Page 1

Page 2

Preface

This quick start will be helpful in the installation, wiring, inspection, and operation of Delta ASDA-AB series AC

servo drive and ECMA series servo motor. Before using the product, please read this quick start to ensure

correct use. You should thoroughly understand all safety precautions before proceeding with the installation,

wiring and operation. If you do not understand please contact your local Delta sales representative. Place this

quick start in a safe location for future reference. Please observe the following precautions:

Do not use the product in a potentially explosive environment.

Install the product in a clean and dry location free from corrosive and inflammable gases or liquids.

Do not connect a commercial power supply to the U, V, W terminals of motor. Failure to observe this

precaution will damage either the Servo motor or drive.

Ensure that the motor and drive are correctly connected to a ground. The grounding method must

comply with the electrical standard of the country (Please refer to NFPA 70: National Electrical Code,

2005 Ed.).

Do not disconnect the AC servo drive and motor while the power is ON.

Do not attach, modify or remove wiring when power is applied to the AC servo drive and motor.

Before starting the operation with a mechanical system connected, make sure the emergency stop

equipment can be energized and work at any time.

Do not touch the drive heat sink or the servo motor during operation. Otherwise, it may result in

serious personnel injury.

Further information on the AC servo drive and motor can be obtained from the user manual. You can download

the user manual via the link http://www.delta.com.tw/industrialautomation/

The content of this quick start may be revised without prior notice. Please consult our distributors or download

the most updated version at http://www.delta.com.tw/industrialautomation/

Safety Precautions

Carefully note and observe the following safety precautions when receiving, inspecting, installing, operating,

maintaining and troubleshooting. The following words, DANGER, WARNING and STOP are used to mark

safety precautions when using the Delta’s servo product. Failure to observe these precautions may void the

warranty!

ASDA-AB series drives are open type servo drives and must be installed in an NEMA enclosure such as a

protection control panel during operation to comply with the requirements of the international safety standards.

They are provided with precise feedback control and high-speed calculation function incorporating DSP (Digital

Signal Processor) technology, and intended to drive three-phase permanent magnet synchronous motors

(PMSM) to achieve precise positioning by means of accurate current output generated by IGBT (Insulated Gate

Bipolar Transistor).

ASDA-AB series drives can be used in industrial applications and for installation in an end-use enclosure that

do not exceed the specifications defined in the ASDA-AB series user manual (Drives, cables and motors are for

use in a suitable enclosure with a minimum of a UL50 type 1 or NEMA 250 Type 1 rating).

Unpacking Check

¾ Please ensure that both the servo drive and motor are correctly matched for size (power rating).

Failure to observe this precaution may cause fire, seriously damage the drive / motor or cause

personal injury.

Installation

above in PDF format.

.

¾ Do not install the product in a location that is outside the stated specification for the drive and motor.

Failure to observe this caution may result in electric shock, fire, or personal injury.

English-1

Page 3

Wiring

¾ Connect the ground terminals to a class-3 ground (Ground resistance should not exceed 100Ω).

Improper grounding may result in electric shock or fire.

¾ Do not connect any power supplies to the U, V, W terminals. Failure to observe this precaution may

result in serious injury, damage to the drive or fire.

¾ Ensure that all screws, connectors and wire terminations are secure on the power supply, servo drive

and motor. Failure to observe this caution may result in damage, fire or personal injury.

Operation

¾ Before starting operation with a mechanical system connected, change the drive parameters to match

the user-defined parameters of the mechanical system. Starting the operation without matching the

correct parameters may result in servo drive or motor damage, or damage to the mechanical system.

¾ Ensure that the emergency stop equipment or device is connected and working correctly before

operating the motor that is connected to a mechanical system.

¾ Do not approach or touch any rotating parts (e.g. shaft) while the motor is running. Failure to

observe this precaution may cause serious personal injury.

¾ In order to prevent accidents, the initial trial run for servo motor should be conducted under no load

conditions (separate the motor from its couplings and belts).

¾ For the initial trial run, do not operate the servo motor while it is connected to its mechanical

system. Connecting the motor to its mechanical system may cause damage or result in personal

injury during the trail run. Connect the servo motor once it has successfully completed a trail run.

¾ Caution: Please perform trial run without load first and then perform trial run with load connected.

After the servo motor is running normally and regularly without load, then run servo motor with load

connected. Ensure to perform trial run in this order to prevent unnecessary danger.

¾ Do not touch either the drive heat sink or the motor during operation as they may become hot and

personal injury may result.

Maintenance and Inspection

¾ Do not touch any internal or exposed parts of servo drive and servo motor as electrical shock may

result.

¾ Do not remove the operation panel while the drive is connected to an electrical power source

otherwise electrical shock may result.

¾ Wait at least 10 minutes after power has been removed before touching any drive or motor terminals

or performing any wiring and/or inspection as an electrical charge may still remain in the servo

drive and servo motor with hazardous voltages even after power has been removed.

¾ Do not disassemble the servo drive or motor as electric shock may result.

¾ Do not connect or disconnect wires or connectors while power is applied to the drive and motor.

¾ Only qualified personnel who have electrical knowledge should conduct maintenance and inspection.

Main Circuit Wiring

¾ Install the encoder cables in a separate conduit from the motor power cables to avoid signal noise.

Separate the conduits by 30cm (11.8inches) above.

¾ Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for signal, encoder (PG)

feedback cables. The maximum length of command input cable is 3m (9.84ft.) and the maximum

length of encoder (PG) feedback cables is 20m (65.62ft.).

¾ As a charge may still remain in the drive with hazardous voltages even after power has been

removed, be sure to wait at least 10 minutes after power has been removed before performing any

wiring and/or inspection.

¾ It is not recommended to frequently power the drive on and off. Do not turn the drive off and on more

than once per minute as high charging currents within the internal capacitors may cause damage.

English-2

Page 4

Main Circuit Terminal Wiring

¾ Please perform the wiring after the terminal blocks are all removed from the drive.

¾ Insert only one wire into one terminal on the terminal block.

¾ When inserting wires, please ensure that the conductors are not shorted to adjacent terminals or

wires.

¾ Ensure to double check the wiring before applying power to the drive.

¾ If the wiring is in error, perform the wiring again with proper tools. Never use force to remove the

terminals or wires. Otherwise, it may result in malfunction or damage.

Installation and Storage Conditions

The product should be kept in the shipping carton before installation. In order to retain the warranty coverage,

the AC drive should be stored properly when it is not to be used for an extended period of time. Some storage

suggestions are:

Store in a clean and dry location free from direct sunlight.

Store within an ambient temperature range of -4°F to 149°F (-20°C to +65°C).

Store within a relative humidity range of 0% to 90% and non-condensing.

Do not store in a place subjected to corrosive gases and liquids.

Correctly packaged and placed on a solid surface.

Do not mount the servo drive or motor adjacent to heat-radiating elements or in direct sunlight.

Do not mount the servo drive or motor in a location subjected to corrosive gases, liquids, or airborne

dust or metallic particles.

Do not mount the servo drive or motor in a location where temperatures and humidity will exceed

specification.

Do not mount the servo drive or motor in a location where vibration and shock will exceed

specification.

Do not mount the servo drive or motor in a location where it will be subjected to high levels of

electromagnetic radiation.

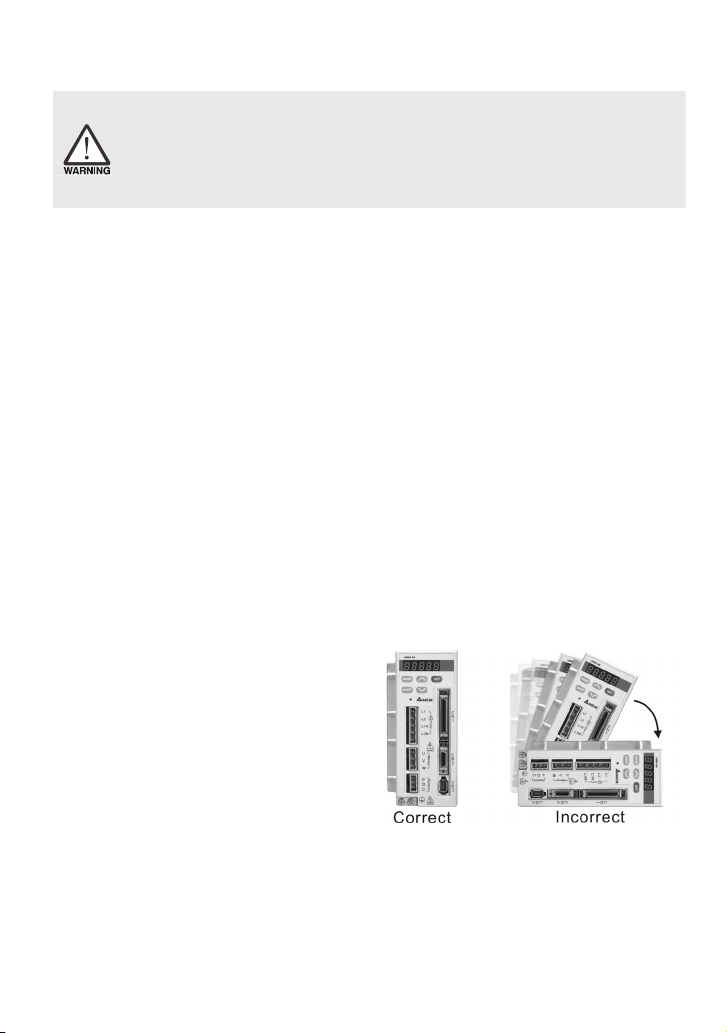

Installation Note and Minimum Clearances

Installation Note:

Incorrect installation may result in a drive

malfunction or premature failure of the drive and

or motor. Please follow the guidelines in this

instruction when installing the servo drive and

motor.

The AC servo drive should be mounted

perpendicular to the wall or in the control panel.

In order to ensure the drive is well ventilated,

ensure that the all ventilation holes are not

obstructed and sufficient free space is given to

the servo drive.

Do not install the drive in a horizontal position or

malfunction and damage will occur.

English-3

Page 5

Minimum Clearances:

Install a fan to increase ventilation to avoid ambient temperatures that exceed the specification. When installing

two or more drive adjacent to each other please follow the clearances as shown in the following diagram.

Servo Drive and Servo Motor Combinations

Power Servo Drive Servo Motor

100W

200W

400W

750W ASD-A0721-AB

1000W ASD-A1021-AB

1500W ASD-A1521-AB ECMA-E31315S (S=22mm)

2000W ASD-A2023-AB

The boxes () at the ends of the model names are for optional configurations (keyway, brake and oil seal).

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ECMA-C30401S (S=8mm)

ECMA-C30602S (S=14mm)

ECMA-C30604S (S=14mm)

ECMA-C308047 (7=14mm)

ECMA-E31305S (S=22mm)

ECMA-G31303S (S=22mm)

ECMA-C30807S (S=19mm)

ECMA-G31306S (S=22mm)

ECMA-C31010S (S=22mm)

ECMA-E31310S (S=22mm)

ECMA-G31309S (S=22mm)

ECMA-C31020S (S=22mm)

ECMA-E31320S (S=22mm)

ECMA-E31820S (S=35mm)

English-4

Page 6

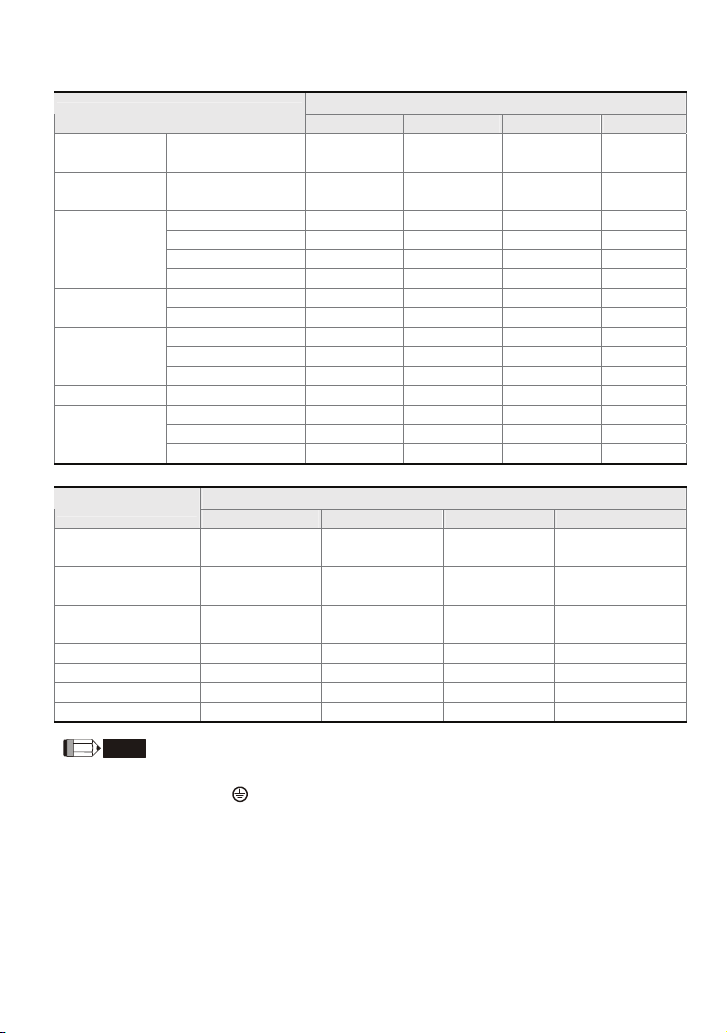

Cable Specifications for Servo Drive

Servo Drive and Servo Motor

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ASD-A0721-AB

ASD-A1021-AB

ASD-A1521-AB ECMA-E31315S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ASD-A2023-AB

ECMA-C30401S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C30602S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C30604S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C308047 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-E31305S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-G31303S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C30807S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-G31306S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C31010S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ECMA-E31310S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ECMA-G31309S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ECMA-C31020S 1.3 (AWG16) 2.1 (AWG14) 2.1 (AWG14) 2.1 (AWG14)

ECMA-E31320S 1.3 (AWG16) 2.1 (AWG14) 2.1 (AWG14) 2.1 (AWG14)

ECMA-E31820S 1.3 (AWG16) 2.1 (AWG14) 3.3 (AWG12) 2.1 (AWG14)

Power Cable - Wire Gauge mm2 (AWG)

L1, L2 R, S, T U, V, W P, C

Servo Drive

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ASD-A0721-AB 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A1021-AB 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A1521-AB 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2023-AB 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

NOTE

1) Please use shielded twisted-pair cables for wiring to prevent voltage coupling and eliminate

2) The shield of shielded twisted-pair cables should be connected to the SHIELD end (terminal

Wire Size Core Number UL Rating Standard Wire Length

0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

electrical noise and interference.

marked ) of the servo drive.

Encoder Cable - Wire Gauge mm2 (AWG)

English-5

Page 7

Basic Inspection

After power in connected to the AC servo drive, the charge LED will be lit which indicates that the AC servo

drive is ready.

Item Content

Periodically inspect the screws of the servo drive, motor shaft, terminal block and

the connection to mechanical system. Tighten screws as necessary as they may

loosen due to vibration and varying temperatures.

Ensure that oil, water, metallic particles or any foreign objects do not fall inside the

General Inspection

Inspection before

operation

(Control power is not

applied)

Inspection during

operation

(Control power is

applied)

servo drive, motor, control panel or ventilation slots and holes. As these will cause

damage.

Ensure the correct installation and the control panel. It should be free from airborne

dust, harmful gases or liquids.

Ensure that all wiring instructions and recommendations are followed; otherwise

damage to the drive and or motor may result.

Inspect the servo drive and servo motor to insure they were not damaged.

To avoid an electric shock, be sure to connect the ground terminal of servo drive to

the ground terminal of control panel.

Before making any connection, wait 10 minutes for capacitors to discharge after

the power is disconnected, alternatively, use an appropriate discharge device to

discharge.

Ensure that all wiring terminals are correctly insulated.

Ensure that all wiring is correct or damage and or malfunction may result.

Visually check to ensure that there are not any unused screws, metal strips, or any

conductive or inflammable materials inside the drive.

Never put inflammable objects on servo drive or close to the external regenerative

resistor.

Make sure control switch is OFF.

If the electromagnetic brake is being used, ensure that it is correctly wired.

If required, use an appropriate electrical filter to eliminate noise to the servo drive.

Ensure that the external applied voltage to the drive is correct and matched to the

controller.

Ensure that the cables are not damaged, stressed excessively or loaded heavily.

When the motor is running, pay close attention on the connection of the cables and

notice that if they are damaged, frayed or over extended.

Check for abnormal vibrations and sounds during operation. If the servo motor is

vibrating or there are unusual noises while the motor is running, please contact the

dealer or manufacturer for assistance.

Ensure that all user-defined parameters are set correctly. Since the characteristics

of various machinery are different, in order to avoid accident or cause damage, do

not adjust the parameter abnormally and ensure the parameter setting is not an

excessive value.

Ensure to reset some parameters when the servo drive is off (Please refer to

Chapter 7 of ASDA-AB user manual). Otherwise, it may result in malfunction.

If there is no contact sound or there be any unusual noises when the relay of the

servo drive is operating, please contact your distributor for assistance or contact

with Delta.

Check for abnormal conditions of the power indicators and LED display. If there is

any abnormal condition of the power indicators and LED display, please contact

your distributor for assistance or contact with Delta.

English-6

Page 8

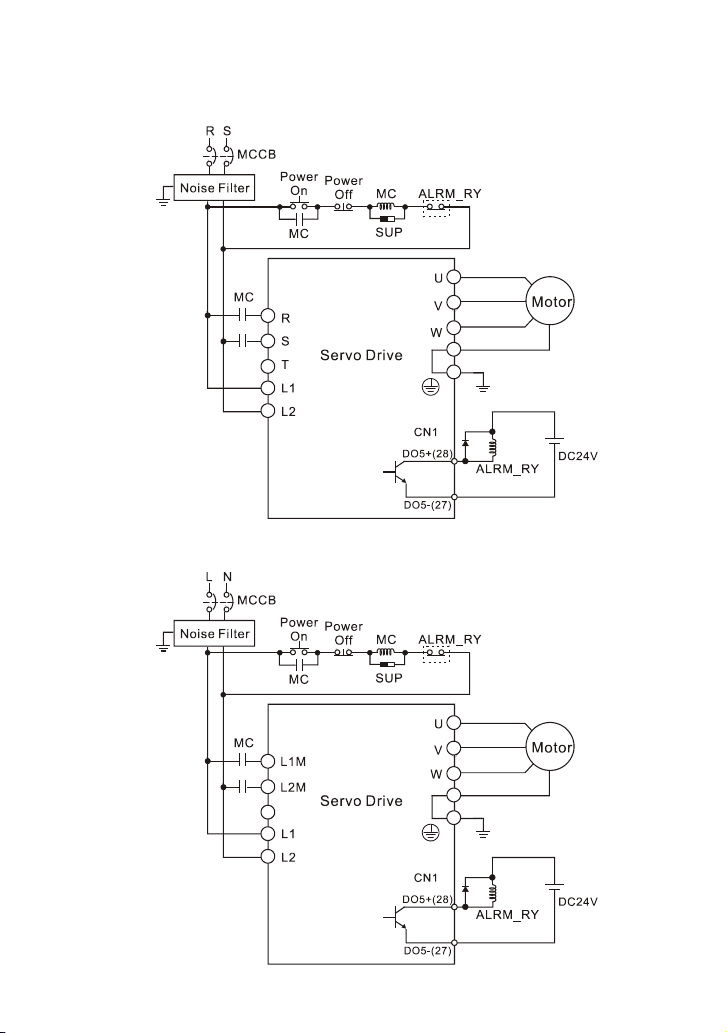

Wiring Methods

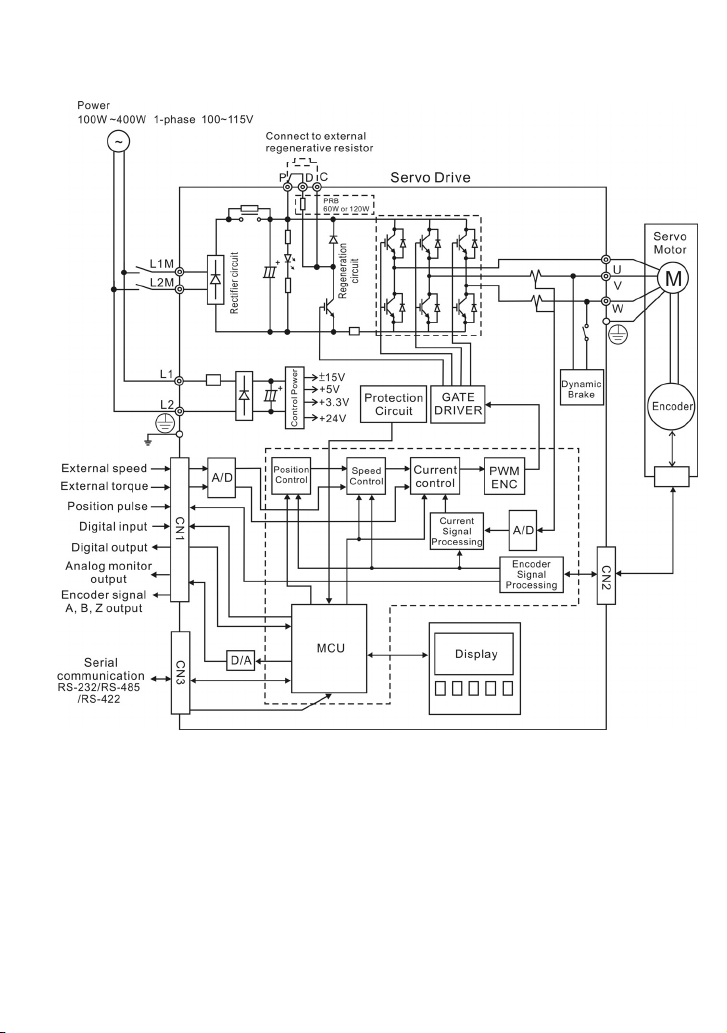

Single-Phase Power Supply Connection (For 1.5kW and below models, 220V series)

Single-Phase Power Supply Connection (For 400W and below models, 110V series)

English-7

Page 9

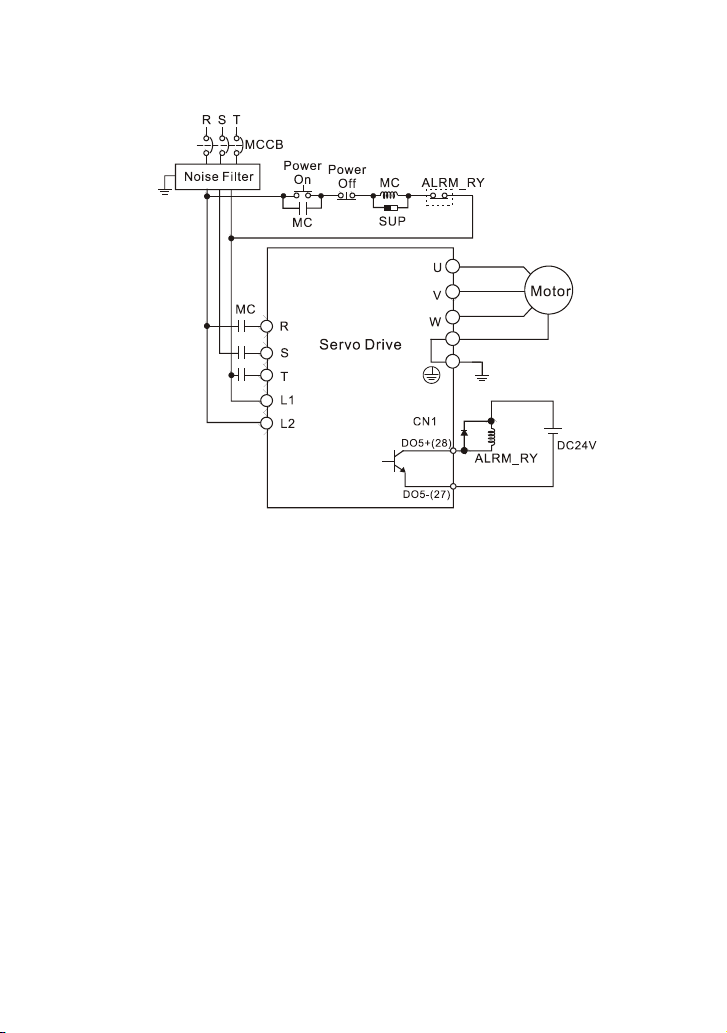

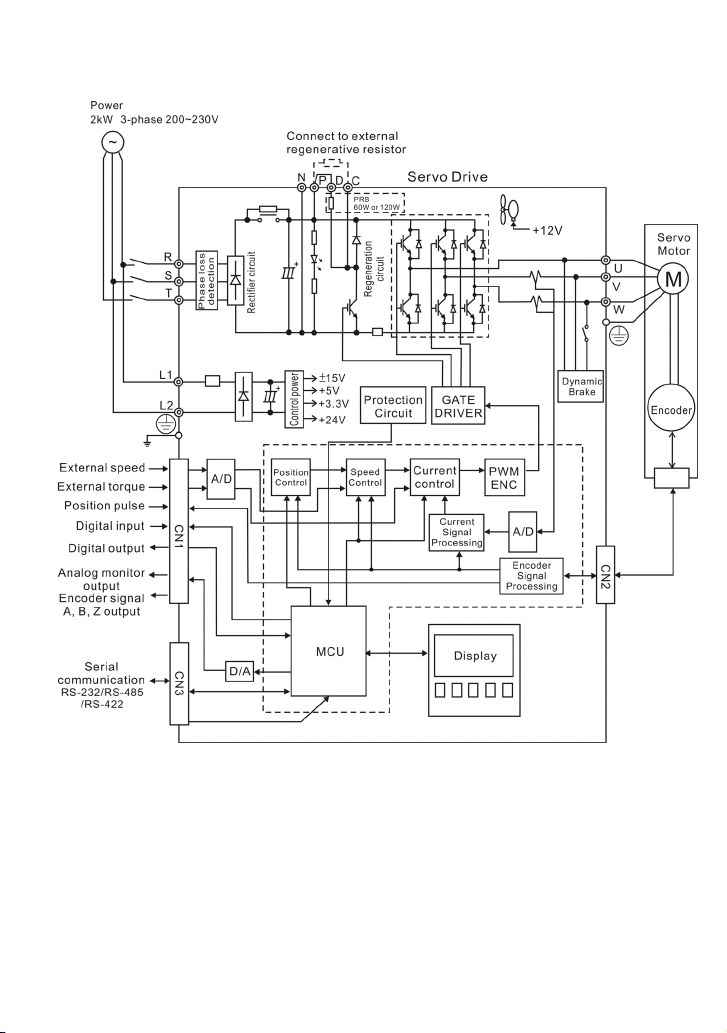

Three-Phase Power Supply Connection (For 2kW models)

English-8

Page 10

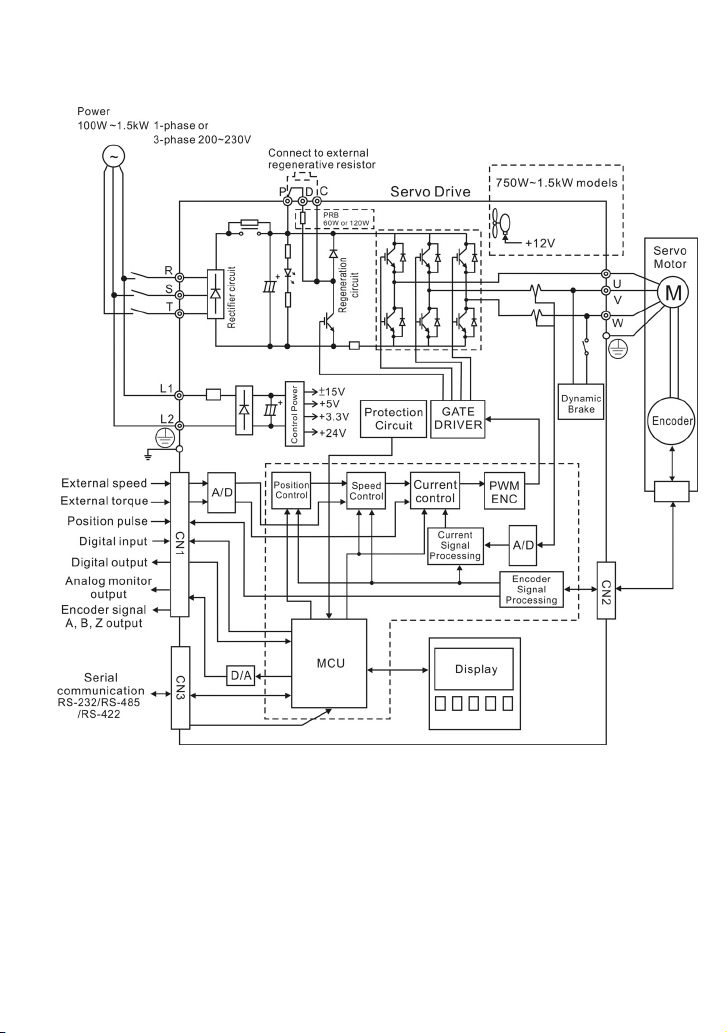

Basic Wiring

English-9

Page 11

English-10

Page 12

English-11

Page 13

Servo Drive Dimensions

A B C D E Weight

100W ~ 400W 162 (6.38) 140 (5.51) 75 (2.95) 69 (2.72) 150 (5.91) 1.5 (3.3)

750W ~ 1.5kW 162 (6.38) 191 (7.52) 93 (3.66) 83 (3.27) 149 (5.87) 2.0 (4.4)

2kW 245 (9.65) 206 (8.1) 110 (4.33) 91.2 (3.59) 229.5 (9.04) 3.0 (6.6)

NOTE

1) Dimensions are in millimeters and (inches).

2) Weights are in kilograms and (pounds).

3) In this quick start, actual measured values are in metric units. The units in (imperial

units) are for reference only. Please use metric for precise measurements.

English-12

Page 14

序言

感謝您使用本產品,此份安裝手冊提供 ASDA-AB 系列伺服驅動器及 ECMA 系列伺服馬達的相關資訊。

在使用之前,請您仔細詳讀本安裝手冊以確保使用上的正確。此外,請妥善將其放置在明顯的地點以便隨

時查閱。下列事項在您尚未讀完本安裝手冊前,請務必遵守:

安裝的環境必須沒有水氣,腐蝕性氣體及可燃性氣體。

接線時禁止將三相電源接至馬達 U、V、W 的接頭,一旦接錯時將損壞伺服驅動器。

接地工程必須確實實施,接地時須遵照國家現行相關電工法規之規定施行(請參考 NFPA 70:

National Electrical Code, 2005 Ed.)。

在通電時,請勿拆解驅動器、馬達或更改配線。

在通電運作前,請確定緊急停機裝置是否隨時啟動。

在通電運作時,請勿接觸散熱片,以免燙傷。

更多 ASDA-AB 系列伺服驅動器及 ECMA 系列伺服馬達的相關資訊詳述於使用操作手冊內,您可至台達

網站(http://www.delta.com.tw/industrialautomation/

如果您在使用上仍有問題,請洽詢經銷商或者本公司客服中心。由於產品精益求精,當內容規格有所修正

時,請洽詢代理商或至台達網站(http://www.delta.com.tw/industrialautomation/

安全注意事項

ASDA-AB 系列為一開放型(open type)伺服驅動器,操作時須安裝於遮敝式的控制箱內。本驅動器利用

精密的回授控制及結合高速運算能力的數位信號處理器(Digital Signal Processor,DSP),控制 IGBT 產

生精確之電流輸出,用來驅動三相永磁式同步交流伺服馬達(PMSM)達到精準定位。

ASDA-AB 系列可使用於工業應用場合上,且建議安裝於使用手冊中之配線(電)箱環境(驅動器、線材

及馬達都必須安裝於符合 UL50 Type 1 或者是 NEMA 250 Type 1 的安裝環境最低要求規格)。

接收檢驗、安裝、配線、操作、維護及檢查時,應隨時注意以下安全注意事項。

接收檢驗

)下載使用操作手冊(pdf 檔)。

)下載最新版本。

安裝注意

配線注意

¾ 請依照指定的方式搭配使用伺服驅動器及伺服馬達,否則可能會導致火災或設備故障。

¾ 禁止將本產品暴露在有水氣、腐蝕性氣體、可燃性氣體等物質的場所下使用,否則可

能會造成觸電或火災。

¾ 請將接地端子連接到class-3(100Ω 以下)接地,接地不良可能會造成觸電或火災。

¾ 請勿連接三相電源至U、V、W 馬達輸出端子,否則可能會造成人員受傷或火災。

¾ 請鎖緊電源及馬達輸出端子的固定螺絲,否則可能造成火災。

繁中-1

Page 15

操作注意

保養及檢查

主電路配線

¾ 當機械設備開始運轉前,須配合其使用者參數調整設定值。若未調整到相符的正確設

定值,可能會導致機械設備運轉失去控制或發生故障。

¾ 機器開始運轉前,請確認是否可以隨時啟動緊急開關停機。

¾ 當馬達運轉時,禁止接觸任何旋轉中的馬達零件,否則可能會造成人員受傷。

¾ 為了避免意外事故,請先分開機械設備的連軸器及皮帶等,使其處於單獨的狀態,再

進行第一次試運轉。

¾ 在伺服馬達和機械設備連接運轉後,如果發生操作錯誤,則不僅會造成機械設備的損

壞,有時還可能導致人身傷害。

¾ 強烈建議:請先在無負載情況下,測試伺服馬達是否正常運作,之後再將負載接上,

以避免不必要的危險。

¾ 在運轉中,請不要觸摸伺服驅動器之散熱器,否則可能會由於高溫而發生燙傷。

¾ 禁止接觸伺服驅動器及伺服馬達內部,否則可能會造成觸電。

¾ 電源啟動時,禁止拆下驅動器面板,否則可能會造成觸電。

¾ 電源關閉10 分鐘內,不得接觸接線端子,殘餘電壓可能造成觸電。

¾ 不得拆開伺服馬達,否則可能會造成觸電或人員受傷。

¾ 不得在開啟電源情況下改變配線,否則可能造成觸電或人員受傷。

¾ 只有合格的電機專業人員才可以安裝、配線及修理保養伺服驅動器以及伺服馬達。

¾ 請不要將動力和小信號線從同一管道內穿過,也不要將其綁扎在一起。配線時,請使

動力線和信號相隔 30 公分(11. 8 英吋)以上。

¾ 對於信號線、編碼器(PG)反饋線,請使用多股絞合線以及多芯絞合整體屏蔽線。對

於配線長度,信號輸入線最長為 3 公尺(9.84 英呎),PG 反饋線最長為 20 公尺(65.62

英呎)。

¾ 即使關閉電源,伺服驅動器內部仍然可能會滯留高電源,請暫時(10 分鐘)不要觸摸

電源端子。並請確認「CHARGE」指示燈熄滅以後,再進行檢查作業。

¾ 請不要頻繁地開關電源。如果需要連續開關電源時,請控制在一分鐘一次以下。

主電路端子座配線

¾ 在配線時,請將端子座從伺服驅動器上拆下來。

¾ 端子座的一個電線插入口,請僅插入一根電線。

¾ 在插入電線時,請不要使芯線與鄰近的電線短路。

¾ 在上電之前,請確實檢查配線是否正確。

繁中-2

Page 16

安裝環境條件

本產品在安裝之前必須置於其包裝箱內,若暫時不使用,為了使該產品能夠符合本公司的保固範圍及日後

的維護,儲存時務必注意下列事項:

必須置於無塵垢、乾燥之位置。

儲存位置的環境溫度必須在-20°C 到+65°C(-4°F 到 149°F)範圍內。

儲存位置的相對溼度必須在 0%到 90%範圍內,且無結露。

避免儲存於含有腐蝕性氣、液體之環境中。

最好適當包裝存放在架子或台面。

本產品適合的安裝環境包括有:無發高熱裝置之場所﹔無水滴、蒸氣、灰塵及油性灰塵之場所﹔

無腐蝕、易燃性之氣、液體之場所﹔無漂浮性的塵埃及金屬微粒之場所﹔堅固無振動、無電磁雜

訊干擾之場所。

安裝方向與空間

注意事項:

安裝方向必須依規定,否則會造成故障原因。

為了使冷卻循環效果良好,安裝交流伺服驅動

器時,其上下左右與相鄰的物品和擋板(牆)

必須保持足夠的空間,否則會造成故障原因。

交流伺服驅動器在安裝時其吸排氣孔不可封

住,也不可傾倒放置,否則會造成故障原因。

安裝示意圖:

為了使散熱風扇能夠有比較低的風阻以有效排出熱量,請使用者遵守一台與多台交流伺服驅動器的安裝間

隔距離建議值(如下圖所示)。

繁中-3

Page 17

伺服驅動器與馬達機種名稱對應參照表

功率 伺服驅動器 對應的伺服馬達

100W

200W

400W

750W ASD-A0721-AB

1000W ASD-A1021-AB

1500W ASD-A1521-AB

2000W ASD-A2023-AB

為煞車或鍵槽/油封仕樣

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ECMA-C30401S(S=8mm)

ECMA-C30602S(S=14mm)

ECMA-C30604S(S=14mm)

ECMA-C308047(7=14mm)

ECMA-E31305S(S=22mm)

ECMA-G31303S(S=22mm)

ECMA-C30807S(S=19mm)

ECMA-G31306S(S=22mm)

ECMA-C31010S(S=22mm)

ECMA-E31310S(S=22mm)

ECMA-G31309S(S=22mm)

ECMA-E31315S(S=22mm)

ECMA-C31020S(S=22mm)

ECMA-E31320S(S=22mm)

ECMA-E31820S(S=35mm)

線材的選擇

本驅動器各端子與信號配線的建議線材,如下表所示:

驅動器與對應馬達型號

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ASD-A0721-AB

ASD-A1021-AB

ASD-A1521-AB ECMA-E31315S

ASD-A2023-AB

ECMA-C30401S

ECMA-C30602S

ECMA-C30604S

ECMA-C308047

ECMA-E31305S

ECMA-G31303S

ECMA-C30807S

ECMA-G31306S

ECMA-C31010S

ECMA-E31310S

ECMA-G31309S

ECMA-C31020S

ECMA-E31320S

ECMA-E31820S

L1, L2 R, S, T U, V, W P, C

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 0.82(AWG1 8)2.1(AWG14)

1.3(AWG1 6)2.1(AWG14) 1.3(AWG16)2.1(AWG1 4)

1.3(AWG1 6)2.1(AWG14) 1.3(AWG16)2.1(AWG1 4)

1.3(AWG1 6)2.1(AWG14) 1.3(AWG16)2.1(AWG1 4)

1.3(AWG1 6)2.1(AWG14) 1.3(AWG16)2.1(AWG1 4)

1.3(AWG1 6)2.1(AWG14) 2.1(AWG14)2.1(AWG1 4)

1.3(AWG1 6)2.1(AWG14) 2.1(AWG14)2.1(AWG1 4)

1.3(AWG1 6)2.1(AWG14) 3.3(AWG12)2.1(AWG1 4)

電源配線-線徑 mm²(AWG)

繁中-4

Page 18

驅動器型號

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ASD-A0721-AB

ASD-A1021-AB

ASD-A1521-AB

ASD-A2023-AB

NOTE

芯線尺寸 芯線條數 線種規範 標準線長

0.13(AWG2 6) 10 條(4 對)

0.13(AWG2 6) 10 條(4 對)

0.13(AWG2 6) 10 條(4 對)

0.13(AWG2 6) 10 條(4 對)

0.13(AWG2 6) 10 條(4 對)

0.13(AWG2 6) 10 條(4 對)

0.13(AWG2 6) 10 條(4 對)

1) 編碼器配線請使用雙絞隔離線((shielded twisted-pair cable),以減低雜訊的干擾。

2) 隔離網必須確實與 SHIELD 端

編碼器配線 — 線徑mm²(AWG)

相連接。

基本檢測

檢測項目 檢測內容

定期檢查伺服驅動器安裝部、馬達軸心與機械連接處的螺絲、端子台與機械部

的螺絲是否有鬆動。

控制箱的間隙或通風扇設置,應避免油、水或金屬粉等異物侵入,且應防止電

一般檢測

操作前檢測

(未供應控制電源)

運轉前檢測

(已供應控制電源)

鑽的切削粉落入伺服驅動器內。

控制箱設置於有害氣體或多粉塵的場所,應防止有害氣體與粉塵的侵入。

製作檢出器接線或其他接線時,必須謹慎注意接線順序,否則可能發生設備暴

衝、燒毀等狀況。

為防止觸電,伺服驅動器的接地保護端子必須連接控制箱的接地保護端子。如

需配線時,請在電源切斷 10 分鐘後進行,或直接以放電裝置進行放電。

配線端子的接續部請實施絕緣處理。

配線應正確,避免造成損壞或發生異常動作。

檢查螺絲或金屬片等導電性物體、可燃性物體是否存在伺服驅動器內。

緊急停止開關是否置於 OFF 狀態。

為避免電磁制動器失效,請檢查立即停止運轉及切斷電源的迴路是否正常。

伺服驅動器附近使用的電子儀器受到電磁干擾時,請使用儀器降低電磁干擾。

請確定伺服驅動器的外加電壓準位是否正確。

檢出器電纜應避免承受過大應力。當馬達在運轉時,注意接續電纜是否與機件

接觸而產生磨耗,或發生拉扯現象。

伺服馬達若有振動現象,或運轉聲音過大,請與廠商聯絡。

確認各項參數設定是否正確,依機械特性的不同可能會有無法預期的動作。勿

將參數作過度極端之調整。

重新設定參數時,請確定驅動器是否在伺服停止(SERVO OFF)的狀態下進

行,否則會成為故障發生的原因。

繼電器動作時,若無接觸的聲音或其他異常聲音產生,請與廠商聯絡。

電源指示燈與 LED 顯示有異常現象,請與廠商聯絡。

UL2464

UL2464

UL2464

UL2464

UL2464

UL2464

UL2464

3 公尺(9.84 英呎)

3 公尺(9.84 英呎)

3 公尺(9.84 英呎)

3 公尺(9.84 英呎)

3 公尺(9.84 英呎)

3 公尺(9.84 英呎)

3 公尺(9.84 英呎)

繁中-5

Page 19

配線

單相電源接線法(1.5kW(含)以下適用, 220V 系列)

單相電源接線法(400W(含)以下適用, 110V 系列)

繁中-6

Page 20

三相電源接線法(2kW 適用)

繁中-7

Page 21

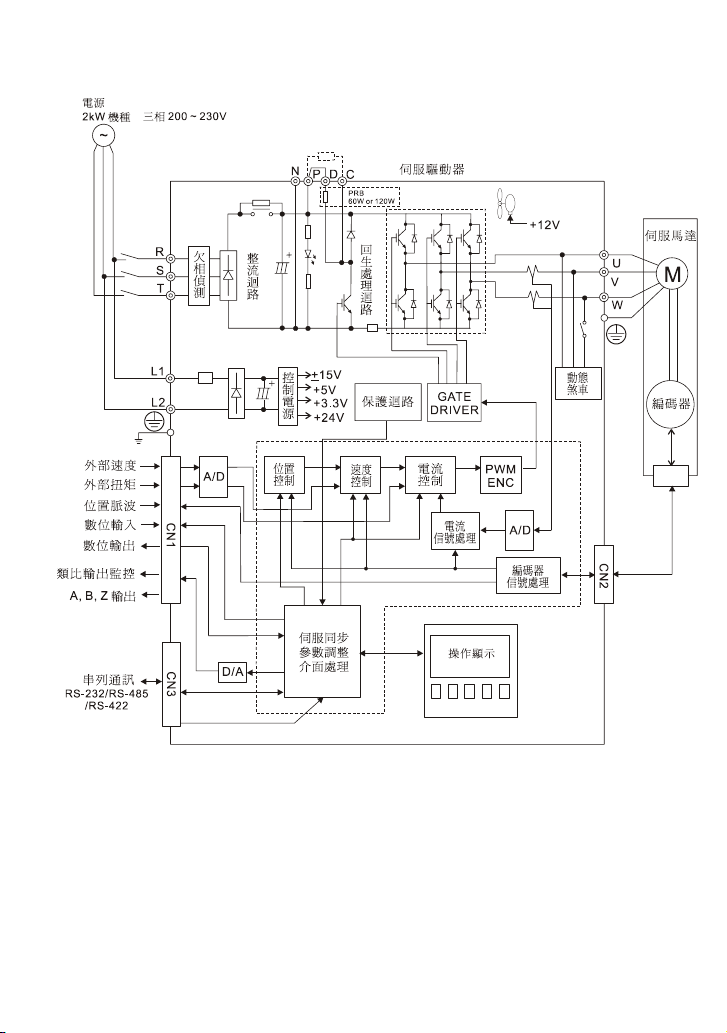

伺服系統基本方塊圖

繁中-8

Page 22

繁中-9

Page 23

繁中-10

Page 24

驅動器尺寸與重量

A B C D E Weight

100W ~ 400W

750W ~ 1.5kW

2kW

NOTE

162(6.38) 140(5.51) 75(2.95) 69(2.72) 150(5.91) 1.5(3.3)

162(6.38) 191(7.52) 93(3.66) 83(3.27) 149(5.87) 2.0(4.4)

245(9.65) 206(8.1) 11 0(4.33) 91.2(3.59) 229.5(9.04) 3.0(6.6)

1) 尺寸單位為公厘(英吋)。

2) 重量單位為公斤(磅)。

3) 本安裝手冊內所標示之數值,以公制單位為準;外型尺寸中之英制單位僅供參考,請

以公制單位為主。

繁中-11

Page 25

(此頁有意留為空白)

繁中-12

Page 26

序言

感谢您使用本产品,此份安装手冊提供 ASDA-AB 系列伺服驱动器及 ECMA 系列伺服电机的相关信息。

在使用之前,请您仔细详读本安装手冊以确保使用上的正确。此外,请妥善将其放置在明显的地点以便随

时查阅。下列事项在您尚未读完本安装手冊前,请务必遵守:

安装的环境必须没有水气,腐蚀性气体及可燃性气体。

接线时禁止将三相电源接至电机 U、V、W 的接头,一旦接错时将损坏伺服驱动器。

接地工程必须确实实施,接地时须遵照国家现行相关电工法规之规定施行(请参考 NFPA 70:

National Electrical Code, 2005 Ed.)。

在通电时,请勿拆解驱动器、电机或更改配线。

在通电运作前,请确定紧急停机装置是否随时启动。

在通电运作时,请勿接触散热片,以免烫伤。

更多 ASDA-AB 系列伺服驱动器及 ECMA 系列伺服电机的相关信息详述于使用操作手冊内,您可至台达

网站(http://www.delta.com.tw/industrialautomation/

如果您在使用上仍有问题,请洽询经销商或者本公司客服中心。由于产品精益求精,当内容规格有所修正

时,请洽询代理商或至台达网站(http://www.delta.com.tw/industrialautomation/

安全注意事项

ASDA-AB 系列为一开放型(open type)伺服驱动器,操作时须安装于遮敝式的控制箱内。本驱动器利用

精密的回授控制及结合高速运算能力的数字信号处理器(Digital Signal Processor,DSP),控制 IGBT 产

生精确的电流输出,用来驱动三相永磁式同步交流伺服电机(PMSM)达到精准定位。

ASDA-AB 系列可使用于工业应用场合上,且建议安装于使用手冊中的配线(电)箱环境(驱动器、线材

及电机都必须安装于符合 UL50 Type 1 或者是 NEMA 250 Type 1 的安装环境最低要求规格)。

接收检验、安装、配线、操作、维护及检查时,应随时注意以下安全注意事项。

接收检验

)下载使用操作手冊(pdf 档)。

)下载最新版本。

安装注意

配线注意

¾ 请依照指定的方式搭配使用伺服驱动器及伺服电机,否则可能会导致火灾或设备故障。

¾ 禁止将本产品暴露在有水气、腐蚀性气体、可燃性气体等物质的场所下使用,否则可

能会造成触电或火灾。

¾ 请将接地端子连接到 class-3(100Ω 以下)接地,接地不良可能会造成触电或火灾。

¾ 请勿连接三相电源至 U、V、W 电机输出端子,否则可能会造成人员受伤或火灾。

¾ 请锁紧电源及电机输出端子的固定螺丝,否则可能造成火灾。

簡中-1

Page 27

操作注意

保养及检查

主电路配线

¾ 当机械设备开始运转前,须配合其使用者参数调整设定值。若未调整到相符的正确设

定值,可能会导致机械设备运转失去控制或发生故障。

¾ 机器开始运转前,请确认是否可以随时启动紧急开关停机。

¾ 当电机运转时,禁止接触任何旋转中的电机零件,否则可能会造成人员受伤。

¾ 为了避免意外事故,请先分开机械设备的连轴器及皮带等,使其处于单独的状态,再

进行第一次试运转。

¾ 在伺服电机和机械设备连接运转后,如果发生操作错误,则不仅会造成机械设备的损

坏,有时还可能导致人身伤害。

¾ 强烈建议:请先在无负载情况下,测试伺服电机是否正常运作,之后再将负载接上,

以避免不必要的危险。

¾ 在运转中,请不要触摸伺服驱动器的散热器,否则可能会由于高温而发生烫伤。

¾ 禁止接触伺服驱动器及伺服电机内部,否则可能会造成触电。

¾ 电源启动时,禁止拆下驱动器面板,否则可能会造成触电。

¾ 电源关闭 10 分钟内,不得接触接线端子,残余电压可能造成触电。

¾ 不得拆开伺服电机,否则可能会造成触电或人员受伤。

¾ 不得在开启电源情况下改变配线,否则可能造成触电或人员受伤。

¾ 只有合格的电机专业人员才可以安装、配线及修理保养伺服驱动器以及伺服电机。

¾ 请不要将动力和小信号线从同一管道内穿过,也不要将其绑扎在一起。配线时,请使

动力线和信号相隔 30 厘米(11. 8 英寸)以上。

¾ 对于信号线、编码器(PG)反馈线,请使用多股绞合线以及多芯绞合整体屏蔽线。对

于配线长度,信号输入线最长为 3 米(9.84 英呎),PG 反馈线最长为 20 米(65.62

英呎)。

¾ 即使关闭电源,伺服驱动器内部仍然可能会滞留高电源,请暂时(10 分钟)不要触摸

电源端子。并请确认「CHARGE」指示灯熄灭以后,再进行检查作业。

¾ 请不要频繁地开关电源。如果需要连续开关电源时,请控制在一分钟一次以下。

主电路接线座配线

¾ 在配线时,请将接线座从伺服驱动器上拆下来。

¾ 接线座的一个电线插入口,请仅插入一根电线。

¾ 在插入电线时,请不要使芯线与邻近的电线短路。

¾ 在上电之前,请确实检查配线是否正确。

簡中-2

Page 28

安装环境条件

本产品在安装之前必须置于其包装箱内,若暂时不使用,为了使该产品能够符合本公司的保固范围及日后

的维护,储存时务必注意下列事项:

必须置于无尘垢、干燥的位置。

储存位置的环境温度必须在-20°C 到+65°C(-4°F 到 149°F)范围内。

储存位置的相对湿度必须在 0%到 90%范围内,且无结露。

避免储存于含有腐蚀性气、液体的环境中。

最好适当包装存放在架子或台面。

本产品适合的安装环境包括有:无发高热装置的场所﹔无水滴、蒸气、灰尘及油性灰尘的场所﹔

无腐蚀、易燃性的气、液体的场所﹔无漂浮性的尘埃及金属微粒的场所﹔坚固无振动、无电磁噪

声干扰的场所。

安装方向与空间

注意事项:

安装方向必须依规定,否则会造成 故障原因。

为了使冷却循环效果良好,安装交流伺服驱动

器时,其上下左右与相邻的物品和挡板(墙)

必须保持足够的空间,否则会造成故障原因。

交流伺服驱动器在安装时其吸排气孔不可封

住,也不可倾倒放置,否则会造成故障原因。

安装示意图:

为了使散热风扇能够有比较低的风阻以有效排出热量,请使用者遵守一台与多台交流伺服驱动器的安装间

隔距离建议值(如下图所示)。

簡中-3

Page 29

伺服驱动器与电机机种名称对应参照表

功率 伺服驱动器 对应的伺服电机

100W

200W

400W

750W ASD-A0721-AB

1000W ASD-A1021-AB

1500W ASD-A1521-AB

2000W ASD-A2023-AB

为煞车或键槽/油封仕样

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ECMA-C30401S(S=8mm)

ECMA-C30602S(S=14mm)

ECMA-C30604S(S=14mm)

ECMA-C308047(7=14mm)

ECMA-E31305S(S=22mm)

ECMA-G31303S(S=22mm)

ECMA-C30807S(S=19mm)

ECMA-G31306S(S=22mm)

ECMA-C31010S(S=22mm)

ECMA-E31310S(S=22mm)

ECMA-G31309S(S=22mm)

ECMA-E31315S(S=22mm)

ECMA-C31020S(S=22mm)

ECMA-E31320S(S=22mm)

ECMA-E31820S(S=35mm)

线材的选择

本驱动器各端子与信号配线的建议线材,如下表所示:

驱动器与对应电机型号

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ASD-A0721-AB

ASD-A1021-AB

ASD-A1521-AB ECMA-E31315S

ASD-A2023-AB

ECMA-C30401S

ECMA-C30602S

ECMA-C30604S

ECMA-C308047

ECMA-E31305S

ECMA-G31303S

ECMA-C30807S

ECMA-G31306S

ECMA-C31010S

ECMA-E31310S

ECMA-G31309S

ECMA-C31020S

ECMA-E31320S

ECMA-E31820S

L1, L2 R, S, T U, V, W P, C

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 0.82(AW G1 8)2.1(AWG14 )

1.3(AWG1 6) 2.1(AWG14) 1.3(AWG16)2.1(AWG14)

1.3(AWG1 6) 2.1(AWG14) 1.3(AWG16)2.1(AWG14)

1.3(AWG1 6) 2.1(AWG14) 1.3(AWG16)2.1(AWG14)

1.3(AWG1 6) 2.1(AWG14) 1.3(AWG16)2.1(AWG14)

1.3(AWG1 6) 2.1(AWG14) 2.1(AWG14)2.1(AWG14)

1.3(AWG1 6) 2.1(AWG14) 2.1(AWG14)2.1(AWG14)

1.3(AWG1 6) 2.1(AWG14) 3.3(AWG12)2.1(AWG14)

电源配线-线径 mm²(AWG)

簡中-4

Page 30

驱动器型号

ASD-A0111-AB

ASD-A0121-AB

ASD-A0211-AB

ASD-A0221-AB

ASD-A0411-AB

ASD-A0421-AB

ASD-A0721-AB

ASD-A1021-AB

ASD-A1521-AB

ASD-A2023-AB

NOTE

芯线尺寸 芯线条数 线种规范 标准线长

0.13(AWG2 6) 10 条(4 对)

0.13(AWG2 6) 10 条(4 对)

0.13(AWG2 6) 10 条(4 对)

0.13(AWG2 6) 10 条(4 对)

0.13(AWG2 6) 10 条(4 对)

0.13(AWG2 6) 10 条(4 对)

0.13(AWG2 6) 10 条(4 对)

1) 编码器配线请使用屏蔽双绞电缆(shielded twisted-pair cable),以降低噪声的干扰。

2) 屏蔽网必须确实与 SHIELD 端

编码器配线 — 线径mm²(AWG)

相连接。

基本检测

检测项目 检测内容

定期检查伺服驱动器安装部、电机轴心与机械连接处的螺丝、端子台与机械部

的螺丝是否有松动。

控制箱的间隙或通风扇设置,应避免油、水或金属粉等异物侵入,且应防止电

一般检测

操作前检测

(未供应控制电源)

运转前检测

(已供应控制电源)

钻的切削粉落入伺服驱动器内。

控制箱设置于有害气体或多粉尘的场所,应防止有害气体与粉尘的侵入。

制作检出器接线或其他接线时,必须谨慎注意接线顺序,否则可能发生设备暴

冲、烧毁等状况。

为防止触电,伺服驱动器的接地保护端子必须连接控制箱的接地保护端子。如

需配线时,请在电源切断 10 分钟后进行,或直接以放电装置进行放电。

配线端子的接续部请实施绝缘处理。

配线应正确,避免造成损坏或发生异常动作。

检查螺丝或金属片等导电性物体、可燃性物体是否存在伺服驱动器内。

紧急停止开关是否置于 OFF 状态。

为避免电磁制动器失效,请检查立即停止运转及切断电源的回路是否正常。

伺服驱动器附近使用的电子仪器受到电磁干扰时,请使用仪器降低电磁干扰。

请确定伺服驱动器的外加电压准位是否正确。

检出器电缆应避免承受过大应力。当电机在运转时,注意接续电缆是否与机件

接触而产生磨耗,或发生拉扯现象。

伺服电机若有振动现象,或运转声音过大,请与厂商联络。

确认各项参数设定是否正确,依机械特性的不同可能会有无法预期的动作。勿

将参数作过度极端的调整。

重新设定参数时,请确定驱动器是否在伺服停止(SERVO OFF)的状态下进

行,否则会成为故障发生的原因。

继电器动作时,若无接触的声音或其他异常声音产生,请与厂商联络。

电源指示灯与 LED 显示有异常现象,请与厂商联络。

UL2464

UL2464

UL2464

UL2464

UL2464

UL2464

UL2464

3 米(9.84 英呎)

3 米(9.84 英呎)

3 米(9.84 英呎)

3 米(9.84 英呎)

3 米(9.84 英呎)

3 米(9.84 英呎)

3 米(9.84 英呎)

簡中-5

Page 31

配线

单相电源接线法(1.5kW(含)以下适用, 220V 系列)

单相电源接线法(400W(含)以下适用, 110V 系列)

簡中-6

Page 32

三相电源接线法(2kW 适用)

簡中-7

Page 33

伺服系统基本方块图

簡中-8

Page 34

簡中-9

Page 35

簡中-10

Page 36

驱动器尺寸与重量

A B C D E

100W ~ 400W

750W ~ 1.5kW

2kW

NOTE

162(6.38) 140(5.51) 75(2.95) 69(2.72) 150(5.91) 1.5(3.3)

162(6.38) 191(7.52) 93(3.66) 83(3.27) 149(5.87) 2.0(4.4)

245(9.65) 206(8.1) 11 0(4.33) 91.2(3.59) 229.5(9.04)3.0(6.6)

1) 尺寸单位为毫米(英寸)。

2) 重量单位为千克(磅)。

3) 本安装手冊内所标示之数值,以公制单位为准;外型尺寸中之英制单位仅供参考,请

以公制单位为主。

簡中-11

重量

Page 37

(此页有意留为空白)

簡中-12

Loading...

Loading...