Page 1

DVPCOPM-SL

CANopen Communication Module

Application Manual

Page 2

Page 3

CANopen Communication Module DVPCOPM-SL

Warning

Please read this instruction carefully before use and follow this instruction to operate the device in order to prevent

damages on the device or injuries to staff.

Switch off the power before wiring.

DVPCOPM-SL is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust,

humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the

device (e.g. key or specific tools are required for operating the enclosure) in case danger and damage on the

device may occur.

DVPCOPM-SL is to be used for controlling the operating machine and equipment. In order not to damage it, only

qualified professional staff familiar with the structure and operation of DVPCOPM-SL can install, operate, wire

and maintain it.

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check

all the wirings again before switching on the power and DO NOT touch any terminal when the power is switched

on. Make sure the ground terminal

1 INTRODUCTION...................................................................................................................................3

2 PRODUCT PROFILE & OUTLINE .......................................................................................................5

Table of Contents

1.1 Features....................................................................................................................................3

1.2 Functions...................................................................................................................................4

2.1 Dimension .................................................................................................................................5

2.2 Product Profiles.........................................................................................................................5

2.3 CANopen Connection Port........................................................................................................6

2.4 Address Switch..........................................................................................................................6

2.5 Function Switch.........................................................................................................................6

2.6 Digital Indicator..........................................................................................................................7

is correctly grounded in order to prevent electromagnetic interference.

3 BASIC OPERATION.............................................................................................................................7

3.1 Connecting DVPCOPM-SL to DVP-SV MPU............................................................................7

3.2 Installing DVPCOPM-SL and DVP-SV MPU on DIN Rail..........................................................7

3.3 Connecting to CANopen Connection Port.................................................................................8

4 CONSTRUCTING CANOPEN NETWORK...........................................................................................8

4.1 How to Construct a CANopen Network.....................................................................................8

4.2 Data Mapping in CANopen Network .......................................................................................10

4.3 How to Configure Network by Delta CANopenBuilder Software.............................................11

4.4 Saving the Configuration Data ................................................................................................19

4.5 CANopen Network Control......................................................................................................19

DVP-PLC Application Manual

1

Page 4

CANopen Communication Module DVPCOPM-SL

5 SENDING SDO, NMT AND READING EMERGENCY BY LADDER DIAGRAM.............................. 20

5.1 The Principle........................................................................................................................... 20

5.2 Structure of SDO Request Message.......................................................................................20

5.3 Structure of NMT Service Message........................................................................................ 21

5.4 Structure of Emergency Request Message............................................................................ 22

5.5 Application Examples ............................................................................................................. 23

6 LED INDICATOR & TROUBLE-SHOOTING ..................................................................................... 27

6.1 POWER LED.......................................................................................................................... 28

6.2 RUN LED................................................................................................................................ 28

6.3 ERR LED................................................................................................................................28

6.4 Codes in Digital Display.......................................................................................................... 28

2

DVP-PLC Application Manual

Page 5

1 Introduction

1. To ensure correct installation and operati on of DVPCOPM-SL, please read this chapter carefully before

using your DVPCOPM-SL.

2. This chapter only provides introductory information on DVPCOPM-SL. For more detaile d information on

CANopen protocol, please refer to relevant references or literatures.

3. DVPCOPM-SL is a CANopen module op erating on the left side of DVP-SV series PLC MPU. When DVP-SV

is connected to CANopen network through DVPCOPM-SL, DVPCOPM-SL will serve as the data exchange

interface between DVP-SV and other slaves on the bus. DVPCOPM-SL is in charge of sending the data in

DVP-SV to the slaves on the bus, and at the same time collecting the data returned from each slave and

sending them back to DVP-SV.

1.1 Features

DVPCOPM-SL can be used as the master in CANopen network, as well as the slave for other masters.

As a master, DVPCOPM-S L features:

z Complying with CANopen standard protocol DS301v4.02.

CANopen Communication Module DVPCOPM-SL

z Supporting NMT Master Service.

z Error control: Supporting Heartbeat/Node Guarding Protocol.

z Supporting PDO Service.

Max. 200 RxPDOs and 390 bytes of data

Max. 200 TxPDOs and 390 bytes of data

Each slave can be allocated maximum 8 TxPDOs and 8 RxPDOs.

z PDO transmission type: Supporting event trigger, time trigger, synchronous cycle, and synchronous

non-cycle.

z PDO mapping: Every PDO is able to map maximum 32 parameters.

Type of mapping data supported:

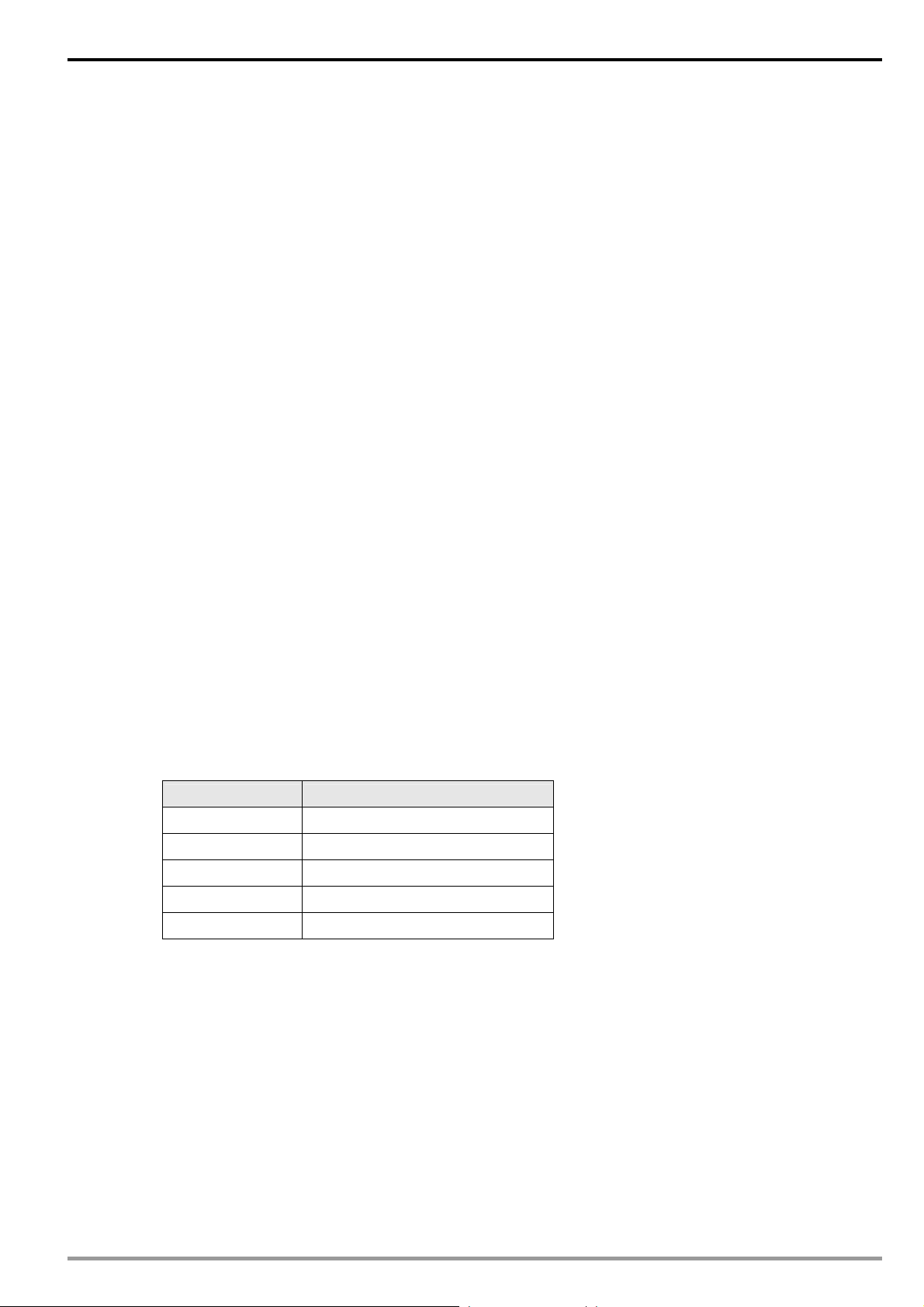

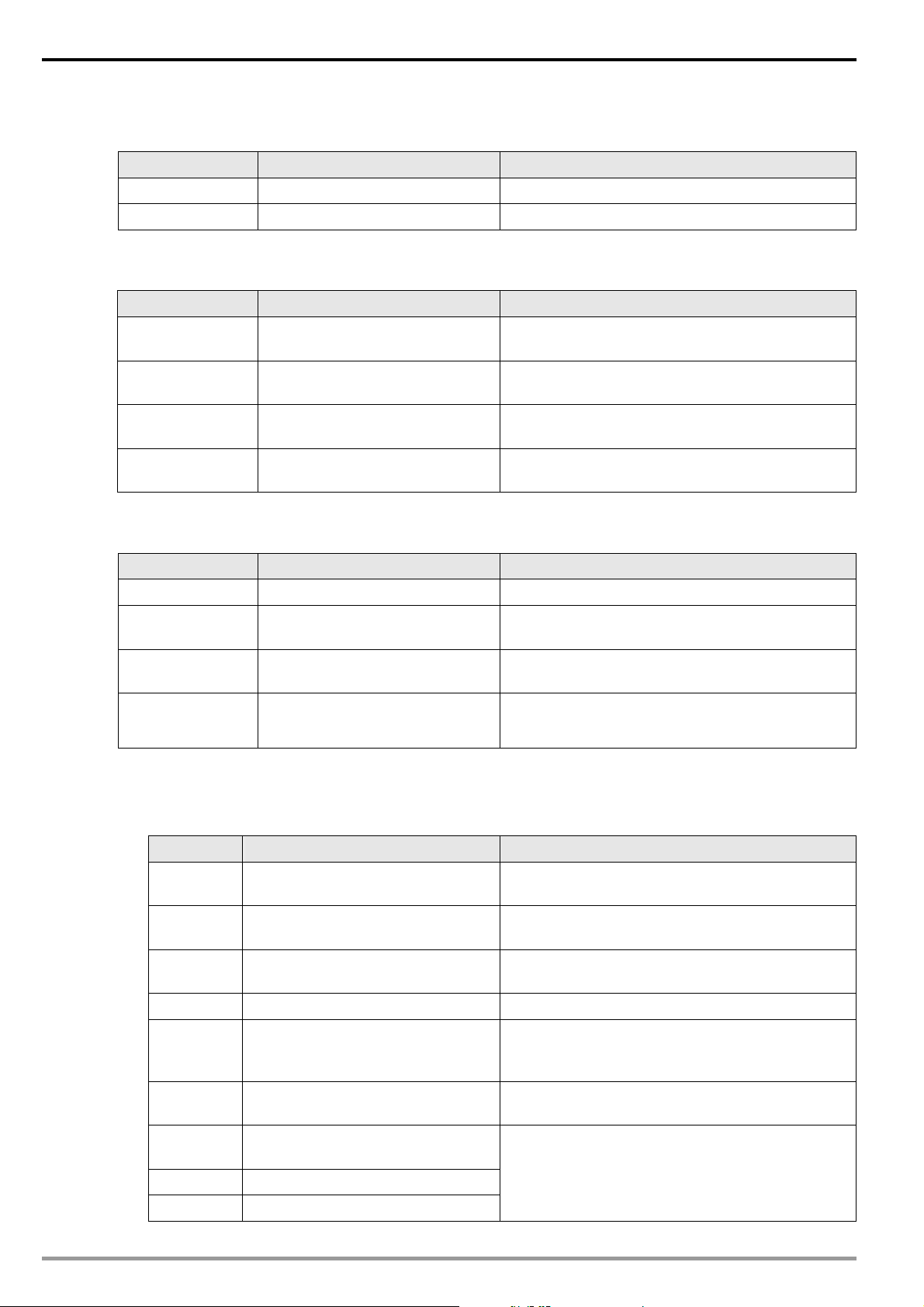

Storage sp ace Data type

1 bit BOOL

8 bits SINT USINT BYTE

16 bits INT UINT WORD

32 bits DINT UDINT REAL DWORD

64 bits LINT ULINT LREAL LWORD

z Supporting SDO Service.

Number of server: 0

Number of user: 3

z Supporting standard expedited SDO transmission mode.

z Supporting Auto SDO func tion. Able to execute maximum 20 Auto SDOs to each slave.

z Supporting reading/writing of data in slave by using SDO Service in the ladder diagram in PLC.

z Supporting Emergency Protocol:

Able to store 5 latest Emergency messages for each slave.

Able to indicate Emergency messages in slave from digital display.

Able to read Emergency message through the ladder diagram in PLC.

z SYNC producer; Range: 0 ~ 65,535ms.

DVP-PLC Application Manual

3

Page 6

CANopen Communication Module DVPCOPM-SL

z As the interface between Delta CANopenBuilder software and CANopen network. The software can

configure the network directly through DVPCOPM-SL.

z In the auto data exchange with DVP-SV, the user only has to program the D register mapped in DVP-SV

without applygin FROM/TO instructions. When connected to DVP-SV/DVP-EH2-L MPU,

D6000 will be adopted temporarily.

As a slave, DVPCOPM-SL features:

z Complying with CANopen standard protocol DS301v4.02

z Supporting NMT Slave Service

z Error control: Supporting Heartbeat Protocol

z Supporting PDO Service: Each slave can be allocated maximum 8 TxPDOs and 8 RxPDO s.

z PDO transmission type: Supporting event trigger, time trigger, synchronous cycle, synchronous

non-cycle.

z Supporting SDO Service.

Number of server: 1

Number of user: 0

z Supporting standard expedited SDO transmission mode.

z Supporting Emergency Protocol.

Able to indicate Emergency event in slave through digital display.

z In the auto data exchange with DVP-SV, the user only has to program the D register mapped in DVP-SV

without applygin FROM/TO instructions.

registers after

1.2 Functions

CANopen connection

Transmission method CAN

Electrical isolation 500VDC

Interface Removable connector (5.08mm)

Transmission cable 2-wire twister shielded cable with 2-wire bus power and drain

Communication

Message type

Baud rates 10k, 20k, 50k, 125k, 250k, 500k, 800k, 1M bps (bit/sec)

Electrical specification

Power voltage 24VDC, supplied by internal bus from PLC MPU (-15% ~ 20%)

Power consumption 1.7W

Isolation voltage 500V

Environment

Noise immunity

PDO, SDO, SYNC (synchronous object), Emergency (Emergency object),

NMT

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discha rge, 4KV Contact

Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV

Analog & Communication I/O: 1KV

Damped-Oscillatory Wav e: Power Line: 1KV, Digital I/O: 1KV

RS (IEC 61131-2, IEC 61000-4-3): 80MHz ~ 1,000MHz, 1.4GHz ~ 2.0GHz,

10V/m

4

DVP-PLC Application Manual

Page 7

CANopen Communication Module DVPCOPM-SL

Opeartion 0ºC ~ 55ºC (temperature); 50 ~ 95% (humidity); pollution degree 2

Storage -25ºC ~ 70ºC (temperature); 5 ~ 95% (humidity)

Shock/vibration

immunity

Certificates IEC 61131-2, UL508

2 Product Profile & Outline

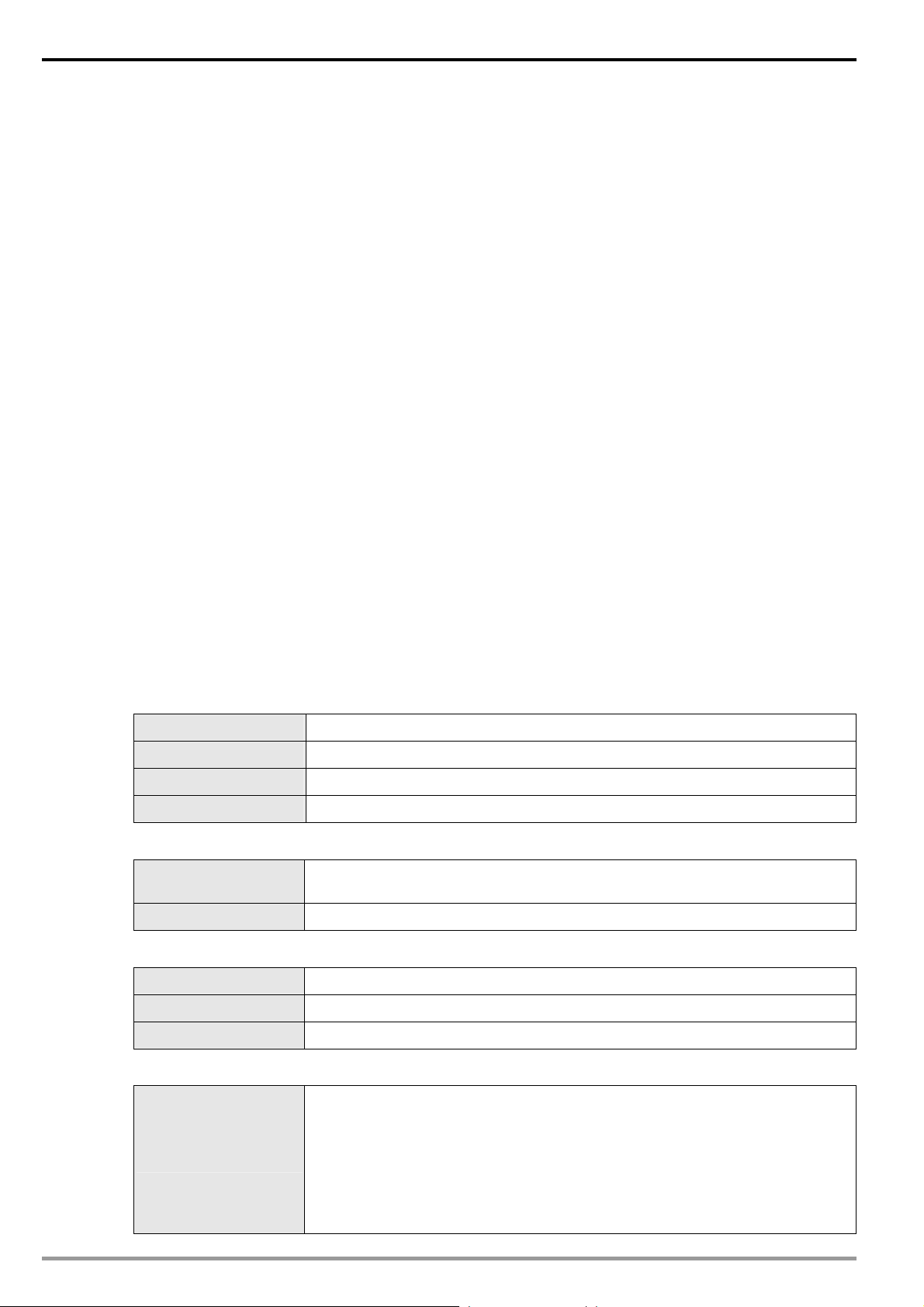

DVPCOPM-SL is composed of CANopen connection port, address switch, function switch, an d digital

display.

2.1 Dimension

DVPCOPM-SL

POWER

RUN

ERR

90 [3.543]

International standard: IEC 61131-2, IEC 68-2-6 (TEST Fc)/IEC 61131-2 & IEC

68-2-27 (TEST Ea)

1

x16

0

x16

NODE ADDRESS

DR 2

DR 1

DR 0

IN 0

SHLD

CAN-

GND

63.4 [2.496]

3 [0.11 8]

2.2 Product Profiles

3

7

8

9

1

6

DVPCOPM-SL

POWER

RUN

ERR

NODE ADDRESS

60 [2.362]

5

x16

x16

DR 2

DR 1

DR 0

IN 0

SHLD

CAN-

GND

2

1

0

6

33.1 [1.303]

2

1. Model name 6. Fixing clip for extension module

2. Extension port 7. Address switch

DVP-PLC Application Manual

6

4

5

Page 8

CANopen Communication Module DVPCOPM-SL

3. POWER, RUN, ERR indicators 8. Function switch

4. DIN rail clip 9. CANopen connection port

5. Digital display

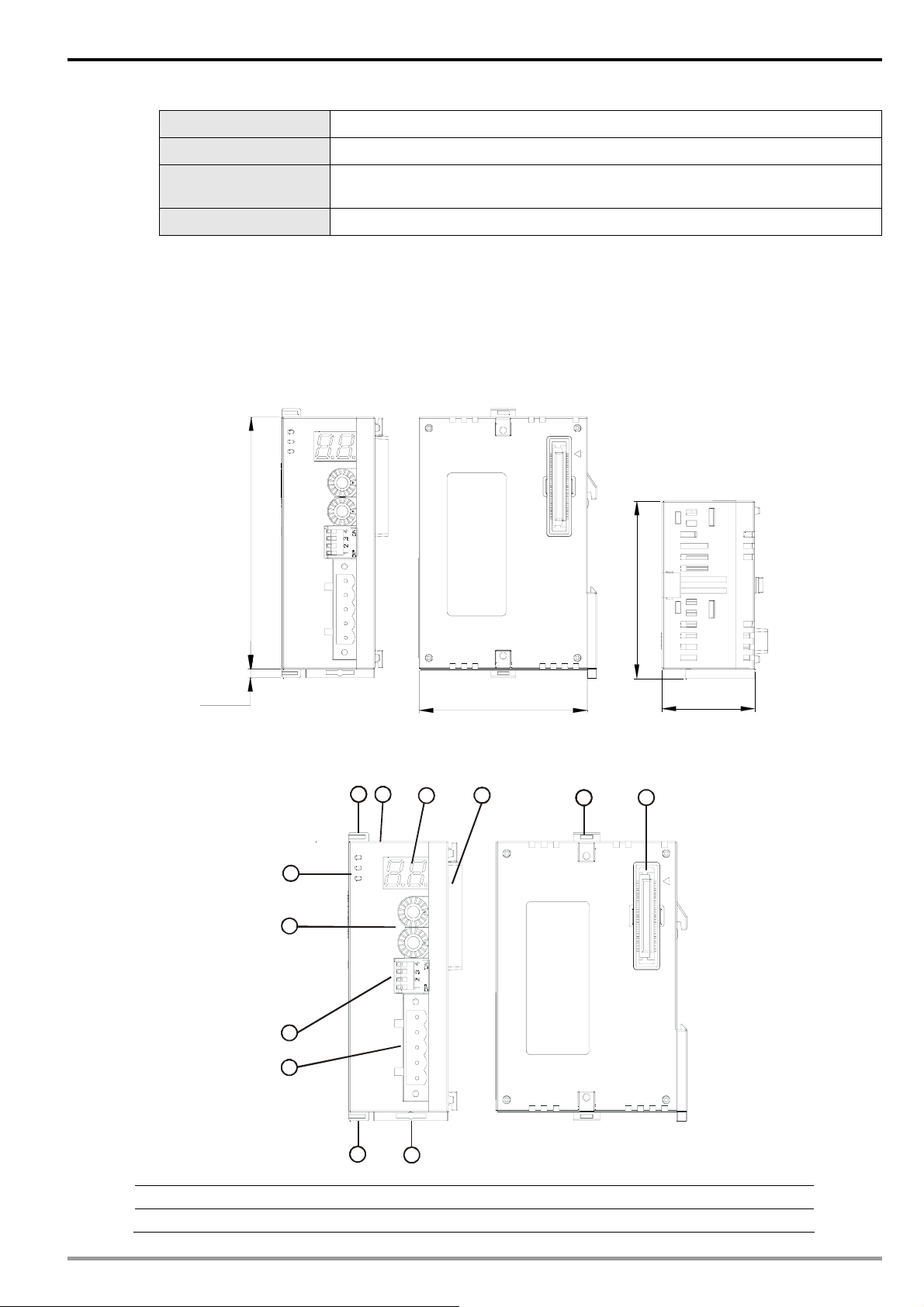

2.3 CANopen Connection Port

The connector is used on the connection to CANopen network. Wire by using the connector enclosed with

DVPCOPM-SL.

PIN Signal Content

1 GND 0 VDC

2 CAN_L Signal3 SHLD Shielded

4 CAN_H Signal+

5 - Reserved

2.4 Address Switch

CAN+

SHLD

CANGND

5

4

3

2

1

The switch is used on setting up the node address of DVPCOPM-SL on CANopen network. Range: 1 ~ 7F (0,

88 ~ FF are forbidden).

Switch setting Content

1 ~ 7F Valid CANopen node address

0, 80 ~ FF Invalid CANopen node address

NODE ADDRESS

x16

x16

1

0

Example: If you need to set the node address of DVPCOPM-SL to 26 (1AH), simply switch the corresponding

1

switch of x16

to 1 and the corresponding switch of x160 to A.

Note:

z Use slotted screwdriver to rotate the switch carefully in case you scratch the switch.

z Please set up the node address when the power is switched off. After the setup is completed, re-poser

DVPCOPM-SL.

2.5 Function Switch

The switch is used on setting up the baud rate between DVPCOPM-SL and CA Nopen network (DR0 ~ DR2 ).

See the table below for the baud rate and its maximum communication distance.

DR2 DR1 DR0 Baud rate (bps) Max. communication distance (m)

6

OFF OFF OFF 10k 5,000

OFF OFF ON 20k 2,500

OFF ON OFF 50k 1,000

OFF ON ON 125k 500

ON OFF OFF 250k 250

ON OFF ON 500k 100

ON ON OFF 800k 50

ON ON ON 1M 25

IN0 Reserved

DVP-PLC Application Manual

Page 9

CANopen Communication Module DVPCOPM-SL

Note:

z Use slotted screwdriver to adjust the DIP switch carefully in case you scratch the switch.

z Please set up the function switch when the power is switched off. After the setu p is completed, re-power

DVPCOPM-SL.

2.6 Digital Indicator

The digital indicator provides the following two functions:

z Displaying the node address of DVPCOPM-SL.

z Displaying the error message of slave.

3 Basic Operation

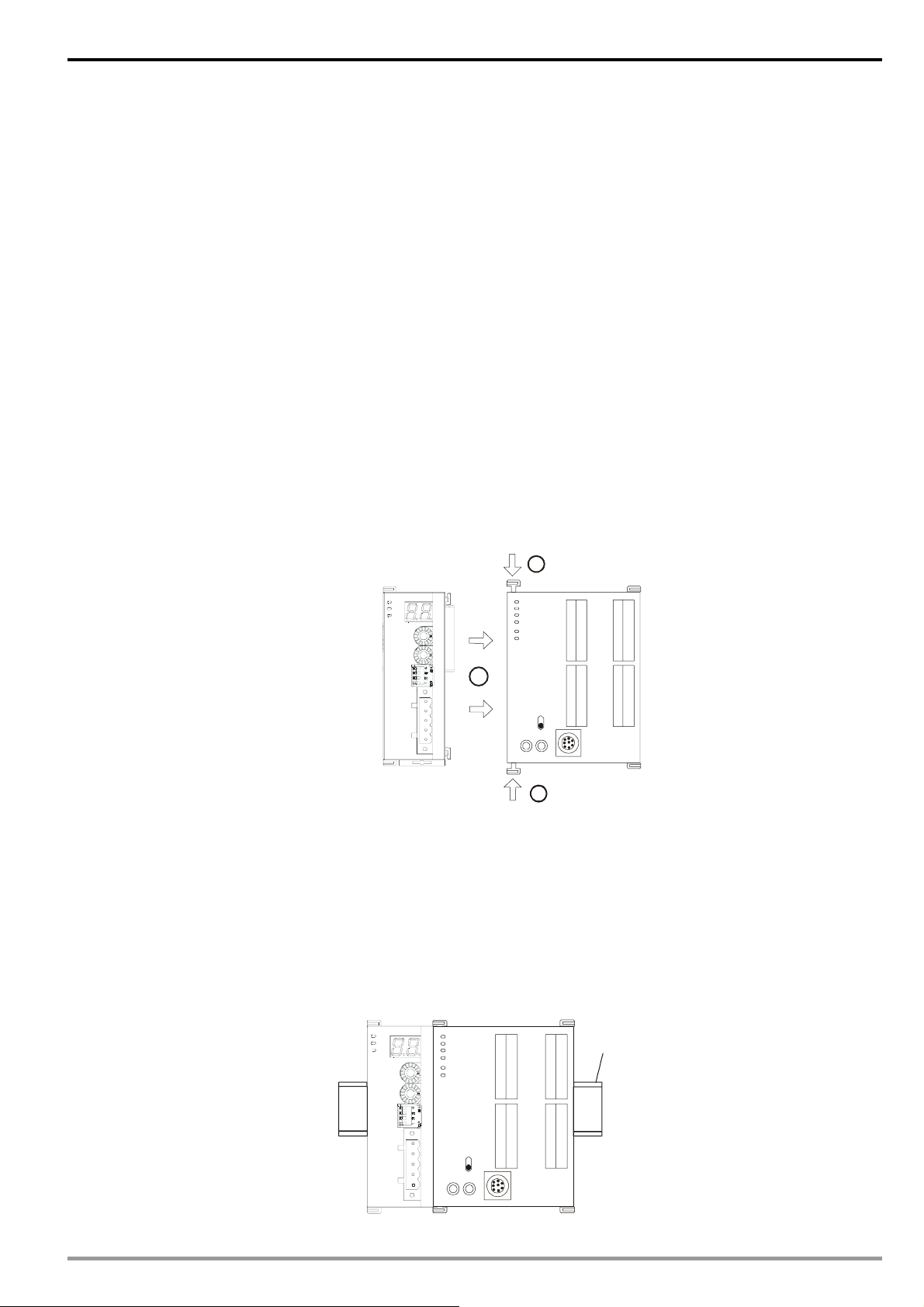

3.1 Connecting DVPCOPM-SL to DVP-SV MPU

z Open the fixing clip on top and bottom of DVP-SV. Meet the extension port of DVPCOPM-SL with

DVP-SV, as

1.

z Press the fixing clips on top and bottom of DVP-SV and check is the connection is fine, as

2

DVPCOPM

POWER

RUN

ERR

1

x16

0

x16

NODEADDRESS

DR 2

DR 1

DR 0

IN 0

CAN+

SHLD

CAN-

GND

DVP28SV

11

RUN

STOP

2

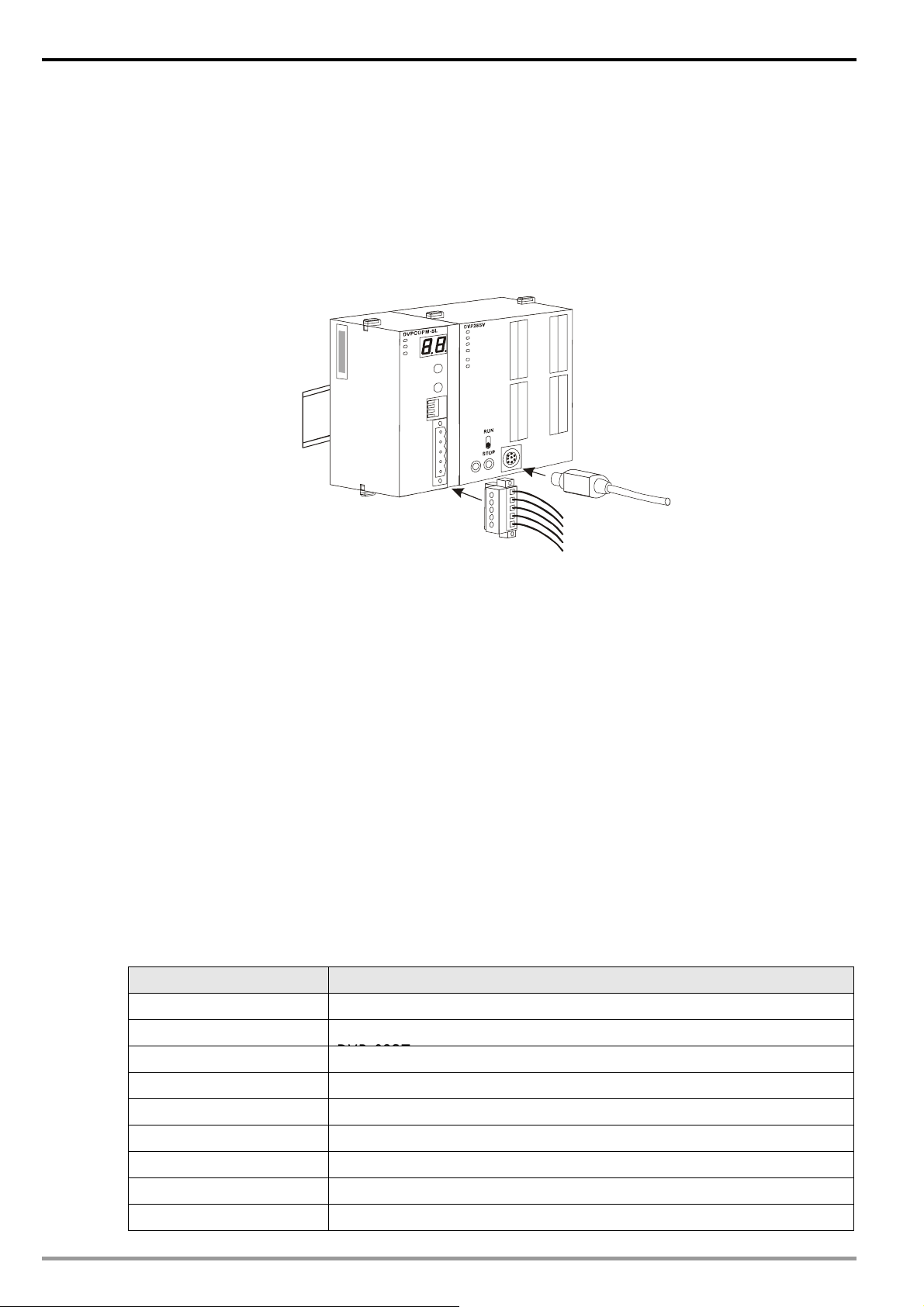

3.2 Installing DVPCOPM-SL and DVP-SV MPU on DIN Rail

z Use 35mm DIN rail

z Open the DIN rail clip on DVP-SV and DVPCOPM-SL. Insert DVP-SV and DVPCOPM-SL onto the DIN

rail.

2.

z Clip up the DIN rail clips on DVP-SV and DVPCOPM-SL to fix DVP-SV and DVPCOPM-SL on the DIN

rail, as shown below.

DVP-PLC Application Manual

DVPCOPM

POWER

RUN

ERR

DVP28SV

35mm DIN rail

1

x16

0

x16

NODE ADDRESS

DR 2

DR 1

DR 0

IN 0

RUN

CAN+

SHLD

CAN-

STOP

GND

7

Page 10

CANopen Communication Module DVPCOPM-SL

3.3 Connecting to CANopen Connection Port

z Please wire following the PIN definition of the connection port.

z There are two communication interfaces on DVP-SV to communicate with the PC. COM1 is the

standard RS-232 interface, and COM2 RS-485. Both interfaces comply with Modbus protocol. The PC

communicates directly to PLC through COM1.

z We recommend you also apply Delta’s power mod ule in the connection.

R

S-232

4 Constructing CANopen Network

In this section, we will introduce how to construct a complete CANopen network by using DVPCOPM-SL an d

other slaves.

Before constructing a network, you have to first know clearly what the network is for and start a preliminary

planning for the data to be exchanged. The plan shall include the slaves to be used, type of transmiaaion and

the data to be exchanged, total length of data to be exchanged, requirement on the response time for data

exchange, and so on. These information will decide whether the net work you constru ct is a reasonable one, or if

it satisfies your needs, and even affect the later-on network sustainability and flexibility of network capacity

upgrade.

In the example below, we will illustrate how to contro l RUN/STOP and speed of a Delta ASD-B servo drive by

a Delta digital I/O module DVP-08ST.

4.1 How to Construct a CANopen Network

Equipment and software required:

8

Equipemt & software Function

DVP-PS02 24V power supply module, supplying CANopen network.

DVP-PS01

DVP-28SV DVP-SV PLC MPU

DVPCOPM-SL CANopen master

DVP-12SA DVP-SA PLC MPU

DVP-08ST Digital I/O module

IFD9503 CANopen bus adapter

ASD-B Delta B series servo drive

WPLSoft DVP series PLC programming software

24V power supply module, supplying DVP-12SA and remote I/O

DVP-PLC Application Manual

Page 11

CANopen Communication Module DVPCOPM-SL

Equipemt & software Function

Delta CANopenBuilder CANopen configuration software for DVPCOM-SL master

z Set up DVPCOPM-SL and IFD9503 according to the table below. For how to operate IFD9503, please

refer to Chapter 13.

Module Node address Baud rate (bps)

DVPCOPM-SL 01 1M

IFD9503 02 (connected to ASD-B) 1M

IFD9503 03 (connected to DVP-12SA) 1M

Set up ASD-B as follows:

Parameter Set value Explanation

P1-01 02 Control mode: speed mode

P1-09 100 (rpm) Internal speed command 1 (SP1)

P1-10 300 (rpm) Internal speed command 2 (SP2)

P1-11 500 (rpm) Internal speed command 3 (SP3)

P2-10 101 Function of DI1: Servo on

P2-11 114 Functin of DI2: SPD0

P2-12 115 Functino of DI3: SPD1

P2-18 102 Function of DO1: Output when servo on

P3-00 1 Modbus communication address

P3-01 5 (115,200 bps) Modbus baud rate

P3-02 1 (7,E,1) Modbus data format

P3-06 3F DI1 ~ DI6 controlled by communication

z Constructing the CANopen network following the figure below.

DVP-PS02

L

N

0V

CANopen

DVPCOPM-SL

DVPCOPM DVP28SV

Node 1

DVP28SV

RUN

STOP

CANopen

network configuration tool

RS-232

ASD-B

DVP-PLC Application Manual

Node 2

IFD9503

Node 3

PORT2PORT1

PORT2PORT1

L

N

0V

T

A

S

S

2

8

1

0

-

-

P

P

V

V

D

D

DVP-08STDVP-12SA

9

Page 12

CANopen Communication Module DVPCOPM-SL

About the connection between IFD9503 and PLC, IFD9503 and ASD-B, or IFD9503 and other equipment,

please refer to Chapter 13. For the electrical specifications of ASD-B, please refer to ASD-B u ser m anual.

4.2 Data Mapping in CANopen Network

z Data mapping in DVP-12SA

DVP-08ST, connected on the right hand side of DVP-12SA, offers 8 channels of digital input and 1 byte of

input data. In this example, we will use X0 and X1 on DVP-08ST to RUN/STOP ASD-B and select speed. Y0 is

for the output signal of ASD-B operational status. See the table below for more information.

Channel Function

X0 Controlling RUN/STOP of ASD-B

Selecting the speed of ASD-B:

X1, X2

Y0

X2 = 0, X1 = 1, selecting SP1

X1 = 1, X2 = 0, selecting SP2

X1 = 1, X2 = 1, selecting SP3

Operational status of ASD-B:

On: RUN

Off: STOP

Supposed IFD9503 is connected to DVP-12SA and exchanging data with DVPCOPM-SL maste r, the default

length of input data is 8 bytes and output data is 8 bytes. D256 in DVP-12SA is the start device for input data,

and D0 is the start device for output data. To realize the control function of X0, X1 and X2, we place the

statuses of X0 ~ X2 to bit 0 ~ 2 of D256. That is, when X0 = On, bit 0 of D256 will become 1. When X1 = O n, bit

1 of D256 will become 1. In this way, we can realize the control of RUN, STOP and speed of ASD-B by the

changes in D256 through WPLSoft. The st atu s word in ASD-B will then be sent to D0. That is, when bit 0 of D0

becomes 1, there will be signals at Y0.

I/O data area for DVPCOPM-SL master:

D register 15 14 13 12 11 10 9 8 7 6 5 4 3u,3 2 1 0

D6032 D256 X2 X1 X0

D6033 D257

D6034 D258

D6035 D259

Input data

…

D6282 D0 Y0

D6283 D1

D6284 D2

D6285 D3

Output data

…

z Data mapping in ASD-B

In this example, IFD9503 is the interface between ASD-B and CANopen network. In default setting, IFD9503

offers 1 word of input data and 1 word of output dat a to exchange dat a with DVPCOPM-SL maste r. See the table

below for the relation between the parameters in ASD-B and the input and o utput dat a in DV PCOPM-SL master .

10

DVP-PLC Application Manual

Page 13

CANopen Communication Module DVPCOPM-SL

Input data D6036 Multi-function digital output

Output data D6286 Multi-function digital input

D register 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

4.3 How to Configure Network by Delta CANopenBuilder Software

z Using CANopenBuilder to scan the network

(1) Open CANopenBuilder software, as below:

(2) Select ”Setup” => ”Communication Setting” => ”System Channel”, and the "Serial Port Setting”

dialog box will appear.

(3) Set up the communication parameters in the PC and DVP-SV, e.g. the communication port,

address, baud rate and communication format.

Item Function Default

COM Port COM port on the PC to be used to communicate COM1

DVP-PLC Application Manual

11

Page 14

CANopen Communication Module DVPCOPM-SL

Item Function Default

with DVP-SV

Address Communication address of DVP-SV 1

Baud rate

Data Bits 7

Parity Even Parity

Stop Bit

Mode

Click on “OK” and return to the main page.

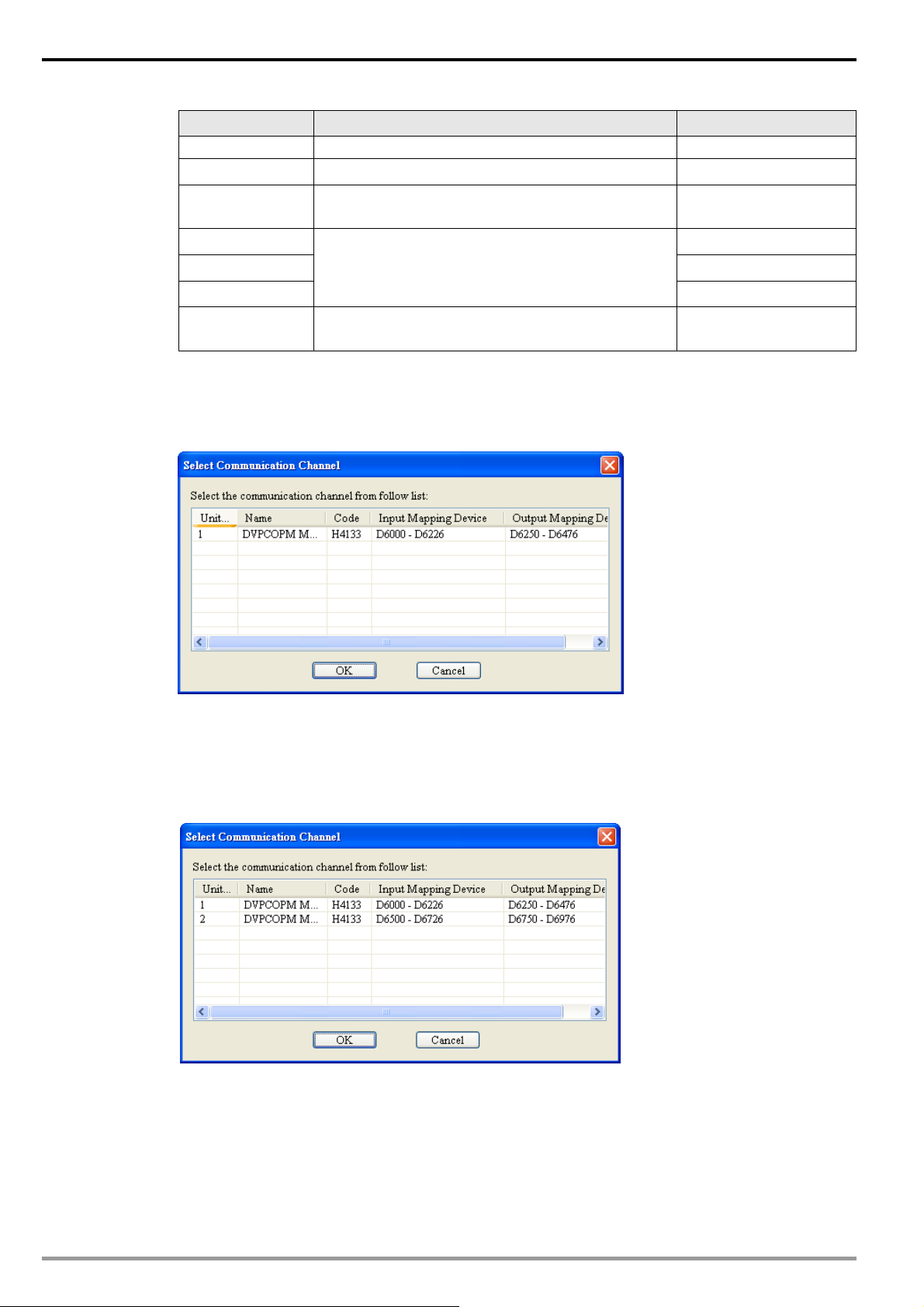

(4) Select “Network” => ”Online”, and the “Select Communication Channel” dialog box will appear. In

this example, if the connection with DVP-SV is in normal status, you will see the screen as below.

Communication speed between the PC and

DVP-SV

COmmuniction protocol between the PC and

DVP-SV

Communication mode between the PC and

DVP-SV

9,600 (bps)

1

ASCII

If there are more than one DVPCOPM-SL modules (less than 8) connected to the left side of

DVP-SV and supposed there are two connected in this example, after clicking on “Online”, you will

see the screen as below. The DVPCOPM-SL which is closest to DVP-SV is regarded the first module,

and so on.

(5) Select the DVPCOPM-SL which needs to establish the communication. Click on “OK” and start to

scan all the slaves on the network. If the network installation and power sup ply are normal, you will

12

see the screen as below.

DVP-PLC Application Manual

Page 15

CANopen Communication Module DVPCOPM-SL

(6) In normal condition, after the scan is over, you will find the master and all the slaves displayed in

CANopen network, as below .

z Setting up parameters in CANopen master

Select “Network” => ”Master Parameter”, and you will see the dialog box as below.

DVP-PLC Application Manual

13

Page 16

CANopen Communication Module DVPCOPM-SL

Work Mode: The work mode of DVPCOPM-SL. You can select either “Master Mode” or “Slave Mode”.

Cycle Period: The period of sending synchronous information.

Master’s heartbeat time: Time for DVPCOPM-SL to send out heartbeat.

After all the parameters are set up, click on “OK".

z Setting up parameters in CANopen slave

Take the parameter settings in ASD-B for example:

(1) Double click on ASD-B, and you will see the dialog box as below.

14

(2) Relevant parameter settings

Error Control Protocol: In the “Node Configuration…” page, clic k on “Error Control Protocol”, and

you will see the dialog box appearing as below.

DVP-PLC Application Manual

Page 17

CANopen Communication Module DVPCOPM-SL

In this page, you can set up parameters for error control, e.g. “Master Consumer Timeout” and

“Node Heartbeat Producer Time”. Please note that the value of “Master Consumer Timeout" shall be

bigger than the value of “Node Heartbeat Producer T i me”. After you have set up the heartbeat function,

and the slave turns off-line and does not turn on-line within “Master Cosume r Timeout”, the master will

consider the slave off-line. If “Heartbeat" is selected, you cannot select “Node Guarding”. In

“Heartbeat consumer”, you can add devices into the node list. Add a device A, and the slave will be

able to monitor whether device A is on-line. Select a device and click on “Edit…” to modify the

“Consumer" and “Producer” value.

Auto SDO Configuration: In the “Node Configuration” page, click on “Auto SDO Configuration”,

and you will see the page as below.

Click on “Add” to edit Auto SDO. Click on “Edit” to modify the Auto SDO selected. Please note that

the Auto SDO cannot be longer than 8 bytes, and every slave is able to posses maximum 20 auto

SDOs.

PDO mapping: In the “Node Configuration…” page, select a TxPDO or RxPDO in “Configured

DVP-PLC Application Manual

15

Page 18

CANopen Communication Module DVPCOPM-SL

PDO” and click on “PDO Mapping”, and you will enter the “PDO Mapping…” page as below. You can

add the parameters in “Available Object s from EDS file” into “Mapped Objects”. The total length of the

parameters added in each PDO cannot exceed 8 bytes. After the configuration is completed, click on

“OK”.

In the “Node Configuration…” page, click on “Properties” to enter the "PDO Properties” page and

modify COB-ID and Tran smit type. After the configuration is completed, click on “OK”. In the “Node

Configuration…” page, click on “Define PDO” to self define RxPDO ir TxPDO.

In this example, we adopt the default configuration. Finally, click “OK” in the “Node

Configuration…” page.

16

z Node List Setting

DVP-PLC Application Manual

Page 19

CANopen Communication Module DVPCOPM-SL

(1) Double click on “DVPCOPM Master” icon, and you will see the “Node List Setting” dialog box as

below.

(2) In this example, first select DVP-SS/SA/EH PLC at Node 003 and click on > to add this node into

the node list. After this, sel ect Node 003 in the node list, and you wi ll be able to see how the I/O dat a

correspond to D registers in DVP-SV from the Output Table and Input Table below.

(3) Add also Node 002 into the node list, and you will be able to see how the I/O data correspond to D

DVP-PLC Application Manual

17

Page 20

CANopen Communication Module DVPCOPM-SL

registers in DVP-SV from the Output Table and Input T able below. Click on “OK” to complete setting

up the node list.

z Downloading the data to the master

Select “Network“ => “Download” to download the configuration data to DVPCOPM-SL master. If

the PLC is in RUN status at this moment, you will be given a warning saying that you have to stop the

operation before the download.

Click on “OK” to stop the PLC and start to download the data to the master.

After the download is completed, you will be given another warning, askin g you if you would li ke to

18

run the PLC again. Click on “OK” to restart the PLC program, or click o n “Cancel” to stop the PLC.

DVP-PLC Application Manual

Page 21

CANopen Communication Module DVPCOPM-SL

4.4 Saving the Configuration Data

Select “File” => "Save” to save the current configuration data.

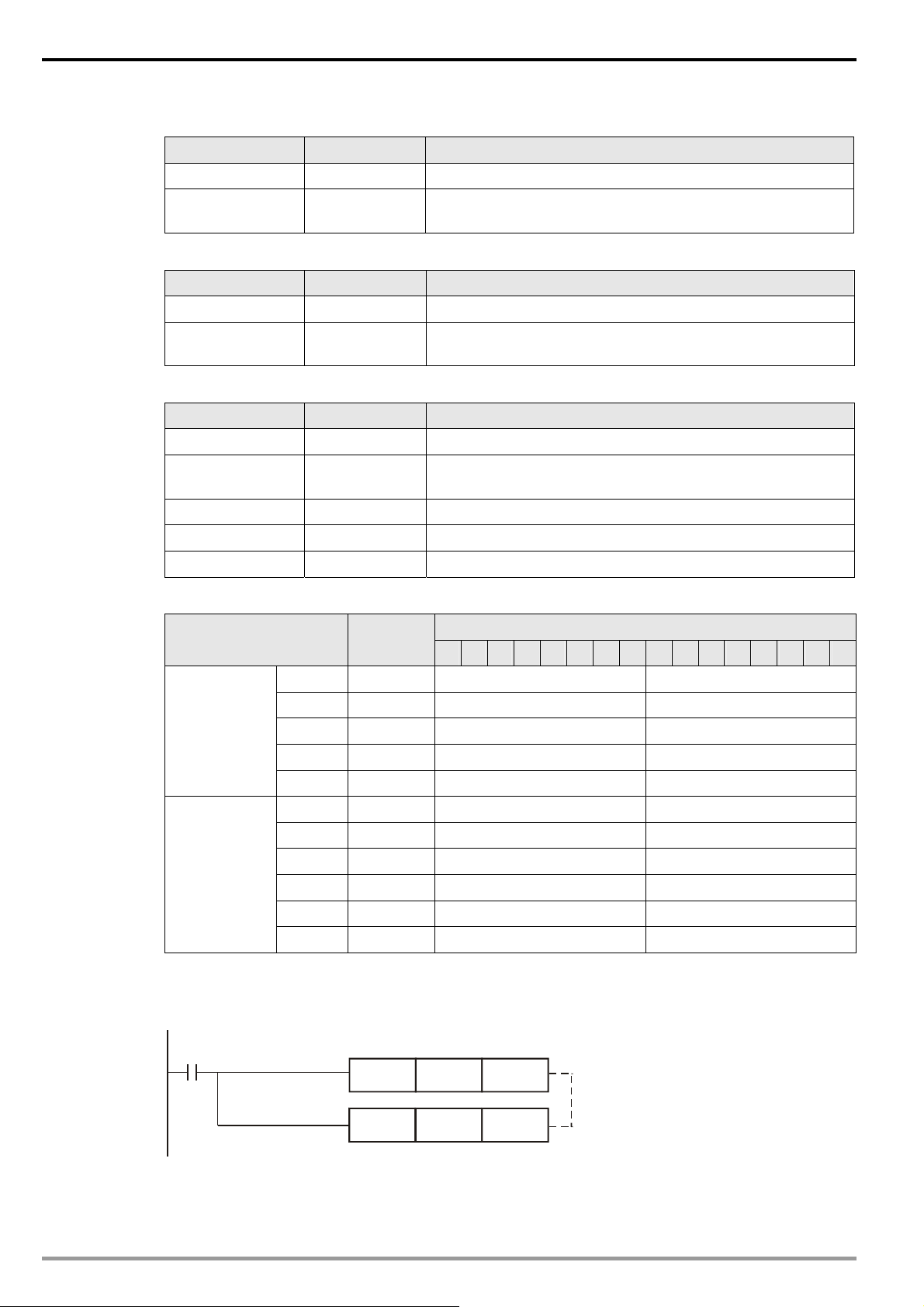

4.5 CANopen Network Control

In this section, we will introduce how to compile WPL program and control CANopen network.

z Target:

1. When SW0 on Slave 3 is closed, the servo drive on Slave 2 will start to run.

2. When SW0 on Slave 3 is open, the servo drive on Slave 2 will stop.

3. When the status of SW1 and SW2 on Slave 3 is switched, the running speed of servo drive on Slave

2 can be modified.

4. When the servo drive is running, the signal LED on Slave 2 will be On.

5. When the servo drive stops, the signal LED on Slave 2 will be Off.

z The program in DVP-SV MPU (master):

M1002

SET M0

M0

MOV D6032

MOV D6282

END

z Program explanations:

nd

1. The 2

row of the program indicates sending the content of D256 in DVP-SA (mapped on D6032 of

DVP-SV) to the control word (Multi-Function Digital Input, mapped on D62 86 of DVP-SV) of the serv o

drive.

rd

2. The 3

row of the program indicates sending the output status of the servo drive (Multi-Function

Digital Output, mapped on D6036 of DVP-SV) to D0 in DVP-SA (mapped on D6282 of DVP-SV).

z The program in DVP-SA MPU (slave):

M1002

MOV H

SET M1120

D6036

C6

D6286

D6286

D1120

D

M0

M10

DVP-PLC Application Manual

RST

SET M0

MOV K2 X20

MOV K2M10

END

M1143

D256

D0

Y0

19

Page 22

CANopen Communication Module DVPCOPM-SL

z Program explanations:

1. The first 3 rows of the program set up the communication format between DVP-SA and IFD9503,

which is 115,200bps, 7E1-ASCII; communication port is COM2.

2. When M0 = On, send the input status of X20 ~ X28 on DVP-08ST to D256, and send the dat a in b0 ~

b15 of D0 to M10 ~ M25.

3. When D0 = 1, M10 will be On, and Y0 on DVP-SA MPU will output.

5 Sending SDO, NMT and Reading Emergency by Ladder Diagram

5.1 The Principle

See the chart below for sending SDO by WPL program:

SDO request message from master

PORT2PORT

1

D

DVPCOPM DVP28SV

B

SDO request message

(PLC -> COPM)

SDO response message

(COPM -> PLC)

RUN

STOP

A

DVP28SVDVPCOPM-SL

SDO response message from slave

C

VFD-B

IFD9503

A: DVP-SV sends out request message to DVPCOPM-SL (master).

B: DVPCOPM-SL (master) sends out request message to the target equipment.

C: The target equipment processes the request message and sends the response message to

DVPCOPM-SL.

D: DVP-SV receives SDO, NMT and Emergency data.

5.2 Structure of SDO Request Message

You can edit SDO, NMT and Emergency in “request message editing are a”. Take the first DVPCOPM-SL

master placed on the left hand side of DVP-SV for example. See the table b elo w for the corresp ondi ng rel eation

between “request message editing area” and “response message editing area” and the devi ces in PLC.

20

DVP-PLC Application Manual

Page 23

CANopen Communication Module DVPCOPM-SL

PLC device Editing area Editing length

D6000 ~ D6031 SDO response message and Emergency response message 64 bytes

D6250 ~ D6281

See the table below for the format of SDO request message:

SDO request message, NMT service message and Emerg ency

request message

64 bytes

PLC device

D6250 ReqID Command

D6251 Reserved Size

D6252

D6253 High byte of main index Low byte of main index

D6254 Reserved Sub index

D6255 Datum 1 Datum 0

D6256 Datum 3 Datum 2

D6257 ~ D6281

z Command: Fixed to “01Hex”.

z ReqID: The request ID. Whenever an SDO request message is sent out, the message will be given a ReqID

for CANopen master to identify. For the next request message to be sent out, you have to change the ID

number. Ran ge of ReqID: 00Hex ~ FFHex.

z Size: The length of the message. Max. 8 bytes. Unit: byte.

z MAC ID: The node address of the target equipment on CANopen network.

z Ty pe: In SDO request message, 01Hex refers to SDO read message service; 02Hex refers to SDO write

Message Header

Message Data

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Request Message

Type MAC ID

Reserved

message service; 4FHex refers to read 1 byte of data; 60Hex refer to write 1/2/4 byte(s) of data; 80Hex refers

to end SDO command. For example, if the type is 02Hex in SDO request message, it will become 60Hex for

SDO response message when the writing of data is successful.

z Status code:

Status code Explanation

0 No data transmission request

1 SDO data transmission is successful.

2 SDO data is being transmitted.

3 Erro r: SDO transmission time-out

4 Erro r: Illegal command

5 Erro r: Size of request message is illegal.

6 Erro r: Size of response message is illegal.

7 Erro r: Equipment to be sent messages is busy.

8 Erro r: Illegal type

9 Error: Incorrect node address

0A Error message (See the error code for SDO response message)

0B ~ FF Reserved

5.3 Structure of NMT Service Message

You can send the NMT request message to D6250 ~ D62 81, and t he slave will not re spond with a me ssage.

DVP-PLC Application Manual

21

Page 24

CANopen Communication Module DVPCOPM-SL

PLC device

D6250 ReqID Command

D6251 Reserved Size (fixed to 04Hex)

D6252

D6253 Reserved NMT service code

D6254

z Command: Fixed to “01Hex”.

z ReqID: The request ID. Whenever an NMT req uest message is sent out, the message will be given a ReqID

for the CANopen master to identify. For the next NMT request message to be sent out, you have to change

the ID number. Range of ReqID: 00 Hex ~ FFHex.

z MAC ID: The node address of the target equipment on CANopen network.

z NMT service code

z 01Hex: Enable remote node; 02Hex: Disable remote node; 80Hex: Enter pre-operational statu s; 81Hex:

Reset application; 82Hex: Reset communication

Example: If you would like to stop node 03 equipment on CANopen network, you have to set NMT servi ce

Message Header

Message Data

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Type (fixed to 03Hex) MAC ID

Request Message

Reserved MAC ID

code to “02Hex” and MAC ID to “03".

5.4 Structure of Emergency Request Message

See the table below for the format of Emergency request message:

PLC device

D6250 ReqID Command

D6251 Reserved Size (fixed to 0)

D6252

D6253 ~ D6281 Message Data Reserved

See the table below for the format of Emergency response message:

PLC device

D6000 ReqID Status

D6001 Reserved Size (2A Hex)

D6002

D6003 Total number of data Number of data stored

D6004 Datum 1 Datum 0

D6005 Datum 3 Datum 2

D6006 Datum 5 Datum 4

D6007 Datum 7 Datum 6

D6008 ~ D6011 Emergency2

D6012 ~ D6015 Emergency3

D6016 ~ D6019

Message Header

Message Header

Message Data

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Type (fixed to 04Hex) MAC ID

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Type (04Hex) MAC ID

Request Message

Response Message

Emergency4

22

DVP-PLC Application Manual

Page 25

CANopen Communication Module DVPCOPM-SL

PLC device

Response Message

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

D6020~ D6023 Emergency5

D6024~ D6031 Reserved

z Command: Fixed to “01Hex”.

z ReqID: The request ID. Whenever an Emergency message is sent out, the message will be given a ReqID for

the CANopen master to identify. For the next Emergency message to be sent out, you have to change the ID

number. Ran ge of ReqID: 00Hex ~ FFHex.

z MAC ID: The node address of the target equipment on CANopen network.

z Total number of data: The total number of Emergency messages CANopen master receives.

z Number of data stored: The latest number of Emergency messages CANopen master receives. (Every slave

gives less than 5 messages.)

Note:

z CANopen master can only send out 1 SDO, NMT or Emergency request message to one e quipment at a

time.

z When you use WPL program to send out SDO, NMT or Emergency request messages, we recommend you

clear the “request message editing area” and “response message editing area” to 0.

5.5 Application Examples

In this section, we will illustrate how to compile a WPL program to send out SDO and NMT messages or

readEmergency request messages.

Example I

z Target:

When M0 = On, read the content of index 2021, sub index 4 (i.e. actual output value of AC motor

drive) in IFD9503.

DVPCOPM DVP28SV

RUN

CAN+

SHLD

CAN-

STOP

GND

Node 1

Master

CANop e n

Node 2

DVP-PLC Application Manual

IFD9503

RS-485

RJ12

VFD-B

23

Page 26

CANopen Communication Module DVPCOPM-SL

Required settings in DVPCOPM-SL:

Parameter Setting Explanation

Node address 01 Set the node address of DVPCOPM-SL to “01”.

Baud rate 1 Mbps

Required settings in IFD9503:

Parameter Setting Explanation

Node address 02 Set the node address of IFD9503 to “02”.

Baud rate 1 Mbps

Required settings in VFD-B AC motor drive:

Parameter Setting Explanation

02-00 04 The main frequency is operated by RS-485 interface.

02-01

09-00 01 Communication address of VFD-B: 01

09-01 03 Baud rate: 38,400 bps

09-04 03 Modbus RTU mode, format <8, N, 2>

03

Set the communication speed between DVPCOPM-SL and

bus to “1 Mbps”.

Set the communication speed between IFD9503 and bus to

“1 Mbps”.

The running command is operated by communication

interface. Operation by keys is valid.

Devices in PLC:

PLC device Content

SDO request

message

editing area

SDO response

message

editing area

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

D6250 0101Hex ReqID = 01Hex Command = 01Hex

D6251 0004Hex Reserved Size = 04Hex

D6252 0102Hex Type = 01Hex MAC ID = 02Hex

D6253 2021Hex High byte of index = 20Hex Low byte of index = 21Hex

D6254 0004Hex Reserved Sub index = 04Hex

D6000 0101Hex ReqID = 01Hex Status = 01Hex

D6001 0006Hex Reserved Size = 06Hex

D6002 4B02Hex Type = 4BHex MAC ID = 02Hex

D6003 2021Hex High byte of index = 20Hex Low byte of index = 21Hex

D6004 0004Hex Reserved Sub index = 04Hex

D6005 0100Hex Datum 1= 01Hex Datum 0 = 00Hex

Explanation

0100Hex in D6005 refers to the actual output frequency of the AC motor drive is 2.56Hz.

z PLC program

24

M1002

ZRST

ZRST D6250 D6281

D6000 D6031

Reset response message editing area

and request message editing area.

DVP-PLC Application Manual

Page 27

CANopen Communication Module DVPCOPM-SL

M0

MOV H0101 D6250

MOV H0004 D6251

MOV H0102

MOV

H2021

D6252

D6253

MOV H0004 D6254

ReqID = 01, Command = 01

Size = 04

Type = 01, MAC ID = 02

Index = 2021

Sub index = 04

END

z Program explanation

1. The program first reset the SDO request message editing area and SDO response message

editing area to 0.

2. When M0 = On, CANopen master will send out SDO request message and read the contents in

index 2021, sub index 4 of the target equipment (at node address 02). If the communication is

successful, the slave will return with the response message.

3. When M0 = On, CANopen master will send out request message only once. If you would like it to

send out messages again, you will have to change the ReqID.

4. The messages returned from the target equipment are stored in D6000 ~ D6005.

Example II

z Target:

When M0 = On, set the content in index 2047, sub index 2 (i.e. the control word of the target

temperature) in IFD9503 to 0104Hex (i.e. 26.0°C). Please note that you have to write 0401Hex into

D6255 of the PLC.

DVPCOPM DVP28SV

RUN

CAN+

SHLD

CAN-

STOP

GND

Node 1

Master

CANopen

Node 2

DVP-PLC Application Manual

IFD9503

RS-48 5

PV

SV

SET

AT

OUT ALM1 ALM2

DTA

DTA4848

°C

°

F

25

Page 28

CANopen Communication Module DVPCOPM-SL

Required settings in DVPCOPM-SL:

Parameter Setting Explanation

Node address 01 Set the node address of DVPCOPM-SL to “01”.

Baud rate 1 Mbps

Required settings in IFD9503:

Parameter Setting Explanation

Node address 02 Set the node address of IFD9503 to “02”.

Baud rate 1 Mbps

Required settings in DTA temperature controller:

Parameter Setting Explanation

D

e

On C WE: Enable/disable communication write-in

ASCII C-SL: Select ASCII or RTU format

1 C NO: Set up communication address

38400 BPS: Set up communication speed

7 LENGTH: Set up data length

E PARITY: Set up parity bit

1 STOP BIT: Set up stop bit

°C UNIT: Select temperature unit, °C or °F

Set the communication speed between DVPCOPM-SL and the bus

to “1 Mbps”.

Set the communication speed between IFD9503 and the bus to “1

Mbps”.

Devices in PLC

PLC device Content

SDO request

message

editing area

SDO response

message

editing area

Explanation

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

D6250 0101Hex ReqID = 01Hex Command = 01Hex

D6251 0006Hex Reserved Size = 06Hex

D6252 0202Hex Type = 02Hex MAC ID = 02Hex

D6253 2047Hex High byte of index = 20Hex Low byte of index = 47Hex

D6254 0002Hex Reserved Sub index = 02Hex

D6255 0401 Hex Datum 1= 04Hex Datum 0= 01Hex

D6000 0101Hex ReqID = 01Hex Status = 01Hex

D6001 0004Hex Reserved Size = 04Hex

D6002 6002Hex Type = 60Hex MAC ID = 02Hex

D6003 2047Hex High byte of index = 20Hex Low byte of index = 47Hex

D6004 0002Hex Reserved Sub index = 02Hex

26

DVP-PLC Application Manual

Page 29

z PLC program

M1002

M0

CANopen Communication Module DVPCOPM-SL

ZRST D6000 D6 03 1

Reset response message editing area

and request message editing area.

ZRST D6250 D6 28 1

MOV H0101 D6250

ReqID = 01, Command = 01

MOV H0006 D6 251

MOV

MOV

MOV

MOV

END

H0202

H2047

H0002 D6254

H0401 D6255

D6252

D6253

Size = 06

Type = 02, MAC ID = 02

Index = 2047H

Sub index = 02

Target temperature for DTA: 0 104H

z Program explanation

1. The program first reset the SDO request message editing area and SDO response message

editing area to 0.

2. When M0= On, CANopen master will send out SDO request message and write 0104Hex into

index 2047, sub index 2 of the target equipment (at node address 02). If the communication is

successful, the slave will return with the response message.

3. When M0 = On, CANopen master will send out request message only once. If you would like it to

send out messages again, you will have to change the ReqID.

4. The messages returned from the target equipment are stored in D6000 ~ D6 004.

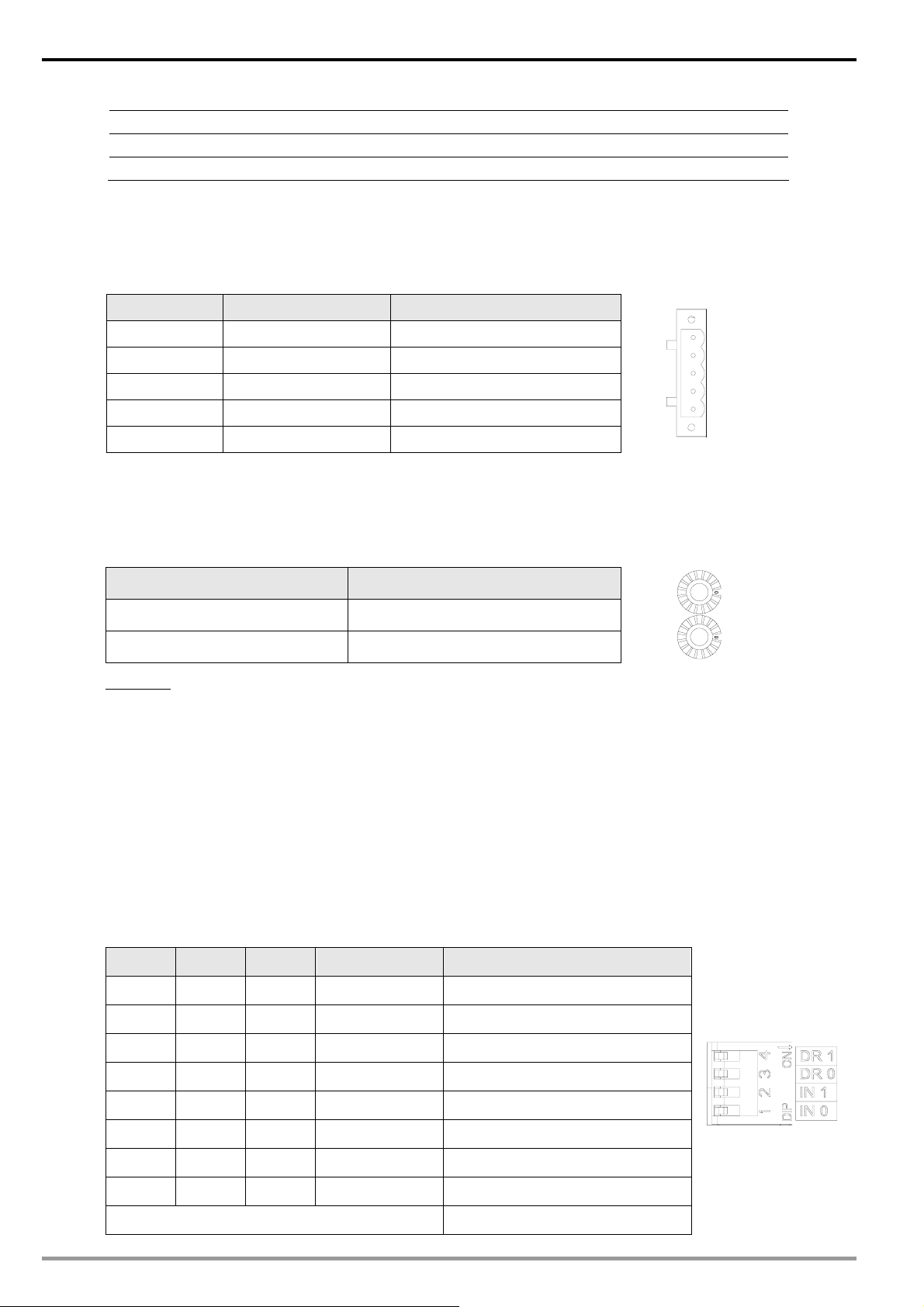

6 LED Indicator & Trouble-shooting

DVPCOPM-SL has three LED indicators and a digit al display on it. POWER LED display s whether the powe r

supply of DVPCOPM-SL is normal. RUN LED and ERR LED display the current operational status. The digital

display shows the node address of DVPCOPM-SL and error messages from the slave.

DVPCOPM

POWER

RUN

ERR

DVP-PLC Application Manual

27

Page 30

CANopen Communication Module DVPCOPM-SL

6.1 POWER LED

LED status Indication How to correct

On Power is abnormal. Check the power supply of DVPCOPM-SL.

Green light On Power is normal. --

6.2 RUN LED

LED status Indication How to correct

Off No power

Green light single

flash

Green light

blinking

Green light steady

on

DVPCOPM-SL in STOP status -DVPCOPM-SL in pre-operational

status

DVPCOPM-SL is operational

status

Check the power of DVPCOPM-SL and make

sure the connection is normal.

--

--

6.3 ERR LED

LED status Indication How to correct

Off Normal -Red light double

flash

Red light single

flash

Red light steady

on

Error control event See the indication from the digital display.

Bus error exceeds the warning

limit.

Bus-off

6.4 Codes in Digital Display

z DVPCOPM-SL as master:

Code Indication How to correct

0 ~ 7F

F1 No slave configured in node list

F2

F3 DVPCOPM-SL in error status Check if the wiring of DVPCOPM-SL is correct.

F4 Bus-off is detected.

F5 Incorrect DVPCOPM-SL settings

F6

F7 Internal error: GPIO check

F8 Internal error: memory check

The node address of DVPCOPM-SL

when in normal operation.

The data are being downloaded to

DVPCOPM-SL.

Internal error: manufacturing

process

Check if the network connection and operation are

normal.

Check if the bus connection is normal and

re-power DVPCOPM-SL.

-Re-configure the node list and download it to

DVPCOPM-SL.

--

Make sure the communication cable is in normal

operation, and all the nodes on the network work

in the same baud rate. Re-power DVPCOPM-SL.

Check the settings of node address and baud

rate and make sure the settings are correct.

Re-power DVPCOPM-SL. If the error still exists,

change to a new DVPCOPM-SL.

28

DVP-PLC Application Manual

Page 31

CANopen Communication Module DVPCOPM-SL

Code Indication How to correct

F9 Low voltage is deteced.

FA

FB

FC

E0

E1

E2

E3 Auto SDO download failed. Check and make sure auto SDO is correct.

E4 PDO parameter setting has failed. Make sure the PDO parameter setting is legal.

E5 Error in key parameter setting.

E6

E7

E8

The firmware of DVPCOPM-SL is

in error status.

The sending buffer in

DVPCOPM-SL is full.

The receiving buffer in

DVPCOPM-SL is full.

DVPCOPM-SL receives

Emergency message sent by the

slave.

PDO data length returned from the

slave is not consistent with the

length set in the node list.

PDO message from the slave has

not been received.

The slave does not exist in the

network.

The slave's error control is

timed-out.

Master/slave node address is

repeated.

Check and make sure the power of

DVPCOPM-SL works normally.

Re-power DVPCOPM-SL.

Make sure the bus works normally and re-power

DVPCOPM-SL.

Make sure the bus works normally and re-power

DVPCOPM-SL.

Read relevant information through PLC MPU or

Delta CANopenBuilder software.

Reset the PDO data length in the slave and

download the new setting to DVPCOPM-SL.

Check and make sure the setting is correct.

Make sure all the slaves connected are

consistentwith the slaves set.

Make sure the power of the slave and the

network connection work normally.

Reset the node address and make sure the new

address is not a repeated one.

z DVPCOPM-SL as slave:

Code Indication How to correct

0 ~ 7F

A0

A1

A3

B0 Heartbeat timed-out Re-connect DVPCOPM-SL to the network.

B1

F4 Bus-off is detected

FB

FC

The node address of DVPCOPM-SL

when in normal operation.

The parameters in DVPCOPM-SL is

being initialized.

DVPCOPM-SL is in pre-operational

status.

The data are being downloaded to

DVPCOPM-SL.

PDO data length returned from the

slave is not consistent with the

length set in the node list.

The sending buffer in

DVPCOPM-SL is full.

The receiving buffer in

DVPCOPM-SL is full.

--

--

--

--

Reset the PDO data length in the slave and

download the new setting to DVPCOPM-SL.

Make sure the communication cable is in normal

operation, and all the nodes on the network work

in the same baud rate. Re-power DVPCOPM-SL.

Make sure the bus works normally and re-power

DVPCOPM-SL.

Make sure the bus works normally and re-power

DVPCOPM-SL.

DVP-PLC Application Manual

29

Page 32

CANopen Communication Module DVPCOPM-SL

MEMO

30

DVP-PLC Application Manual

Loading...

Loading...