Page 1

DVPPF02-H2

PROFIBUS DP Slave Communication

Module

Application Manual

Page 2

Page 3

PROFIBUS DP Slave Communication Module DVPPF02-H2

Warning

3

Please read this instruction carefully before use and follow this instruction to operate the device in order

to prevent damages on the device or injuries to staff.

3

Switch off the power before wiring.

3

DVPPF02-H2 is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust,

humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the

device (e.g. key or specific tools are required for operating the enclosure) in case danger and damage on the

device may occur.

3

DVPPF02-H2 is to be used for controlling the operating machine and equipment. In order not to damage it, only

qualified professional staff familiar with the structure and operation of DVPPF02-H2 can install, operate, wire

and maintain it.

3

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check

all the wirings again before switching on the power and DO NOT touch any terminal when the power is switched

on. Make sure the ground terminal

1 INTRODUCTION ................................................................................................................................3

2 PRODUCT PROFILE & OUTLINE .....................................................................................................4

Table of Contents

1.1 Features..................................................................................................................................3

1.2 Specifications..........................................................................................................................3

2.1 Dimension ...............................................................................................................................4

2.2 Product Profiles.......................................................................................................................4

2.3 Connecting DVPPF02-H2 to DVP-EH2 Series PLC MPU.......................................................4

2.4 Installing DVP-EH2 & DVPPF02-H2 on DIN Rail....................................................................5

2.5 Connecting to PROFIBUS DP Connection Port......................................................................5

2.6 Installation & Wiring.................................................................................................................6

is correctly grounded in order to prevent electromagnetic interference.

3 COMMUNICATION.............................................................................................................................6

3.1 Address Switch .......................................................................................................................6

3.2 PROFIBUS DP Connection Port.............................................................................................6

3.3 Transmission Distance & Baud Rate.......................................................................................7

4 CONTROL REGISTERS.....................................................................................................................7

4.1 Definitions ...............................................................................................................................7

4.2 Data Transmission between DVPPF02-H2 & PROFIBUS DP Master.....................................7

4.3 DFROM & DTO Instructions....................................................................................................8

5 GSD FILE ...........................................................................................................................................9

DVP-PLC Application Manual

1

Page 4

PROFIBUS DP Slave Communication Module DVPPF02-H2

6 LED INDICATORS & TROUBLE-SHOOTING................................................................................. 10

7 APPLICATION EXAMPLE I............................................................................................................. 10

2

DVP-PLC Application Manual

Page 5

PROFIBUS DP Slave Communication Module DVPPF02-H2

1 Introduction

1. To ensure correct installation and operation of DVPPF02-H2, please read this chapter carefully before

using your DVPPF02-H2.

2. This chapter provides only introductory information on DVPPF02-H2. Details of PROFIBUS DP protocol

are not included in this sheet. For more information on PROFIBUS DP protocol, please refer to relevant

references or literatures.

3. DVPPF02-H2 is a PROFIBUS DP slave communication module, connecting DVP-EH2 series PLC to

PROFIBUS DP network.

1.1 Features

1. Supports loop-type data exchange between PROFIBUS DP master and many slaves.

2. The length of I/O data can be freely configured through PROFIBUS DP network configuration tools.

Max. input data length = 100 words (the sum of 4 slots); Max. output data length = 100 words (the

sum of 4 slots).

3. Supports GSD files in PROFIBUS DP network configuration tool.

4. Supports 4 slots in PROFIBUS DP network configuration tool.

5. Auto-detects baud rates; supports Max. 12M bps.

1.2 Specifications

PROFIBUS DP connector

Transmission method High-speed RS-485

Electrical isolation 500VDC

Interface DB9 connector

Transmission cable Shielded twisted pair cable

Communication

Message type DPV0, loop-type data exchange

Equipment ID 0AFE (hex)

GSD file DELT0AFE.GSD

Module name DVPPF02-H2

Transmission speed

(Auto-detect)

9.6 kbps、19.2 kbps、93.75 kbps、187.5 kbps、500 kbps、1.5 kbps、3 Mbps、

6 Mbps、12 Mbps

Environment

Noise immunity

Operation/storage

Vibration/shock

immunity

Certificates IEC 61131-2, UL508

DVP-PLC Application Manual

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV,

Analog & Communication I/O: 1KV

Damped-Oscillatory Wav e: Power Line: 1KV, Digital I/O: 1KV

RS (IEC 61131-2, IEC 61000-4-3): 26MHz ~ 1GHz, 10V/m

Operation: 0°C ~ 55°C (temperature), 50% ~ 95% (humidity), pollution

degree 2

Storage: -25°C ~ 70°C (temperature), 5% ~ 95% (humidity)

Standard: IEC61131-2, IEC 68-2-6 (TES T Fc)/IEC61131-2 & IEC 68-2-27

(TEST Ea)

3

Page 6

PROFIBUS DP Slave Communication Module DVPPF02-H2

2 Product Profile & Outline

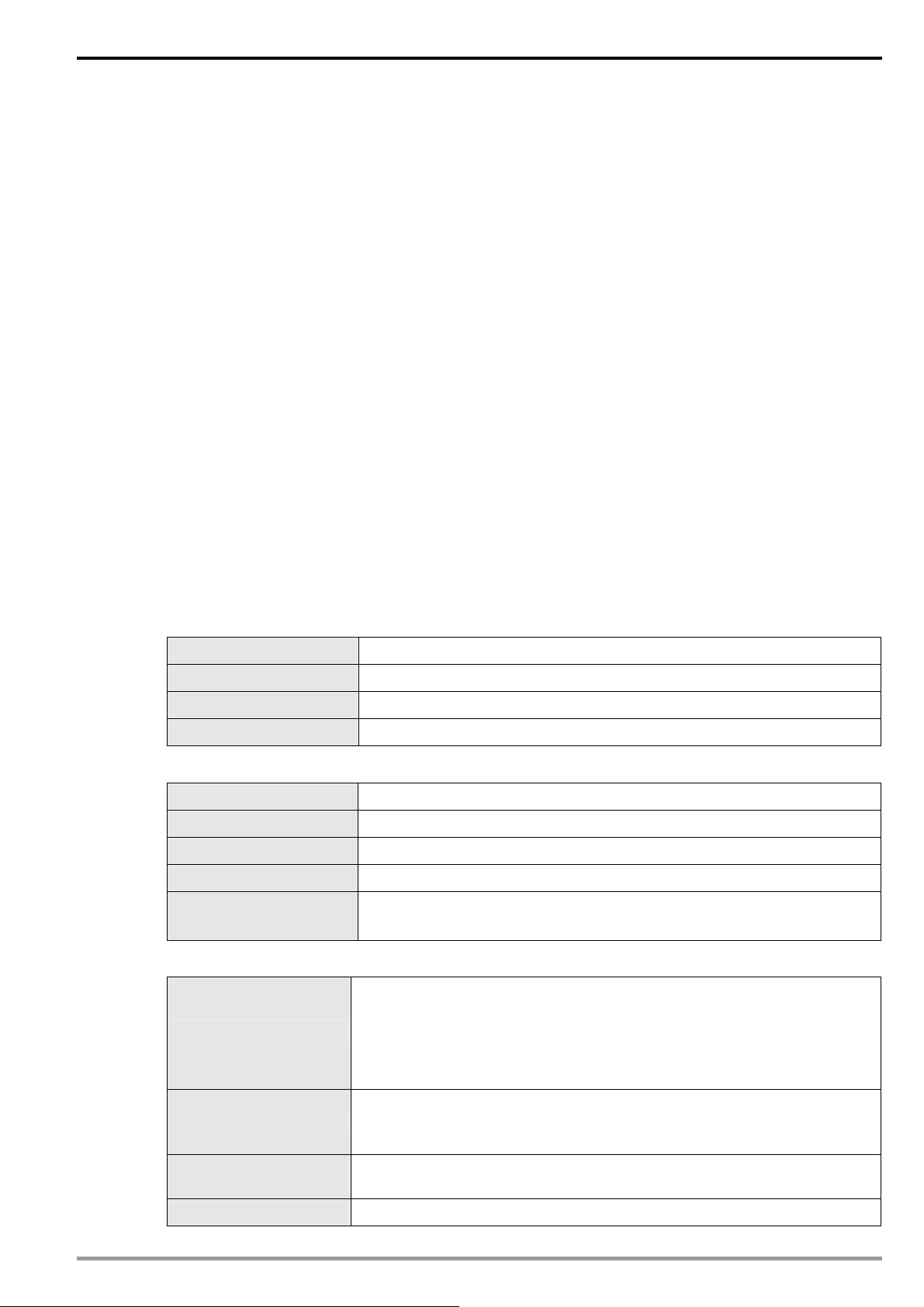

2.1 Dimension

X

16

X

16

POWER

NET

Unit: mm [inch]

2.2 Product Profiles

X

16

2

X

16

POWER

NET

3

4

c Extension port

d Address switch

6

1

8

e POWER indicator

f NET indicator

g PROFIBUS DP connection port

5

h Extension module interface

i DIN rail clip

7

Extension port: For connecting to the next H2 series extension module.

Address switch: For setting up the address of DVPPF02-H2 on PROFIBUS DP network.

POWER indicator: Indicating whether the power supply is normal.

NET indicator:

PROFIBUS DP connection

port:

Extension module interface:

DIN rail clip: Fixing DVPPF02-H2 to DIN rail.

DIN rail: Installing DVPPF02-H2 to DIN rail.

Indicating if the connection between DVPPF02-H2 and PROFIBUS DP

is normal.

Connecting DVPPF02-H2 to PROFIBUS DP network.

Connecting DVPPF02-H2 with DVP-EH2 MPU or H2 series extension

modules.

j DIN rail

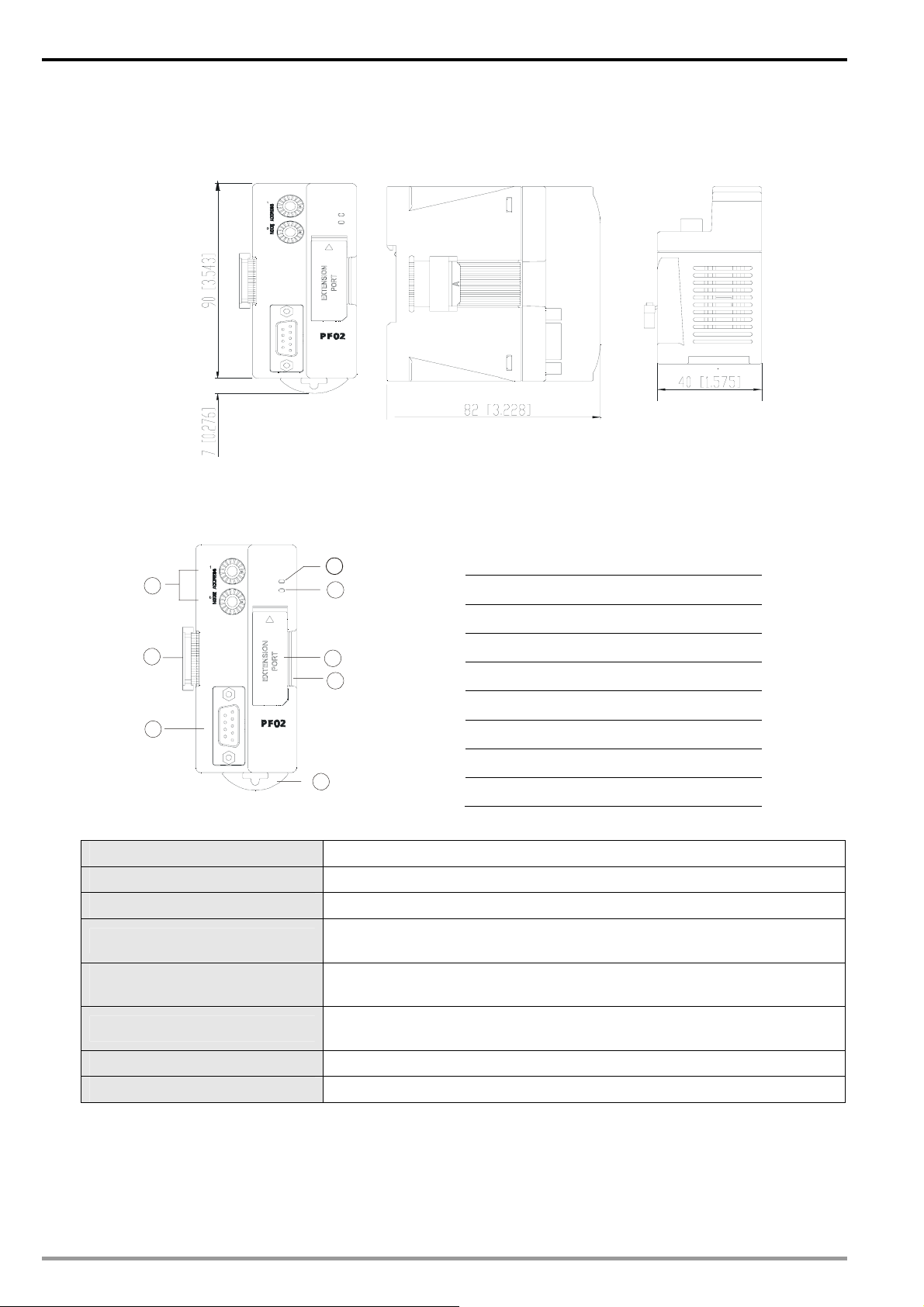

2.3 Connecting DVPPF02-H2 to DVP-EH2 Series PLC MPU

Switch off DVP-EH2. Open the connection port on the right hand side of DVP-EH2 and co nnect

DVPPF02-H2 to DVP-EH2. Switch on DVP-EH2, and DVP-EH2 will supply power to DVPPF02-H2. There is no

need to connect DVPPF02-H2 to an external power supply.

4

DVP-PLC Application Manual

Page 7

PROFIBUS DP Slave Communication Module DVPPF02-H2

1

x16

0

x16

POWER

RUN

ERROR

BAT.LOW

IN

STOP RUN

0

1

DVP-20EH

OUT

2.4 Installing DVP-EH2 & DVPPF02-H2 on DIN Rail

Use 35mm DIN rail.

Open the DIN rail clips on DVP-EH2 and DVPPF02-H2. Insert DVP-EH2 and DVPPF02-H2 on the DIN

rail.

Clip up the DIN rail clips on DVP-EH2 and DVPPF02-H2 to fix DVP-EH2 and DVPPF02-H2 on the DIN

rail.

POWER

RUN

ERROR

BAT.LOW

IN

OUT

STOP RUN

0

1

DVP-20EH

1

x16

0

x16

2.5 Connecting to PROFIBUS DP Connection Port

Insert the PROFIBUS DP bus connector into the PROFIBUS DP connection port on DVPPF02-H2. Screw it

tight to ensure DVPPF02-H2 and the PROFIBUS DP bus are properly connected.

DVP-PLC Application Manual

5

Page 8

PROFIBUS DP Slave Communication Module DVPPF02-H2

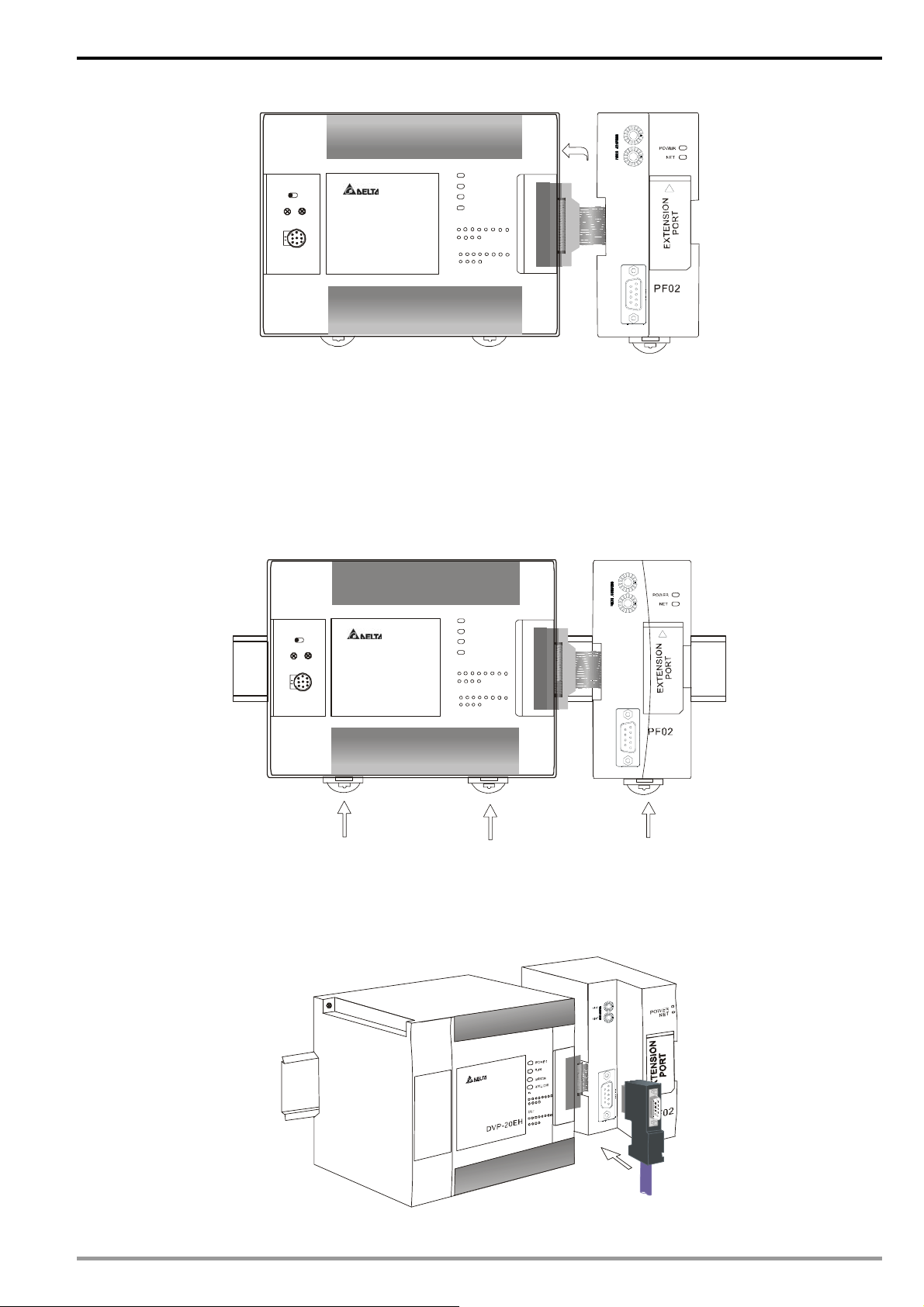

2.6 Installation & Wiring

1. Install DVPPF02-H2 in an enclosure with sufficient

space around it to allow heat dissipation (see the

D

D

figure).

2. DO NOT place the I/O signal wires and power supply

wire in the same wiring circuit.

E2 PLCH

D

PF0 2-H2

D

D

3 Communication

3.1 Address Switch

The address switches are two rotary switches, x160 and x161, setting up the node address of DVPPF02-H2

on PROFIBUS DP network. Rotate the switch to a position to indicate the value of the switch. The range for

each switch is 0 ~ F. The address switches are in hexade cimal form. The factor of x16

1

x16

is 161. The set value of the address switch is the sum of the value of each of the two switches multiplied

by its factor.

Value of address switch Value at x161 Value at x160

Factor of address switch 161 160

Example: If you need to set the node address of DVPPF02-H2 to “26” (decimal), simply switch x161 to “1”

0

and x16

to “A”. 26 (decimal) = 1A (hex) = 1 × 161 + A × 160.

0

is 160, and the factor of

1

x16

0

x16

NODE ADDRESS

D

D>50m m

Range for address switch:

Switch setting Explanation

H’1 ~ H’7D Valid PROFIBUS DP address

H’0 or H’7E ~ H’FF

If the node address in within this range, NET LED will flash quickly in red.

Note:

z Please set up the node address when the power is switched off. After the setup is completed, re-power

DVPPF02-H2.

z When DVPPF02-H2 is operating, changing the set value of the node address will be invalid.

z Use slotted screwdriver to rotate the switch carefully in case you scratch the switch.

3.2 PROFIBUS DP Connection Port

PIN PIN name Definition PIN PIN name Definition

1 -- N/C 6 VP Power voltage – positive

2 -- N/C 7 -- N/C

3 RxD/TxD-P

4 -- N/C 9 -- N/C

5 DGND

Sending/receiving

data P(B)

Data reference

potential (C)

Invalid PROFIBUS DP address

8 RxD/TxD-N

Sending/receiving data

N(A)

9

6

5

1

6

DVP-PLC Application Manual

Page 9

PROFIBUS DP Slave Communication Module DVPPF02-H2

3.3 Transmission Distance & Baud Rate

The communication speed in PROFIBUS DP ranges from 9.6k bps to 12M bps, and the length of

transmission cable varies upon the transmission speed. The transmission distance ranges from 100m to 1,200m.

See the table below for the baud rates DVPPF02-H2 supports and their corresponding transmission speed.

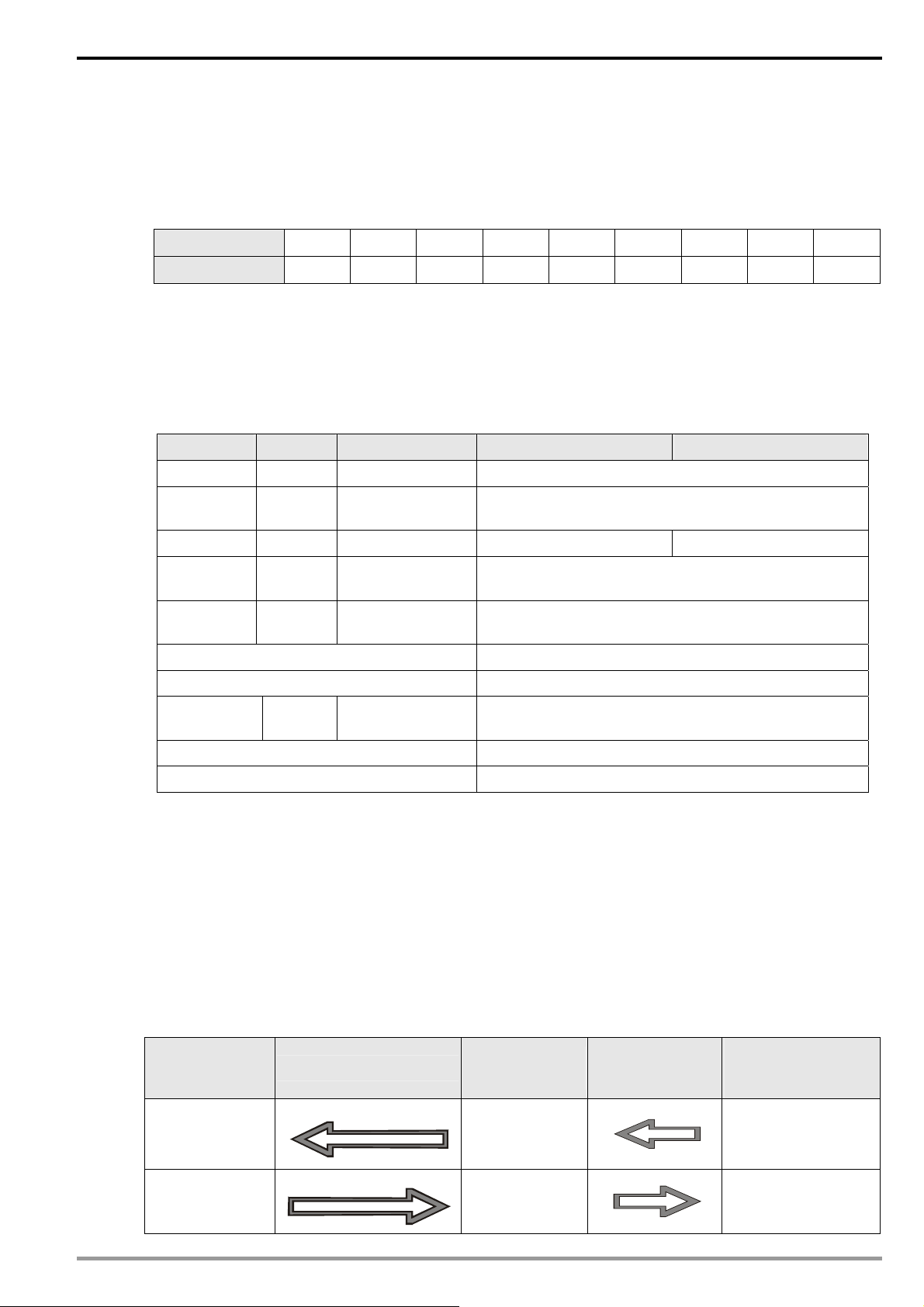

Baud rate (bps) 9.6k 19.2k 93.75k 187.5k 500k 1.5M 3M 6M 12M

Distance (m) 1,200 1,200 1,200 1,000 400 200 100 100 100

4 Control Registers

4.1 Definitions

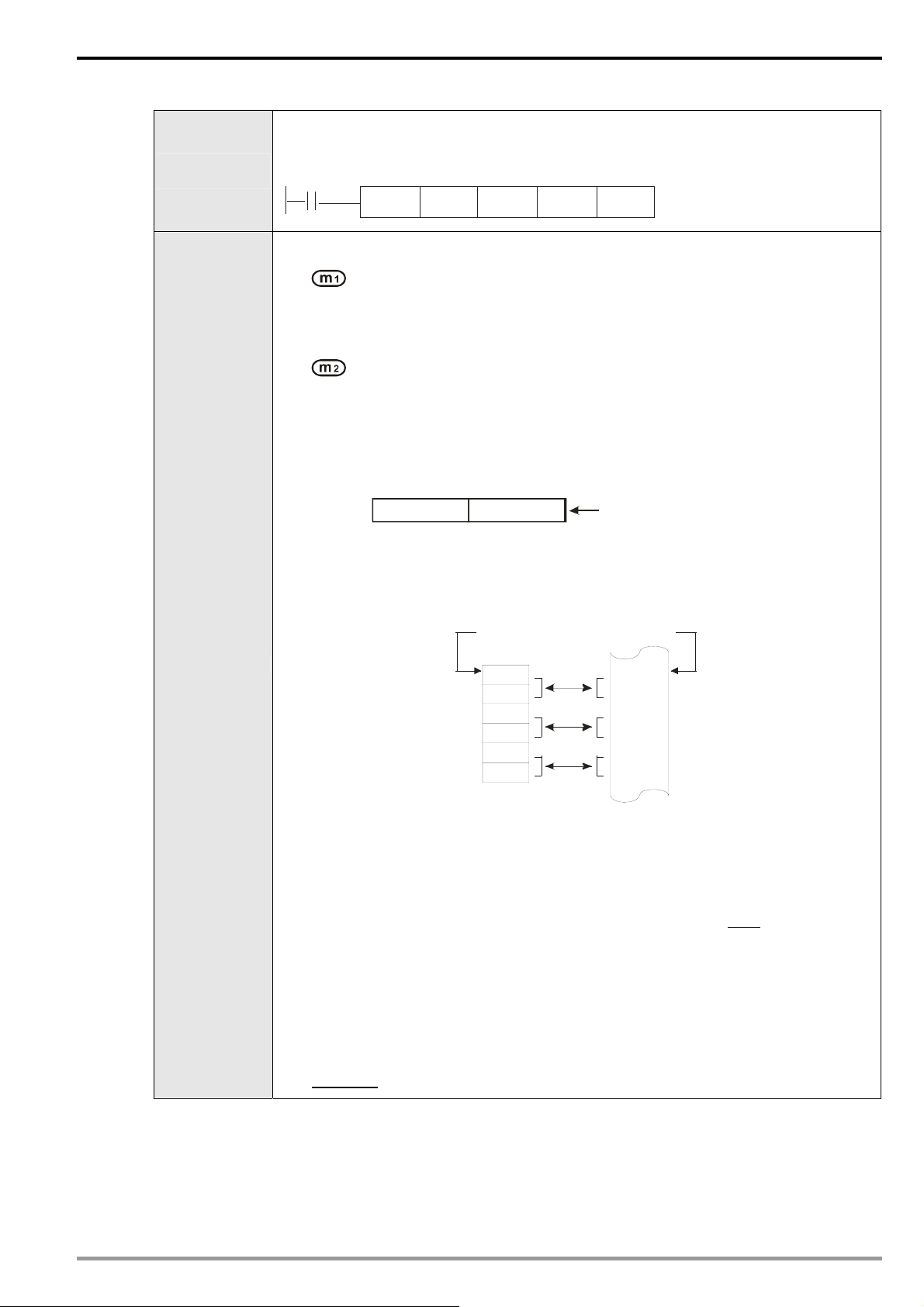

The control registers (CR) are the registers inside DVPPF02-H2. See the t able below for the definitions of

all the CRs. DVP-EH2 series PLC MPU can read or write the CR allowed through DFROM/DT O instructions.

CR# Attribute Content High byte Low byte

#0 Read Model name DVPPF02-H2 model code = H’0250

#1 Read Firmware version

#2 Read Length of I/O data Length of output I/O data Length of input I/O data

#3 ~ #102 Read/write

#103 ~ #202 Read

#203 ~ #206 Set up by the system. DO NOT use it.

#207 ~ #250 Reserved

#251 Read Error code

#252 ~ #383 Reserved

#384 ~ #511 Set up by the system. DO NOT use it.

Input data

mapping

Output data

mapping

Displaying the current firmware version in hex, e.g.

V1.00 is indicated as H’0100.

Area for storing data from DVPPF02-H2 to PROFIBUS

DP master

Area for storing data from PROFIBUS DP master to

DVPPF02-H2

Registers for storing errors. See the error code table in

21.6 for more details.

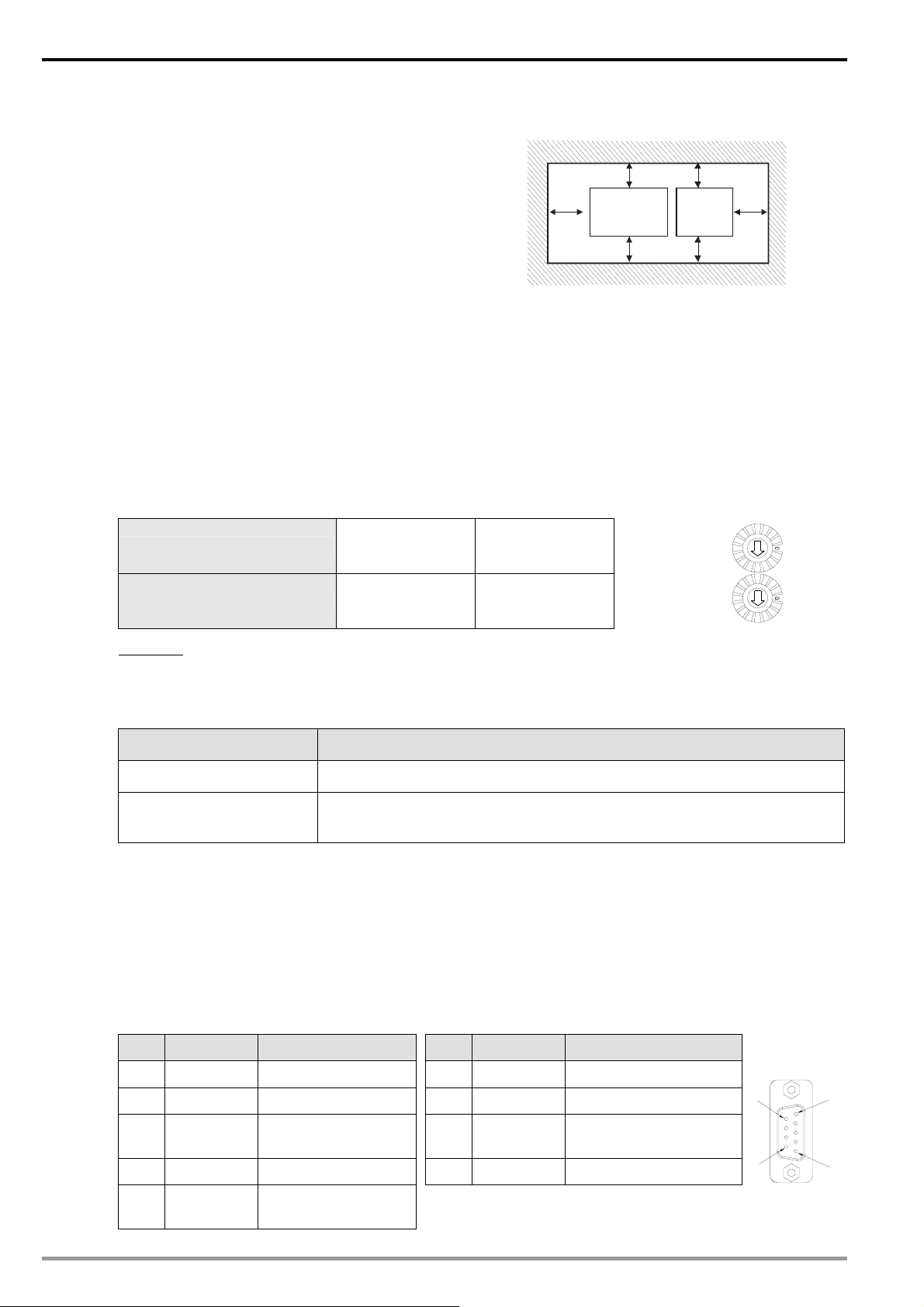

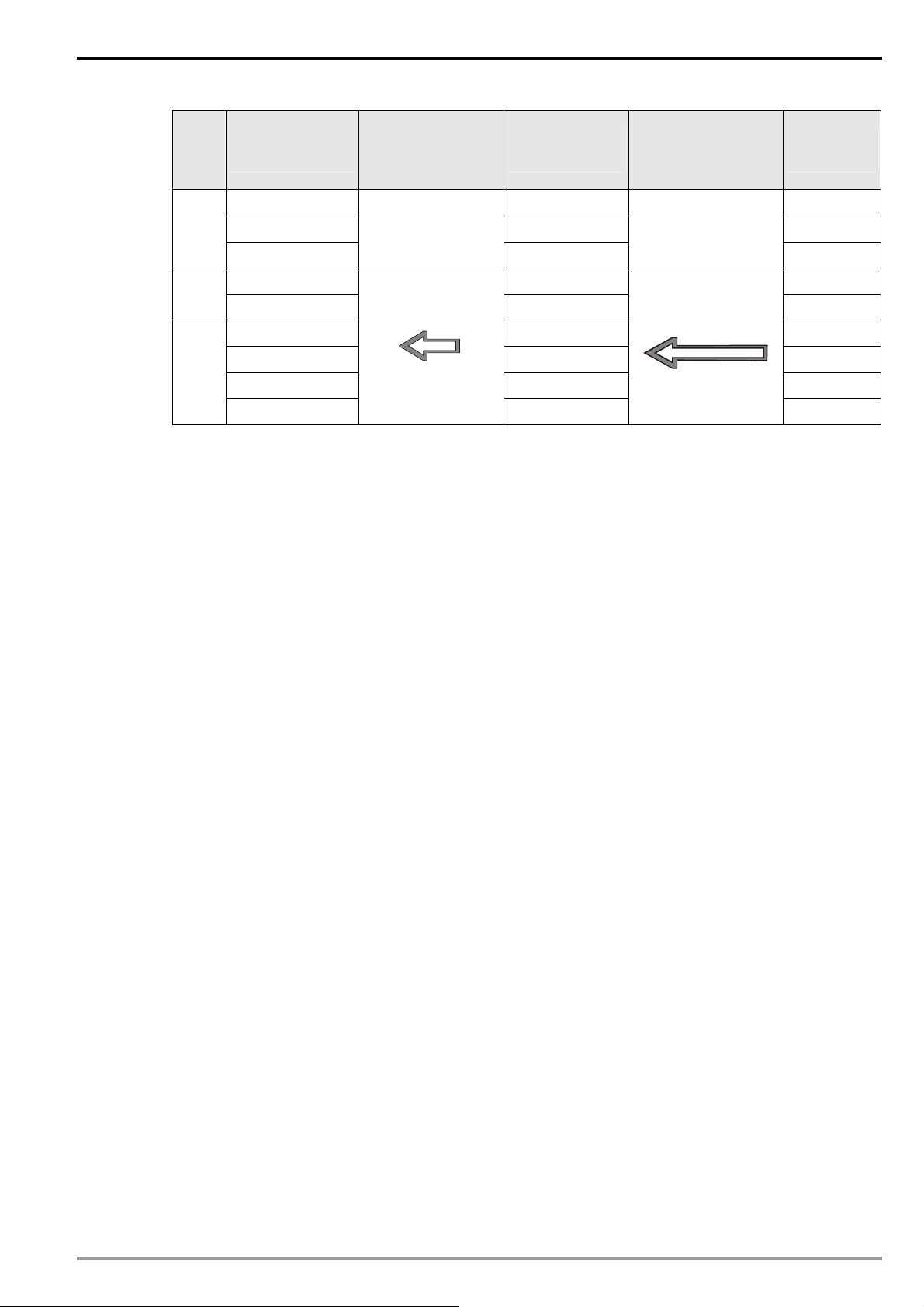

4.2 Data Transmission between DVPPF02-H2 & PROFIBUS DP Master

Once a PROFIBUS DP network is established, the data written into the data mapping area in PROFIBUS

DP will be transmitted automatically to the registers st arting from CR#103 in DVPPF02-H2 through PROFIB US

DP bus. The length of data transmitted is decided by the parameter setting, Max. 100 words at a time. The data

in the registers starting from CR#3 in DVPPF02-H2 will be transmitted automatically to the data mapping area

in PROFIBUS DP master through PROFIBUS DP bus. The length of data transmitted is decided by the

parameter setting, Max. 100 words at a time as well. See the table below for the data transmission between

DVPPF02-H2 and PROFIBUS DP master.

Registers in

DVP-EH2 PLC

MPU

DVP-EH2 reads

CR in

DVPPF02-H2.

DVP-EH2 writes

CR in

DVPPF02-H2.

DVP-PLC Application Manual

DFROM/DTO operation

DFROM (read)

DTO (write)

Registers in

DVPPF02-H2

CR#103 ~ #202

CR#3 ~ #102

Data

transmission on

PROFIBUS DP

Data mapping area

in PROFIBUS DP

master

Output mapping

area in PROFIBUS

DP master

Input mapping area

in PROFIBUS DP

master

7

Page 10

PROFIBUS DP Slave Communication Module DVPPF02-H2

4.3 DFROM & DTO Instructions

1. DVP-EH2 PLC MPU reads or writes data in the CR of DVPPF02-H2 by using DFROM/DTO

instruction.

111

x16x16x16

000

x16x16x16

RUNRUNRUN

STOPSTO PSTOP

000111

DVP-20EHDVP-20EHDVP-20EH

Once DVPPF02-H2 is connected to DVP-EH2 through the connection port, DVP-EH2 will be able to read

or write the CR data in DVPPF02-H2 by using DFROM/DTO instruction. The data transmission between

POWERPO WERPO WER

RUNRUNRUN

ERRORERRORERROR

BAT.LOWBAT.LOWBAT.LOW

INININ

OUTOUTOUT

DVPPF02-H2 and PROFIBUS DP master is done through PROFIBUS DP bus.

Note: Use DFROM/DTO instruction to read/write data instead of FROM/TO instruction.

2. DFROM & DTO instructions

API

78

Operands

DFROM

P

:No. of special module :CR# in special module to be read

:Device for storing read data :Number of data to be read at a time

Ranges of

operands

(For DVP-EH2

models only)

:0 ~ 7 :0 ~ 255

:1 ~ (255 - ) / 2 when is odd number.

1 ~ (256 -

) / 2 when is even number

Read CR#103 of special module No.0 into D20 and CR#104 into D21. Only 1 datum

Program

example

is read at a time (n = 1).

X0

DFROM

K0

K103

API

79

DTO

P

Read CR Data in Special Modules

D20

K1

Write CR Data into Special Modules

8

Operands

Ranges of

operands

(For DVP-EH2

models only)

:No. of special module :CR# in special module to be written

:Data to be written in CR :Number of data to be written at a time

:0 ~ 7 :0 ~ 255

:1 ~ (255 - ) / 2 when is odd number.

1 ~ (256 -

) / 2 when is even number.

DVP-PLC Application Manual

Page 11

PROFIBUS DP Slave Communication Module DVPPF02-H2

Write the content in D10 and D11 into CR#3 and CR#4 of special module No.0. Only 1

Program

example

datum is written in at a time (n = 1).

X0

DTO

K0

K3

D10

K1

Operand rules:

1.

:The No. of special modules connected to PLC MPU. No. 0 is the module

closest to the MPU. Max. 8 modules are allowed to connected to a PLC MPU and

they will not occupy any I/O points.

2.

:Start CR#. CR (control register) is the 16-bit memory built in the special

module, numbered in decimal as #0 ~ #n. PLC MPU reads or writes data in the

CR by DFROM/DTO instruction.

3. DFROM and DTO are 32-bit instructions, reading or writing 2 CRs at a time.

High er 1 6 - bit

CR #10 CR #9

Lo w er 16-bit

Designated CR number

4. Number of data “n” to be transmitted: Due to that DFROM/DTO instruction is

32-bit instruction, the actual number of data read/written should be n×2. The

example below is when n = 3.

Des i gnated device

Des i gnated CR

Remarks

D0

D1

D2

D3

D4

D5

32-bit instruction when n=3

CR #5

CR #6

CR #7

CR #8

CR #9

CR #10

M1083 for switching instruction modes in DVP-EH2 series PLC MPU:

1. When M1083 = Off, during the execution of DFROM/DTO, all external and timer

interruption subroutines will be forbidden. The interruptions within are allowed

only after DFROM/DTO finishes its execution. DFROM/DTO CAN

also be used in

an interruption subroutine.

2. When M1083 = On, during the executino of DFROM/DTO, the interruption

occurring will be processed first (with a 100us delay), and the execution of

DFROM/DTO will be stopped. After the interruption subroutine finishes its

execution, the program will jump to the next instruction. Besides, DFROM/DTO

CANNOT

be used in an interruption subroutine.

5 GSD File

GSD file is a text file for identifying PROFIBUS DP device (master or slave). GSD file contains required

information on configuring a PROFIBUS DP slave on a standard PROFIBUS DP master, including informati on

on the supplier, baud rates supported, I/O sign als available. GSD file is the ba sic tool recording the p arameters

DVP-PLC Application Manual

9

Page 12

PROFIBUS DP Slave Communication Module DVPPF02-H2

of the master. When DVPPF02-H2 is used as PROFI BUS DP slave, you have to add the GSD file of

DVPPF02-H2 into the configuration tool of PROFIBUS DP master. The GSD file of DVPPF02-H2 is available

for download at Delta’s website http://www.delta.com.tw/

.

6 LED Indicators & Trouble-shooting

There are two LED indicators on DVPPF02-H2, POWER LED and NET LED. POWER LED displays

whether the power supply of DVPPF02-H2 is normal. NET LED displays whether the communication of

DVPPF02-H2 is connected normally.

POWER LED

LED status Indication How to correct

Green light steady on The power is norm al. --

1. Check if the power of DVP-EH2 is normal.

Off No power

NET LED

LED status Indication How to correct

Off No power

DVPPF02-H2 is operating but

Red light steady on

Red light flashes

Green light steady on

is not connected to

PROFIBUS DP network.

Depending on the value in

CR#251

DVPPF02-H2 is in data

exchange status

2. Check if the connection between

DVPPF02-H2 and DVP-EH2 is normal.

1. Check if the power of DVP-EH2 is norma l .

2. Check if the connection b etween

DVPPF02-H2 and DVP-EH2 is normal.

Check if DVPPF02-H2 is normally connected to

PROFIBUS DP bus.

See the error code table below for how to

correct.

--

Error codes

Code Description How to correct

00 DVPPF02-H2 operates normally . -01 Hardware error

02 PROFIBUS DP watch dog error

03

04 24V low voltage error

05 5V low voltage error

Address setting error (0, or exceeding

0x01 ~ 0x7D)

7 Application Example I

¡ Target

Complete data exchange between S7-300 (Siemens PLC) and DV P-EH2 (Delta PLC) through PROFIBUS

DP network.

Send your DVPPF02-H2 back to the manufacturer for

repair .

Check if DVPPF02-H2 is normally connected to

PROFIBUS DP bus.

Set the address of DVPPF02-H2 to be within the range

0x01 ~ 0x7D and re-power DVP-EH2.

Check if the power supply voltage of DVP-EH2 is

normal, and check if DVPPF02-H2 is normally

connected to DVP-EH2.

Send your DVPPF02-H2 back to the manufacturer for

repair .

10

DVP-PLC Application Manual

Page 13

PROFIBUS DP Slave Communication Module DVPPF02-H2

¡ Establishing PROFIBUS DP network by DVPPF02-H2 (hardware configuration)

1. Establish the network including S7-300 and DVPPF02-H2 by PROFIBUS DP bus, S7-300 as master

and DVPPF02-H2 as slave.

S7-300

PRO FI B US DPPRO FI B US DPPRO FI B US DP

DVPPF02-H2DVP-EH2DVP-EH2DVP-EH2

2. Set the address of DVPPF02-H2 to “11” (decimal). See "21.3.1 Address Switch” section for how to set

up the address.

After the address is set, re-power DVP-EH2.

3. Check and make sure S7-300, DVP-EH2 and DVPPF02-H2 all operate normally and the wiring of the

entire network is correct.

¡ Configuring DVPPF02-H2 on PROFIBUS DP (software configuration)

Establishing a new file by “Project Wiza rd”.

1. Open SIMATIC Manager software.

2. Select “File” => “New Project Wizard…”.

DVP-PLC Application Manual

11

Page 14

PROFIBUS DP Slave Communication Module DVPPF02-H2

3. Click on “Next”.

12

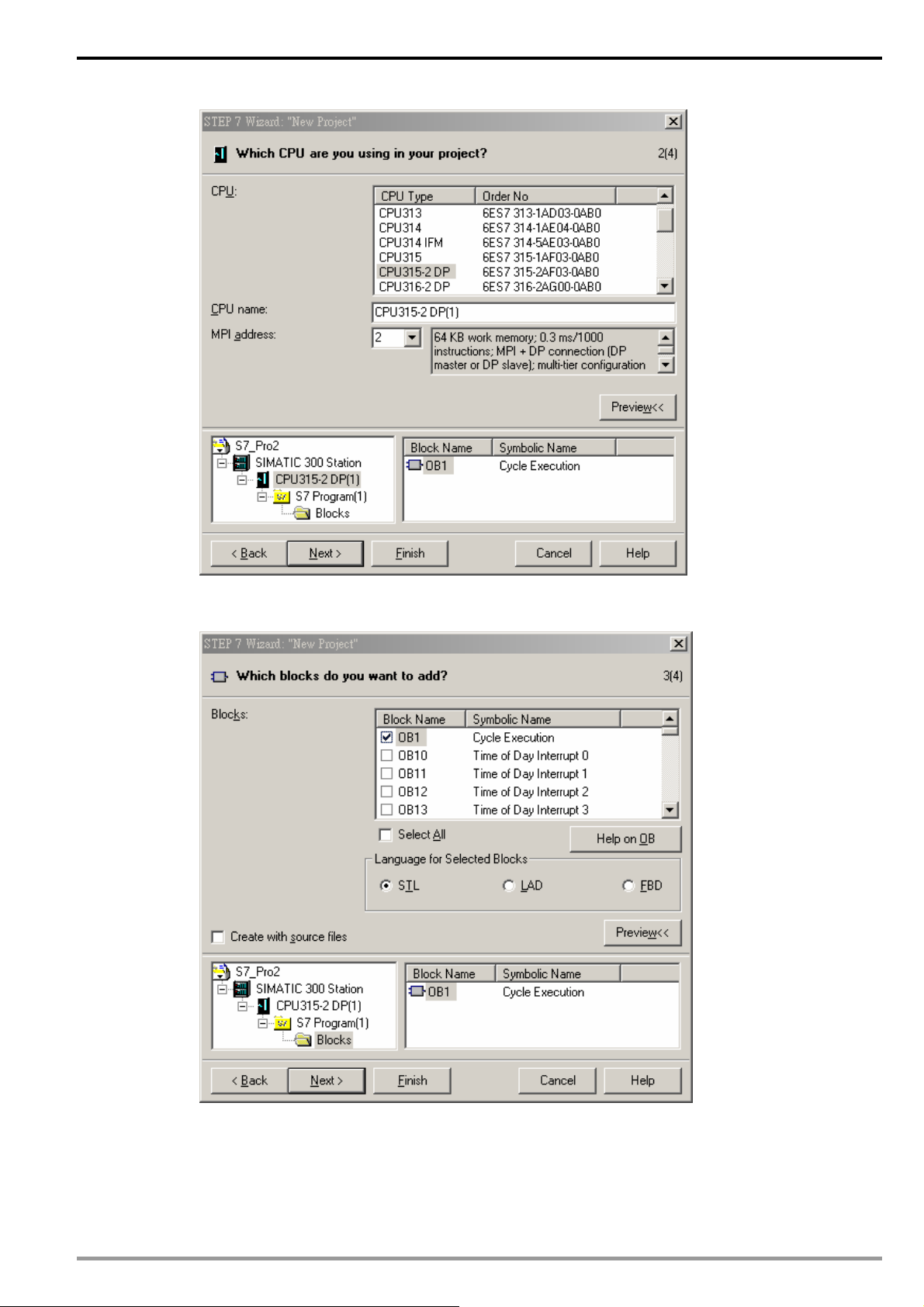

4. Select CPU of S7-300 and click on “Next".

DVP-PLC Application Manual

Page 15

PROFIBUS DP Slave Communication Module DVPPF02-H2

5. Select the block and the language for selected block, and click on “Next”.

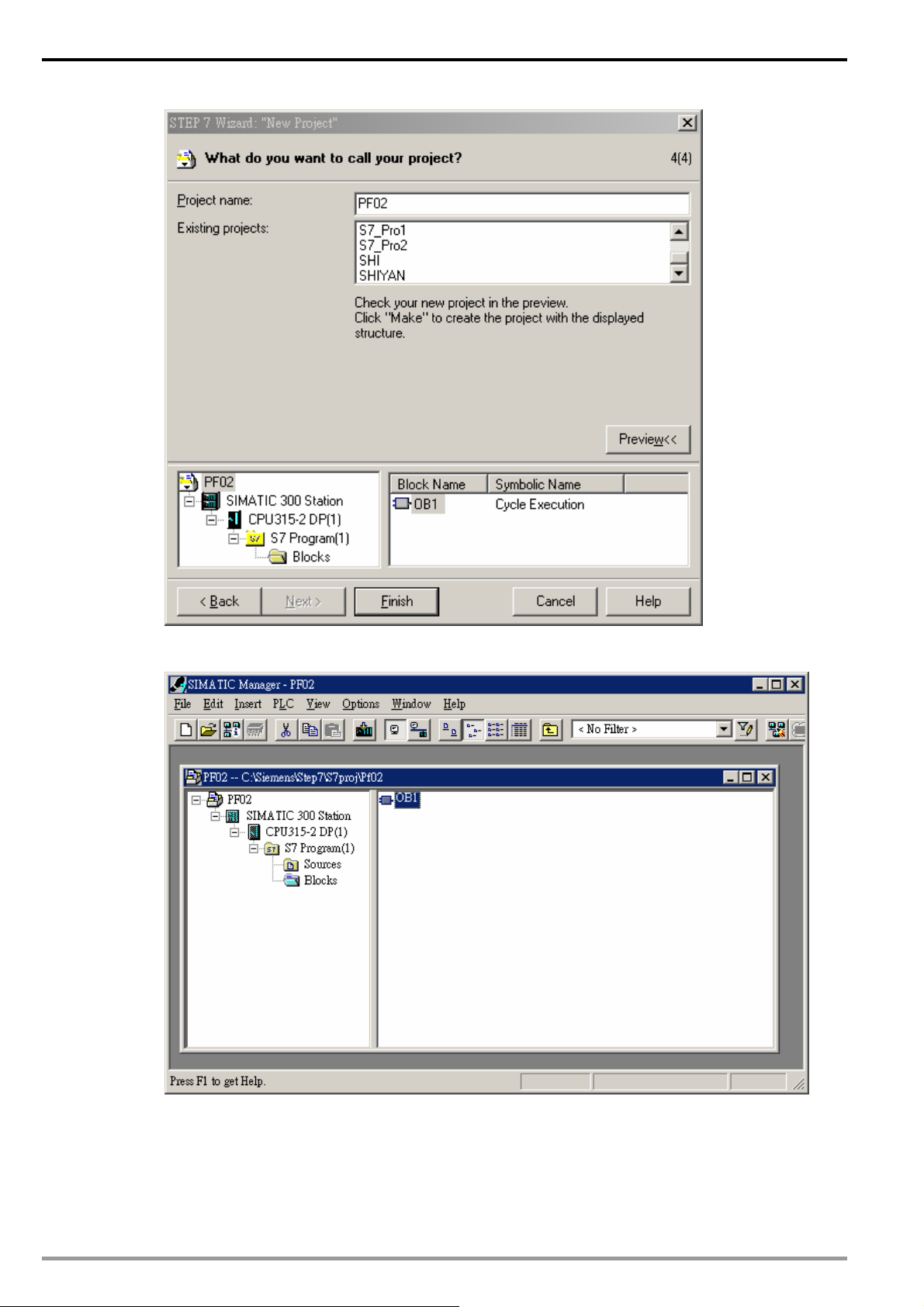

6. Enter the project name and click on "Finish”.

DVP-PLC Application Manual

13

Page 16

PROFIBUS DP Slave Communication Module DVPPF02-H2

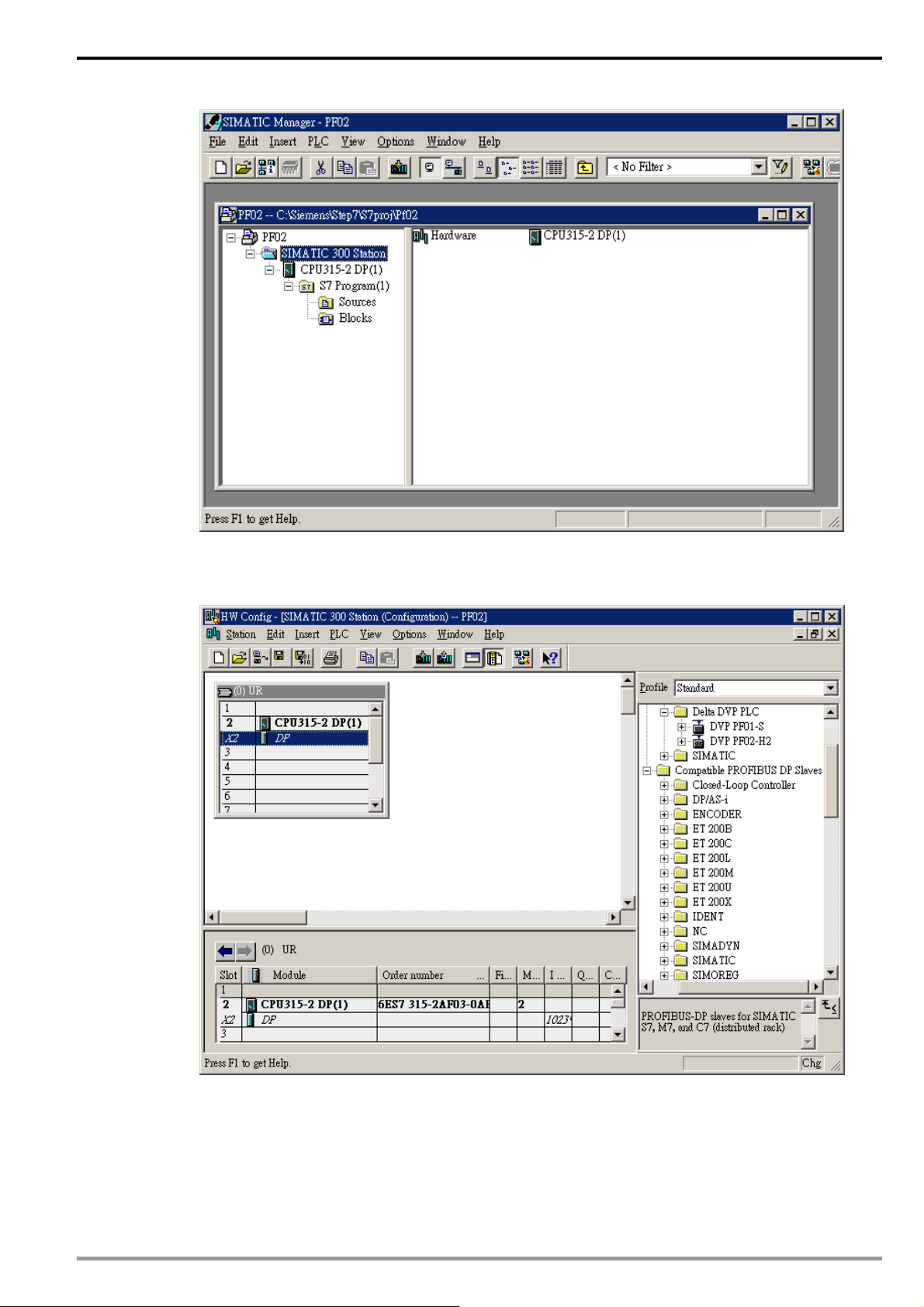

7. You will then see a new window indicating that a new project has been created.

14

Creating PROFIBUS DP bus

1. Select “SIMA TIC 300 Station” in the created project. Double click on “Hardware ” in the right column,

and a new “HW Config” window will appear.

DVP-PLC Application Manual

Page 17

PROFIBUS DP Slave Communication Module DVPPF02-H2

2. In the “HW Config” window, double click on “DP” in the table of the left column, and you will see a

new dialog box appearing.

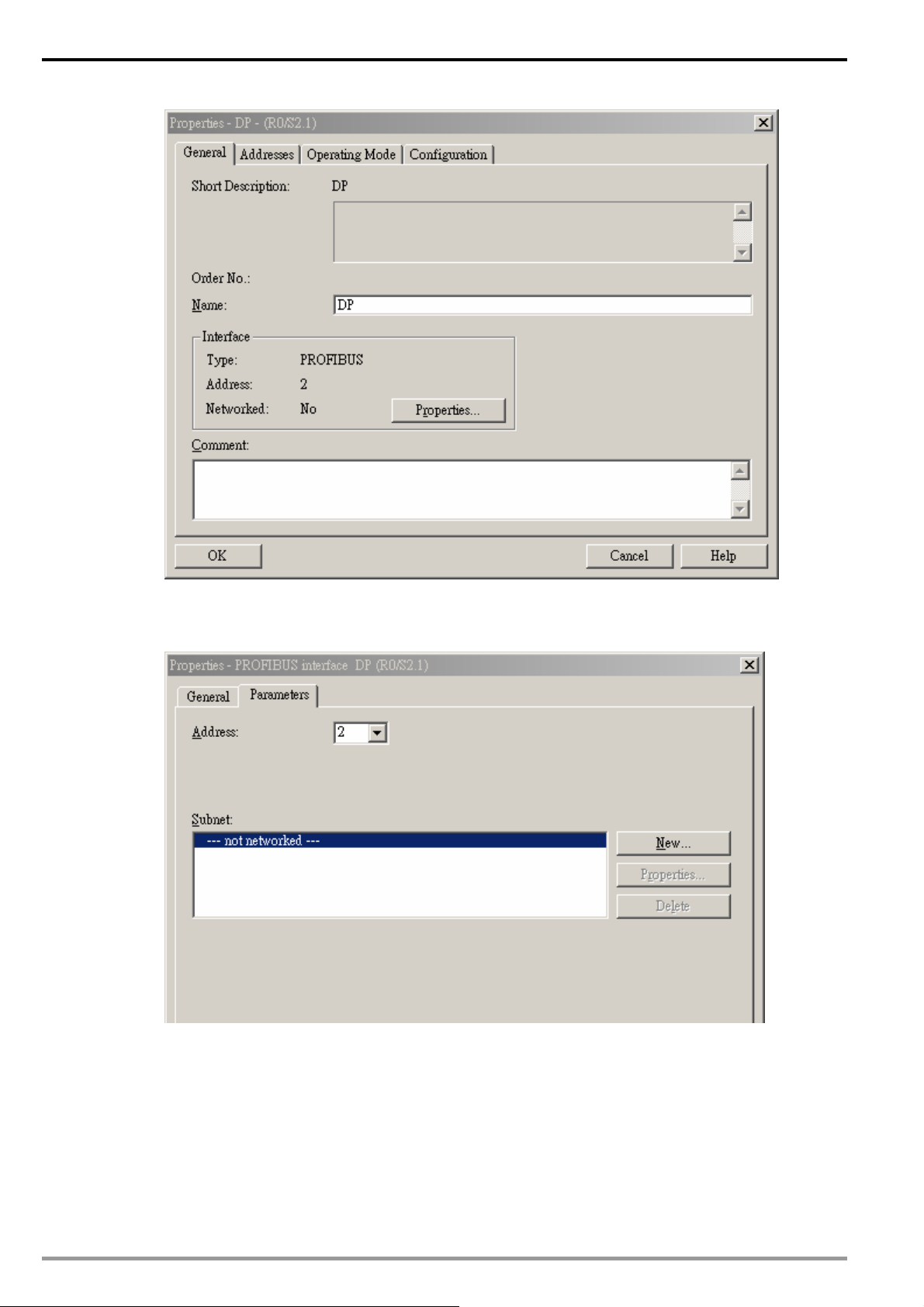

3. Click on “Properties” on the dialog box, and another new dialog box will appear.

DVP-PLC Application Manual

15

Page 18

PROFIBUS DP Slave Communication Module DVPPF02-H2

4. Select “Address” as the address of the master. Next, click on “New”, and you will see a new dialog

box appearing.

16

5. Select “Transmission Rate” and “Profile” and click on “OK”.

DVP-PLC Application Manual

Page 19

PROFIBUS DP Slave Communication Module DVPPF02-H2

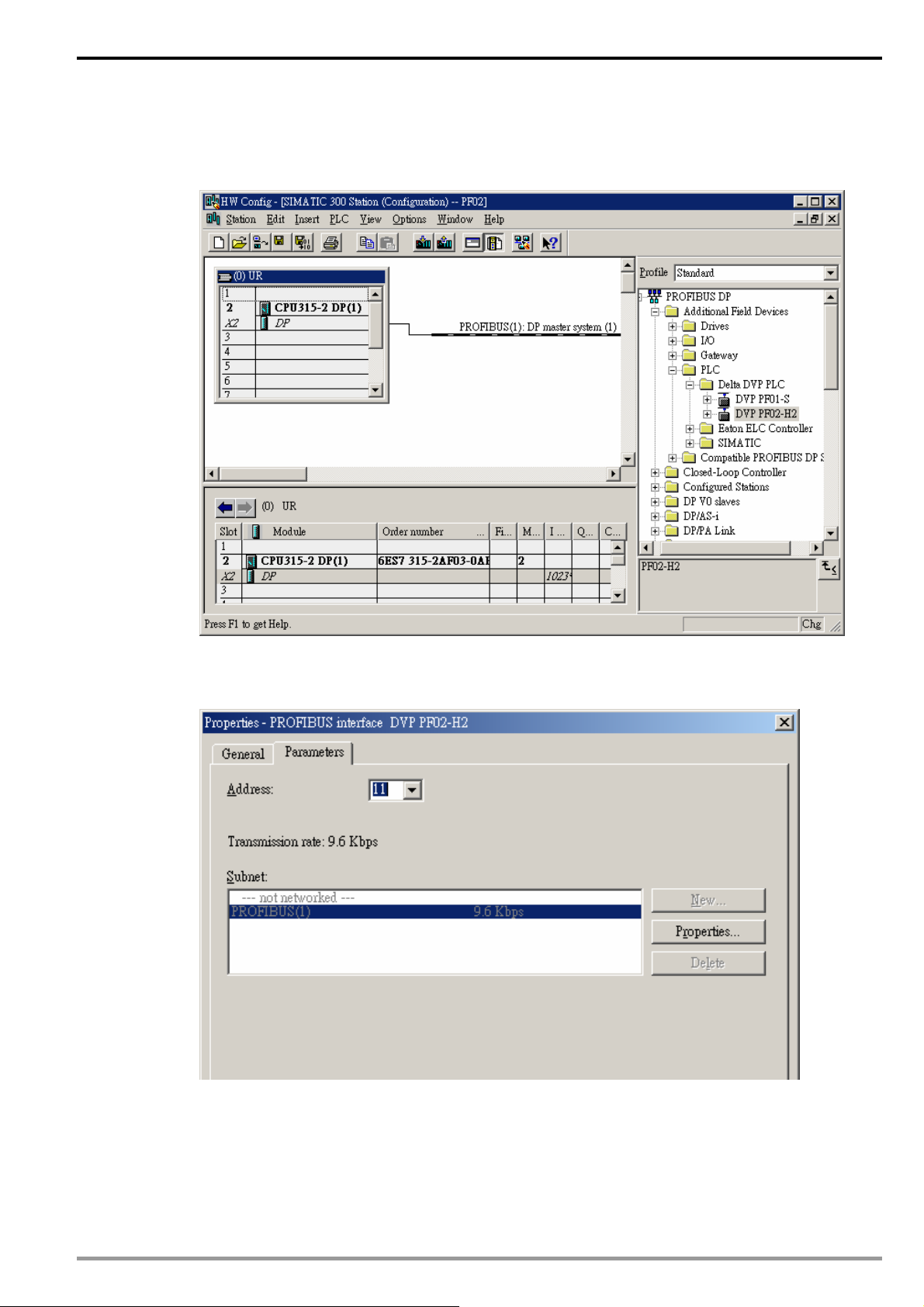

6. Once all the parameters are set, a PROFIBUS DP bus will be created after the UR.

Creating GSD file

1. Select “Options” => “Install New GSD" in the “HW Config” window.

DVP-PLC Application Manual

17

Page 20

PROFIBUS DP Slave Communication Module DVPPF02-H2

2. Find the path of the GSD file, select the GSD file to be installed and click on “Open” to create the

GSD file needed.

3. Once the GSD file is created, you can find the relevant configuration parameters of DVPPF02-H2 in

the right column.

18

DVP-PLC Application Manual

Page 21

PROFIBUS DP Slave Communication Module DVPPF02-H2

Creating DVPPF02-H2 slave and parameter configuration

1. Select PROFIBUS DP bus and double click on the DVPPF02-H2 icon in the right column. A new

dialog box will appear.

2. Select the address of DVPPF02-H2 slave (decimal). This address has to be the same as the

address set by the address switch. Next, click on “OK”.

3. Add DVPPF02-H2 into PROFIBUS DP bus.

DVP-PLC Application Manual

19

Page 22

PROFIBUS DP Slave Communication Module DVPPF02-H2

4. Select “Slot 0" and double click on “2 Word Out” in the right column.

20

5. Configure the parameter of “2 Word Out” to Slot 0.

DVP-PLC Application Manual

Page 23

PROFIBUS DP Slave Communication Module DVPPF02-H2

6. Configure parameters of other slots in the same way.

Note: DVPPF02-H2 is able to configure parameters in the 4 slots of the master. Configurable

parameters in DVPPF02-H2 are in the column on the right hand side. You can configure different

types of parameters in the 4 slots. The same type of parameters can be configured in different slots

DVP-PLC Application Manual

21

Page 24

PROFIBUS DP Slave Communication Module DVPPF02-H2

(e.g. the configuration of slot 0, slot 1). The maximum length of total input data is 100 words (the

sum of input length of 4 slots). The maximum length of total output data is 100 words (the sum of

output length of 4 slots).

Downloading configured parameters

1. After the parameter is configured, click on

dialog box as below. Click on “OK” and another dialog box will appear.

in the “HW Config” window, and you will see the

2. Click on “OK” to start to download the configured parameter.

22

3. The parameter is being downloaded.

DVP-PLC Application Manual

Page 25

4. After the download is completed, the NET LED on DVPPF02-H2 will be constantly on in green.

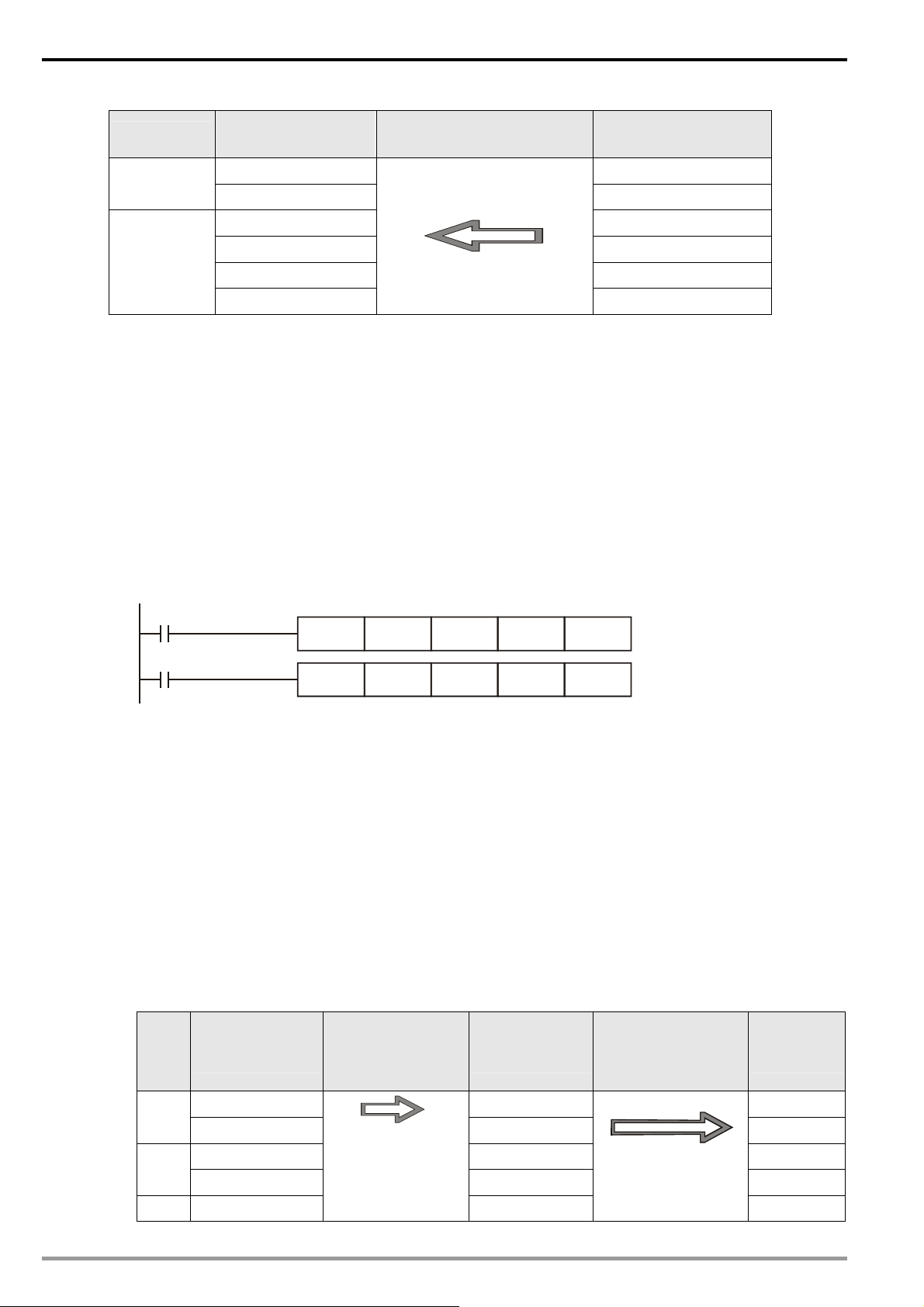

¡ Data mapping

PROFIBUS DP Slave Communication Module DVPPF02-H2

See the data mapping information in the table below under the parameter configuration as shown above:

Slot

0

1

3

DVP-PLC Application Manual

External I/O word

Data transmission direction

for S7-300

PQW256 CR#103

PQW258 CR#104

PQW260 CR#105

PQW262 CR#106

PQW264 CR#107

PQW266 CR#108

PQW268 CR#109

PQW270

in PROFIBUS DP network

Register in

DVPPF02-H2

CR#110

23

Page 26

PROFIBUS DP Slave Communication Module DVPPF02-H2

Slot

2

3

About data mapping:

The I Address of the master (starting from the first address of slot 0 ~ slot 4) corresponds to CR from CR#3

of the slave. The Q Address (starting from the first address of slot 0 ~ slot 4) corresponds to CR from

CR#103. The I/Q Address in every slot increases by 2, in which the I Address i s indicated as PIW and Q

Address as PQW. The CR corresponds to PIW and PQW increases by 1. According to the table above, the

data in PQW256 ~ PQW270 are transmitted automatically to CR#103 ~ CR#110, and the data in CR#3 ~

CR#8 are transmitted automatically to PIW256 ~ PIW266 through PROFIBUS DP bus. The above mapping

relation will be formed automatically after the parameter is configured.

¡ Program example

External I/O word

for S7-300

PIW256 CR#3

PIW258 CR#4

PIW260 CR#5

PIW262 CR#6

PIW264 CR#7

PIW266

Data transmission direction

in PROFIBUS DP network

Register in

DVPPF02-H2

CR#8

Program of slave

M1000

M0

DFROM K0

DTO

K0

K103

K3

D10

D20

K4

K3

z When DVP-EH2 PLC MPU is running and M1000 is On, DVP-EH2 will move the 8 words of data

transmitted from PROFIBUS DP master to CR#103 ~ CR#110 to D10 ~ D17 through PROFIBUS

DP bus. When M0 = On, DVP-EH2 will write the contents in D20 ~ D25 into CR#3 ~ CR#8.

DVPPF02-H2 will transmit these data to PROFIBUS DP master through PROFIBUS DP bus.

z PROFIBUS DP bus completes the data transmission between the master and DVPPF02-H2.

DFROM/DTO instruction however completes the reading/writing of CR data in DVPPF02-H2 by

DVP-EH2.

z Make sure you use DFROM/DTO instruction instead of FROM/TO instruction to deal with the CR

data in DVPPF02-H2 by DVP-EH2.

See the table below for the data transmission informat ion:

Data transmission

Slot

External I/O word

for S7-300

PQW256 CR#103 D10

0

PQW258 CR#104 D11

PQW260 CR#105 D12

1

PQW262 CR#106 D13

3 PQW264

direction in

PROFIBUS DP

network

Register in

DVPPF02-H2

CR#107

DFROM/DTO

operation

DFROM (read)

Register in

DVP-EH2

D14

24

DVP-PLC Application Manual

Page 27

Slot

2

3

PROFIBUS DP Slave Communication Module DVPPF02-H2

Data transmission

External I/O word

for S7-300

PQW266 CR#108 D15

PQW268 CR#109 D16

PQW270 CR#110 D17

PIW256 CR#3 D20

PIW258 CR#4 D21

PIW260 CR#5 D22

PIW262 CR#6 D23

PIW264 CR#7 D24

PIW266

direction in

PROFIBUS DP

network

Register in

DVPPF02-H2

CR#8

DFROM/DTO

operation

DTO (write)

Register in

DVP-EH2

D25

DVP-PLC Application Manual

25

Page 28

PROFIBUS DP Slave Communication Module DVPPF02-H2

MEMO

26

DVP-PLC Application Manual

Loading...

Loading...