Delta AH500 series Quick Start Manual

Chapter 1 Introduction

Table of Contents

1.1 Manuals.....................................................................................................1-2

1.2 System Frameworks..................................................................................1-3

1.3 Operation of the CPU module ...................................................................1-9

1-1

AH500 Quick Start

1.1 Manuals

Delta Electronics, Inc. provides users with the manuals related to the AH500 series programmable

logic controllers according to different application requirements.

AH500 Hardware Manual: It introduces hardware specifications, addre ssing, wiring, maintenance,

troubleshooting, and etc.

AH500 Operation Manual: It introduces the configuration of the hardware, the setting of the

connection, the operation of the CPU module, the setting of the software,

and etc.

AH500 Programming Manual: It introduces devices and instructions.

AH500 Module Manual: It introduces module specifications, installation, setting, trouble sh ooting,

and etc.

AH500 Motion Control Module Manual: It introduces the specifications for the motion control

modules, the wiring, the instructions, and the functions.

ISPSoft User Manual: It introduces the use of ISPSoft, including the variables, the connection, the

programs, and the function blocks.

PMSoft User Manual: It introduces the use of PMSoft, including the editing mode, the connection,

and the encryption.

AH500 Quick Start: It helps users create and use the system in a short time. AH500 Quick Start not

only introduces the basic system frameworks, but also teaches users to write a

program step by step by means of simple examples, and download the program

which includes the variables and the function blocks to the CPU module. Users

can experience the convenience brought by the new functions. If an error

occurs when the system runs, please refer to section 3.3.2 for more information

about debugging the program. (Please refer to chapter 12 in AH500 Operation

Manual for more information about the troubleshooting.)

The graphic representations in the manual

Graph Significance

Clicking the left mouse button

Clicking the right mouse button

Double-clicking the left mouse button

Pressing and holding the left mouse button, and then moving the mouse without

releasing the button.

Typing with a keyboard

Operating sequence (The graphic representation is used when the operating sequen ce

is mentioned. For example,

and .)

Number used with a picture

1-2

Chapter 1 Introduction

1.2 System Frameworks

The AH500 series programmable logic controll er is a medium type of programmable logic control

system. The execution speed and the memory capacity are increased. Besides, the complete

program development function of function blocks is supported. In order to meet users’ more

advanced application requirements, the AH500 series programmable logic controllers provide more

flexible system extension frameworks. Under such system frameworks, users do not need to use

several CPU modules to control the system because of the fact that there are too many I/O points or

the equipment is too far away. The completeness of the system is retained, and use rs can be more

efficient in developing the projects.

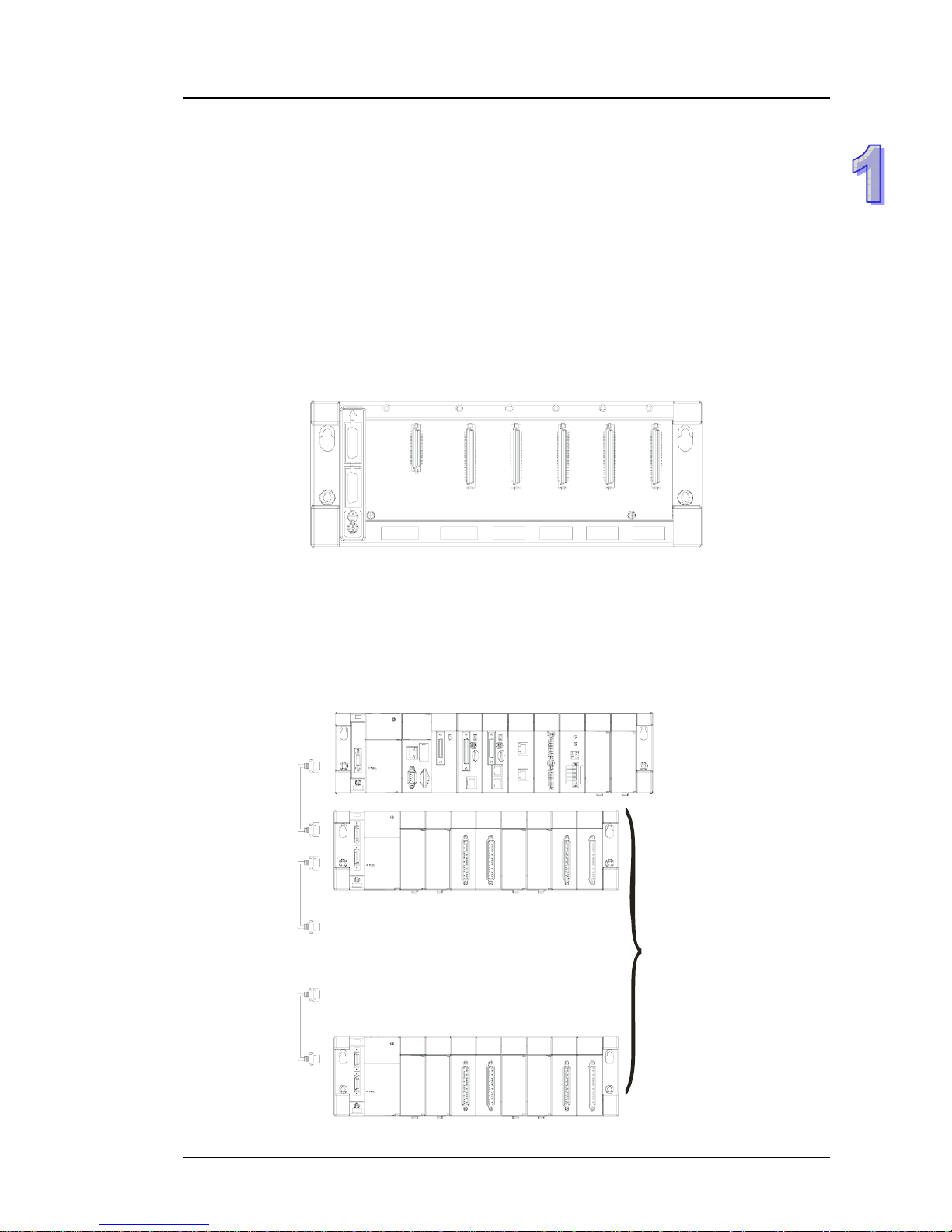

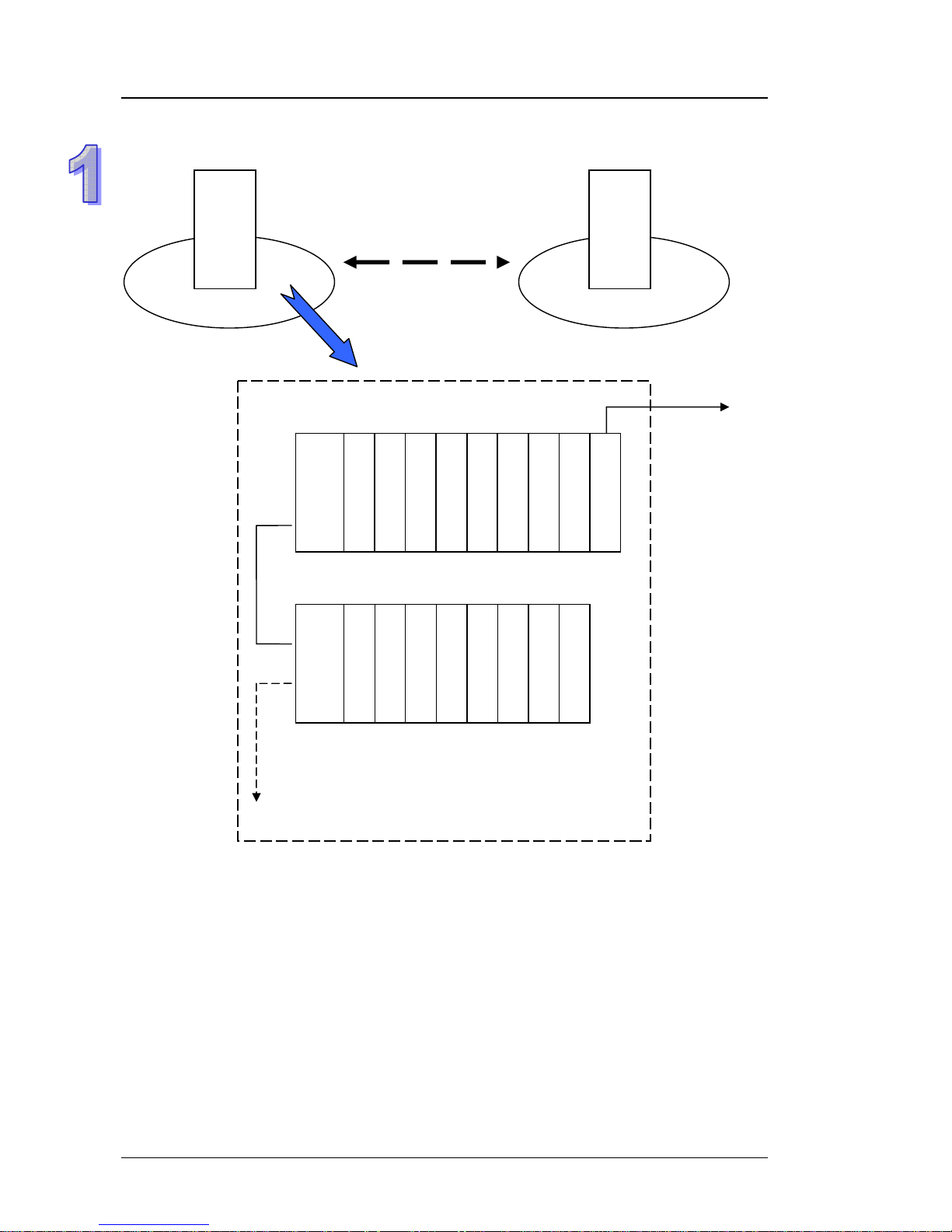

The minimum framework requirement for the AH500 system:

To create the AH500 sy stem, one main backpl ane, one power sup ply module, and one CPU module

are needed for the operation of the CPU module.

Main backplane (four-slot AHBP04M1-5A)

CPU module

Power supply

module

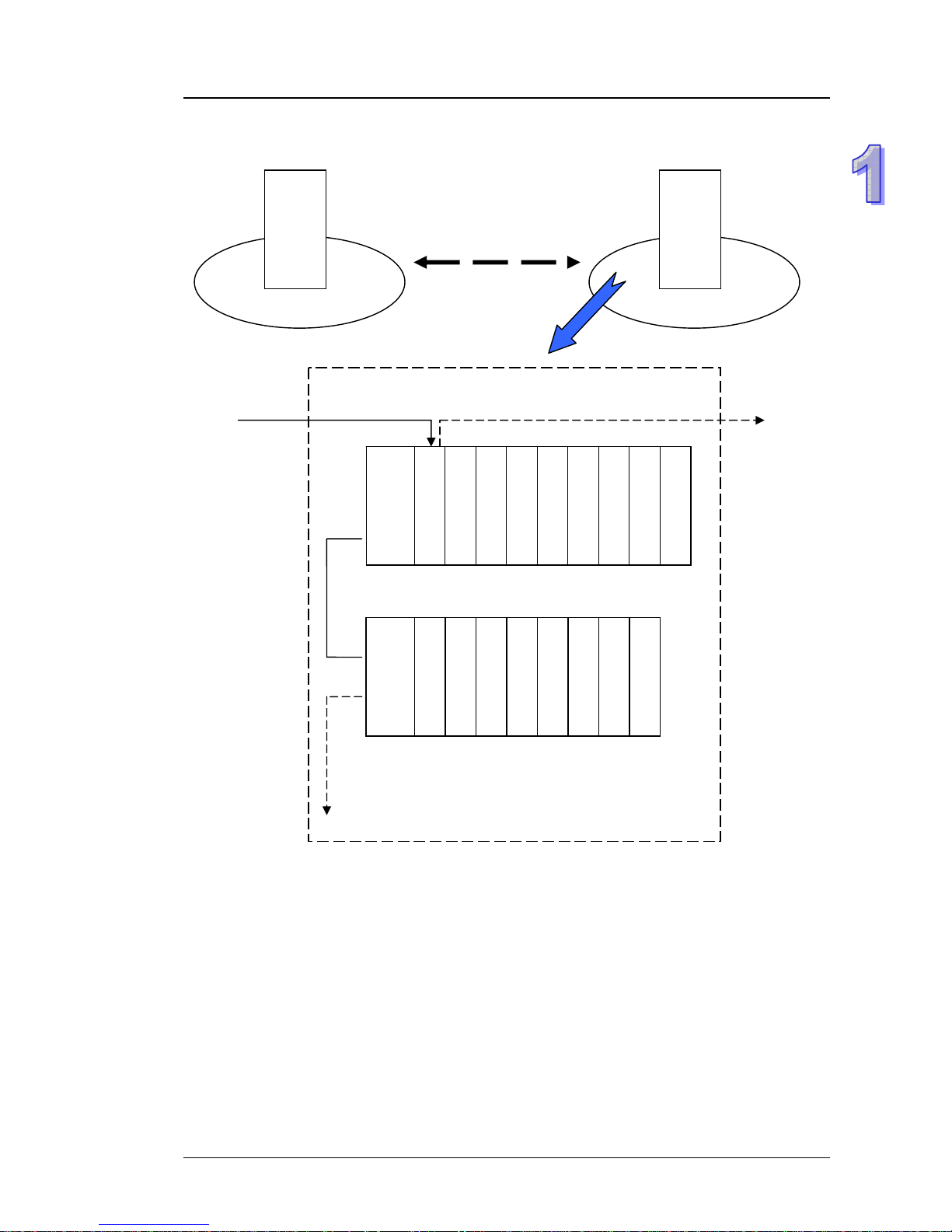

The common framework of the AH500 system (for original equipment manufacturers):

The AH500 system can meet most equipment development re quirements in the application field of

original equipment manufacturers. Generally speaking, one eight-slot main backplane or one

twelve-slot main backplane is chosen. Some advanced equipment can be used with a six-slot

extension backplane or an eight-slot extension backplane under the original framewor k to increase

the number of I/O points and the number of axes, or decrease the wiring cost.

The framework: Rack 1~rack 8

7 backplanes

.

.

.

.

.

.

1-3

AH500 Quick Start

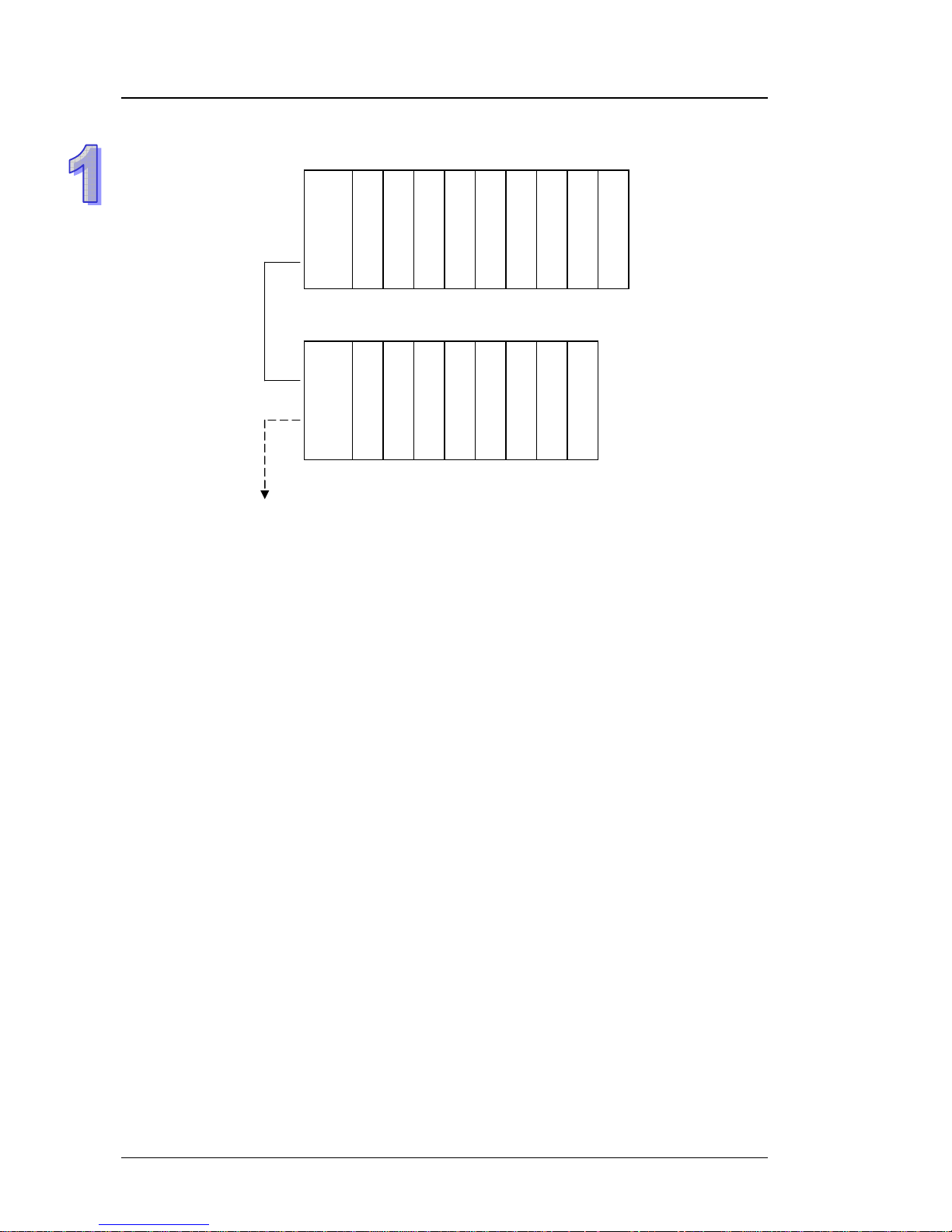

The configuration is as follows.

Power supply

CPU module

Rack 1 (eight-slot main backplane)

Rack 2 (eight-slot extension backplane)

Ei

g

ht racks at most

Motion control module

Network module

Motion control module

Motion control module

Motion control module

Motion control module

Motion control module

Power supply

Digital input module

Digital input module

Digital output module

Analog input module

Temperature

measurement module

Serial communication

module

Note: Owing to the consideration to the data transmission speed, the motion control modules a nd

the network modules (exclusive of the serial communication modules) have to be installed

with the CPU module on the same backplane. Otherwise, the system can not operate

properly.

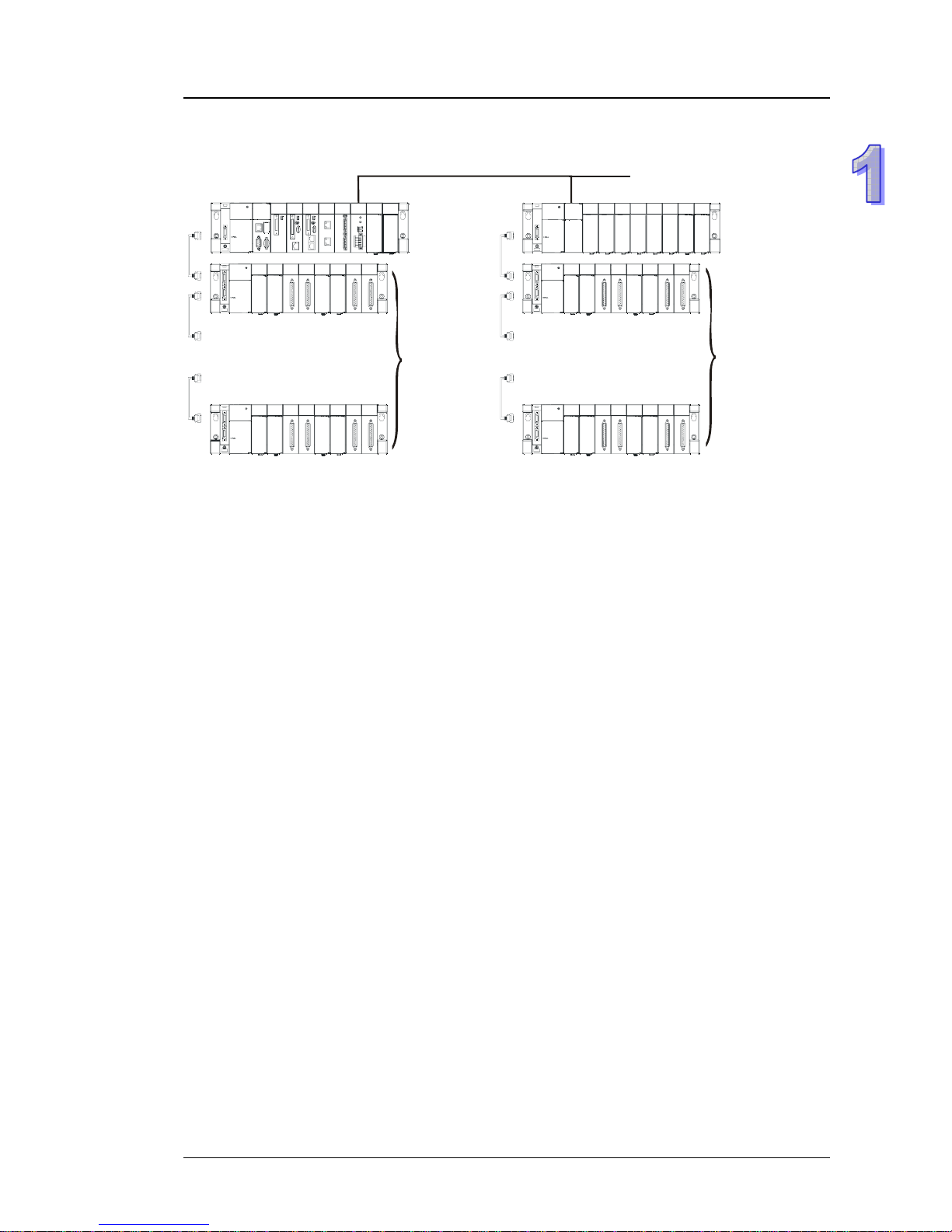

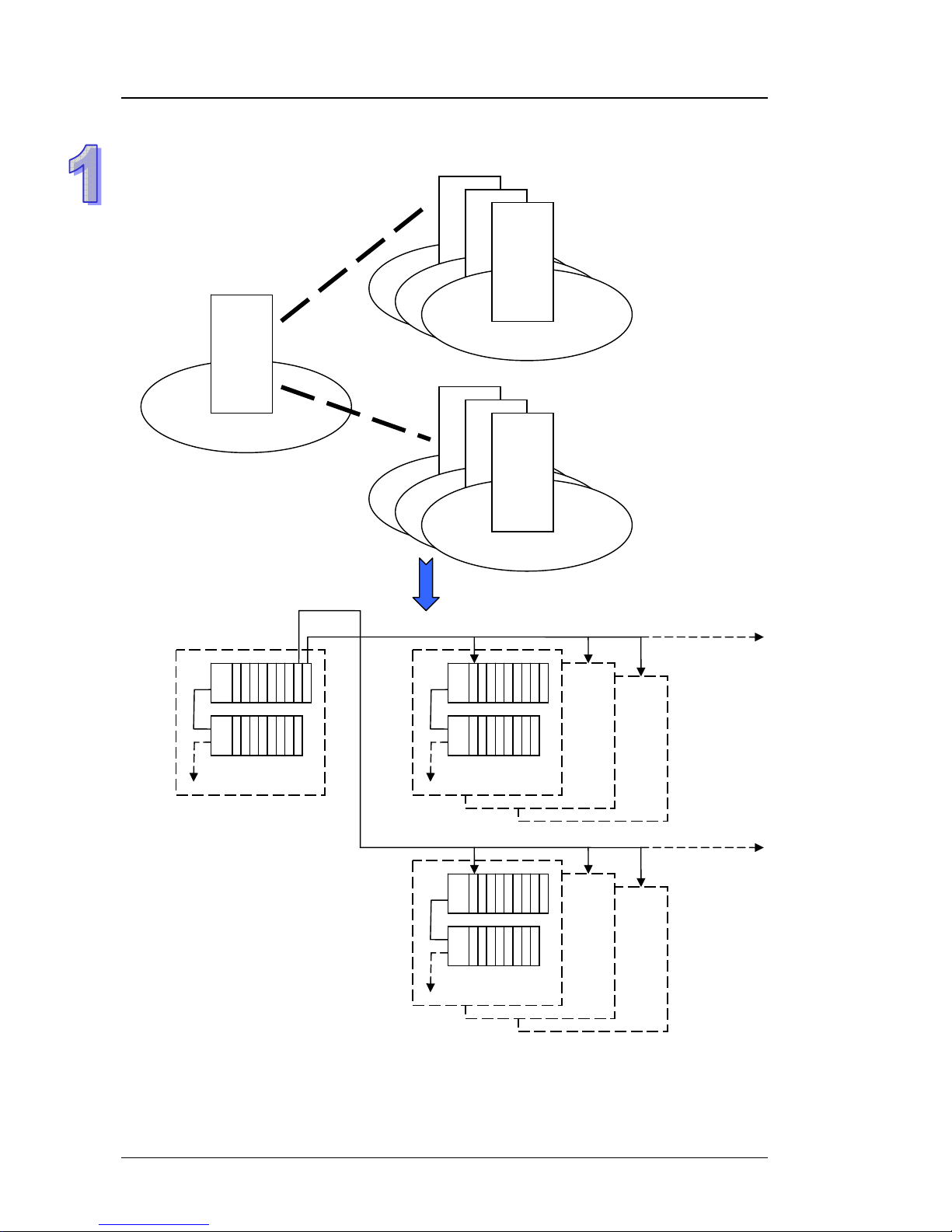

The common framework of the AH500 system (for system integration):

The AH500 system can meet most system control requirement s in the application field of the system

integration. Generally speaking, the system framework is related to the positions of the equipments.

A control pan el is usually p l aced among the equipments which are concentrated to save the wiring

cost. However, there i s usually more than one concentration point, and the distance between the

concentration points is over 100 meters. If it is necessary for users to place more than two control

panels, the RTU modules are required. The re mote framework of the AH5 00 system not only fills the

remote requirement, but also is combined with the extension of the local I/O. Under most conditions,

a control panel instead of a backplane can be regarded as a remote I/O station. In addition, the

backplanes, the power supply modules, and other modules are compatible with one another. The

convenience of planning the system is increased, and the difficulty of choosing the products is also

decreased.

1-4

Chapter 1 Introduction

System framework: Rack 1~rack 8+RTU modules

.

.

.

.

.

.

.

.

.

.

.

.

...

Remote I/O

7 backplanes

7 backplanes

Note: Users are provided with the special cables to connect the extension backplanes. T he length of

a special cable can be up to 100 meters. They are also provided with the fiber cables which

are used with the special adapters. The length of a fiber cable can be up to 2 kilometers.

1-5

AH500 Quick Start

System planning 1

Control panel

Concentration point

Over 100 meters

Rack 1 (eight-slot main backplane)

Master

Master

Slave 1

Control panel

Concentration point

Rack 2 (eight-slot main backplane)

Master

Eight racks at most

Power supply

CPU module

Network module

Digital input module

Digital input module

Digital input module

Digital input module

Digital input module

Digital input module

Remote master

Power supply

Digital output module

Digital output module

Digital output module

Analog input module

Analog input module

Analog input module

Analog output module

Serial communication

module

Slave 1

1-6

Chapter 1 Introduction

System planning 2

Master

Slave 1

Control panel

Control panel

Concentration point

Concentration point

Over 100 meters

Rack 1 (eight-slot main backplane)

Slave 1

Eight racks at most

Sixty-three racks at most

(The remote I/O system is

in use.)

Rack 2

(eight

-slot extension backplane

)

Slave 1

Power supply

Power supply

Analog input module

Analog input module

Analog input module

Analog output module

Analog output module

Analog output module

Serial communication

module

Remote slave

Digital input module

Digital input module

Digital input module

Digital output module

Digital output module

Digital output module

1-7

AH500 Quick Start

System planning 3

Control Panel

設備集中區

Slave 1

Control panel

設備集中區

Slave 2

Control panel

Slave 3

Control panel

設備集中區

Slave 1

Control

p

anel

設備集中區

Slave 2

Control

p

anel

Slave 3

Slave 1

Slave 2

Slave 3

Slave 1 Slave 2

Slave 3

Master

Control panel

Concentration point

Concentration point

Concentration point

Master

Note: The remote masters in DeviceNet are the network modules. They have to be inst alle d with the

CPU modules on the same backplane. A CPU module can support eight masters, and a

master can be connected to sixty-three slaves. Besides, a slave can be connected to seven

1-8

Chapter 1 Introduction

extension backplanes at most.

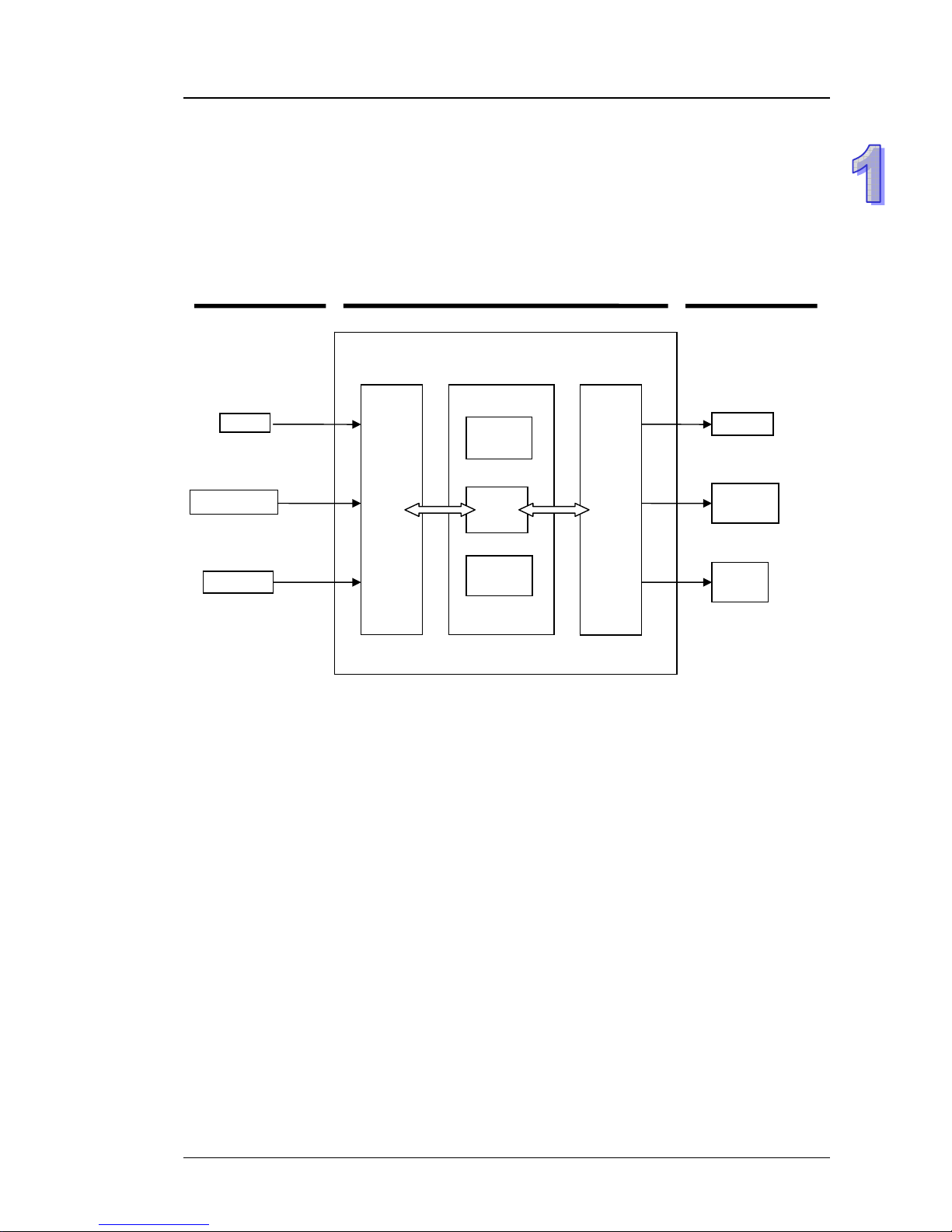

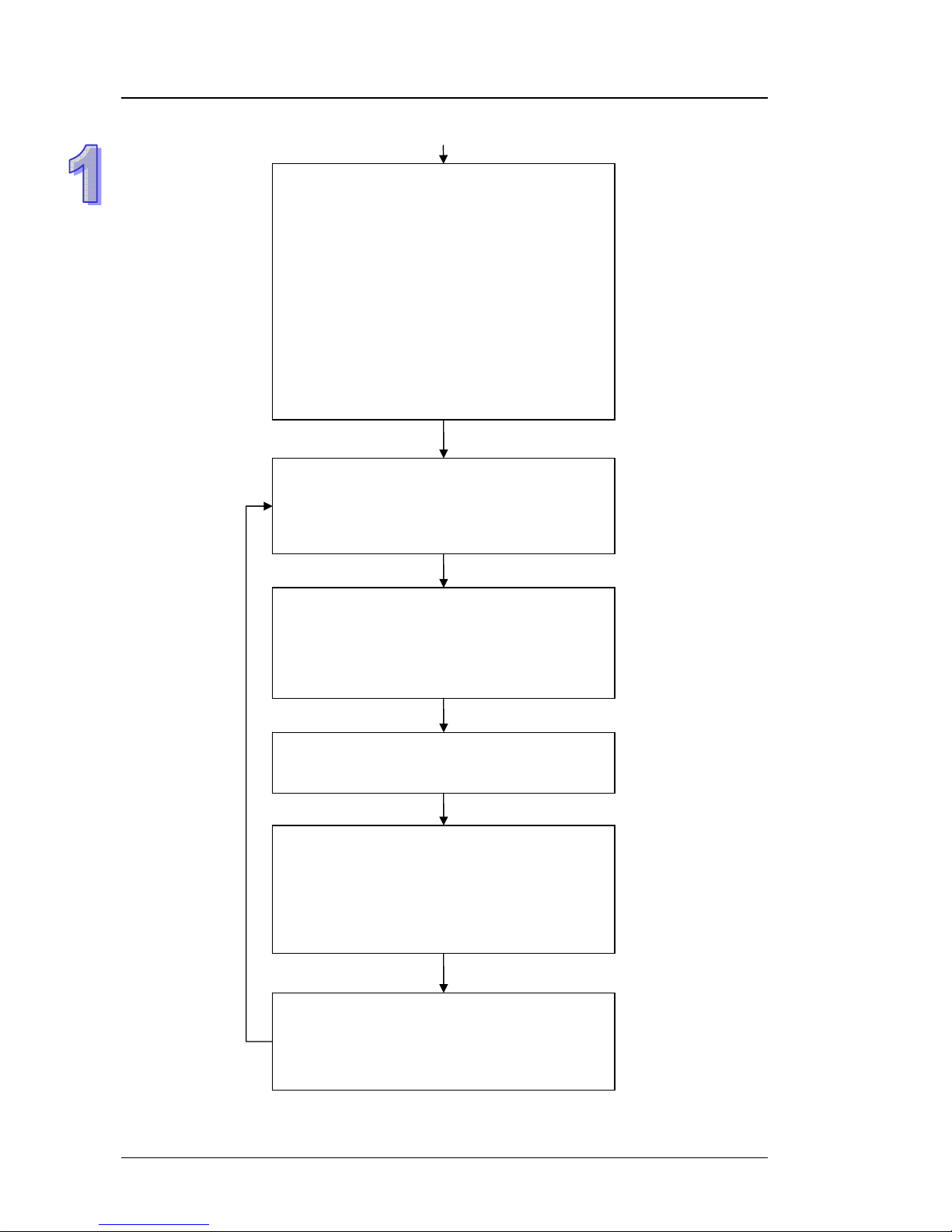

1.3 Operation of the CPU module

The CPU module is the nucleus of the AH500 system. It is responsible for not only the execution of

the logic program, but also the data exchange and the processing of the communication data. The

relation between the AH500 system and the external devices are illustrated below.

System

operation

I/O

refresh

Program

operation

Input module

Output module

CPU module

AH500 system

Switch

Relay

A

C motor

drive

Temperature

Pressure

Electric

valve

External input

device

External output

device

The operation of the CPU module is illustrated above. The system procedures related to the

initialization, the diagnosis, and the communication, and the program procedures related to the

external interrupts and timed interrupts are simplified. Users can refer to other manuals for more

information. The operation of the CPU module is described below.

1-9

AH500 Quick Start

The CPU module is supplied with power.

The system enables the initialization.

y The non-latched memory is initialized.

y The user program is checked.

y The parameters in the CPU module are

checked.

y The parameters in the module table are

checked.

y The module table in the CPU module is

compared with the actual I/O configuration.

y The I/O setting is downloaded to the I/O

module.

y If the memory card is installed, whether to

execute the system copy procedure or not is

checked.

Diagnosis processing:

y The memory card and other setting are

checked.

y The I/O bus is checked.

y The system parameter is checked.

The data sent to the I/O module is refreshed.

y The data sent to the digital I/O module is

refreshed.

y The data sent to the analog I/O module is

refreshed.

y The data sent to other modules are refreshed.

Program execution:

y The user program is executed.

y The interrupt task is executed.

The data sent from the I/O module is refreshed.

y The data sent from the digital I/O module is

refreshed.

y The data sent from the analog I/O module is

refreshed.

y The data sent from other modules are

refreshed.

Communication service:

y The communication through the CPU module

y The communication through other I/O modules

y The internal communication between the CPU

module and the I/O module

1-10

Chapter 2 Programming

Table of Contents

2.1 Preparations ..............................................................................................2-2

2.1.1 Hardware............................................................................................2-2

2.1.2 Software .............................................................................................2-3

2.1.3 Tools and Materials ............................................................................2-3

2.2 Installation .................................................................................................2-3

2.2.1 Installing Modules...............................................................................2-3

2.2.2 Installing Removable Terminal Blocks ................................................2-4

2.3 Wiring ........................................................................................................2-6

2.3.1 Wiring the Power Supply Module .......................................................2-7

2.3.2 Wiring the Digital Input Module...........................................................2-9

2.3.3 Wiring the Digital Output Module........................................................2-9

2.3.4 Wiring the Analog Input/Output Module............................................2-10

2.3.5 Supplying Power ..............................................................................2-10

2.4 Exemplification ........................................................................................2-11

2.5 Creating Projects.....................................................................................2-12

2.6 Hardware Configuration...........................................................................2-14

2.7 Creating Global Symbols.........................................................................2-19

2.8 Creating Function Blocks.........................................................................2-20

2.9 Creating Main Programs..........................................................................2-29

2-1

AH500 Quick Start

2.1 Preparations

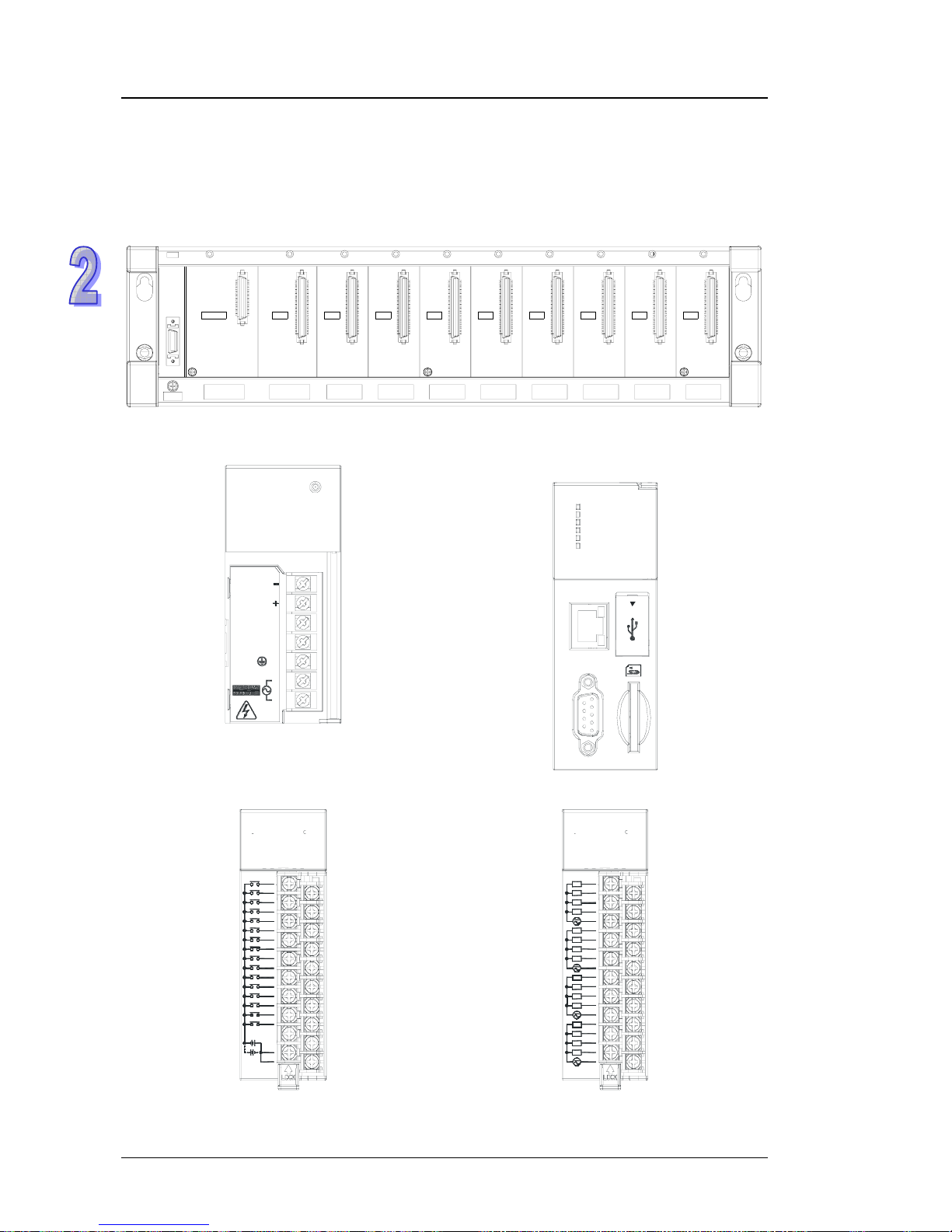

2.1.1 Hardware

The hardware needed in the example is as follows.

1. Eight-slot main backplane

AHBP08M1-5A x 1

POWER CPU I/O0 I/O1 I/O2 I/O3 I/O4 I/O5 I/O6 I/O7

2. Power supply module

AHPS05-5A x 1

PS05

POWER

NC

FG

INPUT

VS

VS

LG

N

L

3. CPU module (with the built-in network

function)

AHCPU530-EN x 1

CPU530-EN

RUN

ERROR

BUS FAUL T

SYSTEM

COM

Ethernet

COM

USB

4. Digital input module (16 inputs)

AH16AM10N-5A x 1

7

10

12

11

9

8

6

5

4

3

2

15

14

6

7

13

S/S

24VDC 5mA

1

0

16AM10N

023154

S/S

98110 11 12 13 14 5

5. Digital output module (16 outputs)

AH16AN01R-5A x 1

16AN01R

10432

567

L

L

L

L

4

5

3

2

L

COM0

12

COM1

L

7

L

L

L

L

L

13

14

15

L

6

11

COM2

24VDC

/24 0V AC 2A

COM3

L

L

L

8

10

9

L

1

0

1110 1413 151289

2-2

Chapter 2 Programming

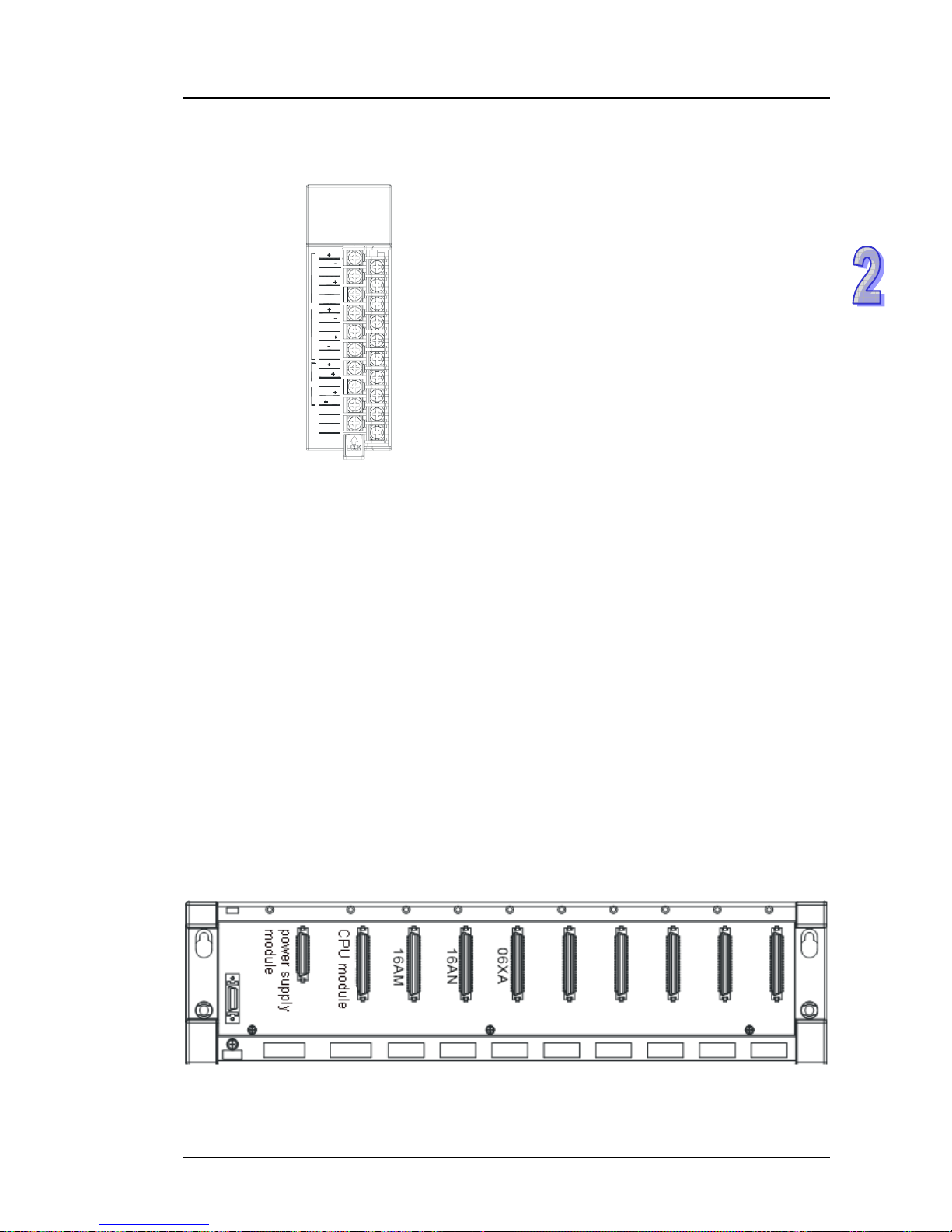

6. Analog input/output module (6 channels)

AH06XA-5A x 1

V2

V1

AI

R1

R0

V0

V1

V3

V3

R3

R2

V2

V0

ERROR

RUN

10V,20mA

10V,0/4~20mA

FE

UP

V0

V1

I1

ZP

COM

AO

I0

06XA

2.1.2 Software

The software needed in the example is as follows.

z ISPSoft version 2.0 or above

z COMMGR version 1.0 or above

2.1.3 Tools and Materials

The tools and the materials need in the example are as follows.

z A personal computer in which the software mentioned above is installed

z A 100~240 V AC and 50/60 Hz power supply socket

z A 24 V DC power supply

z A cable

z A screwdriver

z An USB cable or a network cable (If users want to connect the Ethernet port or the COM port

(RS-232/RS-485) on the CPU module to the computer, they can refer to section 2.3.2 in

ISPSoft User Manual for more information. If users want to know more about installing the

USB driver, they can refer to appendix A in AH500 Operation Manual.)

z If necessary, users can prepare the accessories such as a switch and a bulb (to simulate the

activity of the external equipment).

2.2 Installation

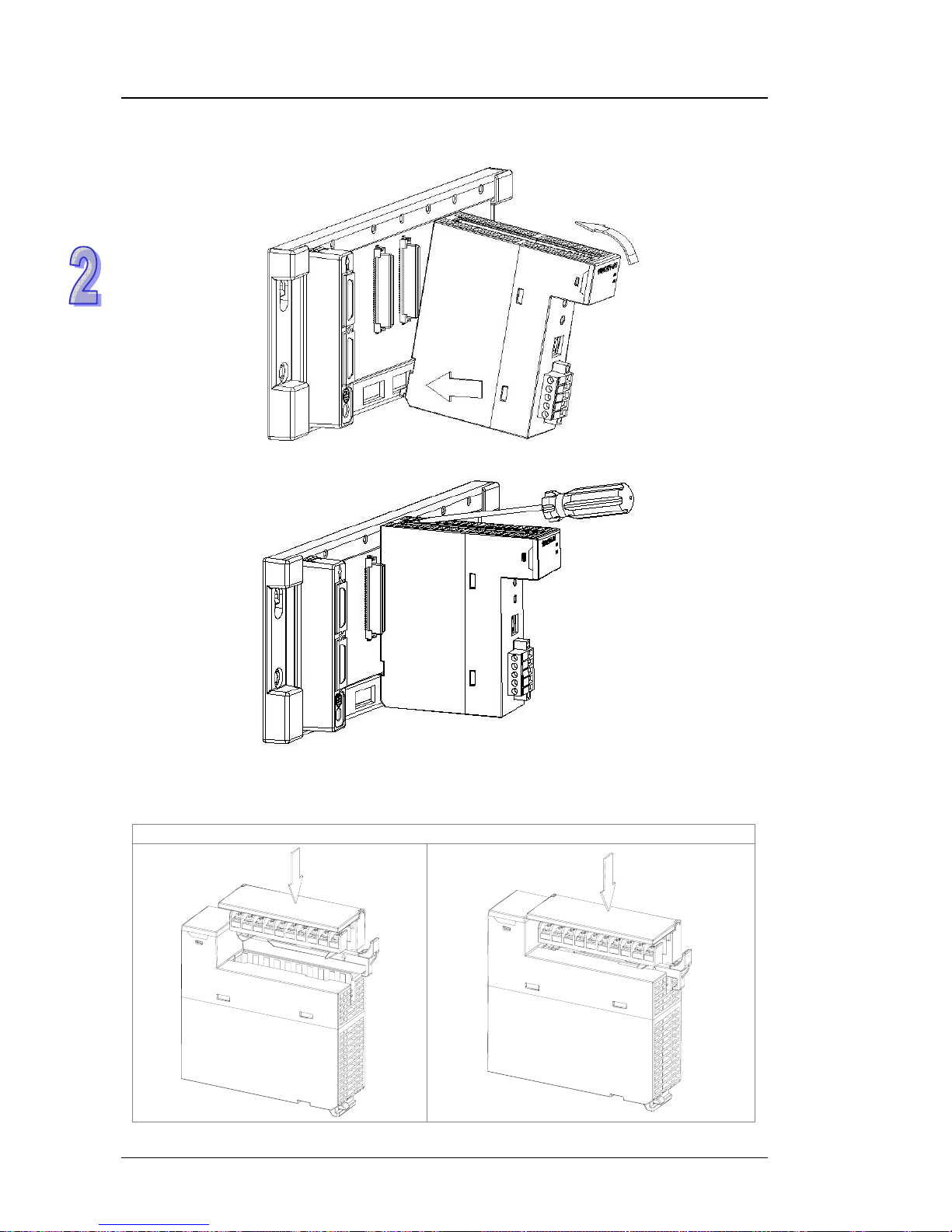

2.2.1 Installing Modules

Please install the modules on the main backplane, as illustrated below.

Connect the module to the connector on the backplane, make sure that the module is installed on

the backplane properly, and tighen the the screw.

2-3

AH500 Quick Start

1. Insert the projection under the module into the hole in the backplane.

2. Push the module in the direction indicated by the arrow until it clicks.

3. Tighten the screw on the module.

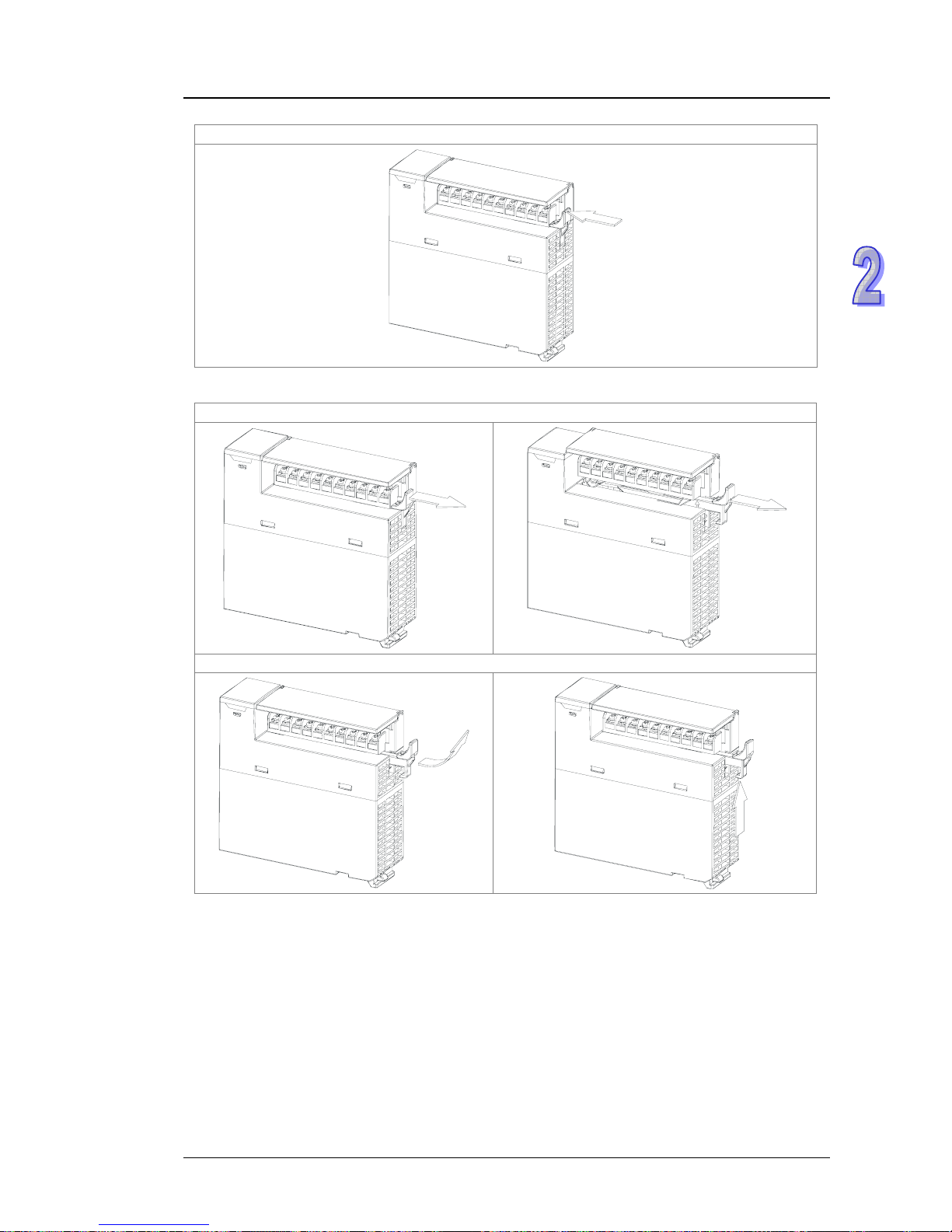

2.2.2 Installing Removable Terminal Blocks

Please install the removable terminal block on the module, as illustrated below.

z

Installation

1. Level the terminal block at the printed circuit board, and press it into the module.

2-4

Chapter 2 Programming

2. Press the clip in the direction indicated by the arrow.

z

Removal

1. Pull the clip in the direction indicated by the arrow.

2. Pull up the clip.

2-5

AH500 Quick Start

3. The terminal block is removed.

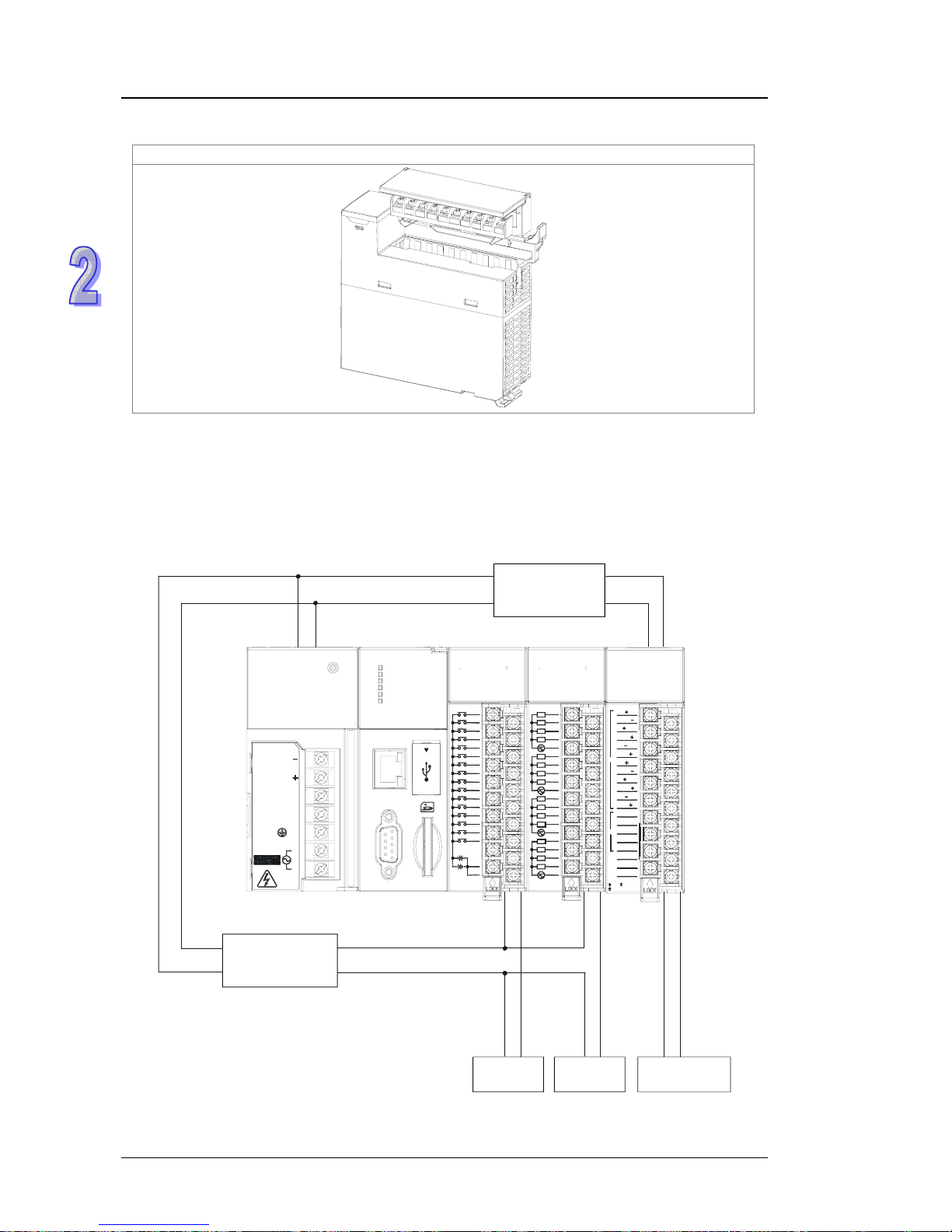

2.3 Wiring

After the modules are installed, the wiring of the modules follows. In order for the following example

to proceed smoothly, the power supply module and the analog module have to be wired. Be sure to

cut off the power supply before wiring the modules. To lend convenience and reality to the

simulation, the signal lines can be connected to the switch and the bulb according to the personal

needs. The rough framework is as follows.

V2

VI1

A

I

I1

I0

VI0

V1

V3

VI3

I3

I2

VI2

V0

ERROR

RUN

±

10V,±20mA

±

10V,0/4~20mA

SG

UP

VO0

VO1

IO1

ZP

A

G

A

O

IO0

06XA

7

10

12

11

9

8

6

5

4

3

2

15

14

6

7

13

S/S

24VDC 5mA

1

0

16AM10N

023154

S/S

981510 11 12 13 14

16AN01R

10432567

L

L

L

L

4

5

3

2

L

COM0

12

COM1

L

7

L

L

L

L

L

13

14

15

L

6

11

COM2

24VDC

/

240VAC 2A

COM3

L

L

L

8

10

9

L

1

0

1110 1413 151289

PS05

POWER

NC

FG

INPUT

VS

VS

LG

N

L

CPU530-EN

RUN

ERROR

BUS FAULT

SYSTEM

COM

Ethernet

COM

USB

L

N

+

-

Bulb

Signal

simulator

+

-

ZP

UP

S/S COM

100~240 V A

C

Switch

DC 24 V

power supply

DC 24 V

power supply

2-6

Chapter 2 Programming

The wiring of the modules is described in detail below. (Please refer to AH500 Hardware Manual for

more information.)

2.3.1 Wiring the Power Supply Module

z The alternating-current input voltage is within the range between 100 V AC and 240 V AC.

Please connect the power supply to the terminals L and N.

If the 110 V AC or the 220 V AC

power supply is connected to the input terminals VS+ and VS-, the PLC will be

damaged.

z In order to ensure that the 24 V DC external power supply is provided stably, it can be

connected to VS+ and VS-. If the PLC detects that the voltage of the external power supply is

lower than the working voltage, users can write a protective program. (Please refer to section

6.6 in AH500 Operation Manual for more information.)

z The length of the wire connecting with the ground is 1.6 millimeters.

z If the power cut lasts for less than 10 milliseconds, the PLC keeps running without being

affected. If the power cut lasts for long, or if the voltage of the power supply decreases, the

PLC stops running, and there is no output. When the power supply returns to normal, the PLC

resumes. (Users have to notice that there are latched auxiliary relays and registers in the PLC

when they write the program.)

z Please use the single-core cable or the twin-core cable. The diameter of the cable used should

be with the range between 12 AWG and 22 AWG. The torque applied to the terminal screw

should be within the range between 5 kg-cm (4.3 Ib-in) and 8 kg-cm (6.9 Ib-in). Please use the

copper conducting wire. The temperature of the copper conducting wire should be 60/75°C.

z Safety wiring: The PLC controls many devices, and the activity of any device affects the

activity of other devices. If a device breaks down, the whole automatic control system goes out

of control, and the danger occurs. The protection circuit is as follows.

2-7

AH500 Quick Start

①

Alternating-current power supply: 100~240 V AC, and 50/60 Hz

②

Circuit breaker

③

Emergency stop: The emergency stop button can be used to cut off the power when an

emergency occurs.

④

Power indicator

⑤

AC power load

⑥

Fuse (2A)

⑦

The ground impedance is less than 100 Ω.

○

8

Direct-current power supply: 24 V DC

2-8

Loading...

Loading...