Page 1

Junction Box

51 x 102mm

(2" x 4")

Stainless Steel

Coverplate

FINISHED

WALL

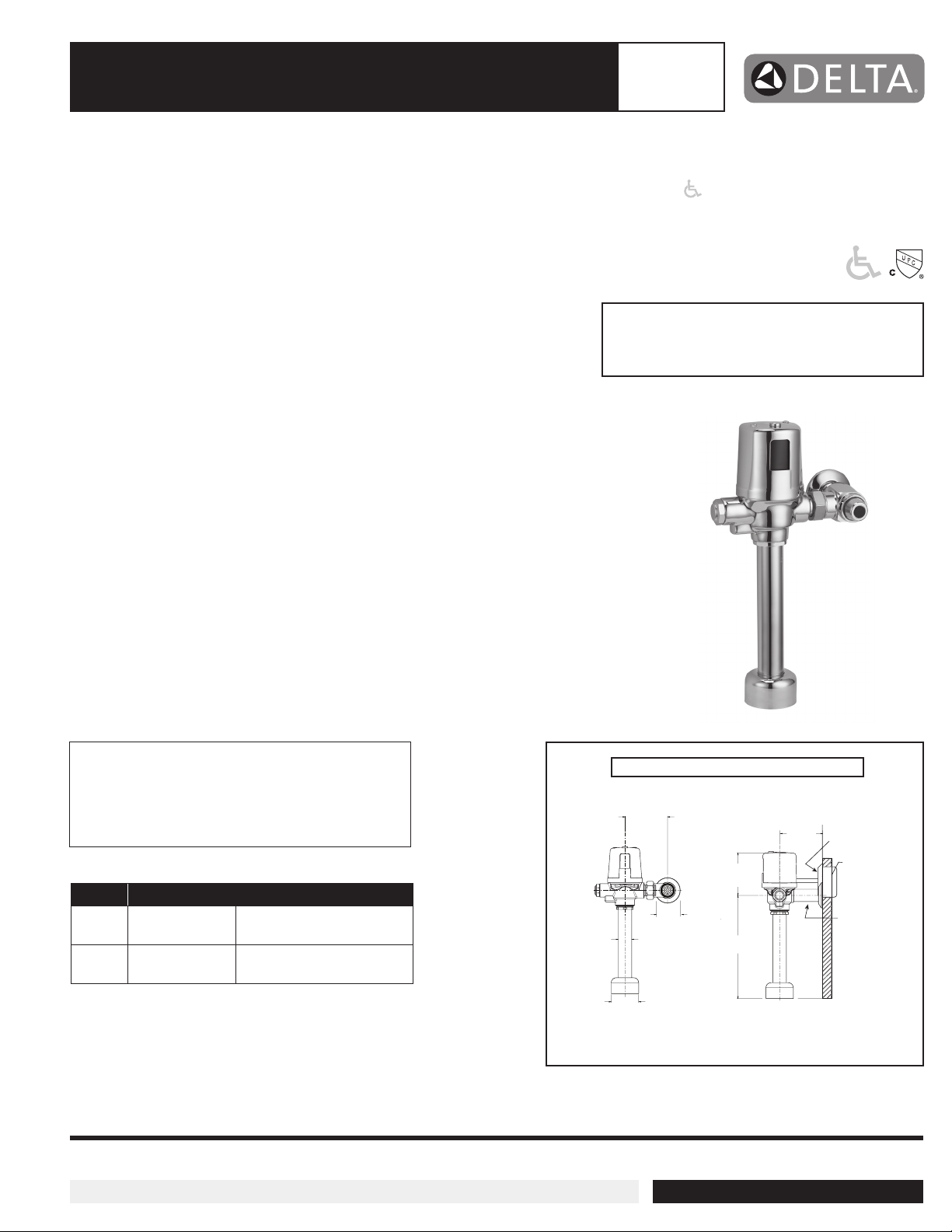

Electronic Exposed TECK® Flush Valve

®

TECK

COMMERCIAL

o 81T201HWA-DF

Exposed Hardwire Operated 1-1/2" Top Inlet Closet Fixture

• Polished chrome-plated vandal resistant metal cover with top mounted

sensor operated H2Optics® electronics

• Right or left-hand supply installation

• ADA compliant, automatic operation hardwire powered infrared sensor

• Scratch resistant replaceable lens window

• Supplied with an advanced infrared sensor activated flush system that uses precise

user distance measurements along with a bowl length setting to activate the correct

flush for each usage

• Hardwire adaptor 24 VAC to 6.4 VDC converter (supplied)

• Vandal resistant copper tube conduit

• Override button activation will always produce a full flush

• Optional 24 hour automatic flush factory set to off

• Set-up sensor range adjustment indicator lights

• 24 VAC input, 6 second arming delay

• Electronic operated non-hold-open metal override button with 5 second lockout

• (110 to 24 VAC Transformer not included. See selection below for

additional part number.)

• Quiet action, TECK® exposed diaphragm flush valve

• Chloramine resistant diaphragm

• Forged brass diaphragm retainer

• Renewable seat

• Polished chrome-plated body

• External water conserving flush adjustment, factory set to 6 litre (1.6 gal.)

• Optional dual flush setting capability factory set to on providing average

30% water reduced flush based on time and distance

• 1" FIP/Copper sweat inlet adaptor, angle check stop with protecting cap

• Adjustable 121mm (4-3/4") plus or minus 11mm (7/16") inlet/valve outlet centers

• Vacuum breaker

• Cover tube, stainless steel wall flange, spud flange, concealed spud nut,

and 292mm (11-1/2") outlet tube

• Recommended water supply:

Minimum flowing pressure – 25 psi (172 kPa)

Minimum flow rate – 25 gpm (95 L/min)

APPROVALS:

• IAPMO listed to ASSE 1037/

ASME A112.1037/ CSA B125.37

•

Indicates compliance to

ICC / ANSI A117.1

(Contact Delta Representative for State and/or

Local Approvals.)

Patented

Engineer/Architect Approval

Model Specified:

Approval: Date:

81T201HWA-DF

AVAILABLE OPTIONS FOR FIELD CONVERSION

o

061047A

Hardwire with Battery Backup

See

DSP-BB

for detailed specification.

4

TRANSFORMERS

060704A

060771A

110 to 24 VAC Class 2 20 VA

(for up to 5 Electronic Valves)

110 to 24 VAC Class 2 40 VA

(for up to 10 Electronic Valves)

VACUUM

BREAKER

TUBE

38mm

(1.5")

38mm (1.5")

SLIP JOINT

NUT &

WASHERS

SUPPLIED

121mm ± 13mm

(4.75" ± .44")

76mm

(3.0")

81T201HWA-DF

71mm

(2.81")

292 mm (11.5")

121mm

(4.76")

FINISHED

FINISHED

WALL

WALL

54mm

(2.13")

min.

TOP OF FIXTURE

Stainless Steel

Stainless Steel

Coverplate

Coverplate

Junction Box

Junction Box

51 x 102mm

51 x 102mm

(2" x 4")

(2" x 4")

INLET:

25mm (1.0")

FIP OR

COPPER SWEAT

W/ADAPTOR

(SUPPLIED)

Note: For high and low pressure applications, please see page

FEA-81T High Water Pressure note for more details.

Note: Measurements may vary ± 6mm (0.25")

Refer to www.specselect.com for individual models. Note: Use this page as a product submittal sheet.

Delta reserves the right (1) to make changes in specifications and materials, and (2) to change or discontinue models, both without notice or obligation.

Dimensions are for reference only. See current full-line price book or www.specselect.com for finish options and product availability.

Verify flow requirements with bowl manufacturer.

DSP–81T201HWA-DF Rev. I Page 6.C.7

DSP–81T201HWA-DF Rev. J

Loading...

Loading...