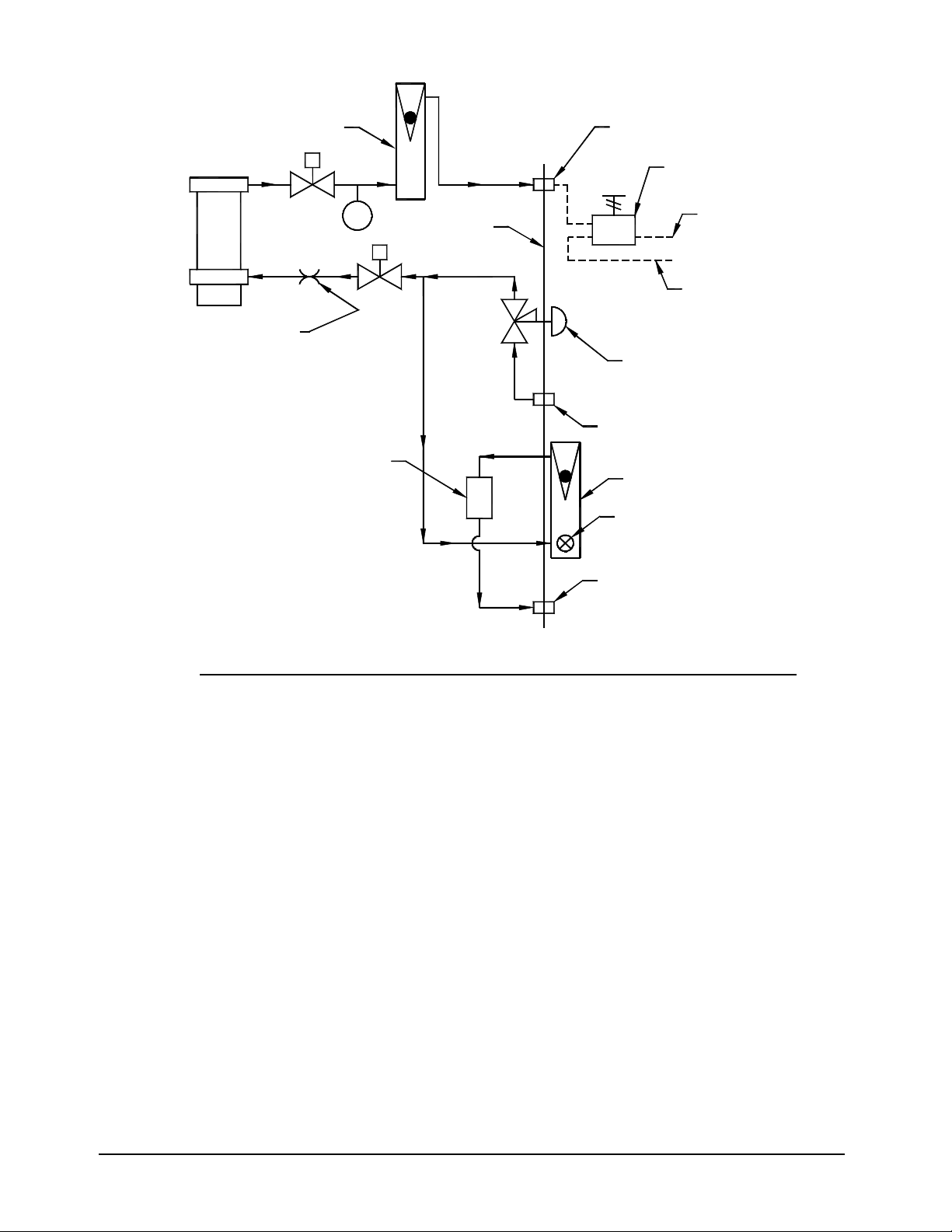

4.2.1 Gas Delivery System

The gas delivery system as shown in Figure 9 is designed to deliver a gas flow rate of 2

liters per minute to the moisture cell while maintaining the highest standards of gas purity

and delivery for ultra-trace analysis. Features include a single inlet line and flow meter for

the gas sample, and optional bypass loop to maintain constant purging, and essentially deadleg free delivery.

The connections at the rear of the gas delivery system include a ¼” VCR swivel connection

for the process inlet, a ¼” compression outlet for the moisture cell, an optional pneumatic

gas connection (1/8” compression), and an optional ¼” compression outlet for the bypass

loop. Also on the rear of the gas delivery system, if equipped, are a sample gas regulator to

adjust the internal sample pressure and a bypass flow meter.

Installation, Start Up and Shut Down DF-745 19

Page 24

The moisture cell outlet will be connected to the supplied aspirator or, if equipped, to the

vacuum pump.

The sample inlet to the moisture analyzer, as well as the zero gas inlet, are heated to 60 C.

This is done to mitigate any effects of adsorption-desorption of trace moisture on the walls

of the tubing.

4.2.2 Gas Pressure and Flow Settings

Attention to the setting of gas pressure and flow is critical to proper operation of the

analyzer. If all steps are followed carefully at the time of start up, subsequent changes to

flow or background gas will be made easier. The following procedure assumes all electrical

and plumbing connections have been made according to instructions in this manual. In

addition, this procedure assumes a Nitrogen gas background unless otherwise noted.

1. Power up the unit. See page 19. If the unit is equipped with a Hydrogen Safety

System, no flow will enter the system until the unit is on power.

2. Ensure that the needle valve on the aspirator is fully open.

3. For a basic analyzer with no cell isolation valves installed,

a. simply provide sufficient pressure (5-30 psi), resulting in a flow of 1 slpm (2

scfh) as indicated on the flow meter located behind the front door. NOTE:

The flow rate will directly impact the overall system speed of response.

b. Turn on the vacuum source (aspirator) by applying gas to the high pressure

inlet. See Figure 3. (Except when measuring in Helium background which is

not run under vacuum but at ambient) NOTE: Once the vacuum source is

connected and running, proper flow is indicated by a full scale reading on the

flowmeter.

c. Go to step 5.

4. For analyzers equipped with optional cell isolation valves:

a. Completely open (turn fully clockwise) the inlet regulator on the rear of the

analyzer. For operation in Nitrogen, Argon and Oxygen the regulator is

closed (turned counter clockwise) to the approximate middle, or 50% of its

range. For operation in Helium and Hydrogen it should be closed to 80-90%

of its range resulting in a flow of 1 slpm (2 scfh) as indicated on the flow

meter located behind the front door. NOTE: The flow rate will directly

impact the overall system speed of response.

b. Open the flowmeter bypass valve on the rear of the analyzer and flow in the

bypass loop will be indicated on the flowmeter. Adjust the flowmeter bypass

valve to 0.5 slpm. See Figure 5.

c. Purge for 15 minutes before opening gas valves to the moisture cell.

d. The state of the gas control valves is indicated on the main display. The

default state of a factory-shipped instrument is isolation. This can be

adjusted in the Power Up Default section. If the moisture cell is isolated,

establish process flow via the Main menu. See page 38.

20 DF-745 Installation, Start Up and Shut Down

Page 25

e. Use the regulator to adjust the flow through the cell to 1 slpm (2 scfh) as

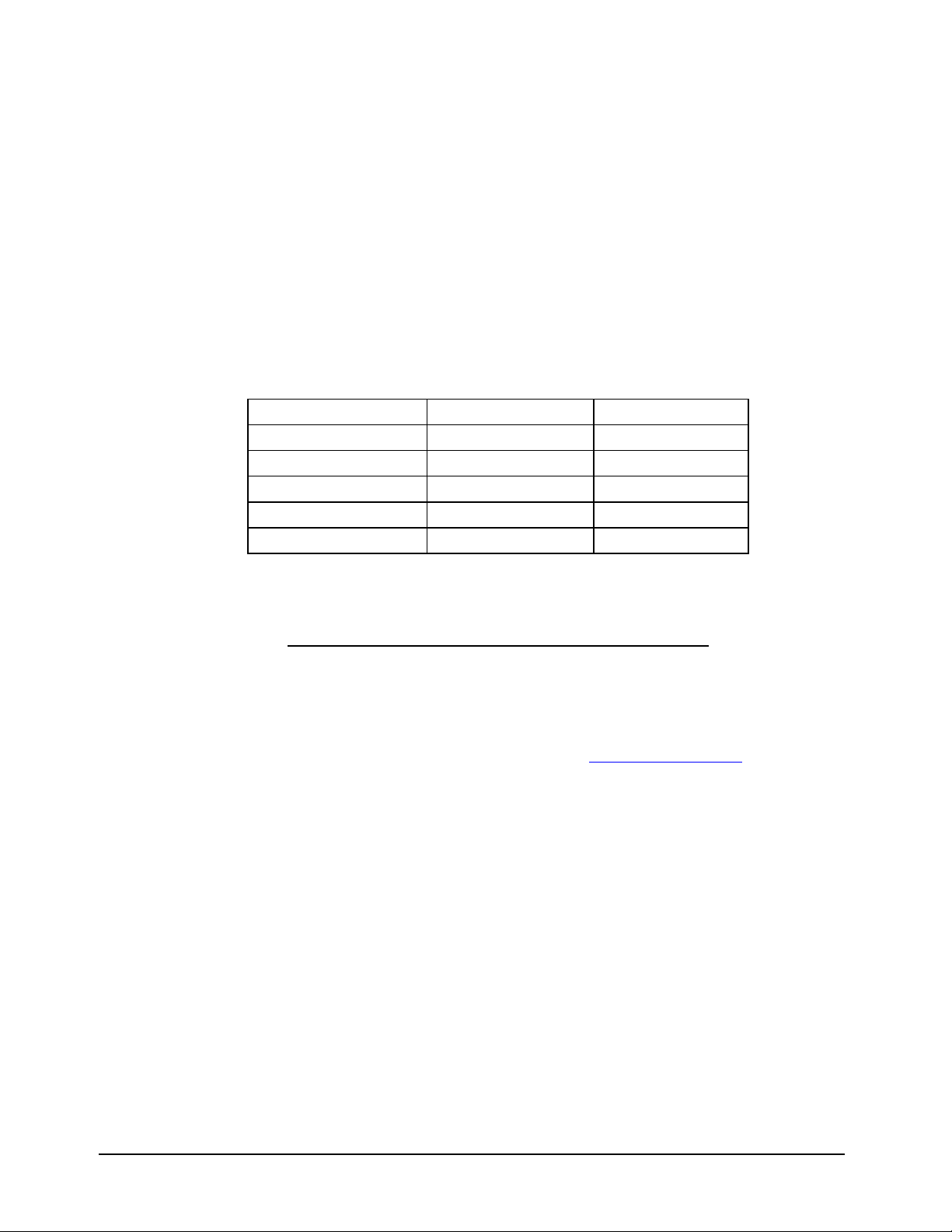

Background Gas

Pressure

Vacuum Source

N2

150 -250 Torr

ONAr280 -380 Torr

ONHe740 -780 Torr

OFF

*H2300 -40

0 Torr

ONO2300 -400 Torr

ON

shown on the flowmeter behind the front door. NOTE: This flow rate may

be reduced to minimize gas consumption but the flow rate will directly

impact the overall system speed of response.

f. Confirm that the needle valve on the vacuum source (aspirator) is fully open

(CCW).

g. Turn on the vacuum source (aspirator) by applying gas to the high pressure

inlet. See Figure 3. (Except when measuring in Helium background which is

not run under vacuum but at ambient)

5. At this point, some adjustment of the aspirator needle valve may be necessary to

achieve the necessary operating cell pressures for each gas (except Helium where

there is no vacuum operation). The proper pressure ranges listed in Table 1 will

automatically appear on the display when the GSF is selected.

*A shut off valve must be installed at the inlet to the aspirator to disable the vacuum.

Table 1: Recommended Sample Outlet Vacuum Pressure

4.2.3 Download System Data

The final step of the installation, after a couple days of dry down, should be to download

the system data (see page 65), and send them by e-mail to service@delta-f.com for review.

This will allow the factory to confirm that the analyzer is working properly by comparison

with data stored at the time of shipment, and in addition will set a baseline for comparison

with future downloads, if any.

4.3 Analyzer Shut Down

In order to minimize the time required for the analyzer to re-achieve a zero baseline on start

up, the following steps should be followed when shutting the analyzer down.

Short Term Shut Down - A short-term shut down, for example to move and restart the

analyzer, can be accomplished by simply shutting off the power switch behind the front

door. This action initiates the standard isolation process (for analyzers equipped with gas

control valves) and computer shut down which takes approximately 40 seconds.

Installation, Start Up and Shut Down DF-745 21

Long Term Shut Down – For analyzers with gas control valves, from the Main Menu go

to System, and select Isolate Analyzer. A routine automatically starts that closes the

downstream valve and allows pressure to build in the moisture cell after which an upstream

Page 26

valve closes as well. Throughout this process a message appears over the display instructing

the user to wait 40 seconds. Once complete, the message disappears and the user may shut

the power off with the switch behind the front door that initiates the computer shut down

sequence that takes an additional 40 seconds.

Additional long-term isolation security can be achieved by closing the valve on the

rotameter on the rear of the instrument as well as completely closing the sample inlet

regulator.

If the analyzer is being disconnected from gas, be sure to tightly cap all gas connections.

On analyzers that have no gas control valves:

1. Remove the vacuum source.

2. Wait a few minutes to allow positive pressure to build in the moisture cell and

monitor the pressure on the Main Display.

3. Be sure to tightly cap all connections.

NOTE: See the section on Power up Default on page 63 for setting user selectable

preferences at the time of power up.

Loss of power will result in automatic valve closure and the following restoration of power

will result in the “Scan Disk” function occurring before system start-up.

FLOW METER

(FRONT)

H O

2

REAR PANEL

PI

.010 ORIFICE

MOISTURE SENSOR OUTLET

ASPIRATOR WITH BUILT

IN VACUUM CONTROL

NEEDLE VALVE

MOISTURE

SAMPLE VENT

80 psi IN

TO CREATE VACUUM

PROCESS INLET

Figure 9: Block Diagram of Gas Flow Path and Aspriator

22 DF-745 Installation, Start Up and Shut Down

Page 27

H O

2

FLOW METER

(FRONT)

V1

PI

REAR PANEL

MOISTURE SENSOR OUTLET

ASPIRATOR WITH BUILT

IN VACUUM CONTROL

NEEDLE VALVE

MOISTURE

SAMPLE VENT

V2

.010 ORIFICE

REGULATOR

ADJUSTMENT

PROCESS INLET

FLOWSWITCH

BYPASS FLOWMETER

BYPASS FLOW ADJUST

BYPASS OUTLET

80 psi IN

TO CREATE VACUUM

(REAR)

Figure 10: Block Diagram of Gas Flow Path with Optional Valves and Aspirator

Installation, Start Up and Shut Down DF-745 23

Page 28

Page 29

5 Options

The following options to the DF-745 are available at the time of order.

5.1 Key Lock

An optional key lock can be installed in the door of the analyzer to prevent access to the

power switch and other internal components. The lock is supplied with two keys.

If the analyzer is operating, the key lock does not prevent adjustments from the front panel.

5.2 Operating Voltage

The analyzer can be wired for operation at either 100-120 Volts AC or 200-240 Volts AC.

The operating voltage is not adjustable in the field.

5.3 Serial Communications

The analyzer can be set for communications by RS-232 or RS-485.

The serial communications option is not adjustable in the field.

See page 31, 65 and 67 for additional information.

5.4 Analog Voltage Output

The maximum analog voltage output can be set at the factory for 0-1, 0-2, 0-5 or 0-10

Volts DC.

The maximum analog voltage output is not adjustable in the field.

See page 32 and 55 for additional information.

5.5 Hydrogen Service Safety System

This option enables the analyzer to be safely used in a hydrogen background application.

See page 89 for additional information.

5.6 Vacuum Pump

An optional pump can be purchased to replace the aspirator in cases where there is

insufficient gas flow for the aspirator or when the analyzer is installed in a portable cart and

connection to an air supply is inconvenient.

NOTE: If a pump is being retrofitted to an analyzer configured with an aspirator, then the

aspirator assembly must be removed completely to uncover the pump power connector and

Options DF-745 25

Page 30

breaker switch. The pump connection should be made directly to the Moisture Sample

Outlet as described in section 5.6.2.

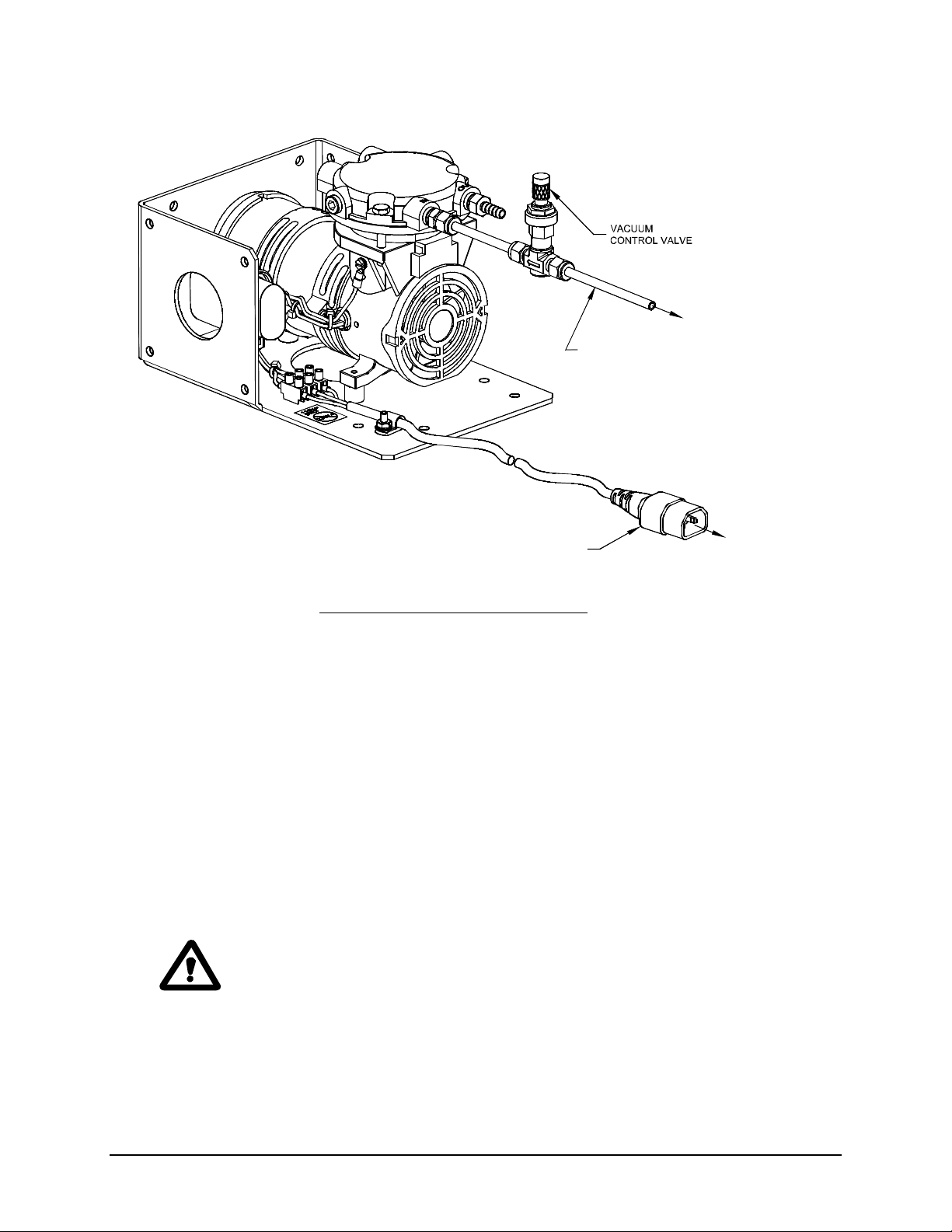

TO MOISTURE

SENSOR OUTLET

PLASTIC TUBING

SUPPLIED

POWER CORD

TO VACUUM PUMP

POWER CONNECTOR

Figure 11: Vacuum Pump Assembly

5.6.1 Installation of the Vacuum Pump

Mount the vacuum pump to the bracket

Connect the line from the moisture sample outlet to the needle control valve and

vacuum pump

Make the electrical power connection to the vacuum pump

5.6.1.1 Vacuum Pump Mounting

Mount the vacuum pump within 8 feet of the analyzer. Refer to Figure 12 and Figure 13 for

mounting hole and pump dimensions.

CAUTION

Be sure the pump outlet is at atmospheric pressure before starting.

The pump is not designed to start against any backpressure.

26 DF-745 Options

Page 31

3.94 [100.08]

Ø.28[Ø7.14]

4 PL

MOUNTING FOR

REAR OF BRACKET

4.92 [124.97]

BOTTOM OF BRACKET

5.17 [131.32]

Ø.28 [Ø7.14]

4 PL

MOUNTING FOR

Ø.28 [Ø7.14]

4 PL

MOUNTING FOR LEFT OR

RIGHT SIDE OF BRACKET

3.94 [100.08]

2 PL

3.94 [100.08]

2 PL

6.89 [175.01]

Figure 12: Vacuum Pump Mount Dimensions

4.92 [124.97]

6.59 [167.33]

7.22 [183.39]

3.23 [81.98]

5.00 [127.00]

10.20 [259.08]

9.58 [243.26]

8.54 [216.79]

4.31 [109.35]4.25 [107.95] 2.18 [55.25]

6.18 [156.85]

5.00 [127.00]

Figure 13: Vacuum Pump Dimensions

Options DF-745 27

Page 32

5.6.2 Moisture Sample Gas Outlet Connection to Vacuum Pump

VACUUM PUMP ON/OFF

The sample gas outlet connection is a ¼ inch compression fitting labeled Moisture Sensor

Outlet as shown in Figure 4 and Figure 5. Use the polyethylene tubing provided with the

analyzer to connect between the outlet fitting and the ¼ inch fittings on the needle control

valve and vacuum pump (included separately). See Figure 11. Open the needle control

valve completely.

NOTE: If the Hydrogen Service Safety System is included, the sample outlet line must be

made of steel. See page 89 for additional information.

5.6.3 Electrical Connections

Plug the vacuum pump power cord into the vacuum pump power receptacle on the rear of

the analyzer. Turn on the vacuum pump power breaker that is adjacent to the receptacle.

The pump will not turn on until the main analyzer power switch is turned on. See Figure 14.

NOTE: The voltage supplied at the vacuum pump power connector is the same as the input

voltage to the analyzer. For example, if 110VAC is supplied to the analyzer then 110VAC is

supplied to the pump.

CAUTION

Be sure the pump outlet is at atmospheric pressure before starting.

The pump is not designed to start against any backpressure.

28 DF-745 Options

VACUUM PUMP AC POWER OUT

Figure 14: Vacuum Pump Power Connections and Controls

Page 33

FLOW METER

(FRONT)

REAR PANEL

MOISTURE SENSOR OUTLET

MOISTURE

SAMPLE VENT

H O

2

H O

2

.010 ORIFICE

PI

.010 ORIFICE

VACUUM CONTROL

NEEDLE VALVE (SUPPLIED LOOSE)

PROCESS INLET

EXTERNAL

VACUUM PUMP

(SUPPLIED LOOSE)

Figure 15: Block Diagram of Gas Flow Path and Optional Vacuum Pump

FLOW METER

(FRONT)

V1

PI

REAR PANEL

V2

MOISTURE SENSOR OUTLET

MOISTURE

SAMPLE VENT

EXTERNAL

VACUUM PUMP

(SUPPLIED LOOSE)

VACUUM CONTROL

NEEDLE VALVE (SUPPLIED LOOSE)

REGULATOR

ADJUSTMENT

PROCESS INLET

FLOWSWITCH

BYPASS FLOWMETER

(REAR)

BYPASS FLOW ADJUST

BYPASS OUTLET

Figure 16: Block Diagram of Gas Flow Path with Optional Valves and Vacuum Pump

Options DF-745 29

Page 34

Page 35

6 Connecting to External Devices

MOISTURE ANALOG OUTPUT

RELAY OUTPUTS

The analyzer can be interfaced to a variety of external devices via the ports on the rear

panel. Alarm contacts, voltage, and current outputs, and serial communications are

supported. All outputs, analog or digital, are fully isolated from earth ground.

NOTE

During the six minute warm up period all analog and digital outputs

are held to an artificial 0.011ppb reading to avoid the reporting of

false readings.

NOT USED

J8

NOT USED

SERIAL COMMUNICATION

J9 J2 J3

J10 J5 J4

Figure 17: Rear Panel Electrical Connectors

6.1 Serial Communication Port – J5

Either of two serial communication ports are available at the time of order: RS232C or

RS485 which enable interface between the analyzer and other operating systems.

Up to 32 units may be accessed via RS-485. Operating parameters are 8 bits, no parity, and

one stop bit. Baud rate may be selected from the menu on the display.

See Table 2 on page 32 for wiring information.

See the chapter on Communications on page 65 for additional information on setting unit

ID’s and baud rates.

Connecting to External Devices DF-745 31

Page 36

A program to facilitate serial communications is available from Delta F.

Pin # Signal Description

J5-8 GND Ground

J5-7 TX- 4 wired 485 paired with TX+

J5-6 Key Unused

J5-5 RX- 4 wire 485 paired with RX+

J5-4 Unused

J5-3 Unused

J5-2 TX+ Data transmitted by the analyzer via RS-232 or RS-485

J5-1 RX+ Data received by the analyzer via RS-232 or RS-485

Table 2: Pin-out of Serial Comm Connector J5

Pin assignments

DF-760/750 PC-DB9/RS-232 PC-DB25/RS-232

1: RX+ 3: TD 2: TD TX+

2: TX+ 2: RD 3: RD RX+

8: Gnd 5: Gnd 7: Gnd

5: RX- TX-

7: TX- RX-

Table 3: Serial Communications Connections

6.2 Analog Signal Outputs – J4

The analog voltage output correlating to the front panel display reading is provided on the

rear of the analyzer through connector J4. The full scale voltage is set at the factory at the

time of order to: 0 to 1 VDC, 0 to 2 VDC, 0 to 5 VDC, or 0 to 10 VDC. The output is

electrically isolated from all other analyzer outputs, and from chassis (Earth) ground. See

page 55 for additional information on setting the Analog Output. The output may be tested

with the use of the analog voltage test routine found on page 59.

6.3 4-20 mA Outputs – J4

J4 Pin # Moisture Signal Description

J4-8 GND Ground

J4-7 Key

J4-6 A Out + Analog Voltage Output (+)

J4-5 A Out - Analog Voltage Output (-)

J4-4 Unused

J4-3 Unused

J4-2 4-20 mA + 4-20 mA Output (+)

J4-1 4-20 mA - 4-20 mA Output (-)

PC/RS-485

converter

Table 4: Pin-Out of Moisture Signal Output Connector J4

32 DF-745 Connecting to External Devices

Page 37

The 4-20 mA analog output correlating to the front panel display reading is provided on the

rear of the analyzer through connector J4. This output is electrically isolated from all other

analyzer outputs, and from chassis (Earth) ground.

The maximum load resistance for each is 1K Ohms and the analyzer provides a compliance

voltage of approximately 28 VDC.

6.4 Relay Ports – J8, J9

Four form C (SPDT) relays (contact closures) are provided to assign to the various alarms.

The contacts are rated at 30 VDC, 1A. They are not designed to switch AC power.

The relay contacts can be programmed through the user interface for up to four moisture

levels, temperature, moisture cell diagnostics, zero calibration in progress, analyzer off line,

freeze of analog outputs during calibration.

The relays are wired for Fail Safe operation such that a Normally Open (No alarm) contact

connects to common when an alarm occurs or when power to the instrument is lost.

The relay wiring can be tested with the Relay test routine found on page 57.

Pin # Moisture Relay Description

J8-8 GND Ground

J8-7 RLY2-NC Relay 2 Normally Closed

J8-6 RLY2-NO Relay 2 Normally Open

J8-5 RLY2-COM Relay 2 Common

J8-4 RLY1-NC Relay 1 Normally Closed

J8-3 RLY1-NO Relay 1 Normally Open

J8-2 RLY1-COM Relay 1 Common

J8-1 KEY Unused

J9-8 GND Ground

J9-7 RLY4-NC Relay 4 Normally Closed

J9-6 RLY4-NO Relay 4 Normally Open

J9-5 RLY4- COM Relay 4 Common

J9-4 RLY3-NC Relay 3 Normally Closed

J9-3 RLY3-NO Relay 3 Normally Open

J9-2 Key Unused

J9-1 RLY3-COM Relay 3 Common

Table 5: Pin-Out of Relay Connectors J8 and J9

Connecting to External Devices DF-745 33

Page 38

Page 39

7 User Interface

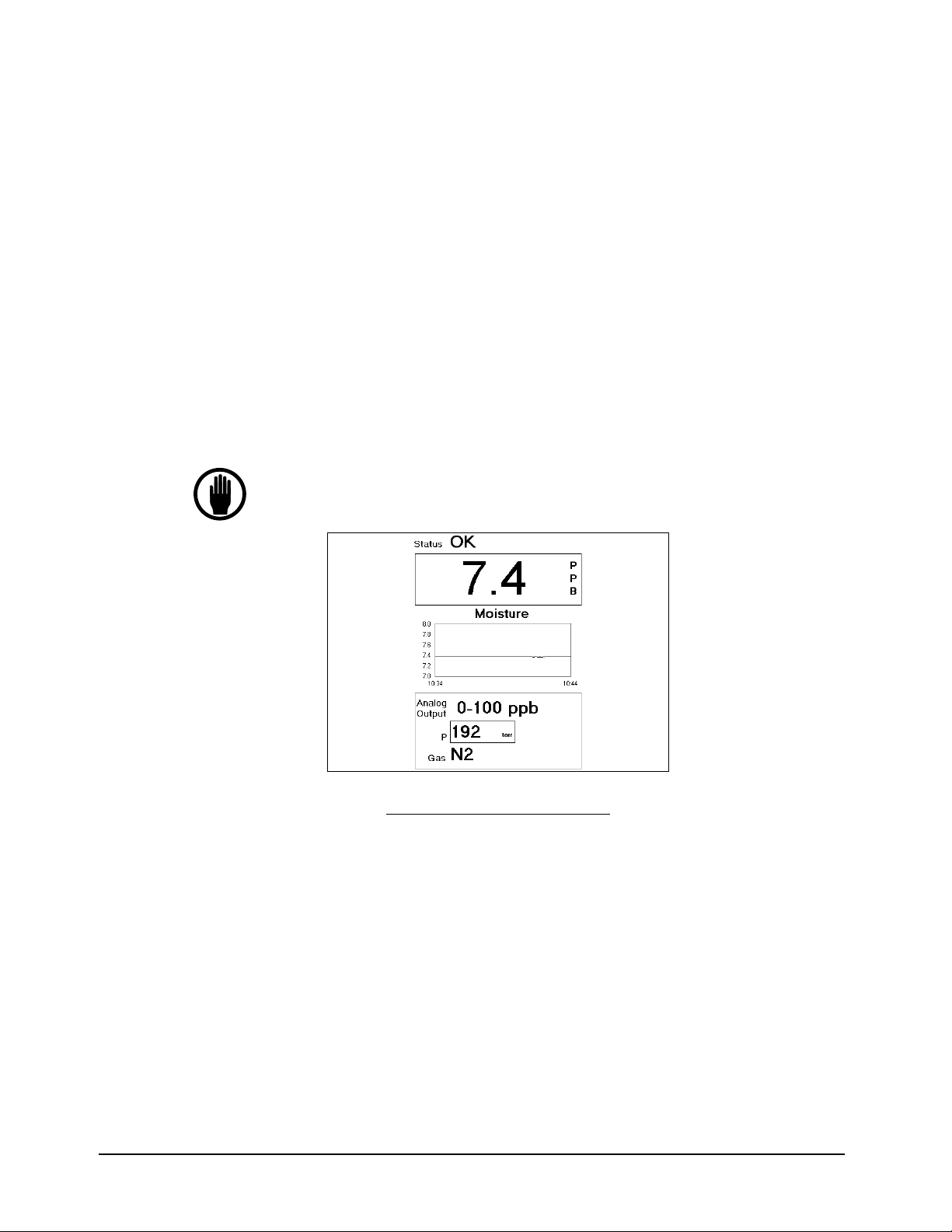

7.1 Data Display Screen

The front panel display consists of the Graphical User Interface (GUI), as displayed on the

view screen in Figure 18 below.

The various elements of the main data display screen are as follows:

Alarm status indicator – ‘1, etc.’ denotes an alarm condition (if enabled), ‘OK’

denotes no alarm conditions (if enabled).

The Data Line, providing the most recent concentration measurement in the large

number display. This box will also provide indication of abnormal operating

conditions for each sensor.

A strip chart history of concentration measurements.

A ppb output range, for the analog outputs, as designated by the user.

Gas pressure within the moisture cell.

Background gas as set by the user

The digital readout of moisture concentration will be over written with a warning if any of

the four moisture level or system alarms are tripped.

7.2 Keypad

The keypad allows the user to control all of the features of the analyzer. The layout of the

keypad on the front panel is represented in Figure 19.

Figure 18: Data Display Screen

User Interface DF-745 35

Page 40

ESC

Figure 19: Keypad

The ‘Menu’ key activates the menu structure along the top of the GUI interface on the

view screen.

Once in the menu, the arrow keys ( and ) highlight the various menu features. When

the desired selection is highlighted, the right arrow will access the submenu if available

(denoted by a right arrow next to the menu text). The ‘Next’ key and the ‘Enter’ key will

do this as well. The arrows also enable the entry of numerical parameters as will be

described below.

The ‘Enter’ key will call up dialogue boxes from the menu (denoted by the sequence …

next to the menu text). It will also enter numerical values within dialogue boxes.

The ‘Next’ key allows the user to change between active inputs within a dialogue box. The

down arrow key will also accomplish this activity.

The ‘ESC’ key allows the user to exit numerical entry boxes within dialogue boxes without

any user changes, dialogue boxes without any user changes, and the menu bar.

EnterNextMenu

7.3 Menu Structure

A bar along the top of the GUI interface on the view screen is reserved for the menu control

of the instrument. The NanoTrace Moisture Analyzer menu tree consists of main menus,

sub-menus and screens and is depicted below. See Appendix A on page 85 for a summary

of the available menus.

7.4 Main Menu

Figure 20: Main Menu

36 DF-745 User Interface

Page 41

The Main Menu is accessed by pressing the Menu key on the front panel. Use the arrow

keys ( and ) to navigate up and down through the list. Select the highlighted item with

the Enter key on the front panel.

If a menu item is grayed out as shown in Figure 21, then the option is not installed, and as a

result the item is not available.

Figure 21: Main Menu (without valve option)

7.4.1 Isolate Analyzer – Optional

Figure 22: Isolate Analyzer

Isolate Analyzer allows the internal gas lines and the moisture sensing cell volume to be

isolated in the case of an impending break in the external delivery lines. It is also considered

the first step in the shut down procedure. Highlight this item and hit the Enter key to

initiate the isolation process. The Isolate Warning shown in Figure 23 will appear for 40

seconds.

User Interface DF-745 37

Page 42

Figure 23: Isolate Warning

While the moisture cell is isolated from gas flow, a warning will appear at the bottom of the

main display indicating “Isolated”.

7.4.2 Restore Sample Gas Flow – Optional

Figure 24: Restore Sample Gas Flow

This command allows the user to return the analyzer gas flow to normal after isolation.

7.4.3 Calibrate Menu

“Calibration” of the moisture analyzer is somewhat of a misnomer. Because of the nature

of absorption measurements, instrumental drift has minimal effect on the quantitative

moisture content result. Once operating parameters are in place from the factory, no other

SPAN “calibration” is necessary.

However, line contributions to offsets in ppb measurements, especially at the sub-ppb level,

are difficult to remove even with a correctly operating system. The moisture analyzer has an

array of zeroing features that enable the user to establish performance near 0.0 ppb.

Any zero action whether completed or aborted is recorded in the Zero Cal Log as shown

in Figure 40.

Use the arrow keys ( and to scroll up and down through the list. Pressing ESC will

return to the main display.

38 DF-745 User Interface

Page 43

7.4.3.1 Check/Adjust Zero

The Check/Adjust Zero screen displays many pieces of information including a live reading

of moisture in ppb (or ppm) and the state of the zero gas control valves. Also depicted are

Zero Reference and Zero Offset values.

Figure 25: Calibrate Menu

Figure 26: Check/Adjust Zero Menu

The Zero Reference value is a reflection of the deviation of the instrument’s baseline from

what was set at the factory. The zero reference of an instrument from the factory will be

0.00. After a manual or auto zero is performed, this value may change slightly.

If the moisture cell has been previously calibrated by the user, Restore Factory Zero will

be enabled on this screen. Enacting this will erase any user zero and restore the factory set

point.

The User Zero Offset and Active Zero Offset are two mechanisms to modify the zero

baseline. When the Active Zero feature is turned on, the User Zero Offset display is

inactive and Active Zero Offset will be displayed instead. See page 57 for additional

information on the Active Zero feature.

User Interface DF-745 39

Page 44

A relay is available on the Analog Output Setup Screen (see page 55) to signal that a zero

calibration is taking place, and the analog output signal can also be frozen or allowed to

update during the calibration process.

7.4.3.1.1 User Zero Offset

Figure 27: Check/Adjust Zero Screen

Figure 28: User Zero Offset

The User Zero Offset function enables the user to add a given moisture ppb value to the

displayed concentration. This can be useful in preventing negative readings to be displayed

should the baseline drift below the calibrated zero point. The value does not affect zero

calibration, it is simply added to the calibrated zero. For example, an offset of 1.0 ppb

could be put into a system reading 0.0 ppb to allow a chart recorder attached to the output

to read slightly above zero. Under this condition, the moisture reading would be 1.0 ppb.

Use the arrow keys ( and to highlight Enter User Zero Offset in the Check/Adjust

Zero screen, Figure 27, hit the Enter key on the front panel, and the zero offset box will

appear on the screen as shown in Figure 28. With the left and right arrow keys move the

cursor to the right of the digit you want to change. With the up and down arrow keys set

the number to the desired value. When done hit the Enter key which will move the

highlighted area to the Apply button and hit Enter to set the value. Use the Next key to go

40 DF-745 User Interface

Page 45

back and change the value or move to the Done button, followed by hitting the Enter key

to leave the screen. Using the ESC key at any time will exit the screen making no changes

and return to the main display.

7.4.3.1.2 Do A Manual Zero

The manual zero command enables the user to zero the moisture cell in an interactive

manner.

Figure 29: Manual Zero Screen

For this purpose, it is necessary to ensure that moisture free gas (sub ppb) is entering the

sensor through the process inlet. When switching to a gas that is moisture free, it is

important to wait a period necessary to allow the reading to re-stabilize.

It is extremely important to note that moisture is inherently slow to move and as a result the

process of doing a zero action can take many hours before the reading is at baseline. A

premature zero, although acceptable, will ultimately result in a negative reading as the

plumbing and analyzer continue to dry out requiring another zero action. See the section on

Active Zero on page 57 for additional information.

After selecting Do a Manual Zero, a screen will appear which displays a trace of the

recent moisture reading. See Figure 29. Observe the trace until the reading is stable and

then press Enter. This action will accept the present value as the new zero setting for the

moisture cell and the Zero Reference field will be updated. After this action, the user will

be brought back to the Check/Adjust Zero screen.

Pressing ESC during the calibration process will abort the action and return to the main

display. Whether the calibration is complete or aborted, pressing Done from the previous

screen will allow the user to return to the main display.

Once complete the gas source must be returned to the original state with process gas going

directly through the sensor.

A relay is available on the Analog Output Setup Screen (see page 55) to signal that a zero

calibration is taking place, and the analog output signal can also be frozen or allowed to

update during the calibration process.

User Interface DF-745 41

Page 46

7.4.4 Data History Routine

The Data History Screen (Figure 31) enables the user to see the data history displayed in

strip chart form on the front display. By default, the data history screen displays data for the

most recent 24 hour period sampled at 1 point per minute (fixed) and the y-axis is autoscaling.

Figure 30: Data History Menu

The Next button can be used to toggle the X axis from 1 day (default), to 1 hour, to 1 week

and then to 3 weeks.

The Next button can also toggle the cursor to the max and min values on the Y axis and the

arrow keys can then be used to adjust the values, and the display will actively update.

The data history may be downloaded to a USB memory stick, by using the Next key to

move to the Download box and hitting ENTER. A screen will appear, requesting that a

memory stick can be placed in the external USB socket. The socket is located behind the

front door on the left side of the chassis.

The downloaded file will be in tab delimited form and will be all moisture data in the system

up to 3 weeks old if available. The download process will take up to 15 seconds and the

display will indicate downloading is in progress. Once the download is complete, control of

the analyzer is returned to the operator. See Figure 33 for an example of a portion of a

download taken between the dates of May 1 and May 22. The complete file covers three

full weeks.

42 DF-745 User Interface

Page 47

Figure 31: Data History Screen

Figure 32: Install Media

Firmware version 0.6.1

Serial # ND-10016

Model # DF-745

Start time 05-01-2003 03:07 PM

End time 05-22-2003 03:07 PM

Date Time H2O

5/16/03 1:24 PM 5.423

5/16/03 1:25 PM 5.423

5/16/03 1:26 PM 5.421

5/16/03 1:27 PM 5.416

5/16/03 1:28 PM 5.411

5/16/03 1:29 PM 5.406

Figure 33: Example of Data Download

User Interface DF-745 43

Page 48

7.4.5 Data Downloader Routine

Figure 34: Data Downloader Menu

The Moisture Data Downloader screen, Figure 35, enables the user to label data with

unique location names as well as to view and download specified data.

The Next key is used to toggle through the various options on the screen and the arrow

keys ( and move up and down through the location list.

7.4.5.1 Set Location

The set location function is used to choose a location from a list of existing locations

previously entered into the system (see Add Location on page 45). On the Moisture Data

Downloader screen Figure 35, use the Next key to move to the list of existing names and

then use the arrow keys ( and to select the location desired. Then use the Next key

to move to Set Location and press Enter to accept the new location.

The action of setting a location starts the logging process and creates a new file. Changing

to a new location will, in turn, end the previous file and start a new one.

44 DF-745 User Interface

Figure 35: Data Downloader Screen

Page 49

7.4.5.2 View Location

The view location function is used to view data previously stored in the system sorted by

location. On the Moisture Data Downloader screen Figure 35, use the Next key to move to

the list of existing names and then use the arrow keys ( and to select the location

desired. Then use the Next key to move to View Location and press Enter. The View

Location screen will appear as in Figure 36.

Figure 36: View Location Screen

Use the arrow keys ( and to select the data block desired and use the Next key to

move to View Location and press Enter. The data history screen will appear as shown in

Figure 31. From the data history screen, the data may also be downloaded to a USB

memory stick.

7.4.5.3 Add Location

The user can create a new location stamp by moving the cursor to the Add Location

button and hitting enter. This brings up the keyboard shown in Figure 37 that is used to

enter the name of the new location.

Figure 37: Keyboard Display

User Interface DF-745 45

Page 50

Use the arrow keys ( and to navigate the keyboard and use the Enter key to accept

each character. If an error is made use the Next key to move to the Clear Entry key and hit

enter. When the location name is complete use the Next key to move the highlight to

Accept New Location and hit Enter. The display will return to the Downloader Screen

and the name will appear in the list of available locations.

7.4.5.4 Delete Location

The delete location function is used to remove a location from the list of available names.

On the Moisture Data Downloader screen Figure 35, use the Next key to move to the list of