Page 1

The power behind competitiveness

Delta InfraSuite

Power Management

Static Transfer Switch

User Manual

www.deltapowersolutions.com

Page 2

Save This Manual

This manual contains important instructions and warnings that you should

follow during the installation, operation, storage and maintenance of this

product. Failure to heed these instructions and warnings will void the warranty.

Copyright © 2016 by Delta Electronics Inc. All Rights Reserved. All rights of this

User Manual (“Manual”), including but not limited to the contents, information,

and figures are solely owned and reserved by Delta Electronics Inc. (“Delta”).

The Manual can only be applied to the operation or the use of this product. Any

disposition, duplication, dissemination, reproduction, modification, translation,

extraction, or usage of this Manual in whole or in part is prohibited without the prior

written permission of Delta. Given that Delta will continuously improve and develop

the product, changes may be made to the information in this Manual at any time

without obligation to notify any person of such revision or changes. Delta will make

all possible efforts to secure the accuracy and the integrity of this Manual. Delta

disclaims any kinds or forms of warranty, guarantee, or undertaking, either expressly

or implicitly, including but not limited to the completeness, faultlessness, accuracy,

non-infringement, merchantability or tness for a particular purpose of the Manual.

InfraSuite Power Management

II

Page 3

Table of Contents

Table of Contents

Chapter 1 : Important Safety Instructions --------------------------- 1

1.1 Important Safety Notes ---------------------------------------- 1

1.2 Electrical Warnings ---------------------------------------------- 1

1.3 Standard Compliance ------------------------------------------ 2

Chapter 2 : Product Introduction --------------------------------------- 3

2.1 Product Description --------------------------------------------- 3

2.2 Features ----------------------------------------------------------- 3

Chapter 3 : Package and Storage -------------------------------------- 4

3.1 Package Contents ----------------------------------------------- 4

3.2 Storage ------------------------------------------------------------- 4

Chapter 4 : Installation ----------------------------------------------------- 5

Chapter 5 : Wiring ----------------------------------------------------------- 7

Chapter 6 : Operation -----------------------------------------------------11

6.1 Front Panel -------------------------------------------------------11

6.2 Rear Panel -------------------------------------------------------13

6.3 Operation ---------------------------------------------------------16

Chapter 7 : InsightPower SNMP IPv6 for STS ---------------------17

7.1 Introduction of InsightPower SNMP IPv6 for STS ------17

7.2 SNMP IPv6 Features ------------------------------------------17

7.3 Top View and Front View of SNMP IPv6 -----------------18

7.4 Console Management -----------------------------------------19

7.5 Upgrade -----------------------------------------------------------23

III

Page 4

7.6 STS Command Settings --------------------------------------25

7.7 Key Generation for SSH --------------------------------------29

Chapter 8 : Troubleshooting --------------------------------------------31

Appendix 1 : Specications ---------------------------------------------32

Appendix 2 : Warranty ----------------------------------------------------33

InfraSuite Power Management

IV

Page 5

Chapter 1 Important Safety Instructions

Chapter 1 : Important Safety Instructions

1.1 Important Safety Notes

z

z

Only qualied personnel can service this equipment.

z

z

Follow the following precautions when working on this unit.

1. Remove watches, rings, or other metal objects.

2. Use tools with insulated handles.

3. Examine the packing container. Notify the carrier immediately if any damage

is present.

4. Do not disassemble the unit.

5. Do not operate the unit near water or in an area with excessive humidity.

6. Keep liquid and foreign objects from getting inside the unit.

7. Do not operate the unit close to gas or re.

z

z

Upstream circuit breaker must be added for each input. The recommended

breaker is D curve 16A.

z

z

Verify whether the branch circuit breaker or fuse on service feed is correct.

z

z

Verify line voltage requirements and the supplied line voltage prior to installation.

1.2 Electrical Warnings

z

z

When servicing this equipment, you will need to remove its protective covers

and disconnect the input power. Please observe great caution during these pro-

cedures. Only qualied personnel can service this equipment.

z

z

Check that power cords, plugs, and outlets are in good condition.

1

Page 6

1.3 Standard Compliance

z

z

Safety

UL (US) (UL 60950) CE (EU) (IEC 60950)

z

z

EMI

CISPR 22 Class A and FCC Class A

z

z

EMS

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-4

IEC 61000-4-5

IEC 61000-4-6

IEC 61000-4-8

IEC 61000-4-11

z

z

IPv6 Certication

IPv6 Ready Logo Phase 2 (Core for Host, Logo ID 02-C-000624)

InfraSuite Power Management

2

Page 7

Chapter 2 Product Introduction

Chapter 2 : Product Introduction

2.1 Product Description

The STS is designed to guarantee the uninterrupted operation of sensitive equipment. It is powered by two independent power sources and automatically makes a

rapid switch from one source to the other when the original power supplying to its

connected load fails.

The user can know the power flow and the STS’s status from the user-friendly

front panel, and can read and write parameters via the built-in NETWORK port and

LOCAL port located at the rear of the unit. The STS is designed to be efcient and

reliable.

2.2 Features

z

z

Self-test function

Power-on self-test

Manual self-test

z

z

Withstands high inrush current

SCR design withstands high inrush current during transferring process.

3

Page 8

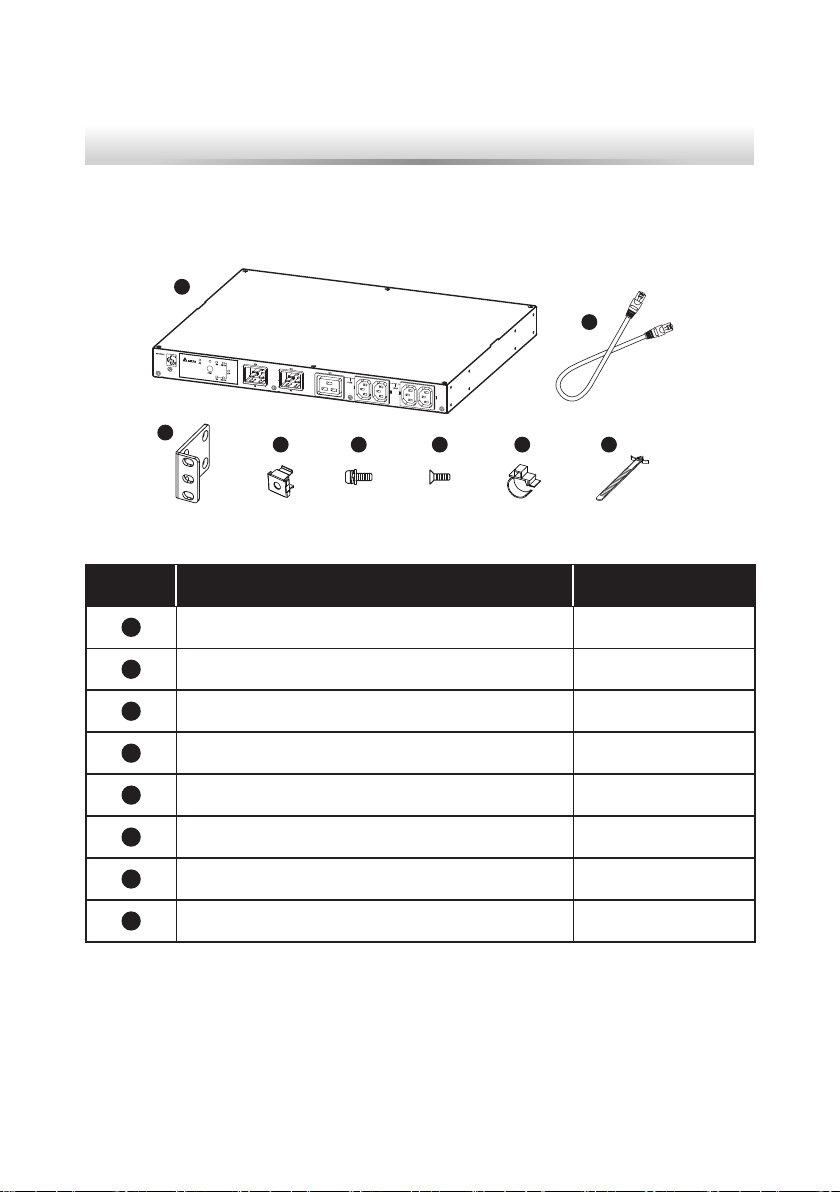

Chapter 3 : Package and Storage

3.1 Package Contents

1

2

3

×

2

4 5

4

×

6

4

×

×

8

7 8

10

×

STS package contains the following items.

No. Item Quantity

1

2

3

4

5

6

7

8

STS module 1 PC

Extension Ethernet cable 1 PC

Bracket Ear 2 PCS

Rack nut 4 PCS

Rack screw 4 PCS

Bracket screw 8 PCS

Wire Mount 10 PCS

Cable Tie 10 PCS

3.2 Storage

10

×

Please store the STS in its original package and in a dry place. Keep the storage

temperature between -15°C~ +50°C.

InfraSuite Power Management

4

Page 9

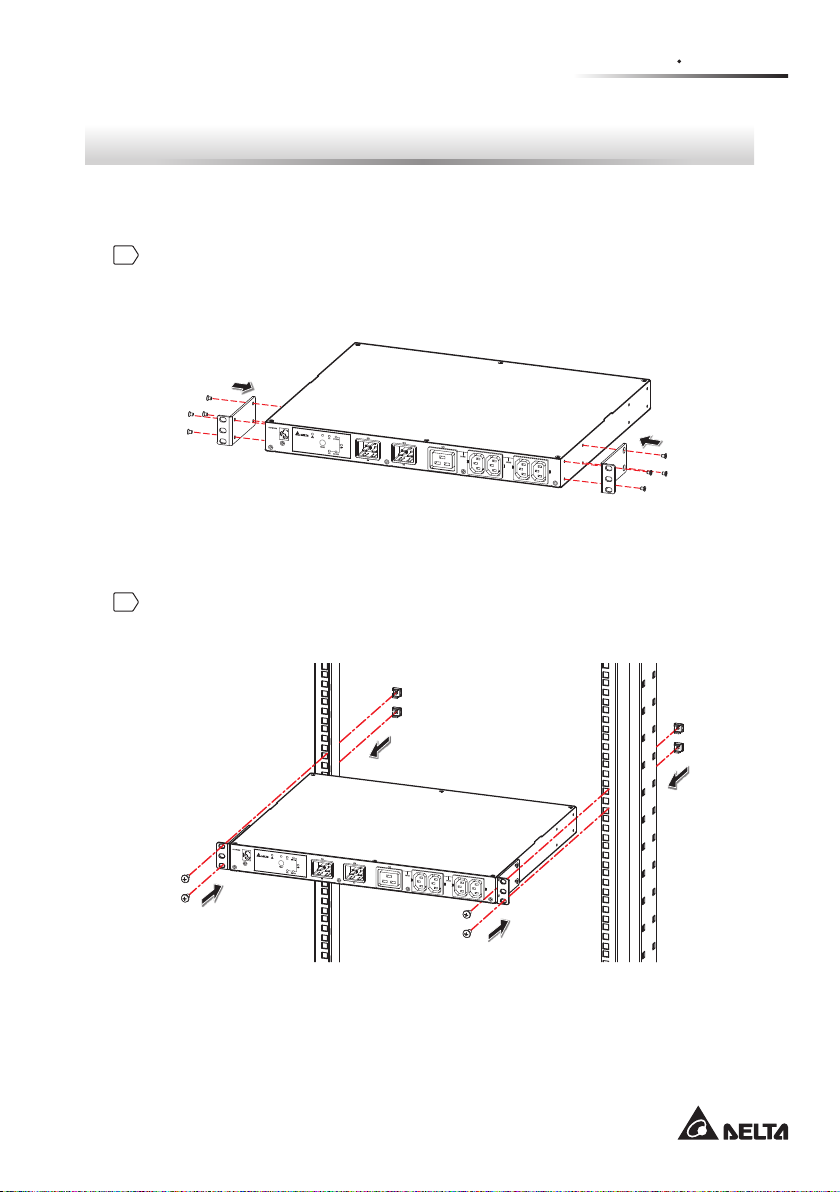

Chapter 4 Installation

Chapter 4 : Installation

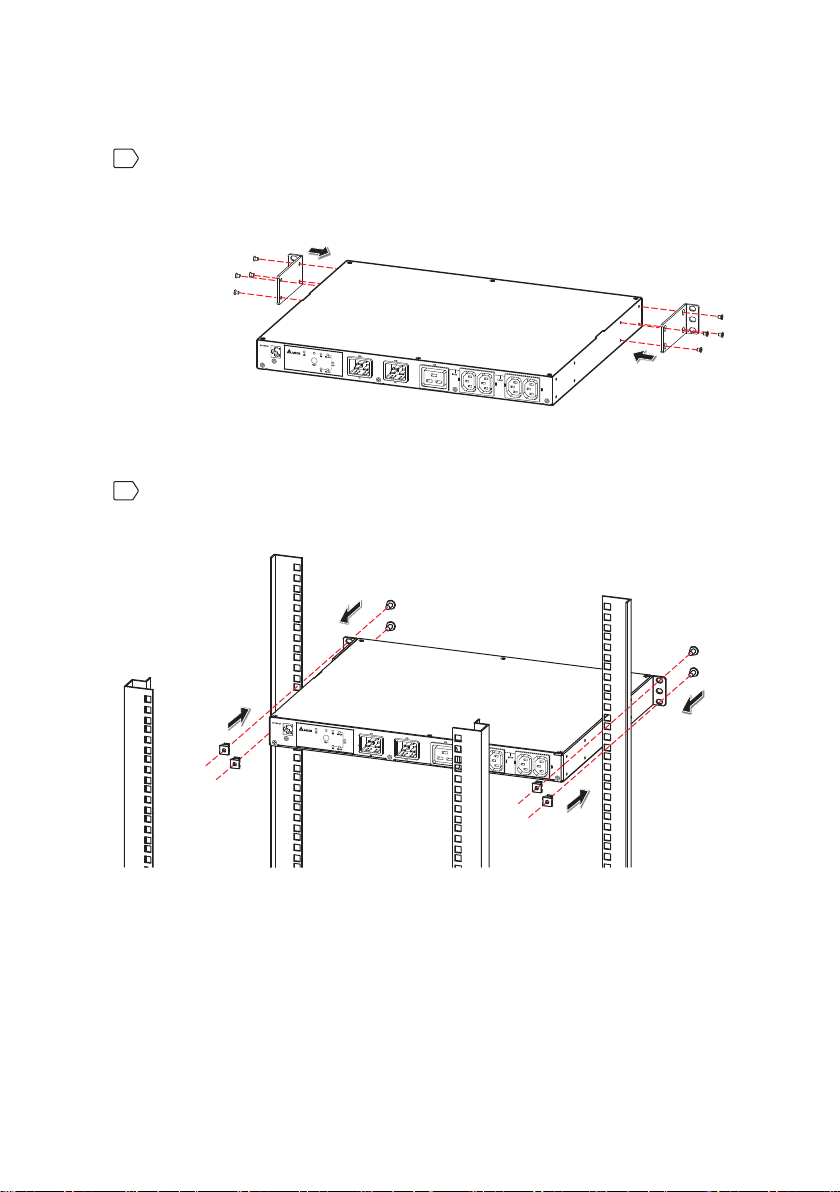

z

z

Front Installation

1

Use the eight bracket screws (provided) to attach the two bracket ears

(provided) to the lateral mounting holes located in the front of the STS.

Please see Figure 4-1.

Bracket Ear x 1

Bracket Screw X 4

Bracket Ear x 1

Bracket Screw X 4

(Figure 4-1)

2

Use the four rack screws (provided) and four rack nuts (provided) to x the

STS on your rack. Please see Figure 4-2.

Rack Screw x 2

Rack Nut x 2

Rack Nut x 2

Rack Screw x 2

(Figure 4-2)

5

Page 10

z

z

Rear Installation

1

Use the eight bracket screws (provided) to attach the two bracket ears

(provided) to the lateral mounting holes located at the rear of the STS.

Please see Figure 4-3.

Bracket Ear x 1

Bracket Screw X 4

Bracket Ear x 1

Bracket Screw X 4

(Figure 4-3)

2

Use the four rack screws (provided) and four rack nuts (provided) to x the

STS on your rack. Please see Figure 4-4.

Rack Screw x 2

Rack Screw x 2

Rack Nut x 2

InfraSuite Power Management

Rack Nut x 2

(Figure 4-4)

6

Page 11

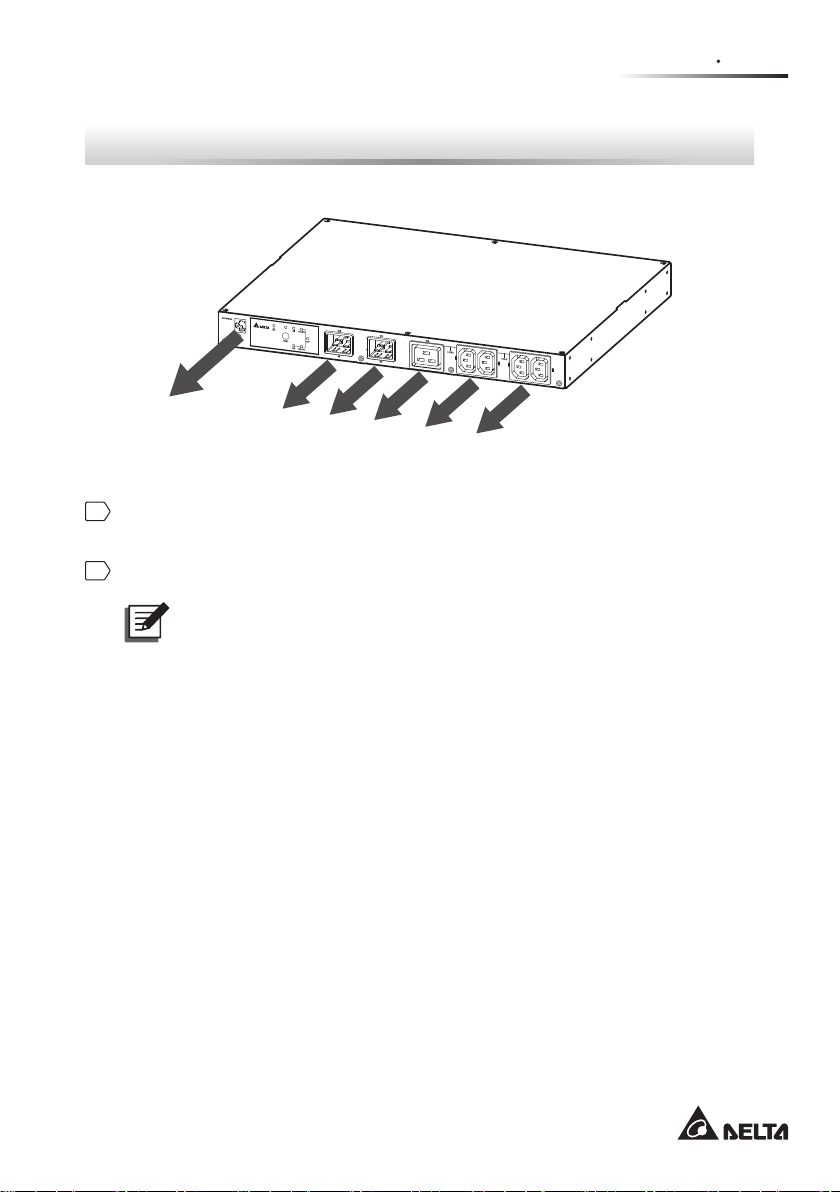

Chapter 5 Wiring

Ethernet Network

To UPS 1

To UPS 2

To load

To load

To load

Chapter 5 : Wiring

(Figure 5-1: Front view)

1

Use input power cables (not provided) to connect the STS and two UPSs (UPS1

(S1) is the preferred source).

2

Use output power cables (not provided) to connect the STS and loads.

NOTE :

To avoid the loose input/ output power cables, please use the provided

wire mounts and cables ties to x the input/ output power cables to the

outlets/ sockets firmly. Please refer to the following procedures and

gures.

7

Page 12

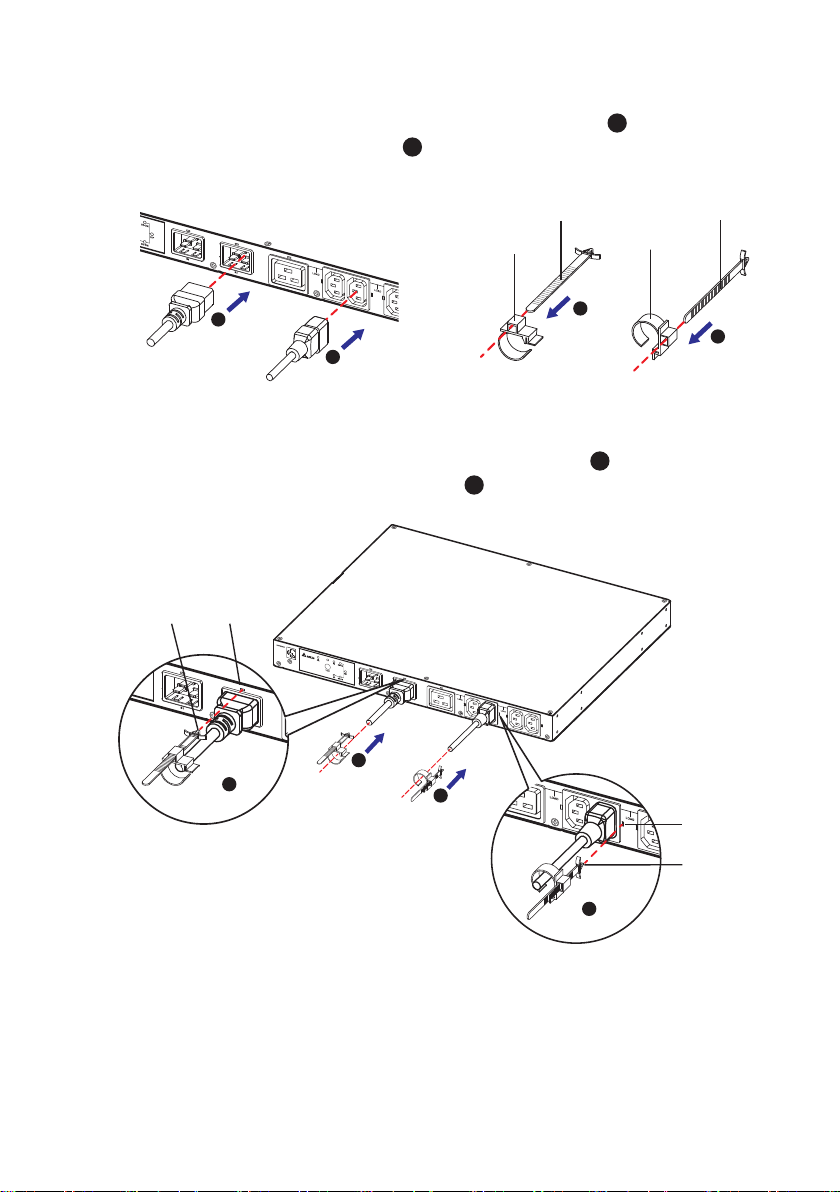

A. Firmly insert the power cables into the outlets/ sockets ( 1 ) and insert the

cable ties into the wire mounts (

2

), Please refer to Figure 5-2.

Cable Tie

Wire Mount

1

1

Wire Mount

2

Cable Tie

2

(Figure 5-2)

B. Firmly insert the wire mounts into the power cables ( 3 ) and insert each

cable tie’s peak into the according slot (

Cable

Tie’s Peak

Slot

3

4

4

). Please refer to Figure 5-3.

3

Slot

InfraSuite Power Management

Cable

Tie’s Peak

4

(Figure 5-3)

8

Page 13

C. Clip each wire mount rmly (

5

5

). Please refer to Figure 5-4.

Chapter 5 Wiring

Wire Mount

Wire Mount

5

(Figure 5-4)

3

Connect to the Ethernet Network. There are two methods.

1. Method 1 (Front Application):

Use the provided extension Ethernet cable to connect the rear panel’s

NETWORK port and the rear panel’s TRANSFER PORT; please see Figure

1

5-5

. Use a user-supplied Ethernet cable to connect to the front panel’s

NETWORK port; please see Figure 5-5

1

2

.

2

NETWORK

LOCAL

TRANSFER

RESET

PORT

(Figure 5-5: Rear View)

9

Page 14

2. Method 2 (Rear Application):

Use a user-supplied Ethernet cable to connect to the rear panel’s

NETWORK port; please see Figure 5-6.

NETWORK

LOCAL

TRANSFER

RESET

PORT

(Figure 5-6: Rear view)

InfraSuite Power Management

10

Page 15

6.1 Front Panel

Chapter 6 Operation

Chapter 6 : Operation

NETWORK

S1 S1-ON

O/P

TEST

S2 S2-ON

S1

S2

78

TEST

6

LOAD

123

S1 S1-ON

O/P

S2 S2-ON

4

LOAD

No. Item Description

1

S1 LED Green. The LED indicates the condition of input source 1. If the

input source 1 is within the acceptable range, the LED will light

up as green. If the input source 1 is out of the acceptable range,

the LED will be off.

2

S2 LED Green. The LED indicates the condition of input source 2. If the

input source 2 is within the acceptable range, the LED will light

up as green. If the input source 2 is out of the acceptable range,

the LED will be off.

5

3

4

S1_ON

LED

S2_ON

LED

Green. If the STS uses input source 1 to supply power to the

output, the LED will light up as green. If not, the LED will be off.

Green. If the STS uses input source 2 to supply power to the

output, the LED will light up as green. If not, the LED will be off.

11

Page 16

No. Item Description

5

O/P

LED

Green. The LED indicates the output condition (voltage is >

60Vac). If there is output, the LED will light up as green. If not,

the LED will be off.

6

Test

Button

Use this button to test the STS. Press the button, the STS will

transfer to the 2nd source for 1 minute and then transfer back to

the original preferred source.

7

Test

LED

Green. If you press the test button, the STS will be on test and

the Test LED will ash (on: 0.5s; off: 0.5s). In normal operation,

the LED will be off.

8

Fault

LED

Red. If the STS has any internal fault, the LED will light up as

red. If the STS has any environmental fault, the LED will ash

(on: 0.5s; off: 0.5s). Via the rear panel’s NETWORK port, fault

messages will be sent to a connected PC. From the PC, you can

see error codes as follows

Internal Fault

Error Code Meaning

E11

E12

Over temperature (due to detection of S1

heat-sink temperature)

Over temperature (due to detection of S2

heat-sink temperature)

E13 Auxiliary power 1 circuit failure

E14 Auxiliary power 2 circuit failure

E21 Input relay of S1 is open

E22 Input relay of S1 is short

E23 Input relay of S2 is open

E24 Input relay of S2 is short

E25 Input SCR of S1 is open

E26 Input SCR of S1 is short

E27 Input SCR of S2 is open

E28 Input SCR of S2 is short

InfraSuite Power Management

12

Page 17

No. Item Description

8

Fault

LED

Environmental Fault

Error Code Meaning

E01 Output overload

E02

E03

E04

Over temperature (due to detection of

ambient temperature)

Output temperature warning (due to detection

of S1 heat-sink temperature)

Over temperature warning (due to detection

of S2 heat-sink temperature)

6.2 Rear Panel

Chapter 6 Operation

NETWORK

LOCAL

RESET

TRANSFER

PORT

1 2 3

NETWORK

4

LOCAL

RESET

5

13

Page 18

No. Item Description

NETWORK

1

2

3

4

Port

LOCAL

Port

RESET

Button

LED

Indicators

Connects to the Ethernet Network.

Connects to a workstation with an RJ45 to DB9 cable to

congure the system.

Resets InsightPower SNMP IPv6 for STS (hereafter referred

to as SNMP IPv6). This does not affect the operation of the

STS.

NET LED (green) indicates network communication status.

STS LED (amber) indicates the STS’s communication status.

NETWORK

NET LED STS LED

LED Condition Meaning

NET LED OFF Ethernet is unlinked.

NET LED Green Ethernet is linked.

STS LED OFF

1. Initialization

2. SNMP IPv6 abnormality

STS LED Amber SNMP IPv6 abnormality

STS LED Blinking

InfraSuite Power Management

14

Every

second

Every

50 ms

Poor connection

between the STS

and the SNMP IPv6.

Normal connection

between the STS

and the SNMP IPv6.

Page 19

No. Item Description

Chapter 6 Operation

5

DIP

Switches

Set up operation mode. Please refer to the following table.

DIP Switch 2DIP Switch 1

1 2

ON

DIP

Switch 1

OFF OFF

OFF ON

ON OFF N/A Invalid state.

ON ON

DIP

Switch 2

Operation

Mode

Normal

Mode

Pass

Through

Mode

Congura-

tion Mode

Description

The built-in SNMP IPv6

provides the STS’s

status information and

parameters through a

network system.

The built-in SNMP

IPv6 stops polling the

STS but transfers the

communication data

between the LOCAL

port and the STS.

In this mode, the user

can login through

the LOCAL port and

congure the built-in

SNMP IPv6’s settings.

15

Page 20

6.3 Operation

(L)

(N)

(G)

(L)

(N)

(G)

UPS

(Source 1)

UPS

(Source 2)

2 poles circuit breaker

(L1)

(N1)

(G)

2 poles circuit breaker

(L2)

(N2)

(G)

ATS

S1

(L)

To the

(N)

sensitive

equipment

(G)

S2

After power connection, the STS will automatically perform power-on self-test. After

the test, the STS will start supplying power to its connected equipment. You can

also press the ‘Test Button’ to force the STS to execute self-test.

InfraSuite Power Management

16

Page 21

Chapter 7 InsightPower SNMP IPv6 for STS

Chapter 7 : InsightPower SNMP IPv6 for STS

7.1 Introduction of InsightPower SNMP IPv6 for STS

The InsightPower SNMP IPv6 for STS, hereafter referred to as SNMP IPv6, is

built in the STS and is a device that provides an interface between the STS and

a network. It communicates with the STS, acquires its information and remotely

manages the STS via a network system. The SNMP IPv6 supports public protocols

including SNMP and HTTP. You can effortlessly congure this SNMP IPv6 using a

network system and easily obtain your STS’s status and manage your STS via the

SNMP IPv6.

7.2 SNMP IPv6 Features

z

z

Network STS management

Allows remote management of the STS from any workstation through Internet or

Intranet.

z

z

Remote STS monitoring via SNMP & HTTP

Allows remote monitoring of the STS using SNMP NMS, Delta MIB (Management

Information Base) or a Web Browser.

z

z

STS and system conguration from any client (password protected)

Sets the STS and system parameters through a Web Browser.

z

z

Event logs & metering data keeping

Provides a history data of the STS’s power events, power quality and status.

z

z

Other features and supported protocols include:

- User notication via SNMP Traps and e-mail

- Network Time Protocol

- Telnet conguration

- BOOTP/ DHCP

- HTTPS, SSH, SFTP and SNMPv3 security protocols

17

Page 22

- RADIUS (Remote Authentication Dial In User Service) login and local

authentication

- Remote event log management through syslog

- IPv6 Ready Logo certied (ID 02-C-000624)

DEFAULT SETTING

User Name: admin

Password: password

DHCP Client: Enable

IPv4 Address: 192.168.1.100

7.3 Top View and Front View of SNMP IPv6

z

z

Top View

Network Port

LED Indicators

Local Port

Reset Button

Dip Switches

z

z

Front View

Network Port

LED Indicators Local Port Reset Button

InfraSuite Power Management

18

1 2

ON

Dip Switches

Page 23

Chapter 7 InsightPower SNMP IPv6 for STS

7.4 Console Management

You can manage the SNMP IPv6 through the LOCAL port. Please use an RJ45 to

DB9 cable to connect the SNMP IPv6’s LOCAL port and your workstation’s COM

port. Make sure both of the DIP switches are set to the OFF position (normal mode).

The baud-rate of the workstation’s COM setting should be 2400 bps.

z

z

Web Card Main Menu

+========================+

Web Card Main Menu

| |

+========================+

Web Card Version 01.12.11f

MAC Address 00-30-ab-26-b1-b4

[1].User Manager

[2].TCP/IP Setting

[3].Network Parameter

[4].Time Server

[5].Soft Restart

[6].Reset All To Default

[d].Device Communication

[z].Exit Without Save

[0].Save And Exit

Please Enter Your Choice =>

z

z

User Manager

+========================+

User Manager

| |

+========================+

RADIUS

[1].RADIUS Auth: Disable

[2].Server:

[3].Secret:

[4].Port: 1812

---------------Local Auth

Administrator

[5].Account: admin

[6].Password: ********

[7].Limitation: Only in This LAN

Device Manager

[8].Account: device

[9].Password: ********

[a].Limitation: Only in This LAN

Read Only User

[b].Account: user

[c].Password: ********

[d].Limitation: Allow Any

[0].Back To Previous Menu

Please Enter Your Choice =>

19

Page 24

z

z

TCP/ IP Setting

+========================+

TCP/IP Setting

| |

+========================+

[1].IPv4 Address: 192.168.1.100

[2].IPv4 Subnet Mask: 255.255.255.0

[3].IPv4 Gateway IP: 192.168.1.254

[4].IPv4 DNS or WINS IP:192.168.1.254

[5].DHCPv4 Client: Enable

[6].IPv6 Address: ::

[7].IPv6 Prefix Length: 0

[8].IPv6 Gateway IP: fe80::226:Sbff:fecc:fdal

[9].IPv6 DNS IP: ::

[a].DHCPv6: Disable

[b].Host Name(NetBIOS): INSIGHTPOWER

[c].System Contact:

[d].System Location:

[e].Auto-Negotiation: Enable

[f].Speed: 100M

[g].Duplex: Full

[h].Status Stable: 3

[i].Telnet Idle Time: 60 Seconds

[0].Back To Previous Menu

Please Enter Your Choice =>

z

z

Network Parameter

+========================+

Network Parameter

| |

+========================+

[1].HTTP Server: Enable

[2].HTTPS Server: Enable

[3].Telnet Server: Disable

[4].SSH/SFTP Server: Enable

[5].FTP Server: Enable

[6].Syslog: Disable

[7].HTTP Server Port: 80

[8].HTTPS Server Port: 443

[9].Telnet Server Port: 23

[a].SSH Server Port: 22

[b].FTP Server Port: 21

[c].Syslog Server1:

[d].Syslog Server2:

[e].Syslog Server3:

[f].Syslog Server4:

[g].SNMP Get,Set Port: 161

[0].Back To Previous Menu

Please Enter Your Choice =>

InfraSuite Power Management

20

Page 25

z

z

Time Server

Chapter 7 InsightPower SNMP IPv6 for STS

+========================+

| |

+========================+

[1].Time Selection: SNTP

[2].Time Zone: +0 hr

[3].1st Time Server:

[4].2nd Time Server:

[5].Manual Date: 01/01/2000 (MM/DD/YYYY)

[6].Manual Time: 00:00:00 (hh:mm:ss)

[0].Back To Previous Menu

Please Enter Your Choice =>

z

z

Soft Restart

+========================+

| |

+========================+

Web Card Version 01.12.11f

MAC Address 00-30-ab-26-b1-b4

[1].User Manager

[2].TCP/IP Setting

[3].Network Parameter

[4].Time Server

[5].Soft Restart

[6].Reset All To Default

[d].Device Communication

[z].Exit Without Save

[0].Save And Exit

Please Enter Your Choice => 5

The Web Card Will Restart.

Are You Sure? [Y]es/[N]o =>

Time Server

Web Card Main Menu

21

Page 26

z

STS> Vs1

216.8

STS> Vs2

217.9

STS> Iout

8.1

STS> Vout

217.1

STS> Vbp2s

180.0

STS> Vbs2p

180.0

STS> Tdp2s

12.0

STS> Tds2p

12.0

STS> TempF

96

STS> TempC

36

STS> Age

1075878

STS> Time

13:3:24 07/18 2011

STS> XCount

4402

STS> Prefer

S1

STS> DevID

12345678901234567890

STS> Serial

STS> Tprevl

13:35:16 07/18/2011

STS> Event1

0x0029

STS> Log

10

STS> Log 1

13:35:16 07/18/2011 0x0029

STS>

STS> SetDevID 1234567890abcdefghijklmn

STS> DevID

12345678901234567890

STS> SetDevID 1234567890abcdefghij

STS> DevID

1234567890abcdefghij

STS>

z

Device Communication

You can enter the STS Command Mode below by selecting Device Communication.

InfraSuite Power Management

22

Page 27

Chapter 7 InsightPower SNMP IPv6 for STS

7.5 Upgrade

z

z

Upgrade via Web

You can upgrade the SNMP IPv6’s rmware or the STS’s rmware through the

InsightPower SNMP IPv6 for STS Web (please see the following gure). The

SNMP IPv6 will restart after finishing self-upgrade. If you upload the STS’s

rmware to the Web, you can see the STS’s rmware upgrade progress from the

Web.

z

z

Upgrade via FTP/ SFTP

You can also upgrade the SNMP IPv6’s rmware or the STS’s rmware by using

FTP or SFTP program. Make sure you upload correct images to upgrade_snmp

when upgrading SNMP IPv6’s rmware, and upload correct images to upgrade_

device when upgrading the STS’s rmware.

23

Page 28

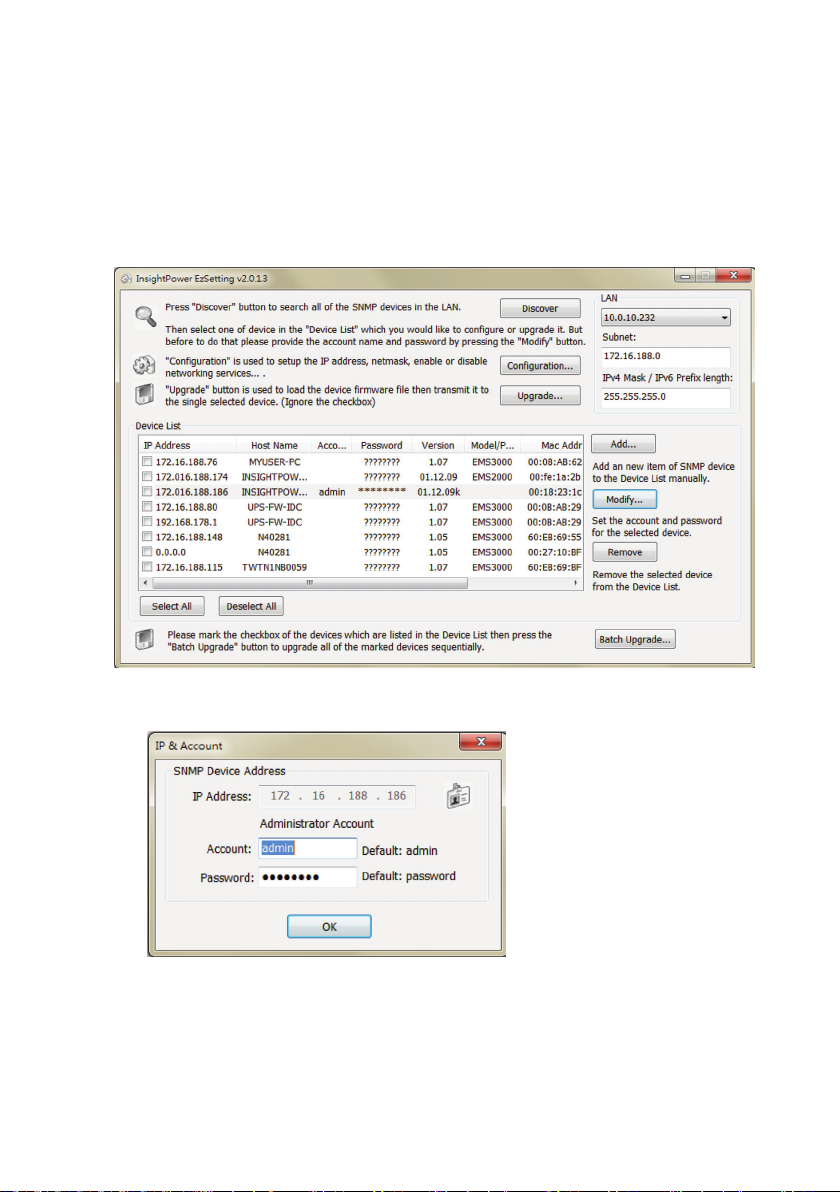

z

z

Upgrade via EzSetting

You can also upgrade the SNMP IPv6’s rmware or the STS’s rmware by using

EzSetting.

1. Click Discover. A list of SNMP devices is shown. Select a device from the

Device List, and click Modify.

2. Enter Administrator account and password.

InfraSuite Power Management

24

Page 29

Chapter 7 InsightPower SNMP IPv6 for STS

3. Click Upgrade. The upgrade dialog box pops up. Click Browse to select

a valid firmware binary file. Verify the firmware version shown under File

Information, and then click Upgrade Now to continue.

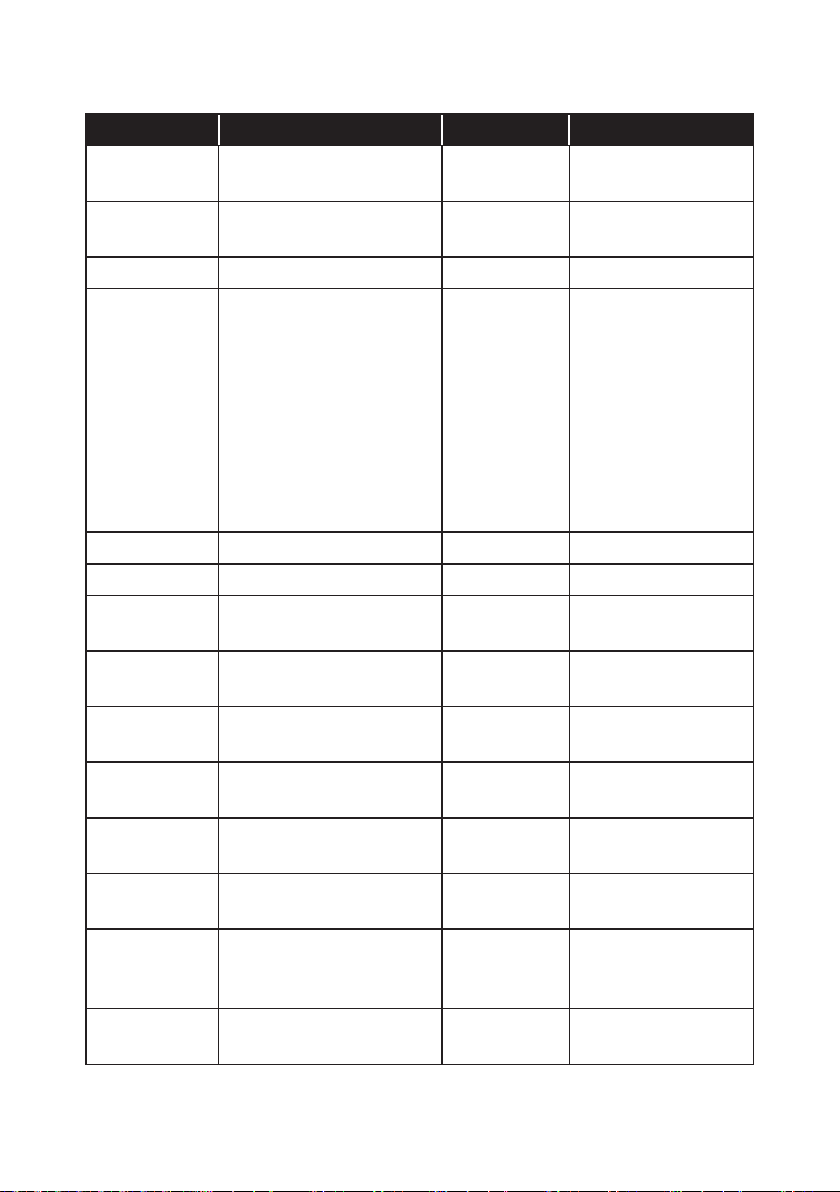

7.6 STS Command Settings

Command Description Parameter Response

Info Report summary

information.

TempF Report internal STS

fahrenheit temperature.

TempC Report internal STS

celsius temperature.

Age Report internal STS age. N/A #

Time Report present time. N/A hh:mm:ss MM/DD/

XCount Report number of times

that STS has transferred.

Model Report the model name. N/A <model name string>

FWVer Report the FW version. N/A <version string>

FWDate Report the FW release

date.

Serial Report the unit’s serial

number.

N/A <Command>:

[<response>] [<unit>]

N/A #

N/A #

YYYY

N/A #

N/A YYYY-MM-DD

N/A <Device serial string>

25

Page 30

Command Description Parameter Response

DevID Report the unit’s device

N/A <Device ID string>

ID.

Prefer Report the preferred

N/A S1 or S2

source.

Sens Report the sensitivity. N/A hi or low

Mode Report the operation

mode.

N/A Initialization

Diagnosis

Off

S1

S2

Safe

Fault

Vout Report the output voltage. N/A #.#

Iout Report the output current. N/A #.#

Vs1 Report the primary

N/A #.#

voltage.

Vs2 Report the secondary

N/A #.#

voltage.

Fs1 Report the primary

N/A #.#

frequency.

Fs2 Report the secondary

N/A #.#

frequency.

Vtp2s Report the primary to

N/A #.#

secondary trip voltage.

Vts2p Report the secondary to

N/A #.#

primary trip voltage.

Vbp2s Report the primary to

N/A #.#

secondary brownout

voltage.

Vbs2p Report the secondary to

N/A #.#

primary brownout voltage.

InfraSuite Power Management

26

Page 31

Chapter 7 InsightPower SNMP IPv6 for STS

Command Description Parameter Response

Tdp2s Report the recover time

N/A #.#

of transfer from primary to

secondary.

Tds2p Report the recover time of

N/A #.#

transfer from secondary to

primary.

Mvs1 Report the max voltage

N/A #.#

of comparing cycles for

primary AC blackout.

Mvs2 Report the max voltage

N/A #.#

of comparing cycles for

secondary AC blackout.

Mts1 Report the max time of

N/A #.#

comparing cycles for

primary AC blackout.

Mts2 Report the max time of

N/A #.#

comparing cycles for

secondary AC blackout.

Log Report the event code and

time of prior transfer.

Tprev[1..9] Report the time of prior

transfer/event.

1 ~ 10 hh:mm:ss MM/DD/

YYYY 0x#

N/A hh:mm:ss MM/DD/

YYYY

Tprev1 is the most recent

time.

Event[1..9] Report the event code for

N/A 0x#

prior transfer.

Event1 is the most recent

event.

ClearLog Clear event log. N/A Various kinds

SetTime Set the present time. hh:mm:ss

Various kinds

[MM/DD/

YYYY]

SetDate Set the present date. MM/DD/YYYY Various kinds

27

Page 32

Command Description Parameter Response

SetPrefer Set the preferred source. 1 or 2 Various kinds

SetDevID Set the unit's device ID. <20

Various kinds

characters>

alphanumeric

only

SetVtp2s Set the primary to

165.0 ~ 175.0 Various kinds

secondary trip voltage.

SetVts2p Set the secondary to

165.0 ~ 175.0 Various kinds

primary trip voltage.

SetVbp2s Set the primary to

180.0 ~ 264.0 Various kinds

secondary brownout

voltage.

SetVbs2p Set the secondary to

180.0 ~ 264.0 Various kinds

primary brownout voltage.

SetTdp2s Set the recover time of

12.0 ~ 1800.0 Various kinds

transfer from primary to

secondary.

SetTds2p Set the recover time of

12.0 ~ 1800.0 Various kinds

transfer from secondary to

primary.

SetMvs1 Set the max voltage of

30 ~ 50 Various kinds

comparing cycles for

primary AC blackout.

SetMvs2 Set the max voltage of

30 ~ 50 Various kinds

comparing cycles for

secondary AC blackout.

SetMts1 Set the max time of

2.0 ~ 4.0 Various kinds

comparing cycles for

primary AC blackout.

SetMts2 Set the max time of

2.0 ~ 4.0 Various kinds

comparing cycles for

secondary AC blackout.

InfraSuite Power Management

28

Page 33

Chapter 7 InsightPower SNMP IPv6 for STS

Command Description Parameter Response

UpProcess Status of upgrade

N/A Idle / Run / Error

progress.

UpStep Stage of upgrade

progress.

N/A Init / File ID / Auth

/ Addr / Erase /

Program / Read

UpPercentage Percentage of upgrade

N/A #.#

progress.

UpResult Result of upgrade

progress.

N/A OK / No response

/ File ID fail /

Authentication fail /

Erase fail / Flash fail

/ Read fail / Upgrade

completion

UpDate Report each FW upgrade

time.

[Index] [# to

show] # = 1 -

hh:mm:ss MM/DD/

YYYY

20

AgentVer Report SNMP card

N/A AA.BB.XXX

version.

Link Check current Modbus

connection.

N/A 1 - Normal /

2 - Abnormal /

3- Upgrading

Bye Terminate remote

N/A Various kinds

connection.

7.7 Key Generation for SSH

z

z

For Linux

(1) Please download and install OpenSSH from http://www.openssh.org.

(2) Launch shell and enter the following command to create your own keys.

Please ignore it when prompted to provide passphrase.

DSA Key:ssh-keygen –t dsa

RSA Key:ssh-keygen –t rsa

(3) Upload DSA and RSA key les on the web.

29

Page 34

z

z

For Windows

(1) Please download and install PuTTY from http://www.putty.org.

(2) Run puttygen.exe from the installed directory.

(3) Select SSH-2 RSA from the Parameters area and click Key→ Generate

key pair to generate an RSA key.

(4) Select Conversions→ Export OpenSSH Key and assign a le name to the

RSA key. Please ignore it when prompted to provide key passphrase.

(5) Select SSH-2 DSA from the Parameters area and select Key→ Generate

key pair to generate a DSA key.

(6) Select Export OpenSSH Key from Conversions and assign a le name to

the DSA key. Please ignore it when prompted to provide key passphrase.

(7) Upload the DSA and RSA key les to the web.

InfraSuite Power Management

30

Page 35

Chapter 8 Troubleshooting

Chapter 8 : Troubleshooting

Problem Possible case Solution

1. Check the output (overload/ short-

All LEDs on

the front

panel are off.

The power sources,

S1 and S2, are both

absent.

circuit).

2. Check both power sources, S1 and

S2.

3. Reset the upstream circuit breakers.

Input S1 or

Input S2 LED

is off.

Fault LED

ashes.

Fault LED

lights up.

Can not

communicate

with the STS.

The corresponding

power source is

absent or out of

range.

Output overload. Reduce the connected loads.

Over temperature. Check the environment temperature.

Internal component

damage.

Wrong setting or

malfunction.

1. Check the corresponding power

source.

2. Reset the corresponding upstream

circuit breaker.

Please contact service personnel.

Refer to the user manual of

InsightPower SNMP IPv6 for STS.

31

Page 36

Appendix 1 : Specications

STS 16A

Nominal Voltage 200/ 208/ 220/ 230/ 240V

Operating Frequency 45Hz to 65HZ

Nominal Current 16A

Input Connection C20 x 2

Output Connection C13 x 4 & C19 x 1

Physical Dimensions

(W x D x H)

Weight 4.85 Kg

Environment

440 x 385 x 43 mm

Operating Temperature 0 ~ 40°C

Storage Temperature -15 ~ 50°C

Humidity

Audible Noise <40 dBA

Operating Altitude 0 to 2000m (0 to 6252 ft)

5% ~ 95% RH

(non-condensing)

NOTE :

1. Refer to the rating label for the safety rating.

2. All specications are subject to change without prior notice.

InfraSuite Power Management

32

Page 37

Appendix 2 Warranty

Appendix 2 : Warranty

Seller warrants this product, if used in accordance with all applicable instructions,

to be free from original defects in material and workmanship within the warranty

period. If the product has any failure problem within the warranty period, Seller will

repair or replace the product at its sole discretion according to the failure situation.

This warranty does not apply to normal wear or to damage resulting from improper

installation, operation, usage, maintenance or irresistible force (i.e. war, fire,

natural disaster, etc.), and this warranty also expressly excludes all incidental and

consequential damages.

Maintenance service for a fee is provided for any damage out of the warranty

period. If any maintenance is required, please directly contact the supplier or Seller.

WARNING!

The individual user should take care to determine prior to use whether the

environment and the load characteristic are suitable, adequate or safe for

the installation and the usage of this product. The User Manual must be

carefully followed. Seller makes no representation or warranty as to the

suitability or tness of this product for any specic application.

33

Page 38

Page 39

Page 40

5013236701

Loading...

Loading...