Delta AHCPU560-EN2 Series, AHCPU5X1-EN Series, AHCPU511-EN, AH10EN-5A Series, AHCPU531-EN Operation Manual

...Page 1

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan City,

Taoyuan County 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province, P.R.C. 215200

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C. 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

T

okyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd.

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

EtherNet/IP

Operation Manual

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A.

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: 55 11 3568-3855 / FAX: 55 11 3568-3865

Europe

Delta Electronics (Netherlands) B.V.

Eindhoven Ofce

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL : +31 (0)40-8003800 / FAX : +31 (0)40-8003898

IA-0269420-03

*We reserve the right to change the information in this manual without prior notice.

2019/05/13

www.deltaww.com

Page 2

Version

Revision

Date

1st

The first version was published.

2016/05/20

2nd

1.Information concerning AHCPU5X1-EN is added in

7.New product information is added in section 9.2.

added in chapter 9.

3rd

EtherNet/IP Operation Manual

Revision His tory

section 1.3.1.

2.Information concerning AHCPU5X1-EN is added in

section 2.1.

3.Information concerning AHCPU5X1-EN and

AHCPU-ETHN-5A is added in chapter 3.

4.Information concerning AH-RTU series is added in

section 4.4 and 4.6.

5.Information concerning TAG is added in section 5.1 and

5.2.

6.Information concerning AHCPU5X1-EN and

AHCPU-ETHN-5A is added in chapter 8.

1.Updates on ISPSoft version, information concerning

AHCPU501-EN, AHRTU-ETHN-5A and AHCPU560-EN2 is

added in chapter 1.

2.Information concerning AHCPU501-EN, AHRTU-ETHN-5A

and AHCPU560-EN2 is added in chapter 2.

3.Information on Ethernet specifications of AHCPU501-EN

and AHCPU560-EN2 is added in chapter 3. New content

regarding maximum transmission speed of Delta

products and calculating CIP connection is added in

section 3.2.4 and 3.2.5

4.Information on ISPSoft version is updated and

descriptions concerning AHCPU501-EN and

AHCPU560-EN2 is added in chapter 4.

5.Notes for error code classification is added in section

6.1 and correct all error code ‘H’ to ‘16#’.

6.New EI P product information and updated content are

2017/03/31

2019/05/13

Page 3

EtherNet/IP Operation Manual

Table of Contents

Chapter 1 Product Introduction

1.1 Introduction ...................................................................................... 1-2

1.1.1 EtherNet/IP ................................................................................... 1-2

1.2 Definition ........................................................................................... 1-2

1.3 Features ............................................................................................ 1-3

1.3.1 Delta EIP Architecture ..................................................................... 1-3

1.3.2 Product Features ............................................................................ 1-4

Chapter 2 Netwo rk Installation

2.1 EtherNet/IP Device ........................................................................ 2-2

2.2 Network Installation ....................................................................... 2-2

2.2.1. Single Port Device .......................................................................... 2-2

2.2.2. Dual Port Device ............................................................................ 2-3

2.2.2. PC Software .................................................................................. 2-4

Chapter 3 Product Specifications

3.1 Ethernet Specifications ................................................................... 3-2

3.1.1 AHCPU5x1-EN/ AHCPU560-EN2 ....................................................... 3-2

3.1.2 AH10EN-5A ................................................................................... 3-2

3.1.3 AHRTU-ETHN-5A ............................................................................ 3-2

3.2 Ethernet/IP Specifications ............................................................. 3-3

3.2.1 AHCPU5x1-EN/ AHCPU560-EN2 ....................................................... 3-3

3.2.2 AH10EN-5A ................................................................................... 3-4

3.2.3 AHRTU-ETHN-5A ............................................................................ 3-4

3.2.4 Maximum Transmission Speed of Delta Products ................................ 3-5

3.2.5 Calcu lating CIP Connection .............................................................. 3-6

i

Page 4

Chapter 4 EIP Builder

4.1 Access EIP Builde r .......................................................................... 4-2

4.1.1 Setting Up EIP Scanner ...................................................................4-2

4.2 Set up the IP Address ..................................................................... 4-4

4.2.1 IP Address Types ............................................................................4-4

4.2.2 Set up the IP Address (Static IP) ......................................................4-5

4.2.3 Set up the IP Address (BOOTP/DHCP) ...............................................4-6

4.2.4 IP Modification (BOOTP/DHCP) ....................................................... 4-11

4.3 Network ....................................................................................... 4-13

4.4 Data Mapping ............................................................................... 4-23

4.5 Diagnosis ...................................................................................... 4-28

4.6 AH Series – Connect to a RTU module .......................................... 4-30

4.6.1 AHCPU5x1-EN Series/AHCPU560-EN2 .............................................. 4-30

Chapter 5 Programming

5.1. DFB_EIP_EXP Function Block ......................................................... 5-2

5.1.1 Parameters .........................................................................................5-2

5.2. TAG Function .................................................................................. 5-7

5.2.1 Produced TAG .................................................................................5-7

5.2.2 Consumed TAG ...............................................................................5-9

Chapter 6 Troubleshooting

6.1 Troubleshooting ............................................................................. 6-2

6.2 Error Code & How to fix them ......................................................... 6-2

6.2.1 Ha rd war e E rr or ...............................................................................6-2

6.2.2 Configuration Error ..........................................................................6-3

6.2.3 Applicatio n Error .............................................................................6-5

Chapter 7 Studio 5000 Software O peration

7.1 Architecture ................................................................................... 7-2

7.2 Create a New Project ..................................................................... 7-2

ii

Page 5

7.3 Create a S canner ............................................................................ 7-4

7.3.1 Create a New Module ...................................................................... 7-4

7.4 Connect to a Delta Adapter ............................................................. 7-6

7.4.1 Import an EDS file .......................................................................... 7-6

7.4.2 Create an Adapter .......................................................................... 7-8

7.5 Download ..................................................................................... 7-11

7.6 Data Mapping ............................................................................... 7-12

Chapter 8 CIP Object

8.1 Object List ...................................................................................... 8-3

8.2 Data Type ....................................................................................... 8-5

8.3 Identity Object (Class ID: 16#01) .................................................. 8-7

8.4 Message Router Object (Class ID: 16#02) ..................................... 8-8

8.5 Assembly Object (Class ID: 16#04) ............................................... 8-9

8.5.1 AHCPU5x1-EN and AH10EN-5A ........................................................ 8-9

8.5.2 AHRTU-ETHN-5A ........................................................................... 8-11

8.6 Connection Manager Object (Class ID: 16#06) ............................ 8-12

8.7 Device Level Ring Object (Class ID: 16#47) ................................. 8-13

8.8 QoS Object (Class ID: 16#48) ...................................................... 8-16

8.9 Port Object (Class ID: 16#F4) ...................................................... 8-17

8.10 TCP/IP Interface Object (Class ID: 16#F5) .................................. 8-18

8.11 Ethernet Link Object (Class ID: 16#F6) ....................................... 8-20

8.12 Vendor Specific Objects ................................................................ 8-24

8.12.1 X Register (Class ID: 16#350) ........................................................ 8-24

8.12.2 Y Register (Class ID: 16#351) ........................................................ 8-25

8.12.3 D Register (Class ID: 16#352) ....................................................... 8-26

8.12.4 M Register (Class ID: 16#353) ....................................................... 8-27

8.12.5 S Register (Class ID: 16#354) ........................................................ 8-27

8.12.6 T Register (Class ID: 16#355) ........................................................ 8-28

8.12.7 C Register (Class ID: 16#356) ........................................................ 8-29

iii

Page 6

8.12.8 HC Register (Class ID: 16#357) ..................................................... 8-30

8.12.9 SM Register (Class ID: 16#358) ..................................................... 8-30

8.12.10 SR Register (Class ID: 16#359) ..................................................... 8-31

8.12.11 Control Register (Class ID: 16#370) ............................................... 8-31

8.12.12 Status Register (Class ID: 16#370) ................................................ 8-33

8.12.13 Input Register (Class ID: 16 # 3 7 1) .................................................. 8-34

8.12.14 Output Register (Class ID: 16#372) ............................................... 8-36

8.12.15 RTU AI Register (Class ID:16#373) ............................................... 8-36

8.12.16 RTU AO Register (Class ID:16#374) .............................................. 8-37

8.12.17 RTU DI Register (Class ID:16#375) ............................................... 8-37

8.12.18 RTU DO Register (Class ID:16#376) .............................................. 8-38

Chapter 9 Delta EIP Product List

9.1 Delta EIP Products ......................................................................... 9-2

9.2 Delta EIP Products, DLR (Device Level Ring) supported ................. 9-2

9.3 Delta EIP Products, Scanner supported .......................................... 9-2

iv

Page 7

1

Chapter 1 Product Introduction

Table of Contents

1.1 Introduction…..…………………….……………………………………………………………… 1-2

1.1.1 EtherNet/IP……………………………………………………………………………………………………………… 1-2

1.2 Definition………………………………………………………………………….………………… 1-2

1.3 Features…………………………………………………………………………………………..… 1-3

1.3.1 Delta EIP Architecture……………………………………………………………………………………………. 1-3

1.3.2 Product Features……………………………………………………………………………………………………. 1-4

1-1

Page 8

EtherNet/IP Operation Manual

_1

1.1 Introduction

1.1.1 EtherNet/IP

EtherNet/IP (“IP” st ands for “Industrial P rot oco l” ) is an industrial Ethernet network managed by ODV A, Inc. (formerly Open

DeviceNet Vendors Association, Inc.), a global trade and standards development organization.

EtherNet/IP works on a TCP/UDP/IP based Ethernet network and uses most widely deployed collections of Ethernet

standards to provide a broad range of applications in different industries that require high-speed and stability including

Factory Automation (FA), Building Automation (BA), Process Automation (PA) and many more.

Delta covers a full range of controller and drive products supported by EtherNet/IP, including Programmable Logic

Controllers (PLC), inverters, Human Machine Interfaces (HMI) and so on. Refer to section 9.1 for a full product list

supported by EtherNet/IP. In addition, users can also use the EDS file to connect to the EtherNet/IP devices of other

brands. Delta EtherNet/IP software, the EIP Builder, can be called or run independently through the ISPSoft v3.06.

1.2 Definition

Term Definition

ODVA Open DeviceNet Vendor Association for EtherNet/IP

EtherNet/IP, an industrial Ethernet network, provides interoperability for system providers. IP

EIP

I/O Connection Via the I/O connection to connect to EtherNet/IP and to exchange data cyclically.

Explicit Message

RPI

ACD Address Conflict Detection to detect IP address duplications.

Produced/Consumed

TAG (P/C TAG)

stands for Industrial Protocol. The term “EIP” (EtherNet/IP) will be used throughout this

manual.

Connect to EtherNet/IP and to exchange data non-cyclically. Data will be exchanged piece

by piece via instructions.

Requested Packet Interval, via the I/O connection to connect to EtherNet/IP to exchange

data at regular time intervals.

TAGs are the methods used for assigning and referencing memory locations for

Rockwell PLCs, the same as the registers for Delta PLCs.

Produced TAG: A TAG that a controller makes available for other controllers. Multiple

controllers can simultane ou sly consu me (re ceive) the dat a . A produced TAG sends its

data to consumed TAGs (consumers) without using logic.

Consumed TAG: A TAG that receives the data of a prod uc ed TAG. The dat a ty pe of the

consumed TAG and the produced TAG must be matched (including any array

dimensions).

The data is transferred over Ethernet/IP, for example, PLC-A needs data from PLC-B,

so PLC-B sends the data to PLC-A. Therefore, PLC-A is the producer and PLC-B is

the consumer.

1-2

Page 9

Chapter 1 Product Introduction

1_

Electronic Data Sheets; EDS files are simple text files used by EtherNet/IP network

EDS

Data Mapping Exchange data between devices

EIP Scanner The master station is called EIP Scanner in EtherNet/IP.

EIP Adapter The slave station is called EIP Adapter in EtherN et/ IP.

DLR

configuration tools to help you identify EtherNet/IP products and easily commission them on

a network.

Device Level Ring (DLR) provides fault-tolerant netw ork desi gn for dai sy-chain and linear

topology. The DLR protocol provides high network availability in a ring topology and was

intended primarily for implementation in EtherNet/IP end-devices that hav e tw o Ethern et

ports and embedded switch technology, providing fast network fault detection and

reconfiguration to support the most demanding control applications.

1.3 Features

1.3.1 Delta EIP Architectu r e

This typical Delta EI P arc hit ecture in cludes EI P Scanner and Adapter; data mapping can be achieved between d evice s via

an I/O connection and explicit message.

The AHCPU5X1-EN series which includes AHCPU501-EN, AHCPU511-EN, AHCPU521-EN and AHCPU531-EN

support Ethernet single port communication and for network installation, it is required to employ EtherNet/IP

devices.

The AHCPU560-EN2, AH10EN-5A and AHRTU-ETHN-5A series support Ethernet dual port and DLR function; thus

it can install, configure, and maintain linear as well as device-level ring (DLR) networks by using EtherNet/IP

devices with embedded switch technology.

1-3

Page 10

EtherNet/IP Operation Manual

_1

1.3.2 Product Features

Flexibility

- Flexible topology: EIP devices may include an Ethernet single port as well as Ethernet dual port, and provide

applicable networks such as linear topology, ring topology and ring topology for faster expansion and easier

management.

- EtherNet/IP works on a TCP/UDP/IP based Ethernet network, uses most widely deployed collections of

Ethernet standards and supports Wifi connection. Even for personnel with no IT background, the network can

still be built up easily.

- Applicable networks include linear topology, ring topology, star topology, Ethernet, EtherNet/IP, one or more

LANs, etc. Configuration can be set via a USB device or an interface.

Simplicity

- Via a connector: Delta provides a full range of product line, including human machine interfaces (HMI),

programmable logic controllers (PLC) and inverter drives, for application in an industri al operation. Simply via a

RJ-45 connector, a network can be built up, saving costs on cables and other connecting tools.

- Single network: In replace with the 3-tier industrial architecture, single network architecture provides 100Mbps

high-speed cyclical and non-cyclical data mapping function, ensuring a complete network diagnosis and

effectively shortening debugging time.

- Graphical user interface designed software: The EIP Builder is graphical user interface designed for intuitive

operation.

Integration

- Data mapping: The EIP Builder provides a consistent setting interface, allowing users to reduce the time to

learn and set up configurations easily.

- Listed device parameters: The EIP Builder presents a parameter list of Delta devices. Instead of looking up in

the user manual, users can quickly check on the para meters from the list.

- EDS file: Users can connect to Delta and other brand EtherNet/IP products via the EDS files.

1-4

Page 11

2

Chapter 2. Network Installation

Table of Contents

2.1 EtherNet/IP Device ......................................................................................... 2-2

2.2 Network Installation ........................................................................................ 2-2

2.2.1 Single Port Device ..…………………………………………………………………….………………………………2-2

2.2.2 Dual Port Device …………………………………………………………………………………………………..…….2-3

2.2.3 PC Software ..…………………………………………………………………………………………………………….…2-4

2-1

Page 12

EtherNet/IP Operation Manual

_2

2.1 EtherNet/IP Device

A Delta EtherNet/IP (EIP) device allows users to build a linear topology, ring topology, and star topology. A

Delta EIP device includes the EIP Builder software, EIP Scanner, EIP Adapter, EIP Tap, and Ethernet switch.

EIP Scanner and EIP Adapter, each of them can be further divided to a single port and dual port.

Ethernet single port: the AHCPU5X1-EN series including AHCPU501-EN, AHCPU511-EN,

AHCPU521-EN and AHCPU531-EN.

Ethernet dual port: the AHCPU560-EN2, AH10EN-5A and AHRTU-ETHN-5A series

2.2 Network Installation

Each EtherNet/IP device is connected to an Ethernet switch via a CAT 5e cable. Please use Delta standard

cables and the DVS series industrial switches. Refer to Delta PLC/HMI Cable Selection Guide for more

information.

2.2.1 Single Port Device

A single port device can build up a linear and a star topology. An Ethernet switch is required to create a star

topology and a ring topology, and additionally an EtherNet/IP Tap is also needed.

Linear Topology

Linear Topology 1

Linear Topology 2

2-2

Page 13

Chapter 2 Network Installation

2_

Star Topology

2.2.2 Dual Port Device

A dual port device can build up a linear, star and ring topology. A DLR function is required to create a ring

topology. Refer to section 9.2 for DLR supported series.

Linear Topology

Star Topology

Ring Topology

A DLR function is required to create a ring topology. Refer to section 9.2 for DLR supported series.

2-3

Page 14

EtherNet/IP Operation Manual

_2

When a switch is needed for topology , the switch should support the DLR function. If not, the connection might

fail.

2.2.3 PC Software

Linear and star topology

Install the EIP Builder on your PC to monitor and configure the EIP devices. Users can also connect an EIP

device to their PCs directly or use a switch to connect to the PCs.

2-4

Page 15

Chapter 2 Network Installation

2_

Ring topology

Install the EIP Builder on your PC to monitor and configure the EIP devices. Be sure to save a network

connection for your PC to connect to the EIP device.

Or you can use an EIP tap to connect your PC so that the ring topology can stay intact.

2-5

Page 16

EtherNet/IP Operation Manual

_2

MEMO

2-6

Page 17

3

Chapter 3 Product Specifications

Table of Contents

3.1 Ethernet Specifications ............................................................................... 3-2

3.1.1 AHCPU5x1-EN/ AHCPU560-EN2 ................................................................... 3-2

3.1.2 AH10EN-5A ............................................................................................... 3-2

3.1.3 AHRTU-ETHN-5A ........................................................................................ 3-2

3.2 Ethernet/IP Specifications ......................................................................... 3-3

3.2.1 AHCPU5x1-EN/ AHCPU560-EN2 ................................................................... 3-3

3.2.2 AH10EN-5A ............................................................................................... 3-4

3.2.3 AHRTU-ETHN-5A ........................................................................................ 3-4

3.2.4 Maximum Transmission Speed of Delta Products ............................................ 3-5

3.2.5 Calculating CIP Connection.......................................................................... 3-6

3-1

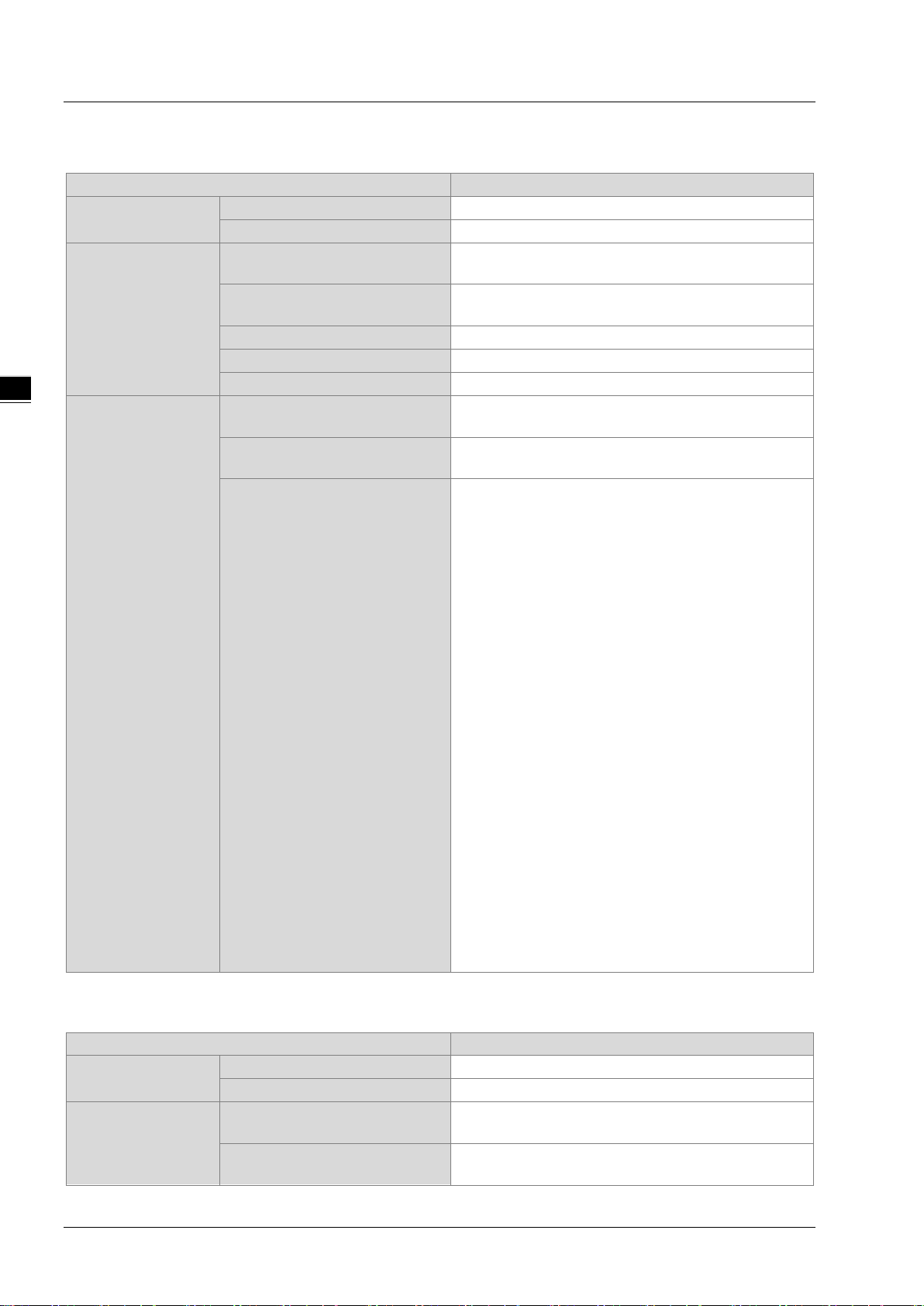

Page 18

EtherNet/IP Operation Manual

_3

Communication Protocols

EtherNet/IP, MODBUS TCP

Protocols

Communication Speed

10/100 Mbps Auto-Detection

Communication Interface

RJ-45 with Auto MDI/MDIX

Communication Protocols

EtherNet/IP, MODBUS TCP

Protocols

BOOTP, DHCP, SMTP, SNMP, NTP

Communication Speed

10/100 Mbps Auto-Detection

Communication Interface

RJ-45 with Auto MDI/MDIX

Communication Port

Communication Protocols

EtherNet/IP, MODBUS TCP

Protocols

BOOTP, DHCP, NTP

Communication Speed

10/100 Mbps Auto-Detection

Communication Interface

RJ-45 with Auto MDI/MDIX

Communication Port

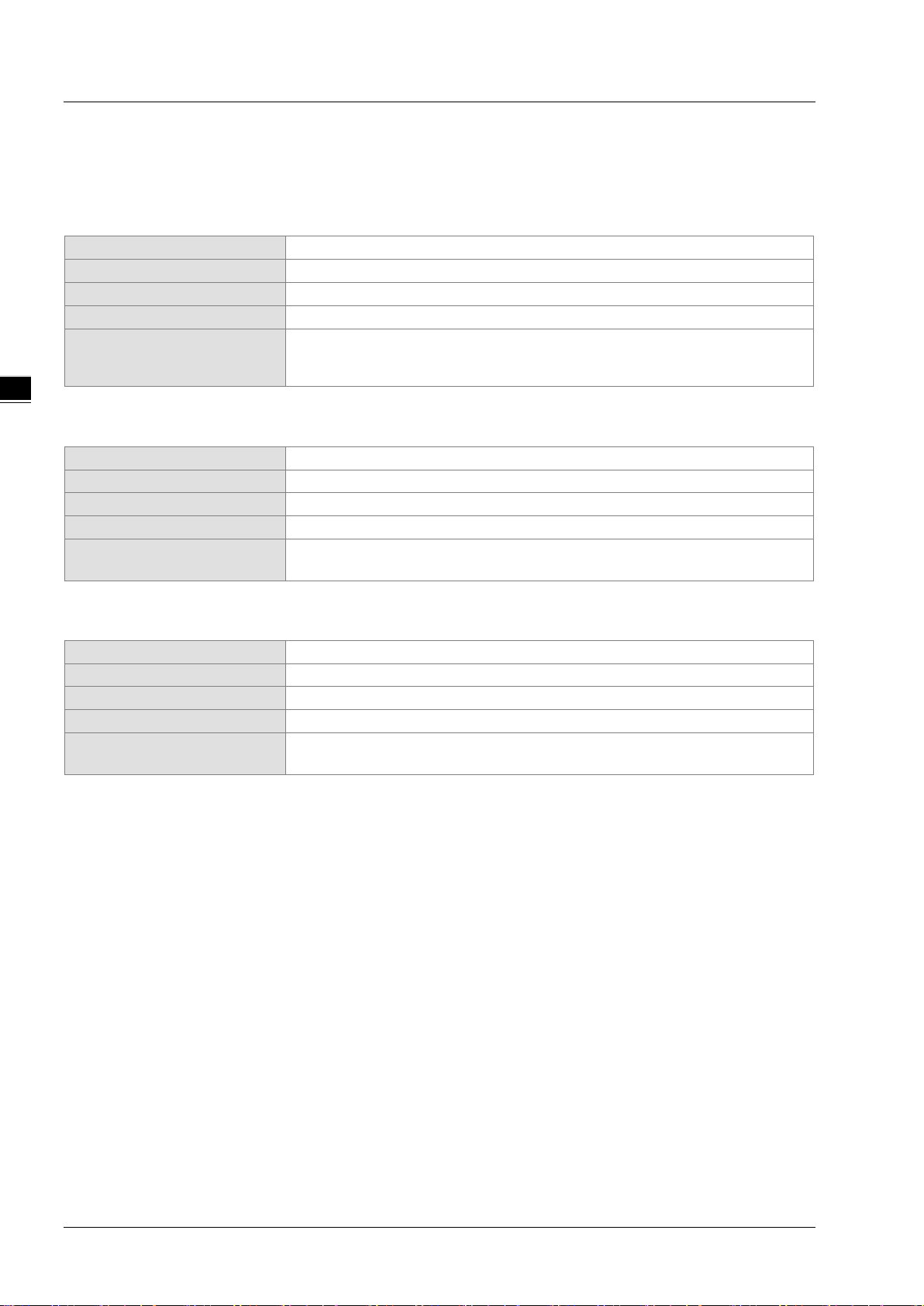

3.1 Ethernet Specifications

3.1.1 AHCPU5x1-EN/ AHCPU560-EN2

BOOTP, DHCP, SNMP, NTP

Numbers of the Ethernet

Communication Port

AHCPU5x1-EN:1

AHCPU560-EN2:2

3.1.2 AH10EN-5A

Numbers of the Ethernet

2

3.1.3 AHRTU-ETHN-5A

Numbers of the Ethernet

2

3-2

Page 19

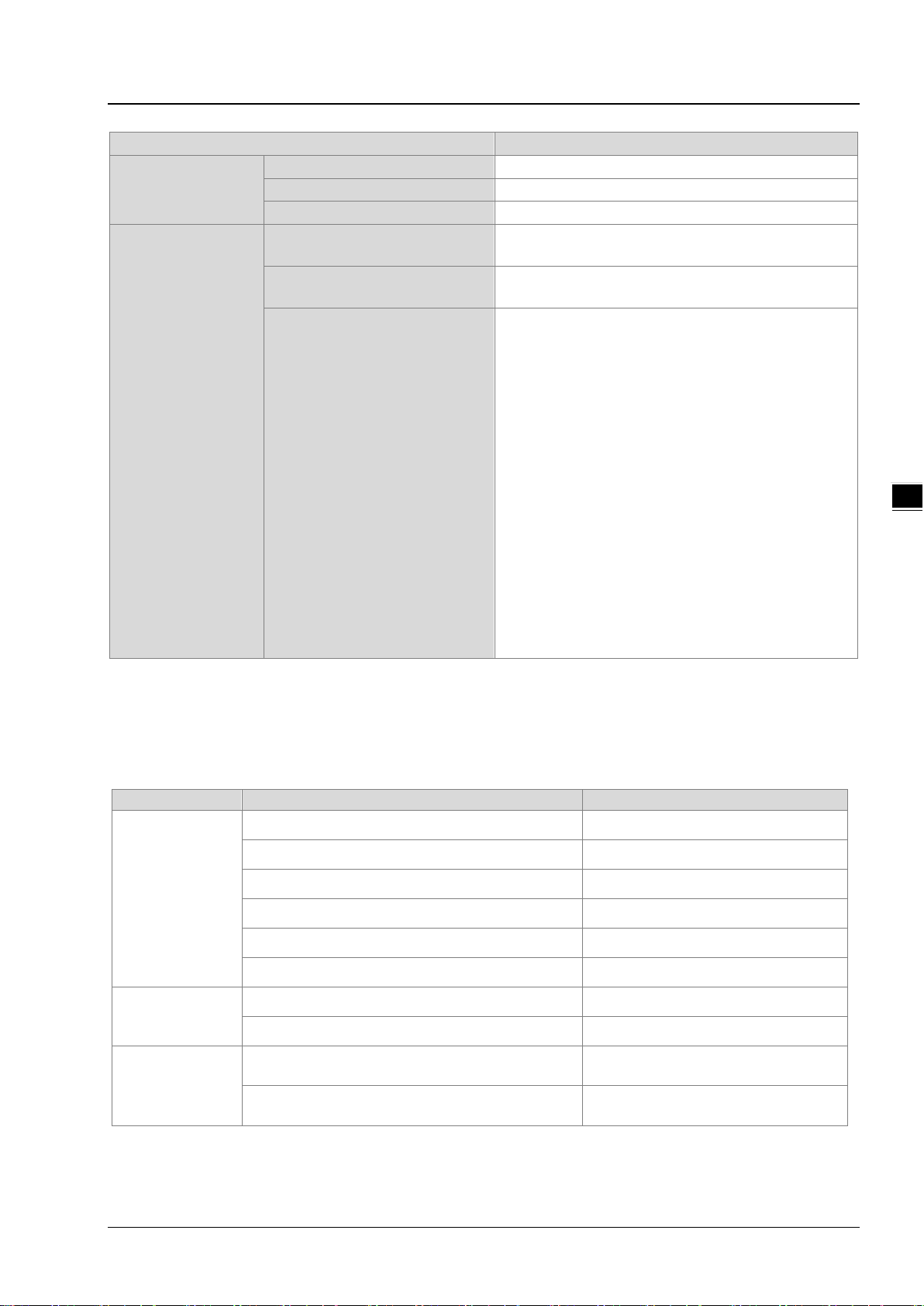

3_

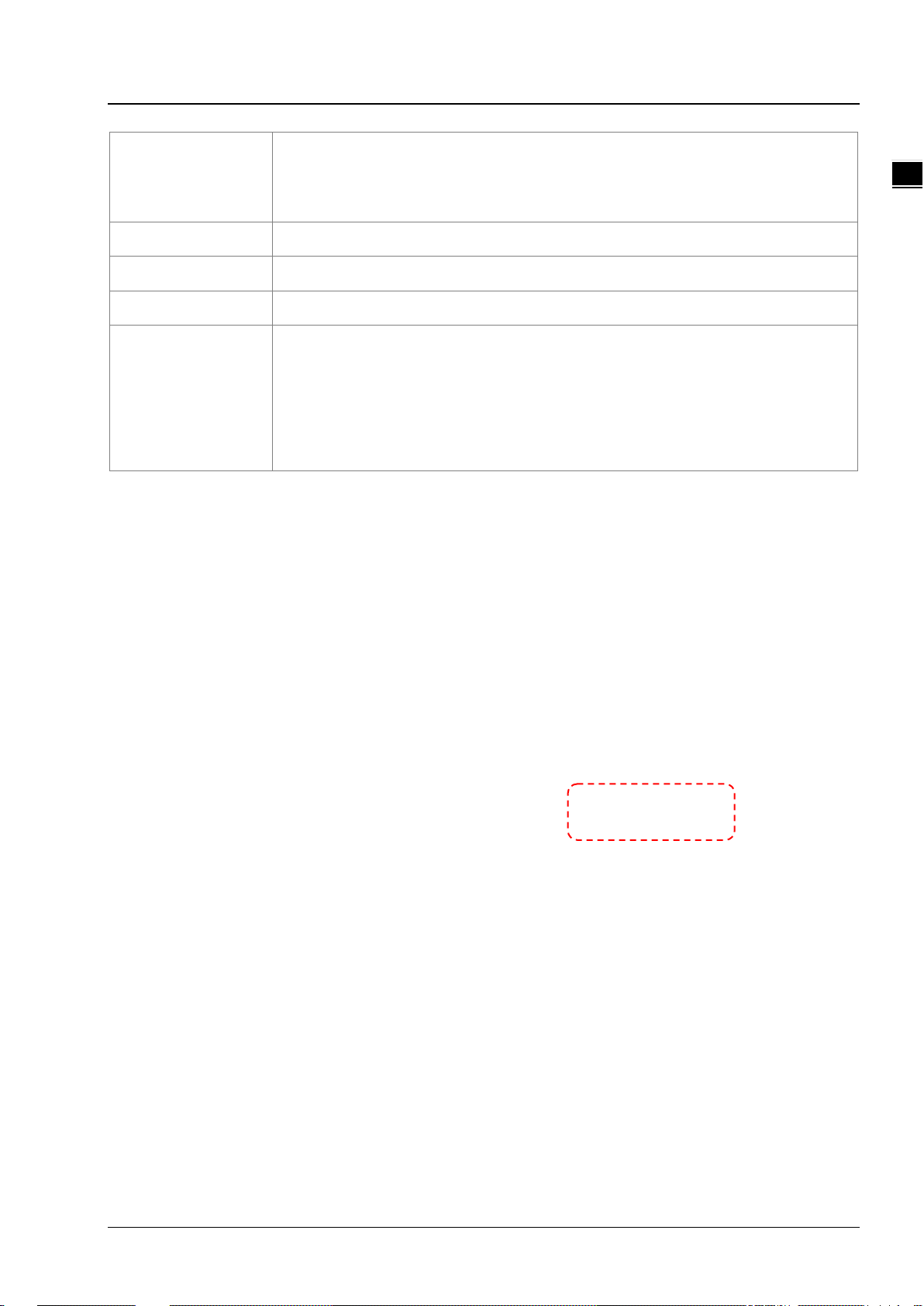

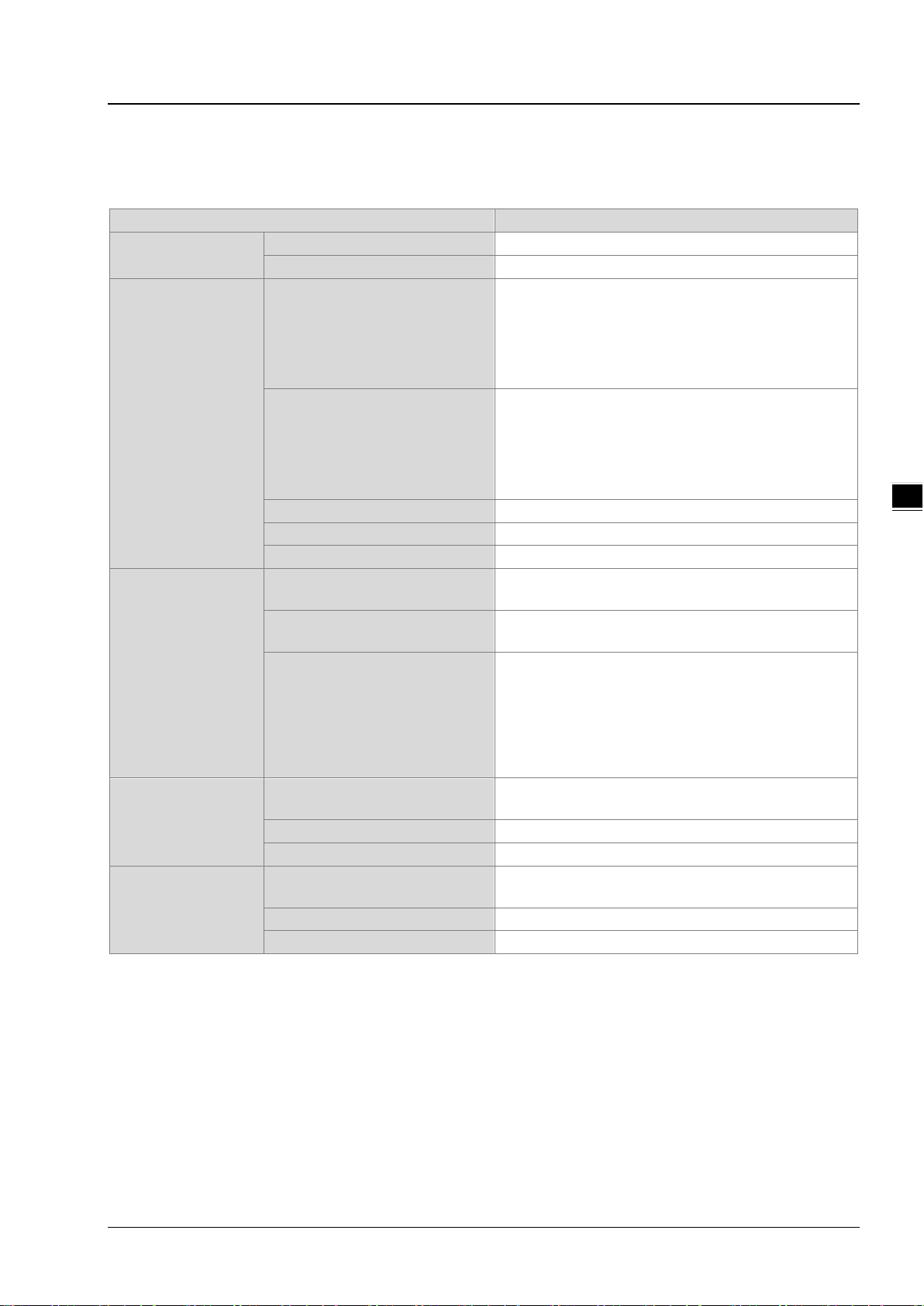

3.2 Ethernet/IP Specifications

Item

Specification

Category

Scanner / Adapter

Topology

Star

Requested Packet Interval (RPI)

1 ms~1000 ms

Max. Transmission Speed

10000 pps

Max. Data Length

500 bytes

servers from the UCMM type (for V2.1 or later version)

servers from the Class 3 (for V2.1 or later version)

Identity Object (16#01)

Ethernet Link Object (16#F6)

Connections

Max. Data Length

500 bytes

Requested Packet Interval (RPI)

1 ms~1000 ms

Connections

Max. Data Length

500 bytes

3.2.1 AHCPU5x1-EN/ AHCPU560-EN2

General

Max. Number of the CIP

Connections

Chapter 3 Product Specifications

AHCPU501-EN: 32 (Clients + Servers)

AHCPU511-EN: 64 (Clients + Servers)

AHCPU521-EN: 128 (Clients + Servers)

AHCPU531-EN: 256 (Clients + Servers)

AHCPU560-EN2: 256 (Clients + Servers)

CIP Network

I/O Connection

CIP Network

Explicit Message

CIP Network

Produced Tag

Max. Number of the TCP

Connections

Class 3 (Connected Type)

UCMM (Non-Connected Type)

CIP Objects

Max. Number of the CIP

AHCPU501-EN: 16 (Clients + Servers)

AHCPU511-EN: 32 (Clients + Servers)

AHCPU521-EN: 64 (Clients + Servers)

AHCPU531-EN: 128 (Clients + Servers)

AHCPU560-EN2: 128 (Clients + Servers)

Total 32 (Clients + Servers), in clud ing the cl ient s +

Total 32 (Clients + Servers) , including the clients +

Message Router Object (16#02)

Assembly Object (16#04)

Connection Manager Object (16#06)

Port Object (16#F4)

TCP/IP Interface Object (16#F5)

32 (Clients + Servers) (for V2.1 or later version)

Max. Number of the CIP

CIP Network

Consumed Tag

Requested Packet Interval (RPI) 1 ms~1000ms

32 (Clients + Servers) (for V2.1 or later version)

3-3

Page 20

EtherNet/IP Operation Manual

_3

Item

Specification

Category

Scanner /Adapter

Topology

Connections

Requested Packet Interval (RPI)

1 ms~1000 ms

Max. Transmission Speed

6400 pps

Max. Data Length

500 bytes

servers from the UCMM type

servers from the Class 3

Identity Object(16#01)

Item

Specification

Category

Adapter

Topology

Connections

3.2.2 AH10EN-5A

General

CIP Network

I/O Connection

CIP Network

Explicit Message

Max. Number of the CIP

Max. Number of the TCP

Connections

Class 3 (Connected Type)

UCMM (Non-Connected Type)

CIP Objects

Star, Linear, Ring

64 (Clients + Servers)

64 (Clients + Servers)

Total 32 (Clients + Servers), including the cl ients +

Total 32 (Clients + Servers), including the cl ients +

Message Router Object(16#02)

Assembly Object(16#04)

Connection Manager Object(16#06)

DLR Object(16#47)

QoS Object(16#48)

Port Object(16#F4)

TCP/IP Interface Object(16#F5)

Ethernet Link Object(16#F6)

Vendor specific object:

X Register(16#350)

Y Register(16#351)

D Register(16#352)

M Register(16#353)

S Register(16#354)

T Register(16#355)

C Register(16#356)

HC Register(16#357)

SM Register(16#358)

SR Register(16#359)

Control Register(16#370)

Input Register(16#371)

Output Register(16#372)

3.2.3 AHRTU-ETHN-5A

General

CIP Network

I/O Connection

3-4

Max. Number of the CIP

Max. Number of the TCP

Connections

Star, Linear, Ring

96

48

Page 21

Chapter 3 Product Specifications

3_

Item

Specification

Requested Packet Interval (RPI)

1 ms~1000 ms

Max. Transmission Speed

10000 pps

Max. Data Length

500 bytes

servers from the UCMM type

servers from the Class 3

Category

Product

Max. Transmission Spe e d (pps)

VFD-MS300 Series

(CMM-EIP01 communication card)

VFD-C2000 Series

CIP Network

Explicit Message

Class 3 (Connected Type)

UCMM (Non-Connected Type)

CIP Objects

Total 48 (Clients + Servers), including the cl ient s +

Total 48 (Clients + Servers) , including the clients +

Identity Object(16#01)

Message Router Object(16#02)

Assembly Object(16#04)

Connection Manager Object(16#06)

DLR Object(16#47)

QoS Object(16#48)

Port Object(16#F4)

TCP/IP Interface Object(16#F5)

Ethernet Link Object(16#F6)

Vendor specification object:

Status Register(16#370)

Input Register(16#371)

RTU AI Register(16#373)

RTU AO Register(16#374)

RTU DI Register(16#375)

RTU DO Register(16#376)

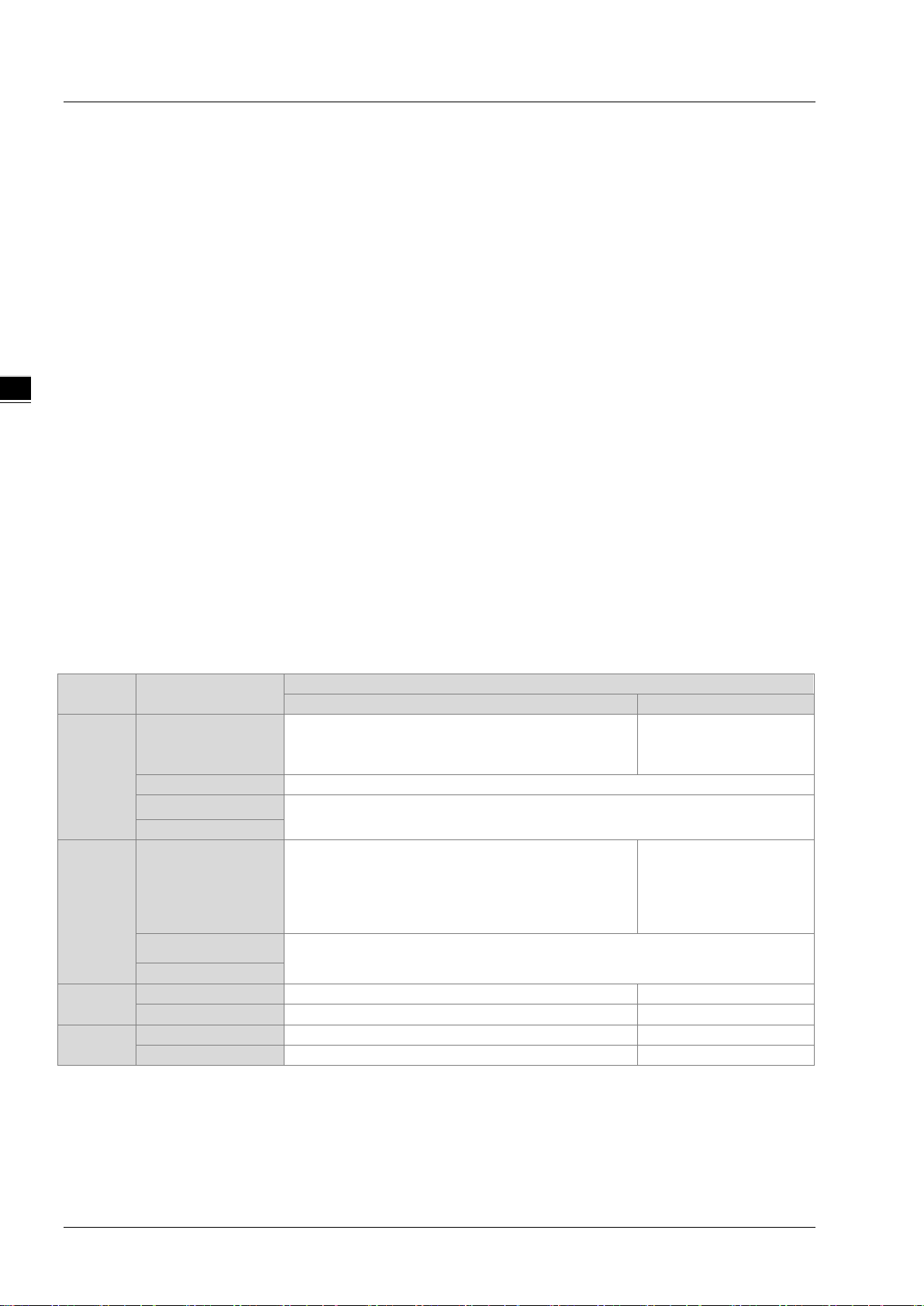

3.2.4 Maximum Transmission Speed of Delta Products

The EtherNet/IP transmission speed is expressed in terms of packets per second (pps). In addition, the actual

transmission speed is affected by the requested packet interval (RPI) and the scan time of the CPU as an EIP

scanner. Below is a list regarding the maximum transmission speed of Delta EIP products for your reference.

AHCPU5X1-EN Series, AHCPU560-EN2 10,000

AH10EN-5A 6,400

Mid-range PLC

Small PLC

AC Motor Drive

AHRTU-ETHN-5A 10,000

AH10EMC-5A 6,400

AS300 Series, AS200 Seri es 3,000

AS-FEN02 communic ati on c ard 10,000

DVPES2-E Series 16,00

DVP26SE 1,600

800

(CMC-EIP01 communication card)

800

3-5

Page 22

EtherNet/IP Operation Manual

_3

Method to Calculate CIP Connection

Adapter

Scanner

Limited to AHCPU and third-party host

2) Each AIO or NIO module uses 1 connection

Do not support

AH10EN-5A

Each data exchange group uses 1 connection

AHCPU560-EN2

1) If using A S series or a thir d -party as the host

uses 1 connection

Do not support

AS200

DVPES2-E

Each data exchange group uses 1 connection

Do not support

DVP26SE

Each data exchange group uses 1 connection

Do not support

CMC-EIP01

Each VFD uses 1 connection

Do not support

CMM-EIP01

Each VFD uses 1 connection

Do not support

3.2.5 Calculating CIP Connection

Users can refer to the EIP Builder data exchange page (see below) to find out the number of CIP and TCP

connections. The method for calculating the number of CIP connection is also listed below. .

Series Model

AHRTU-ETHN-5A

AH

AHCPU5x1-EN

AS-FEN02

AS

AS300

DVP

VFD

1) RTU + DIO uses 1 connection

1) Each data exchange group uses 1 connection

2) Execute instruction API2208 EIPRW uses 1 connection

CPU, RTU + DIO + AIO use 1 connection

2) If using AH ser ies as the host CPU, RTU +

DIO use 1 connection, each AIO module

1) Each data exchange group uses 1 connection

2) Execute instruction API2208 EIPRW uses 1 connection

3-6

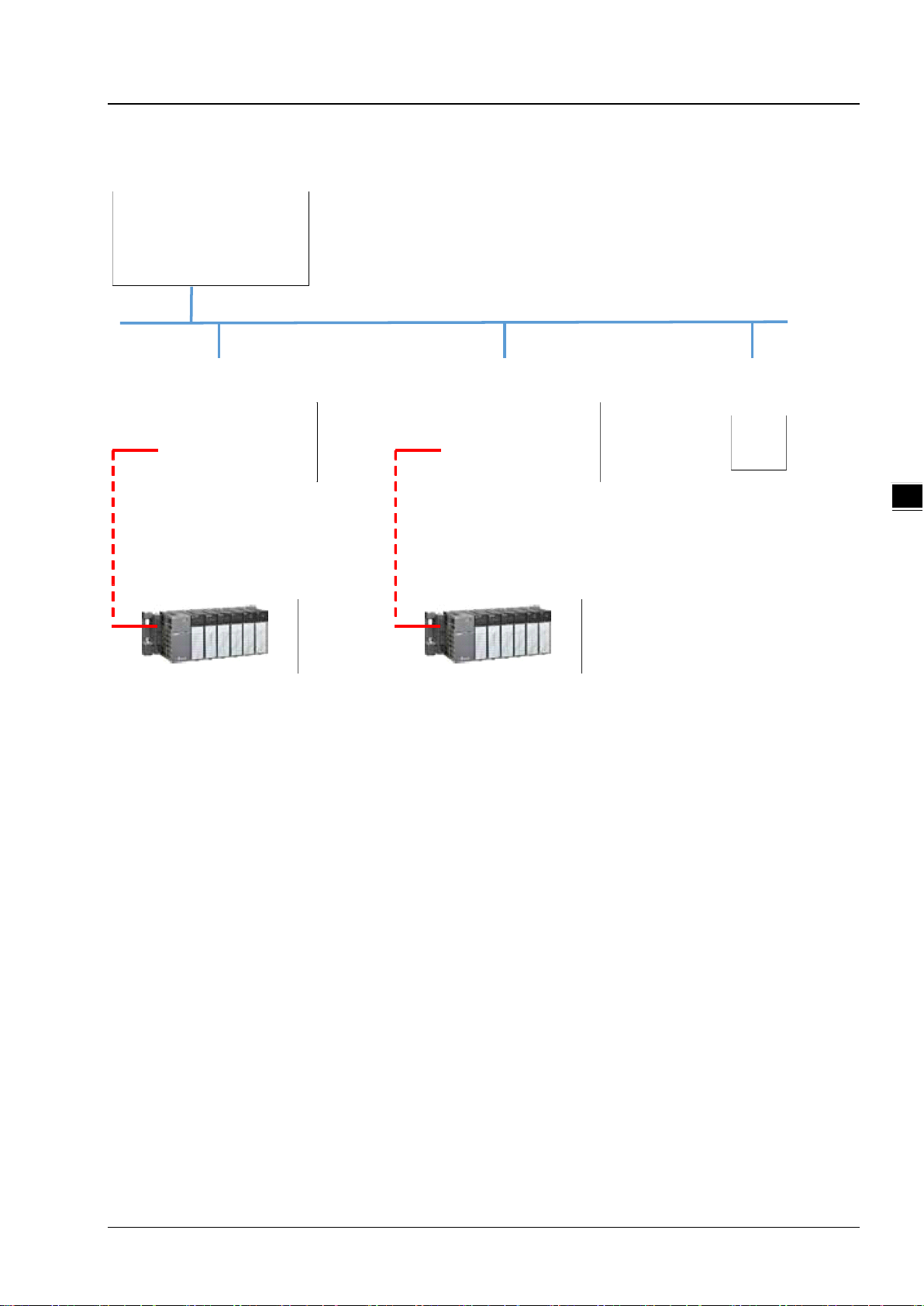

Page 23

Chapter 3 Product Specifications

3_

Long Range Communication

Station A

( AHRTU-ETHN -5A)

Module

Configuration:

AH16AM10N-5A X2

AH16AN01T-5A X2

AH06XA-5A X 3

AH10SCM-5A X 2

Long Range Communication

Station B

Module

Configuration :

AH16AM10N-5A X2

AH16AP11T-5A X 4

AH08DA-5A X 2

AH08AD-5A X 1

AS Series Host

CIP Connection Used

for Data Exchange: 5

AH Series Host

( Scanner )

Calculating CIP Connections:

1. Long Range Communica tio n Station A: 1 ( RTU+DIO)+ 3 ( AI /O)+ 2 (SCM)=6

2. Lon g Ran ge Communication Sta tion B: 1 RTU DIO 3 ( AI/O) = 4 ( + )+

3. AS Series Host: 5 (Connection Used f or Data Exchange)

=> Total of CIP C onnection U sed: 6+4 5 15= =

( AHRTU-ETHN-5A)

※ AH Series Host – Example of Calculating the number of CIP Connection:

3-7

Page 24

EtherNet/IP Operation Manual

_3

MEMO

3-8

Page 25

4

Chapter 4 EIP Builder

Table of Contents

4.1 Access EIP Builder ...................................................................................... 4-2

4.1.1 Setting Up EIP Scanner .............................................................................. 4-2

4.2 Set up the IP Address ................................................................................. 4-4

4.2.1 IP Address Types ....................................................................................... 4-4

4.2.2 Set up the IP Address (Static IP) ................................................................. 4-5

4.2.3 Set up the IP Address (BOOTP/DHCP) .......................................................... 4-6

4.2.4 IP Modification (BOOTP/DHCP) .................................................................. 4-11

4.3 Network ................................................................................................... 4-13

4.4 Data Mapping ........................................................................................... 4-23

4.5 Diagnosis ...................................................................................................4-28

4.6 AH Series – Connect to a RTU module ........................................................4-30

4.6.1 AHCPU5x1-EN Series/AHCPU560-EN2 ......................................................... 4-30

4-1

Page 26

EtherNet/IP Operation Manual

_4

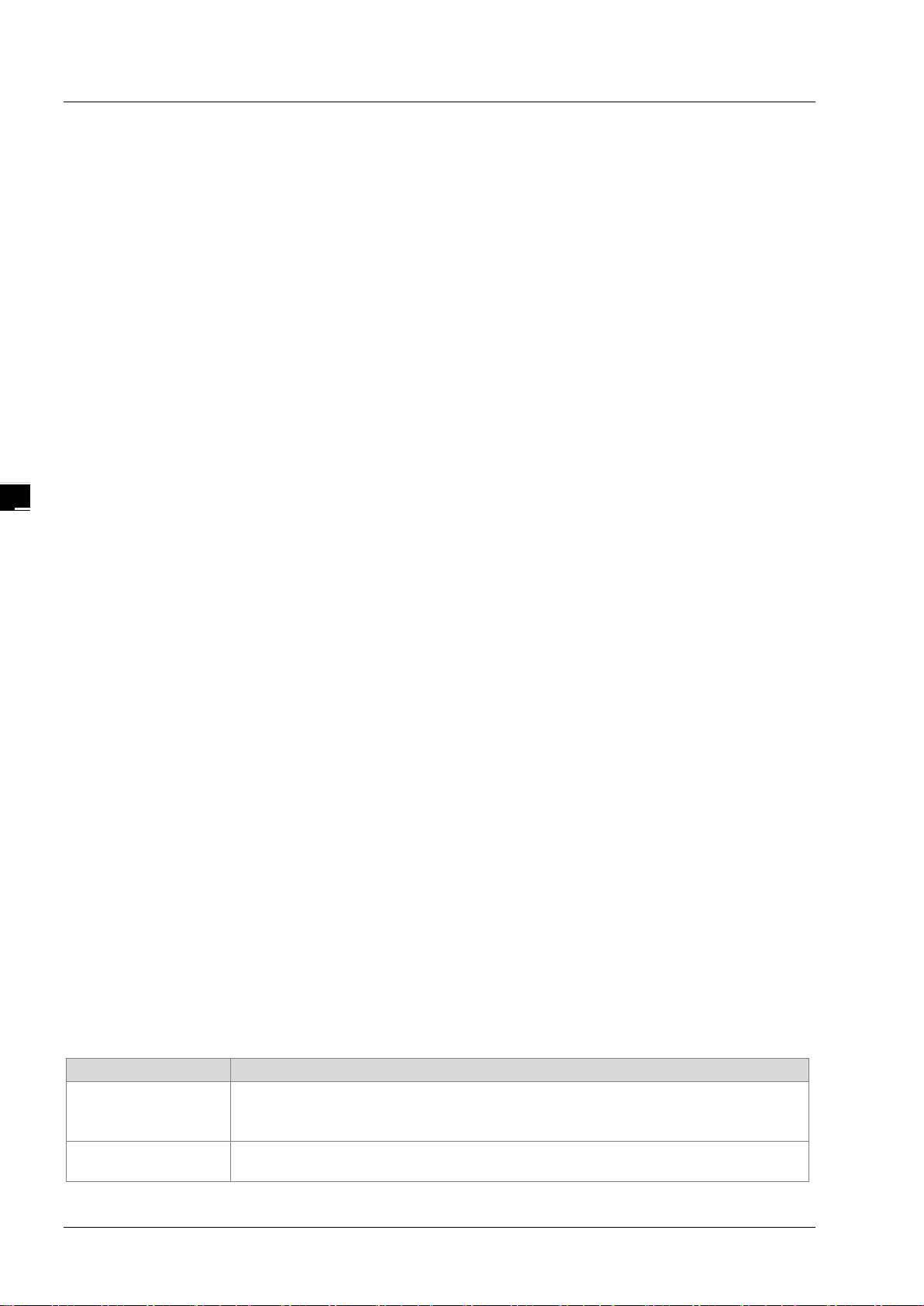

Open

ISPSoft V3 0.

Create

ISPSoft Project

Open

HWCONFIG

Download

HWCONFIG

Create

EIP Module

Y

EIP

PLC

Open

EIP Builder

Start

N

Delta EtherNet/IP software, EIP Builder, is embedded in the ISPSoft. It can be called or run independently

through the ISPSoft software (applicable with version 3.06 and later versions).

4.1 Access EIP Builder

The EIP Builder can be ca lled from Delta EIP Scanner’s HW CONFIG in the ISPSoft. It can also be called

independently to set up parameters for the Adapter. Delta EIP Scanner is equipped with the EtherNet/IP

communication PLC and the EtherNet/IP module. Refer to chapter 9.3 for a list of Delta EIP Scanner products

supported by the EIP Builder.

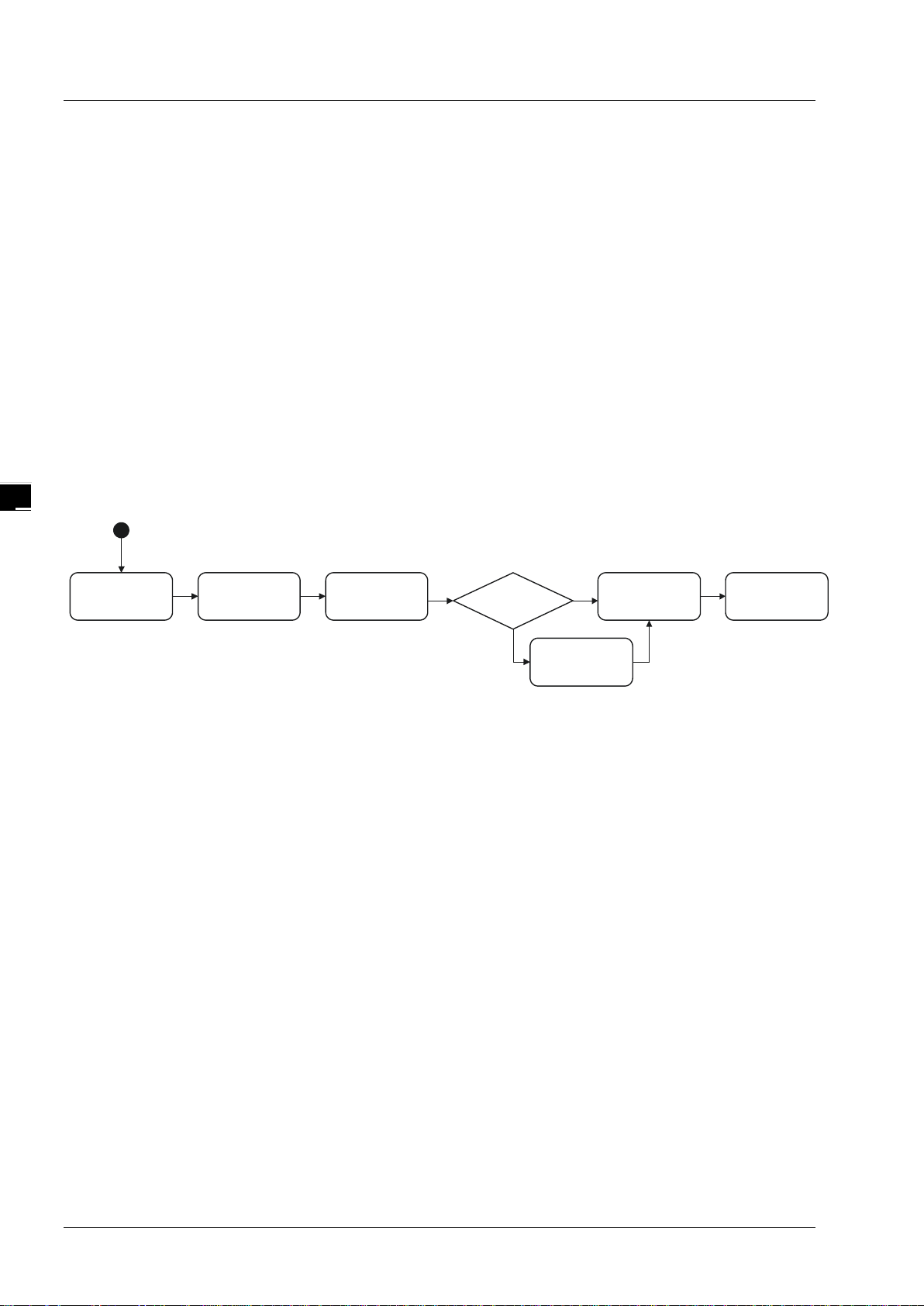

4.1.1 Setting Up EIP Scanner

Running Process

Run the EIP Builder via an EIP Sc an ner ( s ee be lo w). When using a Delta EIP Scanner, users need to set up

an EIP module through the HWCONFIG in the ISPSoft.

Operation Steps

1. Open ISPSoft : Find ISPSoft 3.06 from the start menu in Windows. Click the start menu and go to All

programs > Delta Industrial Automation > ISPSoft 3.06

4-2

Page 27

Chapter 4 EIP Builder

4_

2. Create a new project: Click File > New and you will see the Create a New Project window.

3. Select a PLC: Select a PLC product that supports the EIP builder in the Create a New Project window.

4. Open the HWCONFIG: Double click the HWCONFIG option under the Project.

5. Create an EIP module (AH10EN-5A):

Select the AH10EN-5A from the Network Module in the Product List.

Drag the selected AH10EN-5A to the CPU’s main backplane.

4-3

Page 28

EtherNet/IP Operation Manual

_4

Type of IP Address

Definition

for a network in which each host has a permanent network connection.

gateway, main computer name and the WINS server automatically.

6. Save and download the HWCONFIG:Click Save to save the HWCONFIG settings and then click

Download to PLC to download the file to PLC.

7. Open the EIP Builder:

7.1 Right-click the AH10EN-5A on the CPU’s main backplane and you will see the EIP Builder. Double

click it to open the EIP Builder.

7.2 Right-click the AHCPU5x1-EN on the CPU’s main backplane and you will see the EIP Builder.

Double click it to open the EIP Builder.

4.2 Set up the IP Address

This section will provide an overview of how to set up the IP address for AH10EN-5A IP and

AHCPU5x1-EN/AHCPU560-EN2. The IP address should be set up before configuring EIP related parameters

or data mapping settings.

4.2.1 IP Address Types

The AH10EN-5A series and AHCPU5x1-EN/AHCPU560-EN2 series supports 3 types of IP addressing,

BOOTP, DHCP and static IP address.

Via the TCP/IP Bootstrap Protocol (BOOTP) to set up the IP address, netmask and

BOOTP

DHCP

4-4

gateway. BOOTP server may require some configuration. The Bootp protocol is designed

Via the Dynamic Host Configuration Protocol (DHCP) to obtain IP address, netmask,

Page 29

Chapter 4 EIP Builder

4_

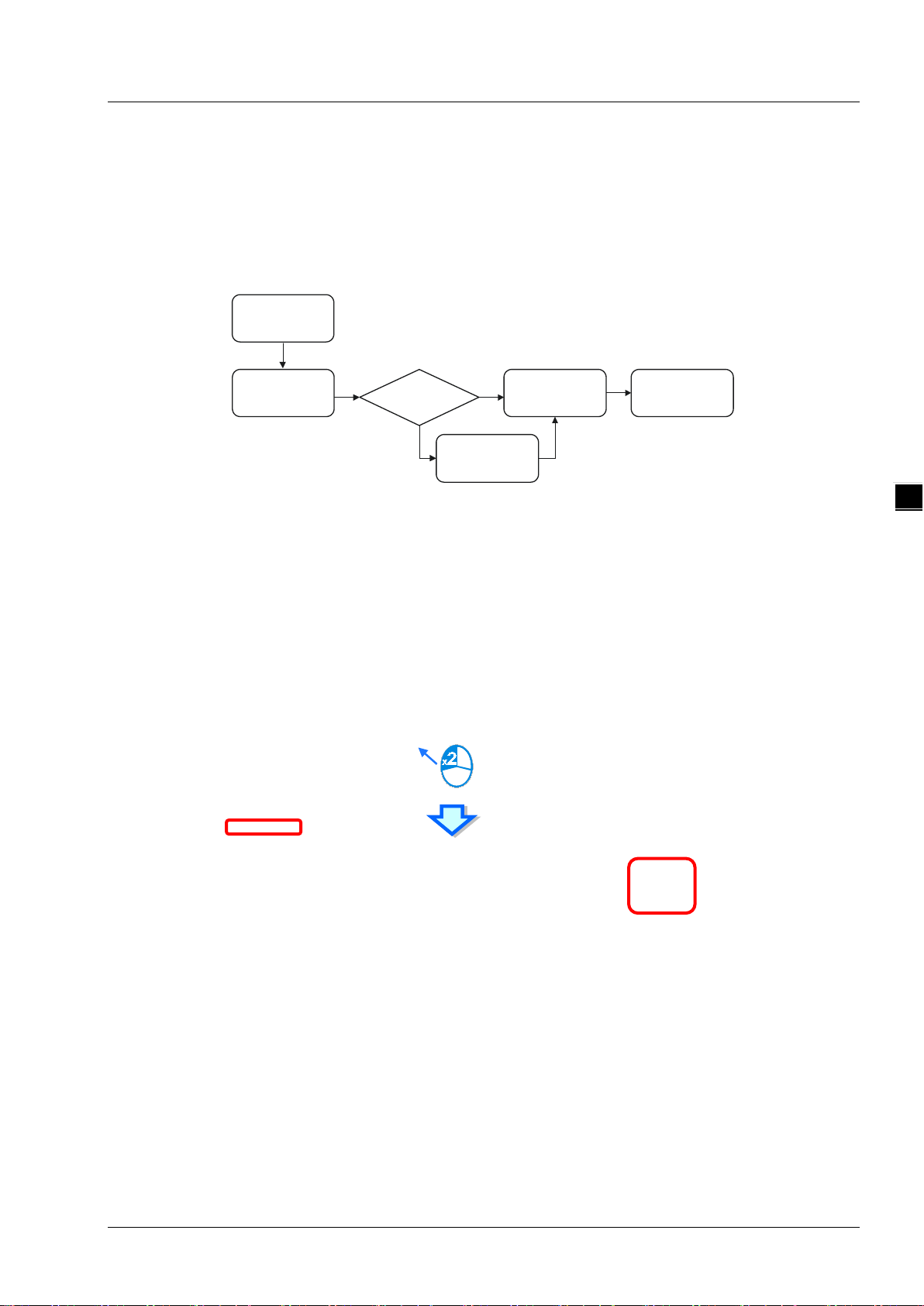

Create

ProjectISPSoft

Open

HWCONFIG

Set up

IP Address

Create

EIP M odule

Y EIP

PLC

N

Download

HWCONFIG

4.2.2 Set up the IP Address (Static IP)

Operation Steps:

When using an EIP product with a static IP address, users need to set up the IP address through the

HWCONFIG in the ISPSoft.

Refer to section 4.1.1 for how to set up an EIP module through the HWCONFIG in the ISPSoft.

1. Configure the network parameters

1.1 AH10EN-5A

Double-click the AH10EN-5A in the HWCONFIG to open the Parameter Setting page.

Set up the IP address under the Network Parameters node. Once the setup is done, click OK to leave

this page.

4-5

Page 30

EtherNet/IP Operation Manual

_4

Create

AddressMAC

Set up IP

Same I assign P

mode after e ach

power-on

Reset I assign P

mode after e ach

power-on

Y

Disable

BOOTP

N

Open

EIP Builder

Open

IP M anager

1.2 AHCPU5x1-EN

Double-click the AHCPU5x1-EN in the HWCONFIG to open the Parameter Setting page.

Set up the IP address under the Ethernet Basic tab. Once the setup is done, click OK to leave this page.

Save and download the HWCONFIG: Click Save to save the HWCONFIG settings and then click

Download.

4.2.3 Set up the IP Address (BOOTP/DHCP)

Operation Steps:

When using an EIP product with a BOOTP/DHCP IP address, users can set up the IP address through

the IP Manager in the EIP Builde

r.

4-6

Page 31

4_

Descriptions for the IP Manager:

1

2

3

4

7

6

8

9

10

5

Item

Definition

from the BOOTP/DHCP server.

name.

Clear List

Clear all the contents on the list.

New

Add new IP/MAC address.

Export

Export the IP/MAC address list; the file format is .CSV.

Enable BOOTP

Enable the BOOTP to assign an IP address for the selected item.

Enable DHCP

Enable the DHCP to assign an IP address for the selected item.

will not request for IP

addresses from the server.

Chapter 4 EIP Builder

Stop the Server

Network Settings

Delete Delete the selected item on the list.

Import Import the IP/MAC address list; the file format is .CSV.

Disable BOOTP/DHCP

Stop the BOOTP/DHCP server; the IP manager will not request for IP addresses

Set up the subnet mask, gateway, primary DNS, secondary DNS, and domain

Disable the BOOTP/DHCP on the device; the device

Operation Steps:

1. MAC address: find the MAC address on the EIP device as its unique identity.

4-7

Page 32

EtherNet/IP Operation Manual

_4

2. Open the IP Manager

Click the Tool tab of the EIP Builder and click to open the IP Manager setup page.

The IP Manager can be the BOOTP/DHCP Server, receiving IP address requests from devices.

4-8

Page 33

4_

3. Set up the IP address

Select and double-click the listed address to open the IP setup page.

Chapter 4 EIP Builder

Type the IP address.

4. Disable DHCP/BOOTP

Click to select the device in the Mapping Table that you’d like to disable its DHCP/BOOTP function and

then click the Disable DHCP/BOOTP button. After that the selected device will not send DHCP/BOOTP

requests. For the modification on the IP address receiving mode, refer to section 4.2.4 for more

information.

4-9

Page 34

EtherNet/IP Operation Manual

_4

Note

1. Enable BOOTP: When the IP address receiving mode is in BOOTP (BOOTP is enabled), the IP

address is assigned, and the device will send out BOOTP requests for IP addresses during each

power-on.

2. Enable DHCP: When the IP address receiving mode is in DHCP (DHCP is enabled), the IP address

is assigned, and the device will send out DHCP requests for IP addresses during each power-on.

3. Disable DHCP/BOOTP: When the IP address receiving mode is in BOOTP (BOOTP is enabled), the

IP address is assigned; once the Disable DHCP/BOOTP button is clicked, the device will not send

out DHCP/BOOTP requests for IP addresses during each power-on.

4-10

Page 35

Chapter 4 EIP Builder

4_

Open

HWCONFIG

Setup

parameters

Setup IP

receiving mode

Open

EIP Builder

Download

HWCONFIG

Open

IP Manager

4.2.4 IP Modification (BOOTP/DHCP)

To enable the DHCP or BOOTP function again, users will need to use the device software to make that

change. Take the AH10EN-5A series as an example, you will need to go to ISPSoft > HWCONFIG > IP

Manager. Open the IP Manager and set up the IP address receiving mode.

Operation Steps:

1. Refer to section 4.1.1 for how to open the HWCONFIG.

2. Set up the parameters: Enable the IP address receiving mode to BOOTP/DHCP.

2.1 AH10EN-5A

◆ Double-click the device you’d like to change its IP address receiving mode.

◆ You will see the option Network Parameters. Click this option to see the Network Parameters setup

page.

◆ Make changes on the items that you’d like to change their IP address receiving modes and click OK to

confirm the settings.

4-11

Page 36

EtherNet/IP Operation Manual

_4

2.1 AHCPU5x1-EN

◆ Double-click the device you’d like to change its IP address receiving mode.

◆ Set up the IP address under the Ethernet Basic tab.

◆ Make changes on the items that you’d like to change their IP address receiving modes and click OK to

confirm the settings.

3. Download the HWCONFIG

◆ Refer to section 4.1.1 for the related information.

4. Open the EIP Builder

◆ Refer to section 4.1.1 for the related information.

5. Open the IP Manager

◆ Refer to section 4.2.2 for the related information.

6. Open the IP setup page

◆ Refer to section 4.2.2 for the related information.

4-12

Page 37

Chapter 4 EIP Builder

4_

Add Device

(Scan Network)

Create Network

(Set u p Connection)

Set up Device

Settings

IP Manager

(Set up IP)

Add Devices

(Manually)

EIPBuilder

1

3

2

4

Item

Definition

Toolbar

Toolbar buttons

Network View

Display the connected devices and their connection status

Configuration Area

Set the parameters and display the configur ati on s

Product List

Display the available devices to be connected to EtherNet/IP

4.3 Network

The EIP Builder provides a graphical user interface; users can see the devices and their EtherNet/IP

connections in the Network View. This section will provide an over v iew of how to add your devices in and

build up the network connections. The procedure of the process is stated below.

Descriptions for the EIP Builder:

4-13

Page 38

EtherNet/IP Operation Manual

_4

Scanner

1

2

3

4

Device Name

Name for the device

The last digit of the IP address will be shown on the COM port.

network.

Toolbar

Icon Name Definition

New Create a new EIP Builder project

Open Open an existing project

Save Save the project

Scan Network Scan the network for device availability

Check Check if the project is planed nicely

On-line Mode Switch to on-line mode

Uploader Upload

Downloader Download

Setup Button

Open the communication setting; set up the path connecting the PC to the EIP

Network View

Station Name Name for the station

Ethernet COM Port

Name Definition

Display the number of devices with Ethernet communication ports.

Network_0

Display connection status; devices on the same line indicate they are in the same

Configuration Area

Refer to section 4.3.3 for more information.

4-14

Page 39

4_

Product List

2

1

Name

Definition

the system.

1

3

2

Name

Definition

Selection checkboxes

Tick to select the devices you’d like to add to the network view

Refresh

Refresh to scan the network again

Join

Add the selected device to the network view

Chapter 4 EIP Builder

Se arch Bar

Product List

Scan Network

Type the module name t o s ear ch; when nothing found, that m eans th er e is n o E DS file in

Categorize the devices according to the definition of the EtherNet/IP; for devices from

rd

the 3

party will be put in the Others folder.

4-15

Page 40

EtherNet/IP Operation Manual

_4

(a)

(b)

(c)

Operation Steps:

1. Add new devices in (scan the network): Click the setup button to bring out the communication

set up page.

Once your PC is connected to the EIP Scanner, there are 3 ways to set up the network

communication.

(a) Select the created Driver: Select the created driver from the COMMGR Driver drop down list.

(b) Edit the created Driver: Click the setup button in the Common Setting section to bring out the

Driver Properties to edit.

(c) Add a new Driver: Click the setup button+ in the Common Setting section to bring out the

Driver Properties to add new Driver.

4-16

Page 41

Chapter 4 EIP Builder

4_

Driver Properties

Click the Scan Network button, the EIP Builder will scan the network and list the scanned devices in

the Device List.

4-17

Page 42

EtherNet/IP Operation Manual

_4

Tick to select the devices you’d like to add to the Network. After that, click Join to add the selected

devices.

2. Add devices (Manually) : Select the devices you’d like to add from the Device List; you can also type in

the module name in the search bar. After that drag the device you’d like to add to the network view.

3. Create Network

Drag the Ethernet communication port of the device to the network to create connection.

4-18

Page 43

4_

Create network connections for the devices.

Chapter 4 EIP Builder

Once the connection is established, click the network line “Network_0”, you will see all the

connected devices in this network.

4-19

Page 44

EtherNet/IP Operation Manual

_4

4. Set up the parameters

Click tabs of the Information, EIP parameter and the EDS Parameter to see and edit the parameters

respectively.

(a) Information Tab

This tab contains information regarding Module Name, Version, Rack, Slot, Slot, IP address, Mask,

Network and Data mapping Setting.

(b) EIP Parameter Tab

This tab contains information regarding parameters in the EDS file. When Off-line, users can only check

the connection parameters for setting up the EDS filtering rules.

Disable Keying: Disable checking on the product information and its versions.

Compatible Keyi ng: Checking if the product information and its master version are matched;

as for the minor version, check for its compatibility.

Exact Match: Checking if the product information, its master version and minor version are

matched.

While the device is connected, you can click the upload button to upload the related parameters back to the

device.

4-20

Page 45

Chapter 4 EIP Builder

4_

Name

Definition

Fault, Internal State, Configuration Status, and Module Identity.

Compatible Keying, and Exact Match.

Hardware Fault.

Status, Ring Supervisor, and Active Supervisor Precedence.

(c) Identification: Display information regarding Vendor, Product

①

Module Status

②

IP Setting

③

Connection

④

Port Status

⑤

Device Level Ring (DLR)

Type, Product Name, Revision, etc.

(d) Status: Display connection status, including Major Fault, Minor

Port1: Indicating port 1 of the device, for editing configurations

of the IP Address, Subnet Mask, Gateway Address, and Host

Name.

Remark: When there is a Port2, that means there are 2 Ethernet

communication ports.

EDS parameters filtering rules include Disable Keying,

Display Link Status, Speed, Duplex, Negotiation Status and

Display DLR information includes Network Topology, Network

4-21

Page 46

EtherNet/IP Operation Manual

_4

(c) EDS Parameter Tab: this is not supported on the AH10EN-5A series.

4-22

Page 47

Chapter 4 EIP Builder

4_

Download

Data Exchange

Data Exchange

Set up

Data Exchange

Table

Network View

1

2

3

4

7

6

8 9

5

10

Name

Definition

number is 64.

Enable

Enable / Disable the data mapping function

beforehand

to select the device’s IP address to add and edit the connection.

how to change the device name.

CPU Address

Start address of the data mapping’s register

modules)

page.

If TAG is selec ted

Consumed TAG can be selected from the drop-down list

Adapter Address/Parameter

Target adapter’s register address / parameters

is the same as TAG in .

4.4 Data Mapping

When the connection between devices is established, users can use the data mapping function to exchange

data between devices. This section will provide an overview of how to create a data mapping table.

Descriptions for the Data Mapping:

Connection Count

TAG

Data mapping connection count; each row represents one

independent EtherNet/IP connection. The number of connections

cannot exceed the maximum connection number that the Scanner

supports. For the AH10EN-5A series, the maximum connection

Use TAGs created to execute data mapping; after selected, this

function is enabled and

read only ()

registers are not available for the row selected

the leghth cannot be modified

comsumed TAG should be created in ISPSoft global symbols

IP Address

Adapter Name

Scanner’s register address +

address offset (EtherNet/IP

If TAG is selected

I/O Mapping Table

The IP address of the Adapter that you’d like to connect to. After the

data mapping connection is established, the system will load the

connected device’s IP address. Users can also use the drop down list

Once the IP address is selected, its name will be displayed but cannot

be modified here. Refer to section 4.3 for more information on

Actual represented register = starting register address + address

offset; starting register address can be set on the HWCONFIG setup

Input the Produced TAG of the EIP to be connected; the default name

Set up the IN/OUT parameters; when there is no I/O representative

table presented for the Adapter, they cannot be opened, for example

some PLCs.

4-23

Page 48

EtherNet/IP Operation Manual

_4

Name

Definition

Length

Set up the data mapping length; unit: byte, the maximum is 500 byte.

Property

Set up the advanced data mapping parameters.

Name

Definition

might have different mapping parameters.

Name to open the mapping table to edit.

Name to open the mapping table to edit.

mapping table to edit.

written to the Adapter.

1

2

3

4

I/O Mapping Table

Delta EIP devices provide I/O mapping table. If needed, users can use the table to edit the parameters.

Connection

In

Out

Select the connection from the drop down list. Different connection

Input the mapping parameters. The column No. states the maximum

number of mapping parameters to input. Double-cli ck the col umn

Output the mapping param eters. The column No. states t he maximum

number of mapping parameters to output. Double-click the column

Name

Value

Property

The parameter name; double-click the column Name to open the

Values; after editing and downloading the values will be stored in the

Scanner. When the connection is established, the values will be

4-24

Page 49

Chapter 4 EIP Builder

4_

Name

Definition

exchange data at regular time intervals, unit: ms

Multicast

Communication mode setup: M ult icast or Point-to-Point

multiple of RPI (RPI*X).

Application: renew data according to the product setup

Data Mapping Tab

Network_0 Data Mapping Table

Requested Packet Interval (RPI)

Timeout

Trigger Mode

RPI setup: via the I/O connection to connect to EtherNet/IP to

Timeout setup; set up the timeout time according to the RPI or the

Trigger Mode: Cyclic, Change of State, and Application

Cyclic: renew data cyclically

Change of State: renew data once there is any change

Operation Steps:

1. Create a data mapping table (※):

Click to select the Scanner Ethernet COM port that you’d like to perform the data mapping and then

right-click to see the options. Click Data Exchange to open the Data Mapping Table.

After the selection is made, the system will create a Data Mapping Tab, shown as Network_0.

4-25

Page 50

EtherNet/IP Operation Manual

_4

2. Set up the Data Mappi ng Par ameters

Type the parameters in the data mapping table

a) See the example of reading the D500~D599 of the Adapter with the IP address 192.168.1.2 to

the D10000~D10099 of the Scanner below.

b) See the example of writing the D20200~D20299 of the Scanner to the D100~D199 of the

Adapter with the IP address 192.168.1.1

Use TAG in data mapping

a) Add a General Device in the network and select the IP address of the Produced TAG of the

device to be connected. For adding devices in the network, please refer to section 4.3 for more

information.

4-26

b) The data mapping page

Page 51

Chapter 4 EIP Builder

4_

c) Select TAG to have this function enabled. And after this function is enabled, the attributes is

read only ().

※ Users can also select TAG and then input the IP address directly to connect to TAGs from other

devices. In this case, there is no need to create a connection to Gerneal Device.

d) Users can use the drop-down list of the CPU Address /TAG to select the already created

Consumed TAG.

After the TAG function is selected, the system will input data in the columns of Adapter register

e)

address, parameter, and address of the TAG with the same name. Users can also edit the data

in the columns. Make sure the TAG name is the same as the Produced TAG of the EIP to be

connected

.

Set up property

a) Click the Property to set up.

b) Type the data mapping parameters

Set the Requested Packet Interval (RPI) to renew the data between the Scanner and Adapter

cyclically, for example every 20ms.

4-27

Page 52

EtherNet/IP Operation Manual

_4

Data Mapping Tab

Network View

3. Download

Click Downloader on the tool bar to open the download window.

Selecting the Scanner communication port of the EIP Builder; every communication port can

download a data mapping table.

4.5 Diagnosis

The EIP Builder can provide the diagnosis on the connection and data mapping status. For the connection

status, refer to Adapter connection status and indicator in the Network View tab and for data mapping status

and error codes, refer to Network_0, the data mapping tab.

4-28

Page 53

4_

Operation Step

Status Indicator

Network View

1. Click the On-line Mode on the toolbar.

2. Network View (Connection Status):

a) Click the Network View tab to check the device status from the indicators, for example RUN /

STOP and Error indicators on the PLC.

Chapter 4 EIP Builder

b) The dotted line and the warning sign indicate connection error, as the image shown below.

Network_0 (Data Mapping):

a) Click the On-line Mode on the toolbar.

4-29

Page 54

EtherNet/IP Operation Manual

_4

Open

ISPSoft

Delta

EIP

Scanner

Y

Open

EIP Builder

N

HWCONFIG

Setups

EIPBuilder

RTU

HWCONFIG

Download

RTU

HWCONFIG

Software

…

Download

to AHRTU

Import

EDS file

b) Click the Network _0 to check the data mapping status and the error codes. For error code

definition, refer to section 6.2.

4.6 AH Series – Connect to a RTU module

This section will provide an overview of how to connect the Delta AH series EtherNet/IP RTU modules such

as AHRTU-ETHN-5A to Delta EIP Scanner and EIP Scanner from other brands. Seet the operation steps

.

below

4.6.1 AHCPU5x1-EN Series/AHCPU560-EN2

AHCPU5x1-EN series with f irm ware vers ion lat er than V2.0 0 and AHCPU560-EN2 supports EtherNet/IP.

Users can connect to Delta AHRTU-ETHN-5A modules via EtherNet/IP. Once the settings are done, users

can use the devices X, Y and D in AHCPU5x1-EN series and

I/O modules connected to AHRTU-ETHN-5A.

Running Process:

AHCPU560-EN2 to control digital and analog

Open EIP Builder and add the module AHRTU-ETHN-5A in the Network View. Open HWCONFIG to set up

digital and analog I/O modules of AHRTU-ETHN-5A.

4-30

Page 55

Chapter 4 EIP Builder

4_

Open

ISPSoft

Delta

EIP

Scanner

Y

HWCONFIG

Setups

EIPBuilder

RTU

HWCONFIG

Download

Operation Steps:

1. Refer to section 4.1 for more information on HWCONFIG in ISPSoft and EIO Builder.

EIP Builder

Add the module AHRTU-ETHN-5A in the Network View and create a connection to the CPU for data

mapping.

2. Double-click the AHRTU-ETHN-5A module to open HWCONFIG.

4-31

Page 56

EtherNet/IP Operation Manual

_4

Name

Description

1

Information: Rack 1

Information of the rack 1

2

Slot number

Slot number of rack 1 (power module and AHRTU module are excluded)

3

Label

Module Name

4

MDS Version

Device firmware version

5

Description

Device description

6

Input Device Range

The input devices assigned to a module are displayed here

7

Output Device Range

The output devices assigned to a module are displayed here

RPI setting value; unit: mm

according to the RPI time set for the AHRTU-ETHN-5A.

9

Multicast

Communication mode setup: M ult icast or Point-to-Point

Timeout setup; set up the timeout time according to the RPI or the

multiple of RPI (RPI*X).

11

Trigger mode

Renew data according to the set RPI time

12

Connection type

Owner or Listen only

R TU

HWCONFIG

Download

Set up

parameters

Add

I/O module

Descriptions for the EIP Builder:

8

10 Timeout

Requested Packet Interval

(RPI)

Operation Steps:

Only analog I/O modules and special modules need to set the RPI time

to renew data; for other digital I/O modules, data can be re ne wed

4-32

Page 57

4_

1. Add an I/O module

Chapter 4 EIP Builder

Add the I/O modules according to the real placement by dragging the modules on the left hand side to the

right side of the RTU module. Make sure the slot assignment is the same as the real placement.

2. Setting parameters

The sy stem automatically assigns devices to a module so that the data in the module can be stored.

The devices assigned to a module are displayed in the Input Device Range cell and the Output

Device Range cell.

Click the … in the “Input Device Range” and “Output Device Range” column to edit the ranges.

4-33

Page 58

EtherNet/IP Operation Manual

_4

RPI setting value; unit: mm

Only analog I/O modules and special modules (for example AH04AD-5A) need to set the RPI time to

renew data. For other digital I/O modules, data can be renewed according to the RPI time set for the

AHRTU-ETHN-5A and values in this column cannot be modified in Network_0 tab.

After the setup is done, the detailed connection information of the ARTU-ETHN-5A modules will be

added in the data mapping tale. Data in the table cannot be modified here.

Parameters for special modules can be seen in the RTU HWCONFIG. Double-click the module in

the Network View tab to open the RTU HWCONFIG and check the corresponding device address in

the Normal Exchange Area tab.

4-34

Page 59

Chapter 4 EIP Builder

4_

3. Download

Save: after the parameters are set, click the Save button to save the parameters.

A warning window will appear if the changed settings have not been saved.

Download: Click the download icon to download.

4-35

Page 60

EtherNet/IP Operation Manual

_4

Tick the Seclt All option or select the module one by one to download the data mapping table.

4-36

Page 61

5

Chapter 5 Programming

Table of Contents

5.1. DFB_EIP_EXP Fu nction Bl ock ........................................................................ 5-2

5.1.1 Parameters .................................................................................................... 5-2

5.2. TAG Function ................................................................................................. 5-7

5.2.1 Produced TAG ............................................................................................ 5-7

5.2.2 Consumed TAG .......................................................................................... 5-9

5-1

Page 62

EtherNet/I P Operation Manual

_5

All connections in EtherNet/IP can be divided into explicit messaging connections and implicit (or I/O) messaging

connections. Explicit messaging us es TCP/IP and r equest/response communic ations procedure or c l ient/serv er

connection, requiring that the memory location of the information to be sent to the client be defined in the instruction it self.

Implicit messaging uses UDP/IP and is when a server sends informa t ion from p re defined memory locations to a client at a

given interval, using a requested packet in terval (RPI) parameter to sp ecify t he rate a t which data updates.

5.1. DFB_EI P_EXP Function Block

See the DFB_EIP_EXP function block below. Refer to the section 9.8 for objects that are supported by AH10EN-5A. For

using slaves via the AH10EN-5A, refer to the slave manual for related information on Objects.

When the AH10EN-5A acts as sc anners for EtherNet/IP, users can use the func t ion blo ck DFB_EIP_EXP to read/write the

objects of the adapters. When the EIP builder uses Objects as its parameters, every Object has various parameters.

The parameter unit is Attribute and the read/write path is ClassInstanceAttribute.

5.1.1 Parameters

The meaning of each parameter in the function blocks are stated below.

Name Description Data Type

When the execution bi t turns from Of f to On, th e function blo ck will be

Execute (Execution B it)

BID (Backplane number) The backplane number of the scanner module: 1 WORD

SID (Slot number) The slot num ber of the scann er m odule:0-11 WORD

PID (Port number) Assigned Ethernet P ort for the scanner module WORD

IP1 (IP address 1)

IP2 (IP address 2)

executed and will send out an explicit message. When the operation is

complete, the Done bit will be On. While an error occurs, a n Error bit will

be On, and an error code will be shown in the ERRCode.

This param eter is used to as sign th e first t wo IP addresses of the

adapter for the assigned scanner to read/write.

Example: IP = 192.168.1.5, IP1 will be writt en as 16#C0A8.

This param eter is used to as sign th e last two IP addr esses of t he

adapter for the assigned scanner to read/write.

Example: IP = 192.168.1.5, IP2 will be written as 16#0105.

BOOL

WORD

WORD

5-2

Page 63

5_

Setups for the explicit message connection:

0: UCMM: do not crea te a CIP connection.

Chapter 5 Programming

Mode

SerCode (Serv ice Code)

ClassId (Class number)

InstId (In s tance number)

AttrId (Attribute number)

1: Connected then close conn; after the transmission is done, close the

connection.

2. Connected then keep conn; after t he transmission is done, keep the

connection.

EtherNet/IP standard service code is similar to the function code. The

service codes specify the actions going to take. Delta products support

the follo w ing service codes.

0x01 – read every At trib ute;

0x0E – read a single one Attribute;

0x05 – reset from th e adapter;

0x10 – writ e a single one Attribute

Attribute is the basics of the EtherNet/IP, used for identifying

configurable parameters (Class) within a device.

Attribute is the basics of the EtherNet/IP, used for identifying

configurable parameters (Instance) within a device.

Attribute is the basics of the EtherNet/IP, used for identifying

configurabl e parameters (Attribute) within a devi ce.

WORD

WORD

WORD

WORD

WORD

If the scanner wants to write a parameter data to the adapter, the

parameter type s hould be also wr itten i n. The uni t for this parameter is

Size (Parameter t ype)

Data (Starting value)

Don (Completion bit ) W hen the operation is complete, the Don bit will be On. BOOL

Error (Error bit )

ErrCode (Error code)

Value (Return Data)

byte. When the Size is 1, it means the parameter type is BYTE . When

the Size is 2, it means the parameter type is WORD. When the Size is 4,

it means the parameter type is DWORD.

If the scanner wants to write a parameter data to the adapter, the

paramet er to be written c an be typed or can use the st artin g r egist er

address. The scanner will send the values in the Data to the adapter.

The Data leng th is determi ned by the Size. The storing order of the

values in the Data wi ll be little-endian first and then big-endian. If

Data=D0, Size=4, the D0 little-endian will be stored fi rst and t hen the D0

big-endian, D1 l i ttle-endian and then D1 big-endian.

Whi le an error occurs, an Error bit will be On, and an error code will be

shown in the ERRCode.

Error codes (refer to the following table)

16#00 indicates a successful communicatio n.

After th e function blocks are executed successfully, the AH10EN-5A will

put the rea d value to the parameter assi gned registers, low by tes first

and the high bytes.

WORD

WORD

BOOL

WORD

WORD

5-3

Page 64

EtherNet/I P Operation Manual

_5

Errors

The meaning of each error code in the function blocks are stated below.

Error

Code

16#01

16#02

16#03 Invalid parameter value The typed value is not in the parameter service range.

16#04

16#05

16#07 Connection lost The messaging connection was lost.

16#08

16#09 Invalid attribute value Invalid attri bute data detec ted

16#0E Attribute not settable A request to modify a non-modifiable attrib ute was receiv ed.

Connection failure A connection related service fai led al ong the c onnection

Resource unavailable Resources needed for the objec t to perform the requested

Path segment error The p ath segment identif ier or t he segment synt ax was not

Path destination unknown The p ath is referencing an object cl ass, instance or structure

Service not supported The requested service was not implemented or was not

Error

Description

path.

service were unavailable

understood by the processing node.

element that is not known or is not contained in the

processing node.

defined f or this Object C l ass/Instance.

16#10

16#11 Reply data too large The data to be transmitted in the response buffer is large

16#13

16#14 Attribute not supported The attribute specified in the request is not supported

16#15 Too much data The service supplied more data than was expected

16#16 Object do es not exist The object specified does not exist in the device.

Example 1: using UCMM to read the m anufac turer code of the IP address 192.168.1.10

Manufacturer code: ClassId=1, InstId=1, AttrId=1

The parameters in the function blocks are as below:

BID 16#01 Backplane 1

SID 16#01 Slot 1

Device state conflict The device’s current mode/state prohibits the execution of

the requested ser vice.

Not enough data The service did not supply enough data to perform the

specified operation

Input

Parameter Value Description

PID 16#01

IP1 16#C0A8 IP address: 192.168.1.10

5-4

Page 65

Chapter 5 Programming

5_

IP2 16#010A

Mode 16#00 UCMM

SerCode 16#0E Read/ write a single one att ribute service

code

ClassId 1 Class ID = 1

InstId 1 Instance ID = 1

AttrId 1 Att r ibute ID =1

Size No need to set up No need to set up

Data No need to set up No need to set up

When the function blocks are executed successfully, the output parameters wi ll be st ated as below.

Output

Parameter Settings Description

Don ON (16#01) Complete

Error No output No error

ErrCode 16#00 No error

Value 16#031F Delta’s manufacturers code

When the function blocks are not executed s uccessfully, the ou tput pa rameters will be stated as below.

Output

Parameter Settings Description

Don No output No output

Error ON (16#01) Error

ErrCode 16#07 Connection lost

Value No output No output

Example 2: Create a CIP conn ection and change the parameter value of the node 192.168.1.10 to 16#01. Close the

connection after the transmission is done.

Parameters: ClassId= 16#9D, InstId= 2, AttrId= 1

The parameters in the function blocks are as below:

Input

Parameter Settings Description

BID 16#01 Backplane 1

SID 16#01 Slot 1

PID 16#01

5-5

Page 66

EtherNet/I P Operation Manual

_5

IP1 16#C0A8 IP address: 192.168.1.10

IP2 16#010A

Mode 16#01 Create a CIP connection and close the

connection after the transmission is

done.

SerCode 16#10 Write a single one Attribute

ClassId 16#9D Class ID = 9D

InstId 16#02 I nstance ID = 2

AttrId 16#01 Attribute ID =1

Size 16#02 Target parameter type: 2Bytes

Data 16#01 Parameter value: 16#01

When the function blocks are executed successfully, the output parameters wi ll be st ated as below.

Output

Parameter Settings Description

Don ON (16#01) Complete

Error No output No error

ErrCode 16#00 No error

Value No output No output

When the function blocks are not executed successfully , the out put par ameters will b e stated as below.

Output

Parameter Settings Description

Don No output No output

Error ON (16#01) Error

ErrCode 16#0E Cannot write the attribute

Value No output No output

The Error bit is On and the ErrCode=16#1401 (The I/O module appears to have an read/write error.)

Don and Value are shown with no output. No other FBs are used.

5-6

Page 67

Chapter 5 Programming

_

5.2. TAG Function

Users can use TAG function to transmit data among different controllers. Controllers can share TAGs while

they are attached to the same network, such as EtherNet/IP. TAG can be further defined as Produced TAG

and Consumed TAG.

1. Produced TAG: a tag that a controller makes available for other controller. Multiple controllers (EIP

scanner devices) can simultaneously consume (receive) the data. A produced tag sends its data to

consumed tags (consumers) without using logic.

2. Consumed TAG: a tag that receives the data of a produced tag. The data type of the consumed tag and

the produced tag must be matched (including any array dimensions).

Before connecting to a Produced TAG, users should check the IP address and the names of the TAGs

(Prodeuced TAG and Consumed TAG). One controller can have multiple TAGs created, including produ ced

TAG and consumed TAG. See the example below:

Produced TAG

Produced TAG 1

Produced TAG 2

Consumed TAG 1

Consumed TAG 2

Consumed TAG

Consumed TAG

Produced TAG

Scanner of other brand

5.2.1 Produced TAG

How to create a Produced TAG:

1. Open the ISPSoft software and unfold the Global Symbols item to see the EtherNet/IP Table (Produced

TAG) and EtherNet/IP Table (Consumed TAG). Double click the EtherNet/IP Table (Produced TAG).

5

5-7

Page 68

EtherNet/I P Operation Manual

_5

Identifier

Status

Address

D100

Type

WORD

Initial Value

--

Comment

PLC Running Status

2. After double clicking the EtherNet/IP (Produced TAG) option, the EtherNet/IP Table (Produced TAG) will

show up for editing.

3. Right click on the EtherNet/IP Table (Produced TAG) to see the context menu and select the option “Add

a Symbol”. And then an Add Symbol window will appear .

4. Set up the Produced TAG: as the example shown below.

After the setups are compl ete, download the parameters to the PLC. Other controllers can receive the data of

a produced tag via the consumed tag. For the creation of a consum ed TAG, r efer to the manual from the

controller to be used for data transmison.

5-8

Page 69

Chapter 5 Programming

5_

5.2.2 Consumed TAG

How to create a Produced TAG:

1. Open the ISPSoft software and unfold the Global Symbols item to see the EtherNet/IP Table (Produced

TAG) and EtherNet/IP Table (Consumed TAG). Double click the EtherNet/IP Table (Consumed TAG).

※ It is only available for PLC with the EtherNet/IP TAG function. Refer to chapter 3 for EtherNet/IP

specifications to learn the supported models and number of TAGs suppored.

2. After double clicking the EtherNet/IP (Consumed TAG) option, the EtherNet/IP Table (Produced TAG) will

show up for editing.

5-9

Page 70

EtherNet/I P Operation Manual

_5

Identifier

Freq

Status

Address

D100

D100

Type

WORD

WORD

Initial Value