Page 1

Automation for a Changing World

Delta

AC Servo Drive & Motor

ASDA-A2

www.deltaww.com

Series

Page 2

More Rapid, More Stable, More Precise

Delta Electronics, Inc., a leading manufacturer of industrial automation products, is pleased to

announce the launch of its new high-performance ASDA-A2 series servo motors and servo drives with

motion control.

The current trend for motion control has the control command source close to the drive. In response,

Delta has developed the new ASDA-A2 series that offers excellent motion control so that the external

controller is almost eliminated. ASDA-A2 series features a built-in electronic cam (E-CAM) function which

provides an excellent solution for flying shear, rotary cut and synchronized motion applications. The all

new position register control PR mode is a unique and significant function that provides a variety of control

modes to enhance system performance.

The ASDA-A2 series also supports various industrial communications protocols, such as CANopen,

DMCNET, EtherCAT which offers higher performance and high speed communications and enable the

drive to integrate with other part of the automation more efficiently and effectively. The full-closed loop

control, auto notch filter, vibration suppression and gantry control functions help to perform complex

motions that require high precision and smooth operation. The 20-bit superior resolution encoder which

is essential for accurate positioning applications is equipped as standard. In addition, the outstanding

Capture and Compare functions for high-speed pulses offer the best support for stepless positioning. Other

additional functionality, such as up to 1kHz frequency response, innovative editing software, high-speed

PC monitoring (similar to a digital oscilloscope), and more, all drastically maximize the performance of the

ASDA-A2 series.

Delta's new ASDA-A2 series is the ultimate servo system providing a total solution

for a wide range of machine tools and industrial applications

1

Page 3

Table of Contents

ASDA-A2 Series Features

3

Product Line-up

9

Model Explanation

13

Servo Motor Features

14

S e r v o M o to r S p e c i c a t i o n s

15

Servo Motor Dimensions

21

Part Names and Functions

29

Wiring

31

ASDA-Soft Conguration Software

39

Optional Accessories

41

Servo Drive Specications

43

Servo Drive Dimensions

45

Optional Cables and Connectors

51

Servo Drive, Servo Motor and

61

Accessories Combinations

Safety Information

69

Regenerative Resistor Specications

70

2

Page 4

ASDA-A2 Series Features

DT3

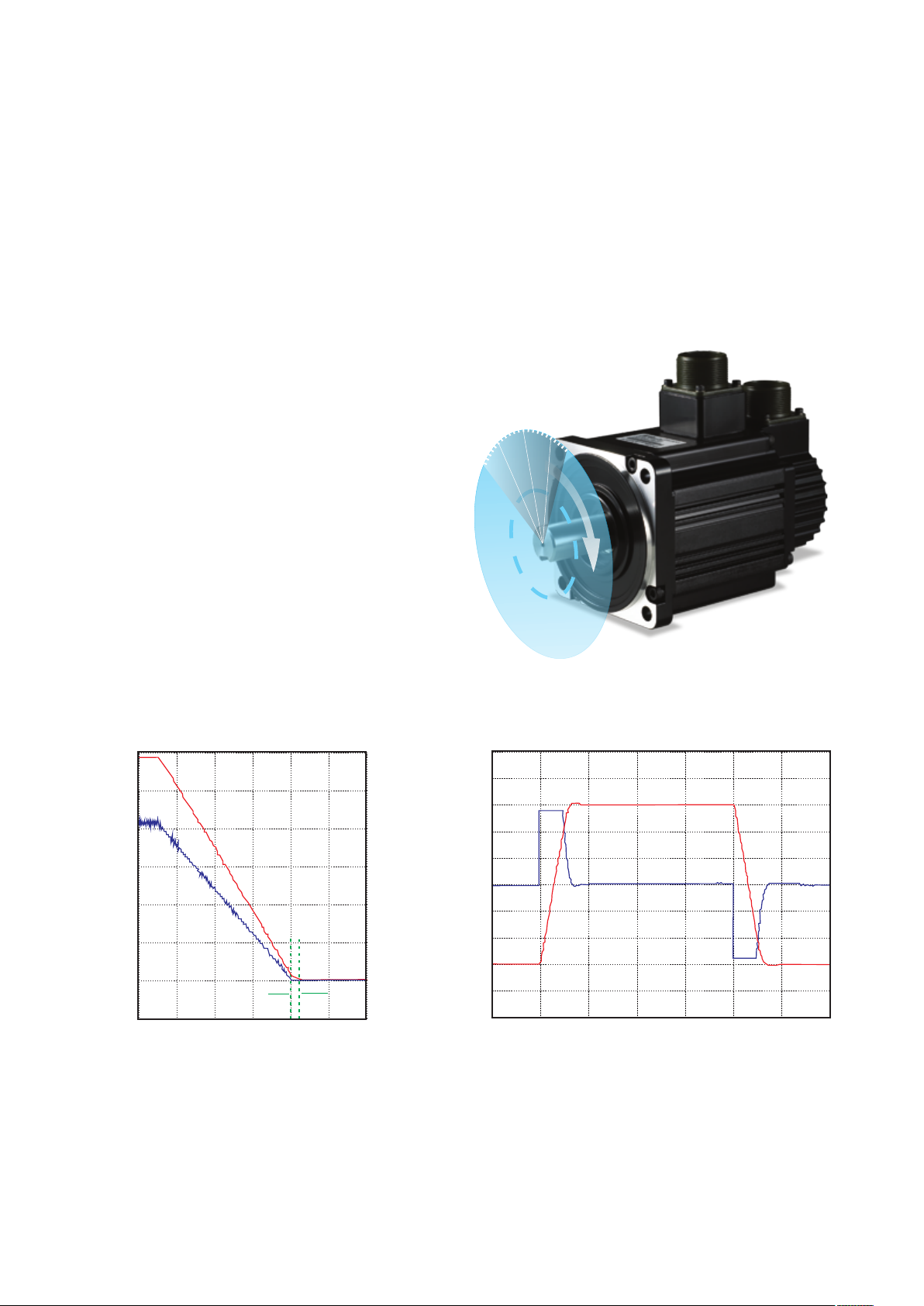

High Positioning Accuracy

►

ECMA series servo motors feature incremental encoders with 20-bit resolution which can eliminate

unstable commands at low speed, smooth motor operation and enhance the accuracy of positioning.

►

Absolute encoder supported. 17-bit motor position will not get lost when power is cut off.

20-bit, incremental encoder /

17-bit, absolute encoder

High Responsiveness

▲

►

Up to 1kHz frequency response.

►

Settling time below 1ms.

►

7ms acceleration time for speeds from -3000 r/min to 3000 r/min with an empty load!

(Note: The test record of a 400W motor with 60mm frame size)

6

5

4

3

2

1

Pulse command

fre quency

0

Postion error & Pulse command freq

-1

0

10

20

Time(ms)

Position error

1ms

30

40

50

60

Speed ( ) & Torque (N-m)r/min

5000

4000

3000

2000

1000

-1000

-2000

-3000

-4000

-5000

0

0

70

10

20

30

Time(ms)

40

50

60 70

3

Page 5

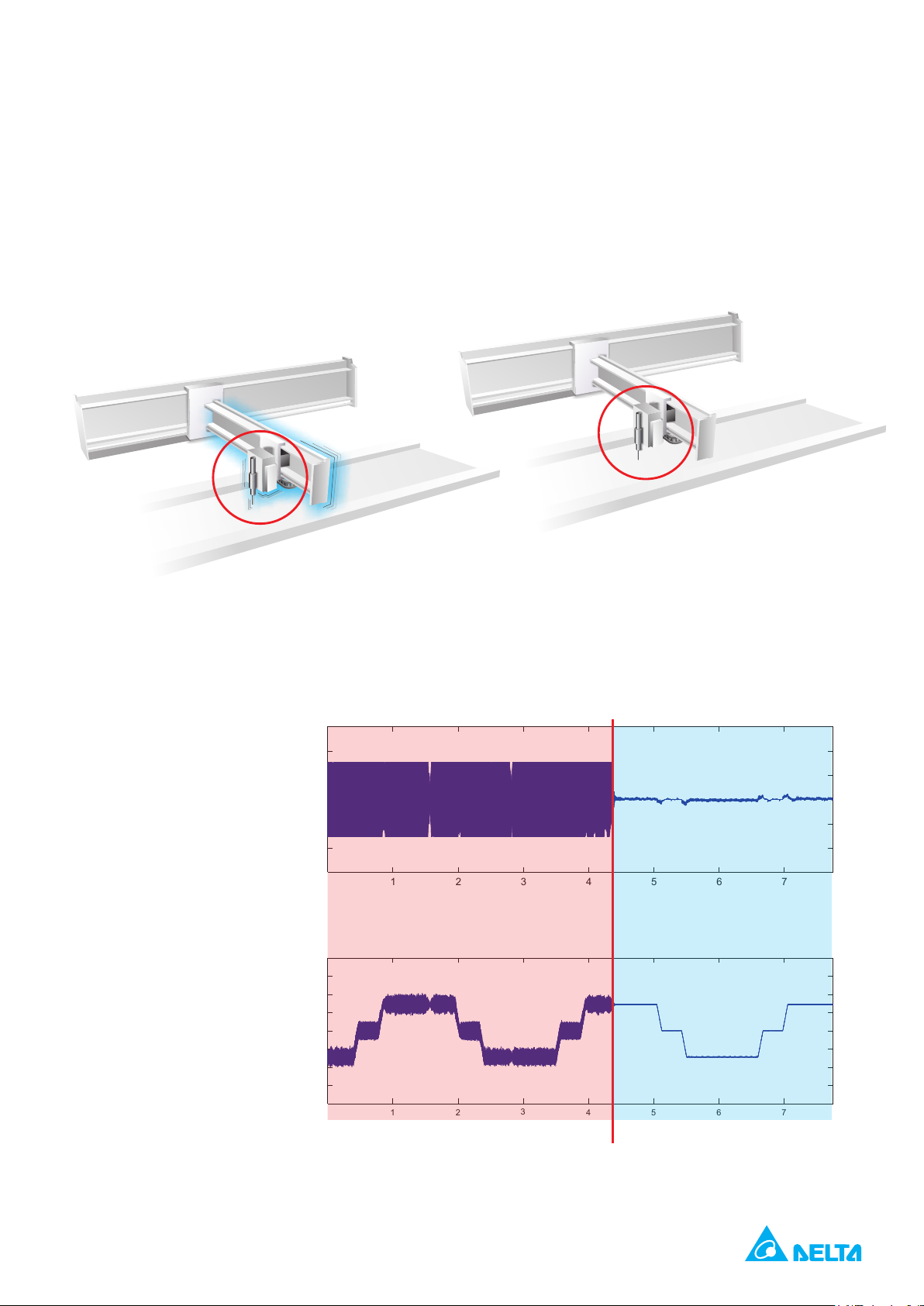

Excellent Suppression Functions

torque (Amp)

Speed (rpm)

t (sec)

t (sec)

►

Vibration Suppression (Low Frequency)

Two vibration suppression filters are provided for long arm system to minimize the vibration at

machine edges effectively.

►

Without Suppression

Function When Settling

Resonance Suppression

(High Frequency)

Two auto notch filters and

one manual notch filter

are provided to suppress

mechanical resonance

efficiently.

With Suppression

Function When Settling

Notch Filter Starts

30

20

10

0

-10

-20

-30

0 1 2 3 4 5 6 7

After SuppressionBefore Suppression

2000

1500

1000

500

-500

-1000

-1500

-2000

0

0

1 2

3

4 5

6 7

4

Page 6

ASDA-A2 Series Features

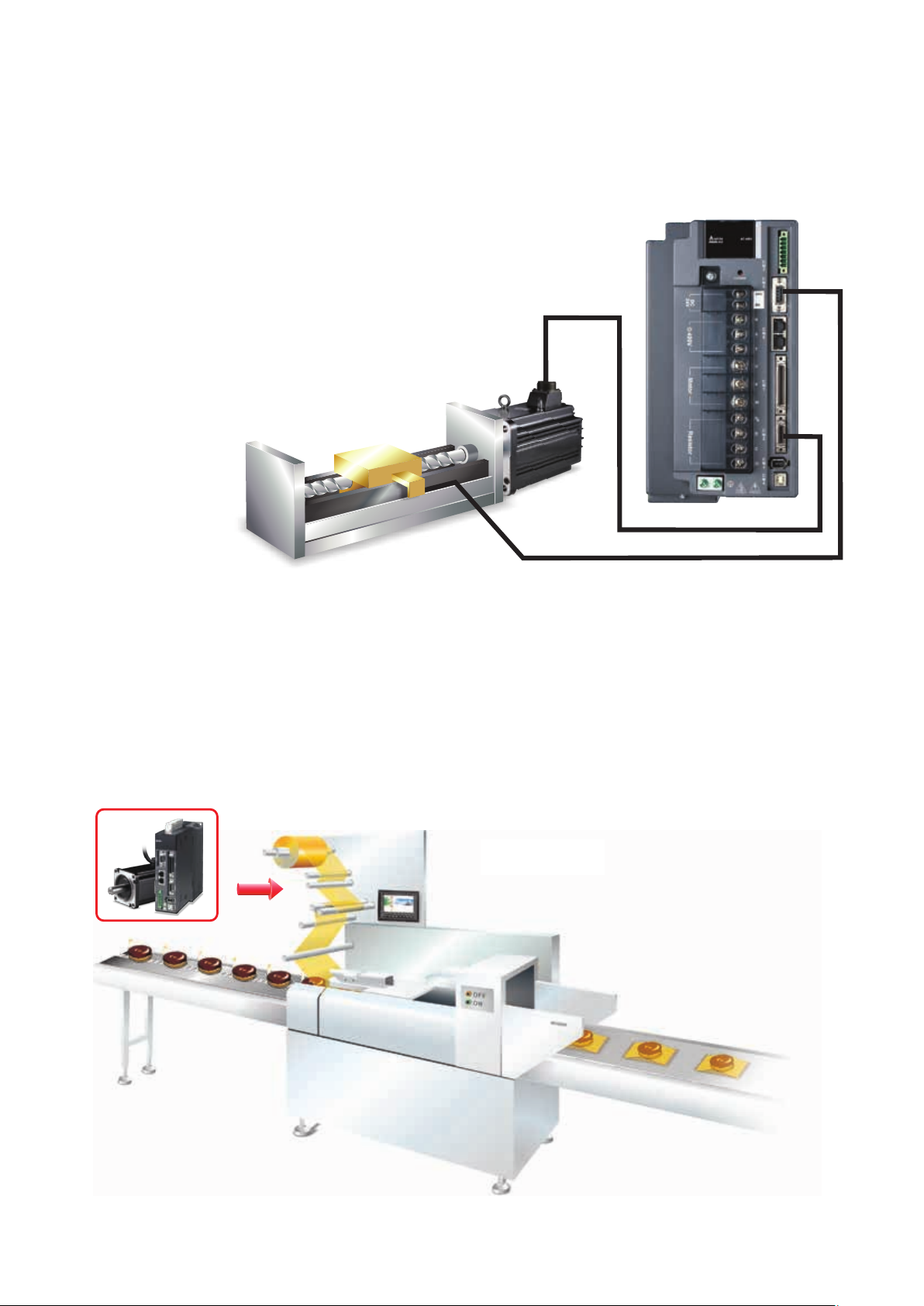

Full-Closed Loop Control Function*1

►

Reduces the effects of backlash and flexibility from the machine and

ensures the accuracy of positioning.

主編碼器

Motor Encoder

光學尺

Linear Scale

Note:

*1. PT and DMCNET mode only.

CN5

CN2

Electronic CAM (E-CAM) Function

►

720 points max. for E-CAM outline.

►

Smooth interpolation between points can be completed automatically to yield a flexible programming.

►

ASDA-Soft configuration software supported.

►

Easy to use for flying shear, rotary cut, and other cam applications.

ASDA-A2 E-CAM 功能於

E-CAM function of ASDA-A2 series

包裝機上的應用

for packaging machines and

packaging lines

5

Page 7

Versatile PR Mode

►

ASDA-Soft configuration software supported.

►

New sub-modes supported, not traditional point-to-point control.

►

64 procedures can be applied.

►

Motion profile can be changed instantaneously.

►

35 Homing modes / Jump mode / Write parameter mode /

Constant speed mode / Position control mode supported.

Speed

Sequential Command

P_Command 1

P_Command 2

Delay 1

A command is executed only when the

previous command is completed.

Speed

Insertion Command

P_Command 2

Time

Speed

Overlap Command

P_Command 2 P_Command 1

Time

The second command is executed after the

delay time or during the deceleration period.

P_Command 1

External command triggered

Insertion changes the command executed at the

moment it is inserted.

Time

6

Page 8

ASDA-A2 Series Features

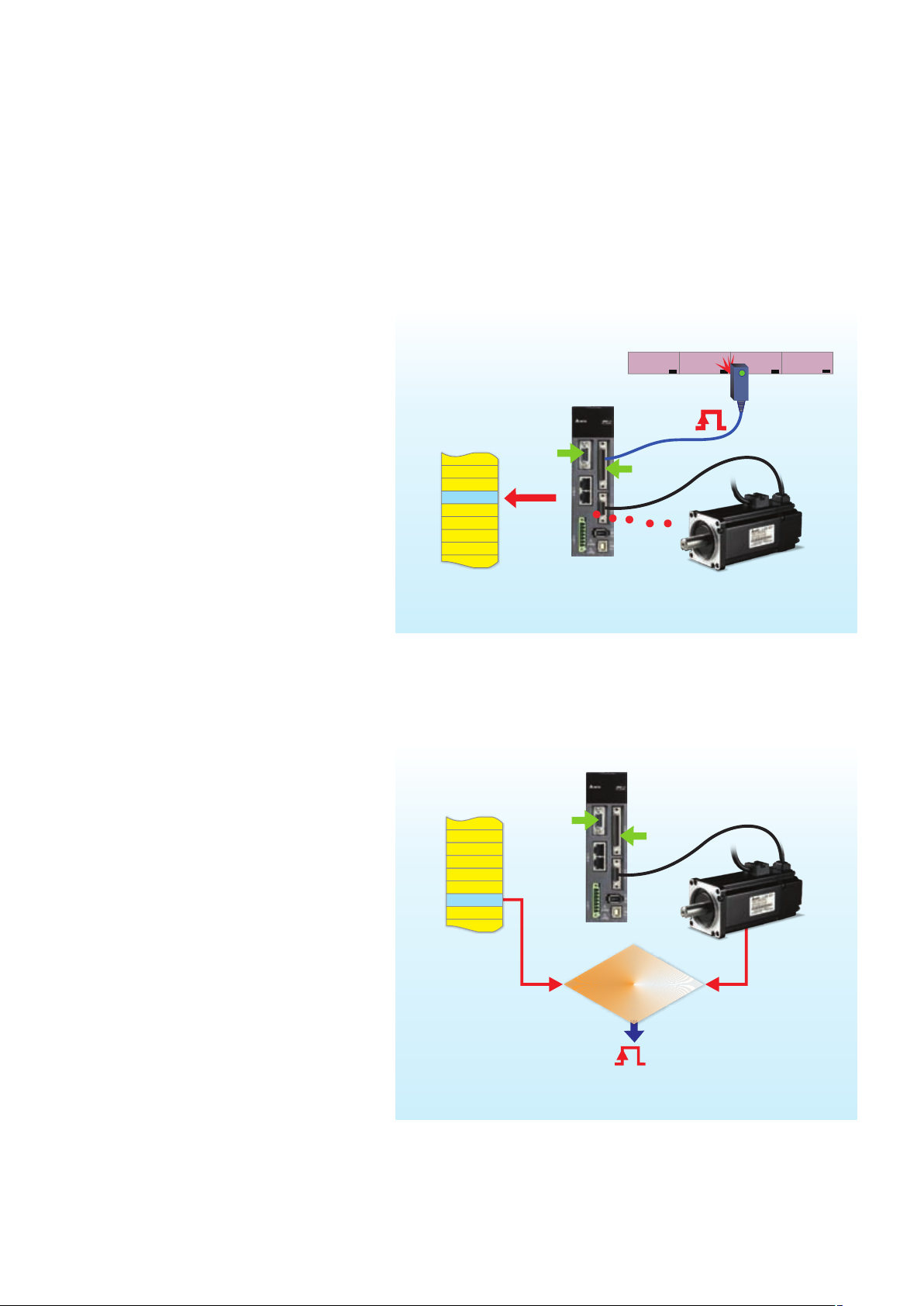

Capture and Compare Functions

Capture - Position Latch Function

►

Latches the coordinate value on the

reference axis.

►

Response time is less than 5us.

►

It can be used to do mark tracing.

►

Maximum 800 records

Data Array

38 3838

When DI7 is triggered, the latched position is

recorded in Data Array.

Linear

Encoder

DI 7

Pulse

Train

383 838

Motor Encoder

Compare - Position Detection

Function

►

Detects the location on the

reference axis.

►

Response time is less than 5us.

►

It can be used for CCD camera

applications.

►

Maximum 800 records

Data Array

383838

When the record in Data Array is the same as the

detected position, DO4 will output.

Linear

Encoder

Posi tion

True

Position

383838

Pulse

Train

==

DO4

Motor Encoder

7

Page 9

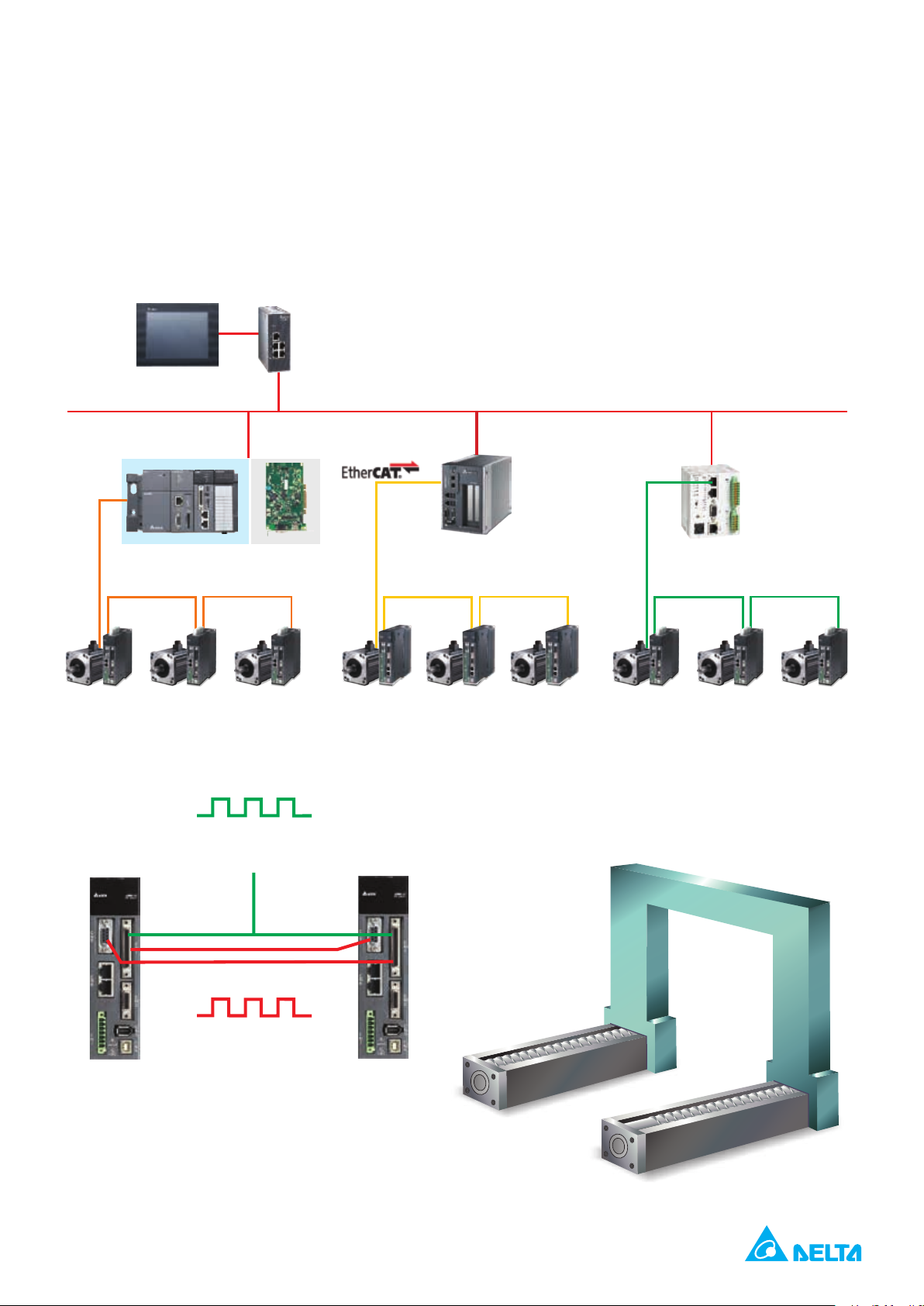

Supports High-Speed DMCNET, EtherCAT, CANopen Protocols for

Multi-Axis Synchronous Control

DOP-B DVS

Ethernet

AH500

PCI-DMC

DMCNET

or

ASDA-A2-F ASDA-A2-E ASDA-A2-M

Integrated Gantry Control

Sent From Host Controller

Axis 1 Axis 2

Pulse Command

CANopen

MH1-S30D DVP-10MC

Position Monitoring

8

Page 10

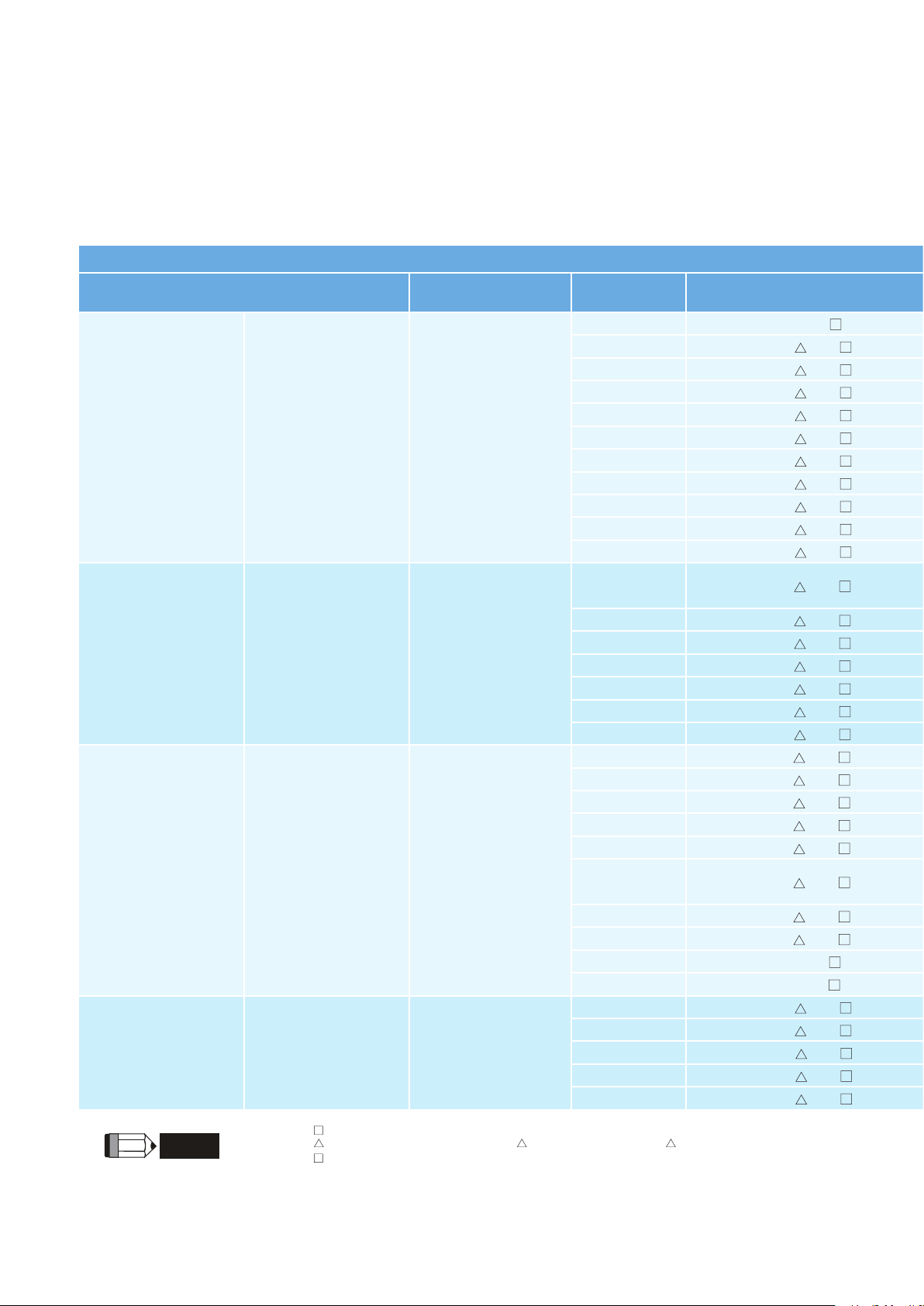

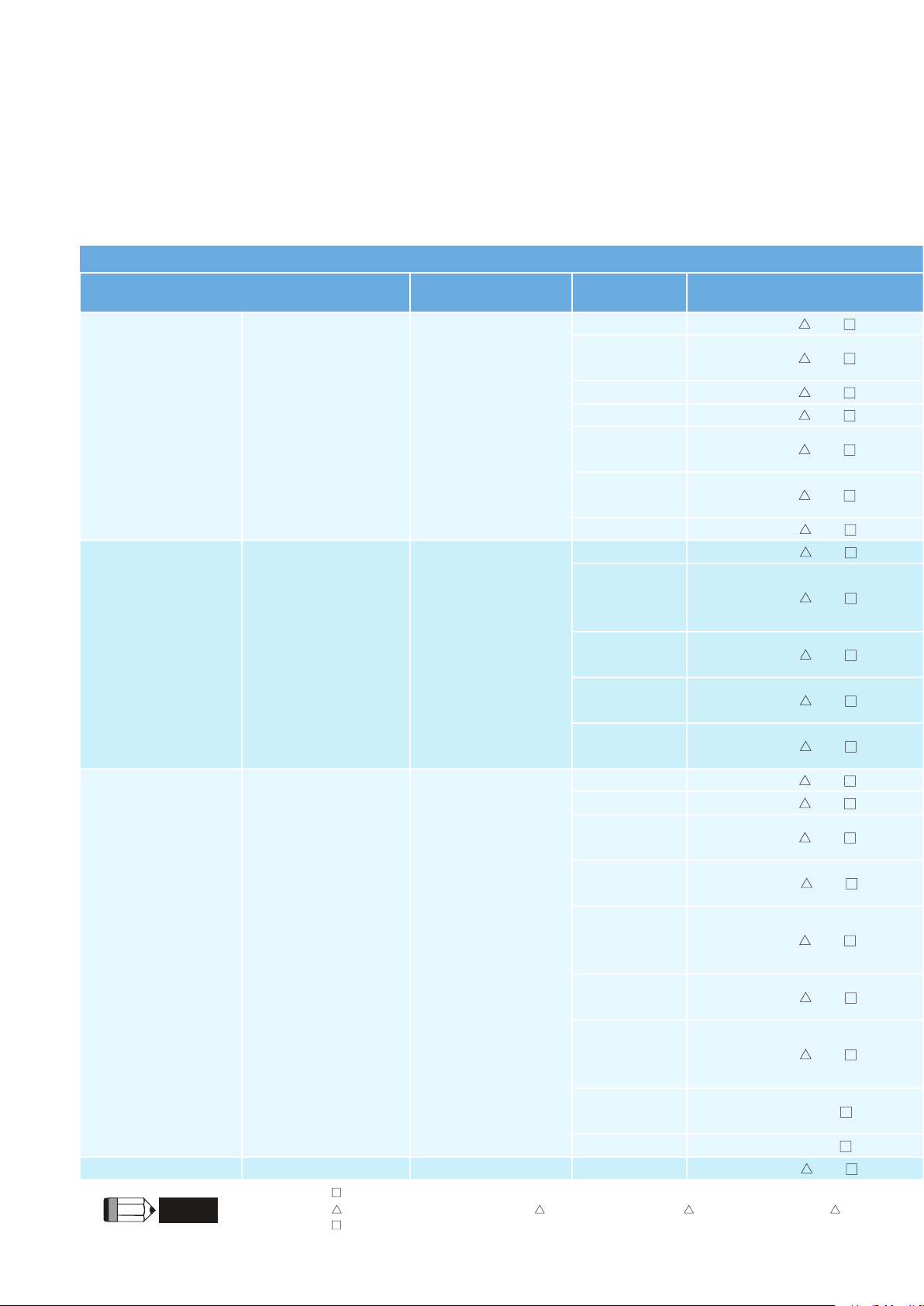

Product Line-up

NOTE

220V Series

Motor Series Phase

Low Inertia ECMA-C 3000 r/min 1-phase / 3-phase

Servo Motors Servo Drives

Rated Output

Power (W)

50 ECMA-C1040F

100 ECMA-C 0401 S 0.90 2.70

200 ECMA-C 0602 S 1.55 4.65 ASD-A2-0221- 1.55 4.65

400 ECMA-C 0604 S 2.60 7.80

400 ECMA-C 0804 7 2.60 7.80

750 ECMA-C 0807 S 5.10 15.30

750 ECMA-C 0907 S 3.66 11.00

1000 ECMA-C 0910 S 4.25 12.37

1000 ECMA-C 1010 S 7.30 21.90

2000 ECMA-C 1020 S 12.05 36.15 ASD-A2-2023- 13.40 40.20

3000 ECMA-C 1330 4 17.2 47.5 ASD-A2-3023- 19.40 58.20

Model Name Rated current (Arms) Maximum current (A) Model Name

S 0.69 2.05

Medium Inertia ECMA-E 2000 r/min 1-phase / 3-phase

Medium-High Inertia ECMA-F 1500 r/min 1-phase / 3-phase

High Inertia ECMA-C/G 3000 r/min 1-phase / 3-phase

500 ECMA-E

1000 ECMA-E 1310 S 5.60 16.80 ASD-A2-1021- 7.30 21.90

1500 ECMA-E 1315 S 8.30 24.90 ASD-A2-1521- 8.66 24.90

2000 ECMA-E 1320 S 11.01 33.03

2000 ECMA-E 1820 S 11.22 33.66

3000 ECMA-E 1830 S 16.10 48.30

3500 ECMA-E 1835 S 19.20 57.60

500 ECMA-F

850 ECMA-F 1308 S 7.10 19.40 ASD-A2-1021- 7.30 21.90

1300 ECMA-F 1313 S 12.60 38.60

1800 ECMA-F 1318 S 13.00 36.00

3000 ECMA-F 1830 S 19.40 58.20 ASD-A2-3023- 19.40 58.20

4500 ECMA-F 1845 S 32.50 81.30

5500 ECMA-F 1855 3 40.00 100.00 ASD-A2-5523- 40.00 106

7500 ECMA-F 1875 3 47.50 118.80 ASD-A2-7523- 47.50 141.1

11000 ECMA-F1221B 3 51.80 129.50 ASD-A2-1B23- 54.40 141.1

15000 ECMA-F1221F S 67 162 ASD-A2-1F23- 70.00 212.2

400 ECMA-C

750 ECMA-C 0807 H 5.10 15.30 ASD-A2-0721- 5.10 15.30

300 ECMA-G 1303 S 2.50 7.50 ASD-A2-0421- 2.60 7.80

600 ECMA-G 1306 S 4.80 14.40 ASD-A2-0721- 5.10 15.30

900 ECMA-G 1309 S 7.50 22.50 ASD-A2-1021- 7.30 21.90

1305 S 2.90 8.70

1305 S 3.90 12.10 ASD-A2-0721- 5.10 15.30

0604 H 2.60 7.80 ASD-A2-0421 2.60 7.80

The boxes (

1)

The boxes (

2)

The boxes (

3)

) at the ends of the servo drive model names are for optional configurations. For the actual model name, please refer to the model explanation of the servo drive.

) in the model names represent encoder type. =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit; ▲ =A: Absolute type

) in the model names represent shaft end/brake or the number of oil seal.

9

Page 11

0.69 2.05

ASD-A2-0121-

Continuous Output

Current (Arms)

0.90 2.70

Max. Instantaneous

Current (A)

ASD-A2-0421-

ASD-A2-0721-

ASD-A2-1021-

2.90 8.70

3.90 12.10 ASD-A2-0721- 5.10 15.30

ASD-A2-0421-

ASD-A2-0721-

ASD-A2-2023-

ASD-A2-3023-

ASD-A2-2023-

2.60 7.80

5.10 15.30

7.30 21.90

2.60 7.80

5.10 15.30

13.40 40.20

19.40 58.20

13.40 40.20

ASD-A2-4523-

ASD-A2-5523-

2.60 7.80 ASD-A2-0421 2.60 7.80

32.50 70.7

40.00 106

10

Page 12

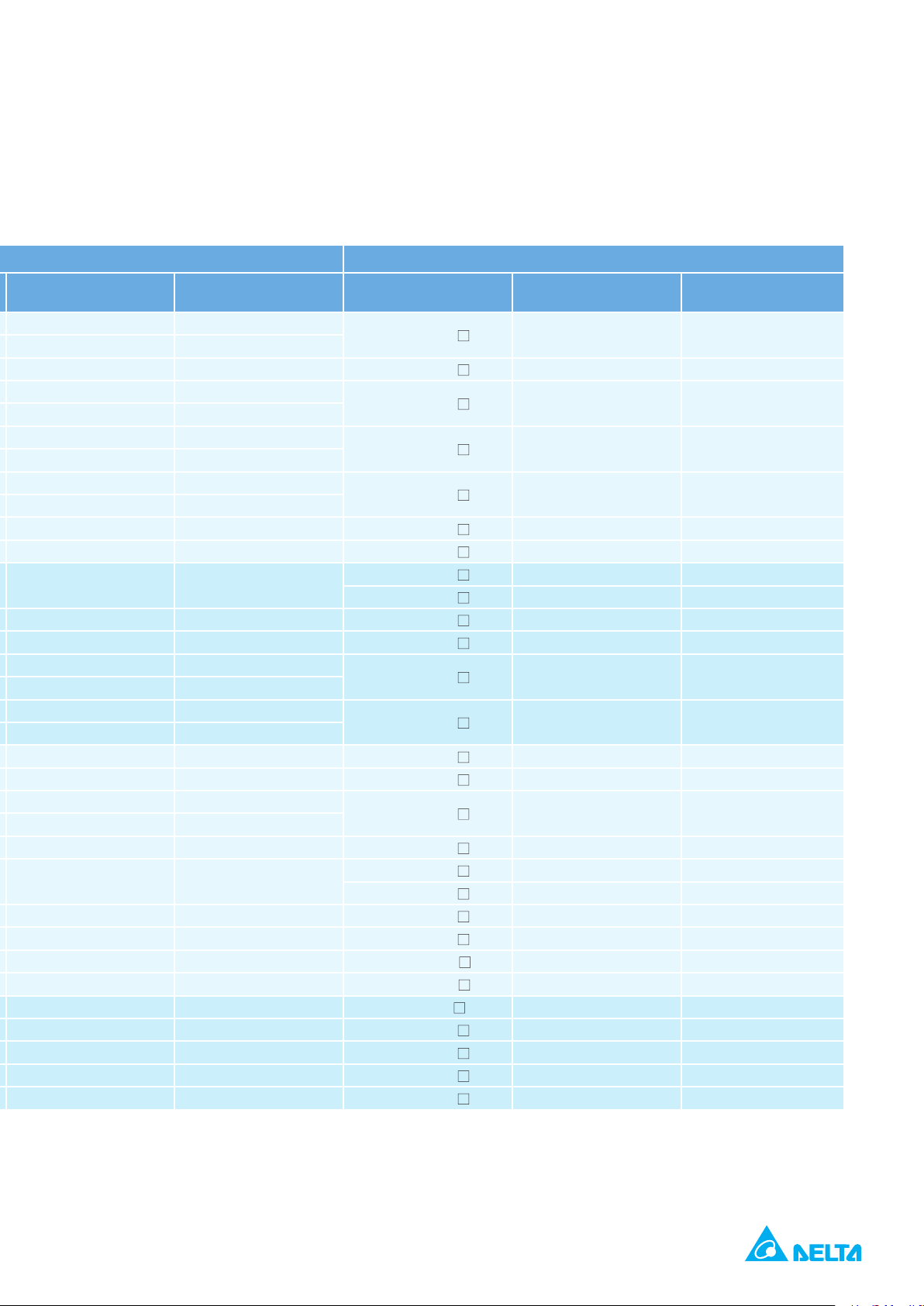

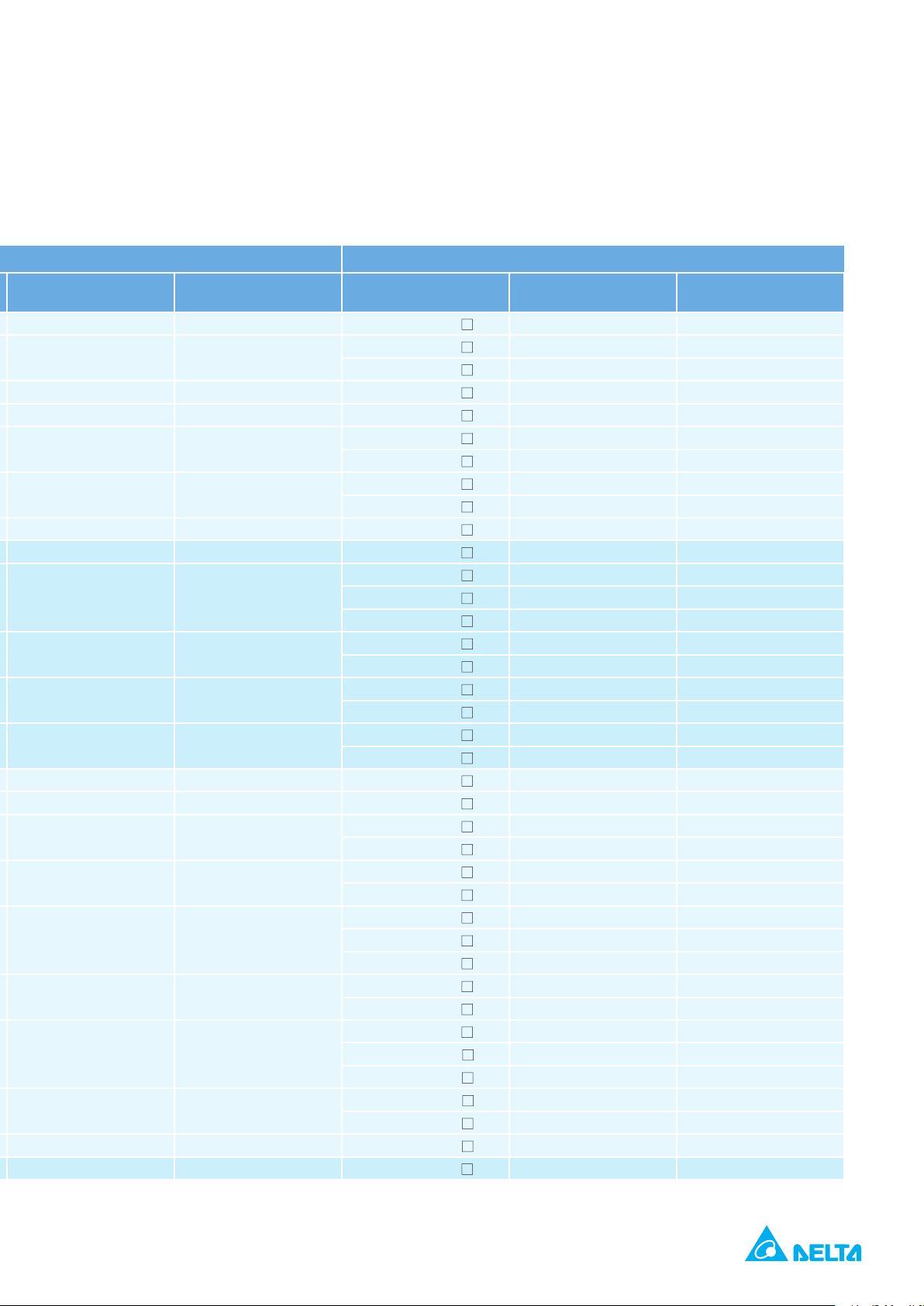

Product Line-up

NOTE

400V Series

Motor Series Phase

Low Inertia ECMA-J 3000 r/min 3-phase

Servo Motors Servo Drives

Rated Output

Power (W)

400 ECMA-J

750 ECMA-J 0807 S 3.07 9.5

750 ECMA-J 0907 S 2.16 6.37 ASD-A2-0743- 3.07 9.21

1000 ECMA-J 0910 S 2.4 7.17 ASD-A2-1043- 3.52 9.86

1000 ECMA-J 1010 S 4.15 12.46

2000 ECMA-J 1020 S 7.09 21.28

3000 ECMA-J 1330 4 9.8 29.99 ASD-A2-3043- 11.9 33.32

750 ECMA-K

1000 ECMA-K 1310 S 3.52 10.56

Model Name Rated current (Arms) Maximum current (A) Model Name

0604 S 1.62 4.85 ASD-A2-0743- 3.07 9.21

1305 S 1.7 5.2 ASD-A2-0743- 3.07 9.21

Medium Inertia ECMA-K 2000 r/min 3-phase

Medium-High Inertia ECMA-L 1500 r/min 3-phase

1500 ECMA-K 1315 S 5.02 15.06

2000 ECMA-K 1320 S 6.66 19.98

2000 ECMA-K 1820 S 6.6 19.88

750 ECMA-L

850 ECMA-L 1308 S 3.4 8.85 ASD-A2-1043- 3.52 9.86

1300 ECMA-L 1313 S 5.02 15

3000 ECMA-L 1830 S 11.53 34.6

4500 ECMA-L 1845 S 20.8 52

5500 ECMA-L 1855 3 22.37 56

7500 ECMA-L 1875 3 27.3 68.3

1305 S 2.1 6.1 ASD-A2-0743- 3.07 9.21

11000 ECMA-L1221B 3 27.2 68

15000 ECMA-L1221F 3 41.6 100 ASD-A2-1F43- 38.65 85.03

High Inertia ECMA-M 3000 r/min 3-phase 900 ECMA-M 1309 S 4.4 13.1 ASD-A2-1543- 5.02 10.04

The boxes (

1)

2) The boxes ( ) in the model names represent encoder type. =1: Incremental encoder, 20-bit ; =2: Incremental encoder, 17-bit; =A: Absolute type

The boxes (

3)

) at the ends of the servo drive model names are for optional configurations. For the actual model name, please refer to the model explanation of the servo drive.

) in the model names represent shaft end/brake or the number of oil seal.

11

Page 13

Continuous Output

Current (Arms)

1.62 4.85 ASD-A2-0743- 3.07 9.21

ASD-A2-0743-

ASD-A2-1043-

3.07 9.21

3.52 9.86

Max. Instantaneous

Current (A)

ASD-A2-1543-

ASD-A2-2043-

ASD-A2-2043-

ASD-A2-3043-

1.7 5.2 ASD-A2-0743- 3.07 9.21

ASD-A2-1043-

ASD-A2-1543-

ASD-A2-2043-

ASD-A2-1543-

ASD-A2-2043-

ASD-A2-2043-

ASD-A2-3043-

ASD-A2-2043-

ASD-A2-3043-

2.1 6.1 ASD-A2-0743- 3.07 9.21

ASD-A2-1543-

ASD-A2-2043-

ASD-A2-3043-

ASD-A2-4543-

ASD-A2-4543-

ASD-A2-5543-

ASD-A2-7543-

ASD-A2-5543-

ASD-A2-7543-

ASD-A2-7543-

ASD-A2-1B43-

ASD-A2-1F43-

ASD-A2-1B43-

ASD-A2-1F43-

5.02 10.04

6.66 18.65

6.66 18.65

11.9 33.2

3.52 9.86

5.02 10.04

6.66 18.65

5.02 10.04

6.66 18.65

6.66 18.65

11.9 33.32

6.66 18.65

11.9 33.32

5.02 10.04

6.66 18.65

11.9 33.32

20 44

20 44

22.04 48.49

28.39 62.46

22.04 48.49

28.39 62.46

28.39 62.46

28.1 61.82

38.65 85.03

28.1 61.82

38.65 85.03

12

Page 14

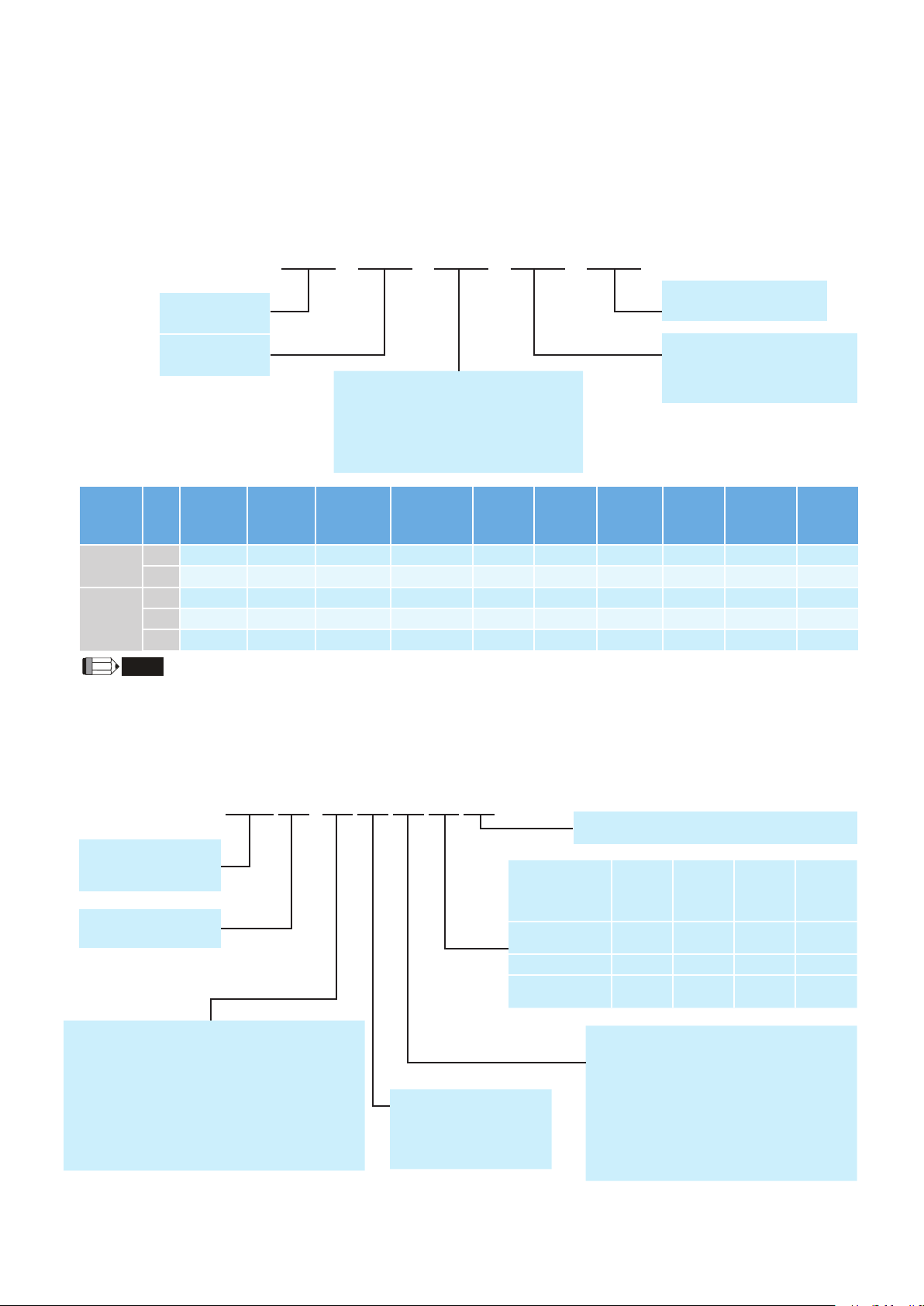

Model Explanation

NOTE

ASDA-A2 Series Servo Drives

ASD - A2*5- 04 21 - M

Product Name:

AC Servo Drive

Series:

A2

Rated Output Power

01: 100 W

02: 200 W

04: 400 W

07: 750 W

10: 1 kW

15: 1.5 kW

20: 2 kW

30: 3 kW

45: 4.5 kW

55: 5.5 kW

75: 7.5 kW

1B: 11 kW

Model Type

(see the table below)

Input Voltage and Phase

21: 220V 1-phase / 3-phase

23: 220V 3-phase

43: 400V 3-phase

1F: 15 kW

Standard

Model

Type

RS-485

(CN3)

Full-Closed

Control

(CN5)

*1

Extension

Port for

Digital Input

(CN7)

EtherCAT *4CANpen DMCNET

L ○ ○ X X X X ○ ○ ○ X

U ○ ○ ○ X X X ○ ○ ○ ○

Analog

Voltage

Control

Pulse

Input Port

E X X ○ ○ X X X X ○ X

Network

Model

F ○ ○ X X X ○ X X ○

M ○ ○ X X ○ X ○ ○ ○ ○

2. When applying communication mode (A2-E, -F, -M models), PR parameters can be read and written through DMCNET only.

3. E-CAM function can only be used in PR mode.

4. For information about ASDA A2-E EtherCAT interface servo drive, please refer to the ASDA A2-E brochure.

5. For communication mode -F/-M models with 400V/11kW, 15kW is categorized as ASDA-A2R.

6. Rated power of 100W to 1.5kW are marked number 21 with 220V, single-phase and three-phase connections

1. In PR mode, only A2-F supports full-closed control function.

PR

Parameters

*2

*6

E-CAM

X

*3

ECMA Series Servo Motors

ECM A - C1 06 02 E S

Product Nam

ECM: Electrical

Commutation Motor

Driving Type

A: AC Servo Motor

Series

Rated Voltage / Rated Speed

C: 220V / 3000 r/min

E: 220V / 2000 r/min

F: 220V / 1500 r/min

G: 220V / 1000 r/min

Encoder Type

1: Incremental encoder, 20-bit

2: Incremental encoder, 17-bit

3: 2500 ppr

e

J: 400V / 3000 r/min

K: 400V / 2000 r/min

L: 400V / 1500 r/min

M: 400V / 1000 r/min

A: Absolute encoder,

Single-turn: 17-bit

Multi-turn: 16-bit

Motor Frame Size

04: 40 mm

06: 60 mm

08: 80 mm

09: 86 mm

Shaft Type and

(with screw hole)

Keyway (with

10: 100 mm

13: 130 mm

18: 180 mm

22: 220 mm

S: Standard Shaft Diameter

H: High Inertia Model

W/O

Brake

Oil Seal

Round Shaft

Keyway E F - -

screw hole)

W/O Oil

Seal

- - C D

P Q R S

Rated Output Power

0F: 50 W

01: 100 W

02: 200 W

03: 300 W

04: 400 W

05: 500 W

06: 600 W

07: 750 W

With

Brake

W/O Oil

Seal

08: 850 W

09: 900 W

10: 1 kW

13: 1.3 kW

15: 1.5 kW

18: 1.8 kW

20: 2 kW

30: 3 kW

W/O

Brake

With

Oil Seal

35: 3.5 kW

45: 4.5 kW

50: 5.0 kW

55: 5.5 kW

75: 7.5 kW

1B: 11 kW

1F: 15 kW

With

Brake

With

Oil Seal

13

Page 15

Servo Motor Features

ECMA

ASDA-A2 220V series AC servo drives from 50 W to 15 kW and 380V to 480V ASDA-A2 400V series

AC servo drives from 750 W to 7.5 kW.

For the 220V series, there are 40 mm, 60 mm, 80 mm, 86 mm, 100 mm, 130 mm, 180 mm, and 200 mm

eight kinds of frame sizes available. The motor speed is from 1000 r/min to 5000 r/min and the torque

output is from 0.477 N-m to 224 N-m.

For the 400V series, there are 60 mm, 80 mm, 86 mm, 100 mm, 130 mm, 180 mm, six kinds of frame

sizes available. The motor speed is from 1500 r/min to 5000 r/min and the torque output is from 3.82

N-m to 119.36 N-m In terms of optional configurations, ECMA series provides brake and oil seal to fully

support our customers' needs. It also offers two different shaft selections, round shaft and keyway, for

various applications.

series servo motors are permanent AC servo motors, capable of combining with 200 to 230V

14

Page 16

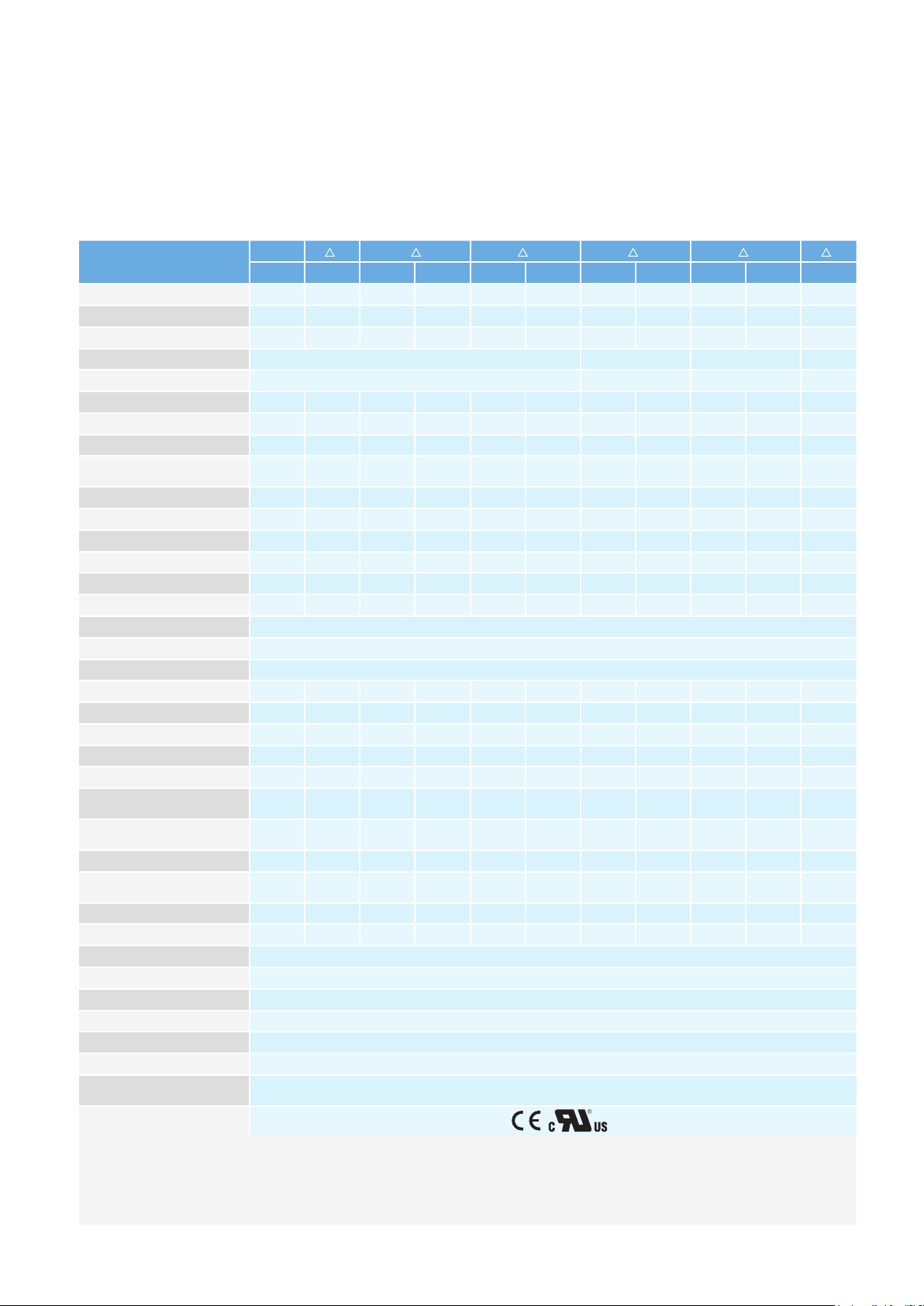

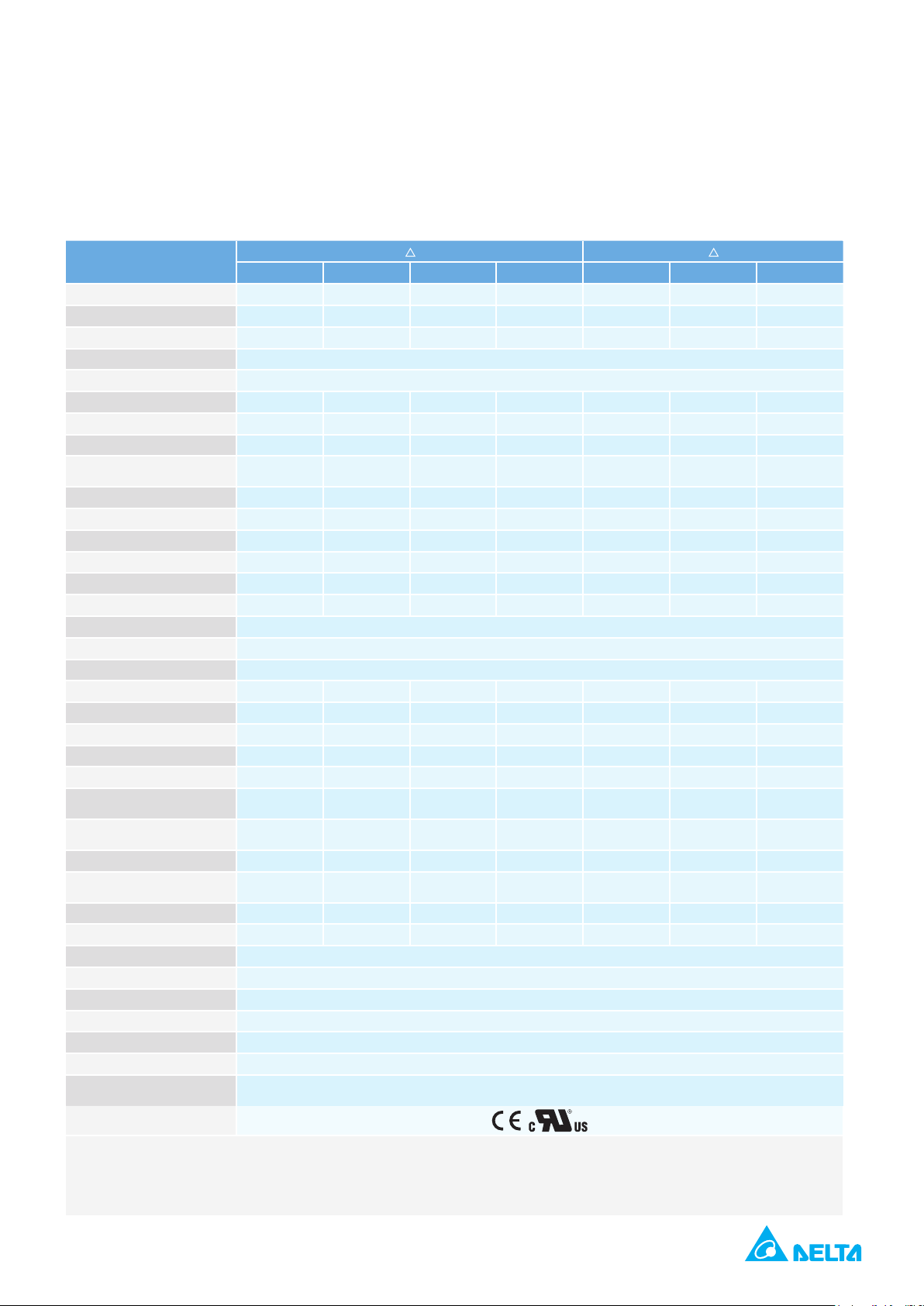

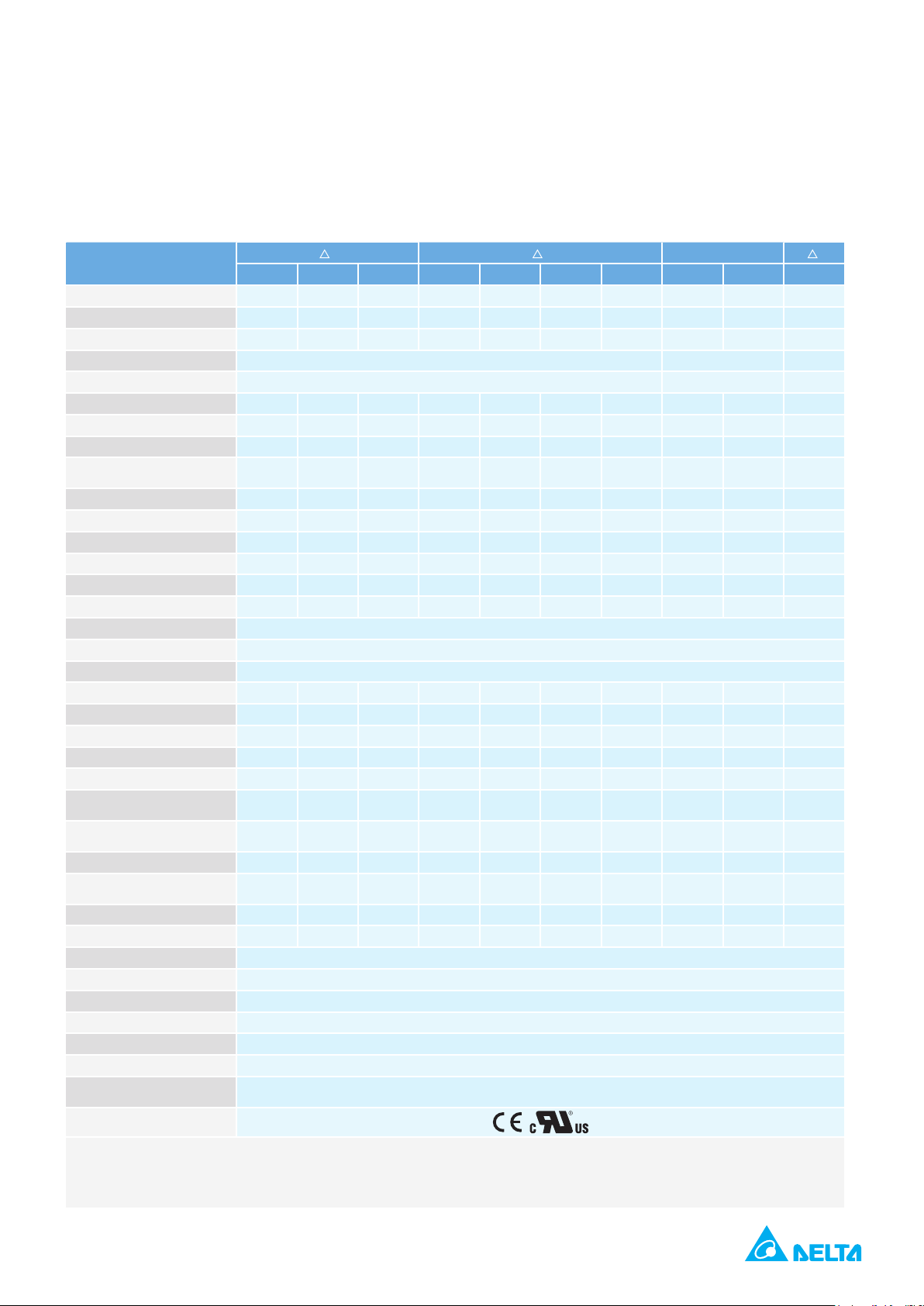

Servo Motor Specifications

Low Inertia Series- 220V Series

ECMA Series

C104 C

0F 01 02 04□S 04 07 07 10 10 20 30

04 C 06 C 08 C 09 C 10 C 13

Rated output power (kW) 0.05 0.1 0.2 0.4 0.4 0.75 0.75 1.0 1.0 2.0 3.0

Rated torque (N-m)

*1

0.159 0.32 0.64 1.27 1.27 2.39 2.39 3.18 3.18 6.37 9.55

Maximum torque (N-m) 0.477 0.96 1.92 3.82 3.82 7.16 7.14 8.78 9.54 19.11 28.65

Rated speed (r/min) 3000 3000 3000 3000

Maximum speed (r/min) 5000 3000 5000 4500

Rated current (A) 0.69 0.90 1.55 2.6 2.6 5.1 3.66 4.25 7.3 12.05 17.2

Maximum current (A) 2.05 2.70 4.65 7.8 7.8 15.3 11 12.37 21.9 36.15 47.5

Power rating (kW/s) 12.27 27.7 22.4 57.6 24.0 50.4 29.6 38.6 38.1 90.6 71.8

Rotor moment of inertia

-4

(x10

kg-m2)

0.0206 0.037 0.177 0.277 0.68 1.13 1.93 2.62 2.65 4.45 12.7

Mechanical time constant (ms) 1.2 0.75 0.80 0.53 0.74 0.63 1.72 1.20 0.74 0.61 1.11

Torque constant-KT (N-m/A) 0.23 0.36 0.41 0.49 0.49 0.47 0.65 0.75 0.44 0.53 0.557

Voltage constant-KE (mV/(r/min) 9.8 13.6 16 17.4 18.5 17.2 24.2 27.5 16.8 19.2 20.98

Armature resistance (Ohm) 12.7 9.30 2.79 1.55 0.93 0.42 1.34 0.897 0.20 0.13 0.0976

Armature inductance (mH) 26 24.0 12.07 6.71 7.39 3.53 7.55 5.7 1.81 1.50 1.21

Electrical time constant (ms) 2.05 2.58 4.3 4.3 7.96 8.36 5.66 6.35 9.3 11.4 12.4

Insulation class Class A (UL), Class B (CE)

Insulation resistance 100MΩ , DC 500V above

Insulation strength 1.8k Vac,1 sec

Weight (kg)(without brake) 0.42 0.5 1.2 1.6 2.1 3.0 2.9 3.8 4.3 6.2 7.8

Weight (kg)(with brake) -- 0.8 1.5 2.0 2.9 3.8 3.69 5.5 4.7 7.2 9.2

Max. radial shaft load (N) 78.4 78.4 196 196 245 245 245 245 490 490 490

Max. thrust shaft load (N) 39.2 39.2 68 68 98 98 98 98 98 98 98

Power rating (kW/s)(with brake) -- 25.6 21.3 53.8 22.1 48.4 29.3 37.9 30.4 82 65.1

Rotor moment of inertia

-4

(x10

kg-m2)(with brake)

Mechanical time constant

(ms)(with brake)

Brake holding torque [Nt-m (min)]

Brake power consumption

(at 20˚C)[W]

-- 0.04 0.19 0.30 0.73 1.18 1.95 2.67 3.33 4.95 14.0

-- 0.81 0.85 0.57 0.78 0.65 1.74 1.22 0.93 0.66 1.22

*2

-- 0.3 1.3 1.3 2.5 2.5 2.5 2.5 8 8 10.0

-- 7.3 6.5 6.5 8.2 8.2 8.2 8.2 18.7 18.7 19.0

Brake release time [ms (Max)] -- 5 10 10 10 10 10 10 10 10 10

Brake pull-in time [ms (Max)] -- 25 70 70 70 70 70 70 70 70 70

Vibration grade (μm) 15

Operating temperature (˚C) 0ºC to 40ºC

Storage temperature (˚C) -10ºC to 80ºC

Operating humidity 20 to 90%RH (non-condensing)

Storage humidity 20 to 90%RH (non-condensing)

Vibration capacity 2.5G

IP Rating

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

Approvals

*1. Rate torque values are continuous permissible values at 0 ~ 40˚C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-_ _ 04 / 06 / 08: 250 mm x 250 mm x 6 mm

ECMA-_ _ 10: 300 mm x 300 mm x 12 mm

ECMA-_ _ 13: 400 mm x 400 mm x 20 mm

ECMA-_ _ 18: 550 mm x 550 mm x 30 mm

ECMA-_ _ 22: 650 mm x 650 mm x 35 mm

Material type : Aluminum – F40, F60, F80, F100, F130, F180, F220

*2. The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

15

Page 17

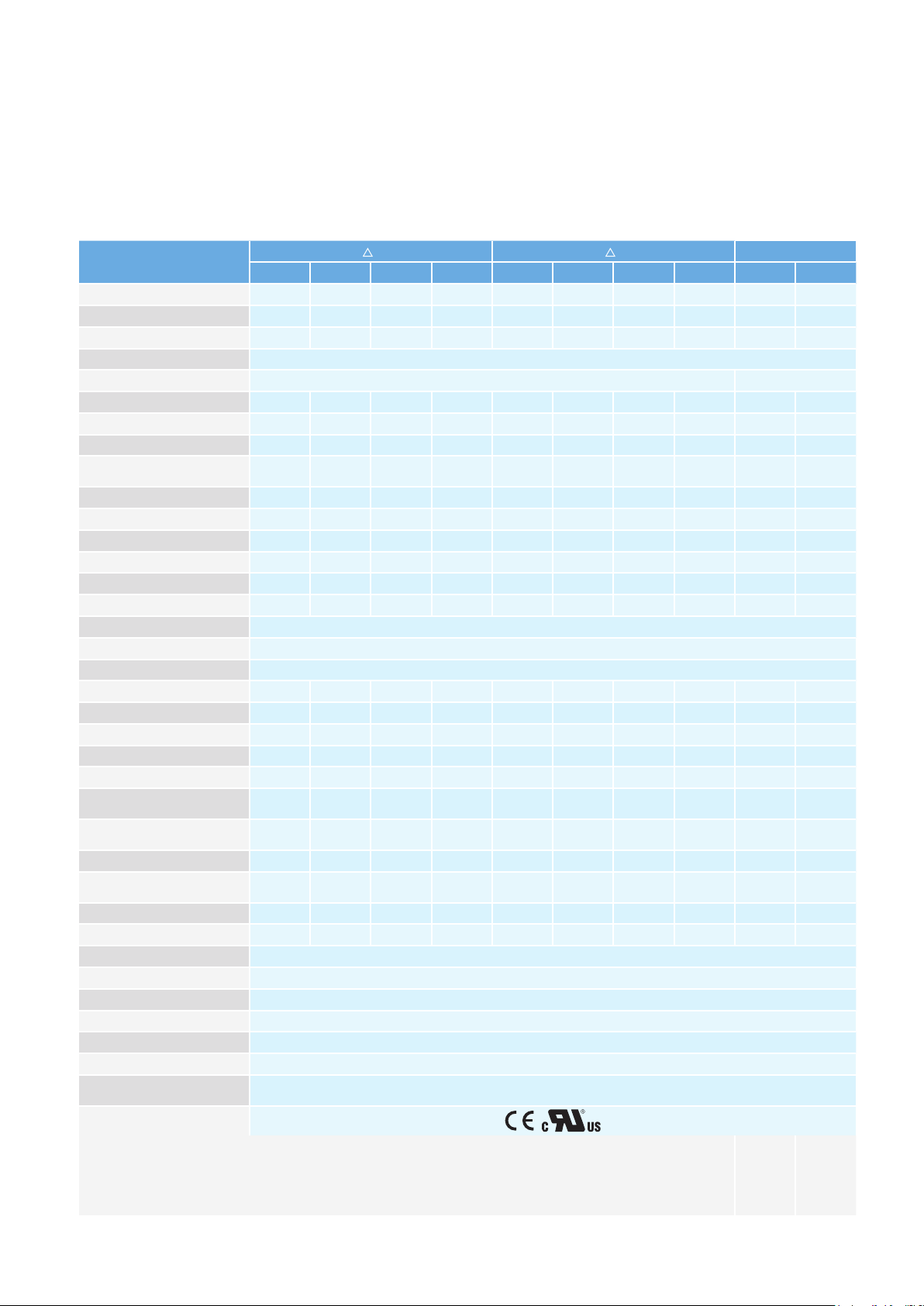

Medium Series- 220V Series

13 E 18

ECMA Series

05 10 15 20 20 30 35

Rated output power (kW) 0.5 1.0 1.5 2.0 2.0 3.0 3.5

Rated torque (N-m)

*1

2.39 4.77 7.16 9.55 9.55 14.32 16.71

Maximum torque (N-m) 7.16 14.3 21.48 28.65 28.65 42.97 50.13

Rated speed (r/min) 2000

Maximum speed (r/min) 3000

Rated current (A) 2.9 5.6 8.3 11.01 11.22 16.1 19.2

Maximum current (A) 8.7 16.8 24.9 33.03 33.66 48.3 57.6

Power rating (kW/s) 7.0 27.1 45.9 62.5 26.3 37.3 50.8

Rotor moment of inertia

-4

(x10

kg-m2)(without brake)

8.17 8.41 11.18 14.59 34.68 54.95 54.95

Mechanical time constant (ms) 1.91 1.51 1.10 0.96 1.62 1.06 1.08

Torque constant-KT (N-m/A) 0.83 0.85 0.87 0.87 0.85 0.89 0.87

Voltage constant-KE (mV/(r/min) 30.9 31.9 31.8 31.8 31.4 32.0 32

Armature resistance (Ohm) 0.57 0.47 0.26 0.174 0.119 0.052 0.052

Armature inductance (mH) 7.39 5.99 4.01 2.76 2.84 1.38 1.38

Electrical time constant (ms) 12.96 12.88 15.31 15.86 23.87 26.39 26.39

Insulation class Class A (UL), Class B (CE)

Insulation resistance 100MΩ , DC 500V above

Insulation strength 1.8k Vac,1 sec

Weight (kg)(without brake) 6.8 7.0 7.5 7.8 13.5 18.5 18.5

Weight (kg)(with brake) 8.2 8.4 8.9 9.2 17.5 22.5 22.5

Max. radial shaft load (N) 490 490 490 490 1176 1470 1470

Max. thrust shaft load (N) 98 98 98 98 490 490 490

Power rating (kW/s)(with brake) 6.4 24.9 43.1 57.4 24.1 35.9 48.9

Rotor moment of inertia

-4

(x10

kg-m2)(with brake)

Mechanical time constant

(ms)(with brake)

Brake holding torque [Nt-m (min)]

Brake power consumption

(at 20˚C)[W]

8.94 9.14 11.90 15.88 37.86 57.06 57.06

2.07 1.64 1.19 1.05 1.77 1.10 1.12

*2

10.0 10.0 10.0 10.0 25.0 25.0 25.0

19.0 19.0 19.0 19.0 20.4 20.4 20.4

Brake release time [ms (Max)] 10 10 10 10 10 10 10

Brake pull-in time [ms (Max)] 70 70 70 70 70 70 70

Vibration grade (μm) 15

Operating temperature (˚C) 0ºC to 40ºC

Storage temperature (˚C) -10ºC to 80ºC

Operating humidity 20 to 90%RH (non-condensing)

Storage humidity 20 to 90%RH (non-condensing)

Vibration capacity 2.5G

IP Rating

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

Approvals

*1. Rate torque values are continuous permissible values at 0 ~ 40˚C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-_ _ 04 / 06 / 08: 250 mm x 250 mm x 6 mm

ECMA-_ _ 10: 300 mm x 300 mm x 12 mm

ECMA-_ _ 13: 400 mm x 400 mm x 20 mm

ECMA-_ _ 18: 550 mm x 550 mm x 30 mm

ECMA-_ _ 22: 650 mm x 650 mm x 35 mm

Material type : Aluminum – F40, F60, F80, F100, F130, F180, F220

*2. The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

E

the rotating shaft (an oil seal model is used))

16

Page 18

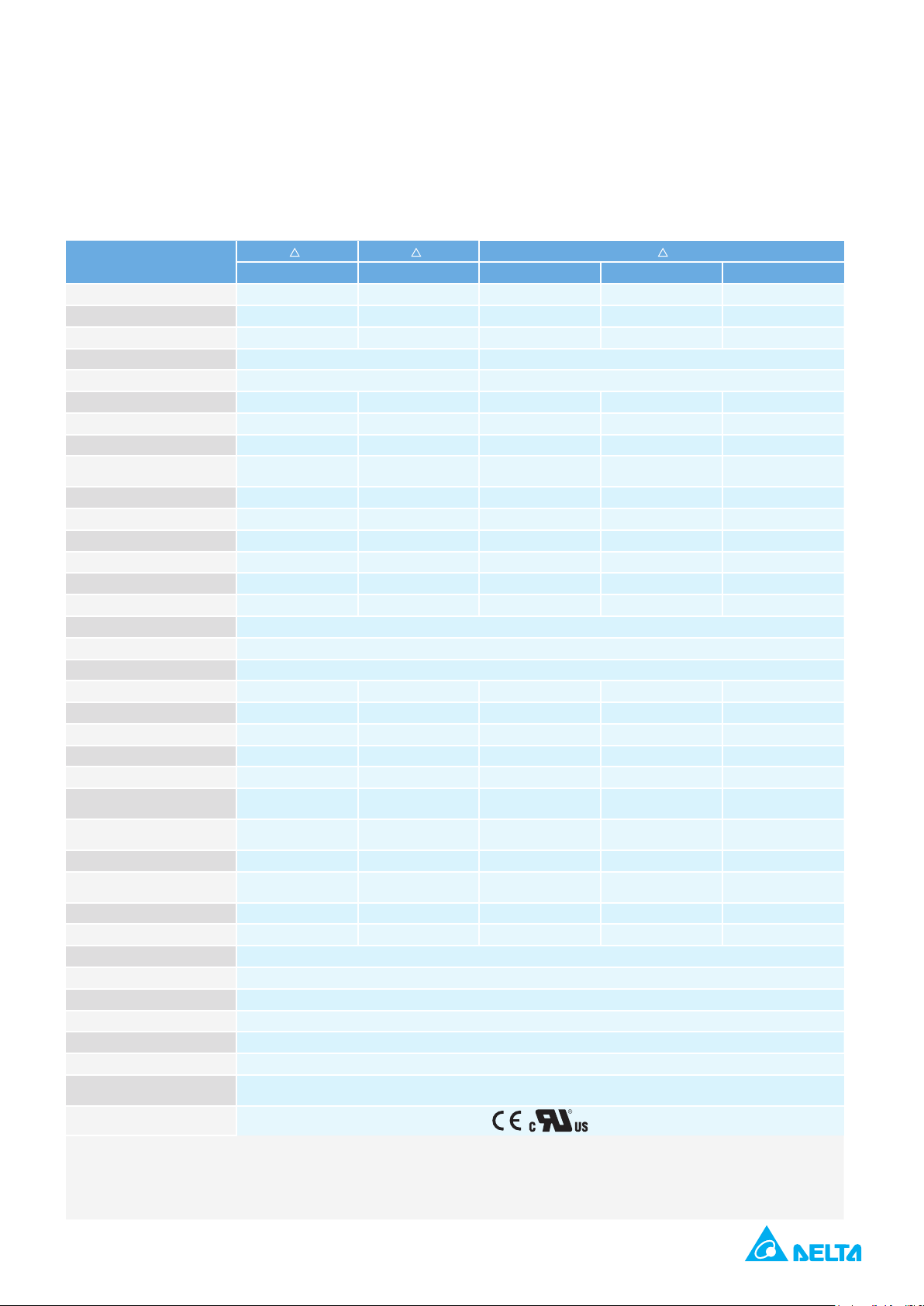

Servo Motor Specifications

Medium-High Inertia Series- 220V Series

13 F 18 F122

ECMA Series

05 08 13 18 30 45 55 75 1B 1F

Rated output power (kW) 0.5 0.85 1.3 1.8 3.0 4.5 5.5 7.5 11 15

Rated torque (N-m)

*1

3.18 5.41 8.34 11.48 19.10 28.65 35.01 47.74 70 95.4

Maximum torque (N-m) 8.92 13.8 23.3 28.7 57.29 71.62 87.53 119.36 175 224.0

Rated speed (r/min) 1500

Maximum speed (r/min) 3000 2000

Rated current (A) 3.9 7.1 12.6 13 19.4 32.5 40.0 47.5 51.8 67

Maximum current (A) 12.1 19.4 38.6 36 58.2 81.3 100.0 118.8 129.5 162

Power rating (kW/s) 9.8 21.52 34.78 52.93 66.4 105.5 122.9 159.7 144.9 201.8

Rotor moment of inertia

-4

(x10

kg-m2)(without brake)

10.3 13.6 20 24.9 54.95 77.75 99.78 142.7 338 451

Mechanical time constant (ms) 2.8 2.43 1.62 1.7 1.28 0.92 0.96 0.63 1.38 1.23

Torque constant-KT (N-m/A) 0.82 0.76 0.66 0.88 0.98 0.88 0.88 1.01 1.37 1.42

Voltage constant-KE (mV/(r/min) 29.5 29.2 24.2 32.2 35.0 32.0 31.0 35.5 49 50

Armature resistance (Ohm) 0.624 0.38 0.124 0.185 0.077 0.032 0.025 0.015 0.026 0.0184

Armature inductance (mH) 7 4.77 1.7 2.6 1.27 0.89 0.60 0.40 0.65 0.48

Electrical time constant (ms) 11.22 12.55 13.71 14.05 16.5 27.8 24.0 26.7 24.79 26.09

Insulation class Class A (UL), Class B (CE)

Insulation resistance 100MΩ , DC 500V above

Insulation strength 1.8k Vac,1 sec

Weight (kg)(without brake) 6.3 8.6 9.4 10.5 18.5 23.5 30.5 40.5 56.4 75

Weight (kg)(with brake) 7.7 10.0 10.8 11.9 22.5 29 36 46 68.4 87

Max. radial shaft load (N) 490 490 490 490 1470 1470 1764 1764 3300 3300

Max. thrust shaft load (N) 98 98 98 98 490 490 588 588 1100 1100

Power rating (kW/s)(with brake) 8.8 19.78 32.66 50.3 63.9 101.8 119.4 156.6 141.4 197.1

Rotor moment of inertia

-4

(x10

kg-m2)(with brake)

Mechanical time constant

(ms)(with brake)

Brake holding torque[Nt-m(min)]

Brake power consumption

(at 20˚C)[W]

11.5 14.8 21.3 26.2 57.06 80.65 102.70 145.55 346.5 461.8

3.12 2.65 1.73 1.79 1.33 0.96 0.99 0.64 1.41 1.25

*2

10 10.0 10.0 10.0 25.0 55.0 55.0 55.0 115 11 5

19 19.0 19.0 19.0 20.4 19.9 19.9 19.9 28.8 28.8

Brake release time [ms (Max)] 10 10 10 10 10 10 10 10 10 10

Brake pull-in time [ms (Max)] 70 70 70 70 70 70 70 70 70 70

Vibration grade (μm) 15

Operating temperature (˚C) 0ºC to 40ºC

Storage temperature (˚C) -10ºC to 80ºC

Operating humidity 20 to 90%RH (non-condensing)

Storage humidity 20 to 90%RH (non-condensing)

Vibration capacity 2.5G

IP Rating

Approvals

*1. Rate torque values are continuous permissible values at 0 ~ 40˚C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-_ _ 04 / 06 / 08: 250 mm x 250 mm x 6 mm

ECMA-_ _ 10: 300 mm x 300 mm x 12 mm

ECMA-_ _ 13: 400 mm x 400 mm x 20 mm

ECMA-_ _ 18: 550 mm x 550 mm x 30 mm

ECMA-_ _ 22: 650 mm x 650 mm x 35 mm

Material type : Aluminum – F40, F60, F80, F100, F130, F180, F220

*2. The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

F

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

17

Page 19

High Inertia Series- 220V Series

06 C 08 G 13

ECMA Series

Rated output power (kW) 0.4 0.75 0.3 0.6 0.9

Rated torque (N-m)

Maximum torque (N-m) 3.82 7.16 8.59 17.19 21.48

Rated speed (r/min) 3000 1000

Maximum speed (r/min) 5000 2000

Rated current (A) 2.6 5.1 2.5 4.8 7.5

Maximum current (A) 7.8 15.3 7.5 14.4 22.5

Power rating (kW/s) 21.7 19.63 10.0 39.0 66.0

Rotor moment of inertia

-4

(x10

kg-m2)(without brake)

Mechanical time constant (ms) 1.42 1.6 1.84 1.40 1.06

Torque constant-KT (N-m/A) 0.49 0.47 1.15 1.19 1.15

Voltage constant-KE (mV/(r/min) 17.4 17.2 42.5 43.8 41.6

Armature resistance (Ohm) 1.55 0.42 1.06 0.82 0.43

Armature inductance (mH) 6.71 3.53 14.29 11.12 6.97

Electrical time constant (ms) 4.3 8.36 13.5 13.50 16.06

Insulation class Class A (UL), Class B (CE)

Insulation resistance

Insulation strength 1.8k Vac,1 sec

Weight (kg)(without brake) 1.8 3.4 6.8 7.0 7.5

Weight (kg)(with brake) 2.2 3.9 8.2 8.4 8.9

Max. radial shaft load (N) 196 245 490 490 490

Max. thrust shaft load (N) 68 98 98 98 98

Power rating (kW/s)(with brake) 21.48 19.3 9.2 35.9 62.1

Rotor moment of inertia

-4

(x10

kg-m2)(with brake)

Mechanical time constant

(ms)(with brake)

Brake holding torque [Nt-m (min)]

Brake power consumption

(at 20˚C)[W]

Brake release time [ms (Max)] 10 10 10 10 10

Brake pull-in time [ms (Max)] 70 70 70 70 70

Vibration grade (μm) 15

Operating temperature (˚C) 0ºC to 40ºC

Storage temperature (˚C) -10ºC to 80ºC

Operating humidity 20 to 90%RH (non-condensing)

Storage humidity 20 to 90%RH (non-condensing)

Vibration capacity 2.5G

IP Rating

Approvals

*1. Rate torque values are continuous permissible values at 0 ~ 40˚C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-_ _ 04 / 06 / 08: 250 mm x 250 mm x 6 mm

ECMA-_ _ 10: 300 mm x 300 mm x 12 mm

ECMA-_ _ 13: 400 mm x 400 mm x 20 mm

ECMA-_ _ 18: 550 mm x 550 mm x 30 mm

ECMA-_ _ 22: 650 mm x 650 mm x 35 mm

Material type : Aluminum – F40, F60, F80, F100, F130, F180, F220

*2. The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

*1

*2

C

▅

04

H 07▅H 03 06 09

1.27 2.39 2.86 5.73 8.59

0.743 2.91 8.17 8.41 11.18

100M

, DC 500V

Ω

0.751 2.96 8.94 9.14 11.9

1.43 1.62 2.0 1.51 1.13

1.3 2.5 10.0 10.0 10.0

6.5 8.2 19.0 19.0 19.0

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

above

18

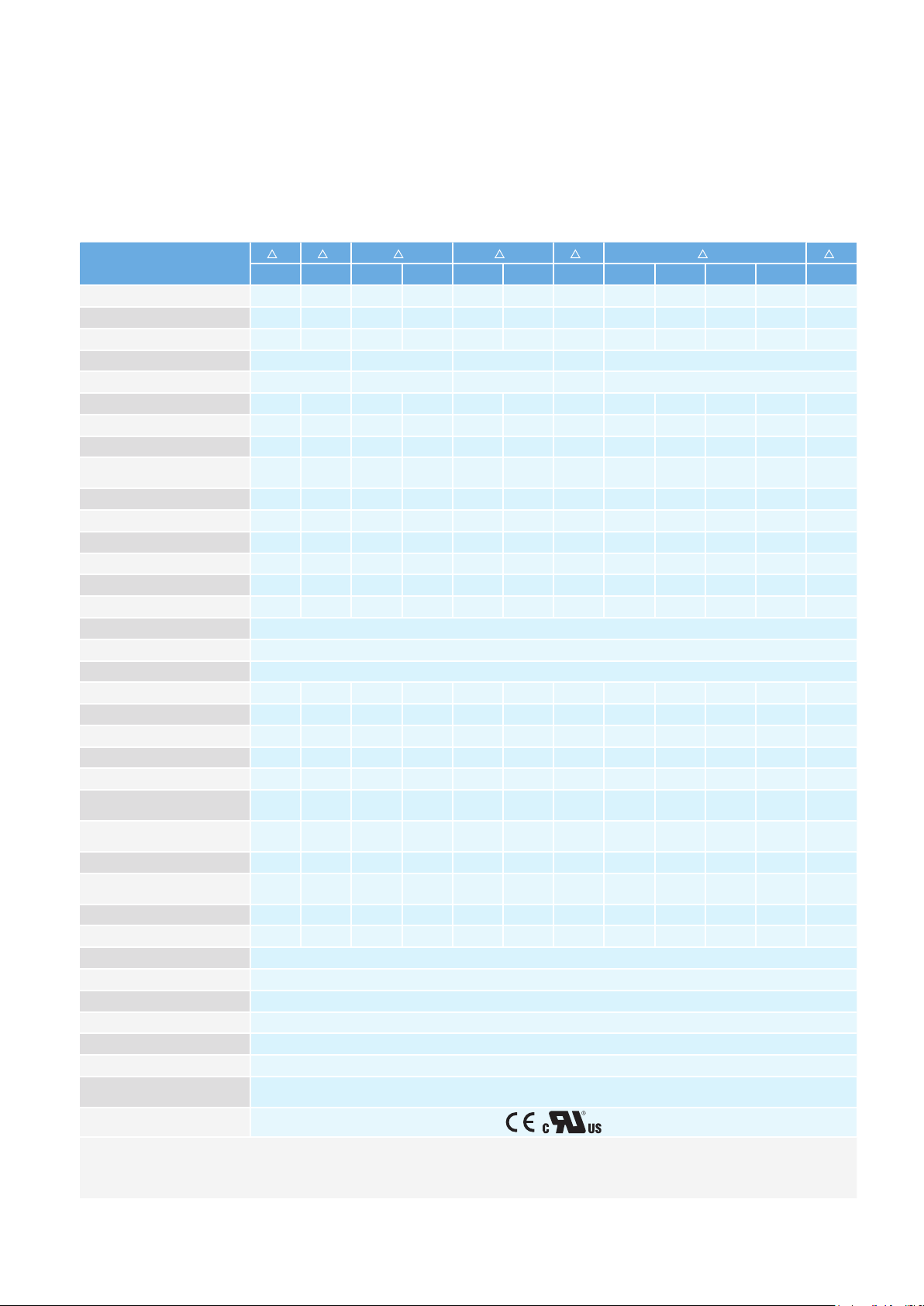

Page 20

Servo Motor Specifications

Low / Medium Series- 400V Series

06 J 08 J 09 J 10 J 13 K 13 K 18

ECMA Series

Rated output power (kW) 0.4 0.75 0.75 1 1.0 2.0 3.0 0.5 1.0 1.5 2.0 2.0

Rated torque (N-m)

Maximum torque (N-m) 3.82 7.16 7.14 8.78 9.54 19.1 28.65 7.16 14.32 21.48 28.65 28.65

Rated speed (r/min) 3000 3000 3000 3000 2000

Maximum speed (r/min) 5000 3000 5000 4500 3000

Rated current (A) 1.62 3.07 2.16 2.4 4.15 7.09 9.8 1.7 3.52 5.02 6.66 6.6

Maximum current (A) 4.85 9.5 6.37 7.17 12.46 21.28 29.99 5.2 10.56 15.06 19.98 19.88

Power rating (kW/s) 58.2 50.4 29.6 38.6 38.2 91.2 71.8 6.99 27.1 45.9 62.5 26.3

Rotor moment of inertia

-4

(x10

kg-m2)(without brake)

Mechanical time constant (ms) 0.47 0.66 1.56 1.06 0.77 0.58 0.99 2.08 1.80 1.24 1.04 1.74

Torque constant-KT (N-m/A) 0.79 0.78 1.12 1.29 0.77 0.9 0.97 1.41 1.35 1.43 1.43 1.45

Voltage constant-KE (mV/(r/min) 30.6 28.24 42 50.9 29.0 34.4 37.3 51.5 53.2 55 55 54.0

Armature resistance (Ohm) 3.95 1.22 3.62 2.58 0.617 0.388 0.269 1.76 1.47 0.83 0.57 0.376

Armature inductance (mH) 21.3 10.68 21.2 15.28 6.03 4.62 3.55 22.4 17.79 11.67 8.29 7.87

Electrical time constant (ms) 5.39 8.75 5.85 5.93 9.77 11.9 13.2 12.73 12.04 14.04 14.39 20.9

Insulation class Class A (UL), Class B (CE)

Insulation resistance 100MΩ, DC 500V above

Insulation strength 2.3k Vac, 1 sec

Weight (kg)(without brake) 1.6 3.0 2.9 3.8 4.3 6.2 7.8 6.8 7.0 7.5 7.8 13.5

Weight (kg)(with brake) 2 3.8 - - 4.7 7.2 9.2 8.2 8.4 8.9 9.2 17.5

Max. radial shaft load (N) 19.6 245 245 245 490 490 490 490 490 490 490 1176

Max. thrust shaft load (N) 68 98 98 98 98 98 98 98 98 98 98 490

Power rating (kW/s)(with brake) 53.8 48.4 29.3 37.9 30.4 82 65.1 6.39 24.9 43.1 59.7 24.1

Rotor moment of inertia

-4

(x10

kg-m2)(with brake)

Mechanical time constant

(ms)(with brake)

Brake holding torque [Nt-m (min)]*21.3 2.5 2.5 2.5 8.0 8.0 10.0 10.0 10.0 10.0 10.0 25.0

Brake power consumption

(at 20˚C)[W]

Brake release time [ms (Max)] 10 10 10 10 10 10 10 10 10 10 10 10

Brake pull-in time [ms (Max)] 70 70 70 70 70 70 70 70 70 70 70 70

Vibration grade (μm) 15

Operating temperature (˚C) 0ºC to 40ºC

Storage temperature (˚C) -10ºC to 80ºC

Operating humidity 20 to 90%RH (non-condensing)

Storage humidity 20 to 90%RH (non-condensing)

Vibration capacity 2.5G

IP Rating

Approvals

*1. Rate torque values are continuous permissible values at 0 ~ 40˚C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-_ _ 08: 250 mm x 250 mm x 6 mm

ECMA-_ _ 13: 400 mm x 400 mm x 20 mm

ECMA-_ _ 18: 550 mm x 550 mm x 30 mm

Material type : Aluminum – F80, F130, F180, F220

*2. The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

*1

J

04 07 07 10 10 20 30 05 10 15 20 20

1.27 2.39 2.39 3.18 3.18 6.37 9.55 2.39 4.77 7.16 9.55 9.55

0.277 1.13 1.93 2.62 2.65 4.45 12.7 8.17 8.41 11.18 14.59 34.68

0.3 1.18 1.95 2.67 3.33 4.95 14.0 8.94 9.14 11.90 15.88 37.86

0.52 0.65 1.57 1.08 0.96 0.65 1.09 2.28 1.96 1.32 1.13 1.9

6.5 8.5 8.2 8.2 18.5 18.5 19.0 19.0 19.0 19.0 19.0 20.4

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

19

Page 21

Medium-High / High Inertia Series- 400V Series

13 L 18 L122 M 13

ECMA Series

05 08 13 30 45 55 75 1B 1F 09

Rated output power (kW) 0.5 0.85 1.3 3.0 4.5 5.5 7.5 11 15 0.9

Rated torque (N-m)

*1

3.18 5.39 8.34 19.10 28.65 35.0 47.74 70 95.4 8.59

Maximum torque (N-m) 8.92 13.8 23.3 57.29 71.62 87.53 119.36 175 224 21.48

Rated speed (r/min) 1500 1500 1000

Maximum speed (r/min) 3000 2000 2000

Rated current (A) 2.1 3.4 5.02 11.53 20.8 22.37 27.3 27.2 41.6 4.4

Maximum current (A) 6.1 8.85 15 34.6 52 56 68.3 68 100 13.1

Power rating (kW/s) 7.72 17.0 29.47 66.4 105.5 122.9 159.7 145 201.8 66

Rotor moment of inertia

-4

(x10

kg-m2)(without brake)

13.1 17.1 23.6 54.95 77.75 99.78 142.7 338 451 11.18

Mechanical time constant (ms) 2.3 1.76 1.44 1.11 0.94 0.88 0.77 1.42 1.34 1.21

Torque constant-KT (N-m/A) 1.5 1.59 1.66 1.66 1.38 1.56 1.75 2.57 2.29 1.95

Voltage constant-KE (mV/(r/min) 55.5 58.9 61.1 64.4 53 58.9 66.4 96 83.9 71.7

Armature resistance (Ohm) 1.41 0.92 0.59 0.21 0.09 0.07 0.06 0.0994 0.0545 1.45

Armature inductance (mH) 20 14.1 9.54 4.94 2.36 2.2 1.7 2.51 1.43 23.3

Electrical time constant (ms) 14.1 15.33 16.17 23.97 28.07 27.6 28.29 25.25 26.26 16.07

Insulation class Class A (UL), Class B (CE)

Insulation resistance 100MΩ, DC 500V above

Insulation strength 2.3k Vac,1 sec

Weight (kg)(without brake) 6.8 8.6 10.7 18.5 23.5 30.5 40.5 56.4 75 7.5

Weight (kg)(with brake) - 10 -- 22.5 29 36 46 68.4 87 8.9

Max. radial shaft load (N) 490 490 490 1470 1470 1764 1764 3300 3300 490

Max. thrust shaft load (N) 98 98 98 490 490 588 588 1100 1100 98

Power rating (kW/s)(with brake) 7.02 14.82 27.82 63.9 101.8 119.4 156.6 141.4 197.1 62

Rotor moment of inertia

-4

(x10

kg-m2)(with brake)

Mechanical time constant

(ms)(with brake)

14.4 19.6 25 57.06 80.65 102.70 145.5 346.5 461.8 11.9

2.54 2.02 1.52 1.16 0.95 0.91 0.79 1.46 1.37 1.29

Brake holding torque [Nt-m (min)]*210.0 10.0 10.0 25.0 55.0 55.0 55.0 115 115 10.0

Brake power consumption

(at 20˚C)[W]

19.0 19.0 19.0 20.4 19.9 19.9 19.9 28.8 28.8 19.0

Brake release time [ms (Max)] 10 10 10 10 10 10 10 10 10 10

Brake pull-in time [ms (Max)] 70 70 70 70 70 70 70 70 70 70

Vibration grade (μm) 15

Operating temperature (˚C) 0ºC to 40ºC

Storage temperature (˚C) -10ºC to 80ºC

Operating humidity 20 to 90%RH (non-condensing)

Storage humidity 20 to 90%RH (non-condensing)

Vibration capacity 2.5G

IP Rating

Approvals

*1. Rate torque values are continuous permissible values at 0 ~ 40˚C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-_ _ 08: 250 mm x 250 mm x 6 mm

ECMA-_ _ 13: 400 mm x 400 mm x 20 mm

ECMA-_ _ 18: 550 mm x 550 mm x 30 mm

ECMA-_ _ 22: 650 mm x 650 mm x 35 mm

Material type : Aluminum – F80, F130, F180, F220

*2. The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

L

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

20

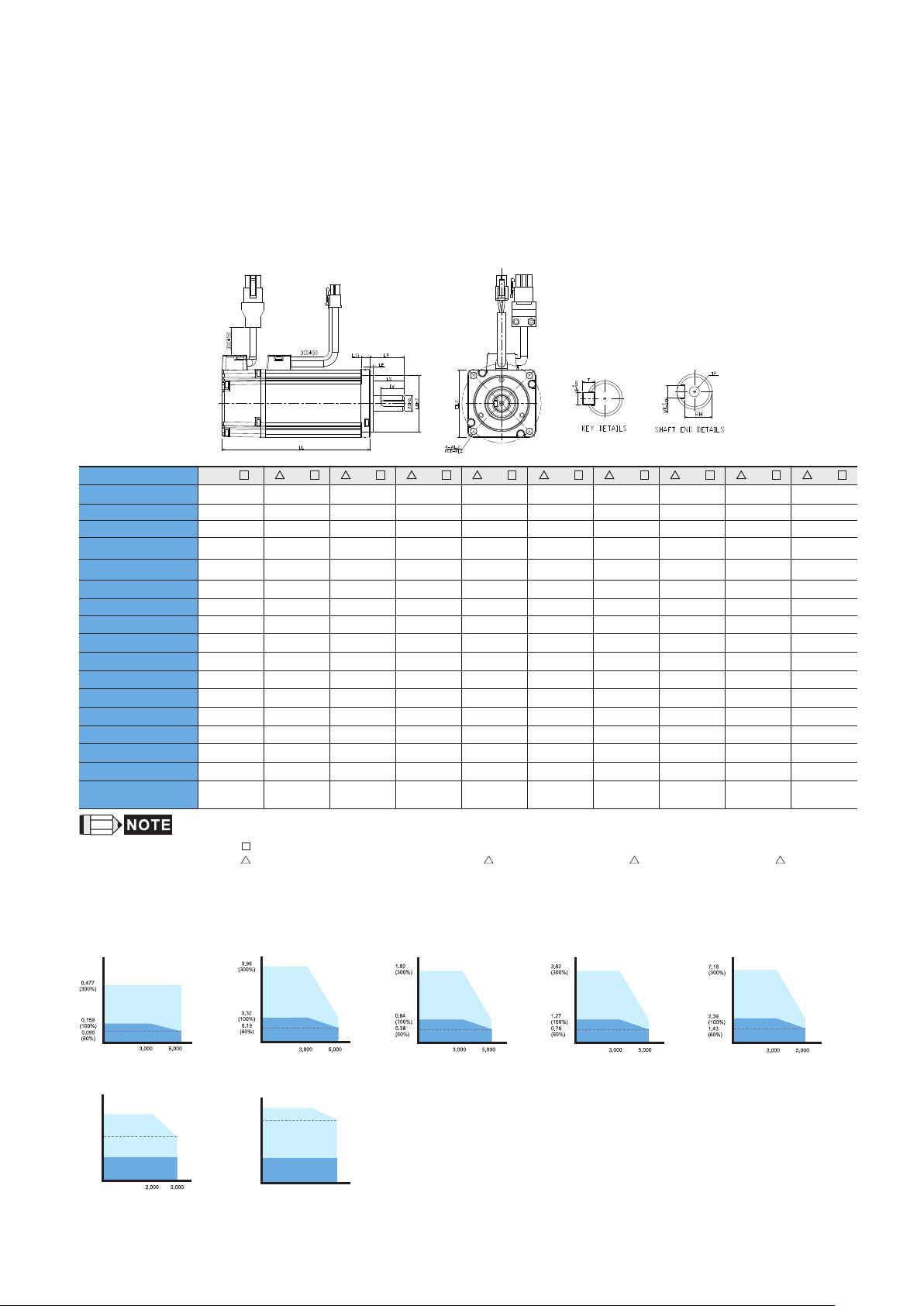

Page 22

Servo Motor Dimensions

220V Series

Frame Size 86mm and below

Model

C1040F

LC

LZ

LA

S

LB

(without brake) 79.1 100.6 105.5 130.7 145.8 112.3 138.3 154.8 130.2 153.2

LL

(with brake) -- 136.8 141.6 166.8 176.37 152.8 178 187.8 161.3 184.3

LL

8 (

30 (

LS

LR

LE

LG

LW

RH

WK

W

T

TP

S C

0401 S C 0602 S C 0604 S C 0604 H C 0804 7 C 0807 S C 0807 H C 0907 S C 0910 S

40 40 60 60 60 80 80 80 86 86

4.5 4.5 5.5 5.5 5.5 6.6 6.6 6.6 6.6 6.6

46 46 70 70 70 90 90 90 100 100

+0

- 0.009

+0

- 0.021

) 8 (

) 30 (

+0

- 0.009

+0

- 0.021

) 14 (

) 50 (

+0

- 0.011

+0

- 0.025

) 14 (

) 50 (

+0

- 0.011

+0

- 0.025

) 14 (

) 50 (

+0

- 0.011

+0

- 0.025

) 14 (

) 70 (

+0

- 0.011

+0

- 0.030

) 19 (

) 70 (

+0

- 0.013

+0

- 0.030

) 19 (

) 70 (

+0

- 0.013

+0

- 0.030

) 16 (

) 80 (

+0

- 0.011

+0

- 0.030

) 16 (

) 80 (

20 20 27 27 27 27 32 32 30 30

25 25 30 30 30 30 35 35 35 35

2.5 2.5 3 3 3 3 3 3 3 3

5 5 7.5 7.5 7.5 8 8 8 8 8

16 16 20 20 20 20 25 25 20 20

6.2 6.2 11 11 11 11 15.5 15.5 13 13

3 3 5 5 5 5 6 6 5 5

3 3 5 5 5 5 6 6 5 5

3 3 5 5 5 5 6 6 5 5

M3

Depth 8M3Depth 8M4Depth 15M4Depth 15M4Depth 15M4Depth 15M6Depth 20M6Depth 20M5Depth 15M5Depth 15

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

4) The boxes (

) in the model names are for optional configurations(keyway, brake and oil seal).

) in the model names are for encoder resolution types. ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit; =A: Absolute type)

Units: mm

+0

- 0.011

+0

- 0.030

)

)

Speed-Torque Curves (T-N Curves)

Speed (r/min)

Torque (N-m)

Continuous Duty Zone Continuous Duty Zone

▲ 0602 □S ECMA-C ▲ 0807 □ S

ECMA-C

Torque (N-m)

Intermittent Duty Zone Intermittent Duty Zone Intermittent Duty Zone Intermittent Duty Zone Intermittent Duty Zone

Torque (N-m)

7.14

(298%)

6.00

(251%)

2.38

(100%)

Continuous Duty Zone

Continuous Duty Zone

ECMA-C1040F □ S

Intermittent Duty Zone

ECMA-C ▲ 0907 □ S

Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min)

Speed (r/min)

Torque (N-m)

Torque (N-m)

8.78

(276%)

5.85

(184%)

3.18

(100%)

Continuous Duty Zone

ECMA-C

▲ 0401 □S

Intermittent Duty Zone

Continuous Duty Zone

2,000 3,000

▲ 0910 □ S

ECMA-C

21

Torque (N-m) Torque (N-m)

▲ 0604 □ S

ECMA-C

ECMA-C ▲ 0604 □ H

ECMA-C ▲ 0804 □ 7

Continuous Duty Zone

ECMA-C ▲ 0807 □ H

Page 23

220V Series

Frame Size 100mm and 130mm

LG

LR

LE

LS

LW

LC

Sh6

LBh7

LL

4-ØZ

PCD- A

0

-0.03 6

W

KEY DE TAILS

0

-0.03 6

SHAF T END DETAI LS

T

TP

RH

Model C 1010 S C 1020 S C 1330 4 E 1305 S E 1310 S E 1315 S E 1320 S

LC 100 100 130 130 130 130 130

LZ 9 9 9 9 9 9 9

LA 11 5 115 145 145 145 145 145

S 22 (

LB 95 (

(without brake)

LL

(with brake)

LL

+0

- 0.013

+0

- 0.035

) 22 (

) 95 (

+0

- 0.013

+0

- 0.035

) 24 (

) 110 (

153.3 199 187.5 147.5 147.5 167.5 187.5

192.5 226 216 183.5 183.5 202 216

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

LS 37 37 47 47 47 47 47

LR 45 45 55 55 55 55 55

LE 5 5 6 6 6 6 6

LG 12 12 11.5 11.5 11.5 11.5 11.5

LW 32 32 36 36 36 36 36

RH 18 18 20 18 18 18 18

WK 8 8 8 8 8 8 8

W 8 8 8 8 8 8 8

T 7 7 7 7 7 7 7

TP

M6

Depth 20

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

4) The boxes (

) in the model names are for optional configurations(keyway, brake and oil seal).

) in the model names are for encoder resolution types. ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit; =A: Absolute type)

M6

Depth 20

M6

Depth 20

M6

Depth 20

M6

Depth 20

M6

Depth 20

Units: mm

+0

- 0.013

+0

- 0.035

M6

Depth 20

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone Continuous Duty Zone

ECMA-E

▲ 1315 □ S

Speed (r/min)

Speed (r/min)

Intermittent Duty Zone

Continuous Duty Zone

Torque (N-m)

Intermittent Duty Zone

ECMA-C

ECMA-E

▲ 1020 □ SECMA-C ▲ 1010 □ S

▲ 1320 □ S

Speed (r/min)

Speed (r/min)

Torque (N-m)

Intermittent Duty Zone Intermittent Duty Zone

Continuous Duty Zone Continuous Duty Zone

ECMA-C

▲ 1330 □ 4

Torque (N-m)

Speed (r/min)

22

ECMA-E

▲ 1305 □ S

Speed (r/min)

Torque (N-m)Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-E

Speed (r/min)

▲ 1310 □ S

Page 24

Servo Motor Dimensions

220V Series

Frame Size 100mm and 130mm

LG

LR

LE

LS

LW

LC

Sh6

LBh7

LL

PCD- A

4-ØZ

0

-0.03 6

W

KEY DETA ILS

0

-0.03 6

SHAF T END DETAI LS

T

TP

RH

Model F 1305 S F 1308 S F 1313 S F 1318 S G 1303 S G 1306 S G 1309 S

LC 130 130 130 130 130 130 130

LZ 9 9 9 9 9 9 9

LA 145 145 145 145 145 145 145

S 22 (

LB 110 (

(without brake)

LL

(with brake)

LL

+0

) 22 (

- 0.013

+0

) 110 (

- 0.035

139.5 147.5 187.5 202 147.5 147.5 163.5

168 183.5 216 230.7 183.5 183.5 198

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

LS 47 47 47 47 47 47 47

LR 55 55 55 55 55 55 55

LE 6 6 6 6 6 6 6

LG 11.5 11.5 11.5 11.5 11.5 11.5 11.5

LW 36 36 36 36 36 36 36

RH 18 18 18 18 18 18 18

WK 8 8 8 8 8 8 8

W 8 8 8 8 8 8 8

T 7 7 7 7 7 7 7

TP

M6

Depth 20

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

4) The boxes (

) in the model names are for optional configurations (keyway, brake and oil seal).

) in the model names are for encoder resolution types. ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit; =A: Absolute type)

M6

Depth 20

M6

Depth 20

M6

Depth 20

M6

Depth 20

M6

Depth 20

Units: mm

+0

- 0.013

+0

- 0.035

M6

Depth 20

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m) Torque (N-m) Torque (N-m)Torque (N-m)Torque (N-m)

8.92

(280%)

5.1

(160%)

3.18

(100%)

1.59

(50%)

Intermittent Duty Zone

Continuous Duty Zone

1,500

Intermittent Duty Zone

Continuous Duty Zone

ECMA-G

▲ 1306 □ S ECMA-G ▲ 1309 □ S

Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min)

3,0002,300

Speed (r/min)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-F

Torque (N-m)Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

▲ 1308 □ S

Speed (r/min)

Intermittent Duty Zone

Continuous Duty Zone

23

Intermittent Duty Zone

Continuous Duty Zone

ECMA-F ▲ 1318 □ S ECMA-G ▲ 1303 □ SECMA-F ▲ 1313 □ SECMA-F ▲ 1305 □ S

Intermittent Duty Zone

Continuous Duty Zone

Speed (r/min)

Page 25

220V Series

Frame Size 180mm

LG

LR

LE

LS

LW

4-ØLZ

PCD -L A

LC

Sh6

Lbh7

LL

W

KEY DETA ILS

SHAF T END DETAI LS

T

TP

RH

Model E 1820 S E 1830 S E 1835 S F 1845 S F 1855 3 F 1875 3

LC 180 180 180 180 180 180

LZ 13.5 13.5 13.5 13.5 13.5 13.5

LA 200 200 200 200 200 200

S 35 (

LB 114.3 (

(without brake)

LL

(with brake)

LL

+0

) 35 (

- 0.016

+0

) 114.3 (

- 0.035

169 202.1 202.1 235.3 279.7 342.0

203.1 235.3 235.3 279.3 311.7 376.1

+0

) 35 (

- 0.016

+0

) 114.3 (

- 0.035

+0

) 35 (

- 0.016

+0

) 114.3 (

- 0.035

+0

) 42 (

- 0.016

+0

) 114.3 (

- 0.035

+0

) 42 (

- 0.016

+0

) 114.3 (

- 0.035

LS 73 73 73 73 108.5 108.5

LR 79 79 79 79 113 113

LE 4 4 4 4 4 4

LG 20 20 20 20 20 20

LW 63 63 63 63 90 90

RH 30 30 30 30 37 37

WK 10 10 10 10 12 12

W 10 10 10 10 12 12

T 8 8 8 8 8 8

TP

M12

Depth 25

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

4) The boxes (

) in the model names are for optional configurations(keyway, brake and oil seal).

) in the model names are for encoder resolution types. ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit; =A: Absolute type)

M12

Depth 25

M12

Depth 25

M12

Depth 25

M16

Depth 32

Units: mm

+0

- 0.016

+0

- 0.035

M12

Depth 32

)

)

Speed-Torque Curves (T-N Curves)

orque (N-m) orque (N-m) orque (N-m) orque (N-m) orque (N-m)

28.65

(300%)

Intermittent Duty Zone

9.55

(100%)

6.40

(67%)

Continuous Duty Zone

ECMA-E ▲ 1820 □ S ECMA-E ▲1830 □ S ECMA-F ▲ 1830 □ S ECMA-F ▲ 1845 □ SECMA-E ▲ 1835 □ S

orque (N-m)

87.53

(300%)

Intermittent Duty Zone

35.01

(100%)

17.51

(50%)

Continuous Duty Zone

▲ 1855 □ 3

ECMA-F

Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min)

3,0002,000

Speed (r/min)

3,0001,500

42.97

(300%)

14.32

(100%)

9.59

(67%)

orque (N-m)

119.36

(250%)

47.74

(100%)

23.87

(50%)

Intermittent Duty Zone

Continuous Duty Zone

Intermittent Duty Zone

Continuous Duty Zone

ECMA-F

▲ 1875 □ 3

3,000 3,0002,000

3,0001,500

Speed (r/min)

57.29

(300%)

19.10

(100%)

9.55

(50%)

Intermittent Duty Zone

Continuous Duty Zone

1,500

24

50.13

(300%)

16.71

(100%)

11.20

(67%)

Intermittent Duty Zone

Continuous Duty Zone

71.62

(300%)

28.65

(100%)

14.33

3,0002,000

(50%)

Intermittent Duty Zone

Continuous Duty Zone

3,0001,500

Page 26

Servo Motor Dimensions

220V / 400V Series

Frame Size 220mm and above

A

Model F1221B 3 F1221F S L1221B 3 L1221F S

LC 220 220 220 220

LZ 13.5 13.5 13.5 13.5

LA 235 235 235 235

S 42 (

LB 200 (

(without brake)

LL

(with brake)

LL

LS 108 108 110 110

LR 116 11 6 116 11 6

LE 4 4 4 4

LG 20 20 20 20

LW 90 90 90 90

RH 37 49 37 49

WK 12 16 12 16

W 12 16 12 16

T 8 10 8 10

TP

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

+0

) 55 (

- 0.016

+0

) 200 (

- 0.046

+0.03

- 0.011

+0

- 0.046

371.4 453.4 371.4 450.4

434.4 513.4 434.4 513.4

M16

Depth 32

) in the model names are for optional configurations (keyway, brake and oil seal).

M20

Depth 40

) 42 (

) 200 (

+0

- 0.016

+0

- 0.046

M16

Depth 32

) 55 (

) 200 (

Depth 40

M20

+0.03

- 0.011

+0

- 0.046

Units: mm

)

)

Speed-Torque Curves (T-N Curves)

175

(250%)

Intermittent Duty Zone

70

(100%)

52.5

Continuous Duty Zone

(75%)

1,500

ECMA-F1221B □ 3 ECMA-F1221F□ S

2,000

Torque (N-m)Torque (N-m)

Speed (r/min) Speed (r/min)

224

(240%)

Intermittent Duty Zone

95.4

(100%)

71.6

(75%)

Continuous Duty Zone

1,500

2,000

175

(250%)

Intermittent Duty Zone

70

(100%)

52.5

Continuous Duty Zone

(75%)

1,500

ECMA-L1221B □ 3 ECMA-L1221F □ S

Speed (r/min) Speed (r/min)

2,000

25

Torque (N-m)Torque (N-m)

224

(240%)

95.4

(100%)

71.6

(75%)

Intermittent Duty Zone

Continuous Duty Zone

1,500

2,000

Page 27

400V Series

Frame Size 80mm and below

Model J 0604 S J 0807 S J 0907 S J 0910 S

LC 60 80 86 86

LZ 5.5 6.6 6.6 6.6

LA 70 90 100 100

S 14(

LB 50(

(without brake)

LL

(with brake)

LL

(without oil seal)

LS

(with oil seal)

LS

LR 30 35 35 35

LE 3 3 3 3

LG 7.5 8 8 8

LW 20 25 20 20

RH 11 15.5 13 13

WK 5 6 5 5

W 5 6 5 5

T 5 6 5 5

TP

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

4) The boxes (

+0

) 19(

- 0.011

+0

) 70(

- 0.025

+0

) 16(

- 0.013

+0

) 80(

- 0.030

+0

) 16(

- 0.011

+0

) 80(

- 0.030

130.7 138.3 130.2 153.2

166.8 178 161.3 184.3

27 32 30 30

-- 29.5 30 30

M4

Depth 15

) in the model names are for optional configurations (keyway, brake and oil seal).

) in the model names are for encoder resolution types ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit); =A: Absolute type

M6

Depth 20

M5

Depth 15

+0

- 0.011

+0

- 0.030

M5

Depth 15

Units: mm

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m) Torque (N-m) Torque (N-m) Torque (N-m)

3.82

(300%)

1.27

(100%)

0.762

(60%)

Intermittent Duty Zone

Continuous Duty Zone

3,000

ECMA-J ▲ 0604 □ S

7.16

(300%)

Intermittent Duty Zone

2.39

(100%)

1.43

(60%)

Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min)

5,000

Continuous Duty Zone

ECMA-J

▲ 0807 □ S

5,0003,000

7.14

(298%)

2.38

(100%)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-J

▲ 0907 □ S

(251%)

26

8.78

(276%)

6.00

3.18

(100%)

Intermittent Duty Zone

Continuous Duty Zone

2,0002,000 3,0003,000

▲ 0910 □ S

ECMA-J

5.85

(184%)

Page 28

Servo Motor Dimensions

400V Series

Frame Size 100mm and 130mm

0

-0.03 6

W

KEY DETA ILS

0

-0.03 6

SHAF T END DETAI LS

S L

T

RH

1305

TP

S L

Model

LC

LG

LR

LE

LS

LW

LC

Sh6

LBh7

J 1010

LL

1020

S J

S J

1330

4 K

1305

4-ØLZ

PCD- LA

SK

1310

SK

1315

1320

SK

100 100 130 130 130 130 130 130 130 130

LZ 9 9 9 9 9 9 9 9 9 9

LA 115 115 145 145 145 145 145 145 145 145

S

LB

(without brake)

LL

(with brake)

LL

+0

22 (

- 0.013

+0

95 (

- 0.035

153.3 199 187.5 139.5 147.5 167.5 187.5 147.5 163.5 194.5

192.5 226 216.0 168 183.5 202 216 168.0 181 223

) 22 (

) 95 (

+0

- 0.013

+0

- 0.035

) 24 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

LS 37 37 47 47 47 47 47 47 47 47

LR 45 45 55 55 55 55 55 55 55 55

LE 5 5 6 6 6 6 6 6 6 6

LG 12 12 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5

LW 32 32 36 36 36 36 36 36 36 36

RH 18 18 20 18 18 18 18 18 18 18

WK 8 8 8 8 8 8 8 8 8 8

W 8 8 8 8 8 8 8 8 8 8

T 7 7 7 7 7 7 7 7 7 7

TP

MP6

Depth 20

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

4) The boxes (

MP6

Depth 20

MP6

Depth 20

MP6

Depth 20

MP6

Depth 20

MP6

Depth 20

MP6

Depth 20M8Depth 25

Depth 20

) in the model names are for optional configurations (keyway, brake and oil seal).

) in the model names are for encoder resolution types ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit); =A: Absolute type

1308

+0

- 0.013

+0

- 0.035

MP6

S L

) 22 (

) 110 (

Units: mm

1313

+0

- 0.013

+0

- 0.035

MP6

Depth 20

S

)

)

Speed-Torque Curves (T-N Curves)

9.54

(300%)

3.18

(100%)

1.91

(60%)

21.5

(300%)

7.16

(100%)

4.8

(67%)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-J ▲ 1010 □ S

Intermittent Duty Zone

Continuous Duty Zone

ECMA-K ▲ 1315 □ S

Torque (N-m)Torque (N-m)

19.11

(300%)

Intermittent Duty Zone

6.37

(100%)

3.82

(60%)

28.65

28.65

(300%)

(300%)

9.55

9.55

(100%)

(100%)

(67%)

(67%)

Torque (N-m)Torque (N-m)

6.4

6.4

Continuous Duty Zone

ECMA-J ▲ 1020 □ S

加速領

Intermittent Duty Zone

Continuous Duty Zone

ECMA-K ▲ 1320 □ S

5,0003,000

3,0002,000

3,0002,000

Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min)

5,0003,000

Speed (r/min)

3,0002,000

Torque (N-m)

28.65

(300%)

Intermittent Duty Zone

9.55

(100%)

6.4

Continuous Duty Zone

(67%)

ECMA-J ▲ 1330 □ 4

Torque (N-m)

8.92

(284%)

Intermittent Duty Zone

3.18

(100%)

Continuous Duty Zone

1.59

(50%)

Speed (r/min) Speed (r/min) Speed (r/min)

ECMA-L

4500

3000

(110%)

1,500 1,500 1,5002,300 2,200 2,2003,000 3,000 3,000

▲ 1305 □ S

27

Torque (N-m)

7.16

(300%)

Intermittent Duty Zone

2.39

(100%)

Continuous Duty Zone

1.6

(67%)

ECMA-K ▲ 1305 □ S

Torque (N-m)

13.80

(255%)

5.39

Intermittent Duty Zone

(100%)

3.5

Continuous Duty Zone

2.70

(50%)

▲ 1308 □ S

ECMA-L

(83%)

Torque (N-m)

14.32

(300%)

Intermittent Duty Zone

4.77

(100%)

3.2

(67%)

Continuous Duty Zone

ECMA-K ▲ 1310 □ S

Torque (N-m)

23.3

(280%)

Intermittent Duty Zone

8.34

4.5

(100%)

4.17

(50%)

Continuous Duty Zone

ECMA-L

▲ 1313 □ S

Speed (r/min)

3,0003,000 2,0002,000

6

(72%)

Speed (r/min)

Page 29

400V Series

Frame Size 180mm and above

W

KEY DETA ILS

SHAF T END DETAI LS

T

RH

Model K 1820

LG

LE

LL

S L 1830

LR

LS

LW

Sh6

4-ØLZ

PCD -L A

LC

Lbh7

S L 1845

S L 1855

3 L 1875

LC 180 180 180 180 180 130

LZ 13.5 13.5 13.5 13.5 13.5 9

LA 200 200 200 200 200 145

S

LB

(without brake)

LL

(with brake)

LL

+0

35 (

114.3(

) 35 (

- 0.016

+0

) 114.3(

- 0.035

169 202.1 235.3 279.7 342.0 163.5

203.1 235.3 279.3 311.7 376.1 198

+0

) 35 (

- 0.016

+0

) 114.3(

- 0.035

+0

) 42 (

- 0.016

+0

) 114.3(

- 0.035

+0

) 42 (

- 0.016

+0

) 114.3(

- 0.035

+0

- 0.016

+0

- 0.035

LS 73 73 73 108.5 108.5 47

LR 79 79 79 11 3 11 3 55

LE 4 4 4 4 4 6

LG 20 20 20 20 20 11.5

LW 63 63 63 90 90 36

RH 30 30 30 37 37 18

WK 10 10 10 12 12 8

W 10 10 10 12 12 8

T 8 8 8 8 8 7

TP

M12

Depth 25

1) Dimensions are in millimeters.

2) Dimensions of the servo motors may be revised without prior notice.

3) The boxes (

4) The boxes (

) in the model names are for optional configurations (keyway, brake and oil seal).

) in the model names are for encoder resolution types ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit); =A: Absolute type

M12

Depth 25

M12

Depth 25

M16

Depth 32

M16

Depth 32

TP

Units: mm

S M 1309 □ S

) 22 (

) 110(

+0

- 0.013

+0

- 0.035

M6

Depth 20

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m) Torque (N-m) Torque (N-m)

28.66

(300%)

9.55

(100%)

6.4

(67%)

Torque (N-m)

21.48

(250%)

8.59

(100%)

4.3

(50%)

Intermittent Duty Zone

Continuous Duty Zone

Continuous Duty Zone

2,000 3,000

Intermittent Duty Zone

Continuous Duty Zone

1,000

ECMA-M ▲ 1309 □ S

57.29

(300%)

Intermittent Duty Zone

19.10

(100%)

9.55

(50%)

Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min) Speed (r/min)

Speed (r/min)

2,000

Continuous Duty Zone

3,0001,500

ECMA-L ▲ 1830 □ SECMA-K ▲ 1820 □ S

71.62

(300%)

28.65

(100%)

14.33

(50%)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-L ▲ 1845 □ S

28

87.53

(300%)

Intermittent Duty Zone

35.01

(100%)

17.51

(50%)

3,0001,500

Continuous Duty Zone Continuous Duty Zone

ECMA-L ▲ 1855 □ 3

Torque (N-m)Torque (N-m)

119.36

(250%)

Intermittent Duty Zone

47.74

(100%)

23.87

3,0001,500

(50%)

ECMA-L ▲ 1875 □ S

3,0001,500

Page 30

Part Names and Functions

●

LED Display / Operation Panel / Charge LED

• LED Display

The 5 digit, 7 segment LED displays the

servo status or fault codes.

• Operation Panel

Function keys used to perform status

display, monitor and diagnostic,

function and parameter setting.

Function Keys:

MODE : Press this key to select/change mode

SHIFT : Press this key to shift cursor to the left

UP : Press this key to increase values on the display

DOWN : Press this key to decrease values on the display

SET : Press this key to store data

• Charge LED

A lit LED indicates that either power is connected to

the servo drive or a residual charge is present in the

drive's internal power components.

●

Full-Closed Loop Control Interface

• Used to connect linear scale and encoder for

controlling A, B, Z phase signals.

●

I/O Interface

• Used to connect Delta's DVP series

PLC or other external controllers for

controlling I/O signals.

●

High-speed Communication Port

• 1-in/1-out communication ports offer easy serial

connection.

●

Motor Encoder Interface

• Used to connect the encoder of the servo motor

●

Extension Digital Input

Connection Port

• Used to connect a removable digital

input terminal block. Max. 6 digital inputs

can be added.

●

Serial Communication Port

• Used to connect PLC, HMI, and other

controllers for RS-485 / RS-232 serial

communication.

●

USB Connection Port

• Used to connect personal computers or

notebooks.

• Ver 1.1 USB is equipped as standard.

• Direct connectivity to personal computers

or notebooks, capable of accessing data

through ASDA-Soft configuration software.

• Monitor speed upon software is up to 1Mbps.

Operation

Panel

Charge LED

LED

Display

29

Page 31

●

Internal & External Regenerative Resistor Terminal /

Control Circuit Terminal / Main Circuit Terminal

• Internal & External Regenerative Resistor Terminal

1. When using an external resistor, connect it to P ⊕ and C , and ensure an open circuit

between P ⊕ and D.

2. When using an internal resistor, ensure the circuit is closed between P ⊕ and D, and

the circuit is open between P ⊕ and C. (Note: Please refer to the table of regenerative

resistor specifications for the models with a built-in regenerative resistor.)

3. When using an external braking unit, connect it to P ⊕ and, and ensure an open circuit

between P ⊕ and D, and P ⊕ and C.

• When using an external braking unit, connect it to P ⊕ and

• Control Circuit Terminal (L1C, L2C or DC24V, DC0V)

- 220V Series: L1C, L2C are used to connect 200 ~ 230Vac,

50/60Hz single-phase or three-phase power supply.

- 400V Series: DC24V, DC0V are used to connect 24Vdc ±10%

power supply.

• Main Circuit Terminal (R, S, T)

- 220V Series: Used to connect 200~230Vac, 50/60Hz commercial

power supply.

- 400V Series: Used to connect 380~480Vac, 50/60Hz commercial

power supply.

●

Servo Motor Output (U, V, W)

• Used to connect servo motor. Never

connect the output terminal to main

circuit power as the AC drive may be

damaged beyond repair if incorrect cables

are connected to the output terminals.

●

Ground Terminal

• Used to connect grounding wire of power

supply and servo motor.

●

Heatsink

• Used to secure servo drive and for heat

dissipation.

*Note: The figures are for illustration purposes only. Actual models may differ slightly

in appearance to illustrations provided.

30

Page 32

Wiring

200V Series

Position (PT) Control Mode (for Pulse Command Input)

Pul se inpu t (Open -coll ector N PN),

for t he use of i ntern al powe r suppl y

Cont rolle r

SG

Pul se inpu t (Open -coll ector P NP),

for t he use of i ntern al powe r suppl y

Cont rolle r

SG

Pul se inpu t (Open -coll ector N PN),

for t he use of e xtern al powe r suppl y

Cont rolle r

SG

Pul se inpu t (Open -coll ector P NP),

for t he use of e xtern al powe r suppl y

Cont rolle r

SG

Pul se inpu t (Line d river ).

It re quire s 5V powe r suppl y only.

Nev er appl y a 24V pow er supp ly.

Cont rolle r

SG

Hig h-spe ed puls e input ( Line dr iver) .

It re quire s 5V powe r suppl y only.

Nev er appl y a 24V pow er supp ly.

Cont rolle r

Pull- hi_S

1KΩ

1KΩ

Pull- hi_S

+

DC 24V

-

/PULS E

+

DC24V

-

1KΩ

1KΩ

SIGN

/SIGN

PULSE

/PULS E

HSIGN

/HSIG N

HPULS E

/HPUL SE

SG

GND GND

VDD

/SIGN

/PULSE

COM-

/PULS E

/SIGN

PULSE

/PULS E

VDD

COM-

PULSE

35

SIGN

/SIGN

SIGN

/SIGN

46

40

38

29

13

17

37

41

45

17

43

41

36

37

45

35

37

41

43

41

36

37

36

37

43

41

100Ω

Serv o Drive

DC24V

Max.

Max.

Input p ulse

Input p ulse

Appro x.

frequ ency is

frequ ency is

1KΩ

200Kp ps

200Kp ps

51Ω

51Ω

Appro x.1KΩ

51Ω

51Ω

Max.

Input p ulse

frequ ency is

200Kp ps

Serv o Drive

DC24V

51Ω

51Ω

51Ω

51Ω

Serv o Drive

Appro x.

1KΩ

51Ω

51Ω

Appro x.1KΩ

51Ω

51Ω

Serv o Drive

51Ω

51Ω

51Ω

51Ω

Max. Input pulse

frequ ency is 200Kpps

Serv o Drive

51Ω

51Ω

51Ω

51Ω

Serv o Drive

2KΩ

100Ω

2KΩ

2KΩ

2KΩ

Max.

Max.

Input p ulse

Input p ulse

frequ ency is

frequ ency is

200Kp ps

200Kp ps

Max.

Input p ulse

frequ ency is

200Kp ps

Max.

Input pulse

frequency is

200Kpps

Max. Input pulse

frequency is

200Kpps

Max. Input pulse

frequency is

200Kpps

Max. Input pulse

frequency is

500Kpps

Max. Input pulse

frequency is

500Kpps

Servo Drive

ASDA-A 2 Se ri es

AC 200/ 23 0V

Singl e- phase o r

Three -p hase

*3

50/60 H z

MCCB

MC

R

S

T

-

L1C

L2C

CN1

/SI GN

Pulse I np ut

(Line D ri ver)

10K Ω±10 V

High- sp eed

Pulse I np ut

(Line D ri ver)

Twis ted-p air or

twi sted- shiel d

cab le

10KΩ

10KΩ

V

V

SG

SON

CCLR

TCM0

TCM1

ARST

NL

PL

EMGS

SRD Y

1.5 KΩ

ZSP D

1.5 KΩ

24V

HOM E

1.5 KΩ

TPO S

1.5 KΩ

1.5 KΩ

ALR M

A Phas e Pulse

B Pha se Puls e

Enc oder

Pul se Outp ut

Please note:

*1. 400W ~ 4.5kW servo drives provide a built-in regenerative resistor.

*2. The brake oil has no polarity.

*3. Single-phase connections are for servo drives 1.5kW and below only.

Z Pha se Puls e

Z Pha se Open

Col lecto r

SIG N

/PU LSE

PUL SE

T-RE F

GND

/HS IGN

HSI GN

/HP ULSE

HPU LSE

MON 1

GND

MON 2

VDD

COM +

COM -

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DO1 +

DO1 -

DO2 +

DO2 -

DO3 +

DO3 -

DO4 +

DO4 -

DO5 +

DO5 -

OA

/OA

OB

/OB

OZ

/OZ

OCZ

GND

37

36

41

43

18

13

40

46

29

38

16

12, 1 3, 19

15

17

11

45, 47,49

9

10

34

8

33

32

31

30

7

6

5

4

3

2

1

26

28

27

21

22

25

23

50

24

48

13

10KΩ

DC24V

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

Max. O utput

Curr ent 50mA

Volta ge 30V

1

0KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

CN2

5

4

7

9

14, 16

13, 15

CN3

6

5

4

3

2

1

CN7

1

2

3

4

5

6

7

CN4

1

2

3

4

CN5

CN6

P

D

C

U

V

W

8

4

5

3

2

9

1

6

7

1,9

2,1 0

3,11

4,1 2

5,1 3

6,1 4

7,1 5

8,1 6

+

+5V

Opt A

Opt / A

Opt B

Opt / B

Opt Z

Opt / Z

GND

GND

*1

Red

White

Black

Green

T+

Blu e

T -

Blu e/Bla ck

-

-

-

-

+5V

Red /Red & Wh it

GND

Bla ck/Bl ack & Whi t

RS4 85-

RS4 85+

RS2 32_RX

-

RS2 32_TX

GND

COM +

EDI 9-

EDI 10-

EDI 11 -

EDI 12-

EDI 13-

EDI 14-

+5V D C

Dat a-

Dat a+

Gro und

CANop en

CAN H

CAN L

CAN G ND

-

-

-

CAN G ND

-

Reg enera tive

Res istor

24V

Pow er

Sup ply

(

BRKR

EMGS

*2

Bra ke

Enc oder

Twis ted-p air or

twi sted- shiel d

cab le

SG

31

Page 33

200V Series

Serv o Dr ive

r

Position (PR) Control Mode (for Internal Procedure Control)

AC 200/23 0V

Single- ph as e or

Three-p ha se

50/60 Hz

Twiste d-p air or

twi sted-sh iel d

cab le

Encod er

Pulse O utp ut

*3

±10 V

10KΩ

10KΩ

CTRG

EMGS

24V

A Phase Pu lse

B Phase P uls e

Z Pha se Pulse

Z Pha se Open

Colle cto r

10K

SON

POS0

POS1

ARST

NL

PL

SRD Y

ZSP D

HOM E

TPO S

ALR M

MCCB

Ω

V

V

1.5 KΩ

1.5 KΩ

1.5 KΩ

1.5 KΩ

1.5 KΩ

MC

R

ASDA -A2 Serie s

S

T

-

L1 C

L2 C

10K

Ω

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

Max. O utput

Curr ent 3A

Volta ge 50V

10KΩ

CN2

DC24V

CN3

CN7

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

4.7KΩ

CN4

CN5

CN6

CN1

18

T-REF

13

GND

16

MON 1

GND

12, 13, 1 9

MON 2

VDD

COM +

COM -

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DO1 +

DO1 -

DO2 +

DO2 -

DO3 +

DO3 -

DO4 +

DO4 -

DO5 +

DO5 -

OA

/OA

OB

/OB

OZ

/OZ

OCZ

GND

15

17

11

45,47 ,49

9

10

34

8

33

32

31

30

7

6

5

4

3

2

1

26

28

27

21

22

25

23

50

24

48

13

SG

P

D

C

U

V

W

5

4

7

9

14,16

13,15

6

5

4

3

2

1

1

2

3

4

5

6

7

1

2

3

4

8

4

5

3

2

9

1

6

7

1,9

2,1 0

3,11

4,1 2

5,1 3

6,1 4

7,1 5

8,1 6

+

*1

Red

White

Black

Green

T+

Blue

T -

Blu e/Black

-

-

-

-

Red/R ed & Wh it

+5V

Bla ck/Bl ack & Whi t

GND

RS4 85-

RS4 85+

RS2 32_RX

-

RS232 _TX

GND

COM +

EDI9-

EDI10 -

EDI11-

EDI 12 -

EDI13 -

EDI14 -

+5V DC

Data-

Data+

Gro und

+5V

Opt A

Opt / A

Opt B

Opt / B

Opt Z

Opt / Z

GND

GND

CANop en

CAN H

CAN L

CAN G ND

-

-

-

CAN G ND

-

Regen era ti ve

Resis tor

24V

EMGS

Power

BRKR

*2

Suppl y

Brake

Encod er

Twiste d-p air o

twi sted- shield

cable

(

SG

Please note:

*1. 400W ~ 4.5kW servo drives provide a built-in regenerative resistor.

*2. The brake oil has no polarity.

*3. Single-phase connections are for servo drives 1.5kW and below only.

32

Page 34

Wiring

Serv o Dr ive

r

200V Series

Speed (S), Torque (T) Control Mode (for Analog Voltage Input and Internal Parameter

Setting)

AC 200/23 0V

Single- ph as e or

Three-p ha se

50/60 Hz

Twiste d-p ai r or

twi sted- sh iel d

cable

TRQLM / S PD LM

SPD0 / TC M0

SPD1 / TC M1

Encod er

Pulse O utp ut

10KΩ

10KΩ

ARST

CCWL

EMGS

24V

A Phase Pu lse

B Pha se Pulse

Z Pha se Pulse

Z Pha se Open

Colle cto r

SON

CWL

SRD Y

ZSP D