Delta VFD055VL23A-J, VFD220VL43A-J, VFD150VL43A-J, VFD075VL23A-J, VFD300VL43A-J User Manual

...Page 1

Page 2

9-(

Page 3

Page 4

Preface

Thank you for choosing Delta’s high-performance Hybrid servo drive VFD-VJ Series

dedicated to plastic injection molding machine. The VFD-VJ series products are made of

high quality components and materials that incorporate the latest microcontroller

technology.

This manual is to be used for the installation, parameter setting, troubleshooting, and daily

maintenance of the Hybrid servo drive. To guarantee safe operation of the equipment, read

the following safety g uideli nes be fore conn ecti ng pow er to the Hy bri d serv o driv e. Keep this

operating manual at hand and distr ibute to all users for reference.

To ensure the safety of operators and equipment, only qualified personnel familiar with

Hybrid servo drive are to do installation, start-up and maintenance. Always read this

manual thoroughly before using VFD-VJ series Hybrid Servo Drive, especially the

WARNING, DANGER and CAUTION notes. Failure to comply may result in personal injury

and equipment damage. If you have any questions, please contact your dealer.

Firmware version: V2.03

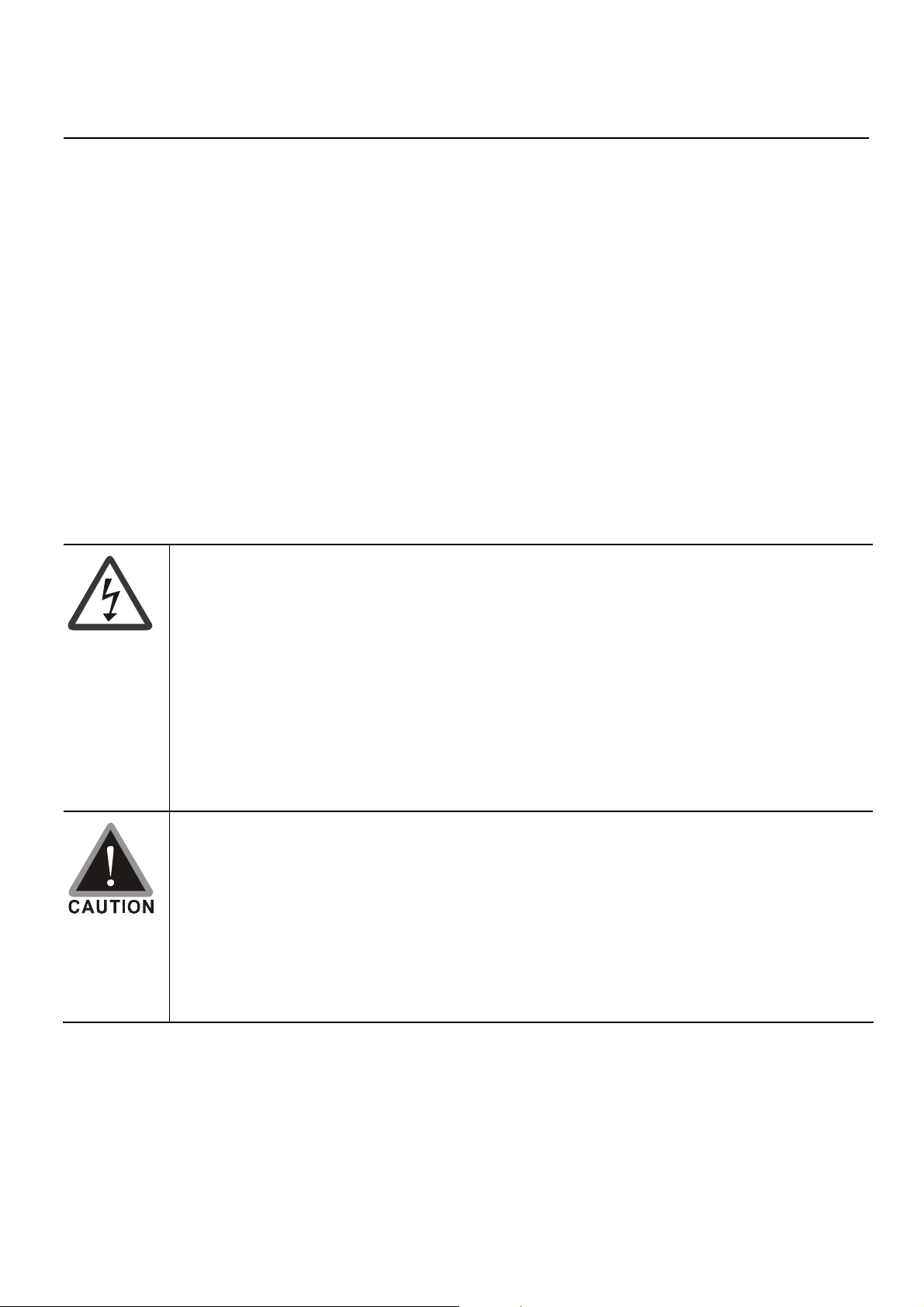

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.

; AC input power must be disconnected before any wiring to the Hybrid

servo drive is made.

; Even if the power has been turned off, a charge may still remain in the

DANGER

DC-link capacitors with hazardous voltages before the POWER LED is

OFF. Please do not touch the internal circuit and components. For safe

maintenance, use a multimeter to measure the voltage across the +1

and – terminals. The measured value should be lower than 25Vdc for the

system to operate normally.

; There are highly sensitive MOS components on the printed circuit boards.

These components are especially sensitive to static electricity. Please do

not touch these components or the circuit boards before taking anti-static

measures. Never reassemble internal components or wiring.

; Ground the Hybrid servo drive using the ground terminal. The grounding

method must comply with the laws of the country where the AC motor

drive is to be installed.

; This series of product s is used to c ontrol the t hree-ph ase in ductio n mot ors

and permanent magnet synchronous motors. It cannot be used for

single-phase motors or for other purposes.

; This series of products cannot be used on occasions that may endanger

personal safety.

; Please prevent children or unauthorized personnel from approaching the

Hybrid servo drive.

Page 5

; Never connect the Hybrid servo drive output terminals U/T1, V/T2 and

W/T3 directly to the AC mains circuit power supply.

; DO NOT use Hi-pot test for internal components. The semi-conductor

used in Hybrid servo drive easily damage by high-voltage.

; Even if the 3-phase AC motor is stop, a charge may still remain in the

main circuit terminals of the AC motor drive with hazardous voltages.

; Only qualified persons are allowed to install, wire and maintain AC motor

drives.

; When the Hybrid servo drive uses an external terminal as its source of

operation commands, the motor may start running immediately after the

power is supplied. In this case, it may be dangerous to any on-site

personnel.

; DO NOT install the Hybrid servo drive in a place subjected to high

temperature, direct sunlight, high humidity, excessive vibration, corrosive

gases or liquids, or airborne dust or metallic particles.

; Only use Hybrid servo drives within specification. Failure to comply may result in

fire, explosion or electric shock.

;

When the motor cable between Hybrid servo drive and motor is too long,

the layer insulation of the motor may be damaged. Please add an AC

output reactor to prevent damage to the motor. Ref e r to appendix A

Reactor for details.

; The rated voltage for Hybrid servo drive must be ≤ 240V (≤ 480V for 460V

models) and the mains supply current capacity must be ≤ 5000A RMS

(≤10000A RMS for the ≥ 40hp (30kW) models).

NOTE

The content of this manual may be revised without prior notice. Please consult our distributors or download the most

updated version at http://www.delta.com.tw/industrialautomation

Page 6

Table of Contents

1. Use and Installation

1-1 Receiving and Inspection 1-2

1-2 Product Specifications 1-3

1-3 Selection of Hybrid Servo Drives and Motors 1-4

1-4 Product Installation 1-6

1-5 Product Dimensions 1-11

2. Wiring

2-1 Description of Wiring 2-2

2-2 Description of Terminals on Main Circuit 2-7

2-3 Description of Terminals on Control Circuit 2-11

3. Machine Adjustment Procedure

3-1 Description of Control Panel 3-2

3-2 Machine Adjustment Procedure 3-4

4. Description of Parameters

4-1 Summary of Parameters 4-2

4-2 Detailed Description of Parameters 4-9

5. Fault Diagnostic Methods

5-1 Error Messages 5-2

5-2 Over Current OC

5-3 Ground Fault Factor GFF

5-4 Over Voltage OV 5-8

5-5 Low Voltage Lv 5-8

5-6 Over Heat OH1 5-9

5-7 Overload OL 5-9

5-8 Phase Loss PHL 5-10

5-9 Electromagnetic/Induction Noise 5-11

5-7

5-7

5-10 Environmental Condition 5-12

6. Suggestions and Error Corrections for Hybrid Servo Drives

6-1 Maintenance and Inspecti ons 6-2

Page 7

6-2 Greasy Dirt Problem 6-2

6-3 Fiber Dust Problem 6-5

6-4 Erosion Problem 6-6

6-5 Industrial Dust Problem 6-7

6-6 Wiring and Installation Problem 6-8

6-7 Multi-function Input/Output Terminals Problem 6-9

7. Recommended Operations for Customers and Troubleshooting

7-1 Regular Maintenance and Check 7-2

7-2 Oil Contamination 7-6

7-3 Lint Issue 7-7

7-4 Corrosion Issue 7-9

7-5 Dust Issue 7-10

7-6 Installation and Wiring/Connection Issue 7-11

7-7 Multi-function Input/Output Terminal Application Issue 7-12

Appendix A Optional Accessories

A-1 Braking Resistor Sele ction Chart A-2

A-2 Non-fuse Circuit Breaker A-6

A-3 Fuse Specification A-6

A-4 Reactor A-7

A-4-1 AC Input Reactor Recommended Value A-7

A-4-2 AC Output Reactor Recommended Va lue A-7

A-4-3 Zero Phase Reactor A-9

A-4-4 DC Reactor A-10

A-5 Digital Keypad KPV-CE01 A-11

A-6 Speed Feedback PG Card Selection A-15

A-7 Communication Card A-19

A-8 EMI Filter A-20

Page 8

1. Use and Installation

1. Description of Hybrid Servo Drives

1-1 Receiving and Inspection

1-2 Product Specifications

1-3 Overview of Hybrid Servo Systems

1-4 Product Installation

1-5 Product Dimensions

The Hybrid servo drive should be kept in the shipping carton or crate before installation. In order to retain

the warranty coverage, the Hybrid servo drive should be stored properly when it is not to be used for an

extended period of time. Storage conditions are:

; Store in a clean and dry location free from direct sunlight or corrosive fumes.

; Store within an ambient temperature range of -20

; Store within a relative humidity range of 0% to 90% and non-condensing

environment.

; Avoid storing the product in an environment containing corrosive gases and liquids.

; DO NOT place on the ground directly. It should be stored properly. Moreover, if the

surrounding environment is humid, you should put exsiccator in the package.

; DO NOT store in an area with rapid changes in temperature. It may cause

condensation and frost.

; If the Hybrid servo drive is stored for more than 3 months, the temperature should

not be higher than 30 °C. Storage longer than one year is not recommended, it could

result in the degradation of the electrolytic capacitors.

; When the Hybrid servo drive is not used for longer time after installation on building

sites or places with humidity and dust, it’s best to move the Hybrid servo drive to an

environment as stated above.

°

C to +60 °C.

1-1

Page 9

1-1 Receiving and Inspection

This VFD-VJ Hybrid servo drive has gone through rigorous quality control tests at the factory before

shipment. After receiving the Hybrid servo drive, please check for the following:

; Inspect the unit to assure it was not damaged during shipment.

; Make sure that the part number indicated on the nameplate corresponds with the part number of

your order.

If the registered information does not match your purchase order, or if the product has any problem,

please contact the dealer or distributor.

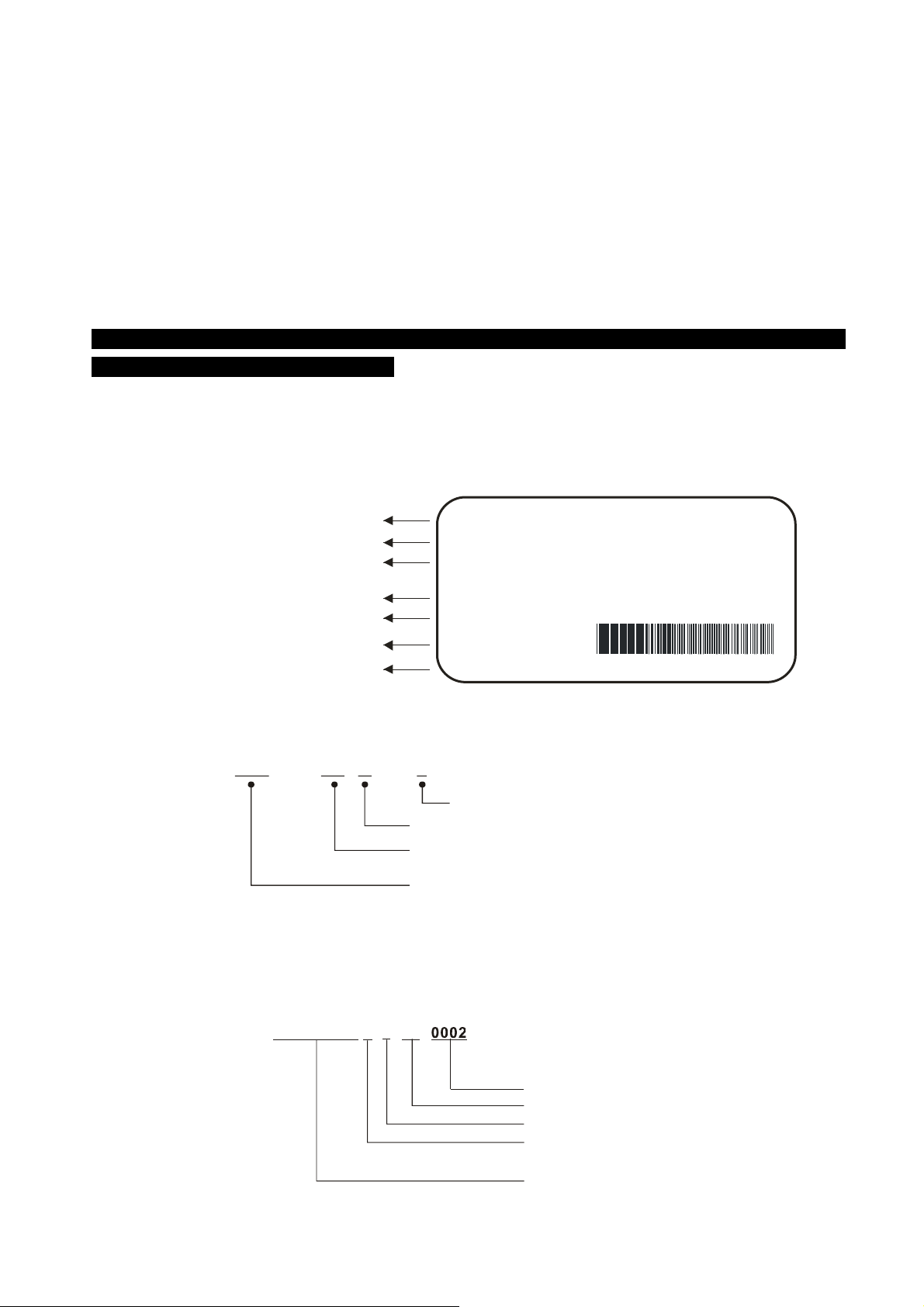

Nameplate Information

Let us take the 15HP/11kW 230V 3-Phase model as an example.

AC Driv e Mode l

Input Spec.

Out put Spec.

Output Frequency Range

Software version

Bar Co de

Seri al Number

Model Explanation

VFD VL - 110 23 A J

MODEL

INPUT

OUTPUT

: V FD110V L23A -J

: 3PH 180-264V 50/60Hz 43A

: 3PH 0-230V 41.1A

11kW/15HP

Freq. Range

: 0~600Hz

Version: 1.00

110VL23AJT9310002

Delta's high-performance H ybrid servo drive

Version Type

MainsInput Voltage

Applicable motor capacity

055:7.5HP(5.5kW)

075:10HP (7 .5k W)

110:15HP(11kW)

150:20HP(15kW)

23: 230V 3-PHASE

43:460V 3-PHASE

185:25HP (1 8.5k W)

220:30H P(2 2kW )

300:40H P(3 0kW )

370:50HP(37kW)

450:60HP(45kW)

550:75HP(55kW)

750:100 HP (75k W)

Series Number Explanation

230V 3-phase 15HP(11kW)

319 T110VL23AJ

Production numbe r

Production week

Production year 2009

Production facto ry

(T: Taoyuan, W: Wujian)

Model

1-2

Page 10

1. Use and Installation

1-2 Product Specifications

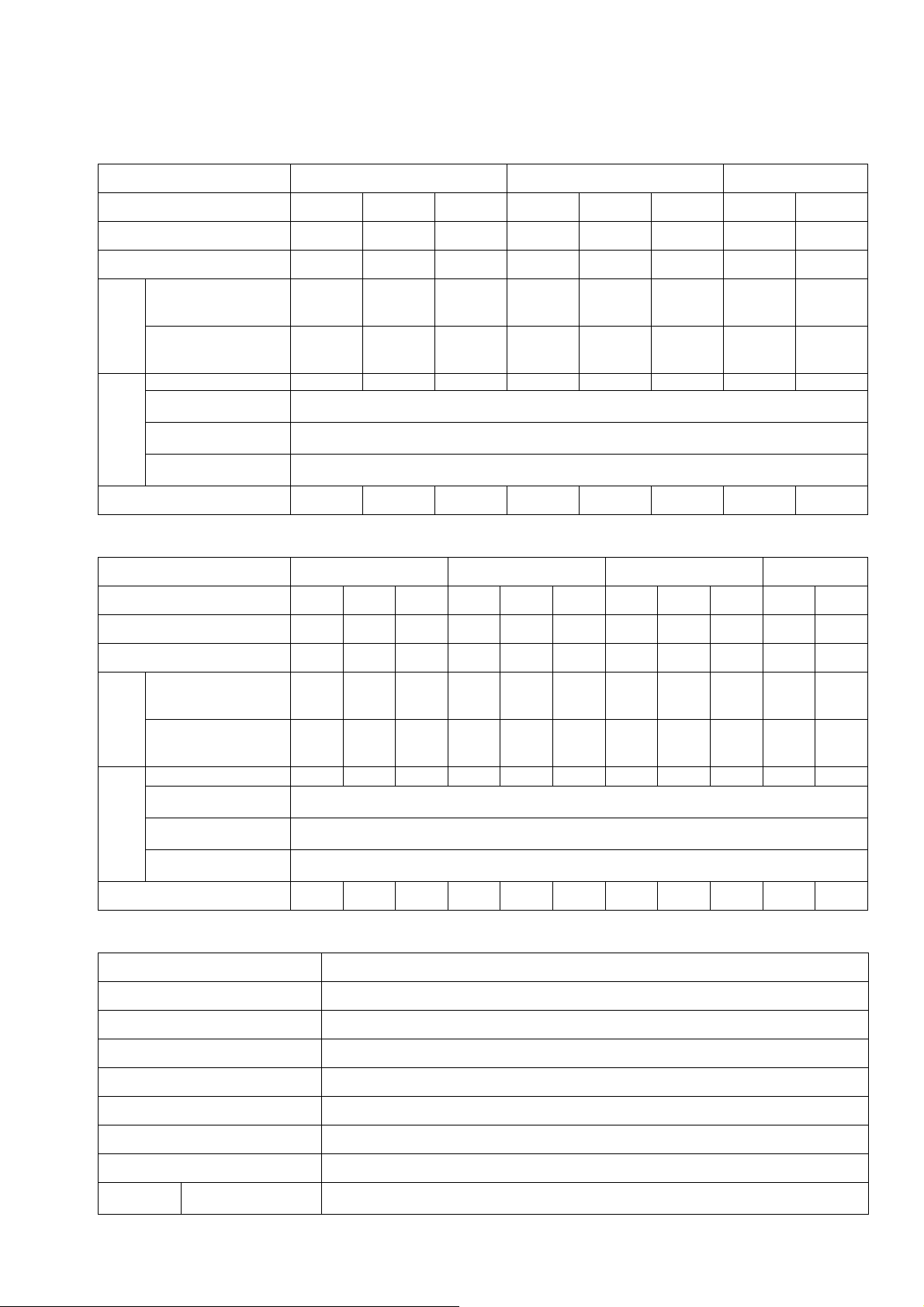

Specifications of 230V Series

Frame No. C D E2

Model No. VFD-_ _VL_ _A-J 055 075 110 150 185 220 300 370

Power (KW) 5.5 7.5 11 15 18.5 22 30 37

Horse Power (HP) 7.5 10 15 20 25 30 40 50

Output Current for

Output

Power

Supply

Continuous Operation

Over 60 sec (A)

Output Current for

Continuous Operation

Over 20 sec (A)

Input Current (A)

Tolerable Input

Voltage Variation

Tolerable Supply

Voltage Variation

Tolerable Supply

Frequency Variation

Weight (kg) 8 10 10 13 13 13 36 36

33 46 62 90 119 119 180 248

37 54 70 106 140 140 204 292

25 31 47 60 80 90 106 126

Three-phase 200~240V 50/60Hz

±10% (180~264V)

±5% (47~63Hz)

Specifications of 460V Series

Frame No. C D E1 E2

Model No. VFD-_ _VL_ _A-J 055 075 110 150 185 220 300 370 450 550 750

Power (KW) 5.5 7.5 11 15 18.5 22 30 37 45 55 75

Horse Power (HP) 7.5 10 15 20 25 30 40 50 60 75 100

Output Current for

Output

Power

Supply

Continuous Operation

Over 60 sec (A)

Output Current for

Continuous Operation

Over 20 sec (A)

Input Current (A)

Tolerable Input

Voltage Variation

Tolerable Supply

Voltage Variation

Tolerable Supply

Frequency Variation

Weight (kg) 8 10 10 13 13 13 36 36 36 50 50

21 27 36 46 58 62 102 124 155 187 255

25 32 42 54 68 78 120 146 182 220 300

14 18 24 31 39 47 56 67 87 101 122

Three-phase 380~480V, 50/60Hz

±10% (342~528V)

±5% (47~63Hz)

Common Features

Control method SVPWM

Speed Detector Resolver / Incremental Encoder

Speed Command Input DC 0~10V, 3-point calibration of analog input is supported

Pressure Command Input DC 0~10V, 3-point calibration of analog input is supported

Pressure Feedback Input DC 0~10V

General Purpose Input Signal 5 ch DC24V 8mA

General Purpose Output Signal 2 ch DC24V 50mA, 1 ch Relay output

Analog Output Voltage 1 ch dc 0~10V

Optional

Peripheral

Speed Feedback PG

Card

Mandatory (Refer to Appendix A-5)

1-3

Page 11

Accessories

Braking Resistor Mandatory (Refer to Appendix A-1)

Mandatory (It must has an output signal ranging within 0~10V, which can be configured

Protection

Feature

Environment

Pressure Sensor

EMI Filter

Motor Protection

Over Current

Protection

Ground Leakage

Current Protection

Voltage Protection

Input Power Supply

Over Voltage

Protection

Over Temperature

Protection

Protection Level

Operation

Temperature

Storage Temperature

Humidity

Vibration

Cooling System

Optional (Refer to Appendix A-7)

by Parameters 03-10~03-11;

The maximum pressure can be configured by Parameter 00-08)

Electronic thermal relay protection

Over current protection is activated at 300% of the rated current

Activated when the leakage current is higher than 50% of the drive’s rated current

Over Voltage Level: Vdc>400/800 V; Low Voltage Level: Vdc<200/400 V

Metal Oxide Varistor (MOV)

Built-in temperature sensor

NEMA 1/IP20

-10°C~45°C

-20°C~60°C

Below 90% RH (non-condensing)

1.0G below 20Hz, 0,6G at 20~60 Hz

Forced air cooling

Installation Altitude

International Certification

Altitude below 1,000m, keep from corrosive gasses, liquid and dust

1-4

Page 12

1. Use and Installation

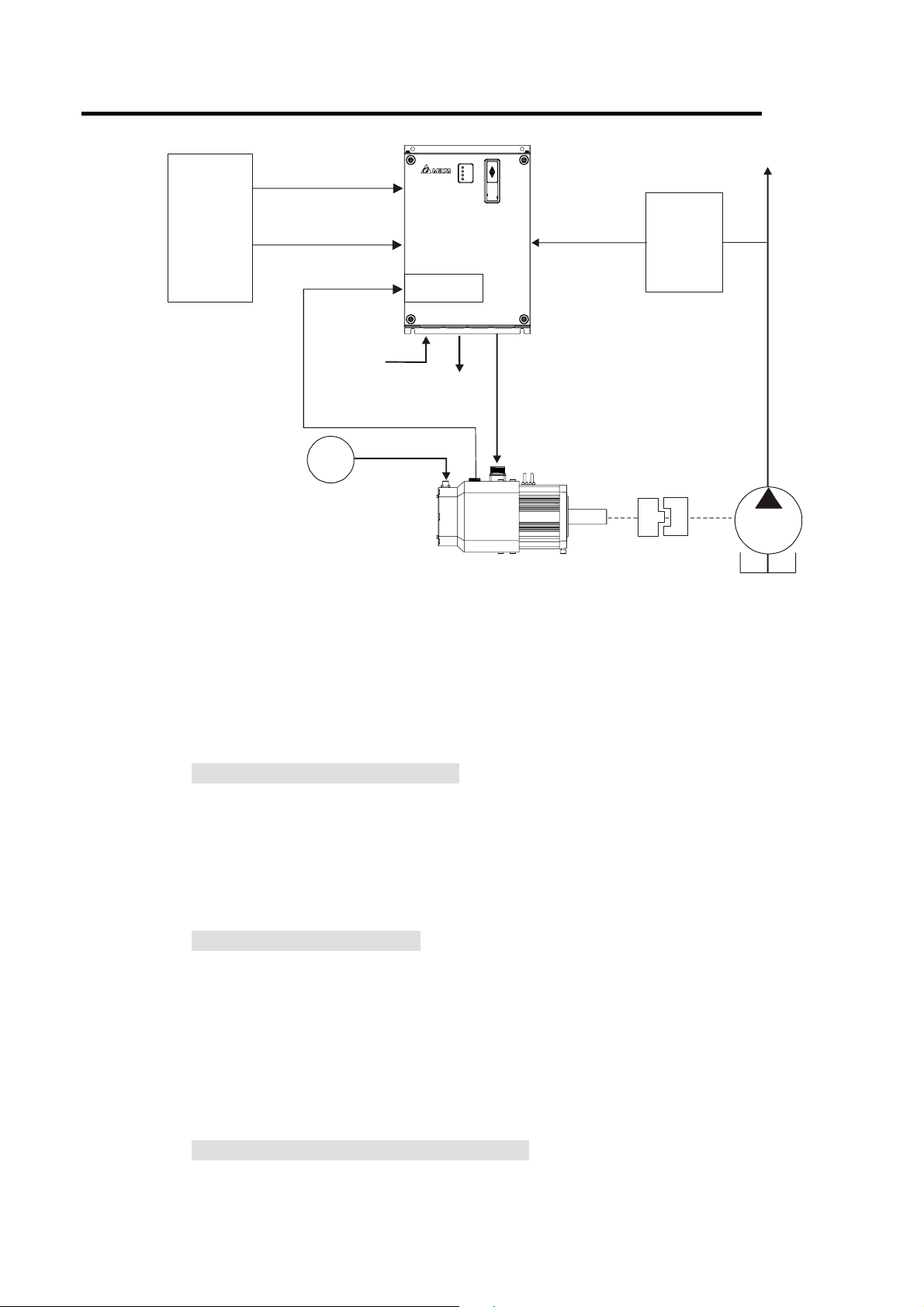

1-3 Overview of Hybrid Servo Systems

Pressure Command

(0~10V)

Injector

Contr ol l e r

Flow Rate Command

(0~10V)

RST

Power

Terminal

Encoder signal

AC

FAN

220V/380V

Del t a Hybrid

Servo

Dri v e

PG Card

U V W

Brake resistance/

Brake Unit

Pressur e

Feedback

(0~10V)

Pressu r e

Sensor

1-3-1 Selection of Hybrid Servo Drives and Motors

Due to the differences in the hydraulic system in practical applications, the following choice of

drives and motors is provided as a reference.

In the following example, a flow of 64L/min and maximum holding pressure of 175Bar are

used.

Oil

Pump

1. Pump Displacement per Revolution

Based on the maximum flow of the system (L/min), the pump displacement per revolution

(cc/rev) can be calculated.

Example: If the maximum flow of the system is 64L/min and the highest rotation speed of

the motor is 2000rpm, the displacement per revolution is 64/2000*1000 = 32

cc/rev.

2. Maximum Torque of the Motor

Based on the maximum pressure (Mpa) and pump displacement per revolution (cc/rev),

the maximum torque can be calculated.

Example: For the required maximum pressure of 17.5 Mpa and pump displacement per

revolution of 32cc/rev

Torque = 17.5*32*1.3/(2*pi) = 116 N-m, where the factor 1.3 is used to compensate the

total loss in the system.

3. Rated Torque and Rated Power of the Motor

At the maximum pressure for the holding pressure, the required torque should be 1.5

times of the motor’s rated torque or less (depending on the data provided by the motor’s

1-5

Page 13

manufacturer). Over such an operating condition, the over-temperature of the motor may

π

ω

−

=

easily occur. Let u s take the factor 1.5 as an example, i f the rated to rque of the motor is 77

N-m, the motor with a power of 12kW* and a rated speed of 1500 rpm can be chosen.

*The power of the motor is calculated by using

××

rpmmNTWP

)60/2()()(

4. Maximum Current of the Motor

Example: Check the parameter kt (Torque/A) in the motor’s specifications, if kt = 3.37, the

maximum current is approximately 116/3.37 = 34A at the maximum torque of

116 N-m.

5. Selection of Matched Hybrid Servo Drive

Example: Look up the over-load capability for each Hybrid servo drive in the product

specification chart

If the holding pressure is at the maximum pressure of 17.5 Mpa, and a pump of

32cc/rev is used, the required motor current is approximately 34A

For such a current value, the following models can be chosen

VFD075VL43A-J, the overload may occur within 20 sec.

VFD110VL43A-J, the overload may occur approximately after 60 sec.

NOTE

If there is no suitable motor that meets the specifications, a motor with a higher rated value can be used instead.

For any information about the Hybrid servo drives or any assistance in detailed configuration of your company's

products, please contact the manufacturer.

1-3-2 Selection of Pump for Hybrid Servo Motor

Select a pump with a suitable displacement based on the required flow rate and motor speed;

If low noise is required, you can choose the screw pump or internal gear type.If a high

volumetric efficiency is required, you can choose the piston pump or dual displacement

piston pump.

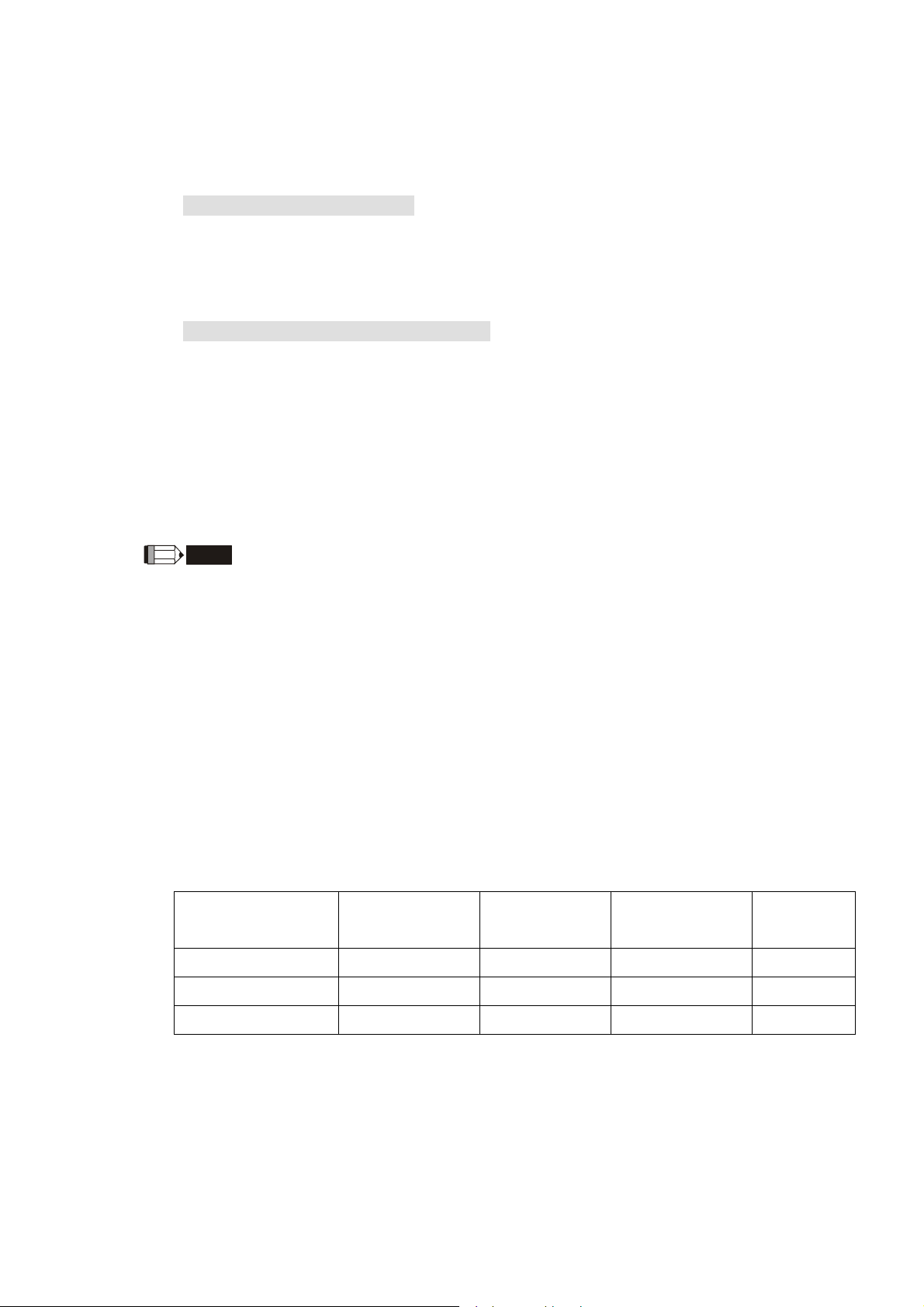

Comparison of Commonly Used Pump (This may vary for different pump manufacturers).

Type of Oil Pump

Internal Gear Pump Low Medium Medium Low

Piston Pump High Low Low High

Screw Pump Medium High High Medium

Volumetric

Flow Pulsation Rotation Speed Noise

Efficiency

1-6

Page 14

1. Use and Installation

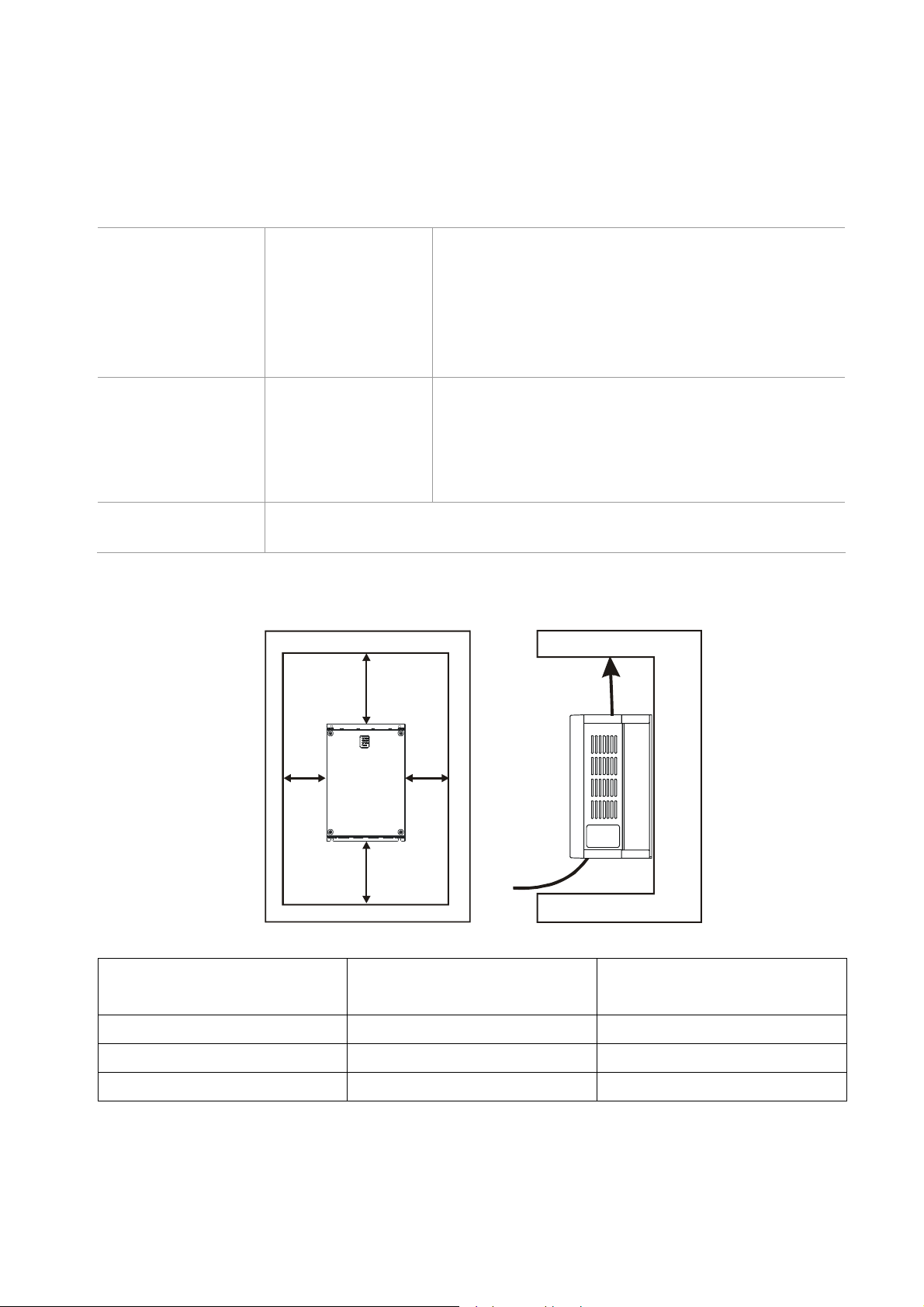

1-4 Product Installation

Please install the Hybrid servo drive under the following environmental conditions to ensure safety of

use:

Environmental

Condition for

Operation

Ambient temperature

Relative Humidity

Pressure

Installa tion Alti tude

Vibration

Environmental

Condition for Storage

and Transportation

Ambient temperature

Relative Humidity

Pressure

Vibration

Contamination

Level 2: Applicable to factory environment with low-to-medium contamination

Protection Level

Space for Installation

-10°C~ +45°C

<90% (non-condensing)

86 ~ 106 kPa

<1000m

<20Hz: 9.80 m/s

2

(1G) max; 20~50H:5.88 m/s2(0.6G)

max

-20°C~ +60°C (-4°F ~ 140°F)

<90% (non-condensing)

86 ~ 106 kPa

<20Hz: 9.80 m/s

2

(1G) max; 20 ~ 50Hz: 5.88 m/s

(0.6G) max

2

W

H

W

Air Flow

H

W

H

HP

mm (inch)

7.5-20HP

25-75HP

100HP

1. Mount the Hybrid servo drive vertically on a flat vertical surface object by screws. Other directions are

75 (3) 175 (7)

75 (3) 200 (8)

75 (3) 250 (10)

mm (inch)

not allowed.

2. The Hybrid servo drive will generate heat during operation. Allow sufficient space around the unit for

heat dissipation.

1-7

Page 15

3. The heat sink temperature may rise to 90°C when running. The material on which the Hybrid servo

drive is mounted must be noncombustible and be able to withstand this high temperature.

4. When Hybrid servo drive is installed in a confined space (e.g. cabinet), the surrounding temperature

must be within -10 ~ 40°C with good ventilation. DO NOT install the Hybrid servo drive in a space with

bad ventilation.

5. When installing multiple Hybrid servo drives in the same cabinet, they should be adjacent in a row with

enough space in-between. When installing one Hybrid servo drive below another one, use a metal

separation between the Hybrid servo drives to prevent mutual heating.

; Prevent fiber particles, scraps of paper, saw dust, metal particles, etc. from adhering to the heat

sink.

1-8

Page 16

1. Use and Installation

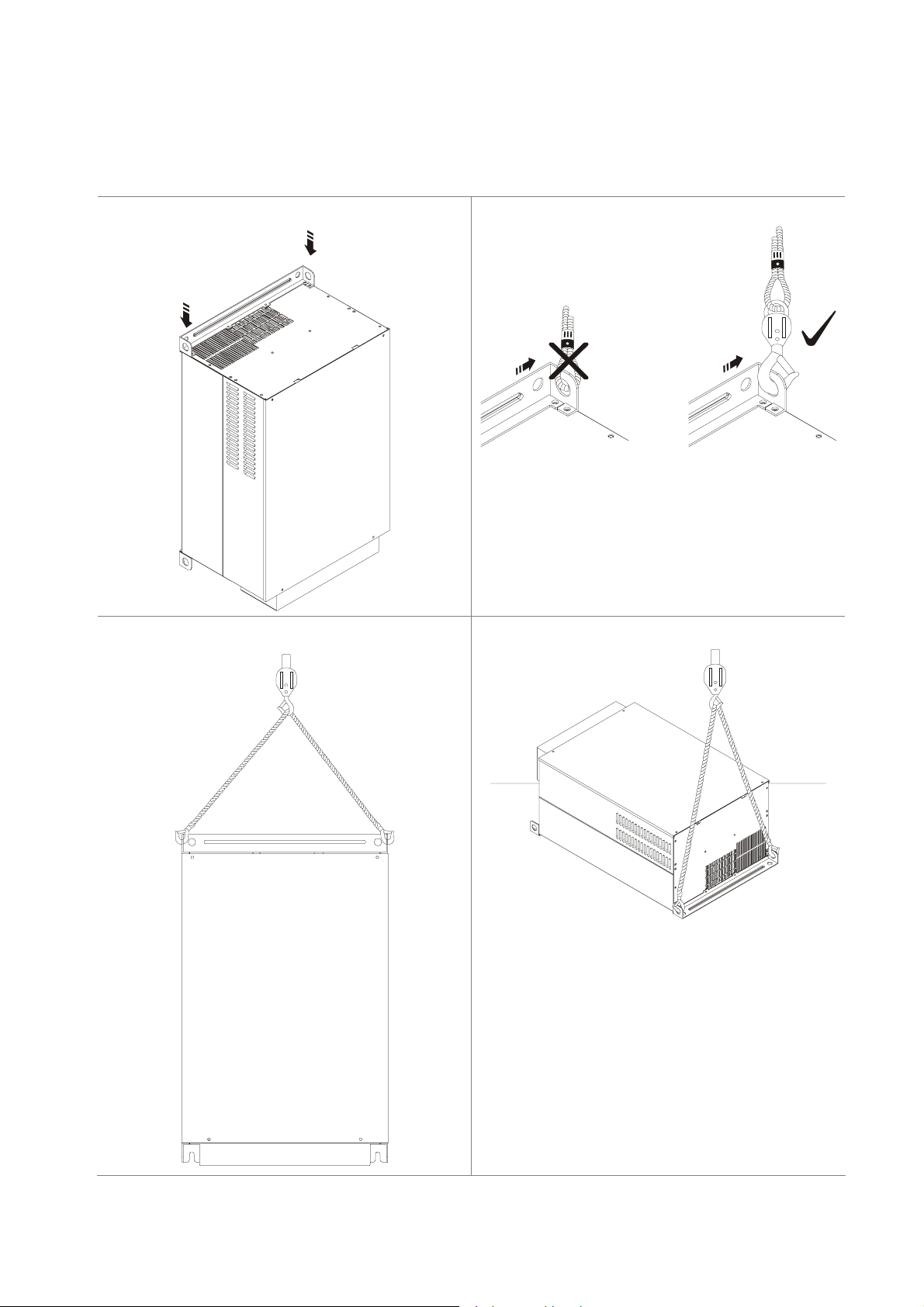

Lifting

Please carry only fully assembled Hybrid servo drives as shown in the following. Lift the Hybrid servo

drive by hooking the lifting hole.

40-100HP (Frame No. E)

Step 1

Step 2

Step 3

Step 4

1-9

Page 17

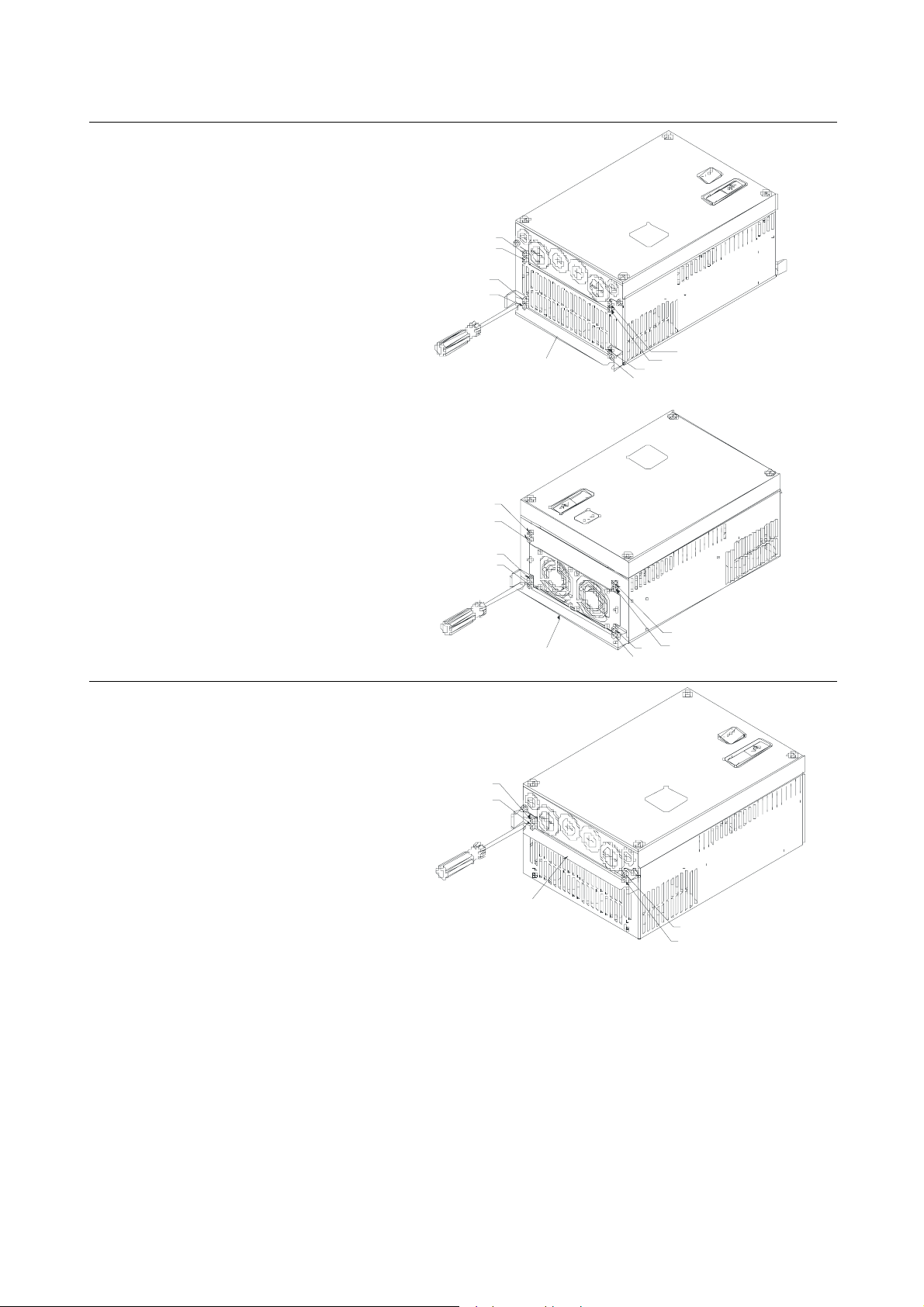

Flange Mounting

Step 1:

Please take out the 16 screws (8

screws for each top and bottom side of

the drive) and remove the fixed plate 1

and fixed plate 2) as shown in the

following figures.

1

2

5

6

fixed plate 1

1

2

5

6

fixed plate 2

3

4

7

8

3

4

7

8

Step 2:

place the 8 screws back in to secure

the fixed plate 1 and fixed plate 2 (as

shown in the following figures) with the

following torque.

Frame No. C: 14-17kgf-cm

[12.2-14.8in-lbf]

Frame No. D: 20-25kgf-cm

[17.4-21.7in-lbf]

Frame No. E: 20-25kgf-cm

[17.4-21.7in-lbf]

1

2

fixed plate 1

4

3

1-10

Page 18

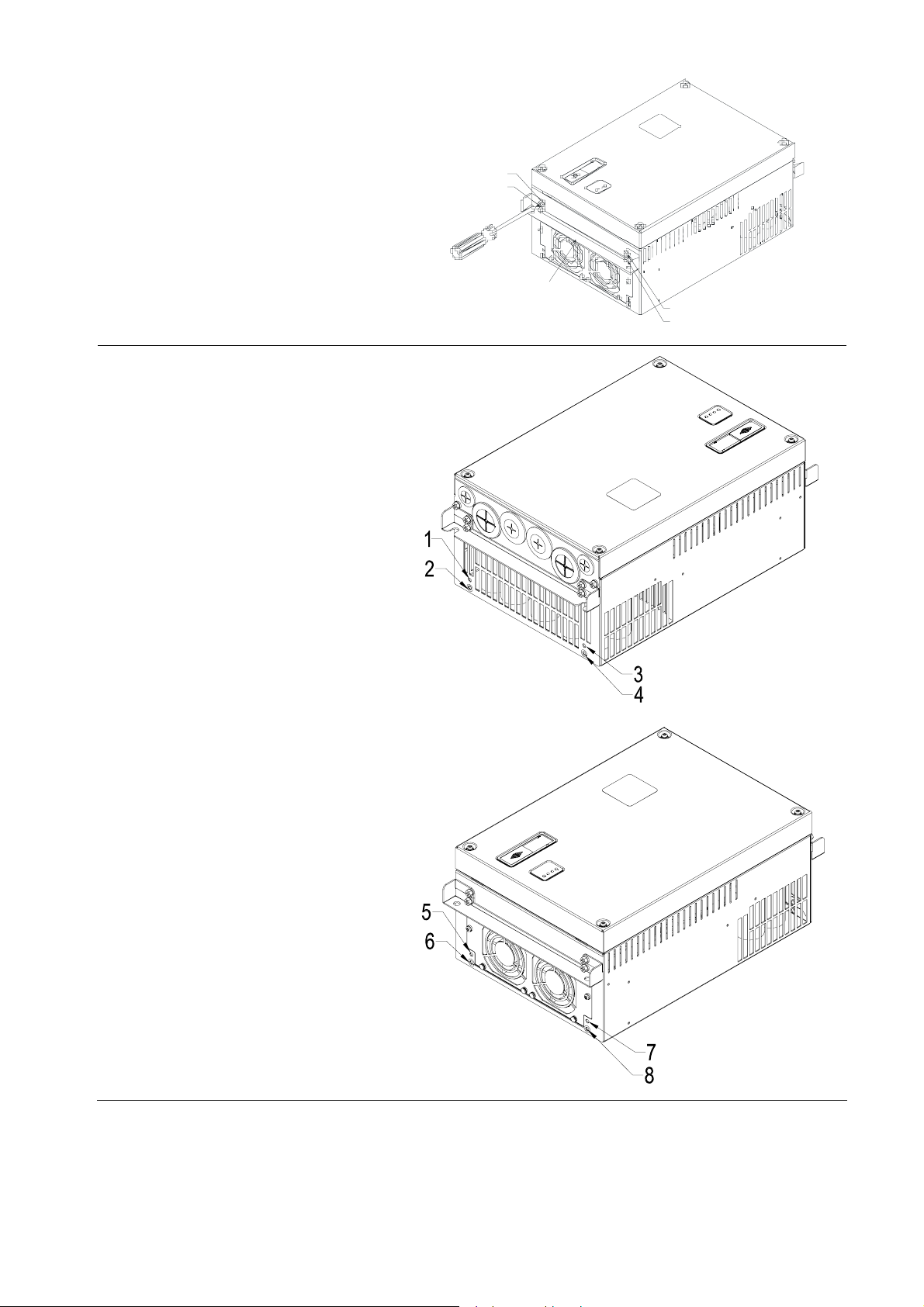

1. Use and Installation

1

2

Step 3:

Please notice that it doesn’t need to

put those 8 screws shown in

the following figures back to

the drive. Moreover, please

make sure that these 2

different fixed plates are put in

the correct side as shown in

the figures.

fixed plate 2

3

4

1-11

Page 19

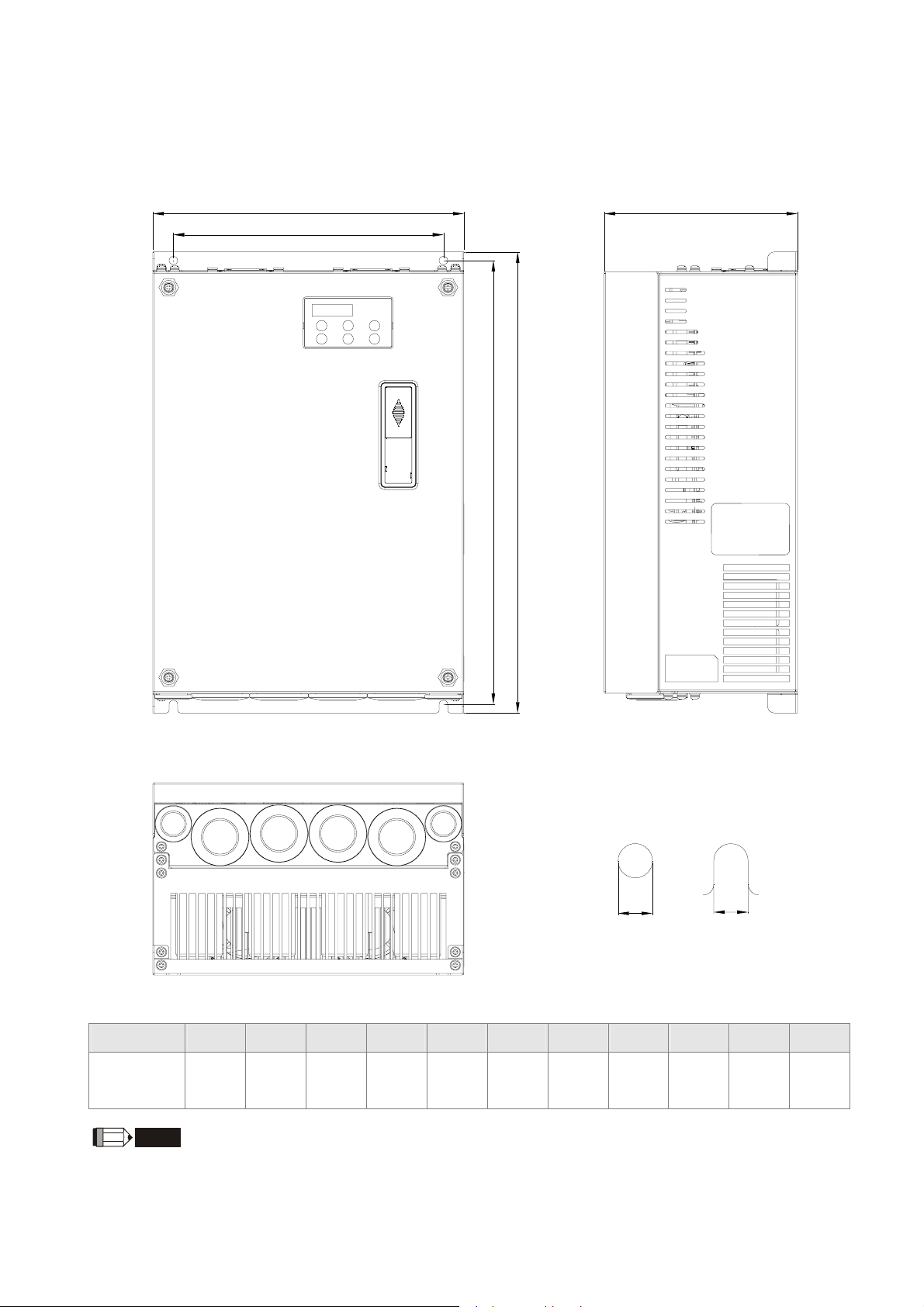

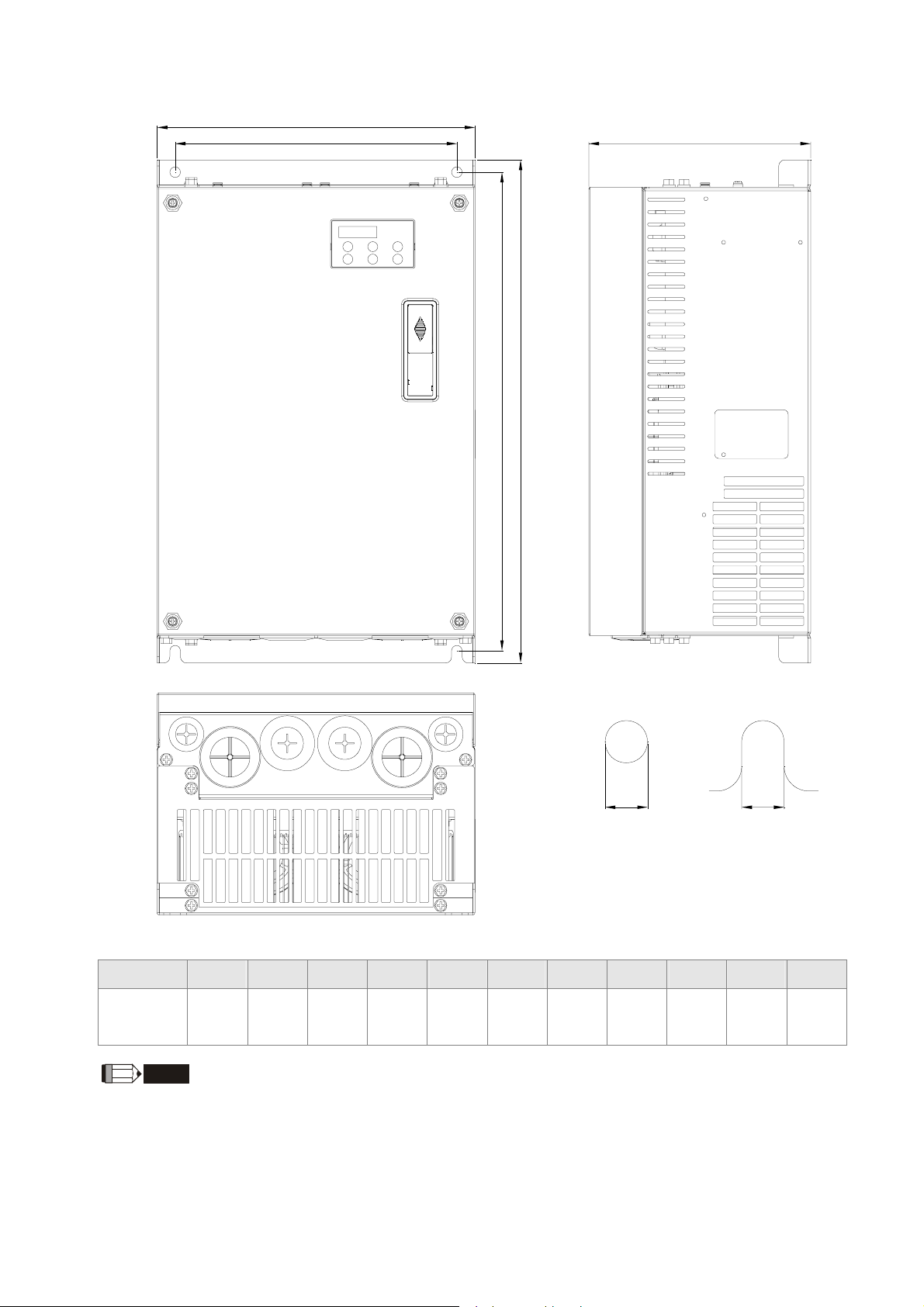

1-5 Product Dimensions

Frame No. C

W

W1

H1

D

H

S1

S1

Unit: mm [inch ]

Frame No. W W1 H H1 H2 H3 D Ø Ø1 Ø2 Ø3

C

235

[9.25]

NOTE

Frame No. C: VFD055VL23A/43A-J, VFD075VL23A/43A-J, VFD110VL23A/43A-J,

204

[8.03]

350

[13.78]

337

[13.27]

320

[12.60]

-

136

[5.35]

6.5

[0.26]

-

34

[1.34]

[0.87]

1-12

22

Page 20

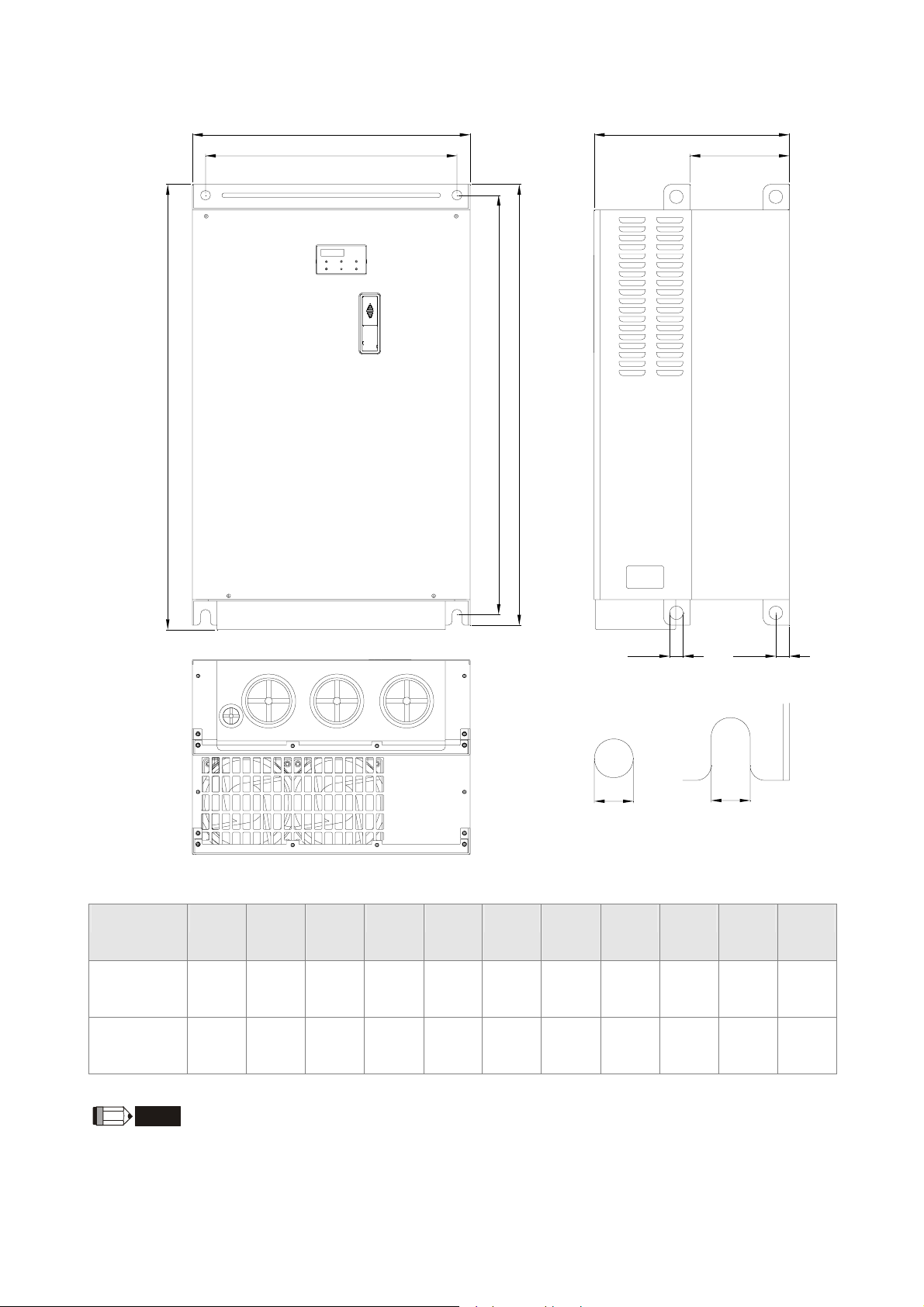

Frame No. D

W

H1

1. Use and Installation

DW1

H

S1S1

Unit: mm [inch ]

Frame No. W W1 H H1 H2 H3 D Ø Ø1 Ø2 Ø3

255.0

226.0

403.8

384.0

360.0

21.9

168.0

8.5

44

34

22

D

[10.04]

NOTE

Frame No. D: VFD150VL23A/43A-J, VFD185VL23A/43A-J, VFD220VL23A/43A-J,

[8.90]

[15.90]

[15.12]

[14.17]

[0.86]

[6.61]

[0.33]

[1.73]

[1.34]

[0.87]

1-13

Page 21

Frame No. E

W D

W1

D1

H

H2

H1

S1

S3

D2

S2

Unit: mm [inch ]

Frame No. W W1 H H1 H2 D D1: D2: S1 S2 S3

E1

370.0

[14.57]

370.0

335.0

[13.19]

335.0

-

595.0

589.0

[23.19]

589.0

560.0

[22.05]

560.0

260.0

[10.24]

260.0

132.5

[5.22]

132.5

18.0

[0.71]

18.0

13.0

[0.51]

13.0

13.0

[0.51]

13.0

[0.71]

E2

[14.57]

NOTE

Frame No. E1: VFD300VL43A-J, VFD370VL43A-J, VFD450VL43A-J,

Frame No. E2: VFD300VL23A-J, VFD370VL23A-J, VFD550VL43A-J, VFD750VL43A-J,

[13.19]

[23.43]

[23.19]

[22.05]

[10.24]

[5.22]

[0.71]

[0.51]

[0.51]

[0.71]

1-14

18.0

18.0

Page 22

2. Wiring

2. Wiring

2-1 Description of Wiring

2-2 Description of Terminals on Main Circuit

2-3 Description of Terminals on Control Circuit

After removing the front cover , check if the power and control terminals are clear. Be sure to observe the

following precautions when wiring.

; Make sure that power is only applied to the R/L1, S/L2, T/L3 terminals. Failure to comply may result in

damage to the equipments. The voltage and current should lie within the range as indicated on the

nameplate

; All the units must be grounded directly to a common ground terminal to prevent lightning strike or

electric shock.

; Please make sure to fasten the screw of the main circuit terminals to prevent sparks which is made by

the loose screws due to vibration

; It is crucial to turn off the Hybrid servo drive power before any wiring installation are

made. A charge may still remain in the DC bus capacitors with hazardous voltages even

if the power has been turned off therefore it is suggested for users to measure the

DANGER

remaining voltage before wiring. For your personnel safety, please do not perform any

wiring before the voltage drops to a safe level < 25 Vdc. Wiring installation with

remaining voltage condition may cause sparks and short circuit.

; Only qualified personnel familiar with Hybrid servo drives is allowed to perform

installation, wiring and commissioning. Make sure the power is turned off before wiring

to prevent electric shock.

; Make sure that power is only applied to the R/L1, S/L2, T/L3 terminals. Failure to

comply may result in damage to the equipment. The voltage and current should lie

within the range as indicated on the nameplate.

; Check following items after finishing the wiring:

1. Are all connections correct?

2. No loose wires?

3. No short-circuits between terminals or to ground?

2-1

Page 23

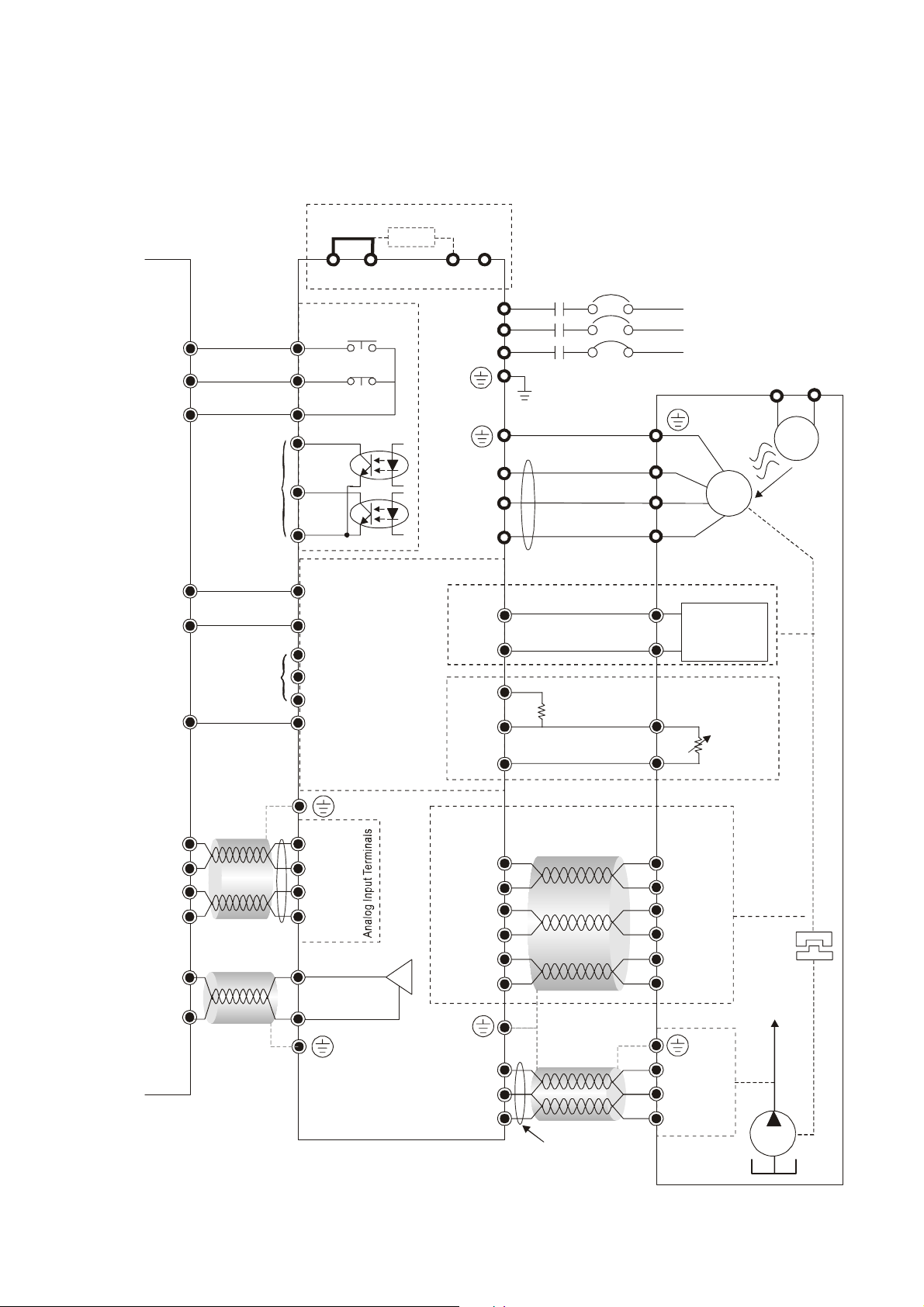

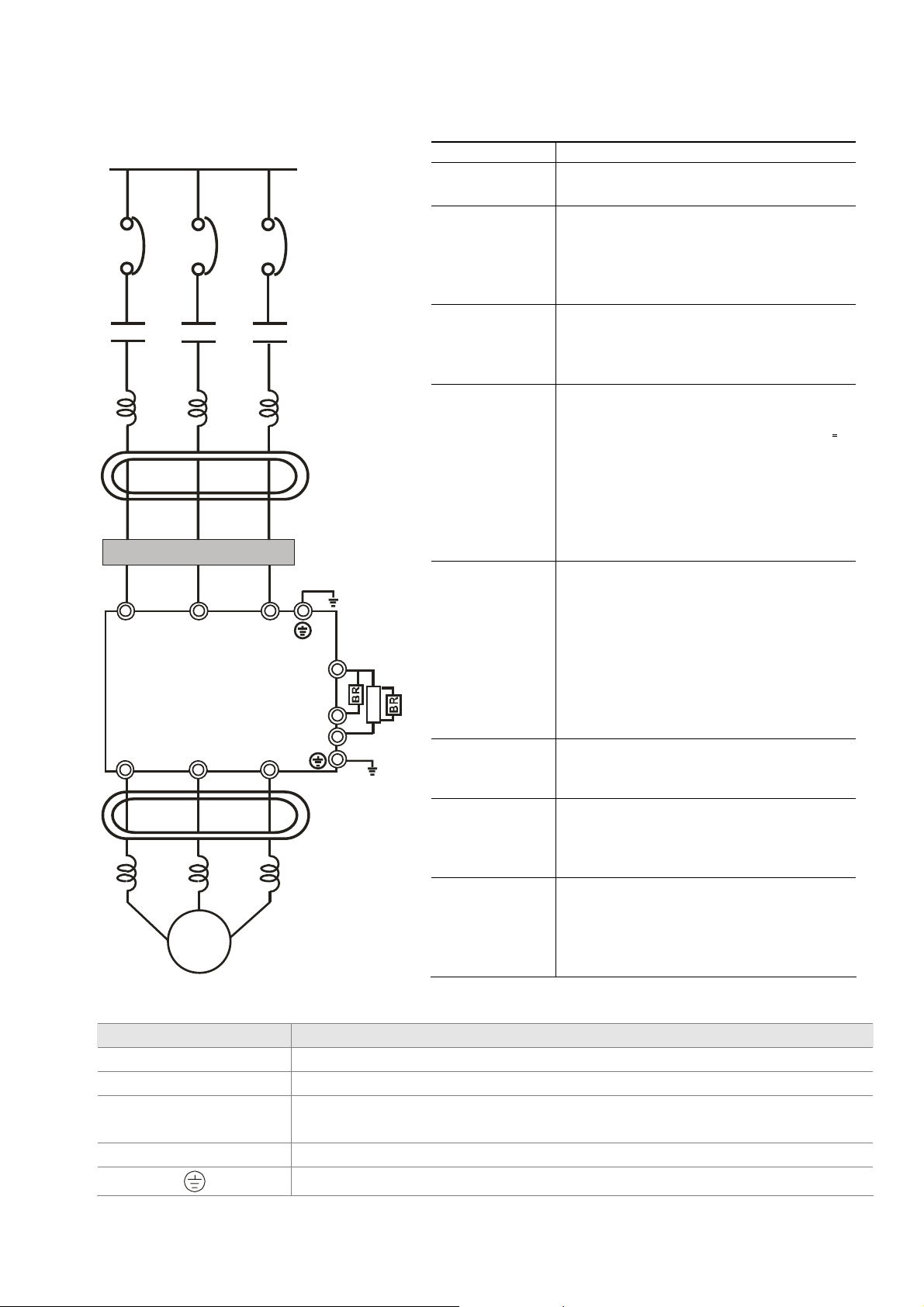

2-1 Description of Wiring

d

Users must connect wires according to the circuit diagrams on the following pages.

Standard wiring diagram of the VFD-VJ Hybrid servo drive in factory

Controller

Start Oil

Pump

Reset

r

o

t

a

c

i

d

n

I

n

o

i

t

c

n

u

f

l

a

M

Unused

Unused

Note 1*

+1

Output terminal

Brake Resistor (optional)

+2/B1

RA

RB

RC

MO1

MO2

MCM

input terminal

SON

RES

MI3

MI4

MI5

COM

B2

R

U

V

W

EMG

COM

+10V

AUI

ACM

-

L1

S

T

L2

L3

220V/380V

AC

FAN

e

U

V

M

3~

h

t

o

r

t

o

r

t

i

o

a

m

w

o

o

r

l

t

c

B

e

l

e

W

Note 3

*

Protection

switch for

electromotor

overheating

Note 4

*

R

Thermal

resistor

Pressure

Command

Flow Rate

Comman

Feedback

Signal

PI

ACM

QI

ACM

AFM

0~10Vdc/2mA

ACM

Set as output frequency

as manufactured

Note 2*

PG Card

14,16

13,15

+24V

ACM

PO

Resolver

R1

R2

5

4

7

9

S2

S4

S1

S3

+V

-V

output

Please use the

enclosed clips

Pressure Sensor

2-2

Page 24

Note 1*

A

A

2. Wiring

pplicable to the models of 22kW or below

(including 22kW models with internal brake unit)

Brake resist or (optional)

-

+1

+2/B1

B2

Note 2*

EMVJ-PG01R/PG02R

PG Card

14,16

13,15

5

4

7

9

Resolver

R1

R2

S2

S4

S1

S3

pplicable to the models of 30kW or above

(including 30kW models with optional internal

brake unit)

+1

Brake Unit

VFDB

+-

+2

B1

Brake resistor

B2

-

EMVJ-PG01U

PG Card

14,16

13,15

5

4

7

9

10

2

Encoder

Vp

GND

A

A

B

B

Z

Z

Note 3*

If the motor’s temperature protection switches are normally close type, please set the Parameter 03-04 to 4 first,

and then carry out the wiring. In this case, the drive may display the EF1 error message. Just clear the message.

Note 4*

Please select the R value in accordance with the thermistor specifications. The related trigger level

can be configured by the Parameters 02-08 to 02-10. If the thermistor of Model Number KTY84 is

used, select the R value as 2k (1/4W) ± 0.1%, and set the Parameter 02-11 with the value of 1.

2-3

Page 25

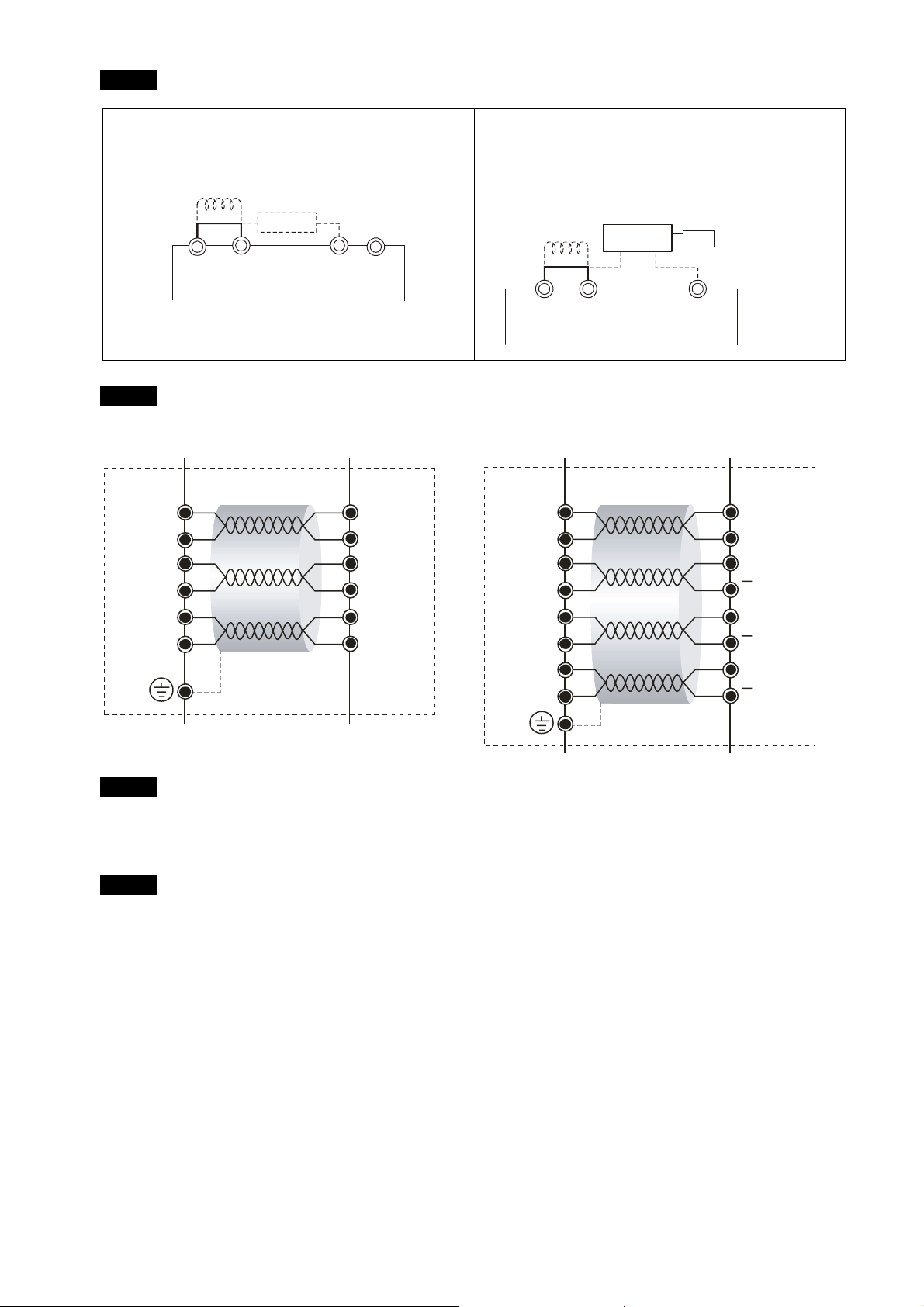

Multi-pump Operation Mode

r

e

Confluence Mode

Pressure

Command

Combine

Command

Hydraulic Pump

Activation

PI

QI

SON

PO

EMVJ-MF01

SG+

SG-

MO

Confluence-Diversion Mode

Master 1

Maste

Pressure

Command

Flow

Command

PI

PO

QI

U

V

W

Pressure

Feedback

Pressure

Feedback

*1

M

3~

Hydraulic

Outlet 1

*2

Operation Indication

Hydraulic

Outlet 2

*

2

Pressure

Feedback

M

3~

EMVJ-MF01

Master 2/ Slave

PI

PO

QI

Slav

U

V

W

SG+

SG-

SON

Pressure

Command

Flow

Command

IN.PWR.

SINK

*

3

MI

U

V

M

3~

M

3~

W

EMVJ-MF01

SG+

SG-

*

MO

IN.PWR.

SINK

*1 For firmware version 2.03 and above, the operating commands are given through the communications.

Therefore, the parameters for the slave is 01-01 = 2

*2 For firmware version 2.03 and above, it is not necessary to install this check valve. By selecting the slave

parameter 03-21 at the slave to see if the slave will perform the reverse depressurization. Parameters 03-21

= 0 for not performing the reverse depressurization.

*3 For firmware version 2.03 and above, the diversion/confluence signal is supplied to only Master 2/Slave. It is

not necessary to supply the signal to Master 1.For the following control arrangement, it is necessary to

disconnect the communications during diversion.

1

Operation Indication

Confluence/Diversion signals

U

V

MI

W

EMVJ-MF01

SG+

SG-

SON

IN.PWR.

SINK

2-4

Page 26

2. Wiring

i

t

- .

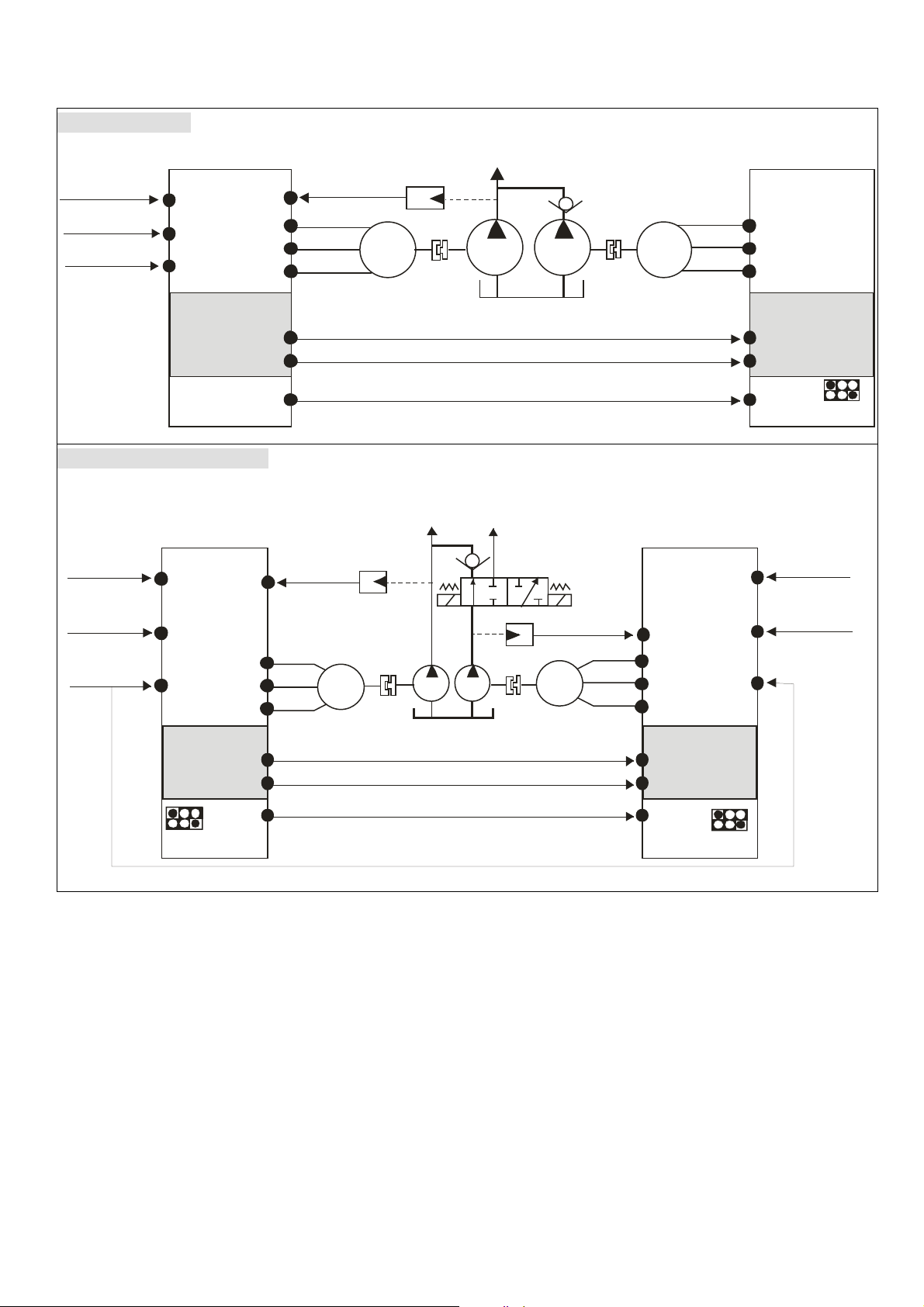

When the signals are confluence, the communication will be a short circuit

When the signals are diversion, the communication becomes an open circu

Pressure

Command

Flow

Command

PI

MI

Pressure

Command

Flow Command

Combined/Divert

Signals

SG+

SG-

PI

QI

Mater 1

03 13 1

-=

PO

M M

The wiring of main circuit and control circuit should be separated to prevent

;

SG+

SG-

Slave Slave

03 13 2

-=

Hydraulic outlet 1

SG+

Hydraulic outlet 2

03 13 2

-=

SG-

SG+

Mater 3

03 13 3

-=

M M

SG-

QI

PO

erroneous actions.

Please use shield wire for the control wiring and not to expose the peeled-off net in

;

front of the terminal.

Please use the shield wire or tube for the power wiring and ground the two ends of

;

the shield wire or tube.

Make sure that the leads are connected correctly and the AC drive is properly

;

grounded. (Ground resistance should not exceed 0.1Ω.)

Use ground leads that comply with local regulations and keep them as short as

;

possible.

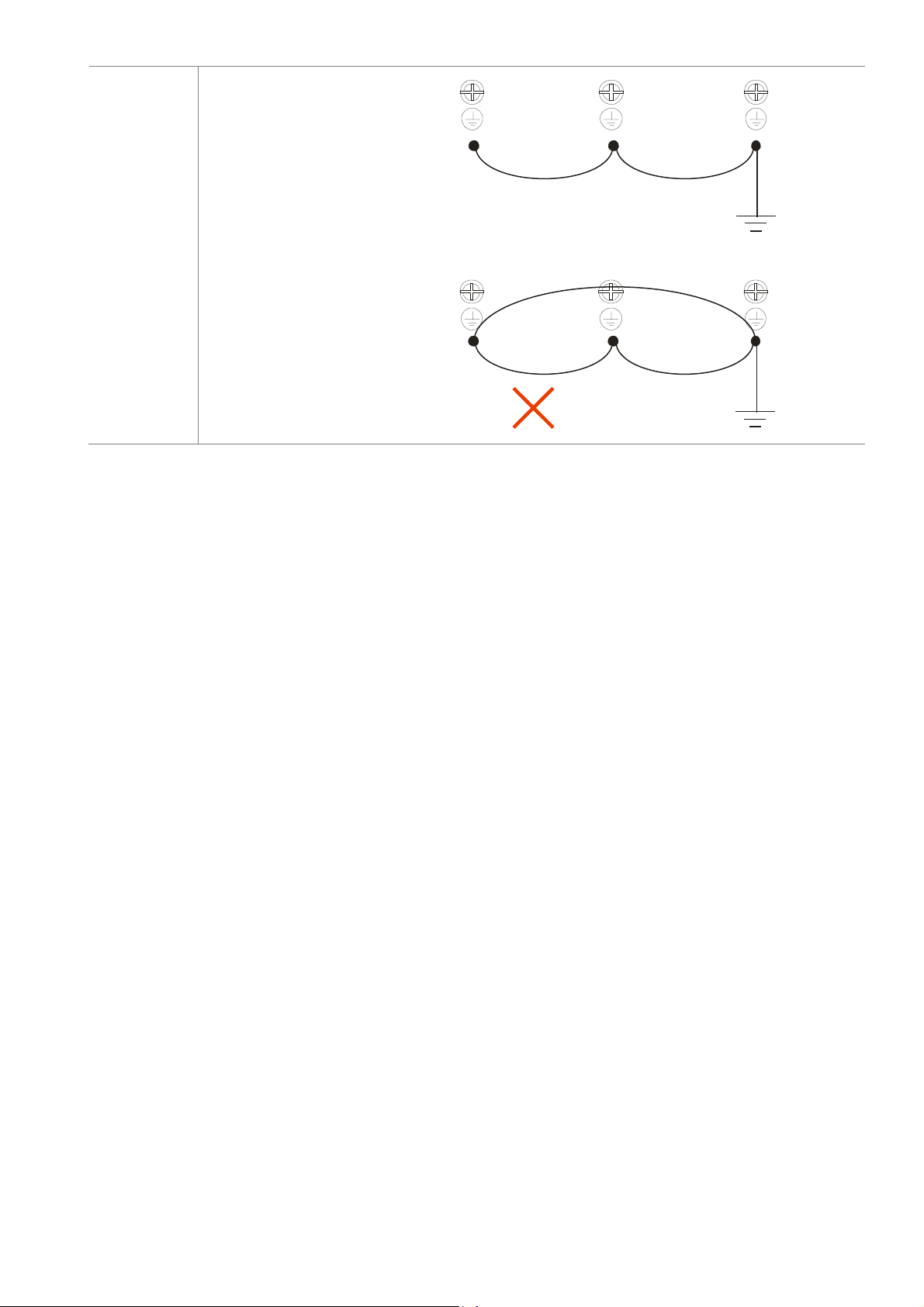

Multiple VFD-VJ units can be installed in one location. All the units should be

;

grounded directly to a common ground terminal, as shown in the figure below.

Ensure there are no ground loops.

Grounding terminals

Excellen

2-5

Page 27

Grounding terminals

good

Grounding terminals

Not allowed

2-6

Page 28

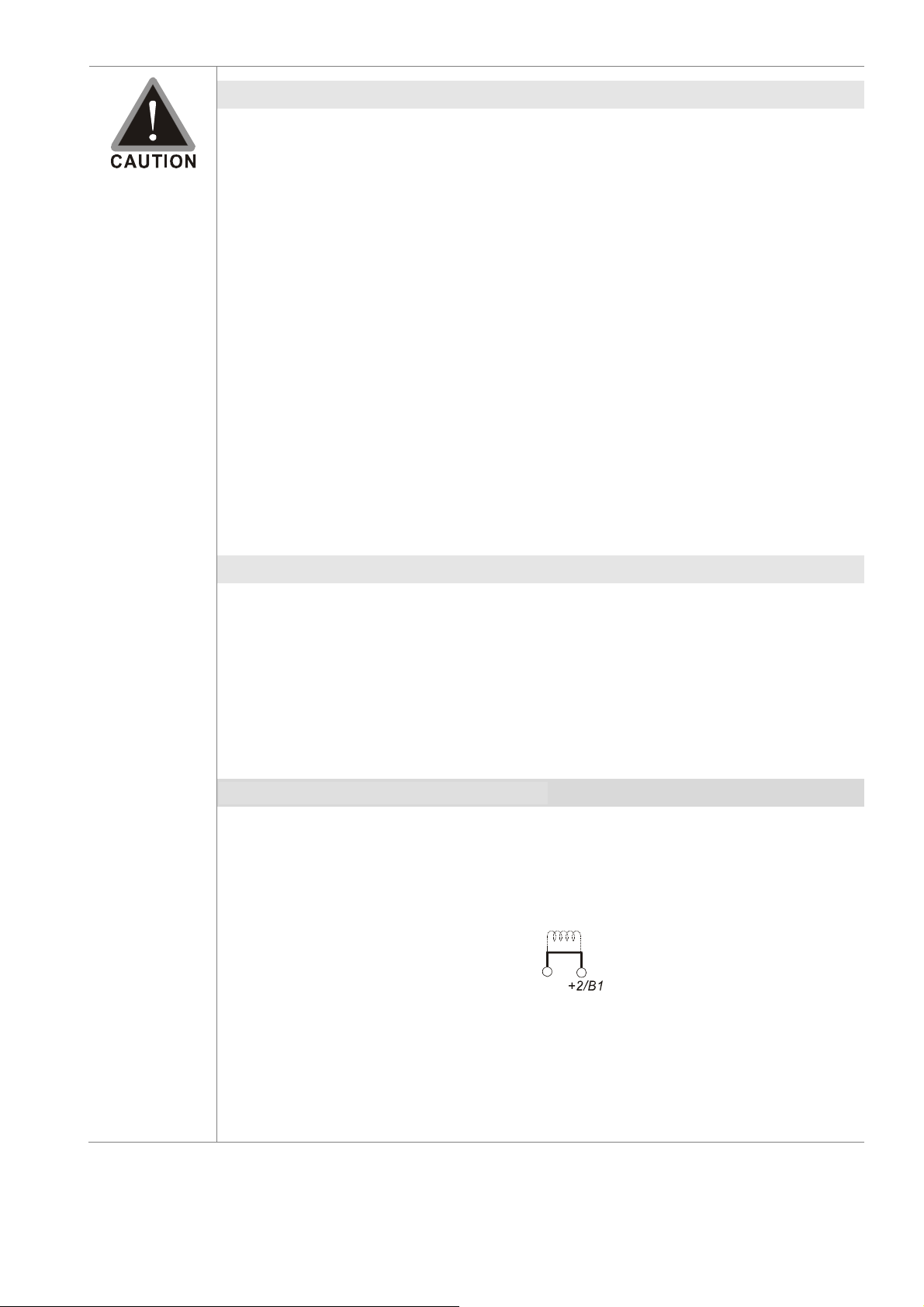

2. Wiring

y

≤

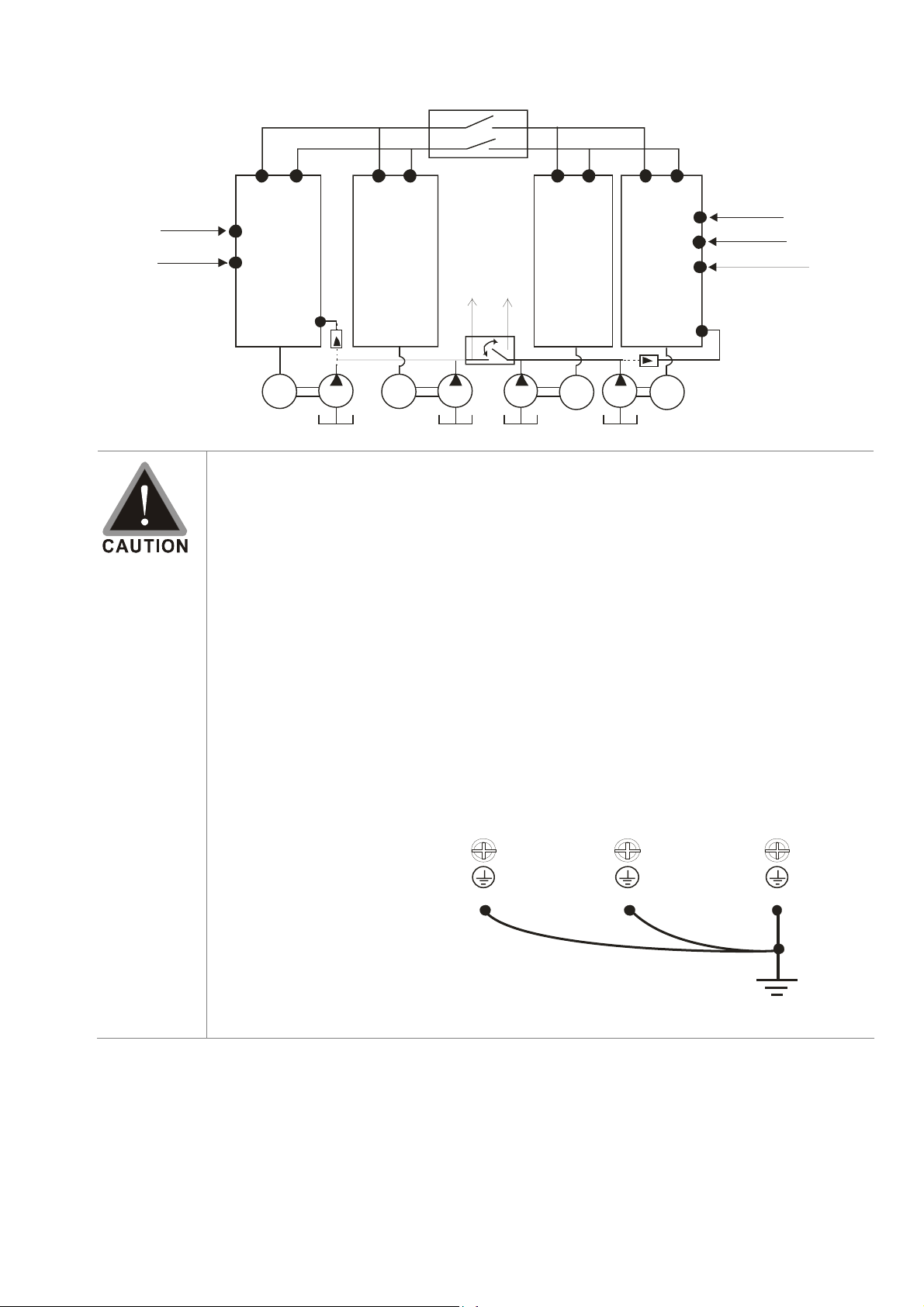

2-2 Description of Terminals on Main Circuit

Power Suppl

EMI Filter

R/L1 S/L2

U/T1 V/T2

Motor

T/L3

W/T3

FUSE/NFB

Magnetic

contactor

Input AC

Line Reactor

Zero-phase

Reactor

+/B1

B2

Output AC

Line Reactor

Br ake resi st er

-

Zero-phase

Reactor

Br ake Un it

VFDB

Items Explanations

Power supply

Fuse/NFB

(Optional)

Magnetic

contactor

(Optional)

Input AC Line

Reactor

(Optional)

Zero-phase

Reactor

(Ferrite Core

Common

Choke)

(Optional)

EMI filter

(Optional)

Brake Resistor

(Optional)

Output AC Line

Reactor

(Optional)

Please follow the specific power supply

requirements shown in Chapter 01.

There may be an inrush current during

power up. Please check the chart of

Appendix A-2 and select the correct

fuse with rated current. Use of an NFB

is optional.

Please do not use a Magnetic

contactor as the I/O switch of the AC

motor drive, as it will reduce the

operating life cycle of the AC drive.

Used to improve the input power factor,

to reduce harmonics and provide

protection from AC line disturbances.

(surges, switching spikes, short

interruptions, etc.). AC line reactor

should be installed when the power

supply capacity is 500kVA or more and

exceeds 6 times the inverter capacity,

or the mains wiring distance

10m.

Zero phase reactors are used to

reduce radio noise especially when

audio equipment is installed near the

inverter. Effective for noise reduction

on both the input and output sides.

Attenuation quality is good for a wide

range from AM band to 10MHz.

Appendix A specifies the zero phase

reactor. (RF220X00A)

To reduce electromagnetic

interference, please refer to Appendix

A for more details.

Used to reduce the deceleration time of

the motor. Please refer to the chart in

Appendix A for specific Brake

Resistors.

Motor surge voltage amplitude

depends on motor cable length. For

applications with long motor cable

(>20m), it is necessary to install a

reactor at the inverter output side.

Motor

Terminal Identification Description

R/L1, S/L2, T/L3 AC line input terminals 3-phase

U/T1, V/T2, W/T3 Output terminals of the Hybrid servo drive that are connected to the motor

+1, +2/B1

Connections for DC reactor to improve the power factor. It needs to remove

the jumper for installation. (DC reactor is built in for models ≧ 22KW)

+2/B1, B2 Connections for Brake Resistor (optional)

Earth connection, please comply with local regulations..

2-7

Page 29

Power supply input terminals for the main circuit:

Do not connect 3-phase model to one-phase power. R/L1, S/L2 and T/L3 has no

;

phase-sequence requirement, it can be used upon random selection..

It is recommend to add a magnetic contactor (MC) to the power input wiring to

;

cut off power quickly and reduce malfunction when activating the protection

function of the AC motor drive. Both ends of the MC should have an R-C surge

absorber.

Fasten the screws in the main circuit terminal to prevent sparks condition made

;

by the loose screws due to vibration.

Please use voltage and current within the specification.. Please refer to Chapter

;

1 for the specifications.

When using a general GFCI (Ground Fault Circuit Interrupter), select a current

;

sensor with sensitivity of 200mA or above and not less than 0.1-second

operation time to avoid nuisance tripping.

Please use the shield wire or tube for the power wiring and ground the two ends

;

of the shield wire or tube.

Output terminals for the main circuit:

When it needs to install the filter at the output side of terminals U/T1, V/T2, W/T3

;

on the Hybrid servo drive. Please use inductance filter. Do not use

phase-compensation capacitors or L-C (Inductance-Capacitance) or R-C

(Resistance-Capacitance), unless approved by Delta..

DO NOT connect phase-compensation capacitors or surge absorbers at the

;

output terminals of Hybrid servo drives.

The terminals of the DC reactor [+1, +2], terminals at DC side [+1, +2/B1]

This is the terminals used to connect the DC reactor to improve the power factor.

;

For the factory setting, it connects the short-circuit object. Please remove this

short-circuit object before connecting to the DC reactor.

DC react or

Jumper

+1

For those models without built-in brake resistor, please connect external brake

;

unit and brake resistor (both of them are optional) to increase brake torque.

DO NOT connect [+1, -], [+2, -], [+1/DC+, -/DC-] or brake resistor directly to

;

prevent drive damage.

2-8

Page 30

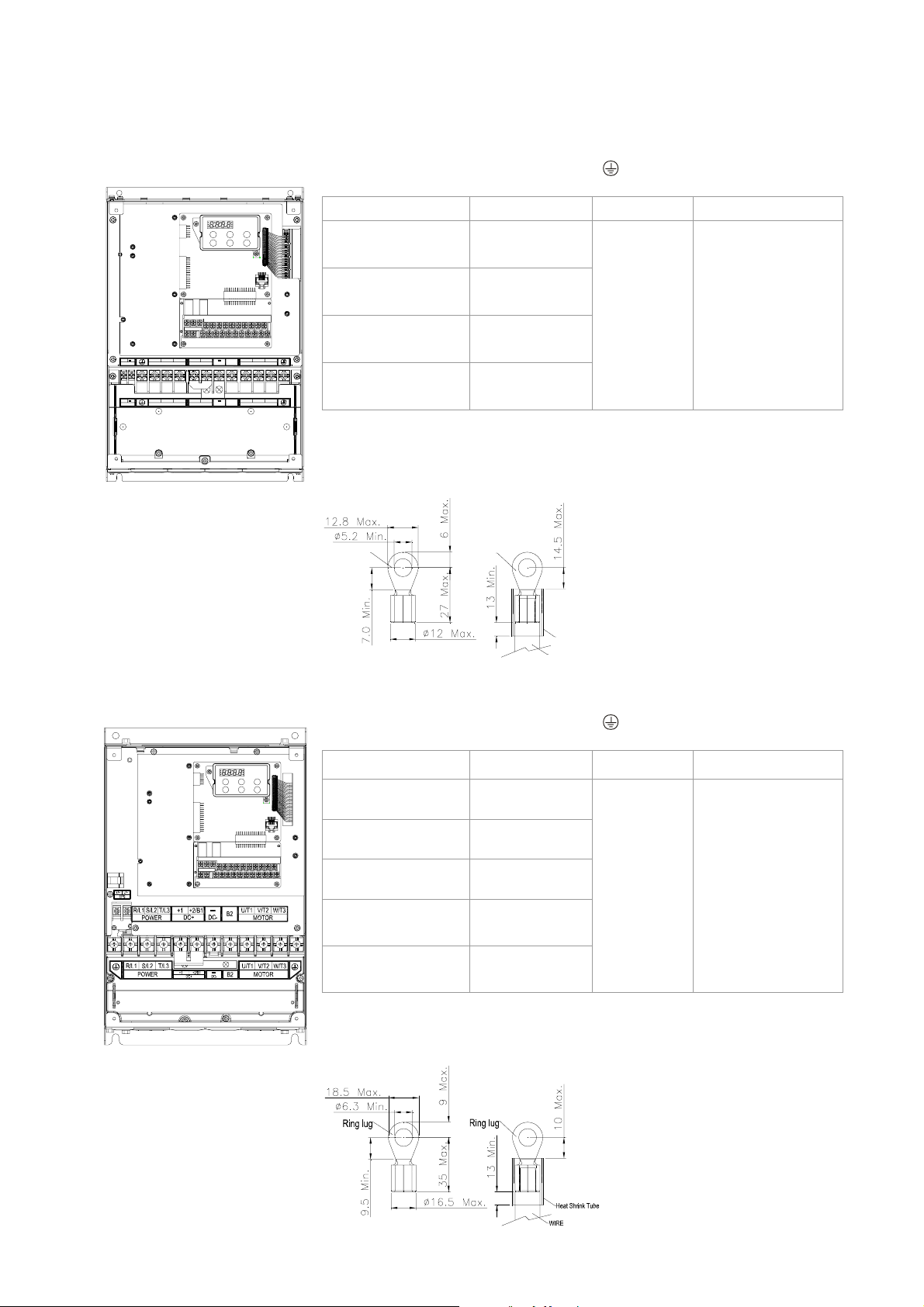

Specifications of the Terminals on the Main Circuit

2. Wiring

Frame No. C

/~ U/T1

+/~ R/L1 S/L2 T/L3B2+1

EPS

/~ U/T1 V/T2 W/T3

+/~ R/L1 S/L2 T/L3

EPS

+2/B1

DC+ DC-

POWER

+1

+2/B1

DC+

POWER MOTOR

Terminals on the main circuit:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

, +1, +2/B1, -, B2

Model Wire Diameter Torque Wire Type

VFD055VL23A-J

VFD110VL43A-J

VFD055VL43A-J

VFD075VL43A-J

VFD110VL23A-J

W/T3

V/T2

MOTOR

B2

DC-

VFD075VL23A-J

Wire Type: Stranded copper only, 75°C

The right figure below shows the specifications of the UL certified insulation heat

shrink tubing which can withstand 600V, YDPU2.

10-6 AWG.

(5.3-13.3mm

12-6 AWG.

(3.3-13.3mm

6 AWG.

(13.3mm

2

8-6 AWG.

(8.4-13.3mm

2

)

2

)

)

2

)

30kgf-cm

(26in-lbf)

Stranded copper

only,75°C

Ring lug

Ring lug

Frame No. D

Heat Shr ink Tube

WIRE

Terminals on the main circuit:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

, +1, +2, -

Model Wire Diameter Torque Wire Type

VFD150VL43A-J

VFD185VL43A-J

VFD150VL23A-J

VFD185VL23A-J

VFD220VL43A-J

VFD220VL23A-J

Wire Type: Stranded copper only, 75°C

The right figure below shows the specifications of the UL certified insulation heat

shrink tubing which can withstand 600V, YDPU2.

8-2 AWG.

(8.4-33.6mm

4-2 AWG.

(21.1-33.6mm

3-2 AWG.

(26.7-33.6mm

6-2AWG

(13.3-33.6mm

3-2AWG

(26.7-33.6mm

2

)

2

)

2

)

(43.4 lbf-in)

2

)

2

)

50Kgf-cm

Stranded copper

only,75°C

2-9

Page 31

Frame No. E

Terminals on the main circuit:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

, +1, +2, -

Model Wire Diameter Torque Wire Type

VFD300VL43A-J

VFD370VL43A-J

VFD450VL43A-J

VFD300VL23A-J

VFD370VL23A-J

VFD550VL43A-J

4-2 AWG.

(21.2-33.6mm

2

)

200kgf-cm

(173in-lbf)

57kgf-cm

(49in-lbf)

Stranded

copper

only,

75°C

VFD750VL43A-J

Wire Type: Stranded copper only, 75°C

2-10

Page 32

2. Wiring

A

2-3 Description of Terminals on Control Circuit

Description of SINK (NPN)/SOURCE (PNP) Mode Selection Terminals

1

Sink Mode

used with internal power (+24Vdc)

SON

EMG

RES

COM

3

Sink Mode

with external power

SON

EMG

+24V

2

Source Mode

used with internal power (+24Vdc)

SON

EMG

RES

COM

4

Source Mode

with external power

SON

EMG

+24V

RES

+

COM

external power +24V

The Position of External Terminals

RB

RA

RC

MCM

MO1

SON

MO2

+24V

EMG

RES

external power +24V

MI4

MI3

MI5

COM

+10V

RES

+

COM

Sink/Source

mode switch

PI ACMQI

AUI

FM

+24V

PO

DCM

ACM

+24V

+E24V

Frame No. Torque Wire Diameter

C, D, E 8 kgf-com (6.9 in-lbf) 22-14 AWG (0.3-2.1mm2)

Terminal: 0V/24V 1.6 kgf-com(1.4 in-lbf) 30-16 AWG (0.051-1.3mm2)

2-11

Page 33

Terminal Features Factory Setting (NPN Mode)

SON Run-Stop Terminal SON-COM: ON for Running; OFF for Stop

EMG External error input External error input

RES Reset from error Reset from error

MI3 Multi-function input selection 3

MI4 Multi-function input selection 4

MI5 Multi-function input selection 5

COM

+E24V

DCM

Common ground (Sink) for digital

control signals

Common source for digital

control signals

Common ground (Sink) for digital

control signals

RA Error terminal 1 (Relay N.O. a)

RB Error terminal 1 (Relay N.C. b)

Command contact for

RC

multi-function output terminals

(Relay)

MO1

Multi-function output terminal 1

(photocoupler)

Configured as no function in factory

When it is ON, the input voltage is 24Vdc (Max:30Vdc)

and then input impedance is 3.75k; when it is OFF, the

tolerable leakage current is 10A.

Common ground for multi-function input terminals

+24V 80mA

Common ground for multi-function input terminals

Resistive load

5A(N.O.)/3A(N.C.) 240VAC

5A(N.O.)/3A(N.C.) 24VDC

Inductive load

1.5A(N.O.)/0.5A(N.C.) 240VAC

1.5A(N.O.)/0.5A(N.C.) 24VDC

The Hybrid servo drive sends various monitoring

signals by means of open-collector configuration.

Max: 48Vdc/50mA

MO1

~

MO2

MO2

MCM

PO

PI

QI

Multi-function output terminal 2

(photocoupler)

Common ground for

Multi-function output terminal

(photocoupler)

PO/PI/QI

ACM

PO/PI/QI circuit

internal circuit

internal circuit

MCM

Max 48Vdc 50mA

Pressure feedback

Impedance: 200k Resolution: 12 bits

Range: 0 – 10V = 0 – the maximum pressure feedback

value (Parameter 00-08)

Pressure Command

Impedance: 200k Resolution: 12 bits

Range: 0 – 10V = 0 – the maximum pressure command

value (Parameter 00-07)

Flow rate command

Impedance: 200k Resolution: 12 bits

Range: 0 – 10V = 0 – the maximum flow rate

AUI Analog Voltage Impedance: 11.3k

2-12

Page 34

2. Wiring

+10V

AUI

-10V

AUI circuit

internal circuit

+10V Power supply for configuration

Power supply terminal for the

+24V

pressure sensor

AFM

AFM

ACM

Resolution: 12 bits

Range: -10 ~ +10VDC

Power supply for analog configuration +10Vdc 20mA

(variable resistance 3~5k)

Power supply for the pressure sensor +24Vdc 100mA

Impedance: 16.9k (voltage output)

Output current: 20mA max

Resolution: 0 – 10V for the maximum operating

frequency

Range: 0 – 10V

Function Setting: Parameter 00-05

Common ground for analog

Common ground terminal for analog control signals

ACM

control signals

* Specifications of analog control signal wire: 18 AWG (0.75 mm

2

), with shielded twisted pair

Analog Input Terminals (PO, PI, QI, AUI, ACM)

; The maximum input voltage of PI, PO, and QI cannot exceed +12V and no more than +/-12V for

AUI. Otherwise, the analog input function may become ineffective.

; Analog input signals are easily affected by external noise. Use shielded wiring and keep it as short

as possible (<20m) with proper grounding. If the noise is inductive, connecting the shield to

terminal ACM can bring improvement.

; If the analog input signals(pressure sensor) are affected by noise from the Hybrid servo drive,

please connect a capacitor and ferrite core as indicated in the following diagrams:

wind each wires 3 times or more around the core

Output

C

-V

PO

ACM

ferrite core

Transistor Output Terminals (MO1, MO2, MCM)

; Make sure to connect the digital outputs to the right polarity.

; When connecting a relay to the digital outputs connect a surge absorber across the coil and check

the polarity.

2-13

Page 35

3. Control Panel and

Machine Adjustment Procedure

3-1 Description of Control Panel

3-2 Machine Adjustment Procedure

; Please re-check if the wiring is correct before start running the machine. Particularly,

make sure that the output terminals of the Hybrid servo drive, U/T1, V/T2, and W/T3,

3. Machine Adjustment Procedure

must not be used as power input terminals. Make sure that the good ground terminal

is grounded.

; It is not allowed to operate the switches with wet hands.

; Make sure that there is no short-circuit or ground short circuit conditions between the

terminals or exposed live parts.

; The power switch can be turned on only with the cover installed.

; If any fault occurs during the operation of the Hybrid servo drive and the motor, stop the

machine immediately, and refer to “Troubleshooting” to check the cause of the faulty

condition. After the Hybrid servo drive stop its output but the main circuit power

terminals L1/R, L2/S, and L3/T are not disconnected, if the operator touches the output

terminals U/T1, V/T2, and W/T3 of the Hybrid servo drive, electric shock may occur.

3-1

Page 36

3-1 Description of Control Panel

Appearance of Keypad Control Panel KPVJ-LE01

Run key

start AC drive

operation

Stop / Rese t ke y

Stop driver operation

and reset in case of

anomaly

Status Display

1

Display the drive r’s current status.

LED Display

2

Indicates frequency, voltage, cur rent, user defined units and etc.

UP and DOWN Key

3

Set the parameter number and changes the numerical da ta, such as Master Frequenc

MODE

4

Change between different display mode.

ENTER

5

Used to enter/modify programming parameters.

Description of Displayed Function Items

Displayed Item Description

The current frequency set for the Hybrid servo drive

The frequency Hybrid servo drive actually delivers to the motor

The user-defined physical quantity (Parameter 00-04)

Load current

Forward command

Reverse command

Displays the selected parameter

Display the parameter value

Display the external fault

3-2

Page 37

If the “End” message (as shown in the left figure) is displayed on the display

area for about one second, it means that data has been accepted and

automatically stored in the internal memory

If the setting data is not accepted or its value exceeds the allowed range, this

error message will be displayed

Keypad Panel Operation Procedure

Setting Mode

START

3. Machine Adjustment Procedure

GO START

NOTE:

Setting parameters

NOTE

In the selection mode, press

:

In the parameter setting mode, you can press

To shift data

Setting direction

to set the parameter s.

Success to

set param ete r.

(When operation so urce is digital keypad)

or

Input da ta error

to return the selecting mode.

3-3

Page 38

List of Characters Shown on the Seven-segment Display of the Digital

Keypad Panel

Numeric 0 1 2 3 4 5 6 7 8 9

Seven-segment Display

English Letter A a B C c D d E e F

Seven-segment Display

English Letter f G g H h I i J j K

Seven-segment Display

English Letter k L l M m N n O o P

Seven-segment Display

English Letter p Q q R r S s T t U

Seven-segment Display

- -

-

-

- - -

-

-

-

- -

-

-

English Letter u V v W w X x Y y Z

Seven-segment Display

English Letter z

Seven-segment Display

- - - - - -

-

-

3-4

Page 39

3-2 Machine Adjustment Procedure

Perform the following operation procedure by using the Digital Keypad (KPVJ-LE01/

KPV-CE01) or the monitoring software VFD-Explorer

Step 1. Enter the motor’s parameters

Restore the factory default values by setting the Parameter 00-02 = 10

Reset parameter settings

Setting value

3. Machine Adjustment Procedure

of Parameter

10: Reset parameter values

00-02

Please make sure if the command source has been restored to the factory default (operation

by external terminals)

If the KPV-CE01 is used, the Parameter is 01-01=0

Source of operation command

Setting value

of Parameter

01-01

0: Operation by using the digital keypad

1: Operation by using the external terminals. The Stop button on the

keypad is disabled.

2: Communication using RS-485. The Stop button on the keypad is

disabled

If the VFD-Explorer is used, the Parameter is 01-01=2

Source of operation command

Setting value

of Parameter

01-01

0: Operation by using the digital keypad

1: Operation by using the external terminals. The Stop button on the

keypad is disabled.

2: Communication using RS-485. The Stop button on the keypad is

disabled

Change the display type from Frequency command (Hz) into Speed (rpm)

Display the speed (rpm) defined by the user

Setting value

of Parameter

0~39999rpm

00-06

Set the Parameter 01-02

Motor’s maximum operation frequency

Setting value

of Parameter

50.00 – 600.00Hz

01-02

3-5

Page 40

Set the Parameter 01-03

Motor’s rated frequency

Setting value

of Parameter

0.00 – 600.00Hz

01-03

Set the Parameters 01-05 & 01-06

Acceleration time setting

Setting value

of Parameter

0.00 – 600.00 seconds

01-05

Deceleration time setting

Setting value

of Parameter

0.00 – 600.00 seconds

01-06

The settings for the induction and synchronous motors are different. Please configure these

parameters according to the related adjustment method for the motor.

Induction motor

Set the Parameter 01-00 = 0

Control mode

Setting value

of Parameter

01-00

0: VF

1: Reserved

2: Reserved

3: FOC vector control + Encoder (FOCPG)

4: Reserved

5: FOCPM

6: Reserved

Set the Parameter 01-26 = 0

Encode type

Setting value

of Parameter

01-26

0: ABZ

1: ABZ+HALL (only used for Delta’s servo motors)

2: ABZ+HALL

3:Resolver

Set the Parameter 01-29

Number of pulses for each revolution of the encoder

Setting value

of Parameter

1~20000

01-29

3-6

Page 41

Set the Parameter 01-08

The rated current of the induction motor

Setting value

of Parameter

0~655.35 Amps

01-08

Set the Parameter 01-09

The rated power of the induction motor

Setting value

of Parameter

0.00 – 655.35kW

01-09

Set the Parameter 01-10

The rated speed (rpm) of the induction motor

Setting value

of Parameter

0~65535

01-10

3. Machine Adjustment Procedure

Set the Parameter 01-11

Number of poles of the induction motor

Setting value

of Parameter

2~20

01-11

Check if the motor can be separated from the pump

1. If it can be separated, set the Parameter 01-07 as 1 and carry out a dynamic

measurement

2. If it cannot be separated, open the safety valve, enter the no-load current of the induction

motor 01-12 and set the Parameter 01-07 as 2. Then carry out the static measurement

Motor Parameter Auto Tuning

Setting

value of

Parameter

01-07

0: No function

1: Rolling test for induction motor(IM) (Rs, Rr, Lm, Lx, no-load current)

2: Static test for induction motor(IM)

3: Reserved

4: Auto measure the angle between magnetic pole and PG origin

5: Rolling test for PM motor

During the automatic measurement process of the induction motor, the digital keypad will

show the message “tun”. After the measurement is finished, the motor automatically shuts

down, and the measurement values are stored into Parameters 01-13 to 01-16.If the digital

keypad shows “AUE”, please check if the wiring is correct and if the parameters are set

correctly.

The machine will shut off the power and then supply the power again

3-7

Page 42

Set the Parameter 01-00 = 3

Control mode

Setting value

of Parameter

01-00

0: VF

1: Reserved

2: Reserved

3: FOC vector control + Encoder (FOCPG)

4: Reserved

5: FOCPM

6: Reserved

Test run

When the motor is in a no-load state, the speed command is set to 10 rpm for low-speed test

run. Make sure that the output current value is close to the no-load current.

If no error occurs, gradually increase the value of speed command to the highest speed.

Make sure that the pump’s oil supply direction is the forward direction of the motor.

Synchronous motor

Set the Parameter 01-00 = 5

Control mode

Setting value

of Parameter

01-00

0: VF

1: Reserved

2: Reserved

3: FOC vector control + Encoder (FOCPG)

4: Reserved

5: FOCPM

6: Reserved

Set the Parameter 01-26 = 3

Encode type

Setting value

of Parameter

01-26

0: ABZ

1: ABZ+HALL (only used for Delta’s servo motors)

2: ABZ+HALL

3:Resolver

Set the Parameter 01-29

Number of pulses for each revolution of the encoder

Setting value

of Parameter

1~20000

01-29

3-8

Page 43

Set the Parameter 01-17

The rated current of the synchronous motor

Setting value

of Parameter

0~655.35 Amps

01-17

Set the Parameter 01-18

The rated power of the synchronous motor

Setting value

of Parameter

0.00 – 655.35kW

01-18

Set the Parameter 01-19

The rated speed (rpm) of the synchronous motor

Setting value

of Parameter

0~65535

01-19

3. Machine Adjustment Procedure

Set the Parameter 01-20

Number of poles of the synchronous motor

Setting value

of Parameter

2~20

01-20

Set the Parameter 01-21

The inertia of the synchronous motor’s rotor

Setting value

of Parameter

0.0~6553.5 *10-4 kg.m2

01-21

Check if the motor can be separated from the pump

If it can be separated, set the Parameter 01-07 as 5 and carry out the parameter measurement

of the synchronous motor

If it cannot be separated, open the safety valve, set the Parameter 01-07 as 5 and carry out

the parameter measurement of the synchronous motor

Motor Parameter Auto Tuning

Setting value

of Parameter

01-07

0: No function

1: Rolling test for induction motor(IM) (Rs, Rr, Lm, Lx, no-load current)

2: Static test for induction motor(IM)

3: Reserved

4: Auto measure the angle between magnetic pole and PG origin

5: Rolling test for PM motor

During the automatic measurement process of the synchronous motor, the digital keypad will

show the message “tun”. After the measurement is finished, the motor automatically shuts

down, and the measurement values are stored into Parameters 01-22 to 01-25.If the digital

3-9

Page 44

keypad shows “AUE”, please check if the wiring is correct and if the parameters are set

correctly.

Set the value of Parameter 01-07 as 4 and press [Run]. When the operation is complete, the

PG offset angle of PM motor is written to Parameter 01-27

Motor Parameter Auto Tuning

Setting value

of Parameter

01-07

0: No function

1: Rolling test for induction motor(IM) (Rs, Rr, Lm, Lx, no-load current)

2: Static test for induction motor(IM)

3: Reserved

4: Auto measure the angle between magnetic pole and PG origin

5: Rolling test for PM motor

The machine will shut off power and then supply power again

Test run

When the motor is in a no-load state, the speed command is set to 10 rpm for low-speed test

run. Make sure that the output current value is close to the zero current.

If no error occurs, gradually increase the value of speed command to the highest speed.

Make sure that the pump’s oil supply direction is the forward direction of the motor.

Step 2. Estimation of Inertia

Set the speed command as 1000 rpm

Set the Parameters 01-05 & 01-06 = 0.3~0.5 seconds

Acceleration time setting

Setting value

of Parameter

0.00 – 600.00 seconds

01-05

Deceleration time setting

Setting value

of Parameter

0.00 – 600.00 seconds

01-06

Set the Parameter 01-31 = 2 and then press [Run]

System control

Setting value

of Parameter

01-31

Check if the value of Parameter 01-32 is converged. If it is converged, stop the operation. If

0: No function

1: ASR automatic tuning

2: Estimation of inertia

not, switch the rotation direction after the speed is stable.

The unity value of the system inertia

Setting value

of Parameter

1~65535 (256 = 1 per unit)

01-32

3-10

Page 45

3. Machine Adjustment Procedure

After the operation stops, select the Parameter 01-32 and press the [PROG/DATA] button to

complete the “write” operation.

Set Parameter 01-31=1 and the estimation of the motor’s inertia is complete.

Step 3. Connect the motor and the pump and then confirm the pressure feedback

signal

Set the Parameter 00-04 = 11 and then supply voltage to PO

Selection of multi-function display

Setting value

of Parameter

00-04

Parameter 00-08 = related pressure setting value of the pressure sensor at 10V

Maximum pressure feedback value

Setting value

of Parameter

00-08

11: display the signal value of the analog input terminal PO with 0~10V

mapped to 0~100%

0~250Bar

Set the speed command as 10rpm and press [RUN] to confirm if the pressure value through

the pre ssure gauge > 0.

If the pressure value 0≦

; Gradually increase the rotation speed

; Confirm the operation direction of the pump

; Make sure that the direction valve is in the close state

If the pressure value > 0

; Make sure the multi-function display on the keypad panel shows the voltage indicating the

same pressure as the pressure gauge

Example: If the pressure sensors indicates 250bar at 10V, when the pressure gauge shows 50

bar, the pressure sensor output voltage should be around 50/250 * 10 = 2V, and the

voltage shown on the keypad panel should be 20.0 (%)

Observe if there is oil leakage.

Step 4. Confirm the pressure command and flow command

Parameter 00-09 = 1 for pressure control mode

Pressure control mode

Setting value

of Parameter

0: Speed control

1: Pressure control

00-09

Parameter 00-04 = 12 PI for input voltage

Selection of multi-function display

Setting value

12: display the signal value of the analog input terminal PI with 0~10V

of Parameter

mapped to 0~100%

00-04

3-11

Page 46

Parameter 00-07 = related pressure value of the pressure command at 10V

Maximum pressure command

Setting value

of Parameter

0~250Bar

00-07

Send the maximum pressure command through the controller and then check the

multi-function display page to enter this value into Parameter 00-14

Send a half pressure command through the controller and then check the multi-function

display page to enter this value into Parameter 00-15

Send the minimum pressure command through the controller and then che ck the multi-function

display page to enter this value into Parameter 00-16

Example: If the pressure sensor indicates 250bar at 10V. If the maximum pressure on the

controller is 140bar and corresponds to 10V, then Parameter 00-07=140.

Set the pressure as 140bar through the controller, the voltage value shown on the

display is about 56.0 (140/250 * 100%). Enter this value into the Parameter 00-14.

Then set the pressure as 70bar on the controller, and now the value displayed on

the keypad panel is about 28.0 (70/250 * 100%). Enter this value to the Parameter

00-15. Then set the pressure as 0 bar on the controller, and the voltage value show n

on the display is about 0.0 (0/250 * 100%). Enter this value in the Parameter 00-16.

Parameter 00-04 = 25 for QI input voltage

Selection of multi-function display

Setting value

25: display the signal value of the analog input terminal OI with 0~10V

of Parameter

mapped to 0~100%

00-04

Send the 100% flow rate through the controller and then check the multi-function display page

to enter this value into Parameter 00-17

Send the 50% flow rate through the controller and then check the multi-function display page

to enter this value into Parameter 00-18

Send the 0% flow rate through the keypad panel and then check the multi-function display

page to enter this value into 00-19

Step 5. Bleed the circuit and make sure if there is any plastic material in the barrel.

The machine can start operation only when there are no plastic materials inside the

barrel.

Parameter 00-09 = 1 for pressure control mode

Pressure control mode

Setting value

of Parameter

0: Speed control

1: Pressure control

00-09

3-12

Page 47

Set the Parameters 01-05 & 01-06 = 0 second

Acceleration time setting

Setting value

3. Machine Adjustment Procedure

of Parameter

0.00 – 600.00 seconds

01-05

Deceleration time setting

Setting value

of Parameter

0.00 – 600.00 seconds

01-06

For low-pressure and low-speed conditions (within 30% of the rated values), use the “manual

operation” through the controller for the operation of each cylinder . During the operation, check

the pipe connection for leaks or strange noise in the pump.

When the air is bleeding completely, if there is any pressure fluctuation during operation,

please adjust the pressure control Parameter PI in accordance with the method described in

the “Description of Parameters”.

Step 6. Send operation command though the controller

Parameter 01-01=1

Source of operation command

Setting value

of Parameter

01-01

0: Operation by using the digital keypad

1: Operation by using the external terminals. The Stop button on the

keypad is disabled.

2: Communication using RS-485. The Stop button on the keypad is

disabled

Step 7. Adjustment for injection/pressure holding

Heat up the barrel to the required temperature and set the controller in manual control mode.

Set the Ki values for the three stages PI to 0 (Parameters 00-21, 00-23 , and 00-25) and Kp

values to small values ( 50.0)≦

Start the plastic injection operation. The “Targ et value” is low pressure (<50Bar) and low flow

rate (<30%)。

Press the “injection" button on the operation panel for the injection operation or the machine

will enter the pressure holding operation (depending on the position of the cylinder)

In the pressure holding state, use the software (VFD-Explorer) to observe the waveform.

Without causing the vibration of the motor, increase the speed bandwidth to the maximum

value 40Hz (Parameter 00-10).

In the pressure holding condition, if the pointer of the pressure gauge or the monitored

pressure waveform has no fluctuation, it means that the pressure is stably fed back. It is

allowed to increase the three Kp values.

3-13

Page 48

When the pressure feedback becomes unstable, reduce the three Kp v alues by 20% (example:

the three Kp values are reduced from 100.0 to 80.0). Adjust the three Ki values to eliminate the

steady-state error so as to speed up system response.

When the above steps are completed, increase the "target value" for the pressure command.

Observe if the pressure feedback is stable. If there is an abnormal condition, please solve it as

follows:

Solve the pressure instability problem

Instability at high pressure

If the Hybrid servo drive has an overload condition, please increase the power rating of the

Hybrid servo drive

Instability over the entire pressure range

1. Set Parameter 00-09 = 0 to switch to the speed control

2. If the hydraulic circuit is in the closed state, send a low speed command so as to allow a

pressure feedback value of 40-50% of the value for pressure command (parameters

00-07)

3. By using the monitoring software, observe if the pressure waveform has irregular

fluctuations.

Pressure waveform fluctuates

It may be a ground interference problem. If the motor or the three-phase power

supply is grounded, disconnect the ground wire. If the motor or three-phase power

supply has no ground wire, you can install a ground wire for anti-interference

protection.

It may be a grounding problem of the shield mesh (as the red thick line shown below).

If the shield mesh is properly grounded, the ground w ire can be removed; i f the shield

mesh has no grounding wire, install a ground wire for anti-interference protection.

3-14

Page 49

3. Machine Adjustment Procedure

PG Card

14,16

13,15

5

4

7

9

+24V

ACM

PO

Resol v e r

R1

R2

S2

S4

S1

S3

+V

-V

Output

Pressure sensor

4. If there is any abnormal condition that can not be solved, please contact the manufacturer.

Step 8. Adjustment of system transient response

Reduce the pressure rise time, increase Kp1 (Parameter 00-20) and reduce the Ki1 time

(Parameter 00-21)

For pressure overshoot, increase the Kp3 time (Parameter 00-24) and reduce the Ki3 time

(Parameter 00-25)

3-15

Page 50

Confluence Machine Tuning Procedure

Wiring according to Chapter 2

Carry out the automatic measurement of the motor’s parameters according to Step 1 and Step 2

described above for the Master and Slave, respectively. Then perform the following procedure

Master setting

Set the Parameter 03-06 = 1

Multifunction Output 2 (MO1)

Setting value

of Parameter

1: Operation indication

03-06

Connect the Master’s MO1 output terminal to the Slave’s SON terminal and Master's MCM

terminal to the Salve's COM terminal.

For the firmware version 2.03 and above, it is not necessary to perform the two steps

described above

Set the Parameter 03-13 = 1

Confluence Master/Slave Selection

Setting value

of Parameter

03-13

0: No function

1: Master 1

2: Slave/Master 2

3: Slave/Master 3

Set the Parameter 03-14

Slave's proportion of the Master’s flow

Setting value

of Parameter

0.0~6553.5%

03-14

For firmware version 2.03 and above, the Parameter 03-17 can be configured to determine the

activation level for the Slave

Slave’s activation level

Setting value

of Parameter

0~100%

03-17

3-16

Page 51

Slave setting

Parameter 01-01=1

Source of operation command

3. Machine Adjustment Procedure

Setting value

of Parameter

01-01

0: Operation by using the digital keypad

1: Operation by using the external terminals. The Stop button on the

keypad is disabled.

2: Communication using RS-485. The Stop button on the keypad is

disabled

For firmware version 2.03 and above, set the Parameter 01-01=2

Source of operation command

Setting value

of Parameter

01-01

0: Operation by using the digital keypad

1: Operation by using the external terminals. The Stop button on the

keypad is disabled.

2: Communication using RS-485. The Stop button on the keypad is

disabled

Set the Parameter 03-15 = 1

Source of Frequency Command

Setting value

of Parameter

0: Digital Operation Panel

1: RS485 Communication

03-15

Shut down the power and then supply the power again

2~5: reserved

Set an arbitrary value of the frequency command at the Master to check if the Slave has the

same value of the frequency command

Set 10rpm at the Master and then press RUN to see if the Slave is also running. If not, check

the wiring or the parameter setting for any problem

Set the Slave Parameter 03-13 = 2

Confluence Master/Slave Selection

Setting value

of Parameter

03-13

0: No function

1: Master 1

2: Slave/Master 2

3: Slave/Master 3

For firmware version 2.03 and above, the Parameter 03-21 can be set at the Slave to decide if

the Salve is performing the reversed operation for depressurization.

Note: If it is required to reverse the operation for depressurization at the Slave, it is necessary

to make sure that the pump outlet port is not installed with a check valve and the Parameter

03-16 should be set as 500%

3-17

Page 52

Slave reverse operation for depressurization

Setting value

of Parameter

03-21

Limit for the Slave reverse depressurization torque

Setting value

of Parameter

03-16

Shut off the power and the re-supply power for the Slave, and then set the Slave in the speed

control mode

Speed Control Mode

Setting value

of Parameter

00-09

In this case, the Master can be tuned according to the Step 3 – Step 8 described above

0: Disable

1: Enable

0~500%

0: Speed control

1: Pressure control

Confluence/Diversion Mode Adjustment

Procedure

Wiring according to Chapter 2

In a diversion condition, adjust various parameters of the Hybrid servo drive according to the Step

1 – Step 8 describe above

In a confluence condition, please refer to the machine adjustment procedure for the confluence

operation

Complete the above steps

Set the Master for pressure control mode

Parameter 00-09 = 1 for pressure control mode

Pressure control mode

Setting value

of Parameter

00-09

Set the Slave for speed control mode

0: Speed control

1: Pressure control

Parameter 00-09 = 0 for speed control mode

Speed Control Mode

Setting value

of Parameter

00-09

0: Speed control

1: Pressure control

3-18

Page 53

3. Machine Adjustment Procedure

Respectively set the master/slave multi-function input state. For the firmware version 2.03 and

above, it is necessary to set these parameters for the Slave only

Parameter 03-00~03-02 = 45 confluence/diversion signal input

Multi-function Input

Setting values

0: No function

of Parameters

45: Confluence/Diversion signal input

03-00~03-02

Through the controller, perform the entire confluence/diversion operation.

3-19

Page 54

4. Description of Parameters

4-1 Summary of Parameters

4-2 Detailed Description of Parameters

4. Description of Parameters

4-1

Page 55

4-1 Summary of Parameters

00 System Parameters a the parameter can be set during oper

ation

Parameter

code

00-00

00-01

00-02 Reset parameter settings

00-03 Software version Read only Read only ○ ○ ○

Function of the parameter Settings

12:230V, 7.5HP

13:460 V, 7.5HP

14:230V, 10HP

15:460V, 10HP

16:230V, 15HP

17:460V, 15HP

18:230V, 20HP

19:460V, 20HP

Hybrid servo drive model

code ID

Display of rated current of

the Hybrid servo drive

20:230V, 25HP

21:460V, 25HP

22:230V, 30HP

23:460V, 30HP

24:230V, 40HP

25:460V, 40HP

26:230V, 50HP

27:460V, 50HP

29:460V, 60HP

31:460V, 75HP

33:460V, 100HP

Display the model specific values Read only ○ ○ ○

5: Rest the kWh at drive stop

10: Reset parameter values

Default

value

Read only ○ ○ ○

0 ○ ○ ○

VF

FOCPG

FOCPM

4-2

Page 56

4. Description of Parameters

Parameter

a

a

code

00-04

00-05

Function of the parameter Settings

0: Display the output current (A)

1: Reserved

2: Display the actual output frequency (H)

3: Display the DC-BUS voltage (U)

4: Display the output voltage (E)

5: Display the output power angle (n)

6: Display the output power in kW (P)

7: Display the actual motor speed rpm (r)

8: Display the estimated output torque (%)

9: Display the PG feedback (G)

10: Reserved

11: Display the signal value of the analog input

terminal PO % (1.)

12: Display the signal value of the analog input

terminal PI % (2.)

Selection of multi-function

display

Analog output function

selection

13: Display the signal value of the analog input

terminal AUI % (3.)

14: Display temperature of the heat sink in °C (t.)

15: Display temperature of IGBT in °C (T)

16: The status of digital input (ON/OFF) (i)

17: The status of digital output (ON/OFF) (o)

18: Reserved

19: The corresponding CPU pin status of the digital

input (i.)

20: The corresponding CPU pin status of the digital

output (o.)

21~24: Reserved

25: Display the signal value of the analog input

terminal QI % (5.)

26: Display the actual pressure value (Bar) (b.)

27: Display the kWh value (K)

28: Display the motor temperature (currently only

support KTY84) (T.)

0: Output frequency (Hz) 0 ○ ○ ○

Default

value

0 ○ ○ ○

VF

FOCPG

FOCPM

a

a

1: Frequency command (Hz) ○ ○ ○

2: Motor speed (Hz) ○ ○ ○

3: Output current (A) ○ ○

00-06

00-07

00-08

Display the speed (rpm)

defined by the user

Maximum value for the

pressure command

Maximum pressure

feedback value

4: Output voltage

5: DC Bus voltage

6: Power factor

7: Power

8: Output torque

9: PO

10: PI

11: AUI

12~20: Reserved

0~39999 rpm 0 ○ ○ ○

0~250 Bar 250 ○ ○ ○

0~400 Bar 250 ○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

4-3

Page 57

Parameter

code

00-09 Pressure control mode

00-10 Speed bandwidth 0~40Hz 20 ○ ○

a

00-11

a

00-12

a

00-13

a

00-14

a

00-15

a

00-16

Function of the parameter Settings

0: Speed control

1: Pressure control

Pressure feedback filtering

0.000~1.000 second 0.000 ○ ○ ○

time PO

Pressure command filtering

0.000~1.000 second 0.000 ○ ○ ○

time PI

Flow command filtering time

0.000~1.000 second 0.000 ○ ○ ○

QI

Percentage for the pressure

0.0~100.0% 100.0 ○ ○ ○

command value (Max)

Percentage for the pressure

0.0~100.0% 50.0 ○ ○ ○

command value (Mid)

Percentage for the pressure

0.0~100.0% 0.0 ○ ○ ○

command value (Min)

Default

value

0 ○ ○ ○

VF

FOCPG

FOCPM

a

00-17

a

00-18

a

00-19

a

00-20 P gain 1 0.0~1000.0 50.0 ○ ○ ○

a