Page 1

VENTING DEVICE

47

37

FIBRE

FIBRE

WASHER

All enclosures are suitable for outdoor use

NO MODIFICATIONS ARE PERMITTED.

UL and CSA:

Groups A, B, C, D: Class II

Groups E, F,

MO D E L GR 2/4 W IT H TE R M IN AL ENC LOS U R E C O D E J

GENERAL: These instructions are to be

used when installing and operating GR

series pressure switches types GR2 and

GR4.

TYPICAL MODEL NUMBER: W GR2 A

A EA HS F See the switch data plate,

accompanying paper work and / or the

product catalogue for the full definition of

the model(s) you have.

CAUTION: The unit should not be

dismantled without isolating from

pressure source and electrical power.

The microswitch assembly with factory

sealed leads has been carefully

positioned at the factory. Any

disturbance may render this unit

inoperative.

INSTALLATION: Install in such a way as

to avoid stresses, excessive shock or

vibration being imparted to the switch

during operation. It is recommended that

either the process connection or the

electrical conduit connection be flexible

enough to avoid stresses. Always use a

suitable spanner to support the pressure

connection and electrical conduit.

Instruments are designed to be mounted

vertically with the process connection

underneath. However, mounting up to 45 deg

from the vertical in any plane is acceptable,

although a small calibration shift may occur.

The

WIRING: The leads are factory sealed so

it is unnecessary to seal the conduit to the

conduit nipple. However, the leads must

be suitably protected against mechanical

damage and terminated in a suitable

junction box or terminal facility in

accordance with local and national codes.

Refer to the wiring diagram (Fig 1).

Junction Box (when fitted): Some

models may be provided with an integral

weatherproof or EExe junction box. Wire

in accordance with local and national

codes using cables no larger than 14

AWG.

SAFETY: Ensure that site safety

practices and procedures are followed

before working on the installed switch.

DIAG 1

DIAG 2

JUNCTION BOX

CABLE GLAND ASSEMBLY

JUNCTION BOX

WASHER

ADAPTOR ASSEMBLY

INSTALLATION AND OPERATING

GR SERIES PRESSURE SWITCHES

INSTRUCTIONS

TYPE GR2/4

ISSUE I 03/10

PRODUCT CODE

ENCLOSURE

MODEL

ELECTRICAL ENTRY

MATERIAL OF WETTED PARTS

RANGE

SWITCHING OPTIONS

PROCESS CONNECTION

OPTIONS AND TREATMENTS

SPECIAL ENGINEERING

F i g 4

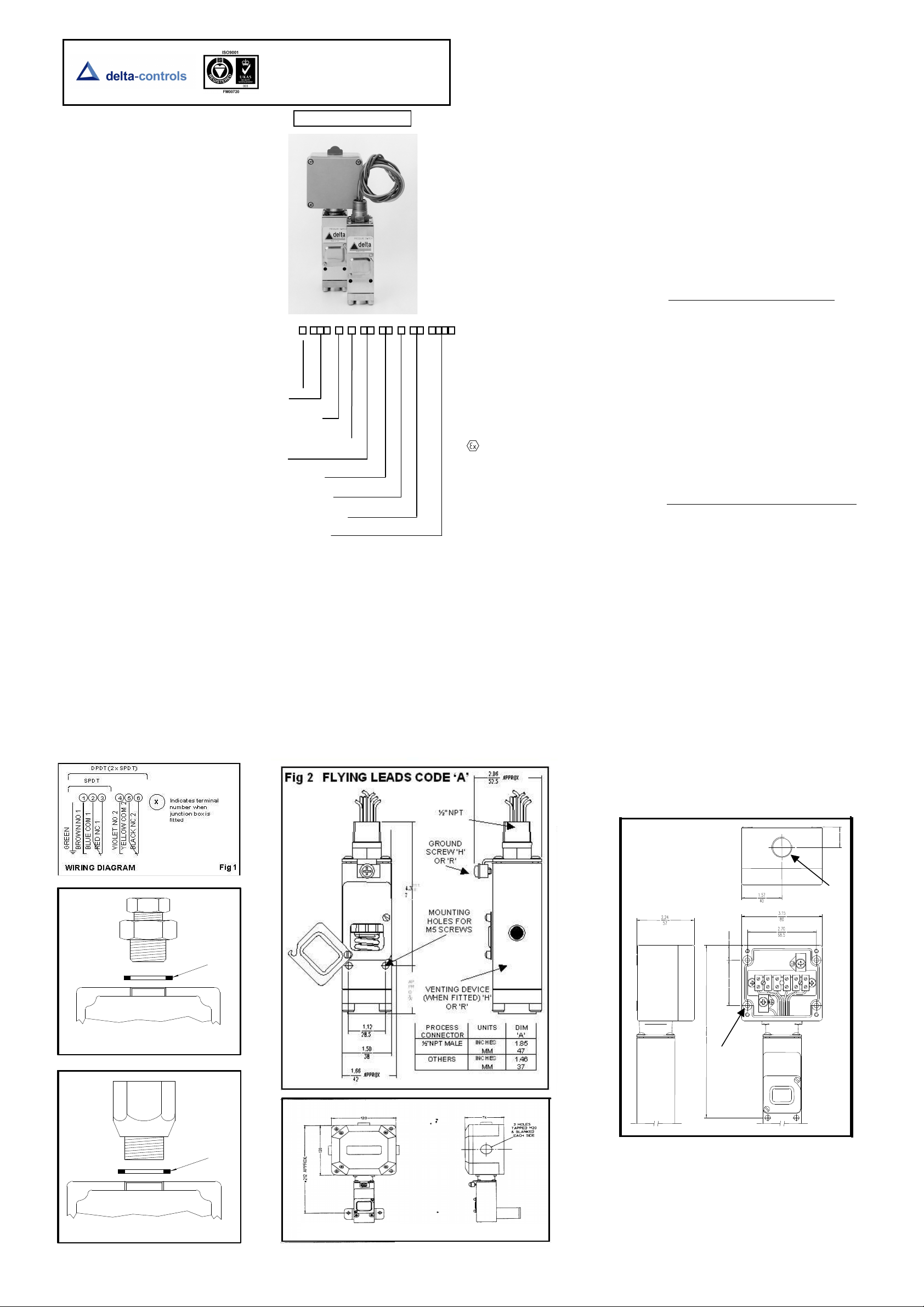

Fig 2 FLYING LEADS CODE ‘A’

To alter the set point:

1. Loosen both cover screws and rotate

cover to allow access.

2.

Using a suitable screwdriver, rotate

the adjuster, right to left to increase

the setting, and left to right to

decrease the setting.

OPERATION: Adjustment of the set point

may be carried out with the unit ‘live’.

Refer to fig 2.

As a guide, one complete revolution of the

adjuster will alter the set point by

approximately 15% of the range. For

accurate setting, a suitable pressure

gauge must be used in conjunction with

the above procedure. Do not attempt to

set the unit outside its range limits.

Though the unit may be set anywhere

within its range, for optimum performance,

it is good practice to have a set point

value between 25% and 75% of the range.

HAZARDOUS AREAS:

CENELEC: Models beginning with code

‘H’ or ‘R’ are also suitable for use in areas

where explosion hazards may exist due to

flammable gases or vapours.

ATEX NUMBER Baseefa02ATEX0214X

EN60 079-0: 2006

EN60 079-1: 2004

II 2G Exd IICT6 (Tamb –40 deg c to +60

deg c) or Exd IIC T4 (Tamb –40 deg c to +85

deg c).

Special condition for safe use

The leads shall be suitably protected against

mechanical damage and terminated in a suitable

junction box or terminal facility

and the majority of products are considered

by Delta controls ltd to be rated IP66. Refer

to the product label and/or leaflet. Only

operation, maintenance or repair procedures

either contained herein or approved by Delta

Controls may be used, to avoid rendering the

equipment unsafe in operation and/or

nullifying the Certification.

½” NPT

GROUND

SCREW ‘H’

OR ‘R’

111

4.3

.0

7

MOUNTING

HOLES FOR

M5 SCREWS

AP

PR

O

X

(WHEN FITTED) ‘H’

'A'

OR ‘R’

CONNECTOR

½”NPT MALE

PROCESS

OTHERS

UNITS DIM

INCHES

MM

INCHES

MM

‘A’

1.85

1.46

Fig 3

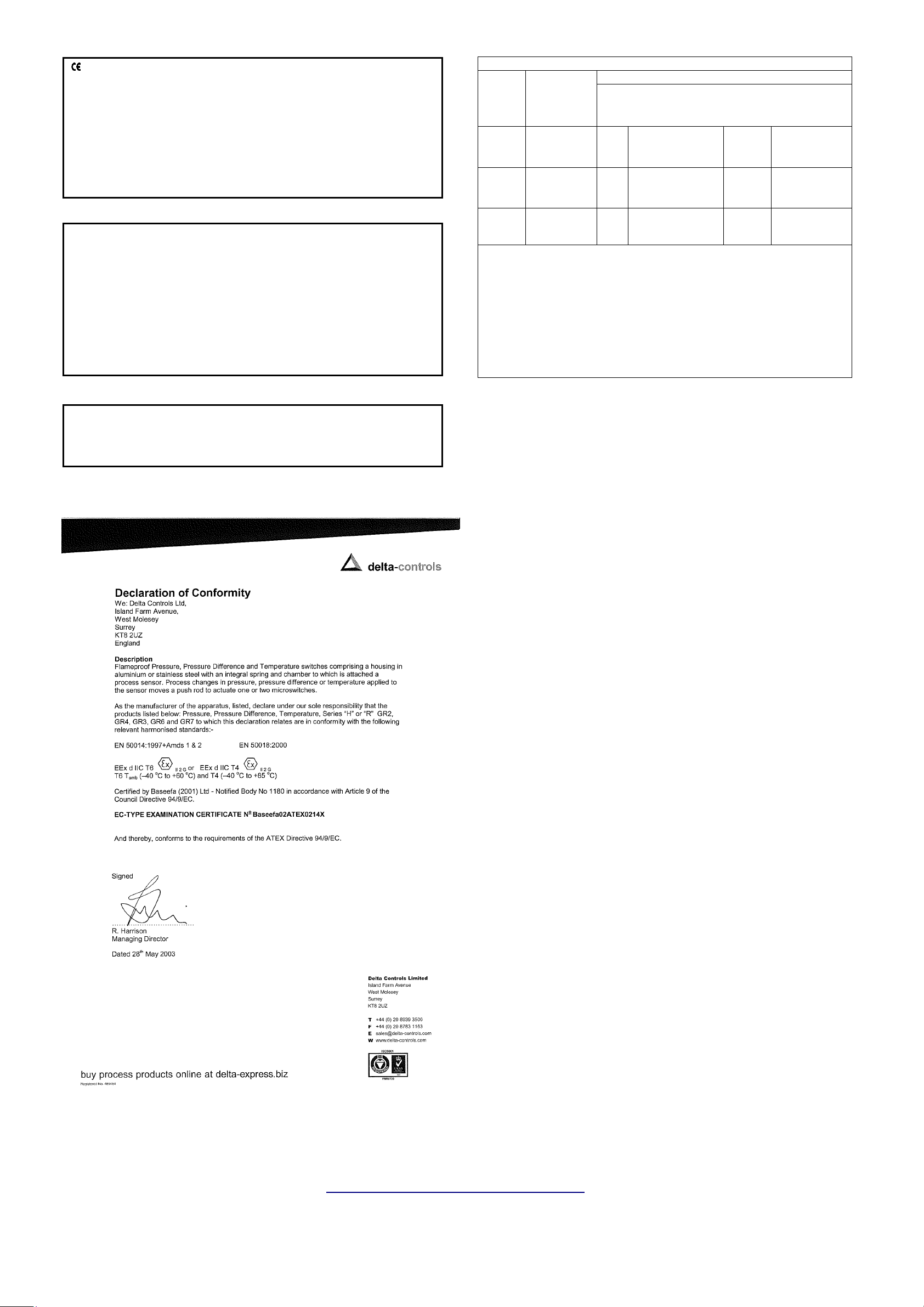

JUNCTION BOX

CODES ‘C’ & ‘D’

are suitable for installing in areas where

explosion hazards may exist due to

flammable gases or vapours, flammable

liquids or combustible dusts, Class I

All models with flying leads

G: Div 1 and 2, by virtue of the

hermetically sealed microswitch, UL file ref

E105842 and CSA file ref LR 67110-5.

Refer to the National Electrical Code,

Article 500 for installation guidance.

JUNCTION BOXES

Code ‘C’: see fig 3

Code ‘D’: same dimensions as code ‘C’ but

EExe approved for use in Zone 1.

Code ‘J’: see fig 4. EExe approved for use in

Zone 1.

Cert Baseefa03ATEX0089X

Certified II2G EExe II T6

When used at 11A, cabling to be 2.5 mm

2

.

Special conditions for safe use-code J

1) Not more than 1 single or multiple lead shall

be connected into either side of any terminal

2) Leads to be insulated for the appropriate

voltage. Insulation to extend to within 1mm of

the terminal throat.

3) All terminal screws used and unused to be

tightened down

4) Circuits to be protected by excess current

protection, which shall operate within 4 hours at

1.5 X the designed load current.

5) All cable entries shall maintain IP66

minimum

6) Kwikstik 3507 inseal gasket must be fitted

between GR series adaptor and enclosure to

ensure IP66 ingress protection.

When weatherproof junction box code ‘C’ is

fitted the unit must not be used in hazardous

areas unless the circuit or system to which it is

connected is Intrinsically Safe.

Note: Should the diaphragm fail the process

will vent to atmosphere via a control orifice

without pressurising the switch enclosure.

Periodically ensure the vent area does not

Become blocked and the vent plug has not

degraded. Ensure that the vent area is not

obstructed.

MAINTENANCE: No maintenance is normally

necessary with these units. However, if a

junction box is fitted depending on the

installation conditions, it is recommended that

the wiring is checked periodically for

contamination and security. Take appropriate

measures to rectify any faults.

REPLACEMENT PARTS: Use only factory

authorised parts and the fitting instructions that

are supplied with these

WARRANTIES: See CONDITIONS OF SALE.

17

6.7

1.0

3

4 MOUNTING

HOLES 4.5

mm DIA

SUITABLE

FOR M4

SCREWS

MAX HEAD

DIA 7.5 mm

15.

0.5

0

9

45.

1.7

0

7

CONDUIT ENTRY

M20 x 1.5

0.7

20

9

Page 2

–

cal rating is dependent on the microswitch fitted to the switch.

Low Voltage Directive (LVD)

‘A’ supplied CE-marked must be installed and used in accordance with the main instructions

and this addendum supplied with each product. Products rated lower than 50V ac and 75 V

dc are outside the scope of the LVD, and therefore, do not require CE-marking under this

directive. The LVD does not apply to products with enclosure codes ‘H’, ‘K’, ‘R’, ‘M’, ‘N’ for

use in hazardous areas. Switch products with enclosure codes ‘H’, ‘K’, ‘R’, ‘M’, ‘N’, are

covered by the Explosive Atmospheres Directive ATEX – 94/9/EC and when CE-marked will

indicate compliance with this directive alone. The following directives do not apply to switch

products manufactured by Delta Controls:

Electromagnetic Compatibility EMC – 2004/108/EC

Machinery Safety Directive MSD – 2006/42/EC

2006/95/AC. Switch products with enclosure codes ‘W’ and

WIRING

Junction box cable glands and adaptors. Optional Junction box code ‘C’ and ‘D’ is supplied

with an M20 x 1.5 tapped hole blanked with a red plug. Discard the red plug and fit a

suitable proprietary brass or nylon M20 cable gland with thread length of 10 mm. Fit a fibre

washer to the outside. See diagram 1.

Alternately the junction box may be supplied from the factory with a threaded adaptor ready

to accept the customer’s gland or conduit system.

Alternatives:

1) A metal or nylon adaptor may be used to accommodate other sizes of gland eg NPT, or

conduit system. See diagram 2.

Earthing / grounding – Use earthing point provided inside the junction box (when fitted). The

user must make suitable local earthing arrangement, if required, to ensure that metal glands /

adaptors are earthed.

TABLE A – MICROSWITCH RATINGS

SWITCH

CODE

(type)

HS, HD, HR

HP, HQ, HT

HV, HW,

HY

UL/CSA

MICROSWITCH

RATING

(Resistive)

*See Note

11A @ 110/250 VAC

5/0.5 @ 30/125 VDC

5A @ 250 VAC

2A @ 30 VDC

1A @ 125 VAC

*1A @ 30 VDC

Uimp

0.8kV

0.5kV 250V

0.5kV 120V

Ui RATING (Ie/Ue)

250V

IEC 947-5-1/EN 60947-5-1 RATING

0.6/0.3A @ 120/240 VAC

0.22/0.1A @ 125/250VDC

0.6/0.3A @ 120/240 VAC

0.22/0.1A @ 125/250VDC

0.3A @ 120 VAC

Designation

&

Utilization

Category

AC14/D300

DC13/R300

AC14/D300

DC13/R300

AC14/E150

AC

DC

AC

DC

AC

MAKE

432 72

28 28

432 72

28 28

216 36

VA

BREAK

The electri

The electrical rating is defined by each approval that the microswitch

complies with and is shown on the product nameplate, ie UL/CSA or

IEC. It should be noted that the switch must be used within the electrical

rating specified from the approval you require. Table A lists the actual

IEC ratings against the Designation and Utilisation Category marked on

the nameplate. If in doubt, seek guidance from factory.

Pollution degree – all products are suitable for use in pollution degree 3.Ref EN60947-5-1

Electrical Isolation – these products are not suitable for electrical isolation. Always isolate

circuit separately to carry out any electrical work.

In the interest of development and improvement Delta Controls Ltd, reserve the right to amend without notice,

details contained in this publication. No legal liability will be accepted by Delta Controls Ltd, for any errors,

DELTA CONTROLS LIMITED, ISLAND FARM AVENUE, WEST MOLESEY, SURREY KT8 2UZ

T +44 (0) 208 939 3511 F +44 (0) 208 783 1163 E sales@delta-controls.com W www.delta-controls.com

omissions or amendments.

YOUR TRUSTED PARTNER IN PROCESS INSTRUMENTATION

Registered Office Registered in England No 5369683

Stock No: 002522/GR2

Loading...

Loading...