Page 1

2008-09-10

V

y

5011669601-1CBU

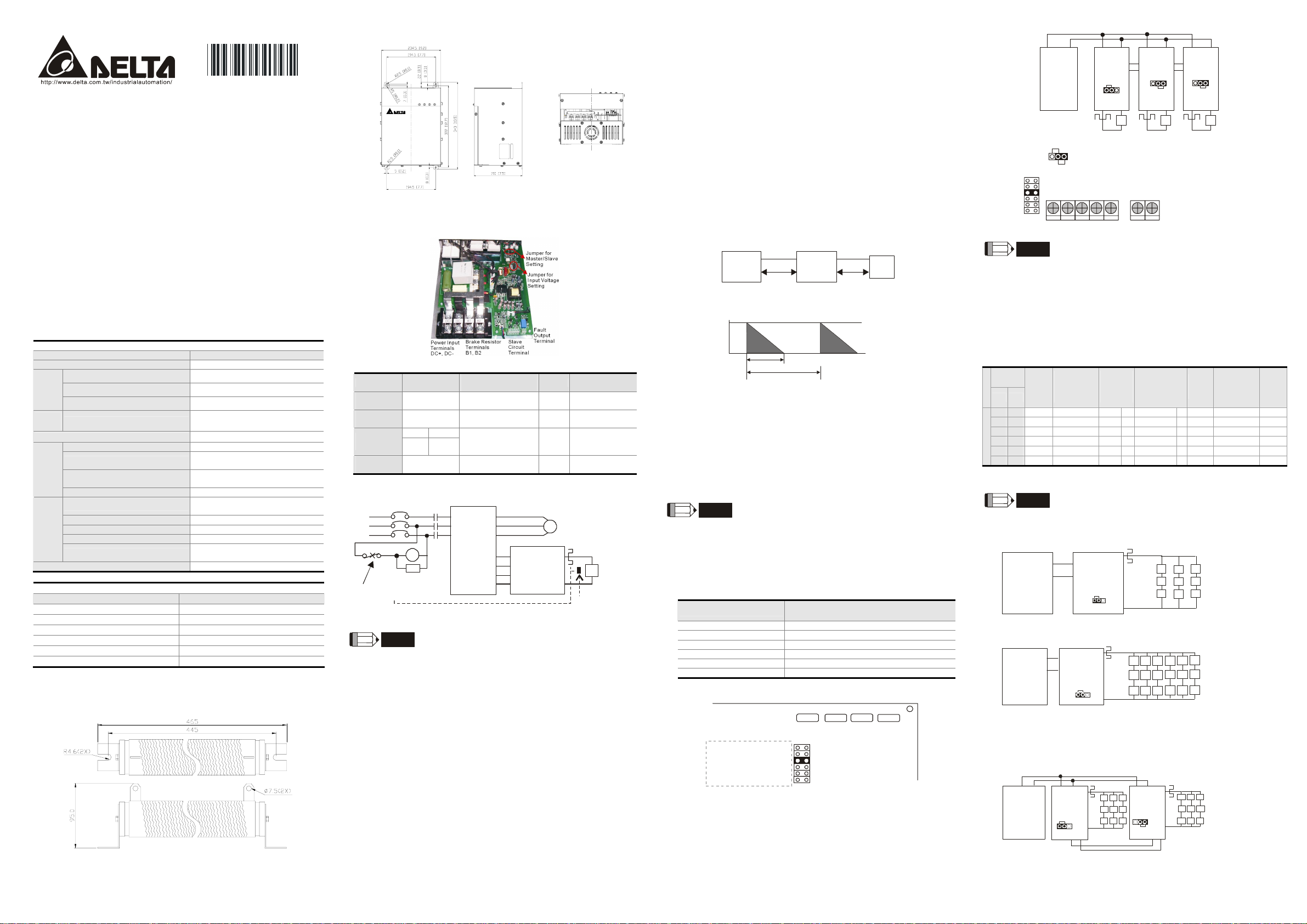

VFDB 4132 Series Brake Modules

Instruction Sheet

X

Preface

Thank you for choosing DELTA’s brake module. VFDB brake units are applied to

absorb the motor regeneration energy when the three-phase induction motor stops by

deceleration. With VFDB brake unit, the regeneration energy will be dissipated in

dedicated brake resistors. To prevent mechanical or human injury, please refer to this

instruction sheet before wiring. VFDB brake units are suitable for DELTA AC Motor

Drives VFD Series 230V/460V/575V. VFDB brake units need to be used in conjunction

with BR series brake resistors to provide the optimum brake characteristics. VFDB

brake units (4132) are approved by Underwriters Laboratories, Inc. (UL) and Canadian

Underwriters Laboratories (cUL). The content of this instruction sheet may be revised

without prior notice. Please consult our distributors or download the most updated

version at http://www.delta.com.tw/industrialautomation.

Y Specifications

Max. Motor Capacity (kW) 132

Specification 460V Series

Max. Discharge Current (A) 10%ED 240

Continuous Discharge Current (A) 75

Output

Rating

Braking Start-up Voltage (DC)

Input

DC Voltage 480-750VDC

Rating

Min. Equivalent Resistor for Each Brake Unit

Heat Sink Overheat Temperature Temperature exceeds +95 oC (203oF)

Alarm Output for Overheat

Power Charge Display

Protection

Over-current Protection Level 320A

Installation Location

Operating Temperature -10oC~+50oC (14oF to 122oF)

Storage Temperature -20oC ~+60oC (-4oF to 140oF)

Humidity Less than 90% Non-condensing

Environment

Vibration

Mechanical Configuration Wall-mounted enclosed type IP10

Model no. Specification

BR1K5W005 1500W 5.0Ω

BR1K2W6P8 1200W 6.8Ω

BR1K2W008 1200W 8.0Ω

BR1K5W040 1500W 40Ω

BR1K0W050 1000W 50Ω

BR1K0W075 1000W 75Ω

VFDB 4132 Brake Units

618/642/667/690/725/750±6V

Relay contact 3A250VAC/30VDC

(RA, RC)

ON until the bus (P-N) voltage is

below 50VDC

Indoor (no corrosive gases, metallic

dust)

9.8m/s

(0.2G) at 20~50Hz

Brake Resistors

3.4Ω

2

(1G) under 20Hz / 2m/s2

Z Dimensions

3.1 Brake resistor

3.2 Brake unit

CHARGE ACT OC OH

VFDB4132

[ Internal Components and Terminals

4.1 Internal Components

4.2 Wire Gauge for Terminals

Circuit Terminals

Power Input

Circuit

Brake

Resistor

SLAVE

Circuit

Fault

Circuit

DC+, DC-

B1, B2

Output M1, M2

Input S1, S2

RA, RC

Wire Gauge AWG

(mm2)

4~6AWG

(13.3~21.2mm

2

)

4~6AWG

(13.3~21.2mm2)

18~20AWG

(0.8~0.5mm

2

)

(With shielded wires)

18~20AWG

(0.8~0.5mm2)

Screw Torque

M8

M8

M2

M2

30 kgf-cm

(26 in-lbf)

30 kgf-cm

(26 in-lbf)

4 kgf-cm

(3 in-lbf)

4 kgf-cm

(3 in-lbf)

\ Basic Wiring Diagram

NFB

MC

SA

MC

R/L1

R/L1

S/L2

S/L2

T/L3

T/L3

VFD Series

+(P)

-(N)

E.F

DCM

R/L1

S/L2

T/L3

O.L.

Surge Absorber

Thermal Overload

Relay or Temperature switch

Note 1: When the AC motor drive is used with DC reactor, please refer to the wiring

diagram in the AC drive user manual for wiring terminal DC+ of brake unit.

DO NOT

Note 2: wire terminal DC- to the neutral point of power system.

NOTE

For safety consideration, install an overload relay between the brake unit and the

brake resistor. In conjunction with the magnetic contactor (MC) prior to the drive,

it can perform complete protection against abnormality.

The purpose of installing the thermal overload relay is to protect the brake resistor

from damage due to frequent brake, or due to brake unit keeping operating

resulted from unusual high input voltage. Under such circumstance, just turn off

the power to prevent damaging the brake resistor.

Please refer to the specification of the thermal overload relay.

The alarm output terminals (RA, RC) of the brake unit will be activated when the

temperature of the heat sink exceeds 95°C. It means that the temperature of the

installation environment may exceed 50°C, or the brake %ED may exceed

10%ED. With this kind of alarm, please install a fan to force air-cooling or reduce

the environment temperature. If the condition not due to the temperature, the

control circuit or the temperature sensor may have been damaged. At this time,

please send the brake unit back to the manufacturer or agency for repair.

The AC Motor Drive and brake unit will be electrified at the same time while

turning on the NFB (No-fuse breaker). For the operation/stop method of the motor,

please refer to the user manual of the AC Motor Drives VFD Series. The brake

unit will detect the inner DC voltage of the AC motor drive when it stops the motor

by deceleration. The extra regeneration will be dissipated away rapidly by the

brake resistor in the form of heat. It can ensure the stable deceleration

characteristic.

Besides, using thermal overload relay to be the protection system and brake

resistor, temperature switch can be installed on brake resistor side as the

protection. The temperature switch must comply with the brake resistor

specification or contact your dealer.

DC+

DC-

RA

RC

Motor

FDB

Brake

Unit

IM

Thermal

Overload

Relay

B1

O.L.

B2

Temperature Switch

BR

Brake

Resistor

] Wiring Warnings

Do not proceed with wiring while power is applied to the circuit.

The wiring gauge and distance must comply with the local regulations.

The +(P), -(N) terminals of the AC motor drive (VFD Series), connected to the

brake unit (VFDB), must be confirmed for correct polarity lest the drive and the

brake unit be damaged when power on.

When the brake unit performs braking, the wires connected to DC+, DC-, B1 and

B2 would generate a powerful electromagnetic field for a moment due to high

current passing through. These wires should be wired separately from other low

voltage control circuits lest they make interference or mis-operation.

Inflammable solids, gases or liquids must be avoided at the location where the

brake resistor is installed. The brake resistor had better be installed in individual

metallic box with forced air-cooling.

Connect the ground terminal to the Earth Ground. The ground lead must be at

least the same gauge wire as leads DC+, DC-.

Please install the brake resistor with forced air-cooling or the equivalent when

frequent deceleration braking is performed (over 10%ED).

Do NOT change any wirings and settings and touch any terminals and

components while power is applied to avoid electric shock.

It is recommended to use the ring terminals for main circuit wiring. Make sure the

terminals are fastened before power on.

Wiring distance

VFD series

AC Motor Drive

Max 8M

VFDB

series

Brake Unit

Max 5M

BR

Brake Re sis tor

^ Definition for the Brake Usage ED%

100%

Brake Time

Cycle Time

T1

ED% = T1/T0x100(%)

T0

The definition of the brake usage ED(%) is to assure having enough time for the brake

unit and brake resistor to dissipate the heat generated by brake. When the brake

resistor heats up, the resistance would increase with temperature, and brake torque

would decrease accordingly.

_ The Voltage Settings

1. Voltage setting: the power source of the brake unit is DC voltage from +(P), -(N)

terminals of the AC motor drive. It is very important to set the voltage of the brake

unit based on the actual input power of the AC motor drive before operation. The

setting has a great influence on the potential of the operation voltage for the brake

unit. Please refer to the table below.

NOTE

Before changing the setting of the power voltage, make sure the power has been

turned off. Please set power voltage as the possible highest voltage for unstable

power system. Take 380VAC power system for example. If the voltage may be up

to 410VAC, 415VAC should be set.

For DELTA’s AC motor drive (VFD Series), please set parameter (Over Voltage

Stall Prevention) as “close” to disable over-voltage stall prevention, to ensure

stable deceleration characteristic.

Table 1: The Selection of AC Power Voltage and Voltage Setting

380VAC (460V Mode) 618VDC

400VAC (460V Mode) 642VDC

415VAC (460V Mode) 667VDC

440VAC (460V Mode) 690VDC

460VAC (460V Mode) 725VDC

480VAC (460V Mode) 750VDC

2. MASTER (M) /SLAVE (S) setting: the factory setting is “M”. The “S” setting is

applied to two or more brake units in parallel, making these brake units be

enabled/disabled synchronously. Then the power dissipation of each unit will be

equivalent so that they can perform the brake function completely.

In the following diagram, it shows jumper setting for the application of three brake

units. After wiring, the jumper in the first brake unit should be set to “M” and others

must be set to “S” to complete the system setting.

AC Power Voltage

Input voltage setting for VFDB 4132

Input Voltage Setting

For VFDB4132

Factory setting: 440V

480V

460V

440V

415V

400V

380V

Brake Start-up voltage

DC Bus (DC+, DC-) Voltage

NOTE: Input Power With Tolerance ±10%

CHARGE

Power lamp

Brake lamp

ACT

OC

Over-curr ent

lamp

OH

Overheat

lamp

-(N) DC -

+P( )

VF D

Series

M

Input Volt age Sett ing

480V

460V

440V

415V

400V

380V

Please make sure that power is OFF before setting the jumper.

M1

SLAVE output/input terminal

NOTE

DC+

M1

M2

M

B1

B2

BR

O.L.

Th e Po s it ion o f the J um per

MASTER/SLAVE

Setting Jumper

S

S1

M2

S2

DC -

DC+

S1

S2

B1

O.L.

RA RC

Alarm output terminals

DC+

M1

S1

M2

S2

S

B2

B1

BR

O.L.

M1: SLAVE output signal +

M2: SLAVE output signal S1: SLAVE input signal +

S2: SLAVE input signal -

NOTE: Please use shielded

wir es w hi le wi ring .

DC -

S

B2

BR

The steps for jumper setting:

Step 1. Remove the top cover.

Step 2. Remove the screws on the side case (3 screws for each side).

Step 3. Remove the screws that connected bottom case to the side case (2

screws for each side).

Step 4. After removing the power line of the fan, pull out the heat sink slowly until

the jumper can be seen. Then the jumper can be set.

` Brake Resistors/Units for Delta VFD

AC Motor Drives Series

Applicable

Motor

Voltage

HP kW

120 90 52.5 13500W 5Ω 4132 1 BR1K5W005 9 120 5Ω 110 A

150 110 61 21600W 4Ω 4132 1 BR1K2W008 18 120 4Ω 135A

175 132 73.5 21600W 4Ω 4132 1 BR1K2W008 18 100 4Ω 135A

215 160 89 21600W 3.4Ω 4132 1 BR1K2W6P8 18 97 3.4Ω 160A

460V

250 185 103 27000W 2.5Ω 4132 2 BR1K5W005 18 115 2.5Ω 220A

300 220 122.5 27000W 2.5Ω 4132 2 BR1K5W005 18 96 2.5Ω 220A

Full-load

Tor q ue

kg-M

Resistor Value

Spec. for Each

AC Motor

Drive

Brake Unit

Part No.

and

Quantity

Brake Resistors

Part No. and

Quantity

Brake

Tor q ue

10%ED

Min.

Equivalent

Resistor Value

for Each AC

Motor Drive

Typic al

Thermal

Overload

Relay

Val ue

a Examples

NOTE

Before wiring, please notice equivalent resistors value shown in the column

“Equivalent resistors specification for each brake unit” in the above table to

prevent damage.

460V 120HP

VFD

Series

VFD900_43_

VFD90 0_43_ uses with 3 BR sets in parall el, which 3PCS 1K5W005 brake resis tors

are connec ted in series.

460V 150HP, 175HP, 215HP

VFD

Series

VFD1100_ 43_

VFD13 20_43_

VFD16 00_43_

VFD1100_ 43_ uses with 6 BR sets in p arallel, which 3PC S 1K2W008 brake resisto rs

are connec ted in serie s.

VFD13 20_43_ uses with 6 BR sets in parallel, wh ich 3PCS

are con necte d in serie s.

VFD16 00_43_use s with 6 BR sets in parallel, wh ich 3PCS 1K2W6 P8 brake resistors

are con necte d in serie s.

460V 250HP, 300HP

+(P) -(N)

VFD

Series

VFD1850_43_

VFD2200_43_

VFD1850_43_ uses with 2 VFDB4132 brake units and each brake unit uses with

3 BR sets in parallel, which 3PCS 1K5W005 brake resistors are connected in series.

VFD2200_43_ uses with 2 VFDB4132 brake units and each brake unit uses with

3 BR sets in parallel, which 3PCS1K5W005 brake resistors are connected in s eries.

+(P)

-(N)

+(P)

-(N)

DC+

DC-

DC+ DC-

VFDB

4132

Brake Unit

M

DC+

VFDB

DC-

4132

Brake Unit

M

B1

VFDB

4132

Brake Unit

M

B2

Thermal Over load Rel ay

B1

BR

O.L.

BR

BR

B2

M1 M2

Thermal O verloa d Rel a

B1

O.L.

Brake

Resistor

B2

Thermal Ov erload Relay

BRBR

BRBR

O.L.

Brake

R esist or

B rak e

Resistor

BRBR

BRBR

BRBR

BRBR

BRBR

BRBR

BRBR

DC+ DC-

BR

BR

VFDB

41 32

BR

BR

B rak e Uni t

BR

BR

S

S1 S2

BR

BR

BR

BR

BR

BR

BR

B1

B2

BR

BR

BR

BR

BR

BR

BR

BR

BR

BR

BR

BRBR

BRBR

BRBR

BRBR

BRBR

BRBR

BRBR

BRBR

BRBR

1K 2W008 brake resistors

Thermal Over load Relay

BR

BR

BR

O.L.

Brake

BR

BR

BR

Resis tor

BR

BR

BR

Page 2

主動從動

設定插梢

輸入電源

電壓設定

請使用隔離線配線施工

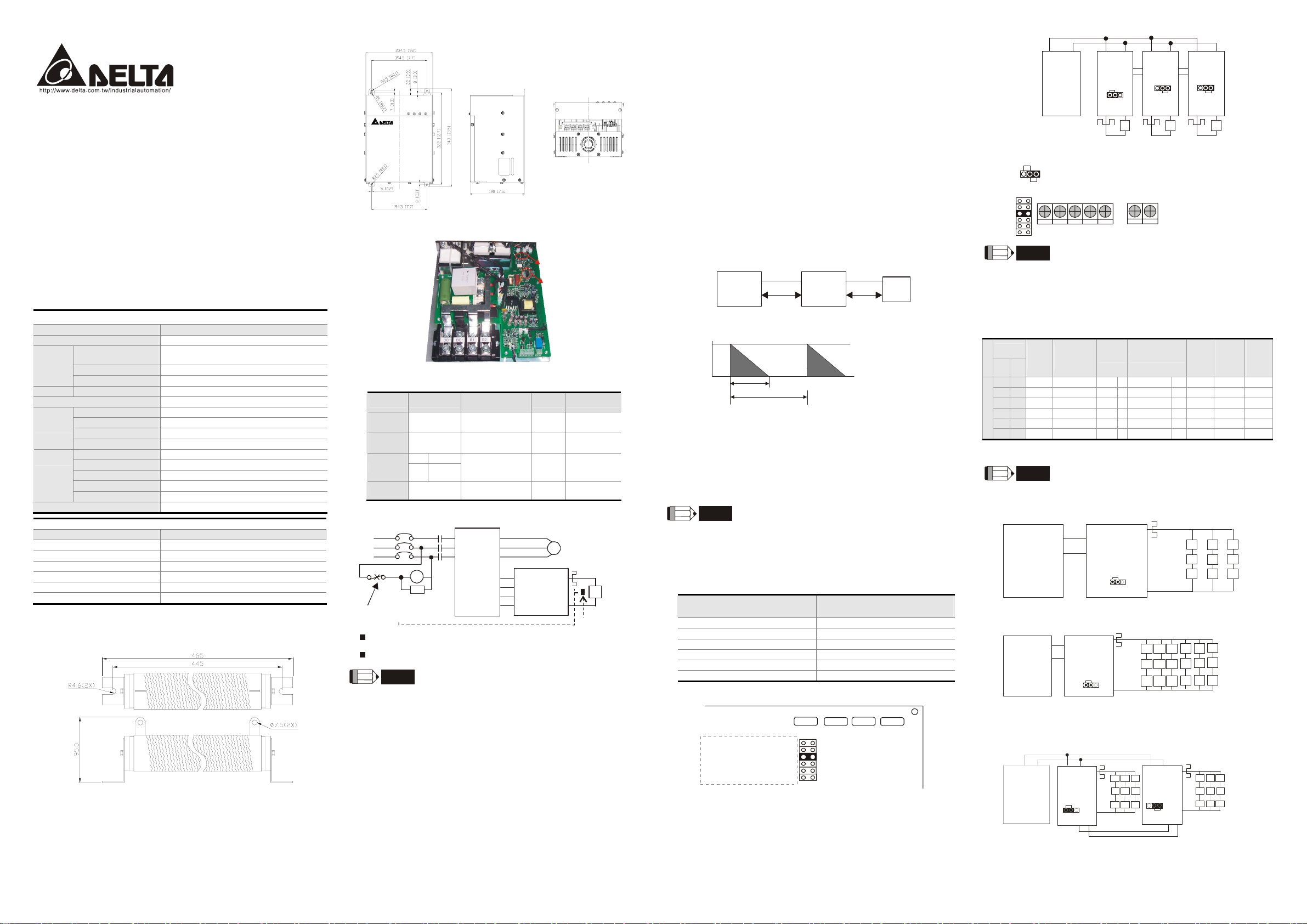

VFDB4132 րЕ֘ሀ

ᄲځ

X

݈֏

感謝您選用台達 VFDB 動力制動煞車模組。本產品主要應用於當三相感應馬達由

交流馬達驅動器所驅動,在減速停止時用以吸收由馬達側所回生的能量。藉由

VFDB 制動單元將此能量以熱能的方式消耗在煞車電阻上。本產品在安裝使用前,

請詳細參閱本說明書再進行施工配線,以免造成機械或人員的傷害。VFDB 動力制

動煞車模組適用於本公司 VFD 所有系列的交流馬達驅動器。VFDB 制動單元需搭

配煞車電阻 BR 系列,才能發揮優異的制動特性,詳細的規格及使用方法請繼續參

閱本說明書。由於產品精益求精,當內容規格有所修正時,請洽詢代理商或至台達

網站(http://www.delta.com.tw/industrialautomation/)下載最新版本。

Yఢ

VFDB 4132 制動單元規格

使用電壓等級 460V 系列

最大適用馬達容量 (kW)

最大放電電流(A peak)

輸出

額定

連續放電電流 (A)

制動起始電壓 (DC)

電源 直流電壓

每台等效最小電阻 3.4Ω

散熱片過熱溫度 溫度超過 +95℃ (203oF)

保護

過熱故障輸出 RELAY 接點 3A250Vac/30Vdc(RA.RC)

過電流 OC 保護準位

使用

環境

機構構造 壁掛型 IP10

型號 規格

BR1K5W005

BR1K2W6P8

BR1K2W008

BR1K5W040

BR1K0W050

BR1K0W075

Z

3.1 煞車電阻

10%ED

618/642/667/690/725/750±6V

充電中顯示 主回路 (P-N) 電壓在 50VDC 以下熄滅

安裝場所 屋內(無腐蝕性氣體、金屬粉塵)

環境溫度 -10℃~+50℃ (14oF to 122oF)

儲存溫度 -20℃~+60℃ (-4oF to 140oF)

濕度 90%RH 以下不結露

振動 20Hz 以下 9.8m/S2(1G)、20~50Hz 2m/S2(0.2G)

煞車電阻

132

240

75

480-750VDC

320A

1500W 5.0Ω

1200W 6.8Ω

1200W 8.0Ω

1500W 40Ω

1000W 50Ω

1000W 75Ω

3.2 VFDB 4132 制動單元

CHARGE ACT OC OH

VFDB4132

[ЧొЩჍΑᄲځ

]ቢڦຍְี

進行配線施工時務必確認相關回路電源均為關閉狀態;配線的線徑及距離亦務必按

照規定選用及施工。

交流馬達驅動器(VFD)連接至制動單元(VFDB)的 DC+、DC- 端子有極性之

分,千萬要確認再確認,否則電源一開啟制動單元立即炸毀,請務必注意。

制動單元在執行煞車時,DC+、DC-、B1、B2 因有大電流通過所連接的導線瞬間

將產生能量很大的電磁場;故在初期配線施工規劃時,應與其它低電壓的控制線路

分離配線,以免造成不必要的干擾或誤動作。

煞車電阻安裝的場所不能有任何易燃性的物體、氣體、液體,最好能安裝在獨立的

金屬箱內並加以風扇散熱。

制動單元的接地工程 230V 級請依第三種接地施工,460V 級請依特別第三種接地

施工。

在減速煞車頻繁的場合(超過 10%ED)煞車電阻請加裝風扇強制風冷或其它冷卻

設備。

在通電中嚴禁修改任何配線及制動單元內部設定,更嚴禁在通電中碰觸相關配線的

端子及 PCB 板中的任一元件,以免因通電中遭極度危險的直流高壓感電造成人員

傷害。

所有的主回路端子請使用 O 型端子配線,並確認端子已鎖緊方可送電運行。

配線距離

M

輸入電壓設定

480V

460V

440V

415V

400V

380V

NOTE

-(N) DC -

+P()

VF D

Series

插梢位置

主動 連動設定端子/

S

M1 M2 S2S1

連動輸出 輸入端子/故障輸出端子

DC+

M

B1

O.L.

VFDB 4132

M1

M2

B2

BR

設定位置

DC+

S1

S2

O.L.

RCRA

B1

DC -

M1

M2

S

B2

BR

O.L.

M1:

連動信號輸出 端

M2:

連動信號輸出 端

S1:

連動信號輸入 端

S2:

連動信號輸入 端

注意:

DC+

S1

S2

B1

DC -

S

B2

BR

+

-

+

-

必須在關電的狀態下,才能切換插梢位置。

VFD

插梢

系列

交流馬達驅動器 制動單元

Max 8M

VFDB

系列

Max 5M

BR

煞車電阻

^ ֹ֘ϡத ED%۞ؠཌྷ

100%

連動

故障

2

2

DC+

DC-

RA

RC

回路

端子

2

)

2

)

)

)

輸出

端子

螺絲規格

M8

M8

M2

M2

Motor

IM

VFDB

制動單元

B1

B2

扭力

30 kgf-cm

(26 in-lbf)

30 kgf-cm

(26 in-lbf)

4 kgf-cm

(3 in-lbf)

4 kgf-cm

(3 in-lbf)

積熱電驛

O.L.

BR

溫度開關

煞車電阻

週期時間

T1

使用率 %= (%)

T0

ED T1/T0x100

制動時間

制定煞車使用率 ED%,主要是為了能讓制動單元及煞車電阻有充份的時間來散除因制

動而產生的熱量;當煞車電阻發熱時,電阻值將會隨溫度的上昇而變高,制動轉矩亦隨

之減少。

_ నؠᄃአፋ

1. 電源電壓的調整:制動單元的電力來源是接受接交流馬達驅動器+ (P)、 - (N)兩端

供應的直流電源。因此,在配線完成準備運轉時,依交流馬達驅動器的實際輸入

電源來設定制動單元的電源電壓是非常重要的步驟;此設定將會影響制動單元動

作電壓的位準,下表為各個電壓動作準位。

NOTE

設定電源電壓時,請務必先將電源關閉後才可更改設定值。若在電源電壓不穩定的

區域,請將電源電壓設定在可能出現的最高電壓。例如:380Vac 的電源系統,若

電壓變動達到 410Vac,請設定在 415Vac。

使用本公司 VFD 系列交流馬達驅動器,請將參數的過電壓失速防止功能設定為關

閉狀態,使失速防止功能失效,如此可得穩定的減速特性。

2. 主動(M)/連動(S)的設定:制動單元在出廠時均設定在“M"主動煞車的位

置。“S"連動位置的功能主要是應用於兩台以上制動單元。

如下圖所示為三台制動單元連動制動的應用;當配線完成後需將第一台設為“M"

主動的設定,其餘的一定要將插梢設定在“S"連動的位置上,如此即可完成動力

制動系統的配線。

表一:電源電壓的選擇與 PN 直流電壓的動作準位

AC 電源電壓

制動開始電壓 DC+、DC-

380Vac(460V Mode)

400Vac(460V Mode)

415Vac(460V Mode)

440Vac(460V Mode)

460Vac(460V Mode)

480Vac(460V Mode)

註:容許輸入電源有±10%的變動

輸入電源電壓設定

VFDB413244系列

請依右邊文字設定

出廠設定值為

0V

VFDB 4132

480V

460V

440V

415V

400V

380V

設定位置

CHARGE

電源燈 煞車燈

ACT

母線 DC 電壓

618Vdc

642Vdc

667Vdc

690Vdc

725Vdc

750Vdc

OC OH

過熱燈

過流燈

電源輸入端子

DC+, DC-

煞車電阻端子

B1, B2

4.1 各端子使用線徑

回路名稱

電源輸入

回路

煞車電阻

回路

連動回路

故障回路

端子記號

DC+, DC-

B1, B2

輸出

輸入

RA, RC

M1, M2

S1, S2

導線線徑

AWG (mm2)

4~6AWG

(13.3~21.2mm

4~6AWG

(13.3~21.2mm

18~20AWG

(0.8~0.5mm

(需用隔離線)

18~20AWG

(0.8~0.5mm

\ૄώቢဦ

NFB

MC

SA

突波吸收器

DC+

MC

DC-

R/L1

S/L2

T/L3

VFD Series

(DC Reator)

R/L1

S/L2

T/L3

+(P)

-(N)

E.F

DCM

R/L1

S/L2

T/L3

O.L.

積熱電驛或溫度開關跳脫接點

當交流馬達驅動器有加裝直流電抗器 時,其煞車模組之電

源輸入迴路 端的配線方法,可參考交流馬達驅動器手冊。

請勿將電源輸入迴路 端,接至電力系統之中性點。

NOTE

在安裝制動單元的應用中為了安全的考量,在制動單元與煞車電阻之間加裝一積熱

電驛(O.L);並與交流馬達驅動器前端的電磁接觸器(MC)作一連鎖的異常保護。

加裝積熱電驛的主要目的是為了保護煞車電阻不因煞車頻繁過熱而燒毀,或是因輸

入電源電壓異常過高導致制動單元連續導通燒毀煞車電阻。此時只有將交流馬達驅

動器的電源關閉才可避免煞車電阻燒毀。

積熱電驛規格的選用請參考制動單元與放電電阻適用一覽表。

制動單元中的故障輸出端子(RA、RC)在散熱裝置溫度高於 95℃時會動作,表

示安裝環境溫度可能超過 50℃以上,或是煞車制動 ED%超過 10%ED;若是此類

的故障請自行加裝風扇強制風冷或改善環境溫度。若非溫度原因,可能控制電路受

損或溫度感測器故障,此時請送廠維修。

本配線電路在電源開關(NFB)開啟時交流馬達驅動器與制動單元便同時通上電

源,馬達的運轉/停止的方式請參考 VFD 系列的使用手冊;制動單元會在交流馬

達驅動器對馬達作減速煞車時自動偵測交流馬達驅動器內部的直流電壓,自動將過

多的回生能量藉由煞車電阻以熱能的方式迅速消耗以達平穩的減速特性。

除了使用積熱電驛作為保護系統及制動電阻外,尚可加裝溫度開關於制動電阻端作

為保護。溫度開關的動作溫度需配合制動電阻規格,或洽詢經銷商詢問。

切換插梢位置動作順序:卸下上蓋,然後卸下外殼兩旁螺絲共六顆(左右各三顆),

再卸下風扇組與外殼間的螺絲共四顆(左右各二顆)。此時,須拔除風扇組的電源

線後,將散熱片緩慢抽出至露出插梢即可,然後切換插梢位置。

` טજಏᄃٸܡዋϡ˘ᜓܑ

每台交流

全載輸

出轉矩

kg-M

每台交流馬達

驅動器等效煞

車電阻規格

制動單元 制動電阻料號

適用馬達

電壓

HP kW

120 90 52.5 13500W 5Ω 4132 1 BR1K5W005 9 120 5Ω 110 A

150 110 61 21600W 4Ω 4132 1 BR1K2W008 18 120 4Ω 135A

175 132 73.5 21600W 4Ω 4132 1 BR1K2W008 18 100 4Ω 135A

215 160 89 21600W 3.4Ω 4132 1 BR1K2W6P8 18 97 3.4Ω 160A

460V

250 185 103 27000W 2.5Ω 4132 2 BR1K5W005 18 115 2.5Ω 220A

300 220 122.5 27000W 2.5Ω 4132 2 BR1K5W005 18 96 2.5Ω 220A

制動

轉矩

10%ED

馬達驅動

器等效最

小電阻值

積熱電

驛

規格中

心值

a טજܡቢဦּ

NOTE

在配線前,注意:每台煞車模組之等效煞車電阻不能低於每台制動單元最小等效電

阻值(參閱制動單元與放電電阻適用一覽表)。

460V 120HP

VFD系列

VFD900_43_

VFD9 00_4 3_ B R1K5W0 05 9P CS 3P CS使用 ,每 串聯後再並聯接線

460V 150HP, 175HP, 215HP

VFD系列

VFD1100_43_

VFD1320_43 _

VFD1600_43 _

VFD1100_43_ 1 K2W008 18P CS 3PCS

VFD1 320_43 _使用

VFD1 600_43_ 1K2W 6P8 18PC S 3 PCS

460V 250HP, 300HP

+( P) -(N)

VFD系列

VFD1850_43_

VFD2200_43_

V FD 185 0_ 43_ 2 V F DB4 13 2 ,

每台使用 每 串聯後再並聯接 線

VFD2200_43_ 2 VFDB4132 ,

每台使用 每 串聯後再並聯接 線

+(P)

-( N)

+(P)

-( N)

使用 ,每 串聯後再並聯接線

使用 ,每 串聯後再並聯 接線

使用 台 制動單元

BR1K5W005 9PCS, 3PCS

使用 台 制動單元

BR1K5W005 9PCS, 3PCS

DC+

DC-

制動單元

VFDB

4132

制動單元

M

B1

B2

M1 M2

B1

B2

O.L.

DC+

DC-

1K2W 008 18PC S 3 PCS

DC+ DC-

VFDB

4132

制動單元

M

B1

VFDB

4132

M

O.L.

積熱電驛

BR

BR

BR

煞車電阻

O.L.

煞車電阻

B2

積熱電驛

BRBR

BRBR

BRBR

BRBR

煞車

電阻

BRBR

BRBR

,每 串聯後再並聯接線

DC+ DC-

BR

BR

VFDB

413 2

BR

BR

制動單元

BR

BR

S

積熱電驛

BRBR

BRBR

BRBR

B1

B2

S1 S2

BR

BR

BR

BR

BR

BR

BRBR

BRBR

BRBR

BRBR

BRBR

BRBR

積熱電驛

BR

O.L.

BR

BR

煞車電阻

BR

BR

BR

BR

BR

BR

BR

BR

BR

BR

BR

BR

BRBR

BRBR

BRBR

BR

BR

BR

BR

BR

BR

Loading...

Loading...