Page 1

Product Application

Industrial Automation BU, Delta Electronics, Inc.

Case

Issued by Solution Center Date November, 2010 Pages 5

Applicable to C2000 series AC motor drive, AFE2000 series active front-end unit

Key words

Introduction

A bridge crane (also known as an overhead travelling crane) finds wide application in warehouses, factories,

docks, open storage yards, and more. A three-phase induction motor offers many benefits including simple structure,

durability, low cost, and easy maintenance. If we employ a Delta AC motor drive to drive the induction motor rather

than using a traditional drive, the crane’s malfunction rate decreases substantially. Moreover, if Delta’s AFE2000

series active front-end unit is employed, it saves the cost of purchasing a brake resistor and excessive energy is

transformed into reusable energy through IGBT switch, which is fed back to the mains for other electronic devices.

Delta’s AC motor drive and AFE2000 is an outstanding combination for bridge cranes.

Application: Delta C2000 Series AC Motor Drive and AFE2000 Active Front-End Unit for Bridge

Crane (Overhead Travelling Crane)

crane, hoist, Delta AC motor drive, high-level field oriented control, built-in PLC, torque control,

reliability, AFE2000 active front-end, power quality, power improvement, power factor, harmonics,

fast braking, brake resistor, current control PWM converter, switch rectifier, energy-saving

Application

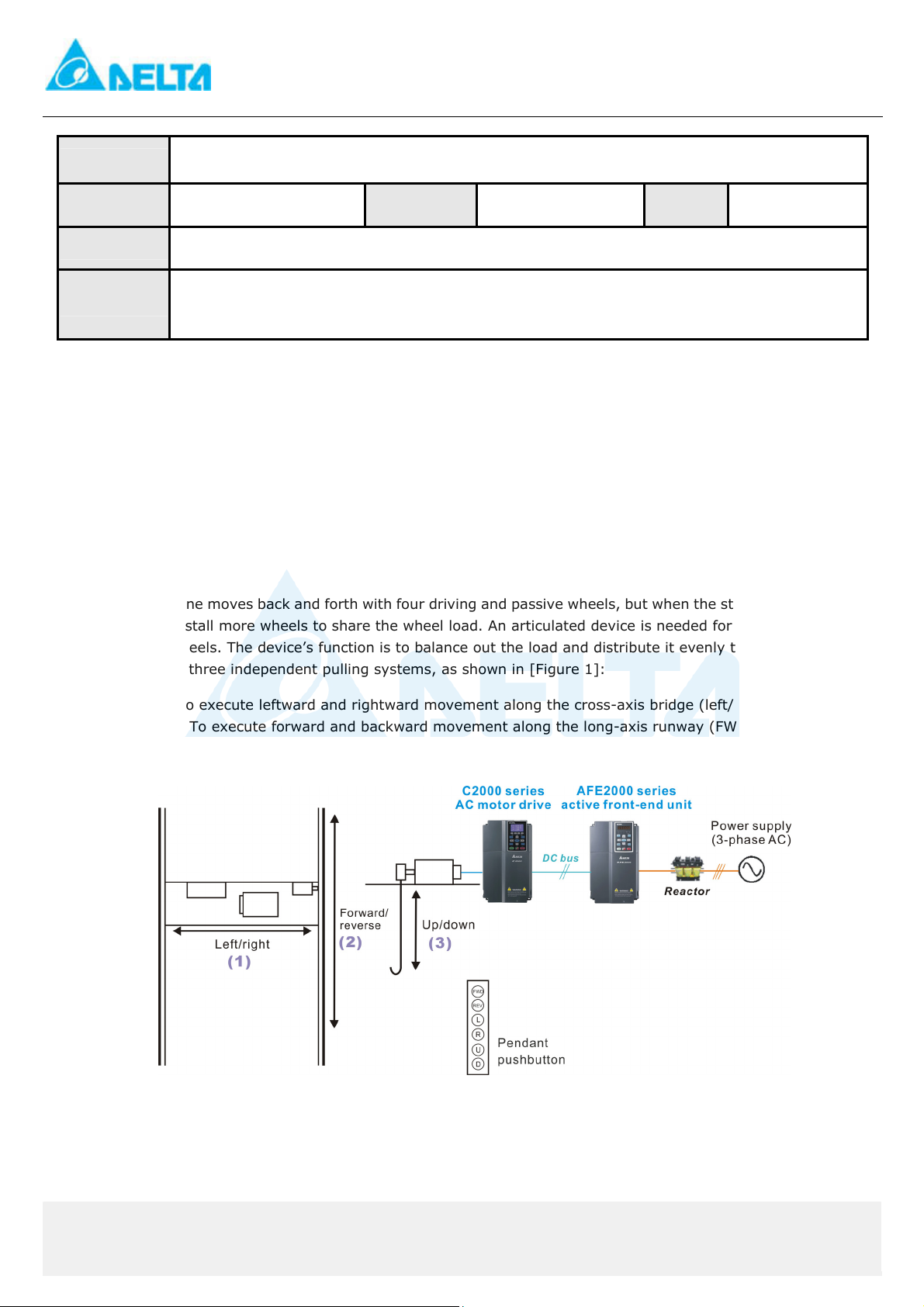

The bridge crane moves back and forth with four driving and passive wheels, but when the starting load is large,

it is common to install more wheels to share the wheel load. An articulated device is needed for bridge cranes with

more than four wheels. The device’s function is to balance out the load and distribute it evenly to each wheel. The

motion is done by three independent pulling systems, as shown in [Figure 1]:

1. Trolley: To execute leftward and rightward movement along the cross-axis bridge (left/right).

2. Endtruck: To execute forward and backward movement along the long-axis runway (FWD, REV).

3. Hoist: To lift and lower the item (up/down).

[Figure 1]

The bridge crane hoist, unlike the trolley and the runway girder, has lower requirements for precision control, and

it benefits a lot from the AC motor drive. Different from traditional drives, an AC motor drive offers more thorough

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most

trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

- 1 -

Page 2

Product Application

Industrial Automation BU, Delta Electronics, Inc.

safety protection and additional features such as large load inertia and 4-quadrant operation. The suggested AC

motor drive and the active front-end unit model for the bridge crane are:

VFD VFD110C23A

AFE AFE075A23A + CHOKE: 2.1mH

Application Case

System Solution

For bridge cranes, the Delta C2000 series AC motor drive has taken overload problems and long-term system

stability issues as target factors and offers excellent features such as:

1. Full vector control. Supports starting torque up to 150% rated torque at a low frequency of 1Hz in steady motion.

2. Optional braking unit is available to perform 4-quadrant operation

3. Constant torque at full speed range

4. With AFE2000, regenerative energy is converted by AFE2000 into reusable energy (clean power) and fed back to

the mains.

System Features

SVC control

The Delta C2000 provides sensorless vector control (SVC) to perform a nearly close-loop control function which

saves from purchasing an encoder and lowers maintenance cost. In addition, it overcomes activation difficulties, and

is capable of initiating a start-up under full load and short-term over-load conditions.

Braking process control

Prevention of sudden drops and jerky movements is an important factor in overall bridge crane system design.

The coordination between the AC motor drive and the mechanical control should be rigid to prevent sudden drops and

jerking, especially when lifting or lowering a heavy load and when stopping a heavy load in mid-air. The Delta C2000

series offers a special set of parameters and multiple output commands to promptly solve the problem.

.

Overload capacity

Normal load: rated output current 120%/min; Heavy load: rated output current 150%/min. This offers sufficient

start-up torque and maintains the DC Bus voltage at 730VDC when torque decreases and it will not trigger OU alarm.

The test report reveals the system allows the bridge crane to operate long-term

Soft-start, soft-stop, wide speed range and precise positioning.

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most

trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

- 2 -

Page 3

Product Application

Industrial Automation BU, Delta Electronics, Inc.

Full torque output at zero-speed. No sudden drops or jerky movements when the braking unit is not working, which

ensures safety and system reliability.

Quick dynamic response, no sudden drops or jerky movements

Modular design of force-cooling fan for heat dissipation. The modular design makes it easy

for fan cleaning and replacement.

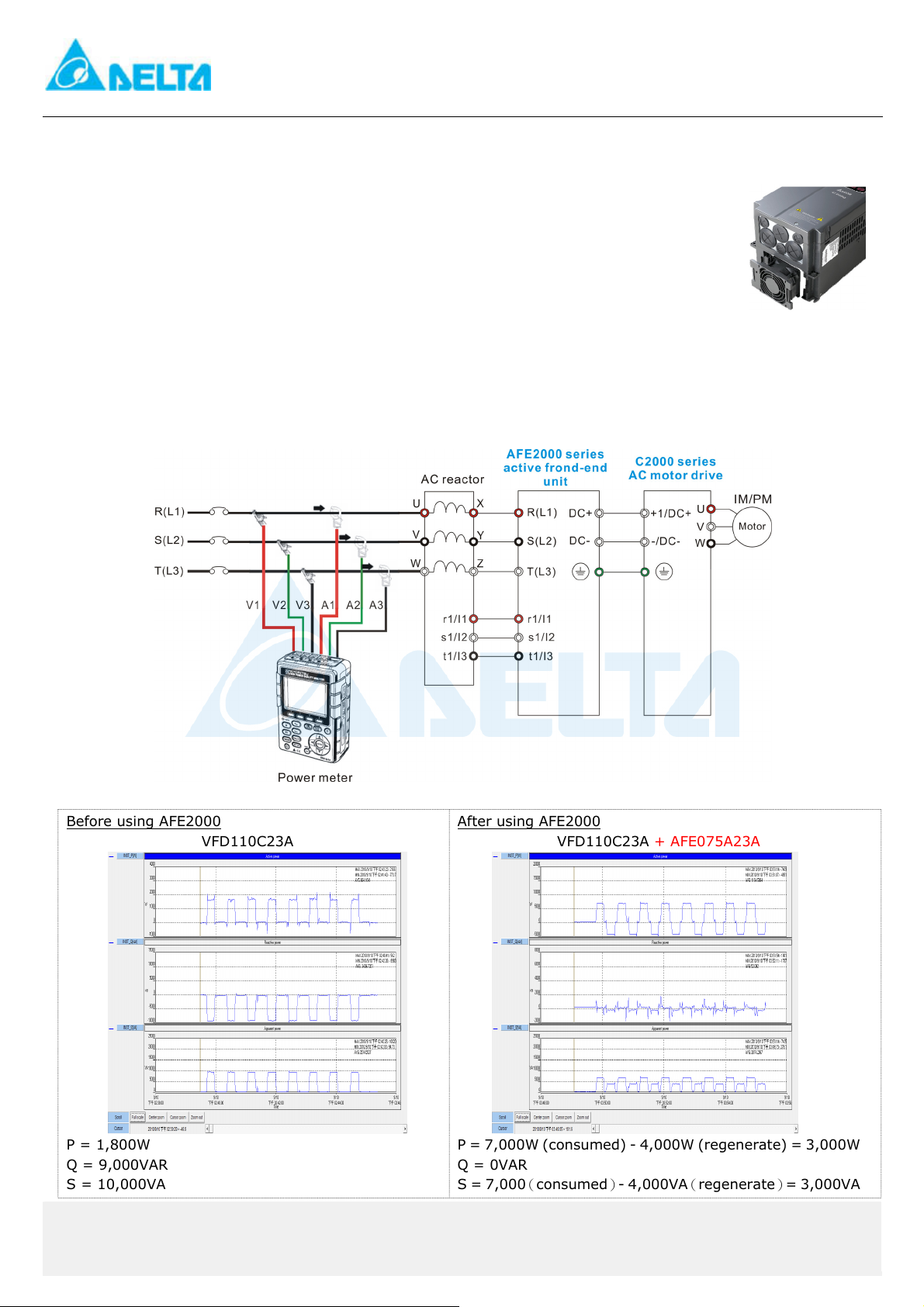

Active Front End Unit

The Delta AFE2000 series is a substitute for traditional heat dissipation methods. It converts regenerative energy

into reusable power and feeds it back to the mains, and allows the AC motor drive to operate in four quadrants to

decrease power consumption. It provides innovative, clean and efficient energy solutions for a better tomorrow.

Experiment Results

Before using AFE2000

VFD110C23A

電動模式電流

P = 1,800W

Q = 9,000VAR

S = 10,000VA

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most

trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

After using AFE2000

P = 7,000W (consumed) - 4,000W (regenerate) = 3,000W

Q = 0VAR

S = 7,000(consumed)- 4,000VA(regenerate)= 3,000VA

VFD110C23A + AFE075A23A

- 3 -

Page 4

Product Application

Industrial Automation BU, Delta Electronics, Inc.

Energy Saved!>

10,000VA

3,000VA)-(10,000VA

%% 40100 x

PF = 0.2 ~ 0.4

WP+ = 61.1912Wh

WP- = 0.013Wh

Delta’s intelligent C2000 AC motor drive and AFE2000 active front-end unit with their larger power and

energy-saving ability offer stunning performance for bridge crane applications.

Delta has built an excellent reputation in the industrial automation market for its AC motor drive technology and

continuous innovation. We have successfully developed our newest AC motor drive, the C2000 series. The bridge

crane application shows the C2000’s SVC control using the auto-tuning function to accurately obtain the motor’s

inductance value and resistance value. Precise calculation of slip deviation enables larger torque output for heavy

loads. Also, system stability is easily attained without speed sensors which makes the wiring for motor and drive less

complicated, and the control ratio is up to 1:100 (if the rated speed is 60Hz, the best speed control range is 0.6 ~

60Hz). This function is applicable to the treadmills, elevator doors, circular knitting machines and cranes.

PF = 0.99

WP+ = 259.317Wh

WP- = 138.014Wh

The Delta C2000 provides sensorless vector control (SVC) to perform a nearly close-loop control function which

saves on purchasing an encoder and lowers maintenance cost. Compared with the traditional V/f control, the SVC

offers better performance for low speed operation, larger starting torque, and speed response to load increases and

decreases is faster. All these benefits allow cranes to activate easier for high friction and inertia load conditions. The

SVC control technology has been widely adopted for constant torque application. The Delta C2000 series AC motor

drive provides you with SVC control to overcome difficult crane start-ups at full load conditions.

Delta’s AFE2000 series active front-end unit not only improves electricity supply quality but also generates

re-usable energy to slow down global energy consumption. Delta’s mission has always been to provide innovative,

clean and efficient energy solutions for a better tomorrow. We are proud to launch our AFE2000 series which can help

you save up to 40% in energy use.

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most

trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

- 4 -

Page 5

Product Application

Industrial Automation BU, Delta Electronics, Inc.

Delta’s professionalism and rich experience in industrial applications provides users with easy maintenance, a low

failure rate and self-diagnosis features at a reasonable price, which enhances users’ competitive advantage in the

market.

For more information on Delta AC motor drives, please visit our website at:

http://www.delta.com.tw/product/em/drive/ac_motor/ac_motor_main.asp

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most

trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

- 5 -

Loading...

Loading...