Page 1

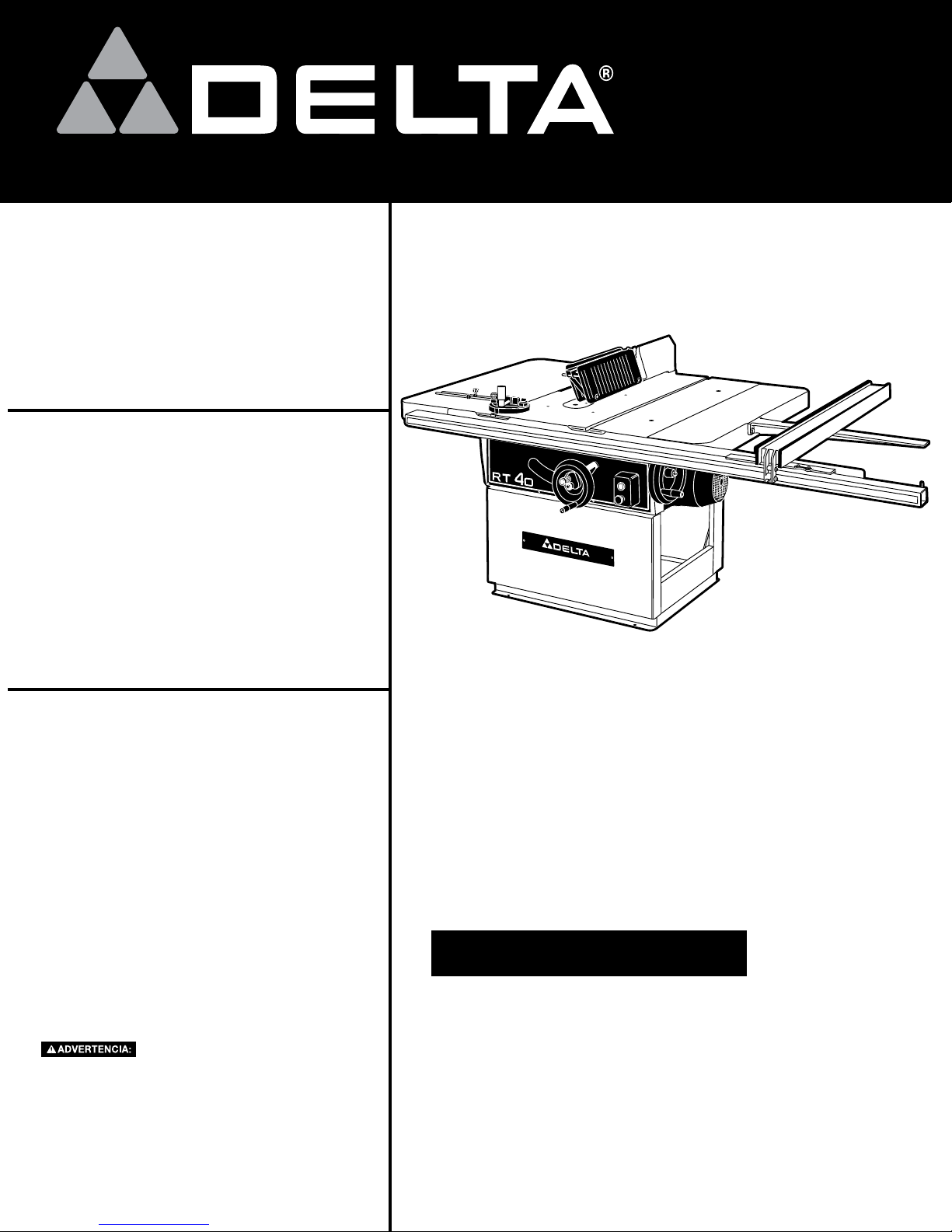

RT-40 14"/16"

Left Tilting

Arbor Saw

RT -40

355 y 406 mm

36-790

14 po/16 po

Scie circulaire

articulée à gauche

RT -40

Sierra de eje con

inclinación hacia la

izquierda de 355 y

406 mm (14”/16”)

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

FRANÇAIS (27) ESPAÑOL (52)

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

A26301 - 03-10-08

Copyright © 2006, 2008 Delta Machinery

www.deltaportercable.com

(800) 223-7278 - US

(800) 463-3582 - CANADA

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ........................ 2

SAFETY GUIDELINES - DEFINITIONS ......................... 2

GENERAL SAFETY RULES ........................................... 3

ADDITIONAL SPECIFIC SAFETY RULES .................... 4

FUNCTIONAL DESCRIPTION .......................................7

CARTON CONTENTS ...................................................7

ASSEMBLY ..................................................................... 8

OPERATION ................................................................... 15

TROUBLESHOOTING .................................................... 25

MAINTENANCE .............................................................. 25

SERVICE ......................................................................... 26

ACCESSORIES ............................................................... 26

WARRANTY .................................................................... 26

FRANÇAIS ...................................................................... 27

ESPAÑOL ........................................................................ 52

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all warnings and operating instructions before using any tool or

equipment. Always follow basic safety precautions to reduce the risk of personal injury. Improper operation,

maintenance, or modification of tools or equipment could result in serious injury and property damage. Our

tools and equipment are designed for certain applications. DO NOT modify and/or use this product for any

application other than that for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written Delta Machinery and we

have advised you. Contact us online at www.deltaportercable.com or by mail at Technical Service Manager, Delta Machinery,

4825 Highway 45 North, Jackson, TN 38305. In Canada,125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool is available from the following sources:

• PowerToolInstitute,1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.org

• NationalSafetyCouncil, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• AmericanNationalStandardsInstitute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1 Safety

Requirements for Woodworking Machines

• U.S.DepartmentofLabor regulations www.osha.gov

SAVE THESE INSTRUCTIONS!

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR SAFETY

and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

CALIFORNIA PROPOSITION 65

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• leadfromlead-basedpaints,

• crystallinesilicafrombricksandcementandothermasonryproducts,and

• arsenicandchromiumfromchemically-treatedlumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with approved safety equipment, al ways wear NIOSH/OSHA

approved, properly fit ting face mask or res pi ra tor when us ing such tools.

2

Page 3

GENERAL SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE.

Learning the machine’s application, limitations, and

specific hazards will greatly minimize the possibility of

accidents and injury.

2. WEAR EYE AND HEARING PROTECTION. ALWAYS

USE SAFETY GLASSES. Everyday eyeglasses are NOT

safety glasses. USE CERTIFIED SAFETY EQUIPMENT.

Eye protection equipment should comply with ANSI Z87.1

standards. Hearing equipment should comply with ANSI

S3.19 standards.

3. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry which

may get caught in moving parts. Nonslip protective

footwear is recommended. Wear protective hair covering

to contain long hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or wet

locations or in rain can cause shock or electrocution. Keep

your work area well-lit to prevent tripping or placing arms,

hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the machine,

check for any damaged parts. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

and any other conditions that may affect its operation.

A guard or any other part that is damaged should be

properly repaired or replaced with Delta or factory

authorized replacement parts. Damaged parts can cause

further damage to the machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can

be injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure that the switch is in the “OFF” position before

plugging in the power cord. In the event of a power failure,

move the switch to the “OFF” position. An accidental startup can cause injury. Do not touch the plug’s metal prongs

when unplugging or plugging in the cord.

10. USE THE GUARDS. Check to see that all guards are in

place, secured, and working correctly to prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES

BEFORE STARTING THE MACHINE. Tools, scrap pieces,

and other debris can be thrown at high speed, causing

injury.

12. USE THE RIGHT MACHINE. Don’t force a machine or

an attachment to do a job for which it was not designed.

Damage to the machine and/or injury may result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by Delta

may cause damage to the machine or injury to the user.

14. USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will

cause a drop in line voltage, resulting in loss of power and

overheating. See the Extension Cord Chart for the correct

size depending on the cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller

the gauge number, the heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to

hold the workpiece when practical. Loss of control of a

workpiece can cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause

the workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you fall

into a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the

tool tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFF. Don’t leave the machine until it

comes to a complete stop. A child or visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing

or removing accessories, changing cutters, adjusting or

changing set-ups. When making repairs, be sure to lock

the start switch in the “OFF” position. An accidental startup can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY REMOVING

STARTER KEYS. The accidental start-up of a machine by

a child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND

USE COMMON SENSE. DO NOT USE THE MACHINE

WHEN YOU ARE TIRED OR UNDER THE INFLUENCE

OF DRUGS, ALCOHOL, OR MEDICATION. A moment of

inattention while operating power tools may result in injury.

24.

AND DISBURSE DUST OR OTHER AIRBORNE

PARTICLES, INCLUDING WOOD DUST, CRYSTALLINE

SILICA DUST AND ASBESTOS DUST. Direct particles

away from face and body. Always operate tool in well

ventilated area and provide for proper dust removal. Use

dust collection system wherever possible. Exposure to

the dust may cause serious and permanent respiratory

or other injury, including silicosis (a serious lung disease),

cancer, and death. Avoid breathing the dust, and avoid

prolonged contact with dust. Allowing dust to get into

your mouth or eyes, or lay on your skin may promote

absorption of harmful material. Always use properly fitting

NIOSH/OSHA approved respiratory protection appropriate

for the dust exposure, and wash exposed areas with soap

and water.

USE OF THIS TOOL CAN GENERATE

3

Page 4

ADDITIONAL SPECIFIC SAFETY RULES

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

1. DO NOT OPERATE THIS MACHINE until it is assembled

and installed according to the instructions.

2. OBTAIN ADVICE FROM YOUR SUPERVISOR, instructor,

or another qualified person if you are not familiar with the

operation of this machine.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections.

4. ALWAYS USE GUARDS, SPLITTER, AND ANTI-

KICKBACK PAWLS whenever possible, including through

sawing. Check to see that they are in place, secured and

working correctly. Test the anti-kickback pawl action before

ripping by pushing the wood under the anti-kickback teeth.

The teeth must prevent the wood from being thrown toward

the front of the saw.

5. CUTTING THE WORKPIECE WITHOUT THE USE OF A

FENCE OR MITER GAUGE IS KNOWN AS “FREEHAND”

CUTTING. NEVER perform “free-hand” operations. Use

either the fence or miter gauge to position and guide the

workpiece.

6. HOLD THE WORKPIECE FIRMLY against the miter gauge

or fence.

7. CUTTING COMPLETELY THROUGH THE WORKPIECE

IS KNOWN AS “THROUGH-SAWING”. Ripping and crosscutting are through-sawing operations. Cutting with the

grain is ripping. Use a fence or fence system for ripping.

NEVER use a miter gauge for ripping. Use push sticks for

ripping a narrow workpiece. Cutting across the grain is

cross-cutting. Never use a fence or fence system for crosscutting. Instead, use a miter gauge.

8. KICKBACK IS THE NATURAL TENDENCY OF THE

WORKPIECE TO BE THROWN BACK AT THE OPERATOR

when the workpiece initially contacts the blade or if the

workpiece pinches the blade. Kickback is dangerous and

can result in serious injury.

AVOID KICKBACK by:

A. keeping blade sharp and free of rust and pitch.

B. keeping rip fence parallel to the saw blade.

C. using saw blade guard and splitter for every possible

operation, including all through sawing.

D. keeping splitter aligned with sawblade.

E. keeping the anti-kickback pawls in place and

sharpened.

F. pushing the workpiece past the saw blade prior to

release.

G. never ripping a workpiece that is twisted or warped,

or does not have a straight edge to guide along the

fence.

H. using featherboards when the anti-kickback device or

the guard and splitter cannot be used.

I. never sawing a large workpiece that cannot be

controlled.

J. never using the fence as a guide when crosscutting.

K. never sawing a workpiece with loose knots, flaws, nails

or other foreign objects.

L. never ripping a workpiece shorter than 10”.

SOME MATERIALS ARE TOO HARD

AND SLIPPERY FOR THE ANTI-KICKBACK PAWLS

TO BE EFFECTIVE. Plastic and compositions (like

hardboard) may be cut on your saw, but be especially

attentive to following proper set-up and cutting

procedures to prevent any kickbacks when cutting

these materials.

9. USE THE CORRECT SAWBLADE FOR THE INTENDED

OPERATION. The blade must rotate toward the front of the

saw. Always tighten the blade arbor nut securely. Before use,

inspect the blade for cracks or missing teeth. Do not use a

damaged blade.

10. NEVER USE ABRASIVE WHEELS on this saw.

11. DO NOT CUT METAL WITH THIS SAW.

12. REMOVE CUT-OFF PIECES AND SCRAPS from the

table before starting the saw. The vibration of the machine

may cause them to move into the saw blade and be

thrown out.

13. CUT-OFF PIECES CAN BE THROWN BACK AT THE

OPERATOR. For large cut-off pieces, use a push stick to

push the piece past the blade and off the back of the saw

table. Do not reach across sawblade. Be careful that small

pieces do not contact the blade.

14.

NEVER ATTEMPT TO FREE A STALLED SAW BLADE

WITHOUT FIRST TURNING THE MACHINE OFF. If a

workpiece or cut-off piece becomes trapped inside the

guard, turn saw off and wait for blade to stop before lifting

the guard and removing the piece.

15. NEVER START THE MACHINE with the workpiece

against the blade.

16. NEVER run the workpiece between the fence and a

moulding cutterhead.

17. KEEP ARMS, HANDS, AND FINGERS away from the

blade. Use a push stick to push small workpieces

through the saw. A push stick is a small wooden stick,

usually homemade, that should be used whenever the

size or shape of the workpiece would cause you to

place your hands within six inches of the blade. See

“CONSTRUCTING A PUSH STICK” in the back of this

manual for guidance on making your own.

18. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause a hand to

move into the blade.

19. NEVER have any part of your body in line with the path of

the saw blade.

20. NEVER REACH AROUND or over the saw blade.

21. PROPERLY SUPPORT LONG (3 feet or longer) OR

WIDE (36” or wider) WORKPIECES. If extension tables

wider than 24” are attached to the saw, bolt the saw

stand to the floor, or use a sturdy outrigger support to

prevent tipping.

22. PREVENT MOTION OF THE SAW WHILE IN USE. If

the mobility kit is installed, lower the foot pedal and level

the feet so the saw does not rock, walk, slide or tip. If

necessary, secure the stand to the floor.

23. NEVER PERFORM LAYOUT, assembly or set-up work

on the table/work area when the machine is running.

24. TURN THE MACHINE “OFF” AND DISCONNECT

THE MACHINE from the power source before installing

or removing accessories, changing the sawblade, or

adjusting or changing set-ups. Lock switch in the “OFF”

position when making repairs.

25. CLEAN THE TABLE/WORK AREA BEFORE LEAVING

THE MACHINE. Lock the switch in the “OFF” position to

prevent unauthorized use.

26. ADDITIONAL INFORMATION regarding the safe and

proper operation of power tools (i.e. a safety video)

is available from the Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851 (www.

powertoolinstitute.com). Information is also available from

the National Safety Council, 1121 Spring Lake Drive, Itasca,

IL 60143-3201. Please refer to the American National

Standards Institute ANSI 01.1 Safety Requirements for

Woodworking Machines and the U.S. Department of

Labor OSHA 1910.213 Regulations.

4

Page 5

MOTOR SPECIFICATIONS

Model 36-790 is equipped with a 7.5 HP three phase motor prewired for 230 V, 60 Hz power. The unit can be reconfigured

for 208 V or 460 V, 60 Hz operation.

POWER CONNECTIONS

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An accidental start-up can cause severe injury.

Model 36-790 is not equipped with a power supply cord and is intended to be permanently connected to the power source. All

electrical connections should be made by a qualified electrician in accordance with the National Electric Code and all local

codes and ordinances. ALWAYS DISCONNECT THE POWER BEFORE SERVICING.

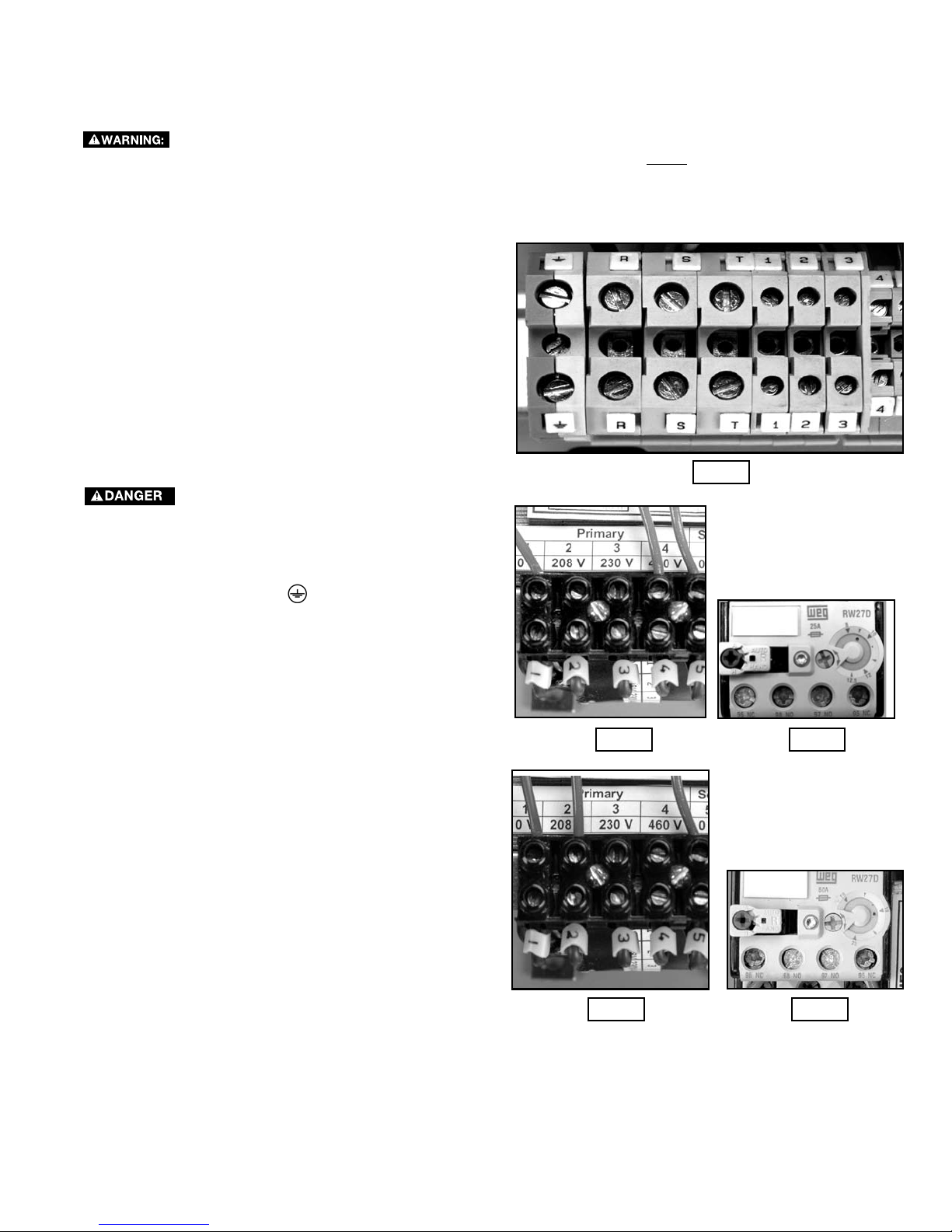

NOTES FOR THE ELECTRICIAN

Use a three-conductor hard-service or junior hard-service

minimum #10 AWG flexible cord with ground to connect the

machine to a protected branch circuit suitable for a 7.5HP,

208-230/460 V three-phase induction motor. The motor

is pre-wired for operation with 208-230 V, 60Hz power.

Connect L1, L2 and L3 to the terminal blocks marked R, S

and T (Fig. A1) and the earthing conductor to the terminal.

Torque the terminal block screws to 4.5-7.0 lb.in. Jog the

power switch and check for proper blade rotation (curvature

of blade should spin towards front of tool). Interchange any

two line leads to reverse.

GROUNDING INSTRUCTIONS

This machine must be grounded while in

use to protect the operator from electric shock.

This tool should be connected to a grounded metal

permanent wiring system; or to a system having an

equipment-grounding conductor. Terminate the connecting

cord earthing conductor in the

of the terminal block. Make certain the other end is securely

bonded to the branch circuit ground.

(earth or ground) terminal

Fig. A1

460 VOLT OPERATION

This unit may be configured to operate from a 460V, 60Hz

source.

(A) Reconnect the motor for 460 V according to motor

nameplate wiring diagram.

B) Change the transformer primary voltage tap from

Terminal 3 (230 V) to Terminal 4 (460 V) (Fig. A2).

(C) Replace the 15-23 A overload with 8-12 A overload set

to 9A trip (Fig. A3).

Torque the overload and contactor terminal screws to 14.2 -

26.6 lb.in. Set the overload to ‘auto’ reset.

208 VOLT OPERATION

The unit is usable from 208 V, 60Hz supply provided

the overload trip current (Fig. A5) is set to 20 A and the

transformer primary voltage tap is changed from terminal ‘3’

to terminal ‘2’ (208 V) (Fig. A4).

Fig. A2

Fig. A4 Fig. A5

Fig. A3

5

Page 6

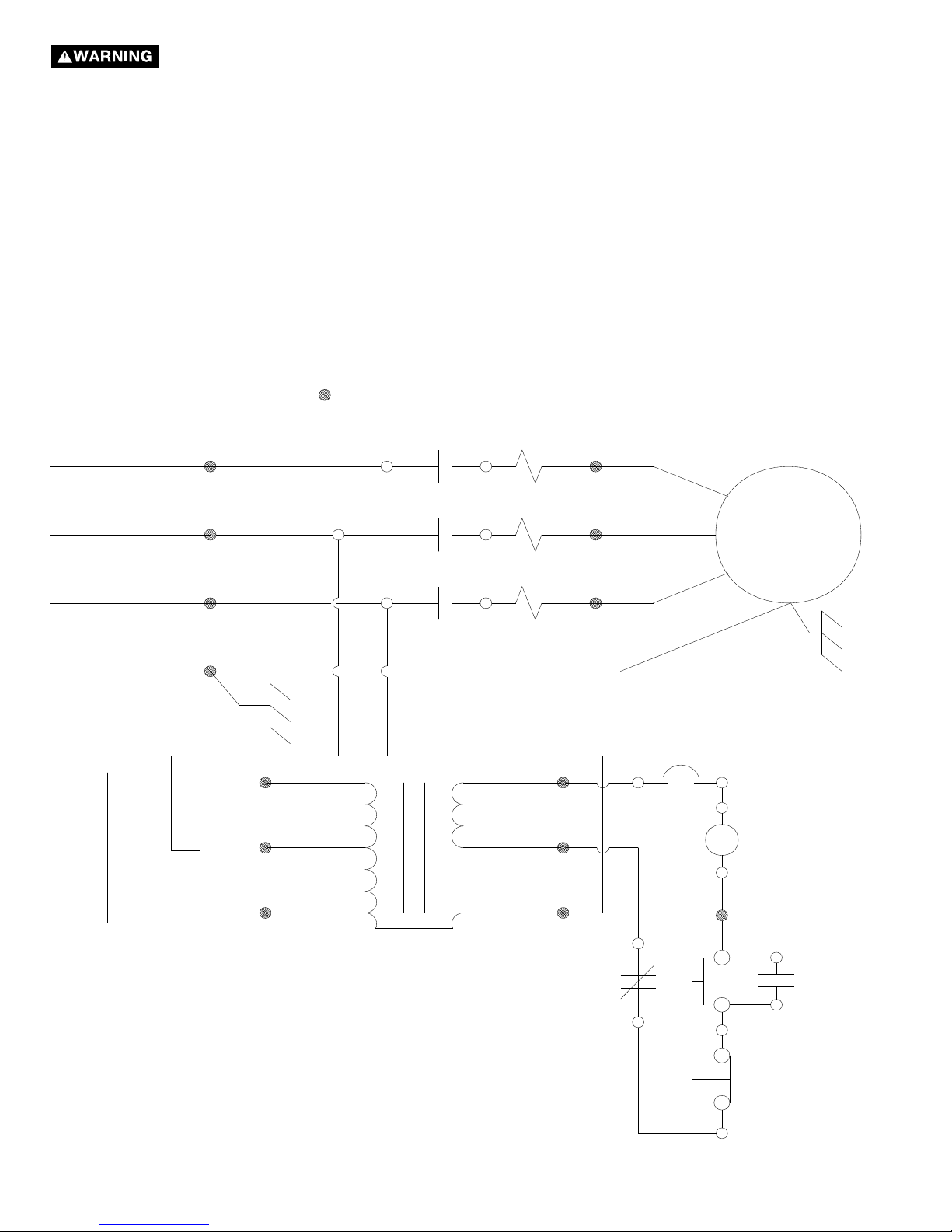

To reduce the risk of serious injury, electrocution, or property damage do not attempt to make

C

1

COM

5

COM

6

24V

4

3

2

460V

230V

208V

Connect as per line

voltage

N

R

S

T

M

2T

1

4T

2

6T

3

4N

O

3N

O

A2

A1

T1

T2

T3

4

5

6

95

NC

96

NC

1L

1

3L

2

5L

3

Connection made by

user

TR

OL

OL

CB

b0

b1

COMPONENTS

b 0

Off Switch

b 1

On Switch

C

Contactor

CB

Circuit Breaker

M

Motor

OL

Overload

Terminal Block

C

C

TR Transformer

any electrical connections on this machine. This diagram is provided only for use by a qualified electrician.

6

Page 7

FUNCTIONAL DESCRIPTION

FOREWORD

The Delta Industrial Model 36-790 14" Tilting Arbor Saw includes a magnetic starter with Low-Voltage Control (LVC)

and automatic reset thermal overload, Biesemeyer® Commercial Fence System, guide bar, miter gage, 43" x 59" table

with two extension wings and fence support extension. A 16” blade can also be used to increase the capacity of the

cut. The maximum depth of cut with 14" blade is 4-1/2" (114 mm) and with a 16" blade it is 5-1/2" (140 mm). At a 45°

angle, the maximum thickness of cut with a 14" blade is 3-1/8" (79 mm) and is 4-1/8" (105 mm) with a 16" bade.

NOTICE: The photo on the manual cover illustrates the current production model. All other illustrations contained in

the manual are representative only and may not depict the actual labeling or accessories included. These are intended

to illustrate technique only.

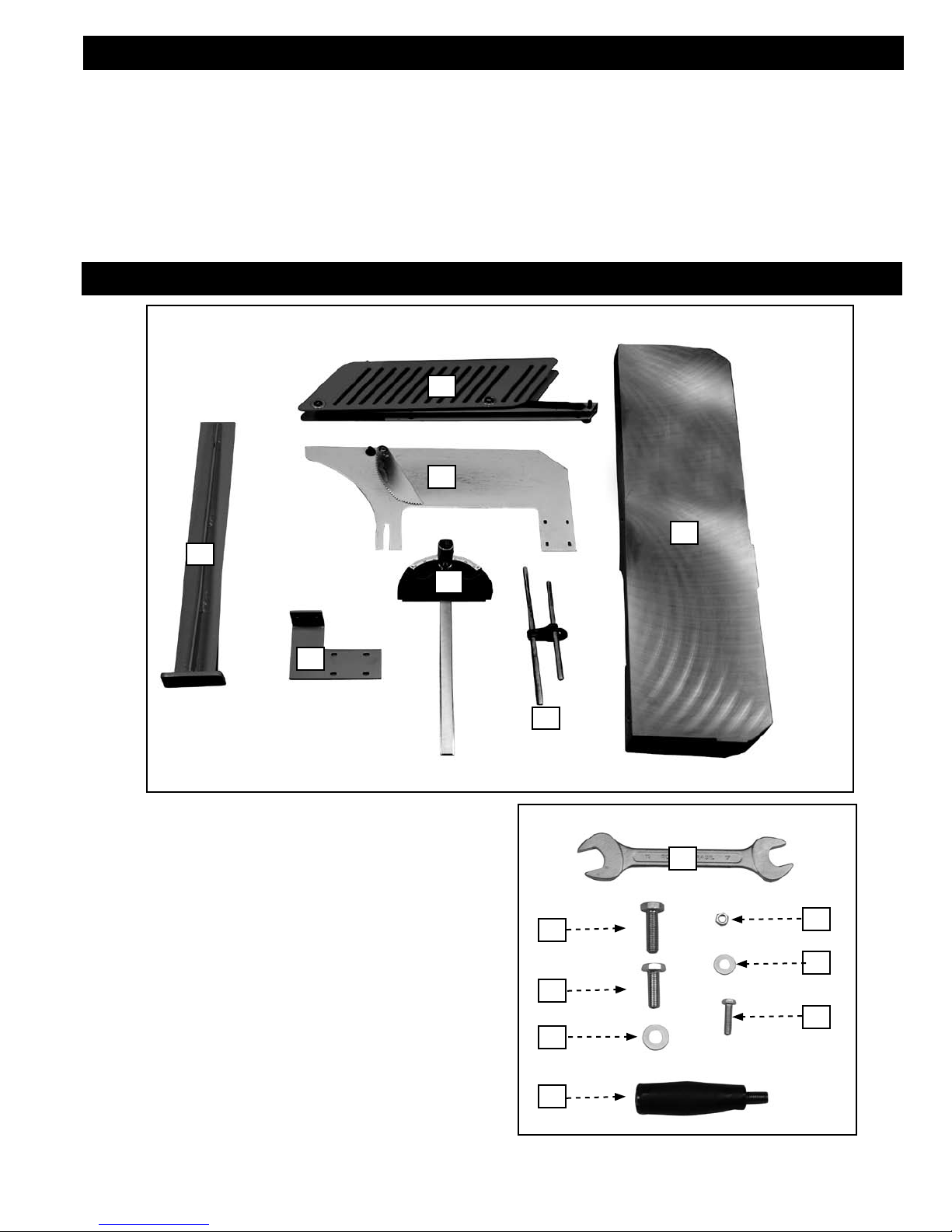

CARTON CONTENTS

2

4

1

5

1. Rip Fence Support Bracket

2. Blade Guard

3. Table Extension Wings

4. Splitter

5. Splitter Mounting Bracket

6. Miter Gauge

7. Stop Rod Assembly

8. 17mm & 19mm Open-End Wrench

9. M10 x 35mm Hex-Head Bolt

10. M6 Nut

11. M8 x 25mm Hex Head Bolt

12. 8mm Flat Washers

13. M10 Flat Washers

14. M6 x 20mm Hex-Head Bolts

15. Handle

3

6

7

8

9

10

12

11

14

13

15

7

Page 8

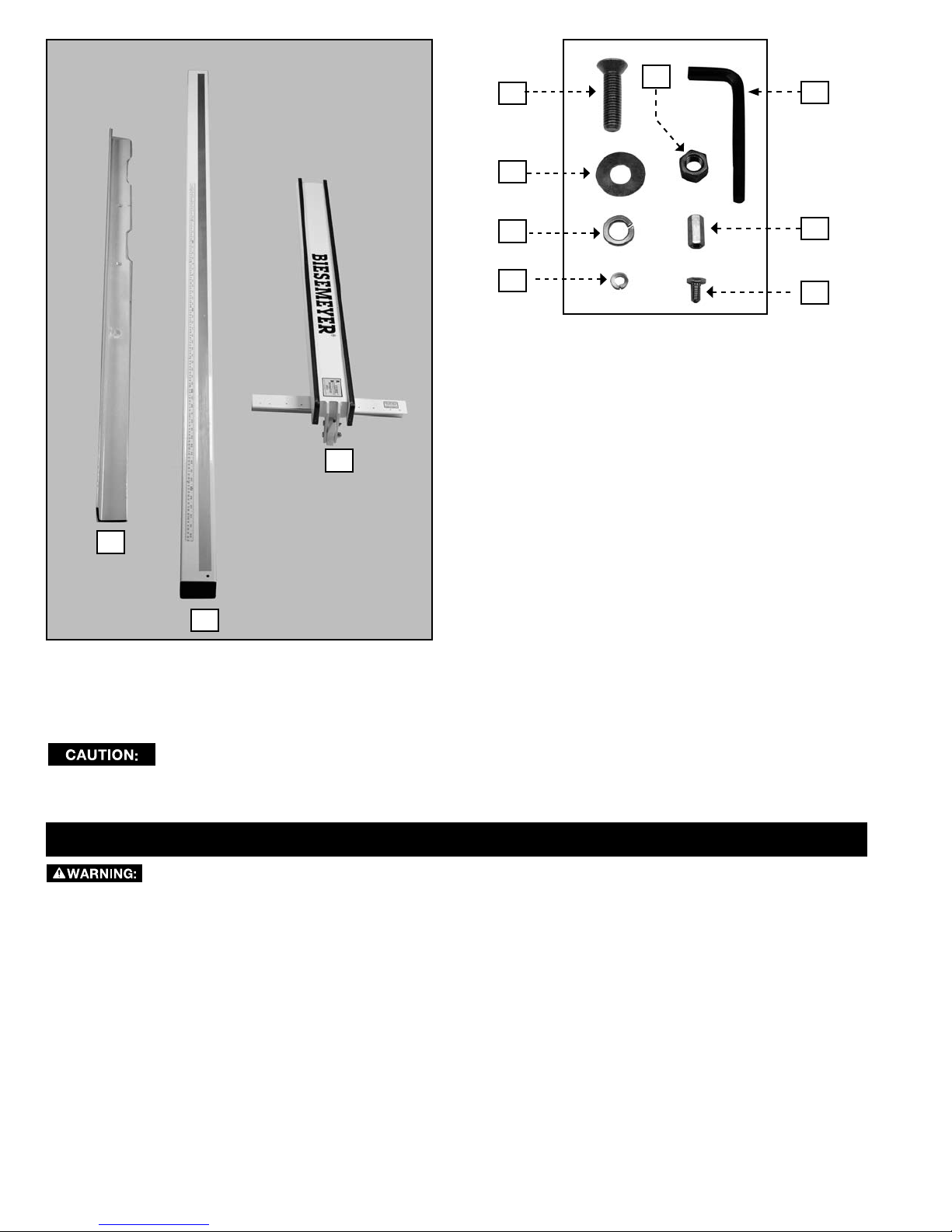

7

4

5

6

8

10

1. Front Rail

2. Guide Tube

3. Fence Assembly

4. 1/2"-13 x 2" Flat Head Bolts

5. 5/16" Hex Wrench

6. 1/2" Flat Washer

3

1

7. 1/2"-13 Hex Nuts

8. Lockwasher

9. Retaining Nut

10. Lockwasher

11. Retaining Nut Bolt

9

11

2

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil from

unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer thinner for cleaning your

machine.

After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

ASSEMBLY

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and remov-

ing accessories, before adjusting or when making repairs. An accidental start-up can cause injury.

ASSEMBLY TOOLS REQUIRED

* 17mm and 19mm open end wrench (supplied)

* Blade wrench (supplied)

ASSEMBLY TIME ESTIMATE

Assembly for this machine takes approximately 2-3 hours.

8

Page 9

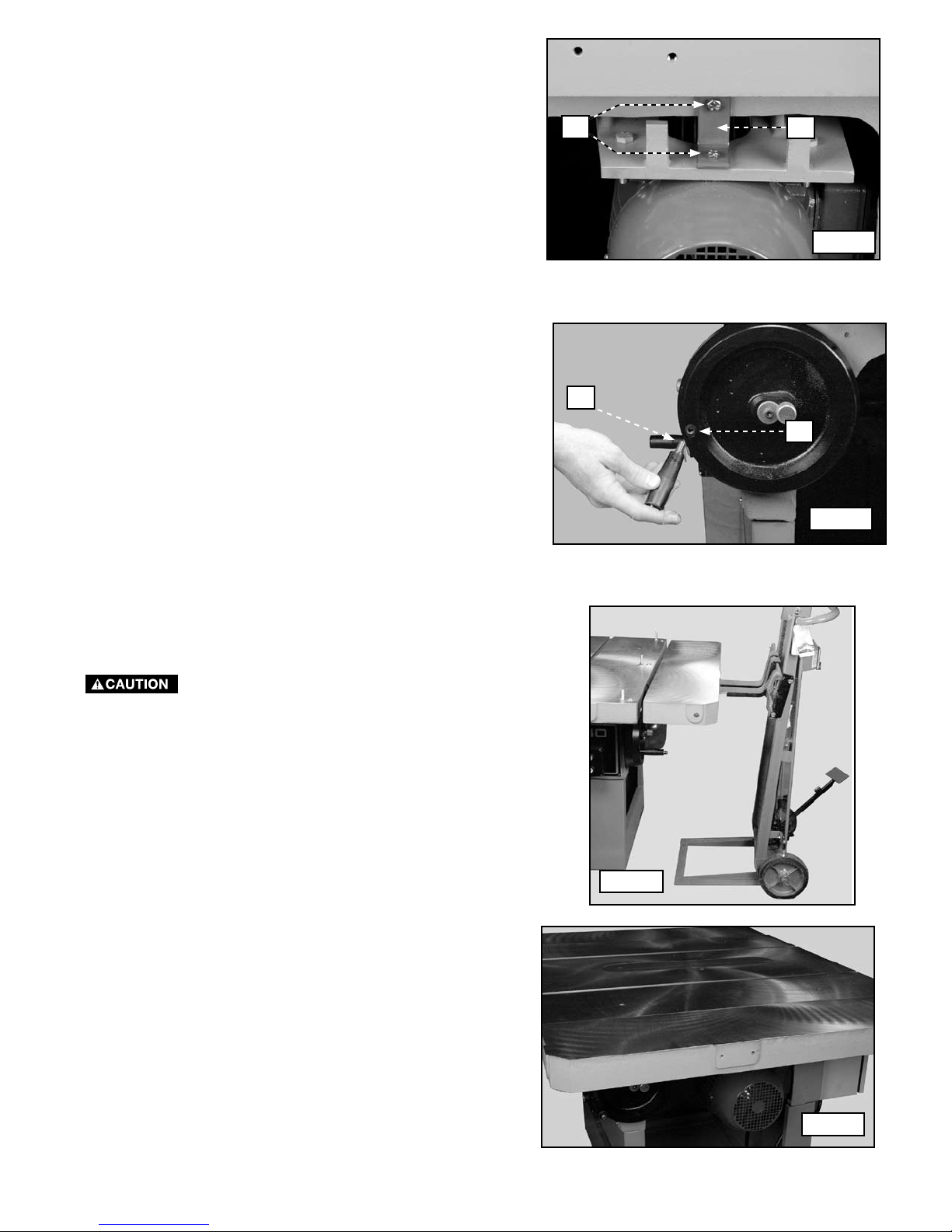

IMPORTANT - Before assembling this machine, remove

the two bolts (A) Fig. 1 and the red shipping strap (B).

This bracket protects the motor during shipment.

A

HOW TO ATTACH THE HANDLE TO THE ELEVATOR MECHANISM

B

Fig. 1

Insert the threaded end of the handle (A) Fig. 2 in the

threaded hole of the elevator wheel (B) and tighten it

securely by turning it clockwise.

HOW TO ATTACH THE TABLE EXTENSION WINGS

The table extension wings are very heavy.

Use a lifting device (Fig. 3) to lift and hold the extension

table in place during installation.

A

B

Fig. 2

This machine is supplied with two table extension wings.

Attach the extension wing with the two tapped holes (A)

Fig. 4 to the right side of the machine.

Fig. 3

Fig. 4

9

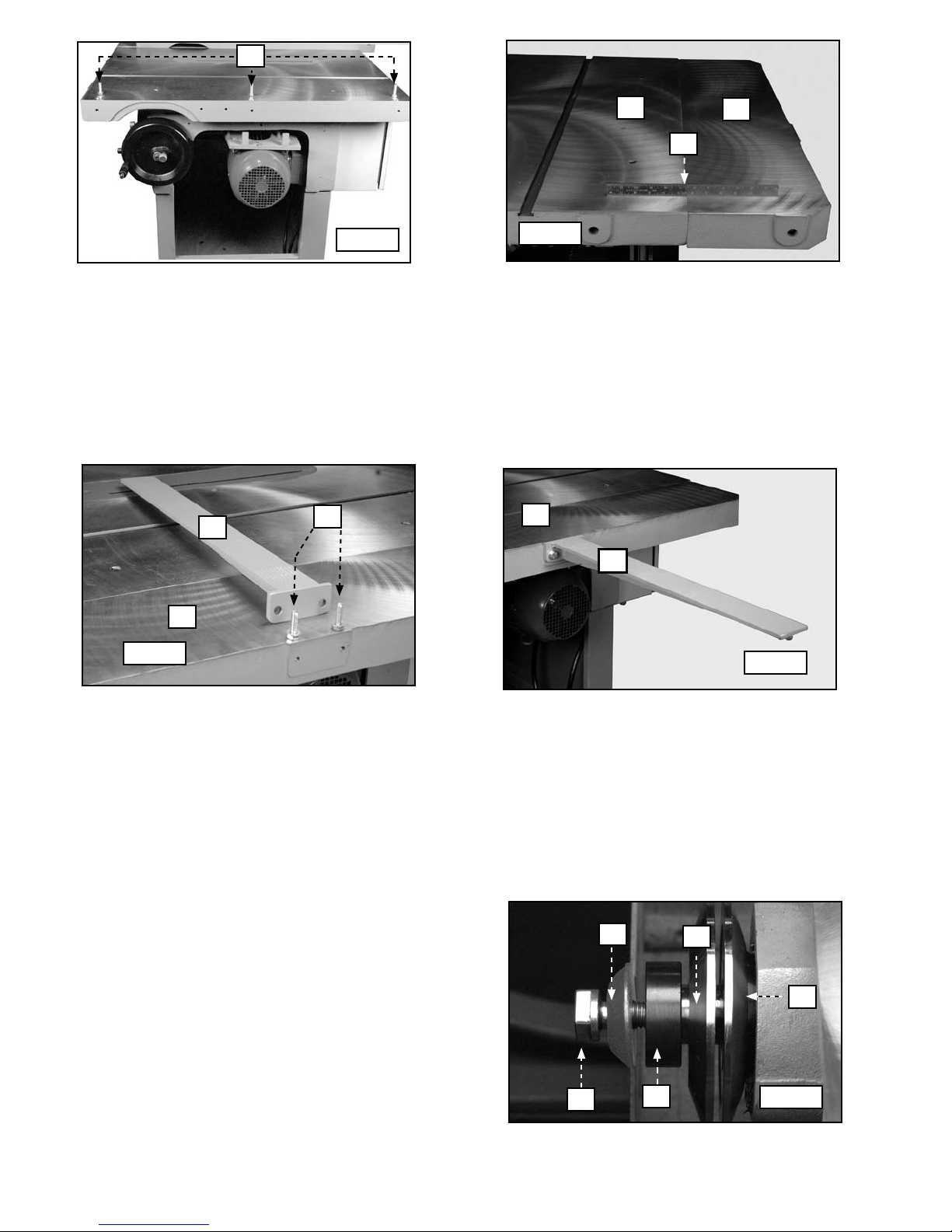

Page 10

A

B

C

A

Fig. 5

Attach the extension wing to the saw with three M10 x 35mm hex-head bolts (A) Fig. 5.

Note: Loosely tighten the bolts for further adjustment.

Place a straight-edge (A) Fig. 6 on the saw (B) and the extension table (C) over the first bolt to check the level. When

the two are level, tighten the bolt. Do the same with the far bolt. Tighten all hardware securely.

Install the other extension wing in the same manner.

Fig. 6

HOW TO ATTACH THE RIP FENCE SUPPORT BRACKET

A

C

B

A

A

B

Fig. 7

Attach the rip fence support bracket (A) Fig. 7 to the saw (B) with two M8 x 35mm hex-head bolts (C) Fig. 7.

Note: Loosely tighten the bolts for further adjustment.

Place a straight-edge on the saw (B) and the fence support bracket (A) to check the level. When the two are level,

tighten the bolts. Tighten all hardware securely.

Fig. 8

HOW TO ATTACH A SAW BLADE

NOTE: No blade is supplied with this saw.

1, Remove the table insert and raise the saw arbor to its

full height by turning the elevation handwheel.

NOTE: Turn the arbor bolt clockwise to loosen.

2. Use the provided blade wrench to remove the arbor

bolt (A), the retainer (B), the spacer (C), and the blade

flange (D).

B

D

E

NOTE: Leave the inside blade flange (E) on the arbor.

NOTE: Press the lock button (A) Fig. 11 to prevent the

arbor from rotating.

10

A

C

Fig. 9

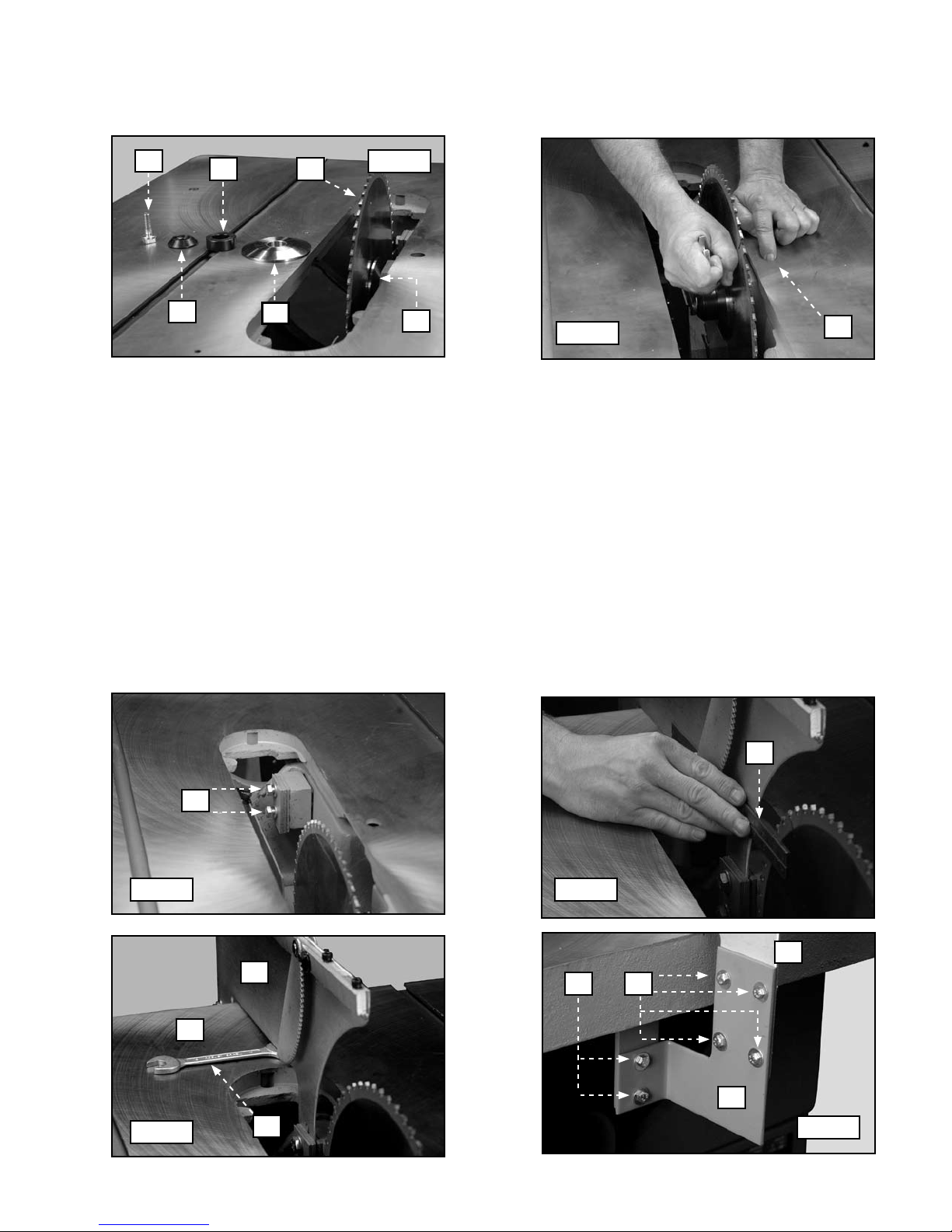

Page 11

3. Place the saw blade (A) Fig. 10 with the teeth pointing down toward the front of the saw, against the interior blade

C

flange (B).

4. Add the exterior blade flange (C ), the spacer (D ), the retainer (E ), and the arbor bolt (F).

5. Press down on the arbor lock button (A) Fig. 11 and securely tighten the arbor bolt by turning it counter-clockwise.

F

D

A

E

Fig. 10

B

Fig. 11

A

HOW TO ATTACH THE BLADE GUARD AND SPLITTER ASSEMBLY

IMPORTANT: The width of the blade determines the correct position of the splitter on the splitter mounting bracket.

1. Loosen the two bolts (A) Fig. 12.

NOTE: Three sizes of individual spacers are located on the splitter mounting bracket.

2. Place a straight edge (A) Fig. 13 against the back of the blade. Align the blade with the splitter.

3. Place the splitter where indicated inside the spacers of the splitter mounting bracket.

NOTE: Position the splitter approximately 1/8" above the table surface.

4. Use the arbor wrench (A) Fig. 14 as a spacer. Place it between the splitter (B) and the table surface (C). Tighten the

two bolts (A) Fig. 12.

5. Use the four M6 x 20mm hex-head screws (A) Fig. 15, the eight flat washers, and four hex nuts to attach the splitter

bracket (C) Fig. 15 to the splitter (D).

6. Use the two M6 x 25mm hex-head bolts (B) Fig. 15, four flat washers, and two hex nuts to attach the splitter bracket

assembly to the clamp.

NOTE: Loosely tighten the bolts for further adjustment.

A

Fig. 12 Fig. 13

B

C

Fig. 14

A

11

A

D

AB

C

Fig. 15

Page 12

6. Lower the blade and attach the table insert (A) Fig.

16 to the saw table. Use a straight edge (B) to see if

the table insert (A) is level with the table surface (C).

Level the table insert by turning the necessary hex

bolts at (D).

B

D

A

7. Use the arbor wrench as a spacer to adjust the

height of the anti-kickback finger (A) Fig. 17. Place

the wrench under the anti-kickback finger, loosen the

screw (B) and adjust the cam (C) so that the antikickback finger (A) is pointing to the rear and not

touching the table. Adjust the other kickback finger

in the same manner.

IMPORTANT: Rotate the blade-beveling handle until

the blade is at the 45° bevel position. Check the anti-

kickback finger to see that it is not touching the table.

B

D

C

Fig. 16

C

A

Fig. 17

8. Use a straight-edge (A) Fig. 18 to see if the splitter

(B) is aligned with the blade (C). Tighten the mounting

bolts.

9. Remove the two bolts (A) Fig. 19 from the top of the

splitter (B) Attach the guard basket assembly Fig. 20

to the splitter with the two bolts.

B

A

Fig. 19

A

Fig. 18

B

C

Fig. 20

12

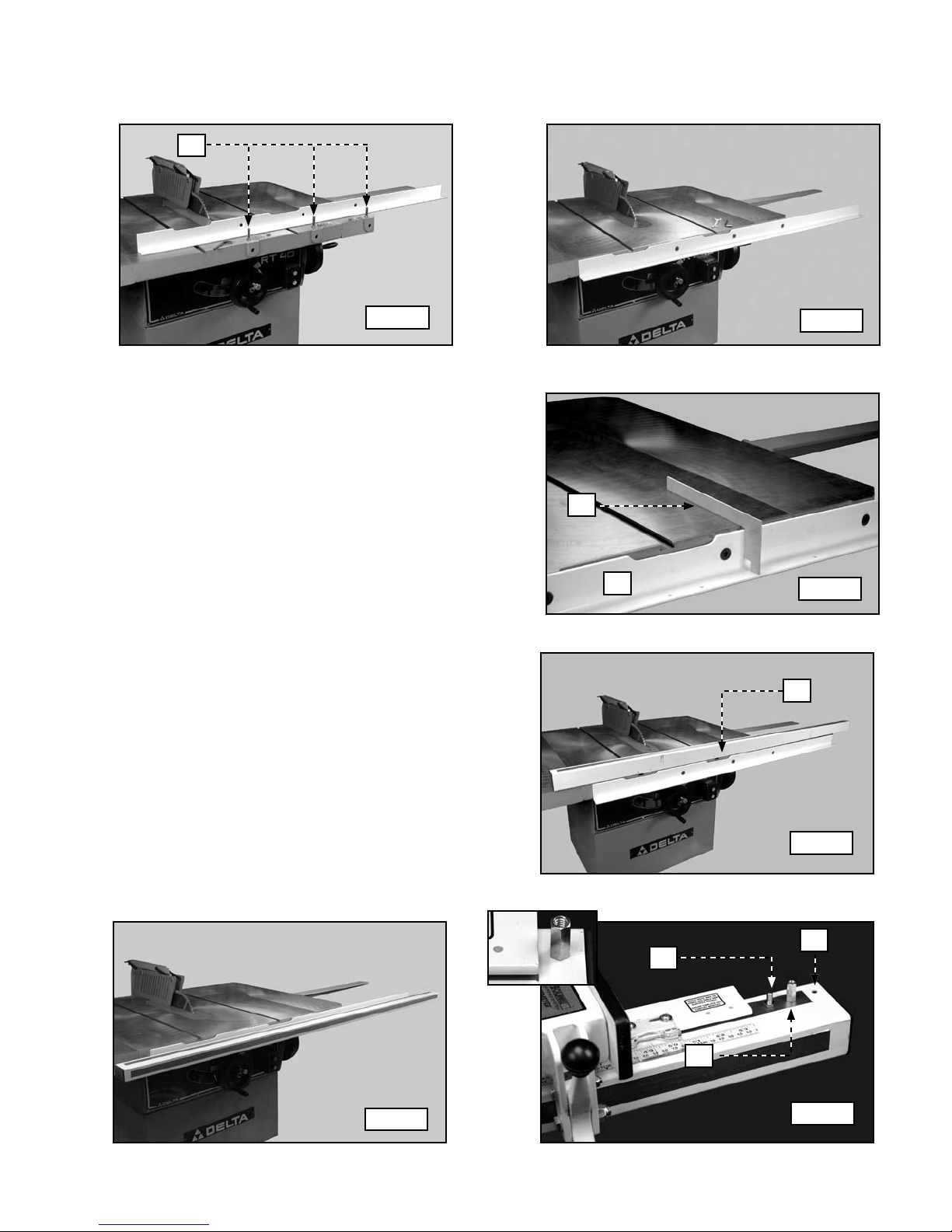

Page 13

HOW TO ATTACH THE RIP FENCE GUIDE RAIL

1. Use three (3) 1/2-13 X 2" flat-head bolts, flat washers, lockwashers, and hex nuts (A) Fig. 21 to attach the guide rail

to the front of the saw table (Fig. 22). Loosely tighten with the supplied hex wrench for further adjustment.

A

Fig. 21

2. Use the template (A) Fig. 23 that is supplied with the

fence system to check and adjust the level of the

front rail (B) to both ends of the saw table. Tighten

the guide rail hardware securely.

NOTE: Do NOT level the rail with the extension wing. Use

the saw table.

3. Place the guide tube (A) Fig. 24 on the saw table.

Align the nine (9) threaded holes with the holes in the

front ledge.

4. Position the guide tube on the front rail. Secure the

guide tube with nine (9) 1/2" hex-head bolts and

lockwashers.

5. Place the rip fence on the guide rail.

6. Insert a bolt (A ) Fig. 26 up through the hole (B ) at

the extreme right end of the guide tube. Thread the

retaining nut (C ) on the bolt (see the inset - Fig. 26)

NOTE: This retaining nut prevents the fence from falling

off the end of the guide rail.

A

B

Fig. 22

Fig. 23

A

IMPORTANT: Before applying power to the saw, en-

sure that the rip fence is parallel to the miter gauge

slot. Refer to the section "HOW TO OPERATE AND

ADJUST THE RIP FENCE".

Fig. 25

Fig. 24

B

A

C

Fig. 26

13

Page 14

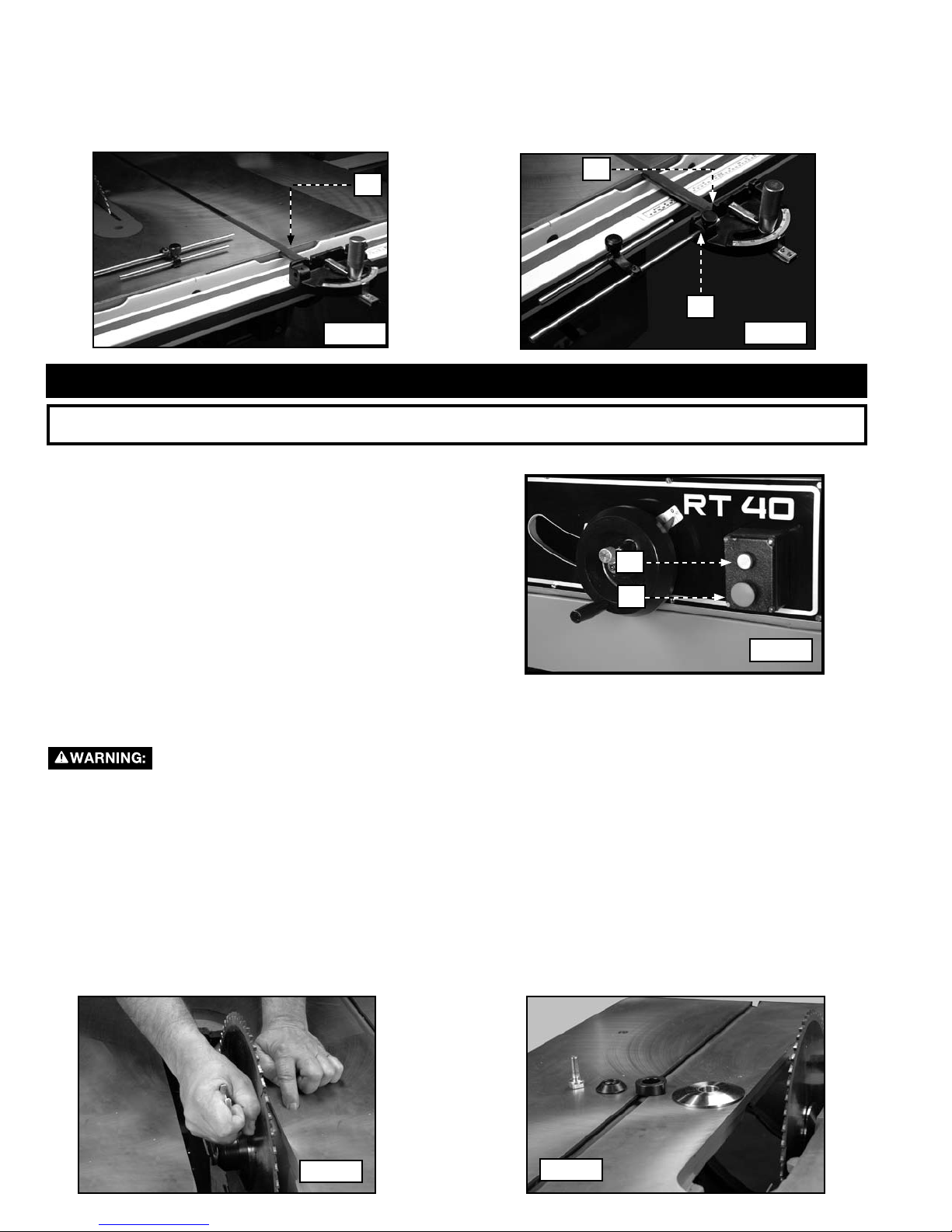

HOW TO ATTACH THE MITER GAUGE AND STOP-ROD ASSEMBLY

1. Insert the miter gauge bar (A) Fig. 27 in the T-Slot of the saw table. The t-slot miter gauge bar will prevent the miter

gauge from falling when it is extended beyond the table surface.

2. Loosen the lock knob (A) Fig. 28 and insert the end of the stop rod (D) in the hole on the side of the miter gauge

body.

3. Tighten the lock knob (A) Fig. 28.

A

A

D

Fig. 27

Fig. 28

OPERATION

OPERATIONAL CONTROLS AND ADJUSTMENTS

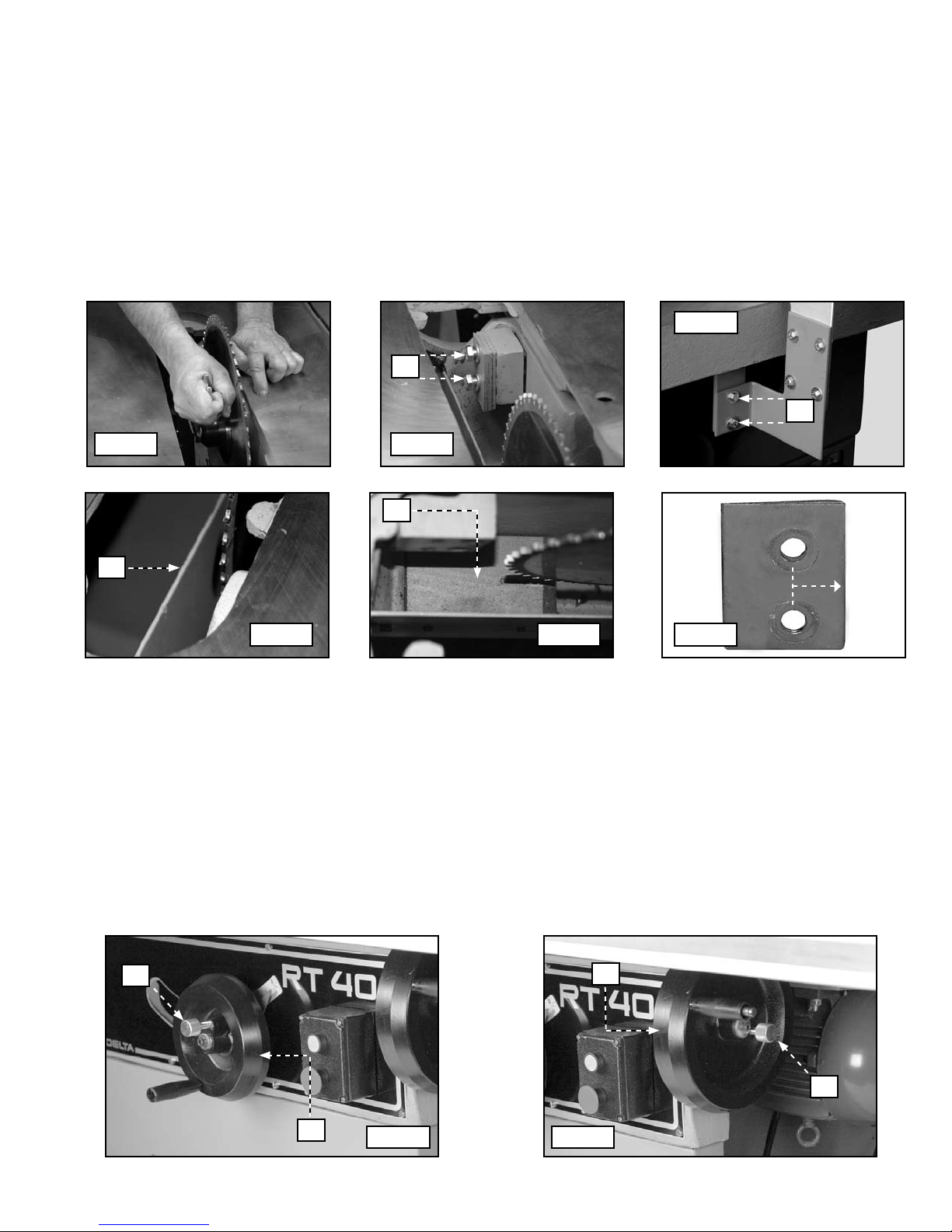

HOW TO START AND STOP THE MACHINE

The start/stop switch is located at the front of the machine.

To start the machine, push the green button (A). To stop the

machine, push the large red button (B).

OVERLOAD PROTECTION

This machine will shut the motor down because of overloading

or low voltage.

If the machine shuts down, let it cool for about five minutes,

then push the green start button.

IMPORTANT: If the saw shuts off frequently, have a qualified

electrician find the problem and correct it.

A

B

Fig. 29

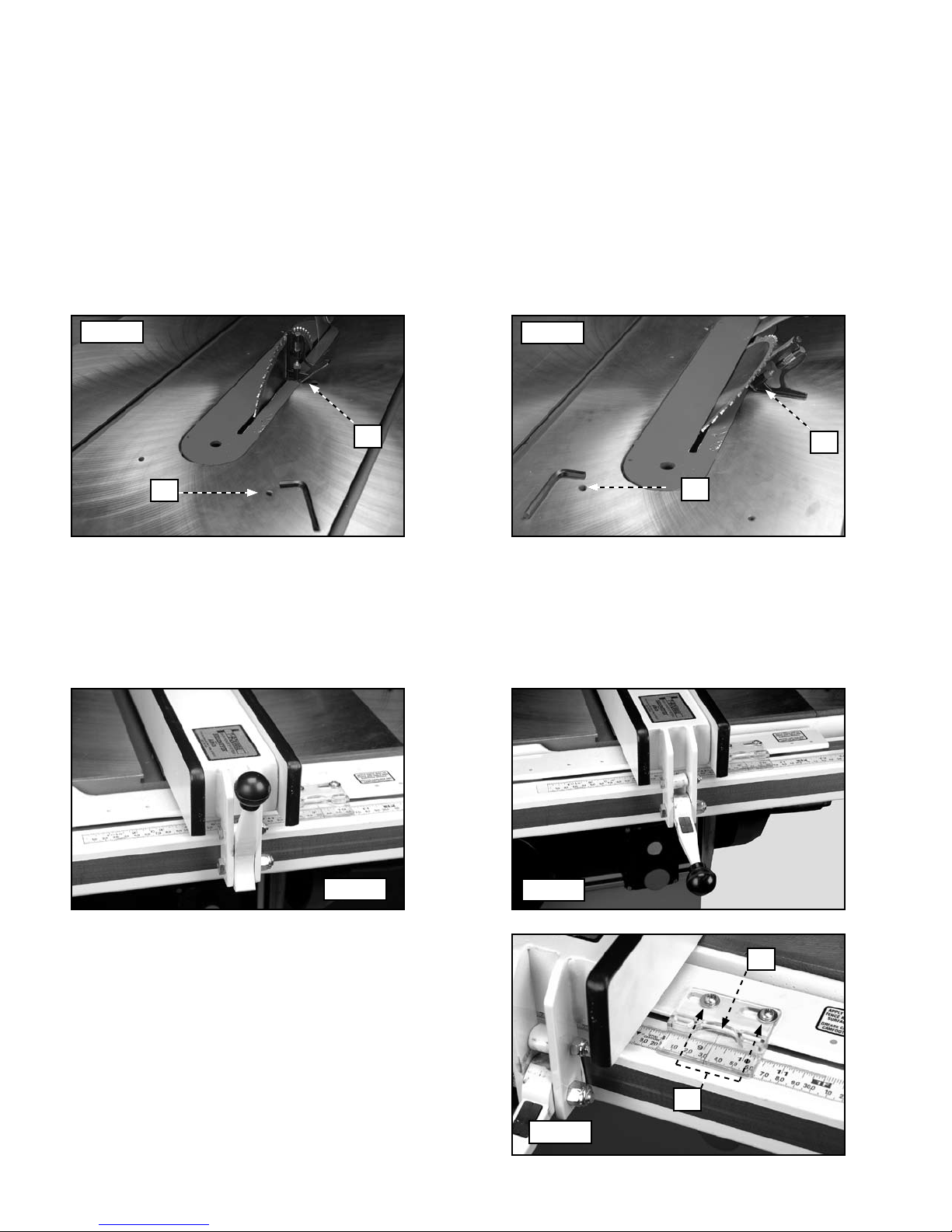

HOW TO CHANGE THE BLADE

Shut off the power source to the machine.

1. Remove the blade guard and the table insert.

NOTE: Remove the splitter assembly ONLY if the thickness of the replacement blade is different from the original blade.

2. Raise the blade to its fullest height.

3. Push the arbor lock button down and use the provided arbor wrench to remove the arbor bolt. Turn the wrench

toward the front of the saw.

4. Position the new blade on the saw arbor. Replace the blade flange, the space, the retainer, and the arbor bolt.

5. Push the arbor lock button down, and tighten the blade assembly by turning the wrench toward the rear of the

saw.

6. Replace the table insert and the blade guard. If you removed the splitter assembly, replace it.

NOTE: If the new blade is of a different thickness from the old blade, refer to "HOW TO ATTACH THE BLADE GUARD

AND SPLITTER ASSEMBLY" for proper placement of the splitter.

Fig. 30

Fig. 31

14

Page 15

HOW TO ATTACH A 16" BLADE

1. Remove the blade guard and the table insert.

2. Raise the blade to its fullest height.

3. Push the arbor lock button down and use the provided arbor wrench to remove the arbor bolt. Turn the wrench

toward the front of the saw.

4. Remove the plates (A) Fig. 33.

5. Remove the two bolts (A) Fig. 34 and take off the splitter bracket.

6. Remove the guard (A) Fig. 35 and wooden block (A) Fig. 36.

7. Position the new blade on the saw arbor. Replace the blade flange, the space, the retainer, and the arbor bolt.

8. Replace the guard and block.

9. Replace the plates with the short area toward the blade (Fig. 37). The holes in the plate are cut off center.

10. Push the arbor lock button down, and tighten the blade assembly by turning the wrench toward the rear of the

saw.

11. Replace the table insert and the splitter assembly.

Fig. 34

A

A

Fig.32 Fig. 33

A

A

Fig. 35

Fig. 36 Fig. 37

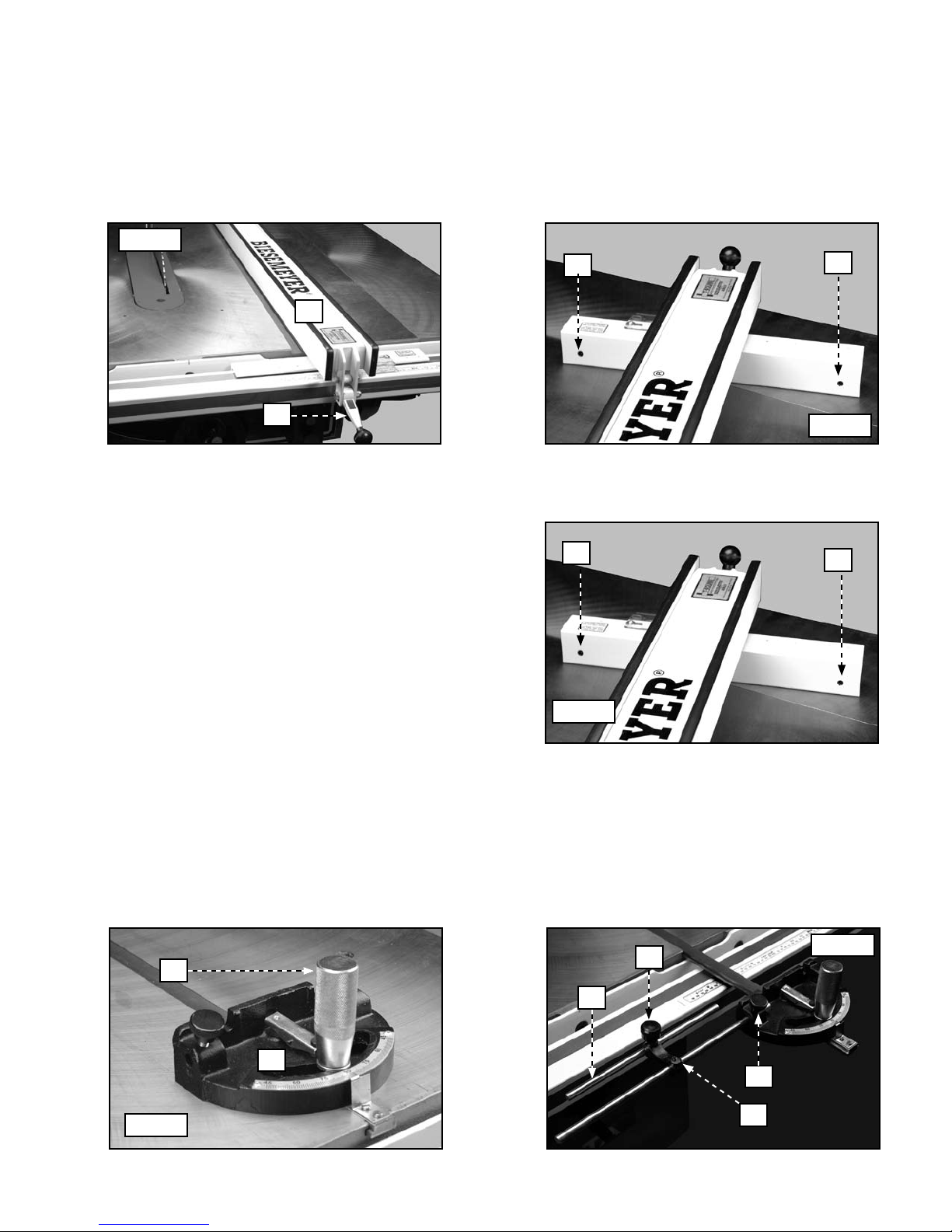

HOW TO RAISE AND LOWER THE BLADE

To raise the blade, loosen the locking knob (A) Fig. 38 and rotate the handwheel (B) clockwise.

To lower the blade, loosen the locking knob and rotate the handwheel counter-clockwise.

Lock the blade at any height with the locking knob (A) Fig. 38.

IMPORTANT: Lock the blade before applying power to the saw.

HOW TO TILT THE BLADE

Loosen the locking knob (A) Fig. 39 and rotate the handwheel (B) clockwise.

Lock the blade at any angle with the locking knob (A) Fig. 37.

IMPORTANT: Lock the blade before applying power to the saw.

Short

area

A

B

B

A

Fig. 38 Fig. 39

15

Page 16

HOW TO ADJUST THE POSITIVE STOPS

This machine has positive stops that will allow you to quickly and accurately position the blade at 90° and 45° to the

table. To check and adjust the positive stops:

1. Raise the blade to its fullest height.

2. Position a square (A) Fig. 40 against the blade and the table to check the angle.

3. If the blade is not 90° to the table, remove the lock screw located inside the hole (B) and slightly loosen the adjustment screw located underneath the lock screw. Rotate the tilting handwheel until the blade is at the correct angle.

Tighten the adjustment screw until it bottoms. Replace the lock screw. Check the angle of tilt indicator on the handwheel is pointing to "0". If not, adjust it.

4. Tilt the blade as far as it will go by turning the tilting handwheel counter-clockwise.

5. Position a square (A) Fig. 41 against the blade and the table to check the angle.

6. If the blade is not 45° to the table, remove the lock screw located inside the hole (C) and slightly loosen the adjustment screw located underneath the lock screw. Rotate the tilting handwheel until the blade is 45° to the table. Tighten

the adjustment screw until it bottoms. Replace the lock screw.

Fig. 40

Fig. 41

A

B

HOW TO OPERATE AND ADJUST THE RIP FENCE

To move the fence along the guide rail, lift the clamp lever (Fig. 42).

To lock the fence in position, push down on the clamp lever (Fig. 43).

NOTE: The clamp lever will remain in the "up" position when you move the fence.

A

C

Fig. 42

The distance the fence is positioned from the blade is

indicated by the witness line (A) Fig. 44 on the cursor.

To adjust the cursor, test cut a workpiece with the fence

locked in position. Measure the width of the workpiece.

Loosen the two screws (B), adjust the cursor until the

witness line (B) is aligned with the previous measurement. Tighten the screws.

Fig. 43

A

B

Fig. 44

16

Page 17

HOW TO ADJUST THE FENCE PARALLEL TO THE MITER GAUGE SLOTS

IMPORTANT: Be certain that the miter gauge slots are parallel with the blade before adjusting the fence.

Move the fence (A) Fig. 45 until the bottom edge is aligned with the edge of one of the miter gauge slots and lock it in

place with the lock clamp (B). If the fence is not parallel to the slot, raise the lock clamp, and lift the fence off of the

guide tube. Use a 3/16" hex wrench (not supplied) to tighten or loosen the adjustment screw (either C or D) Fig. 46 that

applies.

IMPORTANT: Any necessary adjustments should be very small.

Fig. 45

C

D

A

B

Fig. 46

HOW TO ADJUST THE CLAMP HANDLE

When the clamp handle is in the "down" position (Fig.

47), the fence will lock to the guide tube. If this is not the

case, lift the clamp handle and raise the fence assembly

off of the guide tube. Slightly tighten the two adjusting

screws (D) and (E) an equal amount, using a 3/16" hex

wrench. Replace the fence assembly and check for correct clamping. Repeat as necessary.

IMPORTANT: After adjustment of the clamp handle, recheck to see that the fence and miter gauge slots are

parallel.

E

Fig. 47

F

HOW TO ADJUST THE MITER GAUGE AND STOP RODS

You can adjust the miter gauge (A) Fig. 48 right and left by loosening the locking handle (B), pushing down on lever, and

rotating the miter gauge body. Lock the body in position with the locking handle (B)

You can adjust the stop rods (D) Fig. 49 by loosening the set screw (E) or loosening the knob (F). The stop rods can be

removed by loosening the knob (G).

B

A

Fig. 48

17

D

F

Fig. 49

G

E

Page 18

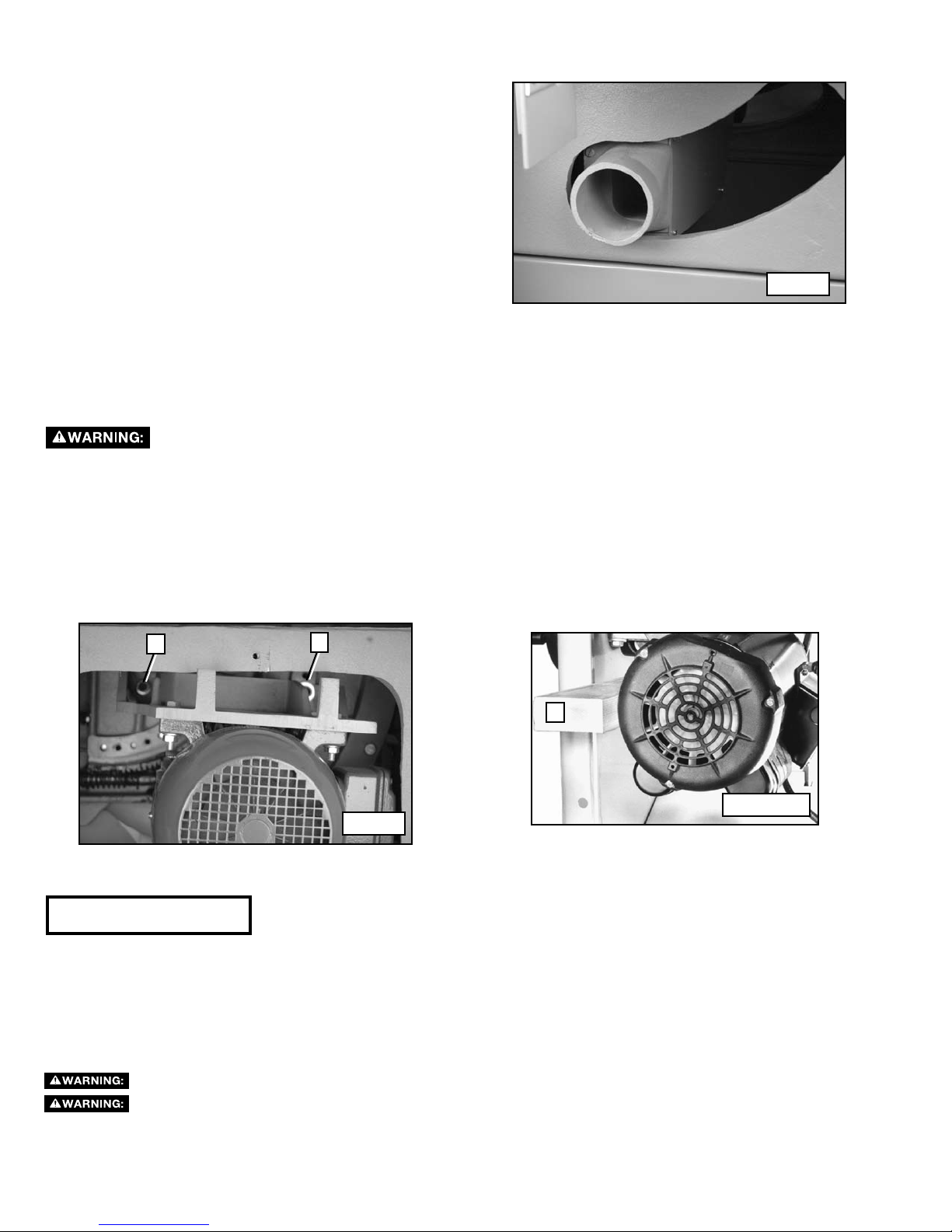

DUST CHUTE

This machine is equipped with a 3-1/2" O.D. dust chute (Fig.

50) that easily adapts to a central dust collection system.

Fig. 50

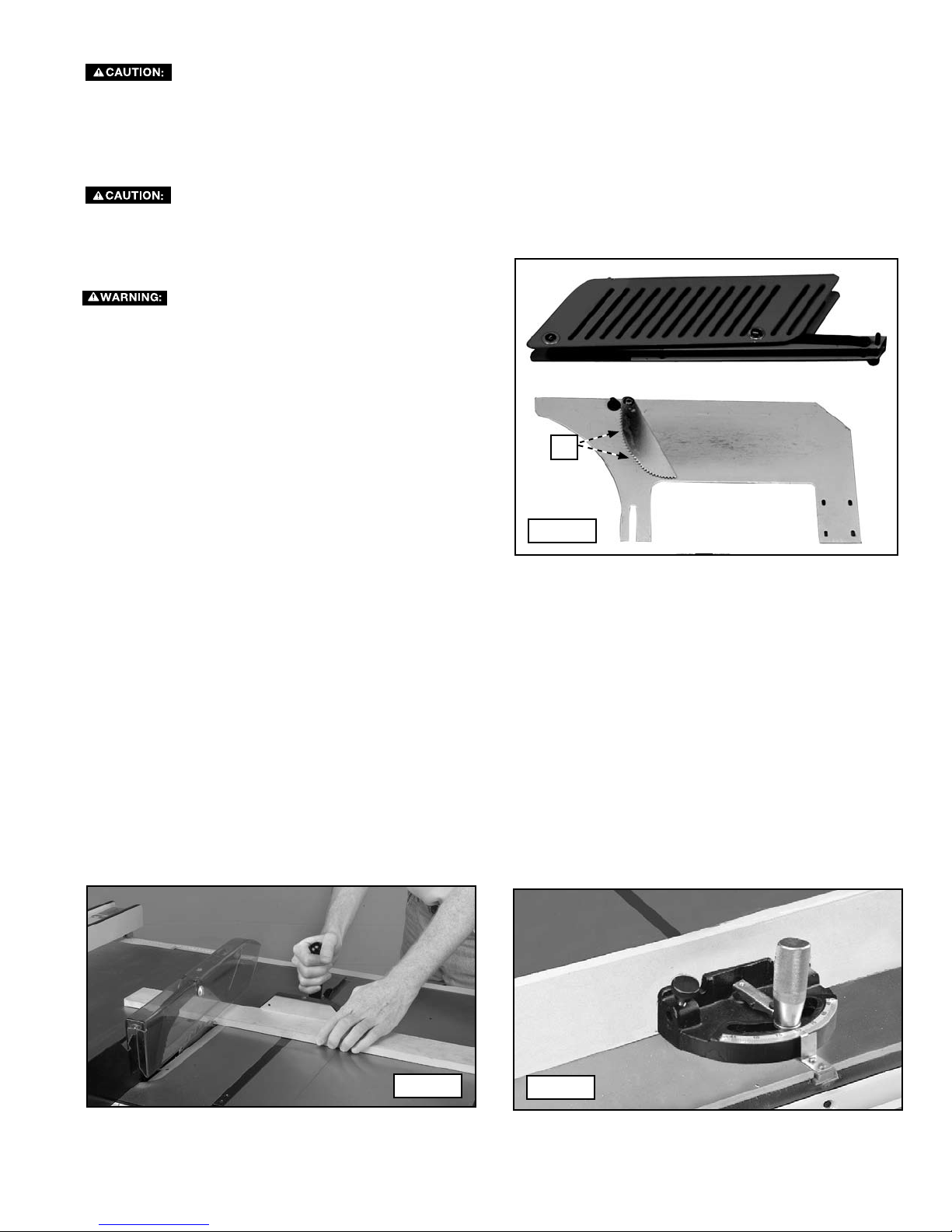

HOW TO CHANGE SPEEDS AND ADJUST BELT TENSION

This saw has a double V-belt drive that provides blade speeds of 3000 and 4500 RPM. To achieve the faster speeds, place the

belts on the largest steps of the motor pulley and the smallest steps of the arbor pulley.

Shut off the power source to the machine.

1. Position the blade in the 90° position and lower the blade about two turns.

2. Loosen the bolt (A) Fig. 51 and remove the bolt (B).

3. Place a block of wood (C) Fig. 51A between the motor and the inside of the saw cabinet. Lower the motor against

the block of wood until the belt tension is released.

4. Position the belts on the motor and spindle pulleys and raise the blade. The weight of the motor is sufficient to

provide proper tension.

5. Tighten the bolt (A). Replace and tighten the bolt (B).

A

B

C

Fig. 51A

Fig. 51

MACHINE USE

Common sawing operations include ripping and cross cutting plus a few other standard operations. As with all power machines,

a certain amount of hazard is involved with the operation and use of the machine. Using the machine with the respect and

caution will considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or

completely ignored, personal injury can result. The following information describes the safe and proper method for performing

the most common sawing operations.

The use of attachments and accessories not recommended be Delta may result in injury.

Never operate the saw without the proper table insert for the saw blade or cutter installed.

18

Page 19

QUICK OPERATIONS CHECKLIST

Before using the saw each time, verify the following:

1, The blade is tight.

2. The bevel angle and height lock-knobs are tight.

3. If ripping, ensure that the fence lock lever is tight and that the fence is parallel to the blade.

4. If crosscutting, ensure that the miter gauge knob is tight.

5. Proper eye, hearing, and respiratory equipment are being used.

6. The blade guard is properly attached and the anti-kickback pawls are functioning.

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

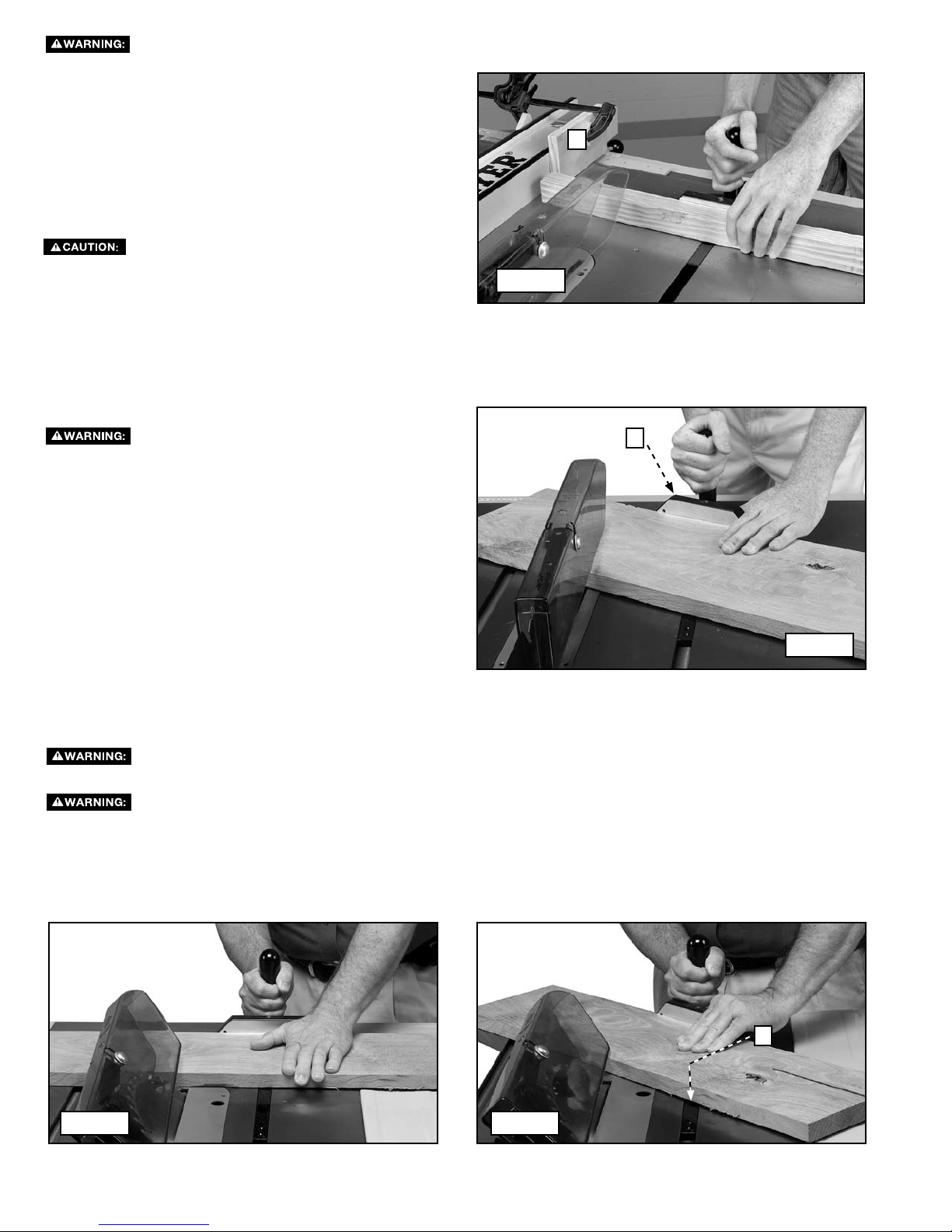

BLADE GUARD AND SPLITTER USE

The blade guard assembly provided with

Delta saws (Fig. 52) must be used for all through-sawing

operations. The splitter prevents the kerf from closing and

binding the blade, causing kickback. The anti-kickback pawls

(A) Fig. 52 prevent the workpiece and the cut-off piece from

being thrown back at the operator. The guard prevents dust

and debris from being thrown at the operator. To use the guard

properly:

1. Make sure that the splitter is aligned with the blade

as described in the section “BLADE GUARD AND

SPLITTER ASSEMBLY AND ALIGNMENT.”

2. Replace or sharpen the anti-kickback pawls when they

become dull.

3. Keep the guard clean.

4. Use caution when feeding workpieces that may catch

on the guard and cause a bind, or force the guard into

the blade (such as when cutting moulding).

A

Fig. 52

CROSS-CUTTING

Cross-cutting requires the use of the miter gauge to posi tion and guide the work. Before starting the cut, raise the blade so that

it is about 1/8” (3.2mm) higher than the top of the workpiece. Place the work against the miter gauge and advance both the

gauge and work toward the saw blade (Fig. 53). You can use the miter gauge in either table slot. Start the cut slowly and hold

the work firmly against the miter gauge and the table. Keep both hands on the miter gauge and workpiece. Do not touch the

cut-off piece. Feed the workpiece steadily through the blade until the workpiece is completely cut. Shift the workpiece slightly

sideways away from the blade, then pull the workpiece and miter gauge back to the starting position. Remove the workpiece,

then use a push stick to push the cut-off piece past the blade and off the table before beginning the next cut.

For added safety and convenience, you can attach an auxiliary wood-facing (C) Fig. 54 to the miter gauge. This facing should

be at least 1" higher than the maximum depth of cut, and should extend out 12" or more to one side or the other depending

on which miter gauge slot is used. Attach this auxiliary wood-facing (C) to the front of the miter gauge by using two wood

screws with a washer through the slots provided in the miter gauge body.

Fig. 53

Fig. 54

19

Page 20

Never use the fence as a cut-off gauge when cross-cutting.

When cross-cutting a number of pieces to the same length,

clamp a block of wood (B) to the fence and use it as a cutoff gauge (Fig. 55). The block (B) must be at least 3/4" thick

to prevent the cut-off piece from binding between the blade

and the fence during removal from the saw table. Always

position this block of wood in front of the saw blade. Once

the cut-off length is determined, lock the fence and use the

miter gauge to feed the work into the cut.

When using the block (B) Fig. 55 as a cut-

off gauge, position the rear end of the block so that the

workpiece is clear of the block before it enters the blade.

Fig. 55

B

MITERING

Mitering (Fig. 56) is the same as crosscutting except the miter gauge (C) is locked at an angle other than 0°. Hold the workpiece

firmly against the miter gauge and feed the work slowly into the blade to prevent the workpiece from moving.

Use caution when starting the cut to prevent

binding of the guard against the workpiece. Miter angles

greater than 45° may force the guard into the saw blade

and damage the guard. Before starting the motor, test

the operation by feeding the workpiece into the guard. If

the guard contacts the blade, place the workpiece under

the guard, not touching the blade, before starting the

motor. Certain workpiece shapes, such as mouldings,

may not lift the guard properly. Feed the work slowly to

start the cut.

C

Fig. 56

BEVEL CROSSCUTTING

Bevel crosscutting (Fig. 57) is the same as crosscutting except the bevel angle is set to an angle other than 0°.

When possible, use the right miter gauge slot when bevel crosscutting so that the blade tilts away from

the miter gauge and your hands.

Use caution when starting the cut to prevent binding of the guard against the workpiece.

COMPOUND MITERING

Compound Mitering (Fig. 58) is a combination of bevel crosscutting and mitering, where the blade is beveled to an angle other than

0° and the miter gauge is locked at an angle other than 0 degrees. Always use the miter slot (D) which allows the blade to tilt away

from the miter gauge and hands.

Fig. 57 Fig. 58

D

20

Page 21

3/4” plywood

6”

Width of saw + 2”

3-5/8”

2” x 4”

block

TOP VIEW

4”

1”

3/8”

1”

2-1/4”

2” x 4”

block

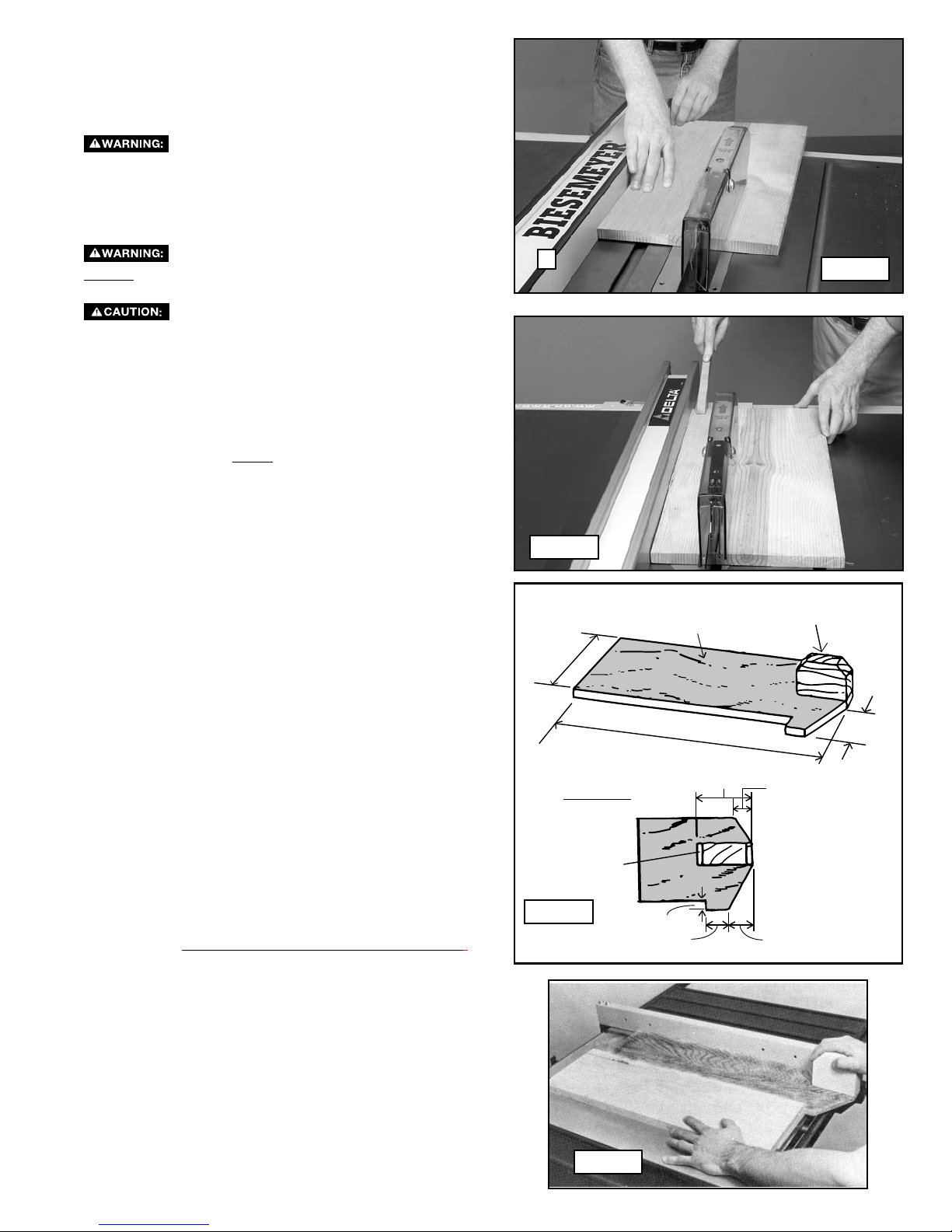

RIPPING

Ripping (Fig. 59) is cutting lengthwise through a board. The

rip fence (A) is used to position and guide the work. One

edge of the work rides against the rip fence while the flat

side of the board rests on the table.

Delta saws, the guard has anti-kickback pawls to

prevent kickback, and a splitter to prevent the wood

kerf from closing and binding the blade. Be sure to

replace or sharpen the anti-kickback devices when the

points become dull.

NEVER perform a ripping operation free-hand. Always

lock the fence to the rail.

against the fence, and must not be warped, twisted or

bowed.

1. Before starting the cut, raise the blade so that it is about

2. When the workpiece is past the blade, the work

3. If the size or shape of the workpiece would cause your

4. Ripping narrow pieces can be dangerous. If possible, rip

NOTE: In Fig. 62, the guard and splitter have been removed

5. For longer pieces, use one or more pushsticks to avoid

NOTE: Some special operations (moulding cutterhead,

etc.) require the addition of an auxiliary wood facing to the

fence, as explained in the section “USING AUXILIARY

WOOD FACING,” and use of a push stick.

You must use the saw blade guard. On

Always use a rip fence for ripping operations.

The workpiece must have a straight edge

1/8” (3.2mm) higher than the top of the workpiece. Start

the motor and advance the work, holding it down and

against the fence. Never stand in the line of the saw cut

when ripping. When the rip width is 6 inches or wider,

hold the work with both hands and push it along the

fence and into the saw blade (Fig. 59). Feed force when

ripping should always be applied between the saw blade

and the fence. Never pull the workpiece from the back

of the saw. The work should then be fed through the

saw blade with the right hand. Keep pressure on the

workpiece against the fence and down on the saw table.

Ensure that you have adequate outfeed support for the

workpiece and KEEP YOUR HANDS AWAY FROM

THE SAW BLADE.

will either stay on the table or tilt up slightly and be

caught by the end of the guard. Alternately, the feed

will continue to the end of the table, and be lifted and

brought along the outside edge of the fence. When

ripping boards longer than three feet, use a work

support at the rear of the saw to keep the workpiece

from falling off the saw table.

hands to be within six inches of the saw blade, use a

push stick to complete the cut (Fig. 60) The push stick

can easily be made from scrap material as explained in

the section “CONSTRUCTING A PUSH STICK.”

the narrow piece from the larger piece. If the workpiece

is short enough, use a pushboard. (A pushboard can be

constructed as shown in Fig. 61 and used as shown in

Fig. 62.)

for clarity. Use the guard and splitter when ripping.

placing your hands between the fence and the blade.

Always use care to avoid binding narrow strips between

the anti-kickback pawls and the splitter.

A

Fig. 60

Fig. 61

Fig. 59

Fig. 62

21

Page 22

BEVEL RIPPING

Bevel ripping (Fig. 63) is the same as ripping except the

bevel angle is set to an angle other than 0°.

When possible, place the fence on the right

side of the blade so that the blade is tilted away from

the fence and hands. keep your hands clear of the blade

and use a pushstick to feed the workpiece if there is less

than 6” between the fence and the blade.

Use caution when starting the cut to prevent

binding of the guard against the workpiece.

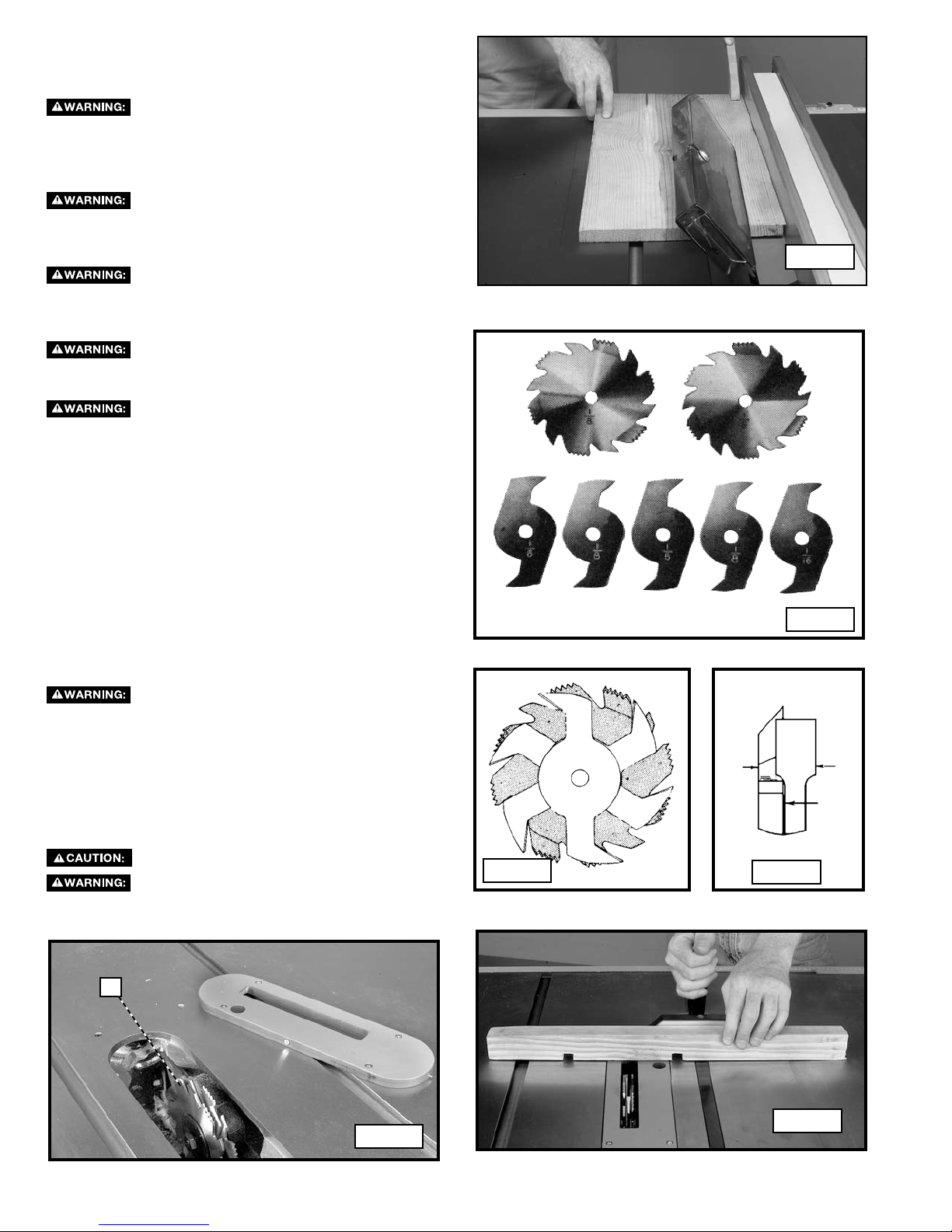

USING AN ACCESSORY DADO HEAD

The blade guard and splitter assembly cannot

be used when dadoing or moulding. It must be removed

as described in “USING AN ACCESSORY MOULDING

CUTTERHEAD” section.

Use pushsticks, hold-downs, jigs, fixtures,

or featherboards to help guide and control the workpiece

when the guard cannot be used.

You must make your own table insert (throat

plate) to use when cutting dados. The standard table insert will

not work with dado cutters.

Dadoing is cutting a rabbet or wide groove into the workpiece.

Most dado head sets are made up of two outside saws and

four or five inside cutters, (Fig. 64). Various combinations of

saws and cutters are used to cut grooves from 1/8" to 13/16"

for use in shelving, making joints, tenoning, grooving, etc. The

cutters are heavily swaged and must be arranged so that the

teeth do not hit each other during rotation. The heavy portion

of the cutters should fall in the gullets of the outside saws (Fig.

65). The saw and cutter overlap is shown in Fig. 66 - (A) being

the outside saw, (B) an inside cutter, and (C) a paper washer or

washers, used as needed to control the exact width of groove.

A 1/4"groove is cut by using the two outside saws. Position the

teeth of the saws so that the raker on one saw is beside the

cutting teeth on the other saw.

Do not attempt to stack dado blades thicker

than 13/16” (20mm) Do not use dado blades larger than 12”

(305 mm) in diameter. Also, your accessory dado set must

have a 1" arbor hole.

Attach the dado head set (D) Fig. 67 to the saw arbor.

NOTE: If the arbor nut does not fully engage the thread on the

arbor, remove the outside arbor flange and tighten the arbor nut

against the dado head set body. Do not lose the outside arbor

flange. It will be needed when reattaching a blade to the arbor.

Never use the dado head in a bevel position.

Always install the blade guard and standard

table insert after the dado operation is complete.

A typical dado operation is illustrated in Fig. 68

.

Fig. 65

A

Fig. 63

Fig. 64

B

C

Fig. 66

D

Fig. 68

Fig. 67

22

Page 23

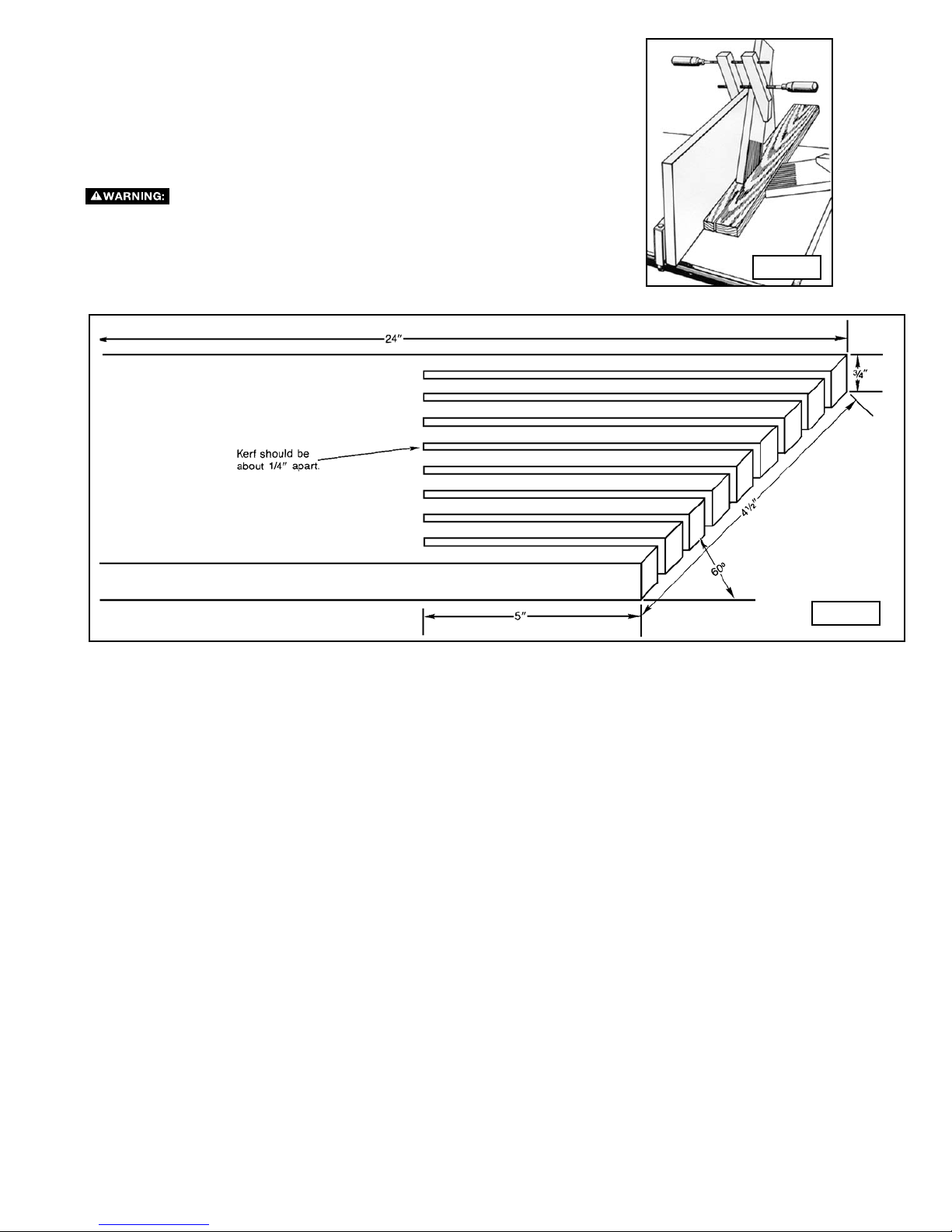

CONSTRUCTING A FEATHERBOARD

Featherboards are used to keep the work in contact with the fence and table (Fig.

69), and help prevent kickbacks. Dimensions for making a typical featherboard

are shown in Fig. 70. Make your featherboard from a straight piece of wood that

is free of knots and cracks. Clamp the featherboard to the fence and table so

that the leading edge of the featherboard will support the workpiece until the

cut is complete. An 8" high flat board can be clamped to the rip fence and the

featherboard can be clamped to the 8" high board.

guard and splitter assembly cannot be used. Always replace the guard and

Use featherboards for all non-thru-sawing operations where the

splitter assembly when the non-thru-sawing operation is complete. Make

sure the featherboard presses only on the portion of the workpiece in front

of the blade.

Fig. 69

Fig. 70

23

Page 24

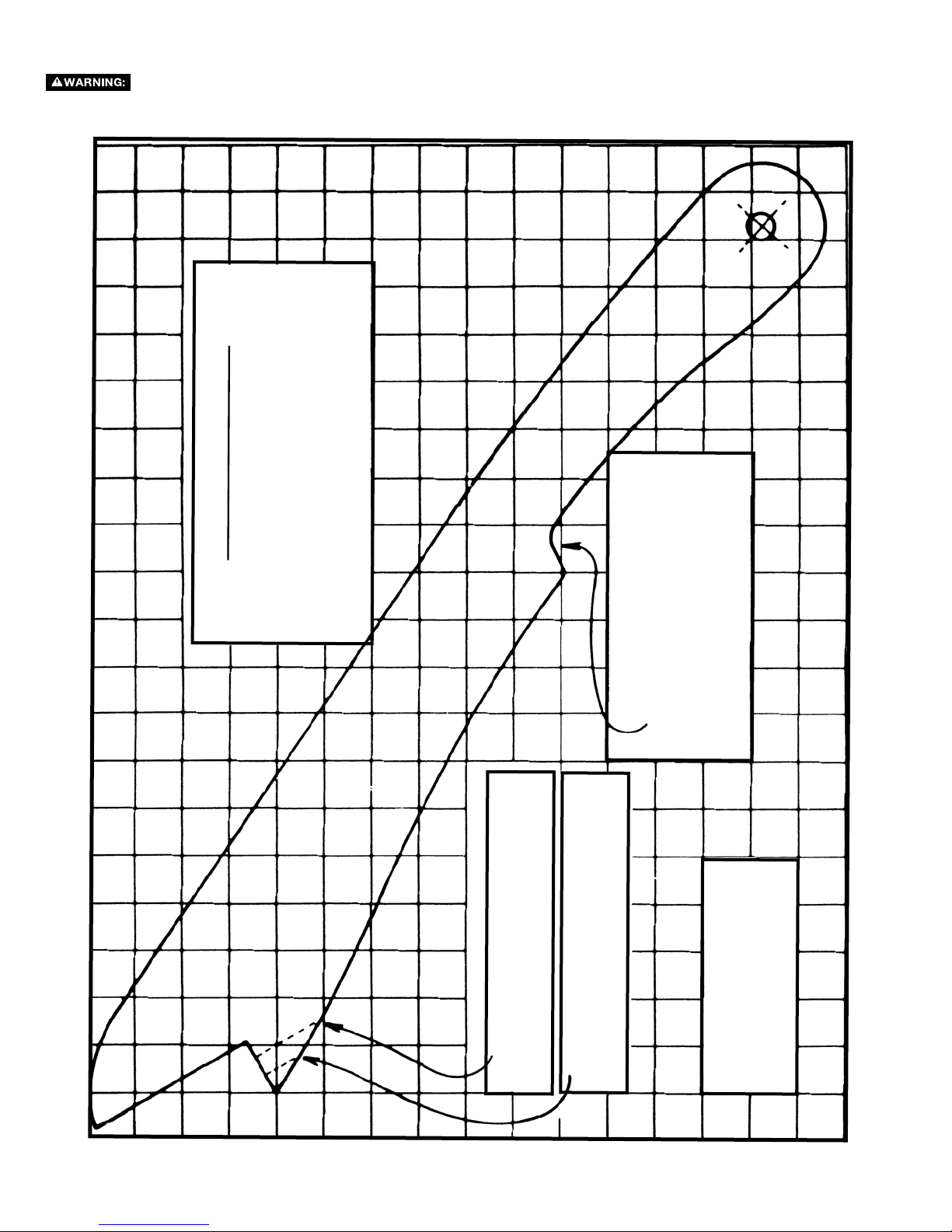

CONSTRUCTING A PUSH STICK

When ripping work less than 6" wide, use a push stick to complete the feed, You can make one from

scrap material by using this pattern.

"

OR 3/4

"

PUSH STICK

WOOD OR THICKNESS

MAKE FROM 1/2

LESS THAN WIDTH OF

MATERIAL TO BE CUT

WOOD

"

NOTCH TO HELP

WOOD

"

PREVENT HAND

FROM SLIPPING

24

CUT OFF HERE TO

PUSH 1/4

SQUARES

PUSH 1/2

CUT OFF HERE TO

"

1/2

Page 25

Further information on the safe and proper operation of table saws is available in the Delta “Getting the Most Out of

ELECTRICAL HAZARD.

HIGH VOLTAGE EXISTS

WITHIN THIS ENCLOSURE.

RISK OF ELECTRIC SHOCK.

DISCONNECT POWER

BEFORE OPENING DOOR OR

SERVICING.

PELIGRO DE DESCARGA ELÉCTRICA.

DENTRO DE LA CUBIERTA HAY PIEZAS CON

ALTO VOLTAJE.

RIESGO DE DESCARGA ELÉCTRICA.

DESCONECTE LA ALIMENTACIÓN ANTES DE

ABRIR LA PUERTA O REALIZAR TAREAS DE

MANTENIMIENTO.

RISQUE D’ORIGINE ÉLECTRIQUE.

UNE TENSION ÉLEVÉE EST PRÉSENTE À

L’INTÉRIEUR DE CE COFFRET.

RISQUE DE CHOC ÉLECTRIQUE.

COUPER L’ALIMENTATION AVANT D’OUVRIR

LA PORTE POUR MAINTENANCE.

Your Table Saw” How-To Book, Catalog No. 11-400. Additional Information on table saw safety, including a table saw

safety video, is available from the following:

POWER TOOL INSTITUTE

1300 Sumner Avenue

Cleveland, OH 44115-2851

www.powertoolinstitute.com

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltaportercable.com for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at

You can also order parts from your nearest factory-owned branch, or by calling our Customer Care Center at 1-800-223-7278 to

receive personalized support from highly-trained technicians.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

1-800-223-7278

for a free replacement.

www.deltaportercableservicenet.com.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about Delta Machinery, its factoryowned branches, or an Authorized Warranty Service Center, visit our website at www.deltaportercable.com or call our Customer

Care Center at 1-800-223-7278. All repairs made by our service centers are fully guaranteed against defective material and

workmanship. We cannot guarantee repairs made or attempted by others.

You can also write to us for information at Delta Machinery, 4825 Highway 45 North, Jackson, Tennessee 38305 - Attention:

Product Service. Be sure to include all of the information shown on the nameplate of your tool (model number, type, serial number,

etc.)

25

Page 26

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth.

NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also,

check for blown fuses or open circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a commercially

available protective product designed for this purpose. Follow the manufacturer’s instructions for use and safety.

To clean cast iron tables of rust, you will need the following materials: a sheet of medium Scotch-Brite

a can of WD-40

the table, then apply the protective product as described above.

®

and a can of degreaser. Apply the WD-40 and polish the table surface with the Scotch-Brite pad. Degrease

™ Blending Hand Pad,

ACCESSORIES

Since accessories other than those offered by Delta have not been tested with this product, use of

such accessories could be hazardous. For safest operation, only Delta recommended accessories should be used with

this product.

A complete line of accessories is available from your Delta Supplier, Porter-Cable • Delta Factory Service Centers, and Delta

Authorized Service Stations. Please visit our Web Site www.deltaportercable.com for a catalog or for the name of your

nearest supplier.

WARRANTY

To register your tool for warranty service visit our website at www.deltaportercable.com.

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service

center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity

to verify the alleged defect by inspection. For all refurbished Delta product, the warranty period is 180 days. Delta may require that electric

motors be returned prepaid to a motor manufacturer’s authorized station for inspection and repair or replacement. Delta will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for incidental or consequential

damages resulting from defective products. This warranty is Delta’s sole warranty and sets forth the customer’s exclusive remedy, with respect

to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly

disclaimed by Delta.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see coun-

try specific warranty information contained in the packaging, call the local company or see website for warranty information.

26

Page 27

LES INSTRUCTIONS IMPORTANTES DE SURETE

Lire toutes instructions d'avertissements et opération avant d'utiliser n'importe

quel outil ou n'importe quel équipement. En utilisant les outils ou l'équipement, les précautions de

sûreté fondamentales toujours devraient être suivies pour réduire le risque de blessure personnelle.

L'opération déplacée, l'entretien ou la modification d'outils ou d'équipement ont pour résultat la

blessure sérieux et les dommages de propriété. Il y a de certaines applications pour lequel outils et l'équipement

sont conçus. La Delta Machinery recommande avec force que ce produit n'ait pas modifié et/ou utilisé pour

l'application autrement que pour lequel il a été conçu.

Si vous avez n'importe quelles questions relatives à son application n'utilisent pas le produit jusqu'à ce que vous

avez écrit Delta Machinery et nous vous avons conseillé. La forme en ligne de contact à www.deltaportercable.com

Courrier Postal: Technical Service Manager, Delta Machinery, 4825 Highway 45 North, Jackson, TN 38305.

Mural St. Suite 300, Richmond Hill, ON, L4B 1M4.

Information en ce qui concerne l'opération sûre et correcte de cet outil est disponible des sources suivantes:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne www.powertoolinstitute.org

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

Dans Canada, 125

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous deviez bien saisir. Cette information porte sur VOTRE SÉCURITÉ

et sur LA PRÉVENTION DE PROBLÈMES D’ÉQUIPEMENT. Afin de vous aider à identifier cette information, nous avons

utilisé les symboles ci-dessous. Veuillez lire attentivement ce guide en portant une attention particulière à ces

sections.

Indique un danger imminent qui, s'il n'est pas évité, causera de graves blessures ou la mort.

Indique la possibilité d’un danger qui, s’il n’est pas évité, pourrait causer de graves blessures

ou la mort

dommages; mineures ou moyennes.

perçage et par toute autre activité de construction contiennent des produits chimiques reconnus par l’État de la

Californie comme pouvant causer le cancer, des anomalies congénitales ou d’autres problèmes liés aux fonctions

reproductrices. Voici quelques exemples de ces produits chimiques :

• leplombdespeinturesàbasedeplomb,

• lasilicecristallineprovenantdesbriques,ducimentetd’autresproduitsdemaçonnerieainsique,et

• l’arsenicetlechromeissusduboistraitéchimiquement.

Les risques reliés à l’exposition à ces produits chimiques varient selon la fréquence à laquelle l’utilisateur effectue ce type de

travail. Pour réduire l’exposition à ces produits chimiques : travailler dans un endroit bien ventilé et porter un équipement de

sécuritéapprouvé,notammentunmasqueantipoussièresconçuspécialementpourfiltrerlesparticulesmicroscopiques.

.

Indique la possibilité d’un danger qui, s’il n’est pas évité, peut causer des dommages à la propriété.

S

ans le symbole d’alerte.

Certaines poussières produites par les travaux de ponçage, de sciage, de meulage, de

Indique la possibilité d'un danger qui, s'il n'est pas évité,

peut causer des

27

Page 28

RÈGLES DE SÉCURITÉ GÉNÉRALES

L’inobservation de ces règles peut conduire à des blessures graves.

1. POUR SA SÉCURITÉ PERSONNELLE, LIRE LA NOTICE

D’UTILISATION, AVANT DE METTRE LA MACHINE EN MARCHE, et

pour aussi apprendre l’application et les limites de la machine ainsi que

les risques qui lui sont particuliers ainsi, les possibilités d’accident et de

blessures seront beaucoup réduites.

2. PORTEZ DES DISPOSITIFS DE PROTECTION DES YEUX ET DE

L'OUÏE. UTILISEZ TOUJOURS DES LUNETTES DE SÉCURITÉ. Des

lunettes ordinaires ne constituent PAS des lunettes de sécurité. UTILISEZ

DES ÉQUIPEMENTS DE SÛRETÉ HOMOLOGUÉS. Les dispositifs de

protection des yeux doivent être conformes aux normes ANSI Z87.1. Les

dispositifs de protection de l'ouïe doivent être conformes aux normes

ANSI S3.19.

3. PORTER UNE TENUE APPROPRIÉE. Pas de cravates, de gants, ni

de vêtements amples. Enlever montre, bagues et autres bijoux. Rouler

les manches. Les vêtements ou les bijoux qui se trouvent pris dans les

pièces mobiles peuvent entraîner des blessures.

4. NE PAS UTILISER LA MACHINE DANS UN ENVIRONNEMENT

DANGEREUX. L’utilisation d’outils électriques dans des endroits

humides ou sous la pluie peut entraîner des décharges électriques ou

une électrocution. Garder la zone de travail bien éclairée pour éviter de

trébucher ou d’exposer les doigts, les mains ou les bras à une situation

dangereuse.

5. GARDER LES OUTILS ET LES MACHINES EN PARFAIT ÉTAT.

Garder les outils affûtés et propres afin d’obtenir le meilleur et le plus

sûr rendement. Suivre les instructions pour lubrifier et changer les

accessoires. Les outils et les machines mal entretenus peuvent se

dégrader davantage, et/ou entraîner des blessures.

6. INSPECTER LES PIÈCES POUR DÉCELER TOUT DOMMAGE.

Avant d’utiliser la machine, la vérifier pour voir s’il n’y a pas de pièces

endommagées. Vérifier l’alignement des pièces mobiles et si ces pièces

ne se coincent pas, la rupture de pièces, ou toute autre condition pouvant

en affecter le fonctionnement. Toute pièce ou protecteur endommagé doit

être réparé ou remplacé. Les pièces endommagées peuvent dégrader

davantage la machine et/ou entraîner des blessures.

7. GARDER L’AIRE DE TRAVAIL PROPRE. Les zones et établis

encombrés favorisent les accidents.

8. GARDER LES ENFANTS ET LES VISITEURS À DISTANCE. L’atelier est

un lieu potentiellement dangereux. Les enfants et les visiteurs peuvent se

blesser.

9. ÉVITER LE DÉMARRAGE ACCIDENTEL. S’assurer que l’interrupteur

est sur « OFF » (ARRÊT) avant de brancher le cordon. En cas de coupure

de courant, placer l’interrupteur à la position « OFF » (ARRÊT). Un

démarrage accidentel peut entraîner des blessures.

10. UTILISER LES DISPOSITIFS PROTECTEURS. Vérifier que tous les

dispositifs protecteurs sont bien en place, bien fixés et en bon état de

marche pour éviter les blessures.

11. ENLEVER LES CLÉS DE RÉGLAGE ET CELLES DE SERRAGE AVANT

DE METTRE LA MACHINE EN MARCHE. Les outils, les chutes et les

autres débris peuvent être projetés violemment et blesser.

12. UTILISER LA BONNE MACHINE. Ne pas forcer la machine ou

l’accessoire à faire un travail pour lequel il n’a pas été conçu. Des

dommages à la machine et/ou des blessures pourraient s’ensuivre.

13. UTILISER LES ACCESSOIRES RECOMMANDÉS. L’utilisation

d’accessoires non recommandés par Delta peut endommager la machine

et blesser l’utilisateur.

14. UTILISER LE CORDON PROLONGATEUR APPROPRIÉ. S’assurer

que le cordon prolongateur est en bon état. Lorsqu’un cordon

prolongateur est utilisé, s’assurer que celui-ci est d’un calibre suffisant

pour l’alimentation nécessaire à la machine. Un cordon d’un calibre

insuffisant entraînera une perte de tension d’où une perte de puissance

et surchauffe. Voir le tableau sur les cordons prolongateurs pour obtenir

le calibre approprié selon la longueur du cordon et l’ampérage de la

machine. S’il y a un doute, utiliser un cordon d’un calibre supérieur. Plus

le chiffre est petit, plus le fil est gros.

15. FIXER LA PIÈCE. Utilisez les brides ou l'étau quand vous ne pouvez pas

fixer l'objet sur la table et contre la barrière à la main ou quand votre main

sera dangereusement près de la lame (à moins de 6").

16. AVANCER LA PIÈCE DANS LE SENS CONTRAIRE À LA ROTATION

DE LA LAME, DE LA FRAISE OU DE LA SURFACE ABRASIVE.

L’alimentation dans l’autre sens peut entraîner une projection violente de

la pièce.

17. NE PAS FORCER LA MACHINE EN AVANÇANT LA PIÈCE TROP

VITE. Des dommages et/ou des blessures peuvent s’ensuivre.

18. NE PAS SE PENCHER AU-DESSUS DE LA MACHINE. Une perte de

l’équilibre peut entraîner une chute sur la machine en marche et causer

des blessures.

19. NE JAMAIS MONTER SUR LA MACHINE. On peut se blesser

gravement si la machine bascule ou si l’on touche accidentellement son

outil tranchant.

20. NE JAMAIS LAISSER LA MACHINE EN MARCHE SANS

SURVEILLANCE. COUPER LE COURANT. Ne pas quitter la machine

tant qu’elle n’est pas complètement arrêtée. Un enfant ou un visiteur

pourrait se blesser.

21. METTRE LA MACHINE À L’ARRÊT « OFF » ET LA DÉBRANCHER

avant d’installer ou d’enlever des accessoires, d’ajuster ou de changer

des montages, ou lors des réparations. Un démarrage accidentel peut

entraîner des blessures.

22. METTRE L’ATELIER À L’ABRI DES ENFANTS AU MOYEN DE

CADENAS, D’INTERRUPTEURS PRINCIPAUX OU EN ENLEVANT

LES BOUTONS DES DISPOSITIFS DE MISE EN MARCHE. Le

démarrage accidentel de la machine par un enfant ou un visiteur peut

entraîner des blessures.

23. RESTER VIGILANT, ATTENTIF, ET FAIRE PREUVE DE BON SENS.

NE PAS UTILISER LA MACHINE LORSQUE L’ON EST FATIGUÉ

OU SOUS L’INFLUENCE DE DROGUES, D’ALCOOL OU DE

MÉDICAMENTS. Un instant d’inattention lors de l’utilisation d’outils

électriques peut entraîner des blessures graves.

24.

PRODUIRE ET DISPERSER DE LA POUSSIÈRE OU D'AUTRES

PARTICULES EN SUSPENSION DANS L'AIR, TELLES QUE LA

SCIURE DE BOIS, LA POUSSIÈRE DE SILICIUM CRISTALLIN ET

LA POUSSIÈRE D'AMIANTE. Dirigez les particules loin du visage

et du corps. Faites toujours fonctionner l'outil dans un espace bien

ventilé et prévoyez l'évacuation de la poussière. Utilisez un système de

dépoussiérage chaque fois que possible. L'exposition à la poussière

peut causer des problèmes de santé graves et permanents, respiratoires

ou autres, tels que la silicose (une maladie pulmonaire grave) et le

cancer, et même le décès de la personne affectée. Évitez de respirer de

la poussière et de rester en contact prolongé avec celle-ci. En laissant

la poussière pénétrer dans vos yeux ou votre bouche, ou en la laissant

reposer sur votre peau, vous risquez de promouvoir l'absorption de

substances toxiques. Portez toujours des dispositifs de protection

respiratoire homologués par NIOSH/OSHA, appropriés à l'exposition à la

poussière et de taille appropriée, et lavez à l'eau et au savon les surfaces

de votre corps qui ont été exposées.

L'UTILISATION DE CET OUTIL PEUT

28

Page 29

RÈGLES SPÉCIFIQUES ADDITIONNELLES DE SÛRETÉ

L’inobservation de ces règles peut conduire à des blessures graves.

1. NE PAS FAIRE FONCTIONNER CETTE MACHINE avant qu’elle

ne soit entièrement assemblée et installée conformément à ces

directives.

2. DEMANDER CONSEIL À UN SUPERVISEUR, instructeur,

ou toute autre personne qualifiée si vous ne maîtrisez pas

parfaitement l’utilisation de cette machine.

3. SUIVRE TOUS LES CODES DE CÂBLAGE et les connexions

électriques recommandées.

4. TOUJOURS UTILISER LES PARE-MAINS, LE COUTEAU

SÉPARATEUR, ET LES CLIQUETS ANTI-EFFET DE REBOND

chaque fois que possible, y compris tout débitage complet.

Vérifier qu’ils sont bien en place, fixés et qu’ils fonctionnent

correctement. Effectuer un essai du fonctionnement du cliquet

anti-effet de rebond avant de scier en long en poussant la pièce

de bois sous les dents anti-effet de rebond. Les dents doivent

empêcher la projection de la pièce de bois vers l’avant de la scie.

5. LA COUPE DE L’OUVRAGE SANS UTILISER DE GUIDE OU

DE JAUGE À ONGLET EST APPELÉE COUPE « À MAINS

LIBRES ». NE JAMAIS effectuer d’opération « à mains libres ».

Utiliser le guide ou la jauge à onglet pour positionner et guider

l’ouvrage.

6. TENIR FERMEMENT L’OUVRAGE contre la jauge à onglet ou le

guide.

7. L’ACTION DE COUPER COMPLÈTEMENT À TRAVERS

L’OUVRAGE EST APPELÉ « DÉBITAGE COMPLET ». Le sciage

en long et la coupe transversale sont des opérations de débitage

complet. L’action de couper dans le sens du fil s’appelle sciage

en long. Utiliser un guide ou un système de guidage pour scier

en long. NE JAMAIS utiliser une jauge à onglet pour le sciage en

long. Utiliser des poussoirs pour scier en long un ouvrage étroit.

L’actionde couper à contrefil s’appelle tronçonnage. Ne jamais

utiliser un guide ou un système de guidage pour tronçonner.

Utiliser plutôt une jauge à onglet.

8. L’EFFET DE REBOND EST LE FAIT QUE L’OUVRAGE A

NATURELLEMENT TENDANCE À ÊTRE PROJETÉ VERS

L’OPÉRATEUR après avoir heurté ou pincé la lame. L’effet de

rebond est dangereux et peut résulter en de graves blessures.

POUR ÉVITER L’EFFET DE REBOND :

A. maintenir la lame affûtée, exempte de rouille ou de résine.

B. garder le guide longitudinal parallèle à la lame de la scie.

C. utiliser un pare-main et un couteau séparateur pour toutes

les opérations demandant leur utilisation, y compris tout

débitage complet.

D. maintenir le couteau séparateur aligné avec la lame de la

scie.

E. maintenir les cliquets anti-effet de rebond en place et bien

affûtés

F. pousser l’ouvrage pour qu’il dépasse de la lame avant la

relâche.

G. ne jamais scier en long un ouvrage tordu ou déformé, ou

n’ayant pas un bord droit qui permette de le déplacer le long

du guide.

H. utiliser des planches en éventail lorsque le dispositif anti-

effet de rebond ou le pare-main et le couteau séparateur ne

peuvent être utilisés.

I. ne jamais scier un gros ouvrage dont on ne peut pas assurer

le contrôle.

J. ne jamais utiliser le guide comme pare-main pour un

tronçonnage.

K. ne jamais scier un ouvrage à noeud vicieux, avec défauts,

clous ou tout autre corps étranger.

L. ne jamais scier en long un ouvrage de moins de 254 mm

(10 po).

CERTAINS MATÉRIAUX SONT TROP DURS

ET GLISSANTS POUR UN FONCTIONNEMENT EFFICACE DES

CLIQUETS ANTI-EFFET DE REBOND. Le plastique et les composés

(tel un panneau pressé) peuvent être coupée par la scie. Toutefois,

être particulièrement attentif et effectuer tous les réglages adéquats

et suivre les procédures de sciage pour empêcher tout rebond lors du

sciage de ces matériaux.

9. UTILISER LA LAME DE SCIE APPROPRIÉE POUR

L’UTILISATION PRÉVUE À CET EFFET. La lame doit tourner

vers l’avant de la scie. Toujours serrer solidement l’écrou d’axe de

la lame. Avant l’utilisation, inspecter la lame pour des fissures ou

des dents manquantes. Ne pas utiliser de lame endommagée.

10. NE JAMAIS UTILISER DE MEULES ABRASIVES sur cette scie.

11. NE PAS COUPER DE MÉTAL AVEC CETTE SCIE.

12. DÉGAGER LA TABLE DES PIÈCES COUPÉES ET CHUTES

avant de démarrer la scie. Les vibrations de la machine peuvent

les entraîner vers la lame de la scie et les projeter.

13. LES PIÈCES COUPÉES PEUVENT -TRE PROJETÉES VERS

L’OPÉRATEUR. Pour les grandes pièces coupées, utiliser un

poussoir pour pousser la pièce au-delà de la lame puis vers

l’arrière de la table de la scie. Ne pas se pencher au-dessus de la

table pour atteindre l’autre côté. -tre attentif et empêcher que de

petits morceaux ne touchent la lame.

14. NE JAMAIS TENTER DE DÉBLOQUER UNE LAME COINCÉE

SANS AVOIR ÉTEINT LA MACHINE AU PRÉALABLE. Si un

ouvrage ou une pièce coupée se coince à l’intérieur du pare-main,

éteindre la scie et attendre que la lame s’arrête avant de soulever

le pare-main pour retirer la pièce.

15. NE JAMAIS DÉMARRER LA MACHINE avec l’ouvrage contre la

lame.

16. NE JAMAIS placer l’ouvrage entre le guide et la fraise à moulurer.

17. TENIR LES BRAS, MAINS, ET DOIGTS éloignés de la lame.

Utiliser un poussoir pour pousser les petits ouvrages sous la scie.

Un poussoir est un petit bâton de bois, normalement fait maison,

qui s’utilise pour éviter d’approcher vos mains à près de 15,2 cm

(6 po) de la lame à chaque fois que la taille ou la forme de

l’ouvrage l’exige. Consulter « FABRICATION D’UN POUSSOIR »

à la fin de ce mode d’emploi pour les directives relatives à la

fabrication de votre propre poussoir.

18. ÉVITER LES OPÉRATIONS MALADROITES ET ÉVITER D’AVOIR

LES MAINS MAL PLACÉES : en glissant soudainement, une

main pourrait percuter la lame.

19. AUCUNE partie du corps ne doit se trouver dans la trajectoire de

la lame de la scie.

20. NE PAS LAISSER LES MAINS AUTOUR de la lame ou sur celle-

ci.

21. SOUTENIR CORRECTEMENT LES OUVRAGES LONGS (91 cm

(3 pi) ou plus) OU LARGES (91 cm (36 po) ou plus). Si des

tables extensibles plus larges que 61 cm (24 po) sont reliées à

la scie, boulonner le socle de la scie au plancher ou utiliser des

stabilisateurs robustes pour empêcher le basculement.

22. EMP-CHER LES MOUVEMENTS DE LA SCIE EN COURS

D’UTILISATION. Si les accessoires de la trousse de mobilité

sont installés, abaisser la commande à pieds et mettre les pieds

de la table à niveau de sorte que la scie ne puisse balancer,

« marcher », glisser ou basculer. Le cas échéant, fixer solidement

le socle au plancher.

23. NE JAMAIS EFFECTUER D’OPÉRATION DE TRAÇAGE,

d’assemblage, ou de réglage sur la table/l’espace de travail

lorsque la machine est en marche.

24. ÉTEINDRE L’APPAREIL ET LE DÉBRANCHER DE LA SOURCE