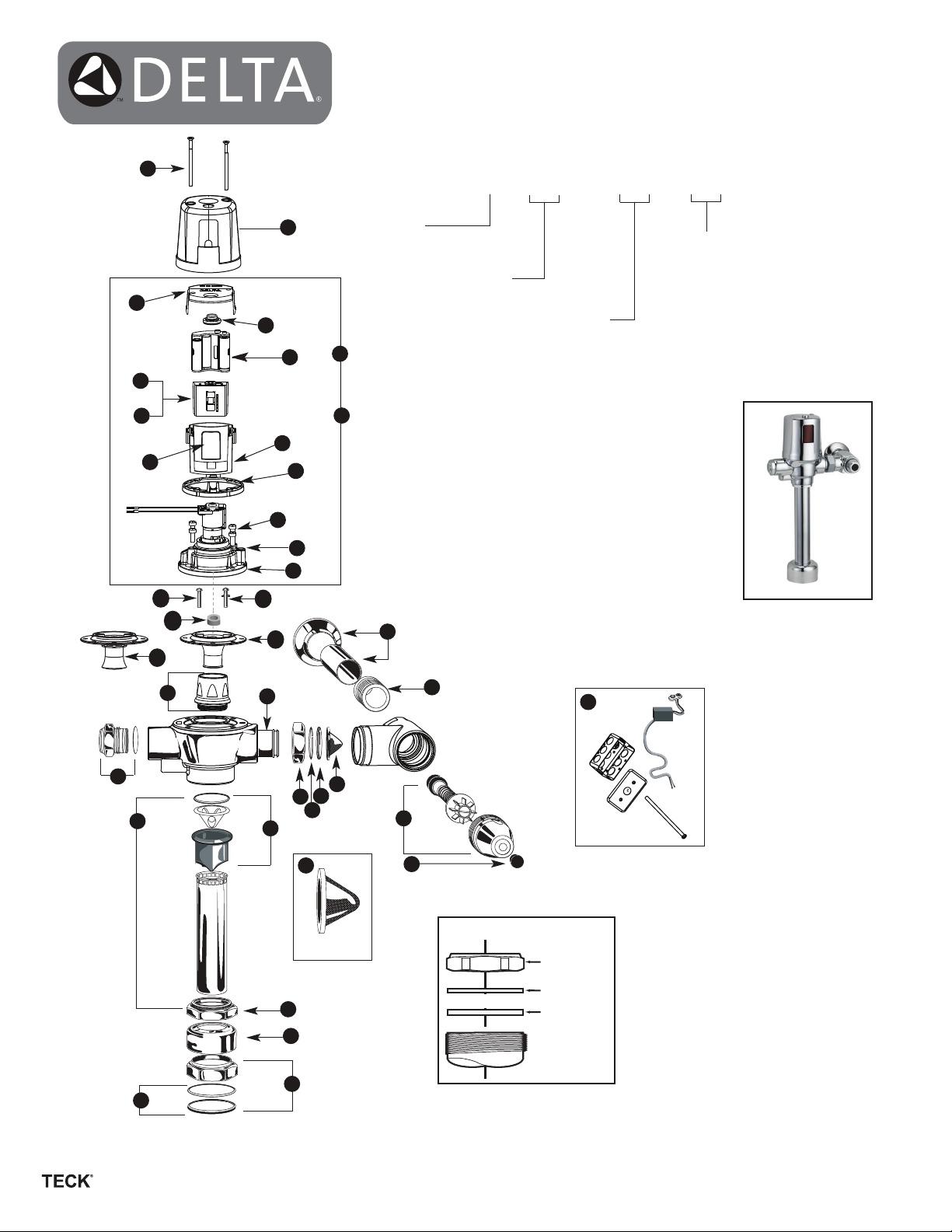

Page 1

Electronic Exposed

®

TECK

210233 210233 210233 210233

(with H2Optics

II Flush Valves

™)

2

Record model number:

81T2__ 1__ __A - __ __ - __ __

3

5a

4

6

7a

7b

5b

1

10

a

10

b

11

b

12

9a

9b

8a

8b

10

c

11

a

14

Valve Type

0 = W/C (Water Closet)

2 = W/C - 22” outlet tube

3 = Urinal

19

20

18

Power Option

BT = Battery

HW = Hardwired

21

Additional Options

(leave blank if not applicable)

30 = w/Sloan ZurnTail

20 = Less Stop Assy

1 = V/B Tube w/Tee Assy (WC only)

30

Alternate Flush Volumes

(leave blank if not applicable)

6 = 6 litre (1.6 gal) fixed flush (WC only)

13 = 13 litre (3.4 gal) flush (WC Retrofit Kits only)

48 = 4.8 litre (1.27 gal) fixed flush (WC only)

38 = 3.8 litre (1.0 gal) fixed flush (Urinal only)

19 = 1.9 litre (0.5 gal) fixed flush (Urinal only)

05 = 0.5 litre (0.13 gal) fixed flush (Urinal only)

210233 210233 210233 210233

13

26

24

31

17

15

16

31

22

23

Slip Joint Nut Installation

Filter Screen

25

27

28

29

PLEASE LEAVE this M&I Sheet with the owner, maintenance plumber, etc. as items

Nut

Fibre Washer

Rubber Washer

For valves manufactured

after January 2013.

relating to ongoing maintenance suggestions and procedures are included.

www .specselect.com

210233 Rev. A

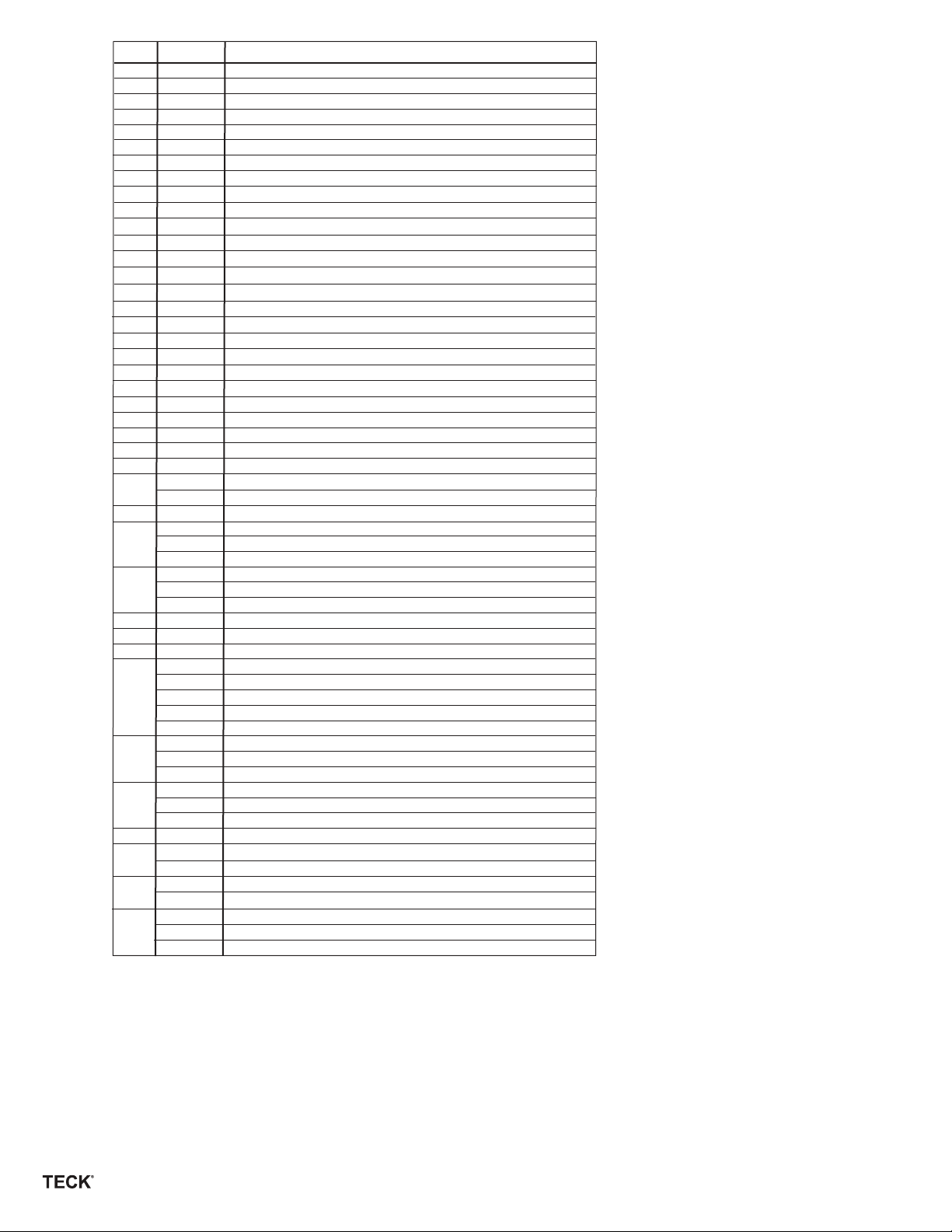

Page 2

Item #

1 061063A

2 061138A

3 061139A

see #7

4

061140A Case Top for 3rd Generation E-FV

5a

5b 061170A

060334A

6

7a

061161A

7b

061162A

061024A

8a

8b

061169A Cast Cap/Solenoid & Regulating Screw Assembly

9a

061141A*

9b

060078A*

10a

060507A

062025A

10b

10c

060508A

11a

061216A**

11b

061217A**

11c

060079A

12

062007A**

060342A Plug & O-Ring for Handle End

13

060506A

14

060735A

15

060692A

16

060082A*

17

060504A

18

061142A

19

061143A

061144A

20

060697A

21

060694A

060764A

060843A

22

060844A

060859A

23

060081A*

060785A

24

060094A

25

060782A

26

060783A

060863A

060784A

060781A

060004A 1½” Spud Flange

27

060463A

060745A

060778A 1½” Rough Coupling Nut & Washer

28

060773A

060463A

060083A *

29

30

061069A

061069A-BB

060344A

31

060972A

060704A

060771A

060772A

DescriptionPart #

Replaceable Lens for 3rd Generation E-FV

Cover Screws for 3rd Generation E-FV

CP Metal Cover

Button Head Assembly

Plastic Case for 3rd Generation E-FV

Battery Holder

Water Closet Board for 3rd Generation E-FV & Override Button

Urinal Board for 3rd Generation E-FV & Override Button

Regulating Screw & O-Ring

Cover Gasket (3/pkg)

Screws for Cast Cap (4/pkg)

Poppet Pin Pack (3/pkg) (also see 10b)

Washer (3/pkg) (required for 6.0 & 4.8L Valves only)

Poppet Pin Pack (3/pkg) (0.5L Valves only)

Diaphragm/Guide Assembly Complete - WC

Diaphragm/Guide Assembly Complete - UR

Diaphragm Package

Brass Seat with O-Ring

Standard Adjustable Tail CP

Union Nut CP

Retaining Ring

Adjustable Tail O-Ring Package (20/pkg)

S/S Wall Flange & Cover Tube

Electronic Water Closet Repair Kit for 3rd Generation E-FV

Electronic Urinal Repair Kit for 3rd Generation E-FV

Electronic Water Closet Repair Kit for DF 3rd Generation E-FV

1” Copper Sweat Inlet Adaptor

¾” Copper Sweat Inlet Adaptor

¾” FIP Inlet Adaptor

Retrofit Check Stem Unit, Capnut & Button Complete

Seat Washer, Spring, Button & O-Ring Kit

Angle Stop with Union Nut & Tail Complete

Plug Button Package (12/pkg)

VB Sleeve Complete

CP Male Threaded Coupling Ring

1½” x 10” VB, Ring & Tube Complete (for 81T201)

1½” x 22¾” VB, Ring & Tube Complete (for 81T221)

1¼” x 10” VB, Ring & Tube Complete (for 81T291)

¾” x 11½” VB, Ring & Tube Complete (for 81T231)

1½” x 10” VB, Side Outlet Tee Tube Complete

¾” CP Coupling Nut, ¾” Washer & ¾” Spud Flange

1¼” Spud Flange

1¼” Rough Coupling Nut & Washer

¾” CP Coupling Nut, ¾” Washer & ¾” Spud Flange

1½” Rubber Slip Joint Washer (12/pkg)

Hardwire Converter & Rigid Connection Assembly for 3rd Gen E-FV

Hardwire Converter & Rigid Connection with Battery Back-up

Filter Screen Kit (12/pkg) for Teck tails

Filter Screen Kit (6/pkg) for Sloan

Transformer (110 to 24 VAC) for 5 Sensor Modules***

Transformer (110 to 24 VAC) for 10 Sensor Modules***

Transformer (110 to 24 VAC) for 25 Sensor Modules***

®

/Zurn® tails (-30 models)

* Package Quantities May Change. Check the parts section of the latest Delta Commercial Faucet Price List for current

quantities.

** For valves manufactured before January 2013, you must replace both 061216A/061217A diaphragm assembly and

062007A brass seat wih O-ring.

***Each individual sensor module requires its own 24 VAC to 6 VDC hardwire converter.

NOTE: Refer to TECK Flushometer Repair Parts and Maintenance Manual for additional

parts and information.

www .specselect.com

Page 2

210233 Rev. A

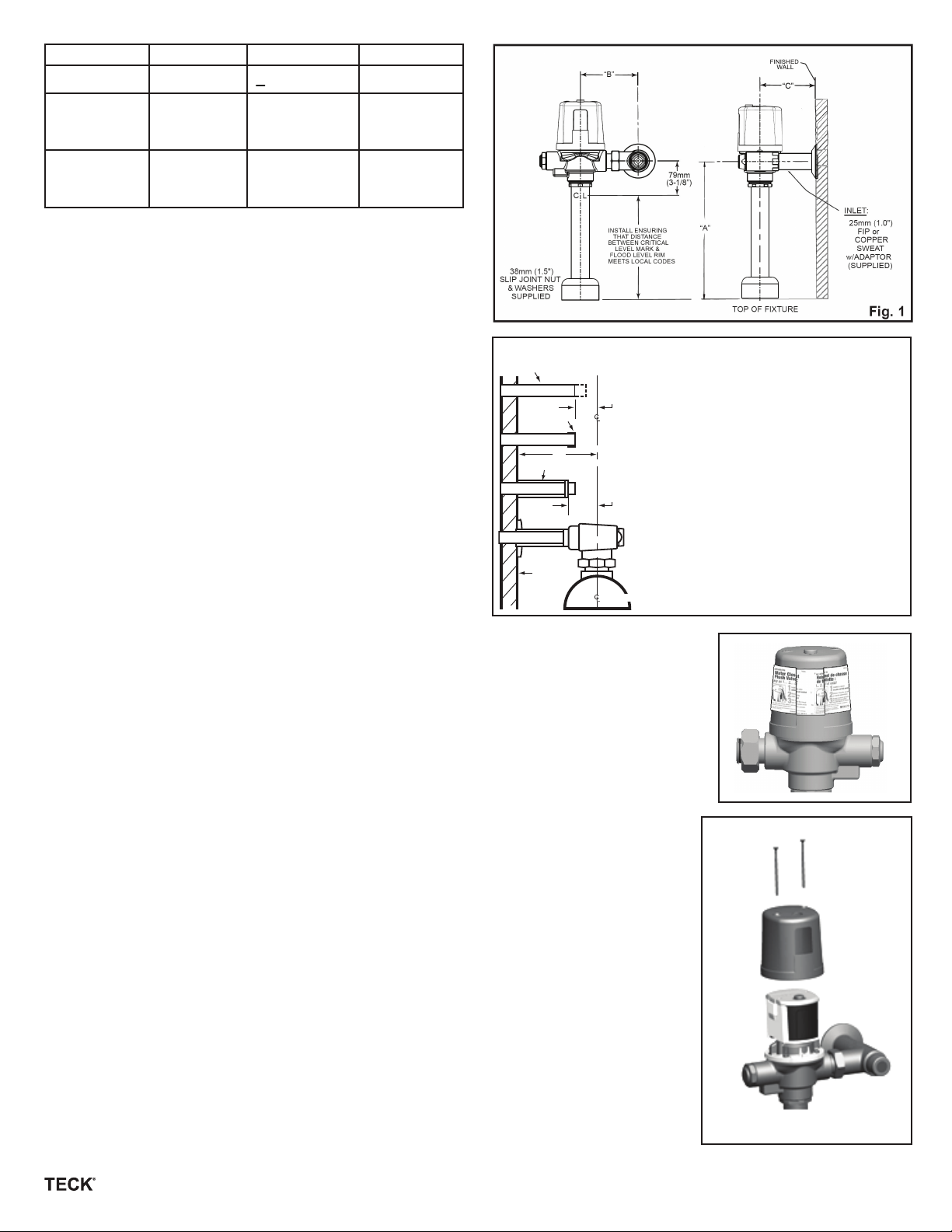

Page 3

Product #

All 81T201BT/

81T201HW

variations*

A

Max.

B C

+ 11mm (

121mm (4¾”) 54mm (2.13”)292mm (11½”)

7

”

)

16

/

Min.

All 81T231BT/

330mm (13”)

121mm (4¾”) 54mm (2.13”)

81T231HW

variations*

* Note: -30 models, B = 114mm - 131 mm (4.5” to 5.18”)

BEFORE THE FIRST FLUSH (COMPLETE VALVES)

FLUSH BOTH OLD AND NEW PIPES:

It is important to FLUSH and CLEAN thoroughly both new and old

water piping to ELIMINATE contaminants (eg. scale, sediment, gravel,

cuttings, solder, etc.) from the line.

Where the water has a sediment content, a PIPE STRAINER in the

supply line should alleviate that condition and protect working parts of

flushometers and faucets.

On a NEW INSTALLATION, always flush the valve 4 or 5 times to

clean out supply line debris. It is also advisable where more than one

flushometer is installed on a water line, to flush out the water piping

through the last flushometer outlet of the pipe line.

INSTALL FILTER SCREEN (included):

Note: Place filter in stop bore with conical screen facing the water flow.

Caution: Do not push filter in too far. Let filter seat against face of flush

valve tail. Periodic cleaning of the filter screen with water is recommended depending on local water conditions to remove any dirt or

sediment. See filter screen M&I for additional installation information.

ELIMINATE AIR FROM VALVES:

The FIRST FLUSH should ELIMINATE all air from the TECK flushometer. DO NOT ADJUST flushometer based on the results of the first

flush.

1" Copper Inlet Supply

1" Copper Inlet Adapter Installation

Adapter

"D"

Cover Tube

Finished

Wall

25mm

(1")

38mm

(1½”)

Of Fixture Spud

1. Measure distance “D” from centre line

of fixture spud to finished wall.

2. Cut copper tube 1” shorter than

dimension “D”.

3. Push adapter onto copper tube until it

stops on the shoulder.

4. Solder adapter to copper tube.

5. Cut cover tube 1½” shorter than

dimension “D”.

6. Slide the wall flange and cover tube

over the supply pipe.

7. Thread the union stop onto the adapter,

and tighten set screw in flange.

Fig. 2

TO PREVENT WATER HAMMER:

A water hammer arrestor may be installed at the last flushometer and/or at the back of an individual

installation. This assures SMOOTHER OPERATION of the valves and longer life for the working parts.

HANDS SHOULD BE CLEAN AND FREE OF GREASE AND OIL during any maintenance or handling of

electronic housing components to prevent possible damage to internal circuitry.

IF LEFT HAND STOP REQUIRED:

• Remove the chrome cover by taking out the two cover screws. See Figure 4.

• You will now see the clear electronic compartment with a grey cover.

• Now take hold of the compartment and very carefully, slowly lift the compartment about 1/4” and turn it

180°.

• The sensor eye should now be on the other side.

• Gently push the compartment back down, aligning the two screw holes on the clear case with the

screw holes on the brass solenoid cap.

• Rotate cover gasket 180° on brass cap.

• Check for pinched wires between cover and clear case.

• Ensure grey cover is snapped onto clear case and chrome button is properly seated.

• Replace the chrome cover and two cover screws - do not overtighten cover screws.

Flush volume adjustment:

3.43 U.S. gallons / 13.0 litres for water closets

1.60 U.S. gallons / 6.0 litres for water closets

1.27 U.S. gallons / 4.8 litres for water closets

1.0 U.S. gallon / 3.8 litres for urinal valves

0.5 U.S. gallon / 1.9 litres for urinal valves

0.13 U.S. gallon / 0.5 litre for urinal valves

The Regulating Screw (061024A, item #8) may be adjusted, according to job conditions and fixture

installed to the proper water volume to flush that particular fixture (except -6, -48, -38, -19 and -05

models which are not field adjustable).

NOTE: 4.8 and 6 Litre water closets or washdown urinals may require the Angle Stop to be set at only

ONE TURN OPEN. For a SHORTER flush, turn the Regulating Screw (061024A, item #8) left

(counter-clockwise) and right (clockwise) for a LONGER flush (except -6, -48, -38, -19 and -05 models

which are not field adjustable).

Fig. 3

Fig. 4

www .specselect.com

Page 3

210233 Rev. A

Page 4

INSTALLATION INSTRUCTIONS - BATTERY FLUSHOMETER

(for Hardwire, skip to Step 3)

Step 1:

• Install battery flushometer to fixture.

• Open inlet stop.

Step 2:

• Follow instructions on yellow static label (Figure 3). Note: The batteries are already installed and the product is in hibernation mode

waiting to be activated.

• After you remove the yellow label, you must push the manual over-ride button three times within five seconds to activate the valve and to

place it into operation mode. To signify the valve has entered operation mode, you will see an ascending and descending light sequence.

• Proceed to Step 5.

INSTALLATION INSTRUCTIONS - HARDWIRED FLUSHOMETER

Step 3:

• Before installing the flush valve body. Install 2” x 4” electrical box into wall with centre of box in line with the cut-out in the back of the

metal flush valve cover. See Figure 5.

• Securely attach box to wall structure. Install CSA and/or UL approved Class 2 transformer

or equivalent in a convenient location or in a pipe chase. (Do NOT install the transformer

inside the control box.) Run suitable wires from 24 VAC step down transformer into the

electrical box. The transformer is to be installed in an adjacent accessible space. Use cable

which complies to local electrical codes for 1 amp load. No. 18 cable is usually sufficient.

• Assemble plastic bushing into the hole on the coverplate.

• Measure and cut tube assembly to appropriate length so that the bushing will fit under the

metal flush valve cover and the free end will protrude into the box through the coverplate by

1/2” minimum. Rotate cover gasket, if necessary, so that the U-shaped wire guides align with

the rear opening in valve cover.

• Assemble flush valve to fixture. When ready, remove metal cover and feed the wires from

the hardwire converter through the tube assembly and the tube assembly through the bushing

on the coverplate.

• Attach the converter wires to the 24 VAC wires from a step down transformer.

• With power to the flushometer, you will see an ascending and descending light sequence to

signify that the valve is now in operation mode.

• Assemble coverplate using the bracket and screws provided.

• With the tube bushing located in position, assemble metal cover to flush valve body with tube assembly located in metal cover cut-out.

NOTE:

Hardwire junction box installed behind

flush valve on the centreline of fixture.

Fig. 5

Step 4:

• Open inlet stop.

Step 5: Operation Mode

Upon power up - a sequence of descending and ascending red lights will signify that the valve is in operation mode.

Once in operation mode, if factory settings are preferred, no further action is required and the valve installation is complete.

Factory pre-set functions are:

WC bowl length of 24”, 24 hour flush is off.

Urinal sensing distance of 16”, 24 hour flush is off.

MAKING ADJUSTMENTS TO THE ELECTRONIC FEATURES

(Optional: Only required if factory settings are not preferred)

Once in operation mode, if adjustments are preferred, installer must move into set up mode.

If desired adjustments are not made within 30 minutes of initial power-up, the power must be disconnected for 10 seconds and

then reconnected to obtain another adjustment period.

Step 6: Set-Up Mode

• If 30 minutes have passed since the initial power-up of the valve - open up the battery compartment (Figures 9 and 10) and disconnect the

battery snap for 10 seconds. Reconnect and replace the chrome cover and screws. If hardwired - disconnect battery snap to the hardwire

converter for 10 seconds.

• To move from operation mode into set-up mode, push and hold manual override button for five seconds. Release the override button

when a solid blue light is visible.

• The watercloset flushometer models have 2 settings which are adjustable via the Set-Up Mode - Bowl Length Selection and 24

Hour Flush Adjustment.

• The urinal flushometer models have 2 settings which are adjustable via the Set-Up Mode - Range Adjustment and 24 Hour Flush

Adjustment.

• While in Set-Up Mode, the user will move through the different adjustment modes one by one, in the order as described above. Use the

override button to toggle through the different settings of the adjustment feature being altered. To advance to the next adjustment mode,

hold down override button until blue light is present, then release the button. See Figure 6.

www .specselect.com

Page 4

210233 Rev. A

Page 5

ENTER SETUP MODE

Bowl Length

TO ENTER SETUP MODE - HOLD DOWN

OVERRIDE BUTTON UNTIL BLUE LIGHT

PRESENT. RELEASE BUTTON.

EXIT SETUP MODE

TO EXIT SETUP AND RETURN TO

OPERATION MODE - HOLD DOWN

OVERRIDE BUTTON UNTIL BLUE

LIGHT PRESENT. RELEASE BUTTON.

HOLD DOWN OVERRIDE

BUTTON UNTIL SOLID

BLUE LIGHT PRESENT

TO ADVANCE RELEASE

BUTTON.

HOLD DOWN OVERRIDE

BUTTON UNTIL SOLID

BLUE LIGHT PRESENT

TO ADVANCE RELEASE

BUTTON.

Fig. 6

▼ ▼ ▼

7.1 SENSOR RANGE ADJUSTMENT MODE

- Press and release override to toggle through the

settings

- Blue light flashes when object is detected

- Red lights signify range choices

Lights visible

1 Red

2 Reds

3 Reds

4 Reds

5 Reds

W/C Bowl

Length

20”

22”

24”

26”

28”

Urinal

Sensing Distance

8”

12”

16”

20”

24”

(WC only - designed for future options)

INACTIVE MODE

Step 7: Making Adjustments (Optional: Only required if factory settings are not preferred)

7.1 Sensor Adjustment:

For Waterclosets:

• Configure the sensing ranges by selecting the appropriate bowl length. Refer to Figure 6 for the

different bowl length settings.

• The bowl length is the distance from the centre line of the valve to the lip of the bowl (see Figure 7).

• To ensure the correct distance is selected, stand or place a target at the end of the bowl. Starting

with one illuminated red light, step through the distances until the blue light begins to flash.

The flashing light confirms that the sensor is configured for that bowl length.

• NOTE the WC bowl length setting is NOT the sensing range. The advanced sensor activated flush

system uses multiple detection distances and the bowl length to react appropriately to different

usage patterns.

• If no further length adjustments are desired, press and hold down the override button for 5 seconds,

until a solid blue light is present. Release the override button to advance to the next adjustment

feature.

• A blue and red light will be present. This mode is currently inactive and is designed for any future options.

• To advance to the 24 Hour Flush, press and hold down override button for 5 seconds until the solid blue light is present.

• Release override button, you are now in 24 Hour Flush configuration.

For Urinals:

• Configure the sensing range by selecting the desired detection distance.

• Each press and release of the override button advances to the next length/distance. (See Figure 6 for a list of distances.)

• Start with one red visible light.

• Stand or place a target at the desired detection distance, the top blue light will be flashing if an object is detected.

• Press and release override button to step through the distance options until the blue light begins to flash, indicating that the target

has been detected. The blinking blue light indicates that the sensor is configured for that length/distance.

• The sensor is now set at your desired configuration.

• If no further sensing range adjustments are desired, press and hold down the override button for 5 seconds, until a solid blue light

is present.

• Release override button, you are now in 24 Hour Flush configuration.

7.2 24 HOUR FLUSH ADJUSTMENT

- Press and release override to toggle through the

settings

- No Blue light will be present

- Red lights signify 24 Hour flush on or off

Lights visible

2 Reds 24 Hour Flush OFF

3 Reds 24 Hour Flush ON

Fig. 7

7.2 24 Hour Flush Adjustment Mode:

• When the 2 red lights are present - 24 hour flush is OFF.

• When the 3 red lights are present - 24 hour flush is ON.

• Press manual override button to toggle between ON and OFF mode.

www .specselect.com

Page 5

210233 Rev. A

Page 6

Exiting Set-Up Mode:

• Can be accomplished in one of two ways;

1. During the 24 Hour Adjustment feature, press and hold down override button for 5 seconds until solid blue light is present. Release

override button.

2. During all modes, valve will revert back to operation mode automatically if the override button is not pressed within 2 minutes.

* After the last adjustment has been completed and the flush valve has returned to operation mode, there is a window of

approximately 30 minutes where additional changes can be made. If desired adjustments are not made within 30 minutes,

the batteries or hardwire converter must be disconnected for 10 seconds and then re-connected to obtain another adjustment

period. To make changes, begin at step #6 above.

BATTERY STRENGTH INDICATOR & BATTERY REPLACEMENT

TO CHECK BATTERY STRENGTH:

1. During Operation Mode - press and hold down the override button for approximately 10 seconds.

2. DO NOT RELEASE BUTTON WHEN SOLID BLUE LIGHT IS PRESENT - KEEP HOLDING DOWN.

3. After 10 seconds, the battery strength will be displayed via the red lights. The more lights that are

present, the more life the batteries have. See Figure 8.

4. When you are satisfied with the strength indication, release the override button to return to Operation

mode.

BATTERY STRENGTH INDICATION

VERY HEALTHY - 5 RED LIGHTS

HEALTHY - 4 RED LIGHTS

AVERAGE - 3 RED LIGHTS

LOW AVERAGE - 2 RED LIGHTS

REPLACE BATTERIES - 1 RED LIGHT

Fig. 8

TO REPLACE BATTERIES:

1. Remove the two cover screws and lift off CP metal cover, see Figure 9.

2. Hold case/cover securely with one hand and open hinged lid of the battery

compartment in the back of the unit.

3. Pull the battery holder out and insert new set of four “AA” batteries into battery

holder. (Use the +/- signs on the batteries and the +/- signs on the battery holder

for correct positioning.) Note: Do not use a metal screwdriver to remove snap

from battery holder.

4. Install the refreshed battery holder back into the electronic housing. (When the

new batteries are installed and connected, an initial ascending and descending

red light sequence will occur.)

5. Close the battery compartment lid ensuring wires are neatly tucked into compart ment and are not pinched between case and cover. Test the manual override

button. Blue light flashes once when override is activated.

6. Place the CP metal cover back onto flushometer and replace the two cover

screws. DO NOT OVERTIGHTEN. Flushometer is now ready for use.

* NOTE: All previously adjusted settings will be retained when batteries are

changed.

1. Start-Up: When batteries are first inserted, there is an initial ascending and

descending red light sequence that will occur.

2. Override Button in Operating Mode: Blue light flashes once when Override

Button is activated.

3. Low Battery Level Indicator: One RED light flashes every 15 seconds,

indicating approximately 5,000 flushes remain from when RED light first started

flashing.

Fig. 9

Fig. 10

www .specselect.com

Page 6

210233 Rev. A

Page 7

PROBLEM SOLVING & MAINTENANCE SUGGESTIONS:

NO LIGHTS - NO POWER

Check that the 4 “AA” batteries are positioned properly in the battery holder. Use the +/- signs on the batteries and the +/- signs on the battery

holder for correct positioning.

If the batteries are positioned correctly, but there are still no lights, replace with 4 new “AA” Alkaline batteries (see Battery Replacement on page 6).

NOTE: DO NOT USE EXCESSIVE FORCE to close the inlet stop stem. We RECOMMEND that the fllushometer be flushed while closing the inlet

stop. The noise created by the water flow or the flow into the fixture will stop when the inlet water is shut off.

NOTE: Always use DELTA COMMERCIAL GENUINE PARTS to maintain the warranty.

EXCESSIVE NOISE:

1. PARTIALLY close the inlet stop.

2. Pressures OVER 75 PSI may lead to an increase in NOISE, water could SPLASH out of the fixture more easily and the LIFE of any plumbing

valve may be SHORTENED.

3. INSTALL a Pressure Reducing Valve set at a lower pressure if actual pressure is over 75 PSI. While the TECK Flushometer will operate up to

125 PSI, the preferred operating range is between 35 to 65 PSI.

4. On flushometers that have been installed for a number of years, check the Renewable Seat (062007A, item #12) for wear and replace if necessary.

EXCESSIVE WATER FLOW RATE:

1. OPEN inlet stop ONE TURN and adjust Regulating Screw (061024A, item #8a) to the fixture requirement (except on -6, -38, -19, -05 and -48 models

which are fixed volume).

2. Operation of flushometer with inlet stop BELOW ONE TURN OPEN may cause EXCESSIVE NOISE. The lowest open setting for the inlet stop

may vary dependent on the installation.

SHORTAGE OF WATER TO PROPERLY FLUSH BOWL:

1. OPEN inlet stop fully.

2. CHECK pipeline for size or obstruction, partially closed gate or other supply line valve, corroded or undersize water piping.

3. CHECK water pressure.

4. Water flow rate is determined by BOTH the water pipe size AND the water pressure available.

5. A water closet flush valve requires a minimum water supply of 1” (or larger), depending on a number of different factors including water pressure

(PSI) available, pipe size and length of pipe run, number of fixtures per washroom and per building, fixture type, fixture usage factor, elevation of

valve above the water main, etc. We strongly recommend that pipe size calculations be done to insure proper water supply sizes. A Piping

Calculation Guide is available on request.

Flushometers do NOT provide a water supply; they are merely automatically timed self-closing valves. The inlet supply piping is the water reservoir

that must supply sufficient water volume in a short period of time (4 to 10 seconds) to properly flush and clear the fixture.

CONTINUOUS FLUSHING:

1. The Regulating Screw (061024A, item #8a) may be turned RIGHT (clockwise) TOO FAR. Adjust by slowly turning the Regulating Screw LEFT

(counter-clockwise). (Except -6, -48, -38, -19 and -05 models which are fixed volume).

2. If flush is still continuous, remove 061024A Regulating Screw, CLEAN bypass slot in the Screw, REPLACE it in the valve and ADJUST slowly for

proper flush (except -6, -48, -38, -19 and -05 models which are fixed volume).

3. Remove cast cap assembly and Diaphragm/Guide Assembly (061216A - WC or 061217A - UR, item #11), check for contaminants at renewable

seat and diaphragm and check for debris in the cap for blockage. Also CHECK that the Diaphragm/Guide slides easily in the Renewable Seat.

VALVE WILL NOT FLUSH:

1. When the valve has been taken apart for servicing and re-assembled and does NOT operate, check that the Cast Cap has been put on the body

properly. The Regulating Screw (061024A, item #8a) should always be on the same side as the inlet stop.

2. When all lights operate as expected but valve will not flush, check that the solenoid makes a clicking sound. If no clicking sound is present, then

replace with Electronic Repair Kit (WC - 061142A or UR - 061143A, item #19).

3. After a number of years, the valve will flush but shuts off immediately when activated. The Diaphragm (060079A, item #11c) is worn or split and

needs replacing.

SLIGHT WATER LEAK INTO FIXTURE:

1. EXAMINE the seating surface of the Diaphragm (060079A, item #11c) for imbedded sediment.

CLEANING INSTRUCTIONS:

CLEAN the outside of the chrome plated flushometer with a damp cloth.

CAUTION: MOST Tub & Tile fixture cleaners contain ACIDS. DO NOT WIPE the cloth used to clean ceramic fixtures over the flushometer as it will

remove the chrome plating and leave a discoloured surface.

For a copy of the “TECK Flushometer Maintenance Manual/Piping Calculation Guide”, contact your local Delta Representative.

www .specselect.com

Page 7

210233 Rev. A

Page 8

Delta Commercial Faucet Limited Warranty

All parts of the Delta® HDF® and TECK® faucets are warranted to the original consumer purchaser to be free from defects in material, finish and workmanship for a period of

five (5) years unless otherwise specifically stated in the catalogue and price book. This warranty is made to the original consumer purchaser and shall be effective from date

of purchase as shown on purchaser’s receipt.

Delta will, at its option, repair or replace, FREE OF CHARGE, during the warranty period, any part which proves defective in material or workmanship under normal installation,

use and water and service conditions. If Delta Faucet concludes that the returned part was manufactured by Delta Faucet and is, in fact, defective, then Delta Faucet will

honour the warranty stated herein. Replacement parts can be obtained from your local dealer or distributor listed in the telephone directory or by returning the part along

with the purchaser’s receipt to our factory, TRANSPORTATION CHARGES PREPAID, at the address listed. THIS WARRANTY IS THE ONLY EXPRESS WARRANTY MADE BY DELTA.

ANY CLAIMS MADE UNDER THIS WARRANTY MUST BE MADE DURING THE FIVE YEAR PERIOD REFERRED TO ABOVE. ANY IMPLIED WARRANTIES, INCLUDING THE IMPLIED

WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE DURATION OF THIS WARRANTY. LABOUR CHARGES AND/OR

DAMAGE INCURRED IN INSTALLATION, REPAIR OR REPLACEMENT AS WELL AS INCIDENTAL AND CONSEQUENTIAL, SPECIAL, INDIRECT OR PUNITIVE DAMAGES CONNECTED

THEREWITH ARE EXCLUDED AND WILL NOT BE PAID BY DELTA FAUCET.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the above limitations or

exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

This warranty is for commercial products only from Delta Faucet Company and Delta Faucet Canada (a division of Masco Canada Limited) and is void for any damage to this

faucet due to misuse, abuse, neglect, accident, improper installation, any use in violation of instructions furnished by Delta Faucet or any use of replacement parts other than

genuine Delta parts.

Garantie Limitée Delta Commercial

Toutes les pièces des robinets de marque Delta® HDF® et TECK® sont garanties contre tout défaut de matériel, de finition et de main-d’oeuvre pour une période de cinq (5)

ans, sauf indication contraire stipulée dans le catalogue et la liste des prix. Cette garantie est offerte à l’acheteur original et entre en vigueur à compter de la date d’achat

indiquée sur la preuve d’achat.

Delta procédera, à son entière discrétion, à la réparation ou au remplacement, SANS FRAIS, durant la période de garantie, de toute pièce qui présente un défaut de matériel

ou de main-d’oeuvre dans des conditions d’installation, d’usure, d’eau et de service normales. Si Delta Faucet détermine que la pièce retournée a été fabriquée par Delta

Faucet et qu’en effet, cette pièce défectueuse, Delta Faucet respectera alors la garantie mentionnée ci-dessous. Les pièces de rechange peuvent être obtenues chez votre

marchand local ou le distributeur inscrit dans votre annuaire téléphonique, ou en retournant la pièce ainsi que la preuve d’achat à notre usine, FRAIS DE TRANSPORT

PRÉPAYÉS, à l’adresse indiquée. CET TE GARANTIE EST LA SEULE GARANTIE EXPRESSE FAITE PAR DELTA.

TOUTE RÉCLAMATION FAITE EN VERTU DE CETTE GARANTIE DOIT ÊTRE PRÉSENTÉE DURANT LA PÉRIODE DE CINQ ANS MENTIONNÉE CI-DESSUS. TOUTE GARANTIE IMPLICITE,

Y COMPRIS LA GARANTIE IMPLICITE DE VALEUR COMMERCIALE D’ADÉQUATION POUR UN USAGE PARTICULIEUR, EST LIIMITÉE DANS LE TEMPS À LA DURÉE DE LA PRÉSENTE

GARANTIE.

LES FRAIS DE MAIN-D’OEUVRE ET/OU LES DOMMAGES ENCOURUS DURANT L’INSTALLATION, LA RÉPARATION OU LE REMPLACEMENT AINSI QUE LES DOMMAGES ACCIDENTELS ET CONSÉCUTIFS, SPÉCIAUX, INDIRECTS OU PUNITIFS QUI SONT RELIÉS SONT EXCLUS ET NE SERONT PAS PAYÉS PAR DELTA FAUCET.

Certains états ne permettent pas la limitation de la durée de la garantie implicite, ou l’exclusion ou la limitation des dommages accidentels ou consécutifs, et par conséquent,

les limitations ou les exclusions stipulées ci-dessus peuvent ne pas s’appliquer dans votre cas. Cette garantie vous accorde certains droits reconnus par la loi et vous pouvez

aussi avoir d’autres droits qui varient d’un état à l’autre.

Cette garantie s’applique seulement aux produits commerciaux de Delta Faucet Company et Delta Faucet Canada (une filiale de Masco Canada Limited) et est nulle de plein

droit pour tout dommage causé à ce robinet en raison d’une mauvaise utilisation, d’abus, de négligence, d’accident, de mauvaise installation, pour tout usage en contravention des directives fournies par Delta Faucet ou pour tout usage de pièces de rechange autres que des pièces originales Delta.

Garantía Limitada de las Llaves de Agua Comerciales Delta

Todas las piezas de las llaves de agua (grifos) Delta® HDF®, TECK® están garantizadas al comprador consumidor original de estar libres de defectos de material, acabado y

fabricación por un periodo de cinco (5) años a menos que sea establecido específicamente de otra manera en el catálogo o libro de precios. Esta garantía se le otorga al

comprador consumidor original y será efectiva desde la fecha de compra indicada en el recibo del comprador.

Delta, a su opción, reparará o reemplazará, GRATUITAMENTE, durante el periodo de garantía, cualquier pieza que resulte defectuosa en material o fabricación bajo

instalación, uso, agua y condiciones de servicio normales. Si Delta Faucet concluye que la pieza devuelta fue fabricada por Delta Faucet y es, de hecho, defectuosa, entonces

Delta Faucet honrará la garantía establecida en este documento.

Las piezas de reemplazo se pueden obtener de su tienda o distribuidor local listado en la guía telefónica o devolviendo la pieza junto con el recibo de compra a nuestra

fábrica, CON LOS GASTOS DE ENVÍO PRE-PAGADOS, a la dirección indicada. ESTA GARANTÍA ES LA ÚNICA GARANTÍA EXPRESA HECHA POR DELTA. CUALQUIER RECLAMO

HECHO BAJO ESTA GARANTÍA DEBE SER HECHO DURANTE EL PERÍODO DE CINCO AÑOS ARRIBA MENCIONADO. CUALQUIER GARANTÍA IMPLÍCITA, INCLUYENDO LA

GARANTÍA IMPLÍCITA DE COMERCIABILIDAD DE EMPLEO PARA UN PROPÓSITO PARTICULAR, TIENE UNA DURACIÓN LIMITADA A LA DURACIÓN DE ESTA GARANTÍA. LOS

CARGOS DE MANO DE OBRA Y/O DAÑO INCURRIDO DURANTE LA INSTALACIÓN, REPARACIÓN O REEMPLAZO, COMO TAMBIÉN DAÑOS INCIDENTALES O RESULTANTES,

ESPECIALES, INDIRECTOS O PUNITIVOS RELACIONADOS CON LO MENCIONADO, QUEDAN EXCLUIDOS Y NO SERÁN CUBIERTOS POR DELTA FAUCET.

Algunos estados no permiten limitaciones de la duración de una garantía implícita, o la exclusión o limitación de daños incidentales o consecuentes, de manera que las

limitaciones o exclusiones arriba mencionadas puedan no aplicarse en su caso. Esta garantía le otorga derechos legales específicos, y usted también puede tener otros

derechos que varían de estado a estado.

Esta garantía es solo para productos comerciales de Delta Faucet Company y Delta Faucet Canada (una división de Masco Canada Limited), y queda anulada por cualquier

daño ocasionado a esta llave de agua resultante del mal uso, abuso, descuido, accidente, instalación incorrecta, cualquier uso en violación de las instrucciones proporcionadas

por Delta Faucet o el uso de cualquier parte de repuesto que no sea una parte genuina de Delta.

Delta Faucet Canada, a division of Masco Canada Limited

350 South Edgeware Road, St. Thomas, Ontario, N5P 4L1

1-800-567-3300 (English) 1-800-265-9245 (French)

For further technical assistance, call Delta Commercial Technical Service at 1-800-387-8277.

Pour obtenir de l’assistance technique, appelez le Service Technique de Delta Commercial au 1-800-387-8277.

Por la asistencia técnica adicional, llame al servicio técnico de Delta Comercial al 1-800-387-8277.

Delta Faucet Company

Box 40980, 55 East 111th St., Indianapolis, IN, U.S.A. 46280

(317) 848-1812

www.deltacommercialfaucets.com

Page 8

210233 Rev. A

Loading...

Loading...