Page 1

Operating manual

pH meters / thermometers

HD2105.1 – HD2105.2

www.deltaohm.com

Companies / Brands of GHM

English

Keep for future reference.

Page 2

HD2105 - 2 - V2.3

CONTENTS

INTRODUCTION ..................................................................................................................................................... 3

KEYBOARD AND MENU DESCRIPTION ............................................................................................................ 8

pH MEASUREMENT ..............................................................................................................................................15

AUTOM ATIC OR M ANUAL pH COMPENSATION ..........................................................................................................16

pH ELECTRODE CALIBRATION .................................................................................................................................17

Temperature characteristics of Delta OHM buffer solutions ...............................................................................19

DIRECT INPUT INTO Pt100, Pt1000 AND NI1000 TEMPERATURE PROBES ...................................................................20

How to measure ................................................................................................................................................20

Instructions to connect the TP47 connector for 4-wire Pt100, Pt1000 and Ni1000 probes ...................................20

Direct connection of 4-wire Pt100 sensors .........................................................................................................22

WARNINGS AND OPERATING INSTRUCTIONS ..............................................................................................23

NOTES ON THE USE OF THE pH ELECTRODES ............................................................................................................24

INSTRUMENT SIGNALS AND FAULTS ..............................................................................................................25

LOW BATTERY WARNING AND BATTERY REPLACEMENT .......................................................................27

INSTRUMENT STORAGE .....................................................................................................................................28

SERIAL INTERFACE AND USB ...........................................................................................................................29

STORING AND TRANSFERRING DATA TO A PERSONAL COMPUTER ......................................................31

THE LOGGING FUNCTION - ONLY FOR HD2105.2 ......................................................................................................31

CLEARING THE MEMORY - ONLY FOR HD2105.2 ......................................................................................................31

THE PRINT FUNCTION ...........................................................................................................................................32

CONNECTION TO A PC ........................................................................................................................................33

CONNECTION TO THE RS232C SERIAL PORT OF THE INSTRUMENT .............................................................................33

CONNECTION TO THE USB 2.0 PORT OF THE INSTRUMENT - ONLY FOR HD2105.2 ......................................................33

NOTES ABOUT WORKING AND OPERATIVE SAFETY ..................................................................................34

INSTRUMENT TECHNICAL CHARACTERISTICS ...........................................................................................35

TECHNICAL DATA OF PROBES ........................................................................................................................37

pH Electrodes ...................................................................................................................................................37

Redox Electrodes ..............................................................................................................................................39

4-wire Pt100 and 2-wire Pt1000 Probes .............................................................................................................39

Temperature probes Pt100 sensor using SICRAM module .................................................................................40

ORDER CODES ......................................................................................................................................................41

Page 3

HD2105 - 3 - V2.3

INTRODUCTION

The HD2105.1 and HD2105.2 are portable instruments with a large LCD display. They measure the

pH, the mV, and the redox potential (ORP) in mV. They measure the temperature using Pt100 or

Pt1000 immersion, penetration or contact probes.

The electrode calibration can be carried out manually or automatically on one, two or three points

and the calibration sequence can be chosen from a list of 13 buffers.

The temperature probes are fitted with an automatic detection module, with the factory calibration

settings already being memorized inside.

The HD2105.2 is a datalogger. It memorizes up to 34,000 pH or mV and temperature samples

which can be transferred from the instrument connected to a PC via the RS232C serial port or USB

2.0 port. The storing interval, printing, and baud rate can be configured using the menu.

The HD2105.1 and HD2105.2 models are fitted with an RS232C serial port and can transfer the acquired measurements in real time to a PC or to a portable printer.

Display, printing and, for the model HD2105.2, storing always include temperature, in °C or °F, and

pH or mV.

The Max, Min and Avg function calculates the maximum, minimum or average values.

Other functions include: the relative measurement REL, the Auto-HOLD function, and the automatic turning off that can also be disabled.

The instruments have IP66 protection degree.

This manual describes the HD2105.1 and HD2105.2 models: if not otherwise specified, the description is intended to be applicable to both models.

Page 4

HD2105 - 4 - V2.3

Temperature-pH meter

HD2105.1

Page 5

HD2105 - 5 - V2.3

HD2105.1

1. BNC connector for the pH/mV electrode.

2. 8-pole DIN45326 connector, input for Pt100 temperature probes with SICRAM module, 4-wire

direct Pt100 probes, 2-wire Pt1000 probes complete with TP47 module.

3. External auxiliary power supply connector input.

4. Battery symbol: displays the battery charge level.

5. Function indicators.

6. Secondary display line.

7. CAL/ key: during normal operation starts the pH electrode calibration; in the menu, in-

creases the current value.

8. FUNC/ENTER key: during normal operation displays the maximum (MAX), the minimum

(MIN) and the average (AVG) of current measurements; in the menu, confirms the current selection.

9. REL/ key: enables the relative measurement (displays the difference between the current

value and the logged value when the key is pressed); in the menu, decreases the current value.

10. SERIAL key: starts and ends the data transfer to the serial communication port.

11. MENU key: allows access to and exit from the menu.

12. pH/mV-ESC key: when pressed for at least one second, changes the main variable measure-

ment between pH and mV. When the Auto-HOLD function is enabled, slight pressure updates

the measurement. In the menu, cancels the operation in progress without making changes.

13. °C/°F key: when the probe is not connected, allows manual modification of the temperature.

When double pressed, changes the unit of measurement for the temperature between degrees

Celsius and Fahrenheit.

14. ON-OFF/AUTO-OFF key: turns the instrument on and off; when pressed together with the

MENU key, disables the automatic turn off.

15. Electrode efficiency indicators.

16. MAX, MIN and AVG symbols.

17. Main display line.

18. Line for symbols and comments.

19. 8-pole MiniDin connector for RS232C. For the connection to PC (with cable HD2110CSNM or

C206) or printer (with cable HD2110CSNM).

Page 6

HD2105 - 6 - V2.3

Temperature-pH meter

HD2105.2

Page 7

HD2105 - 7 - V2.3

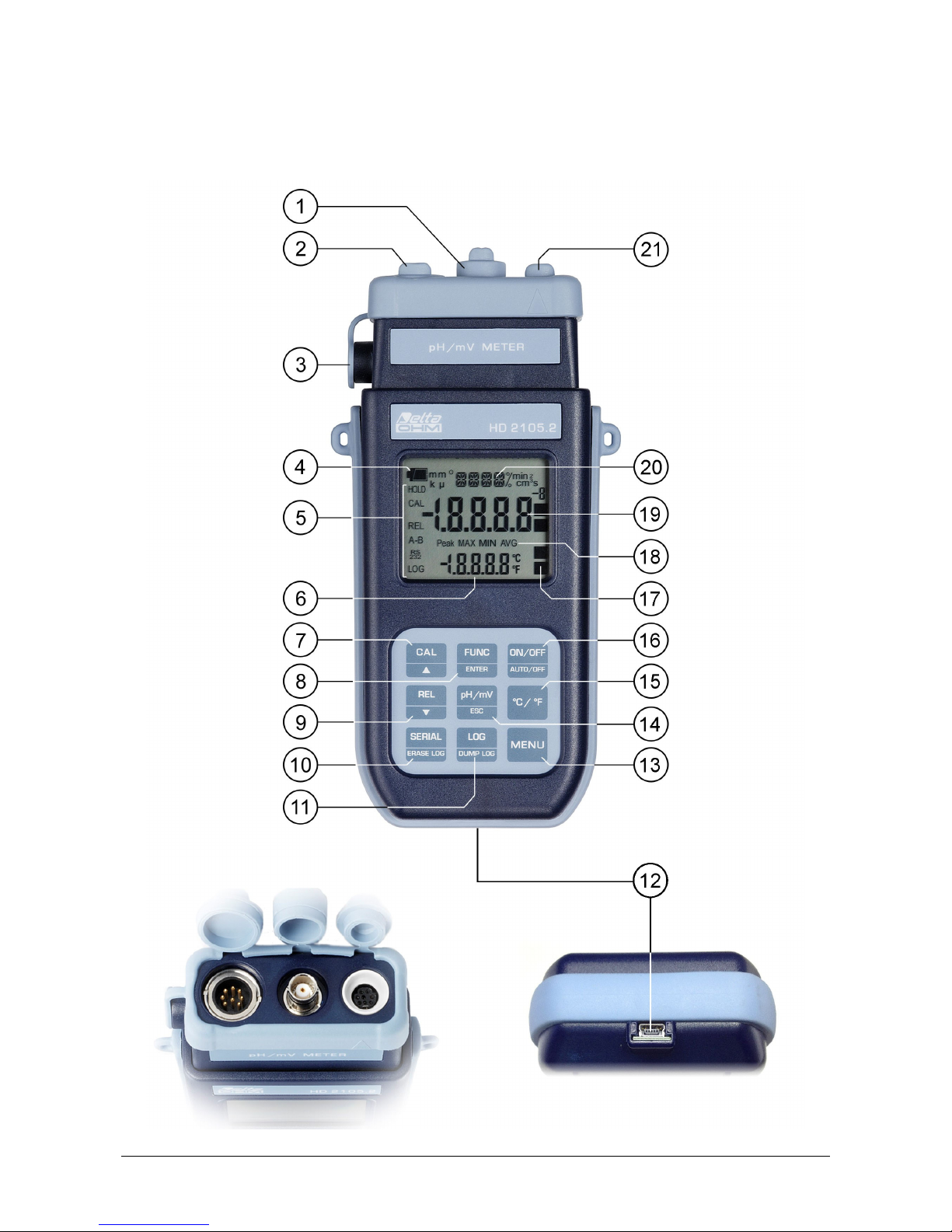

HD2105.2

1. BNC connector for the pH/mV electrode.

2. 8-pole DIN45326 connector, input for Pt100 temperature probes with SICRAM module, 4-wire

direct Pt100 probes, 2-wire Pt1000 probes complete with TP47 module.

3. External auxiliary power supply connector input.

4. Battery symbol: displays the battery charge level.

5. Function indicators.

6. Secondary display line.

7. CAL/ key: during normal operation starts the pH electrode calibration; in the menu, in-

creases the current value.

8. FUNC/ENTER key: during normal operation displays the maximum (MAX), the minimum

(MIN) and the average (AVG) of current measurements; in the menu, confirms the current selection.

9. REL/ key: enables the relative measurement (displays the difference between the current

value and the logged value when the key is pressed); in the menu, decreases the current value.

10. SERIAL/ERASE LOG key: starts and ends the data transfer to the serial communication port.

In the menu, clears the data contained in the instrument's memory.

11. LOG/DUMP LOG key: during normal operation, starts and ends the saving of the data in the

internal memory; in the menu, starts the data transfer from the instrument's memory to the PC.

12. Mini-USB type B connector for USB 2.0. For the connection to PC (with cable CP23).

13. MENU key: allows access to and exit from the menu.

14. pH/mV-ESC key when pressed for at least one second, changes the main variable measure-

ment between pH and mV. When the Auto-HOLD function is enabled, slight pressure updates

the measurement. In the menu, cancels the operation in progress without making changes.

15. °C/°F key: when the probe is not connected, allows manual modification of the temperature.

When double pressed, changes the unit of measurement for the temperature between degrees

Celsius and Fahrenheit.

16. ON-OFF/AUTO-OFF key: turns the instrument on and off; when pressed together with the

MENU key, disables the automatic turn off.

17. Electrodes efficiency indicators.

18. MAX, MIN and AVG symbols.

19. Main display line.

20. Line for symbols and comments.

21. 8-pole MiniDin connector for RS232C. For the connection to PC (with cable HD2110CSNM or

C206) or printer (with cable HD2110CSNM).

Page 8

HD2105 - 8 - V2.3

KEYBOARD AND MENU DESCRIPTION

Foreword

The instrument keyboard is composed of single-function keys, like the MENU key, and doublefunction keys such as the ON-OFF/Auto-OFF key.

In the double-keys, the function in the upper part is the “main function”, while the one in the bottom

part is the “secondary function”. When the instrument is in standard measurement mode, the main

function is active. In the menu or in conjunction with the FUNC key, the secondary function is enabled.

The pressing of a key is accompanied by a short confirmation beep: a longer beep sounds if the

wrong key is pressed.

Each key specific function is described in detail below.

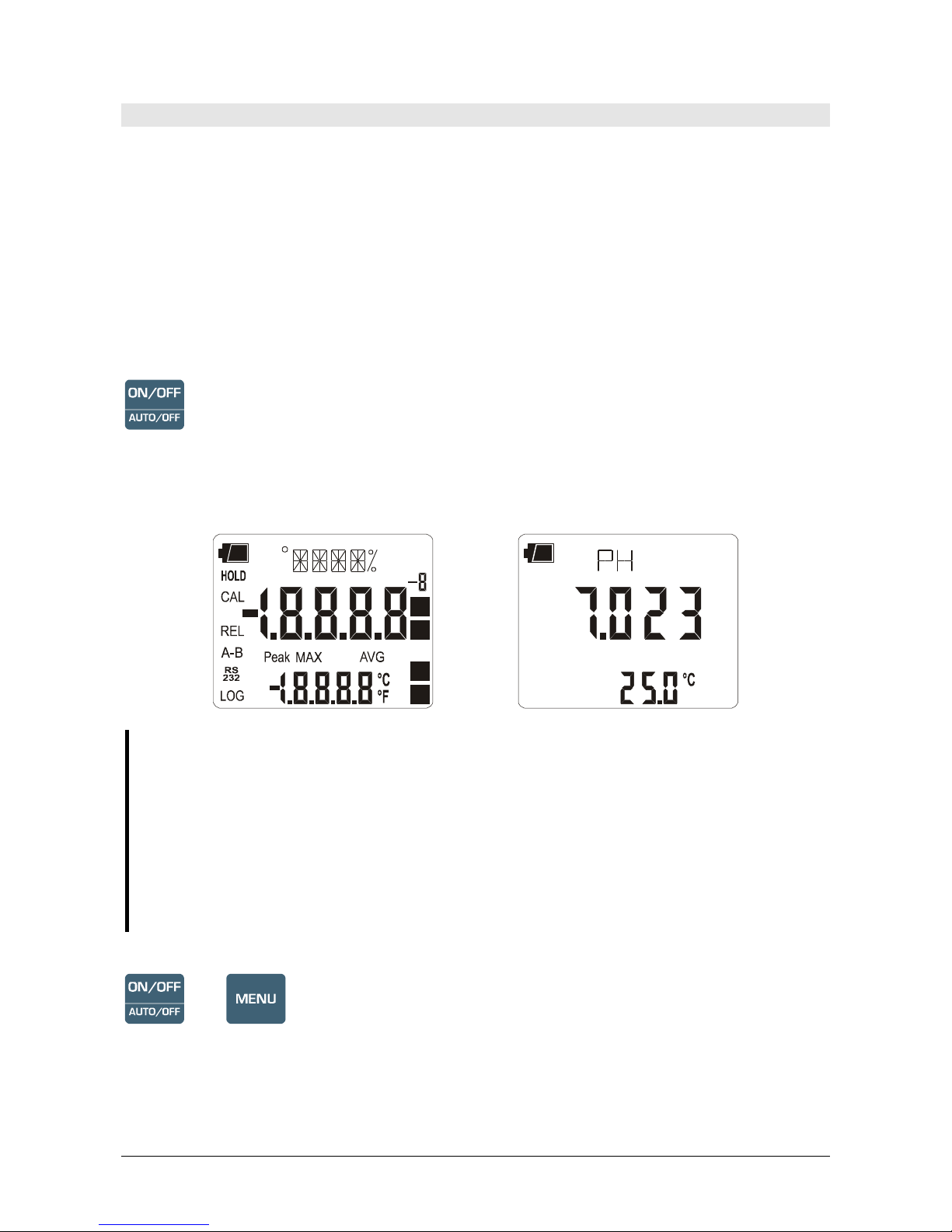

ON-OFF/Auto-OFF key

The instrument is turned on and off using the ON/OFF key. The turning on enables all display segments for a few seconds, starts an auto-test including the detection of the temperature probe connected to the input, and sets the instrument ready for normal measurement.

MIN

cm

min

s

2

3

m

µmk

>>>

During turning on, should no probes be connected, the message "NO_PRBE_

SER_NUM" is displayed in the line for symbols for a few seconds, and in the secondary

line the last manually-set temperature appears. The unit of measurement symbol (°C or

°F) starts blinking, and a letter "m" meaning "manual" appears next to the battery symbol.

When the probe fitted with SICRAM module is inserted into a functioning instrument,

the "NEW_PROB_DET" (New probe detected) message appears: as the probe's data are

captured upon turning the instrument on, it is necessary to turn the instrument off and on

again.

Replace the probes when the instrument is off.

+

Automatic turning off

The instrument has an AutoPowerOff function that automatically turns the instrument off after about

8 minutes if no key is pressed during the intervening time. The AutoPowerOff function can be dis-

abled by holding the MENU key pressed down when turning the instrument on: the battery symbol

will blink to remind the user that the instrument can only be turned off by pressing the <ON/OFF>

key.

Page 9

HD2105 - 9 - V2.3

The automatic turning off function is disabled when external power is used. On the other

hand, it cannot be disabled when the batteries are discharged.

FUNC/ENTER key

During normal measurement this enables the display and logging of the maximum (MAX), minimum (MIN) and average (AVG) value of the pH, mV and temperature measurements, updating

them with the acquisition of new samples. The acquisition frequency is once a second.

In the menu, the ENTER key confirms the current parameter and then goes to the next one.

The MAX, MIN and AVG measurements remain in the memory until the instrument is on, even after exiting the calculation function. To reset the previous values and restart with a new measurement

session, press FUNC until the message “FUNC CLR” appears, then use the arrows to select YES

and confirm using ENTER.

The pH and temperature values are displayed at the same time. According to settings in the

"RCD Mode" menu item, the maximum, minimum and average indications have different

meanings: please see the description of this menu item below.

Attention: the data captured using the Record function cannot be transferred to the PC.

CAL/ key

It increases the current parameter when used in the menu; when used in measurement mode, it

starts the pH electrode calibration (please see the chapter dedicated to calibration on page 17).

°C/°F key

When the temperature probe is connected, the measured value is used to compensate the pH measurement; the key changes the unit of measurement from degrees Celsius to Fahrenheit.

If the probe is not present, the compensation temperature must be entered manually: to manually

change the value shown in the display lower line, press °C/°F once. The temperature indicated starts

blinking. While the display is blinking, it is possible to change the compensation temperature using

the arrows ( and ). Confirm using ENTER. The display stops blinking, and that temperature is

used for compensation.

If the temperature probe is not present, to change the unit of measurement between °C and °F, it is

necessary to press twice the °C/°F key.

pH/mV-ESC key

Changes the main variable measurement between pH and mV. The selected parameter is used for

display, printing, and logging.

Page 10

HD2105 - 10 - V2.3

The instrument has an Auto-Hold function, which can be set in the MENU, that “freezes” the measurement automatically when it has been stable (within 1 mV) for over 10 seconds: the message

HOLD is displayed.

To perform a new measurement, it is necessary to press the pH/mV key.

The HOLD message starts blinking, while the display follows the actual measurement trend, until it

stabilizes again and the HOLD message remains still.

NOTE: when the Auto-Hold function is enabled, the pH/mV key allows the pH measurement to be

relaunched, and the measurement in mV is disabled. To restore the display in mV, disable the

Auto-Hold function in the menu.

In the menu, the key clears or cancels the active function (ESC).

REL/ key

In measurement mode, displays for both measurements – mV and temperature – the difference

between the current value and that measured on pressing the key. The REL message appears on

the display; press the key again to return to the current measurement.

When used in the menu, it decreases the current variable value.

MENU Key

Upon turning on the instrument, the AutoPowerOff function can be disabled by holding the MENU

key down (please see the ON-OFF key description).

The first menu item is accessed by initially pressing on the MENU key; press ENTER to go to the

following items. To modify the item displayed, use the arrow keys ( and ). The current value is

confirmed by pressing the ENTER key and the display moves on to the next parameter. If pressing

ESC the setting is cancelled.

To exit the menu, press the MENU key at any time.

The menu items are listed in this order:

1) Management of memorized data (only HD2105.2): the message “LOG_DUMP_or_E-

RAS” (Transfer data or erase) is scrolled in the comment line. The center figure reports

the number of free memory pages (FREE). All memory data are permanently erased by

pressing SERIAL/EraseLOG. By pressing LOG/DumpLOG, the data transfer of the logged

data on the serial port is started: the “BAUD-RATE” must have previously been set to the

maximum value (please see the menu items described below and the paragraph "STORING

AND TRANSFERRING DATA TO A PERSONAL COMPUTER" on page 31).

2) Identifier of the sample being measured: it is an automatically increased progressive

number associated with the single PRINT function (print interval set to 0). The index appears in the single sample printing together with date, time, pH or mV and temperature

measured values. This menu item allows the value of the first sample to be set: each time the

PRINT key is pressed, the identification ID in the printing is increased by 1 allowing progressive measurement of all measured samples. If the Auto-Hold function, described below

in this chapter, is enabled, the print time interval is forced to zero. Pressing SERIAL only

causes the print to occur when the measurement has stabilized (HOLD symbol still). Later, it

Page 11

HD2105 - 11 - V2.3

is possible to repeat the print at will, but while the HOLD mode is on, the sample identifier

number is not increased. This is useful when more labels must be printed with the same

identification code without increasing the code each time.

The message "SMPL ID REL=RSET SER=PRINT" is scrolled in the comment line: using

the arrows ( and ) the currently measured sample identifier value can be changed.

By holding the REL/ key down the proposed number is rapidly set to zero.

The instrument's heading information will be printed using the SERIAL key.

3) AUTO-HOLD function: the instrument normally operates in continuous view mode,

which is set by default. In this mode the displayed measurement is updated every second. If

the Auto-Hold function is enabled, the instrument performs the measurement and when it

stabilizes it goes in HOLD mode. To update the display indication, press pH/mV (please see

the description of the pH/mV key for further explanation).

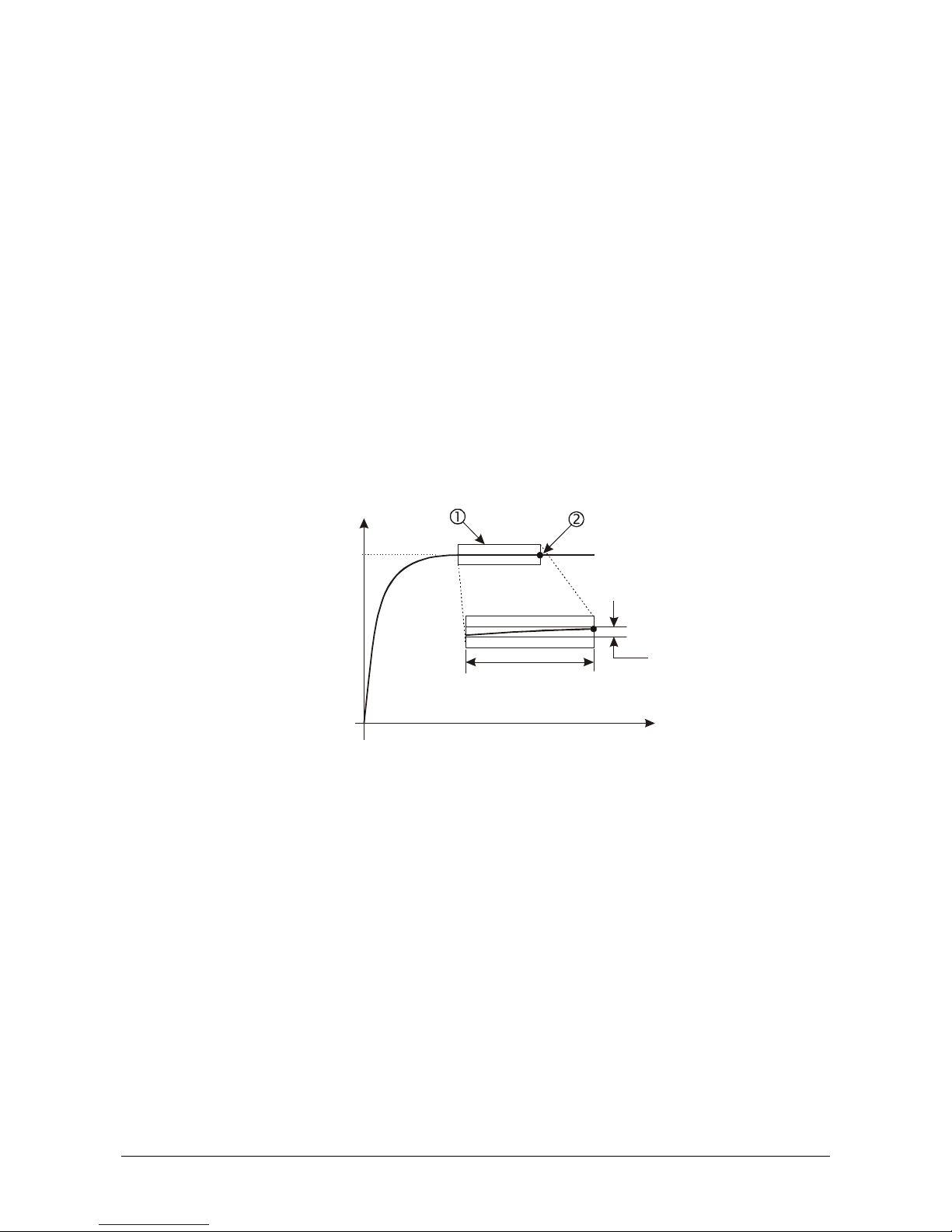

In the following figure you can see an example of the measurement process with the AutoHold function enabled. An electrode is immersed into a liquid and, to perform the measurement, the pH/mV key is pressed: The pH measurement raises progressively reaching the final value. The HOLD symbol blinks. In the stretch indicated by 1, the measurement remains

stable for 10 seconds, within two digits: at the end of this interval (point 2), the instrument

goes into HOLD mode, presenting the final stable value.

2 digit

10s

t

p

H

pH

1

To perform a new measurement, it is necessary to press again the pH/mV key.

4) Print and log interval: sets the interval in seconds between two loggings or data transfers

to the serial port. The interval can be set at 0, 1s, 5s, 10s, 15s, 30s, 60s (1min), 120s (2min),

300s (5min), 600s (10min), 900s (15min), 1200s (20min), 1800s (30min) and 3600s (1hour).

If the value 0 is set, SERIAL works on command: the sending of data to the serial port

is performed each time the key is pressed. Recording (LOG) is performed with one sec-

ond intervals even if the interval is set to 0. With an interval from 1 to 3600s, continuous

data transfer is started when the SERIAL key is pressed. To end the recording (LOG) and

continuous data transfer operations (SERIAL with an interval greater than 0), press the

same key again.

5) Sleep_Mode_LOG (Automatic turning off during recording) (only HD2105.2): this

function controls the instrument's automatic turning off during logging, occurring between

the capture of a sample and the next one. When the interval is lower than 60 seconds, the instrument will always remain on. With intervals greater than or equal to 60 seconds, it is possible to turn off the instrument between loggings: it will turn on at the moment of sampling

and will turn off immediately afterwards, thus increasing the battery life. Using the arrows

select YES and confirm using ENTER in order to enable the automatic turning off, select

NO and confirm to disable it and keep the instrument on continuously.

Page 12

HD2105 - 12 - V2.3

Note: even if Sleep_Mode_LOG=YES is selected, the instrument does not turn off for less

than one minute intervals.

6) LAST CAL m/d h/m (Last pH calibration): the display shows the month and day (m/d) in

the main line, and the hour and minutes (h/m) in the secondary line of the last pH electrode

calibration. This menu item cannot be modified. The calibration year is not displayed.

7) pH RES: selects the number of leading digits for the pH measurement: using the arrows se-

lect 1.23 to obtain the pH hundredths or 1.234 to obtain the thousandths. The chosen resolution is applied to the new logged measurements, while the previous choice still applies for

the already memorized ones.

8) BUFR_1 (First buffer): selects the value of the first buffer for the pH electrode calibration.

The preset buffers are compensated for temperature. The ATC indication is displayed in the

lower line. The USER buffer, defined by the user, is not compensated for temperature: to

change its value, go to the "SET USER BUFR" step.

Please see the paragraph dedicated to calibration on page 17.

9) BUFR_2 (Second buffer): selects the value of the second buffer for the pH electrode cali-

bration. No buffer solution values too close (less than 2pH) to the first buffer are proposed.

This is also true for the USER buffer, defined by the user at the "SET USER BUFR" step: if,

for example BUFR_1=6.860 and USER=5.000, the BUFR_2 USER does not appear among

the values because it is too close to BUFR_1. The selection NIL (=no buffer) disables the

current buffer. The USER buffer, defined by the user, is not compensated for temperature.

Please see the paragraph dedicated to calibration on page 17.

10) BUFR_3 (Third buffer): selects the value of the third buffer for the pH electrode calibra-

tion. No buffer solution values too close (less than 2pH) to the first two buffers are proposed. This is also true for the USER buffer, defined by the user at the "SET USER BUFR"

step: The selection NIL (=no buffer) disables the current buffer. The USER buffer is not

compensated for temperature.

Please see the paragraph dedicated to calibration on page 17.

11) SET USER BUFR (Set user buffer): this is a buffer whose value can be defined by the

user using the arrows; all values from 0 to 14pH are available. This buffer is not compensated for temperature, so the buffer value must be set at the actual solution temperature. As

an alternative, the correct value according to temperature can be set in the calibration phase.

12) RCD MODE (Record mode): the instrument captures a pH/mV and a temperature value

every second. If the RCD MODE parameter is set to "pH" (factory default), the maximum

and minimum values displayed using FUNC/ENTER refer to pH: the indicated temperature

is that measured at the maximum and minimum pH and is not the maximum and minimum

temperature.

If the RCD MODE parameter is set to "tp" (=temperature), the maximum and minimum

values displayed using FUNC/ENTER refer to temperature: the indicated pH is that measured at the maximum and minimum temperature and is not the maximum and minimum pH.

Finally, if the RCD MODE parameter is set to "Indep" (=independent), the maximum and

minimum values displayed using FUNC/ENTER are independent: the indicated pH and

temperature are the maximum and minimum measured values but are not necessarily referred to the same measurement moment.

13) Probe type: the message “PRBE_TYPE" is scrolled in the comment line. The main line in

the center of the display shows the type of probe connected to the instrument. The following

probes can be connected to the input:

Page 13

HD2105 - 13 - V2.3

• temperature probes Pt100 complete with SICRAM module

• 4 wire Pt100 probes through module TP47

• 2 wire Pt1000 probes through module TP47

• 2 wire Ni1000 probes through module TP47

The probes fitted with SICRAM module are automatically detected by the instrument upon

turning on: the Probe Type menu item is configured by the instrument and cannot be modi-

fied by the user.

If the direct 4-wire Pt100, Pt1000 and Ni1000 temperature probes are connected, the message "NO_PRBE_SER_NUM" appears when turning on. In this case the probe type must be

entered manually. Select Probe type using the MENU key and then select the type of probe

with the arrow keys; confirm using ENTER.

14) YEAR: to set the current year. Use the arrows to modify this parameter and confirm using

ENTER.

15) MNTH (month): to set the current month. Use the arrows to modify this parameter and con-

firm using ENTER.

16) DAY: to set the current day. Use the arrows to modify this parameter and confirm using

ENTER.

17) HOUR: to set the current hour. Use the arrows to modify this parameter and confirm using

ENTER.

18) MIN (minutes): to set the current minutes. In order to correctly synchronize the minute, it is

possible to reset the seconds by pressing the °C/°F key. Use the arrows to set the current

minute plus one, and as soon as that minute is reached press °C/°F: this synchronizes the

time to the second. Press ENTER to go onto the next item.

19) BAUD_RATE: indicates the frequency used for the serial communication with the PC.

Values from 1200 to 38400 baud. Use the arrows to modify this parameter and confirm using ENTER. The communication between instrument and PC (or serial port printer)

only works if the instrument and PC baud rates are the same. If the USB connection is

used this parameter value is automatically set (please see the details on page 31).

LOG/DUMP LOG key - only HD2105.2

In measurement mode, this function starts and stops the logging of a data block to be saved in the

instrument's internal memory. The data logging frequency is set in the "Print and log interval"

menu parameter. The data logged between a start and subsequent stop represent a block.

When the logging function is on, the LOG indication is displayed, the battery symbol blinks and a

beep is issued each time a logging occurs; the battery symbol does not appear when using an

external power supply.

To end the logging, press LOG.

If the Auto-HOLD function is enabled (please see the menu), the data logging is disabled.

The HD2105.2 can turn off during logging between a capture and the next one: the function is

controlled by the Sleep_Mode_LOG parameter. When the logging interval is less than one minute,

the logging instrument remains on; with an interval of at least one minute, it turns off between one

capture and the next if the parameter Sleep_Mode_LOG=YES.

Page 14

HD2105 - 14 - V2.3

>>>

Dump LOG - only HD2105.2

When the LOG key is pressed after the MENU key, the transfer of the logged data on the serial port

is started.

Please see the paragraph dedicated to data transfer on page 31.

SERIAL key - only HD2105.1

SERIAL/EraseLOG key - only HD2105.2

In measurement mode, this function starts and stops the data transfer to the RS232C serial output.

According to the settings entered in the Print and log interval menu item, a single sample can be

printed if Print and log interval=0 or a continuous indefinite printing of the measured data can be

set up if Print and log interval=1…3600.

The printing operation is accompanied by the display of the RS232 symbol and the blinking of the

battery symbol; when using an external power supply the battery symbol does not appear.

Press SERIAL to end the continuous printing.

Before starting the printing with SERIAL, set the baud rate. To do so, select the Baud Rate menu

item and select the maximum value equal to 38400 baud by using the arrows. Confirm by pressing

ENTER.

The DeltaLog9 software for PC will automatically set the baud rate value during connection. If you

are using a different program than DeltaLog9, be sure the baud rate is the same for both the

instrument and the PC: the communication will only work in this way.

>>>

Erase memory - only HD2105.2

When pressed after the MENU key, the SERIAL key permanently erases all the data contained in

the instrument's memory.

Page 15

HD2105 - 15 - V2.3

pH MEASUREMENT

The instrument works with pH measurement electrodes, redox potential measurement electrodes

(ORP), and specific ion electrodes. The pH measurement must always be accompanied by a temperature measurement. The probes with 4-wire Pt100, 2-wire Pt1000 or Ni1000 sensors may be

used for measuring temperature or for the automatic compensation of the Nernst coefficient with the

pH electrode.

Some probes are fitted with SICRAM module that acts as an interface between the sensor on the

probe and the instrument. There is a microprocessor circuit with a permanent memory inside the

module that enables the datalogger to recognize the type of probe connected and to read its calibration information.

The fitted with SICRAM module are automatically detected while the direct 4-wire Pt100, the

Pt1000 and Ni1000 temperature probes are not automatically detected by the instrument and must

be set up in the Probe type menu item (please see the description of the menu on page 12).

The pH or mV indication is displayed in the main line; the secondary line shows the temperature.

The electrode for pH measurement

The electrode for pH measurement, generally in glass, generates an electrical signal proportional to

the pH according to Nernst law. Of this signal the following aspects are considered:

Zero point: The pH where the electrode generates a potential of 0 mV. In most electrodes, this value

is found at about 7pH.

Offset or Asymmetry Potential: mV generated by an electrode when immersed in a buffer solution at

7pH. Generally oscillates between ± 20 mV.

Slope: response of the electrode expressed in mV per pH units. The theoretical electrode slope at

25°C is 59.16 mV/pH. When the electrode is new the slope is close to the theoretical value.

Sensitivity: it is the electrode's slope expression in relative terms. It is obtained by dividing the actual value of the slope by the theoretical value, and is expressed as a %. The asymmetry potential

and the slope vary in time with the use of the electrode, which necessitates regular calibration.

The pH electrodes must be calibrated using the buffer solutions (see the calibration chapter below).

The ORP and specific ion electrodes do not need calibration as their absolute voltage is measured.

The redox buffer solutions are only used to check the quality of a redox electrode.

No calibration of the temperature sensor is required by the user: the sensor is calibrated in

the factory and the Callendar Van Dusen parameters are recorded in the SICRAM module.

The probes are detected during turn on, and this cannot be performed when the instrument is

already on, therefore if a probe is connected and the instrument is on, it is necessary to turn it

off and on.

Page 16

HD2105 - 16 - V2.3

AUTOMATIC OR MANUAL pH COMPENSATION

In a correct measurement of pH, the results need to be expressed together with the temperature

value at which the reading is performed.

The electrode slope varies according to the temperature in a known mode according to Nernst law:

e.g., a 1pH variation, that at 25°C means 59.16mV, at 100°C means 74.04mV.

6pH 7pH

pH

8pH

74.04mV

-74.04mV

59.16mV

-59.16mV

54.20mV

-54.20mV

0mV

mV

T=100°C, 74.04mV/pH

T=25°C, 59.16mV/pH

T=0°C, 54.20mV/pH

When a temperature probe is present, the instrument automatically applies the ATC automatic temperature compensation function. To disable it, the temperature probe must be disconnected.

If the temperature probe is not present, and the correct value is not entered manually, the extent of

the error committed in pH measurement is proportional to temperature and pH value itself.

In absence of the temperature probe, the lower display shows the manually set compensation temperature (default=25°C).

To point this condition out, the °C or °F symbol blinks intermittently near the temperature value.

Moreover, on the main display an “m” (manual) is turned on near the battery symbol (if present).

On the print-outs, the MT indication is printed. Instead, if the probe is present, the AT symbol is

printed.

To manually change the compensation temperature press °C/°F once: the indicated temperature

value starts blinking. By using the arrows select the desired temperature value and confirm with

ENTER. The display stops blinking, and that temperature is used for compensation.

To change the unit of measurement between °C and °F, it is necessary to press twice the °C/°F key.

Page 17

HD2105 - 17 - V2.3

pH ELECTRODE CALIBRATION

The electrode calibration is used to compensate the zero potential and slope deviations to which the

electrode is subject with time.

The calibration frequency depends on the accuracy desired by the user and by the effects that the

measured sample have on the electrode. Generally, we recommend daily calibration, but it is the

user's responsibility from personal experience, to establish the most appropriate frequency.

The calibration may be carried out using 1, 2 or 3 points. When using 1 point, the electrode offset is

corrected, with 2 points the offset and the gain is corrected; finally, in case a three points calibration

is carried out two offsets and two slopes are calculated, the second point is the one in which the

zero is performed.

The instrument has a memory of 13 buffers with relevant temperature compensation tables (ATC)

plus an “User” buffer, not compensated. The three buffers can be selected by using the BUFR_1,

BUFR_2, BUFR_3 menu items. Usually one for the acid, one for the neutral, and one for the alkaline band will be selected:

@25°C

BUFR_1 (NEUTRAL)

6.860

6.865 7.000 7.413 7.648

BUFR_2 (ACID)

1.679 2.000 4.000 4.008

4.010

BUFR_3 (ALKALINE)

9.180

9.210 10.010

The buffers in bold are predefined in the factory, these are the “DeltaOHM” ones.

If electrode calibration was not carried out on the instrument, or the batteries have been

changed or the last calibration failed, the display blinks the CAL message.

Calibration procedure

1) Insert the temperature probe and the electrode in the solution of a calibration buffer. If no tem-

perature probe is available, use another thermometer and enter the value manually as indicated in

the paragraph “Automatic or manual pH compensation”.

2) The electrode calibration mode is started by pressing CAL.

3) Among the three prepared buffers, the instrument automatically detects the closest to the pH

value being read and flags it up on the lower display.

If the buffer is not detected the first buffer BUFR_1 is proposed.

4) At this point the CAL symbol is not blinking on the display and the following is shown from the

upper side downward:

a) the chosen buffer nominal value at 25°C (scrolling indication)

b) the pH measurement value with the current calibration

c) the temperature compensated buffer value

The detected and temperature compensated buffer value, shown in the lower line, can be modified using the arrows.

Page 18

HD2105 - 18 - V2.3

5) To proceed with the calibration press ENTER. The electrode offset mV value (OFFS) is shown

on the display for few seconds.

After a few seconds the instrument shows the measurement again, corrected according to the

new calibration, but remains in calibration mode.

Pressed repeatedly the ENTER key allows the calibration on the point to be repeated, for example, in order to obtain a more stable value.

6) To end the electrode calibration, press pH/mV (ESC) to exit calibration, or continue the calibration for the second point.

7) Extract the electrode from the buffer, clean it carefully, and insert it in the following buffer.

8) Press MENU.

The instrument displays the value detected on the new buffer: continue by repeating the steps from

point 3.

NOTES:

• After calibration, the instrument displays an electrode quality indication:

• No signal: electrode functioning.

• 1 small square blinking on the lower right: electrode almost exhausted.

• 2 small squares blinking on the lower right: electrode exhausted to be replaced.

• The 3 point calibration must always be carried out according to the fixed sequence:

NEUTRAL>>ACID>>BASIC. The basic buffer must be the last in the sequence.

• Without having pressed ENTER at all, the calibration is interrupted by pressing pH/mV

(ESC); the previous values will continue to be used.

• The buffers are always presented in the sequence set in the menu with the BUFR_1-BUFR_2-

BUFR_3 parameters. The 2 point calibration is possible using the sequence BUFR_1-BUFR_2

or BUFR_2-BUFR_3 or even BUFR_1-BUFR_3. The 3 point calibration is only possible us-

ing the exactly described sequence BUFR_1-BUFR_2-BUFR_3.

Allowed calibration sequences:

Number of

calibration

points

1 BUFR_1 BUFR_2 BUFR_3

2 BUFR_1 - BUFR_2 BUFR_2 - BUFR_3 BUFR_1 - BUFR_3

3 BUFR_1 - BUFR_2 - BUFR_3

• A buffer can be disabled in the option selection phase (MENU mode) by choosing the NIL

value. In this case, the disabled buffer is excluded from the sequence and will not be proposed.

• If no other buffer is expected after the first, as the BUFR_2 and BUFR_3 have been set to NIL,

the calibration mode is exited by pressing MENU.

• In any case where no operation is performed, the calibration mode automatically stops af-

ter 60 seconds.

• If the calibration is rejected by the instrument because it is considered to be excessively cor-

rupted, the CAL ERR message will appear, followed by a long beep. The instrument remains in

calibration mode and maintains the previous calibration values: at this point, if the calibration is

interrupted using ESC, the instrument signals the anomaly through the CAL message blinking.

Page 19

HD2105 - 19 - V2.3

Temperature characteristics of Delta OHM buffer solutions

The 13 standard buffers reported in the table on page 17 are memorized in the instruments with

relevant variations according to temperature: The characteristics of the three Delta Ohm standard

buffers at 6.86pH, 4.01pH and 9.18pH (@25°C) are reported below.

6.86 pH @ 25°C 4.01 pH @ 25°C

°C pH °C pH °C pH °C pH

0 6.98 50 6.83 0 4.01 50 4.06

5 6.95 55 6.83 5 4.00 55 4.07

10 6.92 60 6.84 10 4.00 60 4.09

15 6.90 65 6.85 15 4.00 65 4.10

20 6.88 70 6.85 20 4.00 70 4.13

25 6.86 75 6.86 25 4.01 75 4.14

30 6.85 80 6.86 30 4.01 80 4.16

35 6.84 85 6.87 35 4.02 85 4.18

40 6.84 90 6.88 40 4.03 90 4.20

45 6.83 95 6.89 45 4.05 95 4.23

9.18 pH @ 25°C

°C pH °C pH

0 9.46 50 9.01

5 9.39 55 8.99

10 9.33 60 8.97

15 9.28 65 8.94

20 9.22 70 8.92

25 9.18 75 8.90

30 9.14 80 8.88

35 9.10 85 8.86

40 9.07 90 8.85

45 9.04 95 8.83

Page 20

HD2105 - 20 - V2.3

DIRECT INPUT INTO Pt100, Pt1000 AND NI1000 TEMPERATURE PROBES

The instrument accepts the direct input of Platinum temperature probes with a 100Ω, 1000Ω resistance and Nickel temperature probes with a 1000Ω resistance.

The Pt100 are connected to 4 wires, the Pt1000 and Ni1000 to 2 wires, with the excitation current

chosen minimizing the sensor self-heating effects.

All probes with SICRAM module are calibrated in the factory; the 2 or 4-wire probes with direct

input are checked for conformity with class A tolerance according to norm IEC751 - BS1904 DIN43760.

The probes with SICRAM module are detected by the instrument; the model configuration is required for the other probes (please see the description of the Probe Type menu item on page 12).

The °C or °F unit of measurement can be chosen for display, printing, and logging using the °C/°FESC key.

How to measure

The temperature measurement by immersion is carried out by inserting the probe in the liquid for at

least 60mm; the sensor is housed in the end part of the probe.

In the temperature measurement by penetration the probe tip must be inserted to a depth of at least

60mm, the sensor is housed in the end part of the probe. When measuring the temperature on frozen

blocks it is convenient to use a mechanical tool to bore a cavity in which to insert the tip probe.

In order to perform a correct contact measurement, the measurement surface must be even and

smooth, and the probe must be perpendicular to the measurement plane.

So as to obtain the correct measurement, the insertion of a drop of oil or heat-conductive

paste is useful (do not use water or solvents). This method also improves the response time.

Instructions to connect the TP47 connector for 4-wire Pt100, Pt1000 and Ni1000 probes

All Delta Ohm probes are provided with a connector. The HD2105.1 and HD2105.2 instruments

also work with direct 4-wire Pt100, Pt1000 and Ni1000 probes manufactured by other producers:

for the instrument connection is prescribed the TP47 connector to which the probe's wires should be

welded.

The instructions to connect the Platinum or Nickel probe to the TP47 module are provided below.

The module is supplied complete with fairlead and gasket for 5mm maximum diameter cables.

Page 21

HD2105 - 21 - V2.3

Do the following to open the module and connect a probe:

unscrew the fairlead and extract the gasket, remove the label using a cutter, unscrew the ring on the

opposite side as illustrated in the figure:

Open the two module shells: the printed circuit to which the probe must be connected is housed inside. On the left there are the 1…4 points on which the sensor wires must be welded. The JP1…JP4

jumpers are in the center of the board. These must be closed with a tin bead for some type of sensors:

1

2

3

4

Pt100 3 wires

Pt1000

Ni1000

Not Used

Before welding, pass the probe cable through the fairlead and gasket.

Weld the wires as shown in the table:

Sensor TP47 card connection Jumper to close

Pt100 4 wires

4

JP4

3

JP3

1

JP1

2JP2

Pt100

4 wires

None

Pt1000 2 wires

JP4

4

JP3

3

JP1

1

JP22

Pt1000

2 wires

JP2

Ni1000

JP4

4

JP3

3

JP1

1

JP2

2

Ni1000

2 wires

JP3

Page 22

HD2105 - 22 - V2.3

Ensure the welds are clean and perfect. Once the welding operation is complete, close the two

shells, insert the gasket in the module, and screw the fairlead. At the other end of the module, enter

the ring with the O-Ring as indicated in the picture.

Make sure the cable is not twisted while you are screwing the fairlead. Now the probe is ready.

Direct connection of 4-wire Pt100 sensors

4-wire Pt100 sensors can be soldered

directly to the pins of the free female

connector without making use of the

TP47 board. The 4 wires of the Pt100

sensors have to be soldered as indicated

in the figure on the left.

In order to use this type of probe it is

necessary to set up the menu item

“Probe Type” as described at page 12.

The P100 probe is recognized upon

turning on the instrument: connect the

probe when the instrument is switched

off and then turn it on.

Sensor Direct soldering to the connector

Pt100 4 wires

View of the soldering side

of the free female connector

Page 23

HD2105 - 23 - V2.3

WARNINGS AND OPERATING INSTRUCTIONS

1. Do not expose the probes to gases or liquids that could corrode the material of the sensor or the

probe itself. Clean the probe carefully after each measurement.

2. Do not bend the probe connectors or force them upward or downward.

3. Do not bend or force the contacts when inserting the probe connector into the instrument.

4. Do not bend, deform or drop the probes, as this could cause irreparable damage.

5. Always select the most suitable probe for your application.

6. Do not use probes in presence of corrosive gases or liquids. The sensor container is made of

AISI 316 stainless steel, while the contact probe container is made from AISI 316 stainless steel

plus silver. Avoid contact between the probe surface and any sticky surface or substance that

could corrode or damage it.

7. Above 400°C and below –40°C, avoid violent blows or thermal shocks to Platinum temperature

probes as this could cause irreparable damage.

8. To obtain reliable measurements, temperature variations that are too rapid must be avoided.

9. Temperature probes for surface measurements (contact probes) must be held perpendicular

against the surface. Apply oil or heat-conductive paste between the surface and the probe in order to improve contact and reduce reading time. Whatever you do, do not use water or solvent

for this purpose. A contact measurement is always very hard to perform. It has high levels of

uncertainty and depends on the ability of the operator.

10. Temperature measurements on non-metal surfaces usually require a great deal of time due to the

low heat conductivity of non-metal materials.

11. Probes are not insulated from their external casing; be very careful not to come into contact with

live parts (above 48V). This could be extremely dangerous for the instrument as well as

for the operator, who could be electrocuted.

12. Avoid taking measurements in presence of high frequency sources, microwave ovens or large

magnetic fields; results may not be very reliable.

13. Clean the probe carefully after use.

14. The instrument is water resistant and IP66, but is not watertight and therefore should not be

immersed in water without closing the free connectors using caps. The probe connectors must

be fitted with sealing gaskets. Should the instrument fall into the water, check for any water infiltration. Gently handle the instrument in such a way as to prevent any water infiltration from

the connectors' side.

Page 24

HD2105 - 24 - V2.3

NOTES ON THE USE OF THE pH ELECTRODES

The average life of a pH electrode is about 1 year, depending on the use and maintenance.

The electrodes used at high temperatures or in strong alkaline environments normally have a shorter

life.

The new electrodes should be conditioned for half a day immersed in a 6.86pH or 4pH buffer.

Calibrate the electrode using buffer solutions close to the values to be measured. A new electrode

should always be calibrated at neutral pH (6.86pH) as first point, and at least in a second point.

Following are listed some problems that frequently occur and the possible solutions.

Wrong pH measure. Perform the following checks:

Check the diaphragm is not blocked and if necessary clean it using HD62PT solution.

Check the reference system is not polluted and, if the electrode is refillable, replace the electrolyte.

Check that the tip of the electrode has no air bubbles inside and that the electrode is sufficiently

immersed.

Even residues of dirt deposited on the membrane can alter the measure: use the solution for protein

cleaning HD62PP.

Slow response and wrong measures. A possible cause can be the aging or the erosion of the

membrane, or a short-circuit in the connector.

Storage. Store the electrode immersed in the solution HD62SC.

Page 25

HD2105 - 25 - V2.3

INSTRUMENT SIGNALS AND FAULTS

The following table lists all error indications and information displayed by the instrument and supplied to the user in different operating situations:

Display indications Explanation

ERR

This message appears if the pH measurement exceeds the

-2.000pH…19.999pH limits, if the mV measurement exceeds the

±2.4V limits, if the temperature probe, already detected by the instru-

ment, is disconnected. At the same time an intermittent beep is issued.

PROB COMM LOST

This appears if the probe, has already been detected by the instrument,

but is disconnected. At the same time an intermittent beep is issued.

OVER

Measurement overflow: this appears when the probe measures a value

exceeding the measurement range or the mV measurement is included

in the +2.0…+2.4V range.

UNDR

Measurement overflow: this appears when the mV measurement is included in the -2.4…-2.0V range.

LOG

MEM

FULL

Memory full; the instrument cannot store further data, the memory

space is exhausted.

NEW PROBE DET

This message appears when a probe is inserted into a functioning instrument. Turn the instrument off and then back on again.

PROB

ERR

A probe with SICRAM module has been inserted when not admissible

for that specific instrument.

SYS

ERR

#

Instrument management program error. Contact the instrument's supplier and communicate the numeric code # reported by the display.

CAL

LOST

Program error: it appears after turning on for a few seconds. Contact

the instrument's supplier.

CAL

blinking

Calibration not completed correctly.

BATT TOO LOW

CHNG NOW

Indication of insufficient battery charge appearing on turning on. The

instrument issues a long beep and turns off. Replace the batteries.

Page 26

HD2105 - 26 - V2.3

The following table reports the indications provided by the instrument as they appear on the display,

together with their description.

Display indications Explanation

>>>_LOG_DUMP_or_ERAS

transfer or erase data

>>>_PRBE_TYPE

type of probe connecte

d

AUTO-HOLD

automatic function holding the displayed measurement

BATT TOO LOW - CHNG NO

W

battery discharged - replace it immediatel

y

BAUDRATE >>

>

baud rate valu

e

BUFR_1

first buffer value

BUFR_2

second buffer value

BUFR_3

third buffer valu

e

CAL ERR

calibration error

COMM STO

P

p

rinting complete

COMM STRT

p

rinting starte

d

DAY

_

da

y

DUMP_END

data transfer complete

DUMP_In_PROG >>

>

data transfer in progress

FUNC CLR

max, min and average values clearing

FUNC CLRD

max, min and average values cleare

d

HOUR

hour

LAST CAL m/d h/m

last calibration date month/day hour/minutes

LOG In PROG

logging in progress

LOG MEM FULL

memory full

LOG_CLRD

memory data cleare

d

LOG_STO

P

logging complet

e

LOG_STRT

logging starte

d

MIN >>> USE_UNIT_TO_ZERO SEC

minutes >>> use the UNIT key to reset the seconds

MNTH

month

NEW_PROB_DET

new probe detected

NIL

disable current buffer

OFFS

offset

OVER

maximum limit exceede

d

pH RES

p

H measurement resolution

PLS_EXIT >>> FUNC RES_FOR_FACT ONLY

p

lease exit using ESC >>> function reserved to factory calibra-

tion

PRBE_SER #### ###

#

serial number #### #### of the connected probe

PRNT AND LOG INTV

p

rinting and logging intervals

PRNT INTV >>

>

p

rinting interval

PROB COMM LOST

lost communication with probe

PROB ERR

error - unexpected probe

RCD MODE

record function operating mode (max, min, avg)

SET USER BUFR

user define buffer value

SLP_MODE_LOG

turning off during recording mode

SLPE%

gain %

SMPL ID REL=RSET SER=PRINT

identifier of the sample - REL=reset - SERIAL=print heading

SYS ERR

#

p

rogram error number

#

UNDR

minimum limit exceede

d

YEAR

year

Page 27

HD2105 - 27 - V2.3

LOW BATTERY WARNING AND BATTERY REPLACEMENT

The battery symbol

on the display constantly shows the battery charge status. To the extent that batteries have discharged, the symbol "empties". When the charge decreases still further it starts blinking…

In this case, batteries should be replaced as soon as possible.

If you continue to use it, the instrument can no longer ensure correct measurement. The memory

data are maintained.

If the battery charge level is insufficient, the following message appears when you turn the instrument on:

BATT TOO LOW

CHNG NOW

The instrument issues a long beep and turns off. In this case, replace the batteries in order to

turn the instrument back on.

In order to avoid data loss, the logging session is ended, if the HD2105.2 is logging and battery

voltage falls below the minimum operating level.

The battery symbol turns off when the external power supply is connected.

To replace the batteries, switch the instrument off and unscrew the battery cover counter clockwise.

After replacing the batteries (4 1.5V alkaline batteries - type AA) screw the cover on clockwise.

After replacing the batteries, the date, time, baud rate, type of probe, printing interval, logging parameters must be set again: in order to simplify the operation, on insertion of the new batteries

the instrument turns on automatically and requests these parameters in sequence. To go to the

next item press ENTER; to return to measurement mode, press MENU.

Page 28

HD2105 - 28 - V2.3

MALFUNCTIONING UPON TURNING ON AFTER BATTERY REPLACEMENT

After replacing the batteries, the instrument may not restart correctly; in this case, repeat the operation. After disconnecting the batteries, wait a few minutes in order to allow circuit condensers to

discharge completely; then reinsert the batteries.

WARNING ABOUT BATTERY USE

• Batteries should be removed when the instrument is not used for an extended time.

• Flat batteries must be replaced immediately.

• Avoid batteries leaking.

• Always use good quality leakproof alkaline batteries. Sometimes on the market, it is possi-

ble to find new batteries with an insufficient charge capacity.

INSTRUMENT STORAGE

Instrument storage condit ions:

• Temperature: -25…+65°C.

• Humidity: less than 90%RH without condensation.

• Do not store the instrument in places where:

Humidity is high.

The instrument may be exposed to direct sunlight.

The instrument may be exposed to a source of high temperature.

The instrument may be exposed to strong vibrations.

The instrument may be exposed to steam, salt or any corrosive gas.

The instrument case is made of ABS plastic and the protections are rubber: do not use any incompatible solvent for cleaning.

Page 29

HD2105 - 29 - V2.3

SERIAL INTERFACE AND USB

The HD2105.1 and HD2105.2 instruments are fitted with an electrically isolated RS-232C serial interface; the HD2105.2 also has an USB 2.0 interface.

The following serial cables can be used:

• HD2110CSNM: serial connection cable with 8-pole MiniDin connector on one end and

9-pole Sub D connector on the other end;

• C.206: serial connection cable with 8-pole MiniDin connector on one end and USB type A

connector on the other end. With integrated RS232/USB converter;

• CP23: connection cable with Mini-USB type B connector on one end and USB type A con-

nector on the other end (only for HD2105.2).

The connection via the C.206 cable requires the previous installation of the cable USB drivers. Install the drivers before connecting the C.206 cable to the PC.

The connection via the CP23 cable does not require the installation of USB drivers: when connecting

the instrument to the PC, the Windows® operating system automatically recognizes the device as an

HID device (Human Interface Device) and uses the drivers already included in the operating system.

Cable

Instrument

port

PC

port

Installation of

USB drivers

HD2110CSNM RS232 (MiniDin) RS232 (9-pole SubD) No

C.206 RS232 (MiniDin) USB Yes

CP23 USB (Mini-USB) USB No

The instrument standard serial transmission parameters are:

• Baud rate 38400 baud

• Parity None

• N. bit 8

• Stop bit 1

• Protocol Xon/Xoff

It is possible to change the RS232C serial port baud rate by setting the "Baudrate" parameter in the

menu (please see page 13). The possible values are: 38400, 19200, 9600, 4800, 2400, 1200. The

other transmission parameters are fixed.

The USB 2.0 connection does not require the setting of parameters.

The instruments are provided with a complete set of commands and data queries to be sent via the PC.

The serial commands work with a standard serial communication program (e.g. Hyperterminal) only

through the RS232 serial port of the instrument, using the cable HD2110CSNM or the cable C.206.

All the commands transferred to the instrument must have the following structure:

XYcr where: XY is the command code and cr is the Carriage Return (ASCII 0D)

Command Response Description

P0 & Ping (locks the instrument keyboard for 70 seconds)

P1 & Unlocks the instrument keyboard

S0 AT 21.3 6.778

Captured measurements (24 characters) AT = automatic temperature

compensation, temperature, pH or mV.

G0 Model HD2105 -2 Instrument model

Page 30

HD2105 - 30 - V2.3

Command Response Description

G1 M=pH / Thermometer Model description

G2 SN=12345678 Instrument serial number

G3 Firm.Ver.=01-01 Firmware version

G4 Firm.Date=2004/06/15 Firmware date

G5 cal 0000/00/00 00:00:00 Calibration date and time

G6 Probe=Sicram Pt100 Type of probe connected to input

G7 Probe SN=11119999 Probe serial number

G8 Probe cal.=2004/01/12 Probe calibration date

GB User ID=0000000000000000 User code (set with T2xxxxxxxxxxxxxxxx)

GC Print instrument's heading

K1

PRINTOUT IMMEDIATE

MODE

Immediate printing of data

K0 Stop printing data

K4 & Start logging data

K5 & Stop logging data

K7 & Enable REL function

K6 & Disable REL function

KP & Auto-power-off function=ENABLE

KQ & Auto-power-off function=DISABLE

LN &1999 Number of free pages in the flash memory

LD PRINTOUT OF LOG Print data logged in flash

LE & Erase data in flash memory

LUAn

&

Sets the unit of measurement for the temperature. n=0 > °C

n=1 > °F

LUBn

&

Sets the unit of measurement for the pH. n=0 > pH

n=1 > mV

RA & # Reading of LOG/PRINT interval set

RP & 600 Battery level (Resolut. 0.01V)

RUA U= °C Channel A unit of measurement

RUB U= pH Channel B unit of measurement

WA# &

Setting LOG/PRINT interval.

# is a hexadecimal number 0…D that represents the position of the in-

terval in th e list 0, 1, 5, 10, …, 3600 seconds.

WC0 & Setting SELF off

WC1 & Setting SELF on

Command characters are exclusively upper case characters. Once a correct command is entered, the

instrument responds with “&”; when any wrong combination of characters is entered, the instrument responds with “?”. The instrument response strings end with the sending of the CR command

(Carriage Return). The instrument does not send the LF command (Line Feed).

Before sending commands to the instrument via the serial port, locking the keyboard to avoid functioning conflicts is recommended: use the P0 command. When complete, restore the keyboard with

the P1 command.

Page 31

HD2105 - 31 - V2.3

STORING AND TRANSFERRING DATA TO A PERSONAL COMPUTER

The HD2105.1 and HD2105.2 instruments can be connected to a personal computer via an RS232C

serial port or USB 2.0 port, and exchange data and information through the DeltaLog9 software

running in a Windows operating environment. Both models can send in real time input measured

values directly to a PC, through the PRINT function; the HD2105.2 can also store the values

measured by using the Logging function (LOG key) in its internal memory. If necessary, the data

stored in the memory can be transferred to a PC later.

THE LOGGING FUNCTION - ONLY FOR HD2105.2

The Logging function allows the recording up to 40000 data pair [T-pH] registered by the probe

connected to the inputs. Logging always includes two parameters. Each data pair is composed of:

[temperature in °C or °F], [pH or mV]. The time interval between two consecutive measurements

can be set from 1 second to 1 hour. The logging starts by pressing the LOG key and ends by pressing the same key again: the data memorized in this way form a continuous block of data. The

logged parameters are selected using the “°C/°F” and “pH/mV-ESC” keys.

See the description of the menu items on page 10.

If the automatic turning off option between two recordings (MENU >> Sleep_Mode_LOG) is en-

abled, upon pressing the LOG key the instrument logs the first data and turns off. 15 seconds before

the next logging instant, it turns on again to capture the new sample, and then turns off.

The data stored in the memory can be transferred to a PC using the DUMP LOG command: MENU

>> LOG. During data transfer the display shows the message DUMP; to stop the data transfer press

ESC on the instrument or on the PC.

CLEARING THE MEMORY - ONLY FOR HD2105.2

To clear the memory use the Erase Log function (MENU >> SERIAL).

The instrument starts clearing the internal memory; at the end of the operation, it goes back to normal display.

NOTES:

• Data transfer does not cause the memory to be erased; the operation can be repeated as many

times as required.

• The stored data remain in the memory independently of battery charge conditions.

• In order to print the data to a parallel interface printer, you must use a parallel-serial adaptor (not

supplied).

• The direct connection between instrument and printer via a USB connector does not work.

• Some keys are disabled during logging. The following keys work: ON/OFF, FUNC (Max-Min-

Avg) and SERIAL.

• The recording started with the display in Max-Min-Avg mode proceeds normally with the actual

measured values. Only the display shows respectively the Max, Min or Avg values.

• The logging is disabled, if the Auto-HOLD funct ion is enabled.

• If the logging is started when the display is in REL mode, the relative values are logged.

• It is possible to activate both the logging (LOG) and direct transfer (PRINT) functions at the

same time.

Page 32

HD2105 - 32 - V2.3

THE PRINT FUNCTION

The PRINT function sends the measurements taken in real time by the instrument inputs directly to

a PC or a printer. Print data units of measurements are the same as those used on the display. Printing always includes two parameters. Each pairs data is composed of: temperature in °C or °F, pH or

mV. The printed parameters are selected using the “°C/°F”, and “pH/mV” keys.

The function is started by pressing SERIAL. The time interval between two consecutive prints can

be set from 1 second to 1 hour (please see the Print and log interval menu item on page 10). If the

print interval is equal to 0, by pressing SERIAL the single data is sent to the connected device. If

the print interval is higher than 0, the data transfer continues until the operator stops it by pressing

SERIAL again.

The PRINT function works with a standard serial communication program (e.g. Hyperterminal) only

through the RS232 serial port of the instrument, using the cable HD2110CSNM or the cable C.206.

Connect the HD40.1 printer using cable HD2110CSNM.

NOTES:

• The print out is formatted across 24 columns.

• Some keys are disabled during serial transmission. The following keys work: ON/OFF, FUNC

(Max-Min-Avg) and LOG.

• The FUNC key has no effect on the print-outs, only on the display.

• If the Auto-Hold function is enabled, the print time interval is forced to zero: pressing SERIAL

only causes the print to occur when the measurement has stabilized (HOLD symbol still). Later,

it is possible to repeat the print at will, but while the HOLD mode is on, the sample identifier

number is not increased. This is useful when more labels must be printed with the same identification code without increasing the code each time.

• If the serial transfer is started when the display is in REL mode, the relative values are trans-

ferred.

• It is possible to activate both the logging (LOG) and direct transfer (PRINT) functions at the

same time.

Examples of print-outs obtained using the HD40.1 printer

Page 33

HD2105 - 33 - V2.3

CONNECTION TO A PC

HD2105.1

Connection to the PC with the cable:

• HD2110CSNM: 8-pole MiniDin connector on one end and 9-pole Sub D connector on the

other end;

• C.206: 8-pole MiniDin connector on one end and USB type A connector on the other end.

With integrated RS232/USB converter (requires the installation of the USB drivers).

HD2105.2

Connection to the PC with the cable:

• CP23: Mini-USB type B connector on one end and USB type A connector on the other end;

• HD2110CSNM: 8-pole MiniDin connector on one end and 9-pole Sub D connector on the

other end;

• C.206: 8-pole MiniDin connector on one end and USB type A connector on the other end.

With integrated RS232/USB converter (requires the installation of the USB drivers).

The instruments are supplied with the DeltaLog9 software that manages the connection, data

transfer, graphic presentation, and printing operations of the captured or logged measurements.

The DeltaLog9 software is complete with "On-line Help" (also in PDF format) describing its

characteristics and functions.

CONNECTION TO THE RS232C SERIAL PORT OF THE INSTRUMENT

1. The measurement instrument must be switched off.

2. Using the Delta Ohm HD2110CSNM or C.206 cable, connect the measurement instrument to the

first free RS232C (COM) or USB serial port of the PC.

3. Turn on the instrument and set the baud rate to 38400 (MENU >> ENTER until the Baud Rate

parameter >> select 38400 using the arrows >> confirm with ENTER). The parameter remains in

the memory until replacement of the batteries.

4. Start the DeltaLog9 application and press CONNECT. Wait for the connection to occur and fol-

low the indications on the screen. For a description of the DeltaLog9 application, please refer to

its on-line Help.

CONNECTION TO THE USB 2.0 PORT OF THE INSTRUMENT - ONLY FOR HD2105.2

The connection via the CP23 cable does not require the installation of USB drivers: when connecting

the instrument to the PC, the Windows® operating system automatically recognizes the device as an

HID device (Human Interface Device) and uses the drivers already included in the operating system.

To check if the connection has been successfully completed, double-click on "Device Manager"

from the Control Panel. The following items should appear:

"Human Interface Device" >> "HID-compliant device"

"Human Interface Device" >> "USB Human Interface Device"

When the USB cable is disconnected, the items disappear and reappear when it is connected again.

Page 34

HD2105 - 34 - V2.3

NOTES ABOUT WORKING AND OPERATIVE SAFETY

Authorized use

The technical specifications as given in chapter "TECHNICAL CHARACTERISTICS" must be observed. Only the operation and running of the measuring instrument according to the instructions

given in this operating manual is authorized. Any other use is considered unauthorized.

General safety instructions

This measuring system is constructed and tested in compliance with the EN 61010-1:2010 safety

regulations for electronic measuring instruments. It left the factory in a safe and secure technical

condition.

The smooth functioning and operational safety of the measuring system can only be guaranteed if

the generally applicable safety measures and the specific safety instructions in this operating manual are followed during operation.

The smooth funct ioning and operational safety of the instrument can only be guaranteed under the

environmental and electrical operating conditions that are in specified in chapter "TECHNICAL

CHARACTERISTICS".

Do not use or store the product in places such as listed below:

• Rapid changes in ambient temperature which may cause condensation.

• Corrosive or inflammable gases.

• Direct vibration or shock to the instrument.

• Excessive induction noise, static electricity, magnetic fields or noise.

If the measuring system was transported from a cold environment to a warm environment, the formation of condensate can impair the functioning of the measuring system. In this event, wait until

the temperature of the measuring system reaches room temperature before putting the measuring

system back into operation.

Obligations of the purchaser

The purchaser of this measuring system must ensure that the following laws and guidelines are observed when using dangerous substances:

EEC directives for protective labour legislation

National protective labour legislation

Safety regulations

Page 35

HD2105 - 35 - V2.3

INSTRUMENT TECHNICAL CHARACTERISTICS

Instrument

Dimensions (Length x Width x Height) 185x90x40mm

Weight 470g (complete with batteries)

Materials ABS, rubber

Display 2x4½ digits plus symbols

Visible area: 52x42mm

Operating conditions

Operating temperature -5…50°C

Warehouse temperature -25…65°C

Working relative humidity 0…90%RH without condensation

Protection degree IP66

Power Supply

Batteries 4 1.5V type AA batteries

Autonomy 200 hours with 1800mAh alkaline batteries

Power absorbed with instrument off 20μA

Mains (cod. SWD10) Output mains adapter 100-240Vac/12Vdc-1A

Units of measurement pH, mV, °C, °F

Security of memorized data Unlimited, independent of battery charge

conditions

Time

Date and time Schedule in real time

Accuracy 1min/month max drift

Measured values storage - model HD2105.2

Type 2000 pages containing 17 samples each

Quantity 34000 pairs of measurements composed

of [pH or mV] and [°C o °F].

Selectable storage interval 1s, 5s, 10s, 15s, 30s, 1min, 2min, 5min,

10min, 15min, 20min, 30min and 1hour

Serial interface RS232C

Type RS232C electrically isolated

Baud rate Can be set from 1200 to 38400 baud

Data bit 8

Parity None

Stop bit 1

Flow Control Xon/Xoff

Serial cable length Max 15m

Selectable print interval immediate or 1s, 5s, 10s, 15s, 30s, 1min,

2min, 5min, 10min, 15min, 20min, 30min

and 1hour

Page 36

HD2105 - 36 - V2.3

USB interface - model HD2105.2

Type 1.1 - 2.0 electrically isolated

Connections

Input module for the temperature probes 8-pole male DIN45326 connector

pH/mV input Female BNC

RS232 serial interface 8-pole MiniDin connector

USB interface (only HD2105.2) Mini-USB type B connector

Mains adapter (cod. SWD10) 2-pole connector (positive at centre)

Measurement of pH by instrument

Measurement range -2.000…+19.999pH

Resolution 0.01 or 0.001pH selectable from menu

Accuracy ±0.001pH ±1digit

Input impedance >1012Ω

Calibration error @25°C |Offset| > 20mV

Slope > 63mV/pH or Slope < 50mV/pH

Sensitivity > 106.5% or Sensitivity < 85%

Automatic/manual temperature compensation -50…+150°C

Standard solutions automatically detected (@25°C)

1.679pH - 2.000pH - 4.000pH - 4.008pH -

4.010pH - 6.860pH - 6.865pH - 7.000pH -

7.413pH - 7.648pH - 9.180pH - 9.210pH -

10.010pH

Measurement of mV by instrument

Measurement range -1999.9…+1999.9mV

Resolution 0.1mV

Accuracy ±0.1mV ±1digit

Drift after 1 year 0.5mV/year

Measurement of temperature by instrument

Pt100 measurement range -200…+650°C

Pt1000 measurement range -200…+650°C

Ni1000 measurement range -50…+250°C

Resolution 0.1°C

Accuracy ±0.1°C ±1digit

Drift after 1 year 0.1°C/year

Page 37

HD2105 - 37 - V2.3

TECHNICAL DATA OF PROBES

pH ELECTRODES

ORDER CODE

MEASURING RANGE

AND USE

DIMENSIONS

KP20

0…14pH / 0…80°C / 2bar

Glass body - GEL filled

1 ceramic diaphragm

Waste water, Drinking wa-

ter, Water emulsions, Gal-

vanic, Fruit-juices, Water

suspensions, Paints, Titra-

tion, Varnish.

KP30

0…14pH / 0…80°C / 2bar

Glass body - GEL filled

1 ceramic diaphragm

Cable L=1m with BNC

Waste water , Drinking wa-

ter, Water emulsions, Gal-

vanic, Paints, Varnish, Wa-

ter suspensions, Fruit-juices

Titration.

KP50

0…14pH / -5…100°C / 2bar

Glass body - GEL filled

1 Teflon ring diaphragm

Varnish, Cosmetics, Water

emulsions, Galvanic, Creams,

Deionised water, TRIS

buffer, Drinking water, Fruit-

juices , Solutions of low ionic

content, Mayonnaise, Pre-

served foods, Paints, Titra-

tion, Titration in water solu-

tions, Water suspensions,

Soap, Waste water, Viscous

samples.

KP61

2…14pH / 0…80°C / 2bar

Glass body

Liquid reference

3 ceramic diaphragms

Waste water, Mixtures,

Bread, Fruit-juices , Varnish,

Cosmetics, Creams, Deionised water, Drinking water,

Water emulsions, Galvanic,

Soap, Yoghurt, Milk, Titration, Preserved foods, Titration in water solutions, Wa-

ter suspensions, Mayon-

naise, Wine, Solutions of

low ionic content, Butter,

Proteic substances, Paints,

Viscous samples.

Page 38

HD2105 - 38 - V2.3

ORDER CODE

MEASURING RANGE

AND USE

DIMENSIONS

KP62

0…14pH / 0…80°C / 2bar

Glass body– GEL filled

1 ceramic diaphragm

Paints, Varn ish, Drinkin g wa-

ter, Water emulsions, Fruit-

juices , Galvanic, Water sus-

pensions, Titration, Waste

water.

KP63

0…14pH / 0…80°C / 1bar

Glass body

Liquid reference KCl 3M

1 ceramic diaphragm

Cable L=1m with BNC

Paints, Varn ish, Drinkin g wa-

ter, Water emulsions, Fruit-

juices , Galvanic, Water sus-

pensions, Titration, Waste

water.

KP64

0…14pH / 0…80°C / 0.1bar

Glass body

Liquid reference KCl 3M

Teflon ring diaphragm

Paints, Varnish, Cosmetics,

Creams, Deionised water,

Drinking water, Water emul-

sions, Fruit-juices, Soap, So-