Page 1

SPECIFICATION FOR APPROVAL

Customer : MSI

Part No : S93-0408230-D04 Rev :

Description : ADAPTER

Delta Model No : ADP-36CH AH Rev : 00

Sample Issue Date : Feb. 12 , 2009

DELTA ELECTRONICS, INC.

3, Tung Yuan Road

Chungli Industrial Zone.

Taoyuan Hsien 320, Taiwan, R.O.C

Internet : http:/www.deltaww.com

TEL:886-3-4526107 FAX:886-3-4343617

Page 2

TABLE OF CONTENTS

1. Revision History

2. Electrical Specification

3. Schematic

4. PCB Artwork

5. Physical Dimension

6. Label Drawing

7. Packing

8. BOM (Part List)

9. Safety License

Please send one copy of this specification back after you signed

approval for production pre-arrangement.

Approved By :

Date :

Engineer By:Danny Chen M.Engineer By: Aaron Yang Approved By: Jimmy Chiang _

Page 3

1. Revision History

Page 4

DELTA P/N ADP-36CH AH SHEET 1 OF 1

CONTENT Revision History DATE Feb. 12 ,2009

1.Revision History

REV. DESCRIPTION ENGINEER DATE

--------------------------------------------------------------------------------------------------------------- 00 ISSUE Danny Chen 02/12/2009

Page 5

2. Electrical Specification

Page 6

1. Electrical

1.1 Input Characteristics Page

1.1.1 Nominal Voltage…………………………………….…………..…………….…………………… 4

1.1.2 Input Voltage Range………………………………….………………………….……………….. 4

1.1.3 Rated Frequency……………………………………………………………….………………….. 4

1.1.4 Frequency Range……………………………………………………………….…………………. 4

1.1.5 Input current …………………………………………………………………………………………4

1.1.6 Inrush Current Limit(cold start)…………………………………………………………………….4

1.1.7 Efficiency ………………………………………………………………………...………………….4

1.1.8 No Load Power Consumption………………………………………………..…………. .…….….5

1.1.9 Small Load Power Consumption……………………………………………………… …………..5

1.2 Output Characteristics

1.2.1 Rated Voltage……………………………………………………………………………..……….. 5

1.2.2 Voltage Range ……………………………………………………………………………………...5

Table Of Contents

1.2.3 Current………………………………………………………………….……………….…………...5

1.2.4 Output Ripple and Noise………………………………………………………………………….. 5

1.2.5 Turn On delay time………………………………………………………………………………… 5

1.2.6 Hold – up Time…………………………………………………………………………………….. 5

1.2.7 Rise time…………..………………………………………………………………………………. 6

1.2.8 Surge load:………………………………………………………………………………………… 6

1.2.9 Load transient response…………………………………………………………………………. 6

1.2.10 Protection………………………………………………………………………………………….. .6

1.2.10.1 Over Voltage Protection…………………………………………………………………..6

1.2.10.2 Over Current Protection…………………………………………………………………..6

1.2.10.3 Short Circuit Protection……………………………………………………………….…..6

1.2.10.4 Over Temperature Protection…………………………………………………………….7

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

REV.

S00

File Name:DF-PSLA4V-2R00.DOC SHEET 2 OF 10

Page 7

2. Environmental

2.1 Temperature………………………………………………………………………………….…………….. 7

2.2 Humidity …………………………………………………………………………………………………….. 7

2.3 Immunity………………………………..…………………………………………………………………… 8

2.3.1 Lightning Surge Immunity………………………………………………………………………… 8

2.3.2 Electric Fast Transients (EFT)…………………………………………………… ……………… 8

2.4 Electrostatic Discharge (ESD)………..………………………..…………………………………… …….. 8

2.5 Surface Temperature rise……..…………………………………………………………………………….8

2.6 Dielectric Withstand Voltage (HI-POT)……..……………………………………………………………. 8

2.7 Leakage Current.…………………………….…………………………………………………………….. 8

2.8 Insulation Resistance……………………………….……………………………………………………… 8

2.9 Electromagnetic Interference (EMI).…..…………………………………………………………………. 9

2.10 MTBF………………………………………………………………………………………………………… 9

3.

Mechanical

3.1 Outline Dimension……………………………………………………………………………….…………. 10

3.2 AC Inlet type………………………………………………………………………………………………… 10

3.3 DC Cable Length……………………………………………………………………………….……………10

3.4 DC Cable Type …………………………………………………………………… ……………………..….10

3.5 DC Connector Dimension..…………………………………………………………………………………10

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

REV.

S00

File Name:DF-PSLA4V-2R00.DOC SHEET 3 OF 10

Page 8

1. ELECTRICAL

1.1 Input Characteristics:

1.1.1

1.1.2 Input Voltage Range

1.1.3 Rated Frequency

1.1.4 Frequency Range

1.1.5 Input Current

1.1.6 Inrush Current Limit (cold start)

1.1.7

Nominal Voltage

It is normal for 100 ~ 240Vac input AC voltage.

The Adapter shall operate from 90 ~ 264Vac.

It is normal for 50Hz or 60Hz and single phase.

The Adapter shall operate with an input frequency from 47 Hz to 63 Hz.

1.2A Max at 100Vac input voltage.

No damage at 240Vac.

Efficiency (Warm Up)

1.1.7.1 83 % min. at nominal input voltage, maximum load and measured a t the end of DC cable.

1.1.7.2 Active mode efficiency:

More than 82.25% of average efficiency of 25%,50%,75% and 100% load tested at 115Vac and

230Vac. (Warm up after 30 minutes)

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

File Name:DF-PSLA4V-2R00.DOC SHEET 4 OF 10

REV.

S00

Page 9

1.1.8 No Load Power Consumption

Maximum non-load power consumption is less than 0.5W at 115Vac/60Hz and 230Vac/50HZ

1.1.9 Small Load Power Consumption

Vin=115Vac/60Hz and 230Vac/50Hz

Output load(W) Input power (max)

1W 1.7W

1.5W 2.4W

1.2 Output Characteristics:

1.2.1 Rated Voltage

The rated output voltage is specified at 12V.

1.2.2 Voltage Range

The output voltage will be performed 11.4~ 12.6V when the load is 0A ~ 3A steadily.

1.2.3

1.2.4

Current

This Adapter can work from 0A to 3A and output voltage is in section 1.2.2 specified range.

Output Ripple and Noise

Output ripple voltage is 350 mV peak to peak or less.

Measured methods:

T1. Performed by 20M Hz bandwidth in oscilloscope.

T2. Applied 0.1uF high frequency capacitor and 10uF electrolytic capacitor across output connector terminals.

T3. Measured at the end of DC cable.

T4. 47Hz and 63Hz tested at 90Vac and 264Vac.

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

File Name:DF-PSLA4V-2R00.DOC SHEET 5 OF 10

REV.

S00

Page 10

1.2.5 Turn On delay time

The Adapter shall switch on in less than 2 seconds at input voltage is 100Vac.

1.2.6 Hold –up time

The output voltage shall be sustained 6mS within regulation requirement after loss 100Vac and maximum load.

1.2.7 Rise time

DC output rise time from 10% to 90% of output voltage shall be less than 40ms at nominal line

and maximum load

1.2.8 Surge load:

The adapter shall support a surge load with 110% of maximum load for 1mS.

1.2.9 Load transient response

The adapter must within regulation when applied a step load from 0% to 50% and 50% to 100%

load at 0.5A/us slew rate and 10mS time period.

The output voltage

1.2.10 Protection

1.2.10.1 Over Voltage Protection

will be performed 11.4~ 12.6V.

The output shall be protected to latch off at over-voltage condition, maximum value can’t be over 20V.

That might be return to normal state by AC reset, reset ≤ 2 Minutes.

1.2.10.2 Over Current Protection

The maximum constant current shall be less than 5A.

The ADAPTOR SHALL BE AUTO-RECOVERY.

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

File Name:DF-PSLA4V-2R00.DOC SHEET 6 OF 10

REV.

S00

Page 11

1.2.10.3 Short Circuit protection

Output can be shorted without damage. The adaptor shall be auto-recovery. (It will enter into norm al

condition when the fault condition is removed.)

1.2.10.4 Over Temperature Protection

No deformation and no discoloration on case and will be shut down. That will be return to normal state

by ac reset, reset≦2 minutes.

2. Environmental

2.1 Temperature

2.1.1 Operating

The AC Adapter shall be capable of operating at full load with an ambient temperature range of 0 ℃

to +40℃.

2.1.2 Shipping/Storage

The AC Adapter shall be capable of withstanding ambient temperature from -20℃ to +70℃.

2.2 Humidity

2.2.1 Operating

The AC Adapter shall be capable of operation in relative humidity of 10% to 90% relative humidity,

non-condensing.

2.2.2 Shipping/storage

The AC Adapter shall be capable of withstanding ambient relative humidity of 5% to 95% relative

humidity, non-condensing.

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

REV.

S00

File Name:DF-PSLA4V-2R00.DOC SHEET 7 OF 10

Page 12

2.3 Immunity

2.3.1 Lightning Surge Immunity

This is to follow the norm of IEC-1000-4-5 Level 3 requirements

L-N 1KV/1.2

2.3.2 Electric Fast Transients (EFT)

This is to follow the norm of IEC-61000-4-4/1995

(EN 61000-4-4) Level 3 requirements

* 50uS 5 times No function error.

2.4 Electrostatic Discharge ( ESD )

This Adapter is capable to withstand ESD test voltage at any point around the enclosure as below.

(Refer to IEC61000-4-2)

±12KV air discharge No damage.

±6KV contact discharge No damage.

2.5 Surface Temperature rise

Output 36W and ambient

35℃±3℃;input voltage 100Vac/240Vac case temperature rise≦45℃.

2.6 Dielectric Withstand Voltage ( HI – POT )

100% of line products of this Adapter shall be applied 3000Vac for 2 seconds between AC

input terminals and output terminals. Cut off current is 3mA.

2.7 Leakage Current :

The AC leakage current is less than 100μA when adapter is connected to 240Vac/60Hz at normal condition.

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

File Name:DF-PSLA4V-2R00.DOC SHEET 8 OF 10

REV.

S00

Page 13

2.8 Insulation Resistance

The insulation resistance shall be not less than 30M ohms after application of 500Vdc/10mA for 1 minute.

2.9 Electromagnetic Interference (EMI)

2.9.1 The adapter shall comply with the following national standards.

(a) CISPR 22 Class B

VCCI Class B

(b)

2.10 MTBF

2.10.1 MTBF(Mean-Time-Between-Failures)Calculation

2.10.2 MTBF Verification

The calculated MTBF shall be 150,000 hours of continuous operation at 25℃,

maximum load and normal voltage.

The MTBF shall be verified from life testing performed by factory Quality department.

The operating conditions are:40℃ambient temperature, sea level ,both nominal line voltage

ranges(110VAC or 220VAC) and a minimum load of 75% of the maximum load.

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

File Name:DF-PSLA4V-2R00.DOC SHEET 9 OF 10

REV.

S00

Page 14

3. Mechanical

3.1 Outline Dimension: 96.0*42.0*28.7 mm , Color : Black

3.2 AC Inlet type:

3.3 DC Cable Length:

3.4 DC Cable Type

3.5 DC Connector Dimension:

OD= 5.5 mm

ID= 1.7 mm

Length= 12.5 mm

Socket C8 type

1800 mm

: UL1571, AWG #18

台達電子工業股份有限公司

DELTA ELECTRONICS, INC.

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF DELTA

ELECTRONICS, INC. AND SHALL NOT BE REPRODUCED OR USED AS THE

BASIS FOR THE MANUFACTURE OR SELL OF APPARATUSES OR DEVICES

WITHOUT PERMISSION.

Date Drawn Design (EE) Design (ME)

12/18/2008

洪若蘭 陳俊志 楊基祥

DESCRIPTION :

電氣規格 (Electrical Specification)

MODEL NO. :

ADP-36CH AH

DOCUMENT NAME. :

ES-36CH AH

File Name:DF-PSLA4V-2R00.DOC SHEET 10 OF 10

REV.

S00

Page 15

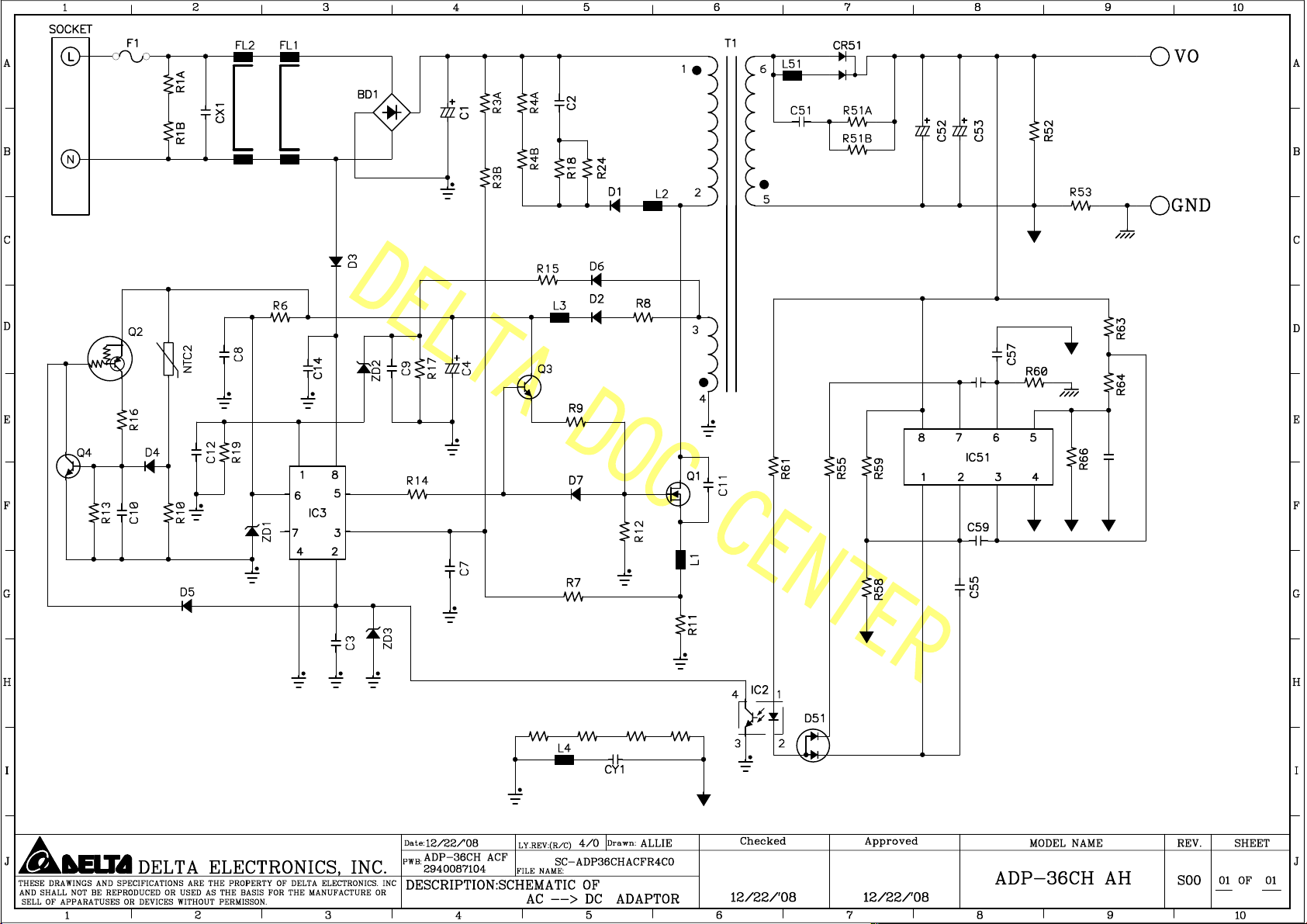

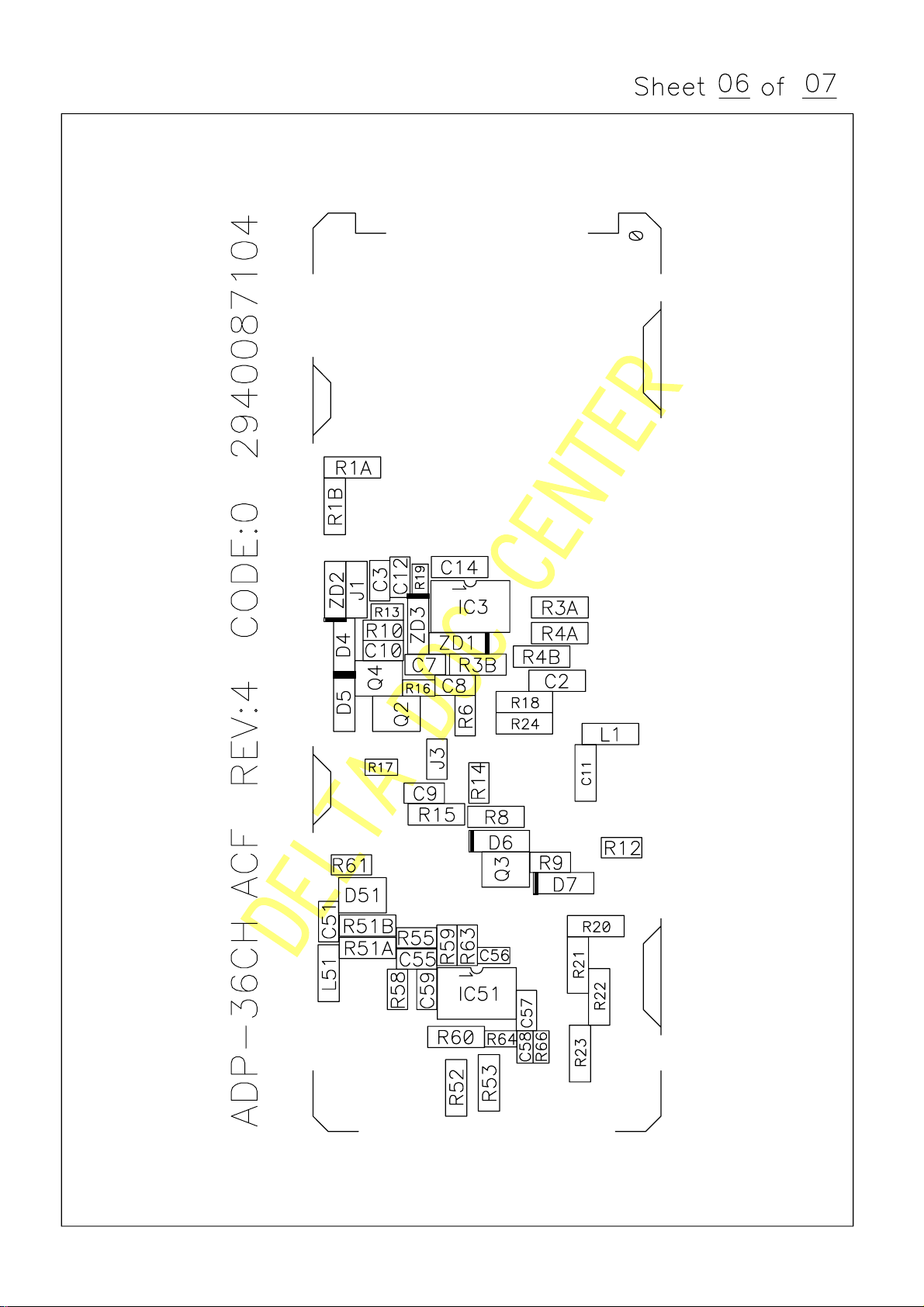

3.Schematic

Page 16

C56

C58

R20 R22 R2 3

R21

陳俊志 蔣進財

Page 17

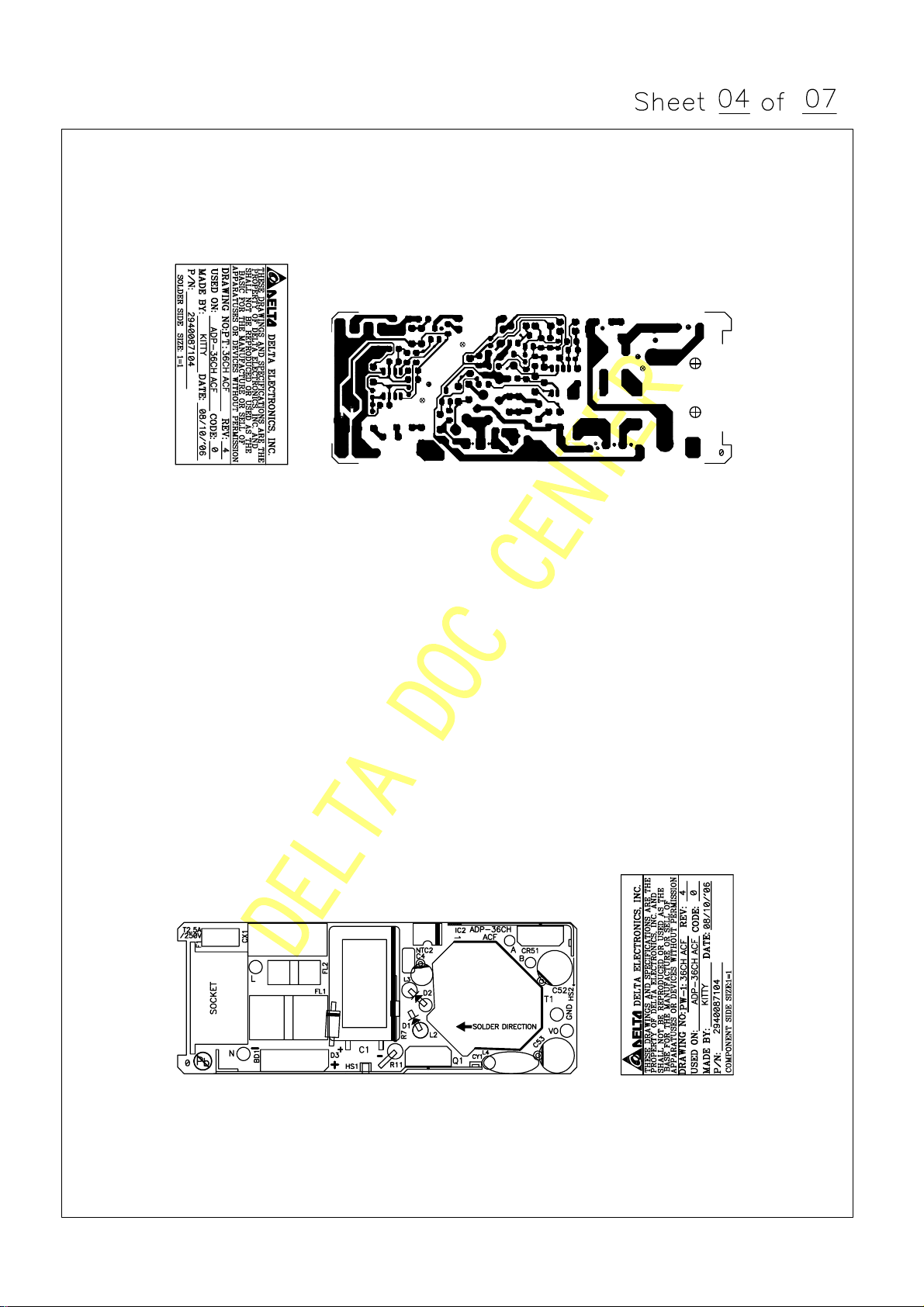

4. PCB Artwork

Page 18

Page 19

Page 20

Page 21

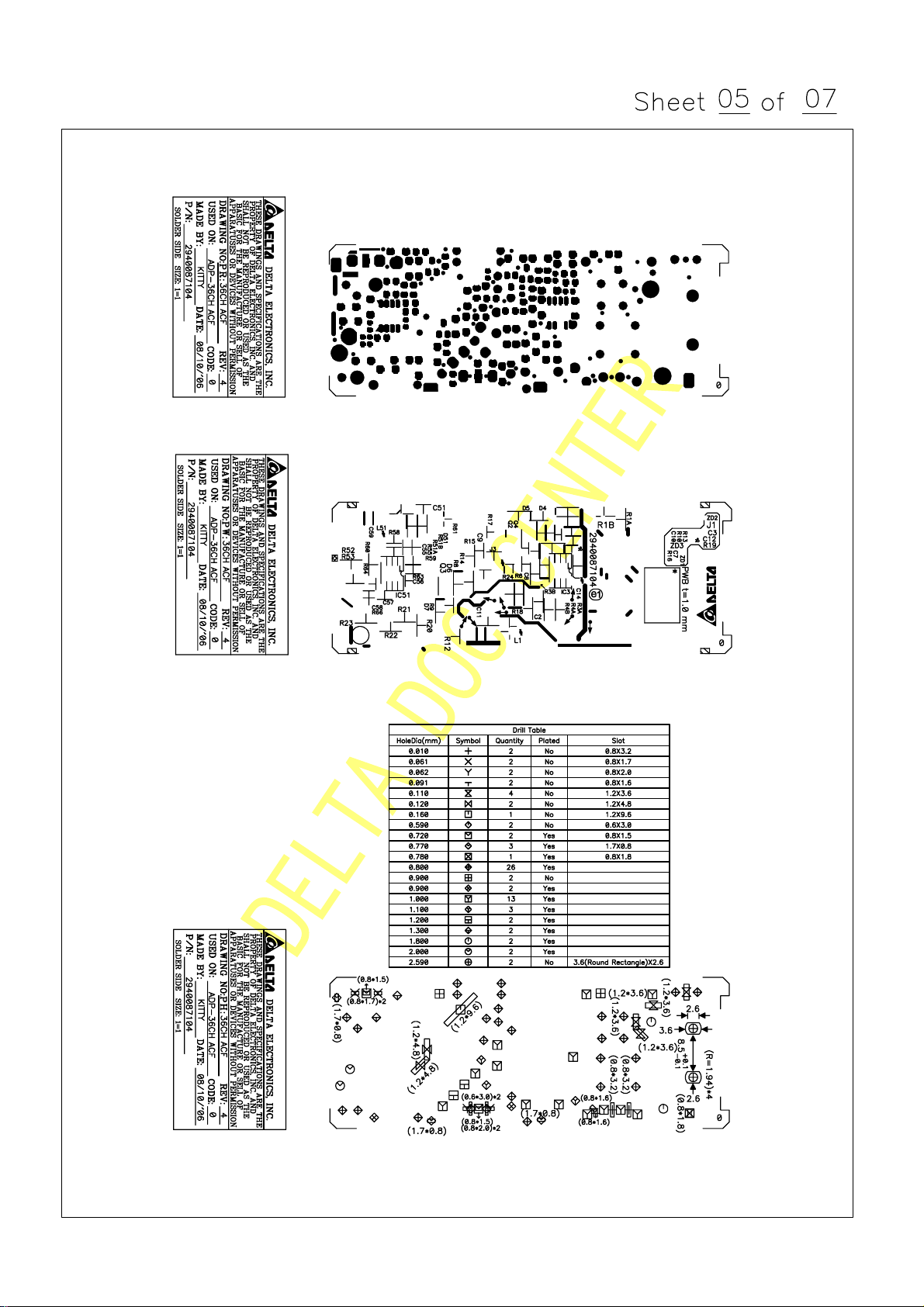

5.Physical Dimension

Page 22

Page 23

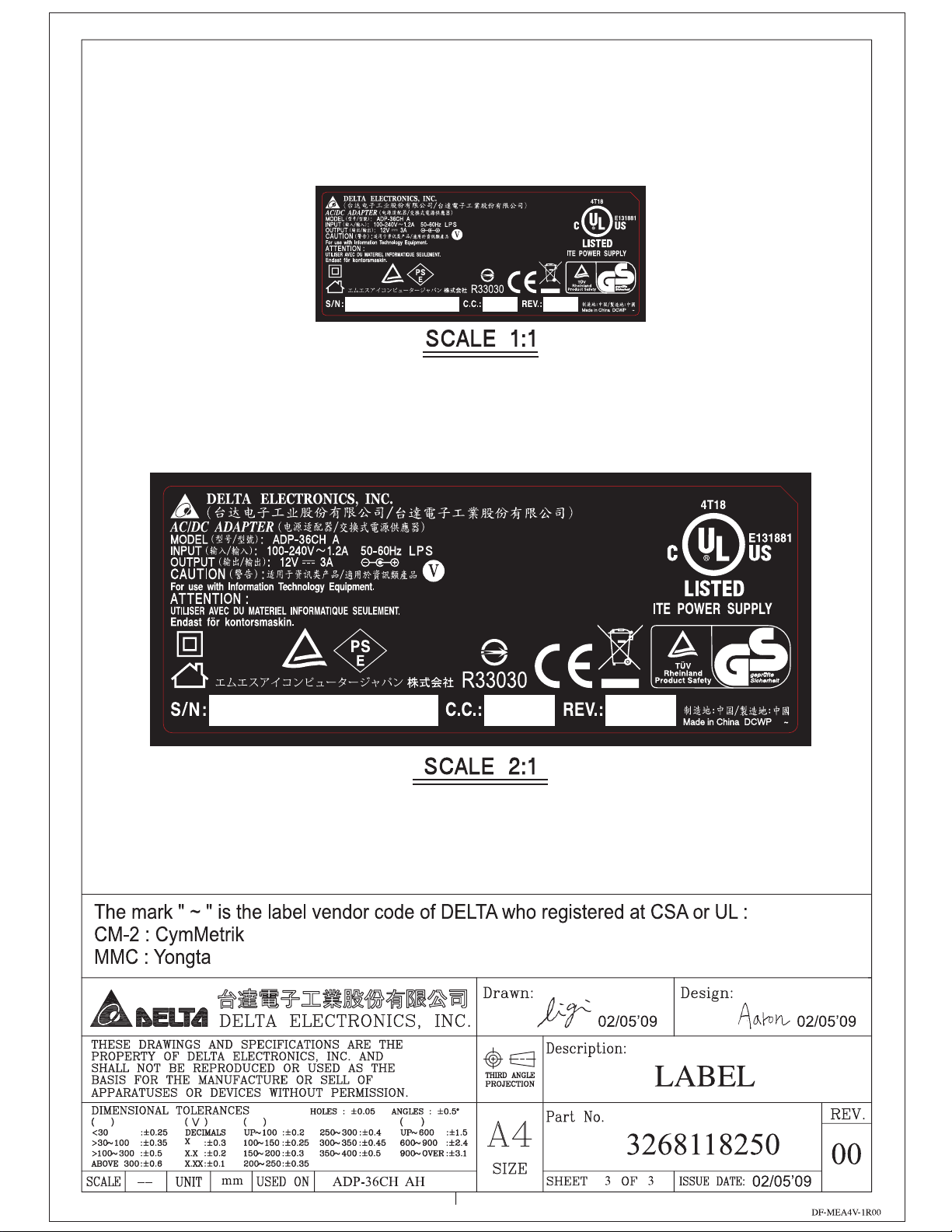

6.Label Drawing

Page 24

Page 25

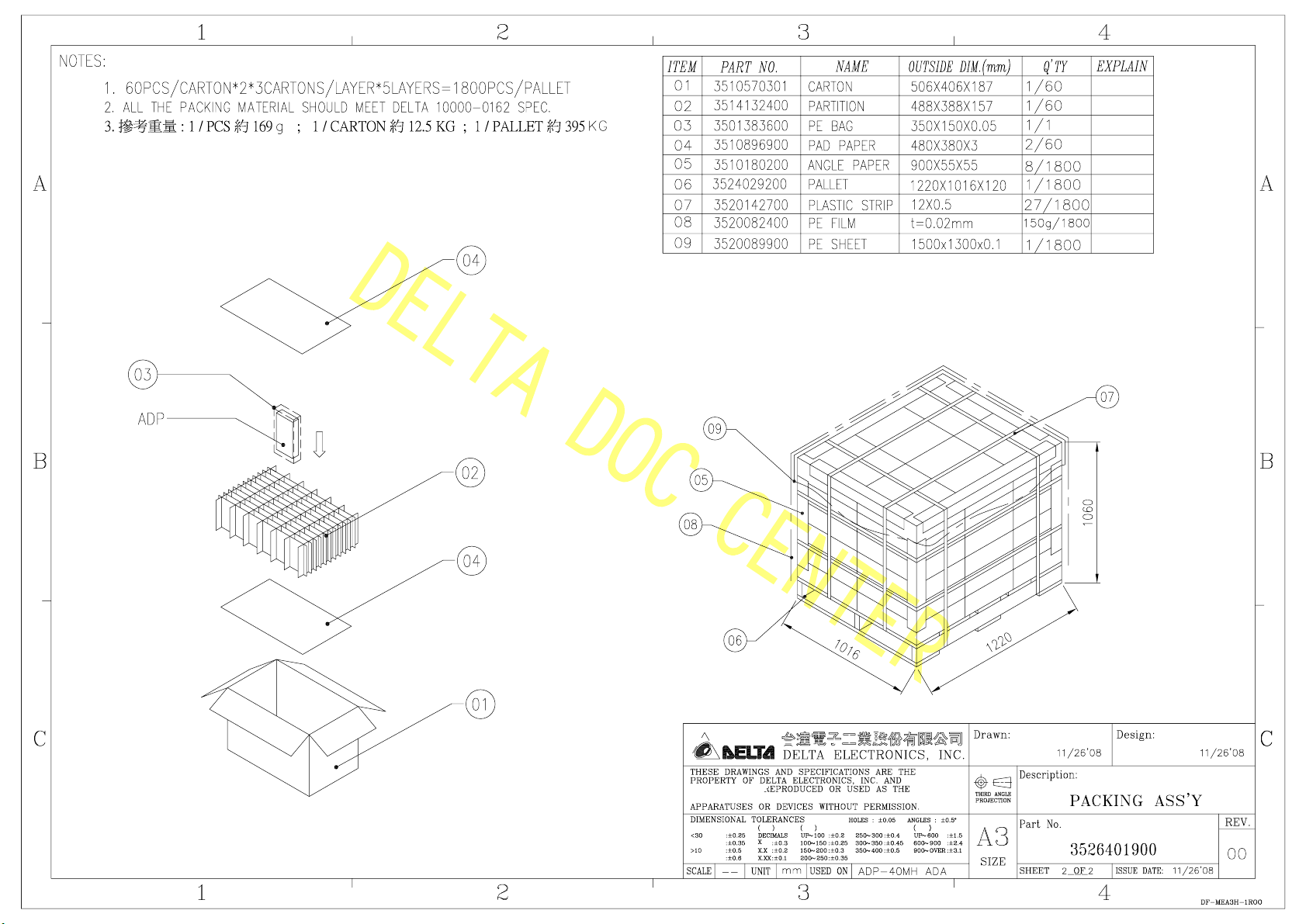

7.Packing

Page 26

Page 27

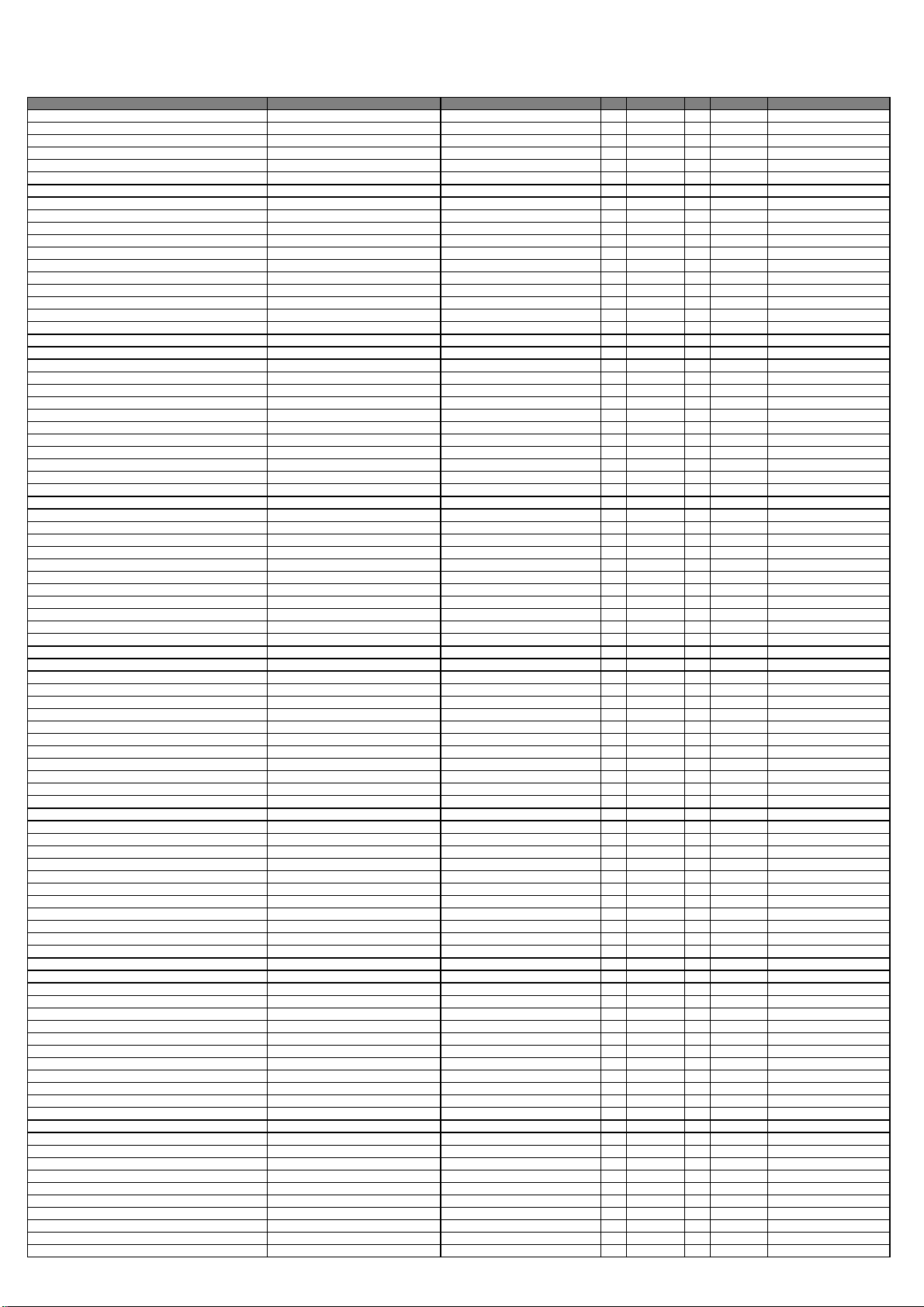

8. BOM (Part list)

Page 28

R

L

R

L

O

O

T

S

S

O

< ADP-36CH AH CUSTOMER BOM LIST >

DATE: 01/21/2009

DESCRIPTION MFG NAME MFG PART % QPA UNIT DESIGN NO Item text 1

RES CF 1/4W 2.7Kohm J SMALL KAMAYA 1.000 PCE R7

RES MOF 1W 560mohm J SMALL FR FUTABA 1.000 PCE R11

FUSE T S 2.5A 250V L BEL FUSE LIMITED RST 2.5 0 1.000 PCE F1

FUSE T S 2.5A 250VAC L LITTELFUSE FAR EAST PTE LTD. 392-2.5A 0 1.000 PCE F1

FUSE T S 2.5A 250V L CONQUER ELEC.CO.,LTD MST2.5 0 1.000 PCE F1

FUSE T S 2.5A 250VAC L Walter Electronic Co Ltd 2010T2.5A 100 1.000 PCE F1

RES NTC 470Kohm J 5200K +/-7% UPPERMOST ELECTRONIC INDUST

RES NTC 470Kohm J 5200K +/-7% THINKING ELECTRONIC INDUSTRIA

RES NTC 470Kohm J 5200K +/-5% TRA UPPERMOST ELECTRONIC INDUST

RES NTC 470Kohm J 5200K TRA THINKING ELECTRONIC INDUSTRIA

CAP Y1/X1 CD 250VAC 680pF K B VI10 MURATA MANUFACTURING CO.LTD DE1B3KX681KA4BL01 0 1.000 PCE CY1

CAP Y1/X1 CD 250VAC 680pF K B VI10 WALSIN TECHNOLOGY CORPORATI

CAP Y1/X1 CD 250VAC 680pF M E VI10 TDK Corporation CD75-E2GA681MYGS 0 1.000 PCE CY1

CAP Y1/X1 CD 250VAC 680pF K B TP VI10 MURATA MANUFACTURING CO.LTD DE1B3KX681KN4AL01 0 1.000 PCE CY1

CAP Y1/X1 CD 250VAC 680pF K B TP VI10 WALSIN TECHNOLOGY CORPORATI

CAP Y1/X1 CD 250VAC 680pF M E TP VI10 TDK Corporation CD75-E2GA681MYVS 100 1.000 PCE CY1

CAP AL LD 25V 330uF M 8*15 P3.5 NICHICON CORPORATION UHD1E331MPD1CV 100 1.000 PCE C52

CAP AL LD 25V 330uF M 8*15 P3.5 NICHICON CORPORATION UHD1E331MPD1CV 100 1.000 PCE C53

CAP AL LD 25V 330uF M 8*15 P3.5 TAICON CORPORATION THD1E331MK08150CK3 0 1.000 PCE C52

CAP AL LD 25V 330uF M 8*15 P3.5 TAICON CORPORATION THD1E331MK08150CK3 0 1.000 PCE C53

CAP AL LD 25V 330uF M 8*15 P3.5 NIPPON CHEMI-CON CORPORATION EKZE250EC3331MH15D 0 1.000 PCE C52

CAP AL LD 25V 330uF M 8*15 P3.5 NIPPON CHEMI-CON CORPORATION EKZE250EC3331MH15D 0 1.000 PCE C53

CAP AL LD 25V 330uF M 8*16 P3.5 RUBYCON CORPORATION 25ZL330MEFCCE8*16 0 1.000 PCE C52

CAP AL LD 25V 330uF M 8*16 P3.5 RUBYCON CORPORATION 25ZL330MEFCCE8*16 0 1.000 PCE C53

CAP AL LD 35V 33uF M 5*11 TP P5 NICHICON CORPORATION UPW1V330MDD1TA 0 1.000 PCE C4

CAP AL LD 35V 33uF M 5*11 TP P5 TAICON CORPORATION TPW1V330MK05110TC1 100 1.000 PCE C4

CAP AL LD 35V 33uF M 5*11 TP P5 LUMINOUS TOWN ELECTRIC CO., LT ZGD1VM330D11A 0 1.000 PCE C4

CAP AL LD 35V 33uF M 5*11 TP P5 RUBYCON CORPORATION 35YXG33MEFCTA5*11 0 1.000 PCE C4

CAP AL LD 35V 33uF M 5*11 TP P5 NIPPON CHEMI-CON CORPORATION EKY-350ETC330ME11D 0 1.000 PCE C4

CAP AL 400V 68uF M 16*25 P7.5 NIPPON CHEMI-CON CORPORATION EKMG401ELL680ML25S 0 1.000 PCE C1

CAP AL 400V 68uF M 16*25 P7.5 NICHICON CORPORATION UPT2G680MHD3 0 1.000 PCE C1

CAP AL 400V 68uF M 16*25 P7.5 LUMINOUS TOWN ELECTRIC CO., LT TYJ2GM680K25O 100 1.000 PCE C1

CAP X2 MP PC 275VAC 0.33uF K P15 HUA JUNG COMPONENTS CO., LTD. MKP-334K0275AB1151 0 1.000 PCE CX1

CAP X2 MP PC 275VAC 0.33uF M P15 ARCOTRONICS ITALIA SPA R46KI333045M 0 1.000 PCE CX1

CAP X2 MP PC 300VAC 0.33uF K S15 OKAYA HONG KONG TRADING LTD. LE334-MX-30-C3.2 100 1.000 PCE CX1

DIO BRD 2A 800V D3K-4P SHINDENGEN ELECTRIC MANUFAC

DIO FRD 1A 1000V DO-41-2P 500nS FAGOR ELECTRONICA, S. COOP RGP10MAMP 0 1.000 PCE D1

DIO FRD 1A 1000V DO-41-2P 500nS VISHAY SEMICONDUCTOR RGP10M-E3/73 0 1.000 PCE D1

DIO FRD 1A 1000V DO-41-2P 500nS PAN JIT INTERNATIONAL INC. PG1010R T/B 100 1.000 PCE D1

DIO SBD 10A 100V TO-220AB-3P C.C. STMicroelectronics Asia Pacific Pte STPS10H100CT 100 1.000 PCE CR51

DIO SBD 10A 100V TO-220AB-3P C.C. PAN JIT INTERNATIONAL INC. SB10100CT 0 1.000 PCE CR51

DIO SI 1A 1KV DO-41-2P FAIRCHILD SEMICONDUCTOR HK LT 1N4007 0 1.000 PCE D2

DIO SI 1A 1KV DO-204AL-2P VISHAY SEMICONDUCTOR 1N4007-E3/73 0 1.000 PCE D2

DIO SI 1A 1KV DO-41-2P PAN JIT INTERNATIONAL INC. 1N4007 T/B 100 1.000 PCE D2

DIO SI 1A 1KV DO-41-2P Tianjin Zhong-Huan Semiconductor T1N4007 0 1.000 PCE D2

DIO SI 1A 1KV DO-41-2P GULF SEMICONDUCTOR LIMITED 1N4007-47L 0 1.000 PCE D2

DIO SI 1A 1KV DO-204AL-2P VISHAY SEMICONDUCTOR 1N4007-E3/73 1.000 PCE D3

PHOTO TR 40mA 80V 4P 150-300% 10.16mm NEC CORPORATION PS2561BL1-1-V-A(G) 0 1.000 PCE IC2

PHOTO TR 50mA 70V DIP-4P 160-300% SHARP ELECTRONIC COMPONENTS PC123Y92FZ0F 100 1.000 PCE IC2

FET 600V 6A 1.2ohm TO-220FP-3P STMicroelectronics Asia Pacific Pte STP6NK60ZFP 0 1.000 PCE Q1

FET 600V 6A 1.25ohm TO-220F-3P TOSHIBA CORP. 2SK3562(Q) 0 1.000 PCE Q1

FET 600V 7.5A 1.2ohm TO-220F-3P FAIRCHILD SEMICONDUCTOR HK LT FQPF8N60C 0 1.000 PCE Q1

FET 600V 6A 1.1ohm TO-220FI(LS)-3P SANYO ELECTRONIC CO.,LTD. 2SK2628LS 0 1.000 PCE Q1

FET 600V 7A 1.2ohm TO-220F-3P AUK CORPORATION STK0760F 100 1.000 PCE Q1

INDUCTOR CR T10 251uH MIN DELTA ELECTRONICS,INC. CR-10-NB84A 1.000 PCE FL2

TRANSFORMER MAIN RM10/18.1 580uH +/-5% DELTA ELECTRONICS,INC. SMT-RM10-NB2075D 1.000 PCE T1

LINE FILTER T14 10.3mH MIN DELTA ELECTRONICS,INC. HFV-NB7103 1.000 PCE FL1

CORE BEAD 2.5*1*3 33ohm F4D FENGHERYIN CORPORATION F4D RH 2.5*1.0*3 0 1.000 PCE L4 FOR CY1

CORE BEAD 2.5*1*3*2.5*2.5 33ohm W4B TAI-TECH ADVANCED ELECTRONIC

CORE BEAD 3.5*1.2*6*3.5*3.5 40ohm W5 TAI-TECH ADVANCED ELECTRONIC

CORE BEAD 3.5*1.2*6 40ohm F7D FENGHERYIN CORPORATION F7D RH 3.5*1.2*6 0 1.000 PCE L2 FOR D1

RES SMD 1/4W 0ohm J 1206 KAMAYA 100 1.000 PCE J1

RES SMD 1/4W 0ohm J 1206 WALSIN TECHNOLOGY CORPORATI

ROYAL

TY-OHM

YAGEO

KOA

TDC05D447J(TDC05D447)-5m1 100 1.000 PCE NTC2

TTC05474JSY751(TTC474) 0 1.000 PCE NTC2

TDC05D447J-5X1TAmlhf 0 1.000 PCE NTC2

TTC05474JIYDA1 0 1.000 PCE NTC2

AH10B681KD0L-S 0 1.000 PCE CY1

AH10B681KD0LM-S 0 1.000 PCE CY1

UD2KB80-7000 1.000 PCE BD1

W4B RH2.5*3.0*1.0 100 1.000 PCE L4 FOR CY1

BRH3.5*6*1.2 100 1.000 PCE L2 FOR D1

ROYAL

TA-I

YAGEO

WR12X000 PTL 0 1.000 PCE J1

REV: 00

Page 29

< ADP-36CH AH CUSTOMER BOM LIST >

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

DATE: 01/21/2009

DESCRIPTION MFG NAME MFG PART % QPA UNIT DESIGN NO Item text 1

RES SMD 1/4W 100ohm J 1206 KAMAYA 100 1.000 PCE R18

RES SMD 1/4W 100ohm J 1206 KAMAYA 100 1.000 PCE R24

RES SMD 1/4W 100ohm J 1206 KAMAYA 100 1.000 PCE R51A

RES SMD 1/4W 100ohm J 1206 KAMAYA 100 1.000 PCE R51B

RES SMD 1/4W 100ohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 100ohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 100ohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 100ohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 100Kohm J 1206 KAMAYA 0 1.000 PCE R4A

RES SMD 1/4W 100Kohm J 1206 KAMAYA 0 1.000 PCE R4B

RES SMD 1/4W 100Kohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 100Kohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 1.5Kohm J 1206 KAMAYA 0 1.000 PCE R52

RES SMD 1/4W 1.5Kohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 1.5Mohm J 1206 KAMAYA 0 1.000 PCE R1A

RES SMD 1/4W 1.5Mohm J 1206 KAMAYA 0 1.000 PCE R1B

RES SMD 1/4W 1.5Mohm J 1206 KAMAYA 0 1.000 PCE R3B

RES SMD 1/4W 1.5Mohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 1.5Mohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 1.5Mohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 160ohm J 1206 KAMAYA 0 1.000 PCE R15

RES SMD 1/4W 160ohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 1.8Mohm J 1206 KAMAYA 100 1.000 PCE R3A

RES SMD 1/4W 1.8Mohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 5.1Kohm J 1206 KAMAYA 100 1.000 PCE R60

RES SMD 1/4W 5.1Kohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/4W 8.2ohm J 1206 KAMAYA 0 1.000 PCE R8

RES SMD 1/4W 8.2ohm J 1206 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/2W 10mohm F 1206 CYNTEC CO.,LTD. RL1632L R010 FN 1.000 PCE R53

RES SMD 1/10W 10Kohm F 0603 KAMAYA 0 1.000 PCE R16

RES SMD 1/10W 10Kohm F 0603 KAMAYA 0 1.000 PCE R17

RES SMD 1/10W 10Kohm F 0603 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/10W 10Kohm F 0603 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/10W 20Kohm F 0603 KAMAYA 0 1.000 PCE R13

ROYAL

TA-I

YAGEO

ROYAL

TA-I

YAGEO

ROYAL

TA-I

YAGEO

ROYAL

TA-I

YAGEO

WR12X101 JTL 0 1.000 PCE R18

WR12X101 JTL 0 1.000 PCE R24

WR12X101 JTL 0 1.000 PCE R51A

WR12X101 JTL 0 1.000 PCE R51B

ROYAL

TA-I

YAGEO

ROYAL

TA-I

YAGEO

WR12X104 JTL 100 1.000 PCE R4A

WR12X104 JTL 100 1.000 PCE R4B

ROYAL

TA-I

YAGEO

WR12X152 JTL 100 1.000 PCE R52

ROYAL

TA-I

YAGEO

ROYAL

TA-I

YAGEO

ROYAL

TA-I

YAGEO

WR12X155 JTL 100 1.000 PCE R1A

WR12X155 JTL 100 1.000 PCE R1B

WR12X155 JTL 100 1.000 PCE R3B

ROYAL

TA-I

YAGEO

WR12X161 JTL 100 1.000 PCE R15

ROYAL

TA-I

YAGEO

WR12X185 JTL 0 1.000 PCE R3A

ROYAL

TA-I

YAGEO

WR12X512 JTL 0 1.000 PCE R60

ROYAL

TA-I

YAGEO

WR12X8R2 JTL 100 1.000 PCE R8

ROYAL

TA-I

YAGEO

ROYAL

TA-I

YAGEO

WR06X1002FTL 100 1.000 PCE R16

WR06X1002FTL 100 1.000 PCE R17

REV: 00

Page 30

< ADP-36CH AH CUSTOMER BOM LIST >

O

O

O

O

O

O

O

O

O

O

O

O

O

O

D

D

D

D

DATE: 01/21/2009

DESCRIPTION MFG NAME MFG PART % QPA UNIT DESIGN NO Item text 1

RES SMD 1/10W 20Kohm F 0603 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/10W 121Kohm F 0603 KAMAYA 0 1.000 PCE R64

RES SMD 1/10W 121Kohm F 0603 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 4.53Kohm F 0805 KAMAYA 0 1.000 PCE R58

RES SMD 1/8W 4.53Kohm F 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/10W 2.05Kohm F 0603 KAMAYA 0 1.000 PCE R66

RES SMD 1/10W 2.05Kohm F 0603 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 30.1ohm F 0805 KAMAYA 100 1.000 PCE R55

RES SMD 1/8W 30.1ohm F 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 17.8Kohm F 0805 KAMAYA 0 1.000 PCE R59

RES SMD 1/8W 17.8Kohm F 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 332ohm F 0805 KAMAYA 0 1.000 PCE R10

RES SMD 1/8W 332ohm F 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 0ohm J 0805 KAMAYA 0 1.000 PCE J3

RES SMD 1/8W 0ohm J 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 10ohm J 0805 KAMAYA 100 1.000 PCE R14

RES SMD 1/8W 10ohm J 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 100Kohm J 0805 KAMAYA 100 1.000 PCE R12

RES SMD 1/8W 100Kohm J 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 120ohm J 0805 KAMAYA 0 1.000 PCE R9

RES SMD 1/8W 120ohm J 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 300ohm J 0805 KAMAYA 0 1.000 PCE R6

RES SMD 1/8W 300ohm J 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 330ohm J 0805 KAMAYA 0 1.000 PCE R61

RES SMD 1/8W 330ohm J 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD 1/8W 6.2Kohm J 0805 KAMAYA 0 1.000 PCE R63

RES SMD 1/8W 6.2Kohm J 0805 WALSIN TECHNOLOGY CORPORATI

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TAIWAN KAMAYA ELECTRIC CO.,LT

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TAIWAN KAMAYA ELECTRIC CO.,LT

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TAIWAN KAMAYA ELECTRIC CO.,LT

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TAIWAN KAMAYA ELECTRIC CO.,LT

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TA-I TECHNOLOGY CO.,LTD. RH12JTN 915 0 1.000 PCE R20

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TA-I TECHNOLOGY CO.,LTD. RH12JTN 915 0 1.000 PCE R21

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TA-I TECHNOLOGY CO.,LTD. RH12JTN 915 0 1.000 PCE R22

RES SMD HI-VOL 1/4W 9.1Mohm J 1206 TA-I TECHNOLOGY CO.,LTD. RH12JTN 915 0 1.000 PCE R23

ROYAL

TA-I

YAGEO

WR06X2002FTL 100 1.000 PCE R13

ROYAL

TA-I

YAGEO

WR06X1213FTL 100 1.000 PCE R64

ROYAL

TA-I

YAGEO

WR08X4531FTL 100 1.000 PCE R58

ROYAL

TA-I

YAGEO

WR06X2051FTL 100 1.000 PCE R66

ROYAL

TA-I

YAGEO

WR08X30R1FTL 0 1.000 PCE R55

ROYAL

TA-I

YAGEO

WR08X1782FTL 100 1.000 PCE R59

ROYAL

TA-I

YAGEO

WR08X3320FTL 100 1.000 PCE R10

ROYAL

TA-I

YAGEO

WR08X000 PTL 100 1.000 PCE J3

ROYAL

TA-I

YAGEO

WR08X100 JTL 0 1.000 PCE R14

ROYAL

TA-I

YAGEO

WR08X104 JTL 0 1.000 PCE R12

ROYAL

TA-I

YAGEO

WR08X121 JTL 100 1.000 PCE R9

ROYAL

TA-I

YAGEO

WR08X301 JTL 100 1.000 PCE R6

ROYAL

TA-I

YAGEO

WR08X331 JTL 100 1.000 PCE R61

ROYAL

TA-I

YAGEO

WR08X622 JTL 100 1.000 PCE R63

RVC32915JTP 100 1.000 PCE R20

RVC32915JTP 100 1.000 PCE R21

RVC32915JTP 100 1.000 PCE R22

RVC32915JTP 100 1.000 PCE R23

REV: 00

Page 31

< ADP-36CH AH CUSTOMER BOM LIST >

O

O

O

O

O

O

DATE: 01/21/2009

DESCRIPTION MFG NAME MFG PART % QPA UNIT DESIGN NO Item text 1

CAP MC SMD 50V 100pF J C0G 0805 AVX 100 1.000 PCE C7

CAP MC SMD 50V 100pF J C0G 0805 WALSIN TECHNOLOGY CORPORATI

CAP MC SMD 50V 560pF J C0G 0603 AVX 1.000 PCE C56

CAP MC SMD 50V 680pF J C0G 0805 AVX 1.000 PCE C59

CAP MC SMD 50V 1000pF K X7R 0805 AVX 100 1.000 PCE C3

CAP MC SMD 50V 1000pF K X7R 0805 WALSIN TECHNOLOGY CORPORATI

CAP MC SMD 50V 0.1uF K X7R 0603 AVX 1.000 PCE C58

CAP MC SMD 50V 0.1uF K X7R 0805 AVX 100 1.000 PCE C12

CAP MC SMD 50V 0.1uF K X7R 0805 WALSIN TECHNOLOGY CORPORATI

CAP MC SMD 50V 0.1uF K X7R 0805 AVX 1.000 PCE C55

CAP MC SMD 50V 0.1uF K X7R 0805 AVX 100 1.000 PCE C8

CAP MC SMD 50V 0.1uF K X7R 0805 AVX 100 1.000 PCE C9

CAP MC SMD 50V 0.1uF K X7R 0805 WALSIN TECHNOLOGY CORPORATI

CAP MC SMD 50V 0.1uF K X7R 0805 WALSIN TECHNOLOGY CORPORATI

CAP MC SMD 200V 1000pF K X7R 0805 AVX 1.000 PCE C51

CAP MC SMD 25V 1uF K X7R 0805 AVX 100 1.000 PCE C10

CAP MC SMD 25V 1uF K X7R 0805 WALSIN TECHNOLOGY CORPORATI

CAP MC SMD 25V 1uF K X7R 0805 AVX 1.000 PCE C57

CAP MC SMD 500V 1000pF K X7R 1206 AVX 1.000 PCE C2

DIO ZEN 500mW 11.74-12.35V MINIMELF-2P VISHAY SEMICONDUCTOR TLZ12C-GS08 0 1.000 PCE ZD3

DIO ZEN 500mW 11.74-12.35V MINIMELF-2P ROHM CO.,LTD. RLZ TE-11 12C 100 1.000 PCE ZD3

DIO ZEN 500mW 11.76-12.24V MINIMELF-2P VISHAY SEMICONDUCTOR TZMB12-GS08 0 1.000 PCE ZD3

DIO ZEN 500mW 12.55-13.21V MINIMELF-2P VISHAY SEMICONDUCTOR TLZ13B-GS08 0 1.000 PCE ZD2

DIO ZEN 500mW 12.55-13.21V MINIMELF-2P ROHM CO.,LTD. RLZ TE-11 13B 100 1.000 PCE ZD2

DIO ZEN 500mW 14.35-15.09V MINIMELF-2P ROHM CO.,LTD. RLZ TE-11 15C 100 1.000 PCE ZD1

DIO ZEN 0.5W 14.7-15.3V MINIMELF-2P SMD VISHAY SEMICONDUCTOR TZMB15-GS08 0 1.000 PCE ZD1

KEMET

MURATA

PHYCOMP

TDK

0805N101J500LT 0 1.000 PCE C7

KEMET

MURATA

PHYCOMP

TDK

KEMET

MURATA

PHYCOMP

TDK

KEMET

MURATA

PHYCOMP

TDK

0805B102K500CT 0 1.000 PCE C3

KEMET

MURATA

PHYCOMP

TDK

KEMET

MURATA

PHYCOMP

TDK

0805B104K500CT 0 1.000 PCE C12

KEMET

MURATA

PHYCOMP

TDK

KEMET

MURATA

PHYCOMP

TDK

KEMET

MURATA

PHYCOMP

TDK

0805B104K500CT 0 1.000 PCE C8

0805B104K500CT 0 1.000 PCE C9

KEMET

MURATA

PHYCOMP

TDK

KEMET

MURATA

PHYCOMP

TDK

0805B105K250CT 0 1.000 PCE C10

KEMET

MURATA

PHYCOMP

TDK

KEMET

MURATA

PHYCOMP

TDK

REV: 00

Page 32

< ADP-36CH AH CUSTOMER BOM LIST >

S

S

Z

DATE: 01/21/2009

DESCRIPTION MFG NAME MFG PART % QPA UNIT DESIGN NO Item text 1

DIO SW 250mA 110V SOT-23-3P SMD NXP Semiconductors BAS35,235 100 1.000 PCE D51

DIO SW 200mA 120V SOT-23-3P C.A. SMD FAIRCHILD SEMICONDUCTOR HK LT BAS35 0 1.000 PCE D51

DIO SW 200mA 100V LL-34-2P SMD FAIRCHILD SEMICONDUCTOR HK LT FDLL4148 100 1.000 PCE D4

DIO SW 200mA 100V LL-34-2P SMD FAIRCHILD SEMICONDUCTOR HK LT FDLL4148 100 1.000 PCE D5

DIO SW 200mA 100V LL-34-2P SMD FAIRCHILD SEMICONDUCTOR HK LT FDLL4148 100 1.000 PCE D6

DIO SW 200mA 100V LL-34-2P SMD FAIRCHILD SEMICONDUCTOR HK LT FDLL4148 100 1.000 PCE D7

DIO SW 150mA 75V MINIMELF-2P SMD VISHAY SEMICONDUCTOR LL4148-GS08 0 1.000 PCE D4

DIO SW 150mA 75V MINIMELF-2P SMD VISHAY SEMICONDUCTOR LL4148-GS08 0 1.000 PCE D5

DIO SW 150mA 75V MINIMELF-2P SMD VISHAY SEMICONDUCTOR LL4148-GS08 0 1.000 PCE D6

DIO SW 150mA 75V MINIMELF-2P SMD VISHAY SEMICONDUCTOR LL4148-GS08 0 1.000 PCE D7

DIO SW 150mA 75V LL-34-2P SMD ROHM CO.,LTD. RLS4148N TE-11 0 1.000 PCE D4

DIO SW 150mA 75V LL-34-2P SMD ROHM CO.,LTD. RLS4148N TE-11 0 1.000 PCE D5

DIO SW 150mA 75V LL-34-2P SMD ROHM CO.,LTD. RLS4148N TE-11 0 1.000 PCE D6

DIO SW 150mA 75V LL-34-2P SMD ROHM CO.,LTD. RLS4148N TE-11 0 1.000 PCE D7

DIO SW 150mA 100V MINIMELF-2P SMD PAN JIT INTERNATIONAL INC. LL4148 0 1.000 PCE D4

DIO SW 150mA 100V MINIMELF-2P SMD PAN JIT INTERNATIONAL INC. LL4148 0 1.000 PCE D5

DIO SW 150mA 100V MINIMELF-2P SMD PAN JIT INTERNATIONAL INC. LL4148 0 1.000 PCE D6

DIO SW 150mA 100V MINIMELF-2P SMD PAN JIT INTERNATIONAL INC. LL4148 0 1.000 PCE D7

TR 40V 600mA SOT-23-3P 100-300 SMD ON Semiconductor Corporation MMBT4401LT1G 1.000 PCE Q3

TR 40V 600mA SOT-23-3P 100-300 SMD ON Semiconductor Corporation MMBT4401LT1G 1.000 PCE Q4

TR -50V -100mA 2-3F1A-3P 50 SMD TOSHIBA CORP. RN2402(T5L,F) 100 1.000 PCE Q2

TR -50V -500mA CP-3P 50 SMD SANYO ELECTRONIC CO.,LTD. 2SA1518-TB-E 0 1.000 PCE Q2

IC ASIC DUAL OP+VOL REF SOIC-8P SMD STMicroelectronics Asia Pacific Pte DAS01A 1.000 PCE IC51

IC ASIC PWM SO-8P SMD ON Semiconductor Corporation DAP008ADR2G 1.000 PCE IC3

BEAD CH 31ohm 6A 1206 CHILISIN ELECTRONICS CORP. UPB321611T-310Y-NA 0 1.000 PCE L1

BEAD CH 31ohm 6A 1206 CHILISIN ELECTRONICS CORP. UPB321611T-310Y-NA 0 1.000 PCE L51

BEAD CH 31ohm 6A 1206 TAI-TECH ADVANCED ELECTRONIC

BEAD CH 31ohm 6A 1206 TAI-TECH ADVANCED ELECTRONIC

PWB S 0 E2 CEM-1 90.8*34.4*1

SOCKET C8 SK-1022M 1.2 #20 DELTA 1.000 PCE

DC POWER CORD PLUG L1800 BLK T1 ASLINK (2007/10/09) 1.000 PCE

SCREW M M3*0.5*6 FF C S18C ZN DURABLE (2008/04/26) 1.000 PCE FOR HS1

NUT HEXH+FLANGE M3*3.2 S18C ZN DURABLE (2008/04/26) 1.000 PCE FOR HS1

TAPE POLYESTER 10mm 1L #1350F-1 YEL Minnesota Mining Manufacture Co., #1350F-1 W=10 100 60.000 MMT FOR SHIELD

TAPE POLYESTER 10mm 1L CT-280 LIGHT YEL YAHUA STICKING TAPE CO LTD CT-280 W=10 0 60.000 MMT FOR SHIELD

TAPE PET 12mm 3L #1350F-1 YEL Minnesota Mining Manufacture Co., #1350F-1 W=12 3L 30.000 MMT FOR SOCKET

TAPE PET 12mm 3L #1350F-1 YEL Minnesota Mining Manufacture Co., #1350F-1 W=12 3L 30.000 MMT FOR HSK2

TAPE POLYESTER 30mm 3L #1350F-1 LIGHT Minnesota Mining Manufacture Co., #1350F-1 W=30 3L 16.500 MMT FOR HSK2

TAPE POLYESTER 6mm 2L #44 YEL Minnesota Mining Manufacture Co., #44 W=6 2L 18.000 MMT FOR T1

TUBE HS PO 6*0.25 BLK 600V 125℃ RAYCHEM CORPORATION VERSAFIT 6*.25 BLK 18.000 MMT FOR D1

TUBE PTFE 20*0.3 #20 TW CLEAR MARKEL TFE-200C-150V 11.000 MMT FOR C1(-)

INSULATOR PP 26*10*6*0.45 BLK BORNSUN (2008/10/17) BN-ZD16 1.000 PCE

BRITE PLUS

KEENRICH

AE

WANNIENFU

HSIANG KUO

TECHNI

DRACO

SHANGHAI WANZHENG

CAROL

EVERFULL

FOXCONN

JI-HAW

WENTAI

LIANYING

SCREWTECH

LIANYING

SCREWTECH

LONGWELL COMPANY LHS-125FR 6*0.25 BLK

MARKEL CORPORATION LHS-125FR 6*0.25 BLK

DONGGUAN SALIPT CO.,LTD SALIPT S-901-600 6*0.25 BLK

CHANGYUAN ELECTRONICS (SHEN

SUMITOMO CORPORATION TAIWAN F32 6*.25 BLK

MARKEL TFE-200C-300V

MARKEL TFE-200C-600V

ZEUS TFE-SW-600

ZEUS TFE-TW-300

ZEUS TFE-LW-150

ITW FORMEX FORMEX-18

ITW FORMEX FORMEX GK-17

SABIC FR25A

SABIC FR700

SUN DELTA (2008/04/15) VS120

HCB3216KF-310T60 100 1.000 PCE L1

HCB3216KF-310T60 100 1.000 PCE L51

1.000 PCE PWB

CB-HFT6*0.25 BLK

REV: 00

Page 33

< ADP-36CH AH CUSTOMER BOM LIST >

DATE: 01/21/2009

DESCRIPTION MFG NAME MFG PART % QPA UNIT DESIGN NO Item text 1

SUN DELTA (2008/04/15) VS520

INSULATOR CR RUBBER 10*3 T2.5 5.000 PCE

LABEL PACKING ART PAPER 60*30 T0.1 100 16.667 TP FOR JANUARY

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR FEBRUARY

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR MARCH

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR APRIL

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR MAY

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR JUNE

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR JULY

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR AUGUST

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR SEPTEMBER

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR OCTOBER

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR NOVEMBER

LABEL PACKING ART PAPER 60*30 T0.1 0 16.667 TP FOR DECEMBER

LABEL PACKING ART PAPER 75*105 T0.125 16.667 TP FOR PSE REQUEST

LABEL ROHS POLYESTER 60*60 T0.05 16.667 TP FOR RoHS LABEL

LABEL SPEC POLYESTER 72*28 T0.15 1.000 PCE

CYMMETRIK

YONG TA

CASE CHASSIS PC 94V0 96*42 BLK BAYER MAKROLON 6465 1.000 PCE

BAYER MAKROLON 6485

DOW EMERGE 8600

SABIC LEXAN 945

TEIJIN PANLITE MN-3600H

TEIJIN (2007/12/18) PANLITE LN-2520HB

CASE COVER PC 94V0 96*42*20.2 BLK BAYER MAKROLON 6465 1.000 PCE

BAYER MAKROLON 6485

DOW EMERGE 8600

SABIC LEXAN 945

TEIJIN PANLITE MN-3600H

TEIJIN (2007/12/18) PANLITE LN-2520HB

HSK STAMP SPTE 60.5*16.5 T0.5 TIN PLATED 1.000 PCE HS1

HSK STAMP SPTE 28.5*7.5*21.9 T0.5 1.000 PCE HS2

HENG YU

HOO THAI

WANCHENG (2008/01/10)

WEIDI

WEISHENG

SHIELD AL 68.4*37.2*22.2*0.2 1.000 PCE

SHIELD ASSY ADP-36CH ACF 1.000 PCE

CHON YANG

HOO THAI

REV: 00

Page 34

9.Safety License

Page 35

Page 36

Page 37

DEL T A ELECT RONICS, IN C.

Statement of Compliance

**************** ********** ***

Reference no: SE49011501

Issued Date: 2009/02/05

This equipment ha s been eva luated in acco rdance w ith Japan Technic al

requi

is stated as the following.

Model name: ADP-36 CH A (AD P-36CH A H)

Customer: MSI

Importer Name: エムエスアイコンピュータージャパン株式会社

PSE certificate No.:

Issued date of certificate : 2006/05/18

Validity of certif icate: 2 011/05/1 7

Factory: Delta Electronics (Jiang Su), Ltd.

Prepared by Reviewed by:

rements Clause 2 and fou nd to comply with the requirements. Detailed inform ation

JD 50084630

Jason Chen Parry Pan

Engineer Senior Engineer

Regulatory & Reliability Engineering Regulatory & Reliability Engineering

Power System Business Group Power System Business Group

Safety@delta.com.tw

Ext.6428 Ext.6428

Provide the certificate via Delta sales

Signed by Delta Sales

Signed by Customer:

Company name/ Contact Person

Safety@delta.com.tw

Date

Date

Page 38

Page 39

Page 40

Page 41

Page 42

120YB

第 1 頁,共 2 頁QQGQ.E131881 - Power Supplies, Information Technology Equipment Including El...

UL Online Certifications Directory

QQGQ.E131881

Power Supplies, Information Technology Equipment Including Electrical Business

Equipment

Page Bottom

Power Supplies, Information Technology Equipment Including Electrical Business

Equipment

See General Information for Power Supplies, Information Technology Equipment Including Electrical Business Equipment

DELTA ELECTRONICS INC E131881

3 TUNG YUAN RD

CHUNGLI INDUSTRIAL ZONE

TAOYUAN, TAOYUAN HSIEN 320 TAIWAN

AC Adapter, Model(s) 92P1153,92P1154, 92P1155, 92P1156, 92P1189, 92P1191, A1172, A1188, ADP-120TB A, ADP-64CB B, VGP-AC16V9, ADP-90NB B,

ADP-90NB C, ADP-90NB D, EA-RD1V, EADP-108AB A, EADP-10CB A, FCLSD-0604, EADP-12CB B, EADP-15DB A, EADP-24DB A, EAPD-15DB A, K30266,

PA3241U-2ACA, PA3282U-2ACA, PA3377E-2ACA, PA3282U-2ACA, PA3377E-2ACA, PA3378E-2ACA, PCGA-AC19V7 , PCS-AC19V6A, SADP-65KB CX(a), SADP65KB DX(a), SADP-75PB A, PA3283U-5ACA, SADP-75PB B, PA3378E-3AC3, SADP-90FH A, SADP-90FH B, VGP-AC19V17.

AC Adaptor, Model(s) 1AV4U11B30200, A1071, A1184, AC-380, ADP-100FB XX, ADP-120UB B, ADP-120VB B, ADP-180EB B, ADP-180EB D, ADP-36CH A, ADP-

36CH B, ADP-36EH B, ADP-40FH A, ADP69, ADP-45AD A, ADP-50UH A, ADP-64CB, ADP-65DB CX (c), ADP-65DB DX (c), ADP-65HB AX, ADP-65HB BX,

PPP0009D(#), ADP-75RB A, ADP-75SB AX (a), ADP-75SB BX (a), ADP-80NB A, ADP-90NB A, ADP-90YB C, DA65NS0-00, DA90PS0-00, DW7187, EA-TX1V, EATX22V and SADP-220DB A, EADP-12BB B, EADP-15BB A, EADP-24CB B, EADP-25AB A, EADP-30BB A, EADP-30BB B, EADP-42BB A, EADP-45AB B(.), EADP45BB B, EADP-48BB A, EADP-48BB B, EADP-50AB B, EADP-60DB, EADP-60EB A, 1AV4U11B30100, EADP-60EB B, EADP-60FB B, EADP-90AB B, HSTNN-DA03,

K30245, K30270, NL-A72J, PA2521U-3ACA, PA3507U-1ACA, ADP-120YB A, PC-AP8200, PCGA-AC19V4, SADP-120CH A, SADP-120CH B, SADP-135EB B, SADP65KB C, SADP-65KB D, SADP-75TB A, VGP-AC16V8.

AC Adaptors, Model(s) 02K7087, 02K7088, 02K7089, 02K7090, 08K8206, 08K8207 , 08K8208, 08K8209, 0950-4197, 0950-4199, 0950-4334, 0950-4335,

0950-4340, 0950-4401, 0950-4406, 1031105 -0001 REV.3, 12J0201, 2862, 2862A, 92P1028, 92P1029, 92P1030, 92P1031, A1003, A1021, A1096, A1036,

A1070, A1102, A1105, A291B, A351H, AC-007XX, AC-DP001, ADP-10TB REV.F, ADP-120GB A, ADP-120GB B, ADP-120GB C, ADP-120GB D, ADP-120JB A,

92P1026, 92P1027, ADP-120MB, ADP-120NB A, ADP-120NB B, ADP-120SB A, ADP-120SB B , ADP-120TB B, ADP-120ZB AA, ADP-120ZB AB, ADP-120ZB AC,

ADP-120ZB AD, ADP-120ZB BX(a), ADP-12CH A, ADP-12DH A, ADP-135DB AX, ADP-135DB BX, ADP-13CBA, ADP-14EB A, ADP-14EB B, ADP-150BB B, ADP150CB A, ADP-150CB B, ADP-150EB B, ADP-150GB A, ADP-150GB BA, ADP-150GB BB, ADP-15GH B, ADP-15HH A, ADP-15NH A, ADP-16GB A, ADP-180AB,

ADP-180BB B, ADP-180CB B, ADP-18PB, ADP-220AB B, ADP-24MB, ADP-29EB A, ADP-33AB XX*, ADP-36DH A, ADP-40CH A, EA-CG1V, ADP-4EB XX*, ADP50UH A, ADP-55CB B, ADP-5VBC, ADP-60NH, ADP-60NH B, ADP-60RH A, ADP-60RH B, PA3282U-1ACA, PA3365U-1ACA, PA3377E-1ACA, ADP-64AB REV.B,

ADP-64BB B, ADP-65JB B, ADP-65LB AX (b), ADP-65MB B, ADP-72DB B, 65P8322, 92P1018, 92P1019, ADP-72EB A, 92P1020, 92P1021, ADP-75FB BXX, ADP75FB XX, ADP-75HB REV.B, ADP-75HBXX*, ADP-75KB A, ADP-75KB B, ADP-80LB A, ADP-90AH B, ADP-90HB, ADP-90HBB, ADP-90SB AX (a), ADP-90YB, ADP90YB B, D220P-01, EADP-150DB B, DPS-136AP, DPS-200TP, DPS-30NB XX, DTL-H10020, DTL-H10200, EA-AL1V, EADP-10BB REV.B, EADP-15CB A, NL-A75J,

EADP-60BB B, ESRPS1 XX, F1236A#ABA, f4600a, f4814a, L1864-80001, MCS-AC1, EADP-10AB A, PA3283U-3ACA, PA3378E-1ACA, PA3507E-1AC3, ADPB, PC-AP7000, PCGA-AC19V3, PWSP0022 XY, RPS-800-1, RPS-800-2, SADP-220CB BX(a), SADP-220DB B, SADP-65KB AX, PC-AP7800, SADP-65KB BX, VGPAC19V10, VGP-AC19V12, VGP-AC5V1.

AC/DC Adaptor, Model(s) ADP-15ZB B.

Accessory Xbox 360 Quick Charger Kit, Model(s) DPSN-10EB XX (m).

Accessory-Switching Power Supply, Model(s) DPS-180KB-7 XX, DPS-220DB XX(&), DPS-225KB XX ($), DPS-225KB-1 XX ($), DPS-225LB XX ($), DPS-

225LB-1 XX ($), DPS-310HB XX, DPS-310HB-2 XX, DPS-230JB XX, DPS-230JB-2 XX($).

Direct plug-In adapters, Model(s) 0950-4404, 190162-0000, AD-20, ADP-18LB B, ADP-3ZB A, ADP-4RB B, ADP-5FH B, EA-75, ADP-5ZB B, PV-AC01.

Direct Plug-In Power Adaptor, Model(s) A391UC, PV-AC11.

Listed Accessory AC Adaptor, Model(s) DPSN-186CB XX, DPSN-186DB XX($), DPSN-186EB XX(m), DPSN-216BB XX.

Listed Accessory-Switching Power Supply, Model(s) DPS-280FB XX($).

Power Adaptor, Model(s) ADP-90SB BX (a).

Power Backup Supply, Model(s) EADP-18RB A, PB-1000.

Power Supply, Model(s) ADP-180EB B, ADP-60AF, ADP-58AF, ADP-60ZH A, ADP-63BB B, ADP-90AB B, ADP-90AH B, ADP-9HB A, DPS-200PB-156 XX($), DPS-

225DB XX (=).

Switching power supplies, Model(s) A181B, ADP-18KB AX, ADP-30CH A, ADP-58AF, ADP -60AF, DPS-230HB XX, DPS-310CB XX.

Switching power supply, Model(s) DPS-225GB XX, DPS-225HB XX ($), DPS-225HB CX ($).

2006/7/21http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpage.html?name=QQ...

Page 43

UL permits the reproduction of the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide Information, Designs

第 2 頁,共 2 頁QQGQ.E131881 - Power Supplies, Information Technology Equipment Including El...

# - X=A, B, C, D or blank

($) - Where X can be 0-9, A-Z or blank

(=) - where X could be 0-9, A-Z, a-z or blank

(a) - Where X can be A, B, C or D

(b) - Where X may be A, B, C or D for different output rating, A is for +18.5 V, B is for +19 V, C is for +19.5 V, D is for +20 V

(c) - Where X may be A, B, C or D for different output rating; A is for +18.5V/3.51A, B is for +19V/3.42A, C is for 19.5/3.33A, D is for 20V/3.25A

* - Where "X" is A-Z, 0-9, dash, dot, or blank.

Last Updated on 2006-07-20

Questions? Notice of Disclaimer Page Top

Copyright © 2006 Underwriters Laboratories Inc.®

The appearance of a company's name or product in this database does not in itself assure that products so identified have been manufactured under UL's

Follow-Up Service. Only those products bearing the UL Mark should be considered to be Listed and covered under UL's Follow-Up Service. Always look for the

Mark on the product.

and/or Listings (files) must be presented in their entirety and in a non-misleading manner, without any manipulation of the data (or drawings). 2. The

statement "Reprinted from the Online Certifications Directory with permission from Underwriters Laboratories Inc." must appear adjacent to the extracted

material. In addition, the reprinted material must include a copyright notice in the following format: "Copyright © 2006 Underwriters Laboratories Inc.® "

2006/7/21http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpage.html?name=QQ...

Page 44

第 1 頁,共 2 頁QQGQ7.E131881 - Power Supplies, Information Technology Equipment Including ...

UL Online Certifications Directory

QQGQ7.E131881

Power Supplies, Information Technology Equipment Including Electrical Business

Equipment Certified for Canada

Page Bottom

Power Supplies, Information Technology Equipment Including Electrical Business

Equipment Certified for Canada

See General Information for Power Supplies, Information Technology Equipment Including Electrical Business Equipment Certified for Canada

DELTA ELECTRONICS INC E131881

3 TUNG YUAN RD

CHUNGLI INDUSTRIAL ZONE

TAOYUAN, TAOYUAN HSIEN 320 TAIWAN

AC Adapter, Model(s) 92P1153,92P1154, 92P1155, 92P1156, 92P1189, 92P1191, A1172, A1188, ADP-120TB A, ADP-64CB B, VGP-AC16V9, ADP-90NB B,

ADP-90NB C, ADP-90NB D, EA-RD1V, EADP-108AB A, EADP-10CB A, FCLSD-0604, EADP-12CB B, EADP-15DB A, EADP-24DB A, EAPD-15DB A, K30266,

PA3241U-2ACA, PA3282U-2ACA, PA3377E-2ACA, PA3282U-2ACA, PA3377E-2ACA, PA3378E-2ACA, PCGA-AC19V7 , PCS-AC19V6A, SADP-65KB CX(a), SADP65KB DX(a), SADP-75PB A, PA3283U-5ACA, SADP-75PB B, PA3378E-3AC3, SADP-90FH A, SADP-90FH B, VGP-AC19V17.

AC Adaptor, Model(s) 1AV4U11B30200, A1071, A1184, AC-380, ADP-100FB XX, ADP-120UB B, ADP-120VB B, ADP-180EB B, ADP-180EB D, ADP-36CH A, ADP-

36CH B, ADP-36EH B, ADP-40FH A, ADP69, ADP-45AD A, ADP-50UH A, ADP-64CB, ADP-65DB CX (c), ADP-65DB DX (c), ADP-65HB AX, ADP-65HB BX,

PPP0009D(#), ADP-75RB A, ADP-75SB AX (a), ADP-75SB BX (a), ADP-80NB A, ADP-90NB A, ADP-90YB C, DA65NS0-00, DA90PS0-00, DW7187, EA-TX1V, EATX22V and SADP-220DB A, EADP-12BB B, EADP-15BB A, EADP-24CB B, EADP-25AB A, EADP-30BB A, EADP-30BB B, EADP-42BB A, EADP-45AB B(.), EADP45BB B, EADP-48BB A, EADP-48BB B, EADP-50AB B, EADP-60DB, EADP-60EB A, 1AV4U11B30100, EADP-60EB B, EADP-60FB B, EADP-90AB B, HSTNN-DA03,

K30245, K30270, NL-A72J, PA2521U-3ACA, PA3507U-1ACA, ADP-120YB A, PC-AP8200, PCGA-AC19V4, SADP-120CH A, SADP-120CH B, SADP-135EB B, SADP65KB C, SADP-65KB D, SADP-75TB A, VGP-AC16V8.

AC Adaptors, Model(s) 02K7087, 02K7088, 02K7089, 02K7090, 08K8206, 08K8207 , 08K8208, 08K8209, 0950-4197, 0950-4199, 0950-4334, 0950-4335,

0950-4340, 0950-4401, 0950-4406, 1031105 -0001 REV.3, 12J0201, 92P1028, 92P1029, 92P1030, 92P1031, A1003, A1021, A1096, A1036, A1070, A1102,

A1105, A291B, A351H, AC-DP001, ADP-10TB REV.F, ADP-120GB A, ADP-120GB B, ADP-120GB C, ADP-120GB D, ADP-120JB A, 92P1026, 92P1027, ADP120MB, ADP-120NB A, ADP-120NB B, ADP-120SB A , ADP-120SB B, ADP-120TB B, ADP-120ZB AA, ADP-120ZB AB, ADP-120ZB AC, ADP-120ZB AD, ADP-120ZB

BX(a), ADP-12CH A, ADP-12DH A, ADP-135DB AX, ADP-135DB BX, ADP-13CBA, ADP-14EB A , ADP-14EB B, ADP-150BB B, ADP-150CB A, ADP-150CB B, ADP 150EB B, ADP-150GB A, ADP-150GB BA, ADP-150GB BB, ADP-15GH B, ADP-15HH A, ADP-15NH A, ADP-16GB A, ADP-180AB, ADP-180BB B, ADP-180CB B,

ADP-18PB, ADP-220AB B , ADP-24MB, ADP-29EB A, ADP-33AB XX*, ADP-36DH A, ADP-40CH A, EA-CG1V, ADP-4EB XX*, ADP-50UH A, ADP-55CB B, ADP-5VBC,

ADP-60NH, ADP-60NH B , ADP-60RH A, ADP-60RH B, PA3282U-1ACA, PA3365U-1ACA, PA3377E-1ACA, ADP-64AB REV.B, ADP-64BB B, ADP-65JB B, ADP-65LB

AX (b), ADP-65MB B, ADP-72DB B, 65P8322, 92P1018, 92P1019, ADP-72EB A, 92P1020, 92P1021, ADP-75FB BXX , ADP-75FB XX, ADP-75HB REV.B, ADP75HBXX*, ADP-75KB A, ADP-75KB B, ADP-80LB A, ADP-90AH B, ADP-90HB, ADP-90HBB, ADP-90SB AX (a), ADP-90YB, ADP-90YB B, D220P-01, EADP-150DB

B, DPS-136AP, DPS-200TP, DPS-30NB XX, DTL-H10020, DTL-H10200 , EA-AL1V, EADP-10BB REV.B, EADP-15CB A, NL-A75J, EADP-60BB B, f4600a , f4814a,

L1864-80001, MCS-AC1, EADP-10AB A, PA3283U-3ACA, PA3378E-1ACA, PA3507E-1AC3, ADP-120YB B, PC-AP7000, PCGA-AC19V3, RPS-800-1, RPS-800-2,

SADP-220CB BX(a), SADP-220DB B, SADP-65KB AX, PC-AP7800, SADP-65KB BX, VGP-AC19V10, VGP-AC19V12, VGP-AC5V1.

AC/DC Adaptor, Model(s) ADP-15ZB B.

Accessory Xbox 360 Quick Charger Kit, Model(s) DPSN-10EB XX (m).

Accessory-Switching Power Supply, Model(s) DPS-180KB-7 XX, DPS-220DB XX(&), DPS-225KB XX ($), DPS-225KB-1 XX ($), DPS-225LB XX ($), DPS-

225LB-1 XX ($), DPS-310HB XX, DPS-310HB-2 XX, DPS-230JB XX, DPS-230JB-2 XX($).

Direct plug-In adapters, Model(s) 0950-4404, 190162-0000, AD-20, ADP-18LB B, ADP-3ZB A, ADP-4RB B, ADP-5FH B, EA-75, ADP-5ZB B, PV-AC01.

Direct Plug-In Power Adaptor, Model(s) A391UC, PV-AC11.

Listed Accessory AC Adaptor, Model(s) DPSN-186CB XX, DPSN-186DB XX($), DPSN-186EB XX(m), DPSN-216BB XX.

Listed Accessory-Switching Power Supply, Model(s) DPS-280FB XX($).

Power Adaptor, Model(s) ADP-90SB BX (a).

Power Backup Supply, Model(s) EADP-18RB A, PB-1000.

Power Supply, Model(s) ADP-180EB B, ADP-60AF, ADP-58AF, ADP-60ZH A, ADP-63BB B, ADP-90AB B, ADP-90AH B, ADP-9HB A, DPS-200PB-156 XX($), DPS-

225DB XX (=).

Switching power supplies, Model(s) A181B, ADP-18KB AX, ADP-30CH A, ADP-58AF, ADP -60AF, DPS-230HB XX, DPS-310CB XX.

Switching power supply, Model(s) DPS-225GB XX, DPS-225HB XX ($), DPS-225HB CX ($).

# - X=A, B, C, D or blank

2006/7/21http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpage.html?name=QQ...

Page 45

UL permits the reproduction of the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide Information, Designs

第 2 頁,共 2 頁QQGQ7.E131881 - Power Supplies, Information Technology Equipment Including ...

($) - Where X can be 0-9, A-Z or blank

(=) - where X could be 0-9, A-Z, a-z or blank

(a) - Where X can be A, B, C or D

(b) - Where X may be A, B, C or D for different output rating, A is for +18.5 V, B is for +19 V, C is for +19.5 V, D is for +20 V

(c) - Where X may be A, B, C or D for different output rating; A is for +18.5V/3.51A, B is for +19V/3.42A, C is for 19.5/3.33A, D is for 20V/3.25A

* - Where "X" is A-Z, 0-9, dash, dot, or blank.

Last Updated on 2006-07-20

Questions? Notice of Disclaimer Page Top

Copyright © 2006 Underwriters Laboratories Inc.®

The appearance of a company's name or product in this database does not in itself assure that products so identified have been manufactured under UL's

Follow-Up Service. Only those products bearing the UL Mark should be considered to be Listed and covered under UL's Follow-Up Service. Always look for the

Mark on the product.

and/or Listings (files) must be presented in their entirety and in a non-misleading manner, without any manipulation of the data (or drawings). 2. The

statement "Reprinted from the Online Certifications Directory with permission from Underwriters Laboratories Inc." must appear adjacent to the extracted

material. In addition, the reprinted material must include a copyright notice in the following format: "Copyright © 2006 Underwriters Laboratories Inc.® "

2006/7/21http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpage.html?name=QQ...

Page 46

DECLARATION OF CONFORMITY

Manufacturer:

Name: Delta Electronics, Inc.

Address:

No 3, Tung Yuan Road, Chungli

Industrial Zone, Taoyuan, TAIWAN

Tel: 886- 3- 4526107

Fax: 886 -3- 4515804

Declares that:

Product Name: AC ADAPTER

Type Designation: ADP-36CH A, Trademark: DELTA and TOSHIBA

Input/Output Rating:

Input: 100-240V, 1.2A, 50-60Hz

Output: +12V/3A

ADP-36CH AB, Trademark: PANASONIC

Importer:

Name: Delta Electronics Europe.

Address:

No 1, Redwood Court

Peel Park Campus

East Kilbride, G74 5PF

Scotland, UK

Tel: 44-0-1355-588 875

Fax: 44-0-1355-588 889

Ref.# SE94122106

Page 1 of 2

Compliance with the Following:

Standards Directives

IEC 60065: 1998

EN 60065: 1998

IEC 60950-1: 2001

EN 60950-1: 2001

EN 55013: 1990 + A12: 1994 + A13: 1996

EN 55022: 1998 + A1: 2000 + A2: 2003, Class B

EN 61000-3-2: 2000, Class A

EN 61000-3-3: 1995 + A1: 2001

EN 55024: 1998 + A1: 2001 + A2: 2003

IEC 61000-4-2: 2001

IEC 61000-4-3: 2002

IEC 61000-4-4: 1995 + A1: 2000 + A2: 2001

IEC 61000-4-5: 2001

IEC 61000-4-6: 1996 + A1: 2000

IEC 61000-4-8: 2001

IEC 61000-4-11: 2001

73/23/EEC

93/68/EEC

(Low Voltage Directive)

89/336/EEC

92/31/EEC

93/68/EEC

(EMC Directive)

NO. 3, TUNG YUAN ROAD, CHUNGLI INDUSTRIAL ZONE, TAOYUAN 320, TAIWAN

Page 47

DECLARATION OF CONFORMITY

Ref.# SE94122106

Page 2 of 2

Switching Power Supply, Model ADP-36CH A for DELTA and TOSHIBA, ADP-36CH AB for

PANASONIC conforms to the following product specifications.

Standards Tested by Test Report No.

(Certificate No.)

Product Safety:

IEC 60065: 1998

EN 60065: 1998

IEC 60950-1: 2001

EN 60950-1: 2001

EMC:

Nemko

SPORTON International Inc.

Test Report NO.:

200306194; 10030; 11838; 30186

(Certificate No.:

NO 18791 & NO 18792;

NO 18791/M1 & NO 18792/M1;

NO 18791/M2 & NO 18792/M2;

NO 30627)

Test Report NO.:

33546

(Certificate No.:

NO 31249 & NO 31250 & NO 31251)

Report no.: C312912, EC312912-01

EN 55013: 1990 + A12: 1994 + A13: 1996

EN 55022: 1998 + A1: 2000 + A2: 2003, Class B

EN 61000-3-2: 2000, Class A

EN 61000-3-3: 1995 + A1: 2001

EN 55024: 1998 + A1: 2001 + A2: 2003

IEC 61000-4-2: 2001

IEC 61000-4-3: 2002

IEC 61000-4-4: 1995 + A1: 2000 + A2: 2001

IEC 61000-4-5: 2001

IEC 61000-4-6: 1996 + A1: 2000

IEC 61000-4-8: 2001

IEC 61000-4-11: 2001

Signed:

AHUI WANG

Engineer

Regulatory & Reliability Engineering

Power System Business Group I

Delta Electronics, Inc.

Date: 12-28-04

Place: Taiwan

NO. 3, TUNG YUAN ROAD, CHUNGLI INDUSTRIAL ZONE, TAOYUAN 320, TAIWAN

Signed:

JACKIE CHANG

Sales Manager

Delta Electronics Europe

Date: 12-28-04

Place: UK

Page 48

DECLARATION OF CONFORMITY

Manufacturer:

Name: Delta Electronics, Inc.

Address:

No 3, Tung Yuan Road, Chungli

Industrial Zone, Taoyuan, TAIWAN

Tel: 886- 3- 4526107

Fax: 886 -3- 4515804

Declares that:

Product Name: AC ADAPTER

Type Designation: ADP-36CH A and ADP-36CH AB

Input/Output Rating:

Input: 100-240V, 1.2A, 50-60Hz

Output: +12V/3A

Importer:

Name: Delta Electronics Europe.

Address:

No 1, Redwood Court

Peel Park Campus

East Kilbride, G74 5PF

Scotland, UK

Tel: 44-0-1355-588 875

Fax: 44-0-1355-588 889

Ref.# SE94101201

Page 1 of 2

Compliance with the Following:

Standards Directives

IEC 60065: 1998

EN 60065: 1998

EN 55013: 1990 + A12: 1994 + A13: 1996

EN 55022: 1998 + A1: 2000 + A2: 2003, Class B

EN 61000-3-2: 2000, Class A

EN 61000-3-3: 1995 + A1: 2001

EN 55024: 1998 + A1: 2001 + A2: 2003

IEC 61000-4-2: 2001

IEC 61000-4-3: 2002

IEC 61000-4-4: 1995 + A1: 2000 + A2: 2001

IEC 61000-4-5: 2001

IEC 61000-4-6: 1996 + A1: 2000

IEC 61000-4-8: 2001

IEC 61000-4-11: 2001

73/23/EEC

93/68/EEC

(Low Voltage Directive)

89/336/EEC

92/31/EEC

93/68/EEC

(EMC Directive)

NO. 3, TUNG YUAN ROAD, CHUNGLI INDUSTRIAL ZONE, TAOYUAN 320, TAIWAN

Page 49

DECLARATION OF CONFORMITY

Ref.# SE94101201

Page 2 of 2

Switching Power Supply, Model ADP-36CH A and ADP-36CH AB conforms to the following

product specifications.

Standards Tested by Test Report No.

(Certificate No.)

Product Safety:

IEC 60065: 1998

EN 60065: 1998

EMC:

Nemko Test Report NO.:

200306194, 10030, 11838,

30186

(Certificate No.:

18791/M1-M2, 18792/M1-M2,

)

SPORTON International Inc.

30627

Report no.: C312912,

EC312912-01

EN 55013: 1990 + A12: 1994 + A13: 1996

EN 55022: 1998 + A1: 2000 + A2: 2003, Class B

EN 61000-3-2: 2000, Class A

EN 61000-3-3: 1995 + A1: 2001

EN 55024: 1998 + A1: 2001 + A2: 2003

IEC 61000-4-2: 2001

IEC 61000-4-3: 2002

IEC 61000-4-4: 1995 + A1: 2000 + A2: 2001

IEC 61000-4-5: 2001

IEC 61000-4-6: 1996 + A1: 2000

IEC 61000-4-8: 2001

IEC 61000-4-11: 2001

Signed:

AHUI WANG

Engineer

Product Safety Engineering

Power System Business Group I

Delta Electronics, Inc.

Date: 10-12-04

Place: Taiwan

Signed:

JACKIE CHANG

Sales Manager

Delta Electronics Europe

Date: 10-12-04

Place: UK

NO. 3, TUNG YUAN ROAD, CHUNGLI INDUSTRIAL ZONE, TAOYUAN 320, TAIWAN

Page 50

Page 51

CE Test Report Report No. : C312912

CE TEST REPORT

According to

European Standard EN 55013:1990/A12:1994/A13:1996,

EN 55022:1998 Class B,

EN 61000-3-2: 2000, EN 61000 -3-3:1995 and EN 55024:1998

( IEC 61000-4-2:1995, IEC 61000-4-3:1995, IEC 61000-4-4:1995,

IEC 61000-4-5:1995, IEC 61000-4-6:1996, IEC 61000 -4-8:1993,

IEC 61000-4-11:1994 )

AC/DC Adapter

Equipment

Model No.

Applicant

The test result refers exclusively to the test presented test model / sample.

Without written approval of SPORTON International Inc., the test report shall not be

reproduced except in full .

This test report is only applicable to European Community.

:

:

ADP-36CH A

DELTA ELECTRONICS, INC.

:

No. 3, Tung Yuan Road, Chungli Industrial Zone,

Taoyuan Hsien, Taiwan, R.O.C .

SPORTON International Inc.

6F, No. 106, Sec. 1, Hsin Tai Wu Rd., Hsi Chih, Taipei Hsien, Taiwan, R.O.C.

SPORTON International Inc.

TEL : 886-2-2696 -2468

FAX : 886-2-2696 -2255

Page 52

SPORTON International Inc.

Page No.

: i TEL : 886

-2-

2696-2468 Issued Date

:

FAX : 886

-2-

2696-2255

CE Test Report Report No. : C312912

Table of Contents

History of this test report.........................................................................................................iv

CERTIFICATE OF COMPLI ANCE ..............................................................................................................1

1. General Description of Equipment under Test ......................................................................................2

1.1 Applicant.......................................................................................................................................................................................2

1.2 Manufacturer .................................................................................................................................................................................2

1.3 Basic Description of Equipment under Test..................................................................................................................................2

1.4 Feature of Equipment under Test.................................................................................................................................................2

2. Test Configuration of Equipment under Test ........................................................................................3

2.1 Test Manner..................................................................................................................................................................................3

2.2 Description of Test System...........................................................................................................................................................3

3. Test Software ........................................................................................................................................4

4. General Information of Test ..................................................................................................................5

4.1 Test Facility...................................................................................................................................................................................5

4.2 Test Voltage ..................................................................................................................................................................................5

4.3 Standard for Methods of Measurement.........................................................................................................................................5

4.4 Test in Compliance with................................................................................................................................................................5

4.5 Frequency Range Investigated.....................................................................................................................................................5

4.6 Test Distance ................................................................................................................................................................................5

5. Test of Conducted Powerline for Broadcast Receivers and Associated Equipment .............................6

5.1 Description of Major Test Instruments...........................................................................................................................................6

5.2 Test Procedures............................................................................................................................................................................7

5.3 Typical Test Setup Layout of Conducted Powerline for Broadcast Receivers and Associated Equipment....................................8

5.4 Test Result of AC Powerline Conducted for Broadcast Receivers and Associated Equipment Emission.....................................9

5.5 Photographs of Counducted Powerline for Broadcast Receivers and Associated Equipment Test Configuration......................10

6. Test of Conducted Powerline for ITE ..................................................................................................11

6.1 Description of Major Test Instruments.........................................................................................................................................11

6.2 Test Procedures..........................................................................................................................................................................12

6.3 Typical Test Setup Layout of Conducted Powerline for ITE........................................................................................................13

6.4 Test Result of AC Conducted Powerline for ITE Emission..........................................................................................................14

6.5 Photographs of Conducted Powerline for ITE Test Configuration...............................................................................................15

7. Test of Disturbance Power..................................................................................................................16

7.1 Major Measuring Instruments......................................................................................................................................................16

7.2 Limits of Disturbance Power Test...............................................................................................................................................16

7.3 Test Procedures..........................................................................................................................................................................17

7.4 Test Result of Disturbance Power Test.......................................................................................................................................18

7.5 Photographs of Disturbance Power Test.....................................................................................................................................21

8. Test of Radiated Emission for ITE......................................................................................................22

8.1 Major Measuring Instruments......................................................................................................................................................22

8.2 Test Procedures..........................................................................................................................................................................23

8.3 Typical Test Setup Layout of Radiated Emission for ITE............................................................................................................24

8.4 Test Result of Radiated Emissi on for ITE...................................................................................................................................25

8.5 Photographs of Radiated Emission for ITE Test Configuration...................................................................................................26

9. Harmonics Test...................................................................................................................................27

10. Voltage Fluctuations Test .................................................................................................................28

Feb. 10, 2003

Page 53

SPORTON International Inc.

Page No.

:

TEL : 886

-2-

2696-2468 Issued Date

:

FAX : 886

-2-

2696-2255

CE Test Report Report No. : C312912

10.1 Standard.....................................................................................................................................................................................28

10.2 Test Procedure...........................................................................................................................................................................28

10.3 Test Equipment Settings .............................................................................................................................................................28

10.4 Test Setup ..................................................................................................................................................................................28

10.5 Test Result Of Voltage Fluctuation And Flicker Test...................................................................................................................29

10.6 Photographs Of Harmonics Test, Voltage Fluctuation And Flicker Test......................................................................................30

11. Electrostatic Discharge Immunity Test (ESD) ...................................................................................31

11.1 Test setup...................................................................................................................................................................................31

11.2 Test Setup for Tests Performed in Laboratory ............................................................................................................................32

11.3 ESD Test Procedure...................................................................................................................................................................33

11.4 Test Severity Levels....................................................................................................................................................................34

11.5 Test Points ..................................................................................................................................................................................35

11.6 Photographs of Electrostatic Discharge Immunity Test...............................................................................................................37

12. Radio Frequency Electromagnetic Field Immunity Test (RS)............................................................38

12.1 Test setup...................................................................................................................................................................................38

12.2 Test Procedure...........................................................................................................................................................................39

12.3 Test Severity Levels....................................................................................................................................................................39

12.4 Photographs of Radio Frequency Electromagnetic Field Immunity Test.....................................................................................40

13. Electrical Fast Transient/Burst Immunity Test (EFT/BURST)............................................................41

13.1 Test setup...................................................................................................................................................................................41

13.2 Test on Power Line.....................................................................................................................................................................42

13.3 Test on Communication Lines.....................................................................................................................................................42

13.4 Test Procedure...........................................................................................................................................................................43

13.5 Test Severity Levels....................................................................................................................................................................44

13.6 Photographs of Electrical Fast Transient/Burst Immunity Test....................................................................................................45

14. Surge Immunity Test.........................................................................................................................46

14.1 Test Record................................................................................................................................................................................46

14.2 Test Level...................................................................................................................................................................................47

14.3 Test Procedure...........................................................................................................................................................................47

14.4 Operating Condition ....................................................................................................................................................................48

14.5 Photographs of Surge Immunity Test..........................................................................................................................................49

15. Conducted Disturbances Induced by Radio-Frequency Field Immunity Test ( CS )..........................50

15.1 Test Level...................................................................................................................................................................................50

15.2 Operating Condition ....................................................................................................................................................................50

15.3 Test Procedure...........................................................................................................................................................................51

15.4 Photographs of Conducted Disturbances Induced by Radio-Frequency Field Immunity Test.....................................................52

16. Power Frequency Magnetic Field immunity Tests............................................................................53

16.1 Test Record................................................................................................................................................................................53

16.2 Test Setup ..................................................................................................................................................................................53

16.3 Photographs of Power Frequency Magnetic Field immunity Tests..............................................................................................54

17. Voltage Dips and Voltage Interruption Immunity Tests.....................................................................55

17.1 Test Record of Voltage Interruption............................................................................................................................................55

17.2 Test Record of Voltage Dips .......................................................................................................................................................55

17.3 Testing Requirement and Procedure..........................................................................................................................................56

17.4 Test Conditions ...........................................................................................................................................................................56

17.5 Operating Condition ....................................................................................................................................................................56

17.6 Photographs of Voltage Dips and Voltage Interruption Immunity Tests ......................................................................................57

18. List of Measuring Equipment Used...................................................................................................58

19. Notice for Class A Product ...............................................................................................................61

ii

Feb. 10, 2003

Page 54

SPORTON International Inc.

Page No.

:

TEL : 886

-2-

2696-2468 Issued Date

:

FAX : 886

-2-

2696-2255

CE Test Report Report No. : C312912

20. Declaration of Conformity and the CE Mark......................................................................................62

Appendix A. Photographs of EUT..................................................................................................A1 ~ A8

Appendix B. Normalized Site Attenuation ………………………………………………. Annex 3/1 ~ Annex 3/7

iii

Feb. 10, 2003

Page 55

SPORTON International Inc.

Page No.

:

TEL : 886

-2-

2696-2468 Issued Date

:

FAX : 886

-2-

2696-2255

CE Test Report Report No. : C312912

History of this test report

Original Report Issue Date: Feb. 10, 2003

■ No additional attachment.

□ Additional attachment were issued as following record:

Attachment No. Issue Date Description

iv

Feb. 10, 2003

Page 56

CE Test Report Report No. : C312912

Certificate No. : C312912

CERTIFICATE OF COMPLIANCE

According to

European Standard EN 55013:1990/A12:1994/A13:1996,