Page 1

SCREW

GENERAL

The unit is manufactured, checked and supplied in

accordance with our published specification, and when

installed and used in normal or prescribed

applications, with the lid in place and within the

parameters set for mechanical and electrical

performance, will not cause danger or hazard to life or

limb.

HEALTH AND SAFETY AT WORK ACT 1974

WARNINGS

1. THE USERS ATTENTION IS DRAWN TO

THE FACT THAT, WHEN THE UNIT IS ‘LIVE’

WITH RESPECT TO ELECTRICAL OR

PRESSURE SUPPLIES, A HAZARD MAY

EXIST IF THE UNIT IS OPENED OR

DISMANTLED.

2. UNITS MUST BE SELECTED AND

INSTALLED BY SUITABLY TRAINED AND

QUALIFIED PERSONNEL IN ACCORDANCE

WITH APPROPRIATE CODES OF PRACTICE

SO THAT THE POSSIBILITY OF FAILURE

RESULTING IN INJURY OR DAMAGE

CAUSED BY MISUSE OR MISAPPLICATION

IS AVOIDED.

OPERATING PRINCIPLES

A diaphragm is used to sense the difference between

two pressures applied to either side of the diaphragm.

The diaphragm transmits a force proportional to the

applied pressure difference to a push rod. The rod is

restrained by an adjustable spring. When the force on

the rod overcomes the spring tension the rod moves

and operates a switch or switches. On reduction of

the applied pressure difference the force applied to the

rod also falls, the rod is restored to its original position

by the spring, and the switch or switches reset.

TERMINAL ENCLOSURE CODE K (Fig 4 & 9)

– INSTALLATION

Terminal enclosure is rated IP65 for outdoor use.

This is a certified enclosure Zone 1 (Div 1) IEC 79-1

BS 5501: Parts 1 and 5: EN 50 014 and EN 50 018

EExd IIC T6.

Instrument enclosure is certified to Zone 1 (Div 1) IEC

79-1 BS 5501: Parts 1 and 5: EN 50 014 and EN 50

018 Cenelec.

WARNING: Lid and adaptors. It is a safety

requirement that at least 5 full threads are engaged

when the unit is in operation. Never operate the unit

unless this condition is met. Do not use greases or

lubricants not compatible with the environment,

process or aluminium.

REPLACEMENT PARTS

Use only factory authorised parts and procedures.

The only parts normally recommended for site

replacement are the microswitches. However, in some

circumstances other spares kits are available. Apply

for details quoting the serial number and full product

code.

WARRANTIES – SEE CONDITIONS OF SALE

INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS FOR

DIAPHRAGM ACTUATED SERIES GR

PRESSURE DIFFERENCE SWITCHES

(MODELS GR3 & GR6)

ISSUE E 02/10

PRODUCT CODE

ENCLOSURE

MODEL

ELECTRICAL ENTRY

MATERIAL OF WETTED PARTS

RANGE

SWITCHING OPTIONS

PROCESS CONNECTION

OPTIONS AND TREATMENTS

SPECIAL ENGINEERING

ESGAAN DOWNWARD FACING CONNECTIONS

5 % FS

SWITCH

NORMAL

REVERSE

PRESSURE

Fig 2

DRIVER

LOCATION

SLOTS

LOWEST SET

POINT

HIGHEST

SET POINT

ADJUST

RIGHT TO

LEFT TO

INCREASE

SET POINT

Fig 3

INSTALLATION

The instruments are designed to be mounted vertically.

They can be mounted either direct to process or to a wall

or panel using the backplate provided. Select the

mounting point so as to avoid excessive shock, vibration or

temperature fluctuation. Instruments should be mounted

to avoid excessive heat transfer from the process lines or

adjacent plant.

If sudden changes of pressure (pulsations) are likely then

we recommend that snubbers are fitted between the

process line and switch.

Use a spanner to support the process connection when

fitting the instrument. DO NOT OVERTIGHTEN.

WARNING: CHECK THE CONNECTION THREAD SIZE

AND SPECIFICATION ON THE UNIT TO AVOID

MISMATCHING WITH THE PROCESS CONNECTION

ADAPTOR. SEE DIGIT 11 OF PRODUCT CODE.

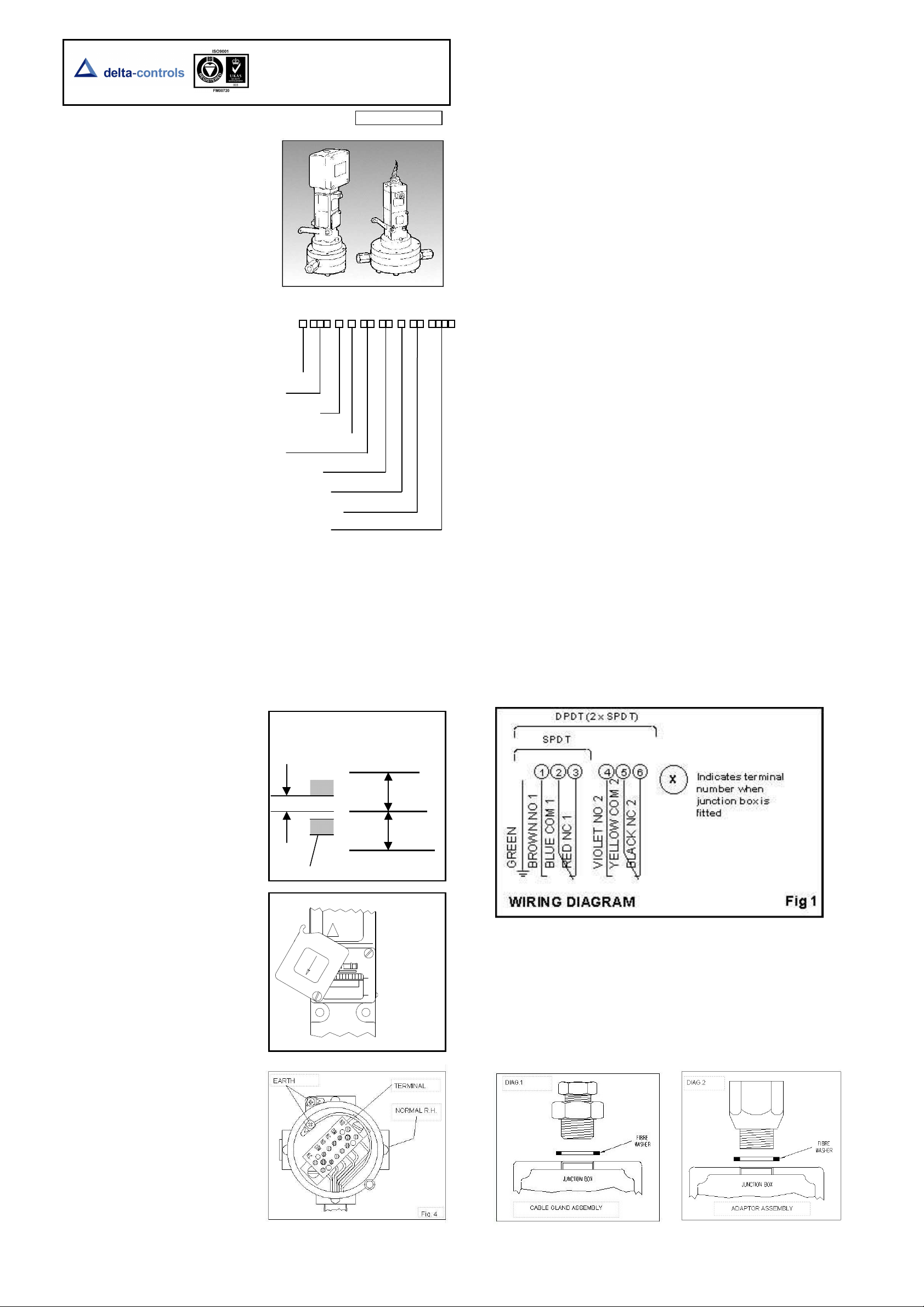

WIRING (Fig 1)

Terminal Enclosure Version (Fig 4)

Wire in accordance with local and national codes. Use

cables no larger than 2.5 mm2 (14 AWG). Deliver

electrical connection through a suitable cable gland, which

will maintain the IP rating of the instrument. Insert bare

wires fully into the terminal block and tighten securely.

Keep wiring tails to a minimum.

Flying Lead Version

The leads are factory sealed so it is unnecessary to seal

the conduit to the conduit nipple. However, flying leads

must be terminated in accordance with local and national

codes. Each conductor is provided with an identity tag. If

these become detached refer to the colour code in the

wiring diagram.

CERTIFIED ENCLOSURES

All Series GR Pressure Difference Switches can be

supplied with BASEEFA certified enclosures to the

following standards:

Zone 1 (Div 1) IEC 79-1

BS 5501: Parts 1 and 5: EN 50 014 and EN 50 018

CENELEC. Codes ‘H’ for aluminium and ‘R’ for stainless

steel EExd IIC T6.

All enclosures are suitable for outdoor use and the majority

of products are rated IP66. Refer to the product label

and/or leaflet. Only operation, maintenance or repair

procedures either contained herein or approved by Delta

Controls may be used, to avoid rendering the equipment

unsafe in operation and / or nullifying the Certification. NO

MODIFICATIONS ARE PERMITTED.

Special Conditions for Safe Use

The integral wires shall be suitably protected against

mechanical damage and be terminated within a terminal or

junction facility suitable for the conditions of use.

Electrical Adaptors

Zone 1. Use only certified adaptors for Zone 1.

EExe for increased safety installations and EExd for

Flameproof installations.

References for Selection and Installation

BSEN60079-14 Part4 for all Enclosure Codes (Intrinsic

Safety)

BSEN 50014 Part 1 for Enclosure Codes H, R

BSEN60529 IP RATING (Ingress Protection)

0

MAINTENANCE

Inspections should be carried out at quarterly to yearly

intervals depending upon operating conditions.

Where a terminal enclosure is fitted, isolate the unit from

process and power and remove the lid. Check all

terminals for tightness. Check that cable tails are not

fouled or chafed. Check for internal condensation. Rectify

as necessary.

It is recommended that instruments used to provide an

alarm are operated periodically to ensure they are

functioning correctly.

If further maintenance is required, seek advice from

DELTA CONTROLS before attempting repair or

replacement of parts.

Note: Should the diaphragm fail the process will vent to

atmosphere via a control orifice without pressurising the

switch enclosure. Periodically ensure the vent area does

not become blocked and the vent plug has not degraded.

Ensure that the vent area is not obstructed.

CAUTION

Moving parts have been treated with a water repelling

lubricant before leaving the factory. Occasional inspection

and the application of a water repelling lubricant is

recommended to ensure moving parts remain free under

all conditions.

WARNING: DOES NOT APPLY TO OXYGEN SERVICE.

OPERATION

Pressure difference switches are supplied calibrated

against falling pressure difference unless otherwise

specified. Set Point Adjustment refers to falling pressure

difference. Switching Differential is the difference between

the set point and the operating value on rising pressure

difference.

Set Point Adjustment: Models GR3/6 (fig 3)

1 Isolate the instrument from the process.

2 Adjustment may be carried out with the unit live.

3 Loosen both cover screws.

4 Rotate cover anti-clockwise to allow access.

5 Using a screwdriver rotate the adjuster to obtain the

desired setting. Turn right to left to increase the setting.

An appropriate setting is shown by pointer against

reference scale.

6 Rotate cover clockwise to close and tighten screws.

NOTE: For accurate setting, a suitable gauge must be

used in conjunction with the above procedure. Do not

attempt to set the switch outside the scale limits. Though

the unit may be set anywhere within its operation range,

for optimum performance, it is good practice to have a set

point value between 25% and 75% of span.

PROCESS CONFIGURATIONS (RANGE BC)

For normal pressure difference operation, the connections

are made to the High Pressure (HP) and Low Pressure

(LP) ports as appropriate. For single-ended positive

pressure operation, the HP only is used and the LP is left

open to atmosphere. The single-ended negative pressure

operation, the LP only is used and the HP is left open to

atmosphere.

Use a breather / filter in the vacant port of single-ended

operation.

COMPOUND RANGE eg –12.5 to +12.5 mbar (RANGE BC)

For normal operation, negative pressure may be applied to

the LP port, whereby the HP port is left open to

atmosphere and the set point is between 0 and +12.5

mbar.

For reverse operation, negative pressure may be applied

to the HP port, whereby the LP port is left open to

atmosphere and the set point is between 0 and –12.5

mbar.

For positive pressures the opposite applies.

It is recommended that the minimum setting is to be not

less than 5% of FS either side approaching zero (see fig

2).

Page 2

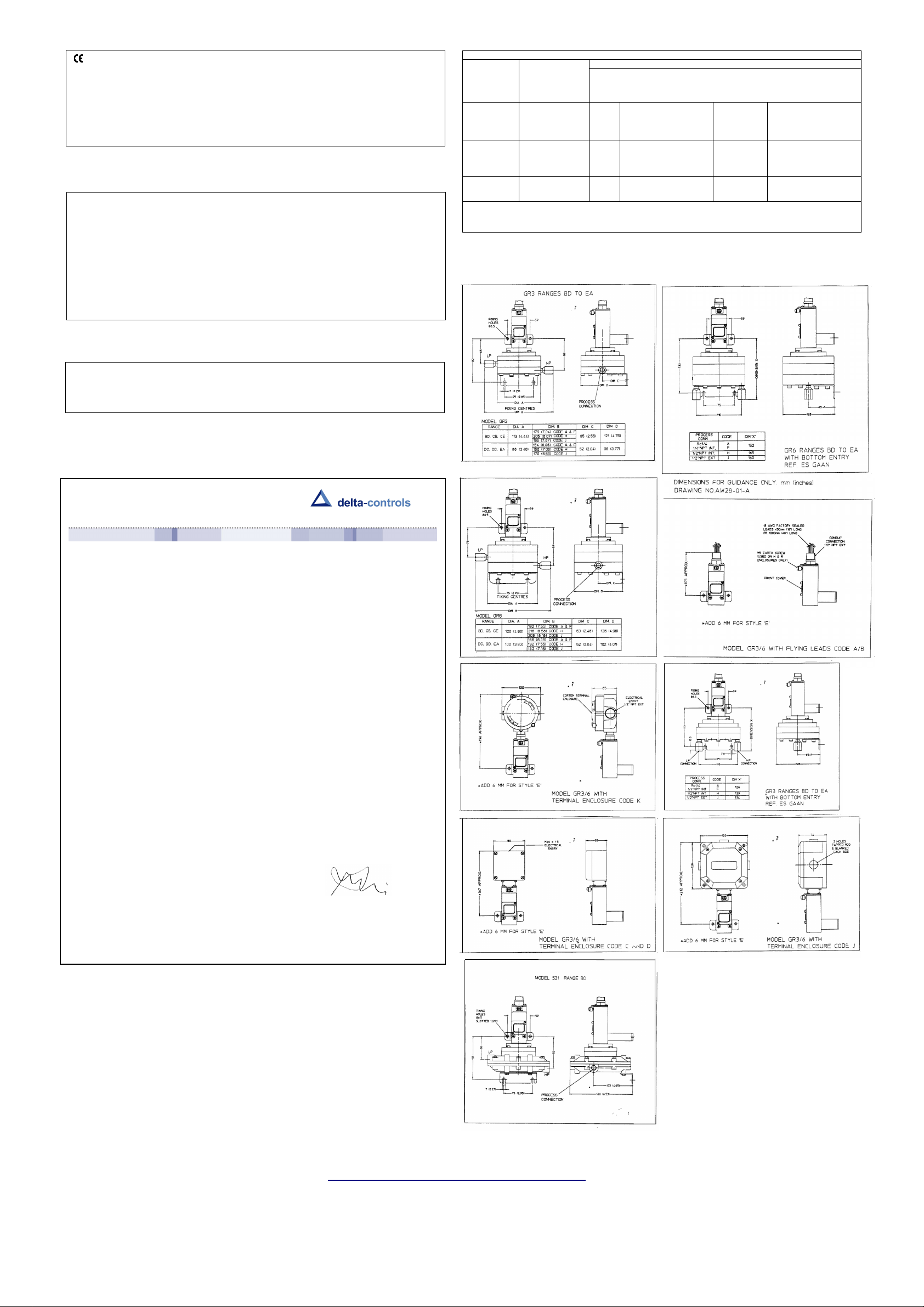

Fig 5

Fig 6

Low Voltage Directive (LVD) – 2006/95/AC. Products with enclosure codes ‘W’ and ‘A’ supplied CEmarked must be installed and used in accordance with the main instructions and this addendum supplied

with each product. Products rated lower than 50V ac and 75 V dc are outside the scope of the LVD. The

LVD does not apply to products with enclosure codes ‘H’ and ‘R’, for use in hazardous areas. Such

products are covered by the Explosive Atmospheres Directive ATEX – 94/9/EC and when CE-marked will

indicate compliance with this directive alone. The following directives do not apply to switch products

manufactured by Delta Controls:

Electromagnetic Compatibility EMC – 2004/08/EC.

Machinery Safety Directive MSD – 2006/42/EC.

WIRING

Junction box cable glands and adaptors. Optional Junction box code ‘C’ is supplied with an M20 x 1.5

tapped hole blanked with a red plug. Discard the red plug and fit a suitable proprietary brass or nylon M20

cable gland with thread length of 10 mm. Fit a fibre washer to the outside. See diagram 1.

Alternately the junction box may be supplied from the factory with a threaded adaptor ready to accept the

customer’s gland or conduit system.

Alternatives:

1) a metal or nylon adaptor may be used to accommodate other sizes of gland eg NPT, or conduit system.

See diagram 2.

Earthing / grounding – Use earthing point provided inside the junction box (when fitted). The user must

make suitable local earthing arrangement, if required, to ensure that metal glands / adaptors are earthed.

Pollution degree – all products are suitable for use in pollution degree 3.Ref EN60947-5-1

Electrical Isolation – these products are not suitable for electrical isolation. Always isolate circuit

separately to carry out any electrical work.

Declaration of Conformity

We: Delta Controls Ltd

Island Farm Avenue

West Molesey

Surrey, UK

KT8 2UZ

As the manufacturers of the apparatus listed, declare under our sole responsibility that the products

listed below:

Pressure, Pressure Difference, Temperature & Flow switches series “W” or “A”:

201, 202, 203, 281, 204, 207, 208, 209, 231, 232, 233, 234, S21, S22, S24, GR2, GR4, VM2, VM4.

301, 303, 304, 381, 384, 306, 386, 310, 316, S31, S34, GR3, GR6.

721, 731, 771, 722, 732, 772, 723, 733, 773, 781, 734, 774, 741, 742, 743, 744, S71, GR7.

131.

To which this declaration relates are in conformity with the following relevant standards or parts

thereof:

EN 60947-1 :1992 Low voltage switch gear and control-gear-general rules.

EN 60947-5-1:1992 Low voltage switch gear and control-gear-control circuit devices and switching

elements.

EN 60529: 1991 Specification for classification of degrees of protection provided by enclosures.

EN 60950:1992 Safety of information technology equipment including electrical business equipment:

section 2.5.

BS 6134:1991 Specification for pressure and vacuum switches.

And thereby conforms to the requirements of the Low Voltage Directive 73/23/EC amended by

93/68/EEC.

………………….

R. Harrison

Managing Director

Original dated 22nd June 2000

th

Signed:

In the interest of development and improvement Delta Controls Ltd, reserve the right to amend without notice,

details contained in this publication. No legal liability will be accepted by Delta Controls Ltd, for any errors,

omissions or amendments.

YOUR TRUSTED PARTNER IN PROCESS INSTRUMENTATION

DELTA CONTROLS LIMITED, ISLAND FARM AVENUE, WEST MOLESEY, SURREY KT8 2UZ

T +44 (0) 208 939 3511 F +44 (0) 208 783 1163 E sales@delta-controls.com W www.delta-controls.com

Registered Office Registered in England No 5369683

SWITCH

CODE

(type)

HS, HD, HR

HP, HQ, HT

HV, HW, HY

The electrical rating is dependent on the microswitch fitted to the switch. The electrical rating is defined by each approval that the

microswitch complies with and is shown on the product nameplate, ie UL/CSA or IEC. It should be noted that the switch must be

used within the electrical rating specified from the approval you require. Table A lists the actual IEC ratings against the Designation

and Utilisation Category marked on the nameplate. If in doubt, seek guidance from factory.

UL/CSA

MICROSWITCH

RATING (Resistive)

*See Note

11A @ 110/250 VAC

5/0.5 @ 30/125 VDC 0.22/0.1A @

5A @ 250 VAC

2A @ 30 VDC

1A @ 125 VAC

*1A @ 30 VDC

TABLE A – MICROSWITCH RATINGS

Uimp Ui

0.8kV

0.5kV

0.5kV

250V

250V

120V

IEC 947-5-1/EN 60947-5-1 RATING

Designation

RATING

(Ie/Ue)

0.6/0.3A @

120/240 VAC

125/250VDC

0.6/0.3A @

120/240 VAC

0.22/0.1A @

125/250VDC

0.3A @ 120 VAC

& Utilization

Category

AC14/D300 AC 432 72

DC13/R300 DC 28 28

AC14/D300 AC 432 72

DC13/R300 DC 28 28

AC14/E150 AC 216 36

VA

MAKE BREAK

Fig 7

Fig 8

Fig 9

Fig 10

Fig 11

Fig 12

Fig 13

Stock No: 002522/GR3

Loading...

Loading...