Page 1

User Manual

DC Power Supply

Continuous 400 – 1000 VDC

Model: HPH-20KA01KAT

Version: Rev. S.00

Page 2

Delta Electronics. Inc. HPH- 20KA01KAT

I

Copyright

All rights reserved. The contents either of manual and design of power supply

may not be reproduced or used in any manner whatsoever without admittance by

Delta Electronics Inc.

Warranty

This product Delta “HPH-20KA01KAT” Model is been warranted against defect in

material and workmanship for a period of “1” year after date of shipment. Delta agrees

to repair or replace the fault unit free-of-charge which fails to perform with specification

and under normal use during this period.

This warranty shall not apply to the following items and will be billed of cost:

1. To exceed the warranty period.

2. Subject to misuse, negligence, accident or natural disaster.

3. Used in a hazardous or dangerous manner either alone or in conjunction

with other equipment.

4. Repaired or altered by person who was not authorized by Delta.

5. Appearance change with environment factor

Delta will be the sole arbiter for those circumstances

To make a warranty claim please contact Delta at telephone number in the table

or support at delta.com, the fault unit transportation to Delta to be prepaid and

responsibility by purchaser, and Delta will take responsibility for ship it back.

Delta Electronics, Inc.

3 Tungyuan Road, Chungli Industrial Zone

Taoyuan County 32063, Taiwan, ROC

Tel: 886-3-4526107

Fax: 886-3-4331706

Web Site: www.deltaww.com

Page 3

Delta Electronics. Inc. HPH- 20KA01KAT

II

INDEX

Chapter 1: Safety and Standard ······························································· 1

1.1. Important Safety Information ············································································· 1

1.2. Safety and Warning Symbols ············································································· 1

1.3. Electromagnetic Compatibility Directives and Standard ·········································· 2

1.4. Industry Guideline ··························································································· 2

Chapter 2: Introduction ··········································································· 3

2.1. Brief Statement ······························································································· 3

2.2. Key Feature ··································································································· 3

Chapter 3: Specification ·········································································· 4

3.1. System Block Diagram ····················································································· 4

3.2. Electrical Specification ····················································································· 5

3.3. Arc Suppression Specification ············································································ 7

3.4. Process and Monitor Function…………………………………………………………………8

3.5. Mechanical Specification ·················································································· 9

3.6. Environment Specification ··············································································· 10

Chapter 4: System Protection Mechanism ··············································· 11

4.1. Input Breaker ································································································ 11

4.2. Protection by MCU ························································································· 11

Chapter 5: Installation ··········································································· 14

5.1. Cooling Requirements ···················································································· 15

5.2. Cabinet Design ····························································································· 15

5.3. Grounding ··································································································· 16

5.4. Connecting For Master/Slave ·········································································· 16

5.5. Configuring Your Master Unit ··········································································· 16

5.6. Configuring Your Slave Units ··········································································· 17

5.7. Monitoring Your Master/Slave System ······························································· 19

5.8. Clearing Faults in a Master/Slave System ·························································· 19

Chapter 6: Interface ·············································································· 20

6.1. Front Panel ·································································································· 20

6.2. Rear Panel ·································································································· 21

6.3. Main Menu Map……………………………………………………………………………….. 22

6.4. Digital Communication Port (Host) ···································································· 23

6.5. Analog Communication Port (User) ··································································· 27

Page 4

Delta Electronics. Inc. HPH- 20KA01KAT

III

Chapter 7: Operation ············································································ 30

7.1. Panel Operating Steps ··················································································· 30

7.2. D-SUB Operating Steps ················································································· 31

7.3. RS232 Operating Steps ·················································································· 31

7.4. RS485 Operating Steps ·················································································· 31

7.5. Parallel Operating Steps ················································································· 32

Chapter 8: Maintenance ········································································ 33

Page 5

Delta Electronics. Inc. HPH- 20KA01KAT

1

Chapter1: Safety and Standard

1.1. Important Safety Information

To keep your safety from hazardous and fatal circumstance, please read and realize the content

of this manual before installing and operating Delta “HPH-series” power supply.

1.2. Safety and Warning Symbols

The following advisory symbols as shown in Table 1.1 will be used in the manual for different

level of warning. The meanings of the advisory symbols are explained below.

Table 1.1 Safety and warning symbols (1)

This danger symbol advises that improper operation will

cause serious personal injury or death.

This warning symbol advises that improper operation will

cause serious personal injury, or catastrophic damage the

generator or any electronic devices connected to the

generator, or lose important data.

This caution symbol advises that improper operation will

cause personal injury, damage the power supply or any

electronic devices connected to the power supply, lose data.

The following advisory symbols as shown in Table 1.2 are used on safety warning labels, and/or

on printed circuit board (only provided with white paint), and/or other part of the generator. The

meanings of these symbols are explained as below.

Table 1.2 Safety and warning symbols (2)

Dangerous voltage symbol indicates the presence of high

voltage. Access the high voltage will cause serious personal

injury or death.

To protect against electrical shock in case of a fault. This

symbol indicates that the terminal must be connected to

ground before operation of equipment.

Residual voltage:

Wait 8 minutes at least for capacitor discharge after power

cord is removed and before servicing.

Heavy object:

Two persons lifting are recommended to avoid muscle strain

or back injuries.

Page 6

Delta Electronics. Inc. HPH- 20KA01KAT

2

1.3. Electromagnetic Compatibility Directives and Standard

Disturbance Characteristic: EN55011 - CRSP11 Class A, Group 1 (>20 kVA)

General Immunity Standard for Industry: EN 61000-6-2

Safety Requirement: IEC-61010-1 (CE and UL certification)

1.4. Industry Guideline

Guideline for Semiconductor manufacturing equipment: SEMI S2 and F47

Page 7

Delta Electronics. Inc. HPH- 20KA01KAT

3

Chapter 2: Introduction

2.1. Brief Statement

Delta “HPH-20KA01KAT” is a high voltage DC generator that meets the exciting requirement in

sputtering system. Tight regulation, small output ripple and superior arc quenching make it very

suitable to be applied in most of plasma-based sputtering application.

Figure 2.1 Delta “HPH-20KA01KAT” power supply

2.2. Key Feature

Excellent Accuracy, Load Regulation, and Stability

Ultrafast Arc Suppression Detect Time

Very Low Arc Energy (< 1 mJ per kW)

Adjustable Ramp and Delay Time

Convenience for Multi-parallel Application

Remote Control Signals, User Port Analog I/O (D-sub), Host Port Digital I/O (RS-

232 and RS-485)

Page 8

Delta Electronics. Inc. HPH- 20KA01KAT

4

Chapter 3: Specification

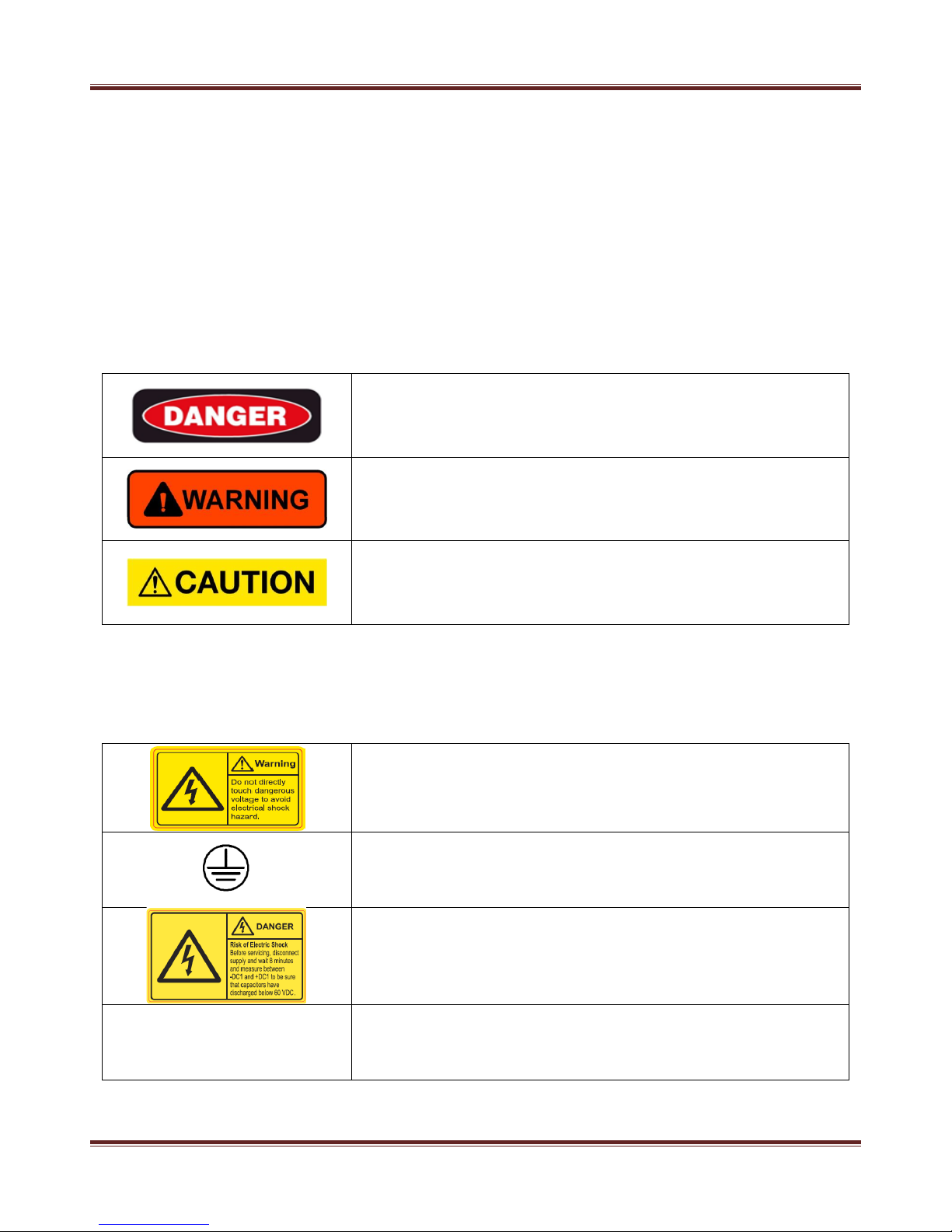

3.1. System Block Diagram

Figure 3.1 System block diagram of Delta “HPH-20KA01KAT”

Table 3.1 Detail description for block diagram

Soft Start and PFC Section

AC line voltage is applied through the circuit breaker. The contactor,

when closed, delivers the line voltage to a rectifier bridge, where it is

converted to DC bus.

Converter Section

The converter section converts DC voltage stored in the bulk

capacitors to high-frequency voltage by alternating the current

through switching power components.

Output Section

In the output section, an isolation transformer steps up the highfrequency voltage from the converter section and delivers it to a fullwave rectifier bridge. The rectified DC power is then passed through

a measurement section to the output connector.

Output Measurement and

Feedback

The output measurement section measures current and voltage, and

feedback the voltage and current information to MCU for voltage,

current and power control and related protection.

Auxiliary Power

The AUX power provides low voltage source to supply the Vcc of

analog OPA, main controller, MCU, fan and LCD display.

MCU.FPGA

The MCU is responsible for controlling the power supply status and

providing status information to the operator through all interfaces.

The FPGA dominates the arc suppression mechanism.

Control Panel Display

Control panel shows operating mode, command level, feedback

values, set up Arc processing, process control, interface setup,

communication set and system status during power supply working.

Remote Control Interface

The power supply supports three types of interfaces: a User port

(analog), a Host port (RS-232, RS-485) and an active front panel. All

three interfaces communicate operator-supplied inputs to MCU and

provide the operator with status information.

EMI Filter

Three-phase

Power Input

PFC DC Bus

DC-DC

Converter

Arc Suppressor

Soft Start

Mechanism

Wide Range

Power Output

System Controller Interface

Sensor & Driver

Auxiliary

Power

Adaptable Fan Isolation

Page 9

Delta Electronics. Inc. HPH- 20KA01KAT

5

3.2. Electrical Specification

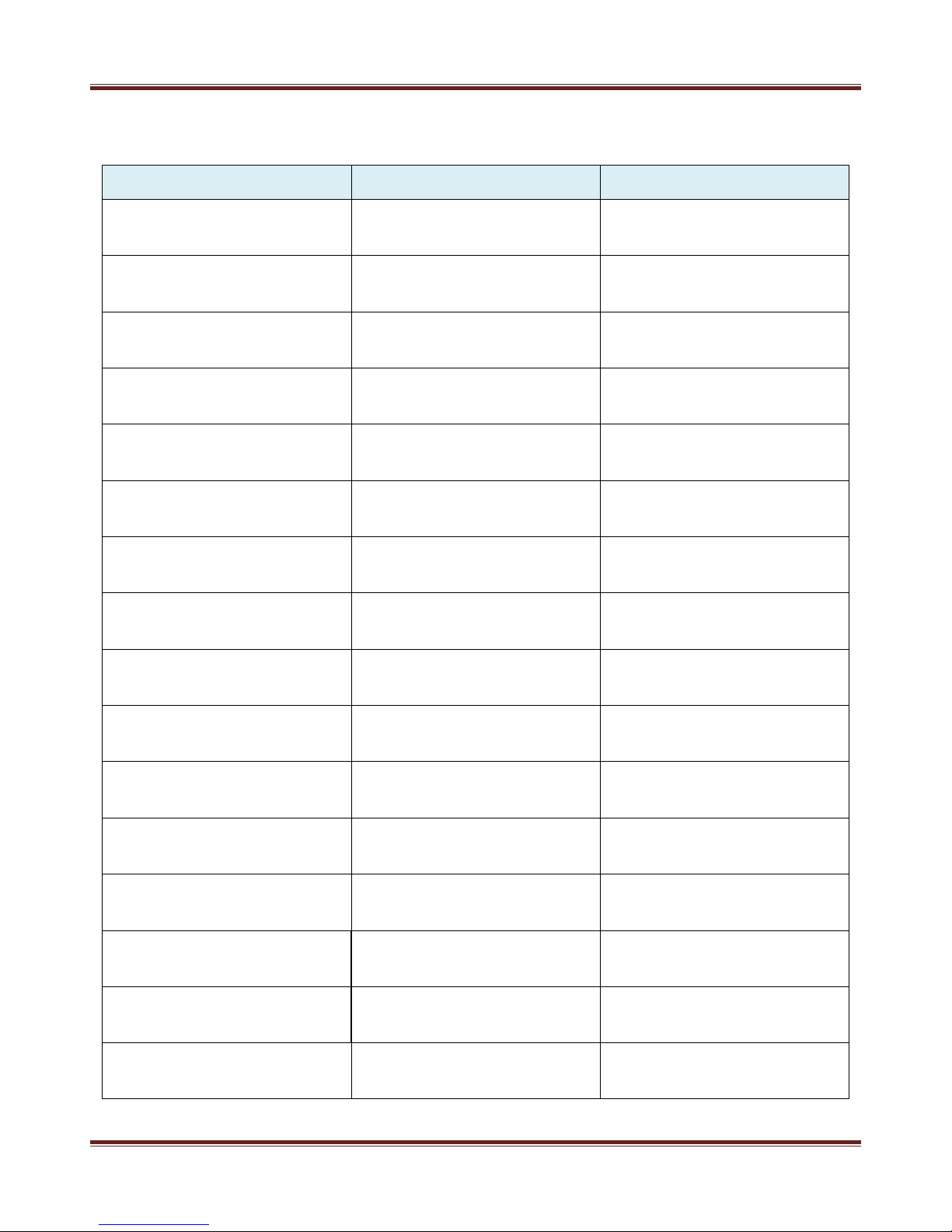

Table 3.2 Electrical specification

Item

Specification

Condition

Input Voltage

208 V

AC

± 10% (Three Phase)

50 / 60 Hz

Input Current (Per Phase)

< 80 A

RMS

208V

AC

Input voltage

Maximum Output Power

20 kW

-

Output Voltage Range

0 to 1000 V

Output accuracy specification

guaranteed from 131 to 1000 V

Output Current Range

0 to 50 A

Output accuracy specification

guaranteed from 5 to 50 A

Power Supply Efficiency

> 90%

Rated output power at 1000 V

Power Factor

> 0.9

Rated output power

Output Voltage Ripple

< 2% (V

RM

S), line frequency

20% to 100% output power

within operation range

Output Voltage Accuracy

1% of command setting or 0.5%

of full scale voltage between

output and command

Within operation range at 25 ˚C

Output Current Accuracy

1% of command setting or 0.5%

of full scale current between

output and command

Within operation range at 25 ˚C

Output Voltage Reader (Digital

Interface) Accuracy

1% of command setting or 0.5%

of full scale voltage between

output and command

Within operation range at 25 ˚C

Output Current Reader

(Digital Interface) Accuracy

1% of command setting or 0.5%

of full scale current between

output and command

Within operation range at 25 ˚C

D-sub Reader/Command

(Analog Interface) Accuracy

1% of full scale rating P/I/V

between output and D-sub

Within operation range at 25 ˚C

Parallel Reader (Digital

Interface) Accuracy

20% of full scale rating P/I/V

between output and D-sub

Within operation range at 25˚C

Parallel D-sub Reader (Analog

Interface) Accuracy

20% of full scale rating P/I/V

between output and D-sub

Within operation range at 25˚C

Load Regulation

1% of command setting or 0.5%

of full scale voltage between

output and command

10% to 100% Output Power

Page 10

Delta Electronics. Inc. HPH- 20KA01KAT

6

Temperature Coefficient

< 50 ppm/˚C

20 to 40 ˚C

Variation in regulated output

Regulation Mode

Constant voltage, current, and power mode

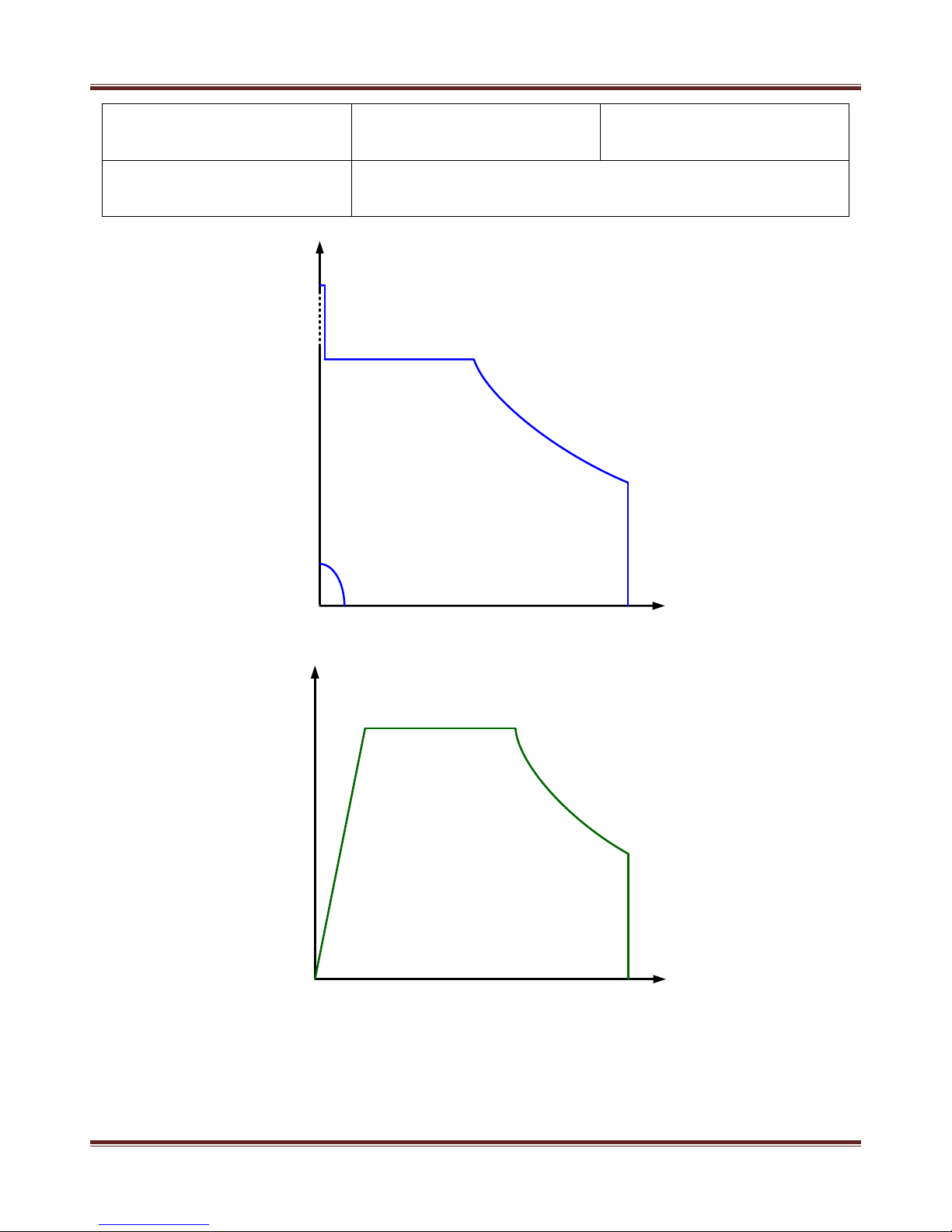

Figure 3.2 Operation curve of output V-I characteristic

Figure 3.3 Operation curve of output impedance characteristic

1000V

200V

400V

50A

600V

5A 20A

Power Limit

Current Limit

Voltage Limit

1900V

Operation Range

V

out

I

out

131V

20kW

10kW

8Ω

Power Limit

Current Limit

Operation Range

Z

out

50Ω 100Ω

P

out

Voltage Limit

Page 11

Delta Electronics. Inc. HPH- 20KA01KAT

7

For Delta “HPH-20KA01KAT” power supply, the maximum output voltage and current level are

1000 V and 50 A. The output characteristic is as the figures above. If the operation point is below

400 V, the power supply can provide at most 50 A, if the operation is more than 400 V, the maximum

output current will decrease to 20 A within the output voltage reaching 1000 V.

Page 12

Delta Electronics. Inc. HPH- 20KA01KAT

8

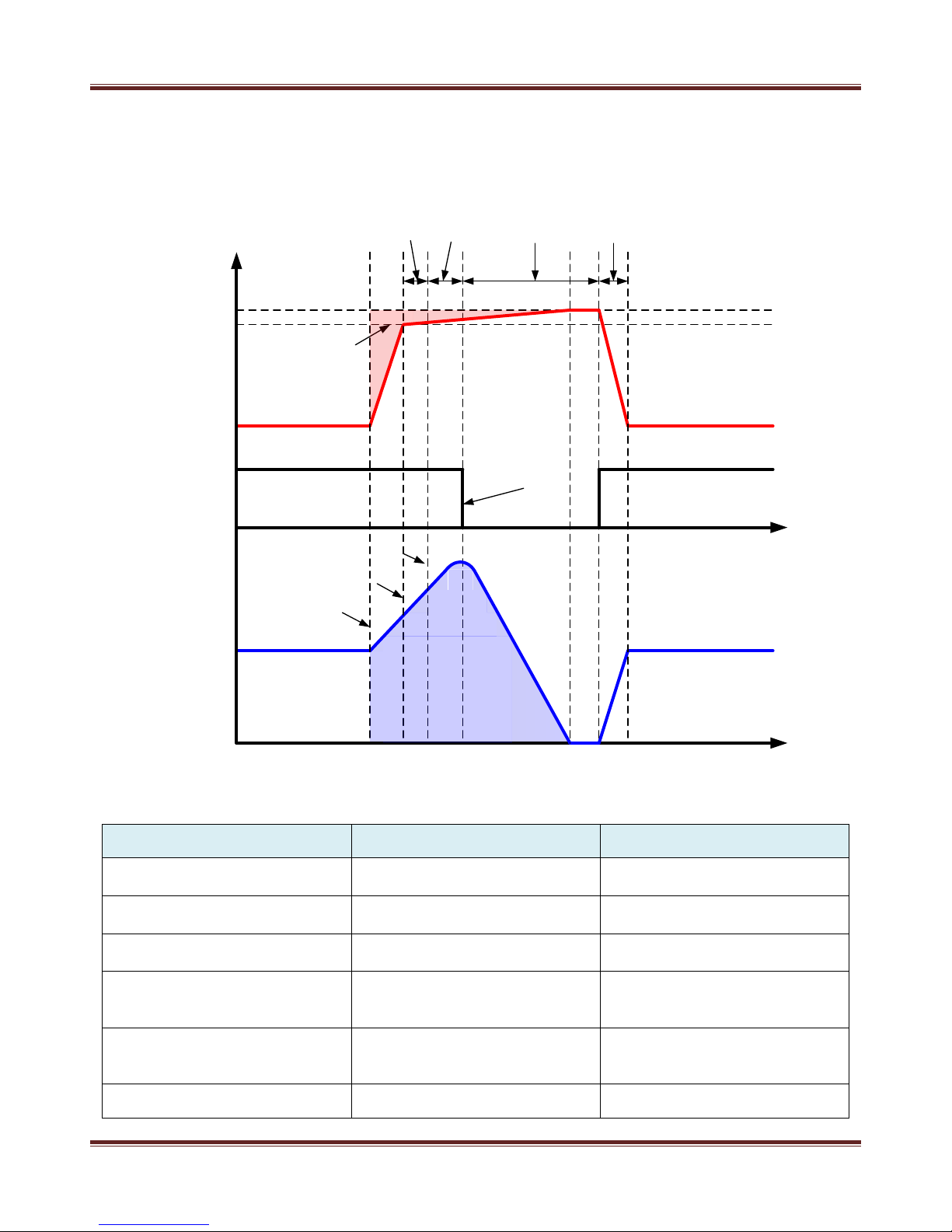

3.3. Arc Suppression Specification

Figure 3.4 shows the waveforms and key parameters under arc condition, and Table 3.3

indicates the arc energy and adjustable parameters for user.

Figure 3.4 Arc Suppression mechanisms

Table 3.3 Arc Energy specification and adjustable parameters for User

Item

Specification

Description

Delay Time

1 to 5 µs

Adjustable delay until cutoff

output after detecting arc

Pause Time

40 to 250 µs

Adjustable time between output

cutoff and recovery

Arc Trip Voltage Level

25 to 200 V

The level to determine if arc

occurs from output

Over Arc Density Protection

1 to 99

Adjustable counter to alarm if

the a frequent arc condition

occurs within 1 second

Over Arc Number Protection

1 to 999

Adjustable counter to alarm if

the arc number is over the

setting.

Arc Energy

< 1 mJ per kW

0V

0A

Arc Occurs

Detection Circuit Activated

Arc Detected

Switching off

Detection

Time

Delay

Time

Pause

Time

Arc Voltage

Trip Level

t

1

t

2

Voltage

Current

Signal of

Switching

t

t

3

t

4

t5t6t

7

Recovery

Time

Page 13

Delta Electronics. Inc. HPH- 20KA01KAT

9

Page 14

Delta Electronics. Inc. HPH- 20KA01KAT

10

3.4. Process and Monitor Function

Table 3.4 Adjustable function parameters for User

Item

Specification

Description

Max. Power

2 to 20 kW

Power will be constrained within

the value of setting prior to the

set point of regulation.

Max. Current

5 to 50 A

Current will be constrained

within the value of setting prior

to the set point of regulation.

Max. Voltage

500 to 1000 V

Voltage will be constrained

within the value of setting prior

to the set point of regulation.

Ignition Mechanism

1000 to 1900 V

A voltage up to 1900 V is

adjustable for igniting the

system.

Ramp Time

50 to 2000 ms

A ramp up to set point is

adjustable for a soft start

mechanism.

Set Point

1 to 10 s

Monitoring if the output reaches

the setting of regulation within

the setting of period.

Energy Mode

1 to 99999 kJ

Monitoring if the output energy

reaches the setting of energy.

Target Life Mode

1 to 15000 kWh

Monitoring if the output energy

reaches the setting of kWh.

3.5. Mechanical Specification

The outward appearance, cooling specification for minimum CFM Requirement, and I/O ports

of Delta “HPH-20KA01KAT” power supply are described as below:

Table 3.5 Mechanical specification

Item

Description

Physical Dimension

482.6 mm (W) x 132.5 mm (H) x 600 mm (L)

19" (W) x 5.2" (H) x 22.0" (L)

19" 3U

Weight

38.7 kg

Cooling

Fan cooling

Noise

Noise generated by this unit under 70 dB (A) at a 1m distance in 25

˚C ambient temperature

AC Input Connector

4 pin terminal block

DC Output Connector

3 pin terminal block

User Port

Analog I/O: 15-pin female D-sub

Host Port

Digital I/O: 9-pin female RS232 and RS485

Parallel Bus

8-pin RJ46

Page 15

Delta Electronics. Inc. HPH- 20KA01KAT

11

Page 16

Delta Electronics. Inc. HPH- 20KA01KAT

12

Figure 3.5 Physical dimension of HPH-20KA01KAT power supply

Cooling requirement

Minimum air flow rate: 7.36 m

3

/min (260 CFM)

Figure 3.6 Air Flow directions

Air InAir In

Air OutAir Out

Air Out Air Out

Page 17

Delta Electronics. Inc. HPH- 20KA01KAT

13

Delta “HPH-20KA01KAT” power supply is the forced air cooling type. Please keep enough

space for air flow cooling capability when it is installing to the cabinet. Air inlet on the front panel and

air outlet on the rear panel is shown in figure 3.6. Air outlet of rear panel is responsible for dissipating

the heat from inside of power supply to outside by internal two fans. The temperature of air inlet

should not exceed 40 degree C.

3.6. Environment Specification

Table 3.6 Climatic specification

Item

Temperature

Relative Humidity

Air Pressure

Operating

0 to 40 ˚C

(32 to 104 ˚F)

10% to 90% RH (Non-

condensing)

80 to 106 kPa

(approximately 2000 m

above sea level)

Storage

-25 to 55 ˚C

(-13 to 131 ˚F)

10% to 95% RH

80 to 106 kPa

(approximately 2000 m

above sea level)

Transportation

-25 to 40 ˚C

(-13 to 104 ˚F)

95% RH

(Maximum)

66 to 106 kPa

(approximately 2000 m

above sea level)

Table 3.7 Environment specification

Item

Description

Operating

Category II

Pollution Degree

Pollution Degree 2

Page 18

Delta Electronics. Inc. HPH- 20KA01KAT

14

Chapter 4: System Protection Mechanism

4.1. Input Breaker

The function of this switch is to prevent over current at input side from any malfunction

happening and simultaneously provide a manual switch for user to turn off the power supply.

4.2. Protection by MCU (A: Auto Recovery, L: Latch)

Table 4.1 Definition and description of MCU protection

Alarm Condition

Code

Description

Mode

HW Fault M1

01

Hardware error from the left module

A

HW Fault M2

02

Hardware error from the right module

A

SW OVP

03

Output over voltage

A

SW OCP

04

Output over current

A

SW OPP

06

Output over power

A

Arc Number Limit

07

Arc number is over setting parameter

L

Target Life Monitor

09

Power off while output reaches setting Energy

L

Output Interlock

11

Uninstallation of output cover

L

Contactor Interlock

12

Uninstallation of contactor pin in D-sub connector

L

Communication Loss

15

Error from internal communication

L

Fan1 Error

17

Error from the left fan

L

Fan2 Error

18

Error from the right fan

L

Bus UVP

20

Input voltage is under operation range

L

Bus OVP

21

Input voltage is over operation range

L

GND Detect

22

Positive output is not connected to system ground

L

Set Point Monitor

23

Error while output fails to reach setting parameter

within setting time

L

Energy Mode Monitor

24

Power off while output reaches setting energy

L

Parallel Fault

000

Fault from other PSU (showing on Slave)

L

Page 19

Delta Electronics. Inc. HPH- 20KA01KAT

15

Parallel Fault IP1

101

Fault from PSU IP 01 (showing on Master)

L

Parallel Fault IP2

102

Fault from PSU IP 02 (showing on Master)

L

Parallel Fault IP3

103

Fault from PSU IP 03 (showing on Master)

L

Parallel Fault IP4

104

Fault from PSU IP 04 (showing on Master)

L

Parallel Fault IP5

105

Fault from PSU IP 05 (showing on Master)

L

Parallel Fault IP6

106

Fault from PSU IP 06 (showing on Master)

L

Parallel Fault IP7

107

Fault from PSU IP 07 (showing on Master)

L

Parallel Fault IP8

108

Fault from PSU IP 08 (showing on Master)

L

Parallel Fault IP9

109

Fault from PSU IP 09 (showing on Master)

L

Parallel Fault IP10

110

Fault from PSU IP 10 (showing on Master)

L

Parallel Fault IP11

111

Fault from PSU IP 11 (showing on Master)

L

Parallel Fault IP12

112

Fault from PSU IP 12 (showing on Master)

L

Parallel Fault IP13

113

Fault from PSU IP 13 (showing on Master)

L

Parallel Fault IP14

114

Fault from PSU IP 14 (showing on Master)

L

Parallel Fault IP15

115

Fault from PSU IP 15 (showing on Master)

L

Parallel Fault IP16

116

Fault from PSU IP 16 (showing on Master)

L

Parallel Fault Master

Communication Loss

223

Master fails to receive the ack from slave while

power on

L

Parallel Fault Slave

Communication Loss

224

Slave fails to receive the ack from Master while

power on

L

Warning Condition

Code

Description

Mode

Arc Density Limit

01

Arc Density is over parameters of setting

A

Output Limit

02

Output is over setting parameters of setting

A

Parallel Number

03

Parallel number is different between setting and

reality

A

Parallel Mode

Communication Fault

04 A

Target Life

05

While output reaches setting Target Life

A

Page 20

Delta Electronics. Inc. HPH- 20KA01KAT

16

Energy Mode Monitor

06

While output reaches setting Energy

A

Page 21

Delta Electronics. Inc. HPH- 20KA01KAT

17

Chapter 5: Installation

Delta “HPH-20KA01KAT” power supply is a high voltage power supply. Please read this manual

carefully and follow the instruction before installation and operation, otherwise an electric shock or

a fatal accident might be caused.

Figure 5.1 Installation diagram

This power supply could only be placed horizontally and connect the protective grounding

to prevent an electric shock before use.

Consideration must be taken not to impede the supply or flow of air to the unit.

Please switch off the power supply before touching the case.

Before applying power, please verify that the product is set to match with the line voltage.

The circumstance temperature should be managed under 40˚C

The installation and operation should be only in pollution degree 2 or better environment.

Do not operate this device in a dusty area or in corrosive gas environment.

Proper grounding: For safe use, must connect ground cable (Yellow / Green wire) from

ground stud on the power supply rear panel to the pure earth ground. Poor grounding may

cause an electric shock or fatal accident.

Output connector must be connected with the attached output cable. (3KV/6AWG/200°C,

with shielding). Do not use other output cables.

Before applying power, please verify that the product is set to match with the line voltage.

When emergency, cut-off the circuit breaker, and then removing mains supply cord.

Operating personnel must not remove the cover of the instrument. Component replacement

and internal adjustment can be done only by qualified service personnel.

Remove mains cord and output cable before exterior maintenance and service.

Use the carrying handle when dismantling it. Avoid drop resulting in hurt.

Page 22

Delta Electronics. Inc. HPH- 20KA01KAT

18

Page 23

Delta Electronics. Inc. HPH- 20KA01KAT

19

5.1. Cooling Requirements

For the HPH-20KA01KAT A supply to be sufficiently cooled, the cabinet must be set up to:.

1. Bring in coolant air of the correct temperature(40 ˚C maximum)

2. Distribute coolant air to the power supplies

3. Prevent air exhausted from the cabinet from circulating back and becoming input air

4. Exhaust the hot air from the cabinet with minimal airflow restriction.

5.2. Cabinet Design

The following is a synopsis of the HPH-20KA01KAT A to follow when designing a cabinet

containing a stack of HPH-20KA01KAT A power supplies.

Coolant air must be drawn easily into the cabinet; exhaust air must be able to pass

unrestricted out of the cabinet. If some physical constriant restricts the flow of exhaust air out of

the cabinet, we recommend that fans or blowers be mounted so that the hot air is removed from

the cabinet as quickly as possible.

Each HPH-20KA01KAT A power supply dissipates up to 10% of its maximum power at full

rated output. The minimum air flows in cubic feet per minute(CFM) required by individual HPH20KA01KAT A supplies are shown in table 5.1. The static pressure(inches of water) of the empty

cabinet should not exceed 0.1 inches of water at the CFM level obtained by adding together the

minimum CFM values for all the power supplies that will be placed in the cabinet. For example, if

three HPH-20KA01KAT A supplies are mounted in a cabinet, the minimum CFM requirement

would be three times the CFM of cabinet air volume compared to an individual supply.

Approximations of this figure, the total power dissipation, and the temperature difference between

coolant air and exhaust air are shown as an example in table 5.2.

Table 5.1 Minimum CFM requirement for HPH-20KA01KAT unit

Type of PSU

CFM Required

20KW

260 CFM (122.7 liters/second)

Table 5.2 Approximate cooling requirements for three units mounted in a cabinet

Type of PSU

CFM for 3 Supplies

Total Power Dissipation

Dif. In Temp. Between

Coolant & Exhaust Air

20 KW x 3

780 CFM

(260+260+260=780)

(368.1 liters/second)

9000 W

(3000+3000+3000=9000)

23 ˚C

5.3. Grounding

For your convenience, the rear panel of the HPH-20KA01KAT supply features three

equipotential ground screw: three M6 screw. These are indicated on the rear panel by a ground

symbol.See figure 6.2 for more information.

Page 24

Delta Electronics. Inc. HPH- 20KA01KAT

20

5.4. Connecting For Master/Slave

The HPH-20KA01KAT A design lets you configure up to sixteen HPH-20KA01KAT as a

master/slave system (the maximum power capability depends on the master unit’s configuration

file). Any HPH-20KA01KAT A unit that features the master/slave Host card can function as either a

master unit or a slave unit. HPH-20KA01KAT units without the master/slave card cannot function

as a master or slave.

The master/slave card is located near the top right side of the unit’s rear panel. It includes

three ports:

1. A 9-pin, female, subminiature-D serial communications port for RS-485.

2. Two modular ports “Master” and “Slave” for interfacing master and slave units in a daisy

chain (see figure 5.3).

5.5. Configuring Your Master Unit

To configure the master unit, do the following steps (see Figure 5-3):

1. Remove all input power from the master and slave units.

2. Connect the interface cable between “Master” port on the master unit and “Slave”

port on the first slave unit.

3. Your master unit will not have an interface cable connected to “Slave” port.

4. Use a grounding strap to connect an equi-potential ground stud on the master unit to

an equi-potential ground stud on the first slave unit.

Note:We recommend you use a ground wire that can conduct the current of one

phase( for example, 40A for HPH-20KA01KAT) that is no longer than 3 feet. We

recommend you connect the ground stud on the master unit to system ground. See

Figure 5.2 for more information.

5. Set the front panel => Interface Setup => Prallel Mode Setup => Master

If you want to configure your master unit as a stand-alone unit, do the following steps:

1. Set the front panel => Interface Setup => Prallel Mode Setup => Master

2. Remove all Master/Slave interface cables from “Master” unit.

5.6. Configuring Your Slave Units

To configure a slave unit, do the following (see Figure 5.3)

1. Remove all input power from the master and slave units.

2. Connect the interface cable between “Master” port on the first slave unit and “Slave”

port on the next slave unit. Continue cabling slave units together in this daisy-chain

manner.

Note:The master/slave interface cables are include with the units. The last slave unit

on your system will not have an interface cable connected to “Master”port.

3. Use a grounding strap to connect an equi-potential ground stud on the first slave unit

to an equi-potential ground stud of the next slave unit.

Page 25

Delta Electronics. Inc. HPH- 20KA01KAT

21

Note:We recommend you use a ground wire that can conduct the current of one

phase( for example, 40A for HPH-20KA01KAT) that is no longer than 3 feet. We

recommend you connect the ground stud on the master unit to system ground. See

Figure 5.3 for more information.

4. Continue connecting togeter subsequent slave unit chassis as done in the previous

step.

5. Set the front panel => Interface Setup => Prallel Mode Setup => Slave

Figure 5.3 Configuration for HPH-20KA01KAT A master/slave system

5.7. Monitoring Your Master/Slave System

Page 26

Delta Electronics. Inc. HPH- 20KA01KAT

22

Following is information on monitoring the master/slave system depending on your monitoring

device:

1. If you have a passive front panel attached to your master unit, you can view the

combined output of your master/slave system (power or current). The passive front

panel of each slave unit displays the individual unit’s output.

2. If you have a host computer connected to a serial port on your master unit, you can

monitor the output (power, current or voltage) of your system and the output of each

individual unit.

3. If you want more than two in parallel, you can’t set more than one master unit at the

same time.

5.8. Clearing Faults in a Master/Slave System

If a slave unit experiences an a self-clearing fault, both the master and slave units display an

error code and the master unit shuts off output from all power supplies. When the fault condition

clears, the master and slave units reset. You may then turn on output.

Page 27

Delta Electronics. Inc. HPH- 20KA01KAT

23

Chapter 6: Interface

6.1. Front Panel

The functions for several buttons on the front panel are described on Table 6.1

Table 6.1 Function description of front panel

“Enter” Button

1. Press the button to change all of adaptive parameters.

2. Press the button to enter the next layer while in menu screen.

“Menu” Button

1. Press the button to menu screen from home screen.

2. Press the button to return to the previous layer while in menu screen.

“P” Button

Press the button to set the output condition in constant power mode. In

constant power mode user could adjust output power regulation level by

“enter button” and “knob”.

“I” Button

Press the button to set the output condition in constant current mode. In

constant current mode user could adjust output current regulation level by

“enter button” and “knob”.

“V” Button

Press the button to set the output condition in constant voltage mode. In

constant voltage mode user could adjust output voltage regulation level by

“enter button” and “knob”.

“ON” Button

Press the button to turn on the output power. While power on, user could

adjust output regulation level by “enter button” and “knob”.

“OFF” Button

Press the button to turn on the output power.

“LOCK” Button

Press the button to lock “Enter”, “Menu”, “P”, “I”, “V”, “ON”, “OFF” button.

This function could prevent any unexpected change from panel while PSU

in operation.

Regulation Knob

Rotate the knob to adjust the regulation level.

LCD Display

The display shows command of output regulation level according to control

modes of Power/Current/Voltage. It also indicates feedback values of

Power/Current/Voltage and system status, such as error conditions for all

protect signals.

Page 28

Delta Electronics. Inc. HPH- 20KA01KAT

24

Figure 6.1 Front panel

6.2. Rear Panel

1. GND terminal is for chamber grounding, and earth grounding should be performed for

safety.

2. Connect output terminal to target and connect +COM to the grounding of the chamber

Figure 6.2 Rear panel

Page 29

Delta Electronics. Inc. HPH- 20KA01KAT

25

6.3. Main Menu Map

Fig 6.1 Panel tree

Page 30

Delta Electronics. Inc. HPH- 20KA01KAT

26

Fig 6.2 Definition of LCM display

6.4. Digital Communication Port (Host)

The 9-pin female RS232/485 connector labeled “Host Port” on the rear of the power supply lets

user connect with computer to control the power supply. Definition of RS232/485 connector is as

follows:

Figure 6.3 Connector of host port, 9 pin female RS232/RS485

Table6.2 Definition of RS232/485 connector

RS232 Pin

Definition

Description

RS485 Pin

Definition

Description

1 - 1

D+

2

Tx

2

D-

3

Rx

3

-

4 - 4 - 5

GND

5 - 6 - 6

-

7 - 7

-

8 - 8 - 9 - 9

-

REG : 2 0 . 0 k W OU T : ON

1 0 0 0 V 5 0 . 0 A 2 0 . 0 k W

D : 9 9

M L T : 0 : 0 0 : 0 0S E 0 0

A

R

Command Power On/Off

Voltage/Current/Power Reader

Arc Number、Arc Density

Set Point、Energy、Target Life Mode

Run Time Hr/Min/SecMaster/Slave

9 99AN :

Lock

0>

Page 31

Delta Electronics. Inc. HPH- 20KA01KAT

27

Table 6.3 Protocol of RS232/485 definition (1)

Remote to PSU

Byte

0 1 2 3 4 5 6 7 8 9 10

IP

Command

Data1

Data2

Check Sum

Termination

Byte

H-Byte

L-Byte

H-Byte

L-Byte

H-Byte

L-Byte

0x00

Byte

0x00

0x0D

CV Mode

IP

0x11

0x00/01/02

0x00

0x00

Value

0x00

Value

0x00

0x0D

CC Mode

IP

0x12

0x00/01/02

0x00

0x00

Value

0x00

Value

0x00

0x0D

CP Mode

IP

0x13

0x00/01/02

0x00

0x00

Value

0x00

Value

0x00

0x0D

Master/Slave

IP

0x14

0x00/01

0x00

0x00

Value

0x00

Value

0x00

0x0D

A/Ri Offset

IP

0x15

0x00/01

0x00

0x00

00/01

Value

0x00

Value

0x00

0x0D

A/Vo Offset

IP

0x16

0x00/01

0x00

0x00

00/01

Value

0x00

Value

0x00

0x0D

A/Io Offset

IP

0x17

0x00/01

0x00

0x00

00/01

Value

0x00

Value

0x00

0x0D

Terminating

Resistor

IP

0x18

0x00/01

0x00

0x00

IP

Value

0x00

Value

0x00

0x0D

Set Point

IP

0x1A

0x00/01/02

Value

Value

0x00

Value

0x00

0x0D

Pause Time

IP

0x1B

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Energy Mode

IP

0x1D

0x00/01/02

Value

Value

0x00

Value

0x00

0x0D

Arc Function

IP

0x1E

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Parallel Number

IP

0x21

0x00/01/02

Value

Value

0x00

Value

0x00

0x0D

Max Power

IP

0x22

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Max Current

IP

0x23

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Max Voltage

IP

0x24

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Ramp Time

IP

0x25

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Target Life

IP

0x26

0x00/01/02

Value

Value

0x00

Value

0x00

0x0D

Delay time

IP

0x28

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Arc Voltage

IP

0x30

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Arc Density

IP

0x31

0x00/01/02

Value

Value

0x00

Value

0x00

0x0D

Arc Number

IP

0x32

0x00/01/02

Value

Value

0x00

Value

0x00

0x0D

Ignition

IP

0x33

0x00/01

Value

Value

0x00

Value

0x00

0x0D

Power On

IP

0x41

0x00/01/02

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Power Off

IP

0x42

0x00/01/02

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Default 1

IP

0x60

0x00

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Default 2

IP

0x61

0x00

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Default 3

IP

0x62

0x00

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Default 4

IP

0x63

0x00

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Reset

IP

0x45

0x00

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Version

IP

0x70

0x02

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Alarm Code/IP

IP

0x71

0x02

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

PSU State

IP

0x80

0x02

0x00

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Note 6.1: For L-Byte of Command, 0x00 means writing command to MCU, 0x01 means reading

command from MCU, and 0x02 means reading feedback value.

Example:

CV Mode command code:

0x11 0x00 means writing command to MCU.

0x11 0x01 means reading command from MCU.

0x11 0x02 means reading voltage from feedback.

Page 32

Delta Electronics. Inc. HPH- 20KA01KAT

28

Table 6.4 Protocol of RS232 definition (2)

PSU to Remote

Byte

0 1 2 3 4 5 6 7 8 9 10

IP

Command

Data1

Data2

Check Sum

Termination

Byte

H-Byte

L-Byte

H-Byte

L-Byte

H-Byte

L-Byte

0x00

Byte

0x00

0x0D

CV Mode

IP

0x11

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

CC Mode

IP

0x12

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

CP Mode

IP

0x13

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

Master/Slave

IP

0x14

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

A/Ri Offset

IP

0x15

0x0A

0x00

0x00

00/01

Value

0x00

Value

0x00

0x0D

A/Vo Offset

IP

0x16

0x0A

0x00

0x00

00/01

Value

0x00

Value

0x00

0x0D

A/Io Offset

IP

0x17

0x0A

0x00

0x00

00/01

Value

0x00

Value

0x00

0x0D

Terminating

Resistor

IP

0x18

0x0A

0x00

0x00

IP

Value

0x00

Value

0x00

0x0D

Set Point

IP

0x1A

0x0A

Value

Value

0x00

Value

0x00

0x0D

Pause Time

IP

0x1B

0x0A

Value

Value

0x00

Value

0x00

0x0D

Energy Mode

IP

0x1D

0x0A

Value

Value

0x00

Value

0x00

0x0D

Arc Function

IP

0x1E

0x0A

Value

Value

0x00

Value

0x00

0x0D

Parallel Number

IP

0x21

0x0A

Value

Value

0x00

Value

0x00

0x0D

Max Power

IP

0x22

0x0A

Value

Value

0x00

Value

0x00

0x0D

Max Current

IP

0x23

0x0A

Value

Value

0x00

Value

0x00

0x0D

Max Voltage

IP

0x24

0x0A

Value

Value

0x00

Value

0x00

0x0D

Ramp Time

IP

0x25

0x0A

Value

Value

0x00

Value

0x00

0x0D

Target Life

IP

0x26

0x0A

Value

Value

0x00

Value

0x00

0x0D

Delay time

IP

0x28

0x0A

Value

Value

0x00

Value

0x00

0x0D

Arc Voltage

IP

0x30

0x0A

Value

Value

0x00

Value

0x00

0x0D

Arc Density

IP

0x31

0x0A

Value

Value

0x00

Value

0x00

0x0D

Arc Number

IP

0x32

0x0A

Value

Value

0x00

Value

0x00

0x0D

Ignition

IP

0x33

0x0A

Value

Value

0x00

Value

0x00

0x0D

Power On

IP

0x41

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

Power Off

IP

0x42

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

Default 1

IP

0x60

0x0A

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Default 2

IP

0x61

0x0A

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Default 3

IP

0x62

0x0A

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Default 4

IP

0x63

0x0A

0x00

0x00

0x00

0x00

Value

0x00

0x0D

Reset

IP

0x45

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

Version

IP

0x70

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

Alarm Code/IP

IP

0x71

0x0A

0x00

0x00

Value

0x00

Value

0x00

0x0D

Byte

0 1 2 3 4 5 6 7 8 9 10

11

IP

Command

Status1

Status2

Warning

Alarm

Voltage

Current

Power

PSU

State

12

13

14

15

16

17

18

19

20

21

22

23

Reg

Arc Density

Arc Number

Check Sum

Termination

Status L-

byte

0 1 2 3 4 5 6

7

Standby

OVP

OCP

OTP

OPP

Interlock

Arc

Protection

Output

Limit

Status H-

byte

0 1 2 3 4 5 6

7

CV Mode

CC Mode

CP Mode

Power On

Remote

Ignition

Warning

Shutdown

Page 33

Delta Electronics. Inc. HPH- 20KA01KAT

29

Note 6.2: Check Sum value is the summation of “1” signal calculated by byte 0 to 7.

Example:

“Master IP is 01, Power On”, Byte 0~7 are “0x01-0x41-0x00-0x00-0x00-0x00-0x00-0x00”.

There are three “1” in this command, so checksum is 3.

Note 6.3: Use 9600bps, 8 data bits, no parity, 1 stop bit (9600/8-N-1).

Note 6.4: PSU state Byte 4(Warning) and Byte 5(Alarm) value refer to table 4.1

Table 6.5 Value definition (Translate decimal to hexadecimal for utilizing)

Command

Byte3

Byte4

Byte5

Byte6

CV Mode

0 to 1000 for 0 to 1000V

CC Mode

0 to 500 for 0~50.0A

CP Mode

0 to 200 for 0 to 20.0kW

Master/Slave

Master: 00, Slave: 01

A/Ri Offset

Plus: 00, Minus: 01

0 to 99 for 0 to 9.9%

A/Vo Offset

Plus: 00, Minus: 01

0 to 99 for 0 to 9.9%

A/Io Offset

Plus: 00, Minus: 01

0 to 99 for 0 to 9.9%

Terminating Resistor

IP for 1 to 16

OFF: 0, On: 1

Set Point

1 to 10 for 1 to 10s

Pause Time

4 to 25 for 40 to 250us, Scale: 10us

Energy Mode

1 to 99999 for 1 to 99999kJ, 0: OFF

Arc Function

OFF: 0, ON: 1

Parallel Number

1 to 16 for 1 to 16 sets

Max Power

20 to 200 for 2 to 20kW

Max Current

50 to 500 for 5 to 50A

Max Voltage

500 to 1000 for 500 to 1000V

Ramp Time

5 to 200 for 50 to 2000ms

Target Life

0 to 1500000 for OFF to 15000.00kWh, 0: OFF

Delay time

0 to 5 for 0 to 5us

Arc Voltage

25 to 200 for 25 to 200V

Arc Density

0 to 99 for 0 to 99 times/s

Arc Number

0 to 999 for 0 to 999 times

Ignition

10 to 19 for 1000 to 1900V

Page 34

Delta Electronics. Inc. HPH- 20KA01KAT

30

6.5. Analog Communication Port (User)

The 15-pin female subminiature-D connector labeled “User Port” on the rear of the power supply

lets you connect with control box to control the power supply in analog signal. Definition of 15-pin

female subminiature-D connector is as follows:

Figure 6.4 Connector of user port, 15pin female subminiature-D

Table 6.6 Definition of subminiature-D connector

Pin Define

I/O

Description

1

+24V

I

External 24V is connected to the collector of photo

coupler

2

VOUT_A

O

Pin 2 shows the reader of output voltage

0 to 10 V for V = 0 to 1000 V

3

POUT_A

O

Pin 3 shows the reader of output Power

0 to 10 V for P = 0 to 20 kW

4

OUTPUT_ENABLE_D

I

Turn on the output power by pulling the pin low

5

XPROG_A

I

User could adjust regulation by Pin 5

0 to 10 V for P = 0 to 20 kW

6

COM_A

-

The return pin for VOUT_A, POUT_A, XPROG_A

7

PWRON_D

O

Pin 7 shows the on/off state of output

8

PWRON COM_D

-

The return pin for PWRON_D

9

OUTPUT_ENABLE_COM_D

-

The return pin for OUTPUT_ENABLE_D

PSU

Digital Signal Output

Digital Signal Input

Vcc

Vcc

+15V_ISO

Analog Signal Input

Vcc

+15V_ISO

Analog Signal Output

15-pin D-sub

+15V_ISO

Page 35

Delta Electronics. Inc. HPH- 20KA01KAT

31

10

MOD GREEN

O

Pin 10 is connected to the emitter of photo coupler

for MOD GREEN function

11

INTERLOCK_D

I

Pin 11 indicates the disconnection of interlock

12

INTLK COM_D

-

The return pin for INTERLOCK_D

13

NET GREEN

O

Pin 13 is connected to the emitter of photo coupler

for NET GREEN function

14

MOD AMBER

O

Pin 14 is connected to the emitter of photo coupler

for MOD AMBER function

15

NET AMBER

O

Pin 15 is connected to the emitter of photo coupler

for NET AMBER function

Note 6.5: Precaution for external connection

Port of Digital Signal Input

To control the input signal, a switch is utilized between the ports and isolated ground.

Open → Floating

Close → Grounding

Port of digital Signal output

The internal resistance of the ports is 5.1 kohm, and a pull-up power supply V

pull-up

is

required with a 5.1 kohm resistor.

Initial → > 0.9 * V

pull-up

Trigger → < 0.5 * V

pull-up

+ 1 V

If V

pull-up

is connected to “+15V_ISO” supplied by pin18 with a 5.1 kohm resistor, initial state

would be high than 13.5 V and trigger state would be lower than 8.5 V.

Analog Signal Input Port

An isolated amplifier is utilized in the ports. The voltage level is 0 to 10 V for user to enter

the command and shall not greater than 12 V.

Analog Signal output Port

An isolated amplifier is utilized in the ports. The voltage level is 0 to 10 V for users to read

out the output values of voltage, current, and power.

Page 36

Delta Electronics. Inc. HPH- 20KA01KAT

32

Chapter 7: Operation

7.1. Local Operating Steps

Step A

Import AC voltage to input connector on rear panel. The mains voltage level should be 400±

10% V

AC

.

Step B

Turn on the breaker to start the power supply. Now, you can see “LCD Display” is working and

shows the default setting of the power supply.

Step C

Choose one operating mode from “P”, “I”, “V” button, and “LCD Display” will show the mode you

selected and change the command unit mode by mode.

Operating mode cannot be changed during power on period. It only can select while power off.

Step D

Rotate the knob to adjust the regulation level. The command (P, I or V) will change by different

mode selection in step B. When in Power mode, the command can be adjusted from 0 to 20 kW;

when in Current mode, command can be adjusted from 0 to 50 A; when in Voltage mode, and

command can be adjusted from 130 to 1000 V

Step E

Press the “On” button to turn on the output power. While power on, user could adjust output

regulation level by “Enter” button and “knob”. “LCD Display” will show the feedback values once the

output is on.

After power on, the electric shock may lead to death or serious injury. Please read this manual

carefully and follow the instruction steps before installation and operation, otherwise an electric

shock or a fatal accident might be caused.

Step F

Press the “Off” button to turn off the output power.

Step G

If the power supply is kept off for a while, please remove AC power cord.

Don’t touch the load before grounding it. And make sure the electricity is fully discharged by meter.

Page 37

Delta Electronics. Inc. HPH- 20KA01KAT

33

7.2. D-sub Operating Steps

Example : CP mode 20 kW output

Operating steps:

1. Set the front panel => Interface Setup => Communnication Setup => D-sub.

2. Command Level: Set +10 V input to pin 5 for 20 kW Command.

3. Power On: Connect pin 4 to pin 9

4. Power Off: Remove pin4 from pin 9.

7.3. RS-232 Operating Steps

1. Set the front panel => Interface Setup => Communnication Setup => RS-232.

2. Follow the protocol defined in chapter 6.4 to operating.

7.4. RS-485 Operating Steps

1. Set the front panel => Interface Setup => Communnication Setup => RS-485.

2. Follow the protocol defined in chapter 6.4 to operating.

7.5. Parallel Operating Steps

Parallel operating example 1: Two sample parallel

Operating steps:

1. Connecting set up follow chapter 5

2. Panel System Configuration Parallel Number 2

3. Parallel port 5~8 set IP position, two sample must set up different IP

Example: sample 1 set 0000, sample 2 set 0001

4. Than can follow chapter 7.1 turn on output

Parallel operating example 2: Three sample parallel

Operating steps:

1. Connecting set up follow chapter 5

2. Panel System Configuration Parallel Number 3

3. Parallel port 5~8 set IP position, two sample must set up different IP

Example: sample 1 set 0000, sample 2 set 0001,sample 3 set 0010

4. Than can follow chapter 7.1 turn on output

Page 38

Delta Electronics. Inc. HPH- 20KA01KAT

34

Chapter 8: Maintenance

Alarm Condition

Code

Description

Suggested Action

HW Fault M1

01

Hardware error from the left module

Take all safety precaution, and

then check if the mains voltage

that is in specification. Turn on

the output power with a dummy

load to ensure if it is under

normal operation.

HW Fault M2

02

Hardware error from the right

module

Take all safety precaution, and

then check if the mains voltage

that is in specification. Turn on

the output power with a dummy

load to ensure if it is under

normal operation.

SW OVP

03

Output over voltage

Take all safety precaution, and

then check if the mains voltage

that is in specification. Turn on

the output power with a dummy

load to ensure if it is under

normal operation.

SW OCP

04

Output over current

Take all safety precaution, and

then check if the mains voltage

that is in specification. Turn on

the output power with a dummy

load to ensure if it is under

normal operation

SW OPP

06

Output over power

Take all safety precaution, and

then check if the mains voltage

that is in specification. Turn on

the output power with a dummy

load to ensure if it is under

normal operation.

Arc Number Limit

07

Arc number is over setting

parameter

Press and hold “OFF” button

with 10 second to clear error.

Contactor Interlock

10

Uninstallation of contactor pin in D-

sub connector

Check if contactor pin in D-sub

connector is short.

Output Interlock

11

Uninstallation of output cover

Check if output cover is

correctly installed.

Communication Loss

15

Error from internal communication

Check if the bus between panel

and control card is correctly

connected.

Fan1 Error

17

Error from the left fan

Check if the cable between fan

in the left module 1 and control

card is correctly connected.

Fan2 Error

18

Error from the right fan

Check if the cable between fan

in the right module 2 and control

card is correctly connected.

Bus UVP

20

Input voltage is under operation

range

Take all safety precaution, and

then check if the mains voltage

that is in specification.

Page 39

Delta Electronics. Inc. HPH- 20KA01KAT

35

Bus OVP

21

Input voltage is over operation range

Take all safety precaution, and

then check if the mains voltage

that is in specification.

GND Detect

22

Positive output is not connected to

protective earth

Check if the output positive

terminal is short to protective

earth.

Set Point Monitor

23

Error while output fails to reach

setting parameter within setting time

Take all safety precaution, and

then turn on the output power

with a dummy load to ensure if

it is under normal operation.

Energy Mode Monitor

24

Power off while output reaches

setting Energy

Monitor Setting is end. Press

and hold “OFF” button with 10

second to clear error.

Parallel Fault IP1

101

Fault from PSU IP 01

Check the PSU with IP 01

independently to ensure the

operation is normal.

Parallel Fault IP2

102

Fault from PSU IP 02

Check the PSU with IP 02

independently to ensure the

operation is normal.

Parallel Fault IP3

103

Fault from PSU IP 03

Check the PSU with IP 03

independently to ensure the

operation is normal.

Parallel Fault IP4

104

Fault from PSU IP 04

Check the PSU with IP 04

independently to ensure the

operation is normal.

Parallel Fault IP5

105

Fault from PSU IP 05

Check the PSU with IP 05

independently to ensure the

operation is normal.

Parallel Fault IP6

106

Fault from PSU IP 06

Check the PSU with IP 06

independently to ensure the

operation is normal.

Parallel Fault IP7

107

Fault from PSU IP 07

Check the PSU with IP 07

independently to ensure the

operation is normal.

Parallel Fault IP8

108

Fault from PSU IP 08

Check the PSU with IP 08

independently to ensure the

operation is normal.

Parallel Fault IP9

109

Fault from PSU IP 09

Check the PSU with IP 09

independently to ensure the

operation is normal.

Parallel Fault IP10

110

Fault from PSU IP 10

Check the PSU with IP 10

independently to ensure the

operation is normal.

Parallel Fault IP11

111

Fault from PSU IP 11

Check the PSU with IP 11

independently to ensure the

operation is normal.

Parallel Fault IP12

112

Fault from PSU IP 12

Check the PSU with IP 12

independently to ensure the

operation is normal.

Parallel Fault IP13

113

Fault from PSU IP 13

Check the PSU with IP 13

independently to ensure the

operation is normal.

Page 40

Delta Electronics. Inc. HPH- 20KA01KAT

36

Parallel Fault IP14

114

Fault from PSU IP 14

Check the PSU with IP 14

independently to ensure the

operation is normal.

Parallel Fault IP15

115

Fault from PSU IP 15

Check the PSU with IP 15

independently to ensure the

operation is normal.

Parallel Fault IP16

116

Fault from PSU IP 16

Check the PSU with IP 16

independently to ensure the

operation is normal.

Parallel Fault Master

Communication Loss

223

Master fails to receive the ack from

slave while power on

Check the RJ46 cable is

correctly connected between

master and slave PSUs.

Parallel Fault Slave

Communication Loss

224

Slave fails to receive the ack from

Master while power on

Check the RJ46 cable is

correctly connected between

master and slave PSUs.

Warning Condition

Code

Description

Suggested Action

Arc Density Limit

01

Arc density is over setting parameter

N/A

Output Limit

02

Output is over setting parameter

N/A

Parallel Number

03

Parallel number is different between

setting and reality

Check if parallel number is

correct between setting and

system detection.

Parallel Mode

Communication Fault

04

Target Life

05

While output reaches setting Target

Life

Monitor setting is end. Re-turn

on the power. It will reset the

setting

Energy Mode Monitor

06

While output reaches setting Energy

Monitor setting is end. Re-turn

on the power. It will reset the

setting

Page 41

Delta Electronics. Inc. HPH- 20KA01KAT

37

Loading...

Loading...