Page 1

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan City,

Taoyuan County 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province,

People's Republic of China (Post code: 215200)

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C.

Post code : 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

Delta Ultimate Integrated AC Servo Drive with

Excellent Performance

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: +55 11 3568-3855 / FAX: +55 11 3568-3865

Europe

Deltronics (The Netherlands) B.V.

Eindhoven Ofce

De Witbogt 15, 5652 AG Eindhoven, The Netherlands

TEL: 31-40-2592850 / FAX: 31-40-2592851

ASDA-M

Delta Ultimate Integrated

Series User Manual

AC Servo Drive with

Excellent Performance

ASDA-M

Series

User Manual

Via Polesine, 1/4

10020 Cambiano ( TO ) Italy

+39 011 9454523

www.e-comtech.it

info@e-comtech.it

*We reserve the right to change the information in this catalogue without prior notice.

V2.0

DELTA_

IA-ASDA_M_UM_EN_20141219

www.delta.com.tw/ia

Page 2

Preface

Thank you for purchasing ASDA-M. This user manual provides the related information of

ASDA-M series servo drives and ECMA series servo motors. This manual includes:

Installation and inspection of servo drive and servo motor

The configuration of servo drive

Procedures of trial run

Control function and adjustment methods of servo drive

Parameters

Communication protocol

Maintenance and inspections

Troubleshooting

This manual addresses personnel with the following qualifications:

Servo system designers

Installation or wiring personnel

Trial and tuning personnel

Maintenance and inspection personnel

Before using the product, please read through this manual carefully in order to ensure the

correct use of the product. In addition, please place this manual safely for quick reference

whenever is needed. Please follow the rules below if you have not finished reading this

manual yet.

No water, corrosive gas and inflammable gas are allowed in installation

environment.

Three-phase power is prohibited to connect to U, V and W connector when wiring.

It is possible to damage the servo drive.

Ground is a must.

Do not disconnect the servo drive, motor or change the wiring when connecting to

the power.

Be ensured that the emergency stop can be activated anytime before connecting to

the power and operation.

Do not touch the heat sink to avoid scald before connecting to the power and

operation.

If you have any enquiry , please contact the distri butors or DEALTA customer service center.

Revision December, 2014 i

Page 3

Preface ASDA-M

Safety Precautions

ASDA-M series is the high resolution and open type servo drive. It should be installed in a

shielded control box during operation. This servo drive uses precise feedback control and

the digital signal processor with high-speed calculation function to control the current output

which generated by IGBT so as to operate three-phase permanent magnet synchronous

motors (PMSM) and to achieve precise positioning.

ASDA-M is applicable on industrial application and is suggested to be installed in the

panel-board of the user manual. (Servo drives, wire rod and motors all should be installed

in the environment which complies with the minimum requirement of UL Level 1.)

Pay special attention to the following safety precautions anytime during inspection,

installation, wiring, operation and examination.

The symbol of danger, warning and stop represent:

It indicates the potential hazards. It is possible to cause severe injury or fatal

harm if not follow the instructions.

It indicates the potential hazards. It is possible to cause minor injury or lead to

serious damage of the product or even malfunction if not follow the instructions.

It indicates the absolute prohibited activity. It is possible to damage the product or

cannot be used due to malfunction if not follow the instructions.

Inspection

Please follow the instruction when using servo drive and servo motor, or it is

Installation

It is prohibited to expose the product with the environment which containing

Wiring

Please connect the ground terminal to class-3 ground system (under 100 Ω),

Do not connect the three-phase source to the motor output terminal U, V and

Please tighten the screws of the power and motor output terminal. Or it is

Please connect wiring according to the wire rod in order to prevent any

possible to cause fire or malfunction.

water, corrosive gas, inflammable gas, etc. Or it is possible to cause electric

shock or fire.

poor grounding may result in electric shock or fire.

W. Or it is possible to cause personnel injury or fire.

possible to cause fire.

danger.

ii Revision December, 2014

Page 4

ASDA-M Preface

Operation

Before the operation, please change the parameter setting value according to

the needs. If it is not adjusted to the correct setting value, it is possible to lead

to malfunction of the machine or the operation might out of control.

Before the machine starts to operate, please be ensured the emergency stop

can be activated anytime.

During the operation, it is prohibited to touch any rotating motor parts. Or it is

possible to cause personnel injury.

In order to prevent any accident, please separate the couplings and belts of

the machine and isolate them. Then conduct the initial trial run.

If users fail to operate the machine properly after the servo motor connects to

the equipments, it would cause the damage of the equipments and lead to the

personnel injury.

In order to prevent the danger, it is strongly recommended to check if the

motor can operate normally without load first. Then, operate the motor with

load.

Do not touch the heat sink of the servo drive. Or it is possible to cause scald

due to the high temperature.

Maintenance and Inspection

It is prohibited to touch the internal parts of the servo drive and servo motor.

Or it is possible to cause electric shock.

It is prohibited to disassemble the panel of the servo drive when turning on the

power. Or it is possible to cause electric shock.

Do not touch the ground terminal within 10 minutes after turning off the power .

Or the residual voltage may cause electric shock.

Do not disassemble the motor. Or it is possible to cause electric shock or

personnel injury.

Do not change the wiring when the power is on. Or it is possible to cause

electric shock or personnel injury.

Only the qualified electrical and electronics professionals can install, wire and

maintain the servo drive and servo motor.

Main Circuit Wiring

Do not put the power cable and the encoder cable in the same channel and

bond them together. Please separate the power cable and the encoder cable

for at least 30 centimeters (= 11.8 inches) when wiring.

Please use stranded wires and multi-core shielded-pair wires for the encoder

cables and encoder feedback cables. The maximum length of command input

cable is 3 meters (= 9.84 feet) and the maximum length of feedback cable is

20 meters (= 65.62 feet).

The high voltage might remain in the servo motor even when the power is off.

Do not touch the power terminal temporally (at least 10 minutes). Please

conduct the inspection not until the indicator light, CHARGE is off.

Revision December, 2014 iii

Page 5

Preface ASDA-M

Do not turn the power on and off too often. If continuous power on and off is

needed, please be ensured the interval is one minute at most.

Terminal Wiring of the Main Circuit

When wiring, please disassemble the terminal socket from the servo drive.

One terminal of the terminal socket for one electric wire only.

When inserting the electric wires, do not connect the conductor to the adjacent

wire.

Before connecting to the power, please inspect and be ensured the wiring is

correct.

NOTE

If there is any difference of each version, please refer to DELTA’s

website (http://www.delta.com.tw/industrialautomation/) for the latest

information.

iv

Revision December, 2014

Page 6

Table of Content

Chapter 1 Inspection and Model Explanation

1.1 Inspection ...................................................................................................... 1-1

1.2 Product Model .............................................................................................. 1-2

1.2.1 Nameplate Information ......................................................................... 1-2

1.2.2 Model Explanation ................................................................................ 1-3

1.3 Servo Drive and Corresponding Servo Motor ................................................ 1-5

1.4 Features of Servo Drive ................................................................................. 1-6

Chapter 2 Installation

2.1 Notes ............................................................................................................. 2-1

2.2 Ambient Conditions of Storage ...................................................................... 2-1

2.3 Ambient Conditions of Installation ................................................................. 2-2

2.4 Installation Direction and Space .................................................................... 2-3

2.5 Specification of Circuit Breaker and Fuse ...................................................... 2-5

2.6 EMI Filters Selection ...................................................................................... 2-5

2.7 Selection of Regenerative Resistor ............................................................... 2-8

Chapter 3 Wiring

3.1 Connection between Peripheral Devices and Main Power Circuit ................. 3-1

3.1.1 Wiring Diagram of Peripheral Devices ................................................... 3-1

Revision December, 2014

Page 7

Table of Content ASDA-M

3.1.2 Connectors and Terminals of the Servo Drive ....................................... 3-3

3.1.3 Wiring Method ....................................................................................... 3-5

3.1.4 Specification of Motor U, V, W Power Cable ......................................... 3-7

3.1.5 Specification of Connector of Encoder Cable ........................................ 3-9

3.1.6 Selection of Wire Rod ............................................................................ 3-12

3.2 Schematic Diagram of Servo System ............................................................ 3-14

3.3 I/O Signal (CN1) Connection ......................................................................... 3-15

3.3.1 I/O Signal (CN1) Connector Terminal Layout ....................................... 3-15

3.3.2 Explanation of I/O (CN1) Connector Signal .......................................... 3-17

3.3.3 Wiring Diagram (CN1) .......................................................................... 3-31

3.3.4 The Specified DI and DO Signal by the User ........................................ 3-40

3.4 CN2 Connector .............................................................................................. 3-41

3.5 Wiring of CN3 Connector ............................................................................... 3-44

3.5.1 Layout of CN3 Connector ..................................................................... 3-44

3.5.2 Connection between CN3 connector and Personal Computer ............. 3-45

3.6 CN4 Serial Connector (USB) ......................................................................... 3-46

3.7 CN5 Connector (Full-closed Loop) ................................................................ 3-47

3.8 CN6 Connector (CANopen) ........................................................................... 3-48

3.9 Standard Wiring Method ................................................................................ 3-50

3.9.1 Position (PT) Mode Standard Wiring .................................................. 3-50

3.9.2 Position (PR) Mode Standard Wiring .................................................. 3-51

3.9.3 Speed Mode Standard Wiring ............................................................. 3-52

3.9.4 Torque Mode Standard Wiring ............................................................ 3-53

Revision December, 2014

Page 8

ASDA-M Table of Content

3.9.5 CANopen Mode Standard Wiring ........................................................ 3-54

Chapter 4 Panel Display and Operation

4.1 Panel Description .......................................................................................... 4-1

4.2 Parameter Setting Procedure ........................................................................ 4-2

4.2.1 Axis Switching Procedure .................................................................... 4-2

4.2.2 Parameter Setting Procedure of Each Axis ......................................... 4-3

4.3 Status Display................................................................................................ 4-4

4.3.1 Setting Saved Display .......................................................................... 4-4

4.3.2 Decimal Point ....................................................................................... 4-4

4.3.3 Alarm Message ..................................................................................... 4-4

4.3.4 Positive and Negative Sign Setting ....................................................... 4-4

4.3.5 Monitor Display ..................................................................................... 4-5

4.4 General Function ........................................................................................... 4-8

4.4.1 Operation of Fault Record Display ........................................................ 4-8

4.4.2 JOG Mode ............................................................................................ 4-9

4.4.3 Forced Digital Output Operation ........................................................... 4-10

4.4.4 Digital Input Diagnosis Operation ......................................................... 4-11

4.4.5 Digital Output Diagnosis Operation ...................................................... 4-12

Chapter 5 Trial Operation and Tuning

5.1 Inspection without Load ................................................................................. 5-1

5.2 Apply Power to the Servo Drive ..................................................................... 5-2

Revision December, 2014

Page 9

Table of Content ASDA-M

5.3 JOG Trial Run without Load .......................................................................... 5-6

5.4 Trial Run without Load (Speed Mode) ........................................................... 5-7

5.5 Trial Run without Load (Position Mode) ......................................................... 5-9

5.6 Tuning Procedure .......................................................................................... 5-11

5.6.1 Flowchart of Tuning Procedure ............................................................. 5-12

5.6.2 Inertia Estimation Flowchart (with Mechanism) .................................... 5-13

5.6.3 Flowchart of Auto Tuning ...................................................................... 5-14

5.6.4 Flowchart of Semi-auto Tuning ............................................................. 5-15

5.6.5 Limit of Load Inertia Estimation ............................................................ 5-17

5.6.6 Mechanical Resonance Suppression Method ....................................... 5-19

5.6.7 Tuning Mode and Parameters .............................................................. 5-20

5.6.8 Tuning in Manual Mode ........................................................................ 5-21

Chapter 6 Control Mode of Operation

6.1 Selection of Operation Mode ......................................................................... 6-1

6.2 Position Mode ................................................................................................ 6-3

6.2.1 Position Command of PT Mode ............................................................ 6-3

6.2.2 Position Command of PR Mode ........................................................... 6-6

6.2.3 Control Structure of Position Mode ....................................................... 6-7

6.2.4 S-curve Filter (Position) ........................................................................ 6-8

6.2.5 Electronic Gear Ratio ........................................................................... 6-12

6.2.6 Low-pass Filter ..................................................................................... 6-14

6.2.7 Timing Diagram in Position Mode (PR) ................................................ 6-16

Revision December, 2014

Page 10

ASDA-M Table of Content

6.2.8 Gain Adjustment of Position Loop ........................................................ 6-16

6.2.9 Low-frequency Vibration Suppression in Position Mode ....................... 6-18

6.3 Speed Mode .................................................................................................. 6-24

6.3.1 Selection of Speed Command .............................................................. 6-24

6.3.2 Control Structure of Speed Mode ......................................................... 6-25

6.3.3 Smooth Speed Command .................................................................... 6-26

6.3.4 The Scaling of Analog Command ......................................................... 6-30

6.3.5 The Timing Diagram in Speed Mode .................................................... 6-31

6.3.6 Gain Adjustment of Speed Loop ........................................................... 6-32

6.3.7 Resonance Suppression....................................................................... 6-39

6.4 Torque Mode ................................................................................................. 6-47

6.4.1 Selection of Torque Command ............................................................. 6-47

6.4.2 Control Structure of Torque Mode ........................................................ 6-48

6.4.3 Smooth Torque Command ................................................................... 6-49

6.4.4 The Scaling of Analog Command ......................................................... 6-50

6.4.5 The Timing Diagram in Torque Mode ................................................... 6-51

6.5 Dual Mode ..................................................................................................... 6-52

6.5.1 Speed/Position Dual Mode ................................................................. 6-53

6.5.2 Speed/Torque Dual Mode .................................................................. 6-53

6.5.3 Torque/Position Dual Mode ................................................................ 6-54

6.6 Others ............................................................................................................ 6-55

6.6.1 The Use of Speed Limit ........................................................................ 6-55

6.6.2 The Use of Torque Limit ....................................................................... 6-55

Revision December, 2014

Page 11

Table of Content ASDA-M

6.6.3 Analog Monitor ..................................................................................... 6-56

6.6.4 The Use of Mechanical Brake ............................................................... 6-61

Chapter 7 Motion Control

7.1 Motion Control Functions of ASDA-M ............................................................ 7-1

7.2 Information of the Servo Drive ....................................................................... 7-1

7.2.1 Description of Monitor Variables ........................................................... 7-3

7.2.2 Description of Data Array ...................................................................... 7-9

7.3 Description of Motion Axes ............................................................................ 7-13

7.4 Description of PR Mode ................................................................................. 7-14

7.5 The Position Unit of PR Mode ....................................................................... 7-14

7.6 Description of Register in PR Mode ............................................................... 7-14

7.7 Description of Homing in PR Mode ................................................................ 7-16

7.8 DI/DO Provide by PR Mode and Diagrams ................................................... 7-16

7.9 Parameter Settings in PR Mode .................................................................... 7-18

7.9.1 The Relation between the Previous Path and Next Path .................... 7-28

7.9.2 Programming the Path in PR Mode .................................................... 7-29

7.10 The Description of E-Cam Function ............................................................... 7-30

7.10.1 Function Description of CAPTURE (Data Capture) ............................ 7-39

7.10.2 Function Description of COMPARE (Data Compare) ......................... 7-42

Chapter 8 Parameters

8.1 Parameter Definition ...................................................................................... 8-1

Revision December, 2014

Page 12

ASDA-M Table of Content

8.2 Parameters .................................................................................................... 8-2

8.3 Parameter Description ................................................................................... 8-12

P0-xx Monitor Parameters .............................................................................. 8-12

P1-xx Basic Parameters ................................................................................. 8-38

P2-xx Extension Parameters .......................................................................... 8-79

P3-xx Communication Parameters ................................................................. 8-118

P4-xx Diagnosis Parameters .......................................................................... 8-127

P5-xx Motion Setting Parameters ................................................................... 8-142

P6-xx PR Parameters ..................................................................................... 8-198

P7-xx PR Parameters ..................................................................................... 8-248

Table 8.1 Function Description of Digital Input (DI) ......................................... 8-298

Table 8.2 Function Description of Digital Output (DO) .................................... 8-305

Chapter 9 Communication

9.1 RS-485/RS-232 Communication Hardware Interface ................................. 9-1

9.2 RS-485/RS-232 Communication Parameters Setting ................................. 9-4

9.3 MODBUS Communication Protocol ............................................................... 9-8

9.4 Write-in and Read-out in Communication Parameters .................................. 9-19

Chapter 10 Troubleshooting

10.1 Alarm of Servo Drive ..................................................................................... 10-1

10.2 Alarm of CANopen Communication ............................................................... 10-4

10.3 Alarm of Motion Control ................................................................................. 10-7

Revision December, 2014

Page 13

Table of Content ASDA-M

10.4 Causes and Corrective Actions ..................................................................... 10-12

10.5 Corrective Actions after the Alarm Occurs ..................................................... 10-36

Chapter 11 Specifications

11.1 Specifications of Servo Drive (ASDA-M Series) ............................................ 11-1

11.2 Specifications of Servo Motor (ECMA Series) ............................................... 11-4

11.3 Torque Features (T-N curve) ......................................................................... 11-12

11.4 Overload Features ......................................................................................... 11-13

11.5 Dimensions of the Servo Drive ...................................................................... 11-15

11.6 Dimensions of the Servo Motor ..................................................................... 11-17

Appendix A Accessories

Appendix B Maintenance and Inspection

Revision December, 2014

Page 14

Chapter 1 Inspection and Model

Explanation

1.1 Inspection

In order to prevent the negligence during purchasing and delivery, please inspect the

following items carefully.

Please c heck if the product is what you have purchased: check the part number of

the motor and the servo drive on the nameplate. Refer to the next page for the model

explanation.

Check if the motor shaft can rotate smoothly: Rotate the motor shaft by hand. If it

can be rotated smoothly, it means the motor shaft is normal. However, it cannot be

rotated by hand if the motor has an electromagnetic brake.

Check if there is any damage shown on its appearance: visually check if there is any

damage or scrape of the appearance.

Check if there is any loose screw: If the screws are un-tightened or fall off.

If any of the above situations happens, please contact the distributors to solve the

problems.

A complete and workable servo set should include:

(1) A Servo drive and a servo motor

(2) Three UVW motor power cables, the U, V and W wires can connect to the socket

attached by the servo drive and another side is the plug which could connect to the

socket of the motor. And a green ground wire which should be locked to the ground

terminal of the servo drive. (selective purchase)

(3) Three encoder cables which connect to the socket of the encoder. One side of it

connects to CN2 servo drive and another side is the plug. (selective purchase)

(4) 50-PIN connector which is used in CN1 (3M analog product) (selective purchase)

(5) 20-PIN connector which is used in CN2 (3M analog product) (selective purchase)

(6) 6-PIN connector which is used in CN3 (IEEE 1394 analog product) and is for

general communication (RS485) (selective purchase)

(7) 4-PIN connector which used in CN4 (USB Type B product) (selective purchase)

(8) RJ45 connector which used in CN6 and is for high-speed communication

(selective purchase)

(9) Servo drive power input:

(a) 750W and 1.5 kW: 2 PIN fast connector (L1c, L2c)

(b) 750W and 1.5 kW: 3 PIN fast connector (R, S, T)

(10) 3 sets of 3-PIN fast connector (U, V, W)

(11) 4-PIN fast connector (P , D, C, )

(12) A plastic lever (attached in all series)

(13) A metal short-circuit chip (attached in all series)

(14) An installation manual

Revision December, 2014 1-1

Page 15

Chapter 1 Inspection and Model Explanation ASDA-M

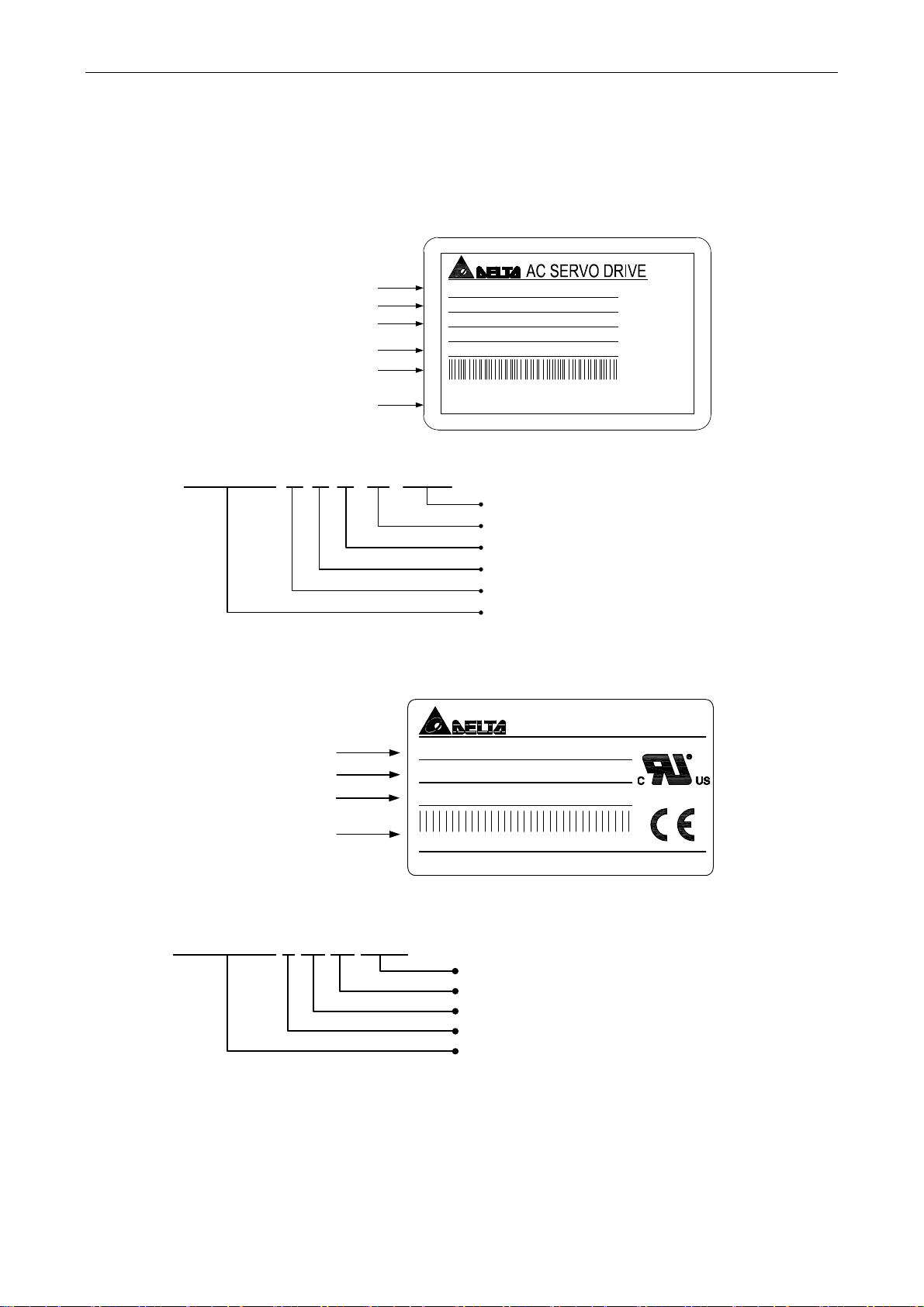

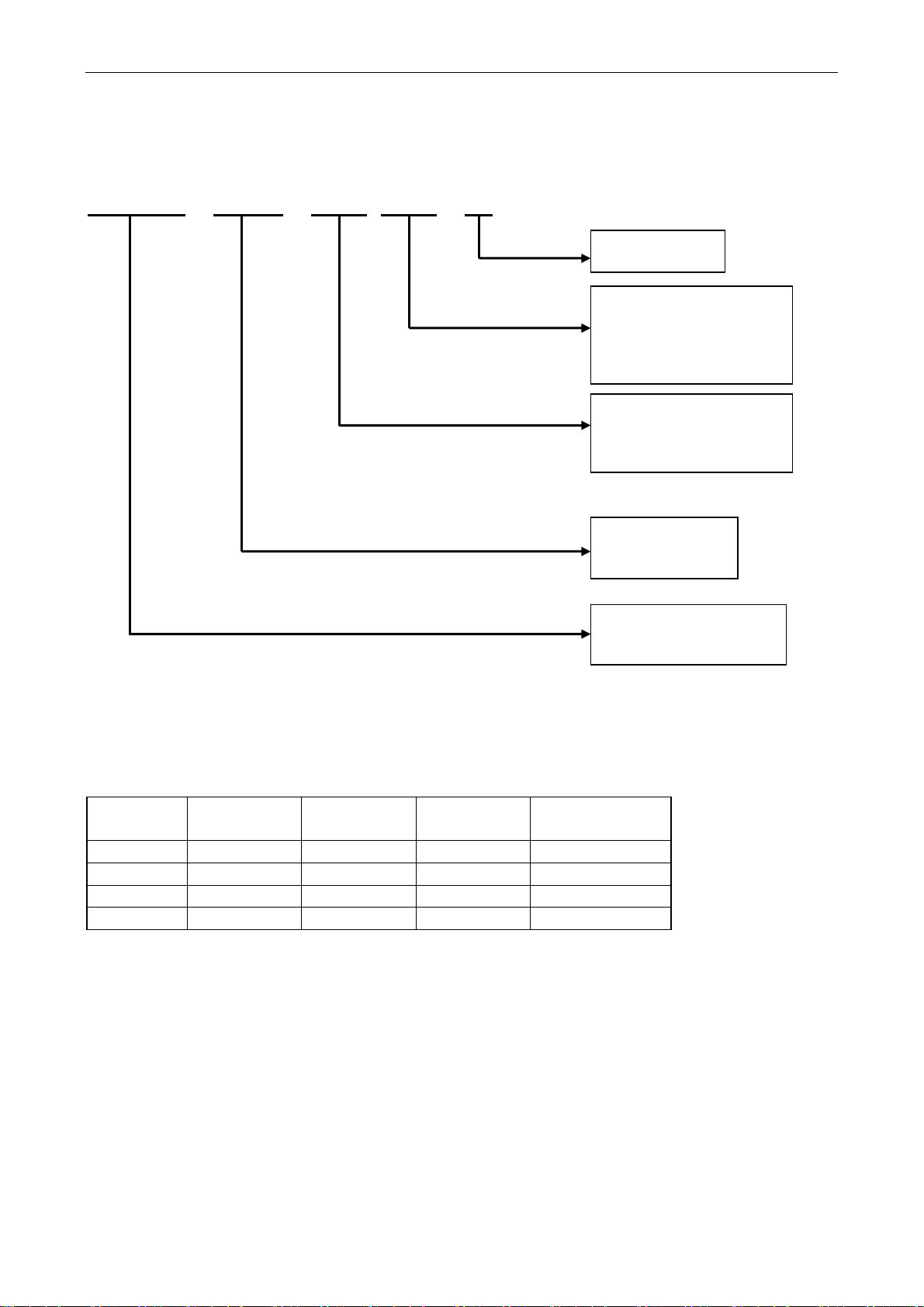

1.2 Product Model

1.2.1 Nameplate Information ASDA-M Series Servo Drive

Nameplate Information

Model Name

Power Specification

Power Input Specification

Power Output Specification

Barcode & Serial Number

Firmware Version

Serial Number

M0721F 6 T 14 45 0003

ECMA Series Servo Motor

Nameplate Information

Model Name

Power Input Specification

Power Output Specification

Barcode &

Serial Number

Serial Number

MODEL : AS D - M-0721- F

POWER : 750W

INPUT : 200 ~ 230V 3PH 50/60H z 9. 51A

200~230V 1PH 50/60Hz 18.3A

OUTPUT : 110V 0-250Hz 5.1A

M0721M6T1100001

01.70

DELT A ELECTRO NICS, INC.

Serial Number

Production Week

Production Year

0: Year of 2010)

(starts from 0001 every week)

(from 1 to 52)

(14: Year of 2014 or

Production Factory

Delta St a ndard (

6: for RoHs)

Model Name

AC SERVO MOTOR

MODE L : ECMA- E 11320 RS

INPUT : kW 2.0 VAC 110 A 11.0

OUTPUT : r/min 2000 N.m 9.55 Ins.A

E11320RS T133 70017

Delta Electronics, Inc.

MADE IN TAIWAN

MADE IN XXXXXX

(T: Taoyuan; W: Wujiang)

E11320RS T 13 37 0017

Serial Num ber (S tarts from 00 01 every week)

Production Week (From 1 to 52)

Production Year (13: Year of 2013)

Production Factory (T: Taoyuan; W: Wujiang)

Model Name

1-2 Revision December, 2014

Page 16

ASDA-M Chapter 1 Inspection and Model Explanation

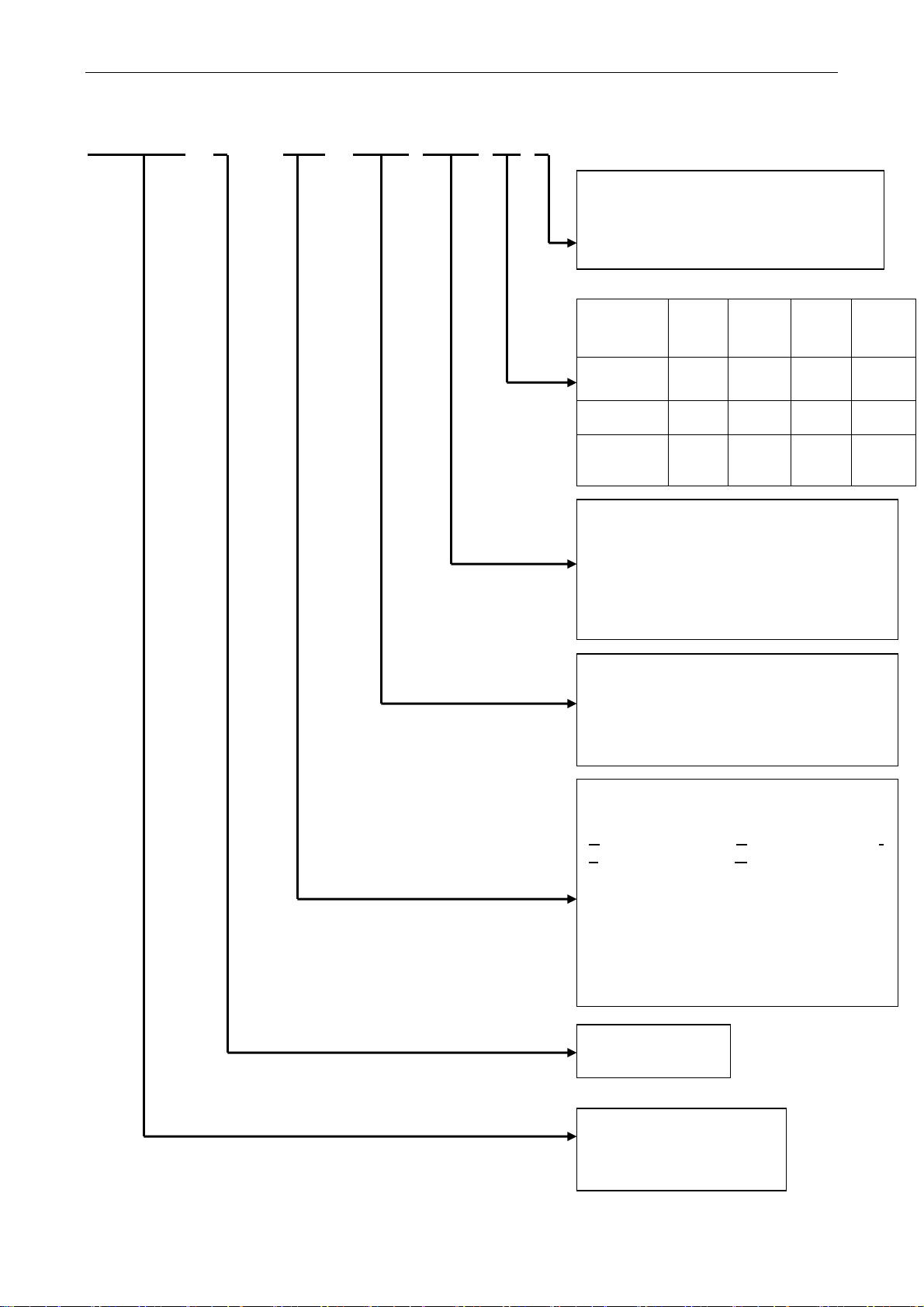

1.2.2 Model Explanation

ASDA-M Series Servo Drive

ASD-M-0721-L

Model T ype

Input Voltage and

Phase

21: 220V 1 phase/3

phase

Rated Power Input

07: 750W

15: 1.5kW

Model T ype

Type

M

F

L

R

Product Series

M

Product Name

AC SERVO Drive

Full-closed

Loop

○ ○ × ○

○ × ○ ○

○ × × ×

○ × ○ ○

CANopen DMCNET E-CAM

Revision December, 2014 1-3

Page 17

Chapter 1 Inspection and Model Explanation ASDA-M

A:A

ECMA Series Servo Motor

ECMA-C10602ES

Standard Shaft Diameter: S

Specific Shaft Diameter: 3=42mm,

7=14mm

Type of Shaft

Diameter and

Oil Seal

Round Shaft

(with fixed

screw holes)

Keyway E F G H

Keyway

(with fixed

screw holes)

w/o

Brake

w/o Oil

Seal

A B C D

P Q R S

with

Brake

w/o Oil

Seal

Rated Power Output

0F:50 W 05:500 W 10:1.0 kW

01:100 W 06:600 W 13:1.3 kW

02:200 W 07:750 W 15:1.5 kW

03:300 W 08:850 W 18:1.8 kW

04:400 W 09:900 W

w/o

Brake

with Oil

Seal

Motor Frame Size

04: 40 mm 09: 86 mm

06: 60 mm 10:100 mm

With

Brake

With Oil

Seal

08: 80 mm 13:130 mm

Name of the Series

Rated Voltage and Rated Speed

C = 220V/3,000 rpm; E = 220V/2,000 rpm;

F = 220V/1,500 rpm; G = 220V/1,000 rpm;

Sensor Type

1: Incremental, 20-bit (For the drive which

is under 3kW)

2: Incremental, 17-bit

3: 2500 ppr

A: Absolute ( Resolution of single cycle:

17-bit; Resolution/multi-cycle:16-bit)

Servo T ype

C Servo

Product Name

ECM: Electronic

Commutation Motor

1-4 Revision December, 2014

Page 18

ASDA-M Chapter 1 Inspection and Model Explanation

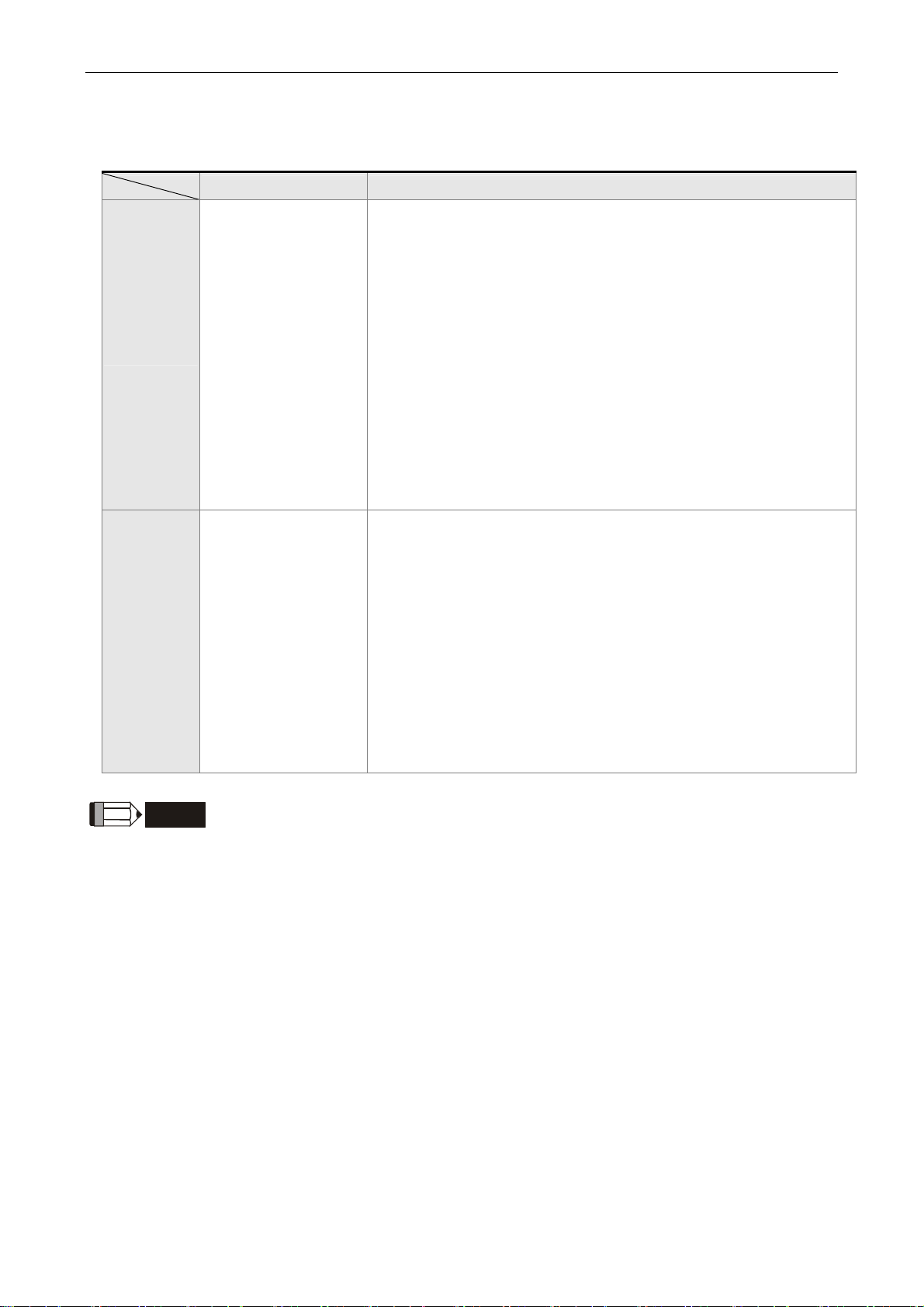

1.3 Servo Drive and Corresponding Servo Motor

ASDA-M Series Servo Drive

Servo Drive Corresponding Servo Motor

ECMA-C1040FS(S=8 mm)

750W ASD-M-0721-

1500W ASD-M-1521-

ECMA-C

ECMA-C

ECMA-C

ECMA-C△0604H ( H = high-inertia)

ECMA-C

ECMA-C

ECMA-C△0807H ( H=high-inertia)

ECMA-C

ECMA-E

ECMA-G

ECMA-G

ECMA-C△0807S(S=19 mm)

ECMA-C△0807H ( H=high-inertia)

ECMA-C

ECMA-C

ECMA-C

ECMA-E

ECMA-F△1308S(S=22 mm)

△0401S(S=8 mm)

△0602S(S=14 mm)

△0604S(S=14 mm)

△08047(7=14 mm)

△0807S(S=19 mm)

△0907S(S=16 mm)

△1305S(S=22 mm)

△1303S(S=22 mm)

△1306S(S=22 mm)

△0907S(S=16 mm)

△0910S(S=16 mm)

△1010S(S=22 mm)

△1310S(S=22 mm)

ECMA-F△1313S(S=22 mm)

ECMA-E△1315S(S=22 mm)

ECMA-G

△1309S(S=22 mm)

NOTE

1) Box, () at the end of the model name of the servo drive represents the code of

ASDA-M. Please refer to the type of purchasing product information.

2) Triangle, (△) in the mode name of the servo motor represents the type of encoder.

△=1: incremental, 20-bit;△=2: incremental, 17-bit; △=3: 2500 ppr; △=A: Absolute.

The listed model name is for reference. To purchase the product, please contact the

local dealer for product availability.

3) Box, () in the model name of the servo motor represents the type of brake or

keyway / oil seal.

The above table shows the specification of servo drive which has triple rated current. If the

user needs the servo drive which has six times of the rated current, please contact with

distributors. For detailed specification of the servo motor and servo drive, please refer to

the appendix.

Revision December, 2014 1-5

Page 19

Chapter 1 Inspection and Model Explanation ASDA-M

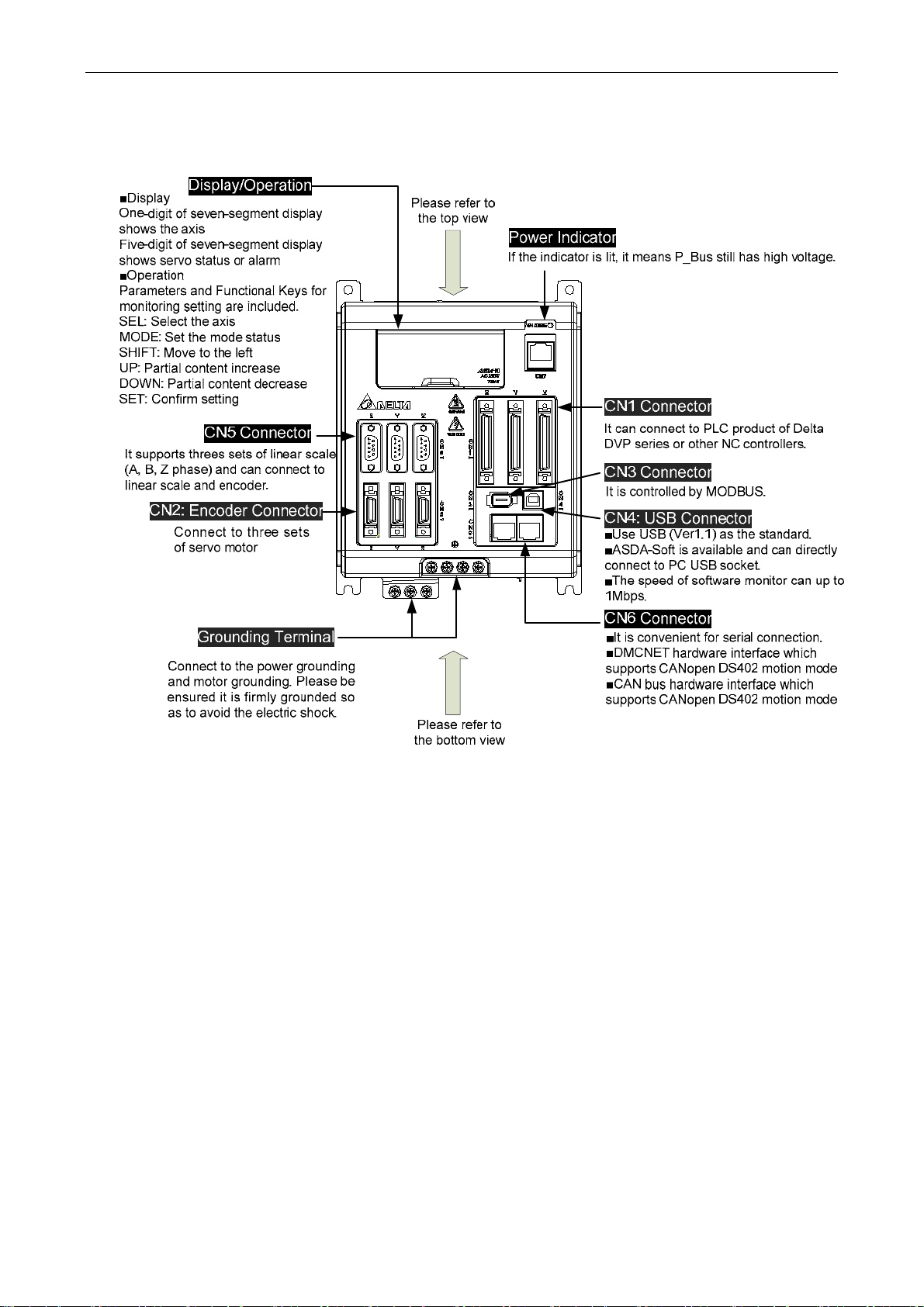

1.4 Features of Servo Drive

ASDA-M Series Servo Drive

1-6 Revision December, 2014

Page 20

ASDA-M Chapter 1 Inspection and Model Explanation

ASDA-M Series Servo Drive (top view)

Revision December, 2014 1-7

Page 21

Chapter 1 Inspection and Model Explanation ASDA-M

ASDA-M Series Servo Drive (bottom view)

1-8 Revision December, 2014

Page 22

Chapter 2 Installation

2.1 Notes

Please pay special attention to the followings:

1) Do not strain the cable connection between the servo drive and the servo motor.

2) Make sure each screw is tightened when fixing the servo drive.

3) The motor shaft and the ball screw should be parallel.

4) If the connection between the servo drive and the servo motor is over 20 meters, please

thicken the connecting wire, UVW as well as the encoder cable.

5) Tighten the fixed four screws of the motor.

2.2 Ambient Conditions of Storage

Before the installation, this product has to be kept in shipping carton. In order to retain the

warranty coverage and for the maintenance, please follow the instructions below when

storage, if the product is not in use temporally:

Store the product in a dry and dust-free location.

Store the product within an ambient temperature range of -20℃ to +65℃.

Store the product within a relative humidity range of 0% to 90% and a non-condensing

environment.

Avoid storing the product in the environment of corrosive gas and liquid.

It is better to store the product in shipping carton and put it on the shelf or working

platform.

Revision December, 2014 2-1

Page 23

Chapter 2 Installation ASDA-M

2.3 Ambient Conditions of Installation

The best temperature of this servo drive is between 0℃ and 55℃. If the temperature is over

45℃, please place the product in a well-ventilated environment so as to ensure its reliability

performance. If the product is installed in an electric box, make sure the size of the electric

box and its ventilation condition will not overheat and endanger the internal electronic

device. Also, pay attention to the vibration of the machine. Check if the vibration will

influence the electronic device of the electric box. Besides, the ambient conditions should

also include:

Location has no over-heat device.

Location has no water drop, vapor, dust and oily dust.

Location has no corrosive and inflammable gas and liquid.

Location has no airborne dust and metal particles.

Location has solid foundation and no vibration.

Location has no interference of electromagnetic noise.

The ambient temperature of the motor is between 0℃ and 40℃ and the ambient conditions

include:

Location has no over-heat device.

Location has not water drop, vapor, dust and oily dust.

Location has no corrosive and inflammable gas and liquid.

Location has no airborne dust and metal particles.

2-2 Revision December, 2014

Page 24

ASDA-M Chapter 2 Installation

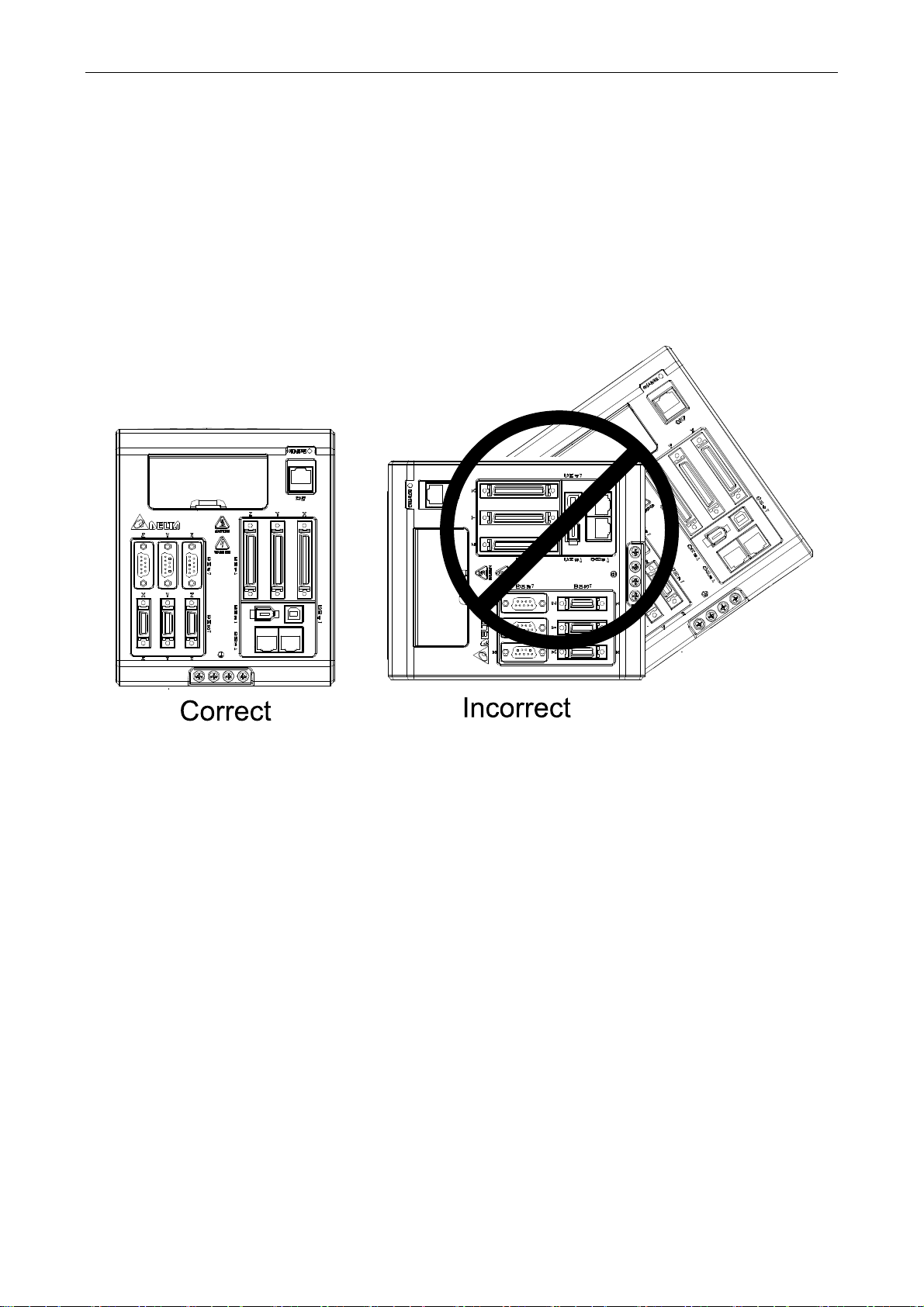

2.4 Installation Direction and Space

Notes:

Follow the instructions for installation direction. Otherwise it is possible to cause

malfunction. In order to have well-cooling and circulation effect, the enough space between

adjacent objects and the baffle is needed. Or it might result in malfunction. When installing

AC servo drive, do not seal the suction hole and the vent hole. Do not place the drive in a

horizontal direction, or it might cause malfunction.

Revision December, 2014 2-3

Page 25

Chapter 2 Installation ASDA-M

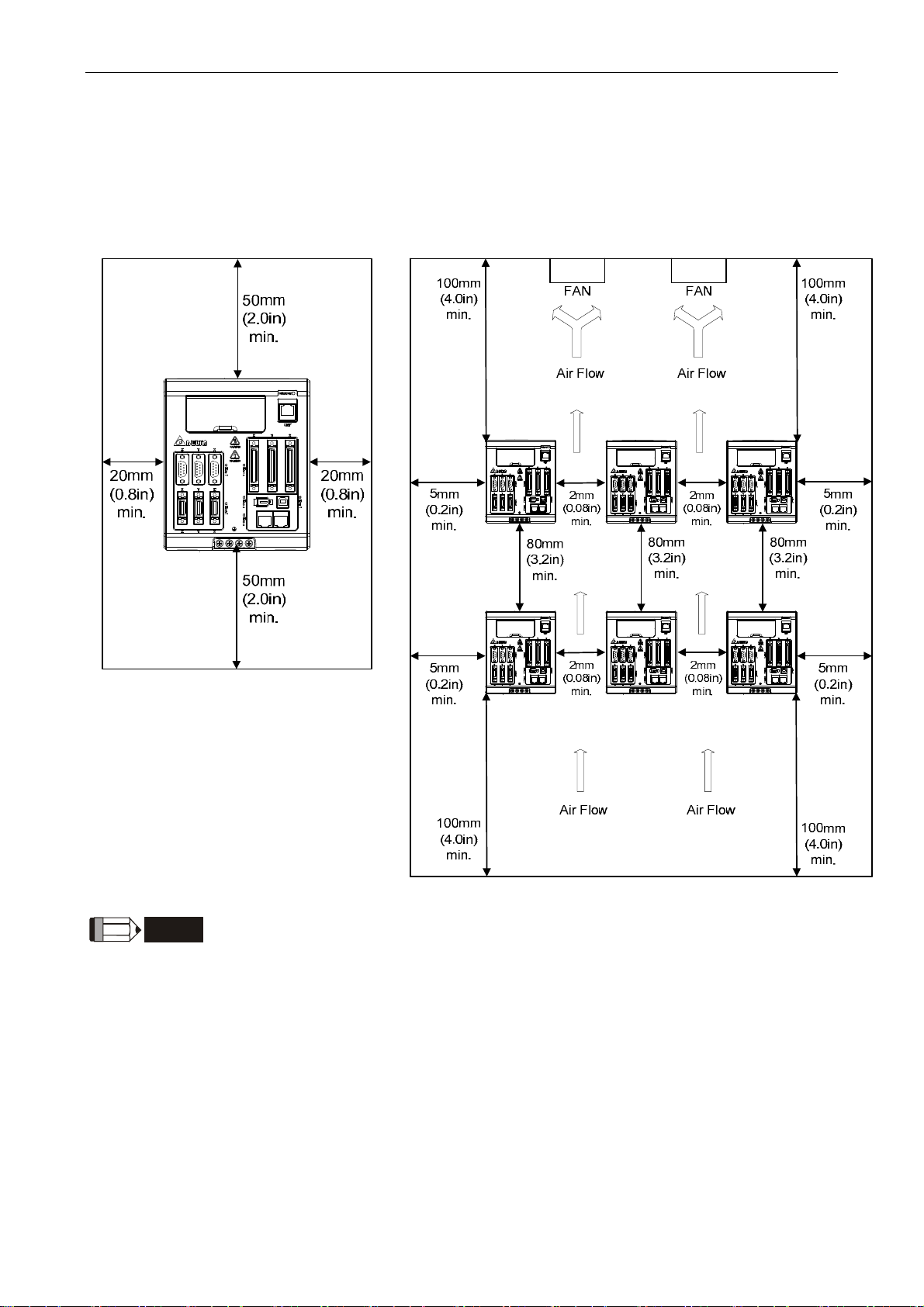

Dimensions:

In order to have smaller wind resistance of the fan and increase the ventilation, please

follow the suggested clearance value when installing one or more than one servo drives.

(Refer to the following diagrams)

NOTE

2-4 Revision December, 2014

The above diagrams are not in equal proportion. Please refer to the

annotation.

Page 26

ASDA-M Chapter 2 Installation

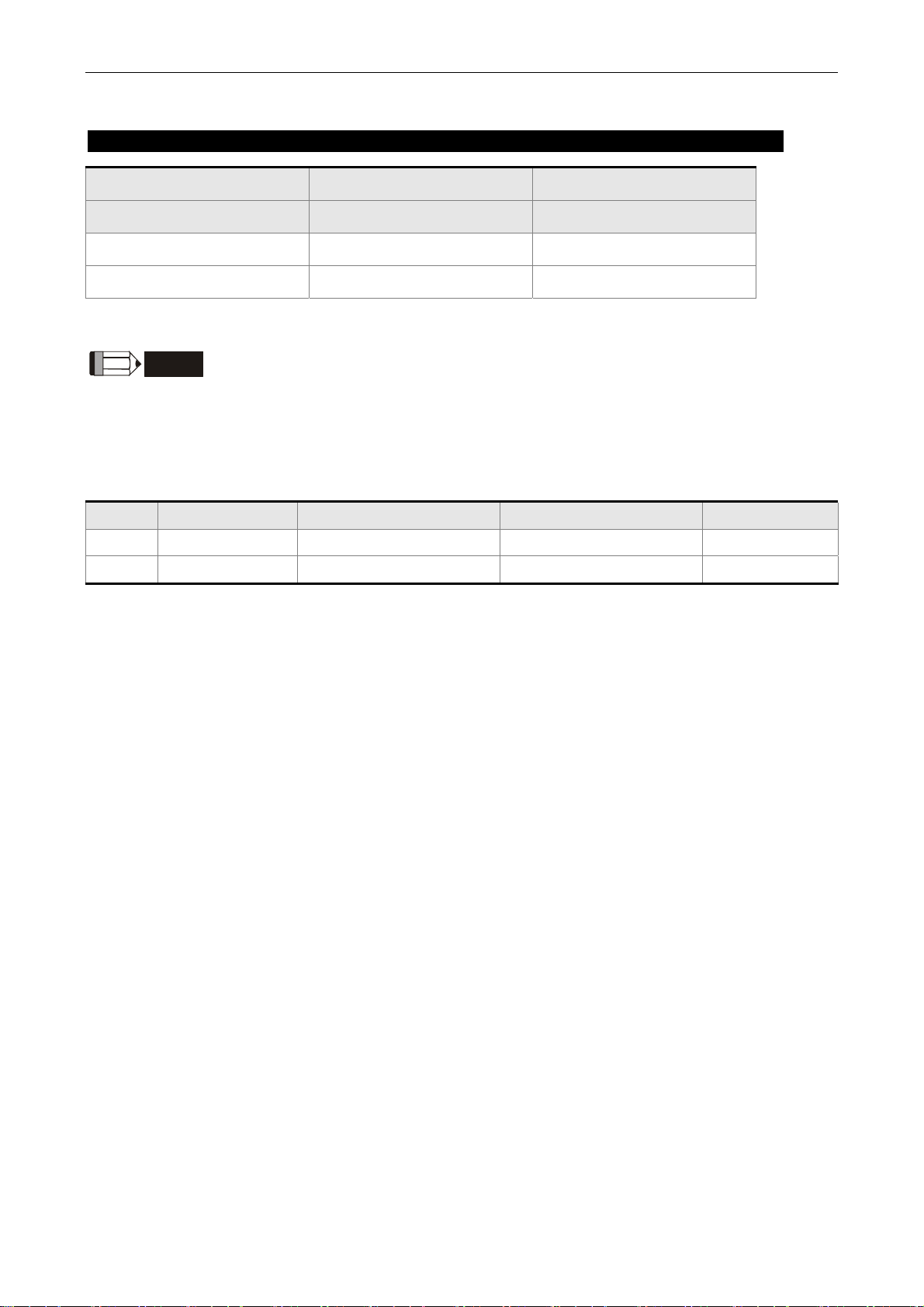

2.5 Specification of Circuit Breaker and Fuse

Caution: Please use the fuse and circuit breaker that is recognized by UL/CSA.

Servo Drive Model Circuit breaker Fuse (Class T)

Operation Mode General General

ASD-M-0721-

ASD-M-1521-

30A 50A

70A 140A

If the servo drive equips with earth leakage circuit breaker for avoiding

NOTE

electric leakage, please choose the current sensitivity which is over

200mA and can continue up to 0.1 seconds.

2.6 EMI Filters Selection

Item Power Servo Drive Model EMI Filter Model FootPrint

1 750W ASD-M-0721- 20TDT1W4D N

2 1500W ASD-M-1521- 20TDT1W4D N

EMI Filter Installation

All electronic equipment (including servo drive) generates high or low frequency noise

during operation and interfere the peripheral equipments via conduction or radiation. With

EMI Filter and the correct installation, much interference can be eliminated.

When installing servo drive and EMI Filter, please follow the instructions of the user manual

and make sure it meets the following specification.

1. EN61000-6-4 (2001)

2. EN61800-3 (2004) PDS of category C2

3. EN55011+A2 (2007) Class A Group 1

Revision December, 2014 2-5

Page 27

Chapter 2 Installation ASDA-M

General Precaution

In order to ensure the best performance of EMI Filter, apart from the instructions of servo

drive installation and wiring, please follow the precautions mention below:

1. The servo drive and EMI Filter should be installed on the same metal plate.

2. When installing servo drive and EMI Filter, the servo drive should be installed above

the EMI Filter.

3. The wiring should be as short as possible.

4. The metal plate should be well grounded.

5. The metal cover of the servo drive and EMI Filter or grounding should be firmly fixed

on the metal plate. Also, the contact area should be as large as possible.

Motor Cable Selection and Installation Precautions

The selection of motor cables and correct installation affect the performance of EMI Filter.

Please follow the precautions mention below.

1. Use the cable that has braid shielding (The effect of double shielding is better)

2. The shield on both sides of the motor cable should be grounded in the shortest

distance and the largest contact area.

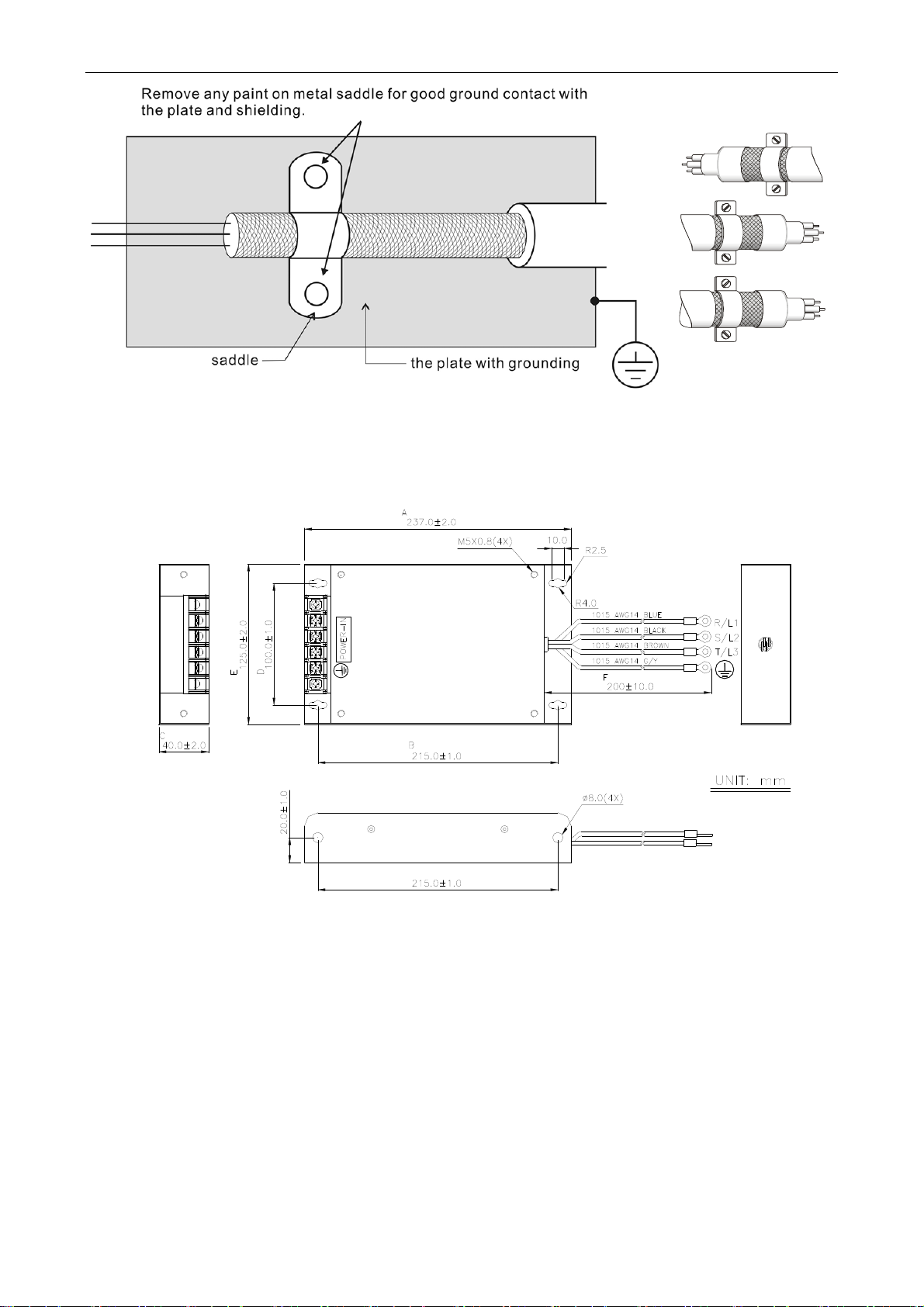

3. The protective paint of the U-shape saddle and metal plate should be removed in

order to ensure the good contact. Please see disgram 1.

4. It should have correct connection between the braid shielding of the motor cable and

the metal plate. The braid shielding on both sides of the motor cable should be fixed

by the U-shape saddle and metal plate. Please see diagram 2 for the correct

connection.

2-6 Revision December, 2014

Page 28

ASDA-M Chapter 2 Installation

Diagram 1 Diagram 2

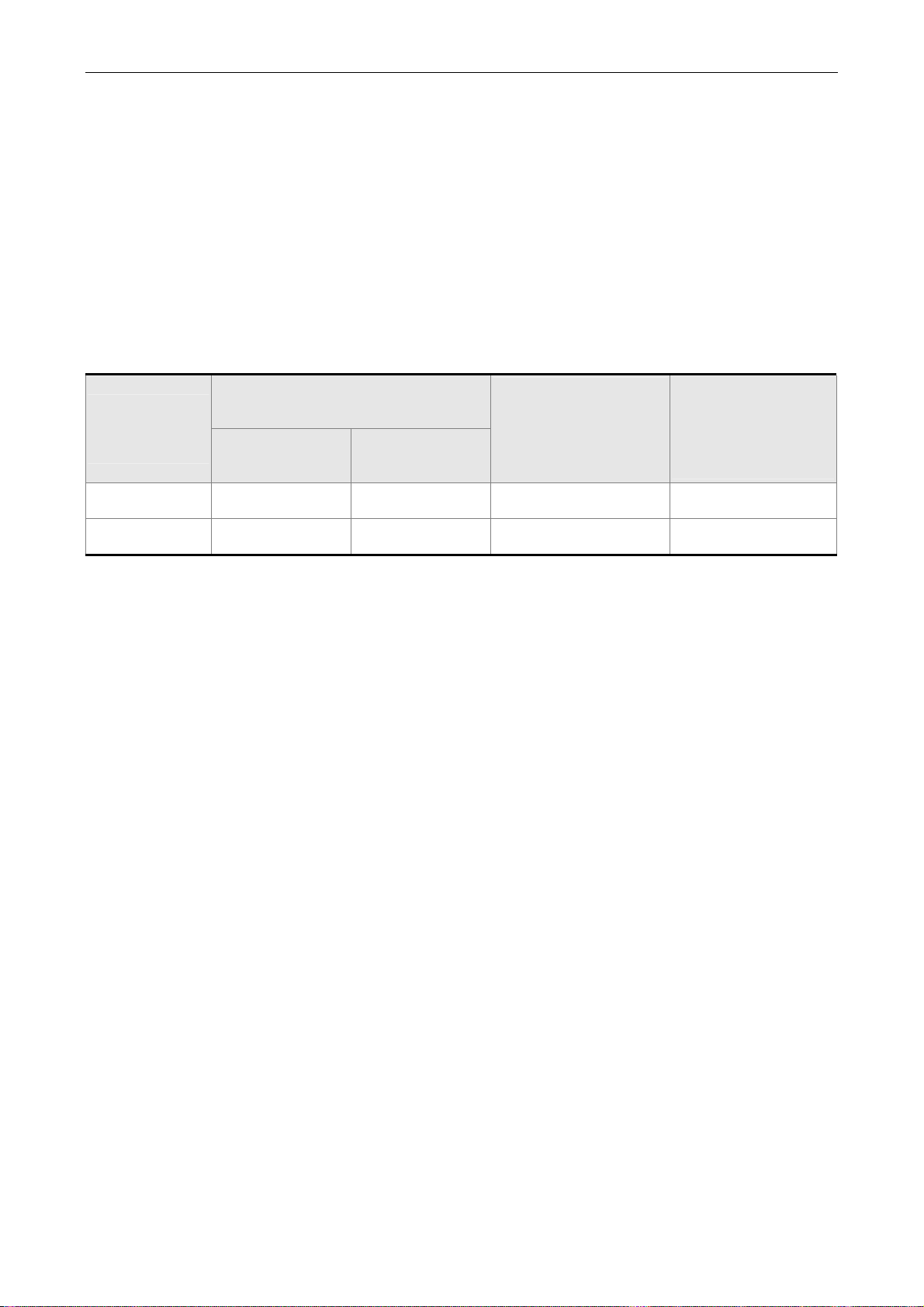

Dimensions of EMI Filter

Delta Part Number: 20TDT1W4D

Revision December, 2014

2-7

Page 29

Chapter 2 Installation ASDA-M

2.7 Selection of Regenerative Resistor

When the direction of pull-out torque is different from the rotation, it means the electricity is

sent back to the servo drive from the load-end. It becomes the capacitance of DC Bus and

increases the voltage. When the voltage increases to a specific value, the come-back

eletricity can only be consumed by regenerative resistor. There is a built-in regenerative

resistor in the servo drive. Users can also use the external regenerative resistor if needed.

The following table is the specification of built-in regenerative resistor provided by ASDA-M

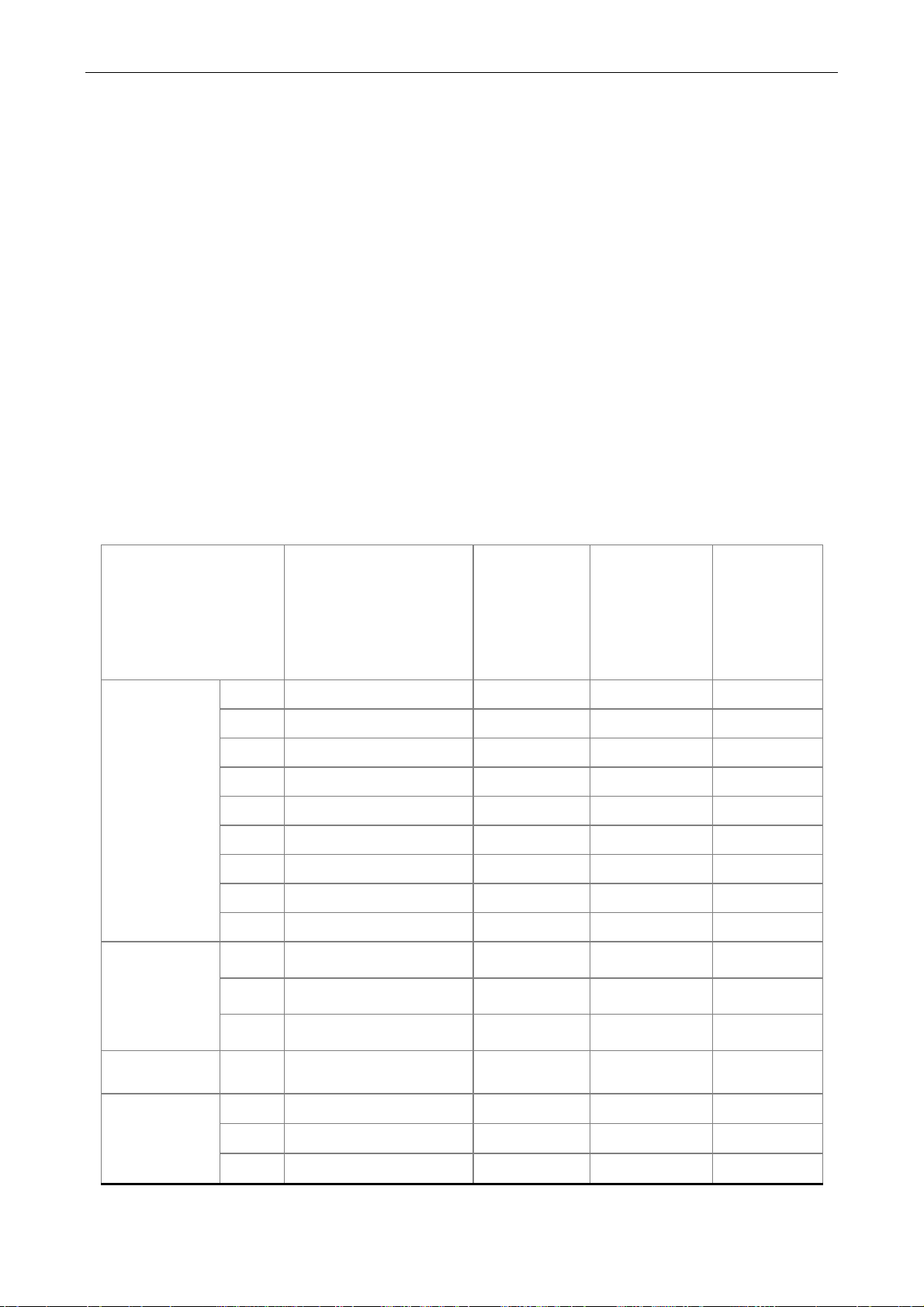

series.

Specification of built-in

Servo Drive

(kW)

0.75 40 60 30 30

1.5 20 100 50 20

*1 The capacity of built-in regenerative resistor (average value) is 50% of the rated capacity

of the built-in regenerative resistor. The capacity of the external regenerative resistor is

the same as the built-in one.

When the regenerative resistor exceeds the capacity of built-in regenerative resistor, the

external regenerative resistor should be applied. Please pay special attention to the

followings when using the regenerative resistor.

1. Please correctly set up the resistance (P1-52) and capacity (P1-53) of the

regenerative resistor. Or it might influence the performance of this function.

regenerative resistor

Resistance

(P1-52) (Ohm)

Capacity

(P1-53) (Watt)

*1 The capacity of

built-in regenerative

resistor

(Watt)

Minimum allowable

resistance

(Ohm)

2. If users desire to use the external regenerative resistor, please make sure the applied

value is the same as the built-in regenerative resistor. If users desire to connect it in

parallel to increase the power of regenerative resistor, please make sure the

capacitance meets the requirements.

3. In natural environment, if the capacity of regenerative resistor (the average value) is

within the rated capacity, the temperature of the capacitance will increase to 120℃ or

even higher (under the condition of regenerative energy keeps existing). For safety

concerns, please apply the method of forced cooling in order to reduce the

temperature of regenerative resistor. Or, it is suggested to use the regenerative

resistor which is equipped with thermal switches. Please contact the distributors for

load characteristics of the regenerative resistor.

2-8 Revision December, 2014

Page 30

ASDA-M Chapter 2 Installation

When using the external regenerative resistor, the resistor should connect to P, C terminal

and the contact of P, D terminal should be opened. It is recommended to choose the above

mentioned capacitance. For easy calculation of regenerative resistor capacity, except the

energy consumed by IGBT, two ways are provided to select the capacity of external

regenerative resistor.

(1) Regenerative Power Selection

(a) When the external load on torque does not exist

If the motor operates back and forth, the energy generated by the brake will go into

the capacitance of DC bus. When the voltage of the capacitance exceeds a specific

value, the redundant energy will be consumed by regenerative resistor. Two ways of

selecting regenerative resistor are provided here. The table below provides the

energy calculation method. Users can refer to it and calculate the selected

regenerative resistor.

Servo Drive

(kW)

0.75

0.75

0.75

0.75

Low

Inertia

0.75

0.75

0.75

1.5

1.5

0.75

Medium

Inertia

1.0

2.0

Motor

ECMA-Cᇞ040F□□

ECMA-Cᇞ0401□□

ECMA-Cᇞ0602□□

ECMA-Cᇞ0604□□

ECMA-Cᇞ0804□□

ECMA-Cᇞ0807□□

ECMA-Cᇞ0907□□

ECMA-Cᇞ1010□□

ECMC-Cᇞ0910□□

ECMA-Eᇞ1305□□

ECMA-Eᇞ1310□□

ECMA-Eᇞ1315□□

Regenerative

Rotor Inertia

J

-4

(× 10

kg.m2)

0.021

0.037

0.177

0.277

0.68

1.13

1.93

2.65

2.62

power from

empty load

3000r/min to

stop

Eo (joule)

0.10 4.21

0.18 4.21

0.87 5.62

1.37 8.42

3.36 8.42

5.59 17.47

9.54 17.47

13.10 21.22

12.96 21.22

8.17 40.40

8.41 41.59

The Maximum

regenerative

power of

capacitance

Ec (joule)

8.42

21.22

11.18 55.29 25.58

Medium-High

Inertia

High

Inertia

Eo= J * wr2/182(joule), Wr : r/min

Revision December, 2014 2-9

1.5

0.75

0.75

1.5

ECMA-Fᇞ1308□□

ECMA-Gᇞ1303□□

ECMA-Gᇞ1306□□

ECMA-Gᇞ1309□□

13.6 67.25 21.22

8.17 17.96 8.42

8.41 18.48 17.47

11.18 24.57 21.22

Page 31

Chapter 2 Installation ASDA-M

Assume the load inertia is N times to the motor inertia and the motor decelerates from

3000r/min to 0, its regenerative energy is (N+1) × Eo. The consumed regenerative

resistor is (N+1) × Eo-Ec joule. If the cycle of back and forth operation is T sec, then

the power of regenerative resistor it needs is 2×((N+1) × Eo-Ec)/ T.

Followings are the calculation procedure:

Steps Item Calculation and Setting Method

Set the capacity of regenerative

1

Set P1-53 to the maximum value

resistor to the maximum

Set T cycle of back and forth

2

Enter by the user

operation

3 Set the rotational speed wr Enter by the user or read via P0-02

4 Set the load/motor inertia ratio N Enter by the user or read via P0-02

Calculate the maximum

5

Eo= J * wr2/182

regenerative energy Eo

Set the absorbable regenerative

6

Refer to the above table

energy Ec

Calculate the needful capacitance

7

2 ×((N+1) × Eo-Ec)/ T

of regenerative resistor

Take 400W as the example, the cycle of back and forth operation is T = 0.4sec, the

maximum speed is 3000r/min and the load inertia is 7 times to the motor inertia. Then,

the needful power of regenerative resistor is 2 ×((7+1) × 1.68-8)/ 0.4 = 27.2W. If it is

smaller than the built-in capacity of regenerative resistor, the built-in 60W

regenerative resistor will do. Generally speaking, when the need of the external load

inertia is not much, the built-in regenerative is enough. The diagram below describes

the actual operation. The smaller power of the regenerative resistor it has, the more

energy it accumulates and the higher temperature will be. When the temperature is

higher than a specific value, ALE05 occurs.

2-10 Revision December, 2014

Page 32

ASDA-M Chapter 2 Installation

(b) When the external load torque exists, the motor is in reverse rotation.

Usually, the motor is in forward rotation, which means the torque output direction of

the motor is the same as the rotation direction. However, in some applications, the

direction of torque output is different from the rotation. In this situation, the motor is in

reverse rotation. The external energy goes into the servo drive through the motor. The

diagram below is one of the examples. When the motor is in constant speed, it is

positive torque in most of the time and a huge amount of energy rapidly transmits to

regenerative resistor.

Negative torque: TL × Wr TL: external load torque

For safety reasons, please calculate it by considering the safest situation.

For example, when the external load torque is the +70% rated torque and the rotation

reaches 3000 r/min, then take 400W (the rated torque is 1.27Nt-m) as the example,

the user has to connect the regenerative resistor which is 2 × (0.7× 1.27) × (3000 × 2 × π

/60) = 560W.

(2) Simple Selection

Choose the appropriate regenerative resistor according to the allowable frequency

and empty load frequency in actual operation. The so-called empty allowable

frequency is the frequency of continuous operation when the servo motor runs from

Revision December, 2014

2-11

Page 33

Chapter 2 Installation ASDA-M

0r/min to the rated speed and then decelerates from the rated speed to 0r/min. The

following table lists the allowable frequency of built-in regenerative resistor when the

servo drive runs without load (times/min).

Allowable frequency of built-in regenerative resistor when the servo drive runs without load

(times/min)

Motor Capacity

Corresponding

Motor

ECMA□□C

ECMA□□E

ECMA□□G

When the servo motor runs with load, the allowable frequency will be different

according to different load inertia or speed. The following is the calculation method.

m represents load / motor inertia ratio.

Allowable frequency =

The comparison table of external regenerative resistor is provided below. Please

600W 750W 900W 1.0kW 1.5kW

06 07 09 10 15

- 312 - 137 -

- - - 42 32

42 - 31 - -

2

Allowable frequency when servo motor run without load

m + 1

Rated speed

x

Operating speed

times

min.

choose the appropriate regenerative resistor according to the allowable frequency.

The table below describes the suggested allowable frequency (times/min) of

regenerative resistor when the servo drive runs without load.

2-12 Revision December, 2014

Page 34

ASDA-M Chapter 2 Installation

Allowable frequency of regenerative resistor when the servo drive runs without load

(times/min)

Motor Capacity

Suggested Regenerative

400W

200W

(F60)

ECMA□□C

400W

750W 1.0kW

(F80)

02 04 04 07 10

Resistor

BR400W040 (400W 40Ω) - 8608 3506 2110 925

BR1K0W020 (1kW 20Ω) - - 8765 5274 2312

Motor Capacity

0.5kW 1kW 1.5kW

ECMA□□E

Suggested Regenerative

Resistor

05 1.0 15

BR400W040 (400W 40Ω) 291 283 213

BR1K0W020 (1kW 20Ω) 729 708 533

Motor Capacity

0.3kW 0.6kW 0.9kW

ECMA□□G

Suggested Regenerative

Resistor

03 06 09

BR400W040 (400W 40Ω) 292 283 213

BR1K0W020 (1kW 20Ω) 729 708 533

If watt is not enough when using regenerative resistor, connecting the same regenerative

resistor in parallel can increase the power.

ASDA-M can control three motors at the same time. If the energy of three

NOTE

motors goes into the servo drive, the power of regenerative resistor

needs to be increased to three times of the origin.

Revision December, 2014 2-13

Page 35

Chapter 2 Installation ASDA-M

Dimensions of Regenerative Resistor

Delta Part Number: BR400W040 (400W 40Ω)

L1 L2 H D W MAX. WEIGHT (g)

265 250 30 5.3 60 930

Delta Part Number: BR1K0W020 (1kW 20Ω)

L1 L2 H D W MAX. WEIGHT (g)

400 385 50 5.3 100 2800

2-14 Revision December, 2014

Page 36

ASDA-M Chapter 2 Installation

Delta Part Number: BR1K5W005 (3kW 10Ω)

Revision December, 2014 2-15

Page 37

Chapter 2 Installation ASDA-M

(This page is intentionally left blank.)

2-16 Revision December, 2014

Page 38

Chapter 3 Wiring

This chapter details the wiring method of servo drive, the definition of each signal and

standard wiring diagram.

3.1 Connection between Peripheral Devices and Main Power

Circuit

3.1.1 Wiring Diagram of Peripheral Devices

Revision December, 2014 3-1

Page 39

Chapter 3 Wiring ASDA-M

NOTE

Installation Notes:

1) Check if the power and wiring among R, S, T and L1c, L2c are correct.

2) Check if the output terminal U, V, W of the servo motor is correctly wired. The

incorrect wiring may disable the operation of the motor or cause the malfunction.

3) When applying to the external regenerative resistor, the contact between P

D should be opened and the external regenerative resistor should connect to

terminal P

contact between P

should be opened.

4) When an alarm occurs or the system is in emergency stop status, use ALARM or

WARN to output and disconnect the power of magnetic contactor in order to

disconnect the power of servo drive.

and C. When applying to the internal regenerative resistor, the

and D should be closed and the contact between P and C

and

3-2 Revision December, 2014

Page 40

ASDA-M Chapter 3 Wiring

3.1.2 Connectors and Terminals of the Servo Drive

Terminal

Name Description

Signal

L1c, L2c Power input of the

control circuit

R, S, T Power input of the main

circuit

U, V, W

FG

P , D,

C,

CN1 I/O connector (option) Connect to the host controller, please refer to Section 3.3

Motor cable Connect to the motor

Regenerative resistor

terminal or brake unit

Ground terminal

Connect to single-phase AC power (select the

appropriate voltage specification according to the

product )

Connect to three-phase AC power (select the appropriate

voltage specification according to the product)

Terminal

Symbol

U Red

V White

W Black

FG Green

Use internal resistor The contact between P

Use external

resister

Use external

braking unit

Connect to the ground wire of the power and the servo

motor

Wire

Color

Description

Three-phase main power cable of

the motor

Connect to the grounding

the servo drive.

end should be closed; contact

between P

opened.

Connect P , C ends to the resistor

and the contact between P

D end should be opened.

P and P of the brake unit

should connect to P

respectively. The contact between

P

and D and P and C should

be opened.

and C end should be

and P

of

and D

and

CN2 Connector (option) Connect to the encoder of the motor, please refer to

Section 3.4

CN3 Connector (option) Connect to RS-485 or RS-232, please refer to Section

3.5

CN4 USB connector

(Type B) (option)

CN5 Connector (option) Connect to the linear scale or encoder to constitute a

CN6 CANopen connector

(option)

Connect to personal computer (PC or NOTEBOOK),

please refer to Section 3.6

full-closed loop, please refer to Section 3.7

RJ45 connector, please refer to Section 3.8

Pay special attention to the followings when wiring:

1) When the power is cutoff, do not touch R, S, T and U, V, W since the capacitance

inside the servo drive still contains huge amount of electric charge. Wait until the

charging light is off.

2) Separate R, S, T and U, V, W from the other wires. The interval should be at least 30

cm (11.8 inches).

Revision December, 2014 3-3

Page 41

Chapter 3 Wiring ASDA-M

3) If the wire of encoder CN2 or CN5 connecter is not long enough, please use shielded

twisted-pair cable which cannot exceed 20 meters (65.62 inches). If it exceeds 20

meters, please choose the bigger wire diameter of signal cable to ensure it will not

cause signal fading. As for the encoder wiring specification of 20-meter-long cable,

please use AWG26 of wire size and Metal braided shield twisted-pair cable which

complies with the standard of UL 2464.

4) When using CANopen, please use the standard shielded twisted-pair cables to

ensure the communication quality.

5) When selecting the wire rod, please refer to Section 3.1.6.

3-4 Revision December, 2014

Page 42

ASDA-M Chapter 3 Wiring

3.1.3 Wiring Method

The wiring method of ASDA-M servo drive is divided into single-phase and three-phase.

In the diagram below, Power On is contact a, Power Off and ALRM_RY are contact b.

MC is the coil of magnetic contactor and self-remaining power and is the contact of main

power circuit.

Wiring Method of Single-phase Power Supply ( suitable for all series)

RS

MCCB

Noise Filter

Power

On

Power

Off

MC

ALRM_RY

DC24V

MC

ALRM_RY

MC

R

S

T

L1C

L2C

DO3+_X

DO3-_X

SUP

Servo Drive

U_X

V_X

W_X

U_Y

V_Y

W_Y

U_Z

V_Z

Motor_X

Motor_Y

Motor_Z

W_Z

DC24V

ALRM_RY

DC24V

ALRM_RY

Revision December, 2014 3-5

DO3+_Y

DO3-_Y

DO3+_Z

DO3-_Z

Page 43

Chapter 3 Wiring ASDA-M

Wiring Method of Three-phase Power Supply ( suitable for all series)

3-6 Revision December, 2014

Page 44

ASDA-M Chapter 3 Wiring

3.1.4 Specification of Motor U, V, W Power Cable

Motor Model

ECMA-C1040FS (50W)

ECMA-C△0401S (100W)

ECMA-C△0602S (200W)

ECMA-C△0604S (400W)

ECMA-C△0604H (400W)

ECMA-C△08047 (400W)

ECMA-C△0807S (750W)

ECMA-C△0807H (750W)

ECMA-C△0907S (750W)

ECMA-C△0910S (1000W)

ECMA-C1040FS (50W)

ECMA-C△0401S (100W)

ECMA-C△0602S (200W)

ECMA-C△0604S (400W)

ECMA-C△0604H (400W)

ECMA-C△08047 (400W)

ECMA-C△0807S (750W)

ECMA-C△0807H (750W)

ECMA-C△0907S (750W)

ECMA-C△0910S (1000W)

U、V、W/Connector of Mechanical Brake

HOUSING: JOWLE (C4201H00-2*2PA)

HOUSING:JOWLE (C4201H00-2*3PA)

Terminal

Definition

A

B

*:with brake

ECMA-G△1303S (300W)

ECMA-E△1305S (500W)

ECMA-G△1306S (600W)

ECMA-F△1308S (850W)

ECMA-G△1309S (900W)

ECMA-C△1010S (1000W)

ECMA-E△1310S (1000W)

ECMA-E△1315S (1500W)

C

Revision December, 2014 3-7

Page 45

Chapter 3 Wiring ASDA-M

Wiring Name

Terminal

Definition A

Terminal

Definition B

Terminal

Definition C

Terminal

Definition D

U

(Red) V (White)W (Black)

1 2 3 4 - -

1 2 4 5 3 6

F I B E G H

D E F G A B

CASE GROUND

(Green)

BRAKE1

(Yellow)

BRAKE2

(Blue)

When selecting the wire rod, please choose 600V PVC cable and the length should not

longer than 30m. If the length exceeds 30m, please take the received voltage into

consideration when selecting the wire size. Please refer to Section 3.1.6 for wire rod

selection.

NOTE

1) Box, () in servo motor model represents brake or keyway / oil seal.

2) Triangle, (△) in servo motor model represents encoder type. △=1: incremental,

20-bit; △=2: incremental, 17-bit; △=3: 2500 ppr; △=A: absolute.

3-8 Revision December, 2014

Page 46

ASDA-M Chapter 3 Wiring

3.1.5 Specification of Connector of Encoder Cable

Encoder connection diagram 1:

NOTE

This diagram shows the connection between the servo drive and the motor encoder. It

is not drew by the practical scale and specification will be dif f erent according to the

selected servo drive and motor model.

1) Please refer to the Section of Specification and Definition of Encoder Connector.

2) Please refer to Section 3.4 CN2 Connector.

Motor Model Connector of Encoder Cable

ECMA-C1040FS (50W)

ECMA-C△0401S (100W)

ECMA-C△0602S (200W)

ECMA-C△0604S (400W)

ECMA-C△0604H (400W)

ECMA-C△08047 (400W)

ECMA-C△0807S (750W)

ECMA-C△0807H (750W)

ECMA-C△0907S (750W)

ECMA-C△0910S (1000W)

Revision December, 2014 3-9

Page 47

Chapter 3 Wiring ASDA-M

Specification and Definition of Encoder Connector:

Connecto r of

Encoder Cable

Housing : AMP( 1-172161-9)

Connecto r of

Motor Encoder

Servo Drive

CN2

Servo Drive

CN2

View from this side

123

Blue

Reserved

T+

Reserved

456

Blue/Black

Reserved Reserved

T-

789

Red/Red &

white

Black/Black

& white

Shield

DC+5V GND

The wire color of the servo drive

is for reference only. Plea se refer

to the real objec t.

1

2

33

44

‧

‧

‧

2

‧

‧

‧

View from

this sid e

(Encoder type is 17bit , 20bit):

23

Reserved

6

Reserved

-

5

-

9

Shield

Blue Brown

(Encoder type is 2500ppr, 33bit):

23

Reserved Reserved

6

Reserved Reserved

5

9

Shield

1

Blue

Motor

Encoder

1

White

T+

4

White/Red

T-

78

DC+5VGND

1

White

T+

4

White/Red

T-

78

Brown

DC+5VGND

Motor

Encoder

If not using housing and directly wire the cores, please follow the corresponding core number for wiring. For

example, core number 1 from the servo drive CN2 should connect to core number 1 from the motor encoder;

core number 2 from the servo drive CN2 should connect to core number 2 from the motor encoder and so on.

Please number the cores from the servo drive in order and then connect it to the encoder.

3-10 Revision December, 2014

Page 48

ASDA-M Chapter 3 Wiring

Encoder connection diagram 2:

NOTE

This diagram shows the connection between the servo drive and the motor encoder. It

is not drew by the practical scale and specification will be different according to the

selected servo drive and motor model.

1) Please refer to Section 3.4, CN2 Connector.

Motor Model Connector of Encoder Cable

ECMA-G△1303S (300W)

ECMA-E△1305S (500W)

ECMA-G△1306S (600W)

ECMA-F△1308S (850W)

ECMA-G△1309S (900W)

ECMA-C△1010S (1000W)

ECMA-E△1310S (1000W)

ECMA-F△1313S (1300W)

ECMA-E△1315S (1500W)

Pin

No.

Terminal

Symbol

Wire

Color

T+ Blue

B T -

Blue &

Black

Red /

S DC+5V

Red &

White

Black /

R GND

Black &

White

BRAID

L

SHIELD

–

Revision December, 2014 3-11

Page 49

Chapter 3 Wiring ASDA-M

A

A

Please select shielded multi-core and the shielded cable should connect to the SHIELD

end. Please refer to the description of Section 3.1.6.

NOTE

1) Box, () in servo motor model represents brake or keyway / oil seal.

2) Triangle, (△) in servo motor model represents encoder type. △=1: incremental,

20-bit; △=2: incremental, 17-bit; △=3: 2500 ppr; △=A: absolute.

3.1.6 Selection of Wire Rod

The recommended wire rods are shown as the following table.

Servo Drive and corresponding

Motor Model

ASD-M-0721-

ASD-M-1521-

ECM

ECMA-C△0401S

ECMA-C△0602S

ECMA-C△0604S

ECMA-C△0604H

ECMA-C△08047

ECMA-C△0807S

ECMA-C△0807H

ECMA-C△0907S

ECMA-E△1305S

ECMA-G△1303S

ECMA-G△1306S

ECM

ECMA-C△1010S

ECMA-E△1310S

ECMA-E△1315S

ECMA-F△1308S

ECMA-G△1309S

ECMA-C△0807S

ECMA-C△0907S

-C1040FS

-C△0910S

Servo Drive

Model

ASD-M-0721-

ASD-M-1521-

Size Number Specification Standard Length

0.13(AWG26)

0.13(AWG26)

1.3(AWG16)2.1(AWG14)0.82(AWG18) 2.1(AWG14)

1.3(AWG16)3.3(AWG12)1.3(AWG16) 3.3(AWG12)

Encoder Wiring —Wire Diameter mm² (AWG)

Power Wiring-Wire Diameter mm² (AWG)

L1c, L2c R, S, T U, V, W P , C

10 cores

(4 pairs)

10 cores

(4 pairs)

UL2464 3 mm (9.84 inches)

UL2464 3 mm (9.84 inches)

NOTE

3-12 Revision December, 2014

1) Please use shielded twisted-pair cable for encoder wiring so as to reduce the

interference of the noise.

2) The shield should connect to the

3) Please follow the Selection of Wire Rod when wiring in order to avoid the danger it

may occur.

4) Box, () at the end of the servo drive model represents the model code of

ASDA-M. Please refer to the model information of the product you purchased.

5) Triangle, () in servo motor model represents brake or keyway / oil seal.

phase of SHIELD.

Page 50

ASDA-M Chapter 3 Wiring

6) Box, (△) in servo motor model represents encoder type. △=1: incremental,

20-bit; △=2: incremental, 17-bit; △=3: 2500 ppr; △=A: absolute.

Revision December, 2014 3-13

Page 51

Chapter 3 Wiring ASDA-M

3.2 Schematic Diagram of Servo System

750W~1.5kW Model (Built-in Regenerative Resistor and Fan)

Power

750W、1.5k W single/three-phas e 200~230V

Lack phase

R

detection

S

T

L1c

L2c

A/D

Current signal

processing

Serial

Communication

RS-232/485

USB

CN3

CN4

CN6

Power

circuit

N

P

Rectifying

Control

A/D

External regenerative

resistor

±15V

18V

24V

5V

GATE

DRIVER

Protect

circuit

Current

Control

Speed Control

Position

Control

DSP

operation

DPC

Regeneration

Circuit

Data Bus

750W one group of fan

1.5 one gr oup of fa n

12V

IGBT_X

IGBT_Y

IGBT_Z

PWM Output

Encoder signal

processing

CPLD

processing

U_X

V_X

W_X

U_Y

V_Y

W_Y

U_Z

V_Z

W_Z

CN2_Z

CN2_Y

CN2_X

CN5_X

CN5_Y

CN5_Z

Motor

Servo Motor

Motor

Servo Motor

Motor

Servo Motor

Full-closed

loop

Full-closed

loop

Full-closed

loop

Encoder

Encoder

Encoder

Encoder

Encoder

Encoder

CN5_X

CN5_Y

CN5_Z

A/D

Operation

Display

SET

UP DOW N

SHIFT

MODE

CN1_X

Ext er na l speed

External torque

CN1_Y

Ext er na l speed

Po si ti on pu lse

Analog outp ut

Digital out put

Digital input

External torque

Po si ti on pu lse

A, B, Z Output

Analog outp ut

Digital out put

Digit al Input

CN1_Z

Ext er na l speed

External torque

Po si ti on pu lse

A, B, Z Output

Digital out put

A,B,Z Output

Analog outp ut

Digital input

SEL

NOTE

1) The extension socket CN6 of ASD-M-0721-M model and ASD-M-1521-M is the function of

CANopen.

2) The extension socket CN6 of ASD-M-0721-F model and ASD-M-1521-F is the function of

DMCNET.

3) ASD-M-0721-L model and ASD-M-1521-L model have no extension socket CN6.

3-14 Revision December, 2014

Page 52

ASDA-M Chapter 3 Wiring

3.3 I/O Signal (CN1) Connection

3.3.1 I/O Signal (CN1) Connector Terminal Layout

In order to have a more flexible communication with the master, 9 programmable Digital

Outputs (DO) and 18 programmable Digital Inputs (DI) are provided. The setting of 6 digital

inputs and 3 digital outputs of each axis provided by ASDA-M, which are parameter

P2-10~P2-15 and parameter P2-18~P2-20 respectively. In addition, the differential output

encoder signal, A+, A-, B+, B-, Z+ and Z-, input of analog torque command, analog

speed/position command and pulse position command are also provided. The followings

are the pin diagrams.

CN1 Connector (female) Side view

Rear view

26

/HPulse

NC /SIGN

27 49

NC DO3+ DO2+ DO1+ DI1-

1

NC

DI5-

PULLHI_S

COM+

HPulse

/HSIGN V_REF

PULLHI_P

MON2

/PULSE PULSE

VDD OB/OBGND

GND

GND OA

HSIGN

COM- COM-

OCZ

COM-

OZDI6- DI3-NCNCNC SIGN

50

25

2 24

DI4- DI2-DO1-DO2-DO3- GND NC

MON1 T_REF

VCC /OA /OZ

The rear wiring terminal of CN1 connector

Revision December, 2014 3-15

Page 53

Chapter 3 Wiring ASDA-M

2 DO3- Digital output

4 DO2- Digital output

6 DO1- Digital output

8 DI4- Digital input

10 DI2- Digital input

Analog input

12 GND

14 NC

16 MON1

18 T_REF

20 VCC

22 /OA

24 /OZ

signal

ground

No

connection

Analog

monitor

output 1

Torque

analog

command

input

+12 power

output (for

analog

command)

Encoder/

A pulse

output

Encoder/

Z pulse

output

1 NC Reserved

3 DO3+

5 DO2+

7 DO1+

9 DI1- Digital input 34 DI3- Digital input

11 COM+

13 GND

15 MON2

17 VDD

19 GND

21 OA

23 /OB

25 OB

Digital

output

Digital

output

Digital

output

Power input

(12~24V)

Analog input

signal

ground

Analog

monitor

output 2

+24V power

output (for

external I/O)

Analog input

signal

ground

Encoder/

A pulse

output

Encoder/

B pulse

output

Encoder/

B pulse

output

27 NC Reserved

High-speed

29 /HPULSE

31 NC Reserved

33 DI5- Digital input

PULL

35

HI_S

(Sign)

37 /SIGN

PULL

39

HI_P

(Pulse)

41 /PULSE

43 PULSE

45 COM-

47 COM-

49 COM-

position

command

pulse (-)

Pull-high

voltage of

sign

Position

command

signal ( - )

Pull-high

voltage of

pulse

Position

command

pulse ( - )

Position

command

pulse ( + )

VDD(24 V)

power

ground

VDD(24 V)

power

ground

VDD(24V)

power

ground

NOTE

1) NC means NO CONNECTION. This terminal is for internal use only.

Do not connect it, or it may damage the servo drive.

26 NC Reserved

28 NC Reserved

30 NC Reserved

32 DI6- Digital input

Position

36 SIGN

38 HPULSE

40 /HSIGN

42 V_REF

44 GND

46 HSIGN

48 OCZ

50 OZ

command

signal (+)

High-speed

position

command

pulse (+)

High-speed

position

command

(-)

Speed analog

command

input

(+)

Analog input

signal ground

High-speed

position

command

(+)

Encoder

Z pulse

open-collector

output

Encoder

Z pulse

differential

output

2) CN1 of the three axes all have MON1 and MON2 output; however, the

internal circuit is parallel-connected (please refer to Chapter 3.3 Basic

Wiring); the three axes share the same set of MON1 and MON2.Thus,

when the external circuit connects to any of the axis’ MON1 and

MON2, the final output will be the same. In addition, monitoring item of

analog output is determined by the setting of P0-03.

3-16 Revision December, 2014

Page 54

ASDA-M Chapter 3 Wiring

3.3.2 Explanation of I/O (CN1) Connector Signal

The following details the signals listed in previous section:

General Signals

Wiring

Signal Name Pin No Function

(1) The speed command of the motor is

-10V ~ +10V which means the speed

command is -3000 ~ +3000 r/min

(default). It can change the

Method

(Refer to

3.3.3)

Analog

Command

(input)

Analog

Monitor

(output)

V_REF 42

(2) The position command of the motor is

The torque command of the motor is -10V ~

T_REF 18

+10V which means the rated torque

command of -100% ~ +100%.

The operating state of the motor can be

shown by analog voltage, such as speed

and current. This drive provides two channel

outputs. Users can select the desired

monitoring data via parameter P0-03. This

MON1

MON2

16

15

signal is based on the power ground. The

internal circuit is parallel-connected (please

refer to Chapter 3.3 Basic Wiring); three

axes share the same set of MON1 and

corresponding range via parameters.

-10V ~ +10V which means the position

command is -3 cycles ~ +3 cycles

(default).

C1

C1

C2

MON2.Thus, when the external circuit

connects to any of the axis’ MON1 and

MON2, the final output will be the same.

Position pulse can be inputted by Line Driver

(single phase max. frequency 500KHz) or

open-collector (single phase max. frequency

200KHz). Three kinds of command type can

be selected via P1-00, CW pulse + CCW

pulse, pulse + direction, A pulse + B pulse.

When position pulse uses open-collector,

C3/C4

Position

Pulse

(input)

PULSE

/PULSE

SIGN

/SIGN

PULL HI_P

PULL HI_S

43

41

36

37

39

35

the terminal should be connected to an

external applied power in order to pull high.

Revision December, 2014 3-17

Page 55

Chapter 3 Wiring ASDA-M

Wiring

Signal Name Pin No Function

Method

(Refer to

3.3.3)

High-speed position pulse only accepts Line

Drive (+5V) as the input type.

High-spee

d position

pulse

(input)

HPULSE

/HPULSE

HSIGN

/HSIGN

38

29

46

40

The max. frequency of single phase is

4MHz. There are three kinds of command

types, A pulse + B pulse, CW pulse + CCW

C4-2

pulse and pulse + direction. Please refer to

parameter P1-00.

Position

pulse

(output)

OA

/OA

OB

/OB

OZ

/OZ

21

22

25

23

50

24

Encoder signal output A, B, Z (Line Drive

output)

C13/C14

Encoder signal output Z (Open-collector

OCZ 48

-

output)

Power

VDD is the +24V power provided by the

drive and is for Digital Input (DI) and Digital

VDD 17

Output (DO) signal. The maximum current is

500mA.

COM+ is the common input of Digital Input

(DI) and Digital Output (DO) voltage. When

COM+

COM-

11

45

47

49

using VDD, VDD should be connected to

COM+. If not using, it needs to apply the

external power (+12V ~ + 24V). Its positive

end should connect to COM+ and the

negative end should connect to COM-.

VCC is the +12V power provided by the

drive. It is used for providing the simple

VCC 20

analog command (speed or torque

command). The maximum current is 100mA.

GND

12,13,

19,44

VCC voltage is based on GND.

NO CONNECTION. This terminal is for

-