Page 1

Startup Guide

RMC100 and RMCWin

Motion Controller Motion Software

for

Page 2

RMC100 Startup Guide

Version 2.3

February 25, 2010

Copyright © 2010, Delta Computer Systems, Inc.

www.deltamotion.com

2

deltamotion.com

Page 3

RMC100 Startup Contents

Contents

Contents ............................................................................................. 3

Overview ............................................................................................. 5

Obtaining a Manual ........................................................................... 6

Getting Started ................................................................................... 7

PC Requirements ........................................................................................ 7

Installation .................................................................................................. 7

Starting RMCWin ...................................................................................... 7

Starting the RMC100 Controller ................................................................ 9

Tuning the System .................................................................................... 13

Saving Configuration Settings .................................................................. 13

Step-by-Step Example .............................................................................. 14

Communications ....................................................................................... 14

Features of the RMC100 .................................................................. 15

Control Options ........................................................................................ 15

Programming ............................................................................................ 18

Diagnostic Tools ...................................................................................... 19

RMC100 Modules ............................................................................. 23

Configuri ng an RMC100 .......................................................................... 23

Communications Choices ......................................................................... 24

Communications Compatibility with Common Host Systems ................. 26

Drive and Transducer Interface Choices .................................................. 29

Transducer Compatibility with Common Manufacturers ......................... 33

Appendix A: Wiring ......................................................................... 35

General Wiring Information. .................................................................... 35

RMC Drive Outputs ................................................................................. 35

Wiring the Analog Feedback Module ...................................................... 36

Wiring the MDT Feedback Module ......................................................... 37

Wiring the SSI Feedback Module ............................................................ 39

Wiring the QUAD Feedback Module ....................................................... 39

Wiring the St epper Mo dule ...................................................................... 42

Appendix B: Tuning ........................................................................ 45

General T uning Guidelines ...................................................................... 45

Tuning a Position Axis ............................................................................. 46

Tuning a Torque Motor ............................................................................ 48

Tuning a Position/Pressure System .......................................................... 50

Appendix C: An Example ................................................................ 59

Example Setup & Tuning of a Hydraulic System .................................... 59

deltamotion.com

3

Page 4

Page 5

RMC100 Startup Overview

RMC100

Position Control

Velocity Control

Pressure Control

PLC or

Industrial PC

Machine Control

Sequencing

Fault Monitoring

HMI

Actuators

and

Feedback

Feedback:

MDT

SSI

Quadrature

Analog

Output:

±10 Volts

Step/Direction

Communication:

Ethernet

Modbus Plus

PROFIBUS-DP

DI/O

Serial

PC running

RMCWin

Setup and

Diagnostics

RS 232 Serial

Ethernet

Overview

The RMC100 series br i ngs the benefits of modular, high-performance motion

control to a wide range of industrial applications. Communicatio ns options—

ranging from high-speed field buses to discrete I/O and a four-line

display/keypad—make these compact, DIN rail mounted controllers an excellent

choice for large and small systems. The ability to “mix and match” position

feedback transducers, plus powerful control modes—including synchronized

moves, pos ition/pressure control, gearing, s plines, a nd teach mode—provide

optimum control for a wide range of applications.

RMCWin is a powerful setup, tuning and diagnostics software package provided

with the RMC100 motion controller.

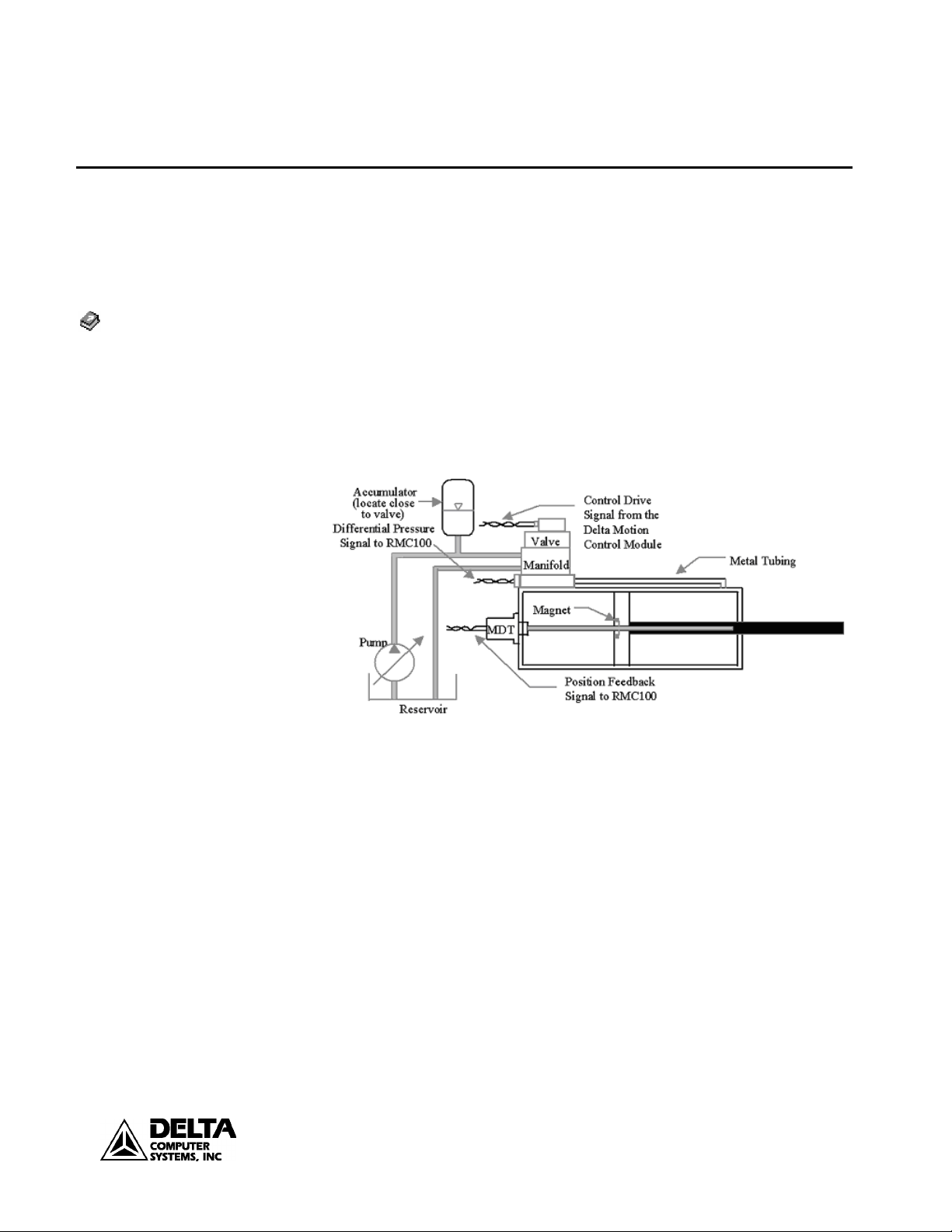

Figure 1 shows a typical installation of an RMC100 controller and the RMCWin

software on a PC. The PC and RMCWin software are only required when setting

up and monitoring the RMC100, and are not required for normal machine operation.

Figure 1. Typical RMC100 and RMCWin installation.

5

deltamotion.com

Page 6

Obtaining a Manual RMC100 Startup Guide

Obtaining a Manual

The RMC100 motion controller manual is available in the following formats:

• Complete and up-to-date information is available in the online help in the

RMCWin software.

• A manual containing the same information as the online help is availab le

as a Portable Document Format (PDF) file from our web site at

www.deltamotion.com.

• If you need a hard-copy manual, contact Delta by telephone at

360-254-8688 or email at sales@deltamotion.com.

6

deltamotion.com

Page 7

RMC100 Startup Getting Started

Getting Started

This chapter describes the minimum hardware requirements, how to install and run

RMCWin, and how to set up a system with an RMC100 controller.

PC Requirements

Operating System Windows 98/ME/NT/2000/XP/Vista/7

Disk Space 20 Mbytes

Memory 8 Mbytes

Serial Port RS-232 or Ethernet connection required for

or Ethernet communication with RMC100.

Installation

1. Obtain a copy of RMCWin either from the CD or diskettes included with the

RMC100 controller or by downloading it from our web site’s download page at

http://www.deltamotion.com/dloads/

.

Starting RMCWin

Getting Help

2. If installing from CD, insert the CD and run drive:\SETUP.EXE where drive is

the letter of the CD drive. Follo w the instructions for installation. It is also

possible to run RMCWin from the CD. Do this by running

drive:\rmcwin\rmcwin.exe.

3. If installing from the web site, run the self-extracting zip file and follow the

instructions.

4. If installing from diskette, insert disk 1 into drive a: and r un SETUP.EXE.

Follow the instructions for insta lla tion.

After installing RMCWin, start it b y clicking the Start menu, clicking Programs and

then RMCWin.

RMCWin inc ludes an extensive online help facility designed to p rovide infor mation

about all aspects of connecting, starting, and using RMCWin and the RMC100

controller. To access Help, click on the Help menu in the RMCWin display and

select Help Topics. To access context-sensitive Help, place the cursor on the

display feature where help is desired and press F1.

In the remaining discussion, references to online Help take one of two forms:

deltamotion.com

7

Page 8

Getting Started RMC100 Startup Guide

Status

Command

Toolbar

Status

Menu

Bar

Plot

Time

Parameter

Area

Index/views/selecti ng

The RMCWin Display

Area

1.

Index/stored commands/Editing the Stored Command Table.

This means to display the online Help, select the Index tab, type the words

stored command on the edit line, and select the topic Editing the Stored

Command Table.

2.

Contents/Using RMCWin/Setup Options/Selecting a Serial Po rt to Use.

This means to display the online Help, sele c t the Contents tab, display Using

RMCWin, select Setup Options, and select the topic Selecting a Serial Port to

Use.

Figure 2 shows the RMCW in main window.

Area

Bar

Figure 2. RMCWin Display.

Note: If RMCWin starts in Read mode (see the status bar), double click on Read to

change it to Write. RMCWin should be in Write mode during RMC100 controller

setup.

In the display, each feedback device has a column of associated data. For example,

Axis0 is one feedback device, while Axis1 is another. Numbers displayed in the

form 0xNNNN are hexadecimal numbers that represent individual bits.

Note: If the RMC100 has 6 or 8 axes the display may be difficult to read in the

default layout. Change to the half view layout (see the help topic listed at left), and

resize the window by dragging a corner with the mouse.

Status area —T hi s area shows important information about what is happening in

the RMC100 controller. It shows the actual position, the drive output, program step

number, actual speed, and the status word, which contains information about the

state of the controller and whether there are any faults.

8

deltamotion.com

Page 9

RMC100 Startup Getting Started

Index/stored

commands/Editing the Stored

Command Table

Contents/U s ing

RMCWin/Setup Options/Selecting

a Serial Port to Use

Contents/Communication

Types/RS-232/Wiring.

Index/specification/general/

power

Command area — The six registers in this area are used to send commands to the

RMC100 controller.

Parameter area — The sixteen registers in this area are the operational parameters.

This area contains information on scaling, tuning, and configuration for fault

detection.

Plot Time — Specifies plot duration, or length of data log, in seconds.

Toolbar — Tools in the toolbar include:

Opens a new board file.

Ope ns an existing board file .

Saves the current board file.

Sends parameters listed in the Parameter area of the display to the RMC100

controller and initializes the axis.

Halts a selected axis (ramps the axis to a stop).

Kills all axes (sets the drive outputs to 0 Volts).

Saves contro lle r information to non-volatile memor y.

Retrieves a plot of the selected axis from the RMC100 controller.

These buttons are pre-programmed commands that you can execute by clicking on

the appropriate number. Instead of entering values in the COMMAND area of the

display you can pre-program c ommands into each button, then by clicking a butt on

or pressing a shortcut key, quickly execute the pre-programmed command.

Status Bar — Indicates the state of the serial communications to the RMC100,

Read or Write mode, and CAPS LOCK.

Starting the RMC100 Controller

deltamotion.com

1. Connect power to the RMC100 controller.

Note: The RMC100 controller requires 24 VDC at various current levels up to 750

mA, depending on the communication and transducer interface modules used.

2. Connect the PC to the RMC100 controller using one of the following two

methods.

• Connect a standard null-modem DB-9 RS-232 serial cable from the PC to

the RMC100 controller.

− If the serial port is configured correctly, the Offline me ssage in the

lower right corner of the RMCWin status bar will change to Online

and a pop-up message window will indicate that RMCWin can

communicate with the RMC100 controller.

− If the display indicates Offline and a n RMC100 controller is connected

and has power, try changing the serial port by double-clicking on

COM in the lower right corner of the RMCWin status bar. The

9

Page 10

Getting Started RMC100 Startup Guide

Index/wiring/topic for your

transducer type.

Index/configuration/MDT

Index/configuration/SSI

Contents/U s ing

RMCWin/Connecting to an

RMC/Communication

Drivers/TCP/IP Direct to RMC-

ENET Configuration

Options dialog box appears. From the Communication tab in the

Options dialog box, select the correct com port.

− If the display indicates Closed after starting RMCWi n, a nother

program may be using the serial port. Try closing other programs that

may be using the serial port.

• If the RMC100 is equipped with an Ethernet communications module and

the PC is equipped with a TCP/IP interface (such as an Ethernet adapter or

modem with TCP/IP installed), yo u may wish to connect the PC to the

RMC100 via Ethernet for noticeably faster communication. Plug an

Ethernet cable into the RMC100 Ethernet module. Use a regular patch

cable when using a hub or router and a crossover cable when connected

directly from the PC to the RMC.

− On the Tools menu, click Options, and then click the

Communication tab.

− Under Communic ation Driver, click TCP/IP Direct to RMC-ENET.

− Select the desired RMC. If the IP address of the RMC is all zeros, you

must configure the RMC100 Ethernet by clicking the Configure

button and entering the correct settings. See the help for more details.

− Click OK.

Connect and Verify a Feedback Device

This section describes wiring and testing connections to feedback devices, such as

MDTs (Magnetostrictive Displacement Transducers) and quadrature encoders.

See the Wiring section in this document for detailed wiring feedback module

diagrams. The online Help also provides wiring information. In all cases, shielded

twisted pair wiring must be used.

Note: Always turn off power to the RMC100 and the feedback device when

connecting wiring from the device to the RMC100 controller.

Decide which axis on the selected RMC100 you want to use and connect the wiring

from the feedback device to that axis according to the wiring diagrams in the Wiring

section of t his document. After connecting t he wiring, re-apply power to the

RMC100 and feedback device. When power is re-applied the RMC100 controller

should indicate that it is online in the RMCW in lower right status bar.

The RMC100 needs to be configured properly before it will communicate with

some types of transducers.

MDT: First, in the RMCWin Tools menu, select Module Config ura tion. Select the

slot for the axis you are configuring, and click on Slot Option. Select either

Standard or Short bla nking period. This setting is transducer de pendent, and

is available in the transducer datasheet. Next, double click on the CONFIG

parameter in the Parameter area to display the MDT Axis Configura tion

Word dialog box. Select the transducer type you are using. Click OK and

10

deltamotion.com

then click t he

to initialize the RMC100

SSI: In the RMCWin Tools menu, select Module Configuration. Select the slo t for

the axis you are configuring, and click on Slot Option. Complete the

necessary information for your transducer type and your application.

Page 11

RMC100 Startup Getting Started

Index/drive /Drive

Index/stepper/wiring

Index/confi guration/analog

transducer

Index/configuration/quadrature

Analog Transducers: Fir st, in the RMCWin Tools menu, s e le c t M odule

Configuration. Select the tab for the axis you are configuring, and click on

Slot Option. Select the option corresponding to the type of application you

have. Next, double click on the CONFIG parameter in the Parameter area to

display the Analog Axi s C onfigurat ion Word dialog box. Select the vol tage

Quadrature Encoders: Double click on the CONFIG parameter in the Parameter

In the Statu s area of the R MCWin disp l ay, the value of COUNTS should now

change. Move the axis manually and look for a corresponding change in the

displayed value of COUNTS, in the status area.

If COUNTS do not change, the most common problem is incorrect wiring. Refer to

the online Help topics.

Connect and Verify an Actuator

This section describes wiring and testing drive output connec t ions and test ing

actuator motion.

For most types of actuators, Drive outp ut wiring consists of a ±1 0V drive outp ut

and a common. For stepper motors a Step and a Direction signal are used.

Note: Always turn off power to the RMC100 and the actuator/amplifier when

connecting wiring from the actuator to the RMC100 controller.

Use the same axis number for the actuator as you did for the feedback device.

Connect the wiring from the actuator to that axis. Refer to the approp r ia te wiring

information in the online Help, or in the specification sheets. After connecting the

wiring, re-apply power to the RMC100, the feedback device, and the actuator.

or current range for your transducer. Click O K and then c lick the

to

initialize the RMC100.

area to display the Quadrature Axis Configuration Word dialog box. Select

the polarity of the Fa ult, Limits, Index (Z) and Home (H) inputs and t he

action of the Homes status bit depending on your application. Click OK and

then click t he

to initialize the RMC100.

Test Actuator Motion

deltamotion.com

The axis is not currently initialized , but it reads counts and you may see a sl ight

movement when the drive output is connected. Test the drive output in either of

these ways:

1. Unplug the drive output from the system and check o utput voltages from the

RMC. Use the open loop (“O”) command described in the following section.

2. Connect the drive output from the RMC100 to the actuator and supply output

voltages to see if the actuator moves. This method is described in the follo wi ng

section.

Connecting drive output from the RMC100 to the actuator and supplying output

voltage is the quickest method of testing actuator motion and dir e c tion. If there is

no movement, remove the connector and verify that the actuator receives a voltage.

Note: Read this section completely before executing any commands on the RMC.

Note: Verify the Simulate bit is NOT set in the CONFIG word.

11

Page 12

Getting Started RMC100 Startup Guide

In the Command area of the RMCWin display, select the correct axis and enter the

following (see Figure 3):

MODE 0x0001

ACCEL 10

DECEL 10

SPEED 0

COMMAND VALUE 100

These values cause the output voltage to change to 100 mV at a rate of 10 mV/ms.

Figure 3. Initial values to verify drive.

Note: Be prepared to stop the system with the

button or ALT+K. Both issue a

Kill (K) command, which will set the drive output to 0 volts.

Send an open loop command by typing O and then ENTER in the Command field

or by pressing ALT+SHIFT+O. You should see t he value of DR IVE in the s t atus

area of the RMCWin display change to 100. You should be able to measure

roughly 100 mV with a voltmeter on the drive output connector.

Observe the COUNTS value in the RMCWin display Status Area, and note whether

the value is increasing or decreasing.

One of three things could have happened at this point:

1. The actuator moved and the COUNTS increased. In this case you are ready to

go to the next section and s et the SCALE.

2. The actuator moved and the COUNTS decreased. In this case you must use the

Reverse Drive Mode bit in the CONFIG parameter to reverse the direction.

Double click on the CONFIG parameter, check the Reverse Drive Mode option

in the dialog box (see Figure 4). Click OK, and then click the

to initialize

the RMC100.

Figure 4. Setting Reverse drive mode.

12

deltamotion.com

Page 13

RMC100 Startup Getting Started

Index/scale/scale and offset

calibration utility

Contents/Transducer Types/Your

Transducer Type/Scaling

Contents/Starting Up the

RMC/Setup Details/

Tuning a

Position Axis

Index/step-by-step startup.

Scroll to Step 10.

3. The actuator does not move. In this case check the output voltage, check that

the actuator is enabled, verify the Si mu la te bit is not set in the CONFIG word,

increase the voltage and repeat the process above.

Note: It is essential that the COUNTS increase when a positive output voltage is

specified with the “O” command. If this condition is not met, you will not be able

to control the axis in closed loop.

At this point the drive has moved in one directi on. Verif y that it moves in the

opposite direction with the fol lowing steps:

Setting the Scale

Tuning the System

1. Click

2. In the COMMAND area of the RMCWin display, select the drive axis and

enter a -100 for the COMMAND VALUE (-100 mV).

3. Send an open loop command by entering ALT+SHIFT+O.

You should see the value of DRIVE in the status area of the RMCWin display

change to -100 and the drive should move in the opposite direction.

It is important to specify the measurement units to be used. Setting the SC A LE

converts the informati on from the t ransducer into meaningful measurement units.

Most transducer types use this parameter with the Prescale Divisor bits in the

CONFIG parameter to convert from the change in transducer counts to a change in

the actual position. Refer to the online Help topics at left for more information.

Note: SCALE is a signed number. If you want your system’s position units to

increase when the COUNTS decrease, set the SCALE to a negative value.

Once the system is set up, it must be tuned in order to operate. Tuning gets the

system to move in a controlled manner, with minimal oscillation, overshoot, or lag

error. Tuning allows the system to a c hieve the best efficiency and stability.

or press ALT+K to turn drive voltage off.

Saving Configuration S e t ti ngs

deltamotion.com

See the Tuning section in this document for instructions on how to tune your

system.

Make sure you save your configuration settings or they may be lost! There are three

ways to save configuration settings.

1. Save settings on the controller in FLASH. Certain types of configur ation

settings may only be set via RMCWin on the PC and stored in FLASH.

To save configuration infor matio n to FL A SH, c lick the

Update Flash (U) command.

2. Save settings o n disk on the P C .

3. Save settings o n the PLC. T he PLC can then send this i nformation to the

controller on startup.

13

button or issue an

Page 14

Getting Started RMC100 Startup Guide

Index/digital

I/O/communication

Index/step-by-step startup. Scroll to

Step 9.

After performing the startup, save your configuration settings. See the appropriate

online Help topic for more information.

Step-by-Step Example

Appendix D contains a step-by-step, illustrated example of setting up and tuni ng a

hydraulic cylinder. Read this to see the practical details of setup and to learn how to

use the plots to tune the axis. T his will help you to quickly set up and control a

hydraulic system!

Communications

After setting up and tuni ng your system, it is rea dy to be programmed and

integrated into the rest of your application. The RMC100 offers numerous

communication options for this purpose.

The purpose of communications is to issue commands and read back status

information. Available RMC100 communications modules include Modbus Plus,

PROFIBUS-DP, Serial, and Ethernet. A simple communications interface between

the RMC100 and the system controller or Programmable Controller (P/C) is also

provided by the Digital I/O module.

See the RMC Modules section of this document for a short overview of each, and

the communications section of the online Help for more detailed infor matio n.

14

deltamotion.com

Page 15

RMC100 Startup Features of the RMC100

Index/Open Loop/Open Loop

Features of the RMC100

The RMC100 contains a host of useful features that will enable you to precisely and

efficiently control any complex motion application. These features include

powerful control options, flexib le programming capabilities, effective diagnostic

tools, a diverse set of feedback options, and support for many popular

communication types.

Control Options

Trapezoidal Profile

Closed-loop motion moves made with the RMC100 have a trapezoidal speed

profile, a s s hown in the following figure.

The axis moves from position A to positio n B in the following manner:

• Accelerates from zero speed to speed S.

• Moves at a constant speed S.

• Decelerates to zero speed and ends at position B.

The RMC100 allows the user to independently specify the acceleration,

deceleration, and speed po rtions of the move. This flexibility is a powerful tool for

any motion control application.

Open Loop (Direct Drive Output)

Although the RMC100 is designed for precise closed-loop motion control, it does

have an ope n-loop mode. In open-loop mode, the user specifies the amount of drive,

and the RMC100 outputs that amount. The RMC100 automaticall y re ver ts to the

open-loop state after certain faults.

Open loop is useful for jogging the axis under manual control and determining

whether the system is working co r rectly after initial setup.

deltamotion.com

15

Page 16

Features of the RMC100 RMC100 Startup Guide

Index/Splines/S

pline Overview

Index/gearing/Gearing Axes

Index/s curves/S curves

scroll to bit 7

S Curves

For applications requiring smooth motion with more gradual starts and stops and

higher peak speeds, the RMC100 offers an "S-curve" option for the trapezoidal

motion profile. When this option is selected, the RMC100 calculate s an s -shaped

target as shown below.

Splines

Gearing

Some applications require that the motion controller move between a number of

given positions. The splines feature of the RMC100 greatly simplifi es such

applications. The user only needs to enter the desired points at certain intervals and

the RMC100 automatically calculates the intermediate positions while maintaining

smooth motion free from jerks or discontinuities.

The splines positions can be placed as a function of time, position units from an

axis, or counter ticks from a digital I/O input. This makes the splines feature a

powerful tool for applications such as curve sawing, animatronics, cyclical testing

and electronic camming among others.

Gearing is u s ed when one axis (the geared axis) must move i ncrementally and

proportionately to another axis (the gear master). The RMC100 easily performs this

so-called electronic gearing (as opposed to mechanical gearing) and allows the user

many options.

The RMC100 allows any axis to be geared to another axis or to a position input

encoder. Setup is simple since the master axis does not need to do anything to be

the master. Multiple axes may be geared to the same master.

The user specifies the gear ratio, which can be changed at any time. When issuing a

gearing command, the geared axis must change its speed to the speed dictated by

the user-specified gear ratio. This is called clutching. The RMC100 has 3 methods

of specifying clutching, which makes the task of synchronizing the a xis to the rest

of the system simple.

16

deltamotion.com

Page 17

RMC100 Startup Features of the RMC100

Index/pressure control/

Using

Analog Channels as Pressure

Inputs

Index/position-pressure

transition/Position-Pressure

Overview

Index/quick mode/quick mode

scroll to Bit 6.

Pressure or Differential Force

The RMC100 excels in pressure control applications. Control can be performed

with either s ingle-ended or double-ended pressure feedback. With double-ended

pressure feedback on a hydraulic systems, the differential force on the piston can be

calculated, allowing force to be controlled. The RMC100 firmware is specifically

designed to handle the characteristics of hydraulic pressure and force control.

Position/Pressure or Position/Differential force.

The RMC100 not only excels at pressure and force control, but is also designed to

smoothly transition from posit ion control to pressure control. This functionality

makes the RMC100 perfect for applications such as injection molding, powder

metal presses, hydroforming and many others.

Pressure Regulating Mode

Pressure or force is controlled in the RMC100 in the same manner as position. That

is, the pressure is made to go to the value to which it is commanded. The RMC100

corrects for any errors while the pressure is changing and when it has reached the

commanded pressure.

Pressure or Differential Force Limit

To fill the needs of pressure control applications requiring more than the sta nd a rd

pressure regulating mode, the RMC100 has a pressure control mode available with

special firmware: Pressure (or force) Limit. This type of pressure control allows the

user to set a maximum value of pressure which is not to be exceeded. The axis can

then be controlled for position. If the pressure approaches the user-defined

maximum pressure, the positio n is li mited so that the pressure does not surpass this

value.

This functionality is very useful in applications where movement is made while

required to remain under a certain pressure, such as molding, extrusion, gripping

and many others.

Quick Mode

A typical move in closed-loop control with the RMC100 is constrained to follow a

certain target path defined by the user. In some applications, the user does not care

about the target path during the initial p ortion of the move.

For these applications, the Quick Mode can be used. The RMC100 simply outputs

an open-loop drive defined by the user and does not enter closed loop control until

the axis approaches the commanded position. It then ramps the speed down and

reaches the commanded position.

This is usef ul for quickly reaching the commanded position because full drive can

be given to the axis initially. Nor mally, this might cause the axis to fault if it were in

full closed-loop control.

deltamotion.com

17

Page 18

Features of the RMC100 RMC100 Startup Guide

Index/analog

transducer/overview

Index/reference

command/Reference Command

Index/command/command

Index/event control/overview

Analog Reference

The RMC100 analog modules can be used as reference inputs. This is very useful

for applications requiring an external target generator or joystick. This externally

generated voltage or current signal can then be used to generate a position or

velocity target for another axis.

Filtered Reference

The RMC100 has very flexible and powerful reference capabilities, allowing any

input axis to be used as a reference axis. Thus, an MDT, SSI, quadrature or analog

signal can be used as a reference. In addition, the RMC100 has digital filtering

capabilities that can be applied to any reference axis to reduce noise.

Programming

Commands

The RMC100 has a simple and consistent, yet versatile command structure. In

addition to the command itself, there a r e 5 command fields that may contain

information for each command. These fields are:

Event Control

• Mode

• Acceleration

• Deceleration

• Speed

• Command Value

For example, the Go ("G") command uses the Mode to determine what type of

move to make, the Acceleration and Deceleration fields determine the accelerations,

and the Speed determines the speed of the move.

Other commands use these same fields, altho ugh they may not have anything to do

with accelerations or speeds. Every command that is issued, regardless of the

method, must also have all the fields set correctly.

The Event Control feature allows a sequence of commands to be executed without

intervention from the Progra mmable Co ntroller (P/C). This lets the module respond

to events within the cont rol-loop time (1ms or 2ms) rather than the scan rate of the

P/C. It also reduces the controller programming required.

Event Control consists of a series of Steps that are linked together in sequences.

The Steps consist of a command area containing the instruction to be executed and a

link area that specifies the next Step number and its trigger. There are a total of 256

Steps that can be shared by all axes.

18

deltamotion.com

The Event Control has many functions that allow powerful progra mmi ng of

complex motion applications. Some are listed here:

• Wait for inputs or states

Page 19

RMC100 Startup Features of the RMC100

Index/plots/

using

• Compare functions

• Math capabilities

• Trigger an event sequence from a digital input

• Conditional branching

Master Control (PLC or PC)

The RMC100 may be controlled from a PLC, a PC or other programmable

controller. The RMC100 provides a full range of communication options between

the RMC and the programmable controller. This enables the user to choose

between broadband control of the RMC for complex applications or limited control

for simpler applications.

The RMCWin on-line help contains highl y d e ta ile d information for controlling the

RMC with each method o f communication. The www.deltamotion.com

also contains many demonstration PLC programs.

This complete programming ability allows complex motions to easily be performed

by the RMC100.

web site

Diagnostic Tools

Plots

The RMC100 contains diagnostic tools for monitoring and troubleshooting every

aspect of any motion it performs. A description of each follows.

The plotting utility in the RMC100 is very powerful. Each move automatica lly

initiates a plot, in addition to the user being able to start a plot at any time. Each plot

contains the following useful information from an axis:

• Actual Position

• Target Position

• Drive

• Status Word

• Actual Speed

• Target Speed

• 2 user-selected pieces of data

The plotting utility is essential for tuning an axis. The user can view exactly wha t

happens at a resolution of down to 1 msec. The plotting utility also calculate s the

Sum Error

2

, a quantitative measure of how close the actual trajectory follows the

target trajectory.

deltamotion.com

The plot data can also be viewed in numerical spreadsheet form.

19

Page 20

Features of the RMC100 RMC100 Startup Guide

Index/status/Using the Status

Bits Window

Index/ i/o Bit Monitor /Using

the I/O Bit Monitor

Index/ parameter error:list/

parameter erro r:list

Index/stat us word/statu s wor d

Index/command log/

Command

Log

Command Log

When debugging problems with a system that is using the RMC, it is of ten difficult

to determine whether the problem is caused by an action of the RMC or the

Programmable Controller (P/C). To help with this problem, the Command Log is

available. The Command Log holds the last 256 commands received through the

communication module; commands sent by RMCWin or the event step table are not

displayed. Therefore, the Command Log can be used to determine which

commands were actually received by the RMC.

Status Words

The Status Words are values showing the state of certain axis properties. These

status words are updated constantly and can be viewed from RMCWin or read from

the RMCWin by a PLC or PC. The status words provide a complete picture of what

is happening in the RMC100. The status words are:

Command Position

Target Position

Actual Position

Transduce r Counts

Axis Status Word

Status Bits and Status Bits Window

The Status register is a collection of 16 bits to provide a summary of the state of the

axis. Eight bits are generally used for error bits. Each of the error bits latch on

when the error is detected.

The Status register is displayed in RMCWin as a 16-bit hexadecimal number. To

make it easier to view each bit, RMCWin provides the Status Bits Window, which

labels each bit independently. These bits are very useful for showing the state of the

axis.

These bits can also be captured and viewed in the plots.

I/O Bit Monitor

The RMC100 provides a visual to ol, called the I/O Bit Monitor, for keeping track of

all the digital inputs and digital outp uts. This tool constantly updates the sta te of

each input for the viewer to see. This simplifies design and verification o f digital

I/O.

Drive

Actual Speed

Null Drive

Step

Link Value

Parameter Error List

20

deltamotion.com

Problems related to user-issued commands cause the Parameter Error bit to be set.

There are dozens of specific problems that can lead to this bit being set. These

problems can identified by using the Parameter Error Lis t Window. T his window

lists the most recent parameter er rors along with a short description.

Page 21

RMC100 Startup Features of the RMC100

Index/ stored commands/

using

Stored Commands

Stored Commands are u s eful when se t ting up and tuning an a xis. Setup and tuning

require repetitively moving the axis. Stored Commands allow the user to enter the

desired mo ves, and issue them with a simple key combination (e.g. CTRL-2) or by

the click of a button in RMCWin. Thi s s peeds up an otherwise monotonous and

time-consuming task.

deltamotion.com

21

Page 22

Page 23

RMC100 Startup RMC100 Modules

Look for this button

on the website!

RMC100 Modules

This sectio n gives an overview of the communications and feedback capabilities of

the modules available for the RMC100.

Configuring an RMC100

The RMC100 series motion controllers have a modular design for configuration

flexibility to meet the needs of a wide variety of applications. Due to this modular

design, Delta is typically able to ship any of the more than 500 available

configurations in 2 weeks or less. However, unlike many modular systems, each

RMC controller is configured at the factory and fully assembled and tested as a

complete unit before shipping.

The RMC100 controllers are packaged in compact din-rail mount enclosures.

Within the package, the first two mod ules ar e the c ommunications and the CPU.

Then, one to four modules are added for I/O. Each module adds 1 inch to the

package wid th, resulti ng in four different fo otprints ranging fro m 4.12 x 5.95 to

7.12 x 5.95 inches. All of the RMC100 motion modules handle two axes resulting

in configurations with two, four, six, or eight axes. Almost a ny combination can be

specified to fit almost any applica tion: linear or rotary, position, pressure, or

position/pressure control.

Configuration Tool

The RMC Configuration Tool on the Delta website at www.deltamotion.com

makes deter mining t he b e st motion controller for a specific application quick and

easy.

The RMC Configuration Tool provides informative screens that show all

communication, control, and interface choices that are available for the RMC100

family of motion controllers. Links are provided to detailed information on every

RMC100 module, and users can request a price quote and additional information on

any specific configuration.

,

deltamotion.com

23

Page 24

RMC100 Modules RMC100 Startup Guide

Comm

EtherNet/IP, CSP,

10Mb, non-deterministic,

9.6kb to 12Mb, deterministic,

Modbus Plus with or

1Mb, deterministic, flexibility

Command Mode, Input to

Index/ENET/RMC Ethernet

Module Overview

Communications Choices

The versatile RMC100 Motion Controllers can be configured with one of five

different communication modules supporting more than 25 protocols. The busbased communication module s are not just for motion data acquisitio n—they

support full motion control via the host system. (RMC100 motion contro lle rs also

have an RS232 serial port for use with Delta’s RMCWin setup, tuning and

diagnostics package.) Your choice of a Comm Module will depend on the required

performance and compatibility match with your communication architecture.

Module Protocols and Modes Performance

Ethernet (-ENET)

-ENET

-PROFI

-MB+

-SERIAL

-DI/O

A short description of each communication module follows. The RMC part number

designation of each module is in parentheses.

The RMC100 offers a communication module for EtherNet/IP. This protocol is an

open protocol that has steadily been gaining popularity in the industrial world.

EtherNet/IP is innovative in that it combines the traditional messaging services with

higher-performance and more deterministic I/O services. The RMC ENET supports

both EtherN et/IP messaging and I/O. The Ethermet module can be used to

communicate with RMCWin.

Modbus/TCP, CAMP, ISOon-TPC, FINS, HEI

PROFIBUS DP Message

Mode or Compact Modes

without Global Data

A-B DF1, Modbus/RTU,

Mitsubishi No Protocol

Mode, consult Delta for

others

Event, Parallel Event,

Parallel Posit ion

High data transfer, update

times vary

high data transfer with

Message mode

allows high data transfer

RS232/RS422/RS485, 9.6kb

to 115,200kb data transfer.

Update times vary

Low data transfer. Events

can be triggered quickly

24

deltamotion.com

Page 25

RMC100 Startup RMC100 Modules

Index/Modbus plus/

Overview

Index/Serial module/RMC

Serial overview

Index/digital i/o /

communication

Index/Profibus/Overview

Profibus (-PROFI)

The RMC100 offers a communication module for the PROFIBUS-DP open

industrial Fieldbus. This Fieldbus is vendor independent and therefore a large range

of Programmable Controllers (P/C) or other PROFIBUS masters can control the

RMC100.

• Operating b aud-rates: 9.6Kbaud to 12Mbaud

• Supported: Freeze mode, sync mode, automatic baud-rate detect, set slave

address

• Modularity: the RMC100 is a modular station that can have one module

selected at a time.

Modbus Plus (-MB+)

The RMC100 offers a communication module for the Modbus Plus local area

network system, whic h supports up to 64 devices (nodes) and transfers data at 1

million bits per second (1Mbaud). The RMC100 acts as a slave, which means it will

respond to master requests, but will not initiate requests.

Serial (-SERIAL)

DI/O (-DI/O)

The SERIAL module adds a single ser ia l port to the RMC for communica tions with

other devices such as HMIs and PLCs. This port cannot be used for RMCWin or

RMCCOM communications, but has a great amount of flexibilit y:

• Protocols: Modbus/RTU, All en-Bradley DF1 (Full- a nd Half-duplex),

Mitsubishi Binary

• Baud Rate: 9,600 to 115,200.

• Parity: Odd, Even, or None

• Line Drivers: RS-232, RS-422, and RS-485

• Flow Control (RS-232 only): None or Hardware (RTS/CTS)

• Termination and Biasing (RS-422/485 only): Both software selectable on Rx

and Tx wire pairs

The Digital I/O module provides a simple communications interface between the

motion controller and the system controller or Programmable Controller (P/C). The

Communication Digital I/O can operate in four modes:

• Parallel Position Mode

− The user can give simple Go and Open Loop commands using just the

discrete inputs.

deltamotion.com

• Input to Event Mode

− Each input is used to trigger certain Event Steps . Can be used when the

positions to which an axis will be moved are known and can be preprogrammed.

25

Page 26

RMC100 Modules RMC100 Startup Guide

• Command Mode

− Allows any command to be sent to the motion controller and a llows a

wide range of status information to be sent back. This mode is more

complicated than the other modes and requires a PLC for the

communications, is much more capable than the other Communication

Digital I/O modes.

• Parallel Event Mode

− Can give commands to up to four axes at a time. This mode is intended for

use with devices that can provide parallel outputs, such as PLCs and

thumb-wheel switc hes.

Communications Compati bility with Common Host Systems

Host

System

A-B

CompactLogix

A-B ControlLogix

A-B MicroLogix

A-B PLC-2, PLC-3

A-B PLC5/x0

A-B SLC500

A-B SoftLogix

5800

A-B SoftLogix 5

DirectLogic

DL205/405

GE Fanuc

Series 90-30

GE Fanuc

Series 90-70

Mitsubishi FX2N

Modicon 800

Series (*1), other

Modicon Premium

Modicon TSX

Momentum

RMC100 Family Communication Module

-ENET -PROFI -MB+ -SERIAL

A-B# 1761-NET-ENI A-B DF1

A-B# 1756-ENBT SST# SST-PFB-CLX A-B DF1

A-B# 1761-NET-ENI

ProSoft# 3300-MBP A-B DF1

Built-in with PLC5/x0E PLCs or use

A-B# 1785-ENET

Built-in with SLC

5/05. Others use

A-B# 1761-NET-ENI

Any Windows comp

Ethernet card

Any Windows comp

Ethernet card

Automation Direct#

H2-COM, H4-COM

Ethernet available

on new models

SST# SST-PFB-GE

Modicon#

TSXETY110

SST# SST-PFB-PLC5 ProSoft# 3300-MBP A-B DF1

(SLC 5/03 or later)

SST# SST-PFB-SLC

A-B DF1

SST# 5136-PFB-PCI

or 5136-PFB-ISA

Horner Electric#

HE693PBM101

Modicon#

TXSPBY100

Modicon#

170 DNT 110 00

(SLC 5/02 or later)

ProSoft# 3350-MBP

Many options available

from Schneider Electric

Many options available

from Schneider Electric

Many options available

from Schneider Electric

A-B DF1 (1500

LRP Recommnd)

A-B DF1

Modicon

Modbus/RTU

RS-232 – Call

Delta for info

Use No Protocol

Mode

Modicon

Modbus/RTU

Modicon

Modbus/RTU

Modicon

Modbus/RTU

26

deltamotion.com

Page 27

RMC100 Startup RMC100 Modules

Modicon TSX

Quantum (*2)

Omron C200

Omron CJ1, CJ1M

and CS1

Omron CV

PC (ISA)

PC (PCI)

PC (3U

CompactPCI)

PC (PC/104)

PC (PCMCIA)

Reliance AutoMax

Siemens Simatic

505 (*3), S5

Siemens Simatic

S7-300, S7-400

SoftPLC

VMEbus (*4)

Modicon#

140 NOE 211 00

Omron# CS1W

Omron#

CV500-ETN01

PC-based SCADA

or control software

that supports any of

the controllers in this

chart that can

communicate over

Ethernet

SST# SST-PFB-REL

(505)

CTI# CTI 2572

Siemens#

CP 343/443-1

PC-based—Ethernet

support standard

SST# 5136-PFB-VME

Modicon#

140 GRP 811 00

SST# 5136-PFB-ISA or

5136–PBMS-ISA

Lan# SMS-CIF30-PB or

SMS-CIF30-DPM

SST# 5136-PFB-PCI

Lan# SMS-CIF50-PB

App# Several versions

App# CPCI1000PFB

or CPCI-DPIO

SST# 5136-PFB-104

Lan# SMS-CIF104-PB

or SMS-CIF104-DPM

App# PCI104PFB

or PC104-DPI

SST# 5136-PFB-PCM

Lan# SMS-CIF60-PB

Many options available

from Siemens

Many options available

from Siemens

Many options available

from Schneider Electric

Schneider Electric#

SA85

Lan# SMS-CIF30-MBP

App# PCI2000MBP

Lan# SMS-CIF104-MBP

Modicon

Modbus/RTU

RS-422/485 – Call

Delta for info

PC-based

software that

supports DF1 or

Modbus/RTU

-ENET -PROFI -MB+ -SERIAL

*See Delta’s Bus-based Products for other Motion Control options for these

platforms: (*1) MMC188/40, MMC188/41, (*2) MMC120, (*3) TMC188/40,

TMC188/40-Q, TMC188/40-TA, TMC188/40-TQ, TMC188/40-TQA, (*4)

VMC186/40, VMC186/40-A, VMC186/40-Q

This is only partial list. The RMC100 motion controllers can communicate with the

above PLCs or any other PLC using the DI/O module. The RMC100 can also

communicate directly to many HMIs via Ethernet, A-B DF1, or Modbus RTU or

other protocols.

This list is provided for the convenience of our customers. Delta shall have no

liability whatsoever for the use of this information, the accuracy or completeness of

the list or of the availability or suitability of any products referenced.

All registered or trademarked names are the property of their respective companies.

A-B: Allen-Bradley (www.ab.com)

App: Applicom (www.applicom-int.com)

deltamotion.com

27

Page 28

RMC100 Modules RMC100 Startup Guide

Automation Direct (www.automationdirect.com)

CTI: Control Technology, Inc. (www.controltechnology.com)

Delta: Delta Computer Syste ms, Inc. (www.deltamotion.com)

GE Fanuc (www.geindustrial.com, www.gefanuc.com)

Hilscher (www.hilsche r.com) available through Lantronix

Horner Electric APG (www.heapg.com)

Lan: Lantronix (formerly Synergetic Micro Systems, Inc.) (www.synergetic.com)

Mitsubishi (www.mitsubishielectric.com)

Modicon or Schnieder Electric: (www.modicon.com)

Omron (oeiweb.omron.com)

Reliance (www.reliance.com)

ProSoft Technology, Inc. (www.psft.com)

Siemens (www.sea.siemens.com) or (www.aut.sea.siemens.com)

SoftPLC Corp (www.softplc.com)

SST: (www.mysst.com)

28

deltamotion.com

Page 29

RMC100 Startup RMC100 Modules

RMC100

Module

Compatibility

Drive and Transducer Interface Choices

Nine different I/O modules are availab le for the RMC100 Motion Controllers. E a c h

motion I/O module handles two axes, and RMC100 controllers can be configured

with one, two, three, or four I/O modules. I/O modules can be “mixed and

matched” for control of as many as eight axes with one mo tion controller. Whe n

combined with the communication module choices, this I/O module flexibility

results in more than 500 configurations of the RMC100 motion controller available

off-the-shelf. Motion I/O modules are available with analog or stepper drive

outputs and interfaces for a wide variety of position feedback devices. Your choice

of Interface Modules will depend on the required performance and compatibility

match with your feedback devices and physical system.

Interface

Motion Modules (Position Interface, Drive Outputs)

-Mn

-Sn

-Qn

-QSTn

-SSTn

Motion or Auxiliary Modules (Analog Inputs for Position, Pressure, etc. Drive Outputs)

-Hn

-Gn

Outputs

2 Drive, ±10V*,

12-bit analog

2 Drive, ±10V*,

12-bit analog

2 Drive, ±10V*,

12-bit analog,

2 Enables

2 Drive, Step &

Direction,

2 Enables

2 Drive, Step &

Direction,

2 Enables

2 Drive, ±10V*

12-bit analog,

+10V Exciter

2 Drive, ±10V*

12-bit analog,

+10V Exciter

2 MDT, PWM or

Start/Stop, RS-422

differential

2 SSI, Binary or Gray

Code, 8-25 bits, RS422 differential

2 Quadrature (A, B, Z),

RS422 differential, and

6 discrete, 5-24Vdc

2 Quadrature (A, B, Z)

RS422 differential, and

6 discrete, 5-24 Vdc

2 SSI, Binary or Gray

Code, 8-25 bits, RS422 differential

4, 16-bit differential

analog

2, 16-bit differential

analog

Inputs

Transducer

Most MTS (Temposonics),

Balluff, and similar types

Absolute rotary encoders,

MDTs with compatible SSI

Quadrature encoders with

RS422 signals

Quadrature encoder

optional (with RS422

signals)

SSI transducer optional

(Absolute rotary encoders,

MDTs with compatible

SSI)

0-10V, ±10V, 0-5V, ±5V,

4-20mA

0-10V, ±10V

Absolute position, 120MHz count

rate for 0.001” res (one recirc)

Absolute or incremental position,

High resolution, noise immunity

Incremental position, 4,000,00 0

counts/sec, fast response to

index and home

Drives up to 1 MHz, open or

closed loop, 4,000,000

counts/sec quadrature

Drives up to 1 MHz, open or

closed loop, High resolution, high

noise immunity SSI, absolute

position

Absolute Position, Pressure or

Force, Position/Pressure

Absolute Position, Pressure or

Force, Position/Pressure

Performance

Auxiliary Modules

-An

-Dn

deltamotion.com

None

8 discrete SSR

(Solid State

Relay), 2.5kV

isolation

4, 12-bit differential

analog

18 discrete, sinking,

Logic Polarity

configurable, 2.5kV

isolation

0-10V, ±10V, 0-5V, ±5V,

4-20mA

Outputs: ±30V, ±100mA,

1.5ms propagation delay

Inputs: 5-24V 6-10mA

max 2.0ms response

Analog reference, Pressure or

Force

Comm DI/O, Fast response to /

triggering external events

*Use Delta’s VC2100 Voltage-to Current converter to convert ±10 V olts to current

29

Page 30

RMC100 Modules RMC100 Startup Guide

Index/MDT/Overview

Index/SSI/Overview

Index/quadrature/Overview

drive for servo valves. The full-scale output of the VC2100 is adjustable from ±10

to ±200mA in 10mA steps.

A short description of each communication module follows. The RMC part number

designation of each module is in parentheses.

MDT Input with Analog Output (-Mn)

Magnetostrictive displacement transducers are designed for use in rugged industrial

environments. They are non-contact, wear-free, highly reliable, and offer accurate

and repeatable linear position meas urement. In the motion control industry

magnetostrictive displacement transducers are typically inserted into hydraulic

cylinders for measurement of the cylinders’ extension/retraction position.

An MDT transducer communicates the position measurement via Start/Stop pulse or

Pulse Width Modulation.

SSI Input with Analog Output (-Sn)

Synchronous Serial Interface (SSI) is a widely accepted controller interface.

Position data from the sensor is encoded in a binary or Gray Code format and

transmitted over a high-speed synchronous interface.

SSI transducers and absolute encoders offer the following advantages:

• Linear or Rotary

• High resolution. Up to 2 µm (approx. 0.00008")

• Noise immunity

• Cost effective data transfer (only one 6-wire cable is needed)

• Transmissi on rate independent of data lengt h and resolution

• Transmission over long distances

• Direct connection to the RMC’s SSI interface module

Quadrature Input with Analog Output (-Sn)

The QUAD interface allows the RMC100 control a wide range of motors and linear

actuators with quadrature encoder feedback.

• Features of the Quadrature Encoder Interface:

− 4,000,000 counts/second

− A and B Input s

− Index Input with High-speed 125ns Position Latch

• Drive Amplifier Interface:

30

deltamotion.com

− Isolated ±10V, 12-bit Analog Drive Output

− Amplifier Enable Output

− Amplifier Fault Input

Page 31

RMC100 Startup RMC100 Modules

Index/analog/Overview

Index/analog/

Overview

Index/stepper/Overview

• Additional Inputs:

− Extend (CW) Travel Li mi t Input

− Retract (CCW) Travel Limit Input

− Home Input with High-speed 50µs Position Latch

− Status LED

• Digital Noise Filters on All Inputs

• All Discrete Inputs are Isolated

• Use with Servo Drives in Velocity or Torque/Force Modes

Analog Input (-An)

The RMC100 offers a 12-bit Analog Input module with no output and wit h optional

pressure control capabilities.

• Four analog inputs wit h 12-bit Analog/Digital Converters.

• No analog out puts.

• Able to utilize Pressure control firmware.

• Uses: speed reference (joystick), position reference (joystick), transitioned

pressure control, transitioned differential force control, and pressure reference.

Analog Input with Analog Output (-Hn, -Gn)

The RMC100 offers a 16-bit Analog module with input and o utput and wit h

optional pressure control capabilities.

• Four analog inputs wit h 16-bit Analog/Digital Converters.

• Two analog outputs with 12-bit Digital/Analog Converters assi gned to analog

channels 0 and 2.

• Uses: position control, velocity control, speed reference (jo ystick), position

reference (joystick), pressure control, differential force control, and pressure

reference.

Stepper Output with Quadrature Input (-QSTn)

The RMC100 offers a quadrature interface module with stepper output. The

quadrature-encoder interface does not have to be used; the motor can be controlled

open loop, but still ca n take advantage of the RMC’s host o f target generating

methods including trapezoidal and s-curve point-to-point moves, gearing,

synchronization, and splines.

deltamotion.com

When used with quadrature feedback, faults can be triggered on following errors,

and motor compensation can be enabled. See Stepper Compensation for details on

this feature.

The stepper has the same features as the quadrature except for the Stepper Motor

Interface:

• 1 MHz Maxi mum Output Frequency

31

Page 32

RMC100 Modules RMC100 Startup Guide

Index/ digital i/o /sensor

• Step Output

• Direction Output

• Drive Enable Output

• Drive Fault Input

Stepper Output with SSI Input (-SSTn)

The RMC100 offers an SSI interface module with stepper output. It combines the

features of the SSI module with the Stepper output.

Additional Digital Inputs and Outputs (-Dn)

The RMC100 offers a Digital I/O module consisting of eighteen digital inputs and

eight digital outputs. The outputs can be set using commands. The inputs on the

Sensor Digital I/O can be used for the following:

• Triggering event sequences using the Input to Event table.

• Controlling transitions betwee n Step s in the Event Step table.

• As an edge or quadrature counter (only inputs 16 and 17).

When used in combination with a Communication DI/O using Paralle l Event mode,

the inputs can be used as part of that mode. Refer to Parallel Event mode for

details.

32

deltamotion.com

Page 33

RMC100 Startup RMC100 Modules

Manufacturer

RMC100 Family Interface Option

-Q, -QST

Quadrature

-H, -G

Analog

Transducer Compatibility with Common Manufacturers

Transducer

Balluff

800-543-8390

www.balluff.com

Baumer Electric Ltd.

800-937-9336

www.baumerelectric.com

BEI Industrial Encoder

800-350-2727

www.beiied.com

Heidenhain

847-490-1191

www.heidenhain.com

MTS Systems Corp

Sensors Division

800-633-7609

www.mtssensors.com

Patriot Sensors & Control

Corp

800-635-0289

www.patriotsensors.com

Stegmann, Inc

800-811-9110

www.stegmann.com

-MDT -SSI

Start-Stop and

PWM supported

(either edge)—

specify external

interrogation*

Start-Stop and

PWM

supported,

specify external

interrogation*

Start-Stop and

PWM

supported,

specify external

interrogation*

MDTs: Specify a

BTL5-S1xx-Mxxx-xSU040-xxx SSI

synchronous

transducer for motion

control**

Absolute rotary

encoders

Absolute rotary

encoders

Absolute rotary

encoders

MDTs: Specify

Synchronous Mode—

output type Sxxxx02—

for motion control**

Absolute rotary

encoders

Quadrature

encoders

Quadrature

encoders

Quadrature

encoders

Quadrature

encoders

Quadrature

encoders

0-10V, ±10V

(All)

0-5V, ±5V,

4-20mA (H

only)

0-10V,

±10V, 0-5V,

±5V, 420mA

0-10V,

±10V, 0-5V,

±5V, 420mA

*For magnetostrictive displacement transducers (MDTs), the Star t-Stop

configuration is the native mode of operation, and typically gives the best

price/performance when used with compatible motion controllers such as the

RMC100 Series.

**Many MDTs are available with an optional synchronous serial interface (SSI).

This extra-cost option offers several advantages including higher resolution and

factory gain compensation wh ile retaining the absolute position characte r istics.

This is only partial list. The RMC100 motion controllers can interface with

transducers from a wide range of manufacturers providing they meet the industrystandard interface specifications supported by the RMC100.

This list is provided for the convenience of our customers. Delta shall have no

liability whatsoever for the use of this information, the accuracy or completeness of

list or of the availability or suitability of any products referenced.

All registered or trademarked names are the property of their respective companies.

33

deltamotion.com

Page 34

Page 35

RMC100 Startup Appendix A: Wiring

Index/wiring/general

Appendix A : Wiring

This section describes how to wire the following RMC modules to feedback

transducers and drives:

• Analog

• MDT

• SSI

• Quadrature

• Quadrature (with stepper output)

General Wiring Informa t ion.

For CE compliance and to minimize electrical interference:

• Use twisted pairs for all wiring where p ossible.

• Use shielded cables for all wiring.

RMC Drive Outputs

• Keep RMC wiring separate from AC mains or conductors carrying high

currents. Especially high frequency switch ing power such as conduc tors

between servo drives and motors or amplifiers and proportional valves.

For UL and C-UL compliance:

• Power supply must be Class 2.

• All RMC inputs and outputs must be co nnected to Class 2 circuits only.

Four-Pin Plug-in Terminal Block

Pin Function

1 Axis 0 Drive

2 Drive Common

3 Axis 1 Drive

4 Case

When positive voltage is sent to an axis ’s drive, the axis must exte nd. The exte nd

direction is defined as the direction that causes the transducer to return increasing

counts. The extend dir ection of a magnetostrictive tra ns ducer is away from the

head.

CAUTION: If the outputs from the RMC are reversed, the axis will be

uncontrollable when power is connected. Confirm that your wiring is co r rect!

deltamotion.com

35

Page 36

Appendix A: Wiring RMC100 Startup Guide

Index/wiring/analog

Index/wiring/

analog

Wiring the Analog Feedback M odule

Voltage Feedback Transducers

Voltage feedback transducers can be connected directly to the +In and -In

connections for the desired channel. The Res connection is unused for voltage

transducers. The following configuration is recommended:

TIP: If you are using a 10 V transducer output, but are only using values in the low

5V, it is recommended that you select a 5 V setting to increase the resolution of the

analog to digital conversion.

Current Feedback Transducers

Current feedback transducers are connected in the same way as voltage transducers

except that a jumper must be inserted between the +In and Res connections. This

places a resistor internal to the RMC across the two inputs, thus converting the

current to a voltage input. The following wiring diagram shows a suggested

configuration:

36

deltamotion.com

Page 37

RMC100 Startup Appendix A: Wiring

Index/wiring/MDT

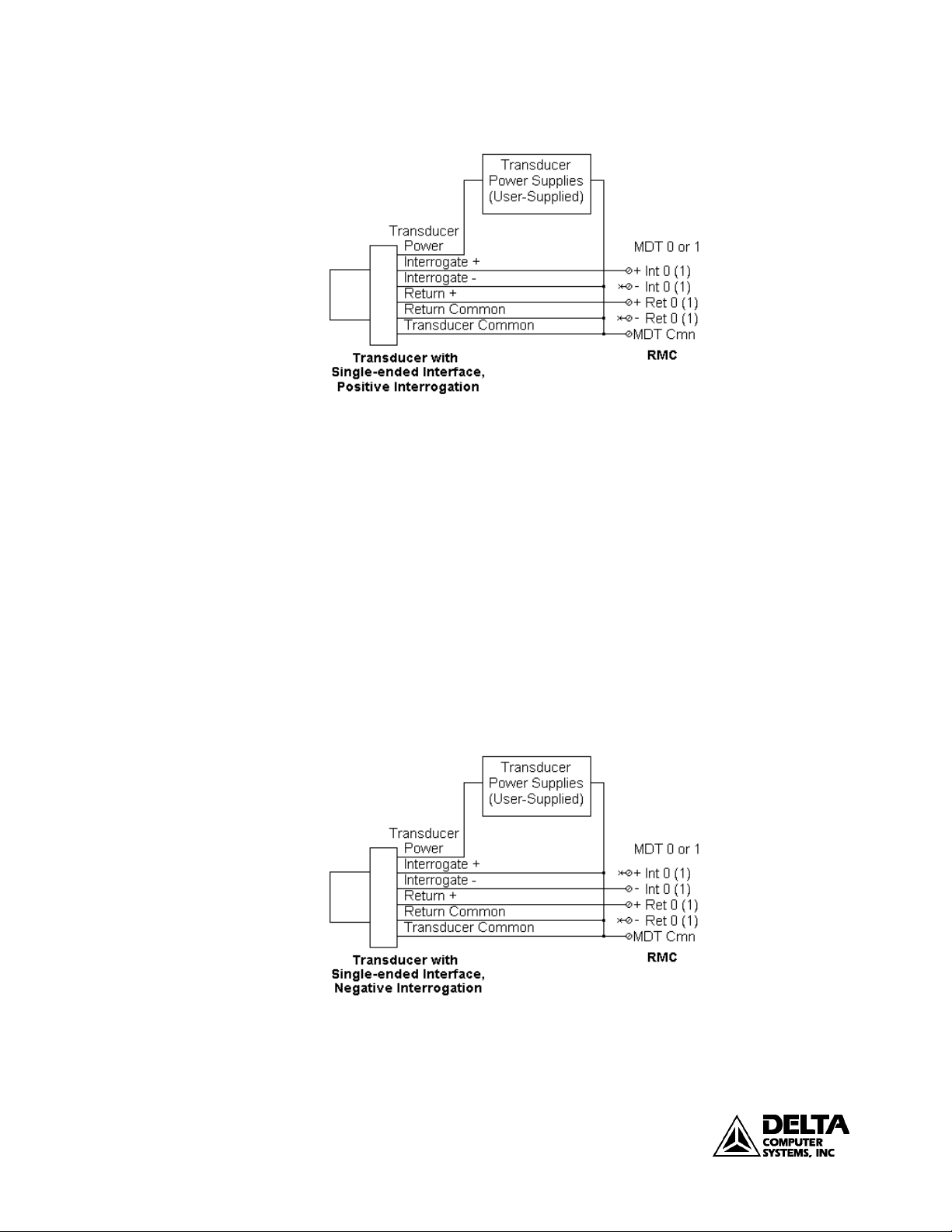

Wiring the MDT Feedback Module

RMC MDT Six-Pin Plug-in Terminal Block Pin-out

Pin Function

1 MDT Axis + Interrogation

2 MDT Axi s - Interrogation

3 MDT Axis Common

4 MDT Axis + Return

5 MDT Axi s - Return

6 Case

The RMC can interface to Magnetorestrictive Displacement Transducers with either

single-ended (TTL) or Differential Line Driver (RS422) interrogation signals.

NOTE: The following example schematics do no t include transducer pin numbers,

color codes, or power supply requirements, since these vary between different

transducers. To determine your power supply needs and connector pin-outs or cable

color codes, consult your transducer manufacturers’ documentation.

RS422 signals

• Connect both the '+Int' and '-Int' between the transducer and the RMC for the

interrogati on signal, and the '+Ret' and '-Ret' between the transducer and the

RMC for the r eturn signal.

• Connect the transduce r DC ground t o MDT Cmn.

Single-ended (TTL) transducers with positive interrogation

• Connect the transducer '- interrogation in' wire to the ‘MDT Cmn’ pin a nd the

transducer '+ interrogation in' wire to the '+ Int' pin.

• CONNECT NOTHING TO THE '-Int' PIN OF THE RMC.

• Connect the transduce r return pl us wire to the '+Ret’ pin on the RMC and the

transducer return common wire to ‘MDT Cmn’ on the RMC.

• CONNECT NOTHING TO THE '-Ret' PIN OF T HE RMC.

37

deltamotion.com

Page 38

Appendix A: Wiring RMC100 Startup Guide

Temposonics I transducer users

• Connect the transducer '+ interrogation in' wire to the ‘MDT Cmn’ pin and the

transducer '- interrogation in' wire to the '-Int' pin.

• CONNECT NOTHING TO THE '+Int' PIN OF THE RMC.

• Connect the transducer return plus wire to the '+Ret’ pin on the RMC and the

transducer return common wire to ‘MDT Cmn’ on the RMC.

• CONNECT NOTHING TO THE '-Ret' PIN OF T HE RMC.

• Some Temposonics I transducers from MTS have 200 Ohm termination

resistors installed between their interrogation pins and common. If yours do

not, it may be necessary to install them as close to the transducers as possible to

reduce electrical noise in the system.

38

deltamotion.com

Page 39

RMC100 Startup Appendix A: Wiring

Index/wiring/SSI

Index/wiring/quadrature

Wiring the SSI Feedback Module

RMC SSI Input Six-Pin Plug-in Terminal Block Pin-out

Pin Function

1 SSI Axis + Clock

2 SSI Axis - Clock

3 SSI Axis Common

4 SSI Axis + Data

5 SSI Axis - Data

6 Case

The SSI module uses differential line driver (RS422) clock and data signals.

• Connect both the +Clock and -Clock between the RMC and transducer for the

clock signal, and both the +Data and -Data between the RMC and transducer

for the data signal.

• The power (+24V) and ground is not provided by the RMC, and therefore must

be provided externally to the transducer.

• Connect the transduce r DC ground t o SSI Cmn.

Wiring the QUAD Feedback Module

Quadrature module DB 25S Pin-out

Pin Function Wire Color Pin Function Wire Color

1 A- Enc: white/blue 14 Index (Z)- Enc: white/green

2 A+ Enc: blue/white 15 Index (Z)+ Enc: green/white

3 B- Enc: white/or ange 16 Encoder Cmn Enc: brown/white

4 B+ Enc: ora nge/white Enc: white/brown

5 N/C 17 N/C

6 Retract Lim- Lim: white/orange 18 Home- Lim: white/green

7 Retract Lim+ Lim: or a nge/white 19 Home+ Lim: green/white

8 Extend Lim- Lim: white/blue 20 Fault- Drv: white/green

9 Extend Lim+ Lim: blue/white 21 Fault+ Drv: green/ white

10 N/C 22 N/C

deltamotion.com

39

Page 40

Appendix A: Wiring RMC100 Startup Guide

11 N/C 23 N/C

12 Drive* Drv: blue/white 24 Enable*- Drv: white/orange

13 Drive Cmn* Drv: white/blue 25 Enable*+ Drv: orange/white

Notes:

• "*" indicates outputs, all others ar e inp uts

• Color codes are for cable part number RMC-CB-QUAD-01. This cable has

three wire groups: encoder, limit s, a nd drive. The wire color column lists the

wire group and the indivi dual wire color within that group .

• The encoder common should be connected to both wires listed.

Encoder Wiring

5 Volt differential driver:

Input Wiring (Home and Limits)

NPN Proximity sensors

Normally Open recommended for Home

Normally Closed recommended for Limits

PNP Proximity sensors

Normally Open recommended for Home

40

deltamotion.com

Page 41

RMC100 Startup Appendix A: Wiring

Normally Closed recommended for Limits

Drive Output Wiring

Fault Input Wiring

From TTL out put:

From Open Collector Output:

Enable Output Wiring

41

deltamotion.com

To TTL input (high = enabl e):

Page 42

Appendix A: Wiring RMC100 Startup Guide

Index/wiring/

stepper

To active low Enable input:

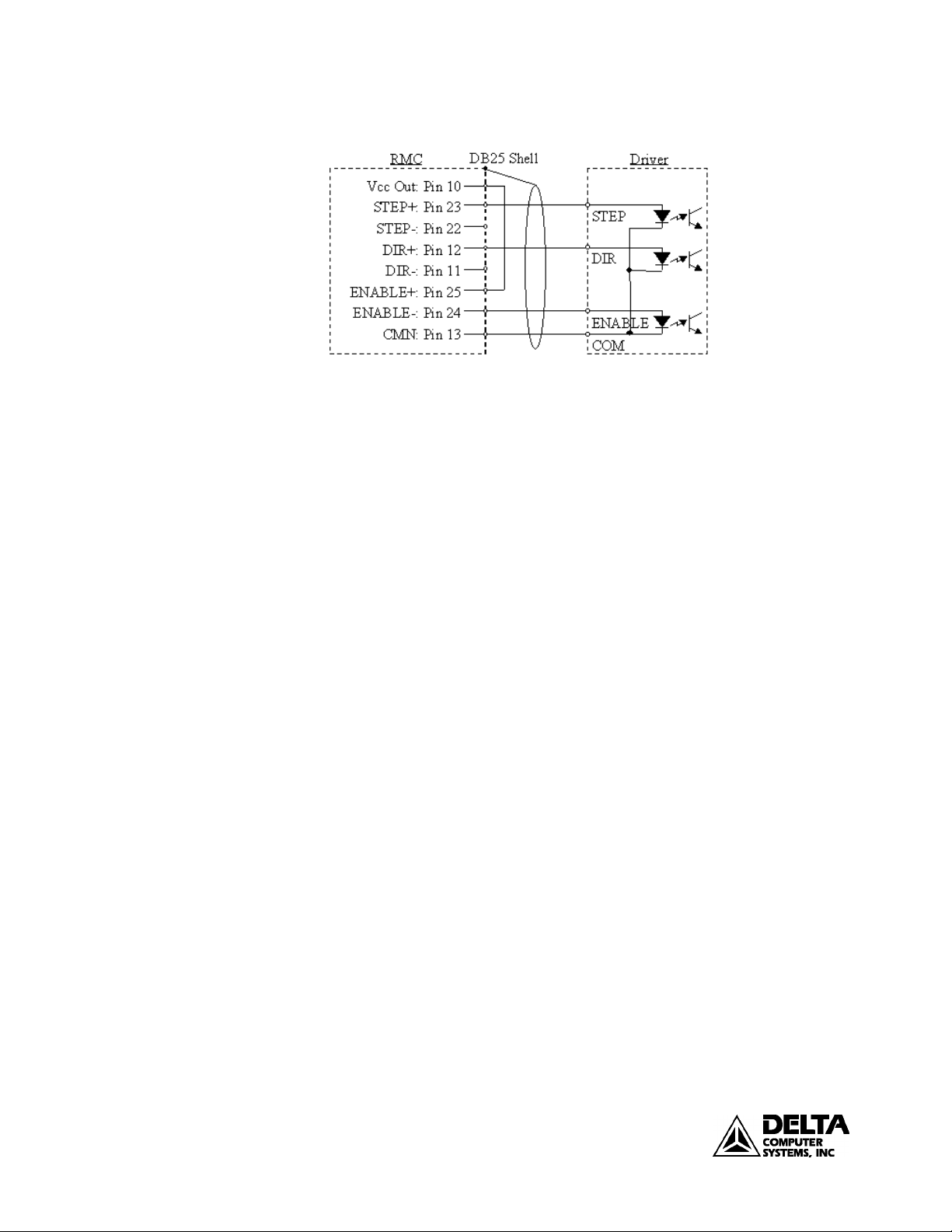

Wiring the Stepper Module

Use shielded twisted pairs for all co nnections to inputs and o ut puts. Route the

quadrature encoder wiring separate from other wiring. You must provide the power

supplies needed by your quadrature encoders and drives, although the RMC can

provide +5 VDC for the optoisolators on the drive module as shown in the Stepper

Output Wiring section below.

DB25S Pin-out

Pin Function Pin Function

1 A- 14 Index (Z)2 A+ 15 Index (Z)+

3 B- 16 Encoder Co mmon

4 B+ 17 N/C

5 N/C 18 Home6 Retract Lim- 19 Home+

7 Retract Lim+ 20 Fault8 Extend Lim- 21 Fault+

9 Extend Lim+ 22* Step10* Vcc Out 23* Step+

11* Direction- 24* Drive E nable12* Direction+ 25* Drive Enable+

13* Drive C ommon

*Outputs, all others ar e inputs

42

deltamotion.com

Page 43

RMC100 Startup Appendix A: Wiring

Stepper Output Wiring

NOTE: Do not use Vcc Out to power your encoder because:

• This output’s voltage is not regulated.

• 50 mA is not adequate current to power the encoder. Each of the encoder

outputs (A, B, and Z) requires 20 to 25 mA in addition to the current used by

the encoder’s internal circuit.

• Using this output to power the encoder would violate the isolation that exists

between the inputs and outputs.

NOTE: The Step and Dir outputs are generated by a differential driver, but the

Enable output is a relay. Therefore, power must be provided through the Enable

output, as s hown in the d iagrams below.

Drive with bipolar inputs:

Drive with c ommon anode inputs:

deltamotion.com

43

Page 44

Appendix A: Wiring RMC100 Startup Guide

Drive with c ommon cathode inputs:

Input Wiring

The wiring for all inputs is identical to the wiring for the quadrature inter face

module with analog outputs. See t he Quadrature wiring section for diagrams on

these input s .

44

deltamotion.com

Page 45

RMC100 Startup Appendix B: Tuning

Index/tuni ng/overview

Index/go

Index/plots/using

Index/stored commands/using

Index/plot time

Appendix B: Tuning

After setting up your system, it must be tuned in order to control it. T he b e tte r tuned

a system is, the better it follows the desired trajectory and holds position.

Tuning procedures differ depending on the type of system. This section contains

procedures that may work for the following s ys tems:

• A Hydraulic Position Axis or Motor in Velo c ity Mode

• A Motor in Torque Mode

• A Position/Pressure System

Please read the "General Tuning Guidelines" before continuing to any of the tuning

procedures.

General Tuning Guideli ne s

Keep these general guidelines in mind throug hout the tu ning proc edure.

There is no s ubstitute for experience when tuning an axis. The procedures offer

some guidelines, tips, and suggestions for tuning your system. While t he steps will

work for many systems, they may not be the best for a particular system.

• The tuning procedure is a reiteration of the following general steps. Use these

steps throughout the tuning procedure:

− Make a move. Use the Go (G) command for making moves.

− View the plotted move. See the Plots topic for more information. Viewing

the plot will help you determine which parameters must be changed.

− Change a parameter. To do this, edit the parameter in RMCWin and then

click

− Repeat these steps using the same move until the parameter is at the

desired value. See the Stored Commands topic for repeating moves.

• Use the Sum of Errors Squared in the R M CWin plotting utility to determine

how the last parameter change affected the system. The Sum of Errors Squared

indicates how closely the Actua l Position is tracking the Target Po sition. If this

number decreases significantly, the last parameter change was good. If this

number increases significantly, the last parameter change was bad.

• Remember, that in order to use the Sum of Errors Squared to compare moves,

the moves must be identical.

• Begin the tu ning proc edure with lo ng, slow moves and lo w Accelerations. This

will prevent you from losing co ntrol of and potentiall y damaging t he system.

• To obtain the greatest tuning pr e c isio n, use the shortest Plot Time possible.

This will spread the move across the e ntire plot window and allow you to see

precisely how the system is responding. See the Plot Time topic in the online

help.

to initialize the RMC100 with this value.

deltamotion.com

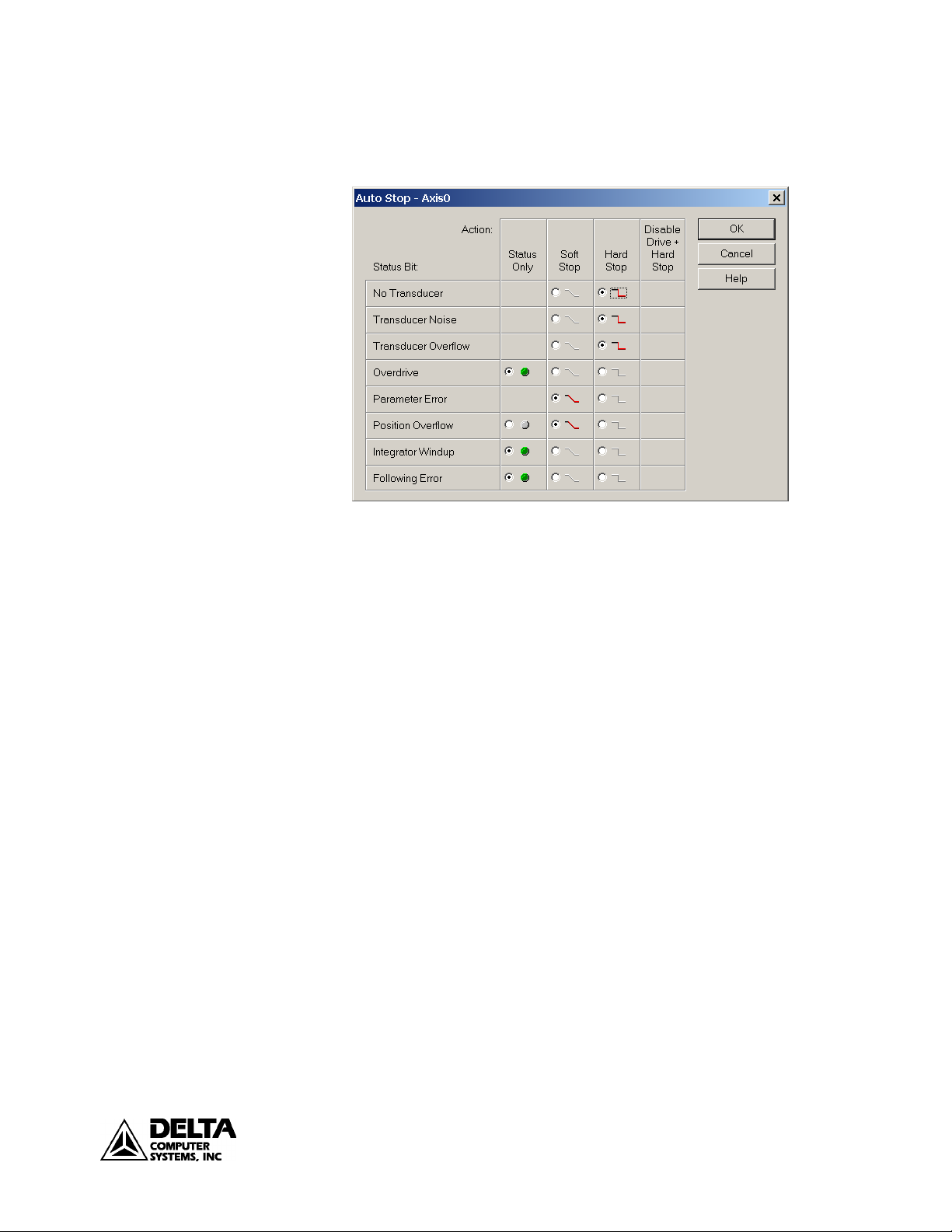

• You may want to turn off some of the Auto Stop bits. The Auto Stop turns off

the Drive if an error occurs. In the i nitial stages of tuning, a Following Error or

other error may occur, causing an undesired halt. Setting these bits to "Status

45

Page 46

Appendix B: Tuning RMC100 Startup Guide

Only" will make the RMC ignore t he errors so you can tune t he axis. Thi s may

not be possible on some systems because of safety concerns. Remember to set

these bits to either "S oft Stop" or "Hard Stop" when you ha ve gained sufficient

control of the axis.

• When changing the parameters, r emember that they are not updated in the

Tuning a Position Axis

RMC until the Set Parameters (P) command

stored into the RMC FLASH me mory until the Update FLASH command

is issued.

The following procedure may be used to tune many hydraulic position axes and

motors in velocity mode.

1. Set all Gains and Feed Forwards to zero

This is done by editing the values in t he main RMCWin window. Then clic k

the

2. Set the Null Drive

The drive it takes to hold the axis in position is referred to as the Null drive. I f

the axis tends to drift significantly when you give it an Open Loop drive of 0,

you should set the null drive. This drive is then always added to the total d r ive

output and helps the RMC100 a c c ura te ly follow the motion profile. To se t the

null drive, issue a P command to hold the axis i n position in closed loop, then

issue the N command.

3. Check Dead Band

If your system has a large dead band, you will need to set the Dead Band