Page 1

Characteristics

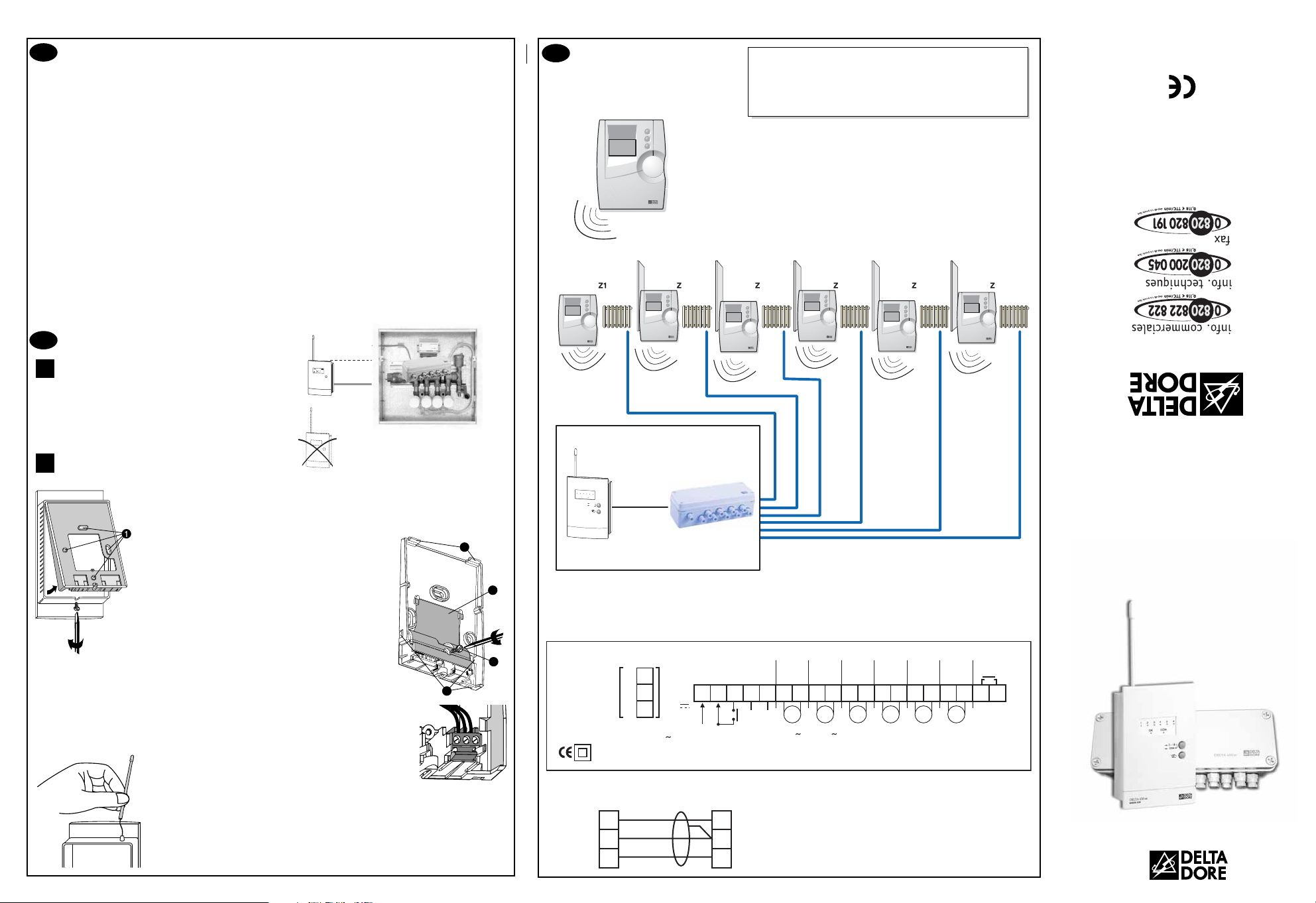

DELTA 600 is made up of a receiver unit and a technical control unit.

Installation

Positioning options

The receiver must be placed in a high position.

The receiver antenna must be kept away from

conductors (electrical cables, electrical switchboard,

metallic surface).

Mountings

To mount the unit on the wall, it must be separated from its base.

To do this, unscrew the clamp screw as shown opposite.

Once separated from the unit, the base must be fixed to the wall with screws and plugs or

on a flush-mounted box (distance between centres 60 mm) using the holes labelled ➊.

To do this:

Unscrew the screw ➋

to remove the terminal box cover ➎.

Temporary partitions, labelled ➌, are provided

to make room for the connection wire if needed.

- Connect the connection wires (see section 3).

- Replace the terminal box cover and secure it with

the screw ➋.

Position the unit on the support by first inserting the tabs ➍, then by pushing it until it is

securely fastened to the support.

3.5 Mounting the antenna

Slide the flexible wire into the tube, then push the tube in

as far as it will go.

Technical unit

• 230 V, 50 Hz power supply, ±10%

• Class II insulation

• Power consumption: 4 VA

• 6 power-supplied operating contact output, 1A,

250V (valves)

• 1 auxiliary contact output, 5 A, 250 V

(burner, circulator, etc.)

• 1 fixed-wire connection bus with the receiver unit

(DELTA 600 BR)

• Dimensions: 80 x 230 x 65 mm

Receiver unit

• TBTS 24 Volt power supply provided by the

technical unit

• Fixed-wire connection bus with the technical unit

(SYT 6/10-type 2 pair telephone cable with shield

and continuity wire, 5 metres max.)

• Receiver frequency: 868 MHz (standard 300 220)

• Radio range 100 to 300 metres outside depending

on the linked equipment (the range can be altered

depending on the installation conditions and the

electromagnetic environment)

• Flexible antenna that slides into its support

• 2 buttons to configure outputs

• Wall mounted

• Dimensions: 128 x 85 x 31 mm

• Protection index: IP 30

• Operating temperature: 0 to +40°C

• Storage temperature: -10 to +70°C

1

2

2700621 Rev.3

Connections

Switch off the mains power before

handling the device.

3

The diagrams provided are simplified for greater clarity.

The protective devices and other accessories required by the standards are

not illustrated.

- Standard UTE C15-100 and good practice must be complied with.

- Connected or nearby equipment must not generate excessive

interference (directive 89/336/EEC).

Technical unit connecting terminal box

Connection between the receiver unit and the technical unit

l

Fixed-wire connection bus (SYT 6/10-type 2 pair

telephone cable with shield and continuity wire,

5 metres max.)

The continuity wire is connected to terminal 2 of

the technical unit.

Product compliant with the requirements of directives

89/336/EEC (electromagnetic compatibility) and 73/23/EEC

modified 93/68/EEC (low voltage)

DELTA 600

Control receiver for 6-channel

heating/air-conditioning

control system

Receiver

YES

NO

Option 1

Centralized

control

Delta 600 COM

Programming

zone

Programming

zone

2

Delta 600 TH

Transmitters

Delta 600

Programming

zone

3

Programming

zone

456

Programming

zone

Programming

Delta 600 TH

Transmitters

zone

pro.deltadore.com

E-mail : deltadore@deltadore.com

DELTA DORE TALCO - Bonnemain - 35270 COMBOURG

Technical unit

1

2

3

456

OK

ZS

....

16

ZS

4

Receiver unit

Solenoid

valve control

5

2

To

8

3

receiver

unit

2721159 Rev. 2

Power supply 230V 4VA

1

2

7

3

6

50Hz / 60 Hz

BUS

24V

N

L

Change-over

power supply

1 A

1 A

1 A

1 A

Max.

Max.

Max.

Max.

1 A

Max.

7854 6 9 10111213141516171819202122

V1 V2 V3 V4 V5 V6

Val ve

24 V to 230 V

1 A

Max.

5 A

Max.

Auxiliary

contact

(Burner,

circulator,

etc.)

Receiver

unit

8

7

6

1

2

3

Technica

unit

Page 2

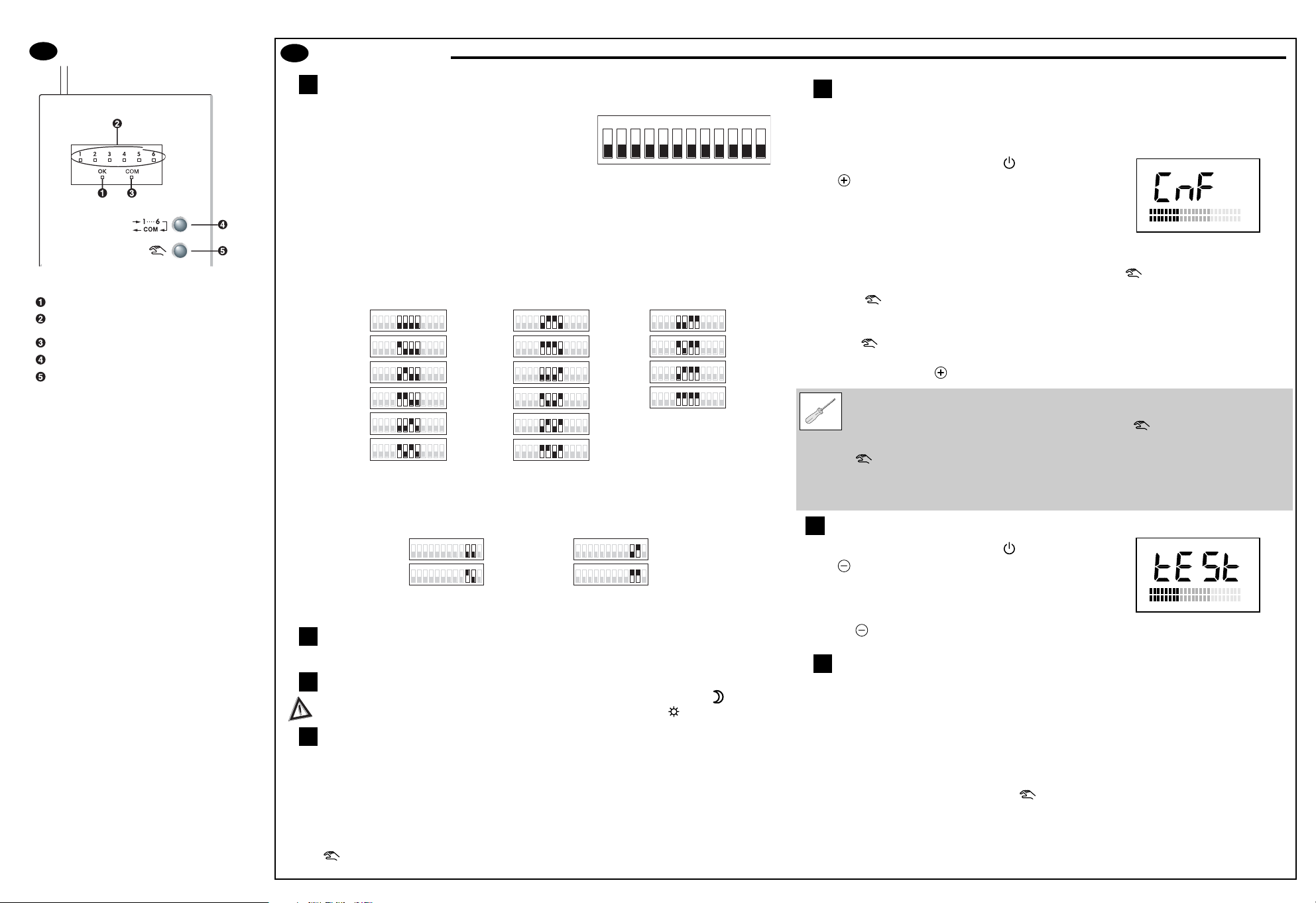

Starting up

Configuring the technical unit outputs

Remove the receiver unit from its base to access the configuration switches.

SW1: Type of relay control (1A outputs)

ON: Normally closed OFF: Normally open

This selection affects all 6 relay outputs simultaneously.

SW2: Burner or circulator selection (output 5A)

ON: Circulator (activates SW3 function) OFF: Burner

SW3: Anti-seizing function of the circulator (active if the SW2 selection is ON)

ON: Anti-seizing OFF: No anti-seizing

SW4: Keep last valve controlled open

(for constant water circulation in the hydraulic circuit).

ON: Keep last valve controlled open OFF: Authorizes closure of last valve controlled

SW5 to SW8: Solenoid valve opening times

Selection to be made according to the solenoid valves' technical characteristics.

SW9: Control time base

ON: 10 minutes (recommended for air-flow systems)

OFF: 20 minutes (best for hot-water radiant floors)

SW10 to SW11: Limit the cooling operation percentage

Limit according to the installation's cooling over-power.

SSW12: Not used

Technical control unit operation

LThe auxiliary contact is closed when one of the transmitters is in need of heat or cold.

Cooling mode operation (air-flow system)

When change-over is activated (Cooling mode), the Economy set-point temperature

on the thermostats must be higher than the Comfort set-point temperature .

Radio receiver operation

The 2 Heating and Cooling controls are calculated simultaneously. The LEDs on the receiver unit's front

side allow either Heating or Cooling controls to be viewed.

Selection method:

from normal display, press the 2 buttons for 5 sec. (the 6 LEDs flash quickly

indicating "control view selection" mode):

• for heating periods (change-over open), use the browsing button “1...6, COM” to select the red LED

(Com).

The unit displays the Heating control.

• for cooling periods (change-over closed), use the browsing button “1...6, COM” to select the green

LED (OK).

The unit displays the Cooling control.

Use the button to exit this mode (automatic exit after 2 min. of inactivity).

Radio configuration / reconfiguration

Configuration mode lets you couple a transmitter (Thermostat Delta 600 TH, Delta 600 COM centralized

control) with the Delta 600 BT receiver (no conflict possible with neighbouring installations). It is also used

to check the radio transmission.

➊ On the transmitter, turn the knob to the position.

➋ Press (~3 sec.) until CnF is displayed.

The transmitter sends its information to the receiver.

➌ On the receiver, push “1...6, COM” repeatedly until the LED of

the relative channel flashes.

• If the green LED (OK) is on steady, the receiver channel is already configured.

To reconfigure it (with another transmitter, for example), press the button for 10 sec. until the

green "OK" LED flashes slowly, then release it.

Press the button again.

The green "OK" LED comes on steady; the receiver channel has been "reconfigured".

• If the green LED (OK) is flashing slowly, the receiver channel is not configured.

Press the button.

The green "OK" LED comes on steady. The receiver channel is configured.

➍ On the transmitter, press to exit configuration mode.

Radio transmission check

➊ On the transmitter, turn the knob to the position.

➋ Press (~3 sec.) until tESt is displayed.

The transmitter sends its information to the receiver.

➌ Transmission is correct if, on the receiver, the "OK" LED and

“the LED of the relative channel” flash together.

➍ Press the button to exit the radio transmission test mode.

Problems?

A channel's red LED flashes (the receiver has not received information from the transmitter of the

relevant channel for more than an hour).

1) Check the transmitter batteries.

2) Go to transmission test mode.

- If the "OK" LED and "the LED of the relative channel" are not flashing together each time

information is received, move the transmitter.

- If the problem persists, reconfigure the units.

Note:

In the event of malfunction, pressing the button on the receiver changes the status of the

selected channel (exemption) until the next transmission from the thermostat (which continues to have

priority). For an override, the red LED flashes.

5.7

5.6

5.5

5.4

5.3

5.2

5.1

5

Description

The

Delta 600

control receiver is made up of 2

units:

- a receiver unit that receives information from

the transmitters (Delta 600 TH programmable

thermostats, Delta 600 COM centralized

control) by radio waves

- a technical unit, connected to the receiver unit

by a fixed-wire bus, which acts as a power

interface for controlling the installation's

valves.

Delta 600

will manage up to 6 hot-water heating or

air-conditioning outputs.

Delta 600

is designed for:

•

hot-water heating (underfloor or radiators)

• air-flow air-conditioning

• cooling floors equipped with dewpoint control

2 operating modes:

•

Current mode:

- Channel status display

- Display of the presence or absence of a

centralized control

•

Configuration mode:

- Display of whether or not a channel is

configured

- Manual activation of the channels in case of

a fault

Because of changes in standards and equipment, the characteristics given

in the text and the illustrations of this document are not binding unless

confirmed by Delta Dore.

4

Unconfiguring a channel

➊ To select a channel to unconfigure,

press “1...6, COM” repeatedly on the

receiver until the LED of the relevant

channel flashes.

➋ Hold the button down until the green "OK"

LED flashes (~30 sec.).

➌ Press the “1...6, COM” repeatedly until you exit

the mode.

Unconfiguring all channels

On the receiver, from the current operating

mode, press the button and hold it down until

the green "OK" LED flashes (~60 sec.).

The unit is now unconfigured.

Normal operation LED

Control status of the programmable

radio thermostats (Delta 600 TH)

Presence of the Delta 600 COM control unit

Scrolling button

Configuration button

ON

123456789101112

Valve opening delay

ON

0 sec.

123456789101112

ON

30 sec.

123456789101112

ON

1min.

123456789101112

1min. 30s.

2min. sec.

ON

123456789101112

ON

2min.

123456789101112

ON

123456789101112

3min.

3min. 30sec.

4min.

4min. 30sec.

5min.

5min. 30sec.

ON

123456789101112

ON

123456789101112

ON

123456789101112

ON

123456789101112

ON

123456789101112

ON

123456789101112

6min. 30sec.

7min. 30sec.

ON

6min.

123456789101112

ON

123456789101112

ON

7min.

123456789101112

ON

123456789101112

56789101112

No limit

75% limit

ON

12345678910 11 12

ON

12345678910 11 12

50% limit

25% limit

ON

12345678910 11 12

ON

12345678910 11 12

Page 3

Characteristics

• Runs on two LR03-type 1.5 V alkaline batteries

(autonomy greater than 1 year)

• Battery level indicator

• Operating mode selector knob (7 positions)

• Choice between 3 continuous temperatures:

Frost protection, Economy, Comfort

and 1 customizable program per day

• The 3 set-point temperatures can be adjusted

from:

5° to 30°C for Economy and Comfort,

5° to 15°C for Frost Protection

• Built-in proportional control (category B), time

basis: 15 min.

• Stand-by mode

• 868 MHz transmission frequency

(300 220 standard)

• Radio range 100 to 300 metres outside

depending on the linked equipment (the range

can be altered depending on the installation

conditions and the electromagnetic environment)

• Addressing: 65536 combinations

• Digital display

• Room unit: 126 x 85 x 31 mm

• Wall-mounted or on base

• Protection index: IP 30

• Class III insulation

Installer commissioning

Installation

2.1 Positioning options

2.1.1 Radio transmission

The thermostat must be positioned correctly.

In dwellings, the propagation of radio waves is reflected

and attenuated by the structures encountered.

We recommend that you check radio transmission

quality using the radio transmission test mode (§ 3.4).

2.1.2 Measuring temperature

Place the unit in a room whose temperature represents

the mean temperature in your dwelling. The recommended

height is 1.5 m; it should be accessible and away from

heat sources (fireplace, sunlight) and from draughts

(window, door).

If the thermostat is on its foldaway base, it can be used as

a genuine heating remote control and taken with you from

room to room.

1

2

3

➃ On the receiver, press “1...6, COM” repeatedly until

the LED of the relevant channel flashes.

• If the green LED (OK) is flashing slowly,

the receiver channel is not configured.

Press the button.

The green "OK" LED comes on steady. The receiver

channel is configured.

• If the green LED (OK) is on steady, the receiver

channel is already configured.

To reconfigure it, press the button for 10 sec.

until the green "OK" LED flashes slowly, then release

it.

Press the button once again.

The green "OK" LED comes on steady. The receiver

channel is "reconfigured".

→ On the transmitter, press to exit configuration

mode.

3.1 Fitting batteries

The unit is powered by 2 LR03 or AAA-type 1.5 V

alkaline batteries.

See user guide overleaf (§ 5.1).

3.2 Time setting

See user guide overleaf (§ 5.2).

3.3 Configuration / Reconfiguration

For each receiver output there is a transmitter.

The configuration mode is used to couple the receiver

output with a transmitter (no conflict possible with

other outputs). It is also used to check the radio

transmission.

Associating a receiver output with a transmitter

Turn the knob on the transmitter to the position.

➀ Press the button (3 sec.) until CnF is displayed.

The transmitter is sending its information to

the receiver.

3.4 Radio transmission check

On the transmitter, turn the knob to the position.

➀ Press the button (~3 sec.)

until the following is displayed:

The transmitter is sending

its information to the

receiver.

➃ Transmission is correct if, on the receiver, the "OK"

LED and “the LED of the relevant channel” flash

together.

→ Press the button to exit radio transmission test

mode.

3.5 Problems?

On the receiver, a channel's red LED flashes

(the receiver has not received information from

the transmitter of the relevant channel for more

than an hour).

1) Check the transmitter batteries.

2) Go to transmission test mode.

- If the "OK" LED and “the LED of the relevant

channel” are not flashing together each time

information is received, move the transmitter.

- If the problem persists, reconfigure the units.

Note:

In the event of malfunction, pressing

the button on the receiver changes the status

of the selected channel (exemption) until the next

transmission from the thermostat (which continues

to have priority). For an override, the red LED flashes.

2.2 Mounting

2.2.1 Wall-mount (preferred)

To mount the unit on the wall, it

must be separated from its base.

Once separated from the case,

the support must be fixed to the wall

with screws and plugs or on a

flush-mounted box (distance

between centres 60 mm).

2.2.2 Using the foldaway base (option)

Using the support provided,

you can place the transmitter

on an item of furniture or a table,

remembering to adhere to

the conditions for transmission

and thermal location.

DELTA 600 TH

Installation . Installation . Installation . Installation . Installation .Installation . Installation . Installation . Installation . Installation . Installation .

1.50 m

Min. 20 cm

Page 4

2700620 Rev.2_GB

Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use .

Temperatures

6.1 Setting the Frost Protection temperature

When starting up: Frost Protection = 7°C

Turn the knob to the position.

➀ Press the or buttons.

Temperature selection (5 to 15°C)

6.2 Setting the Economy temperature

When starting up: Economy = 16°C.

Turn the knob to the position.

➀ Press the or buttons.

Temperature selection (5 to 30°C)

IMPORTANT: In air conditioning mode, the economy

set-point temperature must be higher than the Comfort

set-point temperature.

6.3 Setting the Economy temperature

Default setting: Comfort = 19°C.

Turn the knob to the position.

➀ Press the or buttons.

Temperature selection (5 to 30°C)

6.4 Viewing the measured temperature

Press button.

The temperature of the room

is displayed.

Set the daily program

There are 4 preset programs.

You can select one of them

by turning the knob.

Continuous Frost

Protection (adjustable

from 5°C to 15°C)

Continuous Economy

mode (adjustable from

5°C to 30°C)

Permanent comfort

(adjustable from 5°C

to 30°C)

By default, Comfort

from 6:00 a.m. to

11:00 p.m. throughout

the week.

This program can be modified.

User start-up

5.1 Fitting batteries

Two LR03-type or AAA 1.5V alkaline batteries

(autonomy >1 year).

"No rechargeable batteries"

.

To install them, remove the unit from its base, insert

the batteries, being careful to put them in the correct

direction, then return the unit to its base.

Replacing batteries:

If the low battery LED comes on, do not leave the

flat batteries in the unit (the guarantee does not cover

damage caused by leakage from batteries).

You have approximately 1 minute to insert the new

batteries before the time you have set is erased.

The programs remain saved no matter what.

Presentation

5.2 Time setting

Turn the knob to the position.

Set the time and day by pressing and .

Each time you pass 24:00 you

change the day.

Press and release

Changes in 1-minute steps

Press and hold

Fast forward

5

7

6

4

Heating shutdown /

Standby mode

Switching to standby for operation outside heating

periods.

Turn the knob to the position.

The unit displays 4 dashes.

Modifying and saving your program

Turn the knob to PROG

The temperature display goes off.

The program assigned to the 1st day appears.

The 1st time slot flashes on and off.

➀ Press for 1 Comfort hour or for 1 Economy hour

(goes to next time slot).

Repeat the operation for each time slot.

➃ You must press to confirm and go to the next day

Repeat operations ➀ and ➃ for

each day

.

→ When you have finished programming, turn the knob to

AUTO.

For the , and AUTO modes, the displayed

temperature is the set-point temperature for the current

time slot.

E.g.: Day 3, it is 8:15 p.m

.

The relevant time slot flashes.

The comfort temperature

is requested and its value

is displayed.

or

Day 3, it is 4:20 a.m

.

The Economy set-point

temperature is displayed.

8

Because of changes in standards and equipment, the characteristics given

in the text and the illustrations of this document are not binding unless

confirmed by Delta Dore.

DELTA 600 TH

Wireless room thermostat

with one-week programming

Ref. 6000015

This appliance complies with the requirements of the directive

R&TTE1999/5/CE

OK

Current day

Temperature display

Battery level indicator

Daily program profile

( = Comfort, = Economy)

Modification buttons

Display of the measured

temperature or validation

in programming mode

6

Knob selection mark

7

Operating mode selector

knob (7 positions)

8

1

2

3

4

5

6

7

pro.deltadore.com

E-mail : deltadore@deltadore.com

DELTA DORE TALCO - Bonnemain - 35270 COMBOURG

Diagnosis / Solutions

Nothing appears

on the screen.

The whole display

is flashing.

The symbol appears.

No power supply.

Change the batteries or check

their polarity (correctly fitted).

The thermostat has just

been switched on.

Check the clock and the

temperatures and adjust them

if necessary, otherwise press

any button.

The batteries are low.

Change the batteries.

A

U

T

O

1

2

3

4

5

6

7

1

2

3

4

5

6

7

0h 2 4 6 8 10 12 1416 18 20 22 24

1

2

3

4

5

6

7

0h 2 4 6 81012141618202224

1

2

3

4

5

6

7

0h 2 4 6 81012141618202224

P

R

O

G

1

2

3

4

5

6

7

0h 2 4 6 8 10 12 1416 18 20 22 24

1

2

3

4

5

6

7

0h 2 4 6 8 10 12 1416 18 20 22 24

Page 5

Characteristics

• Runs on two LR03-type 1.5 V alkaline batteries

(autonomy greater than 1 year)

• Class III insulation

• Battery level indicator

• Operating mode selector knob (5 positions)

• Choice between 5 operating modes:

Frost protection, Economy, Comfort, Shutdown

or Auto

• Long absence adjustable from 1 to 99 days

• Transmission frequency 868 MHz:

(I-ETS 300 220 standard)

• Radio range: 100 to 300 metres outside

depending on the equipment associated

(the range can be altered depending on the

installation conditions and the electromagnetic

environment)

• Addressing: 65536 combinations

• Digital display

• Room unit: 128 x 85 x 31 mm

• Wall-mounted or on base

• Protection index: IP 30

• Operating temperature: 0 to +40°C

• Storage temperature: -10°C to +70°C

Installer commissioning

3.1 Fitting batteries

Two LR03-type or AAA 1.5V alkaline batteries

(autonomy >1 year).

"No rechargeable batteries".

To install them, remove the unit from its base, insert

the batteries, being careful to put them in the correct

direction, then return the unit to its base.

Replacing batteries:

If the low battery LED comes on, do not leave

the flat batteries in the unit (the guarantee does not

cover damage caused by leakage from batteries).

3.2 Configuration / Reconfiguration

Configuration mode lets you couple the Delta 600 COM

control unit with the Delta 600 BT receiver (no conflict

possible with neighbouring installations).

It is also used to check the radio transmission.

Installation

2.1 Positioning options

The thermostat must be positioned correctly.

In dwellings, the propagation of radio waves is reflected

and attenuated by the structures encountered.

We recommend that you check radio transmission

quality using the radio transmission test mode (§ 3.4).

2.2 Mounting

2.2.1 Wall-mount (preferred)

To mount the unit on the wall, it must

be separated from its base.

Once separated from the case,

the support must be fixed to

the wall with screws and plugs or

on a flush-mounted box (distance

between centres 60 mm).

1

2

3

Turn the knob on the Delta 600 COM control unit to

the position

➀ Press (~3 sec.) until CnF is displayed.

The control unit sends

its information to the

receiver.

➃ On the receiver, push “1...6, COM” repeatedly until

the “COM” LED flashes.

• If the green LED (OK) is flashing slowly, the

receiver's COM channel is not configured.

Press the button.

The green "OK" LED comes on steady.

The receiver's COM channel is configured.

• If the green LED (OK) is on steady, the receiver's

COM channel is already configured.

To reconfigure it (with another control unit, for

example), press the button for 10 sec. until

the green "OK" LED flashes slowly, then release it.

Press the button again.

The green "OK" LED comes on steady; the

receiver's COM channel has been "reconfigured".

→ Press to exit from configuration mode.

3.4 Radio transmission check

On the control unit, turn the knob to the position.

➀ Press (~3 sec.)

until tESt is displayed.

The transmitter sends

its information to

the receiver.

➃ Transmission is correct if, on the receiver, the "OK"

and “COM” LED flash together.

→ Press the button to exit the radio transmission test

mode.

3.5 Problems?

On the receiver, the “COM” LED flashes (the receiver

has not received information from the transmitter of

the relevant channel for more than an hour).

1) Check the transmitter batteries.

2) Go to transmission test mode.

- If the "OK" and “COM” LEDs are not flashing

together each time information is received, move

the control unit.

- If the problem persists, reconfigure the units.

Note:

In the event of malfunction, pressing the

button on the receiver changes the status of

the selected channel (exemption) until the next

transmission from the thermostat (which continues

to have priority). For an override, the red LED flashes.

2.2.2 Using the foldaway base (option)

Using the support provided,

you can place the transmitter on

an item of furniture or a table,

remembering to adhere to

the conditions for transmission

and thermal location.

DELTA 600 COM

Installation . Installation . Installation . Installation . Installation .Installation . Installation . Installation . Installation . Installation . Installation .

Page 6

Description

The

Delta 600 COM

control unit is

a centralized control that determines

the operating mode of the system.

The control of each zone is determined

by its thermostat (Delta 600 TH).

• AUTO Mode: Each zone applies the

thermostat program associated with it

(Delta 600 TH)

• Comfort Mode: Each zone is controlled

with respect to the Comfort setting of its

thermostat (Delta 600 TH)

• Economy Mode: Each zone is controlled

with respect to the Economy setting of its

thermostat (Delta 600 TH)

• Frost Protection mode: Each zone

is controlled with respect to the Frost

Protection setting of its thermostat

(Delta 600 TH)

• Shutdown mode: The entire system is

shut down.

• Long absence mode is used to enable an

override depending on the mode and period

that you select.

Operating mode selection

The Delta 600 COM control unit determines the operating mode of the system.

Continuous comfort, economy or frost protection

From one of these modes, you can change the mode up to the next change of program (see 5.3).

Automatic Mode

From the AUTO mode, you can change the mode up to the next change of program (see 5.3).

Long absence

5.3.1 Selecting the mode and override period

5.3.2 Enabling the override

You can enable the required override from the auto, comfort, economy and frost protection modes (see 5.3.1).

To do this, all you have to do is press the “OK”/ button.

Example:

Mode selected: Auto. Override programmed: 9 days in frost protection mode

• To cancel an override, press the button “OK”

/

• If you need to change the override period, repeat the programming operation described in 5.3.1

The following functions are not possible:

- From Comfort mode, it is impossible to enable an override to the Comfort mode.

- From Eco mode, it is impossible to enable an override to the Eco mode.

- From Frost Protection mode, it is impossible to enable an override to the Frost Protection mode.

- From Shutdown mode, it is impossible to enable an override.

Heating shutdown

5.4

5.3

5.2

5.1

Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use . Use .

Because of changes in standards and equipment, the characteristics given

in the text and the illustrations of this document are not binding unless

confirmed by Delta Dore.

4

Turn the knob

to AUTO

Each zone applies the programming

of its thermostat (Delta 600TH)

5

2700622 Rev.2_GB

DELTA 600 COM

Centralized control for

a 6-channel hot water

control system

Device complying with the requirements of

the R&TTE 1999/5/EC directive

Ref. 6000016

4

1

5

6

7

8

Continuous Comfort

Turn the

knob to

Continuous Economy

Turn the

knob to

Continuous Frost Protection

Turn the

knob to

pro.deltadore.com

E-mail : deltadore@deltadore.com

DELTA DORE TALCO - Bonnemain - 35270 COMBOURG

2

3

Current operating mode

Current automatic mode

Current long absence (Frost Protection)

(e.g. 9 days)

Battery level indicator

Modification buttons

Long absence or validation

Knob selection mark

Operating mode selector knob

Turn the

knob to

The previous

mode flashes

Select the mode

(e.g. Economy)

Confirm

The number of days

flash on and off

Example: Starting on 10 January,

return to the normal program on

19 January: enter 9 days

Turn the knob to Auto

Confirm

The countdown begins

The entire system is shut down

Turn the

knob to

Confirm

The countdown begins

Loading...

Loading...