Page 1

RTU-485

Modbus Remote I/O Communication Module

Application Manual

Page 2

Page 3

Modbus Remote I/O Communication Module RTU-485

Warning

3

Please read this instruction carefully before use and follow this instruction to operate the device in order to prevent

damages on the device or injuries to staff.

3

Switch off the power before wiring.

3

RTU-485 is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity,

electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g.

key or specific tools are required for operating the enclosure) in case danger and damage on the device may occur.

3

RTU-485 is to be used for controlling the operating machine and equipment. In order not to damage it, only

qualified professional staff familiar with the structure and operation of RTU-485 can install, operate, wire and

maintain it.

3

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check

all the wirings again before switching on the power and DO NOT touch any terminal when the power is switched

on. Make sure the ground terminal

1 INTRODUCTION...................................................................................................................................3

2 PRODUCT PROFILE & OUTLINE .......................................................................................................4

3 BASIC OPERATI ON.............................................................................................................................6

Table of Contents

1.1 Features......................................................................................................................................3

1.2 Specifications..............................................................................................................................3

2.1 Dimension ...................................................................................................................................4

2.2 Product Profiles...........................................................................................................................4

2.3 RUN/STOP Switch......................................................................................................................4

2.4 Address Switch ...........................................................................................................................5

2.5 Communication Mode Switch......................................................................................................5

3.1 Connecting RTU-485 to DVP Slim DI/DO Extension Unit...........................................................6

is correctly grounded in order to prevent electromagnetic interference.

3.2 Installing RTU-485 and DVP Slim DI/DO on DIN Rail.................................................................6

4 AREAS FOR SPECIAL FUNCTIONS ..................................................................................................6

4.1 Areas in Slim DI/DO Extension Unit............................................................................................6

4.2 Areas in Special Module..............................................................................................................7

4.3 Special Functions........................................................................................................................7

4.4 Error Codes.................................................................................................................................8

5 FUNCTION CODES RTU-485 SUPPORTS .........................................................................................8

6 APPLICATI ON OF RTU-485 ................................................................................................................9

6.1 Connection between RTU-485 and Master Device.....................................................................9

6.2 Application Example....................................................................................................................9

DVP-PLC Application Manual

1

Page 4

Modbus Remote I/O Communication Module RTU-485

7 LED INDICATOR & TROUBLE-SHOOTING ..................................................................................... 11

7.1 POWER LED.............................................................................................................................11

7.2 RUN LED...................................................................................................................................11

7.3 ALARM LED..............................................................................................................................11

7.4 RS-485 LED ............................................................................................................................. 12

2

DVP-PLC Application Manual

Page 5

Modbus Remote I/O Communication Module RTU-485

1 Introduction

1. To ensure correct installation and operation of RTU-485, please read this chapter carefully before using your

RTU-485

2. RTU-485 is a Modbus remote I/O communication module for Delta’s PLC to remote-control DVP Slim series

DI/DO and AI/AO extension module s.

3. RTU-485 is a standard Modbu s slave device and is compatible with pther master devices which comply with

Modbus protocol.

1.1 Features

y

Auto-detecting extension modules

y Maximum extension: 8 special modules; 128 input points and 128 output points

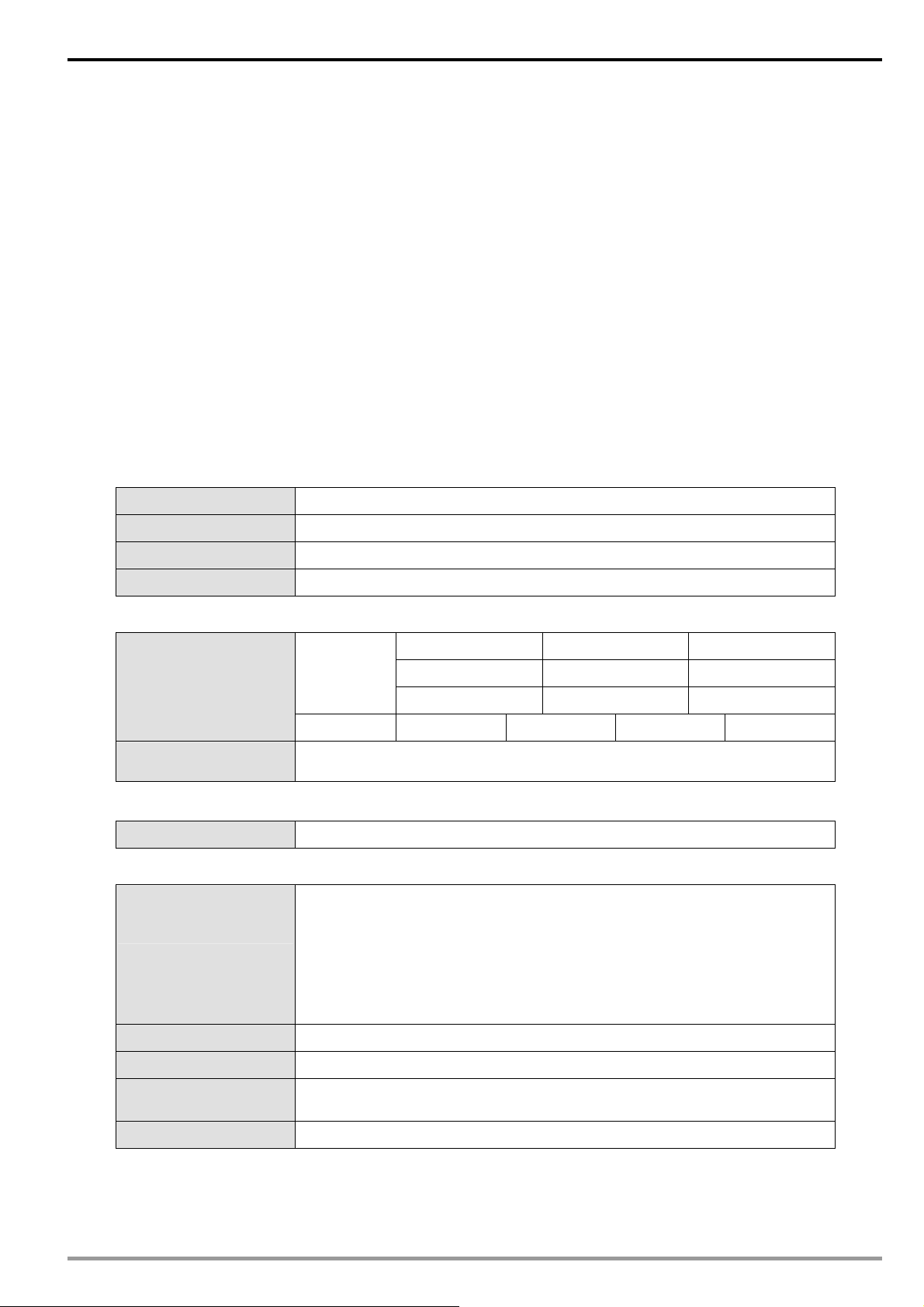

1.2 Specifications

DeviceNet connection

Transmission method RS-485

Electrical isolation 500 VDC

Interface Removable connector (3Pin)

Transmission cable 2-wire twister shielded cablew8

Communication

7, E, 1 7, O, 2 8, O, 1

Mode

Baud rates

Electrical specification

Power supply 24 VDC (-15% ~ 20%) (with DC input polarity reverse protection)

Environment

Noise immunity

Operation 0ºC ~ 55ºC (temperature); 50 ~ 95% (humidity); pollution degree 2

ASCII

RTU 8, E, 1 8, O, 1 8, N, 1 8, N, 2

1,200bps; 2,400bps; 4,800bps; 9,600bps; 19,200bps; 38,400bps;

57,600bps; 115,200bps

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge,4KV Contact

Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV

Analog & Communication I/O: 1KV

Damped-Oscillatory Wav e: Power Line: 1KV, Digital I/O: 1KV

RS (IEC 61131-2, IEC 61000-4-3): 80MHz~1000MHz , 1.4GHz~2.0GHz ,

10V/m

7, O, 1 7, N, 2 8, N, 1

7, E, 2 8, E, 1 8, N, 2

Storage -25ºC ~ 70ºC (temperature); 5 ~ 95% (humidity)

Vibration/shock

resistance

Certificates IEC 61131-2, UL508

DVP-PLC Application Manual

Standard: IEC 61131-2、IEC 68-2-6 (TEST Fc)/IEC 61131-2 & IEC 68-2-27

(TEST Ea)

3

Page 6

Modbus Remote I/O Communication Module RTU-485

2 Product Profile & Outline

2.1 Dimension

2.2 Product Profiles

1. POWER indicator 9. Mounting hole for extension module

2. RUN indicator 10. Nameplate

3. ALARM indicator 11. Extension port

4. RUN/STOP switch 12. DIN rail (35mm)

5. Communication indicator 13. Fastening hole for extension module

6. Address switch 14. DIN rail clip

7. Communication mode switch 15. Mounting rail for extension module

8. RS-485 communication port 16. Power input

2.3 RUN/STOP Switch

RUN/STOP action Explanation

RUN Special module in RUN mo de

RUN → STOP

STOP

STOP → RUN

1. Special module switches from RUN to STOP.

2. Output points on Slim DI/DO extension unit all turn Off.

1. Special module in STOP mode

2. Special module cannot be controlled by communication.

3. Slim DI/DO extension unit cannot be controlled by

communication.

1. Special module switches from STOP to RUN.

2. RTU-485 redetects the number of point s in Slim DI/DO

and the number of special modules.

RUN

STOP

4

DVP-PLC Application Manual

Page 7

2.4 Address Switch

The switch is used on setting up the communication address of RTU-485. Range: H’01 ~ H’F0 (decimal: 1 ~

240)

Switch setting Content

Modbus Remote I/O Communication Module RTU-485

H’01 ~ H’F0

H’00,

H’F1 ~ H’FF

Example: If you need to set the address of RTU-485 to 26, swich the DIP switch corresponding to ID4 to “ON”,

switch corresponding to ID3 to “ON” and switch corresponding to ID1 to “ON”.

Note:

z Please set up the address when the power of RTU-485 is switched of f. After the setup is completed, re-powe r

RTU-485.

z When RTU-485 is operating, changing the setting of communication address will be invalid.

z Use slotted screwdriver to adjust the switch carefully in case you scratch the switch.

2.5 Communication Mode Switch

These switches are for:

z Setting up communication format (PA0 ~ PA3, A/R)

z Setting up baud rate (DR0 ~ DR2)

PA3 PA2 PA1 PA0 A/R Format

Valid communication address

ID0 ~ ID7 are defined as: 2

Invalid communication address

0

, 21, 22, …26, 27

OFF OFF OFF OFF ON 7,E,1, ASCII

OFF OFF OFF ON ON 7,O,1, ASCII

OFF OFF ON OFF ON 7,E,2, ASCII

OFF OFF ON ON ON 7,O,2, ASCII

OFF ON OFF OFF ON 7,N,2, ASCII

OFF ON OFF ON ON 8,E,1, ASCII

OFF ON ON OFF ON 8,O,1, ASCII

OFF ON ON ON ON 8,N,1, ASCII

PA3 PA2 PA1 PA0 A/R Format

ON OFF OFF OFF ON 8,N,2, ASCII

OFF ON OFF ON OFF 8,E,1, RTU

OFF ON ON OFF OFF 8,O,1, RTU

OFF ON ON ON OFF 8,N,1, RTU

ON OFF OFF OFF OFF 8,N,2, RTU

DR2 DR1 DR0 Baud rate (bps)

OFF OFF OFF 1,200

OFF OFF ON 2,400

OFF ON OFF 4,800

OFF ON ON 9,600

ON OFF OFF 19,200

DVP-PLC Application Manual

5

Page 8

Modbus Remote I/O Communication Module RTU-485

ON OFF ON 38,400

ON ON OFF 57,600

ON ON ON 115,200

Note:

z Please set up the switch when the power is switched off. After the setup is completed, re-power R TU-485.

z When RTU-485 is operating, changing the setting of the switch will be invalid.

z Use slotted screwdriver to adjust the switch carefully in case you scratch the switch.

3 Basic Operation

3.1 Connecting RTU-485 to DVP Slim DI/DO Extension Unit

z Open the fixing clips on top and bottom of RTU-485. Meet the extension port of Slim DI/DO with R TU-485.

z Press the fixing clips on top and bottom of Slim DIDO and check if the connection is fine.

POWER

RUN

ALARM

RS-485

ID7

ID6

ID5

RUN

ID4

ID3

ID2

ID1

ID0

STOP

P

PA3

PA2

5

PA1

8

PA0

4

DR2

-

DR1

U

DR0

T

A/R

R

P

S

S

6

6

1

1

-

P

P

V

V

D

D

A

A

D

D

2

2

0

0

-

P

P

V

V

D

D

3.2 Installing RTU-485 and DVP Slim DI/DO on DIN Rail

z Use 35mm DIN rail.

z Open the DIN rail clip on RTU-485 and Slim DI/DO. Insert RTU-4 85 and Slim DI/DO onto the DIN rail.

z Clip up the DIN rail clips on RTU-485 and Slim DI/DO to fix them on the DIN rail, as shown below.

POWER

RUN

ALARM

RS-48 5

ID7

ID6

ID5

ID4

ID3

ID2

ID1

ID0

P

PA3

PA2

5

8

4

U

T

R

S

PA1

6

PA0

1

DR2

-

DR1

DR0

P

A/R

V

D

A

D

2

0

P

V

D

4 Areas for Special Functions

4.1 Areas in Slim DI/DO Extension Unit

Communication

address

H’0400 ~ H’047F X: X000 ~ X177 (Octal) R bit 128 points

H’0500 ~ H’057F Y: Y000 ~ Y177 (Octal) R/W bit 128 points

Devices Attribute Data type Length

35mm DIN rail

6

DVP-PLC Application Manual

Page 9

4.2 Areas in Special Module

Modbus Remote I/O Communication Module RTU-485

Communication

address

H’1600 ~ H’1630 1st special module: CR0 ~ CR48 word 49

H’1640 ~ H’1670 2nd special module: CR0 ~ CR48 word 49

H’1680 ~ H’16B0 3rd special module: CR0 ~ CR48 word 49

H’16C0 ~ H’16F0 4th special module: CR0 ~ CR48 word 49

H’1700 ~ H’1730 5th special module: CR0 ~ CR48 word 49

H’1740 ~ H’1770 6th special module: CR0 ~ CR48 word 49

H’1780 ~ H’17B0 7th special module: CR0 ~ CR48 word 49

H’17C0 ~ H’17F0 8th special module: CR0 ~ CR48

Note:

Maximum 8 special modules are connectible to RTU-485. The first special module connected is the nearestone

on the right hand side of RTU-485, and so on.

4.3 Special Functions

Communication

address

H’0000 R Model name

H’0001 R Firmware version

H’0002 R Issue date

H’0003 R/W RUN/STOP RTU-485

H’0004 R Communication format

H’0005 R Baud rate Displaying the baud rate of RTU-485.

H’0006 R

H’0007 R

H’0008 R Error code

H’0009 R Historical error code

H’0017 R

H’0018 R

H’0019 R

H’001A R

H’001B R

Attribute Content Explanation

Devices Attribute Data type Length

Please refer to

theCR attribute of

each special

module.

word 49

Set up by the system. Model code of RTU-485 =

H’0200.

The current firmware version is displayed in hex,

e.g. V0.1 is indicated as H’0010.

The issue data of the firmware is displayed in

hex, e.g. H’1FD0 = K8150 indicates that the

firmware is issued on the morning of August 15.

H’0003 = K1, RTU-485 RUN;

H’0003 = K0, RTU-485 STOP.

Displaying the communication format of

RTU-485.

Communication

address

Number of DI/DO

points

Number of special

modules

Model code of the 1

special module

Model code of the 2

special module

Model code of the 3

special module

Model code of the 4

special module

Displaying the communication address of

RTU-485.

High byte stores the number of input points. Low

byte stores the number of output points.

Recording the current error. See 17.4.4 for the

meaing of error codes.

The number of errors occurring.

Range: 0 ~ 32

The number of special modules RTU-485

detects.

st

The model code of the 1st special module

connected to RTU-485.

nd

The model code of the 2nd special module

connected to RTU-485.

rd

The model code of the 3rd special module

connected to RTU-485.

th

The model code of the 4th special module

connected to RTU-485.

DVP-PLC Application Manual

7

Page 10

Modbus Remote I/O Communication Module RTU-485

Communication

address

H’001C R

H’001D R

H’001E R

H’001F R

4.4 Error Codes

Code Indication Explanation

0001 Incorrect function code RTU-485 does not support this function code.

0002 Incorrect operand address

0003 Incorrect data The data read/written exceed the maximum length.

0004 RTU-485 STOP RTU-485 in STOP mode.

000B Incorrect communication format The length of data received by RTU-485 is too short.

000C Incorrect communication format The length of data received by R TU-485 is too long.

Attribute Content Explanation

Model code of the 5

special module

Model code of the 6

special module

Model code of the 7

special module

Model code of the 8

special module

th

The model code of the 5th special module

connected to RTU-485.

th

The model code of the 6th special module

connected to RTU-485.

th

The model code of the 7th special module

connected to RTU-485.

th

The model code of the 8th special module

connected to RTU-485.

The address of a certain device is not within the

range, orthe data written into it are incorrect.

5 Function Codes RTU-485 Supports

RTU-485 complies with the standard Modbu s proto col, suppo rting 7 function codes, whi ch are H’01, H’02, H’03,

H’05, H’06, H’0F and H’10. Please refer to the standard Modbus protocol for the specific data format of each

function code.

Code Function Data type Applicable address

H’01

H’02

Reading the output status of bit

device.

Reading the input status of bit

device

bit DO area: H’0500 ~ H’057F

word bit DI area: H’0400 ~ H’047F

Area for special functions: H’0000 ~ H’001F

CR for the 1st special module: H’1600 ~ H’1630

CR for the 2nd special module: H’1640 ~ H’1670

CR for the 3rd special module: H’1680 ~ H’16B0

H’03 Reading register bit

CR for the 4th special module: H’16C0 ~ H’16F0

CR for the 5th special module: H’1700 ~ H’1730

CR for the 6th special module: H’1740 ~ H’1670

CR for the 7th special module: H’1780 ~ H’16B0

th

special module: H’17C0 ~ H’17F0

H’05

Writing single datum into bit

device

CR for the 8

bit DO area: H’0500 ~ H’057F

RTU-485 RUN/STOP mode: H’0003

H’06 Writing single datum into register word

Applicable to CR with R/W attribute in the 1

special module

H’0F DO area: H’0500 ~ H’057F

H’10 Writing many data into bit device bit

Applicable to CR with R/W attribute in the 1

special module

st

~ 8th

st

~ 8th

8

DVP-PLC Application Manual

Page 11

Modbus Remote I/O Communication Module RTU-485

6 Application of RTU-485

6.1 Connection between RTU-485 and Master Device

As a standard Modbus slave, RTU-485 is compatible with pther programmable logic controllers which also

comply with Modbus protocol. The example here takes DVP-SV PLC as the master. The PC downloads the

ladder diagram to DVP-SV through RS-232 communication port (COM1). When DVP-SV executes the ladder

diagram program, it will send out Modbus command through RS-485 communication port (COM2) and conduct

remote I/O control on RTU-485. See the figure on the next page for the connectio n between RTU-485 and the

master device:

DVP28SV

RUN

STOP

6.2 Application Example

Example 1

¡ The station No. of RTU-485 is “1”. Write “H’0001” into CR#6 of the 1

M1002

DVP-SV

RS-485

T

P

S

8

0

P

V

D

DI/DO

Slim

S

6

1

P

V

D

5

8

4

U

T

R

COM2

RTU-485

MOV H86 D1120

RST

SET M1120

M1143

Retain communication protocol

D

A

4

0

P

V

D

P

T

4

0

P

V

D

D

4

2

0

0

-

P

P

V

V

D

D

A

T

C

Special

module

st

special module.

Set up communication protocol

9600,7,E,1,ASCII

M0

M0

M1123

M1129

DVP-PLC Application Manual

MOV K300 D1129

SET M1122

MODWR

K1 H1606 H0001

Set up sending request

Set up communication time-out 300ms

Process received data

RST M1123

Recei vin g of data is compl eted.

The flag is reset.

Process communica tion time-out

RST M1129

END

Wr ite H0001 i nto CR#6 of

st

the 1 special module

9

Page 12

Modbus Remote I/O Communication Module RTU-485

¡ Explanations

1. You have to set up the communication format at the beginning of the program. The communication

format for the master and slave has to be consistent, e.g. you can see the format is 9600, 7, E, 1,

ASCII from this example.

2. After setting up the communication format, you have to set up the communication retention device

M1120 of COM2.

3. After M0 is On, set up the sending request flag, and the master device will send out a request

message to RTU-485 and write H’0001 into CR#6 of the 1

RTU-485.

Example 2

¡ The station No. of RTU-485 is “1”. Set up Y0 of the Slim DI/DO on the right hand side of RTU-485.

M1002

MOV H86

RST M1143

D1120

st

special module on the right hand side of

Set up communicatio n protoco l

9600, 7, E, !, ASCII

M0

M0

SET M1120

MOV

MOV

MOV

MOV

MOV

MOV

MOV

MOV

MOV

MOV

SET M1122

RS D100 K17 D120 K17

K300

H303A D100

H3031 D101

H3035 D102

H3035 D103

H4630 D104

H3046 D105

H4630 D106

HD107

HA

Retain communication protocol

D1129

D36

D108

Set up sending request

Set up communication time-out 300ms

PLC sends out

": "

01 05 05 00 FF 00 F6 CR LF

to RTU-485

10

M1123

When M0 = On, the 17 words in D100 ~ D10 8 will be sen t out.

The 17 words responded by RTU-485 will be stored i n D120 ~ D128 by the m aster.

Process received data

RST M1123

Recei ving of dat a is complete d.

The flag is reset.

DVP-PLC Application Manual

Page 13

M1129

Modbus Remote I/O Communication Module RTU-485

Process communication time-out

RST M11 29

END

Explanations

1. You have to set up the communication format at the beginning of the program. The communication

format for the master and slave has to be consistent, e.g. you can see the format is 9600, 7, E, 1,

ASCII from thie example.

2. The master PLC sends out data to RTU-485 in ASCII, e.g. the high byte “30” in D100 refers to “0” and

low bytes “3A” refers to the head code “:”.

3. After M0 is On, set up M1 122. At this moment, the master PLC will send the 17 words of dat a in D100

~ D108 to RTU-485 by RS instruction. The data in low words will be sent first. The master PLC will

store the responding message sent by RTU-485 into D120 ~ D128.

7 LED Indicator & Trouble-shooting

There are four LED indicators on RTU-485, which are POWER, RUN, ALARM and RS-485, for displaying the

working status and communication connection status of RTU-485.

7.1 POWER LED

LED status Indication How to correct

Off No power, or the power is abnormal.

Green light On The power of RTU-4 85 is normal. --

Check the power of RTU-485 and see if the

connection is normal.

7.2 RUN LED

LED status Indication How to correct

Off RTU-485 is in STOP status. --

Green light On RTU-485 is in RUN status. --

7.3 ALARM LED

LED status Indication How to correct

Off The power is in low voltage. Check if the power of RTU-485 is normal.

Red light On

Incorrect communication format for

RTU-485

Incorrect communication address for

RTU-485

RTU-485 is not connected to

extension module.

More than 8 extension modules

connected to RTU-485.

The number of points on Slim DI/DO

connected to RTU-485 exceeds the

range.

Check if the communication format for RTU-485

is correct.

Check if the communication address of RTU-485

is valid.

Check if RTU-485 is connected to extension

module normally.

Check and make sure that the number of

extension modules connected to RTU-485 is

less than 8.

Check and make sure the number of input points

on Slim DI/DO connected to RTU-485 is less

than 128, and output points also less than 128.

DVP-PLC Application Manual

11

Page 14

Modbus Remote I/O Communication Module RTU-485

7.4 RS-485 LED

LED status Indication How to correct

Red light flashing

Off

RTU-485 is not communicating with

the master device.

RTU-485 is communicating to the

master device normally.

--

--

12

DVP-PLC Application Manual

Loading...

Loading...