Page 1

RMC200 MOTION CONTROLLER

STARTUP

GUIDE

With wiring diagrams

Connect. Control. Optimize.

Page 2

Where to Get Help

Where to Get Help

Video Tutorials

In RMCTools, on the Help menu, click Video Tutorials.

RMCTools Help

In RMCTools, on the Help menu, click Help Topics.

Forum

forum.deltamotion.com

Delta Technical Support

Phone: +1-360-254-8688

support@deltamotion.com

Email:

deltamotion.com ii

Page 3

Important Information

Important Information

Before using the RMC200 motion controller, read this Startup

Guide and relevant manuals carefully.

Installing, putting into service, using, and maintaining the RMC200

must be carried out by suitably trained personnel.

Relevant documentation:

• RMCTools User Manual: provides information on using the

RMC200 motion controller. This information is also provided

in the RMCTools software help topics.

• RMC200 Datasheet: includes full specifications of the

modules.

Maintenance: The RMC200 contains no user-serviceable parts. The

RMC200 should be repaired only by personnel authorized by Delta.

Notices used in this document:

WARNING: Identifies information about circumstances that

can lead to personal injury or death, property damage, or

economic loss.

IMPORTANT: Identifies information that is important for

successfully applying the product.

iii deltamotion.com

Page 4

Important Information

Important Information

WARNING: Using this product in a manner not specified by

the manufacturer may impair the protection provided by the

equipment.

WARNING: Employ safety circuits or devices external to the

motion controller to ensure the machine operates safely even

in the event of a failure in any part of the controller.

WARNING: If deemed necessary by a risk assessment, employ

an emergency stop system to avert harm or to reduce existing

hazards to persons, machinery, or work in progress.

WARNING: Use proper lock-out procedures when working on

the machine to prevent injury or machine damage.

WARNING: On hydraulic systems, use blocking valves or other

suitable methods to prevent the hydraulic system from moving

unexpectedly when working on the machine.

WARNING: Use fuses to limit any fault currents that could

cause smoke or fire due to a fault in the RMC or external

device.

deltamotion.com iv

Page 5

Contents

Contents

Step 1: Mount the Base .................................................. 2

Step 2: Mount the Modules ............................................. 4

Step 3: Wiring ................................................................. 5

Step 4: Install RMCTools ................................................ 6

Step 5: Connect RMC to PC ........................................... 7

Step 6: Start a New Project ............................................ 8

Step 7: Define the Axes ................................................ 13

Step 8: Test each Actuator ........................................... 15

Step 9: Test each Feedback Device............................. 19

Step 10: Scale and Offset ............................................. 23

Step 11: Set the Output Polarity ................................... 24

Step 12: Tuning ............................................................ 25

Continuing the Motion Application ................................ 28

Diagnostic Tools ........................................................... 31

Appendix A: W iring ....................................................... 32

Appendix B: Mounting Dimensions ............................... 51

Appendix C: Agency Compliance ................................. 53

Version 1.04, March 7, 2019

Copyright © 2019, Delta Computer Systems, Inc.

deltamotion.com 1

Page 6

RMC200 Startup Guide

Ambient Temperature

Clearance

122 - 140°F (50 - 60°C)

3 in. (7.6 cm)

Less than 122°F (50°C)

2 in. (5.1 cm)

Operating ambient temperature

-4 to +140°F (-20 to +60°C)

Storage ambient temperature

-40 to +185°F (-40 to +85°C)

Ambient humidity

5-95%, non-condensing

Clearance

Clearance

Step 1: Mount the Base

The RMC base should be mounted upright on a vertical surface, such

that the module ventilation holes are on the top and bottom.

Mounting the Base on a Panel

See Appendix B: Mounting Dimensions for more details

Clearance

The required clearance above and below for airflow

depends on the maximum ambient temperature:

Environment

The environment must conform to the following:

Keep liquids and conductive particles away from the RMC200.

2 Delta Computer Systems, Inc.

Page 7

Step 1: Mount the Base

Enclosure

If the RMC200 is installed in an electronics enclosure, the enclosure

must be large enough to dissipate the power that is being generated

by the components in the cabinet without having the air temperature

in the cabinet exceed the rating on any of the components within the

cabinet.

To ensure sufficient convection, the enclosure should provide the

following clearances:

• At least 2” between front of RMC200 and enclosure

• At least 3” between top of RMC200 and enclosure

• At least 3” plus space for wires between bottom of RMC200

and enclosure

Grounding

IMPORTANT: Make sure to properly ground the base metal.

Mounting via steel screws to a well-grounded surface such as a

metal panel will typically suffice. To ensure a robust

connection, the grounding stud on the bottom of the base may

be used. The Case pins of each module are electrically

connected to the module chassis, which will conduct to the

base chassis.

WARNING: Electrostatic Discharge (ESD): Electrostatic

discharge can cause internal damage and affect normal

operation. When handling this equipment, follow these

guidelines:

• Touch a grounded object to discharge potential static or

wear a grounding wrist strap.

• Do not touch connectors or pins on the module boards, or

electronic components inside the modules.

• Use a static-safe workstation, if possible.

• Store modules in ESD packaging when not in use.

deltamotion.com 3

Page 8

RMC200 Startup Guide

Slot

Compatible Modules

0

PS4D (B5, B7 and B11)

PS6D (B15)

1

CPU40

2+

CA4, CV8, S8, A8, Q4, D24

Hooks

Pins

Connector

Screw

Step 2: Mount the Modules

Module Locations

Modules may only be installed in compatible slots on the base.

Modules are keyed so only compatible modules mount in a given slot.

Install each M odule

1. Tip the module up.

2. Set the upper pins

in the hooks.

3. Rotate the module down

carefully such that the

base connector engages.

4. Tighten the holddown screw

to 5 in-lbs (0.6 Nm).

4 Delta Computer Systems, Inc.

Page 9

Step 3: Wiring

Wiring Topic

Page

General Wiring Information

33

PS4D and PS6D: Power Supply

35

CPU40, CA4, CV8: Discrete I/O

36

CA4, CV8: Control Output ±10V, 4-20 mA, or ±20mA

37

S8: SSI

38

S8: MDT

40

S8: Quadrature Encoder

42

A8: Analog ±10V, 4-20 mA

43

Q4: Quadrature Encoder

46

D24: Discrete I/O

48

Step 3: Wiring

Wire the power, actuators and feedback devices to the RMC according

to the instructions in Appendix A: Wiring on page 32.

IMPORTANT: Remove external power from the device before

wiring. Failure to do so may cause component failure.

deltamotion.com 5

Page 10

RMC200 Startup Guide

PC Requirements for RMCTools

Operating System*

Windows® XP/Vista/7/8/10

Step 4: Install RMCTools

Download

1. Go to http://www.deltamotion.com/dloads/

2. Choose the RMC200 section, then choose the Software section.

3. Choose RMCTools, 32-bit or 64-bit, as required for your computer.

RMCTools supports the RMC70, RMC150 and RMC200 controllers.

4. Run the rmctoolsinstall32.exe or rmctoolsinstall64.exe file and

follow the instructions.

Start RMCTools

On the Windows Start menu, choose All Programs and then

RMCTools.

*Windows XP requires Service Pack 3 or newer.

6 Delta Computer Systems, Inc.

Page 11

Step 5: Connect RMC to PC

Step 5: Connect RMC to PC

USB Cable

Connect an A to B USB cable to the PC and

to the RMC200 USB port.

This type of USB cable is typically used for

PC peripherals such as printers, and is

available at any store that sells electronics.

Or, use Ethernet Cable

Connect an Ethernet cable to the RMC200 and the PC

or Ethernet switch. The RMC200 supports both

straight through and crossover cables.

Setting the IP Address

The IP address need not be set before connecting via Ethernet. If the

PC is on the same physical Ethernet network as the RMC, RMCTools

can detect the RMC even if the IP address is not set.

The RMC’s IP address and subnet mask can be set via RMCTools while

connecting via Ethernet. See the next step Start a New Project for

details.

Or, set the IP address and subnet mask via the CPU display screen:

1. Using the Menu , arrow and Enter buttons, browse to:

Ethernet Change IP Address Set manually

2. Using the arrow buttons, set the IP address.

3. Press Enter for Next and set the subnet mask.

4. Press Enter for Next and use the arrow and Enter

buttons to choose whether to use a default gateway. Set it if so

desired.

deltamotion.com 7

Page 12

RMC200 Startup Guide

Step 6: Start a New Project

1. Start RMCTools.

In the Startup dialog, choose Create a New Project and click OK.

2. Enter the Project Name, then click Finish.

3. In the New Controller Wizard, choose Automatically Detect the

Controller Information, then click Next.

8 Delta Computer Systems, Inc.

Page 13

Step 6: Start a New Project

4. Communication Method:

Via USB:

A. Choose USB and click Next.

B. The RMC200 will appear in the list as R200-CPU40. Choose

the RMC and click Next.

Tip: If multiple controllers are listed, use the serial number to

identify your RMC in the list (Device ID). The serial

number is accessible on the RMC200 display screen:

1. Using the Menu , arrow and Enter

buttons, browse to:

Module InfoSlot 1 (CPU40)

2. The serial number is prefixed by SN:

C. RMCTools will connect to the RMC and display it.

Verify it is correct, then click Finish.

deltamotion.com 9

Page 14

RMC200 Startup Guide

MAC address.

Via Ethernet:

A. Choose Ethernet and click

Next.

B. The RMC200 will appear in the list as R200-CPU40. Click the

RMC and click Next.

Tip: If multiple controllers are listed, use the MAC address to

identify your RMC in the list. The MAC address is

accessible on the RMC200 display screen:

1. Using the Menu , arrow and Enter

buttons, browse to:

Ethernet View IP Address

2. Using the arrow buttons, scroll down to view the

C. If the RMC does not have an IP address (0.0.0.0), you must set

an IP address now in order to connect via Ethernet:

a. Click Configure Device.

10 Delta Computer Systems, Inc.

Page 15

Step 6: Start a New Project

b. Choose Use the following IP address, set the IP Address

and Subnet Mask, then click OK.

Tip: For help on IP addressing, in the RMCTools help, in the Index tab,

type IP Address and choose that item from the list.

D. Click Next. RMCTools will connect to the RMC and display it.

Verify it is correct, then click Finish.

5. The toolbar now displays . This means RMCTools

is communicating with the controller.

Project Pane

The project pane contains all the items in the project. Use the Project

pane to navigate through the entire project.

deltamotion.com 11

Page 16

RMC200 Startup Guide

Saving Settings

Throughout the startup procedure, make sure to save the

configuration changes you make or they may be lost!

1. Save RMCTools Project

On the File menu, click Save.

2. Update Flash

On the Controller menu, click Update Flash.

IMPORTANT: If you do not update Flash, changes to the RMC

will be lost when power is removed!

3. Repeat Often

Make sure to save often to prevent loss of data.

Tip: On the File menu, click Save and Update Flash to perform

both operations at once.

12 Delta Computer Systems, Inc.

Page 17

Step 7: Define the Axes

Position

Feedback

Dual-input Force Feedback

Valve

Hydraulic Cylinder

Analog

Position

Control

Output

Position

Feedback

Valve

Hydraulic Cylinder

Control

Output

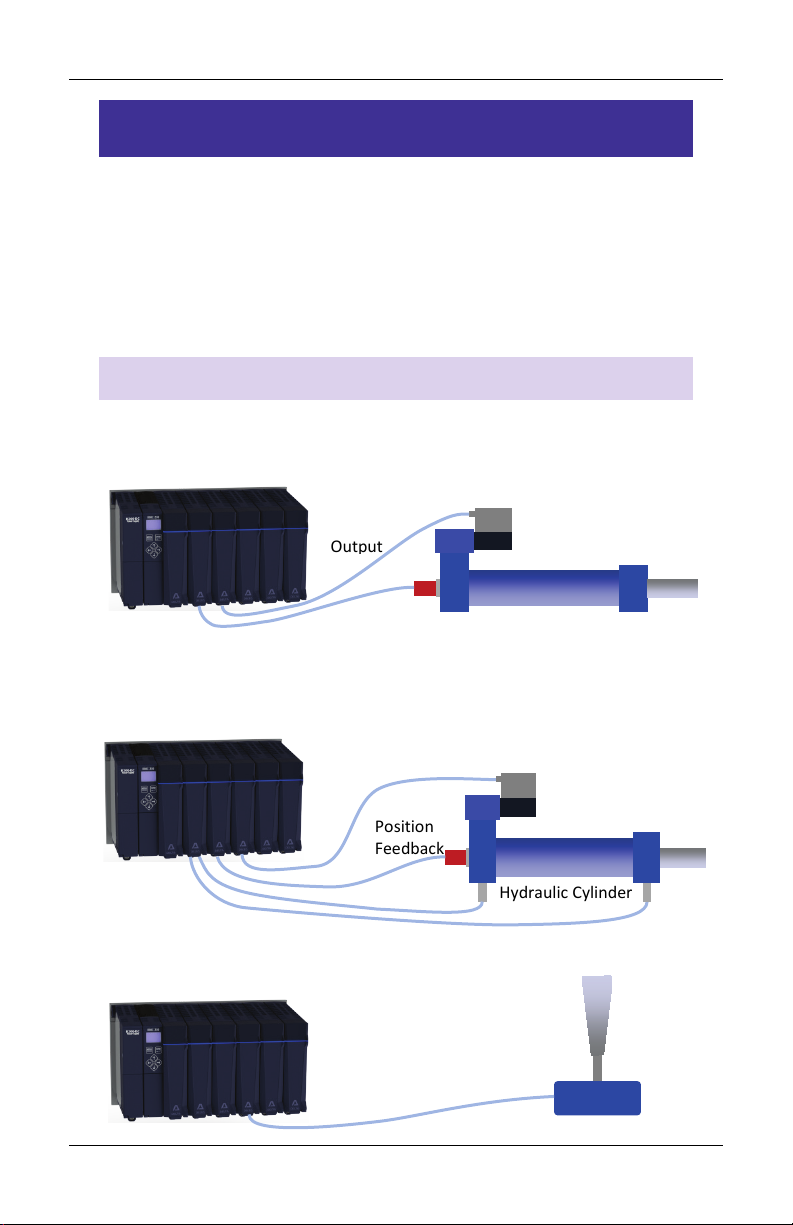

Step 7: Define the Axes

To use a physical input or output, it must be assigned to an internal

software axis. The RMC starts with default axis assignments which you

will likely need to change.

Make sure to define the axes at the start of the project. Major changes

to axis definitions later may result in lost axis parameters.

Example Axis Definitions

Position Control Axis

One Control Output, one position input.

Position-Force Control Axis (all part of a single axis)

One Control Output, one position input, dual- input force

Reference Axis

One position input.

Feedback

deltamotion.com 13

Joystick

Page 18

RMC200 Startup Guide

View Axis Definitions

1. In the Project tree, expand the

Axes folder and double-click

Axis Definitions.

2. The Axis Definitions dialog opens:

The list displays the

software axes. To see the

assigned hardware, click

an axis in the list.

The hardware assigned to

that axis will be

highlighted in the image.

Edit Axis Definitions

Use the Axis Definitions dialog to change the axis definitions:

• Click New to add an axis.

• Click Change to edit the selected axis.

• Click to remove an axis.

If you need to make significant changes to the axis definitions, first

delete all the axes, then create new ones.

For more details, click the Help button.

After changing axis definitions, save the project and update Flash.

14 Delta Computer Systems, Inc.

Page 19

Step 8: Test each Actuator

Step 8: Test each Actuator

You will now test an actuator such as a hydraulic valve or a motor. You

will use the Direct Output command to send a command signal to the

actuator. The actuator must already have been wired to the RMC.

Set the Output Type

1. In the Project tree,

double-click Axis Tools.

2. In the Axis Parameters, on the Setup tab, set the Output Type to

the correct setting for your actuator. Typically, it will be ±10V.

3. Click the Download button

to apply the changes to

the RMC.

4. In the Axis Status Registers, on the

Basic tab, look at the Control

Output.

It should be 0.

Notice that the Final Output shows

the output value in Volts or mA.

deltamotion.com 15

Page 20

RMC200 Startup Guide

Enable the Axis – Enable Controller (7) Command

5. In the Command Tool, in the axis

the actuator is connected to, click

the button.

6. Browse to General Commands,

click Enable Controller, then

click OK.

The Enable Controller command

enables all the axes to motion

commands can be sent to them.

7. In the Command Tool, click Send.

The axes will now be enabled, as

indicated by the Enabled Status bit

in the Axis Status Registers.

16 Delta Computer Systems, Inc.

Page 21

Step 8: Test each Actuator

Move the Axis - Direct Output (9) Command

WARNING: Use the Direct Output (9) command with caution. It

disables the Autostop features of the axis.

Fault Controller Button

In the next steps, if you need to quickly stop the axis, click the

Fault Controller button on the toolbar, or press Ctrl + K on the

keyboard.

8. Browse to Motion Commands, then

Open Loop.

Choose the Direct Output

command and click OK.

The Direct Output command is

useful for setup because it ignores

all axis errors.

9. For the Direct Output command parameters, enter the following:

• Output (%): 10

• Ramp Rate: 1000

When you send the command in

the next step, the Control Output

will ramp to 10 % output at a rate

of 1000 %/sec.

deltamotion.com 17

Page 22

RMC200 Startup Guide

10. In the Command Tool, click Send.

The axis should move, and the

Control Output (in the Axis Status

Registers) should be 10.0.

11. If the axis did not move, resend the command with a larger

Output until the axis moves.

Note: If the Enable Output is wired to the actuator, before

moving, set it with the Set Enable Output command.

12. Now stop the axis:

In the Command tool, enter 0

in the Output box and click

Send.

13. Repeat these steps to move the axis in the other direction. In the

Direct Output command, use a negative Output value.

Move the axis back and forth through the entire travel range to

make sure the axis is moving properly.

18 Delta Computer Systems, Inc.

Page 23

Step 9: Test each Feedback Device

Transducer Type

Module

Page

SSI

S8

20

Start/Stop or PWM (Magnetostrictive)

S8

20

Quadrature Encoder

Q4, S8, D24

21

Analog (Voltage or Current)

A8

21

Step 9: Test each Feedback Device

Now that you have connected and tested an actuator, you will verify a

feedback device. The device must already have been wired to the

RMC.

Configure Feedback

In Axis Tools, in the Axis Parameters pane, on the Setup tab, you will

configure certain parameters depending on the type of input you are

using.

Refer to the procedure for your transducer type and module:

deltamotion.com 19

Page 24

RMC200 Startup Guide

SSI Feedback

1. In the Axis Parameters pane, on the Setup tab, set the Feedback

Type to SSI.

2. Set the following parameters:

• SSI Format

• SSI Data bits (e.g. 24)

• Linear/Rotary

Choose Format and Data Bits per the SSI device data sheet.

For linear transducers, choose Linear. For rotary encoders, choose

Rotary if the axis on your machine can rotate continuously and

the positions wrap around, or Linear if it has a limited travel range

and the encoder will not cross the zero counts point.

Note: For help on a parameter, click the cell and press F1.

3. Click the Download button to apply the changes to the RMC.

4. Continue to the Verify Feedback section on page 22.

Start/Stop or PWM (Magnetostrictive) Feedback

1. In the Axis Parameters, on the Setup tab, set the Feedback Type

to MDT.

2. Set MDT Type to the type of

magnetostrictive transducer

you have.

This information is available

from your transducer

datasheet.

3. Click the Download button to apply the changes to the RMC.

4. Continue to the Verify Feedback section on page 22.

20 Delta Computer Systems, Inc.

Page 25

Step 9: Test each Feedback Device

Analog Feedback

1. In the Axis Parameters, on the

Setup tab, set the Analog Input

Type to Voltage (±10V) or Current

(4-20mA).

If the input is the primary input of

the axis, the Input Type is under the Primary Control Setup

section in the Axis Parameters.

For pressure or force inputs on a dual-loop axis, the Input Type is

in the Secondary Control Setup section in the Axis Parameters.

2. Click the Download button to apply the changes to the RMC.

3. Continue to the Verify Feedback section on page 22.

Quadrature Feedback

1. In the Axis Parameters, on the

Setup tab, set the Linear/Rotary

parameter.

For linear transducers, choose

Linear. For rotary encoders, choose

Rotary if the axis on your machine

can rotate continuously and the

positions wrap around, or Linear if it has a limited travel range

and the encoder will not cross the zero counts point.

2. Click the Download button to apply any changes to the RMC.

3. Continue to the Verify Feedback section on page 22.

deltamotion.com 21

Page 26

RMC200 Startup Guide

Verify Feedback

1. In the Axis Status Registers pane,

on the All tab, expand the Feedback

section.

For secondary inputs, expand the

Pressure/Force/Accel Feedback

section.

2. Depending on your feedback type, look at the Counts, Volts or

Current register. It may be changing slightly.

3. Use the Direct Output command to move the axis back and forth

(as described in the Test an Actuator section).

4. As the axis moves, look for a corresponding change in the Counts,

Voltage or Current. If it does not change smoothly, recheck the

wiring, verify that the parameters on the Setup tab are correct,

and check for smoothly changing Counts, Voltage or Current

again.

5. Save the project and update Flash.

22 Delta Computer Systems, Inc.

Page 27

Step 10: Scale and Offset

Step 10: Scale and Offset

The Scale and Offset parameters convert the Counts, Volts or Current

from the transducer into meaningful measurement units.

First, determine the approximate positions at either end of travel. This

will help you verify later that you performed the procedure correctly.

To set the Scale and Offset:

1. Go to the Axes Parameters pane,

Setup tab, Tools and Wizards

section.

2. Click Launch for the Scale/Offset

Wizard in the desired axis.

3. In the wizard, follow the directions. For help, press the Help

button.

Tip: If the wizard does not work for your system, you can manually

determine the Scale and Offset parameters. See the Scaling topic

in the RMCTools help for details.

4. After completing the wizard, in

the Axis Parameters, locate the

Display Units parameter.

Select the desired display units.

If you wish to use units that are

not listed, choose Custom, then

type up to 4 characters in the Custom Units parameter.

5. Click the Download button to apply the changes to the RMC.

Remember to save your project and update Flash.

deltamotion.com 23

Page 28

RMC200 Startup Guide

Step 11: Set the Output Polarity

The Actual Position, Pressure, Force or Velocity must increase when

the RMC applies a positive Control Output percentage. If this condition

is not met, you will not be able to perform closed-loop control.

1. Send the Direct Output command with a positive Output value

that is large enough to move the axis.

2. On the Basic tab of the Axis Status Registers pane, observe the

Actual Position and note whether it is increasing or decreasing:

Increasing

The Output Polarity is correct. Go to Enable the Axes below.

Decreasing

You must invert the Output Polarity:

A. In the Axis Parameters pane, on the Setup tab, double-click

the Invert Output Polarity parameter to set it.

B. Click the Download button to apply the change to the

RMC.

Enable the Axes

In order to send motion commands other than Direct Output, the axes

must be enabled after the RMC starts up.

1. In the Command Tool, in the Cmd box,

type Enable, and choose

Enable Controller (7) from the list.

2. Click Send. All axes will be enabled.

Entering RUN Mode will also enable the

axes.

24 Delta Computer Systems, Inc.

Page 29

Step 12: Tuning

Step 12: Tuning

In order to control an axis in closed-loop, it must first be tuned. You

can use autotuning or manually tune the axis.

Autotuning – Position Axes Only

Autotuning can be used for most position control axes.

1. Open Tuning Tools

On the Tools menu, click

Tuning Tools.

2. Set Up Tuning Tools

Set up the buttons that you will use

to move the axis back and forth after

the tuning wizard completes.

• Click the first button labeled

[Click to set up].

• Enter a Move Absolute

command with position, speeds,

and acceleration values that will

work for your system.

• Repeat for the other button,

with a different position.

3. Start the Tuning Wizard

In the Tuning Tools, click Tuning

Wizard.

4. Complete the Tuning Wizard

During the autotuning, the wizard will move the axis a short

distance when you prompt it to.

deltamotion.com 25

Page 30

RMC200 Startup Guide

5. When the wizard is complete, the Gain Calculator will open. Use

the slider bar to choose gains. Begin by pulling the slider close to

the bottom, then click Apply Gains.

6. Use the buttons you previously set up to move the axis back and

forth. The plot will automatically be displayed.

Tip: To halt the axis, click the Fault Controller button on the

toolbar, or press Ctrl+K.

7. If the Actual Position is not following the Target Position very well,

pull the slider bar up, apply gains, and move the axis again.

Repeat until the Actual Position tracks the Target Position very

well.

Tuning With an Existing Plot

If the autotuning does not work for your system, you can use the

Tuning Wizard with an existing plot.

1. In the Tuning Tools, use the move buttons to make moves and

adjust the Proportional Gain until the axis has some control.

2. Start the Tuning Wizard and choose Use Existing Plot. The Wizard

will prompt you to choose one of the plots of the moves you

made.

3. When the wizard completes, use the Gain Calculator as described

above.

26 Delta Computer Systems, Inc.

Page 31

Step 12: Tuning

Manual Tuning– Position, Pressure, or Force Axes

You can manually tune systems for which autotuning does not work.

For instructions:

1. On the help menu, choose Help Topics.

2. On the Index tab, type tuning and double-click about.

3. The Tuning Overview topic describes tuning.

In the Manual Tuning section, choose a procedure. For most

position control applications, choose Tuning a Hydraulic Position

Axis or Motor in Velocity Mode. For pressure or force, choose the

procedure that applies to your axis.

After tuning, save the project and update Flash.

deltamotion.com 27

Page 32

RMC200 Startup Guide

Continuing the Motion Application

After setting up and tuning the RMC, it is ready to perform motion and

be integrated into the rest of your application. The RMC has numerous

features to assist you. The major components are listed here to guide

you when continuing your motion application.

Commands

The RMC has a rich set of pre-programmed commands that perform

anything from simple moves to complex motion to system control. For

a list of all the commands, see the Command List topic in the

RMCTools help.

User Programs

A User Program carries out simple or advanced sequences of

commands on the RMC. This allows the RMC to respond to events

within its control-loop time rather than the scan rate of a PLC or other

host controller. It also reduces the PLC programming required.

A User Program consists of multiple steps linked together in

sequences. Each step can issue any RMC command to one or several

axes. The link types allow branching and looping, waiting for

conditions and many other features. Simple and complex

mathematical operations are also possible in the user program.

A User Program runs on a task. Each task can run one user program at

a time. The RMC200 has up to 32 tasks. Therefore, an RMC200

controller may run up to 32 User Programs simultaneously.

For details on creating and running User Programs, see the User

Programs topic in the help.

28 Delta Computer Systems, Inc.

Page 33

Continuing the Motion Application

Communications

Most PLCs or other host controllers can communicate with the RMC,

which includes reading status, writing values, and sending commands

to the RMC. The RMC200 supports a number of Ethernet protocols.

WARNING: When the motion controller is remotely controlled

by some other device, such as a PLC, make sure to design

proper safety interlocks to ensure safe machine operation in

the event of communications loss.

See the Communications section of the RMCTools help for more

detailed information.

Discrete I/O

Discrete I/O augments the communications of the RMC. Discrete I/O is

often faster than the communications, and is therefore well-suited for

starting a sequence in the RMC at a specific time. See the Discrete I/O

topic in the RMCTools help for details.

Variables

Variables help make the User Programs very flexible and easy to

maintain. Variables can be used to effortlessly change programs and

easily modify User Program parameters via a PLC. Variables can also

be used to store data.

For details on using variables, see the Variables topic in the help.

deltamotion.com 29

Page 34

RMC200 Startup Guide

Program Triggers

Use the Program Triggers to start User Programs based on conditions

defined by the user. For example,

• Start a User Program by writing to an RMC variable from a PLC.

• Start a User Program when a discrete input turns on.

• Automatically start a User Program when the RMC starts up.

• When an error condition occurs, automatically start a User

Program to handle it.

See the Program Triggers topic in the RMCTools help for details.

30 Delta Computer Systems, Inc.

Page 35

Diagnostic Tools

Diagnostic Tools

This section describes the main diagnostic tools of RMCTools that will

aid you in monitoring and troubleshooting your system.

Plots

The RMC provides very flexible plotting capabilities. Virtually any

register in the RMC can be plotted, and multiple registers may be

plotted simultaneously. You can easily capture events with the plot

trigger. For details on using plots, see the Plots topics in the help.

Event Log

The Event Log Monitor displays all events that have occurred in the

controller, such as issued commands, changed parameters and errors.

The Event Log Monitor is an important aid in troubleshooting.

The Event Log can help you:

• Determine if a command was successfully issued. The entire

command, with parameters, is displayed.

• Find out which, if any, error occurred.

• See where a command was issued from, for example, from a PLC,

from a User Program or from the Command Tool.

To open the Event Log:

• In the Project Pane, expand the controller, and double-click Event

Log .

Note: The Event Log is very useful! When you don’t know what

happened, or why something did not happen, look at the

Event Log.

deltamotion.com 31

Page 36

RMC200 Startup Guide

Wiring Topic

Page

General Wiring Information

33

PS4D and PS6D: Power Supply

35

CPU40, CA4, CV8: Discrete I/O

36

CA4, CV8: Control Output ±10V, 4-20 mA, or ±20mA

37

S8: SSI

38

S8: MDT

40

S8: Quadrature Encoder

42

A8: Analog ±10V, 4-20 mA

43

Q4: Quadrature Encoder

46

D24: Discrete I/O

48

Appendix A: Wiring

This appendix describes how to wire the RMC. Use the table below to

find the wiring diagram you need. For communications wiring, consult

the RMCTools help.

WARNING: Remove external power from the device before

wiring. Failure to do so may cause the module to fail.

WARNING: Miswiring may cause damage to the RMC200 and

connected components.

WARNING: Pay special attention to wiring the Common pins,

or the RMC may not properly receive signals from connected

transducers.

32 Delta Computer Systems, Inc.

Page 37

Appendix A: Wiring

General Wiring Information

To minimize electrical interference:

• Use twisted pairs for all wiring where possible.

• Use shielded cables for all wiring.

• Keep RMC wiring separate from AC mains or conductors carrying

high currents, especially high frequency switching power such as

conductors between servo drives and motors or amplifiers and

proportional valves.

• Use separate power supplies for sensors and actuators.

Unpluggable Terminal Blocks

All RMC200 modules employ unpluggable terminal blocks. Features of

these terminal blocks include:

• Latching type to prevent unintended extraction

• Spring-cage connectors for consistent wire clamp force

Using Spring-Cage Connectors

Spring-cage connectors may be used for stranded copper wire or

stranded copper wire with ferrules. Wire ferrules provide easy

insertion.

Inserting stranded wire:

1. Press and hold the spring clamp actuator.

2. Insert wire.

3. Release spring clamp actuator.

Inserting wire with ferrule

1. Insert wire (may require some force).

Removing wire (stranded or ferrule):

1. Press and hold the spring-cage actuator.

2. Remove wire.

3. Release spring-cage actuator.

deltamotion.com 33

Page 38

RMC200 Startup Guide

PS4D, PS6D

CPU40, CA4, CV8,

S8, A8, Q4, D24

Wire gauge, stranded

24 – 12 AWG

0.2 – 2.5 mm2

24 – 16 AWG

0.2 – 1.5 mm2

Wire gauge, ferrule no

plastic sleeve

0.25 – 2.5 mm2

0.25 – 1.5 mm2

Wire gauge, ferrule with

plastic sleeve

0.25 – 2.5 mm2

0.25 – 0.75 mm2

Stripping Length

10 mm

10 mm

Ferrule Length

10 – 12 mm

10 – 12 mm

Wire Gauge, Stripping Length and Ferrule Length

IMPORTANT: Use copper wire only.

34 Delta Computer Systems, Inc.

Page 39

Appendix A: Wiring

PS4D or PS6DPower Supply

+24 VDC

Cmn

Protective Earth

Ground

+24V

24Cmn

Case

AC

Line

The PS4D and PS6D Case pins are

PS4D and PS6D: Power

Input Voltage:

Recommended 24 Vdc ±15% (20.4 – 27.6 Vdc), 30 V max.

Overvoltage shutdown at 36 V.

Input Power:

PS4D: 42 W max (1.8 A at 24 Vdc)

PS6D: 60 W max (2.5 A at 24 Vdc)

For a given power draw, the current draw will be greater at a

lower input voltage.

Current draw varies based on number and type of modules

installed in the base.

Power Wiring Diagram

internally connected to the base

deltamotion.com 35

Page 40

RMC200 Startup Guide

Outputs

On Impedance

15Ω max.

Max Current

75 mA

Max Voltage

30 V

RMC Module

Resistive

load

+VCC (12-24 VDC)

DOut +

DOut -

RMC Module

+VCC (12-24 VDC)

DOut +

DOut -

Resistive

load

RMC Module

In+

In -

PLC

+VCC (12-24

VDC)

DOut +

DOut -

PLC

RMC Module

In+

In

-

Power

Output

(24VDC)

CPU40, CA4, CV8: Discrete I/O

CPU40: 2 discrete inputs, 2 discrete outputs

CA4: 4 discrete inputs (Fault), 4 discrete outputs (Enable)

CV8: 8 discrete I/O, individually configurable as inputs or outputs

The CPU40, CA4, and CV8 discrete inputs and outputs are individually

isolated.

Discrete Inputs

Apply 12-24 V to the input. The polarity can be positive or negative.

Max current draw is 3 mA.

Used with a sourcing output Used with a sinking output

Discrete Outputs

The discrete outputs are solid state relays. Outputs can be wired in

either a high-side or low-side configuration.

36 Delta Computer Systems, Inc.

Page 41

Appendix A: Wiring

Drive or AmplifierCA 4 or CV8

Connector

Ctr lOu tn

Cmn

Cas e

Shi eld

+ Re f In

- Re f In

Cmn

Cmn

Drive or AmplifierCA4 or CV8

Connector

Ctr lOu tn

Cmn

Cas e

Shi eld

+ Re f In

Cmn

CA4 and CV8: Control Output

The CA4 has 4 analog outputs, individually software selectable as

0-10 V, ±10 V, 4-20 mA, or ±20 mA, with unipolar or bipolar operation,

or a custom range within the ±10 V or ±20 mA range.

The CV8 has 8 analog outputs, individually software selectable as

0-10 V, ±10 V, with unipolar or bipolar operation, or a custom range

within the ±10 V.

Wiring to Differential Inputs

Differential inputs provide the best noise immunity. This is indicated

by individual +, -, and cmn inputs on the drive or amplifier.

Wiring to Single-ended Inputs

deltamotion.com 37

Page 42

RMC200 Startup Guide

S8

Clock +

Clock -

Data +

Data -

Power Supply

+Pwr

Cmn

Clk+

Clk-

Cmn

Dat+

Dat-

Case

Pwr+

DC Gnd

Notes:

S8: SSI Transducer Wiring

For Synchronous Serial Interface (SSI) transducers and encoders.

For linear SSI transducers, make sure to choose the synchronized type.

Tip: See next page for manufacturer-specific wiring diagrams.

• The user must supply power to the transducer.

• Connect the encoder DC ground to the Cmn pin on the S8

module. The Cmn must be connected to the transducer, or the

signals may not be read correctly!

38 Delta Computer Systems, Inc.

Page 43

Appendix A: Wiring

S8

+ Clk

- Clk

+Data

-Data

+PwrCmn

Clk+

Clk-

Cmn

Dat+

Dat-

Case

+24 V

GND

Yellow

Pink

Gray

Green

Brown

Blue

Do not connect Case pin to cable shield. Cable shield is

internally connected to Balluff sensor housing.

S8

(+) Clock

(-) Clock

(+) Data

+PwrCmn

Clk+

Clk-

Cmn

Dat+

Dat-

Case

+24 Vdc

DC Ground

Yellow

Green

Pink

Gray

Red or Brn

White

(-) Data

S8: SSI Manufacturer-Specific Wiring

These diagrams provide transducer manufacturer labels and colors.

Follow all SSI wiring instructions on page 38.

Balluff Micropulse BTL5 or BTL7 with SSI output

Styles: Z, W, K, P

MTS Temposonics with SSI output

Models: R, RP, RH

deltamotion.com 39

Page 44

RMC200 Startup Guide

S8

Interrogate +

Interrogate

-

Return +

Return -

Power Supply

+

Pwr

Cmn

Int

+

Int

-

Cmn

Ret+

Ret-

Case

Pwr+

DC Gnd

Notes:

S8: Start/Stop or PWM Transducer Wiring

For magnetostrictive transducers with Start/Stop or PWM outputs.

Tip: See next page for manufacturer-specific wiring diagrams.

• The S8 module interfaces to RS-422 (3.5-5V differential) signals.

Single-ended (TTL) signals are not supported.

• The user must supply power to the transducer.

• Connect the encoder DC ground to the Cmn pin on the S8

module. The Cmn must be connected to the transducer, or the

signals may not be read correctly!

40 Delta Computer Systems, Inc.

Page 45

Appendix A: Wiring

S8

Interrogate + Input

Interrogate - Input

Pulse + Output

Pulse - Output

+Pwr

Cmn

Int+

Int-

Cmn

Ret+

Ret-

Case

Pwr+

GND

Yellow

Pink

Gray

Green

Brown

Blue

White

*

GND

*White wire must remain unconnected.

Do not connect Case pin to cable shield. Cable shield is

internally connected to Balluff sensor housing.

S

8

(+) Interrogation or Start

(-) Interrogation or Start

(+)

Gate or (+) Stop

+Pwr

Cmn

Int+

Int-

Cmn

Ret+

Ret-

Case

Cust. Supplied Pwr (+Vdc)

DC Ground

Yellow

Green

Pink

Gray

Red or Brn

White

(-) Gate or (-) Stop

S8

(+) Interrogation

(-) Interrogation

(+) Gate Out, (+) Start/Stop

+Pwr

Cmn

Int+

Int-

Cmn

Ret+

Ret-

Case

+ VDC

DC Ground

Yellow

Green

Pink

Gray

Red

White

(-) Gate Out, (-) Start/Stop

or

or

or

or

or

or

Wh/Gy

Gy/Wh

Or/Wh

Wh/Or

Wh/Gr

Wh/Bu

- VDC

Frame

-Pwr

Blue

or Gr/Wh

Brown

or Bu/Wh

S8: Start/Stop and PWM Manufacturer-Specific Wiring

These diagrams provide transducer manufacturer labels and colors.

Follow all MDT wiring instructions on page 40.

Balluff Micropulse BTL-5, digital RS-485 output

Styles: Z, W, K, E, P, R, AT

MTS Temposonics with digital output (Start/Stop or PWM)

Models: LH, LS, LD, LF, LPS, LPR, G, EP2, ER

MTS Temposonics II with DPM or RPM personality module

deltamotion.com 41

Page 46

RMC200 Startup Guide

Notes:

S8: Quadrature Wiring

The S8 supports one RS-422 quadrature encoder input, using channels

6 and 7.

• The S8 module interfaces to RS-422 (3.5-5V differential) signals

only. Single-ended (TTL) signals are not supported.

• The user must supply power to the transducer.

• Connect the encoder DC ground to the Cmn pin on the S8

module. The Cmn must be connected to the transducer, or the

signals may not be read correctly!

42 Delta Computer Systems, Inc.

Page 47

Appendix A: Wiring

To reduce electrical interference:

connection at the transducer.

Input

Connector

+Analog Out

-Analog Out

Pwr Common

+Pwr

Power Supply

+Pwr

Cmn

In+V

In-

Cmn

Case

Signal Common

Input

Connector

+

Analog Out

Common

Power Supply

+24 VDC

Cmn

In+V

In-

Cmn

Case

+Pwr

A8: Analog Voltage Transducer Wiring

Voltage Transducer, 4- or 5-Wire

Voltage Transducer, 3-Wire

• In- and Cmn must be connected,

either internally in the

transducer or externally as close

as possible to the transducer.

• Use individually shielded

twisted-pair wire.

• Connect cable shield to earth

ground on one end only.

• If transducer has only one

common, connect Pwr Supply

Common and RMC Cmn to it. For

best results, make this

In+

deltamotion.com 43

Page 48

RMC200 Startup Guide

To reduce electrical interference:

Connect cable shield to ground on one end only.

Input

Connector

In+V

In-

Cmn

+10V Exc

Case

Potentiometer

Wiper

A8: Potentiometer with Exciter Pin

Note: Use the Exciter pin to increase the measurement accuracy of

the potentiometer.

• The connection of In- to Cmn should be made as

close as possible to the transducer.

• Use individually shielded twisted-pair wire.

•

44 Delta Computer Systems, Inc.

Page 49

Appendix A: Wiring

Input must be

Input must be

Sensor

Input

Connector

+Analog Out

Power Supply

+24 VDC

Cmn

In+

mA

In-

Cmn

Case

+Pwr

Power Supply

Input

Connector

4-20 mA Out

Signal Cmn

Pwr Common

+Pwr

+Pwr

Cmn

In+mA

In-

Cmn

Case

A8: Analog Current Wiring 4-20 mA

Current Transducer, 2-Wire

configured in software

for current.

Current Transducer, 4-Wire

For three-wire transducers with a single

shared common, the In-, RMC Cmn, and

power supply Cmn should all be connected

as close to the transducer as possible.

The current input

impedance is 250 Ω.

To reduce noise, use

shielded twisted-pair

wire.

configured in software

for current.

The current input

impedance is 250 Ω.

To reduce noise, use

individually shielded

twisted-pair wire.

deltamotion.com 45

Page 50

RMC200 Startup Guide

Q4: Quadrature Encoder Wiring

Important: Set the AB Input Type and Z Input Type axis parameters in

RMCTools to correspond to the physical signal level and type. See the

RMCTools help for details.

Differential Signal

Single-Ended Signal

46 Delta Computer Systems, Inc.

Page 51

Appendix A: Wiring

Q4 Home Inputs

Set the H Input Type axis parameter in RMCTools to correspond to the

type of signal. See the RMCTools help for details.

Q4 Registration Inputs

Set the R Input Type axis parameter in RMCTools to correspond to the

type of signal. See the RMCTools help for details.

deltamotion.com 47

Page 52

RMC200 Startup Guide

DI/O #

Features

Group A

0-7

Input or output – nominal 24V.

outputs share the same output common.

Group B

8-15

Group C

16-19

Fast Inputs

20-23

Inputs only – 5V or 24V. High-speed.

timing.

D24 Outputs

On Impedance

8Ω max, 5Ω typ.

Max Current

75 mA

Max Voltage

30 V

D24

+VCC (12-24 VDC)

Output

Output

Resistive

Load

…

OutCmn

D24

+VCC (12-24 VDC)

Output

Output

Resistive

Load

…

OutCmn

D24: Discrete I/O Overview

The D24 discrete I/O are organized into 4 sections:

Software-configurable. Each group is

isolated. Within each group, all inputs

share the same input common, and all

Each input is individually isolated.

Configurable for pulse counters,

quadrature inputs, and high-speed

D24: Discrete Outputs

The D24 discrete outputs are solid state relays. When off, they have

high impedance, and when on, they have low impedance.

Outputs can be wired in

either a high-side or low-side

configuration. Because all the

outputs in a group share a

common, all outputs in the

same group must be wired the same.

48 Delta Computer Systems, Inc.

Page 53

Appendix A: Wiring

RMC Module

InCmn

In

PLC

+VCC (12-24 VDC)

Douts+

DOut -

PLC

RMC Module

In

In

InCmn

Power

Output

Output

In

D24

Din+

DIn +5V

DIn -

n/c

D24

Din+

DIn +5V

DIn -

n/c

Apply 12-24 VDC

to turn on

Apply 5 VDC to

turn on

Inputs 0-19

Inputs 20-23

Signal Levels

12-24 VDC

5-24 VDC

Max Current Draw

3 mA

7 mA

PLC

D24

Din+

DIn +5V

DIn -

n/c

Power

Output (24VDC)

D24: Discrete Inputs

To turn on a discrete input, apply a voltage of the correct level. The

polarity is unimportant for inputs 0-19, and is important for 20-23.

Inputs 0-19

The inputs 0-19 are polarity-independent and can be sinking or

sourcing. Inputs 0-19 are divided in three groups: 0-7, 8-16, 17-21.

Each group shares a common, so all inputs in a group must be wired

the same.

Used with a sourcing output Used with a sinking output

Inputs 20-23

Each input is individually isolated and has Din+, Din +5V, and Din–

connections. Use only Din+ or Din+5V, not both.

Example:

deltamotion.com 49

Page 54

RMC200 Startup Guide

D24: Quadrature Encoder

The D24 high-speed inputs 20-23 supports the following quadrature

encoder feedback and pulse train signal types:

• 5V Differential

• Differential HTL (High Threshold Logic) for 12V to 24 V

• RS-422

RS-422 will only work in this configuration if the differential

output is greater than 3.5V. Some RS-422 drivers may not

provide sufficient voltage.

• TTL

• Push-pull 5V-24V without complements

• Open collector from 5V to 24 V

• RS-422 (3V)

Use RS-422 in this configuration only if the differential output

is less than 3.5V.

For detailed wiring diagrams, see the D24 wiring topic in the RMCTools

help.

50 Delta Computer Systems, Inc.

Page 55

Appendix B: Mounting Dimensions

Ambient Temperature

Clearance

122 - 140°F (50 - 60°C)

3 in. (7.6 cm)

Less than 122°F (50°C)

2 in. (5.1 cm)

Clearance

Appendix B: Mounting Dimensions

Clearance

The required clearance above and below for airflow

depends on the maximum ambient temperature:

Bases

B5: Side View, All Bases:

deltamotion.com 51

Page 56

RMC200 Startup Guide

B7:

B11:

B15:

52 Delta Computer Systems, Inc.

Page 57

Appendix C: Agency Compliance

Appendix C: Agency Compliance

CE

The following modules are CE compliant: B7, B11, B15, PS4D, PS6D,

CPU40, S8, A8, D24, CA4

For CE compliance and to minimize electrical interference:

• Install a ferrite ring on the power wires to the PS4D or PS6D

power supply module. Recommended ferrite is Fair-Rite

0431167281.

• Use twisted pairs for all wiring where possible.

• Use shielded cables for all wiring.

• Keep RMC wiring separate from AC mains or conductors carrying

high currents, especially high frequency switching power such as

conductors between servo drives and motors or amplifiers and

proportional valves.

UL and CUL

Pending

deltamotion.com 53

Page 58

RMC200 Startup Guide

Notes

54 Delta Computer Systems, Inc.

Page 59

Appendix C: Agency Compliance

Notes

deltamotion.com 55

Page 60

RMC200 Startup Guide

The RMC Family of Motion Control

Connect. Control. Optimize.

56 Delta Computer Systems, Inc.

Loading...

Loading...