Page 1

IFD9503

CANopen Slave Communication Module

Application Manual

Page 2

Page 3

CANopen Slave Communication Module IFD9503

Warning

3

Please read this instruction carefully before use and follow this instruction to operate the device in order to prevent

damages on the device or injuries to staff.

3

Switch off the power before wiring.

3

IFD9503 is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity,

electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g.

key or specific tools are required for operating the enclosure) in case danger and damage on the device may occur.

3

IFD9503 is to be used for controlling the operating machine and equipment. In order not to damage it, only

qualified professional staff familiar with the structure and operation of IFD9503 can install, operate, wire and

maintain it.

3

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check

all the wirings again before switching on the power and DO NOT touch any terminal when the power is switched

on. Make sure the ground terminal

1 INTRODUCTION...................................................................................................................................3

2 COMPONENTS .................................................................................................................................... 5

3 FUNCTIONS OF IFD9503 ....................................................................................................................8

Table of Contents

1.1 IFD9503 Brief............................................................................................................................3

1.2 Features....................................................................................................................................3

2.1 Product Profile and Outline .......................................................................................................5

2.2 CANopen Connector.................................................................................................................5

2.3 Address Setup Rotary Switch....................................................................................................5

2.4 Function Setup DIP switch........................................................................................................6

2.5 Communication Ports on IFD9503............................................................................................7

3.1 Common Functions...................................................................................................................8

is correctly grounded in order to prevent electromagnetic interference.

3.2 When IFD9503 is connected to AC motor drive......................................................................12

3.3 When IFD9503 is connected to temperature controller (DTA/DTB)........................................15

3.4 When IFD9503 is connected to ASD-A servo drive.................................................................19

3.5 When IFD9503 is connected to programmable logic controller...............................................22

3.6 When IFD9503 is connected to Delta DOP-A HMI..................................................................26

3.7 When IFD9503 is connected to custom equipment.................................................................31

4 LED INDICATORS & TROUBLE-SHOOTING....................................................................................35

4.1 RUN LED.................................................................................................................................35

4.2 ERROR LED ...........................................................................................................................35

4.3 SCAN LED ..............................................................................................................................35

DVP-PLC Application Manual

1

Page 4

CANopen Slave Communication Module IFD9503

5 OBJECT DICTIONARY......................................................................................................................35

6 CONNECTION OF IFD9503 WITH OTHER EQUIPMENT ................................................................ 52

2

DVP-PLC Application Manual

Page 5

CANopen Slave Communication Module IFD9503

1 Introduction

1. To make sure that you are able to correctly install and operate IFD9503, please read this chapter carefully

before starting to use IFD9503 and keep this handy for your quick reference.

2. This chapter only provides introductory information and guidelines on IFD9503. Details of CANopen protocol

are not included. For more information on CANopen protocol, please refer to relevant references or

literatures.

3. IFD9503 is defined as CANopen slave station communication module to be used on the connection between

CANopen network and Delta programmable logi c controller, Delta AC motor drive, Delta servo drive, Delta

temperature controller and Delta human machine interface. In addition, the custom function of IFD9503

allows the custom equipment with Modbus protocol to connect with CANopen network.

1.1 IFD9503 Brief

1. RUN indicator and ERROR indicator display the connection status between IFD9503 and CANopen.

SCAN PORT indicator displays the connection status between IFD9503 and the equipment. For more

details on LED indicators, see 13.4.

2. IFD9503 sets up its node address in CANopen by two rotary switches. For more details on the switches,

see 13.2.

3. Functions of DIP switches: selecting equipment conn ected to IFD9503, selecting communication port of

IFD9503, setting up the baud rate between IFD9503 and the master. For more details on DIP switches,

see 13.2.

4. CANopen interface connects IFD9503 to CANopen network. For more details, see 13.2.

5. The communication ports allows IFD9503 to connect with Delta programmable logic controller, Delta AC

motor drive, Delta temperature controller, Delta servo drive, Delta human machine interface and

equipment with Modbus protocol. For more details, see 13.2.

1.2 Features

1. Functions supported:

z CAN2.0A protocol.

z CANopen DS301 V4.02.

2. Services supported:

z PDO (Process Data Object):

PDO1 ~ PDO8: RxPDO maps the equipment parameters writable; TxPDO maps the equipment

parameters readable. PDO information is in peer for transmitting real-time data.

z SDO (Service Data Object):

SDO information adopts ”custom machine/servo” mode for configuring slave nodes and visiting

the object dictionary of every node. There are two types of SDO: request SDO and response

SDO.

z SOP (Special Object Protocol):

Supports the default COB-ID between the connection of pre-definited master and slave.

Supportes broadcasting service (when the address is 0).

Supports SYNC service.

Supports Emergency service

DVP-PLC Application Manual

3

Page 6

CANopen Slave Communication Module IFD9503

z NMT (Network Manegment)

Supports NMT Module control.

Supports NMT Error control.

Supports Boot-up.

z Services not supported

Time Stamp service.

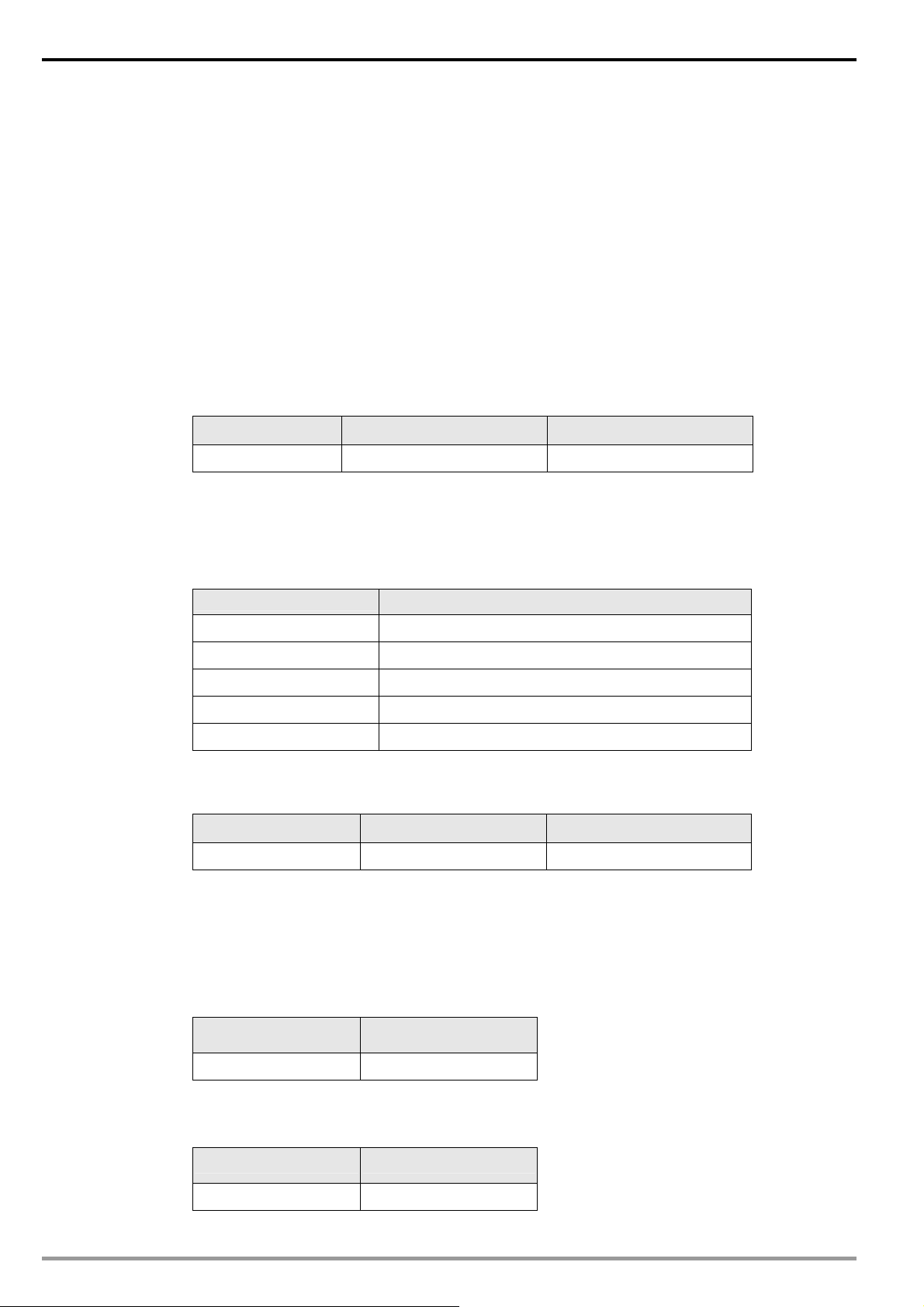

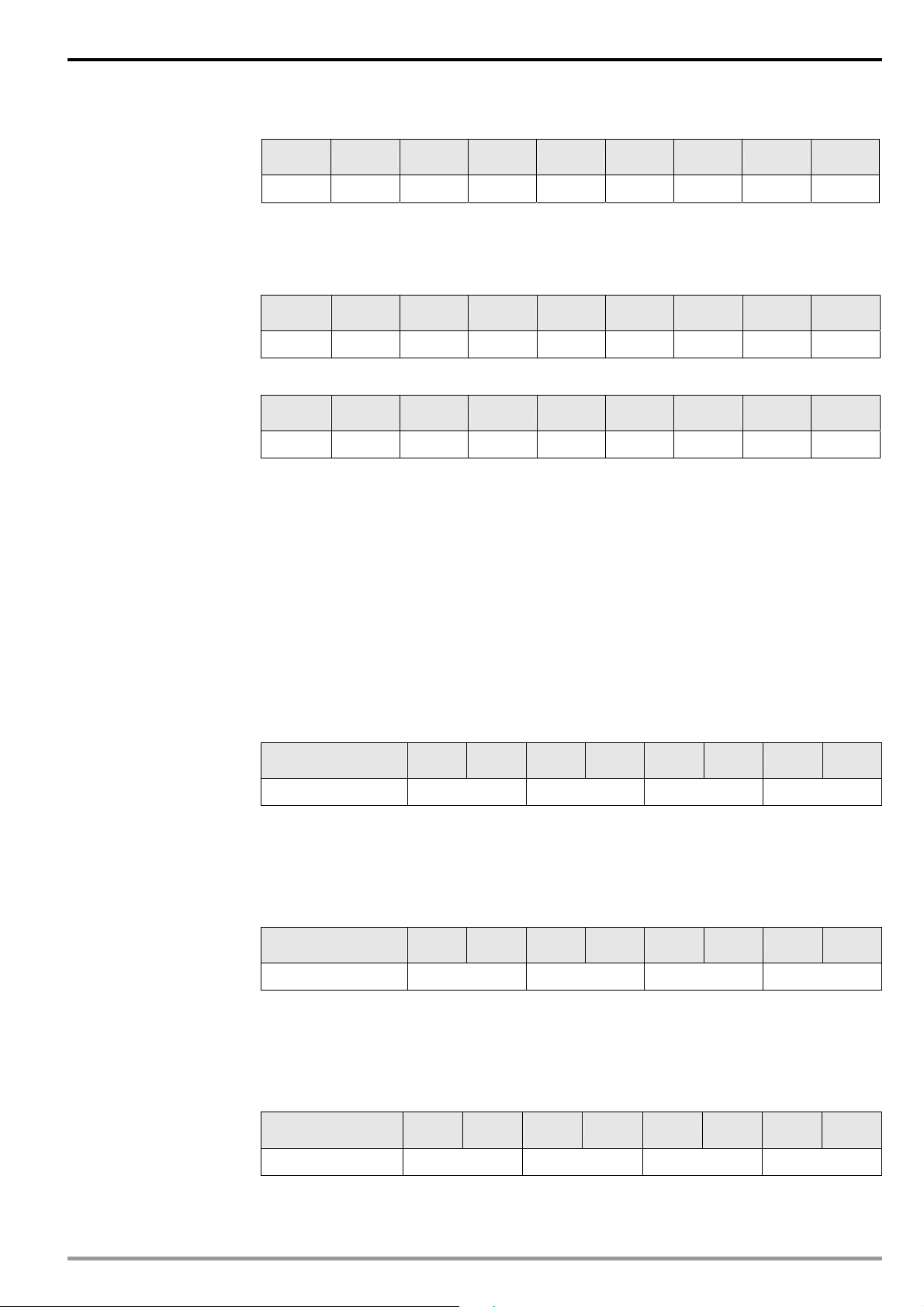

3. Specifications:

CANopen connector

Type Removable connector (5.08mm)

Transmission method CAN

Transmission cable 2 communication cables, 2 power cables and 1 shielded cable

Electrical isolation 500V DC

Communication

Message type

Baud rate

PDO

SDO

SYNC

Emergency

NMT

10 k bps (bit/sec.)

20 k bps (bit/sec.)

50 k bps (bit/sec.)

125 k bps (bit/sec.)

250 k bps (bit/sec.)

500 k bps (bit/sec.)

800 k bps (bit/sec.)

1 M bps (bit/sec.)

Supplier ID 477

Electrical specification

CANopen voltage 11 ~ 25V DC

Safety standard Under EN50178 standard

Certifications CE certified and UL certified

Environment

Operation temperature -4 ~ 122°F (-10 ~ 50°C)

Storage temperature -4 ~ 140°F (-20 ~ 60°C)

Humidity < 90%, (under normal pressure)

Altitude Max. 1,000m

Shock/vibration immunity 0.5G 9 ~ 200Hz

4

DVP-PLC Application Manual

Page 7

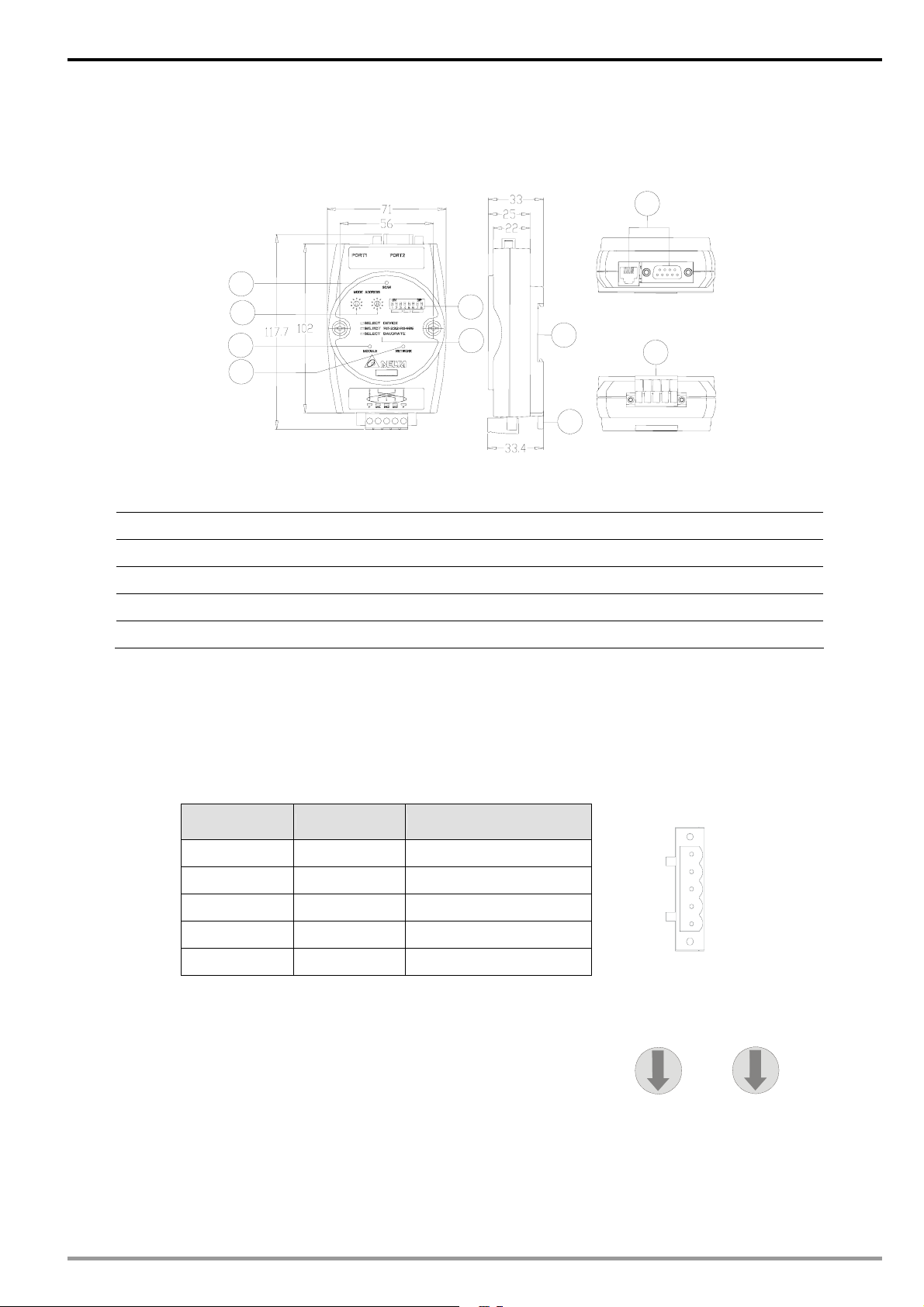

2 Components

2.1 Product Profile and Outline

5

2

6

7

CANopen Slave Communication Module IFD9503

1

3

4

Unit: mm

9

8

10

1. Communicaton ports 6. RUN indicator

2. Address setup rotary switches 7. ERROR indicator

3. Function setup DIP switches 8. CANopen connector

4. Descriptions for DIP switches 9. DIN rail

5. SP (Scan Port) indicator 10. DIN rail clip

2.2 CANopen Connector

To connect with CANopen network, you can use the conne ctor en cl osed with IF D9503 or any conne ctors yo u

can buy in the store for wiring.

z Connect to th bus on CANopen

z Connect to the CANopen communication port on IFD9503

PIN Signal Description

1 V- 0V DC

2 CAN_L Signal3 SHIELD Shielded cable

4 CAN_H Signal+

5 V+ 24V DC

5

4

3

2

1

2.3 Address Setup Rotary Switch

The two rotary switches SW1 and SW2 set up the node address on

CANopen network in hexadecimal form. Setup range: 01 ~ 7F (80 ~

FF are forbidden).

4. Example:

If you need to set the node address of IFD9503 as 26 (H’1A), simply switch the corresponding rotary switch of

ID_H to “1” and the corresponding rotary switch of ID_H to “A”.

DVP-PLC Application Manual

8

9

7

A

6

5

4

3

B

C

D

E

2

F

1

0

ID_H ID_L

8

9

7

A

6

5

4

3

B

C

D

E

2

F

1

0

5

Page 8

CANopen Slave Communication Module IFD9503

Address setting Description

0 ~ 7F Valid CANopen node address

80 ~ FF Invalid CANopen node address

5. Note:

The changed values on SW1 or SW2 are only valid when IFD9503 is re-powered. When IFD9503 is

operating, changing the set value of node address will be invalid.

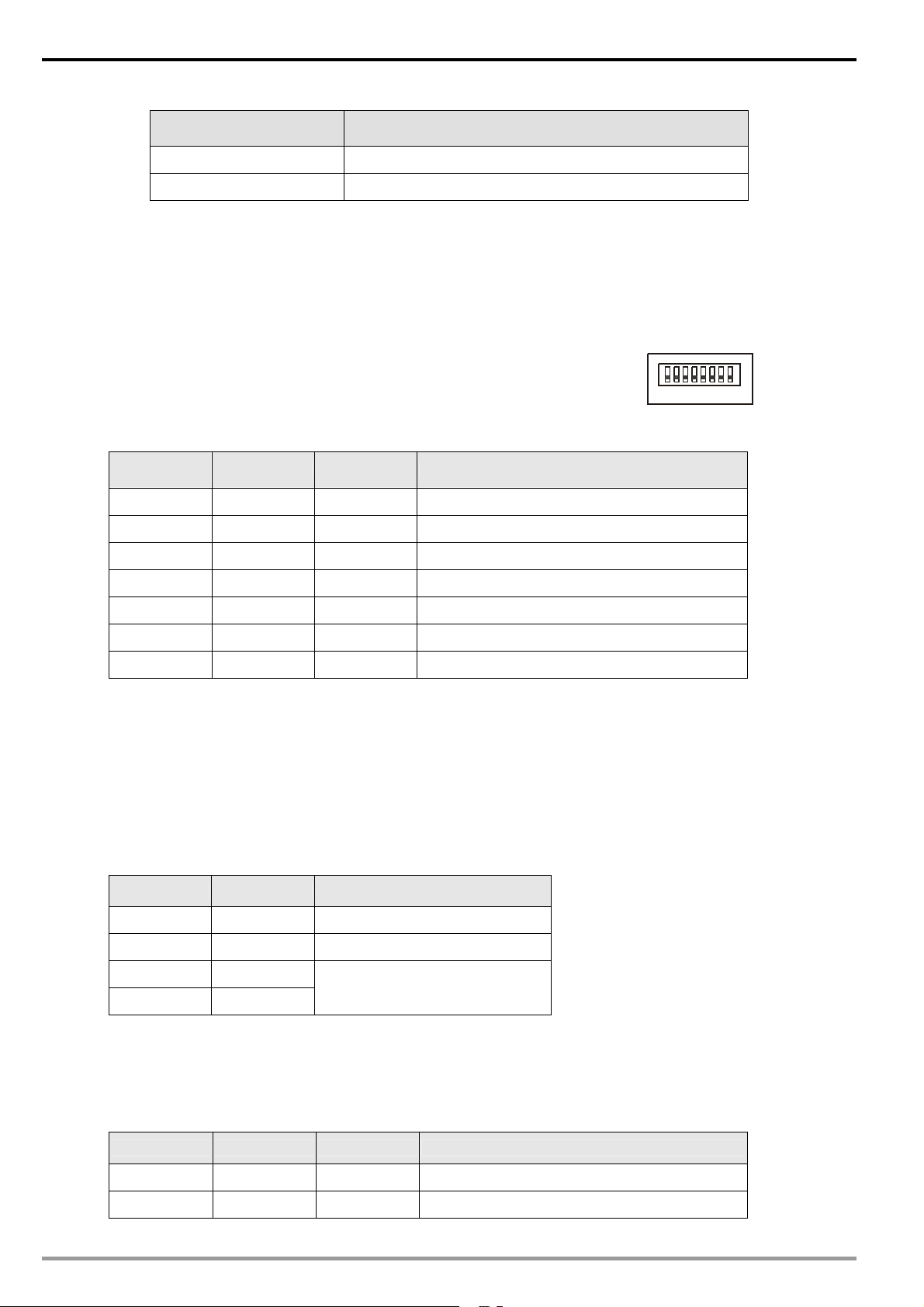

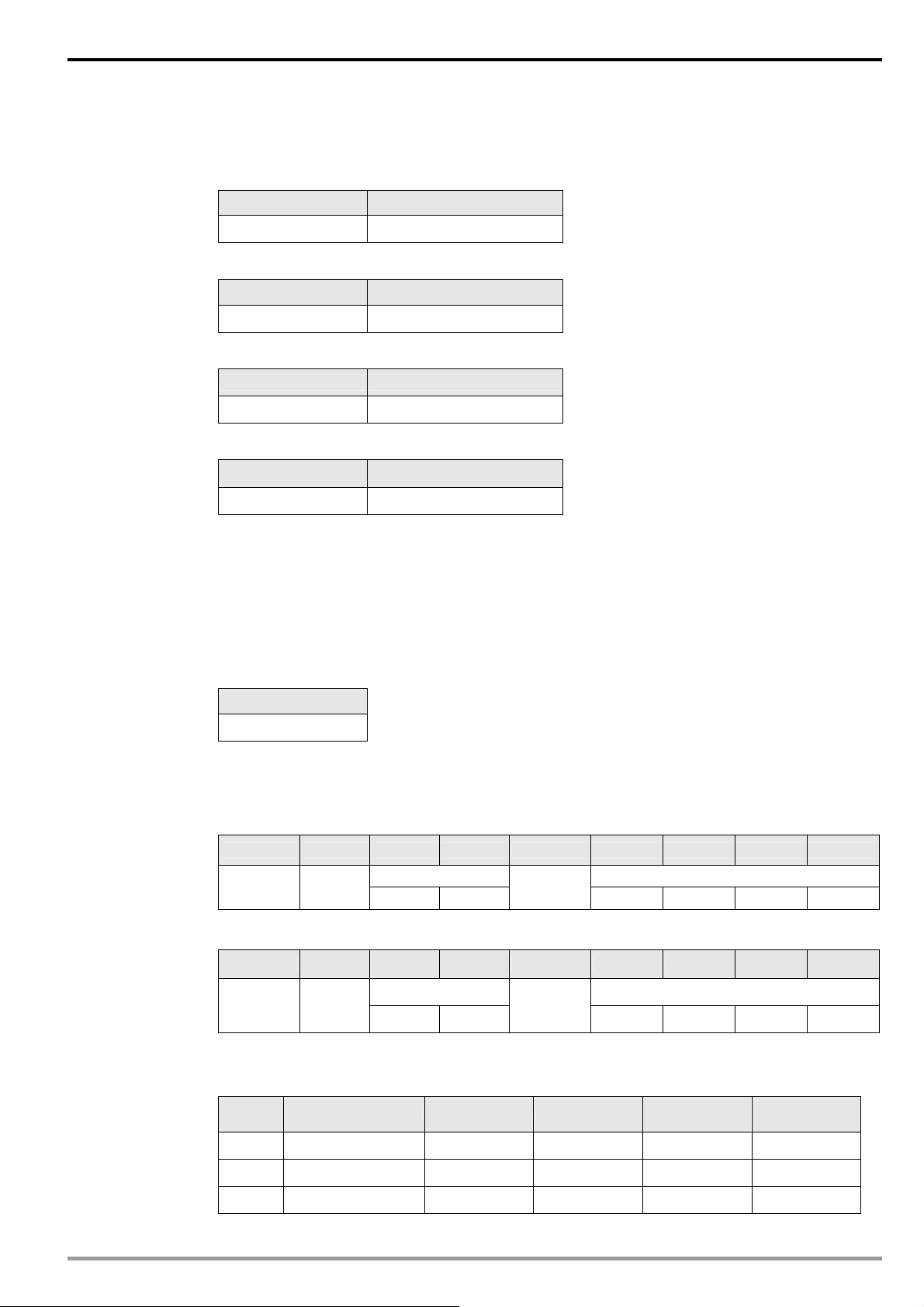

2.4 Function Setup DIP switch

The DIP switch SW3 is to be used on the equipment conne cted to IFD95 03,

the selection of communication ports and setting up the baud rate of

IFD9503 and the master in CANopen.

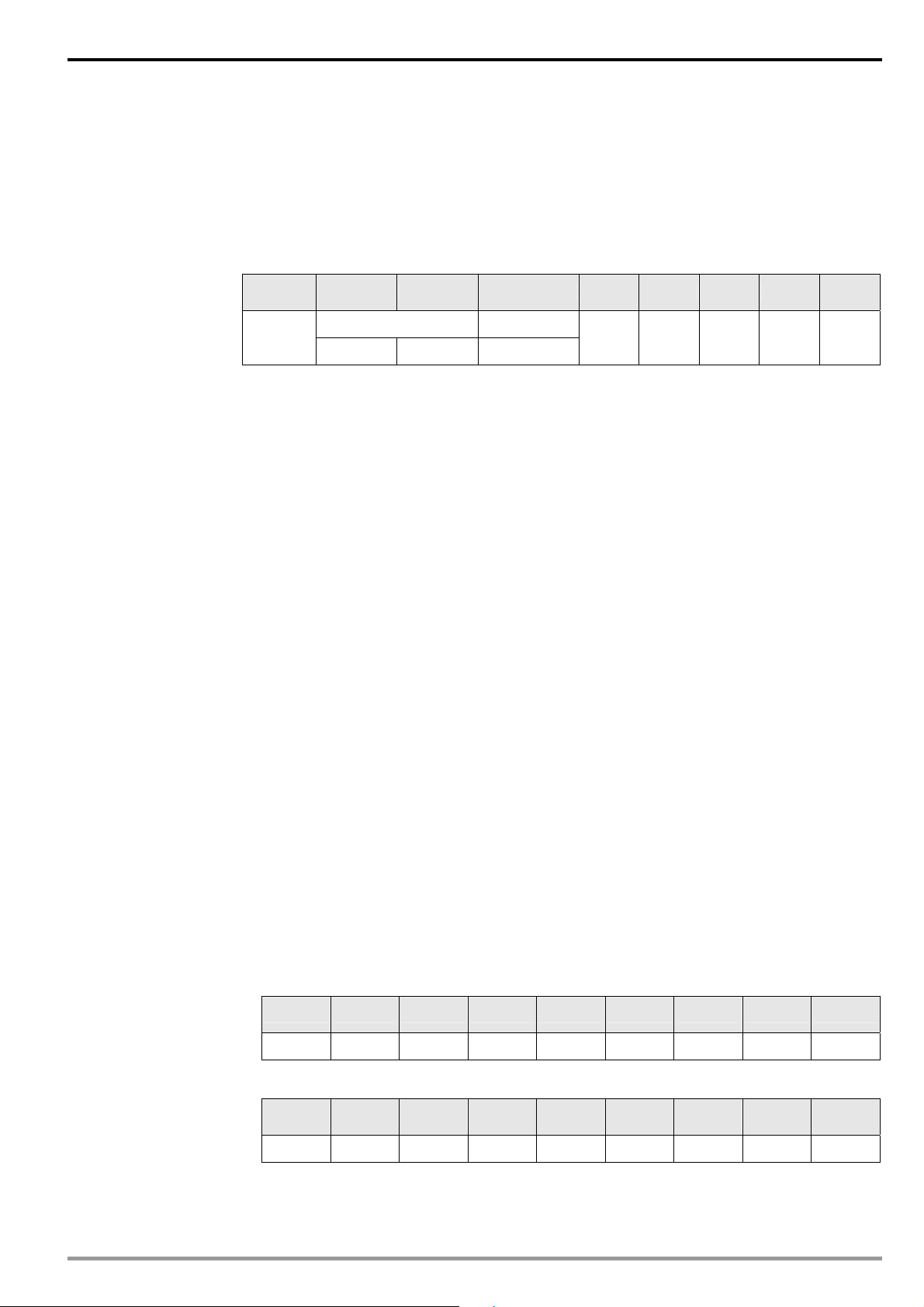

1. Selecting equipment connected to IFD9503

PIN 3 PIN 2 PIN 1 Equipment

Off Off On AC motor drive

Off On Off Programmable logic controller

Off On On Temperature controller

On Off Off Servo drive

On Off On Human machine interface

On On Off Custom equipment

On On On Test mode

z Example

SW3

ON

1234567

DIP

8

If the equipment connected to IFD9503 is Delta servo drive, you only need to switch PIN 3 in SW3 to “On”,

PIN 1 and PIN 2 to “Off” and re-power IFD9503.

z Note:

The changed setting of DIP switch is o nly valid when IFD95 03 is re-powe red. Wh en IFD9503 i s operating,

changing the setting of DIP switch will be invalid.

2. Selecting IFD9503 communication mode

PIN 5 PIN 4 Communication mode

Off Off RS-485

On On RS-232

Off On

On Off

z Note:

The changed setting of the communication mode is only valid when IFD9503 is re-po wered. Whe n

IFD9503 is operating, changing the setting of communication mode will be invalid.

3. Setting up baud rate

PIN 8 PIN 7 PIN 6 Baud rate

Incorrect setting

6

Off Off Off 10k bps

Off Off On 20k bps

DVP-PLC Application Manual

Page 9

CANopen Slave Communication Module IFD9503

PIN 8 PIN 7 PIN 6 Baud rate

Off On Off 50k bps

Off On On 125k bps

On Off Off 250k bps

On Off On 500k bps

On On Off 800k bps

On On On 1M bps

z Note:

The changed setting of the baud rate of CANopen is only valid when IFD9503 is re-powered. When

IFD9503 is operating, changing the baud rate will be invalid.

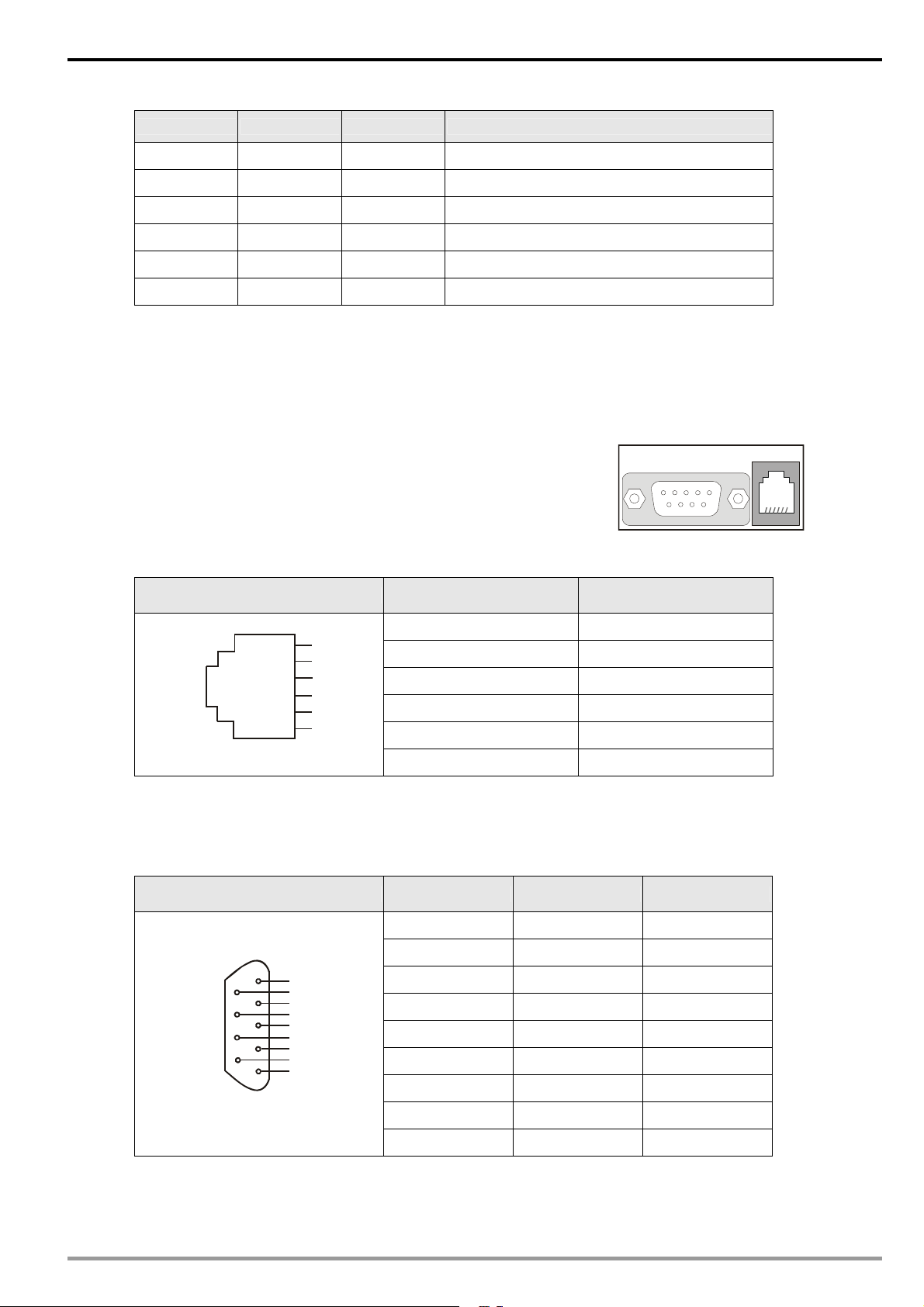

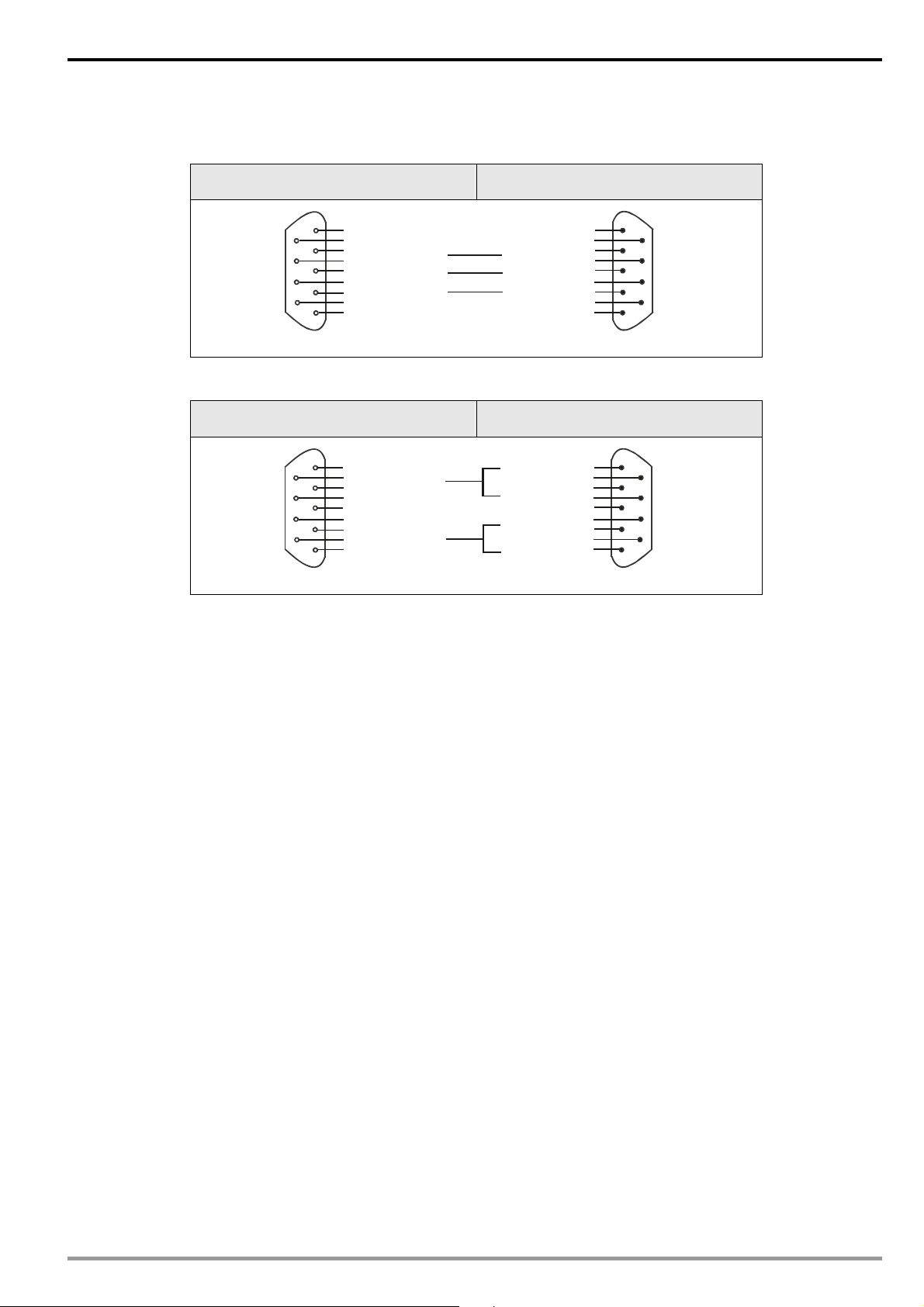

2.5 Communication Ports on IFD9503

The communication ports on IFD9503 are used for the conn ection the

equipment (Delta programmable logic controller, Delta AC motor drive,

Delta temperature controller, Delta servo drive, Delta human machine

interface and custom equipment).

1. PORT 1 PIN definition:

PORT 1 sketch PIN Description

PORT1

z Note:

PORT 1 supports RS-485 communi cation only.

1 N.C.

6

5

4

3

2

1

2 GND

3 DATA4 DATA+

5 N.C.

6 N.C.

PORT1PORT2

2. PORT 2 PIN definition:

PORT2 sketch PIN RS-232 RS-485

DB9 male

z Note:

PORT 2 supports RS-232 and RS-485 communication only.

DVP-PLC Application Manual

1 N.C. N.C.

2 RXD N.C.

1

6

2

7

3

8

4

9

5

3 TXD DATA4 N.C. N.C.

5 GND N.C.

6 N.C. N.C.

7 N.C. N.C.

8 N.C. DATA+

9 N.C. N.C.

7

Page 10

CANopen Slave Communication Module IFD9503

3 Functions of IFD9503

IFD9503 can be connected to different equipment. The function s of IFD9503 va ry upon the equipment conn ected

to it.

3.1 Common Functions

IFD9503 supports NMT, SYNC, EMERGENCY, PDO and SDO, among which the functions of NMT, SYNC

and SDO are fixed, and the functions of others vary upon the equipment connected to IFD9503.

1. NMT module control

This function controls the status of node controlling NMT slave through NMT master.

z Format

Master → IFD9503

COB-ID Byte 0 Byte 1

0 (H’000) Command specifier (CS) Node-ID

If Node-ID =0, the “command specifier” will be broadcasted to all IFD9503 (CANopen slave s).

Every slave will have to execute NMT.

z Commands

See below for the functions of all command specifiers:

Command specifier (CS)

H’01 Enable remote node

H’02 Disable remote node

H’80 Enter pre-operation status

H’81 Reset application layer

H’82 Reset communication

Function

z Explanation

Switching IFD9503 whose node ID = 6 to pre-operation status.

COB-ID Byte 0 Byte 1

8

H’000 H’80 H’06

2. NMT error control

This function is applicable to NMT slave node sending its own operational status back to NMT master.

z After IFD9503 is initialized and enters pre-operation status, IFD9503 will send out the only

BOOT-UP signal.

IFD9503 → master

COB-ID Byte 0

1792(H’700)+Node-ID H’00

z Supposed IFD9503 sends out one status signal during the operation, its format will be:

IFD9503 → master

COB-ID Byte 0

1792(H’700)+Node-ID NMT status

NMT status:

DVP-PLC Application Manual

Page 11

CANopen Slave Communication Module IFD9503

Stop: H’04; Operation in progre ss: H’05; Pre-operation: H’7F.

z Explanation: Assume the Node-ID of a IFD9503 is 6

When IFD9503 operation is in progress:

COB-ID Byte 0

H’706 H’05

When IFD9503 is shut down:

COB-ID Byte 0

H’706 H’04

When IFD9503 is in pre-operation status:

COB-ID Byte 0

H’706 H’7F

Communication reset or application layer reset:

COB-ID Byte 0

H’706 H’00

3. Synchronous signal -- SYNC

SYNC signal is sent out by the loop of CANopen master. SYNC does not contain any data, and its

main purpose is to request the PDO of slave node to operate in synchronous communication mode. In

this way, you can set to synchronous or asynchronous mode while using PDO.

z Format

Master → IFD9503

COB-ID

128(H’080)

4. SDO service

All SDO message are fixed at 8 bytes.

z Request: Master → IFD9503

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

1536(H’600)

+Node-ID

Request

code

z Response: IFD9503 → master

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

1408(H’580)

+Node-ID

Response

code

z If the “request code” (or “response code”) is different, the corresponding “request data” (or

“response data”) will also be different. See the table below.

Object index Request data

LSB MSB

Object index Response data

LSB MSB

Sub-index

of object

Sub-index

of object

bit7-0 bit15-8 bit23-16 bit31-24

bit7-0 bit15-8 bit23-16 bit31-24

Request

code

H’23 Write a 4-byte datum bit7-0 bit15-8 bit23-16 bit31-24

H’2B Write a 2-byte datum bit7-0 bit15-8 H’00 H’00

H’2F Write a 1-byte datum bit7-0 H’00 H’00 H’00

DVP-PLC Application Manual

Explanation Byte 4 Byte 5 Byte 6 Byte 7

9

Page 12

CANopen Slave Communication Module IFD9503

Request

code

H’40 Read data H’00 H’00 H’00 H’00

H’80

Explanation Byte 4 Byte 5 Byte 6 Byte 7

Stop the current SDO

command

H’00 H’00 H’00 H’00

Response

code

H’43 Read 4-byte data bit7-0 bit15-8 bit23-16 bit31-24

H’4B Read 2-byte data bit7-0 bit15-8 H’00 H’00

H’4F Read 1-byte data bit7-0 H’00 H’00 H’00

H’60 Read 1/2/4-byte data H’00 H’00 H’00 H’00

H’80 Stop SDO command End code

z When IFD9503 detects an SDO error, SDO data transmission will be terminated, and IFD9503

will respond SDO master with an end code. See the table below for all end codes:

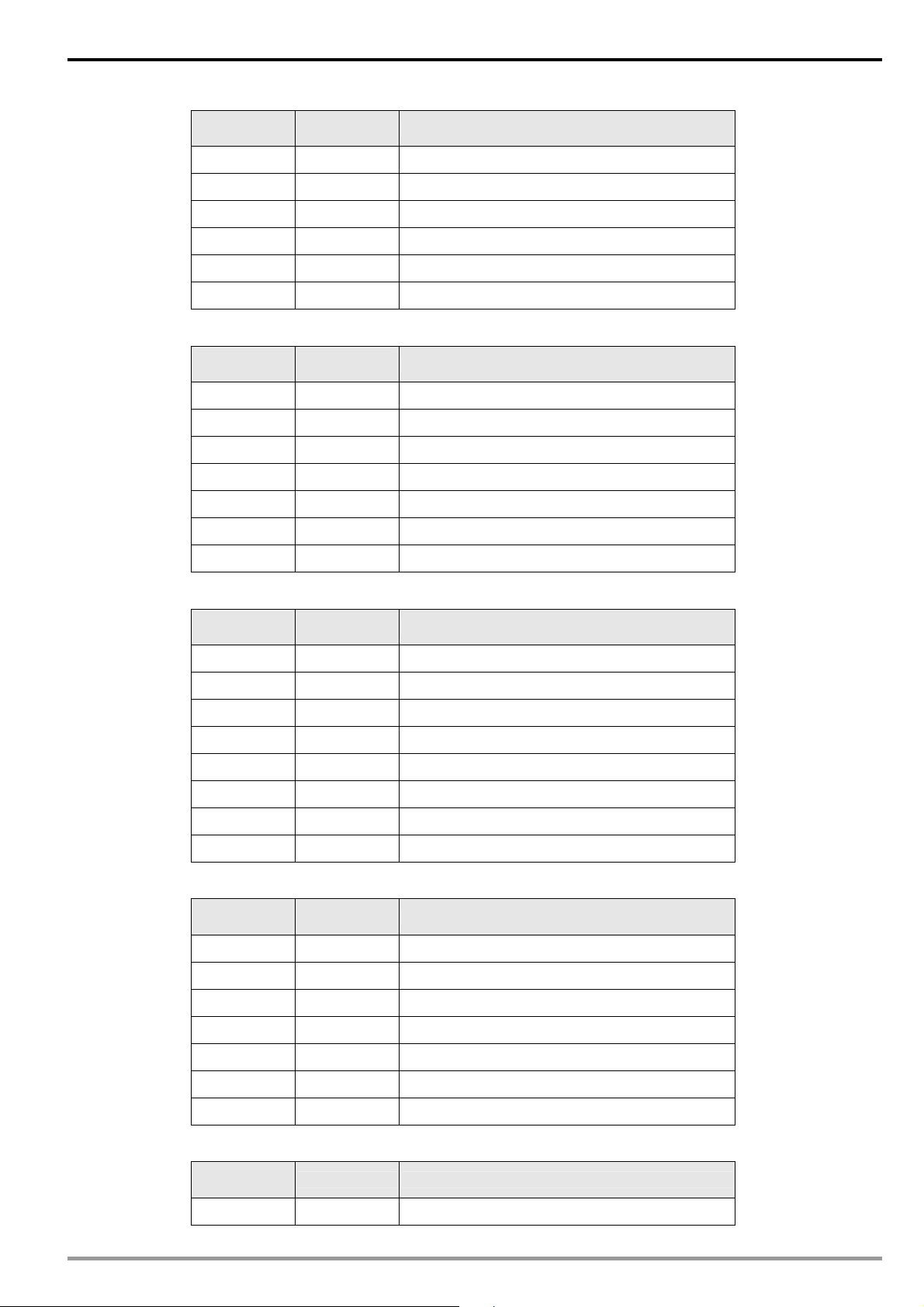

End code (16#) Description

0503 0000 Transmission in sections: “toggle bit” has not been changed

0504 0000 SDO protocol time-out

0504 0001 “Request code” is invalid or unknown

Instruction

explanation

Byte 4 Byte 5 Byte 6 Byte 7

0504 0002 Invalid block length (in block mode)

0504 0003 Invalid serial n umber (in block mode)

0504 0004 CRC error (in block mod e)

0504 0005 Memory is full

0601 0000 When polli ng an object parameter, a polling fault appears

0601 0001 Try to execute reading request to a write only parameter

0601 0002 Try to execute writting request to a read only parameter

0602 0000 The requested index object does not exist in the object dictionary

0604 0041 Object parameters could not be mapped into PDO

0604 0042

0604 0043 Common parameters are incompatible

0604 0047 AC motor drive is incompatible inside

0606 0000 Polling fails be cause of hardware error.

0607 0010 Data type doesn’t match; the length of service parameters doesn’t match

0607 0012 Data type doesn’t match; the length of service parameters is too long

0607 0013 Data type doesn’t match; the length of service parameters is too short

0609 0011 Sub-index doesn’t exit.

0609 0030

0609 0031 Written parameters are too big

The number or length of the parameters to be mappe d have exceeded the

maximum PDO’s length

Having exceeded the parameters’ value selection range (only for writing

authority)

10

0609 0032 Witten parameters are too small

0609 0036 The maximum value of the parameter is less than the minimum value

0800 0000 General error occurs

0800 0020 Parameters could not be transmitted to or stored to application layer

DVP-PLC Application Manual

Page 13

CANopen Slave Communication Module IFD9503

End code (16#) Description

0800 0021

0800 0022

0800 0023

z Explanation: Supposed there is a slave IFD9503 (Node-ID = 6)

1. Read the ID if the IFD9503 supplier (index H’1018, sub-index H’01)

Master → IFD9503:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’606 H’40 H’18 H’10 H’01 H’00 H’00 H’00 H’00

IFD9503 → master:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

For the reason of local control, parameters could not be transmitted to or

stored to application layer

Because of the present status of AC motor drive, parameters could not be

transmitted or stored to application layer

Dynamic creating of the object dictionary fails or object dictionary does not

exit (e.g. object dictionary was created from a file, if this file has an error,

then the creating of object dictionary will fail)

H’586 H’43 H’18 H’10 H’01 H’DD H’01 H’00 H’00

2. Read the maximum output frequency of AC motor drive (index 2001H, sub index 01H,

supposed the value is 60.00Hz)

Master → IFD9503:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’606 H’40 H’01 H’20 H’01 H’00 H’00 H’00 H’00

IFD9503 → master:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’586 H’4B H’01 H’20 H’01 H’70 H’17 H’00 H’00

3. Write the maximum output frequency of AC motor drive (supposed the value is 50.00Hz)

Master → IFD9503:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’606 H’2B H’01 H’20 H’01 H’88 H’13 H’00 H’00

IFD9503 → master:

4. Index 1408 does not exist. If you read or write1408/01, IFD9503 will respond with an end

code.

Master → IFD9503:

DVP-PLC Application Manual

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’586 H’60 H’01 H’20 H’01 H’00 H’00 H’00 H’00

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’606 H’2B H’08 H’14 H’01 H’88 H’13 H’00 H’00

11

Page 14

CANopen Slave Communication Module IFD9503

IFD9503 → master:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’586 H’80 H’08 H’14 H’01 H’00 H’00 H’02 H’06

z Note:

When IFD9503 is connected to different equipments, see 13.5.1 “Communication Objects in

Object Dictionary” for the corresponding relations beween index (sub index) and equipment

parameters.

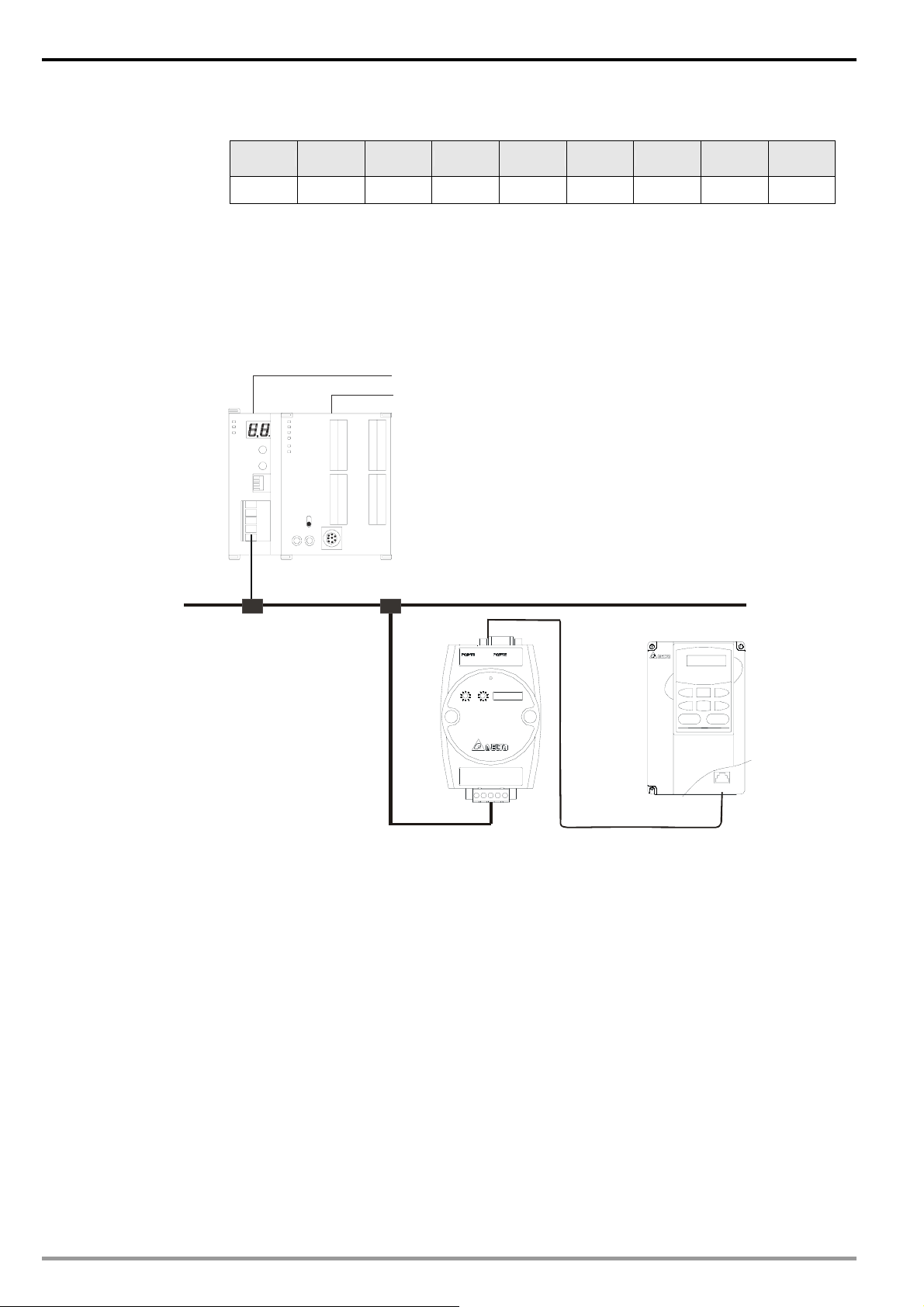

3.2 When IFD9503 is connected to AC motor drive

DVPCOPM-SL

DVP- SV

DVPCOM DVP28SV

CAN+

SHLD

CANGND

RUN

STOP

Master

CANop en

Delta VFD series

AC motor drive

RJ12

IFD9503

RS-485

1. Setting up baud rate and communication format

z Before connecting the AC motor drive to the bus, first set the communication address of the AC

motor drive to 01, baud rate to 38,400bps and communication format to 8, N, 2; RTU (the format

is fixed; other formats will be invalid).

12

z To adjust the baud rate, follow the steps listed below.

Set up the DIP switch SW3 of IFD9503 to custom equipment mode.

Connect IFD9503 to the bus of CANopen and enable the operation of IFD9503.

Modify the index parameter 5003/02 (main index: H’5003, sub index: H’02).

5003/02 = 1 → 19,200; 8, N, 2; RTU

5003/02 = 2 → 38,400; 8, N, 2; RTU (Default)

Return SW3 of IFD9503 back to AC drive mode and re-power IFD9503.

Adjust the baud rate of the AC drive to the corresponding one.

2. Functions & features

In addition, IFD9503 also supports the following two functions.

DVP-PLC Application Manual

Page 15

CANopen Slave Communication Module IFD9503

z Emergency object – EMERGENCY

When IFD9503 detects an internal error, it will send an EMCY message to the CANopen bus.

Format

IFD9503 → master

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

128(H’080)

+Node-ID

Emergency error code Error register

00 00 00 00 00

LSB MSB

y Error register

The value in the error register will be mapped to index address H’1001 in the object

dictionary. V alue = 0 indicates that no error occurs. Value = 1 indicates that a general error

takes place. Value = H’80 indicates that an internal error in the equipment occurs.

y Emergency error code

Internal communication error

This error indicates the communication error between IFD9503 and AC motor drive (e.g.

communicate failure). When such error occurs, the emergency error code will be H’8101,

and the value in the error register will become 1.

CANopen bus communication error

This error indicates the communication error between CANopen master and IFD9503

slave (e.g. master disconnection). When such error occurs, the emergency error code

will be H’8130, and the value in the error register will become 1.

Insufficient length of PDO data

This error indicates that the length of Receive PDO data actually sent out is shorter than

the set data length. When such error occurs, the emergency error code will be H’8210,

and the value in the error register will become 1.

Internal error in the equipment

This error indicates the error taken place inside the AC motor drive (e.g. AC motor drive

in low voltage). When such error occurs, the emergen cy error code will be H’FFXX (XX

refers to the error code of the AC motor driv e), and the value in the error register will

become H’80. After the error is eliminated, the emergency error code will become

H’0000.

Eliminating error

When an error is eliminated, the emergency error code will become H’0000.

Explanation

Take the IFD9503 slave of node ID = 6 as the object and compare the EMERGENGY

messages sent out by IFD9503 in different error conditions.

y When in internal communication error

y When in CANopen bus communication error

DVP-PLC Application Manual

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 01 81 01 00 00 00 00 00

13

Page 16

CANopen Slave Communication Module IFD9503

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 30 81 01 00 00 00 00 00

y When in insufficient PDO data length

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 10 82 01 00 00 00 00 00

y When the AC motor drive in low voltage (internal error of the equipment)

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 0E FF 80 00 00 00 00 00

(When in low voltage, the error code in AC motor drive will be H’0E.)

y When internal error in the equipment has been eliminated

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 80 00 00 00 00 00

y When the error is eliminated

Still other errors existing:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 01 00 00 00 00 00

All errors are eliminated:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 00 00 00 00 00 00

y Note:

IFD9503 sends out EMERGENCY message only when error occurs.

z PDO service

IFD9503 supports PDO1 ~ PDO8. For IFD9503, COB-ID of PDO can be modified but cannot be

repeated.

PDO1 (Default: Open)

y TxPDO1 (IFD9503 → master):

Send the status data of the salve (IFD9503) to the master. Preset the length of data to be

14

mapped to 2 byte and the content to be mapped to status word. You can map any readable

paramemters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’180 + Node-ID Status word

y RxPDO1 (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of the data to

be mapped to 2 bytes and the content to be mapped to control word. You can map any

readable parameters, maximum 8 bytes.

DVP-PLC Application Manual

Page 17

CANopen Slave Communication Module IFD9503

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’200 + Node-ID Control word

PDO2 ~ PDO8 (Default: Close)

y TxPDO (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the length of the data to

be mapped to 0 byte. You can map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’xxxx +Node-ID

y RxPDO (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of the data to

be mapped to 0 byte. You can map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’yyyy +Node-ID

Data tr ansmission mode

y TxPDO in IFD9503 supports many modes: synchronously non-cyclic, synchronously cy clic,

synchronous RTR, asynchronous RTR and asynchronous modes.

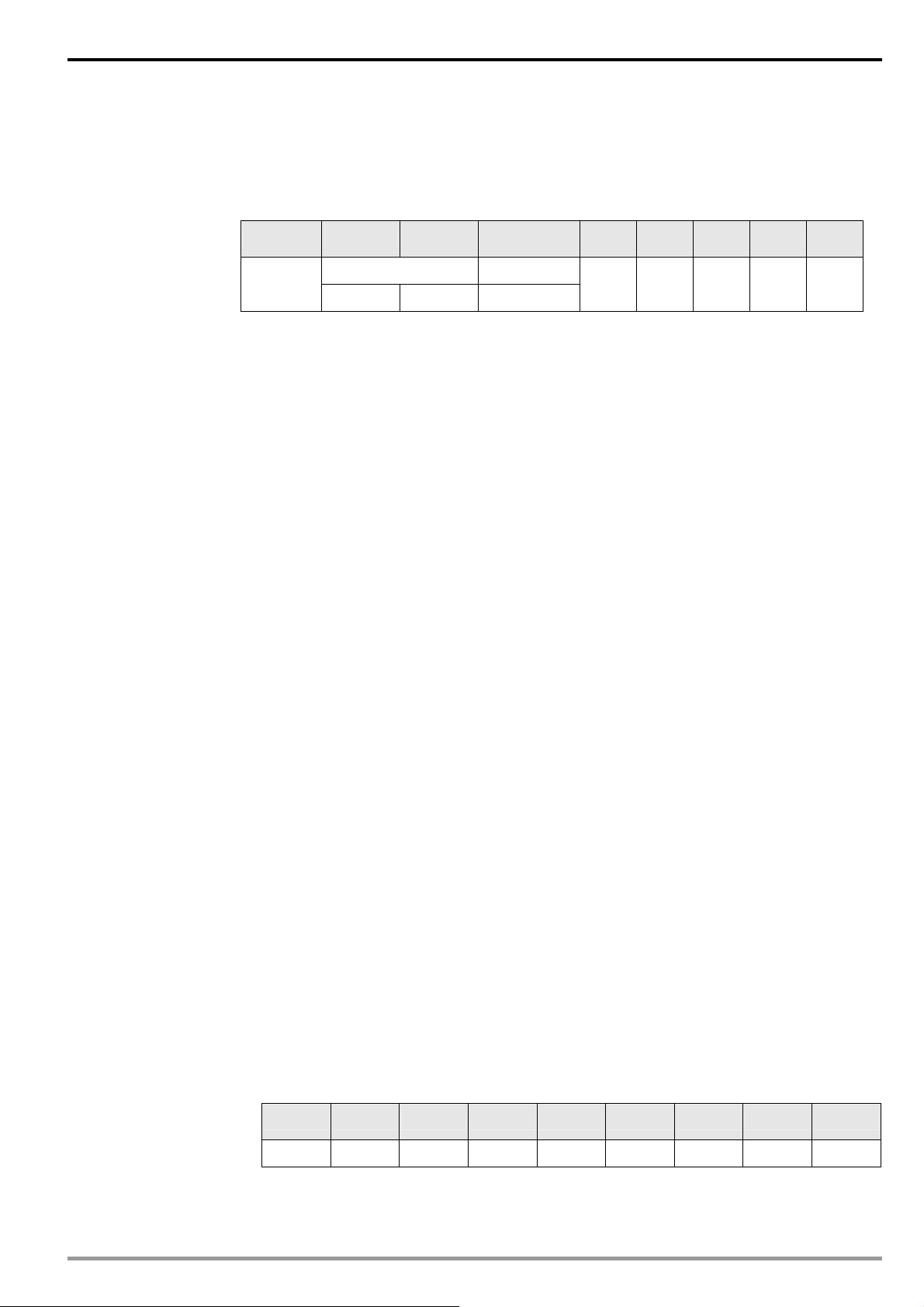

3.3 When IFD9503 is connected to temperature controller (DTA/DTB)

DVPCOPM-SL

DVP-SV

DVPCOM DVP28SV

RUN

CAN+

SHLD

CAN-

STOP

GND

Master

CANop en

RS-485

DTA/DTB

IFD9503

1. Setting up baud rate and communication format

z Before connecting the temperature controller to the bus, first set up the communication address

of the temperature controller to 01, baud rate to 38,400bps and communication format to 7, E, 1;

DVP-PLC Application Manual

15

Page 18

CANopen Slave Communication Module IFD9503

ASCII (the format is fixed; other formats will be invalid).

z Before communicating with DTA series temperature controller, first set the content of H’471A to

H’0001 to allow the write-in of communication.

z Before communicating with DTB series temperature controller, first set the content of H’0810 to

H’FF00 to allow the write-in of communication.

z To adjust the baud rate, follow the steps listed below.

Set up the DIP switch SW3 of IFD9503 to custom equipment mode.

Connect IFD9503 to the bus of CANop en and enable the operation of IFD9503.

Modify the index parameter 5003/04.

5003/04 = 1 → 19,200; 7, E, 1; ASCII

5003/04 = 2 → 38,400; 7, E, 1; ASCII (Default)

Return SW3 of IFD9503 back to temperature controller mode and re-po wer IF D9503.

Adjust the baud rate of the temperature controller to the corresponding one.

2. Functions & features

In addition, IFD9503 also supports the following two functions.

z Emergency object – EMERGENCY

When IFD9503 detects an internal error, it will send an EMCY message to the CANopen bus.

Format

IFD9503 → master

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

128(H’080)

+Node-ID

Emergency error code Error register

00 00 00 00 00

LSB MSB

y Error register

The value in the error register will be mapped to index address H’1001 in the object

dictionary. Value = 0 indicates that no error occurs. Value = 1 incicates that a general error

takes place. Value = H’80 indicates that an internal error in the equipment occurs.

y Emergency error code

Internal communication error

This error indicates the communication error between IFD9503 and the temperature

controller (e.g. communication failure). When such error occurs, the emergency error

16

code will be H’8101, and the value in the error register content will become 1.

CANopen bus communication error

This error indicates the communication error between CANopen master and IFD9503

slave (e.g. master disconnection). When such error occurs, the emergency error code

will be H’8130, and the value in the error register will become 1.

Insufficient length of PDO data

This error indicates that the length of Receive PDO data actually sent out is shorter than

the set data length. When such error occurs, the emergency error code will be H’8210,

and the value in the error register will become 1.

Internal error in the equipment

This error indicates the error taken place inside the temperature controller (e.g. the

DVP-PLC Application Manual

Page 19

CANopen Slave Communication Module IFD9503

temperature has not been acquired immediately after the controller is switched on).

When such error occurs, the emergency error code will be H’FFXX (XX refers to the

error code of the temperature controller), and the value in the error register will become

H’80.

Eliminating error

When an error is eliminated, the emergency error code will become H’0000.

Explanation

Take the IFD9503 slave of node ID = 6 as the object and compare the EMERGENCY

messages sent out by IFD9503 in different error conditions.

y When in internal communication error

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 01 81 01 00 00 00 00 00

y When in CANopen bus communication error

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 30 81 01 00 00 00 00 00

y When in insufficient PDO data length

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 10 82 01 00 00 00 00 00

y When the temperature has not yet been acquired (internal error of the equipment)

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 02 FF 80 00 00 00 00 00

(When temperature has not been acquired, the error code in the temperature controller wil l

be H’02.)

y When the error is eliminated.

Still other errors existing:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 01 00 00 00 00 00

All errors are eliminated:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 00 00 00 00 00 00

y Note:

IFD9503 sends out EMERGENCY message only when error occurs.

z PDO service

IFD9503 supports PDO1 ~ PDO8. For IFD9503, COB-ID of PDO can be modified but cannot be

repeated.

PDO1(Default: Open )

DVP-PLC Application Manual

17

Page 20

CANopen Slave Communication Module IFD9503

y TxPDO1 (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the length of data to be

mapped to 2 bytes and the content to be mapped to present temperature value. You can

map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’180 + Node-ID PV

y RxPDO1 (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of data to be

mapped to 2 bytes and the content to be mapped to present temperature value. You can

map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’200 + Node-ID SV

PDO2 ~ PDO8 (Default: Close)

y TxPDO (IFD9503 → master):

Send the status date of the slave (IFD9503) to the master. Preset the length of data to be

mapped to 0 byte. You can map any readable parameter, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’xxxx +Node-ID

y RxPDO (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of the data to

be mapped to 0 byte. You can map any readbable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’yyyy +Node-ID

Data tr ansmission mode

y TxPDO in IFD9503 supports many modes: synchronously non-cyclic, synchronous cyclic,

synchronous RTR, asynchronous RTR and asynchronous modes.

18

DVP-PLC Application Manual

Page 21

CANopen Slave Communication Module IFD9503

3.4 When IFD9503 is connected to ASD-A servo drive

DVPCOPM-SL

DVP-SV

DVPCOM DVP28SV

CAN+

SHLD

CANGND

RUN

STOP

Master

CANopen

ASD-A servo drive

IFD9503

RS-23 2/ R S -485

1. Setting up baud rate and and communication format

z Before connecting the servo drive to the bus, first set the communication address of the servo

drive to 01, baud rate to 115,200bps and communication format to 7, E, 1; ASCII (the format is

fixed; other formats will be invalid).

z To adjust the baud rate, follow the steps listed below.

Set up the DIP switch SW3 of IFD9503 to custom equipment mode.

Connect IFD9503 to the bus of CANop en and enable the operation of IFD9503.

Modify the index parameter 5003/05.

5003/05 = 1 → 19,200; 7, E, 1; ASCII

5003/05 = 2 → 38,400; 7, E, 1; ASCII

5003/05 = 3 → 57,600; 7, E, 1; ASCII

5003/05 = 4 → 115,200; 7, E, 1; ASCII (Default)

Return SW3 of IFD9503 back to servo drive mode a nd re-power IFD9503.

Adjust the baud rate of the servo drive to the corre sponding one.

2. Functions & features

In addition, IFD9503 also supports the following two functions.

z Emergency object – EMERGENCY

When IFD9503 detects an internal error, it will send an EMCY message to the CANopen bus.

Format

IFD9503 → master

DVP-PLC Application Manual

19

Page 22

CANopen Slave Communication Module IFD9503

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

128(H’080)

+Node-ID

Emergency error code Error register

00 00 00 00 00

LSB MSB

y Error register

The value in the error register will be mapped to index address H’1001 in the object

dictionary. V alue = 0 indicates that no error occrs. Value = 1 incicates that a general error

takes place. Value = H’80 indicates that an internal error in the equipment occurs.

y Emergency error code

Internal communication error

This error indicates the communication error between IFD9503 and the se rvo drive (e.g.

communication failure). When such error occurs, the emergency error code will be

H’8101, and the value in the error register will become 1.

CANopen bus communication error

This error indicates the communication error between CANopen master and IFD9503

slave (e.g. master disconnection). When such error occurs, the emergency error code

will be H’8130, and the value in the error register will become 1.

Insufficient length of PDO data

This error indicates that the length of Receivce PDO data actually sent out is shorter

than the set data length. When such error occurs, the emergency error code will be

H’8210, and the value in the error register will become 1.

Internal error in the equipments

This error indicates the error taken place inside the se rvo drive (e.g. sevo drive

conducts emergency stop). When such error occurs, the emergency error code will be

H’FFXX (XX refers to the error code of the servo drive), and the value in the error

register will become H’80.

Eliminating error

When an error is eliminated, the emergency error code will become H’0000.

Explanation

Take the COA slave of node ID = 6 as the object and com pare the EMERGENCY messages

sent out by IFD9503 in different error conditions.

y When in internal communication error

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 01 81 01 00 00 00 00 00

y When in CANopen bus communication error

20

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 30 81 01 00 00 00 00 00

y When in insufficient PDO data length

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 10 82 01 00 00 00 00 00

DVP-PLC Application Manual

Page 23

CANopen Slave Communication Module IFD9503

y When the servo drive conducts emergency stop (i nternal error of the equipment)

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 0D FF 80 00 00 00 00 00

(When stops urgently, the error code of srovo drive is H’0D)

y Error removed

When there is still other error exiting

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 01 00 00 00 00 00

When all errorss have been removed

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 00 00 00 00 00 00

y Note

Only when error status has changed that IFD9503 could send EMMERGENCY message.

z PDO service

IFD9503 supports PDO1 ~ PDO8. For IFD9503, COB-ID of PDO can be modified but cannot be

repeated.

PDO1 (Default: Open)

y TxPDO1 (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the length of data to be

mapped to 2 bytes and the content to be mapped to “status word of digital output contact”.

You can map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’180 + Node-ID DO1~DO5

y RxPDO1 (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of data to be

mapped to 2 bytes and the content to be mapped to “control word of digital input contact”.

You can map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’200 + Node-ID DI1~ DI8

PDO2 ~ PDO8 (Default: Close)

y TxPDO (IFD9503 → master):

Send the status date of the slave (IFD9503) to the master. Preset the length of data to be

mapped to 0 byte. You can map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’xxxx +Node-ID

y RxPDO (master→IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of data to be

DVP-PLC Application Manual

21

Page 24

CANopen Slave Communication Module IFD9503

mapped to 0 byte. You can map any readable parameters, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’yyyy +Node-ID

Data tr ansmission mode

y TxPDO in IFD9503 supports many modes: synchronously non-cyclic, synchrono usly cy clic,

synchronously RTR, asynchronously RTR and asynchronous modes.

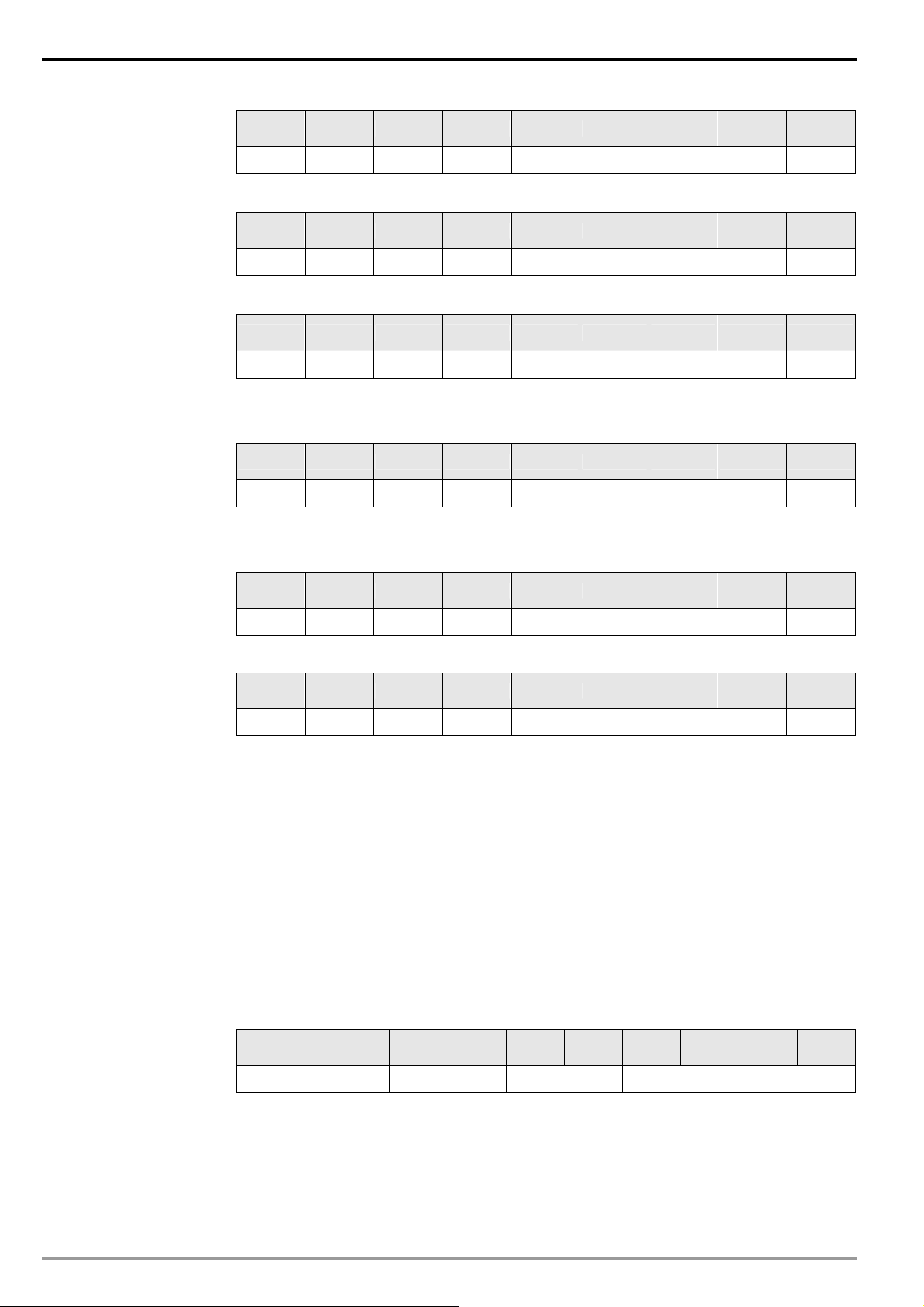

3.5 When IFD9503 is connected to programmable logic controller

DVPCOPM-SL

DVP-SV

DVPCOM DVP28SV

CAN+

SHLD

CANGND

RUN

STOP

Master

CANop en

RS-485

Delta DVP series PLC

IFD9503

1. Setting up baud rate and communication format

z Before connecting the PLC to the bus, first set up the communication address of the PLC to 01,

baud rate to 115,200bps and communication format to 7, E, 1; ASCII (the format is fixed; other

formats will be invalid).

22

z To adjust the baud rate, follow the steps listed below.

Set up the DIP switch SW3 of IFD9503 to custom equipment mode.

Connect IFD9503 to the bus of CANop en and enable the operation of IFD9503.

Modify the index parameter 5003/03

5003/03 = 1 → 19,200; 7, E, 1; ASCII

5003/03 = 2 → 38,400; 7, E, 1; ASCII

5003/03 = 3 → 57,600; 7, E, 1; ASCII

5003/03 = 4 → 115,200; 7, E, 1; ASCII (Default)

Return SW3 of IFD9503 back to PLC mode and re-power IFD9503.

Adjust the baud rate of the PLC to the corresponding one.

DVP-PLC Application Manual

Page 25

CANopen Slave Communication Module IFD9503

2. Functions & features

In addition, IFD9503 also supports the following two functions.

z Emergency object – EMERGENCY

When IFD9503 detects an internal error, it will send an EMCY message to the CANopen bus.

Format

IFD9503 → master

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

128(H’080)

+Node-ID

Emergency error code Error register

00 00 00 00 00

LSB MSB

y Error register

The value in the error register will be mapped to index address H’1001 in the object

dictionary. V alue = 0 indicates that no error occurs. Value = 1 incicates that a general error

takes place. Value = H’80 indicates that an internal error in the equipment occurs.

y Emergency error code

Internal communication error

This error indicates the communication error between IFD9503 and PLC (e.g.

communication failure). When such error occurs, the emergency error code will be

H’8101, and the value in the error register will become 1.

CANopen bus communication error

This error indicates the communication error between CANopen master and IFD9503

slave (e.g. master disconnection). When such error occurs, the emergency error code

will be H’8130, and the value in the error register will become 1.

Insufficient length of PDO data

This error indicates that the length of Receive PDO data actually sent out is shorter than

the set data length. When such error occurs, the emergency error code will be H’8210,

and the value in the error register will become 1.

Eliminating error

When an error is eliminated, the emergency error code will become H’0000.

Explanation

Take the IFD9503 slave of node ID = 6 as the object and compare the EMERGENCY

messages sent out by IFD9503 in different error conditions.

y When in internal communication error

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 01 81 01 00 00 00 00 00

y When in CANopen bus communication error

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 30 81 01 00 00 00 00 00

y When in insufficient PDO data length

DVP-PLC Application Manual

23

Page 26

CANopen Slave Communication Module IFD9503

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 10 82 01 00 00 00 00 00

y When the error is eliminated.

Still other errors exiting:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 01 00 00 00 00 00

All errors are eliminated:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 00 00 00 00 00 00

y Note

IFD9503 sends out EMMERGENCY message only when error occurs.

z PDO service

IFD9503 supports PDO1 ~ PDO8. For IFD9503, COB-ID of PDO can be modified but cannot be

repeated.

Particularly for PLC, the PDO parameters in IFD9503 are divided into an upload area and

download area, featuring:

y TxPDO

TxPDO is only able to map parameter D (upload start address+0) ~ D (upload start

address+31), the 32 registers, in the upload area. By modifying the upload start address,

you can obtain different upload areas. For example,

When the upload start address = 0, the upload area will be D0 ~ D31.

When the upload start address = 10, the upload area will be D10 ~ D41.

y RxPDO

RxPDO is only able to map parameter D (download start address+0) ~ D (download start

address+31), the 32 registers, in the download area. By modifying the download start

address, you can obtain different download areas. For example,

When the download start address = 0, the download area will be D0 ~ D31.

When the download start address = 10, the download area will be D10 ~ D41.

y Note: See 13.5.1 “Communication Objects in Object Dictionary” for the corresponding

24

index and sub-index of upload start address, download st art address and all mapping

parameters.

PDO1 (Default: Open)

y TxPDO1 (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the length of data to be

st

mapped to 8 bytes and the content to be mapped to “the 1

area”. You can map any parameters in the upload area, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’180 + Node-ID D (up+0) D (up+1) D (up+2) D (up+3)

~ 4th registers in the upload

DVP-PLC Application Manual

Page 27

CANopen Slave Communication Module IFD9503

y RxPDO1 (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of the data to

st

be mapped to 8 bytes and the content to be mapped to “the 1

~ 4th registers in the

download area”. You can map any parameters in the download area, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’200 + Node-ID D (down +0) D (down +1) D (down +2) D (down +3)

PDO2 ~ PDO8 (Default: Close)

y TxPDO (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the lengrh of the data to

be mapped to 0 byte. You can map any parameters in the upload area, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’xxxx +Node-ID

y RxPDO (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of data to be

mapped to 0 byte. You can map any parameters in the download area, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’yyyy +Node-ID

Data tr ansmission mode

y TxPDO in IFD9503 supports many modes: synchronous non-cyclic, synchronous cyclic,

synchronous RTR, asynchronous RTR and asynchronous modes.

DVP-PLC Application Manual

25

Page 28

CANopen Slave Communication Module IFD9503

3.6 When IFD9503 is connected to Delta DOP-A HMI

DVPCOPM- S L

DVP-SV

DVPCOM DVP28SV

CAN+

SHLD

CANGND

RUN

STOP

Master

CANopen

Delta DOP-A HMI

IFD9503

RS-23 2/ R S - 48 5

1. Setting up baud rate and communication format

z Before connecting the HMI to the bus, first set up the baud rate to 115,200bps and

communication format to 7, E, 1; ASCII (the format is fixed; other formats will be invalid).

COM1

F1

F2

F3

COM2

z HMI as the master and IFD9503 as the slave. There are 64 virtual D devices (D0 ~ D63) in

IFD9503. CANopen master and HMI are able to map, read and write the virtual D devices in

IFD9503.

z To adjust the baud rate, follow the steps listed below.

Set up the DIP switch SW3 of IFD9503 to custom equipment mode.

Connect IFD9503 to the bus of CANop en and enable the operation of IFD9503.

Modify the index parameter 5003/06.

5003/06 = 1 → 19,200; 7, E, 1; ASCII

5003/06 = 2 → 38,400; 7, E, 1; ASCII

5003/06 = 3 → 57,600; 7, E, 1; ASCII

5003/06 = 4 → 115,200; 7, E, 1; ASCII (Default)

Return SW3 of IFD9503 back to HMI mode and re-power IFD9503.

Adjust the baud rate of the HMI to the corresponding one.

z When IFD9503 is connected to DOP HMI, set up the baud rate and communication format

following the steps below.

26

DVP-PLC Application Manual

Page 29

CANopen Slave Communication Module IFD9503

Open Screen Editor and select “File => New”. You will see the dialog box below.

1

Select “Delta DVP PLC” to be the Base Port Controll er, as step 1. Click “OK” to create a new

file.

Select “Options => Configuration => Communication”, and you will see the dialog box below.

2

3

4

5

6

Follow step 2 ~ 6: PLC Station = 1; communication format = 115,200, 7, E, 1, ASCII.

Click ”OK”.

z When the HMI connected to DNA02 is TP04/TP02, and then please set up its communication

speed and format following the procedure listed below.

Open TPEdit or and select “File => New”. You will see the dialog box below.

DVP-PLC Application Manual

27

Page 30

CANopen Slave Communication Module IFD9503

1

Select “DELTA PLC” in Set Device Type column, as step

Select “Tools => TP Object Communication Default Setting”, and you will see the dialog box

below.

1

. Click “OK” to create a new file.

2

Follow step

2. Functions & features

In addition, IFD9503 also supports the following two functions.

z Emergency object – EMERGENCY

When IFD9503 detects an internal error, it will send an EMCY message to the CANopen bus.

Format

IFD9503 → master

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

128(H’080)

+Node-ID

~ 3: Set PLC ID = 1; check “Select Default PLC ID”. Click “OK”.

Emergency error

code

LSB MSB

Error

register

y Error register

3

2

00 00 00 00 00

28

The value in the error register will be mapped to index address H’1001 in the object

dictionary. V alue = 0 indicates that no error occurs. Value = 1 indicates that a general error

takes place. Value = H’80 indicates that an internal error in the equipment occurs.

y Emergency error code

CANopen bus communication error

This error indicates the communication error between CANopen master and IFD9503

slave (e.g. master disconnection). When such error occurs, the emergency error code

will be H’8130, and the value in the error register will become 1.

Insufficient length of PDO data

This error indicates that the length of Receive PDO data actually sent out is shorter than

DVP-PLC Application Manual

Page 31

CANopen Slave Communication Module IFD9503

the set data length. When such error occurs, the emergency error code will be H’8210,

and the value in the error register will become 1.

Eliminating error

When an error is eliminated, the emergency error code will become H’0000.

Explanation

Take the IFD9503 slave of node ID = 6 as the object and compare the EMERGENCY

messages sent out by IFD9503 in different error conditions.

y When in CANopen bus communication error

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 30 81 01 00 00 00 00 00

y When in insufficient PDO data length

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 10 82 01 00 00 00 00 00

y When the error is eliminated

Still other errors exiting:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 01 00 00 00 00 00

All errors are eliminated:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 00 00 00 00 00 00

y Note:

IFD9503 sends out EMERGENCY message only when error occurs.

z PDO service

IFD9503 supports PDO1 ~ PDO8. For IFD9503, COB-ID of PDO can be modified but cannot be

repeated..

Particularly for PLC, the PDO parameters in IFD9503 are divided into an upload area and

download area, featuring:

y TxPDO

TxPDO is only able to map 32 registers, D32 ~ D63 in the upload area.

y RxPDO

RxPDO is only able to map 32 registers, D32 ~ D63 in the download area.

PDO1 (Default: Open)

y TxPDO1 (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the length of data to be

mapped to 8 bytes and the content to be mapped to “the 1

area”. You can map any parameters in the upload area, maximum 8 bytes.

DVP-PLC Application Manual

st

~ 4th registers in the upload

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’180 + Node-ID D32 D33 D34 D35

29

Page 32

CANopen Slave Communication Module IFD9503

Note: See 13.5.1 “Communication Objects in Object Dictionary” for the corresponding

index and sub-index of upload start address, download st art address and all mapping

parameters.

y RxPDO1 (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of data to be

mapped to 8 bytes and the content to be mapped to “the 1

st

~ 4th registers in the download

area”. You can map any parameters in the download area, maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’200 + Node-ID D0 D1 D2 D3

PDO2 ~ PDO8 (Default: Close)

y TxPDO (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the length of the data to

be mapped to 0 byte. You can map any parameters in the download area, maximum 8

bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’xxxx +Node-ID

y RxPDO (master → IFD9503):

Send the control data of the master to the slave equipment (IFD9503). Preset the length of

the data to be mapped to 0 byte. You can map any parameters in the download area,

maximum 8 bytes.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’yyyy +Node-ID

Data tr ansmission mode

TxPDO in IFD9503 supports many modes: synchronously non-cyclic, synchronously cyclic,

synchronous RTR, asynchronous RTR and asynchronous modes.

30

DVP-PLC Application Manual

Page 33

CANopen Slave Communication Module IFD9503

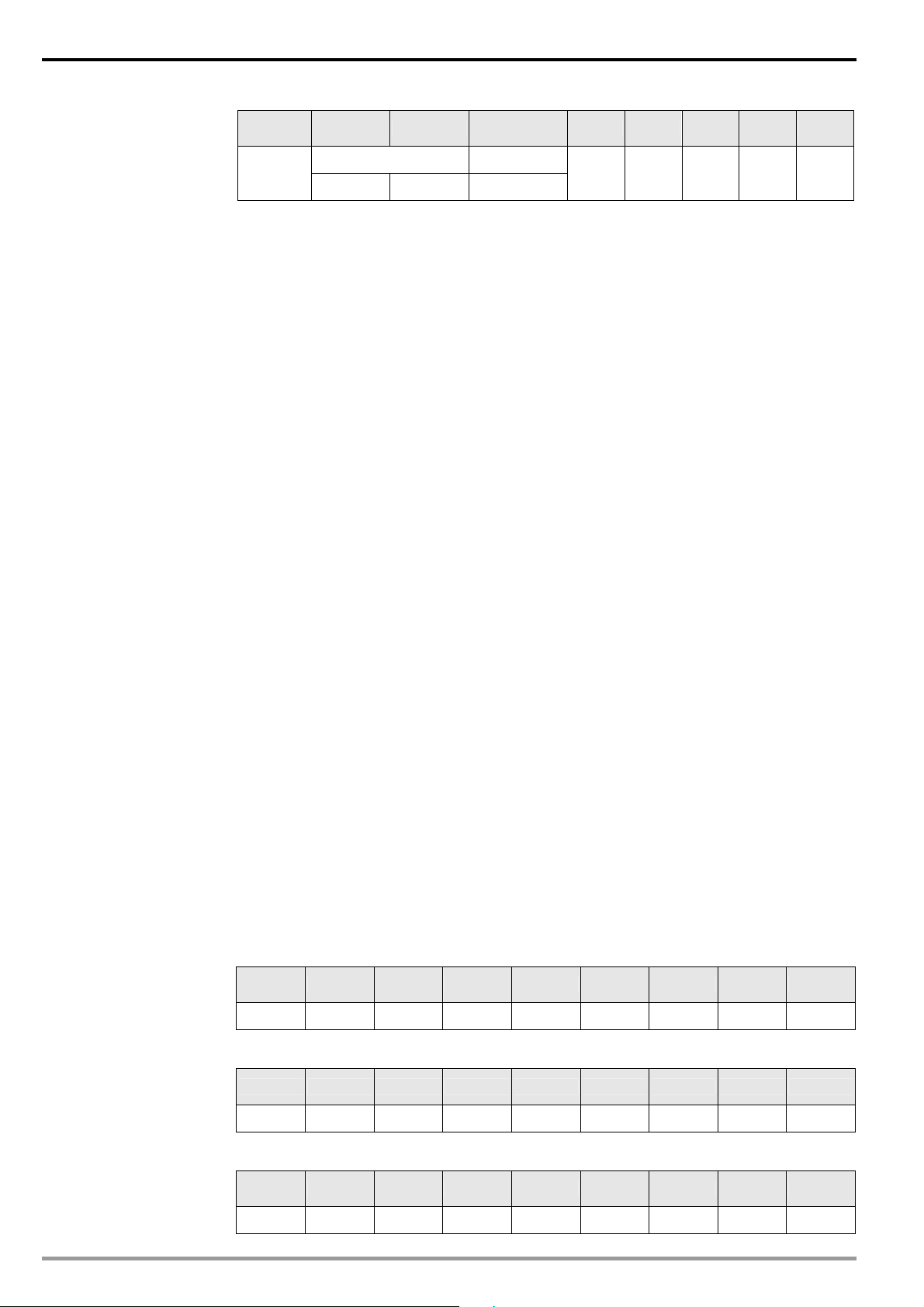

3.7 When IFD9503 is connected to custom equipment

DVPCOPM-SL

DVP-SV

DVPCOM DVP28SV

RUN

CAN+

SHLD

CAN-

STOP

GND

Master

CANop en

custom equipment

IFD9503

RS-485

1. Setting up baud rate and communication format

z Before connecting the custom equipment to the bus, first set up the communication address of

the equipment to 01, baud rate to 19,200bps and communication format to 8, N, 2; RTU (the

format is fixed; other formats will be invalid).

z To adjust the baud rate, follow the steps listed below.

Modify the index parameter 5003/07.

5003/07 = 1 → 19,200; 8, N, 2; RTU (Default)

5003/07 = 2 → 38,400; 8, N, 2; RTU

5003/07 = 3 → 57,600; 8, N, 2; RTU

5003/07 = 4 → 115,200; 8, N, 2; RTU

Re-power IFD9503 and adjust the ba ud rate of the custom equipment to the corresponding

one. Note: When IFD9503 is connected to custom equipment, IFD9503 will enter the pre-run

status automatically after it is powered in any configuration, which allows you to adjust the

baud rate and so on in that mode.

2. Functions & features

In addition, IFD9503 also supports the following two functions.

z Emergency object – EMERGENCY

When IFD9503 detects an internal error, it will send an EMCY message to the CANopen bus.

Format

IFD9503 → master

DVP-PLC Application Manual

31

Page 34

CANopen Slave Communication Module IFD9503

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

128(H’080)

+Node-ID

Emergency error code Error register

00 00 00 00 00

LSB MSB

y Error register

The value in the error register will be mapped to index address H’1001 in the object

dictionary. Value = 0 indicates that no error occurs. Value = 1, it indicates that a general

error takes place. Value = H’80 indicates that an internal error in the equipment occurs.

y Emergency error code

CANopen bus communication error

This error indicates the communication error between CANopen master and IFD9503

slave (e.g. master disconnection). When such error occurs, the emergency error code

will be H’8130, and the value in the error register will become 1.

Insufficient length of PDO data

This error indicates that the length of Receive PDO data actually sent out is shorter than

the set data length. When such error occurs, the emergency error code will be H’8210,

and the value in the error register will become 1.

Eliminating error

When an error is eliminated, the emergency error code will become H’0000.

Explanation

Take the IFD9503 slave of node ID = 6 as the object and compare the EMERGENCY

messages sent out by IFD9503 in different error conditions.

y When in CANopen bus communication error

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 30 81 01 00 00 00 00 00

y When in insufficient PDO data length

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 10 82 01 00 00 00 00 00

y When the error is eliminated.

Still other errors exiting:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

86 00 00 01 00 00 00 00 00

All errors are eliminated:

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

32

86 00 00 00 00 00 00 00 00

y Note:

IFD9503 sends out EMERGENCY message only when error occurs.

z PDO service

IFD9503 supports PDO1 ~ PDO8. For IFD9503, COB-ID of PDO can be modified but cannot be

DVP-PLC Application Manual

Page 35

CANopen Slave Communication Module IFD9503

repeated.

Particularly for custom equipment, the PDO paramete rs in IFD9503 are divided into an upload

area and download area, featuring:

y TxPDO

TxPDO is only able to map 32 parameters (sub-index addess) in the upload area (index

H’5001). For example,

5001/01 (1

5001/02 (2

If you would like to correspond the 1

(parameter address) of the connected equipment, you can write the Modbus address into

5001/01. The same rule also applies to other sub-index addresses.

y RxPDO

RxPDO is only able to map 32 parameters (sub-index addess) in the download area (index

H’5000). For example,

5000/01 (1

5000/02 (2

If you would like to correspond the 1

st

word of TxPDO1)

nd

word of TxPDO1)

st

word of RxPDO1)

nd

word of RxPDO1)

st

word of TxPDO1 to a certain Modbus address

st

word of RxPDO1 to a certain Modbus address

(parameter address) of the connected equipment, you can write the Modbus address into

5000/01. The same rule also applies to other sub-index addresses.

y Note: See 13.5.1 “Communication Objects in Object Dictionary” for the corresponding

index and sub-index of upload start address, download st art address and all mapping

parameters.

PDO1 (Default: Open)

y TxPDO1 (IFD9503 → master):

Send the status data of the slave (IFD9503) to the master. Preset the length of data to be

st

mapped to 0 byte. You can map maximum 8 bytes in the 1

TxPDO1 in the upload area. The mapping relation is corresponding and fixed. For

example,

st

Word 1 (byte 0 & byte 1) → 1

Word 2 (byte 2 & byte 3) → 2

Word 3 (byte 4 & byte 5) → 3

Word 4 (byte 6 & byte 7) → 4

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

word of TxPDO1

nd

word of TxPDO1

rd

word of TxPDO1

th

word of TxPDO1

word of TxPDO 1 ~ 4th word of

y RxPDO1 (master → IFD9503):

Send the contol data of the master to the slave (IFD9503). Preset the length of the data to

be mapped to 0 byte. You can map maximum 8 bytes in the 1

word of RxPDO1 in the download area. The mapping relation is corresponding and fixed.

For example,

DVP-PLC Application Manual

H’180 + Node-ID

st

word of RxPDO 1 ~ 4th

st

Word 1 (byte 0 & byte 1) → 1

word of RxPDO1;

33

Page 36

CANopen Slave Communication Module IFD9503

nd

Word 2 (byte 2 & byte 3) → 2

Word 3 (byte 4 & byte 5) → 3

Word 4 (byte 6 & byte 7) → 4

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’200 + Node-ID

PDO2 ~ PDO8 (Default: Close)

y TxPDO (IFD9503 → master):

Send the status data of the slave equipment (IFD9503) to the master. Preset the length of

the data to be mapped to 0 byte. You can map maximum 8 bytes. Same as TxPDO1,

PDO2 ~ PDO8 map RxPDO2 ~ RxPDO8. The mapping relation is corresponding and

fixed.

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

H’xxxx +Node-ID

word of RxPDO1

rd

word of RxPDO1

th

word of RxPDO1

y RxPDO (master → IFD9503):

Send the control data of the master to the slave (IFD9503). Preset the length of the data to

be mapped to 0 byte. You can map maximum 8 bytes. Same as RxPDO1, PDO2 ~ PDO8

map RxPDO2 ~ RxPDO8 in the download area. The mapping relation is corresponding

and fixed.

H’yyyy +Node-ID

Default COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Explanation

If the custom equipment is a Delta VFD-B AC motor drive, and we would like to control its

RUN/STOP, frequency input and monitor its operation status and frequency, follow the

explanations below:

y Map the 1

TxPDO1 and 2

st

word of RxPDO1 and 2nd word of RxPDO1 in RxPDO1 and map the 1st word of

nd

word of TxPDO1 in TxPDO1.

y Write the Modbus address corresponding to VFD-B in the index addre ss of IFD9503

through SDO, e.g. H’2000 → 5000/01, H’2001 → 5000/02; H’2101 → 5001/01, H’2103

→ 5001/02.

34

y In this way, we will be able to control the control word (H’2000), frequency command

(H’2001) and monitor the status word (H’2101) and running frequency (H’2103) in VFD-B

through RxPDO1 and TxPDO1.

y Note: You can only map the Modbus address of 16-bit word device in the dowbload area

and upload area.

Data tr ansmission mode

y TxPDO in IFD9503 supports many modes: synchronously non-cyclic, synchrono usly cy clic,

synchronous RTR, asynchronous RTR and asynchronous modes.

DVP-PLC Application Manual

Page 37

CANopen Slave Communication Module IFD9503

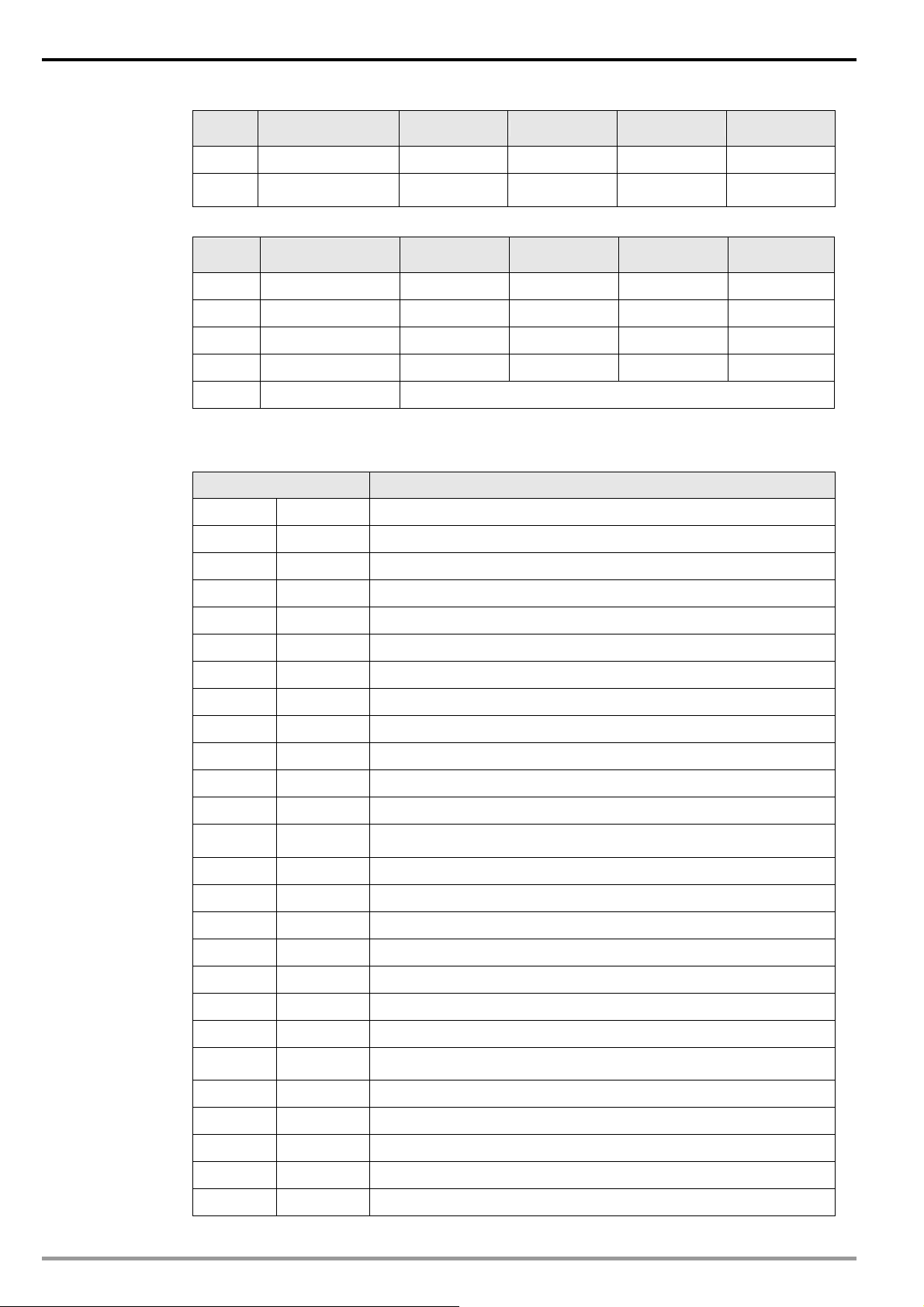

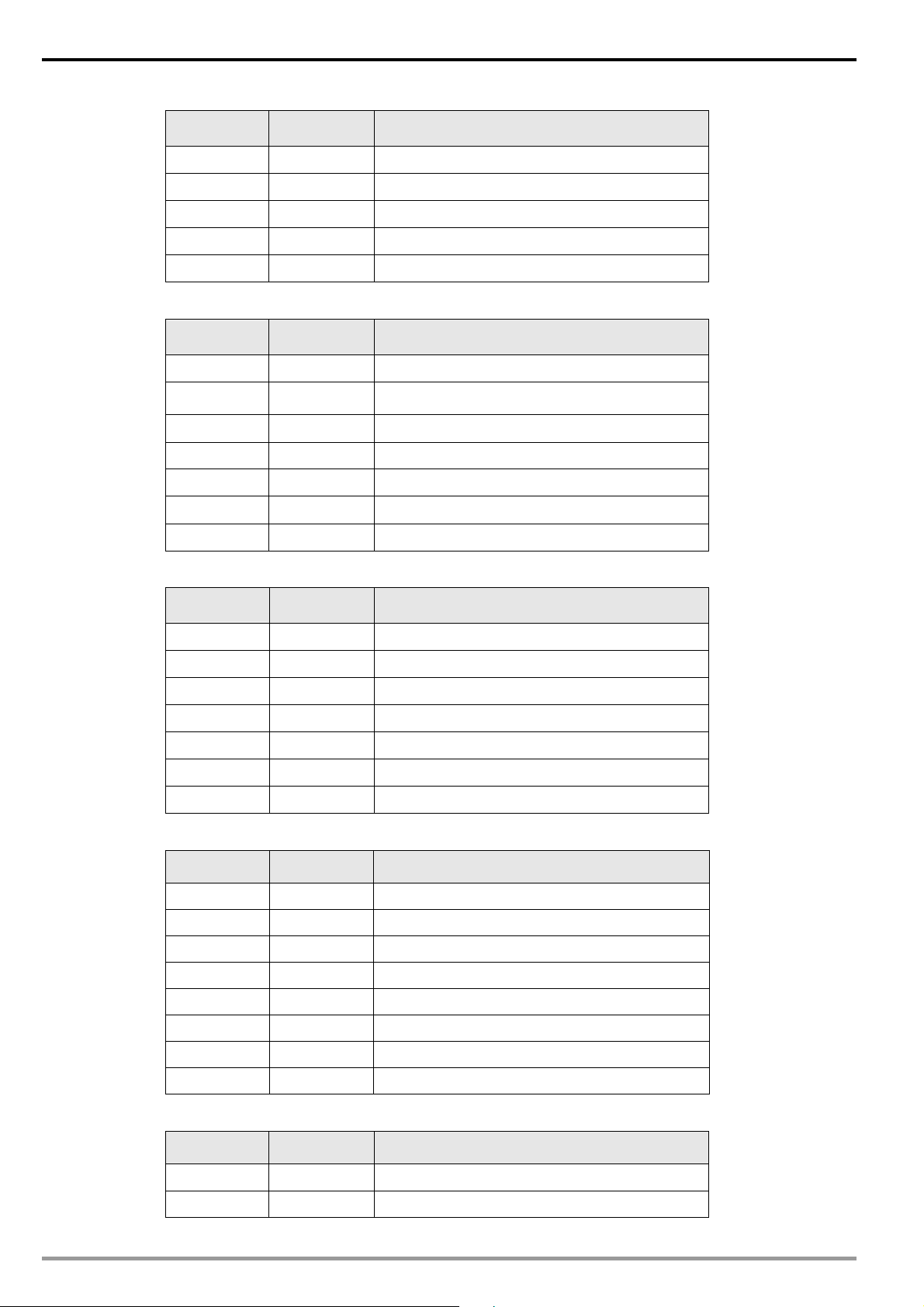

4 LED Indicators & Trouble-shooting

There are 3 LED indicators on IFD9503, RUN, ERROR and SCAN, for displaying the connection status of the

communication in IFD9503.

4.1 RUN LED

LED Status IFD9503 Status How to deal with it

Off No power

Green light 1 flash Stop

Green light flashes Pre-operation

Green light On Operating

Red light On NODE-ID error Check if the setting of NODE-ID of IFD9503 is correct.

4.2 ERROR LED

LED Status IFD9503 Status How to deal with it

Off No error IFD9503 operation is normal.

Red light 2 flashes Erroneous control occurs.

Red light On bus OFF

4.3 SCAN LED

LED Status IFD9503 Status How to deal with it

Off No power

Green light flashes

Green light On

Red light flashes CRC check fails

Red light On Connection fails, or no connection

The correct information of the

equipment connected has not been

detected.

The communication with the

equipment connected is normal.

Check the power of IFD9503 and make sure the

connection is normal.

1. Check if the connection between IFD9503 and the

master station is intact.

2. Check if the communication between IFD9503 and the

master station is normal.

1. Check if the bus connection is normal.

2. Re-power IFD9503.

Check the power of IFD9503 and make sure the

connection is normal.

Re-connect IFD9503 to the equipment.

1. Check if the communication cable between IFD9503

and the equipment is correct.

2. Check if there is electromagnetic interference nearby.

1. Check if the communication format of the equipment is

correct.

2. Check if IFD9503 and the equipment are correctly

connected.

3. Restart the connection and make sure the

communication cable meets the specification.

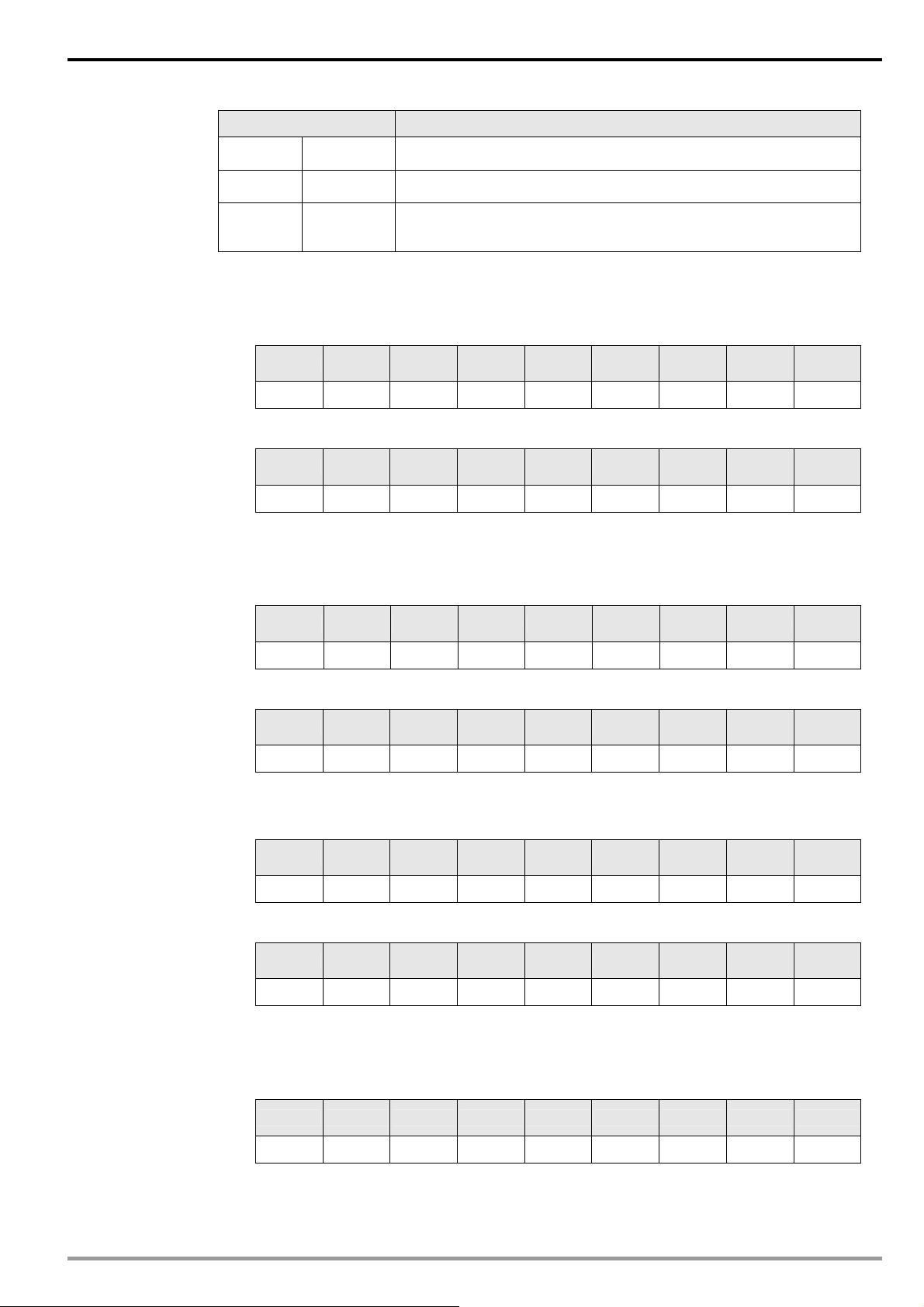

5 Object Dictionary

1. Communication objects in the object dictionary:

Index Sub-index Object name Data type

H’1000 H’00 Equipment type Unsigned 32 bits R 0x00000000

H’1001 H’00 Error register Unsigned 8 bits R 0

Predefined error field

H’1003

DVP-PLC Application Manual

H’00 Number of errors Unsigned 8 bits R 0

H’01 Standard error field Unsigned 32 bits R 0

Access

autorization

Default

35

Page 38

CANopen Slave Communication Module IFD9503

Index Sub-index Object name Data type

H’1005 H’00 COB-ID SYNC message Unsigned 32 bits RW 0x00000080

H’1008 H’00 Equipment name of suppl ier

H’100C H’00 Protection time Unsigned 16 bits RW 0

H’100D H’00 Life time factor Unsigned 8 bits RW 0

H’1014 H’00 COB-ID emergency message Unsigned 32 bits R 0x80 + Node-ID

Pulsant time of the user

H’1016

H’1017 H’00 Pulsant time of generator Unsigned 16 bits RW 0

H’1018

H’1400

H’00 Number of items Unsigned 8 bits R 1

H’01 Pulsant time of the user Unsigned 32 bits RW 0

Identification object

H’00 Number of items Unsigned 8 bits R 3

H’01 Supplier code Unsigned 32 bits R 0x000001DD

H’02 Product code Unsigned 32 bits R

H’03 Version Unsigned 32 bits R 0x00010002

RxPDO1 communication

parameter

H’00 Number of items Unsigned 8 bits R 3

H’01 COB-ID of RxPDO1 Unsigned 32 bits RW 0x0000 0200+Node-ID

Visible charater

string

Access

autorization

R IFD9503

Denpens on the

connected equipment

Default

H’1401

H’1402

H’1403

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 0

RxPDO2 communication

parameter

H’00 Number of items Unsigned 8 bits R 3

H’01 COB-ID of RxPDO2 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 0

RxPDO3 communication

parameter

H’00 Number of items Unsigned 8 bits R 3

H’01 COB-ID of RxPDO3 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 0

RxPDO4 communication

parameter

H’00 Number of items Unsigned 8 bits R 3

H’01 COB-ID of RxPDO4 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

36

H’1404

H’03 Forbidden time Unsigned 16 bits RW 0

RxPDO5 communication

parameter

H’00 Number of items Unsigned 8 bits R 3

H’01 COB-ID of RxPDO5 Unsigned 32 bits RW 0x80000000

DVP-PLC Application Manual

Page 39

CANopen Slave Communication Module IFD9503

Index Sub-index Object name Data type

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsig ned 16 bits RW 0

RxPDO6 communication

H’1405

H’1406

H’1407

parameter

H’00 Number of items Unsigne d 8 bits R 3

H’01 COB-ID of RxPDO6 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsig ned 16 bits RW 0

RxPDO7 communication

parameter

H’00 Number of items Unsigne d 8 bits R 3

H’01 COB-ID of RxPDO7 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsig ned 16 bits RW 0

RxPDO8 communication

parameter

H’00 Number of items Unsigne d 8 bits R 3

H’01 COB-ID of RxPDO8 Unsigned 32 bits RW 0x80000000

Access

autorization

Default

H’1600

H’1601

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsig ned 16 bits RW 0

RxPDO1 mapping parameter

H’00 Number of items Unsigne d 8 bits RW

H’01 The first mapped object Unsigned 32 bits RW

H’01 The sencond mapped object Unsigned 32 bits RW

H’02 The third mapped object Unsigned 32 bits RW

H’03 The forth mapped object Unsigned 32 bits RW

RxPDO2 mapping parameter

H’00 Number of items Unsigne d 8 bits RW 0

H’01 The first mapped object Unsigned 32 bits RW 0

H’01 The sencond mapped object Unsigned 32 bits RW 0

H’02 The third mapped object Unsigned 32 bits RW 0

H’03 The fourth mapped o bject Unsigned 32 bits RW 0

RxPDO3 mapping parameter

Denpens on the

connected equipment

Denpens on the

connected equipment

Denpens on the

connected equipment

Denpens on the

connected equipment

Denpens on the

connected equipment

H’00 Number of items Unsigne d 8 bits RW 0

H’01 The first mapped object Unsigned 32 bits RW 0

H’1602

H’01 The sencond mapped object Unsigned 32 bits RW 0

H’02 The third mapped object Unsigned 32 bits RW 0

H’03 The fourth mapped o bject Unsigned 32 bits RW 0

H’1603

H’00 Number of items Unsigne d 8 bits RW 0

DVP-PLC Application Manual

RxPDO4 mapping parameter

37

Page 40

CANopen Slave Communication Module IFD9503

Index Sub-index Object name Data type

H’01 The first mapped object Unsigned 32 bits RW 0

H’01 The sencond mapped object Unsigned 32 bits RW 0

H’02 The third mapped object Unsigned 32 bits RW 0

H’03 The fourth mapped o bject Unsigned 32 bits RW 0

RxPDO5 mapping parameter

H’00 Number of items Unsigned 8 bits RW 0

H’01 The first mapped object Unsigned 32 bits RW 0

H’1604

H’01 The sencond mapped object Unsigned 32 bits RW 0

H’02 The third mapped object Unsigned 32 bits RW 0

H’03 The fourth mapped o bject Unsigned 32 bits RW 0

RxPDO6 mapping parameter

H’00 Number of items Unsigned 8 bits RW 0

H’01 The first mapped object Unsigned 32 bits RW 0

H’1605

H’01 The sencond mapped object Unsigned 32 bits RW 0

H’02 The third mapped object Unsigned 32 bits RW 0

H’03 The fourth mapped o bject Unsigned 32 bits RW 0

Access

autorization

Default

H’1606

H’1607

H’1800

RxPDO7 mapping parameter

H’00 Number of items Unsigned 8 bits RW 0

H’01 The first mapped object Unsigned 32 bits RW 0

H’01 The sencond mapped object Unsigned 32 bits RW 0

H’02 The third mapped object Unsigned 32 bits RW 0

H’03 The fourth mapped o bject Unsigned 32 bits RW 0

RxPDO8 mapping parameter

H’00 Number of items Unsigned 8 bits RW 0

H’01 The first mapped object Unsigned 32 bits RW 0

H’01 The sencond mapped object Unsigned 32 bits RW 0

H’02 The third mapped object Unsigned 32 bits RW 0

H’03 The fourth mapped o bject Unsigned 32 bits RW 0

TxPDO1 communication

parameter

H’00 Number of items Unsigned 8 bits R 5

H’01 COB-ID of TxPDO1 Unsigned 32 bits RW 0x00000180+Node-ID

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigne d 16 bits RW 50

38

H’1801

H’05 Timer Unsigned 16 bits RW 100

TxPDO2 communication

parameter

H’00 Number of items Unsigned 8 bits R 5

H’01 COB-ID of TxPDO2 Unsigned 32 b its RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigne d 16 bits RW 50

DVP-PLC Application Manual

Page 41

CANopen Slave Communication Module IFD9503

Index Sub-index Object name Data type

H’05 Timer Unsigned 16 bits RW 100

TxPDO3 communication

H’1802

H’1803

parameter

H’00 Number of items Unsigne d 8 bits R 5

H’01 COB-ID of TxPDO3 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 50

H’05 Timer Unsigned 16 bits RW 100

TxPDO4 communication

parameter

H’00 Number of items Unsigne d 8 bits R 5

H’01 COB-ID of TxPDO4 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 50

H’05 Timer Unsigned 16 bits RW 100

TxPDO5 communication

parameter

H’00 Number of items Unsigne d 8 bits R 5

Access

autorization

Default

H’1804

H’1805

H’1806

H’01 COB-ID of TxPDO5 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 50

H’05 Timer Unsigned 16 bits RW 100

TxPDO6 communication

parameter

H’00 Number of items Unsigne d 8 bits R 5

H’01 COB-ID of TxPDO6 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 50

H’05 Timer Unsigned 16 bits RW 100

TxPDO7 communication

parameter

H’00 Number of items Unsigne d 8 bits R 5

H’01

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 50

H’05 Timer Unsigned 16 bits RW 100

H’00 Number of items Unsigne d 8 bits R 5

TxPDO7的 COB-ID

TxPDO8 communication

parameter

Unsigned 32 bits RW 0x8000000 0

H’1807

H’1A00

H’01 COB-ID of TxPDO8 Unsigned 32 bits RW 0x80000000

H’02 Transmission mode Unsigned 8 bits RW 0xFF

H’03 Forbidden time Unsigned 16 bits RW 50

H’05 Timer Unsigned 16 bits RW 100

DVP-PLC Application Manual

TxPDO1mapping parameter

39

Page 42

CANopen Slave Communication Module IFD9503

Index Sub-index Object name Data type

H’00 Number of items Unsigned 8 bits RW

H’01 The first mapped object Unsigned 32 bits RW

H’02 The sencond mapped object Unsigned 32 bits RW

H’03 The third mapped object Unsigned 32 bits RW

H’04 The fourth mapped o bject Unsigned 32 bits RW

TxPDO2 mapping parameter

H’00 Number of items Unsigned 8 bits RW 0

H’01 The first mapped object Unsigned 32 bits RW 0

H’1A01

H’02 The sencond mapped object Unsigned 32 bits RW 0

H’03 The third mapped object Unsigned 32 bits RW 0

H’04 The fourth mapped o bject Unsigned 32 bits RW 0

TxPDO3mapping parameter

H’00 Number of items Unsigned 8 bits RW 0